Wadkin PP Series Instruction Book

"WADKIN"

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

DIMENSION

SAW

INSTRUCTION

TYPE

IIPP"

BOOK

NO:

987

Waakin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

Wadkin

INSTRUCTIONS

Standard

Maximum

Depth

Throat

Saw

Maximum

Will

Length

Ripping

Horse

Speed

of

opening

cants

on

standard

crosscut

cut

power

of

fence

size

depth

cut

with

up to

distance

off

of

saw

spindle

of

saw

of

cut

saw

between

""

between

table

on

standard

using

cants

motor..

DIMENSION

PRINCIPAL

..

.

canted

fixed

..

"

""

saw

..

"

table

stop

on

up to

50

..

..

and

to

45°

and

..

"

and

..

with

mitre

60

cycles

SAW

DIMENSIONS AND CAPACITIES

sliding

".

"

fence

tables

....

...

ripping

.. ..

saw

at

..

.

.'

....

fence

..

90

0

..

.. ..

..

••

TYPE

P.

P.

:-

18"

5!"

3.

6"

45

30"

5!fi x

1

if X 36"

36"

45

5

2800

7/8"

0

29!"

0

r.p.m.

450

mm.

140

mm.

100

mm.

150

mm.

0

45

760

mm.

140 x 750

25 x 915

915

mm.

0

45

5

2800

r.p.m.

mm.

mm.

Details

One

pair

saw

collars

Motor

Saw

Single

and

guard

mitre

control

and

riving

fence

and

gear.

knife.

with

stop

nUt.

included

bar

and

with the

stop.

Page

1

machine.

Canting

Set

of

Tin

of

Ripping

spanners.

lubricant.

fence.

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

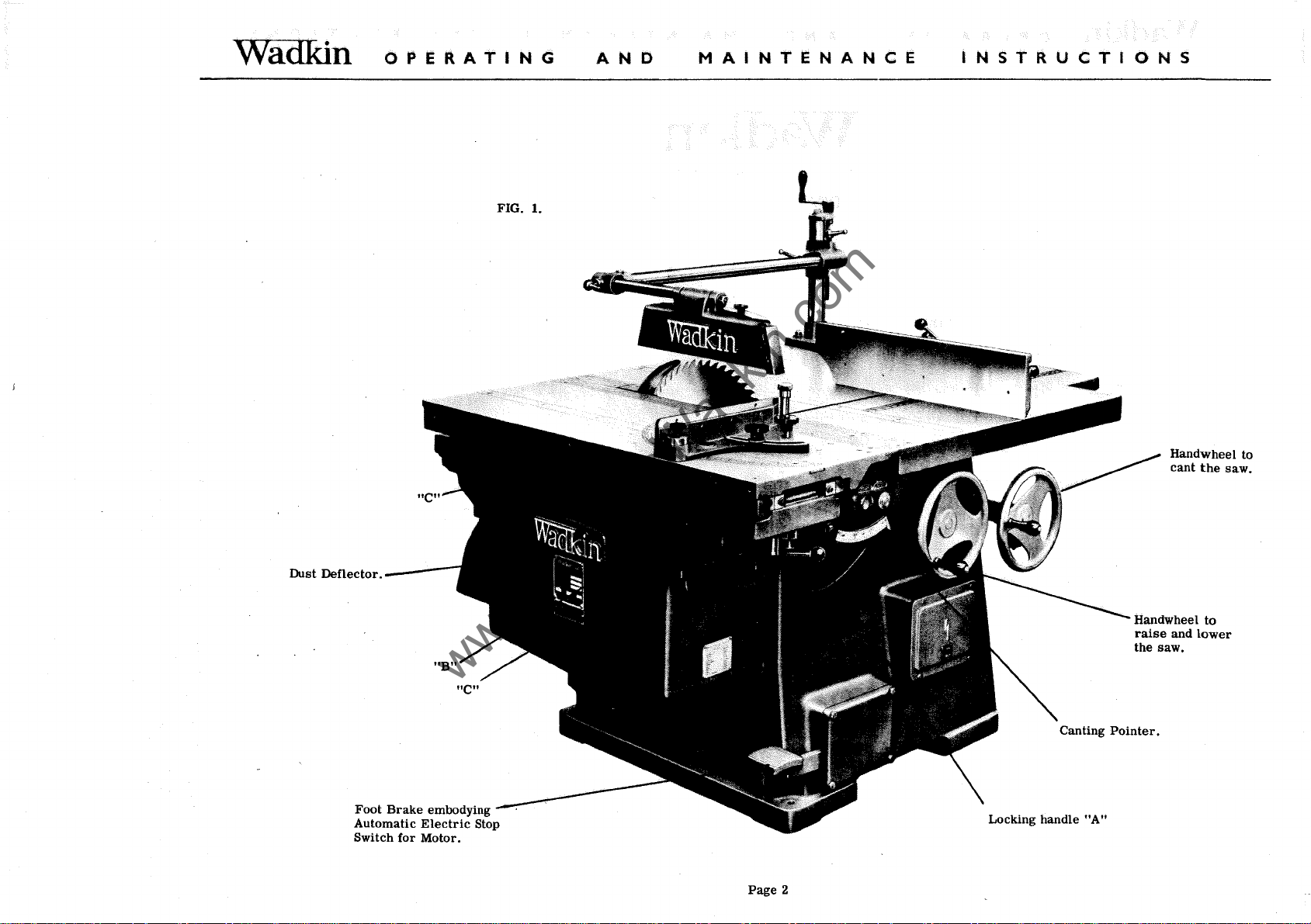

FIG.!.

AND

MAINTENANCE

INSTRUCTIONS

Handwheel to

cant

the

saw.

Dust

Deflector.

----

Foot

Brake

Automatic

Switch

for

embodying

Electric

Motor.

Stop

Page

Handwheel

raise

the

saw.

