Page 1

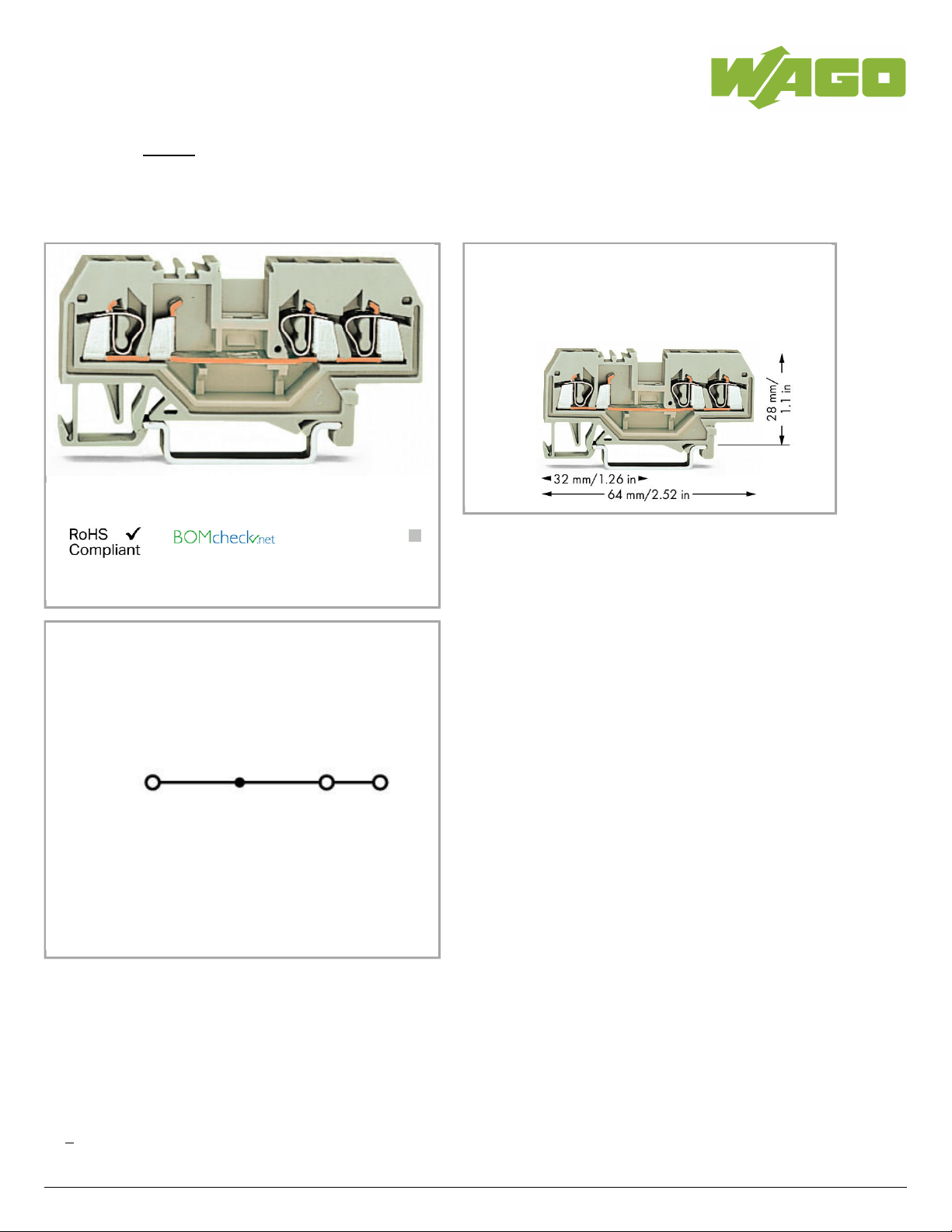

Data sheet | Item number:280-993

3-conductor through terminal block; 2.5 mm²; suitable for Ex e II

applications; center marking; for DIN-rail 35 x 15 and 35 x 7.5; CAGE CLAMP®

Color:

Item description

Note:

Terminating Aluminum Conductors

WAGO spring clamp terminal blocks are suitable for solid aluminum conductors up to 4mm²/12AWG if WAGO “Alu-Plus” Contact Paste is used for

termination.

“Alu-Plus” Contact Paste Advantages:

280-993

01.05.2019Page /1 20

Page 2

Data sheet | Item number:280-993

Automatically destroys the oxide film during clamping.

Prevents fresh oxidation at the clamping point.

Prevents electrolytic corrosion between aluminum and copper conductors (in the same terminal block).

Provides long-term protection against corrosion.

