1

Part 1: INSTALLATION INSTRUCTIONS

FOR THE BUTLER MULTI

(Please keep these Instructions for future Reference)

Important Message to the Owner

Please read fully the Operation & Maintenance Instructions with your Butler Multi BEFORE lighting your

first fire. Your insurance company may require notification of the installation. Please check.

When a Wet Back is fitted it must be connected to the water supply or damage will result.

Such damage is not covered by Warranty. Tempering Valves should be installed to the system for safety.

Tempering Valves may be a Permit Requirement. Check with your Building Inspector or Local Council.

BIA: As from 22 April 2003 Automatic Smoke Detectors/Alarms will be mandatory in all new homes and

when solid fuel heating appliances are installed. Permits will not be signed off if alarms are not fitted.

Important Message to the Installer

The Butler Multi has been tested to and complies with AS/NZS 2918:2001- Domestic Solid Fuel

Burning Appliances

The Butler Multi must be installed in accordance with these installation instructions to comply with AS/NZ

2918-2001-Domestic Solid Fuel burning appliances.

Installer’s Responsibilities

Installation of the Butler Multi must be in accordance with these instructions.

Any variation from these installation instructions or any doubts about them must be checked against

requirements of the AS/NZS 2918-2001.The installation must be carried out by a suitably qualified installer.

We recommend using an NZHHA Accredited Technician.

WARNING: THE APPLIANCE AND FLUE SYSTEM SHALL BE INSTALLED IN

ACCORDANCE WITH AS/NZS 2918: 2001 AND THE APPROPRIATE REQUIREMENTS OF

THE RELEVENT BUILDING CODE OR CODES.

THE APPLIANCE AND FLUE SYSTEM SHOULD NOT BE MODIFIED IN ANY WAY

WITHOUT THE WRITTEN APPROVAL OF THE MANUFACTURER.

WARNING: DO NOT CONNECT WET BACKS TO AN UNVENTED HOT WATER SYSTEM

INSTALL IN ACCORDANCE WITH AS 3500.4.1 OR NZS 4603 AND THE APPROPRIATE

REQUIREMENTS OF THE RELEVENT BUILDING CODE OR CODES

CAUTION: MIXING OF APPLIANCE OR FLUE SYSTEM COMPONENTS FROM DIFFERENT SOURCES OR

MODIFYING THE DIMENSIONAL SPECIFICATION OF COMPONENTS MAY RESULT IN HAZARDOUS

CONDITIONS. WHERE SUCH ACTION IS CONSIDERED, THE MANUFACTURER SHOULD BE

CONSULTED IN THE FIRST INSTANCE.

CAUTION: CRACKED AND BROKEN COMPONENTS, e.g. GLASS PANELS OR FIRE BRICKS MAY

RENDER THE INSTALLATION UNSAFE.

Flue System

Must be manufactured in accordance with AS/NZ 2918-2001 and tested to Appendix F. See installation

instruction section on page 5.

PLEASE LEAVE THESE INSTRUCTIONS WITH THE OWNER WHEN THE INSTALLATION IS COMPLETED

2

PRELIMINARY INSTALLATION PROCEDURES

FOR THE BUTLER MULTI

To get full benefit from the Butler Multi it is important that it is installed correctly, both for efficiency and

safety sake. The following points should be noted:

1. The characteristics of the Butler Multi will determine its position within the home. As a general rule

an interior wall installation suits flue requirements better than against an exterior wall.

2. Check for flue obstructions above the ceiling. (e.g. header tanks, electrical mains or load bearing roof

supports).

3. The minimum vertical flue height for satisfactory operation is 4.2metres above the top of the

Butler Multi Flue Flange. The performance of the Butler Multi depends more on the flue than on any

other single component. It is the draw on the flue that drives the stove.

4. Remember a permit is required from your Local Authority.

Floor Protector/Hearth Requirements

The MINIMUM requirement for the Butler Multi with a wet back fitted or as a DRY model is an

ASH HEARTH only.

