OPERATING

AND

INSTRUCTION

MANUAL FOR

HIGH

SPEED ROUTER TYPE

LS

www.wadkin.com

info@wadkin.com

Wadkin

HIGH

SPEED

ROUTER

TYPE

L.

S.

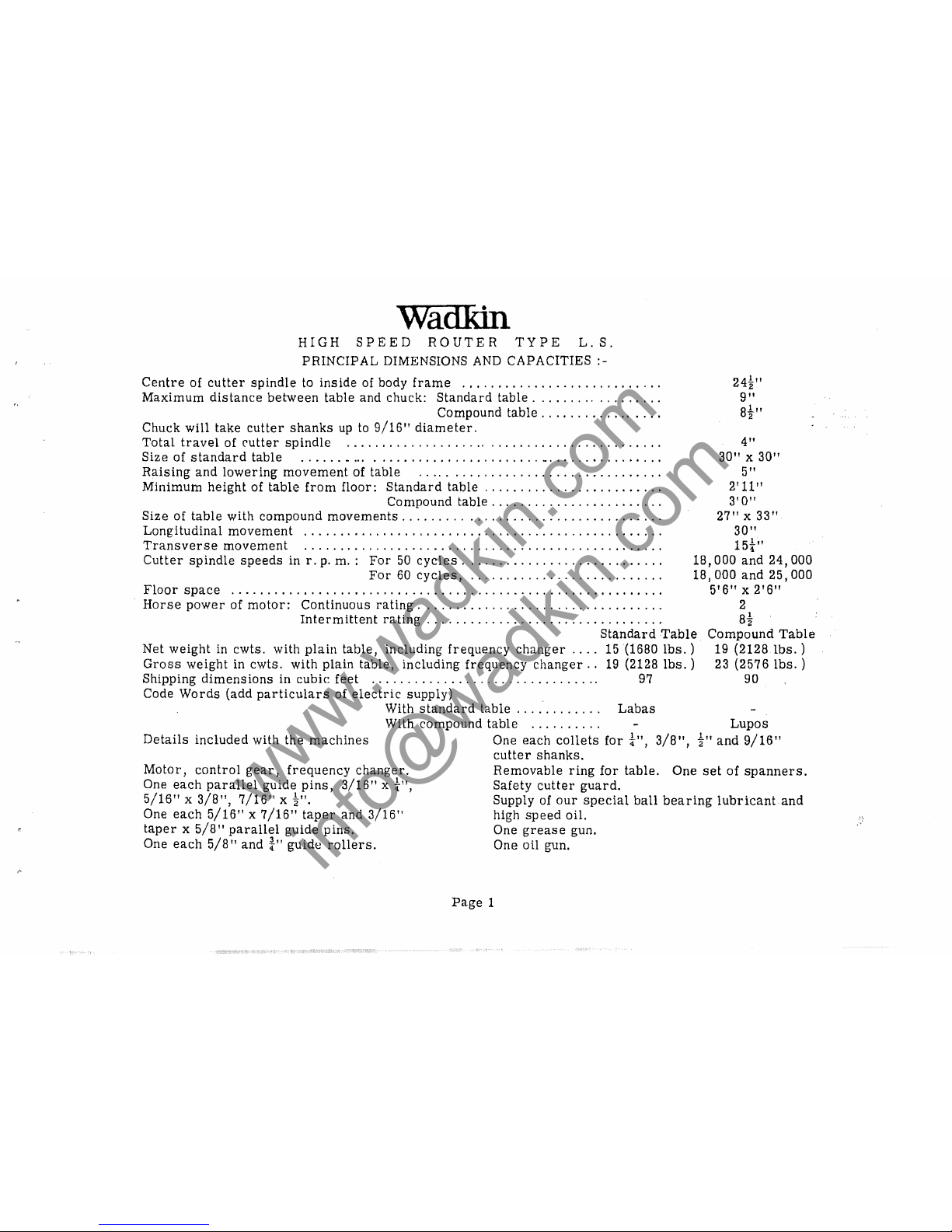

PRINCIPAL DIMENSIONS

AND

CAPACITIES

:-

Centre

of

cutter

spindle

to

inside

of body

frame

...........................

.

Maximum

distance

between

table

and chuck:

Standard

table

.................

.

Compound

table

................

.

Chuck

will

take

cutter

shanks

up

to

9/16"

diameter.

Total

travel

of

('utter

spindle

...........................................

.

Size

of

standard

table

.,

.... _ ..........................

_

...............

.

Raising

and

lowering

movement

of

table

.................................

.

Minimum

height

of

table

from

floor:

Standard

table

........................

