Page 1

TECHNICAL INFORMATION / INSTALLATION INSTRUCTIONS

o

Wagner & C

RATIOfresh Freshwater Station 250/400

Hygienic Water Heating

A continuous flow process is used to heat potable water

quickly and on demand to a preset temperature.

Excellent Performance

The RATIOfresh 250 unit delivers hot water at up to 25 l/

min. Thelarger station RATIOfresh 400 even reaches a tap

ping capacity of 40 l/min and thus is suitable for multi-fam

ily homes with up to 20 individual apartments.

Functional Design

A modern powder-coated metal casing houses all compo

nents in a compact design.

Adaptive Microprocessor Controlling

The microprocessor “learns“ the water withdrawal patterns

of users.This meansthefreely selectable hotwatertemper

ature can be maintained precisely even with fluctuating

flow or inlet temperatures within the primary circuit. This

also offers various options of regulating hot water

circulation.

-

-

-

-

Easy Assembly and Maintenance

The station is suitable for mounting on the wall or the storage tank (in conjunction withall RATIO buffer cylinders and

the additionally available tank expansion kit). Flat sealing

connections simplify assembly and installation aswell as all

service tasks. After the hydraulic integration, the ready-toplug-in station can beoperatedimmediatelyasdelivered.

Numerous Application Options

The freshwater station can be combined with almost any

heat source. Oil, gas, wood logs and pellet boilers are as

suitable as asolar installation orlocal or districtheating dis

tribution systems. All ittakesis a buffer cylinder whosether

mal stratification is supported by minimal return tempera

tures within the primary circuit.

Protection from Legionella Pneumophila Bacteria

If required, the hot water and the circulation piping net

work can be thermally disinfected. Time, temperature, and

duration of the disinfection process are individually

adjustable.

Content

1. Technical Information .................2

1.1 TechnicalData ......................2

1.2 Scope of Delivery ....................3

1.3 Accessories .......................3

2. Safety Information ...................6

2.1 Operator Qualifications ................6

2.2 Intended Use ......................6

2.3 Standards andGuidelines ...............7

2.4 Installation Recommendations ............7

-

-

-

Figure 1 RATIOfresh Freshwater Station 250/400.

3. Installation ........................8

-

3.1 Prior to theInstallation .................8

3.2 Wall Mounting ......................8

3.3 Storage Tank Mounting ................8

3.4 Connecting Potable Water ...............9

3.5 Connecting Circulation .................9

3.6 Installing thePrimaryCircuit .............10

3.7 Switching thePrimaryReturn Flow ..........11

3.8 Connecting theController ..............11

3.9 Closing theHousing..................11

4. ControllerOperation .................13

4.1 Controller Displays ..................13

4.2 Controller Settings...................13

4.3 Controller SettingTables ...............14

5. Initial Startup......................19

6. Notes for Operators ..................20

7. Maintenance and Care ................22

8. Troubleshooting....................23

9. System Solutions – Example .............27

Solar Thermal / Solar Cylinder EN-RATIOfresh-250-400_TI-MA-0809-11214900 1

Page 2

1. Technical Information

1.1 Technical Data

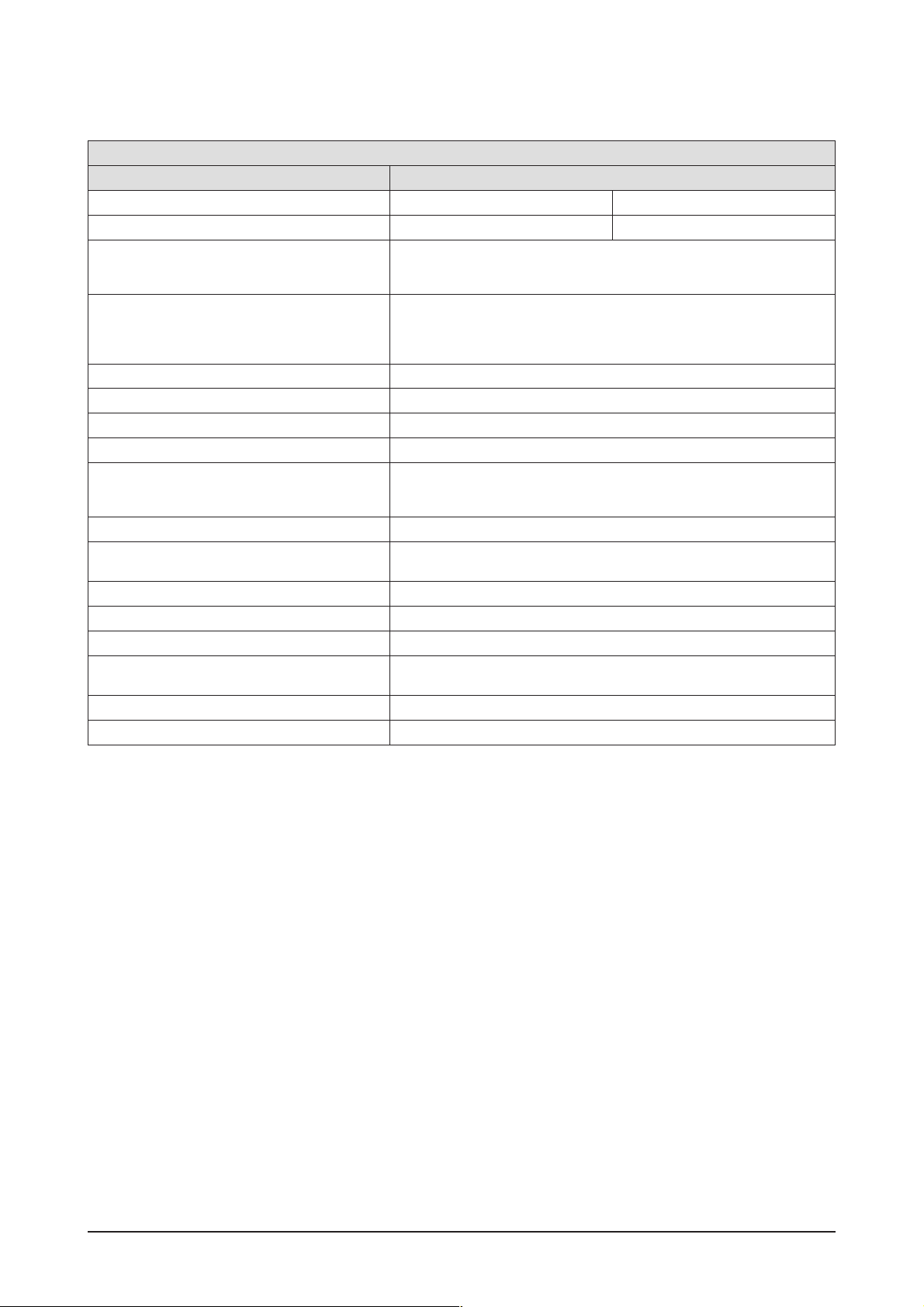

Table 1 Technical Data

Feature RATIOfresh 250

Variation Copper soldered heat exchanger Stainless steel soldered heat exchanger

Order no. 150 300 65 150 301 77

Nominal tapping capacity

10 °C → 45 °C (sec.)

10 °C → 60 °C (sec.)

Coefficient of performance (NL)

10 °C → 45 °C (sec.), 82 °C (prim.) acc. to DIN 4708 T3

10 °C → 60 °C (sec.), 85 °C (prim.)

10 °C → 60 °C (sec.), 75 °C (prim.)

Nominal hot water temperature 25 – 70 °C

Circulation return 5 – 70 °C/5–25K

Pressure loss, Dp secondary < 370 mbar (with 25 l/min)

Voltage supply 230V/50Hz

Fuses

Dimensions of housing (HxWxD) 940x350x181mm

Color (powder-coated)

Max. permissible pressure 6 bar (primary), 10 bar (secondary)

Max. permissible temperature 95 °C (primary and secondary)

Capacity of water space 1.1 l (primary) / 1.2 l (secondary)

Max. electrical power consumption / standby

operation mode

Protection class IP 44

Weight 26 kg

25 l/min

61 kW

87 kW

=13

N

L

N

=11

L

=7

N

L

Operating voltage 230 V, control fuse 100 mAT / 250 V, power fuse 2 AT/250 V.

To replace internal fuses, de-energize the device, remove the screws on the

controller, and lift off cover (fig. 8, 9, 10).

Upper section: RAL 7035 (light gray)

Bottom section: RAL 7021 (black-gray)

2 x 200 W (when connecting two pumps) / 0.6 W

2 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 3

Table 2 Technical Data

Feature RATIOfresh 250

Variation Copper soldered heat exchanger Stainless steel soldered heat exchanger

Order no. 150 300 66 150 301 78

Nominal tapping capacity

10 °C → 45 °C (sec.)

10 °C → 60 °C (sec.)

Coefficient of performance (NL)

10 °C → 45 °C (sec.), 82 °C (prim.) acc. to DIN 4708 T3

10 °C → 60 °C (sec.), 85 °C (prim.)

10 °C → 60 °C (sec.), 75 °C (prim.)

Nominal hot water temperature 25 – 70 °C

Circulation return 5 – 70 °C/5–25K

Pressure loss, Dp secondary < 490 mbar (with 40 l/min)

Voltage supply 230V/50Hz

Fuses

Dimensions of housing (HxWxD) 940x350x181mm

Color (powder-coated)

Max. permissible pressure 6 bar (primary), 10 bar (secondary)

Max. permissible temperature 95 °C (primary and secondary)

Capacity of water space 1.6 l (primary) / 1.2 l (secondary)

Max. electrical power consumption / standby

operation mode

Protection class IP 44

Weight 28 kg

40 l/min

98 kW

139 kW

= 19,5

N

L

N

=17

L

=11

N

L

Operating voltage 230 V, control fuse 100 mAT / 250 V, power fuse 2 AT/250 V.

To replace internal fuses, de-energize the device, remove the screws on the

controller, and lift off cover (fig. 8, 9, 10).

Upper section: RAL 7035 (light gray)

Bottom section: RAL 7021 (black-gray)

2 x 200 W (when connecting two pumps) / 0.6 W

1.2 Scope of Delivery

Table 3 Delivery Scope

Freshwater station, ready for plug-and-play, 4 dowel sets for wall

mounting; 4 solder connection sets LT 22-1; installation

instruction

1.3 Accessories

Table 4 Accessories

Item Order no.

