Wadkin S400 Instruction Manual

J

J

J

]

J

J

'1

--1

LEICESTER

5400

HIGH

PRECISION

SURFACE

PLANERS

,

INSTRUCTION MANUAL No. 3014

www.wadkin.com

info@wadkin.com

PREFACE

IMPORTANT

IT

IS OUR

POLICY

AND THAT OF OUR

SUPPUERS

TO

CONSTANTLY REVIEW

THE

DESIGN AND CAPACITY

OF

OUR

PRODUCTS. WITH THIS IN

MIND

WE

WOULD

REMIND

OUR

CUSTOMERS THAT WHILE

THE

DIMENSIONS AND PERFORMANce

DATA

CONTAINED HEREIN ARE CURRENT

ATTHETIMEOF

GOING

TO

PRESS, IT IS POSSIBLE THAT

DUE

TO

THE INCORPORATION

OF

THE LATEST DEVELOPMENTS

TO

ENHANCE PERFORMANCE,

DIMENSIONS

AND

SUPPLIERS

MAY

VARY

FROM THOSE

ILLUSTRATED

THIS MANUAL IS

WRITTEN AS A GENERAL GUIDE. A TYPICAL

MACHINE

IS SHOWN TO ILLUSTRATE THE MAIN FEATURES.

Failure

to

comply with instructions in this

book

may invalidate -the guarantee

-~--------

www.wadkin.com

info@wadkin.com

J

J

J

~

]

J

J

J

o

o

J

J

J

[J

J

J

J

J

-]

]

HEALTH

&

SAFETY

SAFETY

OF WOODWORKING MACHINES

Woodworking machines can

be

dangerous if improperly used. The

wide

range of work of

which they are

capable, requires adequate safeguarding arrangements against possible

hazards.

Many injuries to machinists

are

caused by carelessness or failure to

use

the guards provided

or to adjust them correctly.

Wadkin

plc supply machinery designed for maximum safety which they believe,

as

a result

of thorough testing, minimizes the risks inevitable

in

their use,

It

is the users responsibility

to see that the following

rules

are

complied with to ensure safety at work:

1)

The operation of the machirie should conform to

the

requirements of

the.

UK Woodworking Machines Regulations, 1974.

All

guards, should be used and

adjusted correctly.

2)

Safe methods of working only should be adopted

as

given

in

BS.6854

Part

1,

"Safeguarding Woodworking

Machines~'

(UKonly) and subsequent parts for specific

machines (obtainable from Her Majesty's Stationery Office) and as advised

by

Wadkin

plc.

3) Only personnel trained in the safe use of a machine should operate

it.

4)

Before making adjustments

or

clearing chips, etc., electrically isolate machine and

ensure all movements have ceased.

5)

All

tools and cutters must be securely fixed and the correct

speed

selected.

Safety is our watchword, but the user must comply with

the

above

rules

in his own interest.

We would be

pleased

to

advise on the safe use

of

our products. .

Wadkin Leicester

Green

Lane

Works

Leicester. LE5

4PF

England

Telephone:

0533769111

Telex:

34646

Wadkin

G

Fax:

0533742310

www.wadkin.com

info@wadkin.com

SAFETY INSTRUCTIONS

Carefully read instruction manual with particular reference to the following

instr.uctions:-

a)

Slinging,

ie,

safe lifting limits for slings, etc.

b)

Installation and foundation,

ie,

safe working area of machine,bolt positions,

etc.

c)

Wiring details, ie, connection

of

machine to mains supply, fuse details, etc.

d) Machine controls and operating instructions.

Ensure tooling

is

of

the

correct type for use with

the

machine and cutters are

securely fixed in position.

Select correct spindle speed and feed rate relevant to the tooling being used.

Set all guards correctly

and

ensure they are securely fixed

in

accordance with the

current regulations.

Use suitable jigs, fixtures and feeding devices etc., (push stick, etc.,) where

appropriate.

Referto

.8S.6854, Part 1, "Safeguarding Woodworking Machines'

UK

market and

subsequent parts for specific machines for safe working practices.

During Machining

Wear suitable protective equipment, where necessary, eg, goggles, ear defenders

and dust mask.

Ensure

all

moving

parts

of

the machine are stationary before setting, cleaning

or

making any adjustments.

Report immediately

to

a person in authority any machine malfunction

or

operator

hazard. Do not attempt

to

repair the machine unless authorised

to

do

so.

Ensure machine

is

electrically isolated before any maintenance/cleaning

work

commences.