Using terminal blocks with CAGE CLAMP® Spring Pressure Connection Technology, and aluminum conductors must first be cleaned with a blade

then immediately be inserted into the clamping units filled with “Alu-Plus” Contact Paste.

It is also possible to apply WAGO “Alu-Plus” on the whole surface of the aluminum conductor before termination.additionally

Please note that the nominal currents must be adapted to the reduced conductivity of the aluminum conductors:

2.5mm² (14 AWG) = 16 A

4mm² (12 AWG) = 22 A

Safety information 1:

Using staggered jumpers, the maximum rated voltage is reduced to 275 V.

Data

Electrical data

Rated voltage EN (Ex e II) 550 V

Ratings per IEC/EN 60664-1

Rated current 22 A

Connection data

Connection technology

CAGE CLAMP

®

Actuation type Operating tool

Connectable conductor materials Copper

Aluminum

Solid conductor 0.08 … 2.5mm²/ 28 … 12AWG

Fine-stranded conductor 0.08 … 2.5mm²/ 28 … 12AWG

Strip length 8 … 9mm/ 0.31 … 0.35inch

Note (conductor cross-section) 12 AWG: THHN, THWN

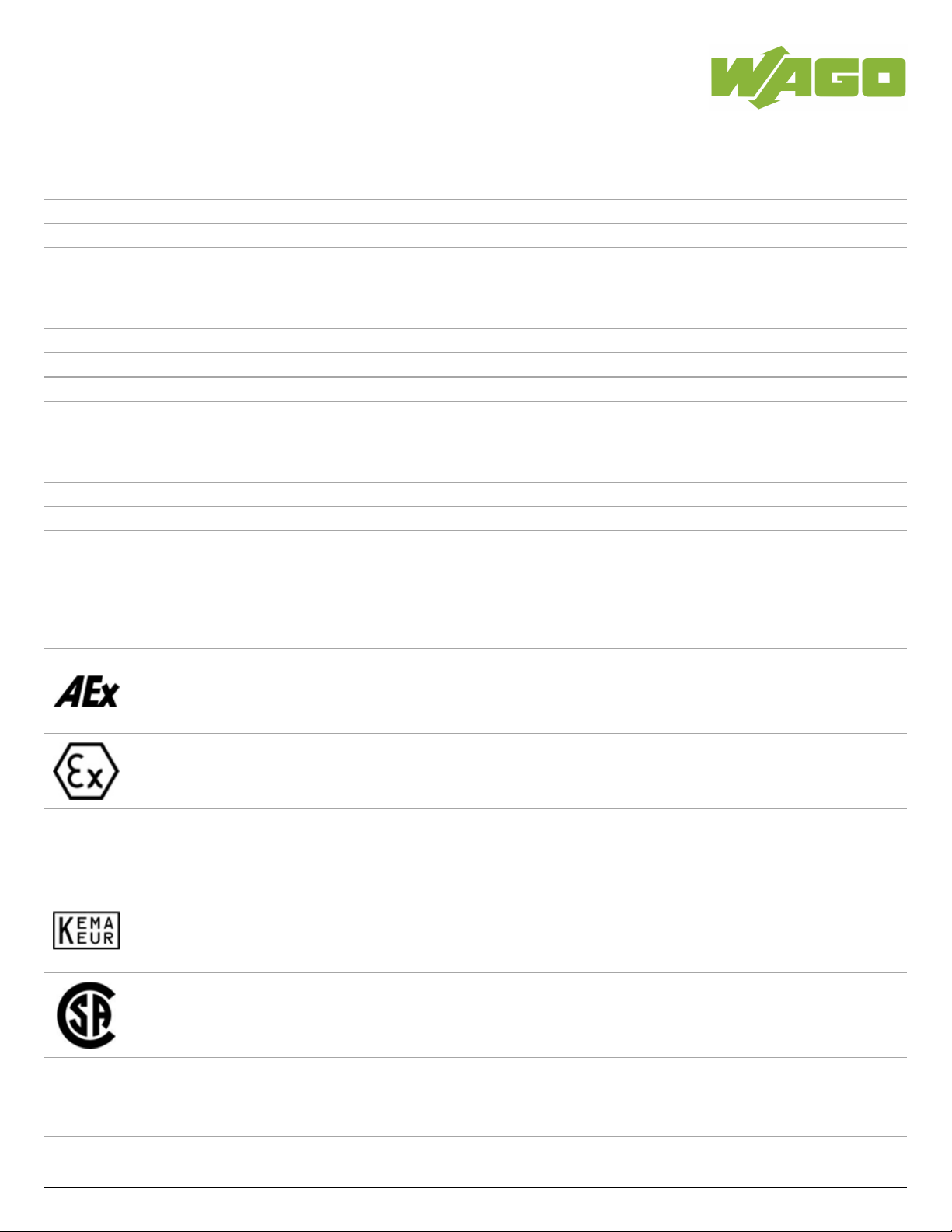

