Page 1

OPERATING INSTRUCTIONS, Issue SW1201/ 2.01/ HW2.4

W agner& C

o

Solar Controller SUNGO S

W agner& C

o

The benefits at a glance

●

Large illuminated display to indicate temperature, bal

-

ance values and system status with clearly visible sym

-

bols for easy readability.

●

Easy and safe operation via four buttons for vertical and

horizontal scrolling through the menus.

●

Extensive diagnostics for monitoring system functions,

eg. sensor cutoff and monitoring of temperature differ

-

ence “∆T too high”

●

Integrated security functions such as collector cooling,

tank cooling, system protection and vacuum tube col

-

lector function.

●

Solar charging of 1 tank systems

●

Current/reset values

●

3 temperature inputs Pt1000

●

1 output, speed-controlled

Contents

1. Technical Description ..................2

2. General Safety Guidelines ...............4

2.1 Installer’s Qualifications .................4

2.2 Operating Requirements ................4

2.3 Installation andOperating Information ........4

3. Installation ........................4

3.1 Installation oftheCase..................4

3.2 Connecting Wires ....................5

4. Operation .........................6

4.1 Display andButtons ...................6

4.2 Information Menu ................... 8

4.3 Settings Menu...................... 8

4.4 Manual Operation Menu................ 9

4.5 Special Functions Menu ................ 9

4.6 Service –SystemMessages ..............10

4.7 Service –SensorControl ................10

5. Application Examples .................11

5.1 Standard Single-Tank System .............11

5.2 SECUSOL System ....................12

Figure 1 Solar Controller SUNGO S.

Solar Thermal / Solar Circuit EN-SUNGO-S-BA-0804-1122P200 1

Page 2

2 EN-SUNGO-S-BA-0804-1122P200

1. Technical Description

Solar Controller SUNGO S

Material

100 % recyclable ABS casing

for wall mounting

Dimensions (LxHxWinmm) 173x138x51

Protection type IP40 according to VDE 0470

Rate of radio interference N according to VDE 0875

Mains supply

230 Volt AC; 50 Hz;

-10% to +15%

Max. size of wiring

for 230 V-connections

2,5 mm² stranded / single

Temperature sensor /

Temperature range

Pt1000; 1000 Ω at 0 °C;

Range: -30 °C to +225 °C

Strain on sensor

Ensure that the cable does not

put strain on the sensor; Do not

put any mechanical strain on

the sensor if temperature is

above 60 °C.

Test voltage

4 kV for 1 min according to

VDE 0631

Switching voltage

Output parameters of switches

230 Volt AC

1A / 230 VA for cos ϕ = 0,7-1,0

Fuse, internal

Low current fuse5x20mm;2

A/T (2 Ampere, slow)

Operating temperature

(inside), storage temp.

0° to +50 °C / -10° to +65 °C

Weight ca. 360 g

Solar Charging

The solar circulation pump isswitched on and off bymeans

of atemperaturedifferencecontrol.Thesensors T1 (collector) und T2(tank,bottom) are required as control elements.

The on/off conditions and the temperature limitation can

be variably setinthe settings menu. Note: Thetemperature

limitation always affects sensor T2 (tank, lower half).

Speed Control

The solar circulation pump can be controlled via speed

control (in this case impulse packet control). This means

that individual sine half-waves in the alternate current are

switched on or off depending on the temperature differ

ence. Therefore the speed can be altered within a range of

30-100% which results inlongersystem run times.The min

imum speed can be custom set.

Sensor T3 (tank, upper half)

SensorT3 (tank,upper half) is a measuring sensor which in

dicates the temperature in the upper tank area. It has no

switch function and is not monitored by the diagnostics

system.

Balance Values

In addition to the actual values of the sensors T1 (collector)

and T2 (tank,lower half) thedisplay also showsbalance val

ues which represent the min.and max.temperature values

for eachsensor.When reset the current actual temperature

value is displayed.

Manual Operation

Manual operation allows to manually switch input and out

put channels on or off. On exiting the manual operation

menu, the software returns to automatic operation. The

manual operation menu can be used for a maximum of

8 hours.After that the software automatically switches back

to automatic operation in the information menu.

Manual Lag Function

In order to checkthe temperature valuesin the information

menu, even when the output channels are set manually, a

time lag hasto be selected inthe manual lag functionof the

manual operation menu. After exiting the manual opera

tion menu this time span passes once and then is set back

to zero. In this modea blinking symbol forthe manual oper

ation is shown in the information menu.

