At

the Cutting Edge

of

Industry

DR

BAND SAWING MACHINES

( 30" & 36" )

INSTRUCTION MANUAL No.823

FACSIMILE

OF

ORIGINAL

WADKIN

OPERATING

& MAINTENANCE MANUAL

BAND

SAViJ1NG

Iv'lliCHINES~

PRINCIP

AL

DIMENSIONS AND

CAPACITIES

:

~

English

Diameter

of

wheels

.... , ...........

,

Width

of

wheels, , .............

0

••••

Maximum

width

of

saw

which

can

be

used

..............

0 • • • • • 1

~.f!

Ma.xirnum

length

of

saw

....

0

••••••••

1F{'0?7

Minimum

length

of

saw

.............

1610"

Depth

of

cut

under

saw

guide

..

, . . . . .

II

Max:lr.llum

width

of

material

accommodated

on

the

left

right,

'!'

Metric

762

mm

44

mm

38mm

5182 ml11.

4877

mm

356

mm

711

m!11

81:i

111Krl

z;:

8

English

mm

EL~L

Metric

914

ml1l

51

fin'].

'14

mm

6096

J(n:m

57~n

mm

470

mm

5

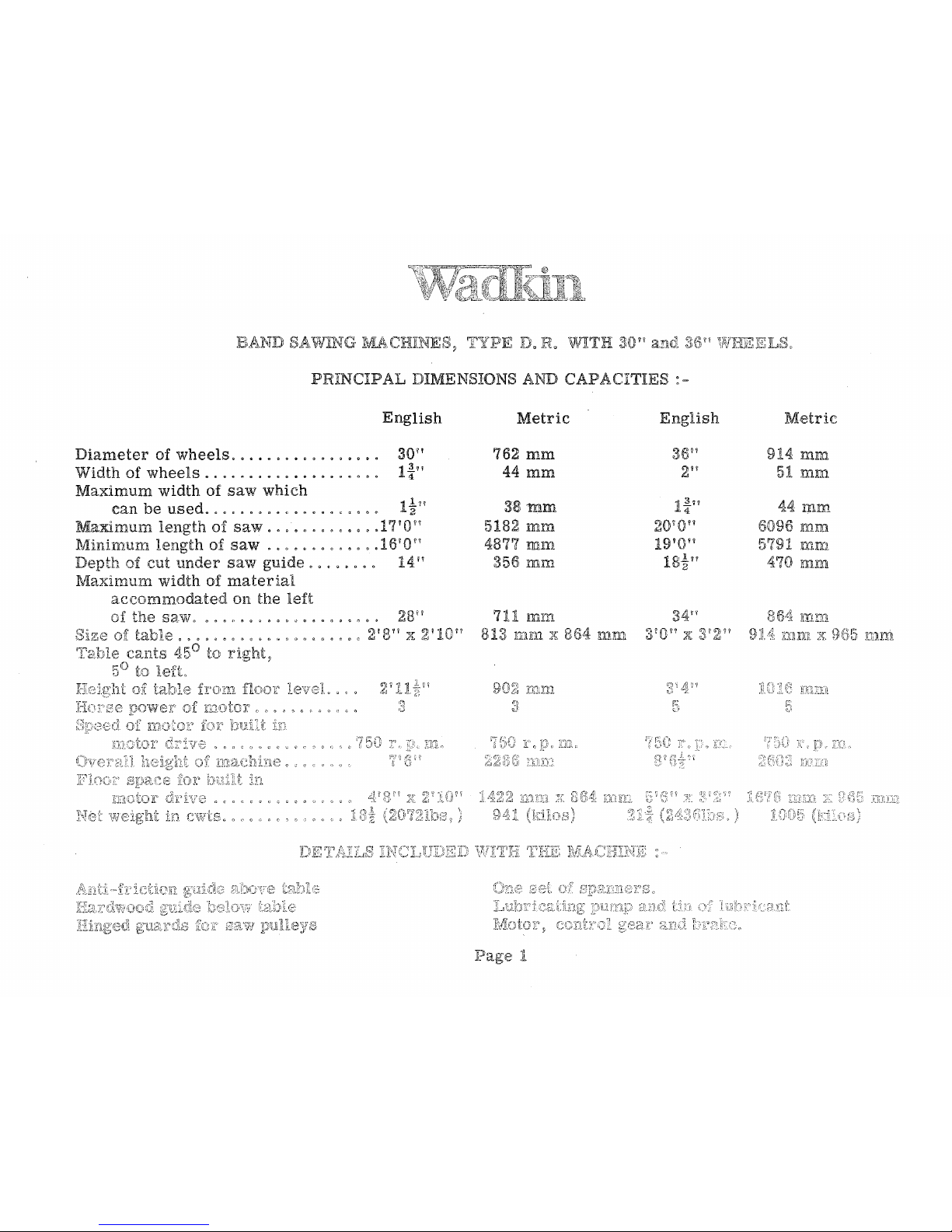

Two

lubrication

points

"A".

Oil

raising

screw

and

slides

every

week

Counterbalanced

saw

guides

Oil

saw

guide weekly

'"d

Degrees

scale

~

CD

t-:I

Lock

for

canting

movement

of

table

Two

lubrication

l'vuu

.... -__

_

"A" on

bottom

pulley

spindle

for

built

in

motor.

Dustoutlet

__

_

For

lubricants

see

page

6.

Fig.

1

Spring

controlling

saw

tension.

Lock

for

tracking

mechanism.

Handwheel

for

tracking

saw

in

centre

of

saw

pulleys.

___

Handwheel

tensioning

saw

to

reading

on

tension

scale.

Stop to

register

table

level.

Handbrake

For

adjustment

of

brake

see

page

6.