Locking handle

2

"A"

and

to

lower

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

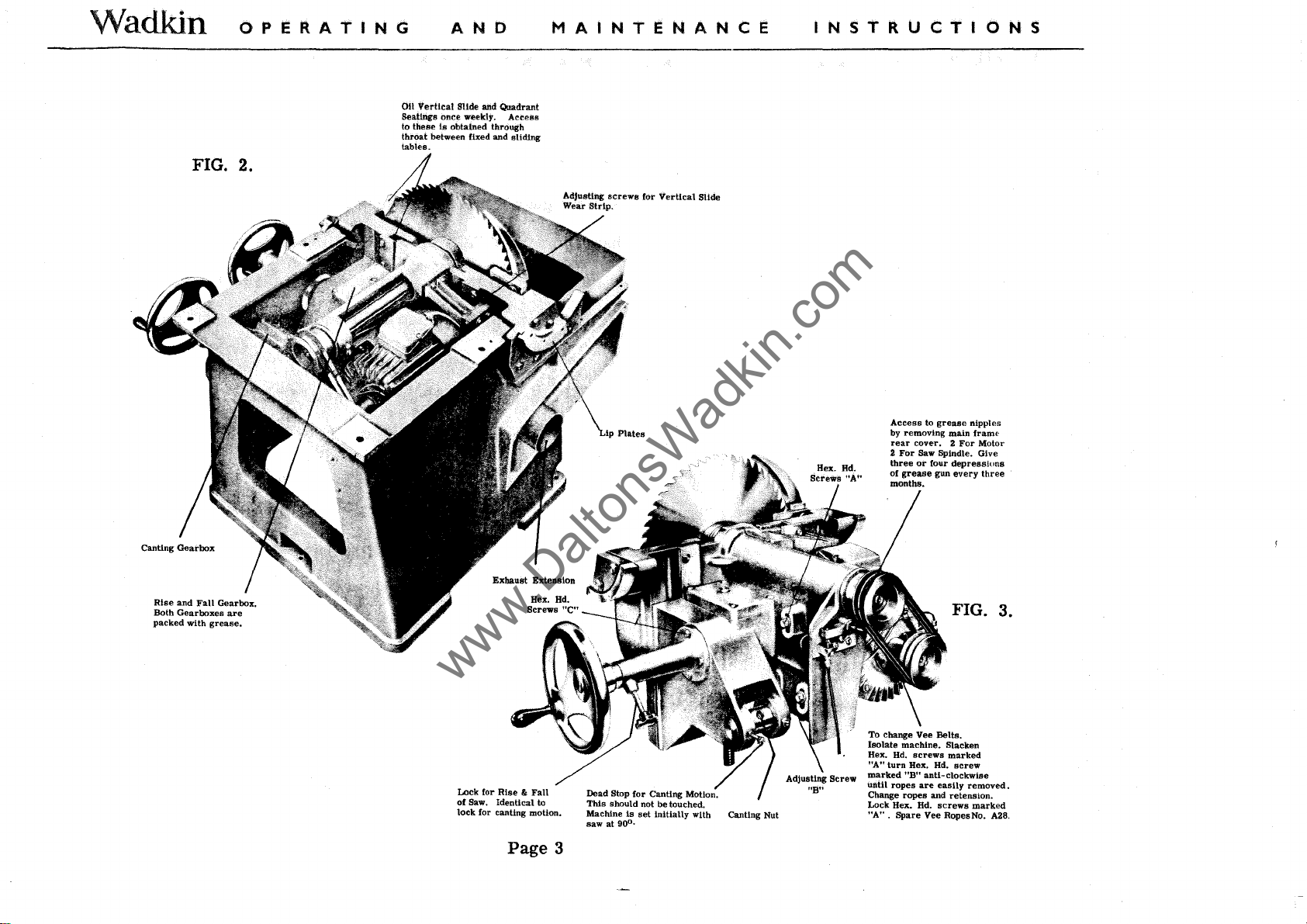

FIG. 2.

OPERATING

011

Vertical

Seatings

to these

throat

tables.

AND

Slide and Quadrant

once

weekly.

is

obtained through

between fixed

and

MAINiENANCE

Actess

sliding

INSTRUCTIONS

Access

to

by removing main

rear

cover. 2 For Motor

2

For

Saw Spindle. Give

three

or

Hex. Bd.

of

grease

months.

four

grease

depressions

gun

every

nipples

frame

three

Rise

and

Fall

Both Gearboxes

packed with

Gearbox.

are

grease.

Lock for

Rise " Fall

of

Saw. Identical to

lock

for canting motion.

Page

3

Dead Stop

This

should not

Machine

saw at

90

for

Canting Motion.

be

Is

set

initially

0

•

touched.

with Canting Nut

FIG. 3.

To change Vee Bella.

Isolate machine. Slacken

Hex.

Hd.

screws

"A"

turn Hex.

marked

ropes

until

Change ropes

Lock Hex.

"A"

. Spare Vee RopesNa. A28,

Hd.

"BH

anti-clockwise

are

easily

and

Hd.

screws

marked

screw

removed.

retension.