The Floor Protector shall extend under the appliance and NOT Less than the width of the Appliance and shall

extend 300mm forward and 200mm each side of the Fuel Loading/Ash-Removal opening.

The Ash Hearth shall have an upper surface, including grouting, of durable, non-combustible material. All joints

in the surface must be sealed to protect and prevent ash or spilled embers reaching the floor. For concrete

floors trim any floor coverings to the same minimum hearth requirement.

NOTE: THE BUTLER MULTI MUST BE AFFIXED TO THE HEARTH AND FLOOR FOR SEISMIC RESTRAINT.

For Seismic Restraint use two holes in the base at the rear and screw through the hearth and into the floor.

NOTE: FOR DRY MODEL AND SPECIAL 2KW WET BACK MODEL PLEASE SEE SEPARATE DRY

INSTALLATION INSTRUCTION SHEET AS CLEARANCES ARE DIFFERENT.

Wet Back Fitting

The Butler Multi is fitted with a wet back unless a Dry Model is requested.( see separate specification sheet )

We recommend that you use the “Lion” Wet Back which has been designed and tested specifically for the

Butler Multi. In general, wet backs are factory fitted at the time of ordering.

However, a suitably qualified person can fit or change the wet back out in the field if this is required.

Water must always be present in the wet back.

The wet back MUST be connected by a Registered Plumber to an open vented system.

Tempering valves are required.

Please check the PH level of the water supply as wet backs can become fouled with lime which will void

the warranty.

NB Some coals are very corrosive and may shorten the life of the wet back – please check with the

supplier as this is NOT covered by warranty.

Please advise the householders NOT to boil the wet back as this will cause vibrations and will fatigue the wet

back, the pipes and the cylinder. This will NOT be covered by the warranty.

Baffle & Brick Assembly for Wet Back Model

Position the baffle on the ledge in the top, central chamber of the wet back, in the ceiling of the firebox.

The round rods on the baffle should face downwards. The baffle should then be pushed back so that there is

no gap at the rear. Position the bricks so that they tuck up under the edge of the wet back.

