Page 1

Modular I/O System

PROFIBUS DPV1

750-333 / 750-833

Manual

Technical description,

installation and

configuration

Supplement for the Manual 750-131

Version 2001-02-27

Page 2

ii • General

Copyright ã 2001 by WAGO Kontakttechnik GmbH

All rights reserved.

WAGO Kontakttechnik GmbH

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 4 30

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time.

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 3

TABLE OF CONTENTS

1 Important comments..................................................................................1

1.1 Legal principles......................................................................................1

1.2 Scope ......................................................................................................2

1.3 Symbols..................................................................................................2

1.4 Font conventions ....................................................................................3

1.5 Number notation.....................................................................................3

1.6 Abbreviation...........................................................................................4

2 WAGO-I/O-SYSTEM 750.........................................................................5

2.1 System Description ................................................................................5

2.2 Installation..............................................................................................8

2.3 Electrical Installation............................................................................11

2.4 Power supply........................................................................................13

2.5 Manufacturing Number ........................................................................16

2.6 Technical Data......................................................................................17

Table of Contents • iii

3 Fieldbus coupler / controller ...................................................................19

3.1 Fieldbus coupler 750-333.....................................................................19

3.2 Fieldbus Controller 750-833 ................................................................74

4 I/O Modules ............................................................................................132

4.1 Digital Input Modules ........................................................................132

4.2 Digital Output Modules......................................................................132

4.3 Analog Input Modules........................................................................132

4.4 Analog Output Modules.....................................................................132

4.5 ............................................................................................................132

5 PROFIBUS..............................................................................................133

5.1 Description .........................................................................................133

5.2 Topology ............................................................................................133

5.3 Wiring ................................................................................................133

6 Configuration example ..........................................................................135

6.1 NETCON............................................................................................135

6.2 Step 7..................................................................................................135

6.3 COM Profibus ....................................................................................135

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 4

iv • Table of Contents

7 Explosive Environments ........................................................................136

7.1 Foreword ............................................................................................136

7.2 Protective measures............................................................................136

7.3 Classification meeting CENELEC / IEC............................................136

7.4 Classifications meeting the NEC........................................................141

7.5 Identification acc. to CENELEC, IEC and ATEX 100a.....................143

7.6 Identification acc. to NEC 500...........................................................144

7.7 Installation regulations .......................................................................145

8 Glossary...................................................................................................147

9 Literature list ..........................................................................................149

10 Index ........................................................................................................150

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 5

1 Important comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanation is

carefully read and adhered to.

1.1 Legal principles

1.1.1 Copyright

This manual is copyrighted, together with all figures and illustrations contained therein. Any use of this manual which infringes the copyright provisions

stipulated herein, is not permitted. Reproduction, translation and electronic

and photo-technical archiving and amendments require the written consent of

WAGO Kontakttechnik GmbH. Non-observance will entail the right of claims

for damages.

Important comments • 1

1.1.2 Personnel qualification

The use of the product detailed in this manual is exclusively geared to specialists having qualifications in PLC programming, electrical specialists or persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH declines all liability resulting from

improper action and damage to WAGO products and third party products due

to non-observance of the information contained in this manual.

1.1.3 Intended use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only admitted within the framework of the possibilities documented in the manuals. All

other changes to the hardware and/or software and the non-conforming use of

the components entail the exclusion of liability on part of WAGO Kontakttechnik GmbH.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 6

2 • Important comments

1.2 Scope

This manual describes the field bus independent WAGO-I/O-SYSTEM 750

with the fieldbus coupler for PROFIBUS.

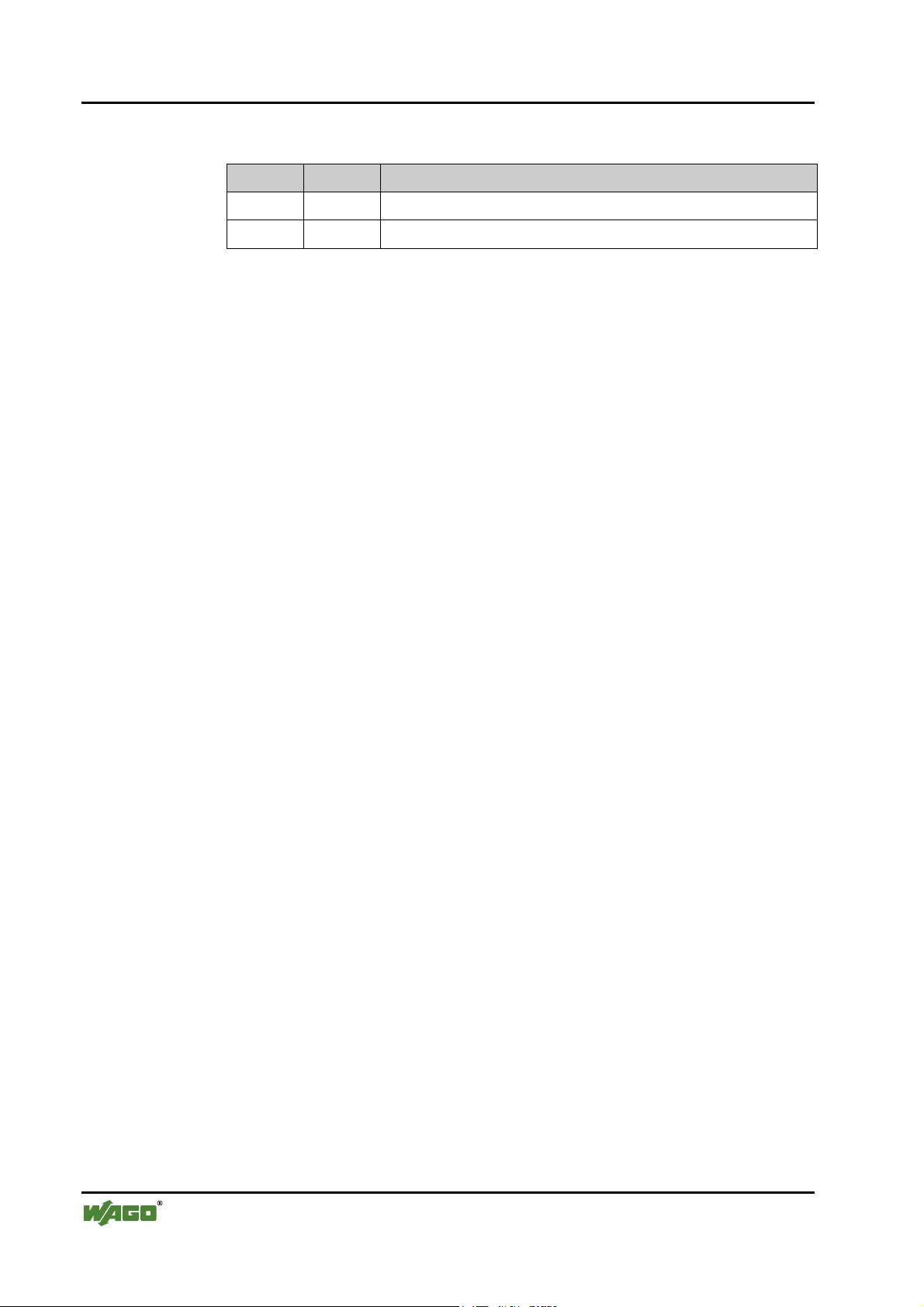

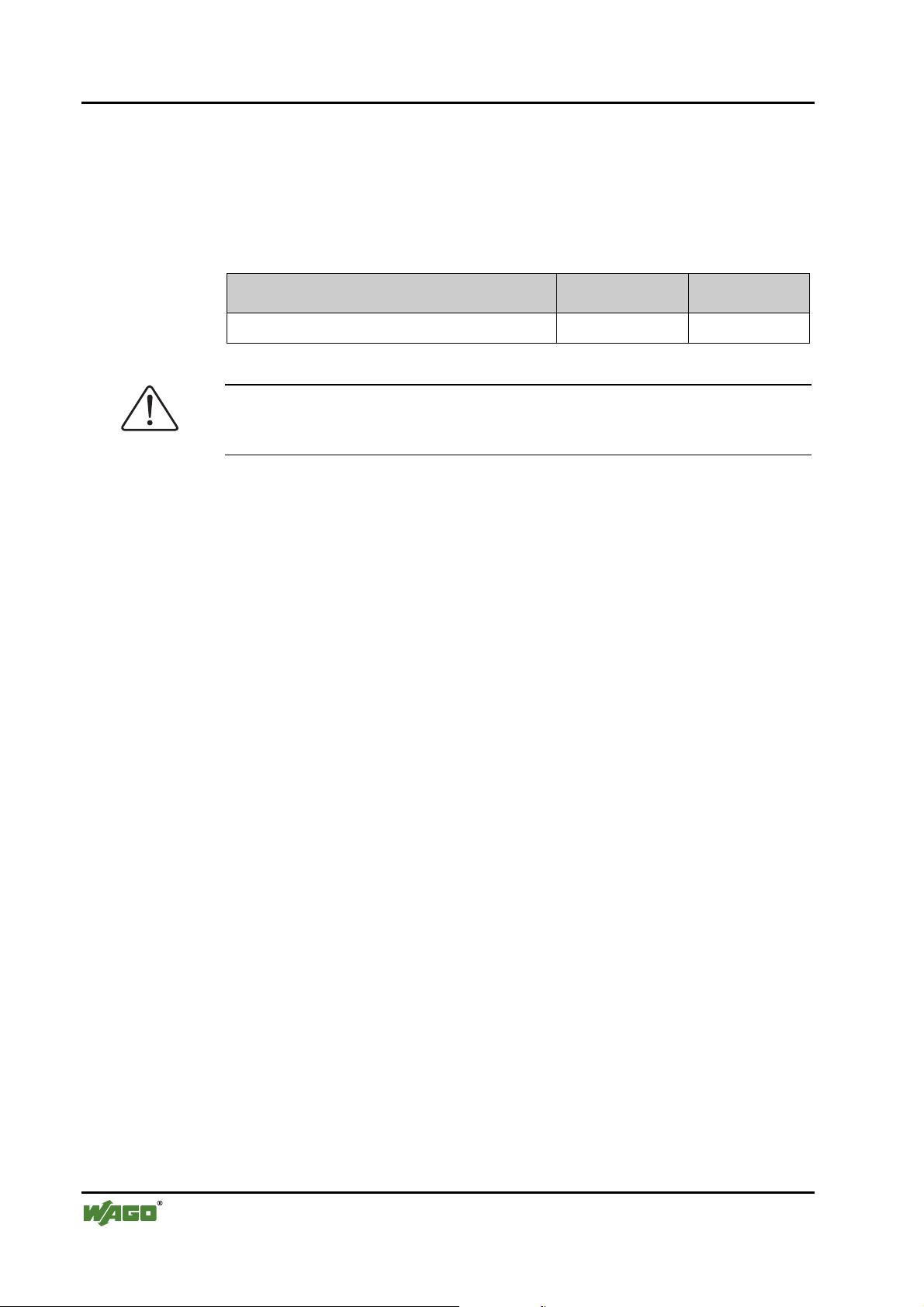

Item-No. Components

750-333 PROFIBUS DP/DPV1 12 MBd

750-833 Contr. PROFIBUS DP/DPV1 12 MBd

750-xxx I/O Modules

1.3 Symbols

Danger

Always observe this information to protect persons from injury.

Warning

Always observe this information to prevent damage to the device.

Attention

Marginal conditions must always be observed to ensure smooth operation.

ESD (Electrostatic Discharge)

Warning of damage to the components by electrostatic discharge. Observe the

precautionary measure for handling components at risk.

Note

Routines or advice for efficient use of the device and software optimisation.

More information

i

References to additional literature, manuals, data sheets and INTERNET

pages

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 7

1.4 Font conventions

Important comments • 3

Italic

Italic

\

END

< >

Courier

1.5 Number notation

Names of path and files are marked italic

e. g.: C:\programs\WAGO-IO-CHECK

Menu items are marked as bold italic

e. g.: Save

A backslash between two names marks a sequence of

menu items

z. B.: File\New

Press bottons are marked as bold with small capitals

e. g.: ENTER

Keys are marked bold within angle brackets

e. g.: <F5>

Program code are printed with the font Courier.

