Page 1

OPERATING INSTRUCTIONS, Version SW1203/3.00/ HW3.0

W agner& C

o

Solar Controller SUNGO SL

W agner& C

o

The benefits at a glance

●

Large illuminated display to indicate temperature, bal

-

ance values and system status with clearly visible sym

-

bols for easy readability.

●

Easy and safe operation via four buttons for vertical and

horizontal scrolling through the menus.

●

Extensive diagnostics for monitoring system functions,

eg. sensor cutoff and monitoring of temperature differ

-

ence “∆T too high”

●

Integrated security functions such as collector cooling,

storage tank cooling, system protection and vacuum

tube collector function.

●

Solar charging of 1 and 2 tank systems

●

Choice of thermostat function or return temperature in

-

crease

●

Balance/reset values

●

5 temperature inputs PT1000

●

1 output, speed-controlled

●

The sensor T5 (solar return) and an external volume

measuring device provide energy measurements

in

kWh.

●

NEW – now also SECUSOL system ready!

Contents

1. Technical Description ................. 2

2. General Safety Guidelines ............... 4

2.1 Installer’sQualifications ................ 4

2.2 OperatingRequirements ............... 4

2.3 Installationand OperatingInformation ....... 4

3. Installation........................ 4

3.1 Installationof the Housing............... 4

3.2 ConnectingWires ................... 5

4. Operation ........................ 6

4.1 Displayand Buttons .................. 6

4.2 InformationMenu ................... 8

4.3 SettingsMenu...................... 9

4.4 ManualOperationMenu ...............10

4.5 SpecialFunctionsMenu ................10

4.6 Service– System Messages ..............11

4.7 Service– Sensor Control ................11

5. Application Examples .................11

5.1 StandardSingleTankSystem .............11

5.2 StandardDualTankSystem ..............12

5.3 SECUSOLSystem....................12

Figure 1 Solar Controller SUNGO SL.