3

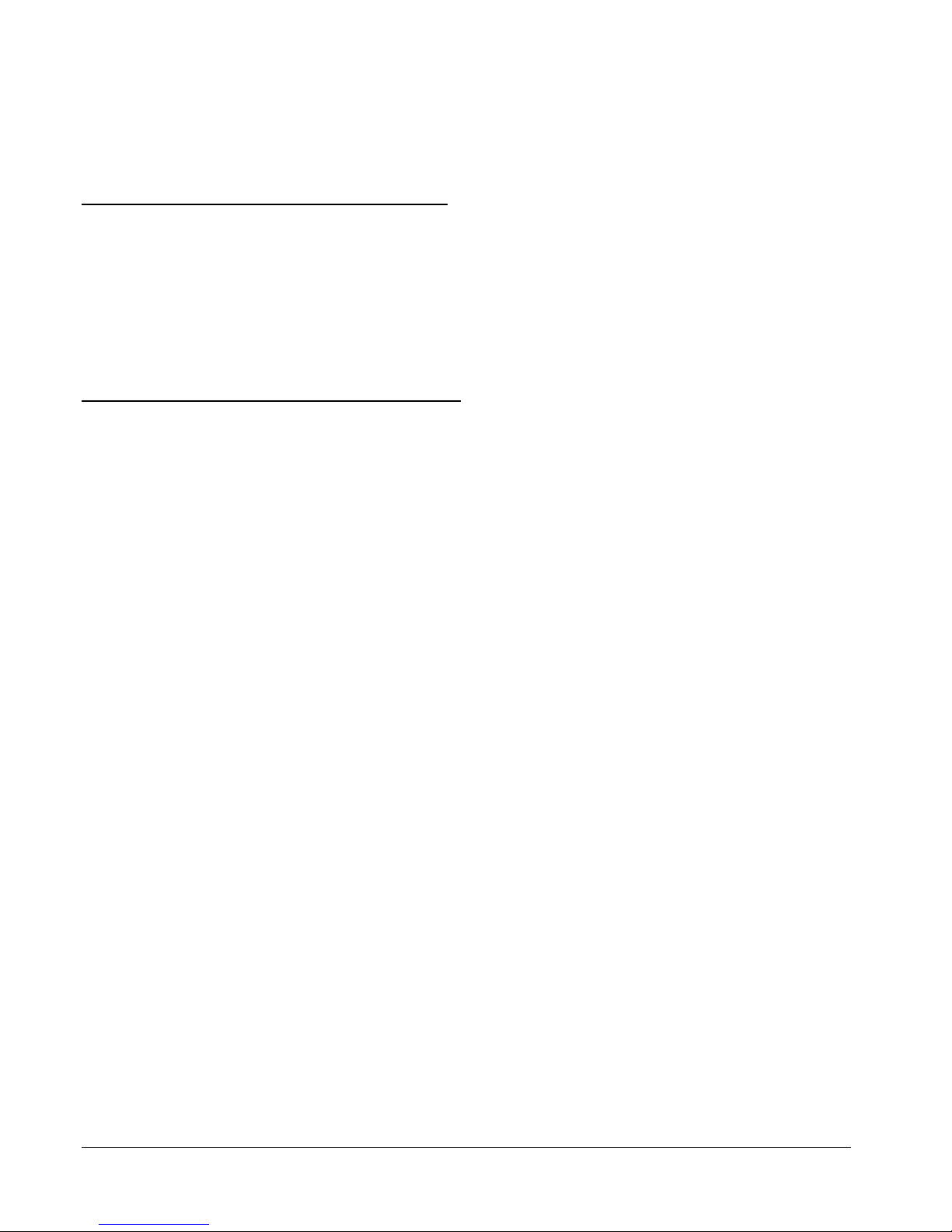

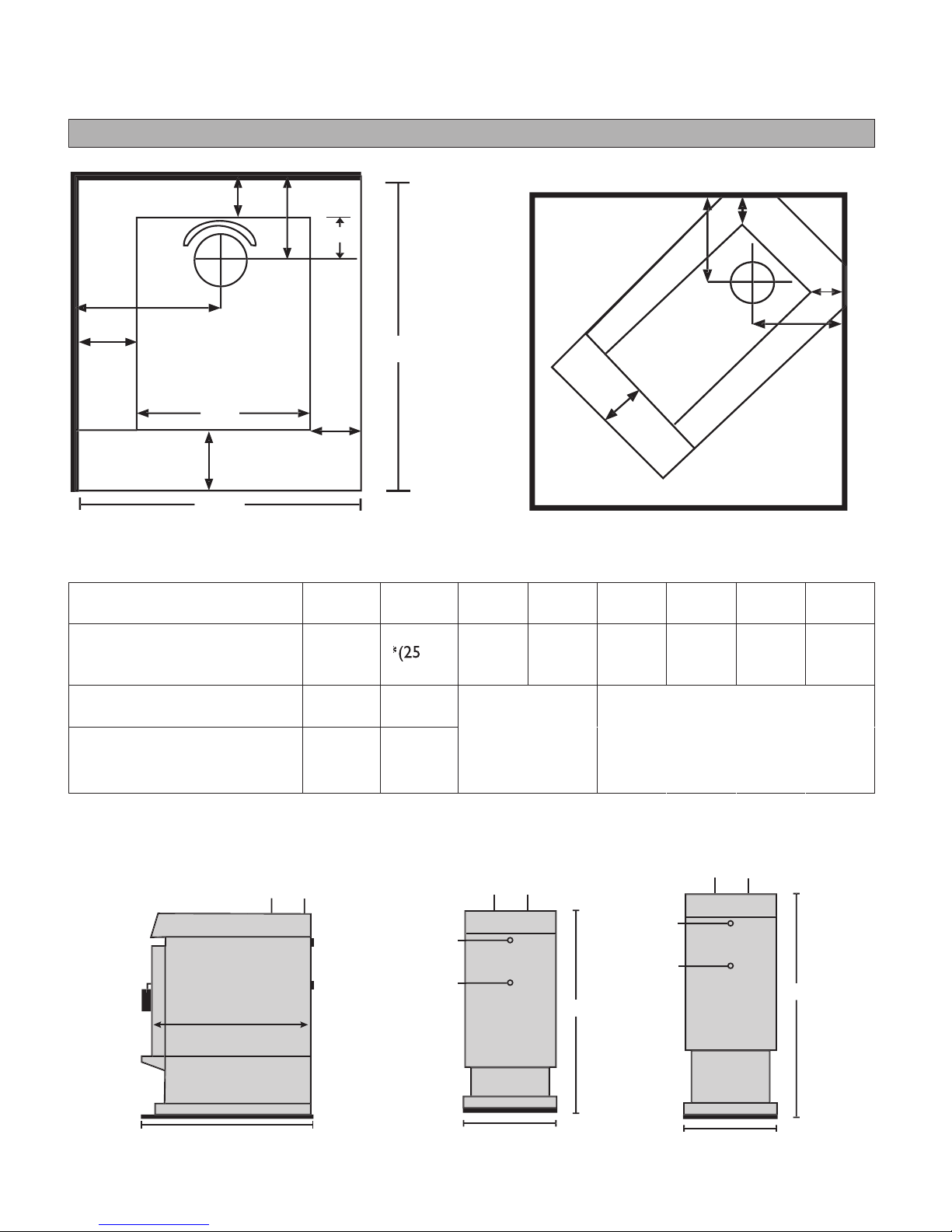

BUTLER MULTI WET 6KW

Fitted with a standard 6kw “Lion” Wet Back only

Wet Installation Clearances AS/NZ Standard 2918:2001

Estimated Heat Output 8kw (depending on fuel used) Estimated Hot Water Output 6kw

Minimum clearance to

Combustible Surfaces

A B C D E F G H

With double stainless steel

Flue shield to unprotected

mm)

wall

50mm 50mm 300mm 175mm 25mm 190mm 210mm 240mm

As above 12mm Eterpan LD

board spaced 25mm off wall

37mm 37mm

As above with sheet metal any

type 0.5mm or thicker spaced

25mm off the wall.

25mm 25mm

Ash Hearth Floor

Protection must

extend under the

stove and forward

300mm extending

200mm either side of

the door opening

Other screening materials are available and clearance factors can be calculated to the AS/NZS 2918:2001.

Please ask your retailer or contact Wagener Stoves if you need further advice.

150

150

320

660mm

585m

770mm770mm

25mm

25mm25mm

wetbackwetback

pipespipes

wetback

pipes

150

320

800mm

725 mm

910mm910mm

E

H

E

H

C

670

D

B

G

A

C

Floor Protector

Ash

Hearth only

320

TOP

TOP

F

140

*

* 1.

One side wall clearance can be reduced

to 25mm by rotating the fl ue shield 45 deg

2.

Bench height side wall only (not above top

of heater) clearance 25mm.

*(185mm)

870

50

50

300

600

520

2017

4

FLUE INSTALLATION 3/05

The Butler Multi uses a 150mm diameter flue.

It is imperative that the connection between the flue

and the flue spigot is sealed using a recommended

flue sealant. If an offset bend is required it should be as

steep as possible to enable ease of cleaning.

Extra flue height may be required to compensate for

lack

of draw. The performance of the Butler Multi

depends more on the flue than on any other single

component as it is the draw on the flue that drives the

Butler Multi. We recommend 4.

2metres of flue.

The top of the flue system should be at

least 1000mm above the roof or at least

600mm higher than any obstacle or ridge

within 3 metres of the flue.

A total minimum vertical flue height

ABOVE the Butler Multi of 4.

2 metres

is normally required for adequate draft.

Joints between sections of the flue pipes

are push fitted so that the upper section

enters the bottom section and

must be SEALED using a flue sealant.

Each section should be secured to prevent

Separation using 3 stainless steel self tapping

screws or pop rivets.