.

Compound table

.......................

.

Size

of

table

with compound

movements

...........

,

.......................

.

Longitudinal

movement

.................................................

.

Transverse

movement

.................................................

.

24~"

9"

8~"

4"

30" x 30"

5"

2'11"

3'

A"

27" x 33"

30 "

15t"

Cutter

spindle

speeds

in

r.

p.

m.:

For

50

cycles

...........................

.

For

60

cycles,

..........................

.

Floor

space

...........................................................

.

18,000

and

24,000

18,000

and

25,000

5'6" x 2'6"

Horse

power

of

motor:

Continuous

rating

.................................

.

Intermittent

rating

................................

.

Net

weight

in

cwts.

with

plain

table,

including

frequency

changer

....

Gross

weight

in

cwts.

with

plain

table,

including

frequency

changer

..

Shipping

dimensions

in

cubic

feet

...............................

.

Code

Words

(add

particulars

of

electric

supply)

Standard

Table

15(1680

lbs.

)

19

(2128

lbs.

)

97

With

standard

table

..........

"

Labas

2

8t

Compound

Table

19 (2128

Ibs.

)

23

(2576

lbs.

)

90

With compound

table

..........

Lupos

Details

included

with the

machines

Motor,

control

gear,

frequency

changer.

One

each

parallel

guide

pins,

3/16"

x t",

5/16"

X

3/8",

7/16"

x

~".

One

each

5/16"

x

7/16"

taper

and 3/16"

taper

x

5/8"

parallel

guide

pins.

One

each

5/8"

and

t"

guide

rollers.

One

each

collets

for

t",

3/8",

~"and

9/16"

cutter

shanks.

Removable

ring

for

table.

One

set

of

spanners.

Safety

cutter

guard.

Supply of

our

special

ball

bearing

lubricant

and

high

speed

oil.

One

grease

gun.

One oil gun.