NOISE

lEVELS

This

machine,

under certain conditions,

will

em~

noise

levels

in

excess

of

85d8(a).

Noise

levels

will

be

affected

by

the

environment

in

which

the

machine

operates

the

timber

being

machined,

tooling,

machine

setting

and

dust

extraction.

Further

information

available

from

Wadkin

on

request.

As a manufacturer ~ is

Wadkin's

policy

to

reduce

the

noise

level

as

far

as

it

is

practicable.

In

[1

o

o

o

[l

[l

'--'

o

o

lJ

o

o

]

o

•

iJ

J

www.wadkin.com

info@wadkin.com

l

cY

J

J

J

]

J

]

rJ

'-

r]

'-

fJ

j

o

D

J

J

]

:J

J

]

]

r

~-O

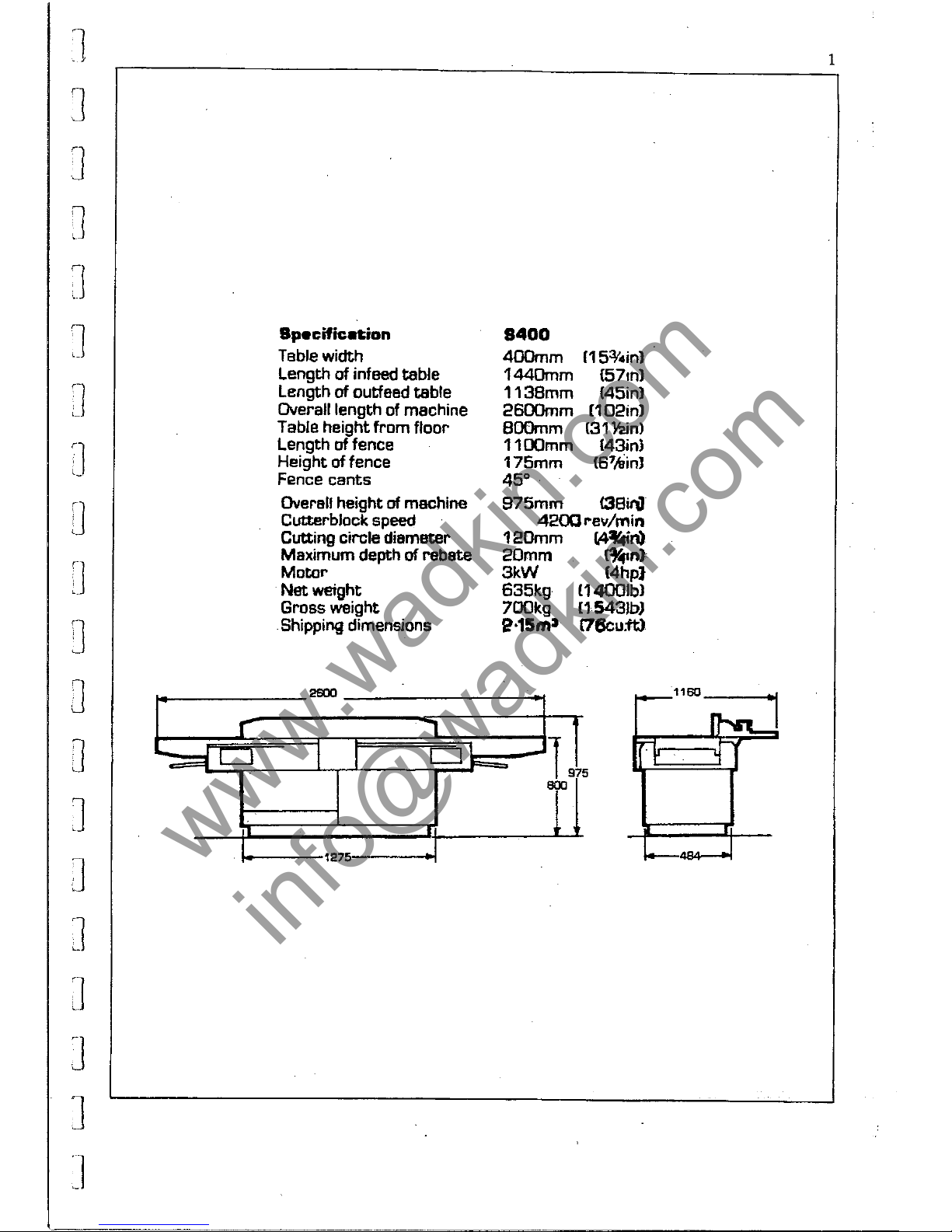

8pecific_ion

Table width

Length

of

infeed table

Length

of

outfeed table

Overall length of machine

Table height from floor

Length

of fence

Height

of

fence

Fence cants

Overall height

of

machine

CutterbJock

speed

Cutting circle diameter

Maximum depth

of

rebate

Motor

Net weight

Gross weight

Shipping dimensions

2SOO

,

I I

D

1275

~

I

8400

400mm

115:Y4inl

144Dmm 157ml

1138mm

145inl

2600mm

1102inJ

800mm

1311'cinJ

1100mm

143inJ

175mm

!67,iiinJ

45°

975mm

!38ircl

4200rev/min

120mm

(4~n)