Only flue systems which comply with the

AS/NZS 2918-2001 should be used.

Please follow flue manufacturers instructions

on page 5

150mm Free Standing Woodfire Flue Kit Installation

Instructions

.

2017

5

150 MM FREE STANDING WOODFIRE FLUE KIT

INSTALLATION INSTRUCTIONS

(See illustration Page 4)

This flue kit has been manufactured in accordance with AS/NZS 2918:2001 and tested to appendix F.

To ensure safety this flue kit must be installed as outlined in these instructions. Heater and flue clearances

from combustible walls must be in accordance with heater manufacturer’s specifications and AS/NZS

2918:2001. Theses installation instructions are for tested appliances only.

1. Locate heater in its proposed position and mark a point on the ceiling that is directly above the centre

of the heater’s flue outlet. Check that the heater’s location allows the OUTER HEAT SHIELD to clear

all structural roof timbers.

2. Cut a 260mm square hole in the ceiling. Directly above cut a hole in the roof to accommodate OUTER

HEAT SHIELD.

3. Fit timber nogs around ceiling and roof holes. i.e. Nogs form a 260mm square aperture which allows

air to circulate freely over the OUTER HEAT SHIELD surface.

4. Position the OUTER HEAT SHIELD so that it is flush with the underneath of the ceiling and protrudes

through the roof the required height. (Refer to AS/NZS 2918/2001 if more details are required).

When calculating roof penetration height allow for an extra 500mm that can be achieved by using the

OUTER HEAT SHIELD SLIP EXTENSION.

a) If the flue is within 3 metres of the ridge, the OUTER HEAT SHIELD must protrude at least

600mm above the ridge of the roof.

b) If the distance from the ridge is more than 3 metres, the OUTER HEAT SHIELD must protrude

at least 1000mm above roof penetration.

Additional OUTER HEAT SHIELD and INNER SHIELD (BAFFLE) may have to be added to ensure the correct

roof penetration heights are obtained.

5. Fix an appropriate flashing around the OUTER HEAT SHIELD to seal onto the roofing material.

6. From the roof slide the INNER SHIELD into the OUTER HEAT SHIELD until it rests 12mm above

ceiling level.

7. Assemble FLUE PIPES together ensuring seams are in line. Secure each joint with 3 rivets or self-

tapping screws. FLUE PIPES must be assembled with crimped ends down. (towards heater)

8. Place CEILING PLATE over heater flue spigot, ensuring the folded edge upstands are facing the ceiling.

9. From the roof lower FLUE PIPE through OUTER HEAT SHIELD into position.

10. Before securing the OUTER HEAT SHIELD SLIP EXTENSION to the OUTER HEAT SHIELD with 3

rivets or self tapping screws, ensure the FLUE PIPE extends above the top of the OUTER HEAT

SHIELD SLIP EXTENSION 145mm. Adjust SLIP EXTENSION to obtain this measurement. If minimum

roof penetration heights described earlier can not be achieved add sufficient stainless steel FLUE PIPE.

11. Fit TOP FLUE SPACER BRACKET to the FLUE making sure the lugs fit snugly inside OUTER HEAT

SHIELD SLIP EXTENSION. Make sure TOP FLUE SPACER BRACKET fits hard down onto OUTER

HEAT SHIELD SLIP EXTENSION.

12. Fit CASING COVER over the FLUE PIPE and push down firmly onto TOP FLUE SPACER BRACKET.

Secure with a rivet or self-tapping screw.

13. Fit COWL but do not secure, as removal for flue cleaning will be necessary.

14. Fasten CEILING PLATE to ceiling using screws and spacers provided. Ensure an even air gap around

FLUE PIPE when fixing. Remove protective plastic from CEILING PLATE.

N.B. It is the responsibility of the installer to ensure that the installation of this flue kit complies

with AS/NZS 2918:2001, the appliance manufacturers specifications for flues and that relevant

Local Body requirements are adhered to.