Total number of connection points 3

Total number of potentials 1

Number of levels 1

Type of wiring Front-entry wiring

Geometrical Data

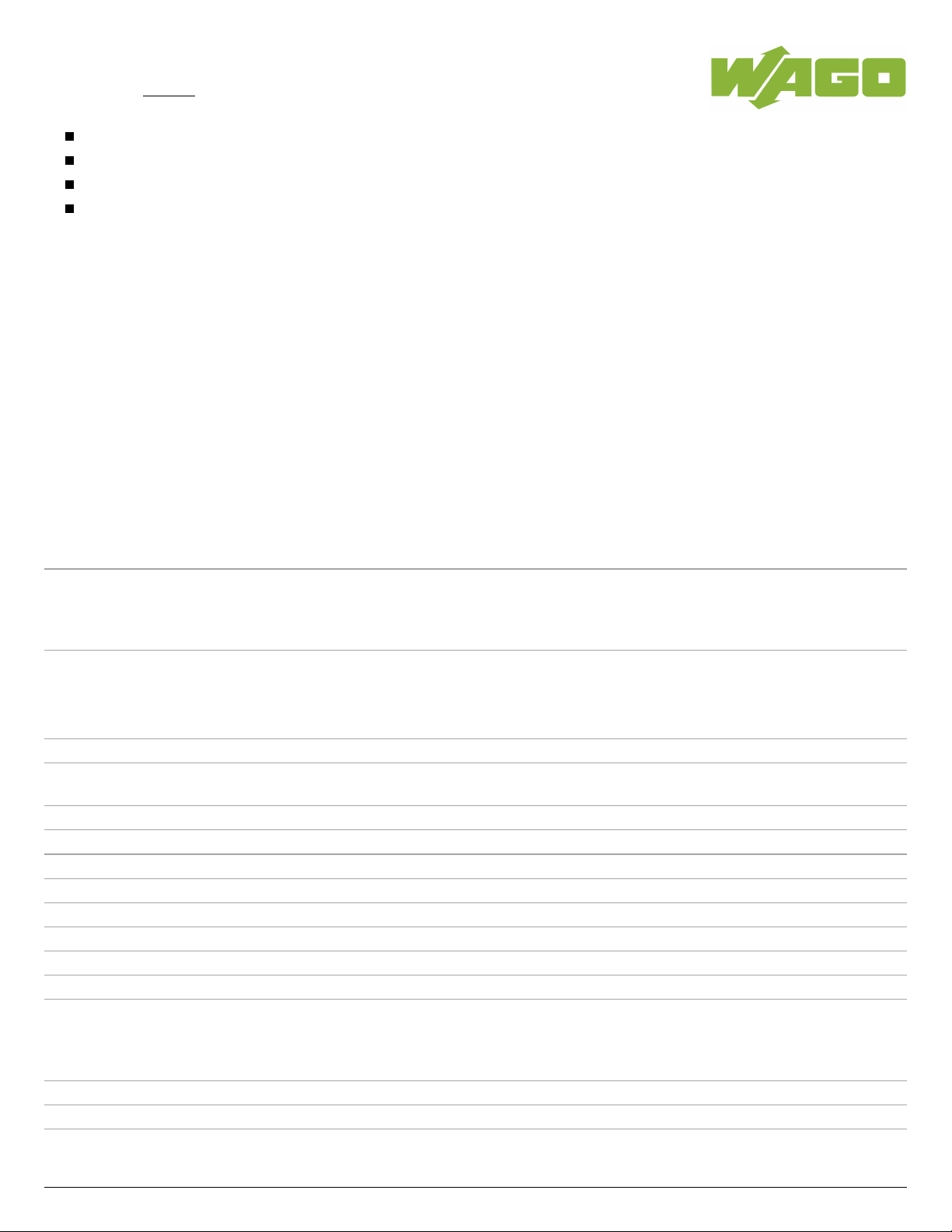

Width 5mm/ 0.197inch

Height from upper-edge of DIN-35 rail 28mm/ 1.102inch

Depth 64mm/ 2.52inch

280-993

01.05.2019Page /2 20

Page 3

Data sheet | Item number:280-993

Mechanical data

Design horizontal

Type of mounting DIN-35 rail

Marking level Center marking

Material Data

Color light gray

Insulating material Polyamide 66 (PA 66)

Fire load 0.123 MJ

Weight 7.576g

Commercial data

Country of origin DE

GTIN 4044918391474

Customs Tariff No. 85369010000

Approvals / Certificates

Ex-Approvals

Logo Approval Additional Approval Text

Certificate

name

AEx

UL International Germany GmbH c/o Physikalisch

Technische Bundesanstalt

UL 60079 E185892

sec.1

ATEx

Physikalisch Technische Bundesanstalt (PTB)

EN 60079 PTB 99

ATEX

3109 U

Country specific Approvals

Logo Approval Additional Approval Text

Certificate

name

CCA

DEKRA Certification B.V.