marked

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

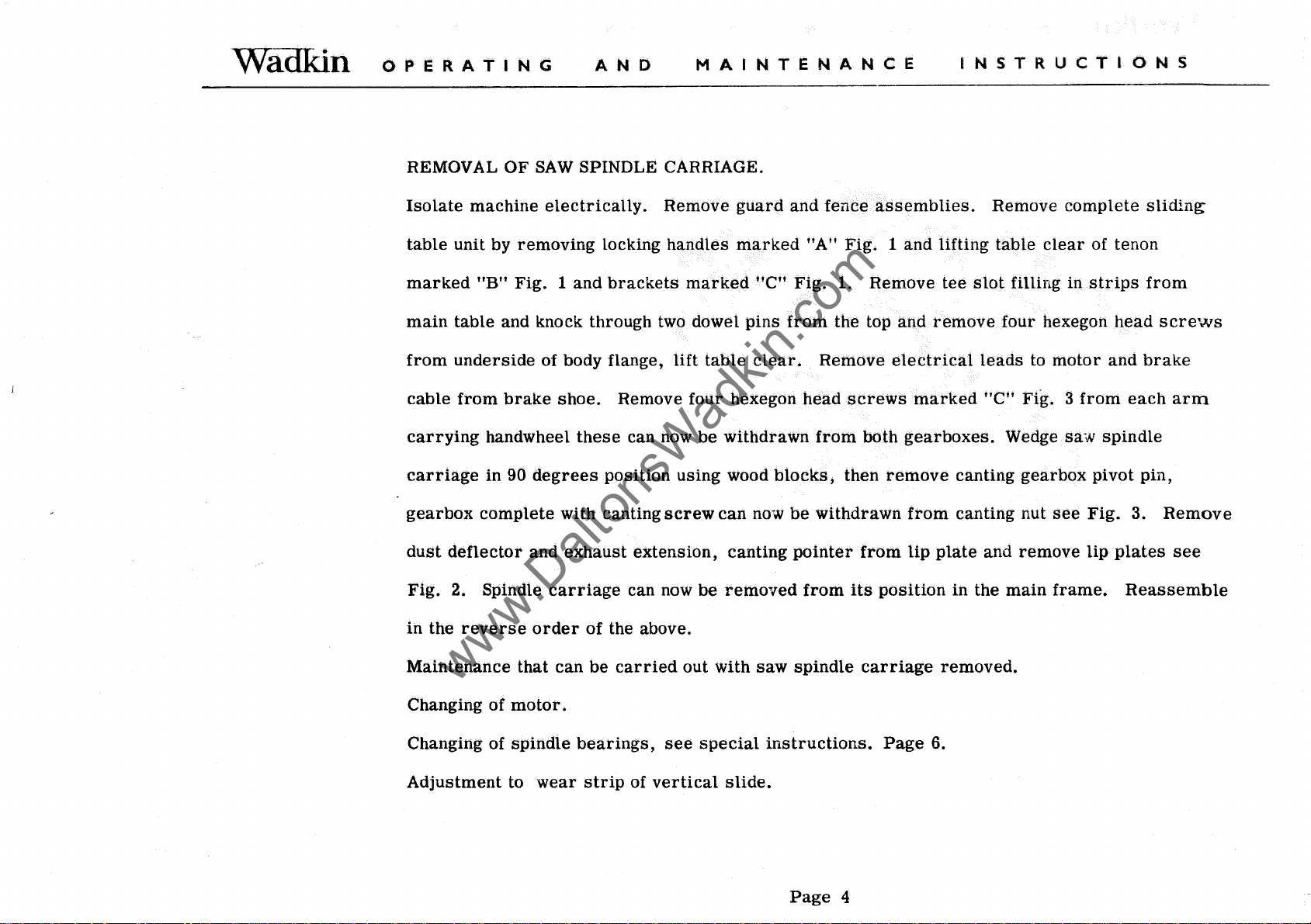

REMOVAL

Isolate

table

marked

main

from

cable

carrying

carriage

gearbox

dust

Fig.

machine

unit by

"B"

table

underside

from

handwheel

in 90

complete

deflector

2. Spindle

OF

SAW

SPINDLE CARRIAGE.

electrically.

removing

Fig. 1 and

and knock through two dowel

of body flange,

brake

degrees

and

carriage

locking

brackets

shoe.

these

position

with canting

exhaust

Remove

handles

lift

Remove

can now

using

screw

extension,

can now

marked

table

four

hexegon

be

withdrawn

wood

can

canting

be

removed

guard

marked

"C"

pins

from

clear.

blocks,

now

and

fence

"A"

Fig.

1. Remove

the top

Remove

head

from

be

withdrawn

pOinter

from

assemblies.

Fig. 1 and

and

electrical

screws

both

then

from

its

marked

gearboxes.

remove

from

lip

pOSition

Remove

lifting

tee

slot

remove

leads

"c"

canting

canting nut

plate

in

and

the

complete

table

clear

filling in

four hexegon

to

Fig. 3

Wedge

gearbox

remove

main

strips

motor

from

saw

see

Fig.

lip

frame.

sliding

of tenon

from

head

and

brake

each

spindle

pivot

pin,

3.

plates

Reassemble

screws

arm

Remove

see

in

the

reverse

Maintenance

Changing of

Changing of

Adjustment

order

that

motor.

spindle

to

wear

of

can

be

bearings,

strip

the above.

carried

of

out with

see

vertical

special

slide.

saw

spindle

instructions.

Page

4

carriage

Page

removed.

6.

WaOKin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

J-~

1'01'.

FOUNDATION

o

l§

~

~

~

o

.1

U)

OPERATING

OIA.

Q&)

H01.U

sia

01A..

(,,)

aOloTS.

AND

-1:----------

MAINTENANCE

..

r-

..