6

Part 2: OPERATION & MAINTENANCE

INSTRUCTIONS FOR THE BUTLER MULTI 3/05

Message to the Owner

Thank you for purchasing the Butler Multi.

With care and common sense the Butler Multi will give you many years of trouble free service.

We recommend an annual safety check of flues, bricks, door seals, door catches, air controls and the like.

WARNINGS AND CAUTIONS

1. WARNING: ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN

WRITING BY THE TESTING AUTHORITY IS CONSIDERED AS BREACHING AS/NZS 4013.

2. WARNING: DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS TO START OR REKINDLE THE FIRE.

3. WARNING: DO NOT USE FLAMMABLE LIQUIDS OR AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHEN IT IS OPERATING.

4. WARNING: DO NOT STORE FUEL WITHIN HEATER INSTALLATION CLEARANCES.

5. WARNING: DO NOT OPERATE THIS APPLIANCE AS AN OPEN FIRE. IT IS NOT TESTED TO BE

USED IN THIS WAY AND WILL BE CONSIDERED AS BREACHING AS/NZS2918:2001.

6. WARNING: OPEN AIR CONTROLTO FULL AIR SUPPLY BEFORE OPENING FIRE DOOR.

7. CAUTION: THIS APPLIANCE SHOULD NOT BE OPERATED WITH A CRACKED GLASS.

8. CAUTION: THIS APPLIANCE SHOULD BE MAINTAINED AND OPERATED AT ALL TIMES IN

ACCORDANCE WITH THESE INSTRUCTIONS.

9. CAUTION: THE USE OF SOME TYPES OF PRESERVATIVE-TREATED WOOD AS A FUEL CAN BE

HAZARDOUS.

Further Cautions & Over Firing

Never use the Butler Multi with the door ajar or open. This will cause over firing and damage to

your stove & flue which will NOT be covered by warranty as well as being potentially dangerous.

SIGNS OF OVER FIRING: Flue turns red hot and stove “roars”.

POSSIBLE CAUSE OF OVER FIRING REMEDY

1. Excess flue length/ windy conditions Move Air Control to reduce or close air supply

2. Door Ajar Close door

3. Faulty door seal Replace faulty door seals

4. Full load of very dry, small wood Don’t load excess fuel

5. Dirty flue catches fire Close Air Supply. Call fire brigade if necessary.

Inspect & Clean Flue when cold.

The Butler Multi is HOT while in operation and contact may cause burns.

CREOSOTE OR SOOT FIRE: In the unlikely event of a soot or creosote fire occurring see Remedy 5 above.

7

OPERATING YOUR BUTLER MULTI 3/05

Fuels – Wood & Coal

1. Wood - Dry, seasoned wood should be used at all times and, as a general rule, the harder the wood the

longer it will burn.

Try to buy wood well in advance and store so that the air can circulate through the pile to assist drying.

Wet, unseasoned wood (under 12 months old) can cause creosote problems, especially if it is burned slowly.

If unseasoned fuel is used, special care should be taken to ensure that the fire is actually burning and not just

smouldering which will precipitate a creosote problem.

DO NOT burn driftwood or treated timber as they will damage your Butler Multi and flue and void your

warranty.

2. Coal – To burn coal you will need to start the fire with wood to establish a good base fire bed of hot

embers. Then add coal a little at a time allowing the coal to burn before adding more. Once the desired fuel

load has been added and is burning well adjust the air controls to achieve desired burn rate.

WARNING: Some coal types are very corrosive to the fire box, flue and wet back. Corrosion is not covered

by the warranty – please check with your coal supplier.

NOTE: The Heat output of the Butler Multi is controlled not only by the air controls but also by the type and

quality of fuel in the firebox.

First Burn for a New Appliance or Repainted Appliance

On INITIAL LIGHTING, the high temperature paint used on the Butler Multi will give off smoke and odour

for a short period. This is a temporary condition.

Open doors and windows to give adequate ventilation.

To condition the firebricks (ie remove moisture to prevent cracking) your first 2-3 fires must be small.)