Page

1

www.wadkin.com

info@wadkin.com

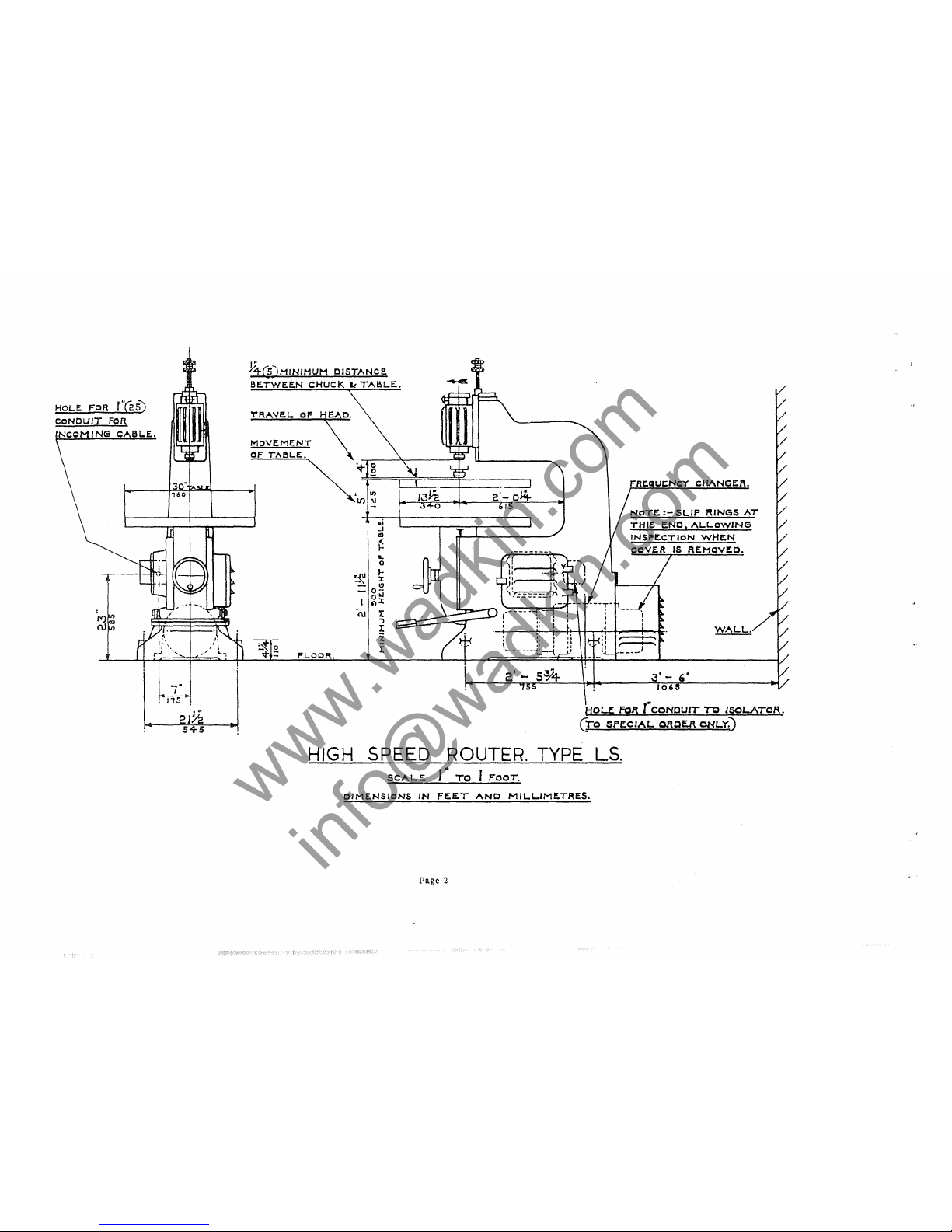

HOLI!.

FOR

r~5)

CONDUIT

FOR

INCOMING

CABLE..

•

rt)

ru

'"

Y+(5)MINIMUM

DISTANCE.

BETWEEN

CHUcK

It

TAaL.E..

TRAVE.L

of

MoVEME.NT

OF

T'ABLE.

FL.OOR.

•

lI)

It)nJ

.j

..J

ID

~

L

o

~~

~

-

I!)

-

O;j

I

~

J:

C\J

r

:J

r

Z

r

WALL.

3' -,"

106

HOLE.

FOJ\

(CONDUIT

"T"Q

lS01..ATOR.

ero

SPECIAL

Q.RQf.R

ONLY)

HIGH SPEED ROUTER. TYPE LS.

SCAL.E.

J"

TO I FOOT.

CIME.NSIONS

IN

FEE.T

AND

MIL.L.IMf.TRES.

Page

2

www.wadkin.com

info@wadkin.com

INSTALLATION

The

machine

is

despatched

from

the

Works

with

all

bright

surfaces

greased

to

prevent

rusting.

This

must

be

removed

by

applying a cloth

damped

with

paraffin

or

turpentine.

FOUNDATIONS.

Four

5/8"

diameter

foundation

bolts

must

be

used

to

bolt

machine

down to

the

floor.

Foundation

bolts

are

not

supplied

by

Wadkin Ltd.

unless

specially

ordered.

"Rag"

type

holding

down

bolts

may

be

used.

If

mill

floor

consists

of

from

4"

to

6"

solid

concrete

no

special

foundation

is

nec-

essary.

Cut out in

concrete

4

f1

to 6

f1

square

holes

and

fill

in

and

grout

with

liquid

cement

after

machine

has

been

carefully

levelled.

E LE

CTRICAL

CONNE CTIONS

See

Page

65

for

details

and

connection

diagram.

IMPOR

TANT:-

The

frequency

changer

must

NOT

be

bolted

down

but

placed

inside

the

main

frame

after

the

machine

is

finally

fixed. Make

sure

that

the

surface

is

level

and

smooth

to

enable

the

frequency

changer

to

be

readily

withdrawn

Alignment

of

Table

Pin

to

Spindle. A Setting

Arbor

is

supplied

for

checking

this

alignment.

The

table

is

not dowe

lled

to the

vertical

slide,

so

that

it

can

be

reset

from

time

to

time

with

the

head.

Fit

the

setting

arbor

in the

spindle

and

lower

head

to

table.

Now

slacken 4 screws

securing

table

to

vertical

slide

and

float

table

horizontally

until

the

arbor

in

spindle

enters

pin

hole

in

table.

Relevel

table

securing

screws,

and

remove

arbor

from

spindle.