20mm

~n)

3kW

!4hp}

635kg

11400lb)

700kg

!1543Jb}

e·15m'

(76cu:ftl

r---1160

1975

P c

T1

1

rr.-J

i

www.wadkin.com

info@wadkin.com

2

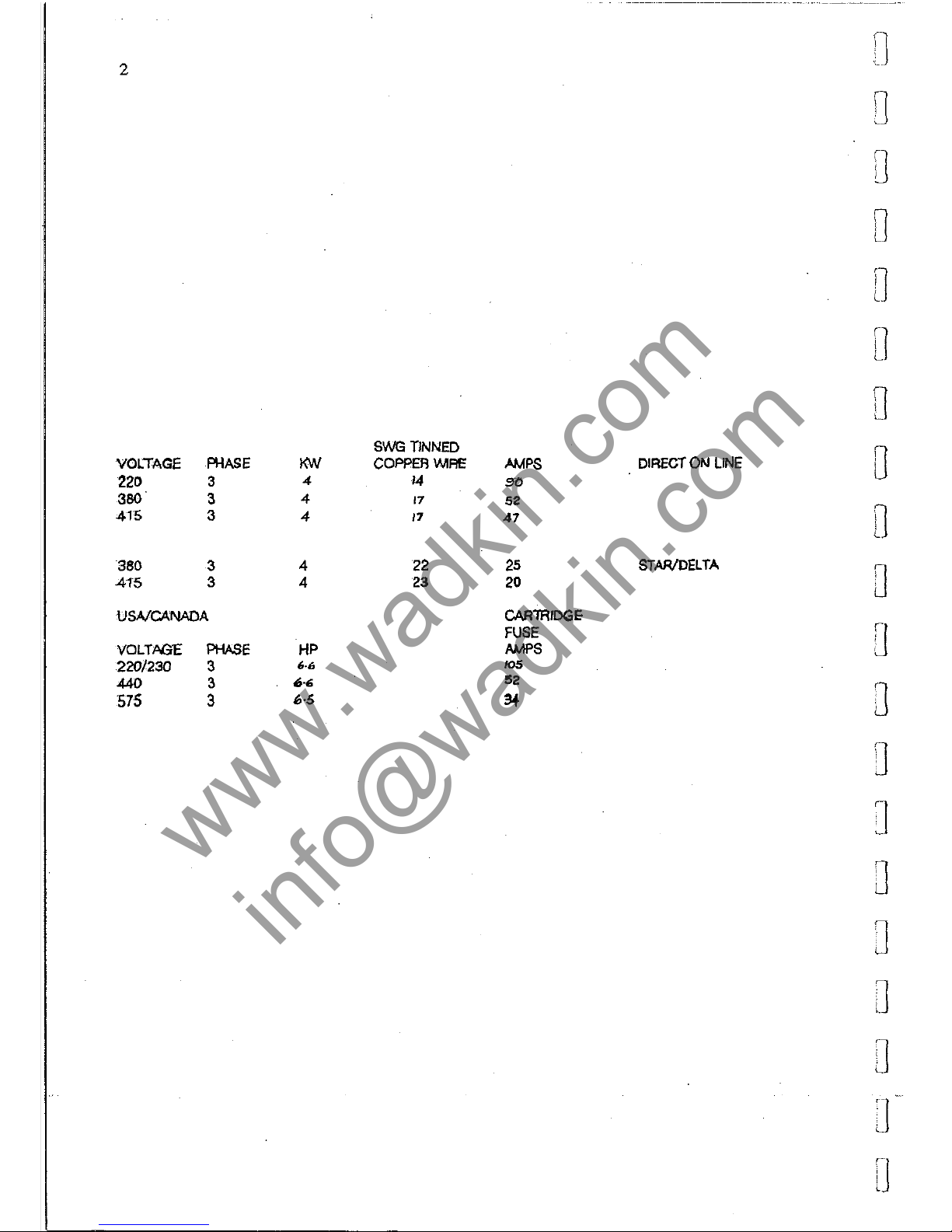

VOLTAGE

PHASE

't<W

220

3

4

380

3

4

415

3

4

380 3 4

415

3

4

USA/CANADA

VOLTAGE

PHASE

HP

220/230 3

6·6

440

3

".,;

