Page 1

R

CS9100

Spray Systems

220V – 240V

International Model

Owner’s Manual • Manual do proprietário • Manual del usuario

Model Numbers:

0279029

0279030

0279031

0279032

Printed in the U.S.A.

Wagner Spray Tech

1770 Fernbrook Lane

Minneapolis, MN 55447 USA

1098 © 1998 Wagner Spray Tech. All rights reserved. Form No. 0279707D

EnglishPortuguêsEspañol

Page 2

Table of Contents

WARNING

CAUTION

WARNING

R

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Extension Cord Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Using an HVLP Spray System. . . . . . . . . . . . . . . . . . . . . 3-4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dual Filtration System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cleaning/Replacing Filters . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Replacing a Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–15

Português. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

NOTE: Notes give important information that should

be given special attention.

All local regulations in force must be observed.

In order to ensure safe operation of the spray systems,

the safety regulations listed below must be followed.

1. Read the operating manual carefully and follow the

instructions given in order to avoid possible danger.

2. Only coating materials with a flash point of 21 °C or over

may be sprayed, without additional heating.

3. Use of this unit is prohibited in workshops which come

under explosion prevention ordinances.

4. Never operate near sources of ignition, e.g., open flames,

cigarettes, cigars and pipes, sparks, red-hot wires, hot

surfaces, etc.

5. Warning! Risk of injury by injection!

Never point the spray gun at persons or animals.

In order to avoid occupational illnesses, always follow the

manufacturer’s instructions for the materials, solvents,

and cleaning agents used when preparing and using such

materials and when cleaning the unit. Protective clothing,

gloves, and, if necessary, skin protection cream should be

used to protect the skin.

7. For safety reasons, never use solvents based on 1,1,1

trichloroethane or methylene chloride.

8. Caution: When operating the spray system indoors or

outdoors, make sure that no solvent vapors are carried

towards the turbo-blower and that no solvent containing

vapors can accumulate in or near the turbo-blower.

Position the turbo-blower on the opposite side to the

object to be sprayed. Check the wind direction when

spraying outdoors. When working indoors, a sufficient flow

of air must be ensured for extracting the solvent vapors.

A minimum distance of 3 m must be maintained between

the turbo-blower and the object being sprayed.

9. Extraction systems should be installed on-site in

accordance with local regulations.

10. The work-pieces to be sprayed must be earthed.

11. When cleaning the unit with solvents, never spray into a

container with only a small opening (bunghole). Formation

of a explosive gas/air mixture may occur. The container

must be earthed.

12. When transporting the system, it must be suitably secured

for the particular means of transport.

13. Always remove the mains plug from the socket before

carrying out any work on electrical components.

14. Work or repairs to the electrical fittings must be carried out

by a specialist electrician. This is also valid even if there

are references to such work in the operating manual. No

liability will be accepted for improper installation.

Extension Cord Guidelines

Use only a 3-wire extension cord that has a 3-blade grounding

plug, and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in

loss of power and overheating.

NOTE: More than 100 feet of extension cord is not

recommended. Use more paint hose, not more

extension cord. Shorter extension cords will

assure maximum electrical power for proper

operation.

For breaks in work always secure the spray gun against

unintentional operation.

6. Always wear a protective mask when spraying.

English

2 © 1998 Wagner Spray Tech Corporation. All rights reserved.

Page 3

Grounding Instructions

WARNING

WARNING

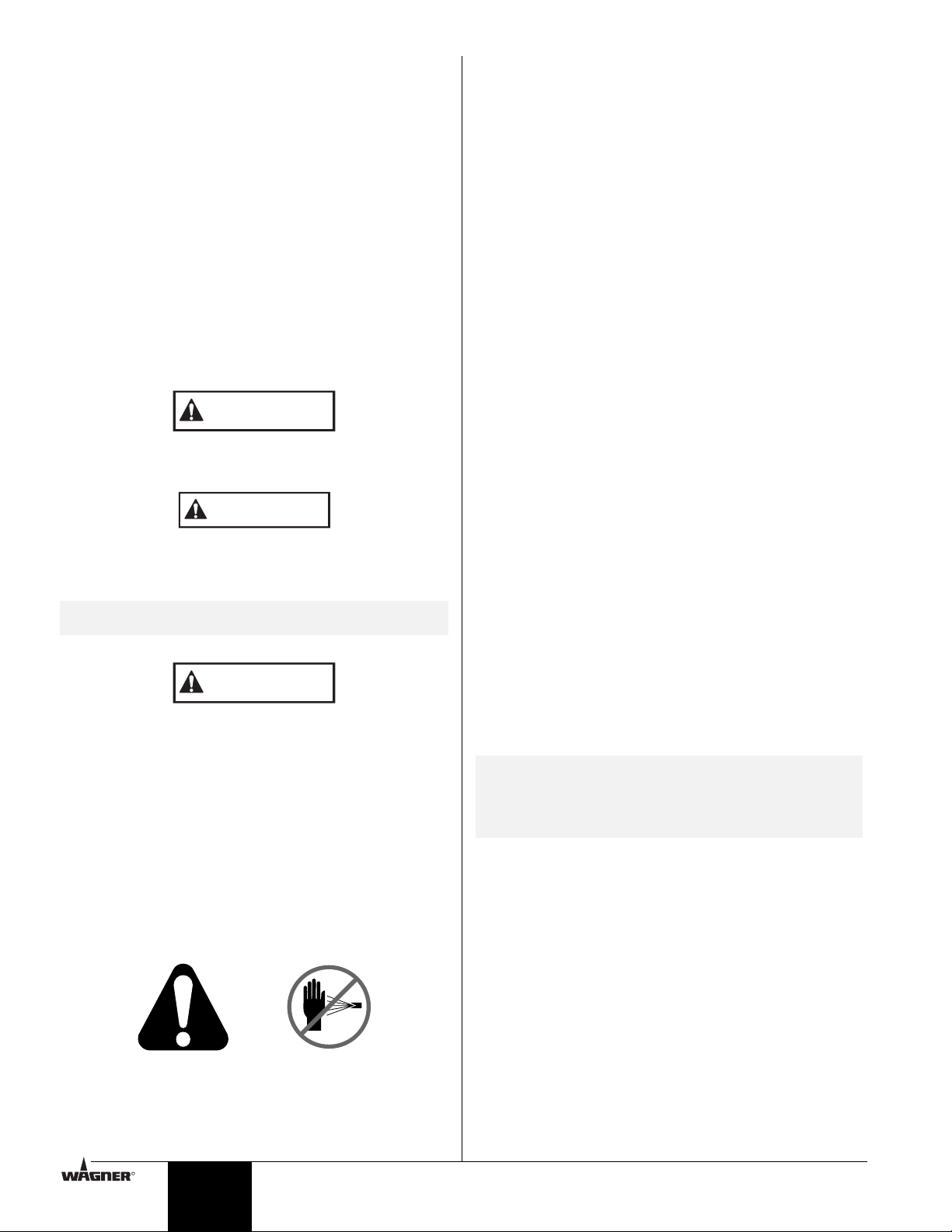

Cup Holder

Fuse

Filter

Warning

Light

Power Switch

Filter

Filter (in end

of filter can)

Air Hose

Air Outlet

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is installed properly and grounded in accordance

with all local codes and ordinances.

Improper installation of the grounding plug can result in a

risk of electric shock.