Collector Cooling

The tank is loaded up to the preset temperature limitation

which affects sensor T2(tank,bottom).If the preset temper

ature limitation is exceeded output A1 (solar circulation

pump) switches off. Ifthe temperature of T1(collector) then

rises above the selectable standard value of 110 °C the so

lar circulation pump is switched on in order to cool the col

lector.Itswitches off againwhen the temperatureat the col

lector sensor has decreased by 10 K.

This type of intermittent operation of the solar circulation

pump means, that the collector is never or only rarely in

an idle state. If the preset tank temperature limitation is

exceeded by 5 K, the collector cooling function is suppressed. The system shuts down completely.

Tank Cooling

Tank cooling means that if necessary the tank temperature

can be reduced to apreset lowest switch-off value (e.g.setting for vacations).

When the collector cooling function is activated tank cooling will also become active.

In order for tank cooling to become active the following 3

conditions must be met:

1. Temperature T2 (tank, lower half) must be higher than or

equal to the preset tank temperature limitation plus 2 K.

2. Temperature T2 (tank, lower half) must be higher than

the preset switch-off value for tank cooling.

3. Temperature T1 (collector) must be lower than tempera

ture T2 (tank, lower half) minus 10 K.

In order for tankcooling to switch off one of the following 2

conditions must be met:

1. Temperature T2 (tank, lower half) is lower than the

switch-off value for tank cooling.

2.Temperature T1 (collector) mustbehigher than tempera

ture T2 (tank, lower half) minus 2 K.

Vacuum Tube Collector Function

The vacuum tubecollector function allows operation of the

solar heating system even if sensor T1 (collector) is in

stalled in the connecting pipe of the collector. If the tem

perature increase at sensor T1 exceeds the preset switchon value for the collector temperature increase (standard:

1 K) the solar circuit pump is switchedon for thedurationof

a preset lag time (standard: 15 s).

During this time the switch-on difference and the solar

charge between sensor T1 (collector) and sensor T 2 (tank,

Page 3

EN-SUNGO-S-BA-0804-1122P200 3

lower half) has to be activated, otherwise the solar circula

tion pump will switch off again.

The rise intemperature at sensor T1(collector) is measured

again immediately after the last runtime of the pump.

System Messages

The system messages for interrupted or shorted-out sen

sors are represented by symbols on the display. For better

readability of the system message the display illumination

switches on and off every second as long as the error pre

vails and no key entry is made.

Triac

The Triac is an electronicon/off switch forthe 230 V outputs

of the SUNGO controllers.

Function: A triac switch consists of 2 diodes which can be

switched anti-parallel (= antiparallel thyristors). The

thyristors switch through the positive or negative sine halfwave as long as a switch-on difference exists. The triac

switch switches off when the temperature falls below the

switch-off difference.

System Protection

In order toprotectsystem components likesolar circulation

pump, 2-/3 way valves etc. that are installed in the solar cir

cuit againstexcess temperatures,solar charging isstopped

entirely as soon as a set temperature limit is exceeded at

sensor T1 (collector), even when charging would still be

possible due to the temperature difference between sen

sor T1 (collector) and sensor T2 (storage cylinder).

The standard temperature value to activate the system pro

tection is set at 135 °C. However,it is possible to set a vari

able value between 115 °C and 200 °C.

Page 4

4 EN-SUNGO-S-BA-0804-1122P200

2. General Safety Guidelines

The following safetyadvice is designedto protect youfrom

dangers that can arise from improper handling of devices,

whether intentional or otherwise. A distinction is made be

tween general advice presented here and specific advice

presented throughout the guidelines. Watch out for the

symbols!

DANGER for danger to the person

Improper electrical installation of the device can lead to

potentially fatal electric shocks as well as other health

hazards.

CAUTION for danger to property

This symbol indicates dangers that can result in damage to

the components or the function of the control.

NOTE for additional information

This symbol indicates practical advice and tricks of the

trade which will be useful for installing and operating the

control.

2.1 Installer’s Qualifications

●

Setting up, installation and commissioning of the

SUNGO S must be carried out by a qualified installer.

●

Please ensure that you comply with national and local

regulations.