575

3

6·5

SWGTINNED

COPPER

WIRE

/4

17

/7

22

23

AMPS

97>

52

47

25

20

CARTRIDGE'

FUSE

AMPS

105

52

3-f

DIRECi

ON

LINE

STARlDELTA

D

o

o

o

o

o

o

o

o

o

J

o

J

o

o

o

o

J

[J

www.wadkin.com

info@wadkin.com

l

~--

~

]

J

~

']

J

]

J

]

]

J

]

]

J

]

J

]

J

J

]

LIFTING

THE

MACHINE

IS

NORMALLY

SUPPLIED

.COVEP£D

IN

PLASTIC

SHEET

WITH

SUNDRY

ITEMS

PACKED

IN

BOXES

AND

STRAPPED

TO

THE

MACHINE

FRAME.

BEFORE

LIFTING

TO

WORK

POSITION

REMOVE

SHEETING

AND

ALL

BOXES

ALONG

WITH

Al<r

LOOSE

ITEMS.

THE

MACHINE

AS

RECEIVED

IN

THIS

FORM

WILL

WEIGH

APPROXIMATELY

1000

kg

AND

SHOULD

THEREFORE

BE

RAISED

WITH

STRONG

ROPES

OR

SLINGS

WHICH

ARE

~~OWN

TO

BE

IN

SOUND

CONDITION.

THE

SLINGS

SHOULD

BE

PLACED

TO

GIVE

A

WIDE

SPREAD

AND

SHOULD

BE

PROTECTED

BY

PADDING

AT

THEIR

POINT

OF

CONTACT

WITH

THE

MACHINE.

(ie)

o

1)

WHEN

LIFTING

WITH

ROPE

TYPE

SLINGS

PROTECT

AROUND

CORNERS

OR

SHARP

EDGES

WITH

OLD

SACKING.

2)

WHL~

USING

POWER

HOISTS

LIFT

SLOWLY

FROM

GROU~~

LEVEL

TO

ASCERTAIN

STABILITY

OF

LIFT. A

LOAD

SHOULD

BE

RAISED

IN

THE

AIR

TO

BE

SUSPENEDED

AS

LEVEL

AS

POSSIBLE.

IF

ON

LIFTING

THE

LOAD

SHOWS

SIGNS

OF

TILTING

LOWER

OFF

A."lD

READJUST

SLINGS.

3)

NEVER·

RAISE A LOAD

WITH

LOOSE

ITEMS

u~ON

IT.

4)

WHEN

MOVING

MACHINE

OR

CRATE

TO

FOUNDATION

POINT

VIA

OVERHEAD

BLOCK

OR

HOIST,BEFORE

MOVING

OFF

LOWER

LOAD

DOWN

TO

WITHIN

A

. .

COUPLE

OF

INCHES

OFF

GROUND

LEVEL.

5)

WHERE

LIFTING

HOOKS

EYE

BOLTS

OR

SPECIAL

GRABS

ARE

PROVIDED

ENSURE

SUCH

FITMENTS

ARE

SECURED

TO

THE

LOAD

BEFORE

LIFTING.

6)

BEFORE

USING

ANY

ROPE,

BELT

SLING

OR

CHAIN:';

ENSURE

IT

IS

IN

SOU;';!)

CONDITION.

CUT

OR

FRAYED

ROPES,

BELTS

OR

CHAINS

WITH

SPRAINED

OR

SUSPECT

LINKS

SHOULD

NEVER

BE

USED.

7)

WHEN

OFF-LOADING

MACHINE

OR

CRATE,

STAlm

WELL

CLEAR.

S)

KEEP

LOAD

STATIONARY

WF..EN

SUSPENDED,

DO

NOT

ALLOW

LOAD

TO

SWING.

9)

BEFORE

LIFTING

CHECK

MACHINE

OR

CRATE

FOR

A~r

SPECIAL

LIFTING

.INSTRUCTIONS

..

10)

IF A CRATE

IS

DAMAGED

TO

THE

POINT

WHERE

IT IS

INSECURE,

UNPACK

A."lD

LIFT

MACHINE

ONLY.

3

www.wadkin.com

info@wadkin.com

Loading...

Loading...