Solder connection set

LT 28.1 ¼“, swivel nut,

gasket and solder connection 22mm

Threaded connection set

GT 1 ¼“, swivel nut,

gasket and threaded connection

RATIOfresh RS 232 PC interface cable 150 400 22

Cylinder mounting kit for CIRCO 139 000 28

Motor actuated 3 way valve 1“ M 160 101 44

Motor actuated 2way ball valve 819 201 33

139 000 44

130 100 88

EN-RATIOfresh-250-400_TI-MA-0809-11214900 3

Page 4

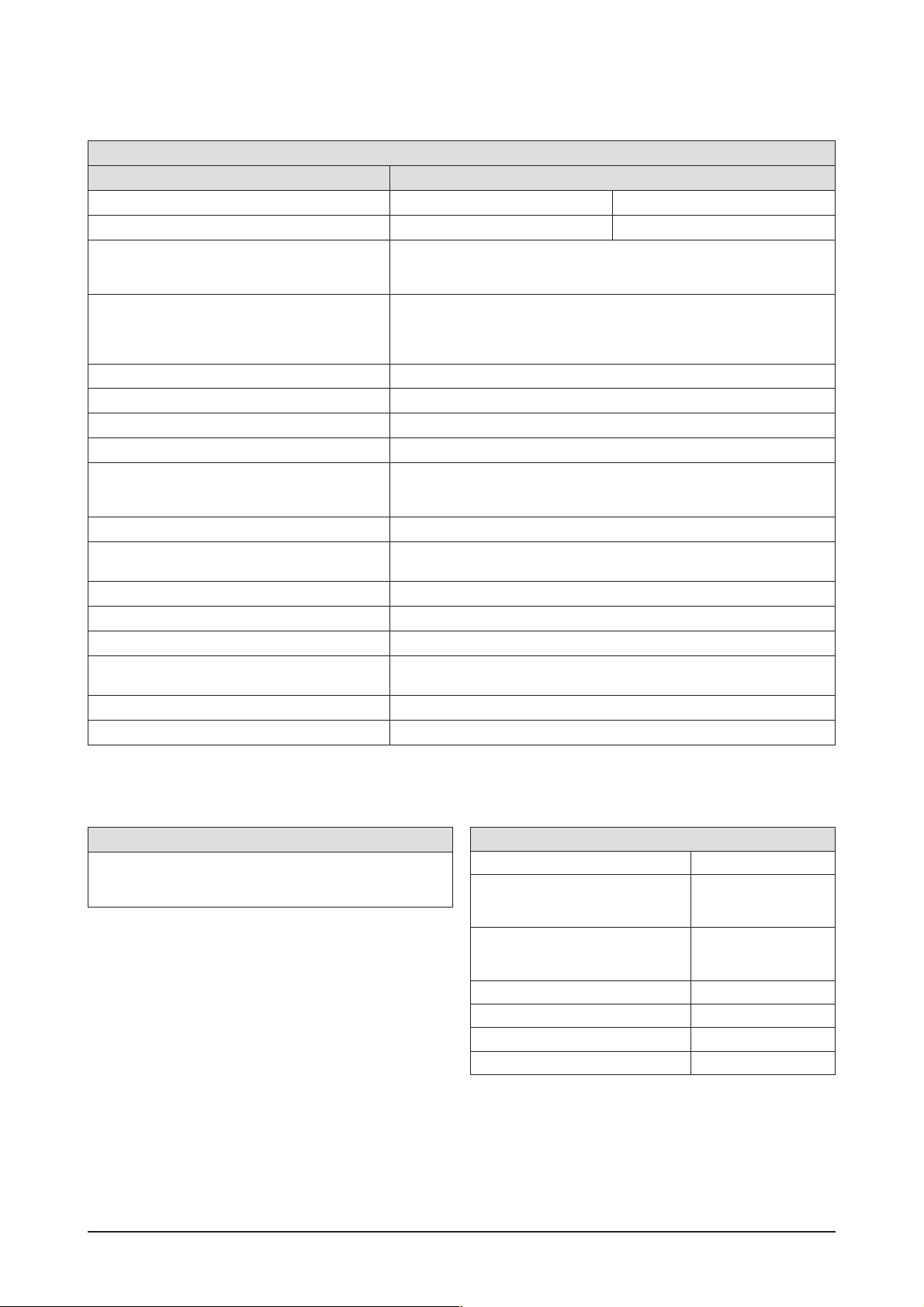

Frontal view

350

4 Primary

flow

80

7 Hot water

Side view

110

100

240

Drill pattern

64

254

32

70

2-Heat ex

changer

6 Cold water

9 Single-jet meter

570

940

8 Circulation

3 Circulation pump

ø55

1 Controller

10 Housing

5 Primary

85

return

Top/bottom view

181

80

57

181

ø55

Figure 2 RATIOfresh freshwater station viewed sectionally, with dimensions and drilling template.

521

827

4 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 5

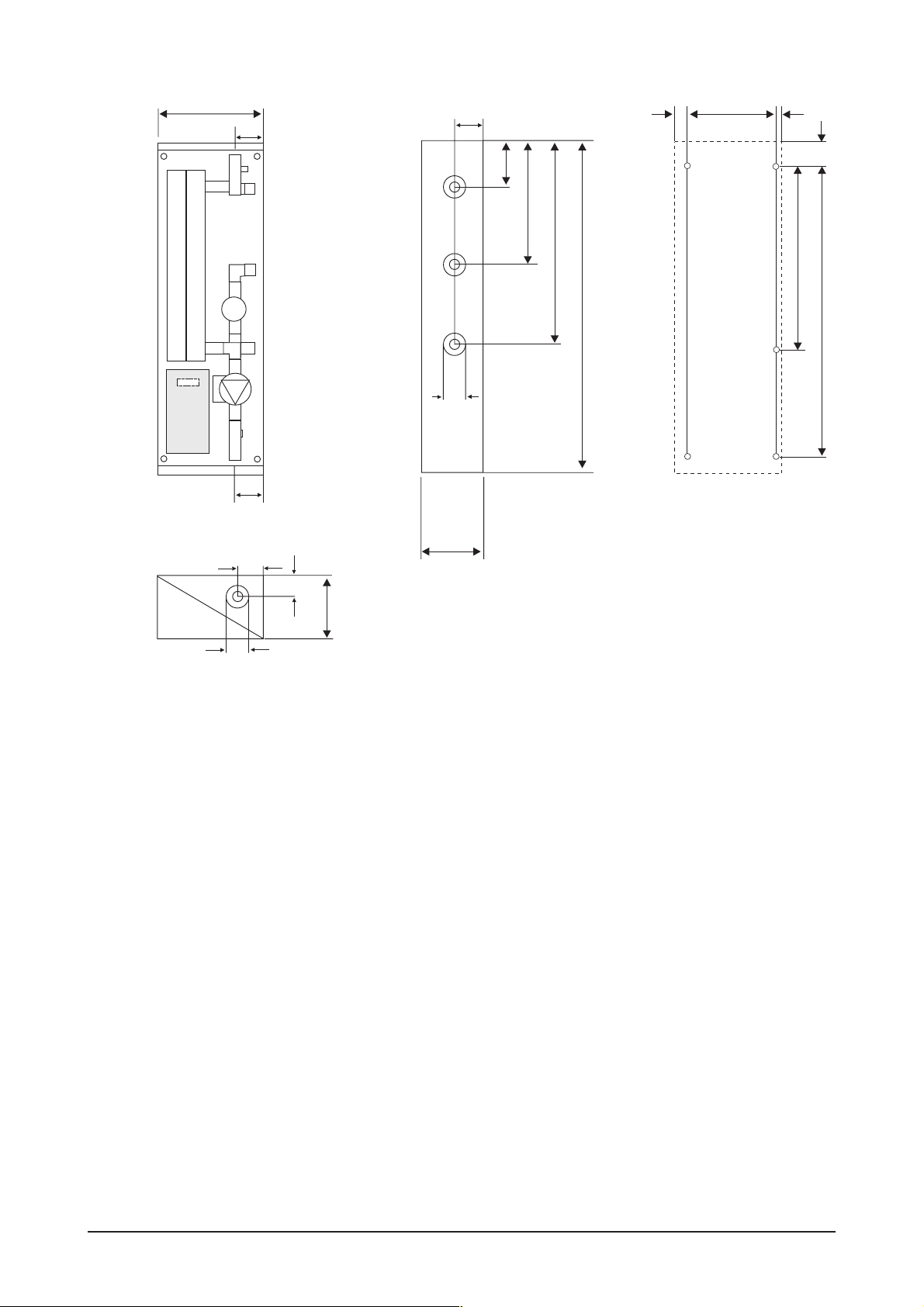

Housing cover

11

12

18

10

Top section of housing

4

7

13

6

9

2

14

16

Wagner &Co

17

1

15

19

Figure 3 Cross-section of RATIOfresh freshwater station with dimensions and drill hole pattern (page 4)

1 Adaptive microprocessor controlto regulatehotwater and circulation,display2x16 characters,plasticfoil keypad with3 keysand 4 LED,2 power

outputs, 3temperaturesensors and 2 immersionsleeves made from chrome-plated brass; 2 Plate heatexchanger made from stainless steel,cop

per-soldered, flat-sealing connection T1" (OT)–quickly disassembled formaintenance,specially embossed platestructuretoavoid lime deposits;

3 Circulation pump in primary return, especially energy-saving design, easy to service due to flat-sealing integration;

4 Primary flow connection T 1" (OT,flat-sealing) made from brass, with shut-off valve; 5 Primary return connection T1" (OT, flat-sealing) made from

brass, with pump shut-offslider incl. backflow preventer; 6 Cold watersupplyconnection T 1" (OT, flat-sealing) made frombrass ; 7 Hot wateroutlet

connection T 1" (OT, flat-sealing) made from brass; 8 Circulation return connection option T ½" (IT) closed with plug; 9 Single-jet meter – brass,

chrome-plated, connections ¾" (OT,flat-sealing),QN 2.5 m³/h; 10 Bottom section of housing made from powder-coated sheet steel with keyhole

drills for wall mounting; 11 Housing cover made from powder-coated sheet steel, removable; 12 EPP shell insulation (expanded polystyrene) for

plate heat exchanger; 13 Temperature sensor hot water; 14 Temperature sensor circulation return; 15 Temperature sensor storage cylinder; 16

Power switch to select pump output level; 17 Backflow preventer (in ball valve); 18 Temperature sensor primary; 19 Mains plug.

8

3

5

-

EN-RATIOfresh-250-400_TI-MA-0809-11214900 5

Page 6

2. Safety Information

The following safety information is intended to protect you

from hazards and dangers that may suddenly occur when

the device is handled incorrectly, either deliberately or un

knowingly. We differentiate between general safety infor

mation, explained onthis page, and special safetyinforma

tion, which is listed throughout the text of this manual. The

following symbols are important!

DANGER – possibility of personal injury

The following may occur during assembly or installation:

hazardous electrical shock, scalding, bruising/contusions,

and other adversehealth effects. Please complywiththe in

structions marked with this symbol in the documentation.

CAUTION – possibility of property damage

This symbol indicates hazards that may result in damage to

components or a significant reduction of the functionality

of the system. Please follow the described assembly steps

and comply with the sequence of these steps.

NOTE – additional information

This symbol indicates useful notes, tips to make work

easier,and other information that may help you with the installation or operation.

2.1 Operator Qualifications

station is designed insuch a way that the lowestpossiblere

turn temperatures are reached, which exhibit only a minor

difference to the cold water temperature.

Thermal Disinfection

The Legionella Pneumophila Bacteria protection function

can be used to disinfectthe entire hotwater and circulation

piping network thermally and during freely selectable

times (day or week program). You choose between once

per week (Mon-Sun) or daily. This function serves to pre

vent the formation of bacteria and viruses in the potable

water network.

The station uses an external relay output to activate the

buffer storage auxiliary or backup heating if the required

primary temperature (= disinfection temp. + hysteresis

) is not detected by the sensor T

dT

NH

picts “DISINFECTION.” If the required temperature exists

within the primary circuit (data logging with the tempera

ture sensor “T

starts. The freely selectable disinfection temperature (e.g.

65 °C) ismaintained across asettable time duration (e.g. 20

min) and across all flooded hot water andcirculation pipes.

Unexpected malfunctions during the disinfection phase

are indicated to theuser in plaintextand additionally witha

visual signal (LED light, fig. 10, no. 4).