EN 60947 2157201.01

CSA

DEKRA Certification B.V.

C22.2 1536071

Ship Approvals

Logo Approval Additional Approval Text

Certificate

name

280-993

01.05.2019Page /3 20

Page 4

Data sheet | Item number:280-993

ABS

American Bureau of Shipping

EN 60947 14-

HG1293677PDA

BV

Bureau Veritas S.A.

EN 60947 07436/E0 BV

DNV GL

Det Norske Veritas, Germanischer Lloyd

- TAE00001V2

LR

Lloyds Register

EN 60947 91/20112

(E9)

UL-Approvals

Logo Approval Additional Approval Text

Certificate

name

UL

Underwriters Laboratories Inc.

UL 1059 20170731-

E45172

Compatible products

assembling

Item no.: 209-106

Mounting carrier; for isolated mounting on DIN 35 rails

209-106

Item no.: 709-153

Cover; Type 1; suitable for cover carrier, type 1; 1 m long

709-153

ferrule

Item no.: 216-101

Ferrule; Sleeve for 0.5 mm² / AWG 22; uninsulated; electro-tin plated

216-101

Item no.: 216-102

Ferrule; Sleeve for 0.75 mm² / AWG 20; uninsulated; electro-tin plated

216-102

280-993

01.05.2019Page /4 20

Page 5

Data sheet | Item number:280-993

Ferrule; Sleeve for 0.75 mm² / AWG 20; uninsulated; electro-tin plated

Item no.: 216-103

Ferrule; Sleeve for 1 mm² / AWG 18; uninsulated; electro-tin plated

216-103

Item no.: 216-104

Ferrule; Sleeve for 1.5 mm² / AWG 16; uninsulated; electro-tin plated

216-104

Item no.: 216-201

Ferrule; Sleeve for 0.5 mm² / 20 AWG; insulated; electro-tin plated

216-201

Item no.: 216-202

Ferrule; Sleeve for 0.75 mm² / 18 AWG; insulated; electro-tin plated

216-202

Item no.: 216-203

Ferrule; Sleeve for 1 mm² / AWG 18; insulated; electro-tin plated

216-203

Item no.: 216-204

Ferrule; Sleeve for 1.5 mm² / AWG 16; insulated; electro-tin plated

216-204

Item no.: 216-301

Ferrule; Sleeve for 0.25 mm² / AWG 24; insulated; electro-tin plated

216-301

Item no.: 216-302

Ferrule; Sleeve for 0.34 mm² / 22 AWG; insulated; electro-tin plated

216-302

Jumper

Item no.: 249-123

Push-in type wire jumper; insulated; wire length 180 mm; Conductor cross section 0.75 mm²

249-123

Item no.: 249-125

Push-in type wire jumper; insulated; wire length 60 mm; Conductor cross section 0.75 mm²

249-125

Item no.: 249-126

Push-in type wire jumper; insulated; wire length 110 mm; Conductor cross section 0.75 mm²

249-126

Item no.: 249-127

Push-in type wire jumper; insulated; wire length 250 mm; Conductor cross section 0.75 mm²

249-127

Item no.: 280-402

Adjacent jumper; insulated; IN = IN terminal block

280-402

Item no.: 280-409

Alternate jumper; insulated; IN = IN terminal block

280-409

Item no.: 280-422

Adjacent jumper; insulated; IN = IN terminal block

280-422

Item no.: 280-482

Comb-style jumper bar; insulated; 2-way; IN = IN terminal block

280-482

Item no.: 280-483

Comb-style jumper bar; insulated; 3-way; IN = IN terminal block

280-483

Item no.: 280-484

Comb-style jumper bar; insulated; 4-way; IN = IN terminal block

280-484

280-993

01.05.2019Page /5 20

Page 6

Data sheet | Item number:280-993

Item no.: 280-485

Comb-style jumper bar; insulated; 5-way; IN = IN terminal block

280-485

Item no.: 280-490

Comb-style jumper bar; insulated; 10-way; IN = IN terminal block

280-490

Item no.: 280-492

Alternate comb-style jumper bar; insulated; 2-way; IN = IN terminal block

280-492

Item no.: 780-452

Staggered jumper; insulated; from 1 to 2; Spacing: 5 mm; suitable for 2-conductor female plugs