Solar Thermal / Solar Circuit EN-SUNGO-SL_BA-0809-1122P300 · 1316BED008-30B-E 1

Page 2

2 EN-SUNGO-SL_BA-0809-1122P300

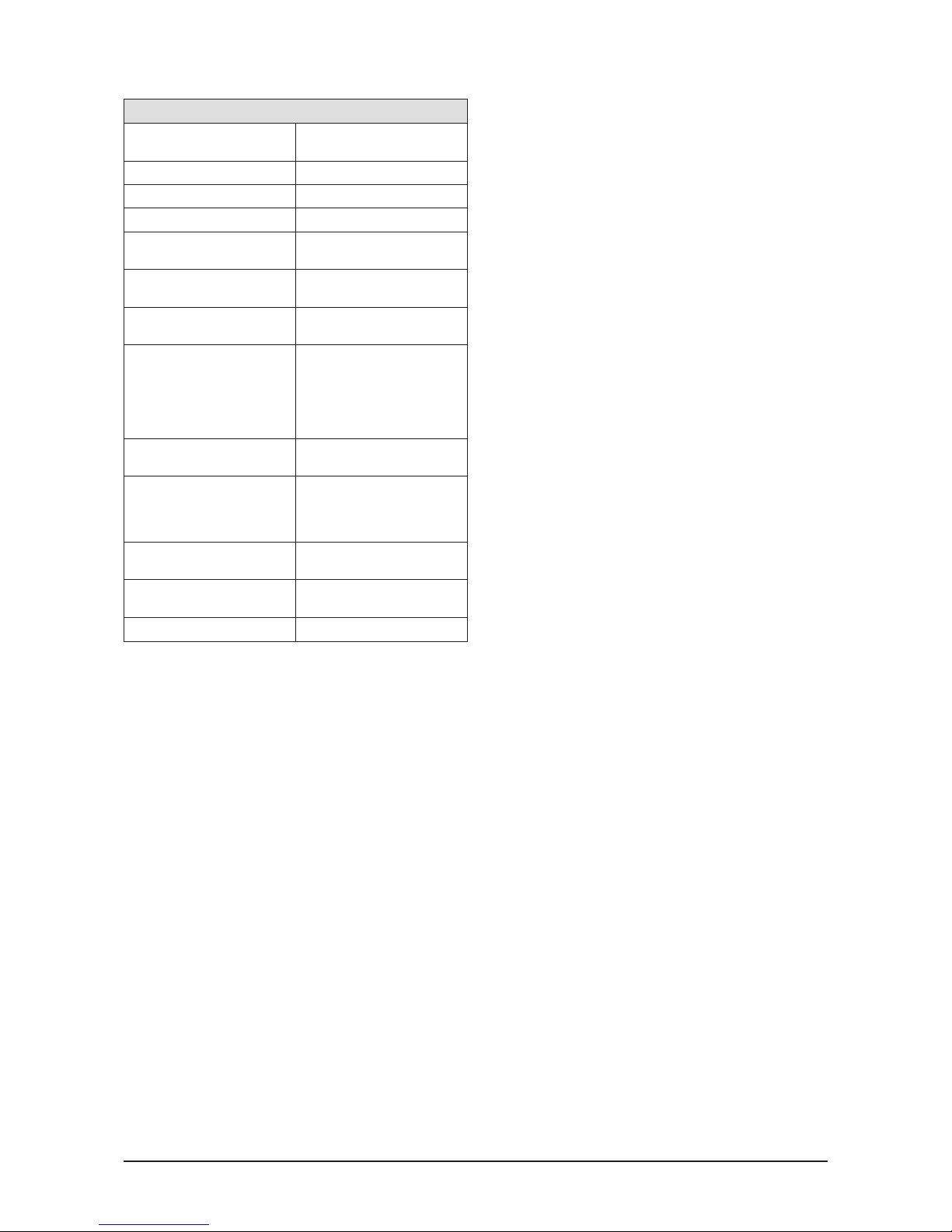

1. Technical Description

Solar Controller SUNGO SL

Material

100 % recyclable ABS-housing

for wall mounting

Dimensions (LxHxWinmm) 173x138x51

Protection type IP40 according to VDE 0470

Rate of radio interference N according to VDE 0875

Operating voltage

230 Volt AC; 50 Hz;

-10% to +15%

Diameter of cable max.

for 230 V connections

2.5 mm² unifilar or finely

stranded

Temperature sensor /

Temperature range

Pt1000; 1000 W at 0 °C;

Range: -30 °C to +225 °C

Sensor load

The cable of the sensor must

be installed with no tension.

The sensor must not be loaded

mechanically when the

temperature of the collector is

more than 60 °C.

Test voltage

4 kV 1 min according to VDE

0631

Switching voltage

Output parameters of switches

230 Volt AC

1A / ca. 230 VA

for cos ϕ = 0.7-1.0 for each

output

Internal mains protection

Microfuse5x20mm;

2 A/T

Operating temperature

(internal) / storage temperature

0° to +50 °C /

-10° to +65 °C

Weight ca. 360 g

Solar Charging

The solar circuit pump is switched on and off by means of a

temperature difference control. The sensors T1 (collector)

und T2 (tank, bottom) are requiredas control elements. The

on/off conditions and the temperature limitation can be

variably set in the settings menu. Note: The temperature

limitation always affects sensor T2 (tank, bottom).

Speed Control

The solar circuit pump can be controlled via speed control

(in this case impulse packet control). This means that indi

vidual sine half-waves in the alternate current are switched

on or off depending on the temperature difference. There

fore the speed can be altered within a range of 30-100%

which results in longer system run times. The minimum

speed can be custom set.

Sensor T3 (tank, top)

Sensor T3 (tank,top) has different functions.By default it is

the measuring sensor for the top of the tank. In that case it

has no switch function and is not monitored by the diag

nostics system.

With the return temperature increase function activated it

functions as ahot sensor (source).Withthe thermostat heat

ing with additional sensor function activated it functions as

an additionalsensor.In both casesthis sensor is used in the

hotareaofthetankandaffectsswitchingoutputA2.

If used in this way the sensor function is monitored as nor

-

mal by the diagnostics system.

Balance Values

In addition to the actual values of the sensors T1 (collector)

and T2 (tank, bottom) the display also shows balance val

ues which represent the smallest and biggest temperature

values for each sensor. After reset the actual temperature

value is displayed.

Manual Operation

Allows switching inputs andoutputs on or off manually. On

exiting themanual operation menu,the software returns to

automatic operation. The manual operation menu can be

used for amaximum of 8 hours. After that the softwareauto

matically switches back to automatic operation and to the

information menu.

Manual Lag Function

In order tocheck the temperature valuesin the information

menu even when the outputs are set manually, a time lag

has to be selected in the manual lag function in the manual

operation menu. On exiting the manual operation menu,

this time span passes once and then is set back to zero. In

this mode a blinking symbol for the manual operation is

shown in the information menu.

Collector Cooling

The tank is loaded up to the preset temperature limitation

which affects sensor T2(tank,bottom).If the preset temperature limitation is exceeded output A1 (solar circuit pump)

switches off. If the temperature of T1 (collector) then rises

above theselectable standardvalue of 110 °C the solar circuit pump is switched on in order to cool the collector. It

switches off again when the temperature at the collector

sensor has decreased by 10 K.

This type of intermittent operation of the solarcircuit pump

means that the collector is never or only rarely in an idle

state. If the preset tank temperature limitation is exceeded

by 5 Kthecollector cooling functionissuppressed.Thesys

tem shuts down completely.

Storage Tank Cooling

Storage TankCoolingmeans that ifnecessary the tanktem

peraturecan be reduced downtoa preset lowest switching

off value (setting for vacations).

When the collector cooling function is activated storage

tank cooling will also become active.

In order for storage tank cooling to become active the fol

lowing 3 conditions must be met:

1. Temperature T2 (tank, bottom) must be higher than or

equal to the preset tank temperature limitation plus 2 K.

2. Temperature T2 (tank, bottom) must be higher than the

preset switching off value for storage tank cooling.

3. Temperature T1 (collector) must be lower than tempera

ture T2 (tank, bottom) minus 10 K.

In order forstorage tank coolingto switch offone of the fol

lowing 2 conditions must be met:

1. Temperature T2 (tank, bottom) is lower than the switch

ing off value for storage tank cooling.

2.Temperature T1(collector) must be higher than tempera

ture T2 (tank, bottom) minus 2 K.