●

Please note that if a complaint is made, the guarantee is

only valid if the correct commissioning has been certi

-

fied by a qualified person in the commissioning report.

2.2 Use and Application

Function

●

Controlling solar thermal systems through the selection

of applicable control patterns and additional functions

to adaptthe control forthe required operation of the hy

-

draulic system.

●

The control is certified for use in dry rooms only.

●

The control can either be integrated into the solar circu

-

lation unit or it can be mounted on the wall.

Limitations of use

●

The control‘s suitability should be checked before oper

ation commencesif it is used for any other purpose than

for control‘s suitability solar thermal systems. If you are

unsure you must check withthe serviceof Wagner & Co.

●

The use of the control for non-specified operation re

sults in a lapse of the guarantee.

2.3 Guidelines for Installation and

Operation

●

Because Triacs carry 230V current at the case, the mains

must be disconnected while any installation and wiring

work is carried out.

●

The mains must beconnected to thecontrolvia an exter

nal ON/OFF switch outsidethesolar circulation unit.This

is alsonecessary inorder to be able to activate the“Spe

cial Function” menu through ON and OFF switching.

●

Operating temperatures above 50 °C are not permissi

ble for the control.

●

LCD display panels are designed in such a way that a

specific reading position isrequired.When installing the

solar circulation unit be careful to place the display so

that it is at eye level or slightly higher. This way you can

ensure optimal display contrast (for SUNGO S and SL).

●

The base of the control is divided into a low voltage sec

tion and a 230 V section by a crosspiece. Make sure that

you do not confuse these.

● Automatic mode is the default operation mode of the

control. Manual mode is only used for testing the different components like thepumpand two/three-way valve.

● The system must not be operated if damage to the con-

trol, the wiring or the mains is detected.

● The control is fitted with a low-current fuse.

● Collectors and pipe work becomevery hot duringsunny

periods. There is a risk of scalding when fitting the collector temperature sensor.

3. Installation

3.1 Installation of the Case

Open the casing

●

You require no tools to open the control. The lid snaps

into thelower half. Youcan dislodge and lift upthe lid by

pulling gently on the side clips.

●

The lid arrests automatically when fully opened to allow

for comfortable mounting and wiring.

Wall mounting

●

Using the supplied drilling template drill out the fixing

holes for the control.

●

Mount the control to the wall.

●

Tighten screws only as far as necessary. Over-tightening

may damage the casing!

Page 5

EN-SUNGO-S-BA-0804-1122P200 5

Installation in the Solar Circulation Unit

●

Affix the SUNGO S with the appropriate screws to the

wall mounting bracket of the solar circulation unit.

●

Open up thecable ducts next to thecentrecrosspiece in

the bottom of the control.

●

Remove outer insulation of the cables in such way that

single isolated wires start as they enter the casing from

the bottom.

●

Hold the connectors with one hand while tightening the

screws in order tominimisepressureonthe circuit board

and to avoid tearing the connectors off.

●

Last connection should be to mains.

●

If power is switched on now, 230V AC will be present on

the casing of the triacs.