Page

3

www.wadkin.com

info@wadkin.com

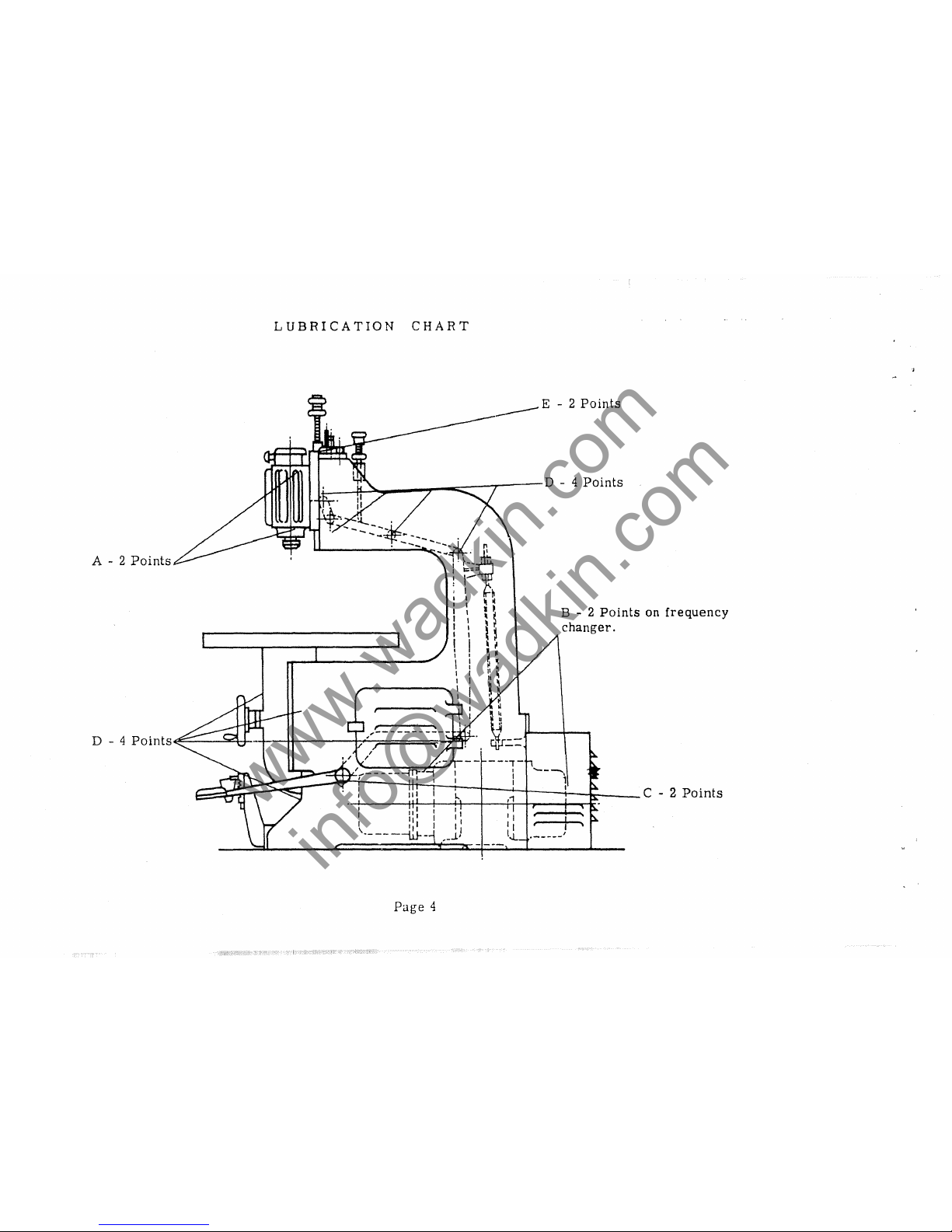

LUBRICATION

CHART

.i-_~~_--r-;;;;;::::=-T--D

- 4

Points

A - 2

Points

-.:.

~~'-~~

I

1:;=

! 1-

; 1

~

::

~ ~

I I •

~

I I

~"

I:

H

I I

~

~

\ I

;-

\

~ ~ ~

I I

,q

I 1 h

~

~---------:

I

~

I i

~

D - 4

Po

ints~~-~tJ-'-r-tt----i7"-,====;P-;~

it=-=

11

I I I I

11' I

I,

l

I11

I

11

-------I.iJ--

__

J..

Page

4

B-2

Points

on

frequency

changer.