Start Up

1. Slide the air control (black knob above the door) to select the HIGH position for full air supply.

Rotate the lower air control on the door to fully open.

2. Open the firebox door. Place crumpled newspaper on top of the firebox grate (if using firelighters

place firelighters under the newspaper). Stack kindling around it like an Indian Tepee and light the

newspaper (or firelighters), then close the firebox door. Once the kindling is well alight add slightly

larger pieces of wood until you have a good healthy fire. If burning coal see instructions above.

3. Refuel once the fire is established.

4. Adjust the air controls to the desired setting when fire is burning well.

5. It should not be necessary to fill the firebox to capacity. Smaller loads of wood or coal burned on half

air supply will produce more heat per kg of wood/coal. Flue length and outside wind may affect the

performance of the fire.

6. Over Firing will damage your stove & flue system and will void your warranty.

Please refer to page 6 - Signs of Over Firing, Causes and Remedies.

Stove Top Cooking

Establish a good fire and allow the Butler Multi to heat up. Never cook food directly on the top of the stove.

The Butler Multi is not a BBQ. Always use kettles, pots and appropriate cooking implements.

8

Slow Burning

Ensure that your Air Control is fully open and that you have a good base of hot embers. Add a full load of

larger pieces of hardwood or coal. Allow to burn for 10-20 minutes before adjusting the Air Controls to low

(almost closed position).

The Butler Multi will now burn away for long periods on low.

Reloading after a Slow Burn

At the end of a slow burn adjust the air controls to the high position for maximum air supply.

Rake the embers and re-establish the fire by adding a few small split logs and allow the firebox temperature to

build up before adding the balance of the fuel.

The addition of large quantities of cold fuel to a low fire will reduce the firebox temperature dramatically and

this may result in ‘losing’ the fire. Proceed with fire as before.

MAINTENANCE AND CLEANING 3/05

Ensure that your Butler Multi is cold and that there are no hot embers in the fire box.

The outside enamel panels of your Butler Multi may be cleaned with a soft rag and non abrasive “spray &

wipe” type products.

Ash Removal

Over a period of time ash will build up in your Butler Multi requiring removal.

Ash build-up will depend upon the quality and quantity of your fuel.

To empty ashes from the fire box, rake ashes on the grate with poker, to loosen and allow to fall through to

ash pan below. Dispose of contents of ash pan in a non-combustible container with a tightly fitting lid.

Place outdoors immediately to a location clear of combustible materials.

Door Glass

Under normal operating conditions, using seasoned fuel, the glass in your Butler Multi should remain relatively

clear. If the glass becomes dirty it can be cleaned by dipping a damp paper towel into the dry cold ashes, and

rubbing gently on the dirty glass to clean. If in the unlikely event your door glass breaks it must be replaced

with a 5mm ceramic glass. This can be purchased through your Wagener Stoves Dealer.

NOTE: Do not operate your Butler Multi with broken glass and under no circumstance should a non-ceramic

type glass be used as it may explode due to the intense heat inside the fire box.

The Door Seals

The door seal should be checked and adjusted to provide a perfect seal at all times. Excess air entering the

fire box past a faulty seal will make it impossible to achieve a slow burn, and may result in over firing the

Butler Multi and causing damage.

Fire Box Bricks

Fire Bricks serve two purposes. Firstly, to protect the steel chassis and secondly to maintain high

temperatures in the fire box to effect complete combustion of the fuel. Cracked and broken bricks should be

replaced. Remember to place your fuel in the firebox rather than throwing it in. This will extend the life of

your bricks.

Flue Cleaning

Flue cleaning and maintenance is probably best done by a professional who can also advise you on the

condition of your flue and other parts like bricks and seals. This should be done annually. However, if you are

cleaning the flue yourself first allow the fire to go out and the Butler Multi to cool down. Remove the cowl

and rod the flue downwards from the roof. Remove the baffle to clean out the soot from the firebox.

Alternatively remove the baffle and rod the flue upwards, from inside, through the open firebox door.

Loading...

Loading...