3.2 Connecting Wires

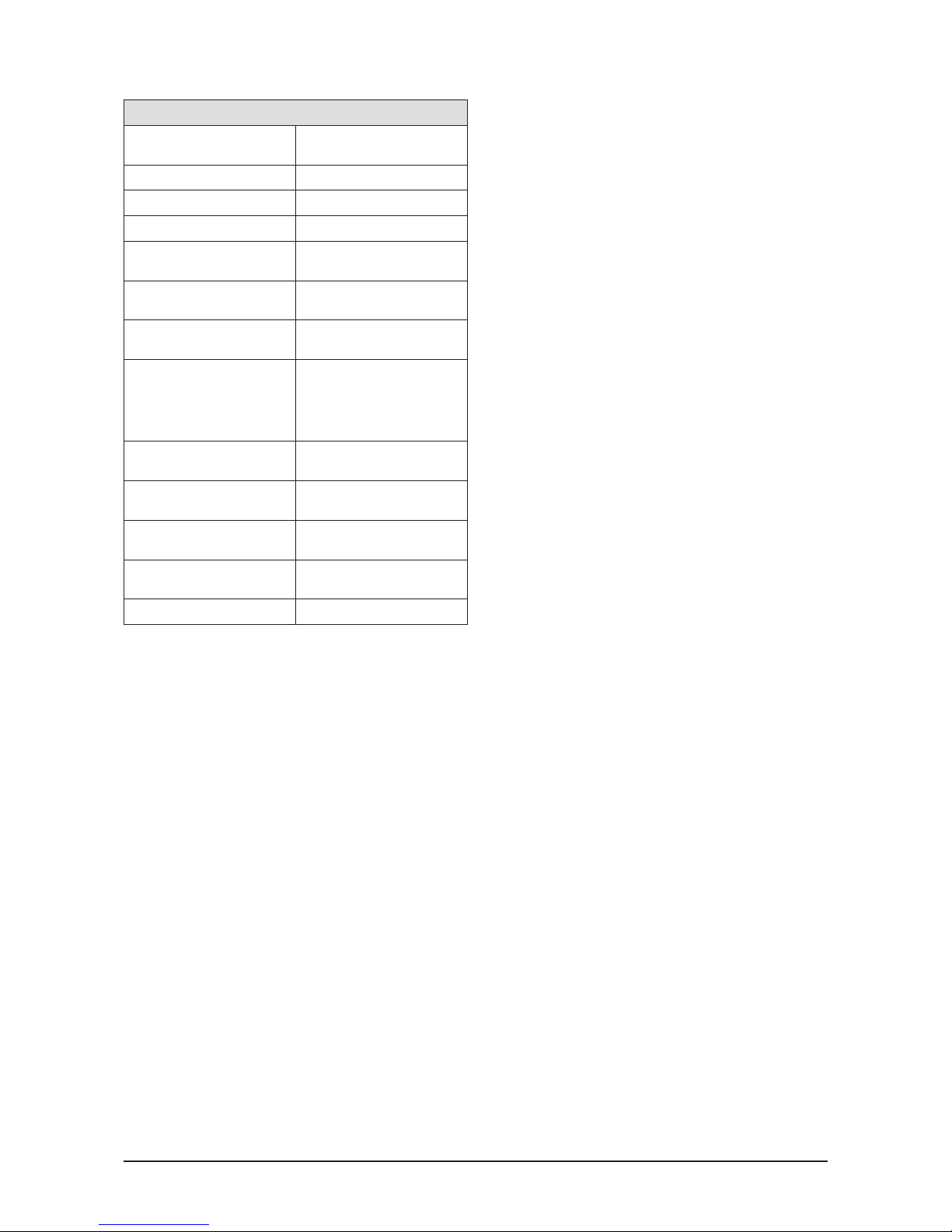

Layout of the SUNGO S connections

All connectionsaremade to the circuit board atthe bottom

of the control. On the right hand side you will find the con

nections for the sensors (low voltage area) while on the left

hand side you will find the connections for mains and

switching output A1.

General connection rules

●

If flexiblewires are used and the controller is fitted to the

wall, wires must be tied externally in such way that strain

to the controller is avoided.

● In this case you must tin or crimp the wire ends.

● If required PG9 screws can befixed at thefeed-throughs

if the control is mounted to the wall.

230 V mains connection

●

Mains power is connected from outside the connector

via an ON/OFF switch.

If the unit isconnected with a plug toa socket, the switch

can be omitted.

●

The unit is designed to work with 230V AC/50Hz.Please

check that your pump has compatible specifications.

●

All earth wires are connected to the PE-connectors.

●

The neutral terminals (N) are connected electrically.

●

Switch output A1 is a230 V normally opencontact which

is activated via speed-control.

Connecting the temperature sensors

●

The wires for the temperature sensors canbe extended:

Up to 15mlength = 2 x0.5 mm² cable canbeused; upto

50m=2x0.75 mm² cable is necessary.

Forlong connections itisrecommended to use shielded

cable.

Do not connect the shielding at the sensor end,just trim

and isolate!

●

Temperature sensors are without polarity and can be

connected any way.

●

Sensor wires must be installed away from mainscarrying

cables.

Lightning protector module

The SUNGO S is fitted with spike protection on all sensor

terminals. Generally, further protection of the cylinder sen

sors is not required.

Sensor T1 (collector) requires installation of sensor connection box SP2 with excess voltage protection.

Safety fuse

Mains voltage area Safety low voltage area

Mains connector

Switch output A1 connector

Mains microfuse 2A/T

Electronic triac switch

Triac control IC

Transformer

for circuit voltage 12 V

Ribbon cable plug

for display circuit

Sensors T1-T3 connectors

Earth potential connector

Figure 2 SUNGO S circuit board components.