Page 3

EN-SUNGO-SL_BA-0809-1122P300 3

Vacuum Tube Collector Function

The vacuum tubecollector function allows operation of the

solar heating system even if sensor T1 (collector) is in

-

stalled in the connecting pipe of the collector. If the tem

-

perature increase at sensor T1 exceeds the preset switch

ing on value for the collector temperature increase

(standard: 1K) the solar circuitpumpis switched on forthe

duration of a preset lag time (standard: 15 s).

During this time the switching on difference and the solar

charge between sensor T1 (collector) and sensor T 2 (tank,

bottom) has to be activated, otherwise the solar circuit

pump will switch off again.

The rise intemperature at sensorT1 (collector) ismeasured

again immediately after the last runtime of the pump.

System Messages

The system messages for interrupted or shorted-out sen

sors are represented by symbols on the display.For better

recognition of the system messages

the display illumina

tion switches on and off every second as long as the error

prevails and no key entry is made.

Triac

The Triac is anelectronic on/off switchfor the 230Voutputs

of the SUNGO Controller.

Function: A triac switch consists of 2 diodes which can be

switched anti-parallel (= antiparallel thyristors). The

thyristors switch through the positive or negative sine halfwave as long as a switching on difference exists. The triac

switch switches off when the temperature falls below the

switching-off difference.

System Protection

In order to protect the system components (solar circuit

pump, 2 or 3 way valves etc.) in the solar heating circuit

from extremely high temperatures the solar charge is

stopped completely if a temperature limit at the collector

sensor is exceeded, even if this was permitted on account

of a temperature difference between sensor T1 (collector)

and sensor T2 (tank, bottom).

The standard temperature value for activating the system

protection function is 135 °C. However, this value can be

variably set within a range of 115° to 200 °C.

Dual Tank Operation

The SUNGO SL is capableof controlling a dual tank system

by using output A2 for switching between tanks with the

help of a 3 way valve.Change the menuitem 0–1to0–2in

order to control a dual tank system.

Note: If the dual tank option is selected menu item 10 can

no longer be activated.

Preference

The SUNGO SL always uses tank 1 as a preference for the

dual tank option. This cannot be changed.

Thermostat

The thermostat function for switching on can be set at a

range between 0° to 130 °C with a variable difference be

tween 1 to 40 K for switching off.Choose between the op

tions heating and cooling.

With the heating option activated output A2 switches on if

the current temperature T4 fallsbelow the preset switching

on level. Output A2 switches off if the current temperature

T4 is higher than the switch-on level plus the switch-off dif

ference.

With the heating option an additional sensor T3 can be ac

tivated. If this is the case A2 is only switched on if tempera

ture T3 ishigher than theswitching on level plus the switch

ing off difference plus the additional difference for T3.

With the cooling option activated output A2 switches on if

the current temperature T4 falls below the preset switch

level. Output A2 switches off if the current temperature T4

is lower than the switch level minus the switching off

difference.

There are 3 independent time windows available for the

thermostat. If no time window is activated time window 1

has to be set to 0:00 and 23:59.

Return Flow Boost

This is a freely adjustable temperature differencefor simple

heating support which leads the heating return-flow T4

(drain) to the heating boiler, either directly or via the solar

tank, depending on the preset temperature difference to

the tank sensorT3 (source) , by switching the3 way valve on

output A2.

Note: In addition to the switching phase (black) on output

A2, the switching head also requires a constant phase

(brown).

SECUSOL Function

The solar heating systemisoperated on a drainback princi

ple. This means if the solar circuit pump is not activated

there is no solar fluid in the collectors and risers. See

SECUSOL instructions for further details.

Measuring the Yield

For measurements of the solar yield in kWh.The heat yield

is measured with a volume flow metre connected to input

T7, an additional sensor T5 (return) and the existing sensor

T1 (collector).