Service

Should your spray system need service during the warranty

period, return your unit and the proof of purchase to the

distributor where it was purchased. At our option, the unit will

be repaired or replaced. In a continued commitment to

improve quality, we reserve the right to make component or

design changes when necessary.

Introduction

This High Volume/Low Pressure (HVLP) spray system is

designed for applying coatings to surfaces that can be sprayed

faster than brushing or rolling and are too small for traditional

airless sprayers. Components of this system include a power

switch, a power cord, a filter warning light, a replaceable fuse,

a dual filtration system, a cup holder, an air hose, and an air

outlet.

With this HVLP spray system, you can achieve the highest

quality professional finish possible with little or no preparation

or setup time. Please review all the information contained in

this manual before operating the system.

Using an HVLP Spray System

Refer to the following information to operate and understand

your HVLP spray system.

Setup

Use the following procedure to set up your HVLP spray system

for operation.

1. Plug the turbine power cord into a grounded, 3-slot

receptacle.

Keep the turbine at the maximum possible distance from

the spray area to safeguard against explosion or fire that

may be caused by sparking electrical parts.

2. Prepare your spray gun for operation. Refer to your spray

gun manual for material preparation, setup, and spraying

information.

3. Attach the air hose to the air outlet on the turbine.

4. Attach the air hose to the air inlet on your spray gun.

5. Turn on the turbine and begin spraying.

© 1998 Wagner Spray Tech Corporation. All rights reserved. 3

English

R

Page 4

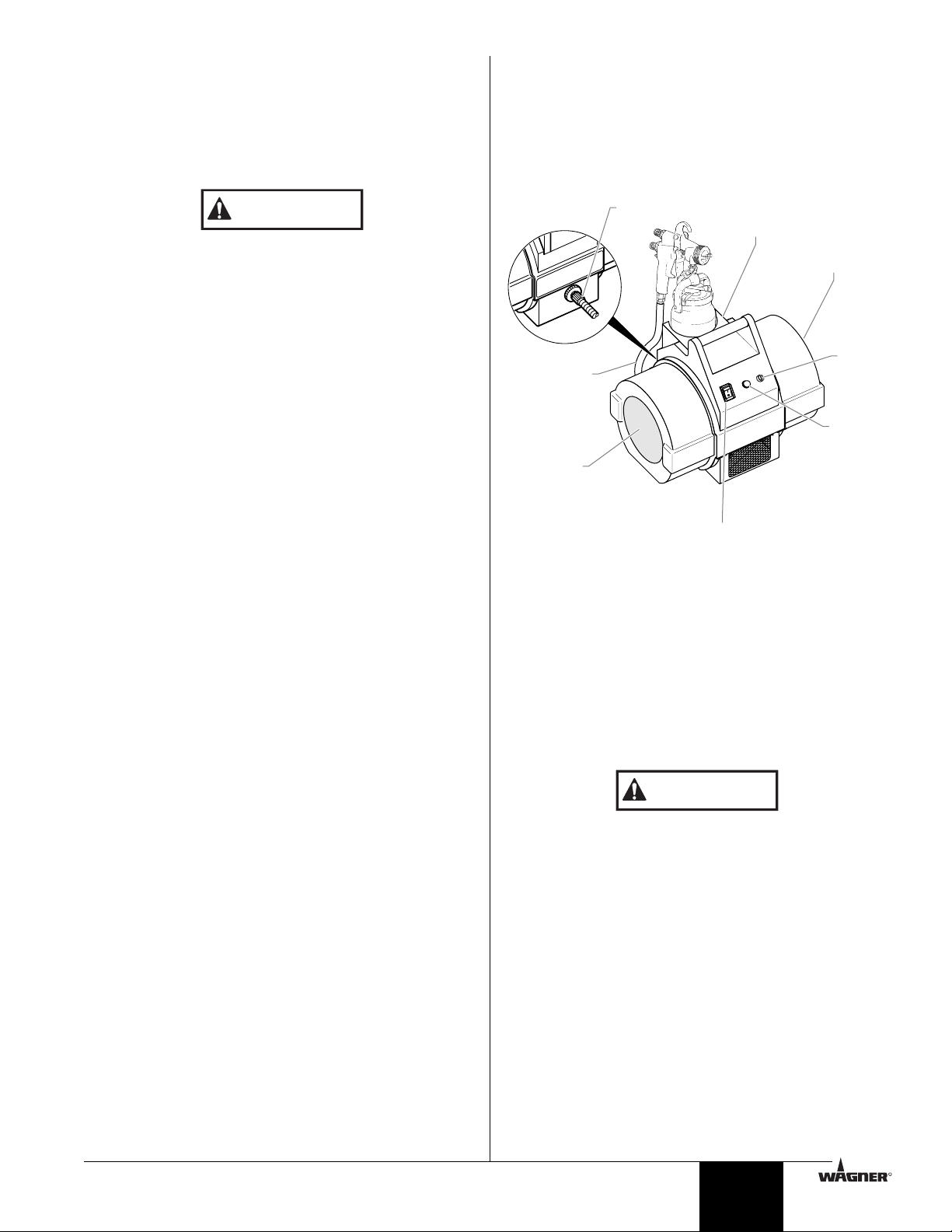

Dual Filtration System

Cooling Air Discharge

Cooling Air

Intake

Atomizing Air

Intake

Atomizing Air

Discharge

Cooling Air Filter

Two-Stage Atomizing

Air Filter

(green side facing

the turbine)

R

The turbine has two different air filters— one for atomizing air

and one for cooling air. The atomizing air filter is a two-stage,

fine mesh filter designed to trap particles that may damage

your finish. The atomizing air is discharged through the nozzle

of the spray gun where it atomizes the coating material. The

cooling air filter is a coarse mesh filter designed to allow the

proper amount of air flow through the turbine for cooling

purposes. Cooling air is exhausted through the cooling air

discharge on the front of the turbine.

Filter Warning System

The filter warning system on your turbine consists of a red filter

warning light on the front control panel and an air flow switch

inside the turbine. When the air flow switch does not detect

the appropriate amount of air flowing through the turbine, the

filter warning light will come on to indicate that it is time to

clean or change the filters.

NOTE: The filter warning system does not shut down

the turbine.

CAUTION

Clean filters regularly. Clogged filters can cause excessive

heat and possibly damage the turbine.

Maintenance

Use the following procedures to keep your HVLP spray system

running properly.