Potable water hygienists recommend a material tempera

ture of 70 °C or higher for a duration of at least3 minutes to

disinfect the piping network. The disinfectiontemperature,

however, should be a few degrees higher or the disinfection time somewhat longer to ensure proper disinfection

occurs. Do not forgetto raise the branchlines to the hotwater tapping points to the required temperatures by withdrawing water several times for several minutes.

Before activating the disinfection function, check whether

the hot water or circulation network can sustain such high

temperature stress (e.g. damaging galvanized steel pipes)

and whether the carbon hardness of the potable water is

within an acceptable range.

The hot water users are at risk of scalding injuries while the

disinfection program is running. The disinfection should

therefore be carried out at night.

”), the thermal disinfection program

buffer

. The display de

buffer

-

-

-

-

-

All tasks and activities involving the transport, installation,

as well as operation and servicing must be performed by

qualified technicalpersonnel. We do not assume responsi

bility or liabilityfordamages resulting from noncompliance

with these instructions.

2.2 Intended Use

Function

Heated water from a storage tank is used with a plate heat

exchanger to prepare hot water with a constant tempera

ture.Thecooled down return water is layeredintothe lower

section of the storage tank.

This is controlled demand-dependent. Only when potable

water is withdrawn and detected by the single-jet meter,

the circulation pump feeds the exchanger with a variable

hot water volumestream from the storagetank so thata de

fined tapping temperature is maintained.

The return temperature is the resultof the storagetank tem

perature, the pump speed, and the plate heat exchanger

design. The heat exchanger of the RATIOfresh freshwater

6 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Circulation

The temperature difference is calculated from the circula

tion flow and return temperature and compared with the

preset nominal difference. If the temperature difference is

too small, the control detects an oversupply of the circula

tion and reduces the output of the circulation pump based

on the deviation. If the temperature difference is too great,

the control increases the output of the circulation pump

based on the deviation. The mass flow is then varied

through a pulsed modulation of the pump output. If an ad

justable return temperature is exceeded, the controller

switches the pump off.

-

-

-

-

-

-

Page 7

Standby Temperature Control

The RATIOfresh freshwater station is also equipped with a

standby temperature control in addition to the circulation

function. The control activates the primary pump and sup

plies the station with hot water to maintain the preset

standby temperature at the primary flow outlet port re

gardless of a withdrawal of hot water.

This function serves to preheat the plate heat exchanger;

this means that hot water is thus much more quickly avail

able at the desired nominal temperature in case water is

withdrawn. This function also protects from frost if the

standby temperature is set to a lower value of 10 °C. The

standby temperature control is only activated if the cylin

der temperature is sufficiently high.

2.3 Standards and Guidelines

The following standards and guidelines must be observed

and complied with when installing hydraulics and/or per

forming electrical wiring: IEC 364 or CENELEC HD 384,

DIN VDE 0100 and IEC-Report 664, DIN VDE 0110 and na

tional accident prevention rules and regulations, as well as

VDE 0100, VDE 0160 (EN 50178), VDE 0113 (EN 60204),

and local rules and specifications of your energy provider

or utility company.

Specifications outlined by DVGW W551 concerning pro

tection from the Legionella pneumophila bacteria must be

observed for multi-family home installations. A circulation

must be operated between hot water heater and tapping

point for potable water volumes greater than 3 liters. The

hot water outlet temperature of the RATIOfresh station

must always be set to ≥ 60 °C.

2.4 Installation Recommendations

Connecting the Circulation

The freshwater station RATIOfresh is designed to be con

nected toa circulation line. The circulation pumpmust be a

commercially available stepped wet pump. E-pumps or

pumps with integrated motor protection or ON/OFF

switching electronics may not be operated.

-

Connecting the Primary Circuit

The pipingof the primarycircuit should be as short as pos

sible to achieve the rapid heating of the heat exchanger

when water is tapped. The max. permissible pressure loss

within the primary circuit may not be exceeded when lines

are longer.

A bleeder is to be installed at the highest point of the pri

mary circuit. The primary flow should be withdrawn at the

hottest pointof the buffer storagetank, and the primary re

turn should bereturnedas close tothe bottom ofthe buffer

storage tank as possible.

Gravity circulations may occur depending on the length,

design, and insulation state of the primary circuit.This con

tinuously withdraws energy from the standby section of the

buffer cylinder.

A gravity brake with low admission pressure must be in

stalled on-site in addition.

Thermal Disinfection / Protection from Legionella

Pneumophila Bacteria

Please note that the “Disinfection” function only can be

used as intended if the cylinder temperature sensor can

correctly measure the derivative temperature within the

connected auxiliary heating range. The sensor should thus

be attached 10 cm below the actual tapping point on the

buffer cylinder (on the tank wall as depicted in fig. 7).

Please also notethat increased temperatures within the hot

water networkand associated pipes pose a risk of scalding

injuries while the disinfection program is running!

-

-

-

-

-

-

The tank must be installed in a frost-free room with short

lines to the consumer.

De-energize the control unit as outlined by the manual be

fore working on the pump or the control unit. Controller

and pump carry electricity even if the controller switches

the pump off!

Cold and Hot Water Line

A safety valve (cf.fig. 5) is required in the cold water supply

line as specified by DIN 4753 T1. Amin.thread diameter of

DN 15 must be selected for a heating output of max. 75 kW.

Thesafety valve can beomittedonly if atypeapprovedflow

monitor limits the water temperature to 95 °C. The valve

must be designed for a blowing-off pressure that corre

sponds with the permissible working overpressure.In case

of 10 bar and higher waterline pressures, install a pressure

reducer behind the water meter. When heating the fresh

water station without watertap,wateris dripping out offthe

safety valve. Use a siphon funnel to catch and dispose off

this water.

Do not install a shut-off between safety valve and freshwa

ter station. A drain valve should be installed for mainte

nance and service tasks. The functionality of the safety

valve must be checked regularly in accordance with DIN

4753.Theexhaust vent may neverbeclosed or restricted. A

corresponding water filter meeting current technology

standards is to beinstalledinto the cold watersupplyline.

Protection from Corrosion and Lime Buildup

All water-conducting parts are basically subject to corro

sion and lime buildup, especially if temperatures exceed

60 °C and with aggressive water. Hot water temperatures

thus should never exceed 60 °C. Significant lime deposits

are not expected with carbonate hardness below approx.

10° dH and temperatures less than 60 °C. If your potable

water is harder than this, we recommend on-site lime

buildup reducing measures. If the plate heat exchanger

must be decalcified on a regular basis, irrigation cocks (fig.

6) should be installed during the system assembly.

The plate heat exchanger of your freshwater station is

made from copper soldered stainless steel plates. Steel

pipes may thus not be used in the flow direction (towards

the freshwater station) since copper is water soluble in

minute particles and causes pitting when deposited on

steel.

Water with low hydrocarbon content and high portion of

neutral salts (e.g. soft water containing chloride) can cause

dezincification of the installed brass elements.

-

-

-

EN-RATIOfresh-250-400_TI-MA-0809-11214900 7

Page 8

3. Installation

4

3.1 Prior to the Installation

Before assembly, please compare thedelivered compo

●

nents with the parts list in table 3.

You need the following tools: drill, stone drill (12 mm),

●

voltage meter, screwdriver, folding meter-rule, wrench

size 10, monkey wrench, ratchet with size 13 socket.

Materials/components needed on-site: sets of union

●

connectors to connect primary and potable water cir

cuit, a safety subassembly to install into potable water

network if needed, a circulation pump if needed, pipe

material, and insulation material.

Open the RATIOfresh freshwater station as depicted in

●

fig. 8 byremoving the housing coverin the lowersection

from the lower part and lift out off the snap-in groove.