Page 4

4 EN-SUNGO-SL_BA-0809-1122P300

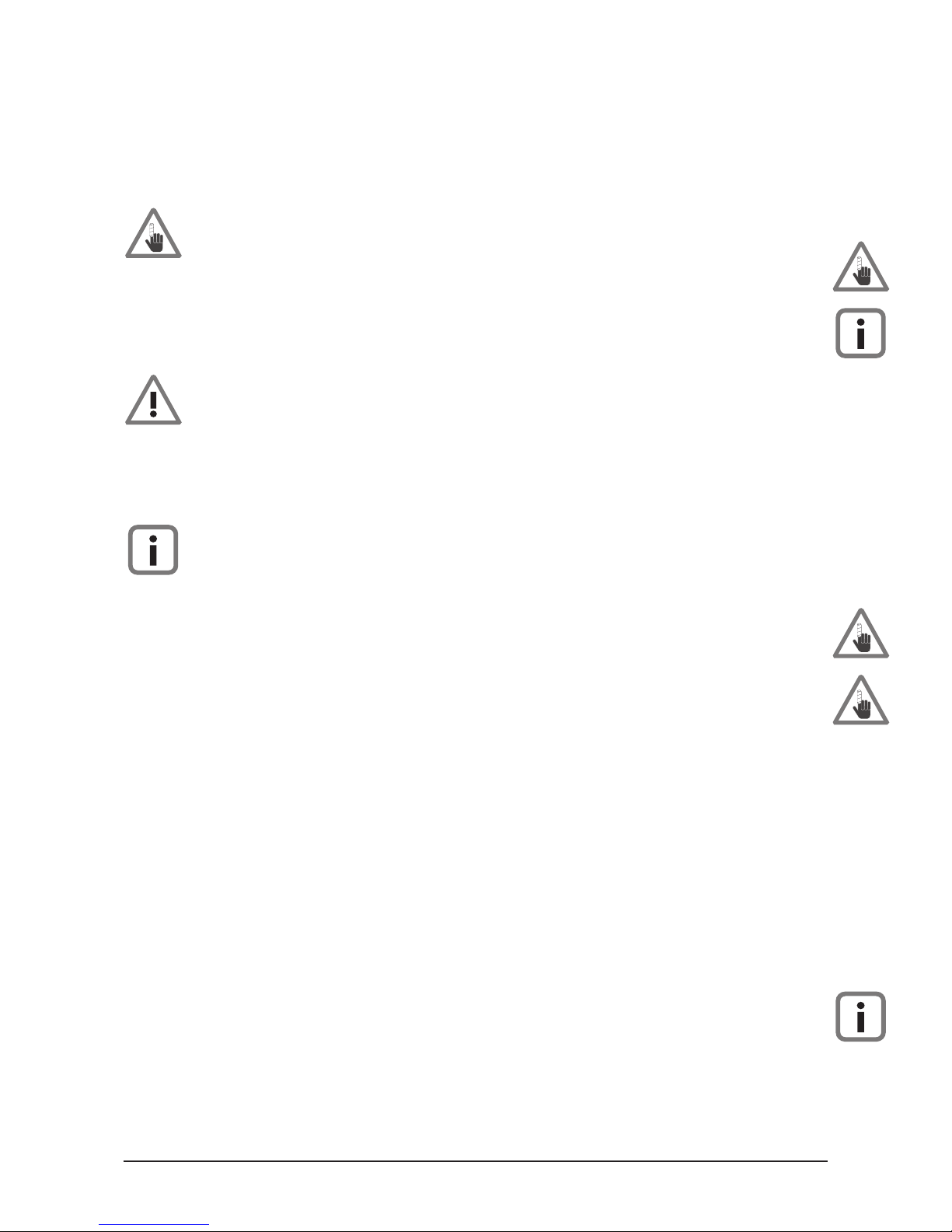

2. General Safety Guidelines

The following safetyadvice is designedto protect youfrom

dangers that can arise from improper handling of devices,

whether intentional or otherwise. A distinction is made be

tween general advice presented here and specific advice

presented throughout the guidelines.

DANGER for danger to the person

Improper electrical installation of the device can lead to

potentially fatal electric shocks as well as other health

hazards.

CAUTION for danger to property

This symbol indicates dangers that can result in damage to

the components or the function of the control.

NOTE for additional information

This symbol indicates practical advice and tricks of the

trade which will be useful for installing and operating the

control.

2.1 Installer’s Qualifications

●

Setting up and commissioning of the SUNGO SL must

be carried out by a qualified installer.

●

All national andlocal safety regulationsneed to be com

-

plied with.

●

Please note that in case of a complaint the guarantee is

only valid if correct commissioning has been certified in

a commissioning report.

2.2 Operating Requirements

Application

●

Controlling solar thermal systems through the selection

of applicable control patterns and additional functions

to adaptthe control forthe required operation of the hy

-

draulic system.

●

The control must only be operated in dry rooms.

●

The control can be integrated into the solar circulation

unit or mounted on the wall.

Limitations of use

●

If usedina non-solar thermalapplicationthe functionality

of thecontrol hastobe checked before commissioning.If

in doubt contact the control service of Wagner & Co.

●

If these operating requirements are not observed any

claims under the warranty will not be accepted.

2.3 Installation and

Operating Information

●

Any installation and wiring work has to be carried out in

an idle state as during operation the voltage on the out

-

side of the triacs is 230 V.

●

Mains power mustbe connected to thecontrolfrom out

side the solar station via an external ON/OFF Switch.

This is also required to activate the special functions

menu through switching the mains power ON/OFF.

●

Operating temperatures above 50 °C are not permitted

for the control.

●

LCD display panels are designed in such a way that a

specific reading position isrequired.When installing the

control, be careful to place the display so that it is at eye

level or slightly higher. This way you can ensure optimal

display contrast.

●

The base of the control is divided into a safety low volt

age section and a 230 V section by a crosspiece. Make

sure that you do not confuse these sections during the

installation process.

● The default operating mode is the automatic mode.

Manual operation is used only for functional testing of

the different hydraulic components (pump, 2/3 way

valve). In this operating mode maximum temperatures

or sensor functions are not monitored.

● Do notoperatethesystemif the control,the wiring or the

connected 230 V mains are visibly damaged.

● The control is fitted with a mains microfuse.

● Collectors and hydraulic pipework can get extremely

hot during sunny periods. There is a risk of scalding

when fitting the collector temperature sensor.

3. Installation

3.1 Installation of the case

Opening the case

●

No tools are required to open the control case. The lid

folds overon top of the lower half. Youcan dislodge and

lift up the lid by pulling gently on the side clips.