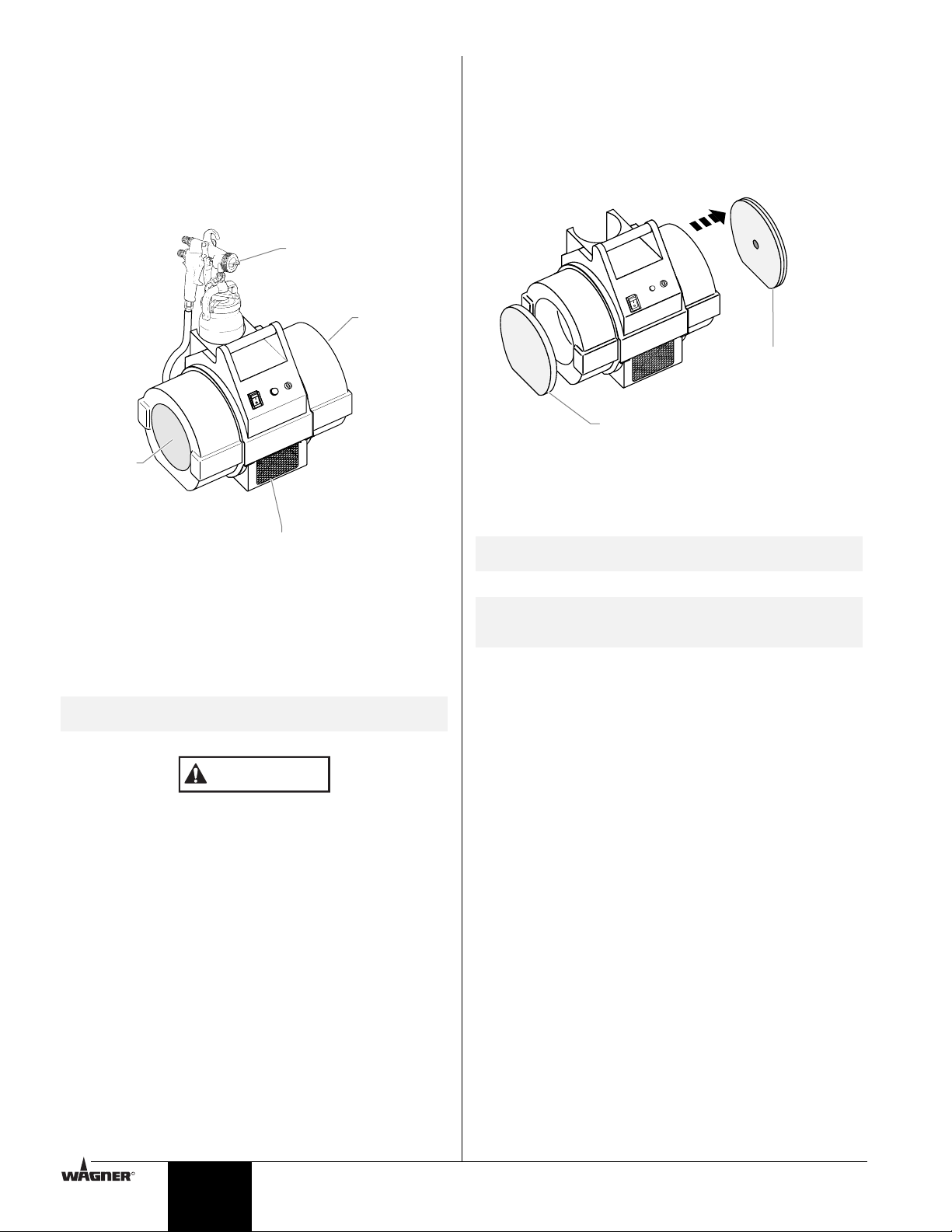

Cleaning/Replacing the Filters

1. Remove each filter by grabbing them and pulling them

straight out of the filter cans on the turbine. This will not

damage the filters.

2. Clean the filters. Either tap the filters to knock out the

contaminants or use pressurized air to blow out the

contaminants. For material that is not blown or knocked

loose easily, soak the filters in soapy water or minearal

spirits. Allow the filters to dry completely before placing

them back in the turbine.

NOTE: Do not use highly flammable solvents, such as

lacquer thinner, to clean the filters.

3. Insert each filter back into its corresponding filter can.

NOTE: The two-stage, atomizing air filter must be

placed in the filter can labeled “2-Stage Filter”

with the green side facing the turbine.

After several cleanings, it may become necessary to replace

the filters. Refer to the parts list near the end of this manual

for the filter replacement kit part number.

Replacing a Fuse

1. Remove the fuse holder cover using a flathead screw

driver. Push the screwdriver into the cover and turn the

cover counterclockwise

2. Pull the old fuse out of the fuse holder cover.

3. Place the new fuse inside the fuse holder cover.

4. Place the new fuse and the fuse holder cover into the fuse

holder. Turn the fuse holder cover clockwise with the

flathead screwdriver to lock it into position.

English

4 © 1998 Wagner Spray Tech Corporation. All rights reserved.

Page 5

R

Problem

Restricted air flow or no air

flow

Troubleshooting

Cause

1. Air flow adjustment knob on the spray

gun is turned off

2. Air filters are clogged

Solution

1. Adjust the air flow adjustment knob

2. Clean or replace the filters

Filter warning light is on

The turbine has no power

Excessive arcing/sparking in

the turbine

1. Air filters are clogged

1. No power at the power supply

2. The fuse is blown

3. Worn turbine brushes

1. Worn turbine brushes

2. Damaged commutator

Patents

These products are covered by one or more of the following U.S. patents:

5,423,395 D322,790 5,181,832 D338,208 5,174,610 5,550,336

D365,569 5,556,255 5,639,222 5,702,131 5,558,492 5,573,371

5,772,711

1. Clean or replace the filters

1. Check the power supply

2. Check and replace the fuse

3. Have the brushes replaced at an authorized

Wagner service center

1. Have the brushes replaced at an authorized

Wagner service center

2. Replace the turbine (contact a Wagner

service technician)

© 1998 Wagner Spray Tech Corporation. All rights reserved. 5

English

Page 6

R

Table Des Matiéres

AVISO

CUIDADO

AVISO

Segurança . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

Recomendações para a Extensão Elétrica . . . . . . . . . . . . . . 6

Instruções de Aterramento . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Manutenção. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introdução. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Uso do Sistema HVLP. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Ajustes Iniciais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sistema de Filtragem Dupla . . . . . . . . . . . . . . . . . . . . . . . . . 8

Manutenção Periódica . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Limpeza/Substituição dos Filtros . . . . . . . . . . . . . . . . . . . . . . 8

Substituição do Fusível. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Diagnóstico de Falhas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lista de Peças. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–15

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Segurança

Este manual contém informações que precisam ser lidas e

entendidas antes do uso do equipamento. Quando você entrar

em uma área com um dos seguintes símbolos, preste muita

atenção e assegure-se de que foram tomadas todas as

medidas de segurança.

Este símbolo indica um potencial perigo que pode causar

sérios prejuízos à saúde ou até mesmo a morte. Seguem

importantes informações sobre segurança.

Este símbolo indica um potencial risco para você ou para o

equipamento. A seguir, informações importantes que dirão

como prevenir danos ao equipamento ou como evitar causar

pequenos prejuízos.

NOTA: Notas contém informações importantes que

devem receber especial atenção.

Todos os regulamentos locais em vigor devem ser

respeitados.

A fim de assegurar a operação segura dos sistemas de

pulverização, deve-se respeitar os regulamentos de

segurança relacionados abaixo:

1. Leia o manual de operação cuidadosamente e siga as

instruções fornecidas para evitar possíveis perigos.

2. Somente materiais de revestimento com um ponto de

ebulição de 21 °C ou acima podem ser pulverizados, sem

aquecimento adicional.

3. O uso desta unidade é proibido em oficinas que possuam

regulamentos de prevenção contra explosões.

4. Nunca opere perto de fontes de ignição, por exemplo:

chamas, cigarros, charutos e cachimbos, faíscas, fios

eletrizados, superfícies quentes, etc.

5. Aviso! Risco de danos físicos por injeção!

Nunca aponte a pistola do pulverizador para pessoas ou

animais.

6. Ao pulverizar, sempre use uma máscara de proteção.

Para evitar doenças decorrentes de trabalho, sempre siga

as instruções do fabricante quanto aos materiais,

solventes e agentes de limpeza usados ao preparar e usar

tais materiais e ao limpar a unidade. Também deve ser

usada vestimentas e luvas protetoras e, se necessário,

creme de proteção para a pele para protegê-la.