Page 6

6 EN-SUNGO-S-BA-0804-1122P200

4. Operation

4.1 Display and Buttons

!

dT min max start stop

R

h

R

ok?

88888

°C %

x

Manual operation men

u

Special functions menu

Balance or

start / stop values

Units

Tank temperature,

upper half

Confirm /

save icon

System error

Settings menu

Information menu

Temperature difference

Number display for

temp. or sensor errors

Collector temperature

Reset symbol

Tank temperature, lower half

Pump ON

Pump OFF

Output A1

Figure 3 Connections.

Safety fuse

T1, collector sensor

T2, tank sensor, lower half

T3, tank sensor, upper half

Mains, PE

Solar circulation pump, PE

Mains, phase (L)

Mains, neutral (N)

Solar circulation pump, phase (L1)

Solar circulation pump, zero (N1)

Mains voltage area

Safety low voltage area

Page 7

EN-SUNGO-S-BA-0804-1122P200 7

Horizontal operating level

Vertical

operating level

Set values

Settings menu

as an example

Temperature limitation tank, bottom

Switch-on difference T1-T2, solar

Switch-off difference T1-T2, solar

Minimum temperature source

Set point temperature difference, speed control, solar

Solar circulation pump

Maximum speed solar circulation pump (SECUSOL)

System filling time (SECUSOL)

dT max

__K

dT min

__K

__°C

T max

__°C

T min

T start

__

d max

__

d min

__

__K

dT

Save

v

alue

Activate

save function

Decrease

value

Increase

value

Ý

Ý

Ý

Activate

value

Ý

Page 8

8 EN-SUNGO-S-BA-0804-1122P200

4.2 Information Menu

Information menu

Menu item Description Display

Collector temperature; Current value °C

Collector temperature; Balance value; minimum, resettable °C

Collector temperature; Balance value; maximum, resettable °C

Tank temperature, lower half; Current value °C

Tank temperature, lower half; Balance value; minimum, resettable °C

Tank temperature, lower half; Balance value; maximum, resettable °C

Tank temperature, upper half

1

; Current value °C

Operating hours, total; Current value h

Reset operating hours since last reset

Balance value, display, resettable;

h

Pump symbol idle: Function display

Temperature difference between collector and tank

is smaller than switch-on difference (solar circulation pump off).

—

Pump symbol active: Function display

Temperature difference between collector and tank

is higher than switch-on difference (solar circulation pump on).

—

1

Sensor T3 (tank, upper half) is simply a measuring sensor, therefore it is not monitored by the sensor control.

4.3 Settings Menu

Settings menu

Menu item Description Range Base value

Temperature limitation tank, lower half 15 - 90 °C 85 °C

Switch-on difference between collector and tank 3 - 40 K 10 K

Switch-off difference between collector and tank 2 - 35 K 3 K

Minimum temperature where analysis of switch-on difference starts 5 - 90 °C 10 °C

Set point temperature difference the speed control adjusts to 2 - 50 K 10 K

Minimum speed of the solar circulation pump

10% increments

30-100% 30%

Maximum speed of the solar circulation pump

SECUSOL only!

30-100% 100%

Charge time (s) of the solar heating system with speed 100 %; in 10 s increments

SECUSOL only!

20 - 360 s 60 s

min

__°C

__°C

__°C

__°C

__°C

__°C

__°C

__h

min

max

max

__h

R

dT max

__K

dT min

__K

__°C

T max

__°C

T min

T start

__

d max

__

d min

__

__K

dT

Page 9

EN-SUNGO-S-BA-0804-1122P200 9

4.4 Manual Operation Menu

Manual operation menu

Menu item Description Range Base value

Off = 0/On = 1

Manual on/off via output A1 (solar circulation pump)

0-1 0

Activation of manual operation lag time in automatic mode 0 - 600 min 0 min

4.5 Special Functions Menu

Within the first minute after switching on the controller,select the “Special Functions“ menu in order to activate it, so that

the individual parameters can be changed.

After leavingit,the menuremains active forone minute.Afterwards the parameters can only beviewed butnot changed.

In order to change the functions again, it is necessary to disconnect the controller from the mains again.

Special functions menu

Menu

item

Application Description Range

Base value

0 System choice

0 - 1: Standard single-tank system

0 - 2: Cannot be selected !