e. g.: END_VAR

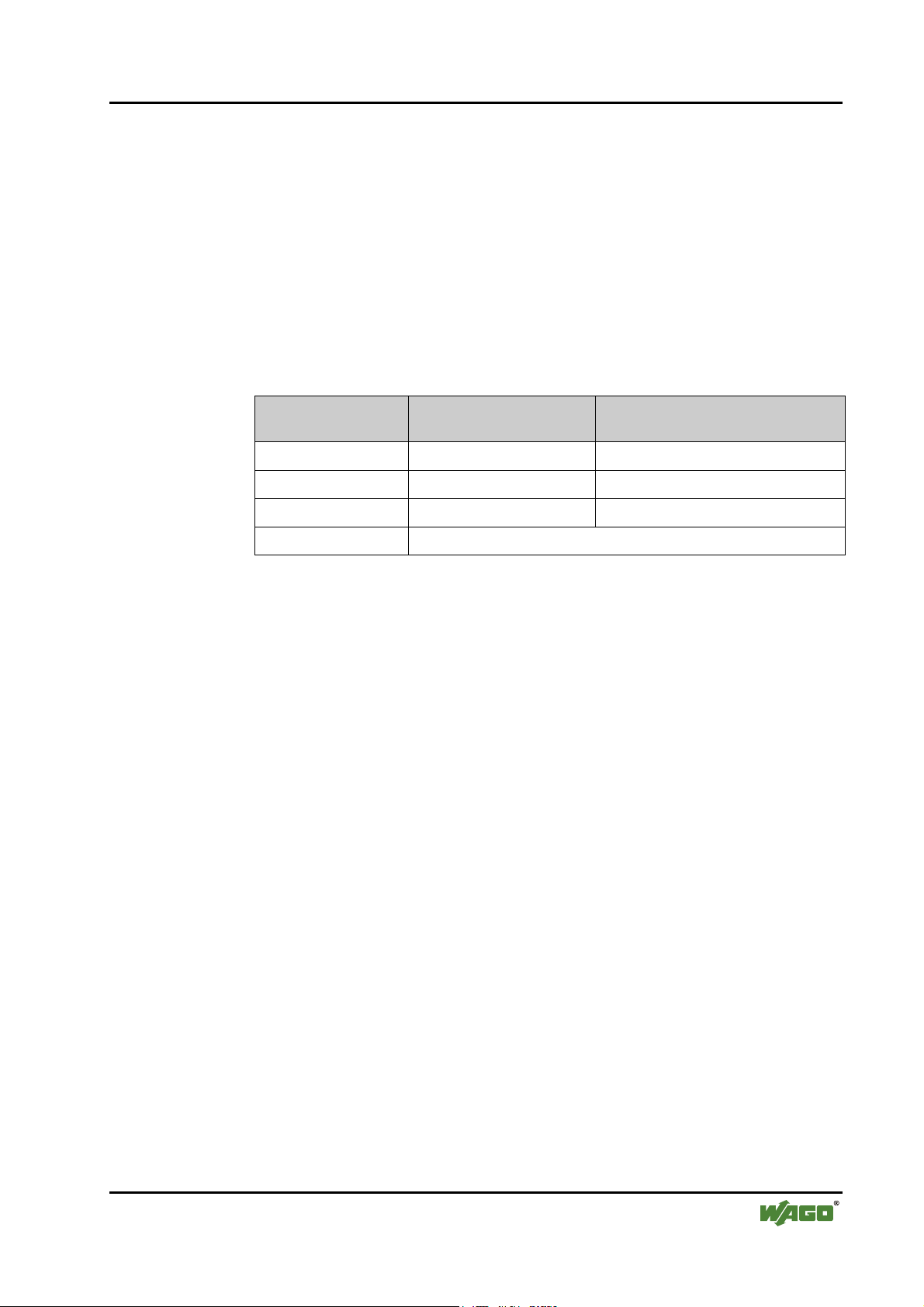

Number Code Example Note

Decimal 100 normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Within ',

Nibble separated with dots

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 8

4 • Important comments

1.6 Abbreviation

DI

DO

I/O

ID

PFC

PFC-PI

PFC-RTS

PI

PLC

AO

AI

SM

Digital Input

Digital Output

Input/Output

Identifier

Programmable Fieldbus Controller

Programmable Fieldbus Controller - Process Images

Programmable Fieldbus Controller - Runtime system

Process Images

Programmable Logic Control

Analog Output Module

Analog Input Module

Special Module

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 9

2 WAGO-I/O-SYSTEM 750

2.1 System Description

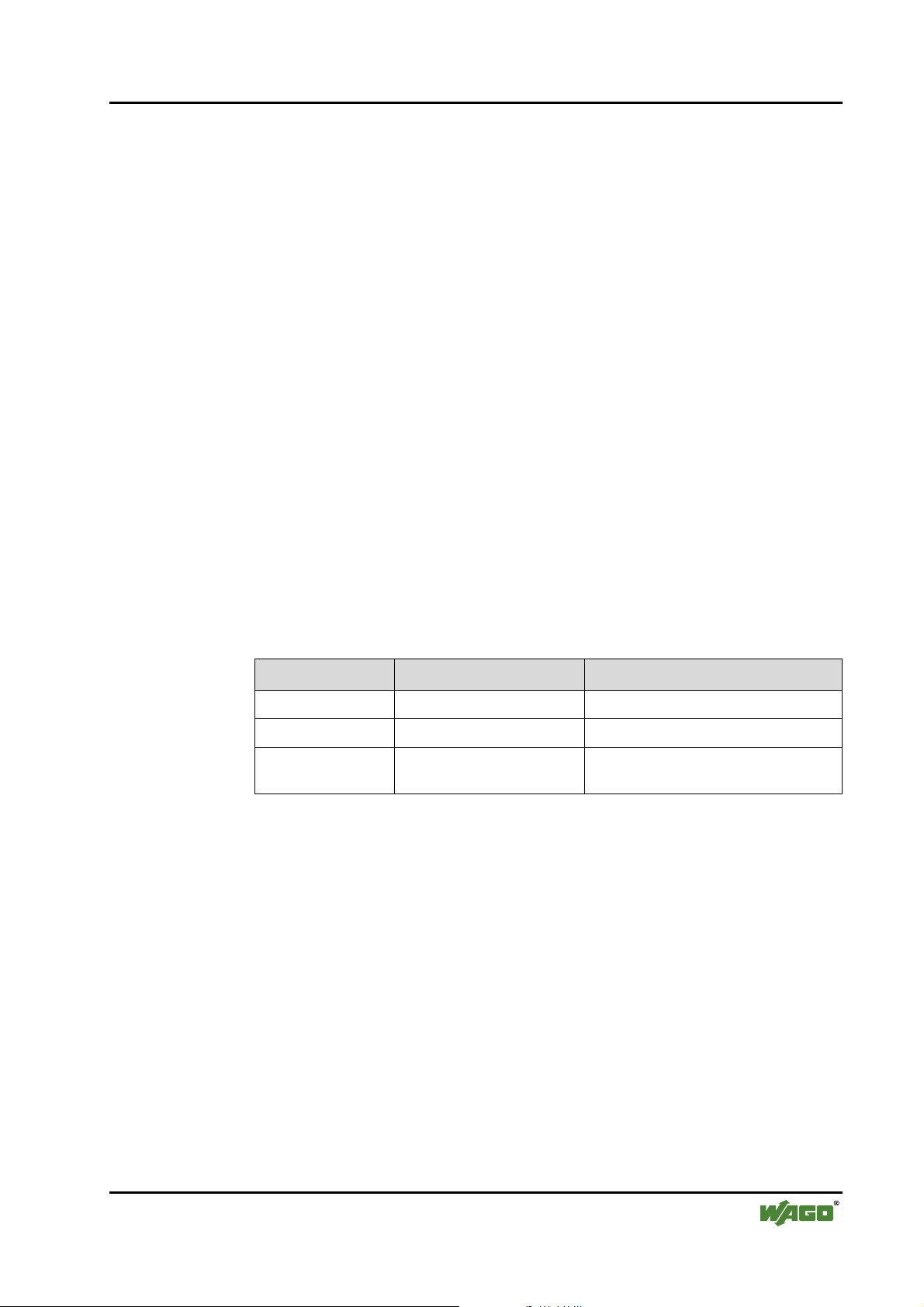

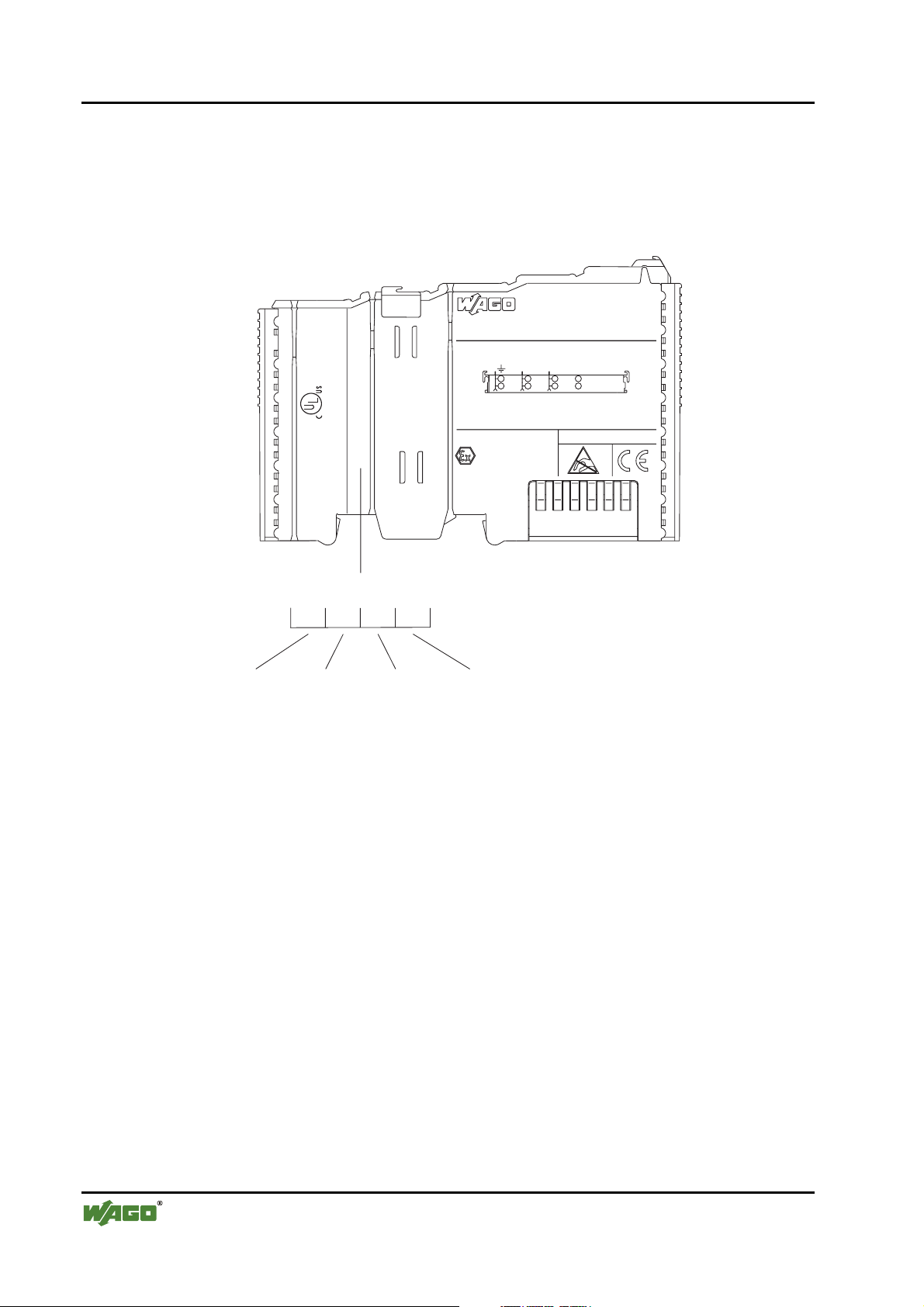

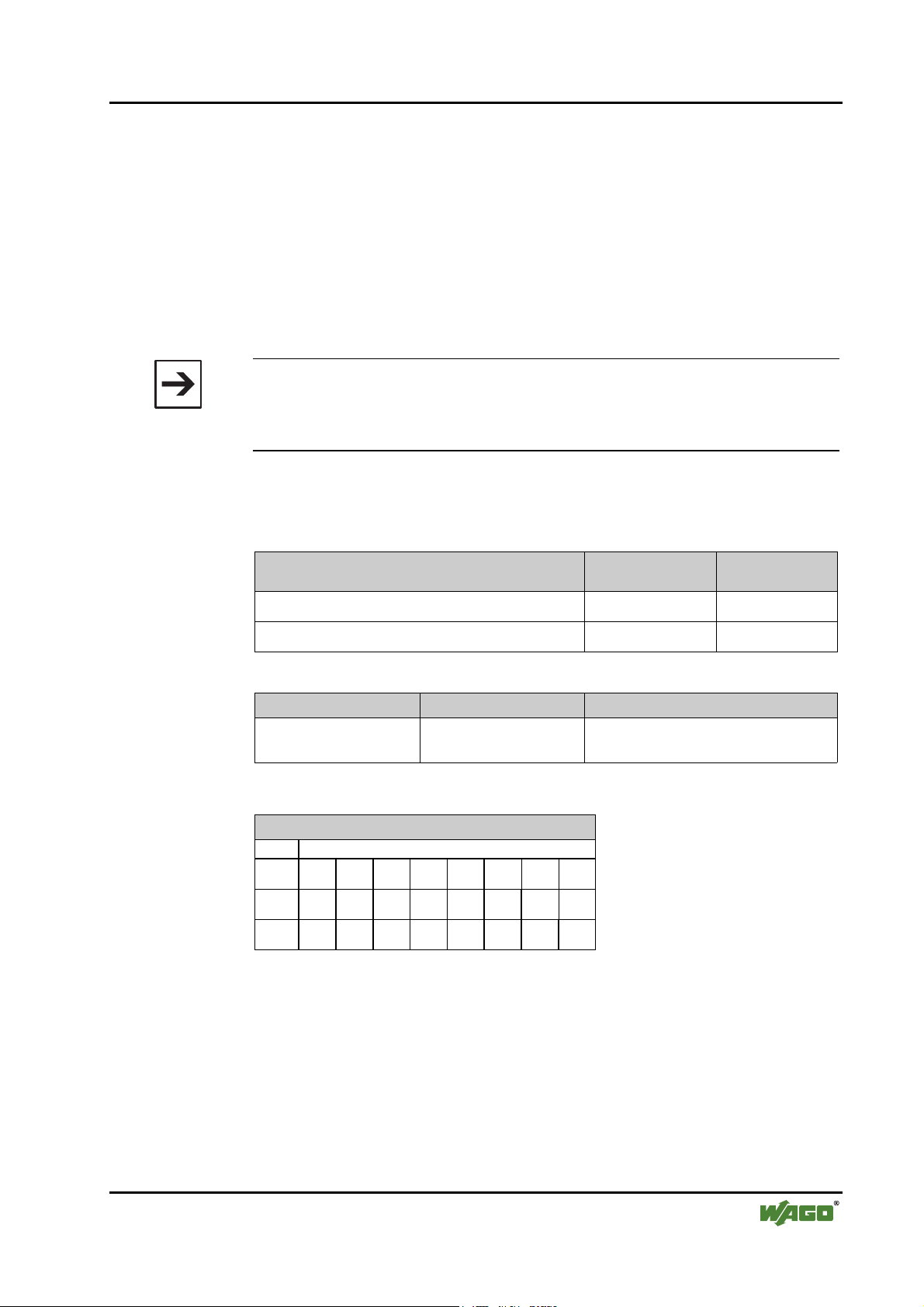

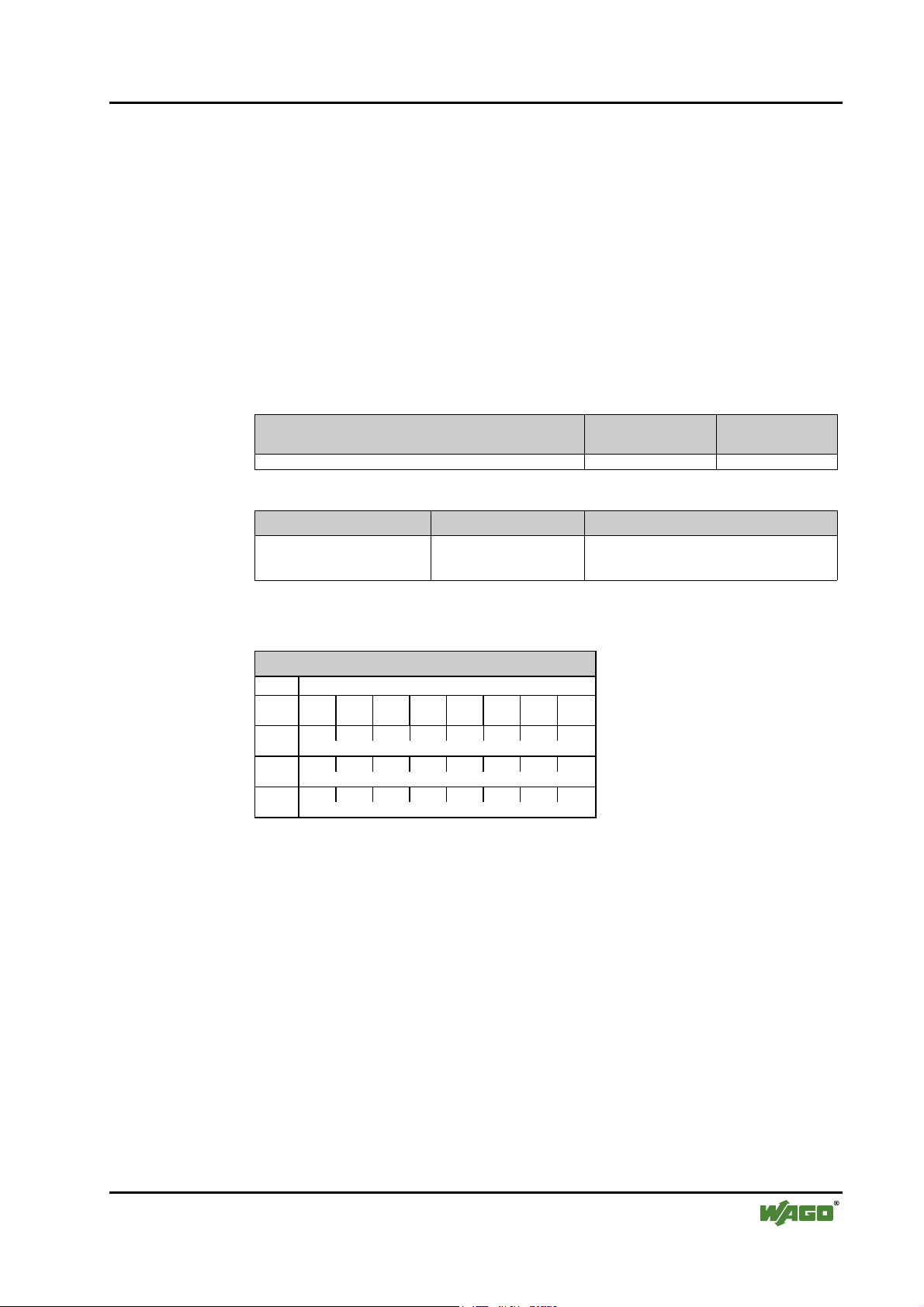

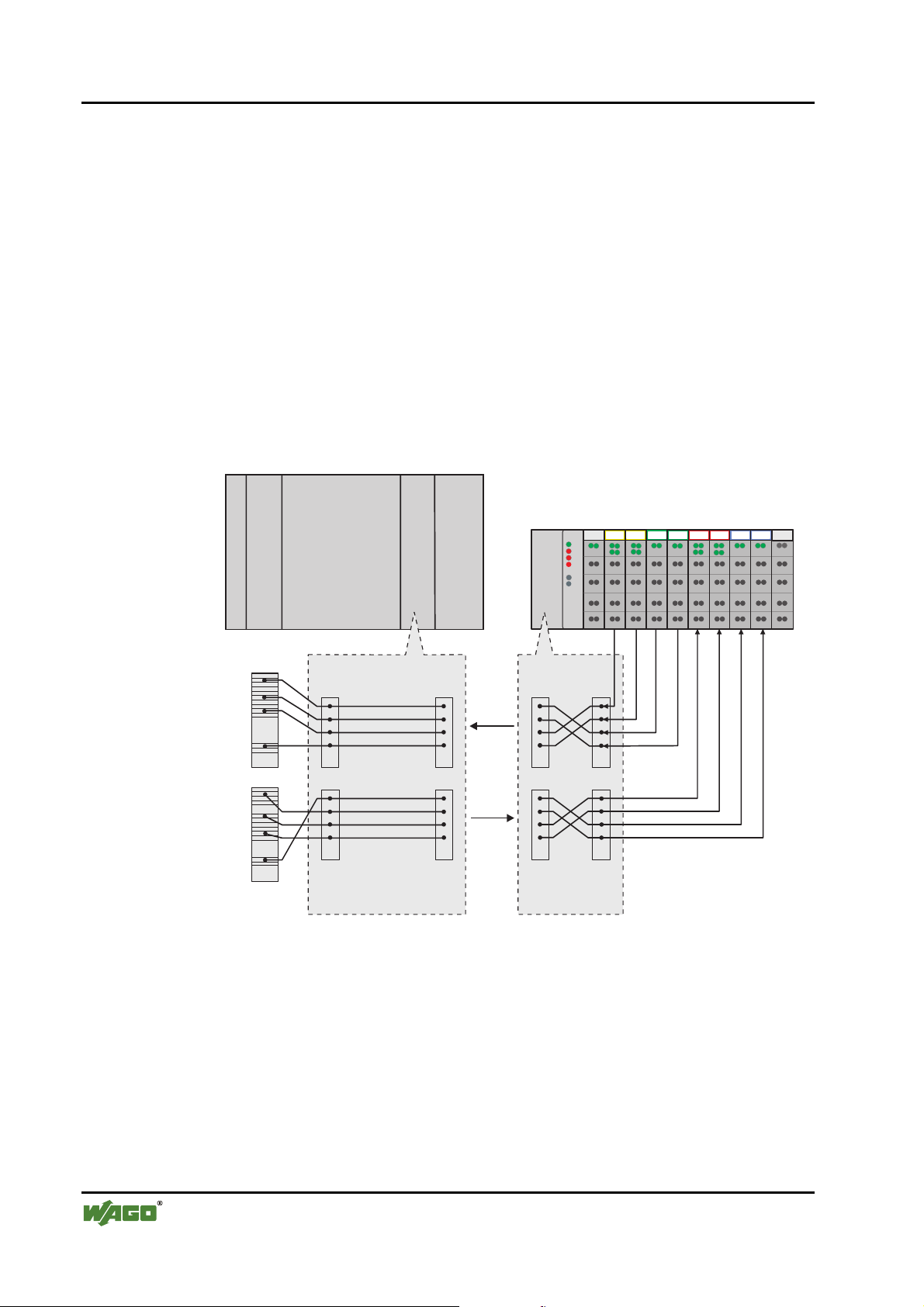

2.1.1 General

The WAGO-I/O-SYSTEM 750 consists of various components which are capable of providing modular and application specific fieldbus nodes for various

fieldbusses.

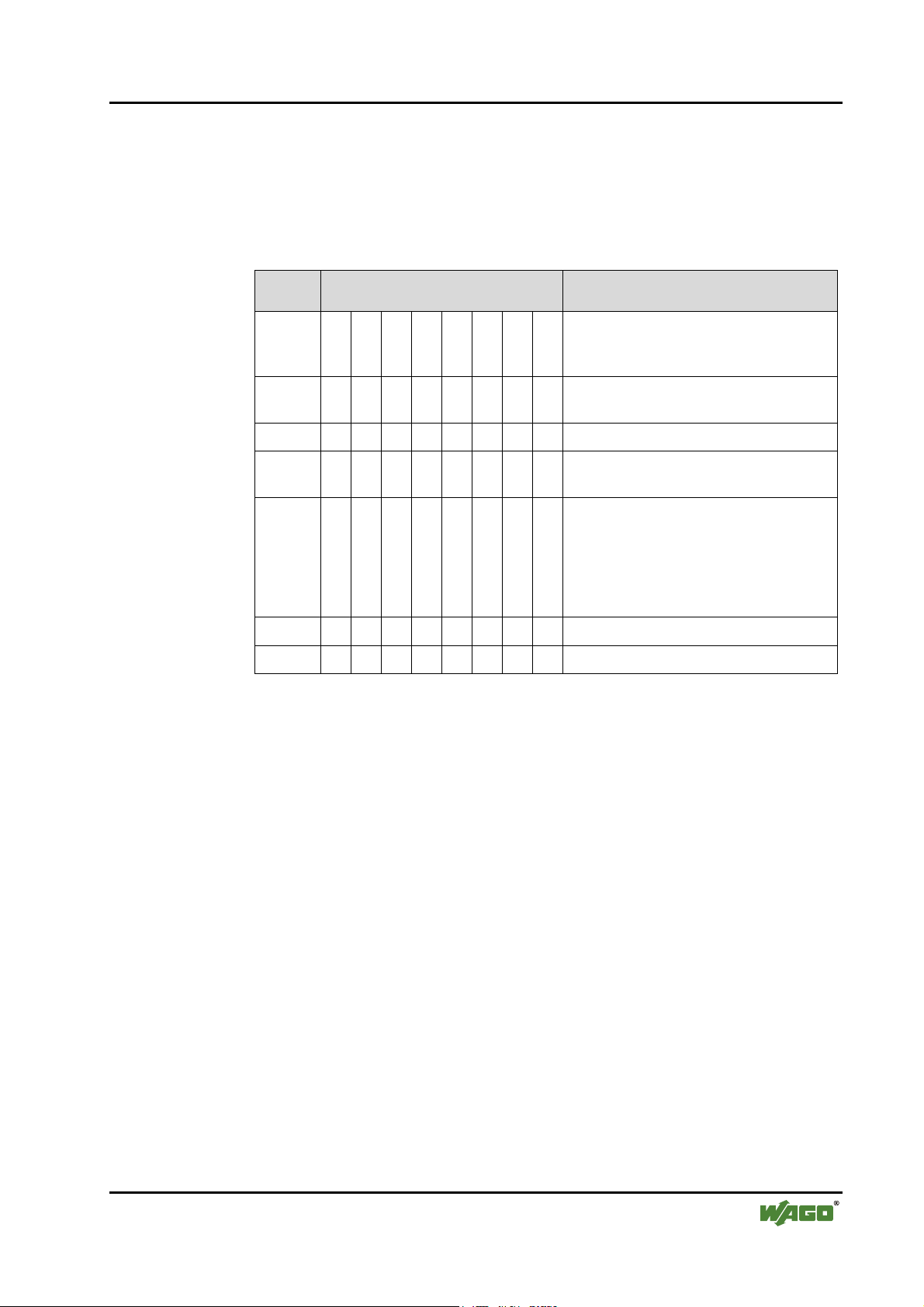

A fieldbus node (short: Node) consists in principle of a fieldbus coupler (short:

Coupler) ) or Programmable Fieldbus Controller (short: Controller) ) (1) at the

front end, a number of special I/O modules (2) and a End Module (3) which is

placed at the other end.

PROFIBUS

RUN

BF

24V

01 02 04 050607

0V

DIA

BUS

I/O

03

++++++++

WAGO-I/O-SYSTEM 750 • 5

System Description

TxD RxD

+ +

D+ D-

+ +

RTS CTS

11 12

09 10

L

L

L

13 23

LL L

17

21 22

26

29

30 31 32

max. 6,3A

250 V

+ +

24

181920

161514

27

CL-CL+

750-630 750-650

MM

SS

3

N

N

0

9

8

7

6

X10

0

9

8

7

6

X1

1

5

1

5

2

3

4

750-333

2

3

4

750-400 750-410 750-403 750-454 750-467 750-461

N

08

750-512 750-512 750-513 750-610

750-612

1 2

NN N

M M

S S

M M

25

28

S S

S SMMSS

S S

750-552750-550 750-600

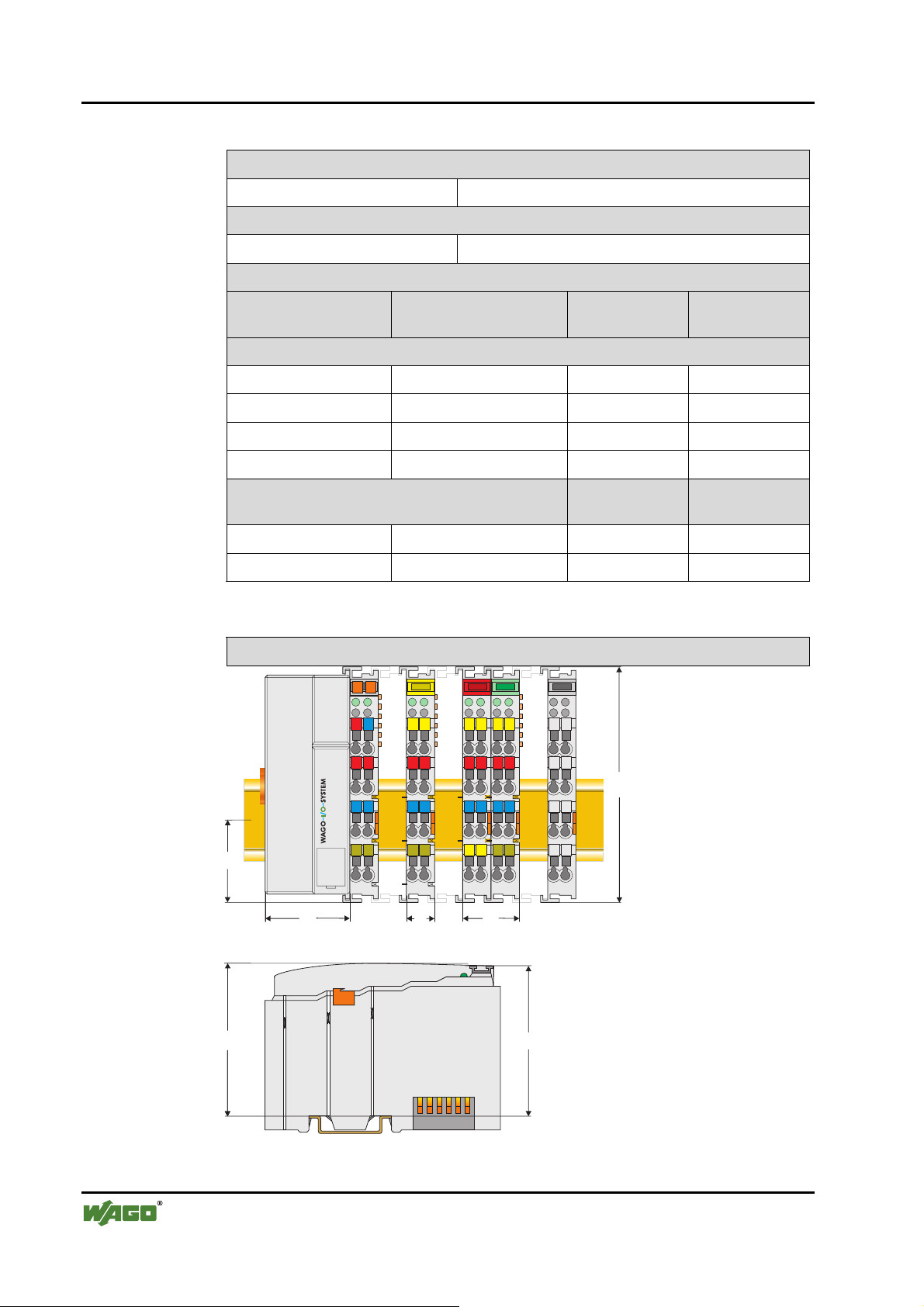

Fig. 2-1: Setting up a fieldbus node for PROFIBUS g01x101x

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 10

6 • WAGO-I/O-SYSTEM 750

System Description

2.1.2 Coupler/Controller (1)

The Coupler/Controller forms the link between the fieldbus and the field devices with their I/O functions. All control functions required for the faultless

operation of the I/O functions are carried out by the Coupler/Controller. The

connection to different fieldbus systems is established by each of the corresponding Coupler/Controller, e.g. for PROFIBUS, INTERBUS, CAN,

MODBUS etc. In this way a change of the fieldbus system is possible.

The programmable fieldbus controller 750-833 combines the PROFIBUS DP

functionality of the fieldbus coupler 750-333 with the functionality of a Programmable Logic Control (PLC). Programming of the application is done with

WAGO-I/O-PRO in accordance with IEC 61131-3, covering all 5 programming languages. The programmer can access all fieldbus and I/O data.

Characteristics and use of the Controllers:

• The use of decentralized control can better support a PLC or PC

• Signal pre-processing reduces fieldbus transmissions

• Complex applications can be divided into multiple tasks

• Tasks can be prioritized

• Peripheral equipment can be controlled directly, resulting in faster system

response times

• Programmable response in the event of a fieldbus failure

• Simple, self-sufficient control

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 11

2.1.3 I/O Modules (2)

In the I/O modules, the incoming process data is converted. Corresponding to

the different requirements, special I/O modules are available for a variety of

functions. There are digital and analog inputs and outputs and modules for

special functions (Counter modules, Terminal blocks for encoder and resolvers

and communication modules).

2.1.4 End Module (3)

A End Module is needed for faultless operation of the node. The termination

module is always placed as the last module in order to obtain a termination of

the fieldbus node. This module has no I/O function.

WAGO-I/O-SYSTEM 750 • 7

System Description

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 12

8 • WAGO-I/O-SYSTEM 750

Installation

2.2 Installation

2.2.1 Safty notes

ESD (Electrostatic Discharge)

The modules are equipped with electronic components which may be destroyed by electrostatic discharge.When handling the modules, ensure that the

environment (persons, workplace and packing) is well grounded. Avoid

touching conductive components, e.g. gold contacts.

Attention

Switch off the system prior to working on bus modules!

2.2.2 Mechanical Installation

All system components can be snapped directly on a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

Attention

Ensure that the carrier rail is fastened with countersunk head screws or blind

rivets as the snap-on foot of the I/O components extends onto the carrier rail.

The installation is simple and space saving. All modules have the same shape

to minimize the project commitment.

The reliable positioning and connection of the coupler and the individual I/O

modules is made using a tongue and groove system. Due to the automatic

locking, the individual components are securely seated on the rail after installing.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 13

WAGO-I/O-SYSTEM 750 • 9

Installation

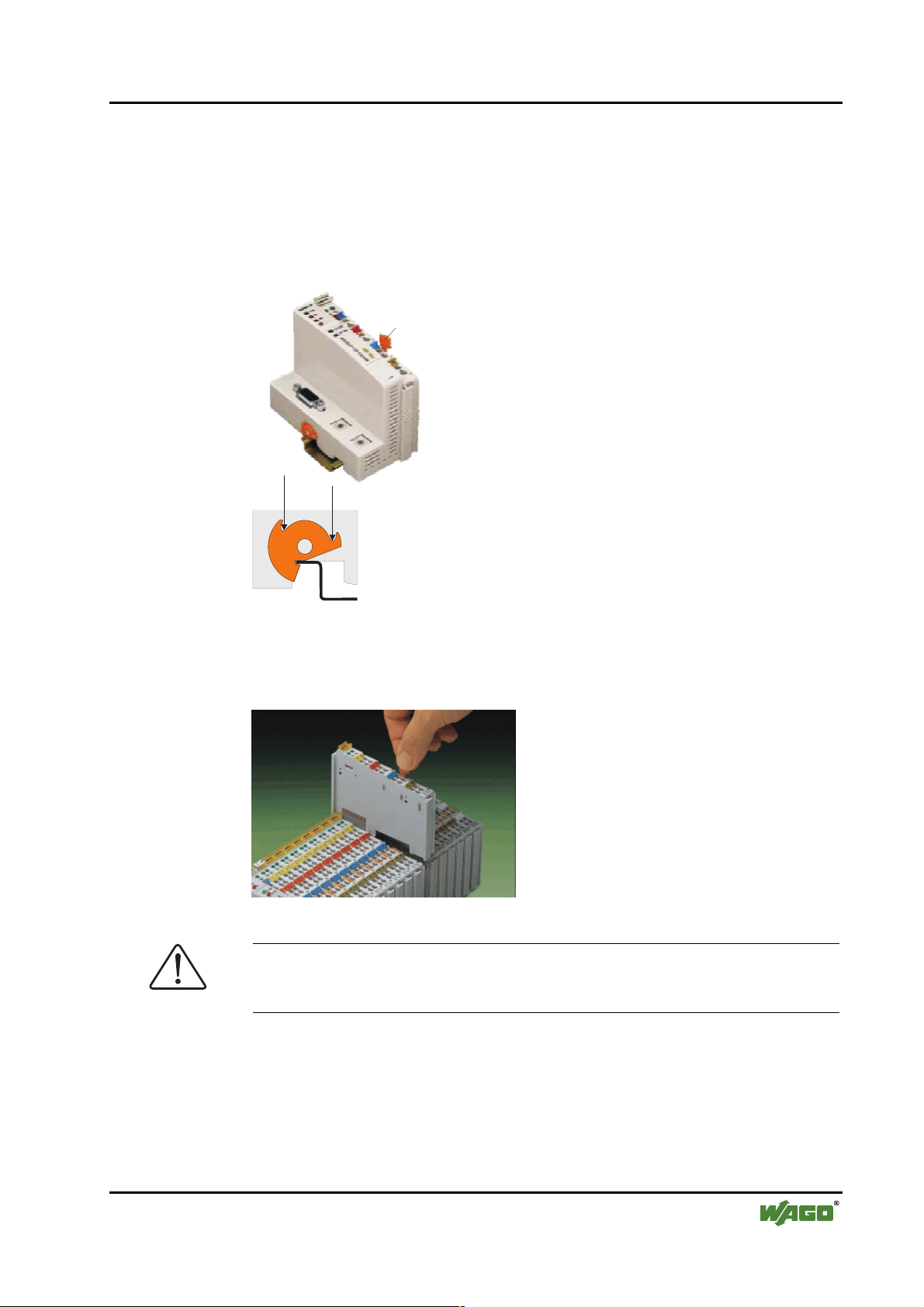

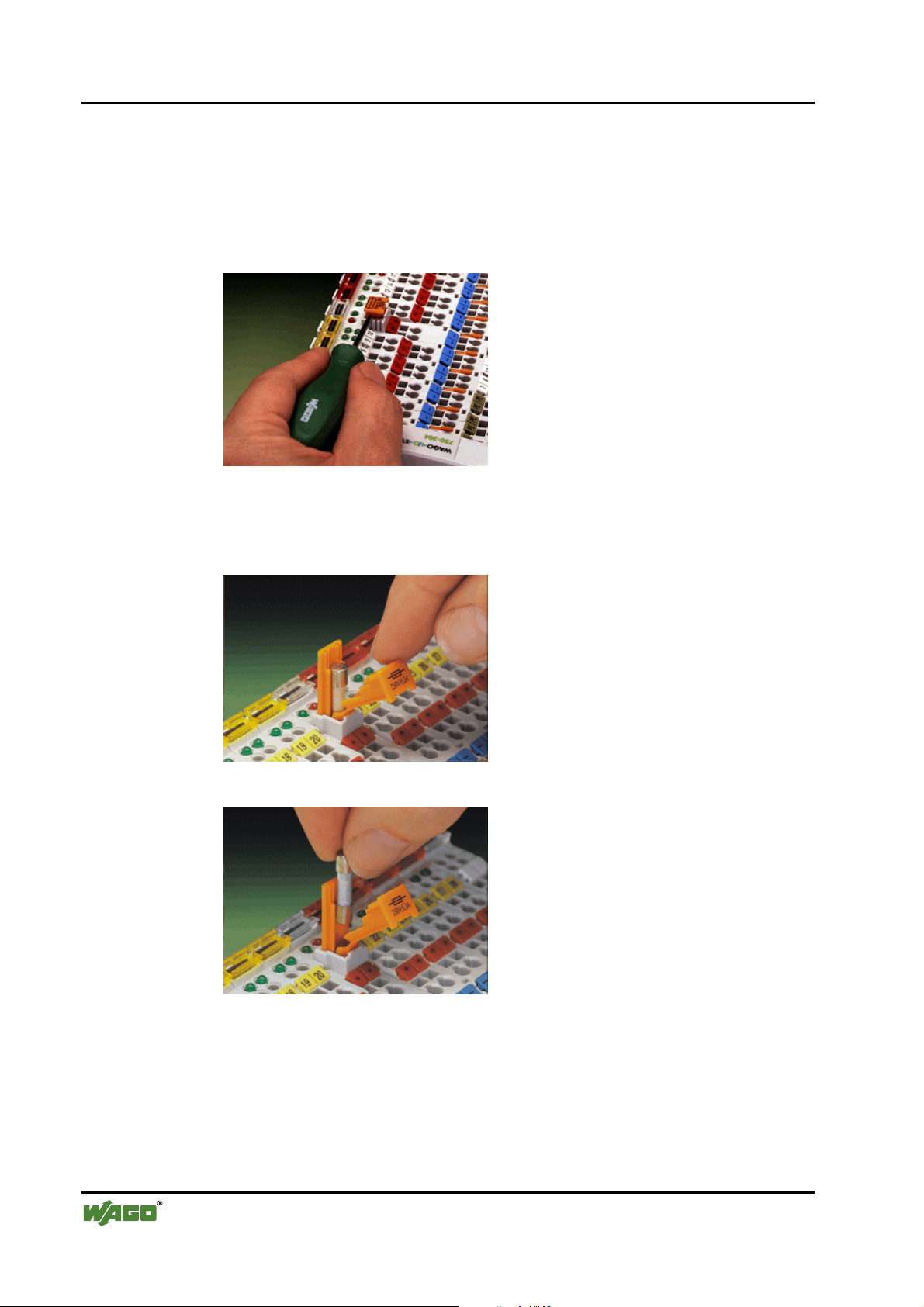

To secure the coupler/controller against moving sideways, fix it with the orange colored locking disc on the carrier rail. To fix, insert a screwdriver into

the top groove of the locking disc and press.