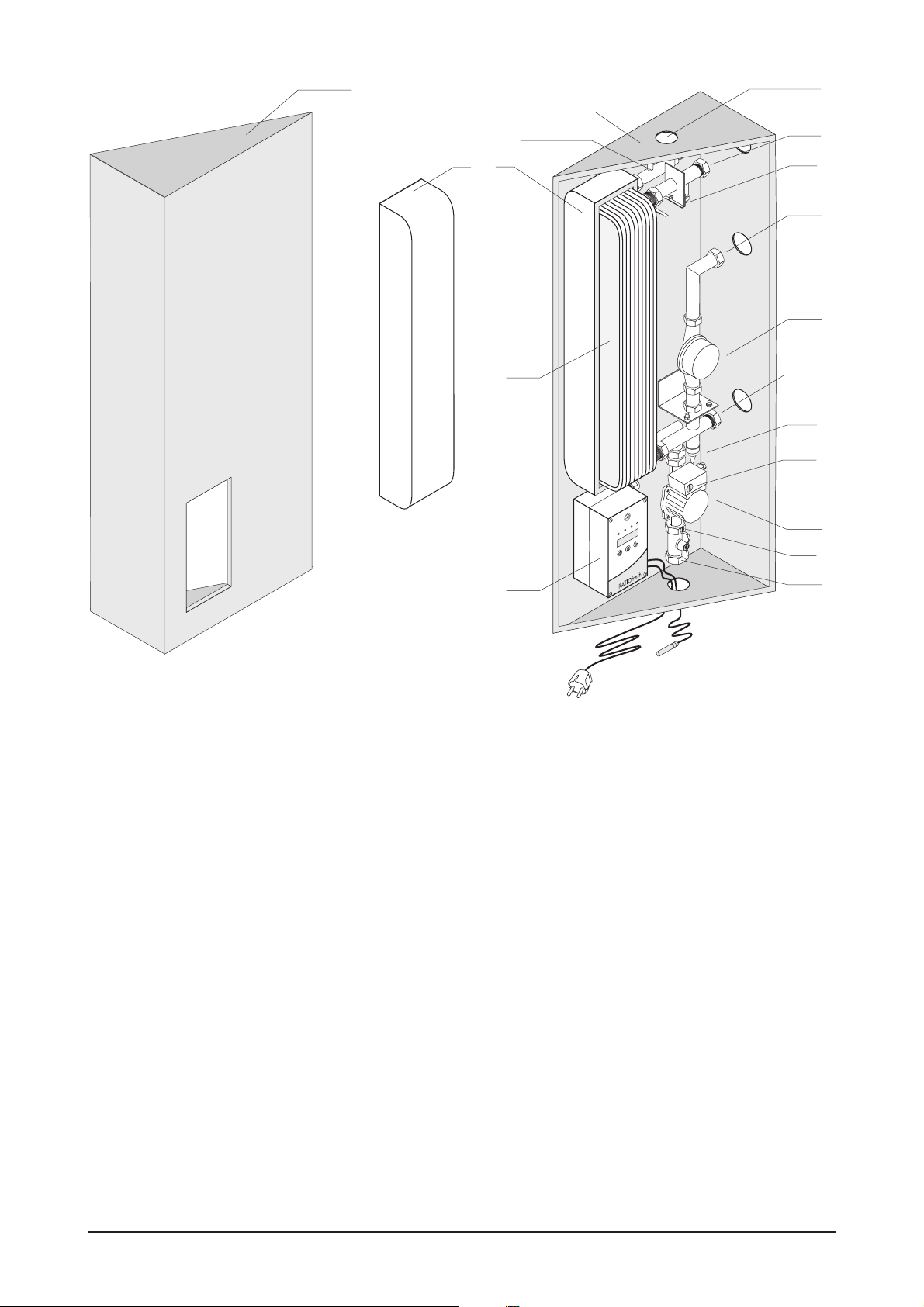

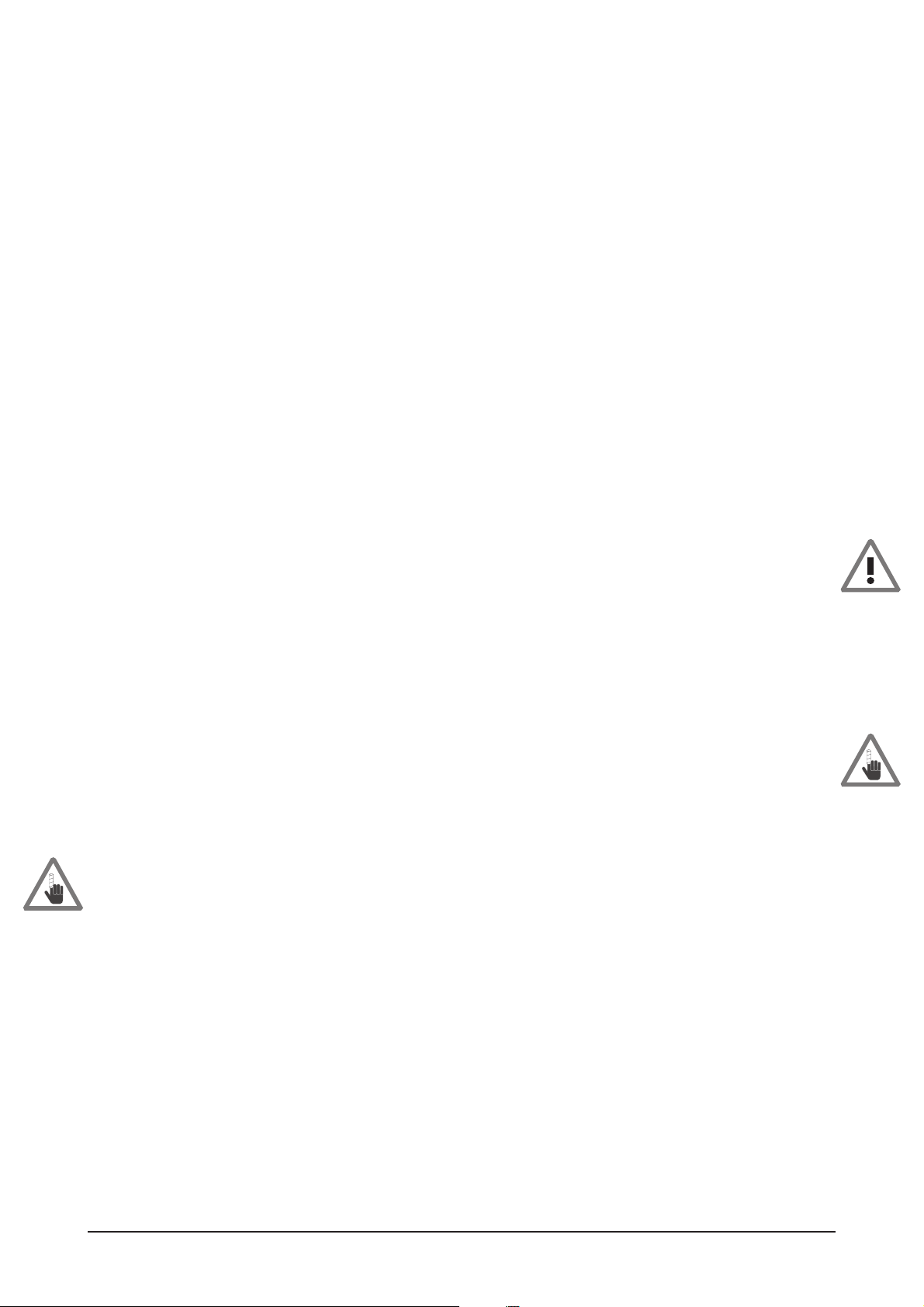

3.2 Wall Mounting (fig. 4)

Transfer the hole pattern to thewallas depicted in fig.4.

●

Drill holes (1) with a 12-mm stone drill and insert in

●

cluded plugs (2).

Insert screws (3) to adistance of 1 cmand insert housing

●

(4) into keyholes (5) and attach screws.

Tighten screws (3) firmly.

●

3

-

1

254

2

4

-

5

827

3

-

5

5

3.3 Storage Tank Mounting (fig. 5)

The RATIOfresh freshwater station is suitable for mounting

directly on all buffer cylinders (RATIO-H series) using the

additionally available tank expansion kit (cf. accessories,

table 4):

● Remove the insulation of the RATIO-H (1) cylinder and

snap the mounting plate (3) with the U-shaped ends (4)

into the second (2)andfifthconnection (5) from the top.

●

Screw down the mounting plate withthe included 1 1/2"

flat swivel nuts (6).

●

Then screw the included 3 hexagonal carriage bolts (7)

halfway into the mounting plate, attach lower part of

housing with keyhole drill holes (fig. 4) and tighten with

the carriage bolts (7).

Figure 4 Wall mounting

1 Holes; 2 Plugs; 3 Screws; 4 Bottom section of housing ;

5 Keyholes.

1

2

5

4

6

4

3

7

Figure 5 Tank mounting

1 RATIO-H cylinder; 2 Second connection from top;

3 Mounting plate; 4 Bracket; 5 Fifth connection from top;

6 1¼" flat swivel nut; 7 Hexagonal carriage bolts.

8 EN-RATIOfresh-250-400_TI-MA-0809-11214900

6

Page 9

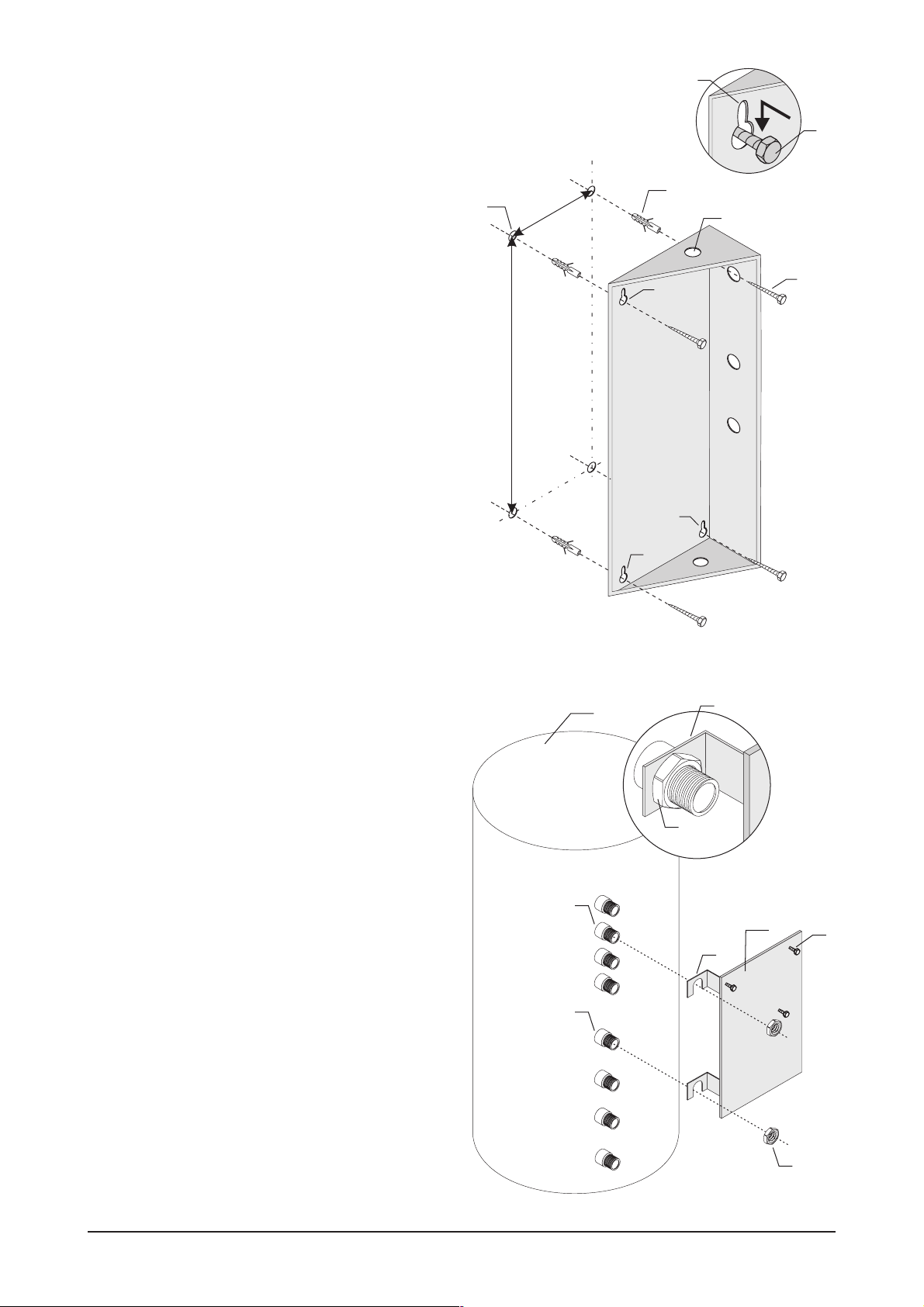

3.4 Connecting Potable Water (fig. 6)

Cold and hot water connections must be connected to the

freshwater station in accordance with the rules and regula

tions issued by the local water utility or water provider. We

recommend connecting to the potable water network in

the manner illustrated in fig. 6.

A safety subassembly (3) with safety, shut-off, and check

●

valve must be installed in the cold water supply (2) in

acc. with DIN 1988. Make sure there is no shut-off be

tween the RATIOfresh station (1) and the safety sub

assembly (3). To connect the piping to the cold water

supply (7) of the station, please use the connection sets

with 1" swivel nuts (4), soldered connection 22 mm (5),

and flat seal (6) or threaded connection sets as an alter

native, both available as additional accessories.

The hot water outlet of the station (8)mustbe connected

●

to thehot water network with soldered or threaded con

nection sets and well insulated as well. Do not forget flat

seals (6)!

Potable water with a high content of lime may require

●

that the heat exchanger is flushed regularly. This re

quires installing irrigation cocks (9) and (10) into the

cold andhot water lines in closeproximity to thestation!

After irrigation cock (10) in the hot water line, an addi

tional shut-off cock(11)isneeded for flushing thepipes.

5

6

3.5 Connecting Circulation

(Optional, fig. 6)

DVGW 551 specifies a circulation element or system in

larger hot water networks. The circulation return (21) must

be installed directly before tapping point (22).The circula

tion pump (23) is supplied with voltage and controlled by

the controller. Chapter 3.7 provides information about the

correct connection of the power cable (24). Please note

that a backflow preventer (integrated inthefigureof the cir

culation pump) must be installed in the circulation line.

-

Remove the 1/2" plug (26) at the circulation return con

●

nection of the station (25) and attach the circulation re

turn line asperconnection diagram.Use a 1/2" threaded

connection (27).

-

-

22

-

-

4

11

21

-

-

-

-

10

8

4

25

5

6

7

3

2

KW

26

27

1/2 AG

9

23

24

1

Wagner& Co

Figure 6 Potable water connection

1 Bottom section of housing; 2 Cold water supply; 3 Safety subassembly ; 4 1" swivel nut ; 5 22-mm soldered connection; 6 Flat seal;

7 Cold water supply; 8 Hot water outlet; 9 Irrigation cock; 10 Irrigation cock; 11 Shutoff valve; 21 Circulation return;

22 Tapping point; 23 Circulation pump; 24 Connection cable to circulation pump; 25 Circulation return connection;

26 ½" plug; 27 ½" threaded sleeve.