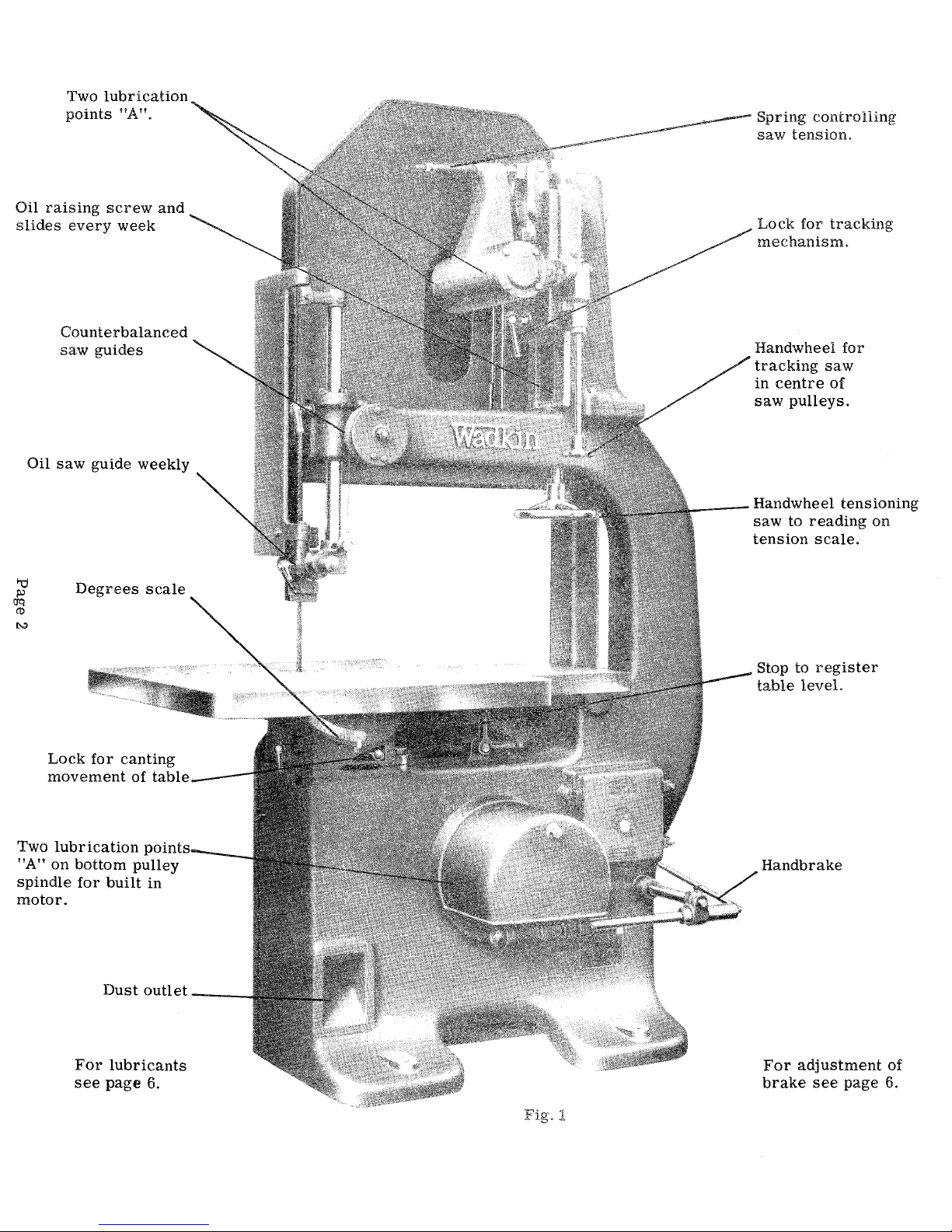

!SOL.A.'TKNG

SW!TCH

~PUE.O

TO

Sf'.ECJAL

QROER

PNL~

____ , ________ ~ ____

~

~AINS

ENTR~'rO----~4-----~~

!SO!...ATOR.

lNCOMING

Cd,\!'!lL~e:

WHEN

!§_SH

••

,A:-r3~TCH

IS

NO'!'

,",fTr.J:~

4-

~-

HOLf.S

rOl't.

o/sOt;"}--

CJI\.. fJOL..TS.

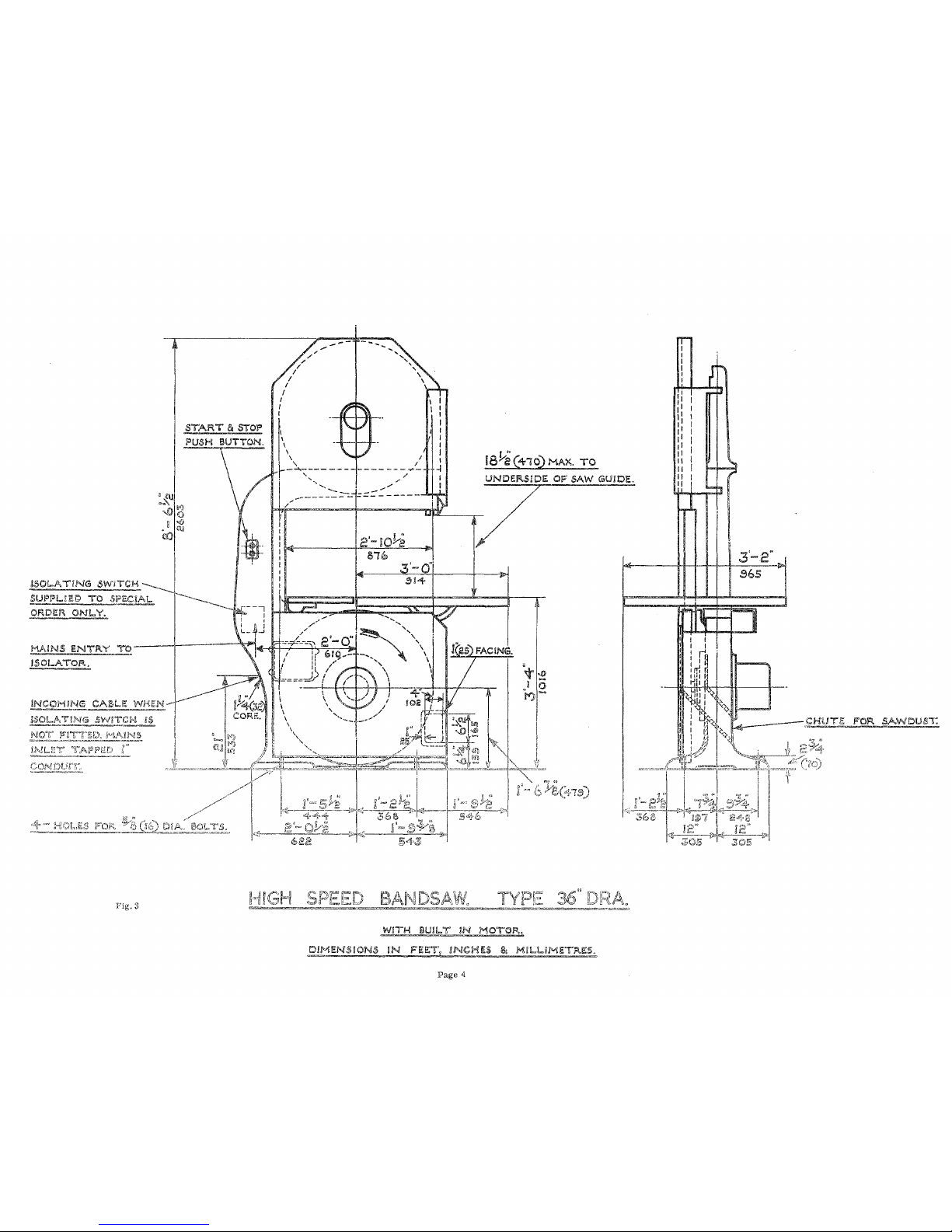

Fig.

2

I

/

'"

---;,,-/--t-

--

14"(§56)MAXIMUM

yo

UNDERSJO.E

OF

SAW

GUJDE,.

-

7-

:,,~

~~

~'I\I

C>

!

@}

~ru

iilGH

SPEE,Q

BANDSAW.

TYJ?E

3Q'I,ORl:\',

Wf1Ji

lSWL.T

AN

I1.~R.

D2l"-j~NSmNS

IN

F~J::'L

U',!CIi~&

,Ml~L..tM,I!,T.f:Ic;,§!~

Page

3

1

I

J>OCA

,INO

=CH

.•

J

START

III

STO!"