7. Para fins de segurança, nunca use solventes baseados

em 1,1,1 tricloroetano ou cloreto de metileno.

8. Cuidado: Ao operar o sistema de pulverização em

ambientes internos ou externos, certifique-se de que

nenhum vapor dos solventes seja carregado em direção

ao turbocompressor e que nenhum solvente que contenha

vapor possa se acumular no turbocompressor ou perto do

mesmo.

Posicione o turbocompressor no lado oposto do objeto a

ser pulverizado. Verifique a direção do vento quando

estiver pulverizando em ambientes externos. Ao trabalhar

em ambientes internos, deve-se assegurar um fluxo de ar

suficiente para extrair os vapores solventes.

Deve-se manter uma distância mínima de 3 m entre o

turbocompressor e o objeto a ser pulverizado.

9. Devem ser instalados sistemas de extração no local em

conformidade com os regulamentos locais.

10. As obras a serem pulverizadas devem ser aterradas.

11. Ao limpar a unidade com solventes, nunca pulverize em

um recipiente com apenas uma pequena abertura

(batoque). Pode ocorrer a formação de uma mistura

explosiva de gás/ar. O recipiente deve ser aterrado.

12. Ao transportar o sistema, ele deve ser devidamente

afixado ao meio de transporte em uso.

13. Sempre retire o plugue principal da tomada antes de

efetuar qualquer trabalho em componentes elétricos.

14. O trabalho ou consertos em acessórios elétricos deve ser

efetuado por um eletricista especializado. Isso também se

aplica mesmo se houver referência a tal trabalho no

manual de operação. Não será assumida nenhuma

responsabilidade pela instalação inadequada.

Recomendações para a Extensão

Elétrica

Use somente uma extensão de 3 fios que tenha um plugue de

aterramento com três contatos, e um soquete com 3 contatos

que aceitarão o plugue do produto. Certifique-se de que a sua

extensão esteja em bom estado. Ao usar uma extensão, use

uma que seja forte o suficiente para agüentar a corrente que o

seu produto utilizará. Uma extensão abaixo das

especificações causará uma queda na tensão em linha,

resultando em perda de potência e super aquecimento.

NOTA: Não se recomenda uma extensão de mais de

30 metros de comprimento. Use uma

mangueira de tinta mais longa e não uma

extensão maior. Extensões mais curtas

assegurarão uma potência elétrica máxima

para a operação adequada.

Durante interrupções no trabalho, sempre proteja a pistola

do pulverizador contra operação não intencional.

Português

6 © 1998 Wagner Spray Tech Corporation. Todos os direitos reservados.

Page 7

R

Instruções de Aterramento

AVISO

AVISO

Suporte do Copo

Fusível

Lâmpada

de Aviso

do Filtro

Botão Liga-Desliga

Filtro

Filtro (na extremidade

do tambor de filtro)

Mangueira

de Ar

Saída de Ar

Este produto deve ser aterrado. Caso haja um curto-circuito

elétrico, o aterramento reduz o risco de choque elétrico dando

um fio de escape para a corrente elétrica. Este produto é

equipado com um fio que tem um fio de aterramento com um

plugue de aterramento adequado. O plugue deve ser ligado a

uma tomada que seja devidamente instalada e aterrada em

conformidade com todos os códigos e regulamentos locais.

A instalação indevida do plugue de aterramento pode

resultar em um risco de choque elétrico.

Manutenção

Se o seu HVLP spray precisar de serviços durante o período

de garantia, apresentar a unidade e o comprovante de compra

ao distribuidor onde foi comprada. Conforme nossa opinião, a

unidade poderá ser reparada ou substituída. Em nosso

contínuo compromisso de melhorar a qualidade, nos

reservamos o direito de efetuar mudanças nos componentes

ou desenho quando necessários.

Introdução

Este sistema de Alto Volume/Baixa Pressão (HVLP) foi criado

para aplicar revestimentos a superfícies que podem ser

pulverizadas mais rapidamente do que pintar com pincel e

rolos e são pequenas demais para o uso de pulverizadores

tradicionais sem ar. Este sistema é composto por: um botão

liga-desliga, um cabo de alimentação elétrica, uma lâmpada

de aviso do filtro, um fusível substituível, um sistema de

filtragem dupla, um suporte do copo, uma mangueira de ar e

uma saída de ar.

Com este sistema HVLP você pode obter o acabamento

profissional da mais alta qualidade com pouco preparo ou

tempo de ajuste. Reveja todas as informações contidas neste

manual antes de operar o sistema.

Uso do Sistema HVLP

Consulte as seguintes informações para operar e compreender

o sistema HVLP.

Ajustes Iniciais

Siga o procedimento abaixo para ajustar o sistema HVLP para

operação.

1. Conecte o cabo de alimentação do compressor a uma

tomada aterrada com três contatos.

Mantenha o compressor o mais longe possível da área

que está sendo pulverizada, para prevenir o risco de

explosões ou de incêndios causados pelas peças

elétricas que produzem faíscas.

2. Prepare o pulverizador para operação. Consulte o manual

do pulverizador para ver as informações sobre o preparo,

ajustes iniciais e pulverização do material.

3. Conecte a mangueira de ar à saída de ar do compressor.

4. Conecte a mangueira de ar à entrada de ar do

pulverizador.

5. Ligue o compressor e inicie a pulverização.

© 1997 Wagner SprayTECH Corporation. Todos os direitos reservados. 7

Português

Page 8

Sistema de Filtragem Dupla

CUIDADO

Descarga do Ar de Resfriamento

Entrada

do Ar de

Resfriamento

Entrada do Ar

de Atomização

Descarga do Ar

de Atomização

Filtro do Ar de Resfriamento

Filtro de Dois Estágios

do Ar de Atomização

(lado verde virado

para o compressor)

R

O compressor possui dois filtros de ar diferentes — um para o

ar de atomização e o outro para o ar de resfriamento. O filtro

do ar de atomização é um filtro de dois estágios com malha

fina destinado à retenção das partículas que poderiam

danificar o acabamento. O ar de atomização é descarregado

pelo bocal do pulverizador, atomizando o material de

revestimento. O filtro do ar de resfriamento é um filtro de

malha comum utilizado para permitir a passagem do fluxo de

ar adequado para o resfriamento do compressor. O ar de

resfriamento é expelido pela saída do ar de resfriamento,

localizada na frente do compressor.

Sistema de Aviso dos Filtros

O sistema de aviso dos filtros do compressor consiste em uma

lâmpada vermelha de aviso localizada no painel frontal de

controle e em um sensor de fluxo de ar, no interior do

compressor. Quando esse sensor não detectar o fluxo correto

de ar pelo compressor, a lâmpada de aviso do filtro será

acesa, indicando que os filtros deverão ser limpos ou

substituídos.

NOTA: O sistema de aviso dos filtros não desliga o

compressor.

Limpe os filtros com freqüência. Filtros entupidos podem

causar calor excessivo e possivelmente danificar a

unidade.

Manutenção Periódica

Siga os procedimentos abaixo para manter o seu sistema

HVLP em perfeitas condições de funcionamento.

Limpeza/Substituição dos Filtros

1. Remova cada um dos filtros, puxando-os para fora dos

tambores de filtro do compressor. Essa operação não

danificará os filtros.