To pull out the fieldbus coupler, release the locking disc by pressing on the

bottom groove with a screwdriver and then pulling the orange colored unlocking lug.

Entriegelungs-

lasche

fixieren

Fig. 2-2: Coupler/Controller and unlocking lug g012201d

lösen

It is also possible to release an individual I/O module from the unit by pulling

an unlocking lug.

Fig. 2-3: Releasing a I/O Module p0xxx01x

Danger

Ensure that an interruption of the PE will not result in a condition which

could endanger a person or equipment!

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 14

10 • WAGO-I/O-SYSTEM 750

Installation

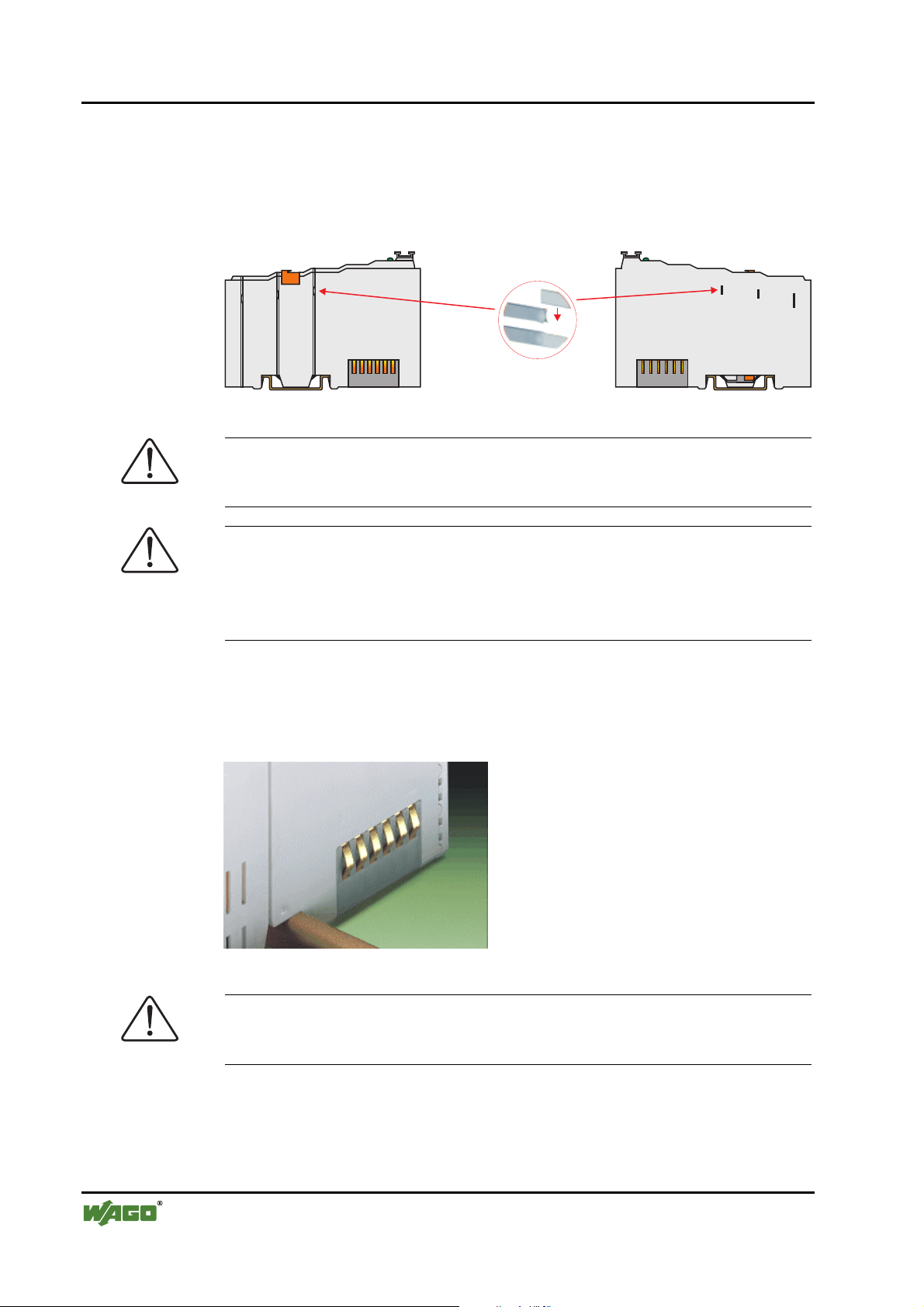

Self-cleaning power jumper contacts conduct the supply voltage for the field

side. They are located on either side of the modules. The female contacts on

the right-hand side of the fieldbus coupler and the bus modules are designed as

spring contacts to protect against accidental contact. Male contacts are located

on the left-hand side of the bus modules.

Fig. 2-4: Power Jumper Contacts g01xx00d

Danger

The power contacts are sharp-edged. Handle the module carefully to prevent

injury.

Pos. 1

Pos. 2

Attention

Please take into consideration that some bus modules have no or only some

power jumper contacts. The design of some modules does not physically allow assembly them in rows as the grooves for the male contacts are closed at

the top.

The data contacts are designed as self-cleaning gold spring contacts which

automatically produce a secure connection.

Fig. 2-5: Data contacts p0xxx07x

Warning

Do not connect the I/O module to gold spring contacts in order to avoid soiling or scratches!

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 15

2.3 Electrical Installation

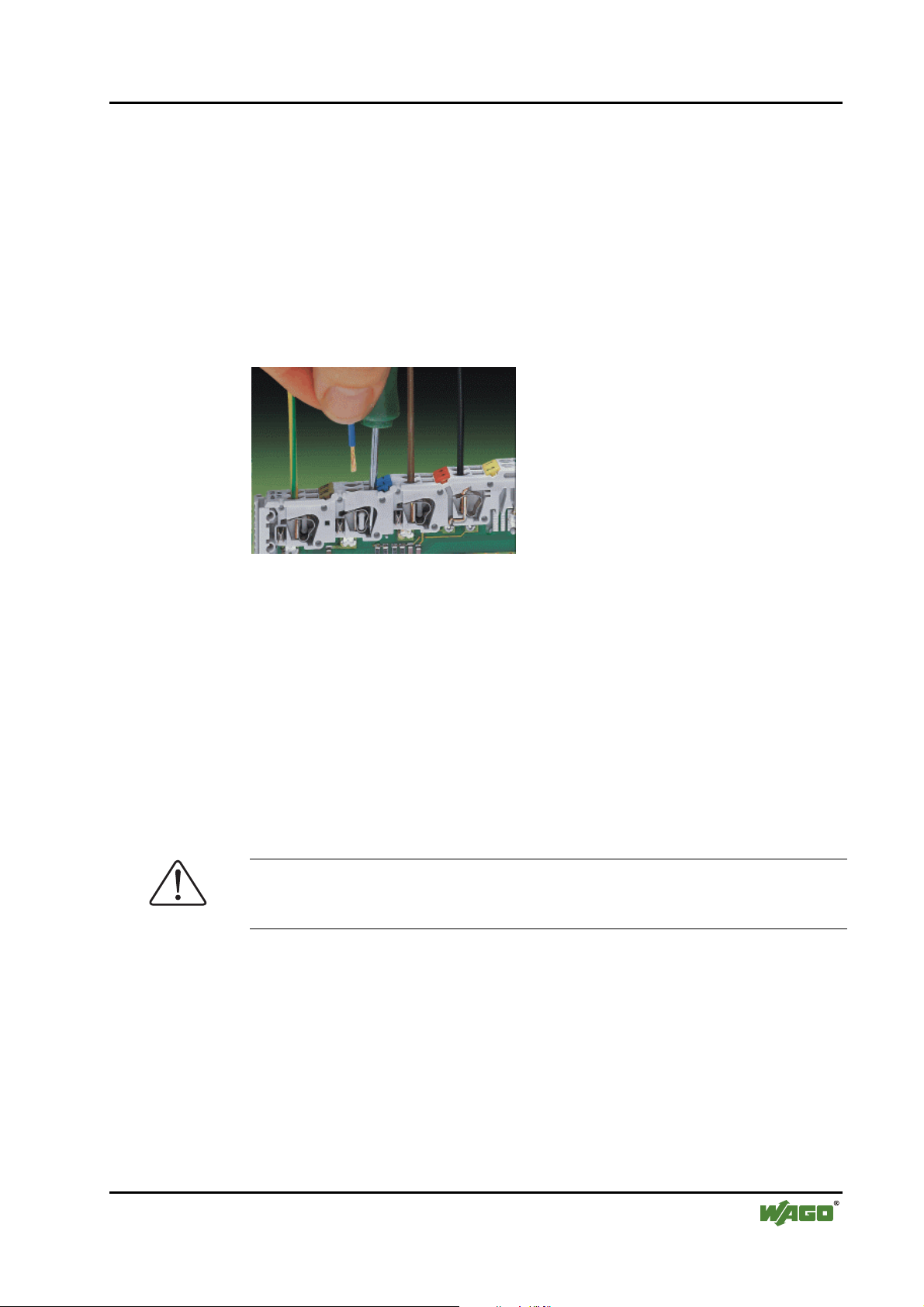

2.3.1 Wire Connection

Conductors with a cross section of 0.08 to 2.5 mm² (AWG 28-12) can be connected using a CAGE CLAMP connection to achieve a vibration resistant,

fast and maintenance free connection. To actuate CAGE CLAMP enter an

actuation tool in the opening above the connection. Following this, enter the

conductor in the corresponding opening. The conductor is clamped securely

with the removal of the actuation tool.

WAGO-I/O-SYSTEM 750 • 11

Electrical Installation

Fig. 2-6: Inserting conductor end p0xxx06x

The clamping force adjusts automatically to the cross section. The full surface

of the CAGE CLAMP pressure is applied against the conductor without

damaging it. Conductor deformation is compensated for and self-loosening is

avoided. The transition point between the conductor and the CAGE CLAMP

is protected against corrosive influences. The connection can be made quickly

and is also maintenance free, saving the costs for a periodic checking of terminal connections.

Two carrier rail contacts responsible for the electrical contact between the

grounded carrier rail and the controller, are fitted underneath the coupler/controller.

Attention

Ensure a perfect contact point between carrier rail contacts and carrier rail.

The carrier rail must be grounded.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 16

12 • WAGO-I/O-SYSTEM 750

Electrical Installation

2.3.2 Change fuse

Some Power supply modules of the WAGO-I/O-SYSTEM 750 are equipped

with a fuse holder. To isolate the modules to the right of the power supply, the

fuse can be removed from the fuse holder. For this insert a srew driver into one

of the slits available on each side and lift the holder

Fig. 2-7: Removing the fuse holder p0xxx05x

The fuses can be removed from or inserted into the holder with the fuse holder

cover and push the fuse holder pushed back into the original position.

Fig. 2-8: Opening the fuse holder p0xxx03x

Fig. 2-9: Change fuse p0xxx04x

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 17

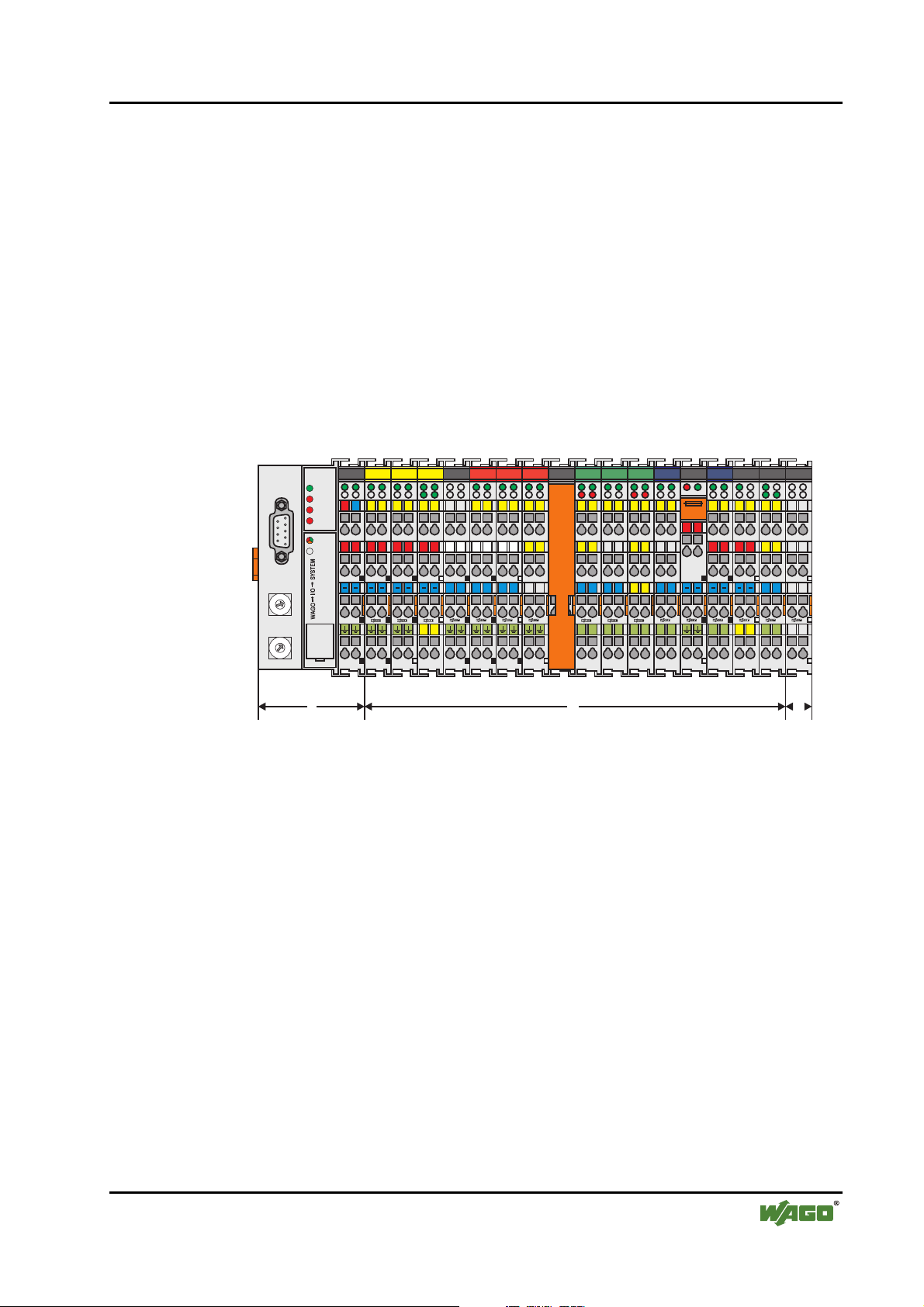

2.4 Power supply

WAGO-I/O-SYSTEM 750 • 13

Power supply

1

2

750-512 750-512 750-513 750-610 750-552750-550 750-600750-616

750-612

~

24V 24V 24V

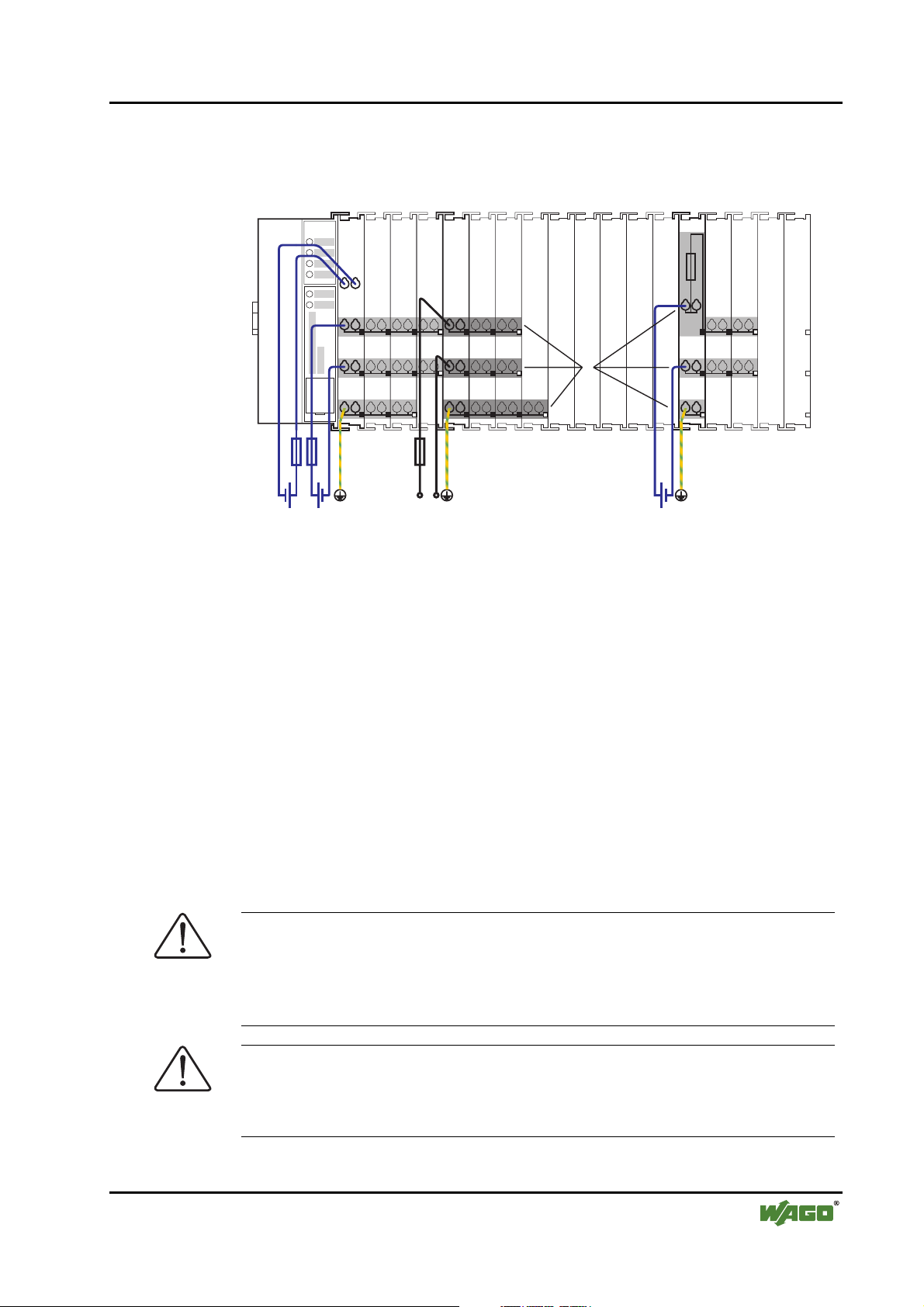

Fig. 2-10: Power supply g01xx02x

230V

750-630 750-650750-400 750-410 750-403 750-454 750-467 750-461

1 – Power supply System

2 – Power supply Field-side

The power supply on the field side is electrically isolated from the system supply. In this manner sensors and actuators can be supplied and fused by a separate voltage source.

If a non-regulated power supply is used for the coupler/controller electronics

24 V voltage supply , it must be filtered through a capacitor (200 µF per 1 A

load current). To this effect a back-up capacitor module (Order-No. 288-824)

was developed for the WAGO-I/O-SYSTEM. This module serves to regulate a

noisy 24 V DC voltage supply, to keep the ripple voltage within specified limits. The cause for these fluctuations could be a voltage interruption on the primary side, a secondary side overload or the switching of ”non quenched“ inductance or capacitance.

Warning

The supply modules + and – which are permanently integrated on the buscouplers, can be supplied with 24 V DC only.

120 V AC and 230 V AC can only be supplied via modules 750-609, 750-611

and 750-612!

Warning

The ground (earth) field side contact should be disconnected when testing the

isolation. Otherwise the results could be wrong or the module could be destroyed.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 18

14 • WAGO-I/O-SYSTEM 750

Power supply

2.4.1 System supply voltage

The system supply voltage (24 V DC) is filtered with a voltage regulator before powering the coupler electronics as well as to the internal bus. Electrical

isolation from the external fieldbus system depends on the type of Coupler/Controller.

The internal bus includes the internal communication between the coupler/controller and the bus modules as well as the power supply for the bus

modules. The power supply is limited to a maximum value. This value depends on the type of Coupler/Controller. If the sum of the internal power consumption of all bus modules exceeds this value, it is necessary to add additional internal system supply modules (Order-No. 750-613).

The control electronics in the bus modules are powered by snap-fit mounting

the bus modules using the internal bus contacts. A reliable contact is assured

by the gold plated, self cleaning slide contacts. The removal of a bus module

will cause an interruption in communication to the following bus modules.

The coupler/controller identifies the interruption point and displays a corresponding fault message.

Warning

Removing or inserting the I/O modules with the voltage applied can lead to

undefined conditions. For this reason only undertake work on the I/O modules

when isolated from the power supply!

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 19

2.4.2 Supply Voltage Field Side

The voltage is automatically supplied when the I/O modules are snapped together. Self-cleaning power jumper contacts (P.J.C.s) ensure safe connections.

The current capacity of the power contacts is 10 A max.

The PE contact is a preceding ground (earth) contact corresponding to the

standards which can be used as a protective earth. The contact has a leakage

capacity of 125 A.

Warning

Produce a low impedance connection from the carrier rail to the PE contact

point in the switch cabinet.

Attention

Depending on the I/O function, some modules do not have P.J.C.s. It is important to note this when assembling a node. Many modules require field side

power, many do not. Please review the circuit diagrams of the individual modules. An additional power supply module may be necessary.

Refer to the individual terminal/module data sheets!

WAGO-I/O-SYSTEM 750 • 15

Power supply

When adding a power supply module, the field supply is always interrupted at

the power contacts. From this point a new power supply is made, which can

also include a potential change. This feature guarantees a high degree of system flexibility.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 20

16 • WAGO-I/O-SYSTEM 750

Manufacturing Number

2.5 Manufacturing Number

The production number is part of the lateral marking on the component. The

number contains the production date, the software version and the hardware of

the component.

Hansastr. 27

D-32423 Minden

ITEM-NO.:750-400

2DI 24V DC 3.0ms

2

0.08-2.5mm

24V DC

CL I DIV

AWG 28-14

Grp. A B C D

55°C max ambient

24246

LISTED 22ZA AND 22XM

0901--02----03

op temp code T4A

0V 24V DI1

II3G

KEMA 01ATEX1024 X

EEx nA II T4

Di2

PATENTS PENDING

Manufacturing Number

0

9

Calendar

week

1

0

-

Year Software

version

2

0

0

-

Hardware

version

Fig. 2-11: Manufacturing Number g01xx09e

The remaining digits and characters represent internal information by

WAGO Kontakttechnik GmbH.