●

When fully opened the lid will not move so that you can

take care of mounting and wiring comfortably.

Wall mounting

●

Use the supplied drillingtemplatetodrill the fixing holes

for the controller.

●

Mount the control to the wall.

●

Do not overtighten the screws to avoid damage to the

lower part of the housing.

Page 5

EN-SUNGO-SL_BA-0809-1122P300 5

Installation in the Solar Circulation Unit

●

With the screws mount the SUNGOSL on the wall holder

of the solar circulation unit.

●

Break out the cable feeds which are located on the base

housing next to the crosspiece.

●

Strip the 230 V cables in a way that the insulated single

cables start directly at the feed to the base housing.

●

Hold cable clamps steady when screwing tight in order

to minimisepressure on the circuit board. Thereis a dan

-

ger of the terminals to be torn off!

●

Finally connect to mains power.

●

When the controlis switched onthe voltage on thetriacs

housing is 230 V AC.

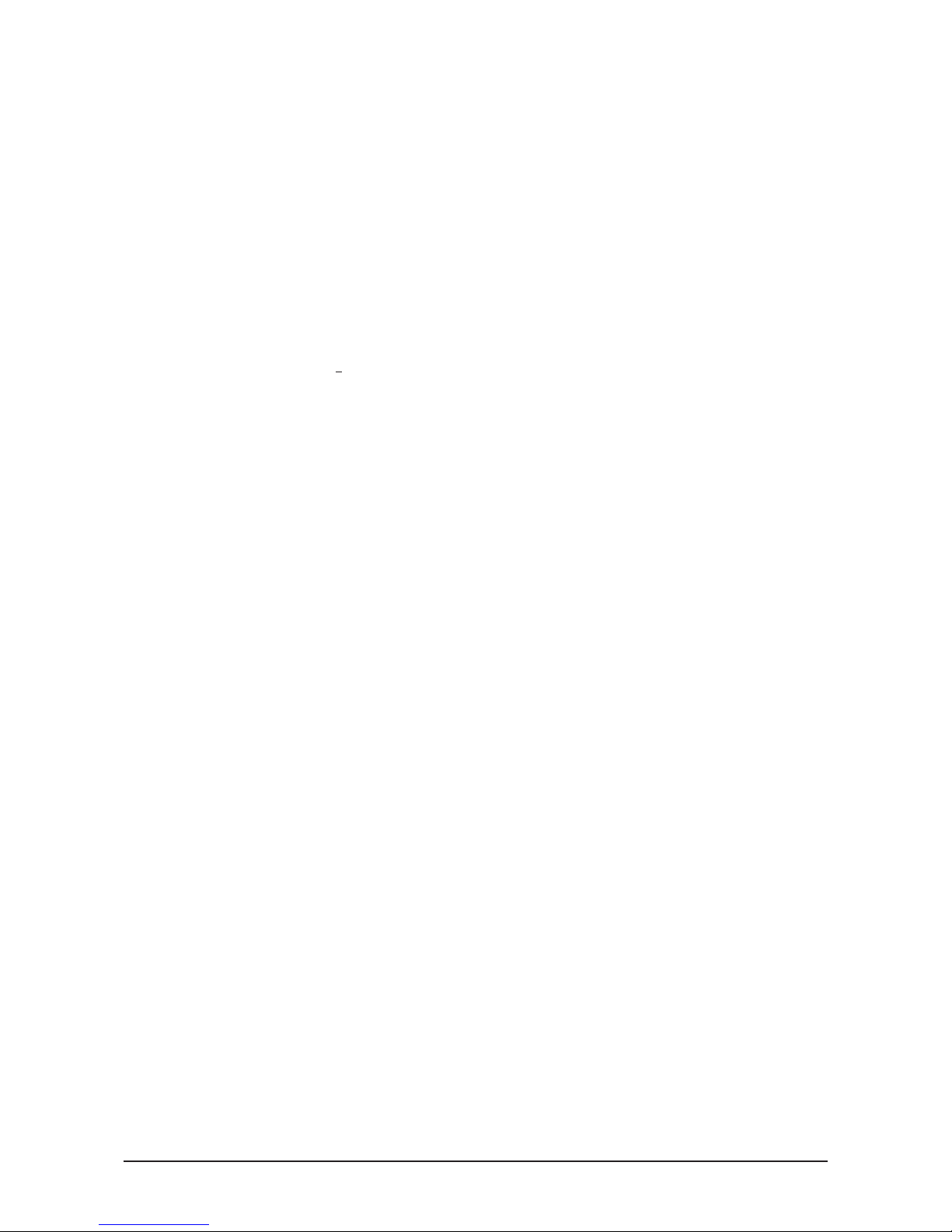

3.2 Connecting Wires

Layout of the SUNGO SL Connections

All electrical connections are made to the circuit board at

the bottom of the control. The sensor connections (safety

low voltage)are located onthe right hand side andthe 230

V mains connections and the switching outputs A1 and A2

on the left hand side.

General connection rules

●

If flexiblewires are used andthe control iswall mounted,

a strain relief must be fixed within or outside of the con

-

trol.

● In this case you must crimp the wire ends.

● If requiredPG9 screws canbe fixed atthe feed-throughs

in case of wall mounting.