0 - 3: SECUSOL system (see SECUSOL instructions for further info)

1or3 1

1

System

Protection

Off = 0/On = 1

Activation of system protection.

Cannot be activated with SECUSOL!

0or1 1

2 System protection start temperature 115 - 200 °C 135 °C

3

Collector Cooling

Off = 0/On = 1

Activation of collector cooling.

Cannot be activated with SECUSOL!

0or1 1

4 Collector cooling start temperature 100 - 150 °C 110 °C

5

Tank Cooling

Off = 0/On = 1

Activation of tank cooling. Only possible with collector cooling.

Cannot be activated with SECUSOL!

0or1 0

6 Switch-off temperature 30 - 90 °C 60 °C

7-10 Menu items 7-10 are not available for the SUNGO S controller

11

Tube collector

function

Off = 0/On = 1

Activation of vacuum tube collector function

0or1 0

12 Run time of solar circulation pump from reaching the switch-on value 1 - 60 s 15 s

13 Switch-on value for temperature increase at sensor T1 (collector) 1.0 - 5.0 K 1.0 K

__

T stop

Only expert personnel

should edit the special functions menu.

Incorrect settings may adversely affect the solar heating

system.

Page 10

10 EN-SUNGO-S-BA-0804-1122P200

4.6 Service – System Messages

Display of system information

Display Description Correction

System Messages

All system messages are displayed with a blinking caution symbol.

In case of sensor errors the sensor in question is also marked with short circuit or interruption symbols.

Interruption

Displayed sensor or line connection interrupted

/ defunct.

●

Check the resistance value of the sensor and

compare to the resistance table.

●

Check all contact points up to the sensor.

Short circuit

There is a short circuit of the sensor on the

display, the line or the sensor input on the

controller.

dT too high

A fixed value of 20 K is added to the

temperature difference between collector (T1)

and tank sensor (T2). The message is displayed

if after 30 minutes the total temperature

difference has not been reduced.

●

Check pump/pump connections/wiring.

●

Check system for air, and vent if required.

●

Check sensors/sensor lines and change sensor if

required.

4.7 Service – Sensor Control

Resistance values for Pt1000-sensors in relation to the temperature

-10°C 0°C 10°C 20°C 30°C 40°C 50°C 60°C 70°C 80°C 90°C 100°C 110°C

961 Ω 1000 Ω 1039 Ω 1078 Ω 1117 Ω 1155 Ω 1194 Ω 1232 Ω 1271 Ω 1309 Ω 1347 Ω 1385 Ω 1423 Ω

The working condition of the sensor can be checked with this table and an Ohm meter.

!

Blinking

!

Blinking

!

Blinking

°C

!

Blinking

°C

Page 11

EN-SUNGO-S-BA-0804-1122P200 11

5. Application examples

5.1 Standard Single-Tank System

Figure 4 Standard single-tank system controlled by SUNGO S.

P3

P2

Ta

A1

T2

T3

T1

CIRCO

T2

ECOplus

Ttw

T3

P1

T1

BWM

Hot water

Cold water

Oil or gas

boiler

Heating circuit

Collector field

T1: Collector sensor

T2: Tank sensor,lower half

T3: Tank sensor,upper half

P1: Solar circulation pump

P2: Heating circuit pump

P3: Tank charging pump

Ttw: Hot water sensor (heatingcontrol)

BWM: Thermostatic mixing valve

Page 12

Figure 5 SECUSOL system controlled by SUNGO S.

5.2 SECUSOL System

T3

A1

T2 T1

SECUSOL

Ta

P3

P2

BWM

T1

T2

T3

Ttw

P1

Hot water

Cold water

Heating circuit

Collector field (EURO C22)

Oil or gas

boiler

T1: Collector sensor

T2: Tanksensor,lower half

T3: Tank1sensor,upper half (optional)

P1: Solar circulationpump

P2: Heating circuitpump

P3: Tank charging pump

Ttw: Hot water sensor(heatingcontrol)

BWM: Thermostatic mixing valve

Subject to modifications, errors excepted. · ©Wagner & Co, 2008 · www.wagner-solar.com

12 WAGNER & CO · Zimmermannstraße 12 · D-35091 Cölbe/Marburg ·

☎

+49 6421 80 07-0 · Fax 8007-22

Loading...

Loading...