780-452

Item no.: 780-453

Staggered jumper; insulated; from 1 to 3; Spacing: 5 mm; suitable for 2-conductor female plugs

780-453

Item no.: 780-454

Staggered jumper; insulated; from 1 to 4; Spacing: 5 mm; suitable for 2-conductor female plugs

780-454

Item no.: 780-455

Staggered jumper; insulated; from 1 to 5; Spacing: 5 mm; suitable for 2-conductor female plugs

780-455

Item no.: 780-456

Staggered jumper; insulated; from 1 to 6; Spacing: 5 mm; suitable for 2-conductor female plugs

780-456

Item no.: 780-457

Staggered jumper; insulated; from 1 to 7; Spacing: 5 mm; suitable for 2-conductor female plugs

780-457

Item no.: 780-458

Staggered jumper; insulated; from 1 to 8; Spacing: 5 mm; suitable for 2-conductor female plugs

780-458

Carrier rail

Item no.: 210-112

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; slotted; according to EN 60715; "Hole width 25 mm

210-112

Item no.: 210-113

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; unslotted; according to EN 60715

210-113

Item no.: 210-114

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; unslotted; similar to EN 60715

210-114

Item no.: 210-115

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; slotted; according to EN 60715; "Hole width 18 mm

210-115

Item no.: 210-118

Steel carrier rail; 35 x 15 mm; 2.3 mm thick; 2 m long; unslotted; according to EN 60715

210-118

Item no.: 210-196

Aluminum carrier rail; 35 x 8.2 mm; 1.6 mm thick; 2 m long; unslotted; similar to EN 60715

210-196

Item no.: 210-197

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; slotted; similar to EN 60715

210-197

Item no.: 210-198

Copper carrier rail; 35 x 15 mm; 2.3 mm thick; 2 m long; unslotted; according to EN 60715

210-198

Item no.: 210-504

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; slotted; galvanized; according to EN 60715

210-504

280-993

01.05.2019Page /6 20

Page 7

Data sheet | Item number:280-993

Item no.: 210-505

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; unslotted; galvanized; according to EN 60715

210-505

Item no.: 210-506

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; unslotted; galvanized; similar to EN 60715

210-506

Item no.: 210-508

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; slotted; galvanized; similar to EN 60715

210-508

General accessories

Item no.: 231-162/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 2-pole

231-162

/003-000

Item no.: 231-163/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 3-pole

231-163

/003-000

Item no.: 231-164/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 4-pole

231-164

/003-000

Item no.: 231-165/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 5-pole

231-165

/003-000

Item no.: 231-166/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 6-pole

231-166

/003-000

Item no.: 231-167/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 7-pole

231-167

/003-000

Item no.: 231-168/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 8-pole

231-168

/003-000

Item no.: 231-169/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 9-pole

231-169

/003-000

Item no.: 231-170/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 10-pole

231-170

/003-000

Item no.: 231-171/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 11-pole

231-171

/003-000

Item no.: 231-172/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 12-pole

231-172

/003-000

Item no.: 231-176/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 16-pole

231-176

/003-000

280-993

01.05.2019Page /7 20

Page 8

Data sheet | Item number:280-993

Item no.: 231-180/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; Pin spacing 5 mm; 20-pole

231-180

/003-000

Item no.: 231-668

Lockout caps; for covering unused clamping units

231-668

Item no.: 231-669

Lockout caps; for covering unused clamping units

231-669

Item no.: 249-105

Group marker carrier

249-105

Item no.: 721-162/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 2-pole

721-162

/003-000

Item no.: 721-163/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 3-pole

721-163

/003-000

Item no.: 721-164/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 4-pole

721-164

/003-000

Item no.: 721-165/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 5-pole

721-165

/003-000

Item no.: 721-166/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 6-pole

721-166

/003-000

Item no.: 721-167/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 7-pole

721-167

/003-000

Item no.: 721-168/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 8-pole

721-168

/003-000

Item no.: 721-169/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 9-pole

721-169

/003-000

Item no.: 721-170/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 10-pole

721-170

/003-000

Item no.: 721-171/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 11-pole

721-171

/003-000

Item no.: 721-172/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 12-pole

721-172

/003-000

Item no.: 721-173/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

280-993

01.05.2019Page /8 20

Page 9

Data sheet | Item number:280-993

mismating; Pin spacing 5 mm; 13-pole

721-173

/003-000

Item no.: 721-174/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 14-pole

721-174

/003-000

Item no.: 721-175/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 15-pole

721-175

/003-000

Item no.: 721-176/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 16-pole

721-176

/003-000

Item no.: 721-180/003-000

Male connector for rail-mount terminal blocks; 1.2 x 1.2 mm pins; straight; 100% protected against

mismating; Pin spacing 5 mm; 20-pole

721-180

/003-000

Marking accessories

Item no.: 2009-115

WMB-Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

Item no.: 2009-115/000-002

WMB-Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-002

Item no.: 2009-115/000-006

WMB-Inline; for smartPRINTER; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-006