As of calendar week 09/2001, the production number is additionally printed on

the cover of the configuration and programming interface of the fieldbus coupler or controller.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 21

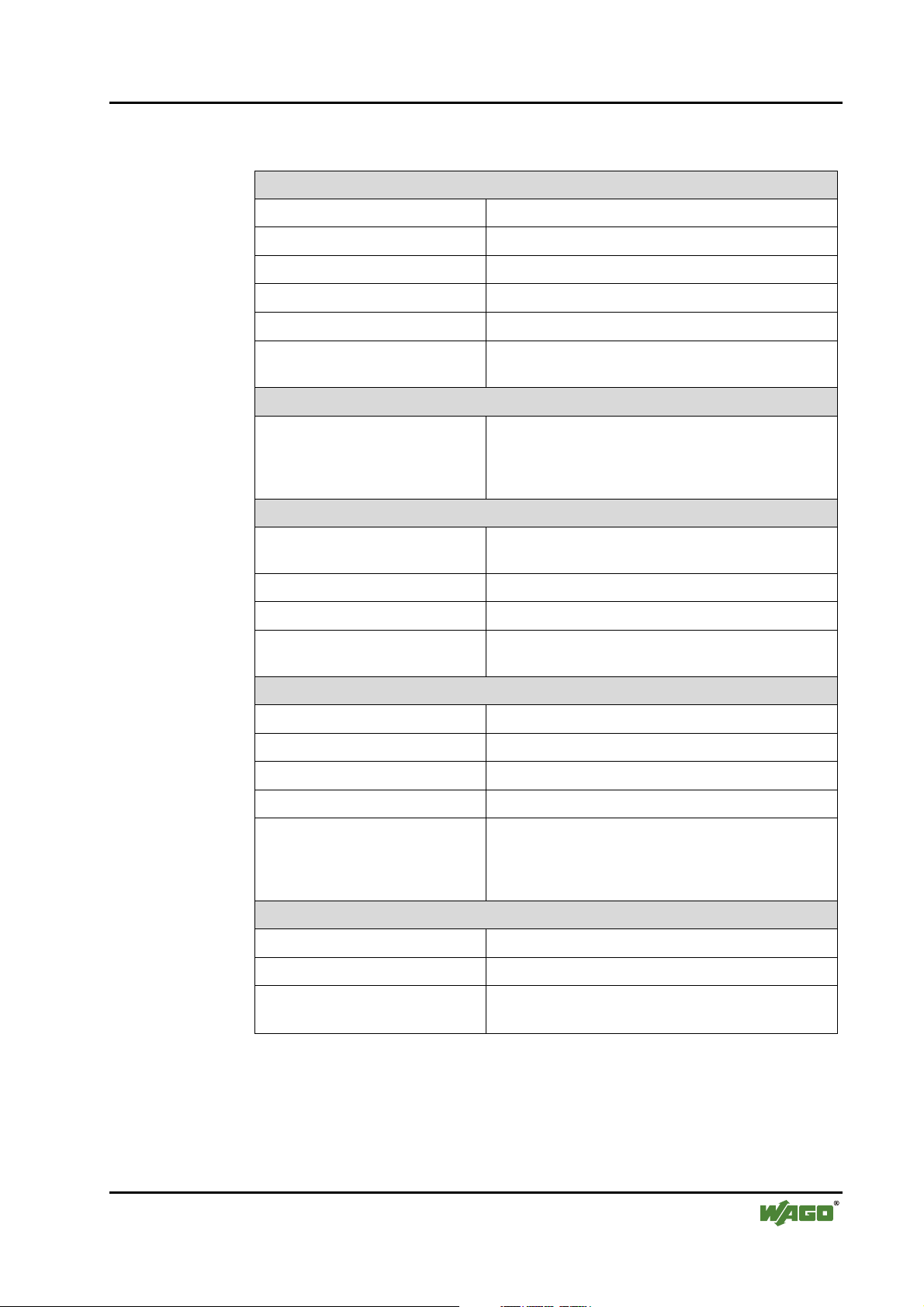

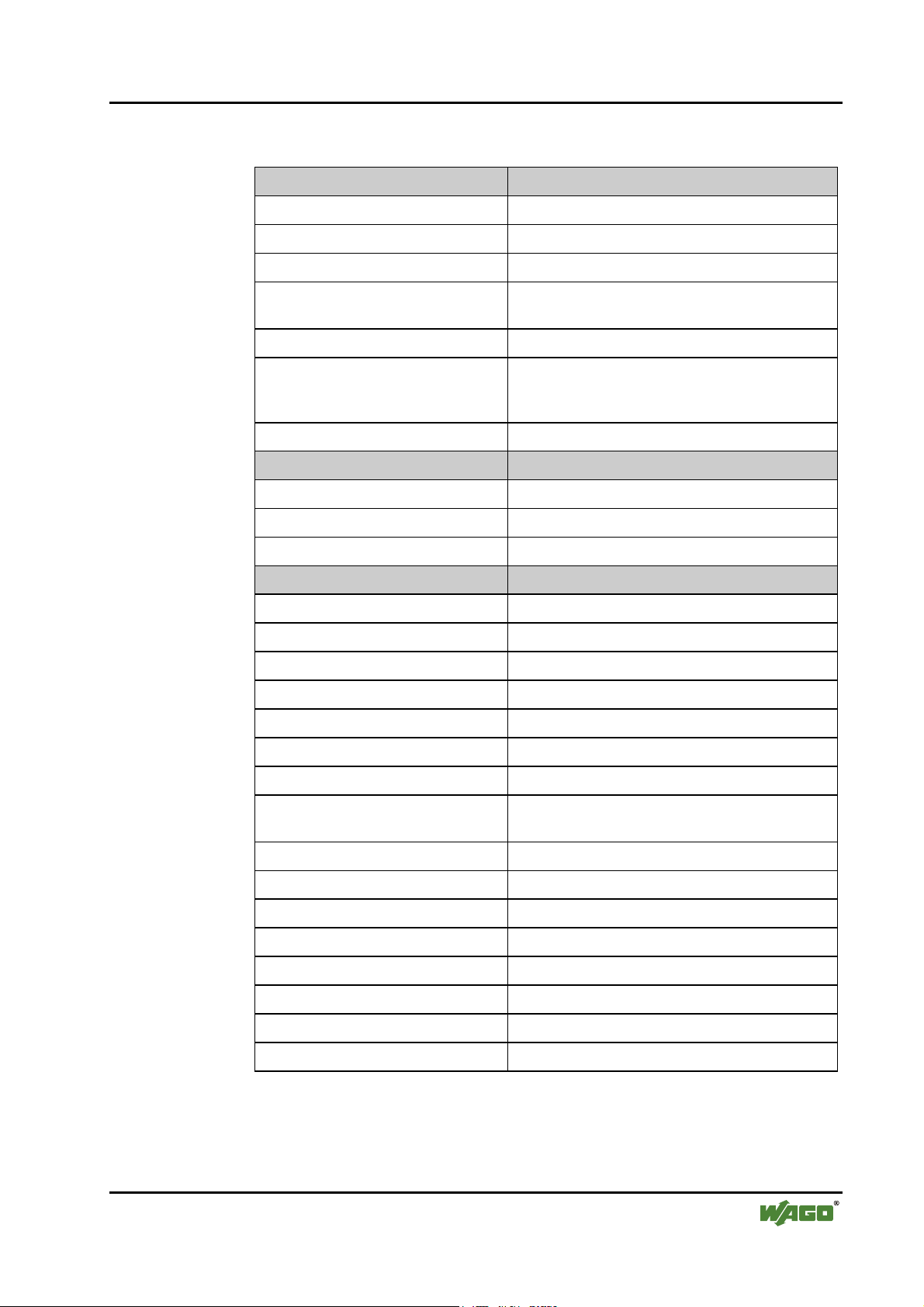

2.6 Technical Data

Mechanic

Material Polycarbonat, Polyamid 6.6

Installation on DIN 35 with interlock

modular by double featherkey-dovetail

Mounting position any position

WAGO-I/O-SYSTEM 750 • 17

Technical Data

Length of entire node

≤ 831 mm

Marking marking label type 247 and 248

paper marking label 8 x 47 mm

Wire range

Wire range CAGE CLAMP® Connection

0,08 mm² ... 2,5 mm²

AWG 28-14

8 – 9 mm Stripped lenght

Contacts

Power jumpers contacts blade/spring contact

self-cleaning

Current via power contacts

Voltage drop at I

max

max

10 A

< 1 V/64 modules

Data contacts slide contact, hard gold plated

1,5µ, self-cleaning

Climatic environmental conditions

Operating temperature 0 °C ... 55 °C

Storage temperature -20 °C ... +85 °C

Relative humidity 95 % without condensation

Resistance to harmful substances acc. to IEC 60068-2-42 and IEC 60068-2-43

Special conditions Ensure that additional measures for components are

taken, which are used in an environment involving:

– dust, caustic vapors or gasses

– ionisating radiation.

Mechanical strenght

Vibration resistance acc. to IEC 60068-2-6

Shock resistance acc. to IEC 60068-2-27

Free fall acc. to IEC 60068-2-32

≤ 1m (module in original packing)

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 22

18 • WAGO-I/O-SYSTEM 750

Technical Data

Safe electrical isolation

Air and creepage distance acc. to IEC 60646-1

Degree of protection

Degree of protection IP 20

Electromagnetic compatibility*

Derective Test values Strenght

class

Evaluation

criteria

Immunity to interference acc. to EN 50082-2 (95)

EN 61000-4-2 4kV/8kV (2/4) B

EN 61000-4-3 10V/m 80% AM (3) A

EN 61000-4-4 2kV (3/4) B

EN 61000-4-6 10V/m 80% AM (3) A

Emmission to interference acc. to

EN 50081-2 (94)

Measuring

distance

Class

EN 55011 30 dBµV/m (30m) A

37 dBµV/m

* Exception: 750-630, 750-631

Dimensions

02

01

A

B

24V 0V

A

C

B

D

A

C

D

A

C

B

B

D

A

C

D

C

B

D

+

+

100

-

-

PE PE

35

51

65

Seitenansicht Koppler/Controller

12

24

64

Abmessungen in mm

Fig. 2-12: Dimensions g01xx05d

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 23

3 Fieldbus coupler / controller

3.1 Fieldbus coupler 750-333

This chapter includes:

3.1.1 Description......................................................................................21

3.1.2 Hardware.........................................................................................22

3.1.2.1 View .........................................................................................22

3.1.2.2 Device supply...........................................................................23

3.1.2.3 Fieldbus connection..................................................................24

3.1.2.4 Display elements ......................................................................25

3.1.2.5 Station address .........................................................................26

3.1.2.6 Configuration interface ............................................................26

3.1.3 Operating system.............................................................................27

3.1.4 Process image..................................................................................28

3.1.4.1 Local process image .................................................................28

3.1.4.2 Allocation of the input and output data....................................29

3.1.5 Configuration ..................................................................................30

3.1.5.1 GSD files..................................................................................31

3.1.5.2 Identification bytes...................................................................32

3.1.5.3 Example....................................................................................34

3.1.6 Parameterising the coupler..............................................................36

3.1.7 Configuring the process data channel .............................................38

3.1.8 Configuration and parameterisation of I/O modules.......................39

3.1.8.1 Digital I/O modules..................................................................39

3.1.8.1.1 2 DI I/O modules......................................................................39

3.1.8.1.2 4 DI I/O modules......................................................................40

3.1.8.1.3 2 DI I/O modules modules with 1 bit diagn. per channel.........41

3.1.8.1.4 2 DO I/O modules ....................................................................42

3.1.8.1.5 2 DO I/O modules with 1 bit diagn. per channel......................43

3.1.8.1.6 2 DO I/O module with 2 bit diagn. per channel .......................44

3.1.8.1.7 4 DO I/O modules ....................................................................45

3.1.8.1.8 2 DI/DO I/O module with 1 bit diagn. per channel..................46

3.1.8.1.9 Internal system supply module with diagnosis.........................47

3.1.8.2 Analog I/O modules .................................................................48

3.1.8.2.1 2 AI I/O modules......................................................................48

3.1.8.2.2 4 AI I/O module .......................................................................49

3.1.8.2.3 2 AO I/O modules ....................................................................50

3.1.8.3 Digital special modules ............................................................51

3.1.8.3.1 Counter modules ......................................................................51

3.1.8.3.2 PWM module ...........................................................................52

3.1.8.4 Distance and Angle Messurment Modules...............................53

3.1.8.4.1 SSI encoder interface................................................................53

3.1.8.4.2 Incremental encoder interface ..................................................54

3.1.8.4.3 Digital impulse interface ..........................................................55

3.1.8.5 Serial interfaces ........................................................................56

3.1.9 Diagnosis.........................................................................................57

Fieldbus coupler / controller • 19

Fieldbus coupler 750-333

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 24

20 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.9.1 Station status 1 to 3 ..................................................................58

3.1.9.2 PROFIBUS-DP master address................................................58

3.1.9.3 Manufacturer‘s identification...................................................58

3.1.9.4 Identification based diagnosis ..................................................58

3.1.9.5 Device status ............................................................................59

3.1.9.5.1 Internal status messages and arguments...................................60

3.1.9.5.2 Internal bus status messages and arguments ............................60

3.1.9.5.3 PROFIBUS-DP status messages and arguments......................61

3.1.9.6 Channel based diagnosis ..........................................................62

3.1.9.6.1 Fault types of I/O modules with diagnostic capability.............63

3.1.9.6.2 I/O modules fault cases ............................................................64

3.1.10 LED signalling ................................................................................65

3.1.10.1 Blink code ................................................................................65

3.1.10.2 Fieldbus status..........................................................................66

3.1.10.3 Fault message via blink code of the BUS-LED........................67

3.1.10.4 Node status ...............................................................................68

3.1.10.5 Fault message via the blink code of the I/O LED.....................69

3.1.10.6 Supply voltage status................................................................70

3.1.11 Fault behaviour ...............................................................................71

3.1.11.1 Fieldbus failure.........................................................................71

3.1.11.2 Internal bus fault.......................................................................72

3.1.12 Technical data .................................................................................73

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 25

3.1.1 Description

The fieldbus coupler 750-333 displays the peripheral data of all I/O modules in

the WAGO-I/O-SYSTEM 750 on PROFIBUS DP.

In the initialisation phase the bus coupler determines the physical structure of

the node and creates a process image from this with all inputs and outputs. I/O

modules with a bit width smaller than 8 can be combined to form one byte in

order to optimise the address space.

In addition the possibility exists to deactivate projected I/O modules. In this

manner the physical structure of the node can be individually designed with

regard to the peripheral signals, without undertaking any changes to an already

existing control application.

The diagnosis concept is based on an identification and channel based diagnosis in accordance with EN 50170. Thus it is not necessary to program modules

for the evaluation of manufacturer specific diagnosis information.

Fieldbus coupler / controller • 21

Fieldbus coupler 750-333

• Max. process data length 128 Byte (input and output process image)

• Automatic recognition of transmission speed on the PROFIBUS from

9.6 kBd to 12 MBd

• All I/O modules from the WAGO-I/O-SYSTEM 750 are supported

• Configuration modules can be parameterised as wildcards.

• Parameterable substitute value for each channel

• D-Sub 9 pole bus connection

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 26

22 • Fieldbus coupler / controller

Fieldbus coupler 750-333

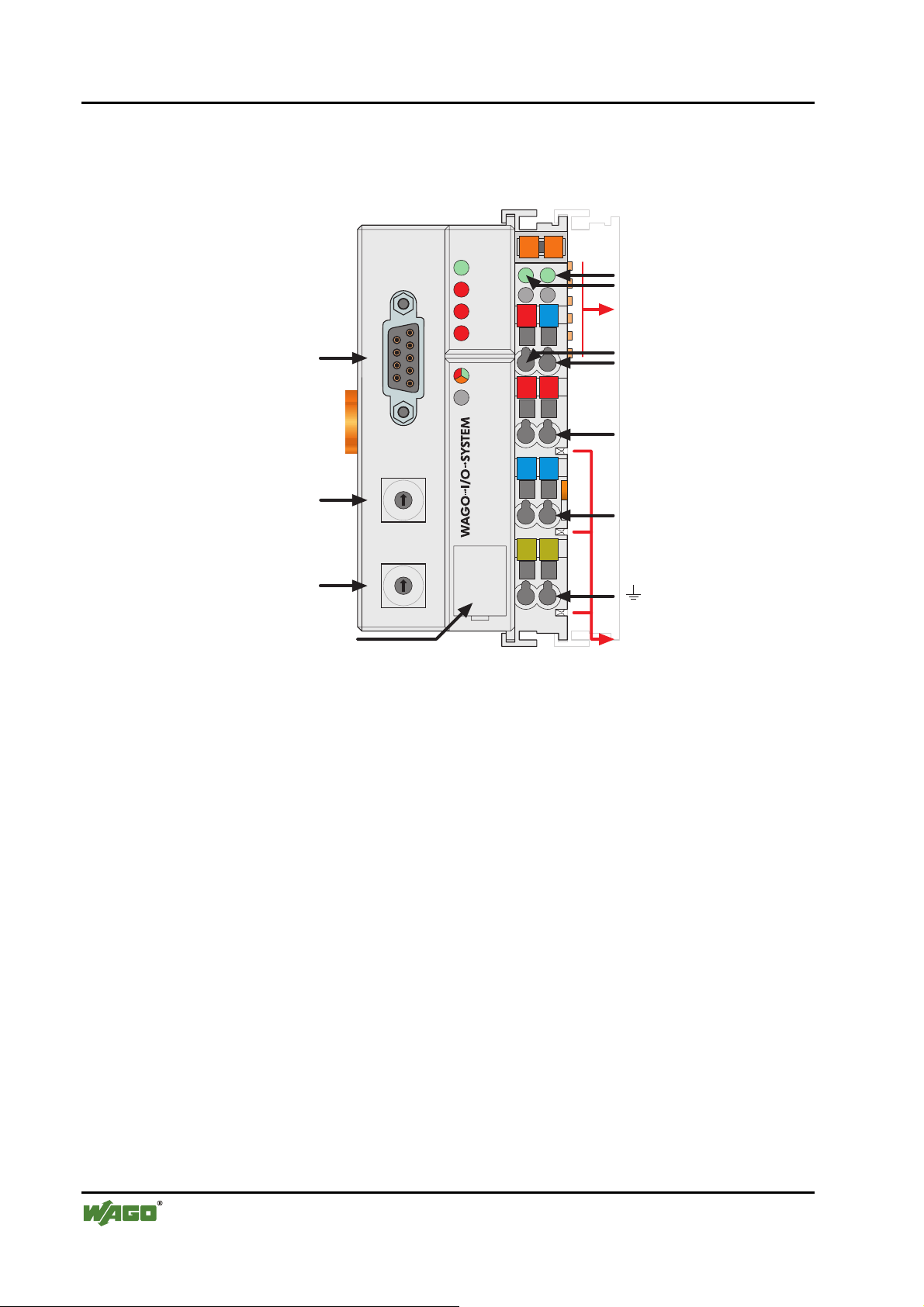

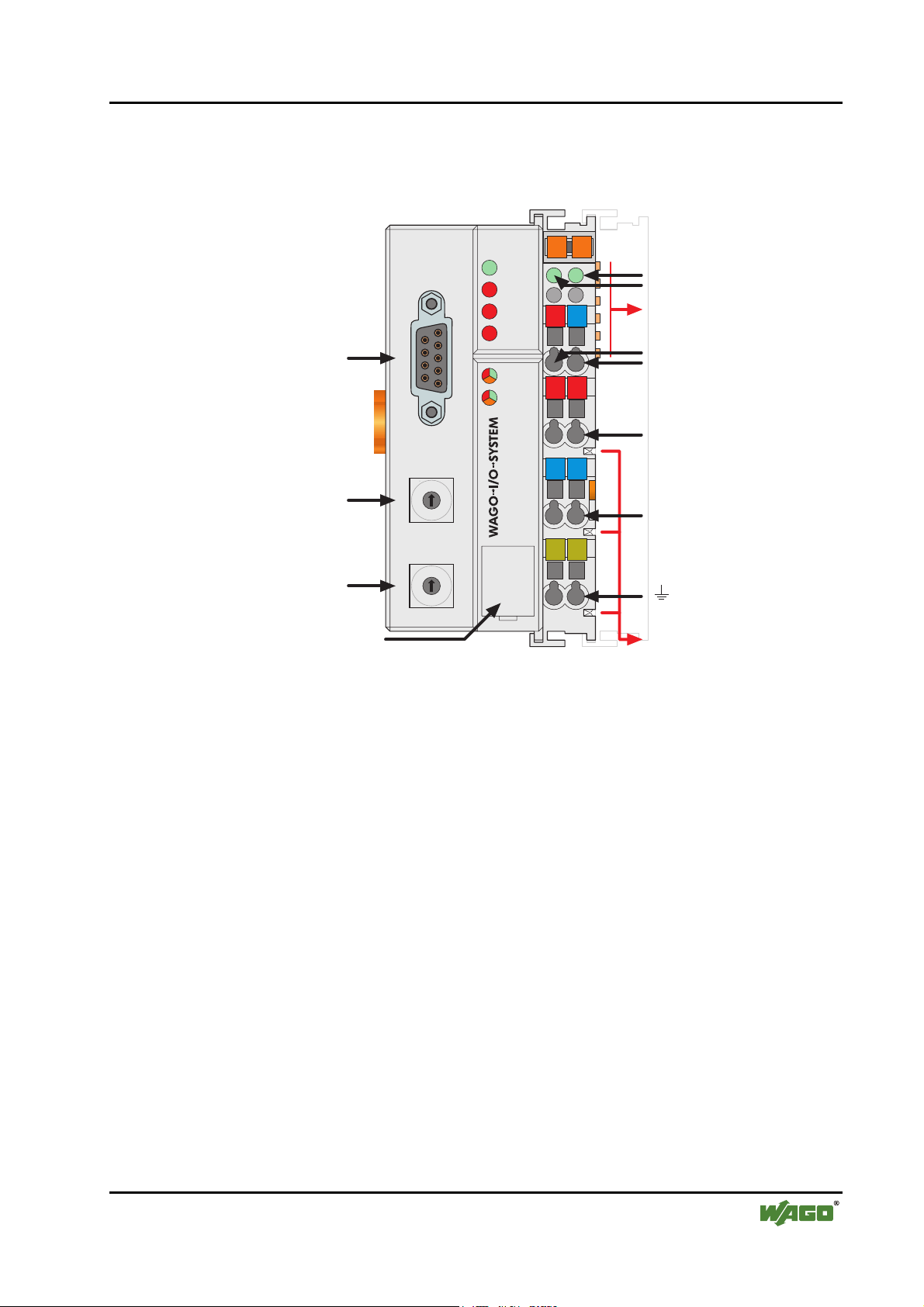

3.1.2 Hardware

3.1.2.1 View

Status der

Feldbusanschluss

D-Sub

PROFIBUS

RUN

BF

DIA

BUS

I/O

01 02

A

B

0V

24V

++

Betriebsspannung

C

D

-Leistungskontakte

-System

Datenkontakte

Versorgung

24V

0V

Versorgung über

Leistungskontakte

24V

ADDRESS

--

0V

Adresse

x1

1

0

9

2

3

8

4

7

6

5

750-333

PE PE

Leistungskontakte

Adresse

KonfigurationsSchnittstelle

9

8

7

x10

1

0

6

5

2

3

4

Fig. 3-1: Fieldbus coupler 750-333 PROFIBUS DP/V1 g033300d

The fieldbus coupler comprises of:

• Supply module with Internal system supply module for the system supply

as well as power jumper contacts for the field supply via I/O module assemblies.

• Fieldbus interface with the bus connection

• 2 rotary switches for the station address (decimal)

• Display elements (LED's) for status display of the operation, the bus com-

munication, the operating voltages as well as for fault messages and diagnosis

• Electronics for communication with the I/O modules (internal bus) and the

fieldbus interface

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 27

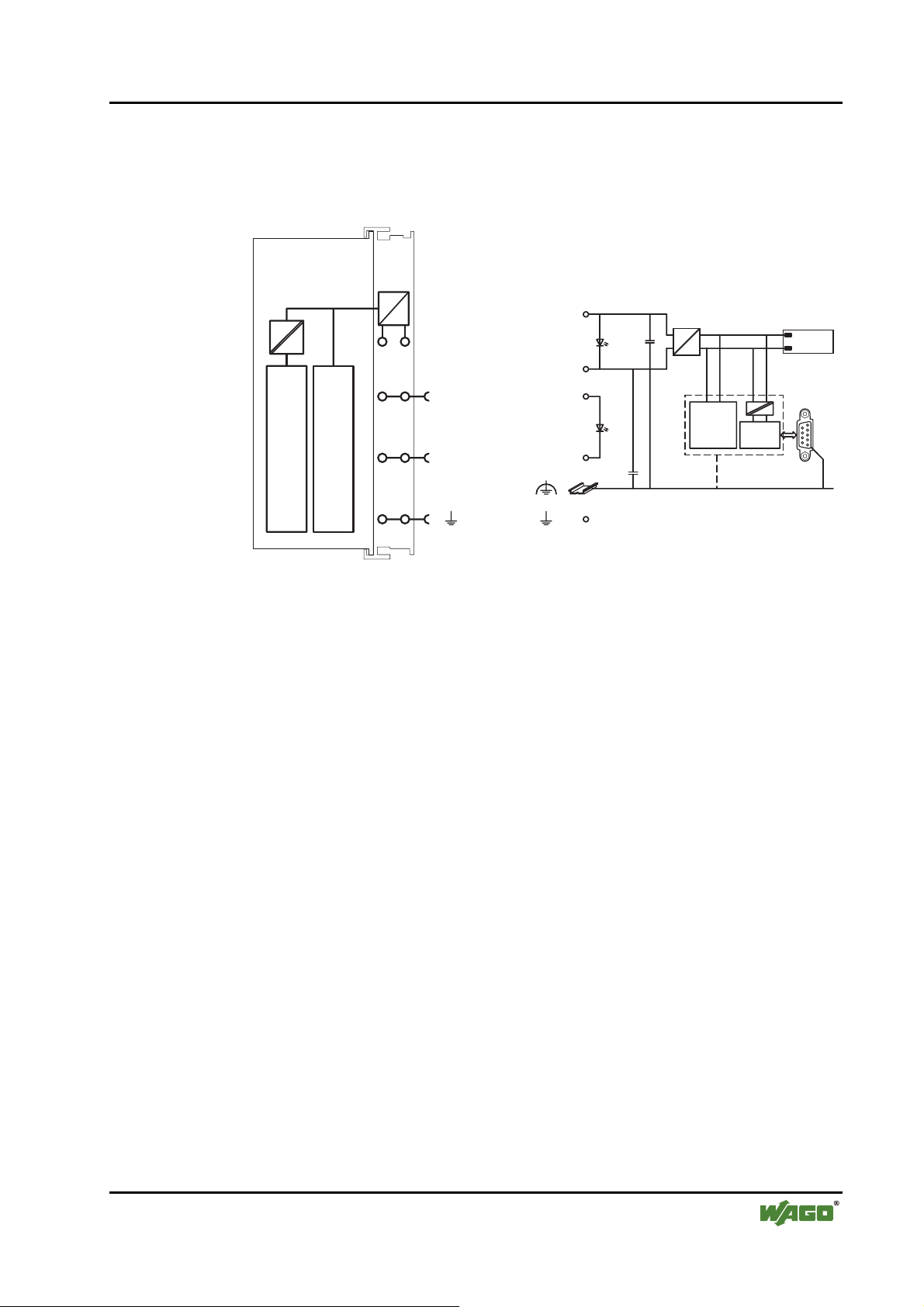

3.1.2.2 Device supply

The supply is made via terminal bocks with CAGE CLAMP® connection. The

device supply is intended both for the system and the field units.