PUSH

BUTTON.

SUI"l"!..nH~

TO

5l"EC!.A,!".

.----

___

-.....

ORDIZl'\

,ON

i_V.

"-

~c;,--:

-~---~---

I ,

MAINS

ENTFW

~ro'

lSOI_ATO!'!.,

Fig.

I A I

t

__

-r-.l

I"

IBYe

(410)

I''IAK

T.£

UNDEFl.SlDE

OF

SAW

GUIDE.

T/

7

i'11!..!..iMETi'i.E5.

~

-

,-

"""

Page

4

INST

LLATION

The

ma.chine

is

despatched

from

the

'Works

wi

all

bright

surfaces

greased

This

protective

covering

must

removed

applying

a

cloth

damped

in

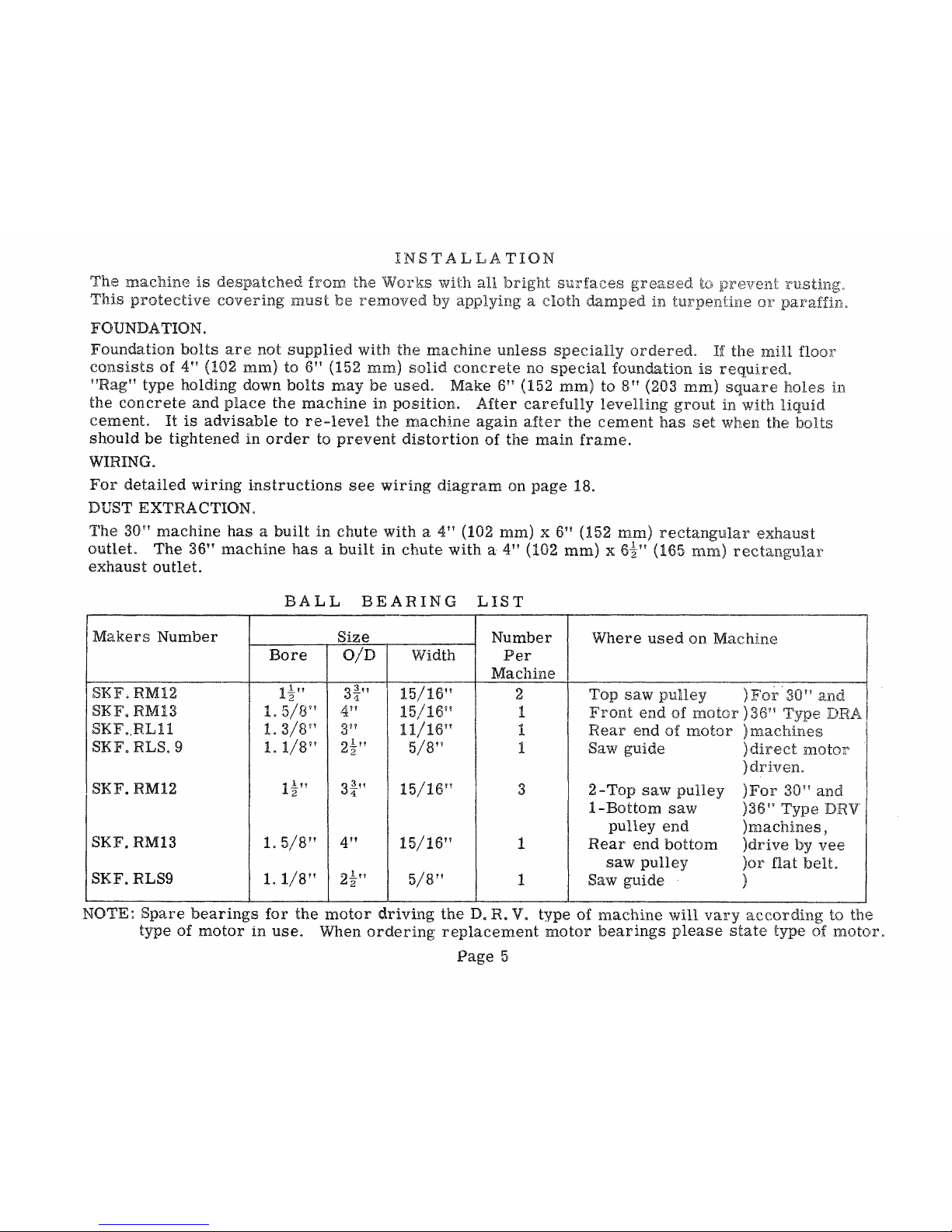

FOUNDATION.

:Foundation

bolts

are

not

supplied

with

the

machine

unless

specially

ordered.

If

the

InHl

floor

consists

of

4"

(102

mm)

to

6"

(152

mm)

solid

concrete

no

special

foundation

is

requiredo

"Rag"

type

holding

down

bolts

may

be

used.

Make

6"

(152

mm)

to

8"

(203

mm)

square

holes

the

concrete

and

place

the

machine

in

position.

After

carefully

levelling

grout

with

liquid

cement.

It

is

advisable

to

re~level

the

machine

again

after

the

cement

has

set

when

the

bolts

should

be

tightened

in

order

to

prevent

distortion

of

the

main

frame.

WIRING.

For

detailed

wiring

instructions

see

wiring

diagram

on

page

18.

DUST

EXTRACTION.

The

30"

machine

has a built

in

chute

with

a

41V

(102

mm) x 6"

(152

mm)

rectangular

exhaust

outlet.

The

36"

machine

has a built

in

chute

with a 4"

(102

mm)

x 6il! (165

mm)

rectangular

exhaust

outlet.

BALL

BEARING

LIST

Makers

Number

Size

Number

Where

used

on

Machine

~-l

Bore

OlD

Width

Per

Machine

SKF.

RM12

1~"

3~n

15/16

11

2

Top

saw

pulley

)

For

30"

and

I

SKF.

RM13

1.

5/8"

4"

15/16" 1

Front

end

of

motor):3 I Type

DRA I

SKF

..

RL11

L

3/8

il

3"

It/16

H

I

1

Rear

end

of

motor

)machiues

I

SKF.

RLS. 9

lot/8Y!

2.!1!

5/8"

1 Saw

guide

)direct

motor

""2

)driven.

I

SKF.

RM12

1~V1

3t"

15/16"

3 2 ·-Top

saw

pulley ) For

30

IV

and

I-Bottom

saw

)36"

Type

DRV

SKF.

RM13

1.

5/8"

4"

15/16"

pulley

end

)machines,

1

Rear

end

bottom

)drive

by

vee

saw

pulley

)01'

flat

belL

SKF.

RLS9

1. 1/8!!

?,.!!1

5/8"

1 Saw

guide

)

""'2

NOTE~

Spare

bearings

for

the

motor

driving

the

D.

R.

V.

type

of

machine

will

vary

according

to

the

type

of

motor

in

use.

When

ordering

replacement

motor

bearings

please

state

type

of

motor,

Page

5

UBRICATION

"A n ~ 4:

POINTS (Shown

on

Fig,

,

Every:3

to 6

months

give

4 to 6

depressions

of

the

grease

gun

using

Wadkin

Ball

Bearing

Grease

Grade

L.