Item no.: 2009-115/000-007

WMB-Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-007

Item no.: 2009-115/000-012

WMB-Inline; for smartPRINTER; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-012

Item no.: 2009-115/000-017

WMB-Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-017

Item no.: 2009-115/000-023

WMB-Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-023

Item no.: 2009-115/000-024

WMB-Inline; for smartPRINTER; on reel; stretchable 5 - 5.2 mm; plain; snap-on type

2009-115

/000-024

Item no.: 209-128

Adaptor

209-128

Item no.: 209-140

Group marker carrier

209-140

280-993

01.05.2019Page /9 20

Page 10

Data sheet | Item number:280-993

Item no.: 209-141

Group marker carrier

209-141

Item no.: 209-142

Group marker carrier

209-142

Item no.: 209-185

Adaptor

209-185

Item no.: 210-612

Marking strips; for self-marking; plain; Self-adhesive

210-612

Item no.: 793-501

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

Item no.: 793-501/000-002

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-002

Item no.: 793-501/000-005

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-005

Item no.: 793-501/000-006

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-006

Item no.: 793-501/000-007

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-007

Item no.: 793-501/000-012

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-012

Item no.: 793-501/000-017

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-017

Item no.: 793-501/000-023

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-023

Item no.: 793-501/000-024

WMB marking card; as card; not stretchable; plain; snap-on type

793-501

/000-024

Item no.: 793-5501

WMB marking card; as card; for terminal block width 5 - 17.5 mm; stretchable 5 - 5.2 mm; plain; snapon type

793-5501

Item no.: 793-5501/000-002

WMB marking card; as card; for terminal block width 5 - 17.5 mm; stretchable 5 - 5.2 mm; plain; snapon type

793-5501

/000-002

Item no.: 793-5501/000-005

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-005

280-993

01.05.2019Page /10 20

Page 11

Data sheet | Item number:280-993

Item no.: 793-5501/000-006

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-006

Item no.: 793-5501/000-007

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-007

Item no.: 793-5501/000-012

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-012

Item no.: 793-5501/000-017

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-017

Item no.: 793-5501/000-023

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-023

Item no.: 793-5501/000-024

WMB marking card; as card; stretchable 5 - 5.2 mm; plain; snap-on type

793-5501

/000-024

Female plug

Item no.: 232-132/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 2-pole

232-132

/005-000

Item no.: 232-132/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 3-pole

232-132

/005-000/039-000

Item no.: 232-133/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 3-pole

232-133

/005-000

Item no.: 232-133/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 3-pole

232-133

/005-000/039-000

Item no.: 232-134/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 4-pole

232-134

/005-000

Item no.: 232-134/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 4-pole

232-134

/005-000/039-000

Item no.: 232-135/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 5-pole

232-135

/005-000

Item no.: 232-135/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 5-pole

232-135

/005-000/039-000

280-993

01.05.2019Page /11 20

Page 12

Data sheet | Item number:280-993

Item no.: 232-136/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 6-pole

232-136

/005-000

Item no.: 232-136/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 6-pole

232-136

/005-000/039-000

Item no.: 232-137/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 7-pole

232-137

/005-000

Item no.: 232-137/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 7-pole

232-137

/005-000/039-000

Item no.: 232-138/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 8-pole

232-138

/005-000

Item no.: 232-138/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 8-pole

232-138

/005-000/039-000

Item no.: 232-139/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 9-pole

232-139

/005-000

Item no.: 232-139/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 9-pole

232-139

/005-000/039-000

Item no.: 232-140/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 10-pole

232-140

/005-000

Item no.: 232-140/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 10-pole

232-140

/005-000/039-000

Item no.: 232-142/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 12-pole

232-142

/005-000

Item no.: 232-142/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 12-pole

232-142

/005-000/039-000

Item no.: 232-146/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 16-pole

232-146

/005-000

Item no.: 232-146/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 16-pole

232-146

/005-000/039-000

Item no.: 232-147/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 17-pole

232-147

/005-000/039-000

280-993

01.05.2019Page /12 20

Page 13

Data sheet | Item number:280-993

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 17-pole /005-000/039-000

Item no.: 232-150/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 20-pole

232-150

/005-000

Item no.: 232-150/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Locking lever; Pin spacing 5 mm; 20-pole