Fieldbus coupler / controller • 23

Fieldbus coupler 750-333

1

5

24V/0V

10nF

DC

DC

Bus-

klemmen

0V

24V

2

6

24V

3

4

750-333

7

0V

8

NTERFACE

FELDBUS I

ELEKTRONIK

24V

0V

10nF

ELEKTRONIK

FELDBUS

INTERFACE

Fig. 3-2: Device supply g012105d

The integrated internal system supply module generates the necessary voltage

to supply the electronics and the connected I/O modules.

The fieldbus interface is supplied with electrically isolated voltage from the

internal system supply module.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 28

24 • Fieldbus coupler / controller

Fieldbus coupler 750-333

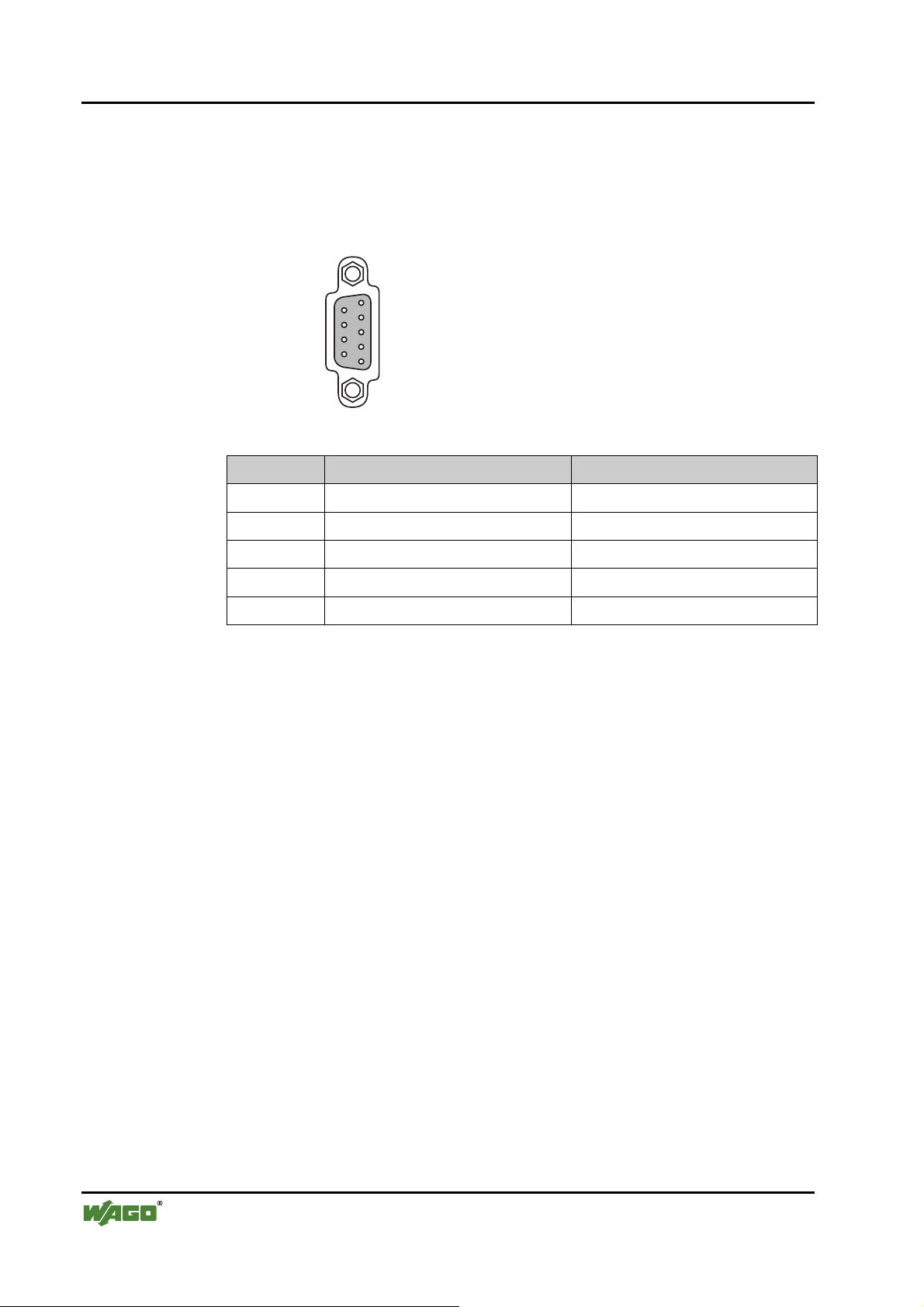

3.1.2.3 Fieldbus connection

The PROFIBUS interface is designed as a Sub-D connection in accordance

with the US Standard EIA RS 485 for cable linked data transmission.

9-pol. D-Sub-Buchse

9

VP

8

7

6

RxD/TxD-N

Fig. 3-3: Bus connection, D-SUB g012102d

Pin Signal Description

3 RxD(TxD)-P Transmit (receive) signal

5

DGND

4

RTS

3

RxD/TxD-P

2

1

4 RTS Ready To Send

5 GND Supply ground (earth)

6 Vcc Voltage supply

8 RxD(TxD) N Transmit (receive) signal

The electrical isolation between the fieldbus system and the electronics is

achieved by means of DC/DC converters and optocouplers in the fieldbus interface.

The connection point is mechanically lowered permitting fitting in an 80 mm

high switch box once connected.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 29

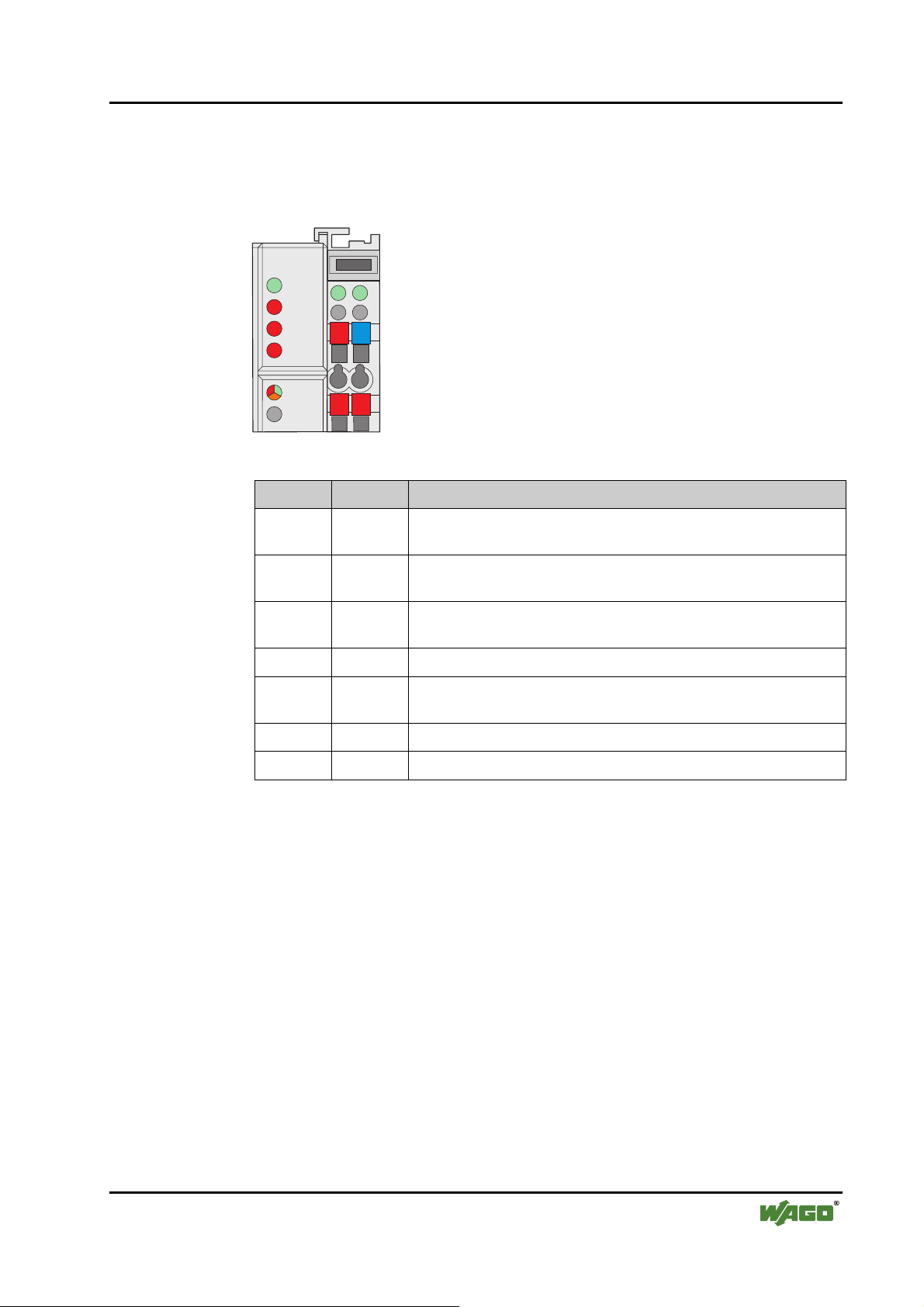

3.1.2.4 Display elements

The operating condition of the fieldbus coupler or node is signalled via light

diodes (LED).

PROFIBUS

A

RUN

B

BF

DIA

BUS

24V

0V

Fieldbus coupler / controller • 25

Fieldbus coupler 750-333

C

D

I/O

++

Fig. 3-4: Display elements 750-333 g012106x

LED Colour Meaning

RUN green The 'RUN' LED indicates to the operator if the fieldbus coupler /

controller is correctly initialised.

BF red The 'BF'-LED indicates whether the communication functions via

the PROFIBUS.

DIA red The 'DIA' LED indicates an external diagnosis. The signalling is not

supported by all devices.

BUS red The 'BUS'-LED signals a projecting fault.

IO red /green

/ orange

The 'I/O'-LED indicates the operation of the node and signals faults

encountered.

A green Status of the operating voltage system

C green Status of the operating voltage – power jumper contacts

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 30

26 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.2.5 Station address

The station address (decimal) is determined using two rotary switches on the

electronic module.

ADDRESS

x1

1

0

9

2

3

8

4

7

6

5

x10

1

0

9

2

3

8

4

7

6

5

Fig. 3-5: Setting the station address g012102d

The switch „x1“ determines the units position of the address. The switch

„x10“ determines the tens positions of the address. Valid station addresses are

between 1 and 99. The coupler also permits the station address 0.

The station address is taken over by the fieldbus coupler after switching on the

device (initialisation phase). Adjustments of the switch have no effect during

operation.

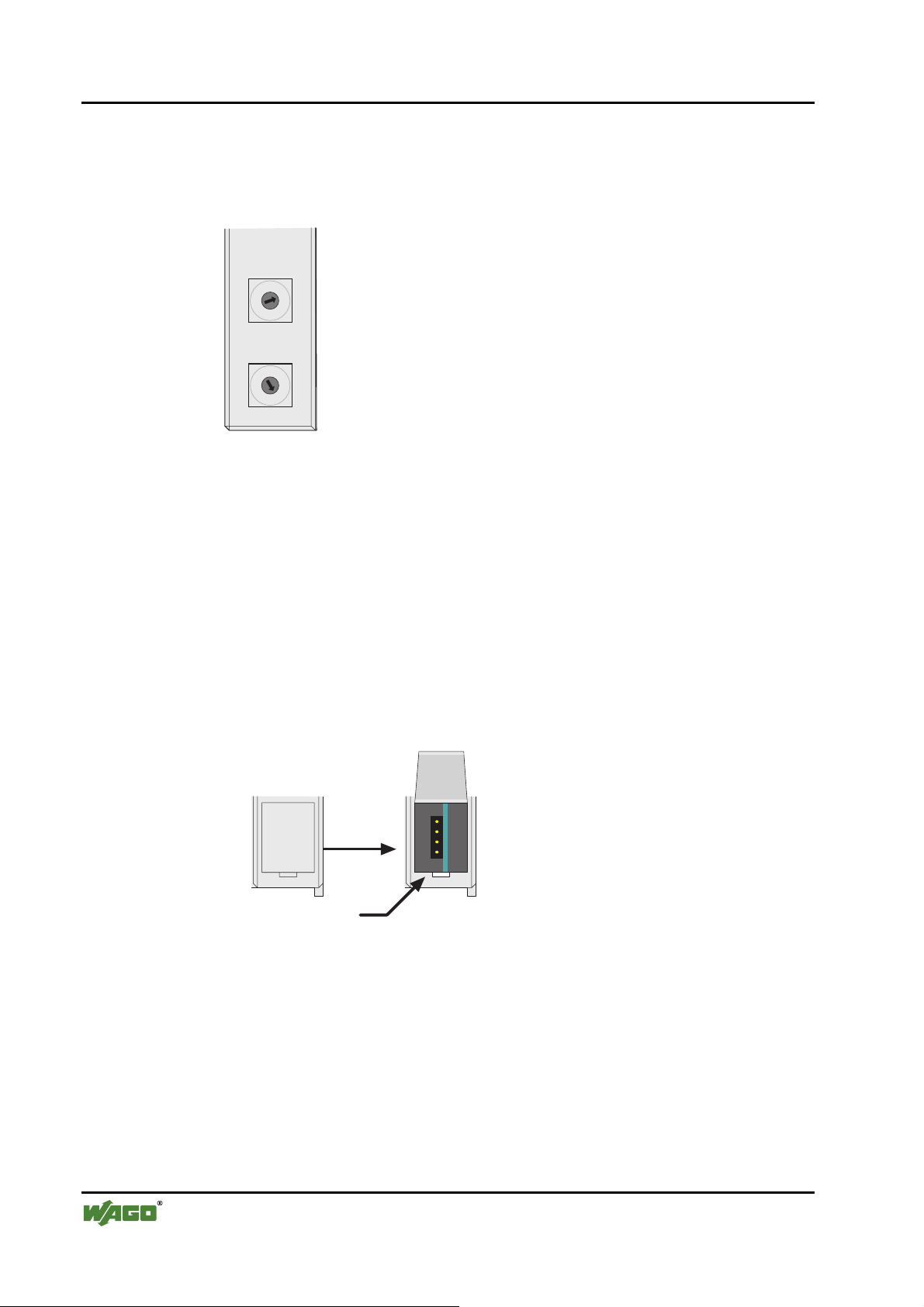

3.1.2.6 Configuration interface

The configuration interface used for the communication with WAGO-I/OCHECK or for firmware upload is located behind the cover flap.

Klappe

öffnen

KonfigurationsSchnittstelle

Fig. 3-6: Configuration interface g01xx06d

The communication cable (750-920) is connected to the 4 pole header.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 31

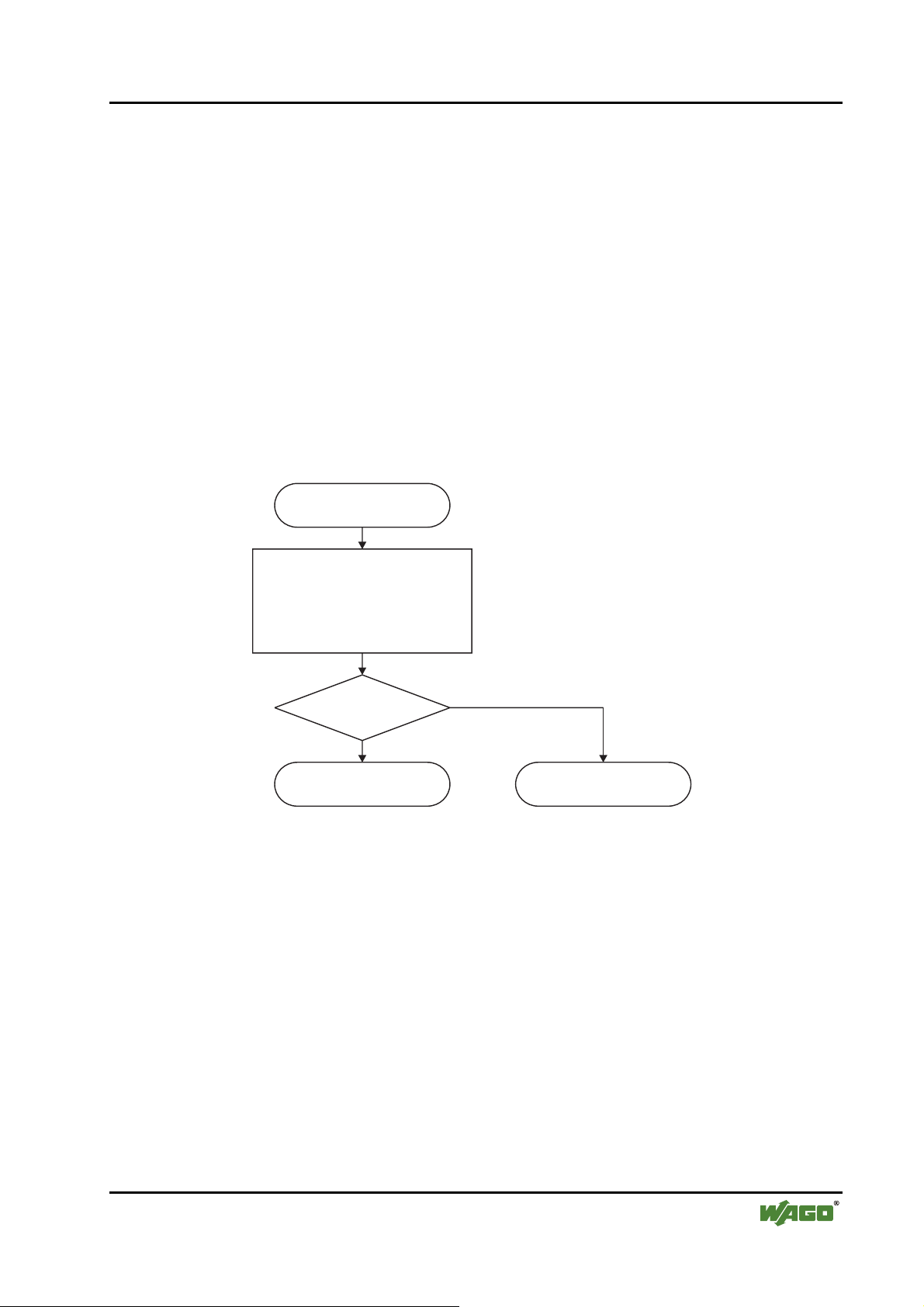

3.1.3 Operating system

Following the configuration of the master activation and the electrical installation if the fieldbus station can start up the system.

After switching on the supply voltage the coupler performs a self test of all

functions of its devices, the I/O module and the fieldbus interface. Following

this the I/O modules and the present configuration is determined, whereby an

external not visible list is generated. This list includes an input and an output

area on which is represented the fieldbus RAM of the protocol chip.

In the event of a fault the coupler changes to the "Stop" condition. The "I/O"

LED flashes red. After a fault free start up the coupler changes to the "Fieldbus

start" status and the "I/O" LED lights up green.

Versorgungsspannung

einschalten

Fieldbus coupler / controller • 27

Fieldbus coupler 750-333

Koppler-Selbsttest,

Ermittlung Busklemmen

und Konfiguration,

Erstellung interner Liste

“I/O”-LED blinkt rot

Fehler

Nein

Feldbusstart

“I/O”-LED leuchtet grün

Fig. 3-7: Operating system 750-333 g012113d

Ja

Stop

“I/O”-LED blinkt rot

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 32

28 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.4 Process image

3.1.4.1 Local process image

After switching on, the coupler recognises all I/O modules plugged into the

node which supply or wait for data (data width/bit width > 0). In nodes analog

and digital I/O modules can be mixed.

Note

For the number of input and output bits or bytes of the individually activated

on I/O modules please refer to the corresponding I/O module description.

The coupler produces an internal process image from the data width and the

type of type of I/O module as well as the position of the I/O modules in the

node. It is divided into an input and an output data area.

The data of the digital I/O modules is bit orientated, i.e. the data exchange is

made bit for bit. The analog I/O modules are representative for all byte orientated I/O modules, i.e. those where the data exchange is made byte for byte.

These I/O modules include for example the counter modules, I/O modules for

angle and path measurement as well as the communication modules.

The data of the I/O modules is separated for the local input and output process

image in the sequence of their position after the coupler in the individual process image.

Note

A process image restructuring may result if a node is changed or extended. In

this case the process data addresses also change in comparison with earlier

ones.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 33

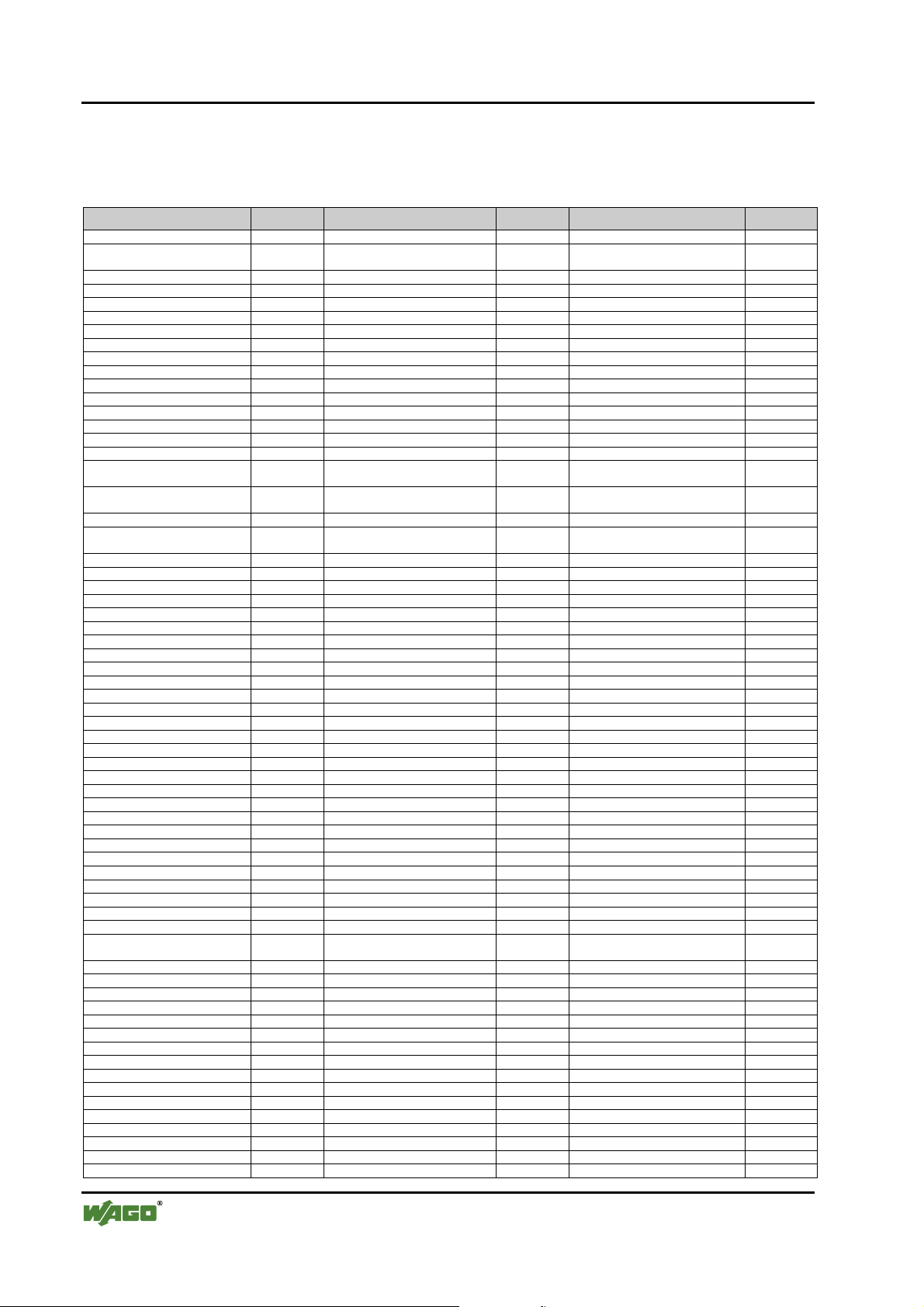

3.1.4.2 Allocation of the input and output data

The process data is exchanged via the PROFIBUS with the higher ranking

controls (master). A maximum of 128 bytes of data is transmitted from the

master to the coupler or from the node to the output data. The coupler responds by returning a maximum of 128 bytes input data to the master.