6,

For

lubrication

of

saw

guide

use

Wadkin

Machine

on

Grade

L.

4,

but

for

details

see

instruction

plate

on

inside

of

saw

guard,

The

raising

screw

and

slides

to top

saw

wheel

should

be

oiled

weekly

using

Wadkin

Machine

Oil

Grade

L.4,

The

machine

should

be

cleaned

down

weekly,

WADKIN RANGE

OF

OIL

AND GREASE WITH EQUIVALENTS.

Equivalent

Lubricants

Wad

kin

Grade

..

Shell

Mex

and

B.

P.

Ltd.

Vacuum

Oil

Co.

Ltd.

CaUex

Lubricants

_",,=~_.

~_

..

~·_c

Oil G rade

L.

4

Shell

Vitrea

Oil

33

"Vactra

II

on

Caltex

Aleph

Oil

(Heavy

Medium)

BaH

Grea

Bearing

Shell

Nerita

Grease

3

Gargoyle

Grease

BRB3

Regal

Starfak

se

Grade

L.

6.

.

...

.

~'-".

Fig

0

4:

BRAKE

AD

..

TUSTMENT

The

brake

is

carefully

adjusted

leaving

our \Vorkso

If

wear

takes

place

brake

linings

after a period

of

running,

the

nuts'

must

be

screwed

sufficient:

only

make

brake

effective

when

controlled

Fig" 5

PLAIN

FENCE

type

fence

will

quite

efficiently

on

either

side

of

savSj

0

No.2

Grease

Fig> 6 CANTING

FENCE

The

canting

fence

is

supplied

to

on

either

the

left

or

side

of

the

saw.

Please

specify

which

hand

of

fence

is

desiredo

FITTING

BANDSAW

BLADES

SAW

GUIDES -

Fig.

7.

When

placing a saw

on

the

machine

the

top

and

bottom

guides

must

be

moved

well

back

and

the

saw

tracked

or

adjusted

to

run

in

the

centre

of

the

saw

wheels.

Afterwards

bring

both

guides

forward

until

the

discs

barely

touch

the

saw

when

not

working

..

The'side

blocks

on

the

guides

should

support

the

saw

on

the

sides,

but

not

allowed

to nip

the

blade.

Keep the

side

blocks

up' to the

gullets

(if

the

teeth

only

leaving

the

teeth

clear.

When

using

saws

of

the

same

width

they

will

usually

run

successfully

without

altering

the

adjustment,

but

when

wider

ones

are

used

the

guides

must

be

moved

back

and

the

saw

re-tracked.

To

obtain

first

class

sawing,

the

guides

must

be

dead

in

line

and

fixed

immediately

above

the

work.

TENSIONING -

Fig.

8.

Incorrect

tension

or

tightness

of

the

blade

over

the

saw

will

end

in

saw

breakage.

The

scale

and

pointer

are

set

before

despatch,

but

should

they

be

displaced

in

transit

it

is

necessary

to

re-set

them

before

use.

In

placing a saw

on

the

pulleys

it

should

be

sufficiently

tight

until

it

can

be

pulled

out

ttl

from

its

true

line

at a central

point,

between

the two

pulleys.

When

this

is

done,

move

the

pointer

until

the

scale

coincides

with

the

width

of

the

saw.

For

a

~"

blade. the

pointer

should

read

~".

If

the

machine

is

left

standing

for a period,

e.

g.

overnight,

the

tension

should

be

reduced,

and

the

blade

re-

tensioned

before

putting

the

machine

into

operation

again.

IMPORTANT.

After

the

pointer

is

fixed

in

this

manner

it

will

read

correctly

for

any

width of

blade

without

further

alteration,

even

if

the

length

of

saw

varies

for

any

given

width.

For a i"blade

the

pOinter

should

read

i",

etc.

Page

7

and

Pointer

Fig.

7

FITTING

BANDSA

W

BLADE

S (Continued)

TRACKING - Fig. 9.

Every

saw

has

slightly

different

running

characteristics

on a

band

saw

machine

due to the condition of the

steel

ribbon

it

is

made

from,

the

brazed

joint

and

the

tension

in the

blade

ribbon.

This

is

compensated

by

using a crowned

(O,r

slightly

curved)

rubber

on the

wheels

and

prov-

•

iding the top wheel with a

slight

tilting movement.

We

call

this

track-

\

ing

and

by

slackening

the

lock

handle

and

adjusting

the

tracking

hand-

wheel,

it

is

possible

to

adjust

the

tilt

of the top wheel,

so

that the

saw

runs

steadily

in the

centre

of the wheel.

This

is

important

because

the

blade

then

passes

in a

straight

line

between the top and bottom

wheel, and does not snake. When the

latter

occurs

the

back

of the

saw,

keeps

hitting the guide

plate

and

woodwork and damaged guides

result.

Do

not

forget

to

re-tighten

the

tracking

lock

bolt

after

adjusting.

SAW

PULLEYS

A

brush

as

shown

in

Fig. 10

is

provided

on the

bottom

pulley to

remove

sawdust,

whilst

the

rubber

on the top

pulley

should be cleaneq daily to

prevent

accumulation

of

sawdust

which would

cause

the

blades

to

run

out

of

true

line.

.

The

saw

pulleys

must

be

kept

in

accurate

balance

to avoid

vibration.

It

is

essential

that

the

rubbers

on the

faces

of the

pulleys

are

kept

at

an

even

thickness

by

truing

up

occasionally

or

if

they

are

badly

worn

should

be

replaced

by new

ones.

If

the

machine

is

used

with badly

worn

pulleys

the

saw

will

vibrate,

resulting

in

bad

sawing and

broken

saws.

We

have a

service

arrangement

which we

recommend

whereby newly

rubbered

pulleys

can

be

supplied

against

the

return

of the

existing

pulleys,

an

appropriate

charge

being

made

to

cover

re-rubbering

only.

Where

it

is

not pra.ctical

for

the

customer

to

use

our

exchange

service

of

vulcanised

wheels

it

is

possible

for

the

customer

to

carry

out

his

ownre-rubbering,

which,

whilst

not

so

good

as

the

vulcanised

process,

is

satisfactory

if

the

instructions

below

are

carefully

followed. Rubber

bands

and

fixing

solution

can

be

supplied to

order.

Page

8

fC!r

tr::acking saw

Brush

Fig.~

Fig. 10

REMOVAL

OF

SAW

PULLEYS.

The top

and

bottom

pulleys

are

idelltical,

and

when taking

them

from

the

machine

for

re-rubber-

ing the

entire

wheel

comprising

plate

and

hub

should

be

removed.

To do

this

remove

the

spindle

nut

and

withdraw the

wheel

complete.

It

should

be

noted

that

for

both

pulleys

this

locknut

has

a

left

hand

thread.

FIXING INSTRUCTIONS FOR THE APPLICATION OF RUBBER

BANDS

TO

BAND

SAW

PULLEYS.

The

Croid

Glue

No.9

supplied

is

ready

for

use

and

should

be

applied

cold.