EN-RATIOfresh-250-400_TI-MA-0809-11214900 9

Page 10

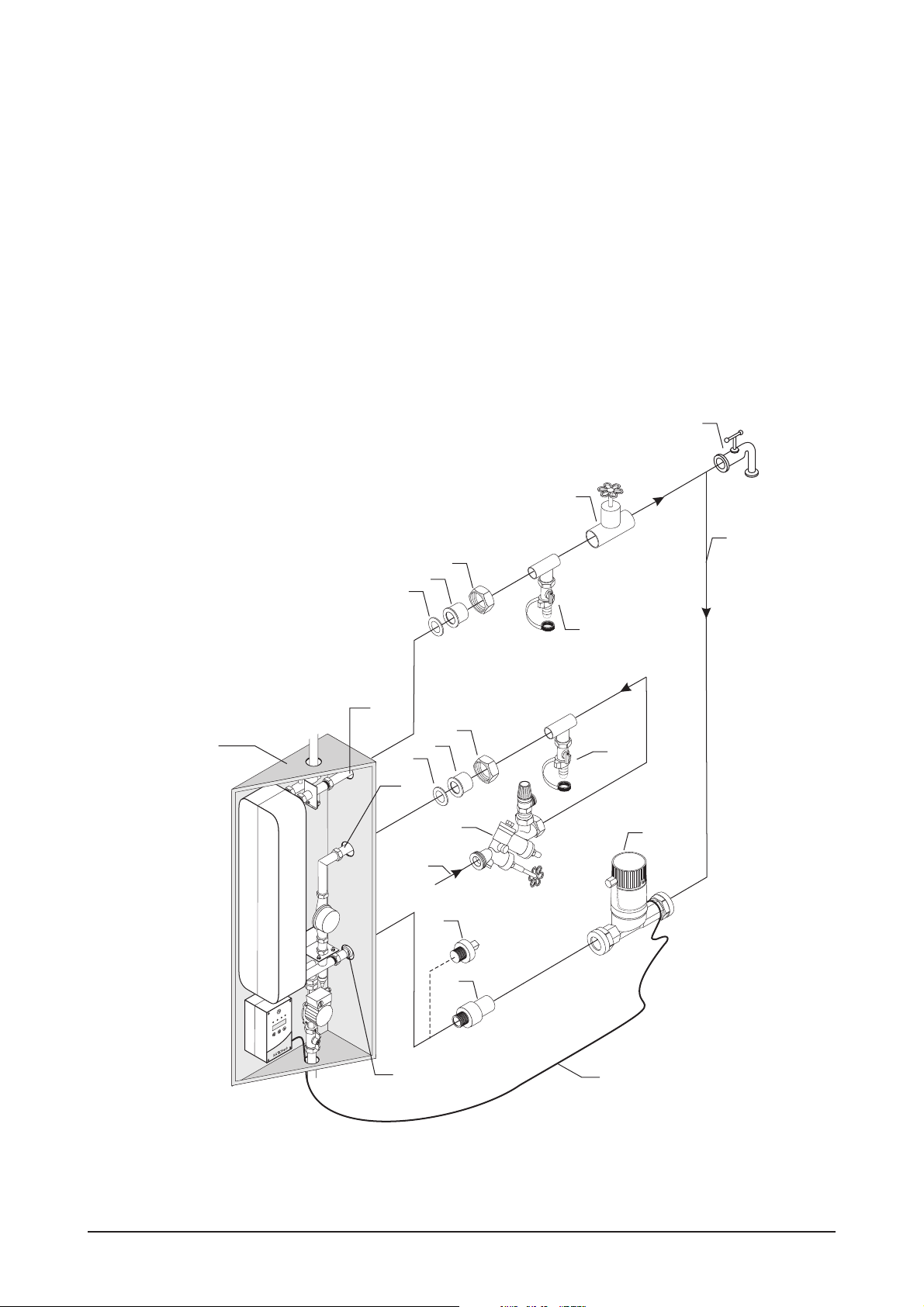

3.6 Installing the Primary Circuit (fig. 7)

In order for the RATIOfresh freshwater station to yield the

desired output, it must be suppliedwith a sufficient volume

of hot water either from a buffer storage tank or a district

heating system. Table 14 lists the required primary flow

temperatures.

The primary circuit may never be serviced by another

pump even only temporarily!

Route primary flowline(1) from the hotstorage tank sec

●

tion to the RATIOfresh-freshwater station and connect

with soldered orthreadedconnection sets. At theRATIO

cylinder use 18-1½" connection sets with swivel nut (4),

soldered or threaded connection (3) and flat seal (2),

and connection sets22-1¼" with swivelnut (7), soldered

or threaded connection(6)and flat seal(5)at the station.

Install a bleederif lines in theprimaryflow are installed in

an upward direction!

Connect the primary return line (8) and route to the cor

●

responding storage tank connection that matches the

temperature level. Table14 lists the return temperatures

of the station in dependency of the operating condi

tions.

Routecableofthetemperaturesensor(9) marked

●

” from the freshwater station along theprimary flow

“T

prim

and attach sensor in the aux. heating section of the

buffer cylinder approx. 10 cm below the actual tapping

point of the primary flow. Use the uppermost position of

-

the connector block (10) at the RATIO buffer cylinder.

The sensor must correctly detect thecylinder temperature.

Check the correct position of the sensors after the initial

startup!

-

-

1

2

3

4

7

6

5

Wagner&Co

5

6

7

2

3

4

8

10 cm

9

9

10

10

Figure 7 Primary circuit installation

6-1 Primary flowline; 6-2 Flat seal; 6-3 Soldered or threaded connection; 6-4 Swivel nut; 6-5 Flat seal; 6-6 Soldered or threaded union; 6-7 Swivel

nut; 6-8 Primary return line; 6-9 Temperature sensor T

10 EN-RATIOfresh-250-400_TI-MA-0809-11214900

; 6-10 Connector block.

buffer

Page 11

3.7 Switching the Primary Return Flow

(fig. 15)

When the RATIOfresh freshwater unit is used in systems

that are continuously operated at water temperatures >=

60 °C and work with circulation nets, we recommend the

controlled switching of the return flow to the buffer cylin

der. Thus it can be avoided that during periods of low hot

water drawing, hot water enters the lower part of the the

buffer cylinder where it could cause unwanted mixing.

The switching canbe carried outby a 3-wayvalve (see solu

tion shown infig.15).Thevalveshould have short switching

times (<30 s) and low pressure loss. (e.g. Wagner & Co 3way-valve, order no. 160 101 44). Control should be based

upon temperature difference, e.g. via solar controller

SUNGO SXL.

3.8 Connecting the Controller (fig. 9)

and opens contact 11-13. Once the boiler is no longer

needed, contact 11-12 is opened again and contact 1113 is closed again. If contact 11-12 is closed, the third

LED from the left (cf. 10-3) is continuously green.

fig. 9 also depicts the control fuse (16) (400mAT / 250 V)

●

and the output fuse (17) (6.3 AT / 250 V).

Hold controller housing cover before the bottom sec

●

-

tion of the housing, reattach the flat ribbon cable to the

display board (3), attach the coverto the bottom section,

press down the 4 Phillips screws (cf. 10-9) and turn to

wards the right by 90°.

-

3.9 Closing the Housing (fig. 8)

To close themetalhousing,insertthe housing cover (1)into

the snap-ingroove (2) at the bottom sectionof the housing

(3) and then snap the two snap-in plugs (4) at the bottom

into sockets (5).

-

-

All tasks and activities involving the transport, installation,

as well as operation and servicing must be performed by

qualified technical personnel.

The controller is for the most part prewired. A fourth tem

perature sensor and a circulation pump can be connected

in addition tothe mains connection.If the disinfection func

tion is utilized, the auxiliary heating of the buffer cylinder

must be activated via the external switching output.

● To openthe controller turnthe 4 Phillipsscrews (cf. 10-9)

to the left by 90° and remove cover of housing. Remove

the flat ribbon cable plug to the display board from

socket (3) and set aside the cover of the controller to

avoid damaging it.

● Remove the plug (4) to the mains connection from

socket (5), route themains cable (cable cross-section 3 x

0.75 to 1.5), e.g. along the primary return and a free PG

gland (cf. 10 no. 10), into the station. Attach phase, zero

conductor,and potential ground to plug(4) and then in

sert this plug into socket (5).

●

If needed, connect the circulation pump with plug (6) in

the same way and plug into socket (7) (required cable

cross-section: 3 x 0.75 to 1.5).

●

A fourth temperature sensor (type KTY, cf. accessories)

can be connected via plug (8) and socket (9).

●

A RS 232 interface cable available as an accessory can

be connected to plug (12) (socket (13)). It is also possi

ble tolog all measured values, the currentcontroller sta

tus, and thecurrent pump output. This requires connect

ing the 9-pin D-SUB plug of the data cable to the serial

RS 232interface of a computer.Possible logging utilities

are a terminal program such as included with Windows

95, 2000, or XP (All Programs -> Accessories). Use these

transfer settings: RS 232 Port = COM1/COM2, Emula

tion = ANSI, Transfer rate = 19200 bit/s, Data bits = 8,

Stop bits = 1, Parity = None, Protocol = No protocol

(XON/XOFF, RTS/CTS).

●

The additional external switching output of the

RATIOfresh freshwater station onplug (14) socket (15)is

intended for the activation of the aux. boiler heating for

the disinfection operation. Please note that the current

applied to this potential-free switching contact may not

exceed a current intensity of max. 0.5 A. If a boiler de

mand is triggered, the controller closes contact 11-12

2

-

-

3

4

-

5

5

-

-

-

Figure 8 Close housing

1 Housing cover; 2 Snap-in groove; 3 Bottom section of housing ;

4 Snap-in plug; 5 Snap-in socket.

-

-

4

1

EN-RATIOfresh-250-400_TI-MA-0809-11214900 11

Page 12

at rest

11 12 13

activated

11 12 13

Hot-/cold water sensors

Hot water sensor (blue)

Mass (brown)

Circulation / cold water

sensor (blue)

Primary circuit sensors

Buffer cyl. sensor (blue)

Mass (brown)

Primary flow sensor (blue)

Low voltage area

14

12 1311

18

1

2

8

3

4

15

19

9

230 V

7

21

16

17

6

Optional circulation pump

Grounding (yellow/green)

PE

N

Zero (blue)

P2

L

Phase (black or brown)

20

Primary pump cable

Grounding (yellow/green)

PE

Zero (blue)

N

P1

L

Phase (black or brown)

Single jet meter

Mass (brown

Impulse (green)

not used

not used

10

11

9

10

+

13

Optional data cable

Plus 5V (yellow)

TxData (white)

RxData (green)

Mass (brown)

12

+

RT

22

+5V

+15V

5

4

Mains connection

Grounding (yellow/green)

PE

N

Zero (blue)

L

Phase (black or brown)

3

Figure 9 Controller connection

3 Socket flatdata cable; 4/5 Mains(plug/socket); 6/7Circulationpump (plug/socket); 8/9 Primarycircuit sensor (plug/socket); 10/11 Meter (plug/

socket); 12/13 Data cable (plug/socket); 14/15 External switching output for heating circuit control (plug/socket); 16 Micro-fuse, 250V/T6,3 A;

17 Micro-fuse, 250V/T400 mA; 18/19 Secondary sensor hot/cold water (plug/socket); 20/21 Primary pump (plug/socket).

12 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 13

4. Controller Operation

4.1 Controller Displays (fig. 10)

Thecontroller of theRATIOfreshfreshwaterstation features

a permanently backlitLCD display (5)with2 lines, LCD- Dis

play (5),4 LEDs depicting information about the operating

status of the station (1) to (4) and 3 control buttons (6), (7),

and (8). Open thecover of thecontroller by unscrewing the

four Phillips screws (9)!