Modules are configured when projecting the node which can be taken over

from a hardware catalogue of the configuration programs. The information

covering the possible modules is contained in the GSD files.

The coupler generates an internal mapping in accordance with the installed and

configured settings of the node, in which the allocation of the input and output

data is determined in the local process image with the position in the

PROFIBUS DP Telegram.

Master, z. B. SPS

CPU

Fieldbus coupler / controller • 29

Fieldbus coupler 750-333

750-

1234 5 6789

DI

AI

AI

DOAOAO

DO

Anschaltung

452

504 504

550 550

600

Master-

Adressen

I

O

I

O

byteweise Zuordnung,

Erstellung aufdem PC

I

O

PROFIBUS

PROFIBUS

402DI402 452

ZuordnungslisteZuordnungsliste

II

OO

bit- und byteweise

Zuordnung,

Erstellung automatisch

durch den Koppler

Fig. 3-8: Allocation of the input and output data g012117d

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 34

30 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.5 Configuration

The configuration of the node is performed in accordance with the physical requirements of the fieldbus coupler and I/O modules.

The fieldbus coupler or the process data channel is to be configured on the first

slot.

The other slots are configured in accordance with the physical requirements of

the I/O modules. Here only I/O modules with process data are relevant. The

supply modules without diagnosis, bus internal system supply module and the

termination module are to be ignored for the configuration because they do not

provide any process data.

One or tow modules are entered in the hardware catalogue for each I/O module. The module appear as 750-xyz ..., for example 750-400 2 DI/24 V DC/3.0

.

ms

For all binary modules an addition is made to the entry *750-xyz .... When us-

ing these denominations the coupler adds the binary information to the current

module in a byte which was previously opened with 750-xyz .... The use of a

„*“ module is only permitted when the number of channels is less than or

equal to the remaining bits in the previously opened byte. The binary I/O modules combined in a byte can be arranged at separate locations, i.e. binary I/O

modules with a different signal type or also byte orientated I/O modules can be

connected between.

In order to be able to individually arrange the scope of connected periphery

units independent of the control program, it is possible to parameterise I/O

modules in the configuration table as „not connected“. In this manner process

data still present is filtered for the individual module and not transferred on the

PROFIBUS DP to and read by the periphery units.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 35

3.1.5.1 GSD files

Under PROFIBUS DP the features of the modules are defined by the manufacturers in the form of a GSD file (unit basic data).

Structure, content and coding of this unit main data are standardised and made

available to the user allowing to project optional DP slaves using the project

units of various manufacturers.

Further information

i

The PNO provides information about the GSD files of all listed manufacturers.

GSD and symbol files for the configuration of the I/O modules are available

under the order number 750-910 on disks or from the WAGO INTERNET

page.

http://www.wago.com

Fieldbus coupler / controller • 31

Fieldbus coupler 750-333

GSD file for I/O-Module 750-333 WAGOB754.GSD

The GSD file is read by the configuration software and the corresponding settings transmitted. For the necessary inputs and handling steps please refer to

the software user manuals.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 36

32 • Fieldbus coupler / controller

Fieldbus coupler 750-333

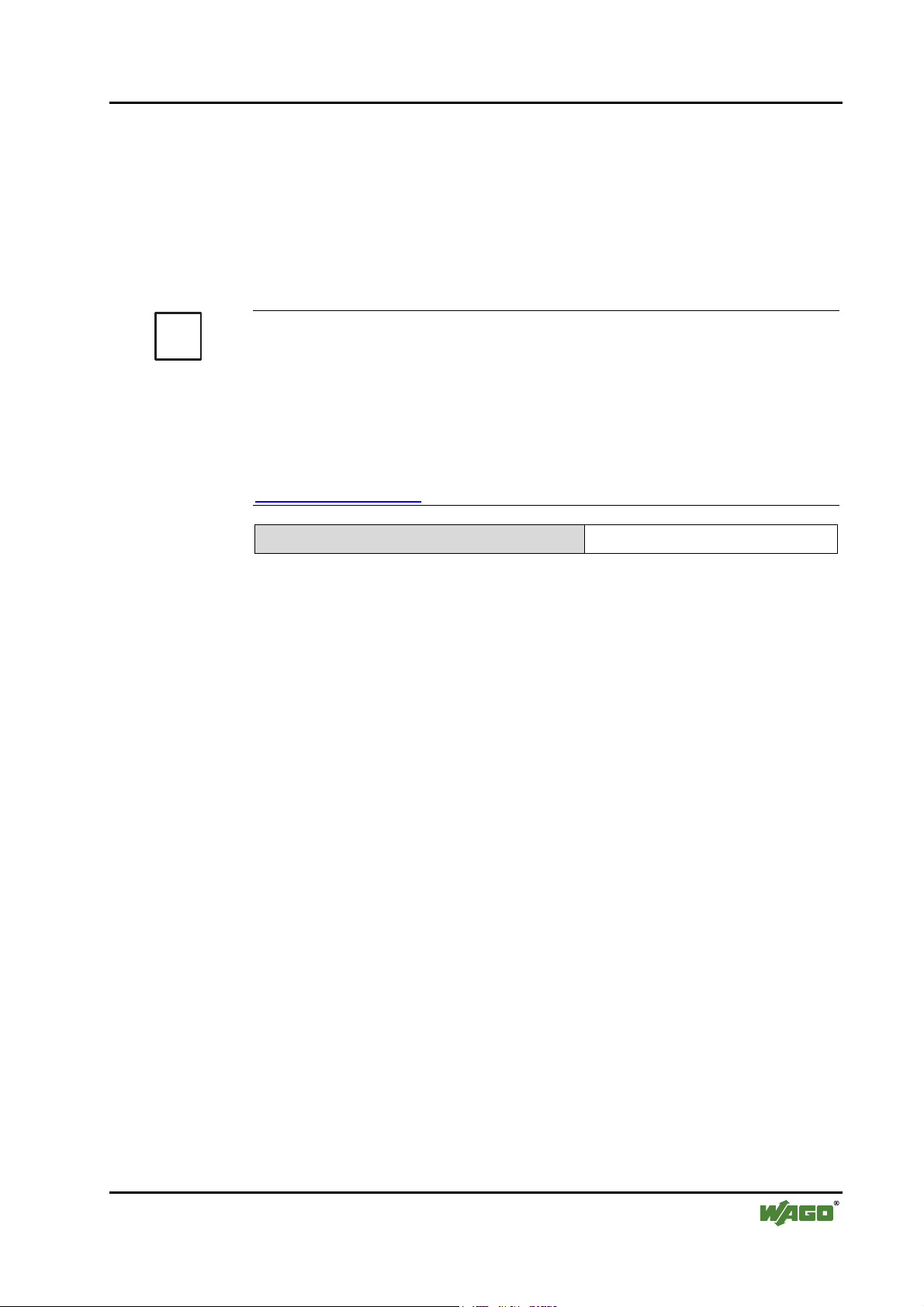

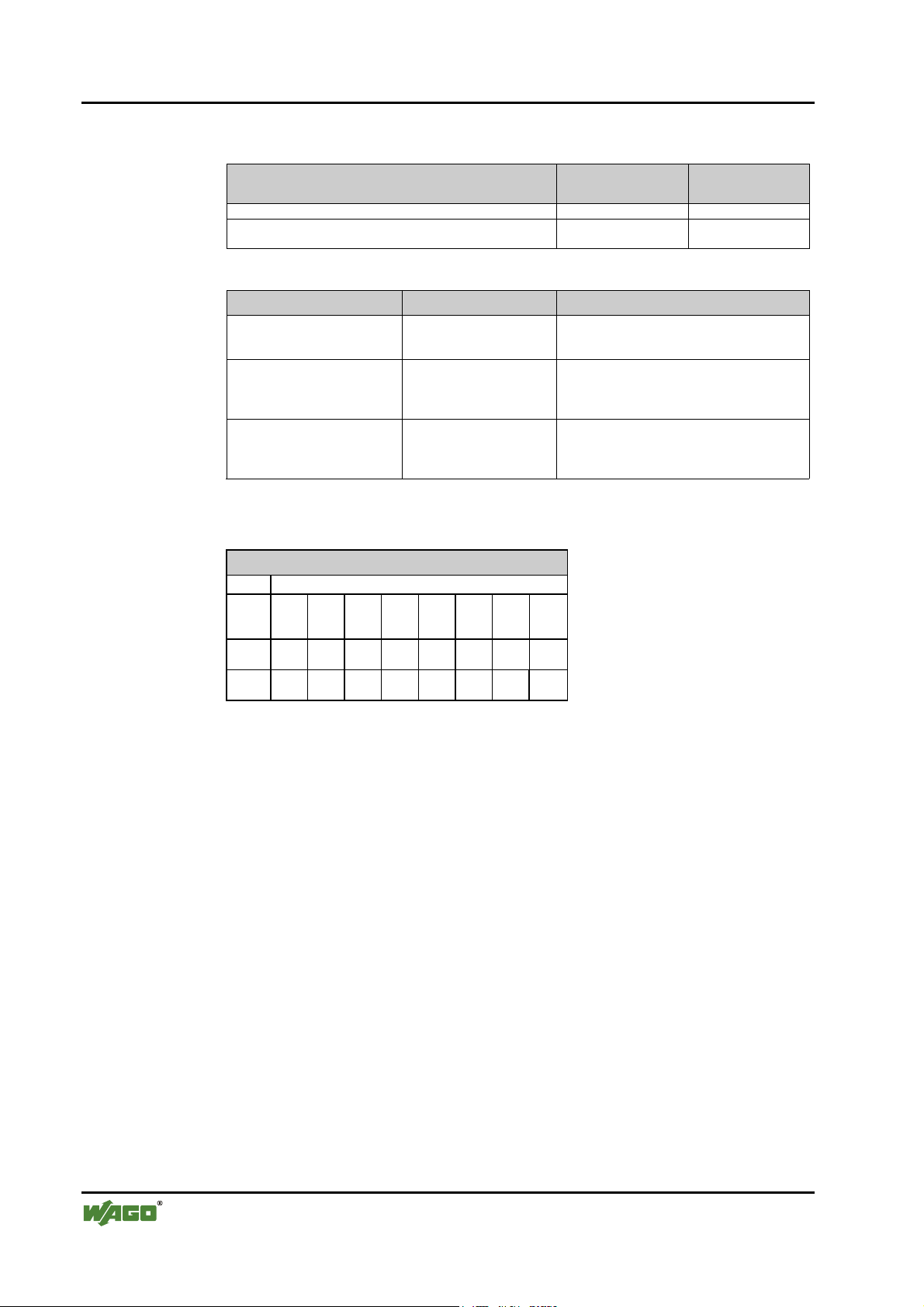

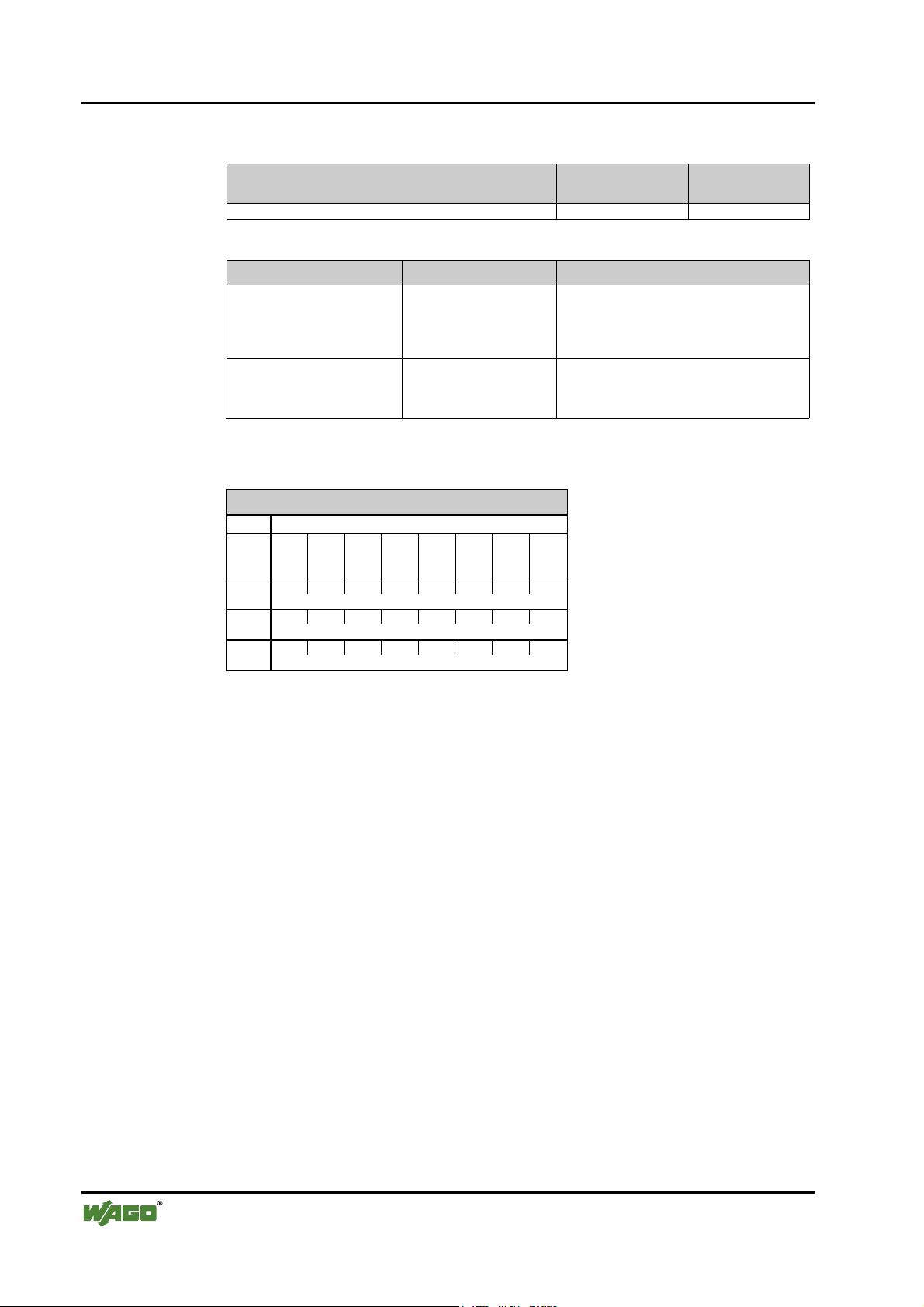

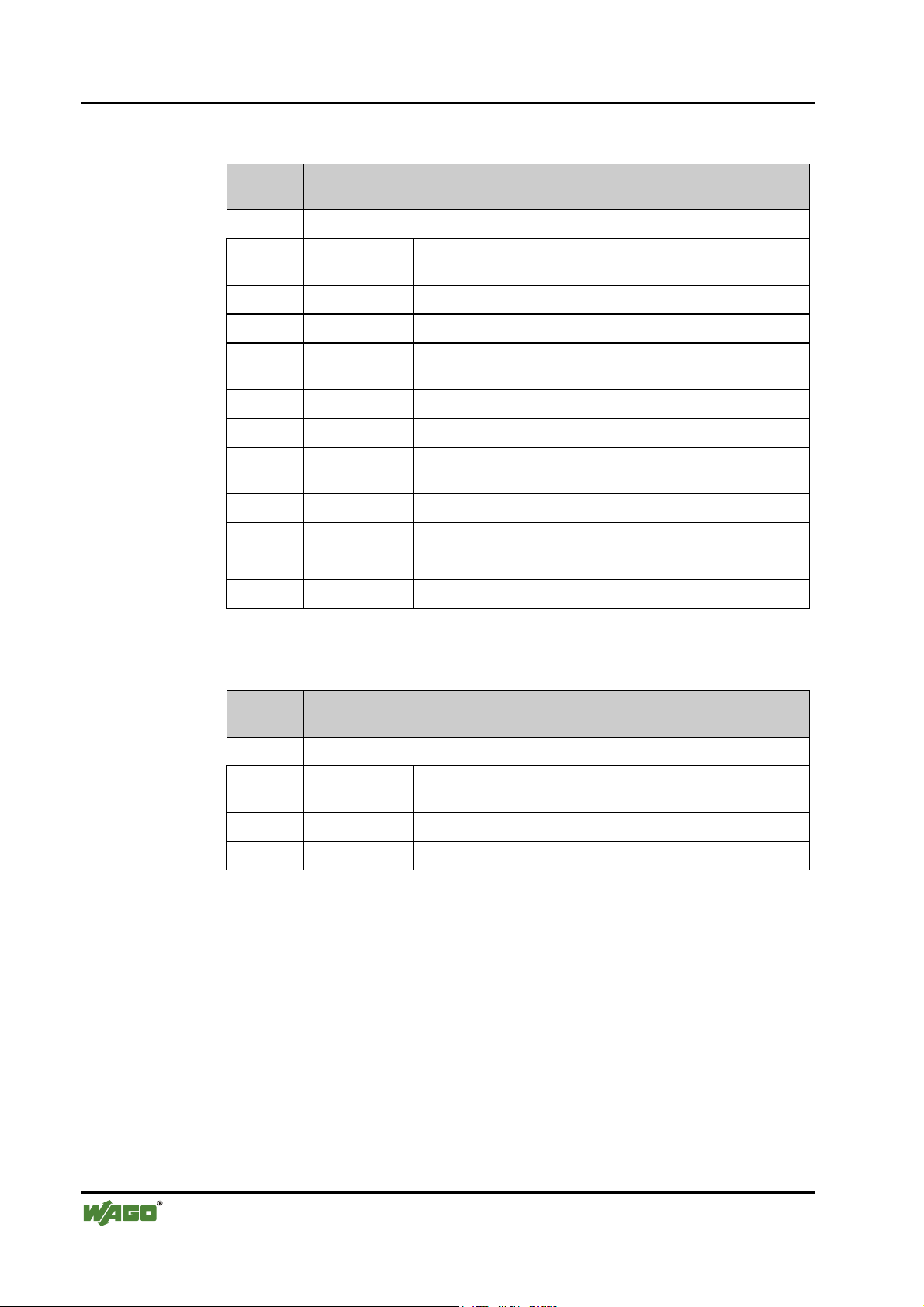

3.1.5.2 Identification bytes

The identification bytes contain information about the design and structure of

the unit inputs and outputs. For projecting each I/O module, or each channel is

allocated an identification (module).

Bit Meaning

7 6 5 4 3 2 1 0

0

0

0

...

1

0

0

1

0

0

1

1

1

Data length

1 byte or word

0

0

0

2 bytes or words

1

0

0

3 bytes or words

0

1

0

...

...

...

...

16 bytes or words

1

1

1

Input and output

spec. identification formats

Input

Output

Input and output

Format

0

1

0 = Byte structure

1 = Word structure

Consistence over

0

1

Byte or word

Total length

This information is saved in the GSD file. During projecting the I/O module is

selected in accordance with the article number using the configuration software in the hardware catalogue.