2. Limpe os filtros. Bata levemente nos filtros para retirar as

impurezas retidas ou aplique jatos de ar comprimido para

removê-las. Caso as impurezas não saiam, mergulhe os

filtros em água com sabão ou em álcoois minerais.

Espere que os filtros sequem completamente antes de

recolocá-los no compressor.

NOTA: Não utilize solventes altamente inflamáveis,

como thinner de laca para limpar os filtros.

3. Recoloque cada filtro nos seus respectivos tambores.

NOTA: O filtro de dois estágios do ar de atomização

deverá ser colocado no tambor com a

inscrição “2-Stage Filter” (filtro de dois

estágios) com o lado verde virado para o

compressor.

Após algumas limpezas, poderá ser necessário substituir os

filtros. Consulte a lista de peças, localizada próxima ao final

deste manual, para obter o número de peça do conjunto de

substituição dos filtros.

Substituição do Fusível

1. Retire a tampa do suporte do fusível usando uma chave

de fenda com ponta plana. Posicione a chave de fenda na

tampa e gire-a no sentido anti-horário.

2. Remova o fusível queimado da tampa do suporte do

fusível.

3. Coloque o novo fusível dentro da tampa do suporte do

fusível.

4. Coloque o novo fusível e a tampa do suporte do fusível

no suporte do fusível. Gire a tampa do suporte do fusível

no sentido horário com a chave de fenda até travá-la na

posição.

Português

8 © 1998 Wagner Spray Tech Corporation. Todos os direitos reservados.

Page 9

R

Problema

Redução ou inexistência do

fluxo de ar

Diagnóstico de Falhas

Causa

1. O botão de regulagem do fluxo de ar

no pulverizador está fechado

2. Os filtros de ar estão obstruídos

Solução

1. Ajuste o botão de regulagem do fluxo de ar

2. Limpe ou substitua os filtros

Alâmpada de aviso dos filtros

está acesa

O compressor não funciona

Ocorrência excessiva de

arcos/faíscas no compressor

1. Os filtros de ar estão obstruídos

1. Não há energia elétrica

2. Fusível queimado

3. Escovas do compressor gastas

1. Escovas do compressor gastas

2. Comutador danificado

Patentes

Esses produtos são cobertos por uma ou mais das seguintes patentes (U.S.A.):

5,423,395 D322,790 5,181,832 D338,208 5,174,610 5,550,336

D365,569 5,556,255 5,639,222 5,702,131 5,558,492 5,573,371

5,772,711

1. Limpe ou substitua os filtros

1. Verifique a alimentação elétrica

2. Verifique e substitua o fusível

3. Substitua as escovas em um centro de

serviço autorizado Wagner

1. Substitua as escovas em um centro de

serviço autorizado Wagner

2. Substitua o compressor (consulte um

técnico de serviços Wagner)

© 1998 Wagner Spray Tech Corporation. All rights reserved. 9

Português

Page 10

R

Idice

ADVERTENCIA

PRECAUCION

ADVERTENCIA

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–11

Normas para el cordón de extensión. . . . . . . . . . . . . . . . . . 10

Instrucciones de conexión a tierra . . . . . . . . . . . . . . . . . . . . 11

Servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Uso del sistema de pulverización HVLP. . . . . . . . . . . . 11–12

Preparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sistema de filtrado doble. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Limpieza / Sustitución de los filtros . . . . . . . . . . . . . . . . . . . 12

Sustitución del fusible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Localización de averias . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lista de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14–15

Português . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Seguridad

Este manual contiene información que tiene que leerse y

entenderse antes de utilizar el equipo. Cuando se encuentre

en una área que tenga uno de los siguientes símbolos, esté

muy atento y asegúrese que tiene en cuenta la seguridad.

Estos símbolos indican un peligro potencial que puede causar

graves daños o pérdidas humanas. A continuación se explica

información importante para la seguridad.

Estos símbolos indican un peligro potencial para usted o para

su equipo. A continuación se explica información que puede

prevenir daños en el equipo o cómo evitar las causas que

provocan daños menores.

NOTA: Las notas dan información importante que

tendría que ser considerada con especial

atención.

Deben observarse todas los reglamentos locales vigentes.

A fin de asegurar un manejo seguro de los sistemas de

pulverización, deben seguirse las normas de seguridad

que se listan a continuación.

1. Leer todo el manual de operación y seguir las

instrucciones dadas para evitar posibles peligros.

2. Solamente pueden pulverizarse materiales de

revestimiento con un punto de inflamación de 21 °C o

superior, sin calentamiento adicional.

3. Se prohíbe el uso de esta unidad en talleres que estén

bajo ordenanzas de prevención de explosiones.

4. No operar nunca cerca de fuentes de combustión, v.gr.:

llamas abiertas, cigarrillos, cigarros y pipas, chispas,

alambres al rojo vivo, superficies calientes, etc.

5. ¡Advertencia! ¡Riesgo de lesiones por inyección!

No apuntar nunca la pistola pulverizadora a personas o

animales.

6. Usar siempre una mascarilla protectora al pulverizar.

Para evitar enfermedades profesionales, seguir siempre

las instrucciones del fabricante con respecto a los

materiales, solventes y agentes limpiadores que se usen

al preparar y utilizar tales materiales y al limpiar la unidad.

Debe usarse ropa protectora, guantes y, si es necesario,

crema protectora para proteger la piel.

7. Por razones de seguridad, no usar nunca solventes con

base de tricloroetano o cloruro de metileno 1,1,1.

8. Precaución: Al hacer funcionar el sistema de pulverización

en el interior o al aire libre, asegurarse de que los vapores

de solvente no vayan hacia el turbosoplador y de que no

puedan acumularse vapores que contengan solventes en

o cerca del turbosoplador.

Emplazar el turbosoplador en el lugar opuesto en el que

se encuentre el objeto que se vaya a pulverizar. Cuando

se pulverice al aire libre, comprobar la dirección del

viento. Al trabajar en el interior, asegurarse de que haya

suficiente caudal de aire para la extracción de los vapores

de solvente.

Debe mantenerse una distancia mínima de 3 m entre el

turbosoplador y el objeto que se esté pulverizando.

9. Los sistemas de extracción deben estar instalados en el

lugar conforme a los reglamentos locales.

10. Las piezas de trabajo a pulverizarse deben estar

conectados a tierra.

11. Al limpiar la unidad con solventes, no pulverizar nunca en

un envase que tenga una abertura pequeña (piquera).

Puede formarse una mezcla explosiva de gas/aire. El

envase debe estar conectado a tierra.

12. Cuando se transporte el sistema, debe estar

convenientemente afianzado para los medios particulares

de transporte.

13. Extraer siempre el enchufe tomacorriente del

tomacorriente antes de llevar a cabo cualquier tipo de

trabajo en los componentes eléctricos.

14. El trabajo en o reparaciones de los elementos de

conexión eléctricos debe ser llevado a cabo por un

electricista especializado. Lo anterior también aplica si

hay referencias a dicho trabajo en el manual de

operación. No se aceptará responsabilidad alguna por

una instalación incorrecta.

Normas para el cordón de extensión

Use solamente extensiones de 3 alambres que tengan una

clavija de 3 patas con conexión a tierra y un enchufe de 3

ranuras que acepte la clavija del producto. Asegúrese de que

la extensión esté en buenas condiciones. Cuando use una

extensión, asegúrese de utilizar una que sea lo

suficientemente resistente como para transportar la corriente

que emplee su producto. Una extensión de una capacidad

menor causará una caída de voltaje en la línea, lo que traerá

como consecuencia que se pierda energía y se sobrecaliente.