IMPORTANT

Only open the controller housing cover when unit is deenergized! Only qualified technical personnel!

A steady green LED (1) is based on the output of thepri

●

mary circuit pump (max. output), with longer green

phases (medium output), or with shorter green phases

(low output).

LED (2) indicates the operating status of the circulation

●

pump (if connected) in the same manner.

A steady green LED (3) indicates that the external

●

switching output to activate the auxiliary heating (only

disinfection function) is closed.

A steady red LED (4) indicates that the disinfection tem

●

perature was less than required during the disinfection

time or that the primary circuit temperature fell below

the required temperature level.

● Use keys < (6) and > (8) to browse within the info level

and depict all currenttemperatures and pumpoutputs.

10

1

-

2

3

4

5

-

Wagner& Co

8

7

6

9

-

4.2 Controller Settings (fig. 10)

● Use key ■ (7) to switch from the info level to the menu

level.

● Use keys < and > to select the desired setting menu.

● Press key ■ to switch to the value level where the set

nominal values are listed in square brackets.

●

Select the desired menu item with the < and > keys and

release for changewiththe ■ key:the square keys are no

longer depicted.

●

Use the < and > keys to set the new nominal value and

press the ■ key to save.

●

Exit themenu level with the menuitem “END …“ and se

lect with the < and > keys and press the ■ key. This re

turns you to the next higher level.

Info Level

Menu level

Value level

-

-

Setting level

Temp. Warmwasser

Temp. hot water

Ist: 47°C

Actual: 46°C

Temp. Warmwasser

Settings:

Ist: 47°C

HOT WATER

Pump 1 mode

[AUTO]

previous

Temp. hot water

Nominal: [45]°C

Temp. Warmwasser

Temp. hot water

Ist: 47°C

Nominal: [45]°C

Settings:

End ...

End ...

post

Temp. hot water

Nominal: [50]°C

Temp. Warmwasser

Temp. hot water

Ist: 47°C

Nominal: [50]°C

Figure 10 Controller display and controller configuration

1 LED, primary circuitpump; 2 LED,circulation pump; 3 LED,Aux.heat

ing activation; 4 LED, temperature; 5 LCD display; 6 Left key; 7 Center

key; 8 Right key; 9 Phillips screws.

EN-RATIOfresh-250-400_TI-MA-0809-11214900 13

-

Page 14

4.3 Controller Setting Tables

Table 5 Info Level

(use the < and > keys to select the desired display, use the

Menu Description Range

TEMP. HOT WATER

Actual: ## °C

TEMP. CIRCULATION

Actual: ## °C

TEMP. VESSEL

Actual: ## °C

PRIMARY FLOW

Actual: ## °C

P 1 – HOT WATER

Output: ### %

P 2 – CIRCULATION

Output: ### %

TAPPING/AREA

###%/##

MONDAY

##:##:##

Temperature at hot water connection of station. While water is being

withdrawn, the hot water temperature is displayed, otherwise the standby

temperature.

Circulation return temperature (with active circulation function or cold water

temperature [without circulation system])

Derivative temperature in aux. heating section of the buffer cylinder. The

RATIOfresh controller corrects the hot water control function based on this

measured value.

Temperature at primary flow connection of the unit. While water is drawn, the

flow temperature is displayed, otherwise the stand-by temperature is shown.

Output of primary circulation pump in % 0 to 100 %

Output of circulation pump in % 0 to 100 %

Tapped volume in % of the set max. tapping volume. The range number

indicates the tapping slot reached when withdrawing water [01 – 10], see also

-> max.tap volume.

Day of the week and current time, in hours:minutes:seconds

key to switch to the menu level)

-20 to 120 °C

-20 to 120 °C

-20 to 120 °C

-20 to 120 °C

0to100%

Monday – Sunday,

00:00 to 24:00

Table 6 Menu Level

(use the < and > keys to select the desired menu and confirm with the

Menu Description

SETTINGS:

HOT WATER

SETTINGS:

CIRCULATION

SETTINGS:

DISINFECTION

SETTINGS:

TIME

SETTINGS:

MAINTENANCE

SETTINGS:

MANUAL FUNCTION

SETTINGS:

LANGUAGE

SETTINGS:

DEFAULTS

END

key)

Settings for the primary circuit pump, nominal hot water

temperature, and standby temperature, details in Table 7

Settings for the circuit pump operating mode, determining the time

frame for the circulation operating, circulation return temperatures,

details in Table 8

Settings for the thermal disinfection, time, duration, temperatures,

details in Table 9

Setting of day of the week and time, details in Table 10

This menu serves to change control parameters with special

applications and requires input of a code to prevent accidentally

changing these parameters (code available upon request), details

in Table 11

This menu is used for maintenance tasks directly affecting the

operating mode of the primary circuit pump and the circulation

pump, details in Table 12

Presetting the desired language for all displays, details in Table 13

Activate this menu with the ■ key and select “YES” with the < or >

keys to restore all values of all menu items to the factory settings

indicated in Tables 7 to 13 (factory settings). Important! All

customized settings are deleted and replaced with the default

settings! Select “END” to return to the menu level.

Select this menu item with the < and > keys and press the ■ key to

return to the info level.

14 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 15

Table 7 Value Level – HOT WATER SETTINGS

(use the < and > keys to select the desired menu item, use the

with the

key)

key to switch to the setting level, use < and > to change values, save

Designation Description Range Base value Your value

PUMP 1 – MODE

[AUTO]

P 1 MIN CAPACITY

[010] %

TEMP. HOT WATER

Nominal: [45] °C

TEMP.

CIRCULATION

Nominal: [45] °C

Software can be used to set the operating mode of the primary circuit

pump and is used for manual operation of the pump.

The min. output indicates the pump capacity used to control the hot

water in standby and circulation. This value cannot be less than 10%

because the pump bearings no longer have a sufficient amount of water

available for use with a value below 10 %.

Setting the desired nominal hot water temperature 25-70 °C 50 °C

Setting the desired circulation flow temperature concerning the

temperature measured as the hot water temperature sensor

OFF

ON

AUTO

AUTO

10–70% 10%

25-70 °C 45 °C

This is the temperature maintained by the system if no water is

withdrawn and the circulation function is not active.

TEMP. STANDBY

Nominal: [40] °C

The lowest set value of 10 °C ensures protection from frost for the

RATIOfresh freshwater station.

The current buffer cylinder temperature must be higher than the

10-70 °C 40 °C

nominal standby temperature by at least5Korthehold function is

deactivated.

Setting the tap volume max. occurring in this system on a regular basis.

For example, if you use a shower with 10 l/min and two water faucets

each with 5 l/min, the max. tapping volume to be expected on a regular

MAX. USAGE

Nominal: [20] l/min

basis amounts to approx. 20 l/min. Set [20] l/min as the max. tap

volume. The selected tapping volume range (here: 0 l/min to 20 l/min)

is divided by the control into 10 time slots and an internal control value

is adjusted for each time window during the adaptation process.

20 to

80 l/min

20 l/min

Selecting an unfavorable max. tap volume value can thus adversely

affect the control performance. The actual max. output of the station is

not reduced by this setting.

END Use the < and > keys to select and then confirm returning to the menu level with the ■ key.

Table 8 Value Level – SETTINGS: CIRCULATION

Designation Description Range Base value Your value

Setting the mode for the hot water circulation. The “continuous” mode

controls the circulation continuously and adjusts circulation to the

specified temperature difference between hot water outlet and

circulation return.

The “time” mode starts the control of the circulation pump as soon as

MODE

[time]

the withdrawal of water is detected (brief opening of a tapping point

suffices). The control ends if the “post-event time” (see below) has

expired after the hot water has been withdrawn.

continuous

time

continuous

Programming the time slots makes it possible to combine both control

modes: When selecting “time” and programming the time slots, the

circulation control functions outside of the time window according to

the detection of the withdrawal of water and within the time window

according to the temperature difference.

PUMP 2 – MODE

[AUTO]

P2 – MIN

CAPACITY

[010] %

FOLLOW-UP TIME

[010] min

Software can be used to set the operating mode of the circulation

pump and is used for the manual operation of the pump.

This setting indicates the min. pump capacity used to control the

circulation. The value must be adjusted depending on used pump type

and check valve.

The follow-up time is only adjustable if the “time” circulation mode is

selected. Set the time in minutes for which the circulation time is to run

after the end of a tapping.

OFF

ON

AUTO

AUTO

10–70% 10%

0 – 255 min 10

EN-RATIOfresh-250-400_TI-MA-0809-11214900 15

Page 16

Table 8 Value Level – SETTINGS: CIRCULATION

Designation Description Range Base value Your value

The time slots 1 to 4 are depicted in the menu only if the circulation mode “time” has been selected.

TIMESLOT

WEEKDAY

slots 1-4

TIMESLOT

WEEKEND

slots 1-4

TIMESLOT 1 (2,3,4)

Start:

[00:00] Time

TIMESLOT 1 (2,3,4)

Stop:

[00:00] Time

TARGET GAP

Nominal: [10] K

MAX.

TEMPERATURE

Nominal: [40] °C

Sub-menu for setting the circulation times on weekdays (Monday

to Friday)

Sub-menu for setting the circulation stimes on weekends (Saturday

and Sunday)

First switching on point for the circulation pump in “time” mode. Press

the ■ key to release the time for changes. Use < and > to set the hours

first and then use ■ to switch to the minute input and change the

minutes with < and > and then use ■ to return to the time window level.

First switching off point for the circulation pump in “time” mode. Follow

the procedure already described.

The nominal difference indicates the temperature difference in K, which

is to be maintained between hot water outlet and circulation return.

This adjustable value indicates the circulation return temperature in °C.

If this value is exceeded, the circulation pump switches off.

00:0024:00

00:0024:00

00:00

00:00

5–25K 10K

5–70°C 40°C

END Select this menu item with the < and > keys and press the ■ key to return to the menu level.

Table 9 Value Level – DISINFECTION SETTINGS

Designation Description Range Base value Your value

The disinfection can be displayed and activated only when the cylinder temperature sensor is connected. Based on the current measured

value, the demand for aux. heating is carried out via the external potential-free output.

Risk of scalding during the disinfection cycle!

Select operating mode for the disinfection of the hot water system.

MODE

Nominal: [OFF]

When in automatic mode (AUTO), the hot water and circulation network

are thermally disinfected at the selected time. Select a time outside of

the typical tapping times to reduce the risk of scalding!

With the operating mode ON, the disinfection is activated continuously

AUTO

ON

OFF

OFF

(e.g. for testing the function), with OFF is it completely deactivated.

STARTING TIME

[23:00]

STARTING DAY

[Monday]

SYSTEM TEMP

Nominal: [65] °C

DURATION

[020] min

Enter the time when disinfection is to start.