In cold

weather

and

if

the glue

is

solidified

warm

up to 800 Fahrenheit

to give fluidity

and

to

assist

spreading.

Thoroughly

scrape

and

clean

the

face

of the wheel

free

from

old

abrasive.

This

is

very

import-

ant.

Stretch

the

rubber

band

over

the wheel.

To

assist

with the

application

of the glue

it

will

be

found

more

convenient to

place

between

the

wheel

rim

and

the

rubber a piece

of wood

approximately

lin

diameter.

Apply the glue

across

the

face

of the

wheel

and

turn

the wood

round

the

rim

thereby

exposing a

section

of the

rim

to

be

glued.

Proceed

until

the whole of the wheel

has

been

covered

taking

care

to

glu"e

the whole

face

in

order

to

obtain

adhesion

over

the whole width to

prevent

the

edges

of

the

band

lifting.

Tightly

apply a

piece

of

tape

of the

same

width

as

the

wheel

around

the

circumference,

thereby

giving

as

much

pressure

as

possible

to the

rubber

band.

Leave

at

least

24

hours

before

use.

Finally

true

up the

rubber

and

put a slight

crown

on the

face.

This

is

done

by

revolving

the

wheel

and

holding

against

it

a wood

block

covered

with

emery

cloth,

preferably

when mounted

on the

machine.

Check wheel

for

balance

before

use.

FOR TROPICAL COUNTRIES a

Croid

Glue No. 10

is

supplied

with a

hardening

powder

which

must

be

added

in

the

proportion

of one

part

of

hardener

to

56

parts

by

weight

of

glue

and

thoroughly mixed. The

remainder

of

the

procedure

for

cleaning

and

fixing

is

the

same

as

in

the

instructions

above.

Page

9

MAINTENANCE

OF

BAND

SAW

BLADES

A

properly

sharpened

band

saw

win

give

clean,

accurate

cutting

and

this

is

achieved

by

proper

setting

and

sharpening

of

the

teetho

Always

set

before

sharpening.

SETTING.

In

order

to

cut

satisfactorily

band

saw

teeth

must

be

seL

This

consists

in

bending

the

teeth

alternately

out

of

the

Hne of

the

blade.

This

presents

alter·

nate

pairs

of

teeth,

wider

than

the

thickness

of

the

ribbon

and

prevents

the

ribbon

rubbing

in

the

wood

being

cut

and

getting

hot

usual

1J'Jays

of

setting

depending

generally

to

be

done.

Saw cut

a

hand

setting

tool

of

the

pUeI'

Amount

of tooth

set

over

shown

shaded

Set

Set

Body of

saw

settingo

Th!~

standard

filing

machine

described

on

page

15

can

be

changed

to

action~

but

many

firms

prefer

to

install a separate

inexpensive

Inachine

2~S

described

on

page

HL

The

difference

between

the

machines

(Figures

15

eapacity

of

saw

width

and

pitch~

and

the

advantage

of

these

machines

is

that

push

the

teeth

over ~ are

arranged

on

opposite

of

the

blade ~ and

sirnultaneously,

In

this

WO'ilY

shock

two

strikers

cancel

each

not

damag€~

the

band

ribbon,

cannot

be

~~nsur!2:d

are

cutting

O'f:lerCOlJl."JJ8

U:l.is

the

shmJ1ld

be

stoned

occaSJlonaUy. An

ordinary

grit

ston~::

is

used

ball

bearing

gujde

should

temporarily

be

brought

forwarduntn

the

thrust.

disc

is

Jin

contact

the

back

of

the

blade.

The

blade

should

then

be

run

and

the

stone

carefully

applied

to

the

teeth

each

side

of the

blade.

Vlhen the

saw

is

subsequently

sharpened

it

will

be

noted

that

each

tooth

has

not

been

marked

with

the

stone,

and

such

teeth

should

only

Page

10

SETTING

(Continued)

be

filed

very

slightly.

The

remainder

of

the

teeth

which

have

actually

been

stoned

should

be

filed

111

the

used

manner

until

the

flat

caused

by

the

stone

disappears.

Bands::tws

may

be

stoned

approximately

once

to

every

six

sharpenings.

The

points

of

the

teeth

are

set

by.

using a handsetting

tool

of

the

plier

type.

The

points

only

of

th.e

teeth

m.ust

be

set

and

as a general

guide the

set

on

each

side'is

.010".

Set

is

applied

in

opposite

d:i.:rections

for

each

alternate

tooth.

SHARPENING.

This

is

normally

done

by

using a triangular

section

file.

Again

the

operation

can

be

done

by

hand.

or

machine.

HAND FILING.

It

is

essential

to

employ

an

efficient

and

quick

acting

vice

and

round

cornered

triangular

fHes,

both

as

illustrated

on

page

14.

The

face

of

each

tooth

should

be

filed

across

and

with

the

same

stroke

the

back

of

the

following

tooth

should

be

filed

at

the

same

time.

One

stroke

of

50

positive

hook

the

file

should

be

sufficient

to

sharpen

each

tooth,

and

this

stroke

should

be

as

light

as

possible

in

order

to

avoid

prod=

ucing a burr.

The

shape

of

the

gullet

is

automatically

maintained

at

60°

by

the

50 negative

hook

file,

while

the

angle

of

the

hook

on

the

File

Rounded

Gullet

;'1~

Positioning

of

file

Page

11

tooth

is

dependable

on

the

positioning

of

the

file.

For

general

"work

approximately

5°

of

positive

hook

should

be

given, A

greater

or

smaller

hook

should

be

applied

for

softer

or

harder

woods

respectively.

In

the

case

of

particularly

hard

woods

a

negative

rake

may

be

necessary

~

'whilt::

a,

wider

LOOUl

pitch

than

standard

may

be

required

for

sawing

Um.ber"s

an

abrasive

nature ~ and

those

containing

gum,

SHAHPENING (Continued)

Ahr.rays

sharpen

square

across

the

face. of

each

tooth

and

NOT

on

the

bevel,

otherwise

the

saw

will

vibrate

violently,

which

shatters

the

steel

and

cracks

appear

causing

saw

breakage.

Use a file

with

rounded

corners

and

of

triangular

section.

It

is

important

to

keep

the

gullet

of

each

tooth

rounded

otherwise

cracks

will

soon

appear,

Saws

111USt

he

sharpened

at

regular

intervals

and

should

never

be

forced

to

cut

with

teeth

which

have

become

blunL

V/hen

reconditioning

handsaw

blades

is

necessary

to

set

the

teeth

first

before

sharpening.

This

ensures

that

the

face

of the

File

position

/

Face

of

each

tooth

to

be

sharpened

square

across.

Note:-

Rounded

gullet

tooth

is

squar(~,

If

the

sharpening

were

carried

out

first,

the

subsequent

setting

would

result

an

angular

tooth

shape

being

obtainedo

A

picture

the

automatic

machine

for

filing

blades

is

given

on

page

15.

}<"'urther

detaHs

of

this

machine

will

be

forwarded

on

request.