232-150

/005-000/039-000

Item no.: 232-232/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 2-pole

232-232

/005-000

Item no.: 232-232/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 2-pole

232-232

/005-000/039-000

Item no.: 232-233/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 3-pole

232-233

/005-000

Item no.: 232-233/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 3-pole

232-233

/005-000/039-000

Item no.: 232-234/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 4-pole

232-234

/005-000

Item no.: 232-234/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 4-pole

232-234

/005-000/039-000

Item no.: 232-235/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 5-pole

232-235

/005-000

Item no.: 232-235/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 5-pole

232-235

/005-000/039-000

Item no.: 232-236/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 6-pole

232-236

/005-000

Item no.: 232-236/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 6-pole

232-236

/005-000/039-000

Item no.: 232-237/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 5 mm; 7-pole

232-237

/005-000

Item no.: 232-238/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 8-pole

232-238

/005-000

280-993

01.05.2019Page /13 20

Page 14

Data sheet | Item number:280-993

Item no.: 232-239/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 9-pole

232-239

/005-000

Item no.: 232-240/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 10-pole

232-240

/005-000

Item no.: 232-240/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 10-pole

232-240

/005-000/039-000

Item no.: 232-242/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 12-pole

232-242

/005-000

Item no.: 232-242/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 12-pole

232-242

/005-000/039-000

Item no.: 232-246/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 16-pole

232-246

/005-000

Item no.: 232-246/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 16-pole

232-246

/005-000/039-000

Item no.: 232-250/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 5 mm; 20-pole

232-250

/005-000

Item no.: 232-250/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Locking lever; Pin spacing 5 mm; 20-pole

232-250

/005-000/039-000

Item no.: 232-732/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 2-pole

232-732

/005-000

Item no.: 232-733/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 3-pole

232-733

/005-000

Item no.: 232-734/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 4-pole

232-734

/005-000

Item no.: 232-734/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 4-pole

232-734

/005-000/039-000

Item no.: 232-735/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 5-pole

232-735

/005-000

Item no.: 232-735/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 5-pole

232-735

/005-000/039-000

280-993

01.05.2019Page /14 20

Page 15

Data sheet | Item number:280-993

Item no.: 232-736/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 6-pole

232-736

/005-000

Item no.: 232-736/005-000/039-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 6-pole

232-736

/005-000/039-000

Item no.: 232-738/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 8-pole

232-738

/005-000

Item no.: 232-740/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 10-pole

232-740

/005-000

Item no.: 232-742/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 12-pole

232-742

/005-000

Item no.: 232-832/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 7.5 mm; 2-pole

232-832

/005-000

Item no.: 232-833/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 7.5 mm; 3-pole

232-833

/005-000

Item no.: 232-834/005-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 7.5 mm; 4-pole

232-834

/005-000

Item no.: 232-836/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 6-pole

232-836

/005-000

Item no.: 232-836/005-000/039-000

Female connector for rail-mount terminal blocks; angled; Pin spacing 7.5 mm; 6-pole

232-836

/005-000/039-000

Item no.: 232-840/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 10-pole

232-840

/005-000

Item no.: 232-842/005-000

Female connector for rail-mount terminal blocks; straight; Pin spacing 7.5 mm; 12-pole

232-842

/005-000

Item no.: 722-132/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 2-pole

722-132

/005-000

Item no.: 722-132/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 3-pole

722-132

/005-000/039-000

Item no.: 722-133/005-000

280-993

01.05.2019Page /15 20

Page 16

Data sheet | Item number:280-993

Item no.: 722-133/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 3-pole

722-133

/005-000

Item no.: 722-133/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 3-pole

722-133

/005-000/039-000

Item no.: 722-134/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 4-pole

722-134

/005-000

Item no.: 722-134/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 4-pole

722-134

/005-000/039-000

Item no.: 722-135/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 5-pole

722-135

/005-000

Item no.: 722-135/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 5-pole

722-135

/005-000/039-000

Item no.: 722-136/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 6-pole

722-136

/005-000

Item no.: 722-136/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 6-pole

722-136

/005-000/039-000

Item no.: 722-137/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 7-pole

722-137

/005-000

Item no.: 722-137/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 7-pole

722-137

/005-000/039-000

Item no.: 722-138/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 8-pole

722-138

/005-000

Item no.: 722-138/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 8-pole

722-138

/005-000/039-000

Item no.: 722-139/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 9-pole

722-139

/005-000

Item no.: 722-139/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 9-pole

722-139

/005-000/039-000

Item no.: 722-140/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

280-993

01.05.2019Page /16 20

Page 17

Data sheet | Item number:280-993

spacing 5 mm; 10-pole

722-140

/005-000

Item no.: 722-140/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 10-pole

722-140

/005-000/039-000

Item no.: 722-141/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 11-pole

722-141

/005-000

Item no.: 722-142/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 12-pole

722-142

/005-000

Item no.: 722-142/005-007/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 12-pole