,~

o

INSTRUCTIONS

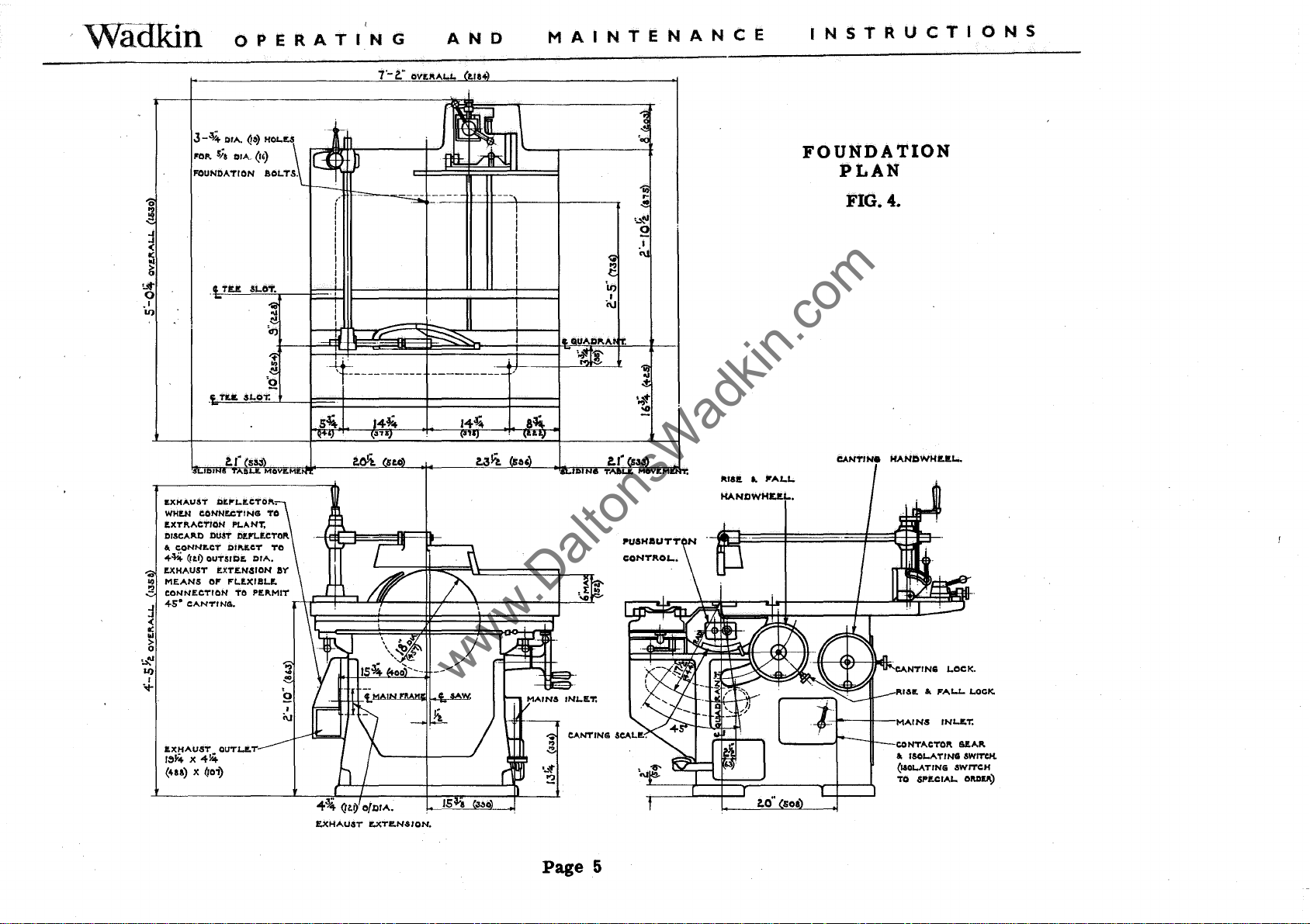

FOUNDATION

PLAN

FIG. 4.

IDJ

ItXHAUST

WHI!.N

r;XT!'.ACTION

DISCA!'.D DUST /If.l'lor;CTOR

&.

<!--¥.4.

..

I!.XHAUST

..

MEANS

!2

CONNECTION

j

<!-s'

-<

:i

>

o

'.:t;'

U)

I

.,..

~s~~A~~l&t.

(U8) le

DItP"1.ItCTO!'..

CDNNECTINEI TO

cONNItCT

<ltl) OUTSIDE.

ItXT£.N,sION

01'

CANTINEI.

QUT1.I!.T

(roi)

PLANT,

OII'.r;CT

P"1..!'l(llIlol!.

TO

14~

MOV'!'ME.

Ta

OIA.

ay

pr;

...

MIT

l-+F=l~:J...LfII-_--U-fL""':~

J

i\J

____

a

-..l-'~'~~::

-

Page

5

1\181t

..

Jl"AI..J..

HANDWHUJ...

loO"

soa

CANT/Ne

HANDWHUJ...

Rllllt

..

FALl..

LOCK.

CONTACTOR

&.

ISOJ..ATINEI SWITCH.

(UOloATING

TO 6Pl!.C IAI.. aMI!.!'.)

6ftA!'.