Page

12

GENERAL

CAUSES

OF

SAW

TROUBLE,

CRACKING AND

BREAKAGE

L

Crystallisation

of

the

ribbon,

produced

by

the

back

of

the

saw

rubbing

against

the

metal

disc

of

the

saw

guide,

The

disc

should

revolve

only

by

contact

with

the ba.ck

edge

of

the

saw

when

actually

cutting.

2.

Using a blade

that

is

too

wide

for

the

radii

being

cuL In

attempting

to

curves

with a saw

too

wide

the

blade

tends

to

twist

against

the

guides

causing

friction

and

over-

heating

which

destroys

the

temper

in

the

steel.

SMALLEST

RADII VI/HICH

)VLA Y BE

SAWN WITH GIVEN WIDTH OF'

BLADE

r~idth

of

Blade

~in:i.m\'i.m

Radius

I

I

L

1/8

t

! 3/16!!

1/Bj17

5/1~':

---------~'--.--

---

NOTE:

ALWAYS USE \!'iIIDEST

BLADE

COMPATIBLE

"WITH

THIS

CHART.

Not

enough

set.

with

a

details

brazing

Page

13

File

TAPER

TRIANGULAR

FILES

FOR

HAND USE

Fig.!I

Length

..

6"

8"

10"

The

edges

of

both

machine

and

hand

files

have

rounded

corners

to

produce

the

round

gullet

which

prevents

saw

cracks.

Fig.

12

BAND

SAW

FILING

VICE

A

specially

designed

vice

for

holding

band

or

fret

saws

also

handsaws.

Jaws

are

17"

long

and

will

take

saws

up

to

2~"

wide.

Jaws

open

instantaneously

by

lever

handle.

Spare

handsaw

blades

for

wood

cutting

on

the

30"

and

36"

D. R.

Bandsaws

are

available

from

stock.

(Maximum

and

minimum

lengths

given

on

page

1).

Where

it

is

preferred

bandsaw

blading

in

strip

form

can

be

supplied

for

customers

to

make

up

their

own

blades.

This

bandsaw

strip

is

offered

either

toothed

only"

or

toothed,

sharpened

and

set.

SPECIAL

MATERIALS.

In

addition

to

woodcutting

we

can

supply

bandsaw

blades

suitable

for

plastics,

bonded

wood,

non~

ferrous

metals ~ meats

etc.,

providing

that

the

correct

machine

speeds

are

available.

If

any

special

material

is

to

be

cut, a sample

should

be

sent

to Wad1dn

Ltd.

for

test

purposes

so

that

the

correct

type

of

blade

may

be

recommended.

We

are

able

to

offer

special

speed

bandsaws

for

specific

purposes

and

full

details

will

be

sent

on

request.

Page

14

WADKIN

BAND

SAW

FILER

AND

SETTER,

TYPE

H.

D.

This

machine

is

fully

automatic

and

ensures

that

each

tooth

is

sharpened

and

set

to tbe

correct

shape

and

depth.

Any length of

saw

can

be

dealt

with,

and

the

maximum

width

is

2i"

with

teeth

up to

5/8"

pitch

for

filing

and

1~"

wide

for

setting.

Fig.

13

Fie:. 14

WADKIN ELECTRIC BAND

SAW

BRAZER.

TYPE

H.E.

This

machine

is

suitable

for

brazing

band-

saws

from

i"

to

1"

wide,

and

is

very

useful

for

the

efficient

brazing

of

blades

which have

become

broken.

The two

ends

of the

saw

are

firmly

held

by

the

clamps,

and

controlled

heat

applied

electrically.

A

small

quantity

of

solder

and

brazing

compound

are

supplied

with

the

machine.

The

actual

brazing

takes

from

25

to 45

seconds

according

to

width

of

blade.

Before

brazing

the ends of

the

saw

blade

must

be

carefully

bevelled. A separ-

ate

instruction

chart

is

issued

with

the

brazer.

Page

15

When

the

amount

of

work

does

not

justify

the

installation

of

the

equipment

shown on

page

15 we

can

offer

a

prompt

and

efficient

repair

and

reconditioning

service.

Any

blades

sent

to

us

for

reconditioning should

be

covered

by

an

official

order.

WADKlN

,BAND

SAW

SETTING MACIDNES

For

manual

setting

the following equipment

is

recommended.

Fig. 15

FOR BAND

SAW

BLADES UP TO

3"

WIDE

7/8"

PITCH

TYPE

B/LS

This

is

a heavy duty

machine

which

sets

two

teeth

at

each

revolution,

giving a

rate

of

approx-

imatel

y 200

teeth a minute

on the

general

run

of work. .

The

machine

may

be

used

either

by

hand

or

power,

the

handwheelbeing

in

the

form

of a

pulley

to

take a belt

from

motor

or

lineshaft.

Fig. 16

FOR NARROW

BAND

SAWS

UP TO 1 i"

WIDE

t"

PITCH

TYPE

Blss

All

adjustments

are

quickly

and

easily

made

to

this

robust

and

thoroughly

practical

tool.

It

is

usually

operated

by

hand

and

setting

is

at

the

rate

of two

teeth

per

revolution

of wheel. When

preferred

the

machine

may

be

power

driven

by

flat

belt

on

the

pulley

face

of the handwheel.