NOTA: No se recomienda usar una extensión de más

de 100 pies. Use una longitud mayor de

manguera de pintura, no una extensión más

larga. Una extensión más corta asegurará que

haya la energía eléctrica máxima para tener un

funcionamiento apropiado.

Durante los descansos en el trabajo, afianzar siempre la

pistola pulverizadora para evitar su funcionamiento

involuntario.

Español

10 © 1998 Wagner Spray Tech Corporation. Reservados todos los derechos.

Page 11

Portacubetas

Fusible

Luz de

advertencia

de filtro

Interruptor de energía

Filtro

Filtro (en el extremo

del alojamiento

cilíndrico del filtro)

Manguera

de aire

Salida de aire

Instrucciones de conexión a tierra

ADVERTENCIA

Este producto debe estar conectado a tierra. En caso de un

cortocircuito eléctrico, la conexión a tierra reduce el riesgo de

sacudidas eléctricas proporcionando un cable de escape para

la corriente eléctrica. Este producto está equipado con un

cordón que tiene un cable de conexión a tierra con una clavija

de conexión a tierra apropiada. La clavija de conexión debe

estar enchufada en una salida que esté correctamente

instalada y conectada a tierra de conformidad con todos los

códigos y ordenanzas locales.

La instalación incorrecta de la clavija de conexión a tierra

puede tener como resultado el riesgo de sacudidas

eléctricas.

Servicio

Si su pistola pulverizadora HVLP necesitara un servicio

durante el periodo de garantía, devuelva la unidad y la prueba

de compra al vendedor donde la adquirió. Siguiendo nuestro

criterio repararemos o cambiaremos la unidad. Como una

continua obligación para mejorar la calidad, nos reservamos el

derecho de añadir componentes o diseñar cambios cuando

creamos necesario.

Introducción

Este sistema de pulverización de volumen alto / presión baja

(HVLP) está diseñado para la aplicación de revistimientos a

superficies que pueden ser pulverizadas más rápidamente que

pintadas con brocha o rodillo y que son demasiado pequeñas

para los sistemas de pulverización sin aire tradicionales. Los

componentes de este sistema incluyen un interruptor de

energía, un cordón de energía, una luz de advertencia de

filtro, un fusible sustituible, un sistema de filtrado doble, un

portacubetas, una manguera de aire, y una salida de aire.

Con este sis tema de pulverización HVLP, se puede lograr el

acabado profesional de la calidad más alta posible con poco o

ningún tiempo de preperación o de instalación. Le rogamos

repase toda la información contenida en este manual antes de

utilizar el sistema.

Utilización de un sistema de

pulverización HVLP

Vea la información dada a continuación para operar y entender

su sistemade pulverización HVLP.

Preparación

Para preparar su sistema de pulverización HVLP para usarlo,

utilice el procedimiento siguiente:

1. Enchufe el cordón de energía de la turbina en una toma

de corriente de 3 patillas, conectada a tierra.

ADVERTENCIA

Mantenga la turbina a la mayor distancia posible de la

zona de pulverización, como precaución contra la

explosión o el fuego que pudieran ser causados por las

chispas producidas por las partes eléctricas.

2. Prepare la pistola para uso. Consulte el manual de su

pistola de pulverización para ver la información sobre la

preparación del material, el montaje y la pulverización.

3. Sujete la manguera de aire a la salida de aire de la

turbina.

4. Sujete la manguera de aire a la entrada de aire de su

pistola de pulverización.

5. Conecte la turbina y comince la pulverización.

© 1998 Wagner Spray Tech Corporation. Reservados todos los derechos. 11

Español

R

Page 12

Sistema de filtrado doble

PRECAUCION

Filtro de aire de refrigeración

Filtro de aire de

atomizado de dos etapas

(lado verde mirando

hacia la turbina)

R

La turbina dispone de dos filtros de aire diferentes - uno para

el aire de atomizado y otro para el aire de refrigeración. El

filtro de aire de atomizado es un filtro de malla fina, de dos

etapas, diseñado para atrapar las partículas que podrían

estropear su acabado. El aire de atomizado es descargado a

través de la boquilla de la pistola de pulverización donde

atomiza el material de revestimiento. El filtro de aire de

refrigeración es un filtro de malla gruesa diseñado para

permitir el paso de la cantidad adecueda de aire para

refrigeración. El aire de refrigeración escapa a través de la

descarga de aire de refrigeratión en la parte frontal de la

turbina.

Descarga de aire

de atomizado

Entrada

de aire

de atomizado

Entrada de aire

de refrigeración

Descarga de aire de refrigeración

Sistema de advertencia de filtro

El sistema de advertencia de filtro de la turbina consiste en

una luz roja de advertencia de filtro en el panal frontal de

control y un interruptor de flujo de aire dentro de la turbina.

Cuando el interruptor de flujo de aire no detecta un flujo de

aire del caudal adecuado a través de la turbina, la luz de

advertencia de filtro se enciende indicando que es hora de

limpiar o de cambiar los filtros.

NOTA: El sistema de advertencia de filtro no para la

turbina.

Limpie los filtros regularmente. Los filtros tapados

pueden causar un calor excesivo y posiblemente que la

unidad se dañe.

Mantenimiento

Para mantener su sistema de pulverización HVLP funcionando

correctamente siga los procedimientos siguentes.

Limpieza/Sustitución de los filtros

1. Desmonte ambos filtros agarrándolos y tirando de ellos

por derecho hacia afuera para sacarlos de sus

alojamientos cilíndricos en la turbina. Esta no dañará los

filtros.

2. Limpie los filtros. Golpee los filtros suavemente para

quitar los contaminantes o utilice aire a presión para

soplar y expulsarlos. Para quitar aquellos materiales que

no se puedan expulsar fácilmente soplando o golpeando

ligeramente, empape los filtros en agua jabonosa o en

alcoholes minerales. Deje que los filtros se sequen por

completo antes de volverlos a colocar en la turbina.

NOTA: Para limpiar los filtros, no utilice solventes

altamente inflamables tales como diluyente

para laca.

3. Inserte cada uno de los filtros dentro de su alojamiento

cilíndrico correspondiente.

NOTA: El filtro de aire de atomizado, de dos etapas,

debe colocarse en el alojamiento cilíndrico

marcado “2-Stage Filter” con el lado verde

mirando hacia la turbina.

Después de varias limpiezas, puede ser necesario reemplazar

los filtros. Diríjase a la lista de plezas, casi al final de este

manual, para ver el número de pieza del conjunto de

sustitución de filtros.

Sustitución del fusible

1. Desmonte la tapa del protafusibles usando un atornillador

plano. Coloque la hoja del atornillador dentro de la tapa y

gírela a izquierdas.

2. Tire del fusible viejo para sacarlo de la tapa del

portafusibles.

3. Coloque el fusible nuevo dentro de la tapa del

portafusibles.

4. Coloque el fusible nuevo y latapa del portafusibles dentro

del portafusibles.Gire la tapa del portafusibles a derechas,

usando el atornillador plano, para fijarla en su sitio.

Español

12 © 1998 Wagner Spray Tech Corporation. Reservados todos los derechos.