SWITCH

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

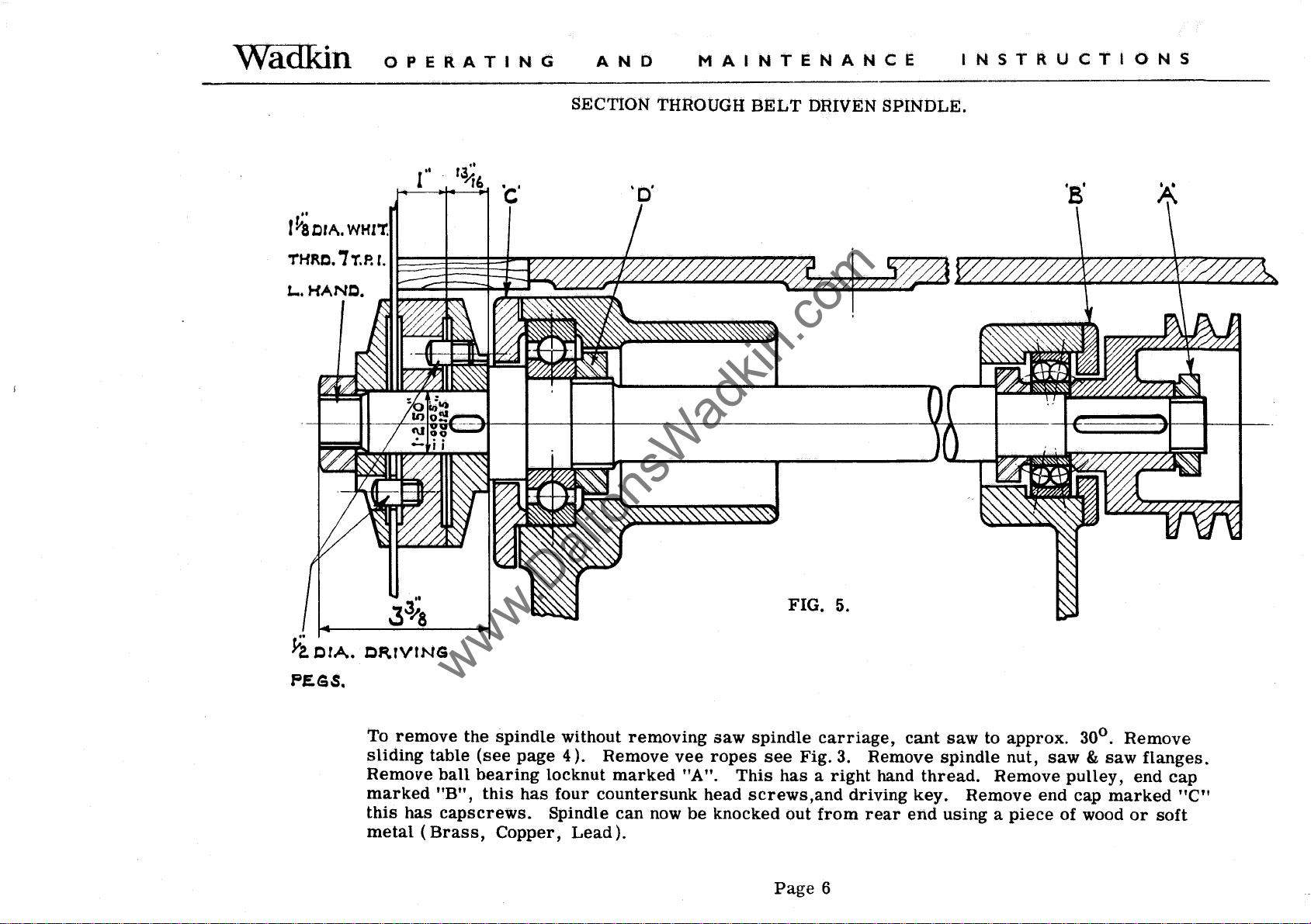

SECTION THROUGH

..

'c'

r~orA.

THRC.i~p.r.

L...