Page

16

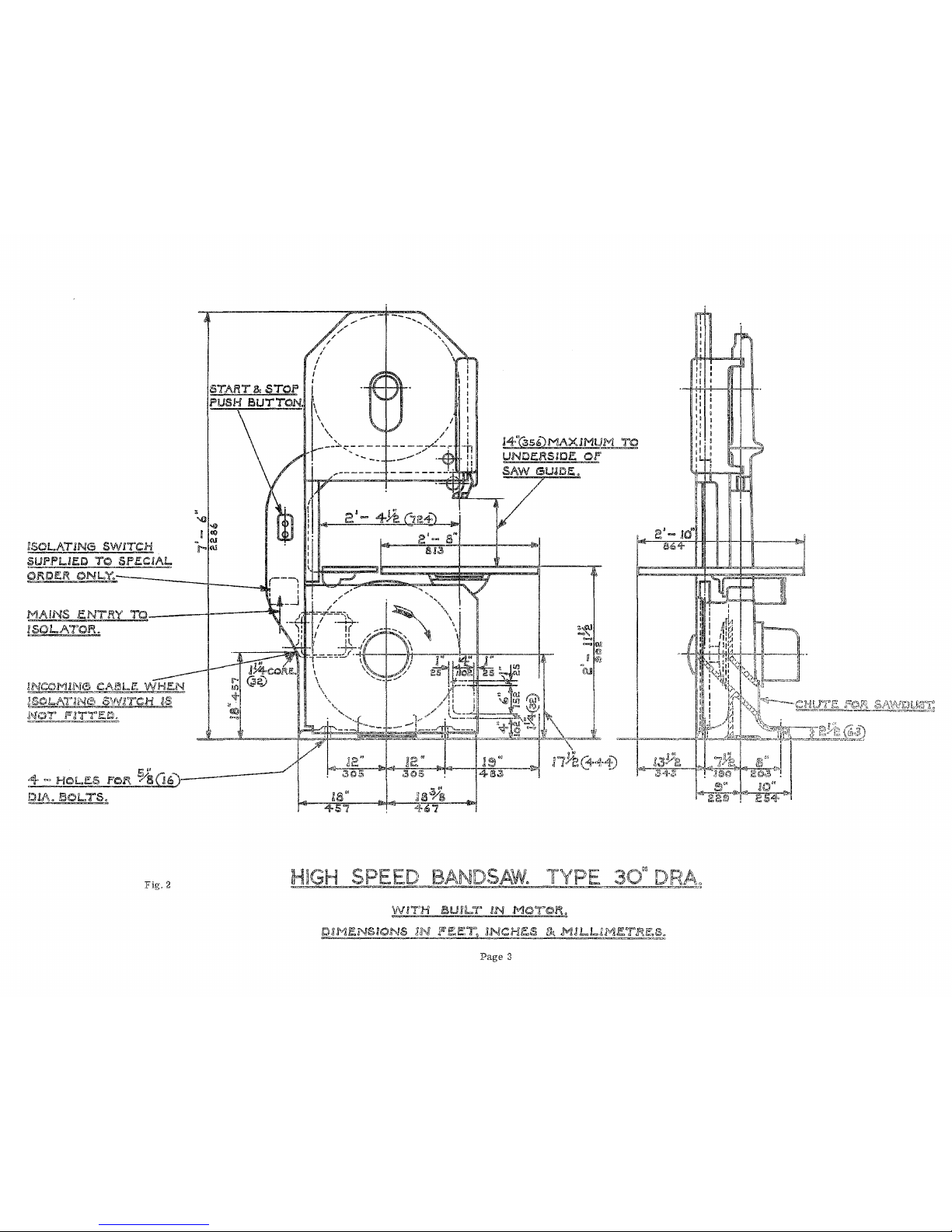

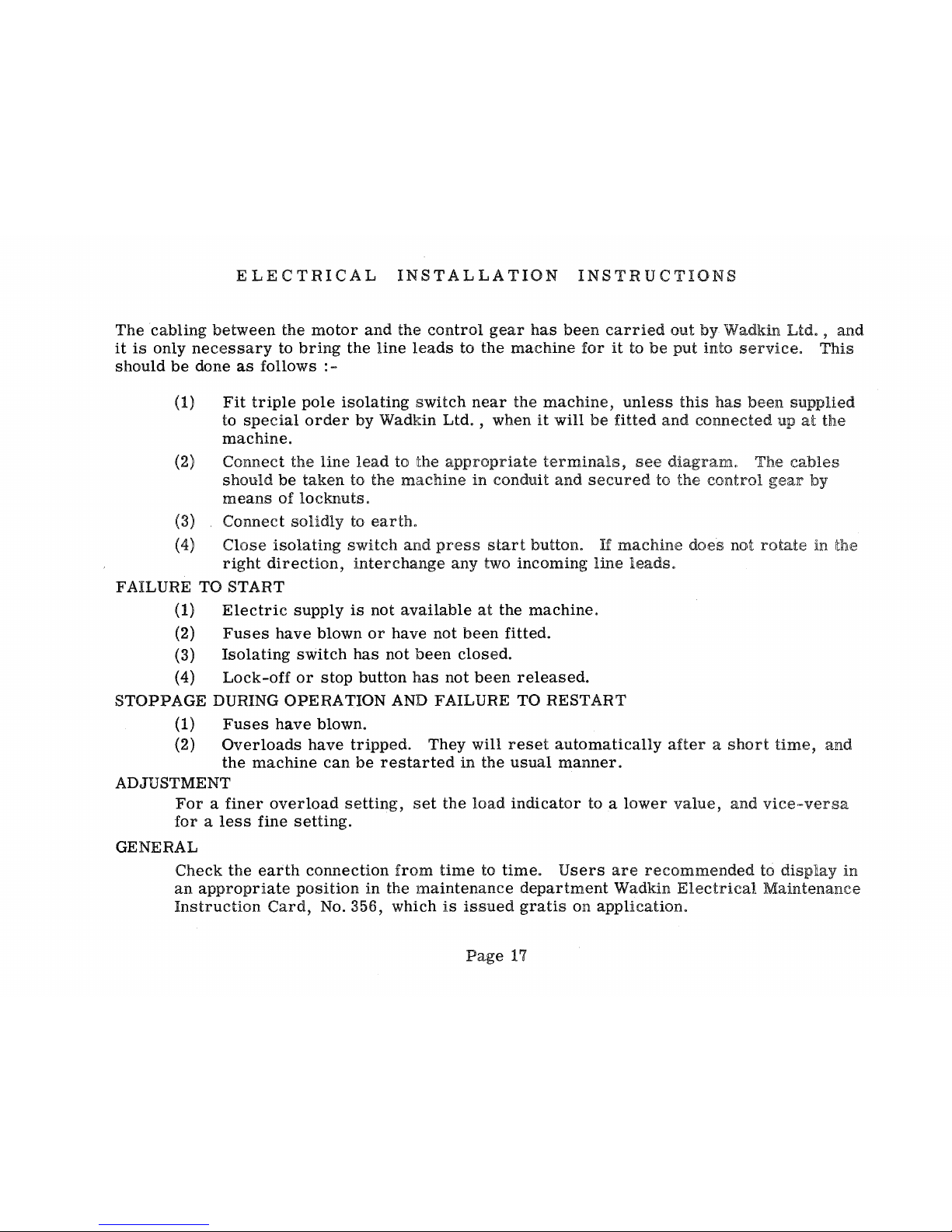

ELECTRICAL

INSTALLATION

INSTRUCTIONS

The

cabling

between

the

motor

and

the

control

gear

has

been

carried

out

by

Wadkin

Ltd.,

and

it

is

only

necessary

to

bring

the

line

leads

to the

machine

for

it

to

be

put

into

service.

This

should

be

done

as

follows

:-

(1)

Fit

triple

pole

isolating

switch

near

the

machine,

unless

this

has

been

supplied

to

special

order

by Wadkin Ltd. , when

it

will

be

fitted

and

connected

up

at

the

machine.

(2) Connect the

line

lead

to the

appropriate

terminals,

see

diagram.

The

cables

should

be

taken

to the

machine

in

conduit

and

secured

to the

control

gear

by

means

of

locknuts.

(3) Connect

solidly

to

earth.

(4)

Close

isolating

switch

and

press

start

button.

If

machine

does

not

rotate

in the

right

direction,

interchange

any two incoming

line

leads.

FAILURE TO START

(1)

Electric

supply

is

not

available

at

the

machine.

(2)

Fuses

have

blown

or

have not

been

fitted.

(3)

Isolating

switch

has

not

been

closed.

(4)

Lock-off

or

stop

button

has

not

been

released.

STOPPAGE DURING OPERATION

AND

FAILURE TO RESTART

(1)

Fuses

have

blown.

(2)

Overloads

have

tripped.

They will

reset

automatically

after a short

time,

and

the

machine

can

be

restarted

in

the

usual

manner.

ADJUSTMENT

For a finer

overload

setting,

set

the

load

indicator

to a

lower

value,

and

vice-versa

for a less

fine

setting.