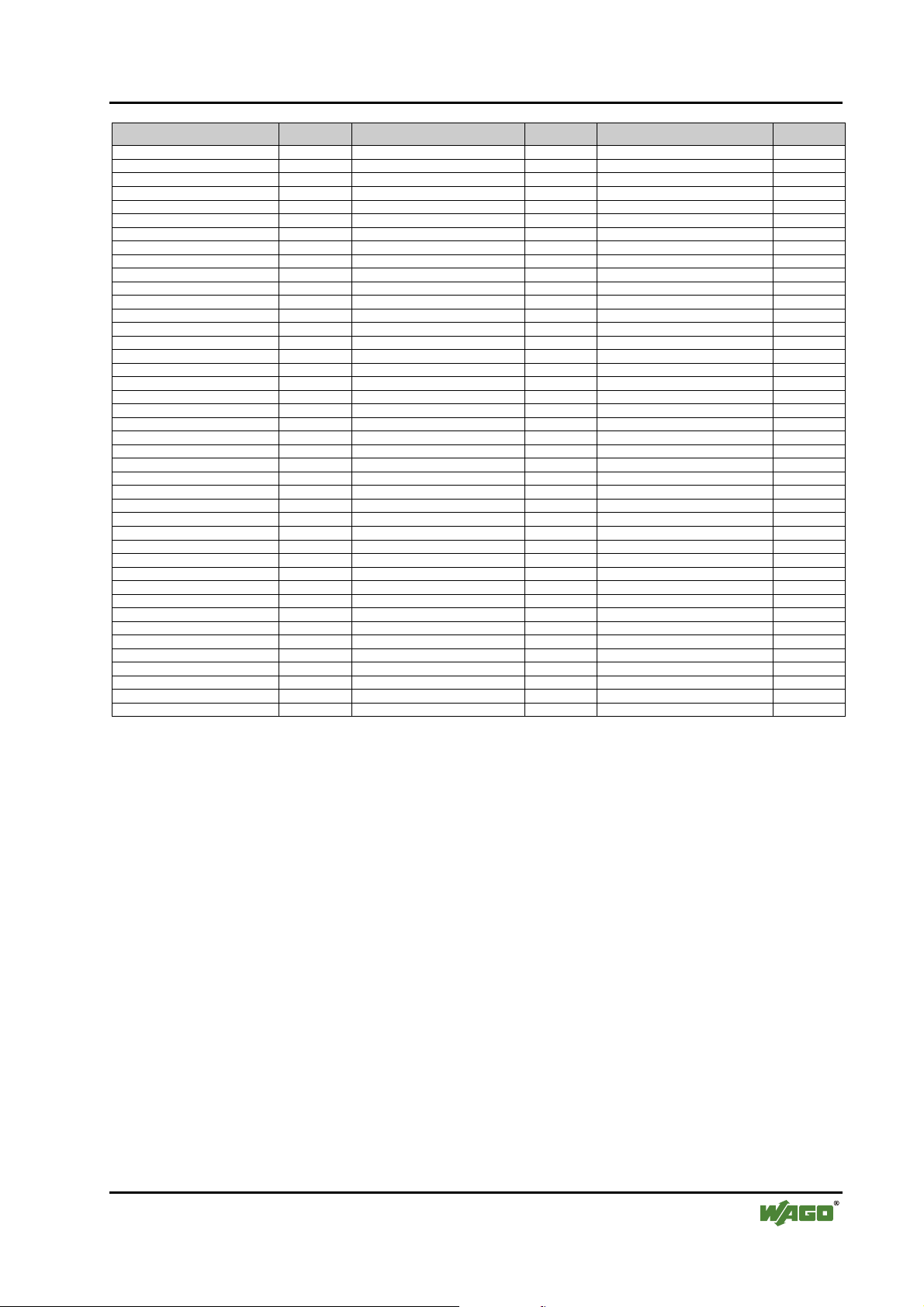

Module Ident. Module Ident

750-333 No process data channel 0x00 750-333 2 Byte process data channel 0xB1

750-400 2 DI/24 V DC/3.0 ms 0x10 *750-400 2 DI/24 V DC/3.0 ms 0x00

750-401 2 DI/24 V DC/0.2 ms 0x10 *750-401 2 DI/24 V DC/0.2 ms 0x00

750-402 4 DI/24 V DC/3.0 ms 0x10 *750-402 4 DI/24 V DC/3.0 ms 0x00

750-403 4 DI/24 V DC/0.2 ms 0x10 *750-403 4 DI/24 V DC/0.2 ms 0x00

750-404 Counter Module 0xF2

750-405 2 DI/230 V AC/10 ms 0x10 *750-405 2 DI/230 V AC/10 ms 0x00

750-406 2 DI/120 V AC/10 ms 0x10 *750-406 2 DI/120 V AC/10 ms 0x00

750-408 4 DI/24 V DC/3.0 ms 0x10 *750-408 4 DI/24 V DC/3.0 ms 0x00

750-409 4 DI/24 V DC/0.2 ms 0x10 *750-409 4 DI/24 V DC/0.2 ms 0x00

750-410 2 DI/24 V DC/3.0 ms 0x10 *750-410 2 DI/24 V DC/3.0 ms 0x00

750-411 2 DI/24 V DC/0.2 ms 0x10 *750-411 2 DI/24 V DC/0.2 ms 0x00

750-412 2 DI/48 V DC/3.0 ms 0x10 *750-412 2 DI/48 V DC/3.0 ms 0x00

750-413 2 DI/48 V DC/0.2 ms 0x10 *750-413 2 DI/48 V DC/0.2 ms 0x00

750-414 4 DI/5 V DC/0.2 ms 0x10 *750-414 4 DI/5 V DC/0.2 ms 0x00

750-415 4 DI/24 V AC/DC/20 ms 0x10 *750-415 4 DI/24 V AC/DC/20 ms 0x00

750-418 2 DI/24 V DC DIA ACK 0x30 *750-418 2 DI/24 V DC DIA ACK 0x00

750-419 2 DI/24 V DC DIA 0x10 *750-419 2 DI/24 V DC DIA 0x00

750-423 4 DI/24 V AC/DC/50 ms 0x10 *750-423 4 DI/24 V AC/DC/50 ms 0x00

750-424 2 DI/24 V DC DIA 0x10 *750-424 2 DI/24 V DC DIA 0x00

750-452 2 AI/0-20 mA/diff. 0x51

750-454 2 AI/4-20 mA/diff. 0x51

750-456 2 AI/±10 V/diff. 0x51

750-461 2 AI/RTD 0x51

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 37

Fieldbus coupler / controller • 33

Fieldbus coupler 750-333

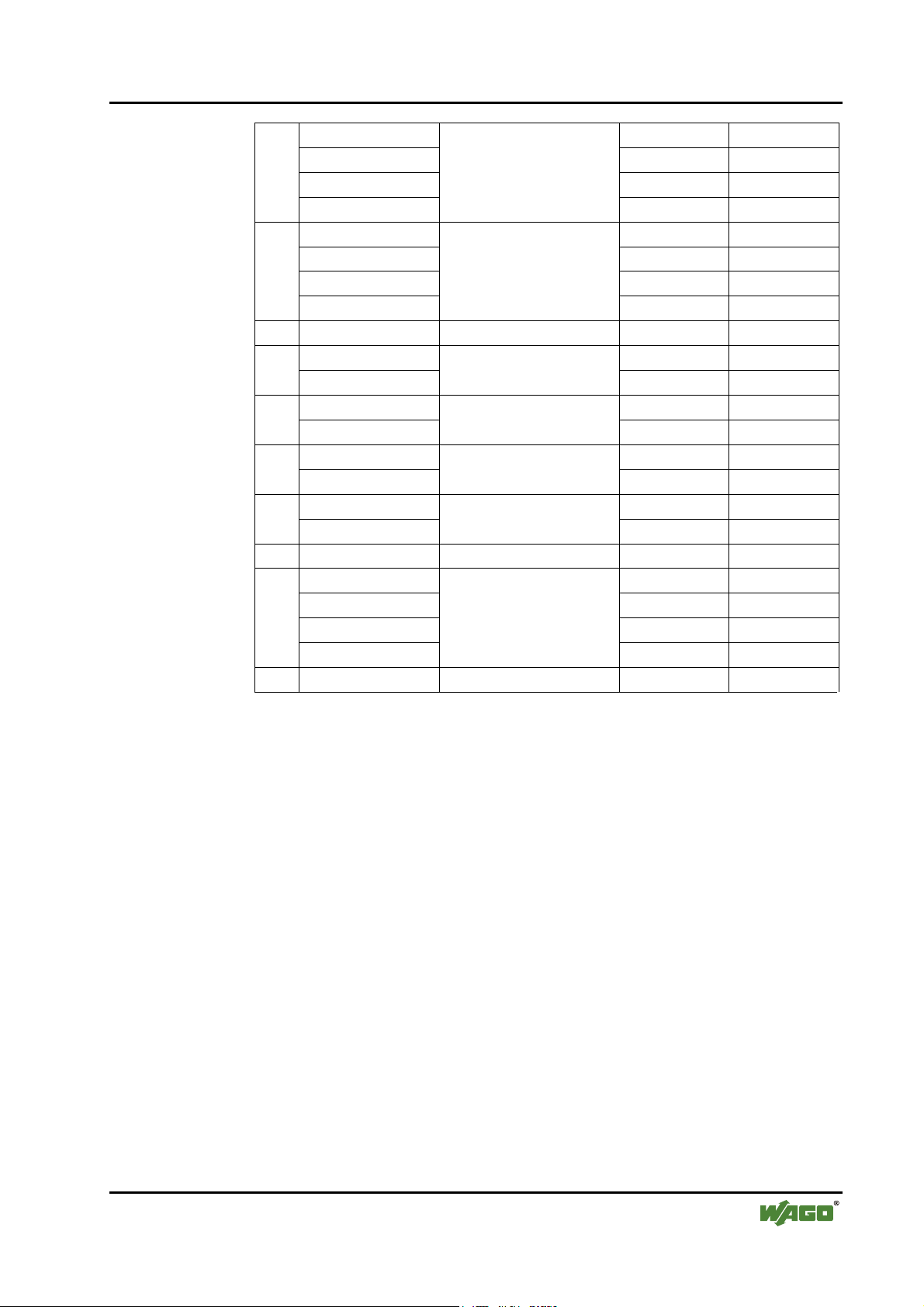

Module Ident. Module Ident

750-462 2 AI/TC 0x51

750-465 2 AI/0-20 mA/SE 0x51

750-466 2 AI/4-20 mA/SE 0x51

750-467 2 AI/0-10 V/SE 0x51

750-468 4 AI/0-10 V/SE 0x53

750-469 2 AI/TC/OCM 0x51

750-472 2 AI/0-20 mA/OVLP 0x51

750-474 2 AI/4-20 mA/OVLP 0x51

750-476 2 AI/±10 V 0x51

750-478 2 AI/0-10 V 0x51

750-501 2 DO/24 V DC/0.5 A 0x20 *750-501 2 DO/24 V DC/0.5 A 0x00

750-502 2 DO/24 V DC/2.0 A 0x20 *750-502 2 DO/24 V DC/2.0 A 0x00

750-504 4 DO/24 V DC/0.5 A 0x20 *750-504 4 DO/24 V DC/0.5 A 0x00

750-506 2 DO/24 V DC/0.5 A DIA 0x20 *750-506 2 DO/24 V DC/0.5 A DIA 0x00

750-507 2 DO/24 V DC/2.0 A DIA 0x20 *750-507 2 DO/24 V DC/2.0 A DIA 0x00

750-509 2 DO/230 V AC/0.3 A 0x20 *750-509 2 DO/230 V AC/0.3 A 0x00

750-511 2 DO 24 V DC/PWM 0xF2

750-512 2 DO Relay/250 V AC 0x20 *750-512 2 DO Relay/250 V AC 0x00

750-513 2 DO Relay/250 V AC 0x20 *750-513 2 DO Relay/250 V AC 0x00

750-514 2 DO Relay/125 V AC 0x20 *750-514 2 DO Relay/125 V AC 0x00

750-516 4 DO/24 V DC/0.5 A 0x20 *750-516 4 DO/24 V DC/0.5 A 0x00

750-517 2 DO Relay/230 V AC 0x20 *750-517 2 DO Relay/230 V AC 0x00

750-519 4 DO/5 V DC/20 mA 0x20 *750-519 4 DO/5 V DC/20 mA 0x00

750-522 2 DO/230V AC/0.5 A DIA 0x20 *750-522 2 DO/230V AC/0.5 A DIA 0x00

750-550 2 AO/0-10 V 0x61

750-552 2 AO/0-20 mA 0x61

750-554 2 AO/4-20 mA 0x61

750-556 2 AO/±10 V 0x61

750-610 P supply 24 V DC/DIA 0x00

750-611 P supply 230 V AC/DIA 0x00

750-630 SSI-Intf. standard 0x95

750-630 SSI-Intf. alternative 0x93

750-631 Encoder Intf. 0xB5

750-650 RS232C Intf. 5 Byte 0xB5

750-650 RS232C Intf. 3 Byte 0xB3

750-651 TTY Intf. 5 Byte 0xB5

750-651 TTY Intf. 3 Byte 0xB3

750-653 RS485 Intf. 5 Byte 0xB5

750-653 RS485 Intf. 3 Byte 0xB3

750-654 Data Exch. Module 0xF1

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 38

34 • Fieldbus coupler / controller

Fieldbus coupler 750-333

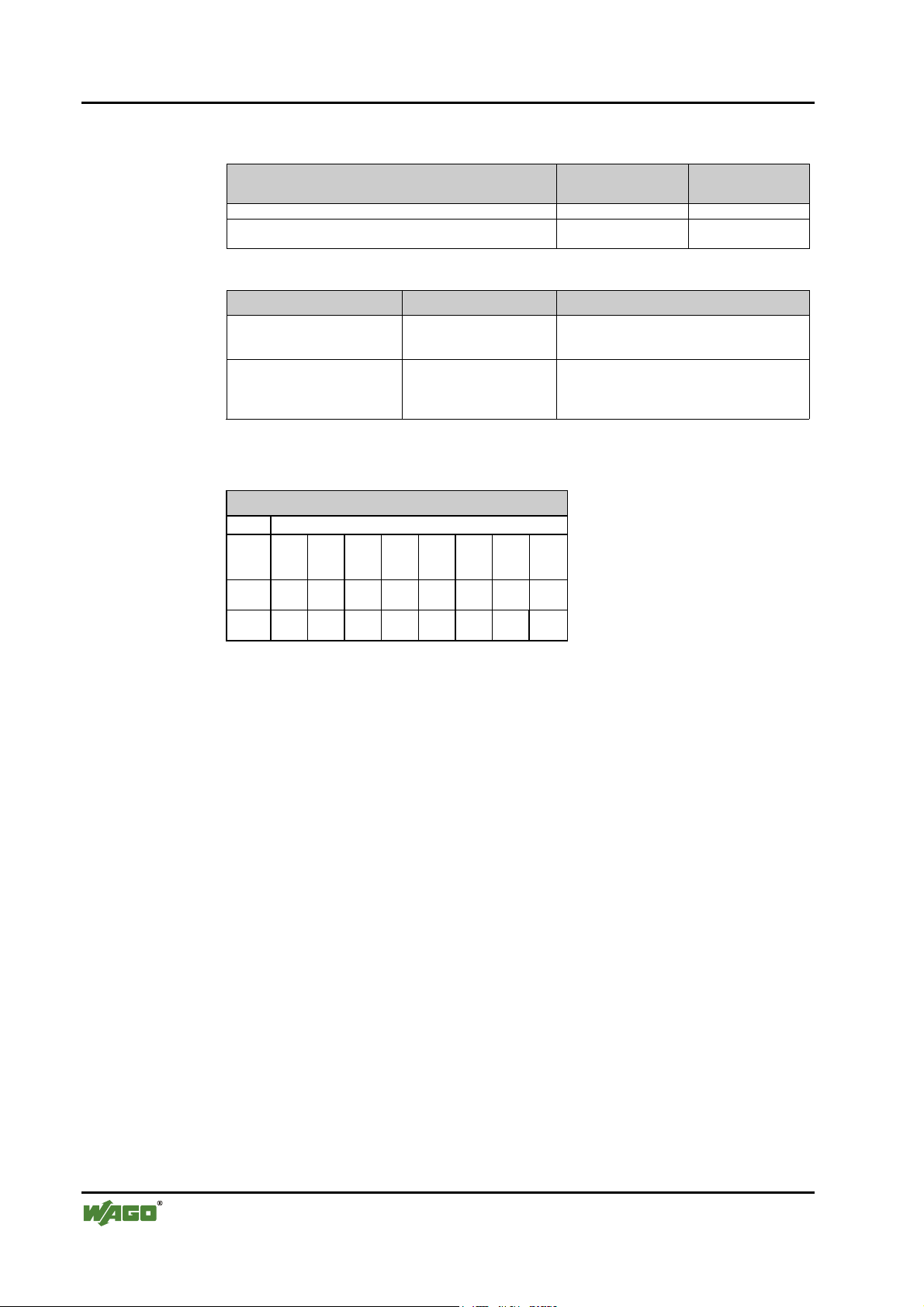

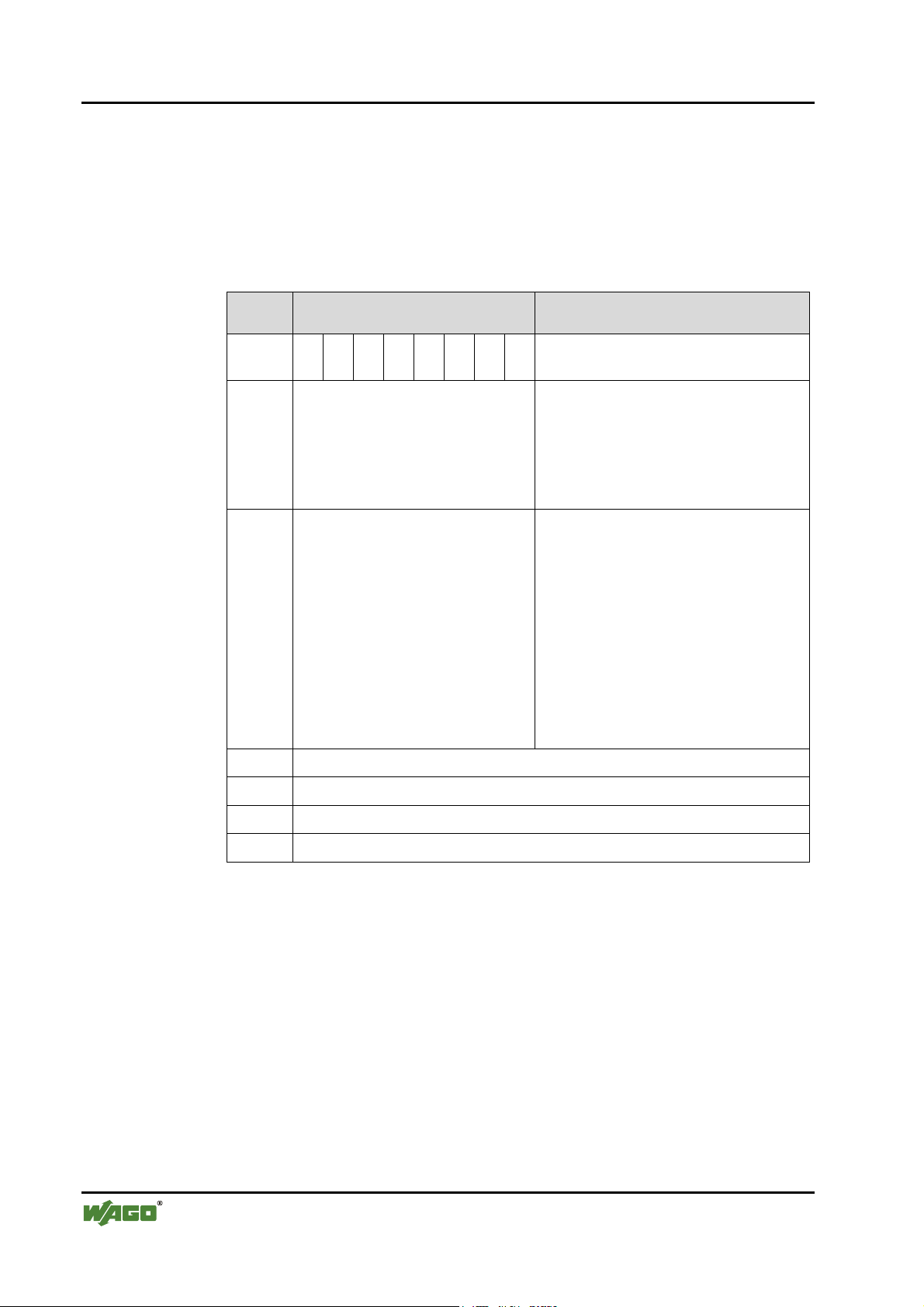

3.1.5.3 Example

The allocation should become clear by way of a fieldbus node with a coupler

and 17 I/O modules.

1234 5 67891011121314151617

DI DI

750-333

402

Fig. 3-9: Example application g012115x

DI DI

402 402

DI DI

AI AI

452

DO DODO DO

602 504

DO DO DO DODO DO

504 504504

DO DO

504

602

AO AO

AI AI

AO AO AI AI DO DO

452

452

602

504

600550 550

PROFIBUS

I/O modules PI Master *No. Modul

Identification

1

2

3

5 Potential supply Potential supply --- ---

6

7

Digital input 750-402 4 DI/24 V DC/3.0 ms EB12.0

Digital input 0x10 EB12.1

Digital input EB12.2

Digital input EB12.3

Digital input *750-402 4 DI/24 V DC/3.0 ms EB12.4

Digital input 0x00 EB12.5

Digital input EB12.6

Digital input EB12.7

Digital input 750-402 4 DI/24 V DC/3.0 ms EB13.0

Digital input 0x10 EB13.1

Digital input EB13.2

Digital input EB13.3

Analog input 750-452 2 AI/0-20 mA/diff. EW04

Analog input 0x51 EW2

Digital output 750-504 4 DO/24 V DC/0.5 A AB8.0

Digital output 0x20 AB8.1

Digital output AB8.2

Digital output AB8.3

Digital output *750-504 4 DO/24 V DC/0.5 A AB8.4

Digital output 0x00 AB8.5

Digital output AB8.6

Digital output AB8.7

Inputs Outputs

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 39

Fieldbus coupler / controller • 35

Fieldbus coupler 750-333

8

9

10 Potential supply Potential supply --- ---

15 Potential supply Potential supply --- ---

16

17 End module End module --- ---

Digital output 750-504 4 DO/24 V DC/0.5 A AB9.0

Digital output 0x20 AB9.1

Digital output AB9.2

Digital output AB9.3

Digital output *750-504 4 DO/24 V DC/0.5 A AB9.4

Digital output 0x00 AB9.5

Digital output AB9.6

Digital output AB9.7

Analog output 750-550 2 AO/0-10 V AW011

Analog output 0x61 AW2

Analog input 750-452 2 AI/0-20 mA/diff. EW412

Analog input 0x51 EW6

Analog output 750-550 2 AO/0-10 V AW413

Analog output 0x61 AW6

Analog input 750-452 2 AI/0-20 mA/diff. EW814

Analog input 0x51 EW10

Digital output 750-504 4 DO/24 V DC/0.5 A AB10.0

Digital output 0x20 AB10.1

Digital output AB10.2

Digital output AB10.3

* The master addresses listed in the table correspond to the allocation of the process data

given in the master configuration.

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 40

36 • Fieldbus coupler / controller

Fieldbus coupler 750-333

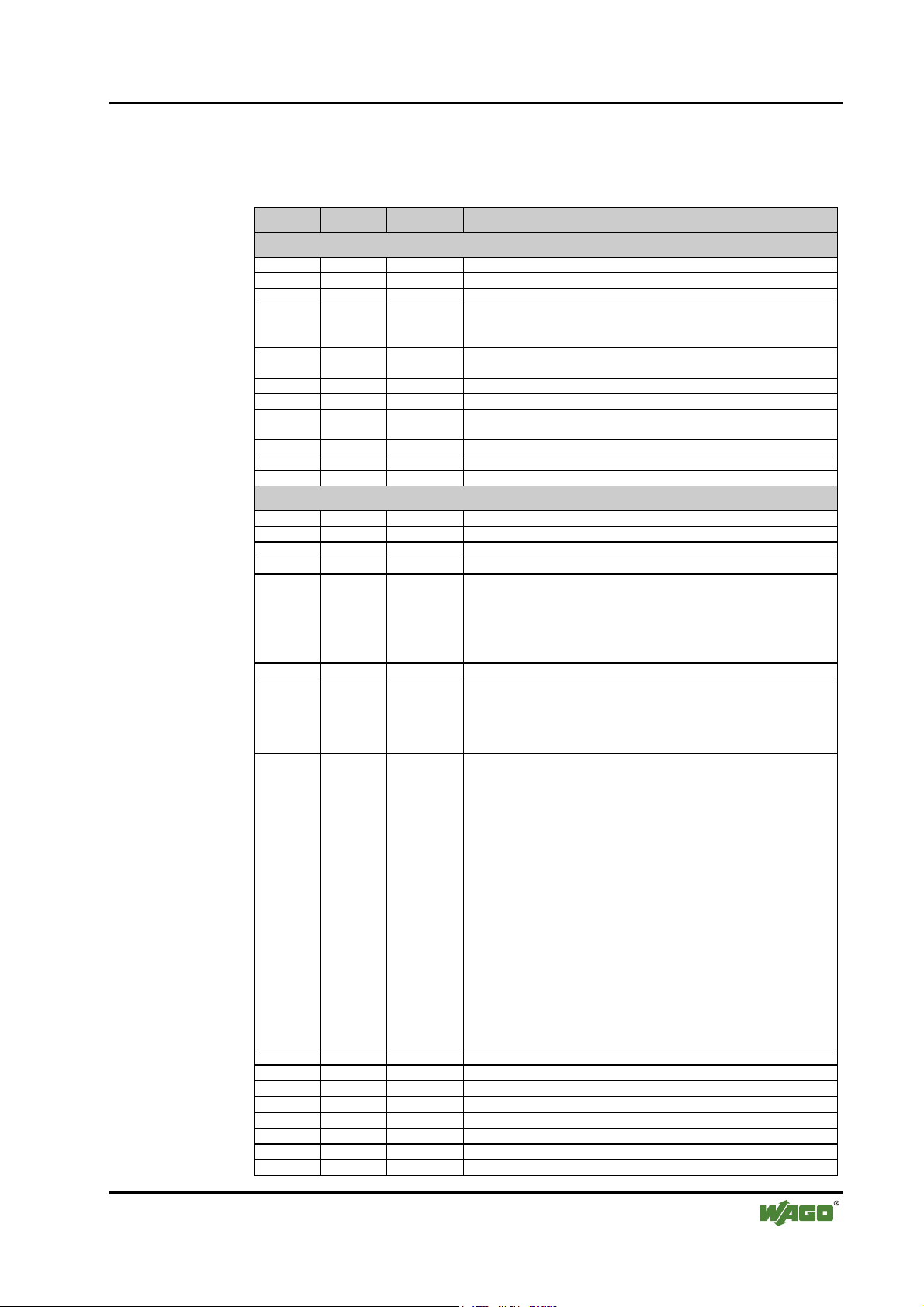

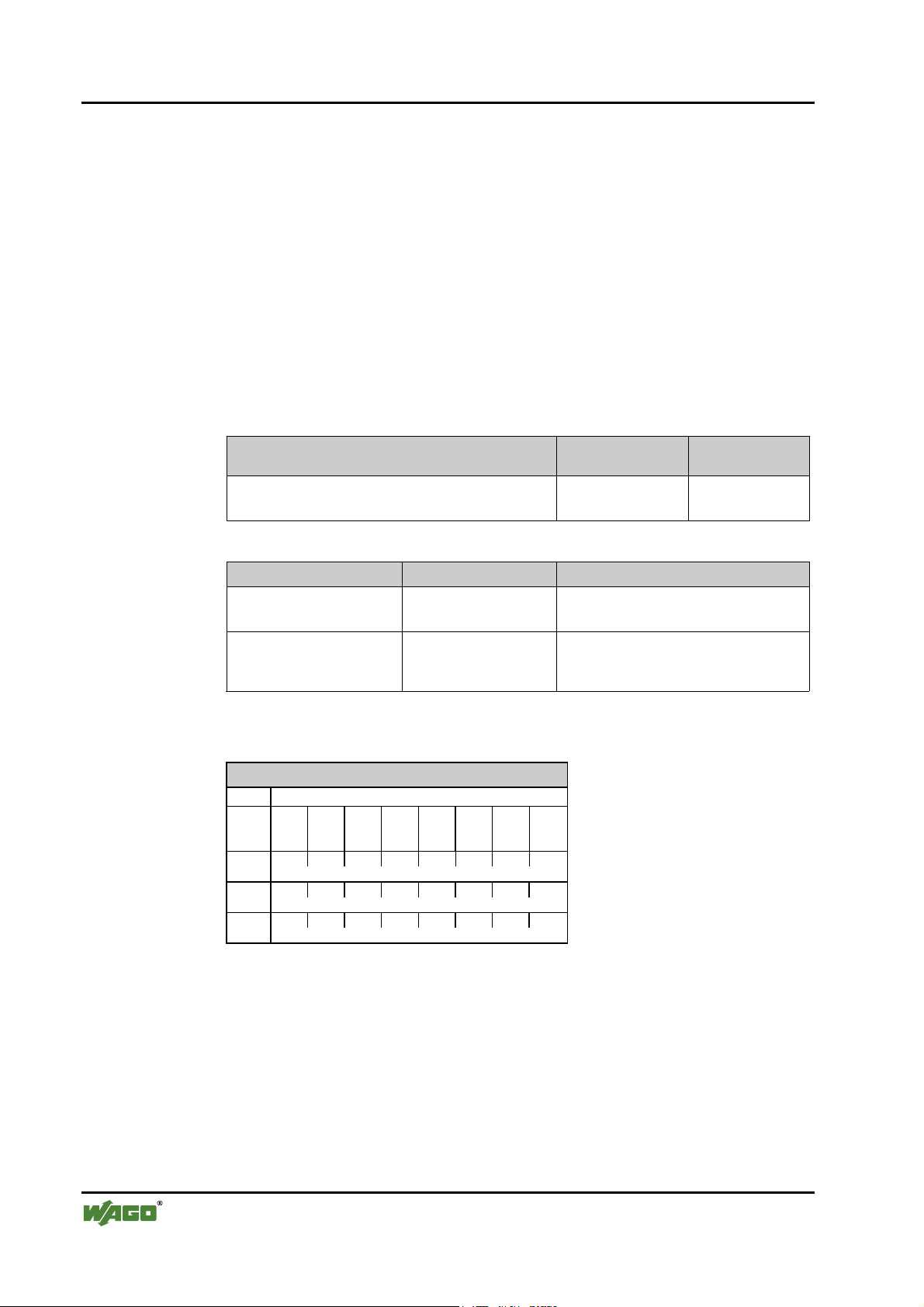

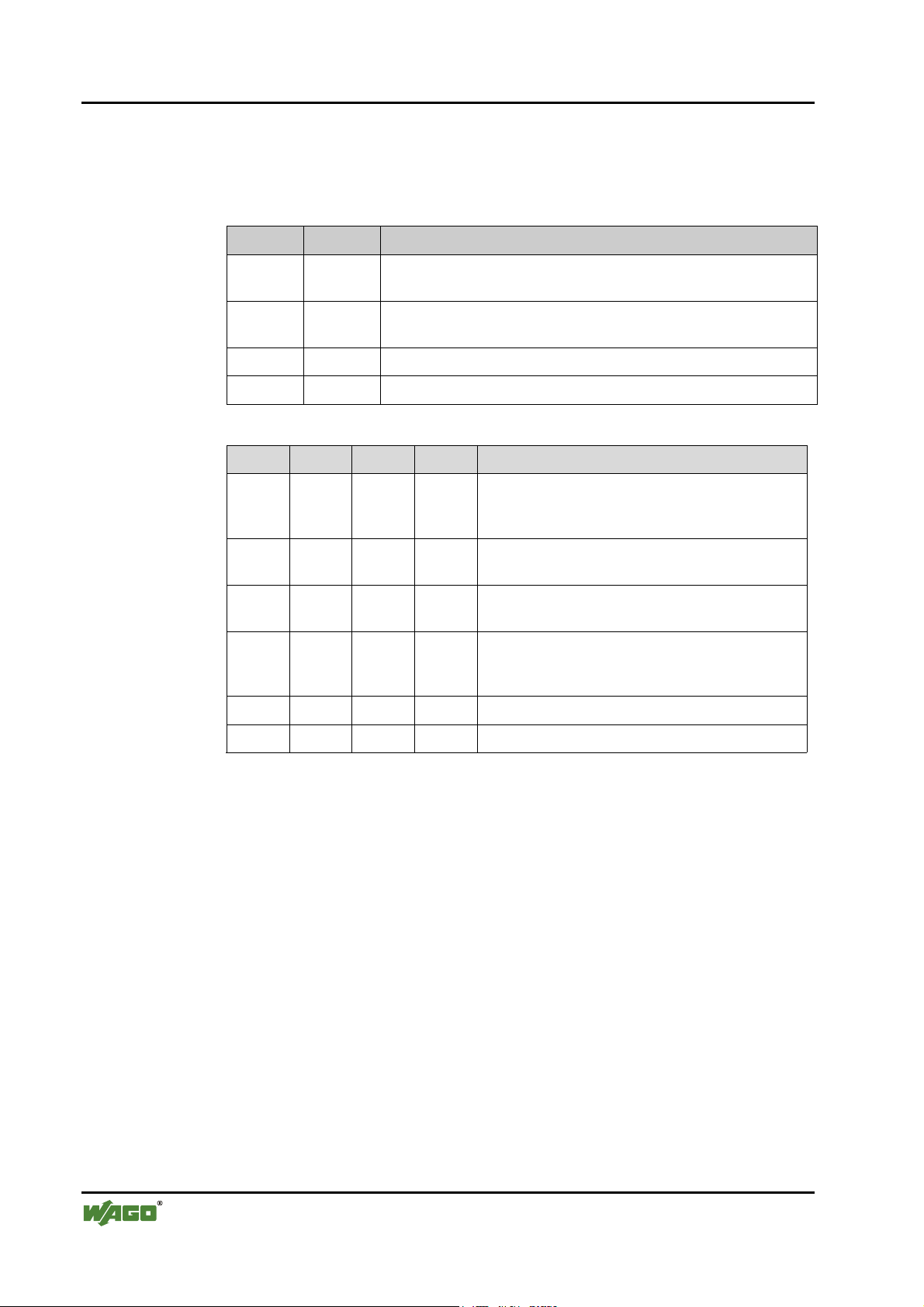

3.1.6 Parameterising the coupler

Before a data exchange is possible between the master and slaves a parameterisation is necessary in addition to the configuration.