WHIT.

~~~~~~~~~~~~~~~~~~~

HAND.

BELT

DRIVEN

__

~https://manualmachine.com/

SPINDLE

.

~z.

CrA.

PESS.

CRfVrNG

To

remove

sliding

Remove

marked

this

has

metal

(Brass,

the

spindle

table

(see

ball

bearing

"B",

this

capscrews.

Copper,

page

locknut

has

Spindle

without

4).

Remove

four

countersunk

Lead).

removing

marked

can

now

saw

vee

ropes

"A".

head

be

knocked out

FIG.

spindle

see

Fig.

This

has a right

screws,and

Page

5.

carriage,

3. Remove

hand

driving

from

rear

6

cant

saw

spindle

thread.

key.

end

Remove

using a piece

to

approx.

nut,

Remove

0

30

.

saw & saw

pulley,

end

cap

marked

of wood

Remove

flanges.

end

cap

"C"

or

soft

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

With the

bearing,

To

Reassemble.

Before

mentioned

the

hammer

The

The

spindle

assembly

bearings

the

inner

grease

removed

remove

clean

procedure,

with Wadkin

races

race

should

lubricant

rear

bearing

locknut

into

marked

out

all

ensuring

ball

position

be

a good

One SKF 6309 Saw

One SKF 1306 Saw

Four

SKF

recommended

"0"

old

lubricant,

that

bearing

but

push-fit

BALL

08 Two

Lubrication

this

no

grease,

give

is

Wadkin

can

dirt

be

lightly

has a right

assemble

or

grit

grade

gentle

on the

Shell-Mex

Mobil

Castrol

taps

spindle

BEARING

spindle

spindle

each

for

see

Figs. 2 and

Grade

Oil

tapped

hand

in

enters

L. 6. When

with a

front

rear

rise

out

thread,

the

reverse

the

bearings

soft

and

the

LIST

bearing.

bearing.

and

fall

of

its

fitting

rod

outer

and

housing. To

and

lightly

order

or

housings.

ball

all

round

race

a good

canting

tap off

of

the

previous

bearings

the

periphery.

sliding-fit.

motions.

change

bearing.

Smear

do

not

frent

3.

1....

6.

Alternative

& B.

P.

Ltd.

Co. MOBILUX GREASE No. 2

grease,

Shell

SPHEEROL

ALVANIA GREASE 3

S

For

oil

lubrication,

use

Wadkin

THOROUGHLY CLEAN DOWN MACHINE WEEKLY.

Grade

L.4.

Shell

Mobil

Castrol

Alternatively

Page

Mex &

Oil

Co.

7.

B.

P.

Ltd.

Shell

Mobil VACTRA