Setting the week program. Disinfection can also be started on a

predefined day (Mon-Sun) or every day.

The system regulates the circulation pump so that the set system

temperature is reached in the circulation return. The hot water temp. is

then adjusted to a temperature that is 50 % higher than the hysteresis of

the aux. heating.

Disinfection duration in minutes. This is the duration for which the

system temperature is maintained in the circulation return. The LED

diode (9-4) lights up red if the system duration falls below this value

during this time.

00:00 –

24:00

Mon to Sun,

daily

23:00

Sun

55–80°C 65°C

0 – 60 min 20 min

Aux. heating hysteresis. The external (potential-free) switching output of

the controller is closed as soon as the temperature in the aux. heating

section of the buffer drops below the sum of disinfection temp. and

TEMP. RISE

[10] K

hysteresis.

The boiler serving for the aux. heating must be connected in a way that

it starts the boiler charge function when the potential-free contact is

5–15K 10K

closed. Since the max. temperature of the boiler is not monitored, the

boiler temperature limitation must be set in a way as to prevent excess

temperatures in the system.

END Select this menu item with the < and > keys and press the ■ key to return to the menu level.

16 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 17

Table 10 Value Level – SETTINGS: TIME

Designation Description Range Base value Your value

WEEKDAY

[Monday]

TIME

[00:00]

Make sure the day of the week and the time are set correctly especially

when using the circulation and disinfection function.

Make sure the day of the week and the time are set correctly especially

when using the circulation and disinfection function.

Monday to

Sunday

00:00 –

24:00

-

-

END Select this menu item with the < and > keys and press the ■ key to return to the menu level.

Table 11 Value Level – SETTINGS: SERVICE

Designation Description Range Base value Your value

CODE NUMBER

800174

MON-005

RS232-INTERVAL

[003] s

This menu serves to change control parameters with special

applications and requires input of a code to prevent accidentally

changing these parameters. The code is available upon request. Use

0 – 255

the < and > keys to set the correct code.

Setting the output interval of the serial interface. 1 – 255 s 3 s

Compensation factor to affect the sensitivity of the hot water control in

PRIMARY FACTOR

[20]

dependency of the buffer cylinder temperature. If the compensation

factor is set to 0, compensation is not active and that also applies to

when neither primary flow sensor nor buffer cylinder sensor are

0 – 240 20

connected.

Kp CIRCULATION

[05] K

IMPULSE/LITRE

[35 ]

Kp VOL

[05] K

RATIOfresh type

[250-400]

Boost factor of pump in relation to the determined temperature

difference hot water-circulation return

1–10K 5K

Impulse value of the volume flow sensor 0 – 100 35

Boost factor of pump in relation to drawn water volume. 1 - 50 K 5 K

Controlling variation - this selection resets all values to factory setting.

250/400/

800

250/400

Start values for calculation of pump power. For all 10 tapping slots start

values are set. They are the base of calculating the required pump

force. The actual temperatures and tapping volumes are incorporated

ADAPTATION

VALUES

in the calculation. The individual values can be examined and changed

by selecting the respective sub-menus. If not all slots are reached

during controlled tapping while commissioning the system (chap. 5.6),

the adaptation values can be set directly. The power of the pump

continuously increases over the ten tapping slots. Each slot must have a

higher value than the previous one.

Adaption value of the first tapping slot. On the left the current hot water

temperature is shown. In the centre you can see the tapping slot

currently in use. On the right, the momentary adaptation value can be

ADAPT. VALUE 1

60 °C 01 [08]

seen. In order to make an adjustment, the adaptation value (display:

top) related to the current tapping slot (display: centre) should be

selected. Increasing this value will also increase the initial pump power

5–90 8

of the slot. Setting the value to high results in risk of scalding, since the

controller only starts with the adaptation after 10 s and then reduces the

pump power until the set water temperature is reached.

ADAPT. VALUE 2

60 °C 02 [15]

ADAPT. VALUE 10

60 °C 10 [71]

PUMP INTERVAL

[200] ms

Adaptation value of the second tapping slot 5 – 90 15

Adaptation value of the tenth tapping slot 5 – 90 71

200 – 600

ms

200 ms

END Select this menu item with the < and > keys and press the ■ key to return to the menu level.

EN-RATIOfresh-250-400_TI-MA-0809-11214900 17

Page 18

Table 12 Value Level – SETTINGS: MANUAL OPERATION

Designation Description Range Base value Your value

P1 – HOT WATER

[AUTO]

P2 – CIRCULATION

[AUTO]

BOILER REQUEST

[AUTO]

END Select this menu item with the < and > keys and press the ■ key to return to the menu level.

Table 13 Value Level – SETTINGS: LANGUAGE

Designation Description Range Base value Your value

LANGUAGE

[English]

END Select this menu item with the < and > keys and press the ■ key to return to the menu level.

Software can be used to set the operating mode of the primary circuit

pump and is used for the manual operation of the pump.

Software can be used to set the operating mode of the circulation

pump and is used for the manual operation of the pump.

Software can be used to set the operating mode of the potential-free

relay and is used for manual operation.

All menu items and displays are depicted in the selected language.

OFF

ON

AUTO

OFF

ON

AUTO

OFF

ON

AUTO

German,

French,

English,

Italian,

Spanish

AUTO

AUTO

AUTO

German

18 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 19

5. Initial Startup

2

5.1 Checking Installation

Check especially the following three points:

The correct connection of the pipes based on the con

●

nection diagrams in fig. 6 and fig. 7 as well as the de

scribed assembly steps.

The correct placement of the temperature sensor T

●

buffer

within the aux.heating section of the buffer cylinder. The

controller uses this sensor to detect the available tem

perature for the functions “circulation” and “standby”.

Temperaturesensor T

also serves toactivate the aux.

buffer

heating boiler during the thermal disinfection process.

If thedisinfection function isto beactivated,the external

●

switching output of the RATIOfresh freshwater station

must be connected with the external switching input of

the aux. heating boiler. In thiscase, the boileris fired and

the storage charge pump starts when the RATIOfresh

issues a boiler request.

5.2 Filling the Primary Circuit (fig. 11)

Now slowly fill the buffer cylinder and the primary circuit.

This requires inserting the mains plug and switching the

primary circuit pumpto the operation mode“Constant” us

ing the “Manual Mode” menu.Open check valve (15)at the

ball cock in the primary return (see fig.11 enlarged section

for the correct position).Vent the primary circuit during the

filling process.

5

-

6

14

-

3

4

-

12

10

11

-

16

5.3 Configuring the Controller (fig. 10)

Now configure the controller for the specific on-site conditions. fig. 10 provides an overview over the menu structure

and explains the use of the control keys. Enter the corresponding values into the setting menus in the following

order: “HOT WATER”, “CIRCULATION”, “DISINFECTION”,

“SERVICE”, “LANGUAGE”, and “TIME”. Tables 7 to 13 pro

vide assistance with selecting the respective values. To

finish, enter the individual configuration into the “Your

Value” column.

5.4 Selecting Pump Level (fig. 11)

The RATIOfresh freshwater station pump has three power

levels (maximum, medium, and minimum). The setting key

(16) is locatedon the upperside of thepump switching box.

Select the matching level for the chosen max. tapping vol

ume based on Table 14. The table values were calculated

based on the assumption that the potable water flows in

with a cold water temperature of 10 °C and is heated by the

RATIOfresh station to a nominal temperature of 45 °C or

60 °C (incl. pressure loss of 0.7 m corrugated tube DN 16

between station and buffer and screw connections):

●

Select the volume flow from column 1, which is the max.

volume you wish to withdraw from the hot water net

work.

●

The pressure loss listed in column 2 occurs additionally

in your hot waternetworkwith the indicated tapping rate

due to the station.

8

15

15

90°

9

Open

Z

A

-

Ready

-

Figure 11 Heat exchanger disassembly

2 1" swivel nut; 3 Heat exchanger; 4 1" swivel nut; 5 Shut-off valve;

-

6 1" swivel nut; 7 Ball valve; 8 Circulation pump; 9 1¼" swivel nut;

10 1" swivel nut; 11 1" swivel nut ; 12 Size 36 wrench; 14 Size 10

wrench; 15 Check valve; 16 Adjustment pump speed.

for operation

7

Z

A

EN-RATIOfresh-250-400_TI-MA-0809-11214900 19

Page 20

Hot water with the temperature indicated in column 3

●

must be available at minimum in the auxiliary heating

section of the buffer cylinder in order to reach the de

sired flow temperature withthe indicated maximumtap

ping volume flow. Select from thelisted auxiliary heating

temperatures.

The volume flowindicated in column 4must be pumped

●

through the heat exchanger in the primary circuit in or

der to reach the nominal hot water temperature. The

heating water is cooled intheheat exchanger to the tem

perature listed in column 5 and then supplied to the

lower buffer cylinder section.

Manually set the pump level (max – med – min) from

●

column 7.

Adjust the set value “wMax. tap volume” in menu “hot

●

water” (Tab. 7). Select the regularly occurring max. vol

ume flow. It should be significantly lower than the maxi

mum volume flow for the heating of which the pump is

set. Generally thetapping volume interval is dividedinto

10 time slots. For each time slot an internal control value

is adapted during the adaptation process. An unfavour

ably chosen maximum tapping value can therefore re

duce the controller performance. The actual maximum

performance of the unit is not affected by the settings.

3. After approx. 30 seconds, the controller starts to adjust

the hot water temperature to the desired temperature.

Select the menu item “Hot Water Temp.” in the info level

-

of the controller and wait until the set nominal tempera

-

ture has been reached.

4. Then select once more the menu item “Tapping/Area”

and now continue opening the hot water tap until the

display depicts “### % / 03”. Now the adjustment starts

-

already after 10 seconds.

Return to the “Hot Water Temp.” menu and wait until the

-

hot water temperature has reached the set nominal

value.

5. Continue with the remaining 7 tapping slots in this man

ner.

If during controlled withdrawl no sufficient volume flow is

available, the adaptation values of the tapping slots that

were not reached can also be set manually. For this pur

pose use the sub-menu "adaptation values" (Tab. 11). The

required service code is available upon request.

At the end of thecontrolled tapping, the controllerdelivers

the desired temperature with small as well as with large

volumes of water being withdrawn.

-

6. Notes for Operators

-

-

-

5.5 Setting the Auxiliary Heating

Temperature at the Heating Boiler

The value you determine for the aux. heating temperature

of the heating boiler corresponds with the standby temperature in the buffer storage tank or the required temperature in the primary flow of the RATIOfresh station.

This nominal temperaturefor the primary flow is listed in table 14 and depends on the selected max. tapping volume

and pump level. Several combinations comprised of “Primary Flow Temperature”, “Primary Return Temperature”,

and “Pump Power Level” are availableto you forthe individual weighting.

5.6 Perform Controlled Tapping

The RATIOfresh has an automatic adjustment function to

ensure the desired temperature is always available regard

less of the tapping volumes. A single-jet meter in the cold

water supply measures the volume and passes the value to

the controller in % of the “Max. Tap Volume”. The selected

tapping volume rangeis divided into 10 equaltapping time

slots. When different volumes are withdrawn within the set

range, the controller “learns” to deliverthe desired temper

ature in each of the 10 tapping slots. The current tapping

volume range can be displayed in the info level of the con

troller in the menu item “Tapping/Area”.