230 V mains connection

●

Mains power is connected from outside the control via

an ON/OFF Switch.

This switch is not required if mains power is with a pro

tective plug to a socket.

●

The control is suitable for mains operation at approx.

230 V/50 Hz.

●

All earth wires are connected to the PE terminals.

●

The neutral terminals (N) are connected electrically.

●

Switching output A1 is a 230 V normally open contact

which is activated via speed-control. Switching output

A2 is purely a normally open contact.

Connecting the temperature sensors

●

The wires of the temperature sensors can be extended:

Up to 15 m length, 2 x 0.5 mm² cable can be used, be

yond 15 m and up to 50 m 2 x 0.75 mm² is necessary.

Shielded cables should be used for long connections to

the collector.

Do not connect the shielding at the sensor end,just trim

and isolate.

●

The polarity of the temperature sensors is irrelevant and

they can be connected either way.

●

The sensor wires mustbeinstalled separately from 230V

mains cables.

Lightning Protector Module

The SUNGO SL is fitted with spike protection on all sensor

terminals. Generally, further protection of the tank sensors

is not required.

Sensor T1 (collector) should be fitted with the sensor

con-

nection box SP2 with an overvoltage protection.

FUSE 5X20

T1 T2 T3 T4 T5

M

MMM

PE-PE A2

A1 L1

PE-PE N N N

M

ControllerIC

Triac

Plug for Display

Trafo

Potential Earth

Switching output

Solar circuit pump

Mains L1

Collector sensor, T1

Tank sensor, bottom,T2

Tank sensor, top /

Additional thermostat sensor /

return flow boost (source)

Thermostat /

return flow boost (sink), T4

Heat meter (yield), return flow sensor, T5

T7

M

“Volume flow meter” for yield measurement, T7

Figure 2 SUNGO SL circuit board components.

Page 6

6 EN-SUNGO-SL_BA-0809-1122P300

4. Operation

4.1 Display and Buttons

!

dT min max start stop

R

R

ok?

88888

°C %

KWh

x

Manual operation menu

Special functions menu

Balance or

start / stop values

Units

Tank temp., top/

thermostat additional senso

r

Temperature thermostat/

return flow boost (sink)

Time slot thermostat

Tank temp., mid section/

return flow boost (source)

Confirm and

save symbol

System error

Settings menu

Information menu

Temperature difference

Numerical display for temp.

or sensor errors

Collector temperature

Symbol for reset value

Tank temp., bottom

Pump ON/

Pump OFF

Output A1

Output A2

Page 7

EN-SUNGO-SL_BA-0809-1122P300 7

dT max

__K

dT min

__K

__°C

T max

dT

__K

dT

__K

__°C

T start

__

d max

d min

__

__K

dT

4

4

1

__:__

__°C

T max

__°C

__K

__K

T min

dT max

dT min

I

I

2

2

2

3

3

__:__

__:__

__:__

__:__

__:__

__:__

R

R

R

R

stop

start

stop

start

stop

start

2

2

2

__°C

T min

Horizontal operating level

Vertical

operating level

Set values

Settings menu

as an example

Ý

Decrease

value

Ý

Increase

value

Activate

save function

ÝÝ

Activate

value

Save

value

Switching off diff. T3 - T4,

return temperature increase

Switching on diff. T3 - T4,

return temperature increase

Min temp. level,

return temperature increase

Temp. limitation,

return temperature increase

Stop time window 3, thermostat

Start time window 3, thermostat

Stop time window 2, thermostat

Start time window 2, xx thermostat

Stop time window 1, thermostat

Start time window 1, thermostat

Temperature limitation tank, bottom

Switching on difference T1 - T2, solar

Switching off difference T1 - T2, solar

Min. temp. source

Design temp. diff. speed control, solar

Min. speed, solar circuit pump

Max. speed solar circuit pump (SECUSOL)

Charge time solar heating system (SECUSOL)

Current time

Switching on temperature, thermostat

Switching off temperature, thermostat

Difference additional sensor T3, thermostat

Page 8

8 EN-SUNGO-SL_BA-0809-1122P300

4.2 Information Menu

Information menu

Menu item Description Display

Collector temperature; Current value °C

Collector temperature; Balance; minimum, resettable °C

Collector temperature; Balance; maximum, resettable °C

Tank temperature, bottom; Current value °C

Tank temperature, bottom; Balance; minimum, resettable °C

Tank temperature, bottom; Balance; maximum, resettable °C

Tank temperature, top; Current value °C

Operating hours, total; Balance h

R operating hours since last reset; Balance, display, resettable h

Tank temperature 1 or 2, bottom;

(if 2 tank system is selected) Current value

°C

Tank temperature 1 or 2, bottom;

(if 2 tank system is selected) Balance; minimum, resettable

°C

Tank temperature 1 or 2, bottom;

(if 2 tank system is selected) Balance; maximum, resettable

°C

Operating hours tank 1 or 2, total;

(if 2 tank system is selected) Balance

h

R operating hours tank 1 or 2

since last reset; (if 2 tank system is selected) Balance; display, resettable

h

Thermostat or return temperature increase (drain); Current value °C

Heat counter, return;

(flow value corresponds to collector temperature) Current value

°C

Heat counter, total yield; Balance kWh

R heat counter since last reset; Balance, display, resettable kWh

Heat counter tank 1 or 2, total; Balance kWh

R heat counter, tank 1 or 2

since last reset; Balance, display, resettable

kWh

Pump symbol idle: Operating symbol

Temperature difference (collector, tank) is smaller than required

to activate the solar circuit pump. The solar circuit pump is off.