PERFECTO.

VITREA OIL 33

medium)

OIL

NN.

(heavy

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

Grubscrew

depress

to

its

full extent.

will

prevent

for

fatigue and

To

replace

switch, disconnect

switch and

and

ensure

to

its

full extent the

the

grubscrew

To

set

first

lock by

secondary

in

anti-clockwise

marked

"A" Fig. 6

micro-switch

Failure

machine being

replace

micro-switch;

electrical

replace

switch on facing.

that when

marked

canting ripping fence

rotating

lock, this

direction

CANTING RIPPING

LOCKING ADJUSTMENT

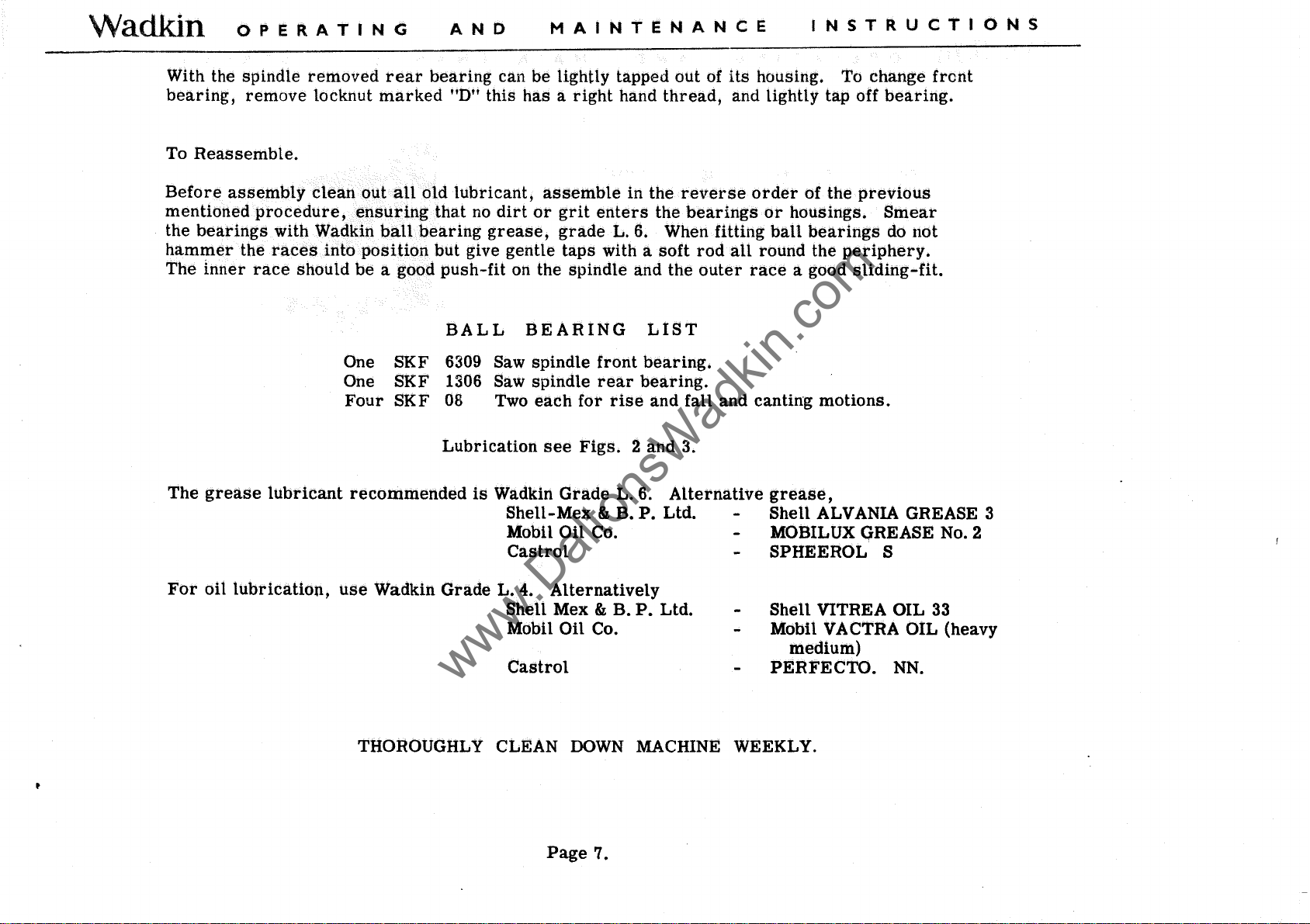

FOOT

is

when foot pedal

of

brake

started,

if

necessary.

isolate

leads,

brake

pedal

micro-switch

"A".

for

clockwise, fine

also

squares

until dead stop

FENCE

OPERATED

initially

is

pedal to

check

machine,

set

operated

return

spring

remove

BRAKE ADJUSTMENT

to

connect new

Start

machine

arm

is

depressed

is

operated

by

"A"

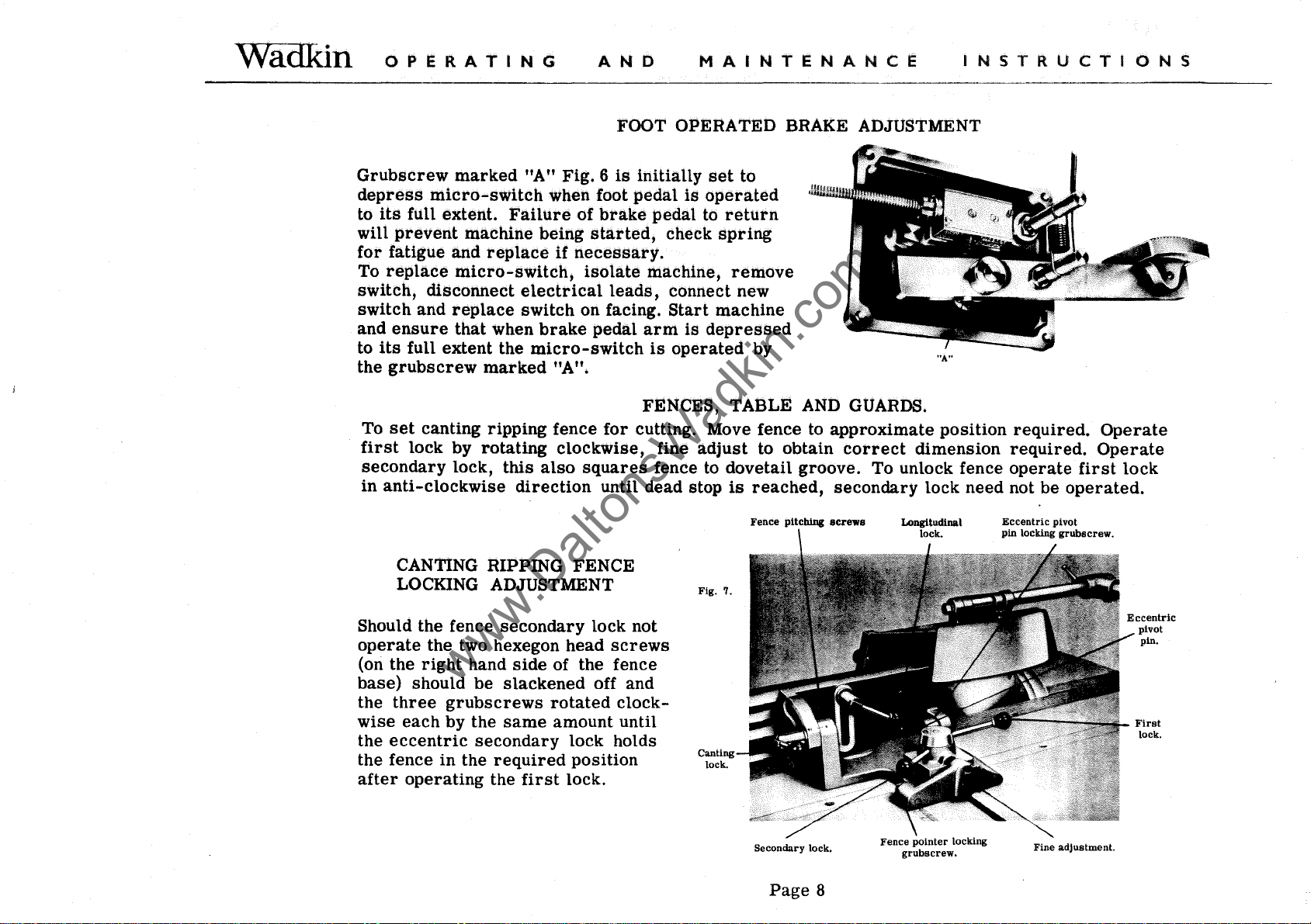

FENCES, TABLE AND GUARDS.

cutting. Move fence to

adjust

to obtain

approximate

correct

dimension

position

fence to dovetail groove. To unlock fence

is

Fig.

reached,

Fence

7.

pitching

secondary lock need not be

screws

required.

required.

operate

operated.

Operate

Operate

first

lock

Should the fence

operate

(on the

base)

the

wise

the

the fence

after

the two hexegon head

right

should be

three

grubscrews

each

by the

eccentric

in

operating

secondary

hand

side

slackened

same

secondary

the

required

the

first

rotated

lock not

screws

of the fence

off and

clock-

amount until

lock holds

position

lock.

Canting

lock.

Secondary

Page

lock.

8

Fence

pOinter locking

grubscrew.

Fine

adjustment.

Eccentric

pivot

pin.

First

lock.

WadKin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

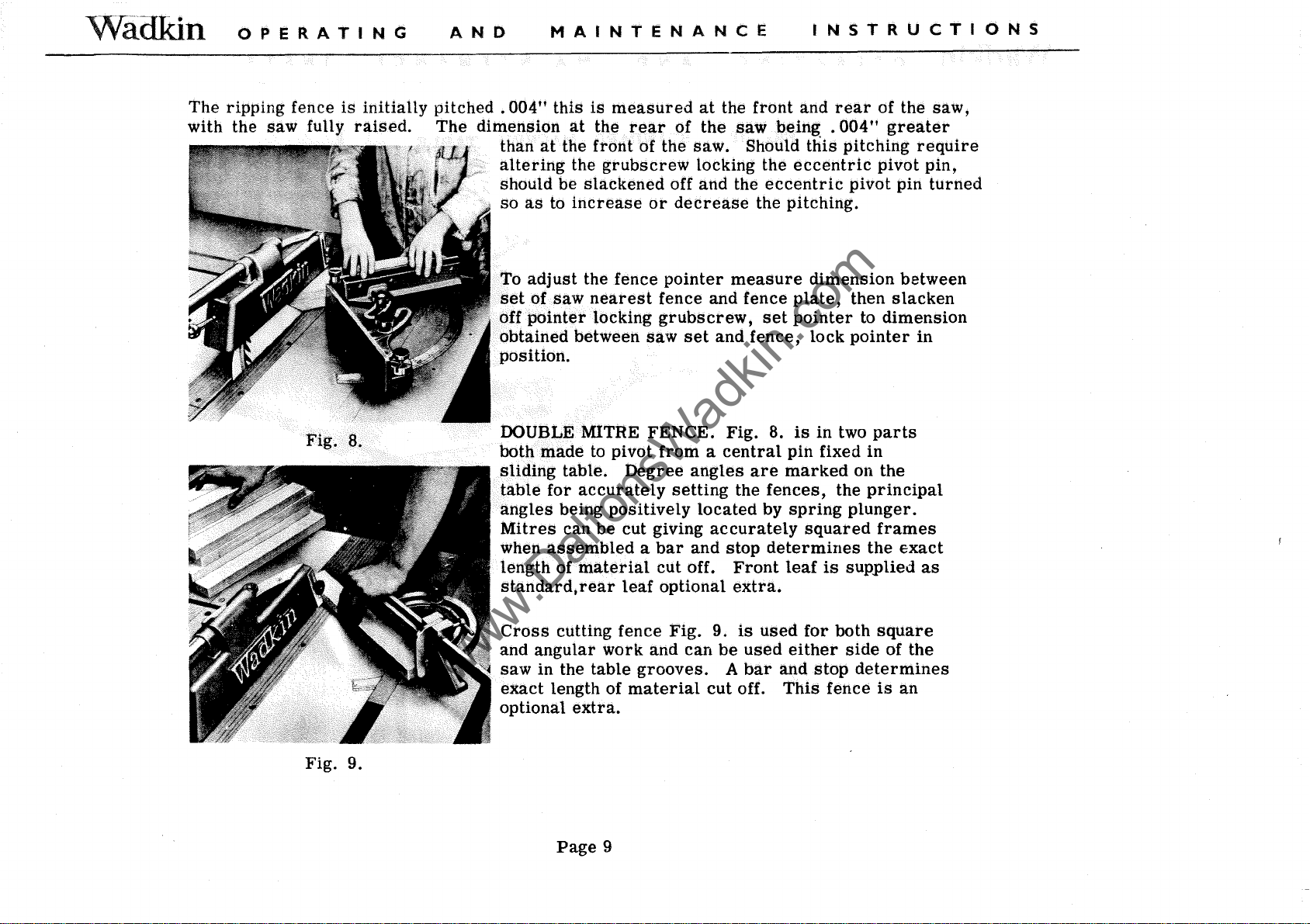

The

with

OPERATING

ripping fence

the

saw

fully

is

initially

raised.

AND

pitched

The

dimension

MAINTENANCE

.004"

than

altering

should be

so

as

at

this

at

the

to

is

measured

the

rear

front

the

grubscrew