To optimally adjust the hot water temperature to different

tapping volumes, a controlled tapping should be per

formed when initially starting up the system. Please follow

these steps and adhere to the described sequence of

these steps:

1. First, select the menu item “Tapping/Area” in the info

level of the controller.

2. Open a hot water tap until the display depicts “### % /

02”.

After professionally trained and qualified service techni

cians performed the initial startup, your freshwater station

is triggered automatically to heat your potable water when

hot water is withdrawn from the system. No other control

steps are necessary if the system is operated as intended.

Please note the following points:

Nominal Hot Water Temperature

The nominal temperature of the hotwater can bepreset on

your freshwater station. Please follow the recommended

steps of this manual.

Energy-Saving Operation

The pumplevel should be set as low as possible; the same

applies to the nominal aux. temperature in the buffer cir

cuit. Consult table 14.

Malfunctions and Defects

-

Please report anymalfunctions and defects immediately to

a trained and qualified service technician!

Maintenance and Care

As with anyother technical equipment,yourfreshwatersta

tion must be serviced and maintained regularly by trained

-

and qualified technicians. If you have very “hard water” the

heat exchanger must be checked for lime buildup and

-

cleaned as needed. Consult Chapter “Maintenance and

Care” for additional information.

-

Placing System in/out off Operation / Vacation

While you are on vacationorduring times when hotwater is

not needed, we recommend de-energizing the freshwater

station by unplugging it from the mains power network to

avoid any unnecessary electricity consumption.

-

-

-

20 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 21

After a Power Outage

The current time and all other settings are saved even dur

ing a poweroutage.However,you should check all settings

and the time after power is restored to ensure the disinfec

tion cycle is not started accidentally.

Table 14 PRIMARY TEMPERATURE AND PUMP LEVEL SETTINGS

1

Tapping volume

flow (= HW) in l/

min

For RATIOfresh 250 at nominal hot water temperature of 45 °C

10 65

15 140

25 370

For RATIOfresh 250 at nominal hot water temperature of 60 °C

10 65

15 140

25 370

For RATIOfresh 400 at nominal hot water temperature of 45 °C

15 82

25 204

40 490

For RATIOfresh 400 at nominal hot water temperature of 60 °C

15 82

25 204

40 490

2

Pressure loss in

secondary circuit

(=HW side)

in mbar

3

Required

temperature in

primary flow,

in °C

50 13.0 23 98 min

60 8.1 16 65 min

50 21.9 26 241 med

60 12.8 18 96 min

60 23.4 22 199 med

70 17.3 18 157 min

65 14.5 30 117 min

75 9.4 21 27 min

65 24.9 34 305 max

75 15.1 24 125 min

75 28.2 29 386 max

80 24 26 285 med

50 19.1 22 115 min

60 12.1 16 58 min

55 26.2 21 203 max

65 18.4 17 109 min

65 31.5 20 287 max

75 24.7 17 181 med

65 21.2 29 138 med

75 14 20 71 min

65 30.4 28 269 max

75 25.2 24 189 med

85 33.7 24 328 max

90 30.4 22 269 max

4

Required

primary volume

flow,

in l/min

Frost Protection

Make sure the heating system remains in operation in case

of frost and that all roomsare sufficiently heatedto prevent

frost.

-

5

Return

temperature in

primary circuit

6

Pressure loss in

primary circuit

7

Output level of

the primary

circuit pump.

EN-RATIOfresh-250-400_TI-MA-0809-11214900 21

Page 22

7. Maintenance and Care

The system should be checked annually:

Check all screw connections and soldered points for

●

leaks.

In case of potable water with an increased carbonate

●

content, the heat exchanger should be checked regu

larly for lime buildup. The following changes are indica

tive of lime buildup: Return temperatures of the primary

circuit are significantly above those listedinTable 14.The

max. hot water volume flow that can be withdrawn has

been reduced.The set nominal hot water temperature is

no longer reached with frequent water withdrawals.

Decalcification of the Heat Exchanger (fig. 6, 11, 12)

If flushing spigots are installed in the cold and hot water

lines, the heat exchanger canbe decalcified by flushing the

system (fig. 11). If flushing spigots are not in place, the en

tire heat exchanger must be removed from the station (fig.

11. This requires the following:

De-energize the station!

●

Depressurize the potable water line by closing the shut-

●

off valves at the safety subassembly (fig. 6, no. 3) and in

the hot water network (fig. 6, no. 11). Empty the potable

water side of the heat exchanger using the drain spigot

(fig. 6, no. 9) installed in the cold water supply line.

Close shut-off valve (fig. 11, no. 5) in the primary circuit

●

flow and pump slider (fig. 11,no.7) to block primarycir

cuit (fig. 11, no. 2, 9).

● Empty heat exchanger (fig. 11, no. 3) onthe primary side

by loosening the 1" bolt (fig. 11, no. 6) at the primary

flow connection and (fig. 11, no. 10) at the primary return.

● To remove the heat exchanger, remove all four 1" swivel

nuts (fig. 11, no. 4, 6, 10, 11) using a size 36 wrench.

Place heat exchanger over night into a commercially

available decalcification solution or a 5 % vinegar solution followed by a thorough cleaning. Be careful when

handling decalcification and vinegar solutions!

●

To flush the heat exchanger (fig.12), pump the cleaning

fluid (fig. 12, no. 1) through the circuit‘s heat exchanger

(fig. 12, no. 13) andthe filling spigot (fig. 12, no. 10) with

a feed pump (fig. 12, no. 2) using the filling spigot (fig.

12, no. 9) and then neutralize it according to the instruc

tions of the manufacturer of the cleaning fluid.

Only use cleaningfluidsapproved for potable waterand

perform the neutralization according to theinstructions!

Be careful when handling any chemical solutions!

●

After reinstalling the heat exchanger or completing the

flushing process, open all shut-off valves and spigots,

apply voltage to the controller, and vent the primary cir

cuit according to Chapter 5 Initial Startup.

-

-

11

90°

10

90°

-

9

3

1

-

13

-

2

Figure 12 Heat exchanger decalcification

1 Cleaning fluid; 2 Feed pump; 3 Safety subassembly; 9 Filling spigot;

10 Filling spigot; 11 Ball valve; 13 Heat exchanger.

-

22 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 23

8. Troubleshooting

Table 15 Malfunction Cause Remedy

Hot water flow volume is

insufficient.

No hot water.

Water does not get hot.

Hot water temperature

is too low.

Hot water temperature

is too high.

Shut-off valve in cold water supply

partially closed.

Clogged cold water supply filter. Shut off the cold water supply, remove filter, clean filter.

Lime buildup on heat exchanger.

Shut-off valve in cold or hot water

network closed.

Power outage or potable water station

without power.

Fuses defective.

Primary circuit pump defective.

Air within the primary circuit prevents

sufficient flow through the heat

exchanger.

Flow through primary circuit

insufficient.

Single-jet meter does not detect when

water is withdrawn.

Incorrectly set nominal temperature. Change the nominal hot water temperature.

Aux. heating temperature set too low.

Incorrectly set power output level of

the primary circuit pump.

Controller not yet adapted. Carry out a controlled tapping (see chapter 5.6).

Air within the primary circuit prevents

sufficient flow through the heat

exchanger.

Flow through primary circuit

insufficient.

Incorrectly set nominal temperature. Change the nominal hot water temperature.

Primary circuit pump mode set

incorrectly.

Disinfection operating mode set

incorrectly (“On”).

Incorrectly set disinfection start time.

Controller not yet adapted. Carry out a controlled tapping (see chapter 5.6).

Incorrectly set power output level of

the primary circuit pump.

Storage tank temperature temporarily

increased significantly due to solar

charging.

Gravity circulation in primary circuit

(detectable only with brief tapping

events).

Primary circuit temperature sensor

attached at incorrect position.

Check all shut-off valves and spigots and open completely.

Check the heat exchanger for lime buildup and decalcify if

necessary (see chapter 7).

Check all shut-off valves and spigots and open completely.

Check whether the display of the potable water station is

illuminated.

Plug the power plug of the potable water station into the wall

socket.

Check fuses in controller of potable water station and replace if

necessary.

Check the function of the primary circuit pump (manual

operation).

Bleed the primary circuit (see chapter 5.2).

Check the entire primary circuit: Shut-off elements, power

supply, pump and controller settings.

Check the function of the single-jet meter (e.g. with acoustic

test of the pulse output using a multimeter).

Compare the set value with the recommendations in table 14

and correct as needed.

Compare the set value with the recommendations in table 14

and correct as needed.

Bleed the primary circuit (see chapter 5.2).

Check the entire primary circuit. Shut-off elements, power

supply, pump and controller settings.

Set the mode of the primary circuit pump to “Auto”.

Set the operating mode of the disinfection to “Auto”.

Change the disinfection start time. Select a time outside of the

typical tapping times (e.g. at night).

Compare the set value with the recommendations in table 14

and correct as needed.

The potable water station automatically adjusts this next time

water is withdrawn.

Check the setting of the gravity brake and possibly of the

hydraulics (e.g. in case of multiuse of the buffer cylinder

connections of the primary circuit).

Check the position of the storage cylinder temperature sensor

and correct if necessary (see chapter 3.6).

EN-RATIOfresh-250-400_TI-MA-0809-11214900 23

Page 24

Table 15 Malfunction Cause Remedy

Circulation pump defective. Check the function of the circulation pump (manual operation).

Shutoff elements closed. Check all shutoff valves and cocks and open completely.

Circulation system heating

is insufficient.

Air in circulation system. Bleed the circulation system.

Min. output of the circulation pump

too low to open the backflow

Increase the value of the min. output of the circulation pump.

preventer.

Defective single-lever mixer at tapping

point.

Check whether the fluctuation occurs only at one tapping point.

If needed, replace single-lever mixer at this tapping point.

Controller not yet adapted. Carry out a controlled tapping (see chapter 5.6).

Hot water temperature

fluctuates.

Incorrectly set power output level of

the primary circuit pump.

Malfunctioning circulation, reduced

volume flow, insufficient heat transfer,

controlling no longer possible.

Compare the set value with the recommendations in table 14

and correct as needed.

Check the entire circulation system: Shut-off elements, pump,

electrical connection, backflow preventer, and air in circulation

system.

Only without circulation system:

Very low tapping volume with very

high primary circuit temperature falls

Reduce the primary circuit temperature.

below the controller limit range.

Incorrectly set circulation. Check the circulation settings.

It takes a long time until hot

water emerges from the

tapping point.

Circulation and standby function

deactivated due to a primary circuit

temperature that is too low.

Check the control/setting of the aux. heating. Increase the

primary circuit temperature.

Circulation pump defective. Check the function of the circulation pump (manual operation).

Check the controller settings of the disinfection and restart

disinfection manually. The LED goes out if the disinfection cycle

runs successfully, in case of a power outage or disconnect from

the mains power supply, or if you set the disinfection operating

mode to “Off”. Increase the primary circuit temperature if

LED has a steady red light.

Disinfection temperature below

required value.

necessary.

Primary circuit temperature too low. Check the control/setting of the aux. heating.

Date/time are incorrect. Power supply outage. Reset date and time.

Display depicts a temperature

of 222 °C.

Temperature sensor defective.

Check the electrical connection of the respective temperature

sensor. If necessary, replace the temperature sensor.

24 EN-RATIOfresh-250-400_TI-MA-0809-11214900

Page 25

EN-RATIOfresh-250-400_TI-MA-0809-11214900 25

Page 26