—

Rotating pump symbol: Operating symbol

Temperature difference (collector, tank) is sufficient to activate

the solar circuit pump. The solar circuit pump is running.

—

min

__°C

__°C

__°C

__°C

__°C

__°C

__°C

__°C

__°C

__°C

__h

__kWh

__kWh

__kWh

__kWh

__h

__h

min

min

max

max

max

__h

R

1

2

__°C

1

2

1

2

1

2

1

2

1

2

1

2

R

R

R

R

__°C

Page 9

EN-SUNGO-SL_BA-0809-1122P300 9

4.3 Settings Menu

Settings menu

Menu item Description Range Default setting

Temperature limitation tank, bottom 15 – 90 °C 85 °C

Switching on difference between collector and tank 3 – 40 K 5 K

Switching off difference between collector and tank 2 – 35 K 3 K

Min. temp. above which the switching difference is analyzed 5 – 90 °C 10 °C

Temperature limitation tank 1 or 2, bottom 15 – 90 °C 85 °C

Switching on difference between collector and tank 1 or 2 3 – 40 K 10 K

Switching off difference between collector and tank 1 or 2 2 – 35 K 3 K

Design temperature difference the speed control adjusts to 2 – 50 K 10 K

Minimum speed of the solar circuit pump

10% increments

30–100% 30%

Maximum speed of the solar circuit pump

Only with SECUSOL!

30–100% 100%

Charge time (s) of the solar heating system with speed 100 %; in 10 s increments

Only with SECUSOL!

20 – 360 s 60 s

Set current time (keep button pressed for faster run-through) 0:00-23:59 0:00

Switching on temperature thermostat

1

0° – 130 °C 30 °C

Switching off difference thermostat

1

1–40K 5K

Additional sensor difference for tank, top, can be selected in heating function.

1

3–20K 10K

Start time slot 1, thermostat

1

0:00-23:59 0:00

Stop time slot 1, thermostat

1

0:00-23:59 23:59

Start time slot 2, thermostat

1

0:00-23:59 0:00

Stop time slot 2, thermostat

1

0:00-23:59 0:00

Start time slot 3, thermostat

1

0:00-23:59 0:00

Stop time slot 3, thermostat

1

0:00-23:59 0:00

Temperature limitation return temperature increase

2

15°–90°C 85°C

Minimum temperature from which the switching on difference is read

2

15°–90°C 20°C

Switching on difference return temperature increase between temperature

measure location T3 and T4

2

3–40K 4K

Switching off difference return temperature increase between temperature

measure location T3 and T4

2

2–35K 2K

1

Only available if heating or cooling thermostat is used.

2

Only available if return temperature increase is used.

dT max

dT min

T max

__K

__K

__°C

dT max

dT min

dT

__:__

__:__

__:__

__:__

__:__

__:__

__:__

T max

d max

T start

T max

dT

dT max

T min

__°C

dT min

d min

1

1

2

1

2

1

2

__K

__K

__K

__K

start

stop

stop

stop

start

start

__K

__K

__K

__°C

__

__°C

__°C

__

__

dT

I

I

2

2

3

3

__°C

T min

2

R

2

R

2

R

2

R

Page 10

10 EN-SUNGO-SL_BA-0809-1122P300

4.4 Manual Operation Menu

Manual operation menu

Menu item Description Range Default setting

Off = 0/On = 1

Switching the solar circuit pump on or off manually (A1)

0–1 0

Off = 0/On = 1

Switching output A2 on or off manually (RLA or thermostat)

0–1 0

Activation of manual operation lag time in automatic mode 0 – 600 min 0 min

4.5 Special Functions Menu

During the first minute after switching on the control

activate the special functionsmenu byselecting it so thatparameterscanbe altered.Themenustays active for 1minuteaf

-

ter exiting it.

On exiting themenuthe parameters can onlybeviewed but notchangedagain.Place the control intheidle position once

again if you need to alter any functions.

Special functions menu

Menu

item

Application Description Range Default

setting

0 System choice

0 – 1: Standard single tank system

0 – 2: Standard dual tank system

0 – 3: SECUSOL system (see SECUSOL instructions for further info)

1–3 1

1

System

Protection

Off = 0/On = 1

Activation of system protection.

Cannot be activated with SECUSOL!

0or1 1

2 System protection start temperature 115 – 200 °C 135 °C

3

Collector

Cooling

Off = 0/On = 1

Activation of collector cooling.

Cannot be activated with SECUSOL!

0or1 1

4 Collector cooling start temperature 100 – 150 °C 110 °C

5

Storage tank

Cooling

Off = 0/On = 1

Activation of tank cooling. Only possible with collector cooling.

Cannot be activated with SECUSOL!