Page 13

R

Problema

Flujo de aire reducido o

inexistente

Localización de averías

Causa

1. Botón de ajuste del flujo de aire de la

pistola cerrado

2. Filtros de aire atascados

Solución

1. Adjuste el botón de ajuste del flujo de aire

2. Limpie o sustituya los filtros

Luz de advertencia de filtro

encendida

La turbina no tienen energía

Salto de arco / chisporroteo

excesivo en la turbina

1. Filtros de aire atascados

1. No hay energía en la alimentación de

energía

2. Fusible fundido

3. Escobillas de la turbina desgastadas

1. Escobillas de la turbina desgastadas

2. Colector dañado

Patente

Estos productos están cubiertos con una o más patentes (U.S.A.):

5,423,395 D322,790 5,181,832 D338,208 5,174,610 5,550,336

D365,569 5,556,255 5,639,222 5,702,131 5,558,492 5,573,371

5,772,711

1. Limpie o sustituya los filtros

1. Compruebe el suministro de energía

2. Compruebe y sustituya el fusible

3. Haga que le sustituyan las escobillas en un

centro de mantenimiento autorizado

Wagner

1. Haga que le sustituyan las escobillas en un

centro de mantenimiento autorizado

Wagner

2. Sustituya la turbina (póngase en contacto

con un técnico de mantenimiento de

Wagner

© 1998 Wagner Spray Tech Corporation. All rights reserved. 13

Español

Page 14

R

• The turbine motor can be damaged if not serviced properly. Have the brushes (Kit P/N 0277918) checked for wear

PRECAUCION

CUIDADO

CAUTION

by an authorized service center every 400 hours.

• Clean filters regularly. Clogged filters can cause excessive heat and possibly damage the unit.

• For additional troubleshooting information, see the manual that came with your gun.

• Le moteur de la turbine peut être endommagé si on n'en effectue pas l'entretien approprié. Faire vérifier l'usure des

brosses (N/P 0277918) par un centre d'entretien autorisé à toutes les 400 heures d'utilisation.

• Nettoyer régulièrement les filtres. Les filtres engorgés peuvent engendrer une surchauffe et peut-être endommager

l'unité.

• Pour obtenir de plus amples renseignements en matière de diagnostic des anomalies, consulter le manuel

accompagnant le pistolet.

• El motor de la turbina se puede dañar si no se le da servicio de manera apropiada. Pida a un centro de servicio

autorizado que verifique el desgaste de las escobillas (Juego N/P 0277918) cada 400 horas.

• Limpie los filtros regularmente. Los filtros tapados pueden causar un calor excesivo y posiblemente que la unidad

se dañe.

• Vea el manual que viene con la pistola para consultar la información de detección de problemas adicional.

15

40

39

38

1

2

3

4

5

41

10

37

36

35

34

33

32

31

11

12

30

13

14

29

28

27

24

25

26

19

42

43

6

7

8

9

20

21

18

22

17

23

16

18

17

15

English

Português Español

16

14 © 1998 Wagner Spray Tech Corporation. All rights reserved.

Page 15

R

English

Item

Part No. Description Quantity

1 0277316 Ring, air outlet retaining . . . . . . . . . . . . . . .1

2 0277439 Air outlet pipe . . . . . . . . . . . . . . . . . . . . . .1

3 9803103 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4 0277443 Bleeder box cover . . . . . . . . . . . . . . . . . . .1

5 0277442 Bleeder box base . . . . . . . . . . . . . . . . . . . .1

6 0277397 Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7 0277402 Foam Tape . . . . . . . . . . . . . . . . . . . . . . . . 2

8 0277457 Bottom housing . . . . . . . . . . . . . . . . . . . . . 1

9 0090628 Foot Pad . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10 9802222 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

11 0277385 Vent plate . . . . . . . . . . . . . . . . . . . . . . . . . 1

12 9800319 Screw, hex soc hd cap 1/4-20 x 0,75 . . . . . 4

13 0277419 Strain relief . . . . . . . . . . . . . . . . . . . . . . . . 1

14 ----------- Cord (see insert 0279719) . . . . . . . . . . . . . 1

15 0293395 Screw, 8-32 x 3/8 Taptite . . . . . . . . . . . . . 12

16 0277366 Filter can, large . . . . . . . . . . . . . . . . . . . . . 2

17 0279938 1st and 2nd stage filter replacements . . . . . 1

18 0277367 Filter screen. . . . . . . . . . . . . . . . . . . . . . . . 2

19 0277371 Fan noise foam . . . . . . . . . . . . . . . . . . . . . 1

20 0277369 Can cover . . . . . . . . . . . . . . . . . . . . . . . . . 1

21 0277396 Can mount foot . . . . . . . . . . . . . . . . . . . . . 6

22 0276598 Foam disk . . . . . . . . . . . . . . . . . . . . . . . . . 1

23 0277501 Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

24 0277368 Foam insert . . . . . . . . . . . . . . . . . . . . . . . . 1

Português

Article

No de pièce Description Quantité

1 0279425 Anel de retenção da saída de ar . . . . . .1

2 0277409 Cano de saída de arr . . . . . . . . . . . . . . .1

3 9803103 Parafuso . . . . . . . . . . . . . . . . . . . . . . . .2

4 0277443 Tampa da caixa de resistor . . . . . . . . . .1

5 0277442 Base da caixa de resistor . . . . . . . . . . . .1

6 0277397 Apoio . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7 0277402 Fita de espuma . . . . . . . . . . . . . . . . . . .2

8 0277457 Carcaça inferior . . . . . . . . . . . . . . . . . . .1

9 0090628 Apoio para o pé . . . . . . . . . . . . . . . . . . .4

10 9802222 Parafuso . . . . . . . . . . . . . . . . . . . . . . . .4

11 0277385 Placa de ventilação . . . . . . . . . . . . . . . .1

12 9800319 Parafuso, hex soc hd cap 1/4-20 x 0,75 .4

13 0277419 Alívio de tensão . . . . . . . . . . . . . . . . . . .1

14 ---------- Extensão (veja anexo

15 0293395 Parafuso, 8-32 x 3/8 Taptite . . . . . . . . .12

16 0277366 Tambor de filtro, grande . . . . . . . . . . . . .2

17 0279938 Reposições de filtro de 1o e 2o estágio . . . .1

18 0277367 Tela de filtro . . . . . . . . . . . . . . . . . . . . . .2

19 0277371 Espuma de ruídos do ventilador . . . . . . .1

20 0277369 Tampa do tambor . . . . . . . . . . . . . . . . . .1

21 0277396 Pé de montagem do tambor . . . . . . . . . .6

22 0276598 Disco de espuma . . . . . . . . . . . . . . . . . .1

23 0277501 Suporte angular . . . . . . . . . . . . . . . . . . .1

24 0277368 Parte interna de espuma . . . . . . . . . . . .1

25 0277159 Montagem do silenciador . . . . . . . . . . . .1

Peça Nº 0279719) . . . . . . . . . . . . . . . . .1

Item Part No.