slackened

increase

of

of the

off

or

decrease

at

the

front

the

saw

saw.

locking the

and

Should

the

eccentric

the pitching.

INSTRUCTIONS

and

rear

being . 004"

this

pitching

eccentric

pivot

of the

greater

require

pivot

pin

saw,

pin,

turned

Fig.

8.

adjust

To

set

of

off pOinter locking

obtained

position.

DOUBLE MITRE

both

sliding

table

angles

Mitres

when

length of

standard,rear

Cross

and

angular

saw

exact

optional

the fence

saw

nearest

between Saw

made

in the

to pivot

table.

for

accurately

being

can

assembled a bar

material

cutting fence

length of

extra.

Degree

positively

be

cut giving

leaf

work

table

grooves.

material

pointer

fence and fence

grubscrew,

set

FENCE.

from a central

setting

cut

optional

Fig.

and

measure

and

Fig.

angles

located

accurately

and

stop

off.

Front

extra.

9.

can

be

A

cut

fence,

are

the

is

used

bar

off.

dimension

plate,

set

pointer

lock

8.

is

in

pin

fixed

marked

fences,

by

spring

determines

leaf

used

either

and

This

the

squared

is

for

both

stop

fence

between

then

slacken

to

dimension

pointer

two

parts

in

on the

principal

plunger.

frames

the

exact

supplied

square

side

of the

determines

is

an

in

as

Fig. 9.

Page

9

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

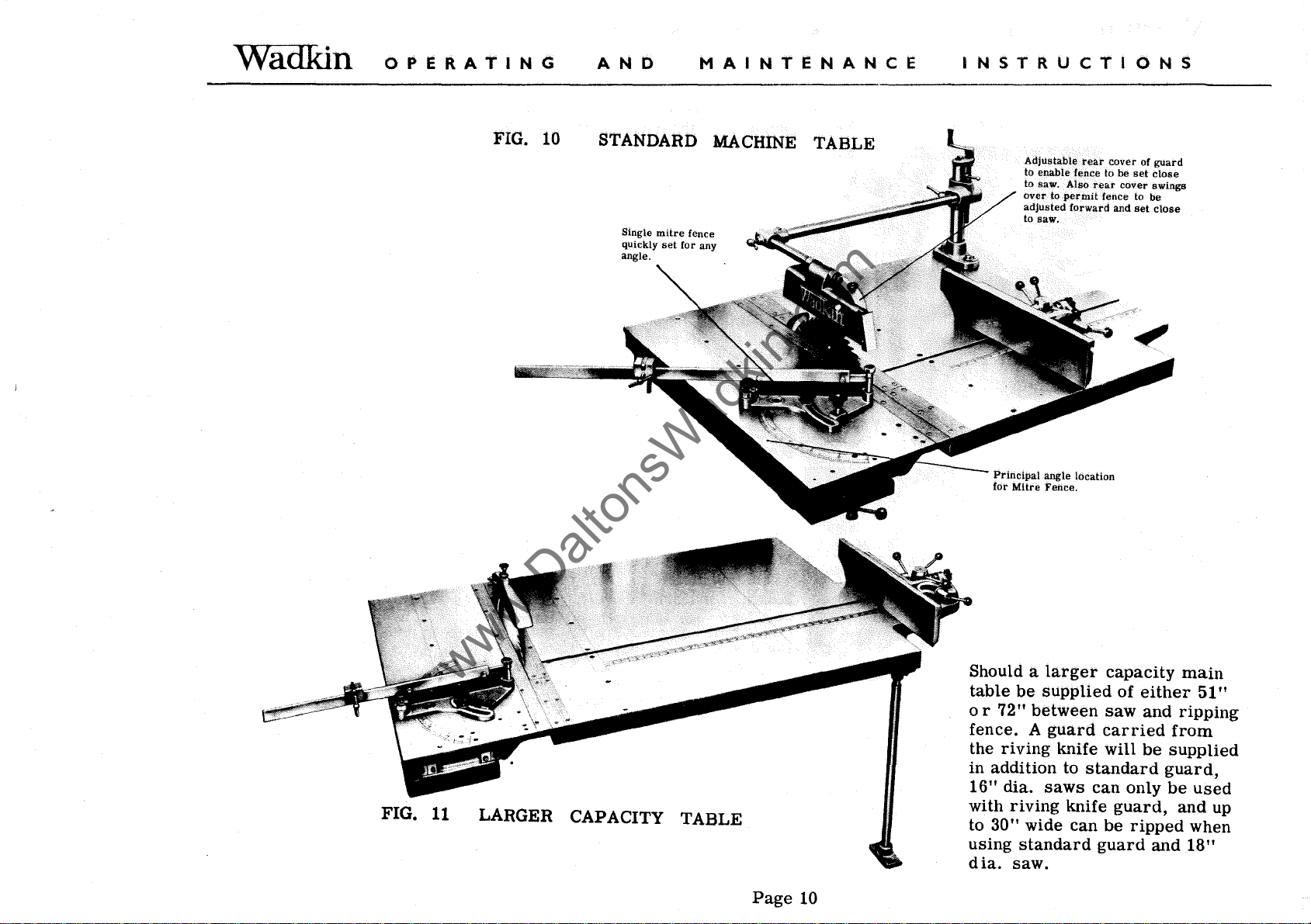

FIG. 10

STANDARD

Single

mitre

set

fence

for any

quickly

angle.

MACHINE

TABLE

Adjustable

to enable fence to

to saw. Also

over

adjusted

to

saw.

Principal

for

Mitre

rear

rear

to

permit

fence to be

forward

angle location

Fence.

cover

be

cover

and

set

set

of

guard

close

swings

close

FIG.

11

LARGER CAPACITY TABLE

Page

10

Should a

table

or

72" between

fence. A guard

the riving knife

larger

be

supplied

capacity

of

either

saw

and ripping

carried

will

be

main

51"

from

supplied

in addition to standard guard,

16" dia.

saws

can only

be

used

with riving knife guard, and

to 30" wide can

using standard guard and

dia.

saw.

be

ripped when

18"

up

Loading...

Loading...