722-142

/005-007/039-000

Item no.: 722-143/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 13-pole

722-143

/005-000

Item no.: 722-144/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 14-pole

722-144

/005-000

Item no.: 722-144/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 14-pole

722-144

/005-000/039-000

Item no.: 722-145/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 15-pole

722-145

/005-000

Item no.: 722-146/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 16-pole

722-146

/005-000

Item no.: 722-146/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 16-pole

722-146

/005-000/039-000

Item no.: 722-150/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 20-pole

722-150

/005-000

Item no.: 722-150/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 20-pole

722-150

/005-000/039-000

Item no.: 722-232/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 3-pole

722-232

/005-000

Item no.: 722-232/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

280-993

01.05.2019Page /17 20

Page 18

Data sheet | Item number:280-993

lever; Pin spacing 5 mm; 3-pole

722-232

/005-000/039-000

Item no.: 722-233/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 3-pole

722-233

/005-000

Item no.: 722-233/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 3-pole

722-233

/005-000/039-000

Item no.: 722-234/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 4-pole

722-234

/005-000

Item no.: 722-234/005-000/039-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 4-pole

722-234

/005-000/039-000

Item no.: 722-235/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 5-pole

722-235

/005-000

Item no.: 722-235/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 5-pole

722-235

/005-000/039-000

Item no.: 722-236/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 6-pole

722-236

/005-000

Item no.: 722-236/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 6-pole

722-236

/005-000/039-000

Item no.: 722-237/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 7-pole

722-237

/005-000

Item no.: 722-237/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 7-pole

722-237

/005-000/039-000

Item no.: 722-238/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 8-pole

722-238

/005-000

Item no.: 722-239/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 9-pole

722-239

/005-000

Item no.: 722-239/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 9-pole

722-239

/005-000/039-000

Item no.: 722-240/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

280-993

01.05.2019Page /18 20

Page 19

Data sheet | Item number:280-993

spacing 5 mm; 10-pole

722-240

/005-000

Item no.: 722-240/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 10-pole

722-240

/005-000/039-000

Item no.: 722-241/005-000

Female connector for rail-mount terminal blocks; straight; 100% protected against mismating; Pin

spacing 5 mm; 11-pole

722-241

/005-000

Item no.: 722-242/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 12-pole

722-242

/005-000

Item no.: 722-242/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 12-pole

722-242

/005-000/039-000

Item no.: 722-243/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 13-pole

722-243

/005-000

Item no.: 722-244/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 14-pole

722-244

/005-000

Item no.: 722-244/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 14-pole

722-244

/005-000/039-000

Item no.: 722-246/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 16-pole

722-246

/005-000

Item no.: 722-246/005-000/039-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Locking

lever; Pin spacing 5 mm; 16-pole

722-246

/005-000/039-000

Item no.: 722-250/005-000

Female connector for rail-mount terminal blocks; angled; 100% protected against mismating; Pin

spacing 5 mm; 20-pole

722-250

/005-000

tools

Item no.: 210-657

Operating tool with partially insulated shaft; Blade (3.5 x 0.5) mm; short

210-657

Item no.: 210-658

Operating tool with partially insulated shaft; Blade (3.5 x 0.5) mm; short; angled

210-658

Item no.: 210-720

Operating tool with partially insulated shaft; Type 2, blade (3.5 x 0.5) mm

210-720

End plate

Item no.: 209-191

Separator for Ex e/Ex i applications; 3 mm thick; 120 mm wide

209-191

280-993

01.05.2019Page /19 20

Page 20

Data sheet | Item number:280-993

Item no.: 209-192

Separator for Ex e/Ex i applications; 3 mm thick; 125.5 mm wide

209-192

Item no.: 280-358

End and intermediate plate; 2.5 mm thick

280-358

Item no.: 280-359

Separator plate; 2 mm thick; oversized

280-359

Insulation stop

Item no.: 280-470

Insulation stop; 0.08 - 0.2 mm² "s" (0.14 mm² "f-st"); 5 pieces/strip

280-470

Item no.: 280-471

Insulation stop; 0.25 - 0.5 mm²; 5 pieces/strip

280-471

Item no.: 280-472

Insulation stop; 0.75 - 1 mm²; 5 pieces/strip

280-472

Protective Warning Marker

Item no.: 280-415

Protective warning marker; with high-voltage symbol, black; for 5 terminal blocks

280-415

Downloads

Documentation

Bid Text

280-993 doc

24.6 kB

Download

CAD/CAE - Smart Data

CAD data

3D Download 280-993 URL Download

280-993

Subject to changes.

01.05.2019Page /20 20

Loading...

Loading...