25 0277159 Silencer assembly . . . . . . . . . . . . . . . . . . . 1

26 0279466 Foam disk . . . . . . . . . . . . . . . . . . . . . . . . . 1

27 0277370 Can cover . . . . . . . . . . . . . . . . . . . . . . . . . 1

28 0279415 Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

29 0277940 Turbine assembly, 4-stage, 220-240V . . . . 1

30 0276511 Exhaust hose fitting . . . . . . . . . . . . . . . . . . 1

31 9881911 Exhaust hose. . . . . . . . . . . . . . . . . . . . . . . 1

32 9803104 Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

33 0277379 Cup holder. . . . . . . . . . . . . . . . . . . . . . . . . 1

34 0275476 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

35 0277194 Warning light assembly, 220-240V . . . . . . . 1

36 0508103 Fuse holder . . . . . . . . . . . . . . . . . . . . . . . . 1

37 9850710 Fuse, 10 amp . . . . . . . . . . . . . . . . . . . . . . 1

38 0277381 Top housing. . . . . . . . . . . . . . . . . . . . . . . . 1

39 0277389 Foam Tape . . . . . . . . . . . . . . . . . . . . . . . . 2

40 0277532 Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

41 0277372 Foam Tape . . . . . . . . . . . . . . . . . . . . . . . . 2

42 0279426 Air flow switch . . . . . . . . . . . . . . . . . . . . . . 1

43 0277475 Air flow tube . . . . . . . . . . . . . . . . . . . . . . . 1

44 0275711 RFI filter (not shown) . . . . . . . . . . . . . . . . .1

45 9850576 Terminal Block (not shown . . . . . . . . . . . . . 1

46 0277337 Air hose (not shown) . . . . . . . . . . . . . . . . .1

47 0275625 Quick disconnect fitting (not shown) . . . . . .1

Article No de pièce Description Quantité

26 0279466 Disco de espuma . . . . . . . . . . . . . . . . . .1

27 0277370 Tampa do tambor . . . . . . . . . . . . . . . . . .1

28 0279415 Mola . . . . . . . . . . . . . . . . . . . . . . . . . . .6

29 0277940 Montagem do compressor, 4 etapas,

30 0276511 Encaixe da mangueira de escape . . . . .1

31 9881911 Mangueira de escape . . . . . . . . . . . . . . .1

32 9803104 Parafuso . . . . . . . . . . . . . . . . . . . . . . . .6

33 0277379 Suporte do copo . . . . . . . . . . . . . . . . . .1

34 0275476 Botão . . . . . . . . . . . . . . . . . . . . . . . . . . .1

35 0277194 Montagem da låmpada de aviso, 220-240V 1

36 0508103 Suporte do fusível . . . . . . . . . . . . . . . . .1

37 9850710 Fusível, 10 amperes . . . . . . . . . . . . . . .1

38 0277381 Carcaça superior . . . . . . . . . . . . . . . . . .1

39 0277389 Fita de espuma . . . . . . . . . . . . . . . . . . .2

40 0277532 Alça . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

41 0277372 Fita de espuma . . . . . . . . . . . . . . . . . . .2

42 0279426 Botão de fluxo de ar . . . . . . . . . . . . . . . .1

43 0277475 Tubo de fluxo de ar . . . . . . . . . . . . . . . .1

44 0275711 Filtro RFI (não mostrado) . . . . . . . . . . . .1

45 9850576 Bloco terminal (não mostrado) . . . . . . . .1

46 0277337 Mangueira de ar (não mostrada) . . . . . .1

47 0275625 Conexão tipo “engate rápido”

Description Quantity

220-240V . . . . . . . . . . . . . . . . . . . . . . . .1

(não mostrada) . . . . . . . . . . . . . . . . . . .1

Español

Renglón No. Pieza No. Descripción Cantidad Renglón No. Pieza No. Descripción Cantidad

1 0279425 Anillo, retendador de salida de aire . .1

2 0277409 Tubo de salida de aire . . . . . . . . . . . .1

3 9803103 Tornillo . . . . . . . . . . . . . . . . . . . . . . . .2

4 0277443 Tapa de la caja del purgador . . . . . . .1

5 0277442 Base de la caja del purgador . . . . . . .1

6 0277397 Almohadilla . . . . . . . . . . . . . . . . . . . .1

7 0277402 Banda de espuma . . . . . . . . . . . . . . .2

8 0277457 Caja inferior . . . . . . . . . . . . . . . . . . . .1

9 0090628 Almohadilla para pata . . . . . . . . . . . .4

10 9802222 Tornillo . . . . . . . . . . . . . . . . . . . . . . . .4

11 0277385 Placa del respiradero . . . . . . . . . . . . .1

12 9800319 Tornillo, de cabeza hex. 1/4-20 x 0,75 4

13 0277419 Protección contra tirones . . . . . . . . . .1

14 ----------- Cordón (ver N/P 0279719

15 0293395 Tornillo, Taptite 8-32 x 3/8 . . . . . . . . .12

16 0277366 Filtro de forma cilíndrica, grande . . . .2

17 0279938 Sustitución del filtro de primero y

18 0277367 Rejilla del filtro . . . . . . . . . . . . . . . . . .2

19 0277371 Espuma antiruido del ventilador . . . . .1

20 0277369 Tapa de forma cilíndrica . . . . . . . . . . .1

21 0277396 Reposapatas de forma cilíndrica . . . .6

22 0276598 Disco de espuma . . . . . . . . . . . . . . . .1

23 0277501 Soporte . . . . . . . . . . . . . . . . . . . . . . .1

24 0277368 Intercalación de espuma . . . . . . . . . .1

© 1998 Wagner Spray Tech Corporation. All rights reserved. 15

del encarte) . . . . . . . . . . . . . . . . . . . .1

segundo escalones . . . . . . . . . . . . . .1

25 0277159 Conjunto del silenciador . . . . . . . . . . .1

26 0279466 Disco de espuma . . . . . . . . . . . . . . . .1

27 0277370 Tapa de forma cilíndrica . . . . . . . . . . .1

28 0279415 Resorte . . . . . . . . . . . . . . . . . . . . . . .6

29 0277940 Conjunto de turbina, 4 etapas,

30 0276511 Conexión de la manguera de escape .1

31 9881911 Manguera de escape . . . . . . . . . . . . .1

32 9803104 Tornillo . . . . . . . . . . . . . . . . . . . . . . . .6

33 0277379 Portacubetas . . . . . . . . . . . . . . . . . . .1

34 0275476 Interruptor . . . . . . . . . . . . . . . . . . . . .1

35 0277194 Conj. de luz de advertencia, 220-240V 1

36 0508103 Portafusibles . . . . . . . . . . . . . . . . . . .1

37 9850710 Fusible, 10 amp . . . . . . . . . . . . . . . . .1

38 0277381 Caja superior . . . . . . . . . . . . . . . . . . .1

39 0277389 Banda de espuma . . . . . . . . . . . . . . .2

40 0277532 Manilla . . . . . . . . . . . . . . . . . . . . . . . .1

41 0277372 Banda de espuma . . . . . . . . . . . . . . .2

42 0279426 Interruptor de caudal de aire . . . . . . .1

43 0277475 Tubo de caudal de aire . . . . . . . . . . .1

44 0275711 Filtro RFI (no mostrado) . . . . . . . . . . . . .1

45 9850576 Bloque de terminales (no mostrado) . . .1

46 0277337 Manguera de aire (no mostrada) . . . .1

47 0275625 Enchufe de manguera de desconexión

Español

220-240V . . . . . . . . . . . . . . . . . . . . . .1

da (no mostrado) . . . . . . . . . . . . . .1

rápi

EnglishPortuguês

Page 16

Wagner Spray Tech

1770 Fernbrook Lane

Minneapolis, MN 55447 USA

Loading...

Loading...