GENERAL

Check the

earth

connection

from

time

to

time.

Users

are

recommended

to

display

in

an

appropriate

position

in

the

maintenance

department

Wadkin

Electrical

Maintenance

Instruction

Card,

No. 356, which

is

issued

gratis

on application.

Page

17

.

r-

oo

-..0

.;

z

t-

ILl

..J

...

4:;

IaJ

..J

ILl

ILl

",

"

<

ILl

~.

..J

4:;

u

it

t

ILl

.

..J

ILl

ILl

~

~

IaI

0

a:

IaI

L

fa.

ILl

t!)

0:

Z

ILl

Z

0::

';5

::J

...

..J

~

U

0:

a:

0

11.

fa.

0:

I

IIJ

<

~

0::

J

19

10

<

U

a

~

U)

x

0

r

~

z

ILl

~

bJ

J

III

10

0::

~

iI:

0

Il.

Z

~

0

~

II.

0

~

<

.J

:>

u

~

0.

"

f

MAINS

:SUPPLY

PARTICULARS

VOLTACSE

TRIPLE POLE ISOLATING

SWITCH.

To

SPECIAL.

ORDER

ONL.~---------

FUSES.

L.OCKNUTS.

PHASE

FREQ.UENCY

OUTPUT

PUSH ISUTTON

CONDUIT

HOLE

'z~"

STATION.

,,-------------------------------

-~---

....

\ I

rSTQP--START; I

r----------------------------

I I

I I :

~

I

In:

I I

I c.=:::I I I I

I

o-+'~'r_,'

----~

I

.1

L

___________

...J

TRIP

~

~;-'IJ'Y'

I

II

" I

I " I L

-1

I

:1

I.

,

I:

I

,

I

I

I

I

I

TO

A2. -

62

-

C2.

AT

CONTACTOR.

A!lRlczl

A2W

AIW

AIW

STAR

O~L.IA

I'

~"

I

C2

':

ji

l

r,----------f'\

: OVERLOAD .

FOR

MOTO",

:

:

HEATER

:1

II

rI I I h

-----..;;..I~i-1--+-_!-""+_

..

,CONNECT~S

r--l

:

COIl:06.

",I

I

LJ

I I

lr--'

L______________________________

SEe:

ABOVE

I I

\.

):

~-,----,--~

-----------------------:---------",

L...

L..

___

.J

L..

__

..J

CONIACTOR

MOUNTED

ON

DOOR.

INSTALLATION

INSTRUCTIONS.

FITTRIPL.E

POL.E

ISOL.AIINe

SWITCH

NEAR

MACHINE UNL.ESS SUPPL.IED

BY

WADKIN

L.

TO.

TO

SPECIAL.

ORDER,

so

THAT

THE

EL.ECTRICAL.

GEAR

MAY READIL.Y

BE

ISOL.ATED FOR

INSPECTION

PURPOSES.

BRINe

L.INE CABL.E.S

TO

ISOL.AIING

SWITCH

AND

TO

L.I

- L.2 -

L.3

AT

CONIACTOR

THROUISH

CONDUIT

WHICH

SHOUL.D

BE

SCREWE.D

INTO

THE

MACHINE

AND

SECURED

BY

MEANS

OF

LOCKNUTS. A HOL.E

15

PROVIDED

IN

THE

MACHINE

FRAME

AT

'Z·

FOR

THE

CONDUIT

CARRYINIS

IHE

L.INES

10

IHE

CONTACTOR.

OPERATING

INSTRUCTIONS.

TO

START

MOTOR,CL.OSE

ISOL.ATINIS

SWITCH

AND

PRESS

START

BUITON.

TO

SlOP

MO-rOR

PRE.SS

S,.OP6UliON

•• 0 L.OCK

OFF

MACHINE

PRESS

AND

TURN

SlOP

BUTTON.IHIS

MUSI

BE.

REL.EASED

BEFORE A START

CAN

BE

MADE..

NOTE:-

CABL.INCS

SHOWN

THUS

~

TO

BE

CARRIEO

OUI

BY

CUSTOMER

tJNLESS

150LA,.INIS

SWIICH

HAS

BEEN

FII,.EO

BY

WAQKIN

L.TD.

\

,

i

I

I

l I

........

IMPORTANT.

MOTOR

SECURE

L.INE CABL.ES

AI

'X'

BY

MEANS

OF

THE

CL.EAT

PROVIOED.

LEAVE

SUFFICIE.NT SL.ACK IN

LINES

AT'Y'

TO

AL.L.OW

THE

OOOR

TO

OPEN

FREEL.Y.

WHEN

DUAL

VOL.

TAISE

MO"ORS

ARE

EMPL.OYED

THE

FOL.L.OWINIS

CONNECI'ONS

SHOULO

BE

MADE

200

eso

VOL.,

CIRCUITS

CONNEC,.

MOTOR

IN

·OEL.

lA', 3 ....

0

440

VOL. T

CIRCUI'TS

CONNECI

MOIOR

IN

'STAR~

THE

CONNECTIONS

BEINIS

MADE

EITHER

WITHIN

THE

CONTROL

<SEAR.

CAVITY

OR

AT

IHE

MOTOR

TERMINAL.

BLOCK.

ENSURE

THAT

'THE

MACHINE

15

ADEQ,UATEl. Y 'EARIHEO'

AND

THAT

THE.

DIREC-rION

OF

RoTATION

IS

CORRECT

BEFORE

PU.-rINCS

INTO

SER.VICE.IO

REVERSE

ROTATION

INTERCHAN<SE

LI & La.

OVERLOAD.

SHOUL.D

IHE

MOIOR.

STOP

DUE

TO

OVERLOAD,

WAIT

FOR A SHORT

"TIME

TO

AL.L.OW

"THE

HEAlER

COIL.S

TO

COOL.

AND

THEN

START

IN

THE

USUAL

MANNER.

EARTH

MACHINE.

WAiKINL.

TO.

L.s.1CES,.ER.

DIAGRAM OF CONNECTIONS.

D.

191

3A.

T

lE

E ElE

RI

RS

l K F

Eft

T

E

SELVES

~

® ®

blow

away

harillful

(iust~

chips

and

dirt

with

a

Blo\ver

adkin

No

motor

can run at its maximum efficiency with its ventilating

duct

or

control covered with

dust

and

dirt.

Sooner

or

later

the

resultant overheating will cause serious

trou

Similarly, accumulations of

ips

and dust,

in

the

mechanical parts of

machine

can interfere with its efficiency. A few minutes a week

for blowing down

ali

Woodworking

Machinery will be amply repaid

in

better

and easier running,

in

increased life, and freedom from

breakdown.

Blowers

can

be supplied for single phase

A.c.

or

Direct

Current

for

any voltage

up

to

250.

Please state voltage when ordering.

SPECI

FICA

TION

Horse-power

of'motor

... :lnl

Net

weight...

7 Ibs.

Speed II

AGO

r.p.m.

Velocity

of

air

in

feet

per

minute

...

14,800

Fully

guarantesd

for

one

year

Loading...

Loading...