0or1 0

6 Switching off temperature 30 – 90 °C 60 °C

7

Measuring the

Yield

Off = 0/On = 1

Activation of yield measurement

0or1 0

8

Frost protection type

8-1: DC20 for standard systems

8-2: DC40 for vacuum tube collectors (ready mix)

1or2 1

9

Glycol fraction in %.

0% = No Glycol (pure water)

100 % = Pure Glycol (no water)

Note: Glycol fraction for solar circuit can only be selected with DC20!

0–100% 40%

10

Function

selection

10 – 0: Additional functions off

10 – 1: Thermostat, heating

10 – 2: Thermostat, heating with additional sensor T3 (tank, top)

10 – 3: Thermostat, cooling

10 – 4: return temperature increase

0–4 0

11

Vacuum Tube

collector function

Off = 0/On = 1

Activation of vacuum tube collector function

0or1 0

12 Run time of solar circuit pump from reaching the switching on value 1 – 60 s 15 s

13 Switching on value for temperature increase at sensor T1 (collector) 1.0 – 5.0 K 1.0 K

The special functions menus should only be edited by expert personnel. Incorrect settings may adversely affect the solar heating system.

T stop

__

Page 11

EN-SUNGO-SL_BA-0809-1122P300 11

4.6 Service – System Messages

System information with display

Display Description Remedy

System messages

All system messages are displayed with a blinking caution symbol. In case of sensor errors the sensor in

question is also marked with short circuit or interruption symbol.

Interruption

The sensor on the display or the pipe is

interrupted.

●

Test the resistance value of the sensors and compare with

the tables.

●

Check all connections to the sensor.

Short circuit

There is a short circuit on the sensor on the

display, the cable or the output on the

control.

dT too high

A value of 20 K is added to the switch-on

difference between T1 and T2. The message

is displayed if after 30 minutes the total

difference has not been reduced.

●

Check wiring to the pump

●

Check system for air and vent if required

●

Check sensors and sensor wiring, replace sensors if

required

4.7 Service – Sensor Control

Resistance values for Pt1000 sensors in relation to the temperature

-10°C 0°C 10°C 20°C 30°C 40°C 50°C 60°C 70°C 80°C 90°C 100°C 110°C

961 Ω 1000 Ω 1039 Ω 1078 Ω 1117 Ω 1155 Ω 1194 Ω 1232 Ω 1271 Ω 1309 Ω 1347 Ω 1385 Ω 1423 Ω

The working condition of the sensor can be checked with this table and an Ohm meter.

5. Application examples

5.1 Standard Single Tank System

!

Blinking

!

Blinking

!

Blinking

°C

!

Blinking

°C

Ttw

T4

T1

T3

T2

A

AB

B

Vr

P2

P3

TERMO

P1P1

CIRCO

T4A1T1

A2

T2T3

T7

T5

T1

Measuring the yield

Solar

return-flow

Collector field

Cold water

Hot water

Version 1 – TERMO Combi Cylinder

Heating circuit

Oil or gas

boiler

P1: Solar circuit pump

P2: Heating circuit pump

P3: Tank chargingpump

Vr: Switch-over valvefor return temperature increase

T1: Collectorsensor

T2: Tank sensor, bottom

T3: Tank sensor, middle

T4: Sensorheating return-flow

T5: Yield measurement,return flow sensor

T7: Yield measurement,volume flow metre

Collector field

Figure 3 Standard single tank system controlled by SUNGO SL.

Page 12

Figure 4 Standard dual tank system controlled by SUNGO SL.

5.2 Standard Dual Tank System

P3

P2

BWM

T1

T2

T3

Ttw

P1

A1

T1

SECUSOL

Ta

T7

T5

T1

T3

T2

Heating circuit

Hot water

Cold water

Measuring the yield

Solar

return-flow

Collector field (EURO C22)

Oil or gas

boiler

T1: Collectorsensor

T2: Tank sensor, bottom

T3: Tank 1 sensor,top (optional)

T5: Yieldmeasurement, return flow sensor

T7: Yieldmeasurement, volume flow metre

P1: Solar circuit pump

P2: Heating circuit pump

P3: Tank charging pump

Ttw: Hot water sensor (heatingcontrol)

BWM: Thermostatic mixing valve

Collectorfield

5.3 SECUSOL System

P1

P3

P2

P1

CIRCO

Vu

T3 T2 T1T4

A1

A2

M

ECOplus

T1

T5

T7

AB

A

B

T4

T2

T1

T3

Ttw

Collector field

Heating circuit

Oil or gas

boiler

Hot water

Cold water

Solar

return-flow

Collector field

Measuring the yield

P1: Solar circuit pump

P2: Heating circuit pump

P3: Tank chargingpump

Vu: Switch-over valve, tank charging

T1: Collector sensor

T2: Tank1 sensor, bottom

T3: Tank1 sensor, top

T4: Tank2 sensor, bottom

T5: Yield measurement,return flow sensor

T7: Yield measurement,volume flow metre

Figure 5 SECUSOL system controlled by SUNGO SL.

Subject to modifications, errors excepted. · ©Wagner & Co, 2008 · www.wagner-solar.com

12 WAGNER & CO · Zimmermannstraße 12 · D-35091 Cölbe/Marburg ·

☎

+49 6421 80 07-0 · Fax 8007-22

Loading...

Loading...