The extended parameters (extended User_Prm_Data) is available as a selectable text in the configuration programs using the GSD files.

Description Value Meaning

Restart the internal bus after a

fault

POWER ON RESET

AUTORESET immediately after overcoming I/O module fault

I/O module diagnosis The diagnosis information about all diagnosis

released

lock not transferred to PROFIBUS-DP master

Process value display Word or double word orientated process data is

INTEL „Little Endian Format“

MOTOROLA

Behaviour in case of a

PROFIBUS DP fault

Stop internal bus transmis-

sion

Set start image to zero all outputs are reset immediately

Freeze starting image all outputs contain the last status before the

Write substitute values

Reaction to internal bus faults In the case of a fault with the internal commu-

Stop PROFIBUS data

exchange

Set start image to zero the input information is set to zero

Restart of the internal bus following a fault,

*)

*)

*)

*)

such as missing termination module,

after interruption of the I/O module supply

capable I/O modules, with which the diagnosis

is released are

transferred to PROFIBUS-DP master

transferred to the PROFIBUS-DP master in:

„Big Endian Format“

In the case of a fault with the PROFIBUS DP

communication the status of the inserted output

periphery can be influenced in various manners:

the process data exchange of the internal bus is

stopped, all outputs drop out after a module

specific monitoring time of 100 ms

fault

*)

all outputs switch a parameter substitute value

nication between the fieldbus coupler and I/O

modules, such as, for example: no termination

module,

the data exchange with the PROFIBUS master

is stopped.

Freeze starting image the input information before the fault is main-

*)

Default settings

tained

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 41

Fieldbus coupler / controller • 37

Fieldbus coupler 750-333

The complete parameter record encompasses 34 parameterisation bytes. The

first 10 bytes are laid down by the DP and DPV1 standard. The others contain

manufacturer specific parameters.

Byte No. Bit No. Value Meaning

Standard parameters

0 0-7 Stations status (see EN 50170)

1 0-7 2-255 Watchdog factor 1

2 0-7 2-255 Watchdog factor 2

3 0-7 11-255 Min T

4 0-7 183, 0xB7 Manufacturer code (high byte)

5 0-7 84, 0x54 Manufacturer code (low byte)

6 0-7 Group allocation,

7 0-7 DPV1 status 1 (see EN 50170)

8 0-7 DPV1 status 2 (see EN 50170)

9 0-7 DPV1 status 3 (see EN 50170)

Manufacturer parameters

10 0-7 0 Table 0, register 0 LB, reserved

11 0-7 0 Table 0, register 0 HB, reserved

12 0-7 0 Table 0, register 1 LB, reserved

13 0-7 0 Table 0, register 1 HB, reserved

14 Table 0, register 2 LB

15 0-7 0 Table 0, register 2 HB, reserved

16 Table 0, register 3 LB

17 Table 0, register 3 HB

18 0-7 '1100.0011' Table 0, register 4 LB, reserved

19 0-7 '0111.1111' Table 0, register 4 HB, reserved

20 0-7 '0000.0000' Table 100, register 0 LB, reserved

21 0-7 '0000.0001' Table 100, register 0 HB, reserved

22 0-7 '0000.0000' Table 100, register 1 LB, reserved

23 0-7 '0000.0000' Table 100, register 1 HB, reserved

24 0-7 '0000.0000' Table 100, register 2 LB, reserved

25 0-7 '0000.0000' Table 100, register 2 HB, reserved

0 0 Module diagnosis locked

01*)Module diagnosis released

1 0 Internal bus restart after fault: POWER-ON-RESET

11*)Internal bus restart after fault: AUTORESET

2-7 0 reserved

0-2 '011' reserved

3 0 Data format byte orientated I/O modules: INTEL

31*)Data format byte orientated I/O modules: MOTOROLA

4-7 '1100' reserved

0-2 Reaction to fieldbus fault:

3-5 Reaction to internal bus fault:

6-7 '00' reserved

'000'

'001'

'010'

'011'

'100'

'101'

'110'

'111'

'000'

'001'

'010'

'011'

'100'

'101'

'110'

'111'

*)

*)

Watchdog:

The reaction monitoring is determined in accordance with the

Watchdog_Factor_1 x Watchdog_Factor_2 x 10 ms (1 ms)

Earliest time in T

Broad and multicast telegrams (SYNC, FREEZE)

- Internal bus transmission stopped

- Set output image to zero

- Freeze output image

- Write substitute values

- PFC fault strategy

- not possible

- not possible

- not possible

- Leave data exchange

- Set input image to zero

- Freeze input image

- not possible

- not possible

- not possible

- not possible

- not possible

SDR

,

after which the slave may answer

Bit

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 42

38 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.7 Configuring the process data channel

The process data channel serves for the communication between the coupler

and the higher ranking systems (Master or projecting and diagnosis PC).

This channel is allocated to the coupler. The fieldbus coupler 750-333 does not

use the process data channel.

Module Identification

hex

750-333 No process data channel 0x00 0

Identification

dec.

Note

The module „750-333 no process data channel“ should be configured as the

1st module.

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 43

Fieldbus coupler / controller • 39

Fieldbus coupler 750-333

3.1.8 Configuration and parameterisation of I/O modules

3.1.8.1 Digital I/O modules

All binary I/O modules contain parameterisation information extended by 3

bytes, to serve, amongst others, for identification on the internal bus and the

structure of the mapping table. With diagnosis capable terminals the diagnosis

message can be suppressed or released for a channel or module. Binary outputs

offer the alternative to switch to parameterisable substitute values in the case

of a master failure.

Note

For simplification the tables only show the article number for the module

designation. The module „750-400“ thus corresponds to the module „750-400

2 DI/24 V DC/3.0 ms“

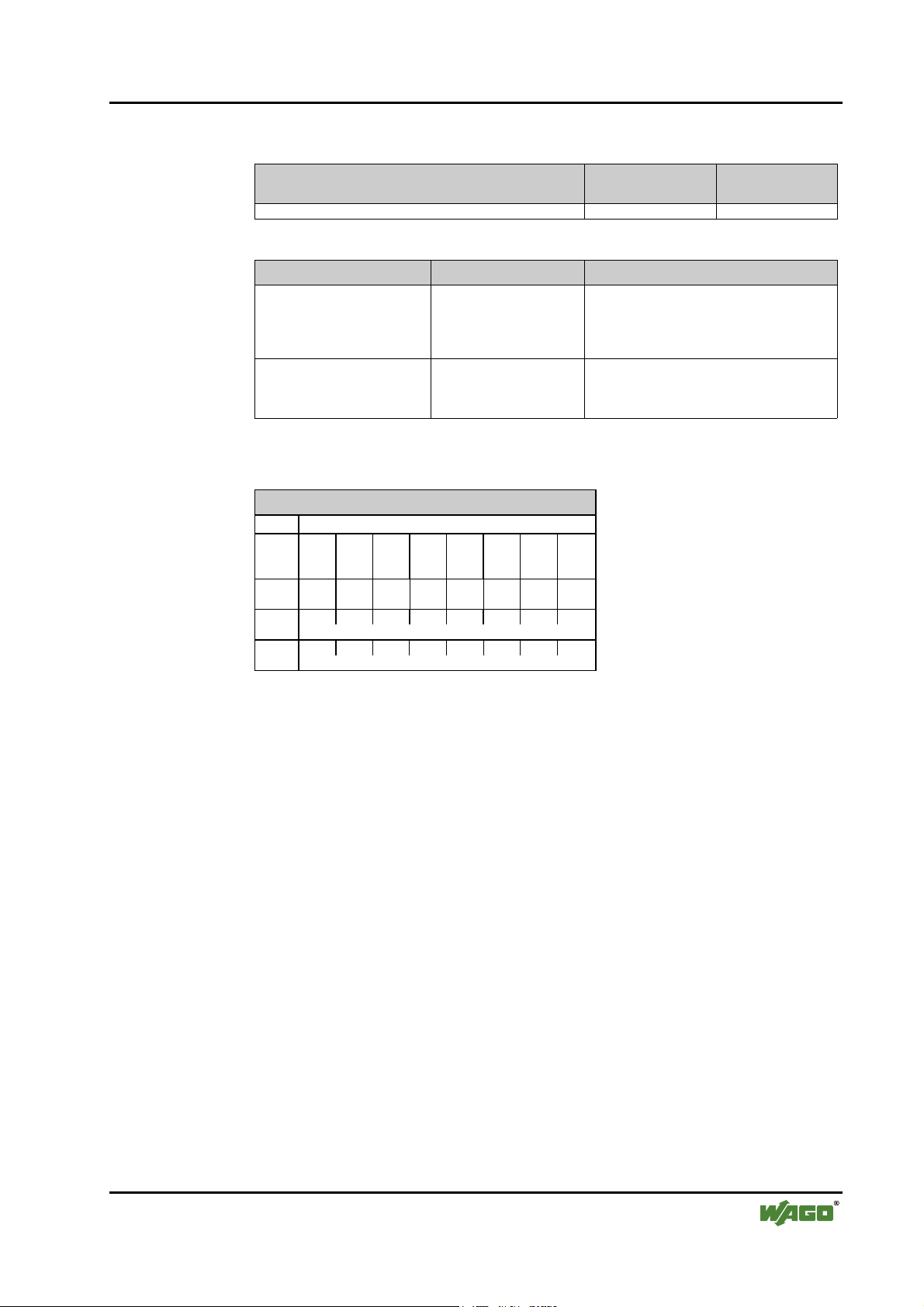

3.1.8.1.1 2 DI I/O modules

Module Identification

750-400, 750-401, 750-405, 750-406, 750-410,

750-411, 750-412

*750-400, *750-401, *750-405, *750-406, *750-410,

*750-411, *750-412

Parameter Value Meaning

I/O module is physically The I/O module process data is:

Parameter

Offset

Information

76543210

0

00Plug 00000

76543210

1

00000001

76543210

2

00000000

hex

0x10 16

0x00 0

plug fitted

not plug fitted - set to zero by the coupler

*)

*)

Default settings

- supplied by the I/O module

Identification

dec

Plug

5

Italic Cannot be changed

0

1

Module is physically not present

Module is physically present (default)

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 44

40 • Fieldbus coupler / controller

Fieldbus coupler 750-333

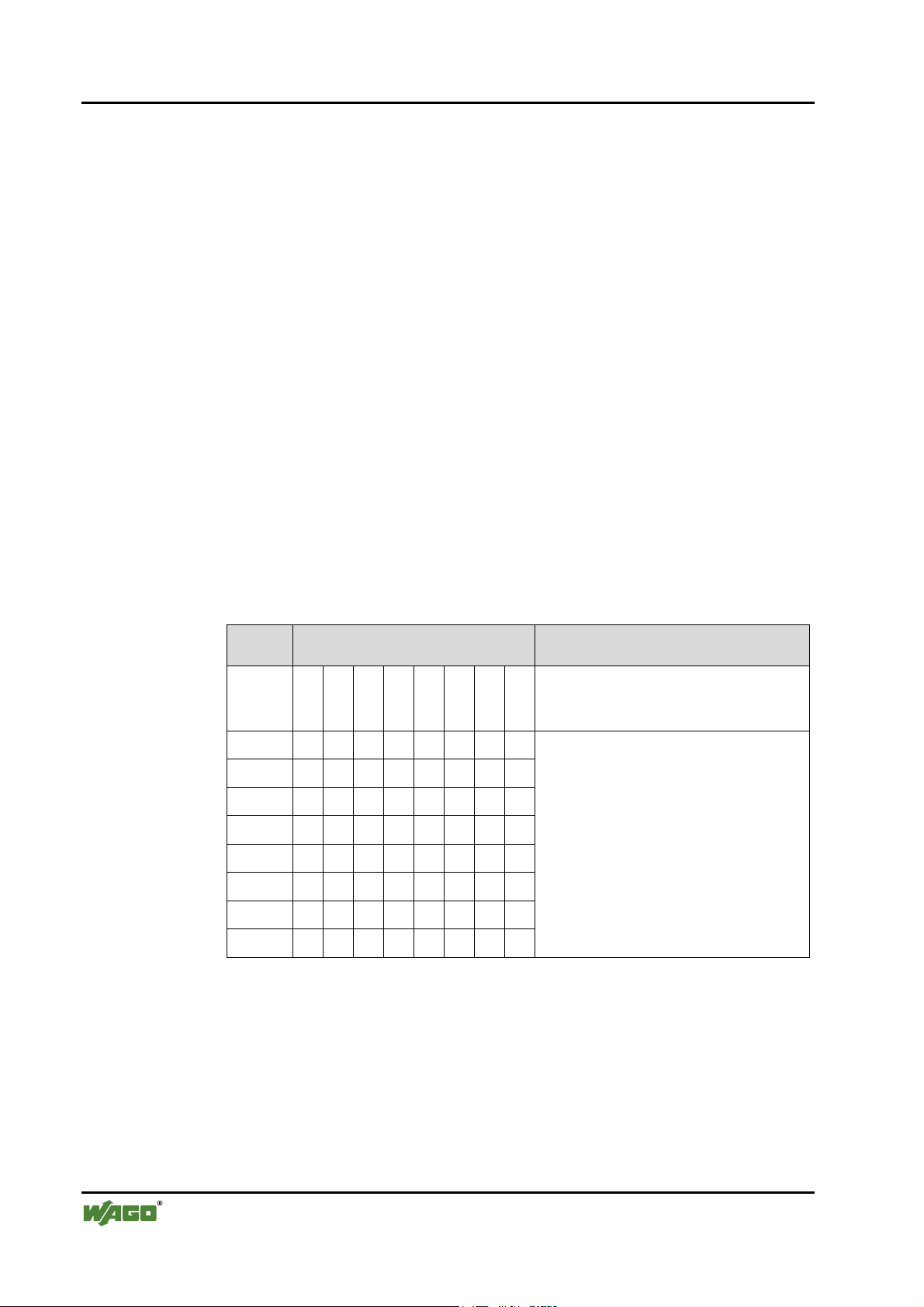

3.1.8.1.2 4 DI I/O modules

Module Identification

hex

750-402, 750-403, 750-408, 750-409, 750-414, 750-415,

0x10 16

Identification

dec

750-423, 750-422, 750-424

*750-402, *750-403, *750-408, *750-409, *750-414, *750-

0x00 0

415, *750-423, *750-422, *750-424

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied by the I/O module

not plug fitted - Set to zero by the coupler

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 00001

76543210

1

00000001

76543210

2

00000000

Plug

5

0

1

Module is physically not present

Module is physically present (default)

Italic Cannot be changed

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 45

Fieldbus coupler / controller • 41

Fieldbus coupler 750-333

3.1.8.1.3 2 DI I/O modules modules with 1 bit diagn. per channel

Module Identification

hex

Identification

dec

750-419, 750-425 0x10 16

*750-419, *750-425 0x00 0

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied by the I/O module

not plug fitted - set to zero by the coupler

Diagnosis channel x The diagnosis information of the corresponding

channel is

released - transmitted to PROFIBUS-DP master

*)

locked

*)

Default settings

- not transmitted to PROFIBUS-DP master

Parameter

Offset

Information

76543210

0

00Plug 0 Diag

76543210

1

En1

Diag

En0

01

00000101

76543210

2

00000000

Plug

5

DiagEn1

DiagEn0

0

1

3

0

1

2

0

1

Module is physically not present

Module is physically present (default)

Diagnosis idle run, short circuit on channel 2

locked

released

Diagnosis idle run, short circuit on channel 1

locked

released

Italic cannot be changed

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 46

42 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.8.1.4 2 DO I/O modules

Module Identification

hex

750-501, 750-502, 750-509, 750-512, 750-513,

0x20 32

Identification

dec

750-514, 750-517

*750-501, *750-502, *750-509, *750-512, *750-513,

0x00 0

*750-514, *750-517

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied to the I/O module

not plug fitted - ignored by the coupler

Substitute channel x

*)

0

1

If, in the case of a PROFIBUS-DP fault, the

switching of substitute values is enabled by the

bus coupler parameterisation, this data is transmitted to the periphery in the case of a fault.

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 00000

76543210

1

00000010

76543210

2

000000SV1 SV0

Plug

SV0

SV0

5

0

1

0

1

Module is physically not present

Module is physically present (default)

Substitute value for channel 1

Substitute value for channel 2

Italic Cannot be changed

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 47

Fieldbus coupler / controller • 43

Fieldbus coupler 750-333

3.1.8.1.5 2 DO I/O modules with 1 bit diagn. per channel

Module Identification

hex

Identification

dec

750-507, 750-522 0x20 32

*750-507, *750-522 0x00 0

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied to the I/O module

not plug fitted - ignored by the coupler

Diagnosis channel x The diagnosis information of the corresponding

released

*)

channel is

- transmitted to PROFIBUS-DP master

locked - not transmitted to PROFIBUS-DP master

Substitute channel x

*)

0

1

If, in the case of a PROFIBUS-DP fault, the

switching of substitute values is enabled by the

bus coupler parameterisation, this data is transmitted to the periphery in the case of a fault.

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 0 Diag

76543210

1

En1

Diag

En0

00

00000011

76543210

2

000000SV1 SV0

Plug

5

DiagEn0

DiagEn1

SV0

0

SV0

1

0

1

2

0

1

3

0

1

Module is physically not present

Module is physically present (default)

Diagnosis idle run, overload, short circuit on channel 1

lock

release

Diagnosis idle run, overload, short circuit on channel 2

locked

released

Substitute value for channel 1

Substitute value for channel 2

Italic Cannot be changed

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 48

44 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.8.1.6 2 DO I/O module with 2 bit diagn. per channel

Module Information

hex

Information

dec

750-506 0x20 32

*750-506 0x00 0

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied to the I/O module

not plug fitted - ignored by the coupler

Diagnosis channel x The diagnosis information of the corresponding

released

*)

channel is

- transmitted to PROFIBUS-DP master

locked - not transmitted to PROFIBUS-DP master

Substitute channel x

*)

0

1

If, in the case of a PROFIBUS-DP fault, the

switching of substitute values is enabled by the

bus coupler parameterisation, this data is transmitted to the periphery in the case of a fault.

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 0 Diag

76543210

1

En1

Diag

En0

01

00000011

76543210

2

000000SV1 SV0

Plug

5

DiagEn0

DiagEn1

SV0

0

SV0

1

0

1

2

0

1

3

0

1

Module is physically not present

Module is physically present (default)

Diagnosis idle run, short circuit, lower voltage on channel 1

locked

released

Diagnosis idle run, short circuit, lower voltage on channel 2

locked

released

Substitute value for channel 1

Substitute value for channel 2

Italic cannot be changed

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 49

3.1.8.1.7 4 DO I/O modules

Fieldbus coupler / controller • 45

Fieldbus coupler 750-333

Module Identification

hex

Identification

dec

750-504, 750-516, 750-519 0x20 32

*750-504, *750-516, *750-519 0x00 0

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied by the I/O module

not plug fitted - ignored by the coupler

Substitute channel x

*)

0

1

If, in the case of a PROFIBUS-DP fault, the

switching of substitute values is enabled by the

bus coupler parameterisation, this data is transmitted to the periphery in the case of a fault.

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 00001

76543210

1

00000010

76543210

2

0000SV3 SV2 SV1 SV0

Plug

SV0

SV0

SV0

SV0

5

0

1

2

3

0

1

Module is physically not present

Module is physically present (default)

Substitute value for channel 1

Substitute value for channel 2

Substitute value for channel 3

Substitute value for channel 4

Italic Cannot be changed

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 50

46 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.8.1.8 2 DI/DO I/O module with 1 bit diagn. per channel

Module Identification

hex

Identification

dec

750-418 0x30 48

*750-418 0x00 0

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied to the I/O module

not plug fitted - ignored by the coupler

Diagnosis channel x The diagnosis information of the corresponding

released

*)

channel is

- transmitted to PROFIBUS-DP master

locked - not transmitted to PROFIBUS-DP master

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 0 Diag

76543210

1

En1

Diag

En0

01

00000111

76543210

2

00000000

Plug

5

DiagEn0

DiagEn1

0

1

2

0

1

3

0

1

Module is physically not present

Module is physically present (default)

Diagnosis idle run, overload, short circuit on channel 1

lock

release

Diagnosis idle run, overload, short circuit on channel 2

locked

released

Italic Cannot be changed

D R A F T WAGO-I/O-SYSTEM 750

2001-02-27 PROFIBUS

Page 51

Fieldbus coupler / controller • 47

Fieldbus coupler 750-333

3.1.8.1.9 Internal system supply module with diagnosis

Module Identification

hex

Identification

dec

750-610, 750-611 0x00 0

Parameter Value Meaning

I/O module is physically The I/O module process data is:

plug fitted

*)

- supplied by the I/O module

not plug fitted - set to zero by the coupler

Diagnosis field voltage loss

Diagnosis fuse blown

released

*)

The diagnosis information of the corresponding

channel is

- transmitted to PROFIBUS-DP master

locked - not transmitted to PROFIBUS-DP master

*)

Default settings

Parameter

Offset

Information

76543210

0

00Plug 0 Diag

76543210

1

En1

Diag

En0

00

00000000

76543210

2

00000000

Plug

5

DiagEn0

DiagEn1

0

1

0

2

1

0

3

1

Module is physically not present

Module is physically present (default)

Diagnosis field voltage failure info, lock

Diagnosis field voltage failure info., release

Diagnosis fuse failure info. lock

Diagnosis fuse failure info. release

Italic Cannot be changed

WAGO-I/O-SYSTEM 750 D R A F T

PROFIBUS 2001-02-27

Page 52

48 • Fieldbus coupler / controller

Fieldbus coupler 750-333

3.1.8.2 Analog I/O modules

All analog I/O modules have 2 bytes of extendable parameterisation information, which serves for identification on internal bus and the formation of a

mapping table.

Analog inputs are followed by 2 bytes reserved for future options. The diagnosis message can be suppressed or released for each individual channel by

means of modules capable of diagnostics.

Analog outputs have 4 byte parameterisation data. These are used to save the

substitute values for a maximum of 2 channels (2 words).

3.1.8.2.1 2 AI I/O modules

Module Identification

750-461, 750-462, 750-469, 750-465, 750-466, 750-467,

750-472, 750-474, 750-476, 750-478, 750-479, 750-480,

750-491

Parameter Value Meaning

I/O module is physically The I/O module process data is:

Diagnosis channel x The diagnosis information of the corresponding

Parameter

Offset

Information

76543210

0

00Plug 0 Diag

76543210

1

reserved

15 14 13 12 11 10 9 8

2

reserved

76543210

3

reserved

plug fitted

not plug fitted - set to zero by the coupler

released

locked - not transmitted to PROFIBUS-DP master

*)

*)

*)