,

..-

____

1

www.wadkin.com

info@wadkin.com

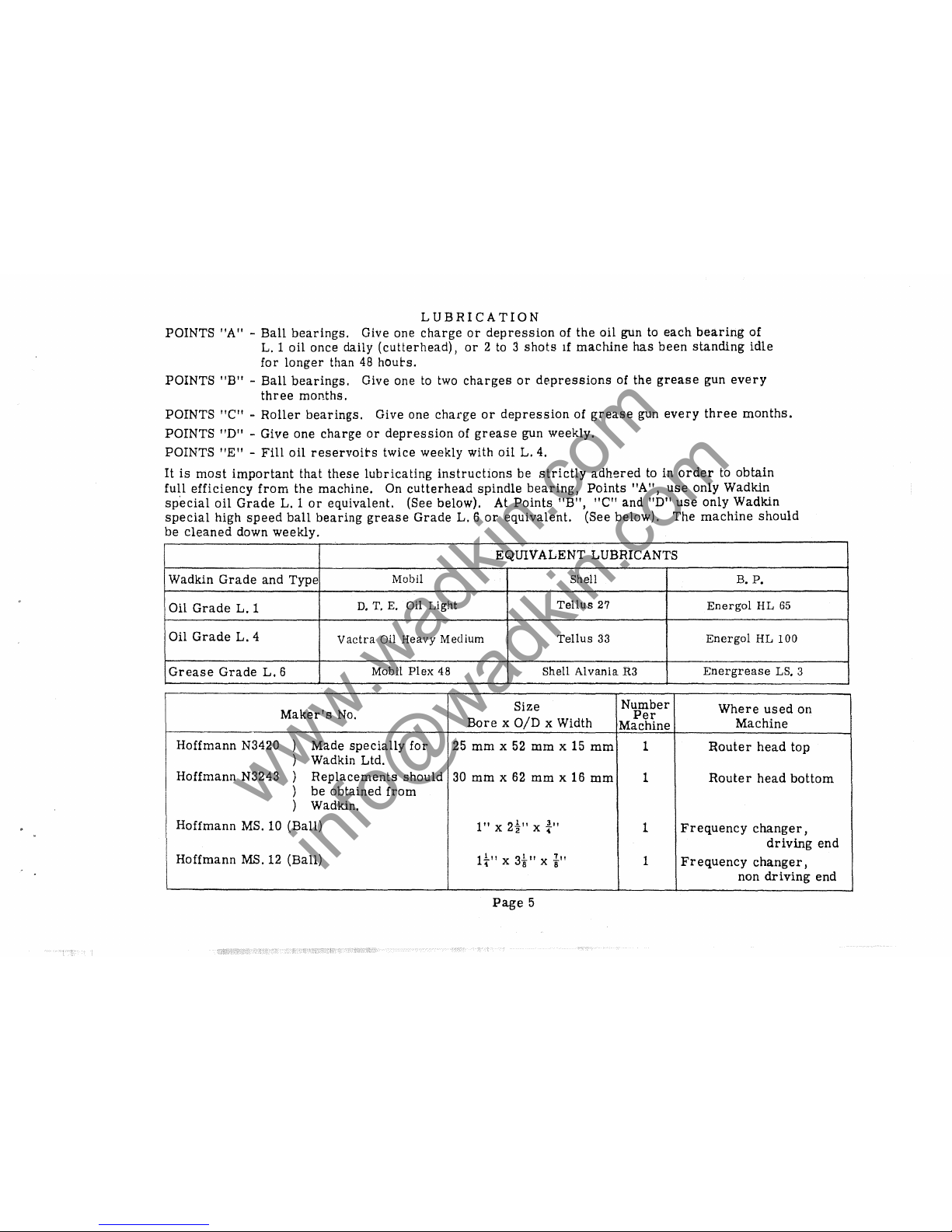

LUBRICATION

POINTS

"A" -Ball

bearings.

Give

one

charge

or

depression

of

the

oil

gun to

each

bearing

of

L.l

oil

once

daily

(cutterhead),

or

2 to 3

shots

If

machine

has

been

standing

idle

for

longer

than 48

houbs.

POINTS

"B" -Ball

bearings.

Give

one

to two

charges

or

depressions

of

the

grease

gun

every

three

months.

POINTS

"Cif -

Roller

bearings.

Give

one

charge

or

depression

of

grease

gun

every

three

months.

POINTS

"D" -

Give

one

charge

or

depression

of

grease

gun

weekly.

POINTS

"E"

-

Fill

oil

reservoirs

twice

weekly

with

oil

L.

4.

It

is

most

important

that

these

lubricating

instructions

be

strictly

adhered

to

in

order

to

obtain

full

efficiency

from

the

machine.

On

cutterhead

spindle

bearing,

Points

"A",

use

only

Wadkin

special

oil

Grade

L. 1

or

equivalent.

(See

below).

At

Points

"B",

"Cif

and

"DI'

use

only

Wadkin

special

high

speed

ball

bearing

grease

Grade

L. 6 or

equivalent.

(See

below).

The

machine

should

be

cleaned

down

weekly.

EQUIVALENT

LUBRICANTS

Wadkin

Grade

and

Type

MobU

Shell

B.

P.

Oil

Grade

L.

1

D.

T.

E.

Oil

Light

Tellus

27

Energol

HL

65

Oil

Grade

L.

4

Vactra Oil Heavy Medium

Tellus

33

Energol

HL

100

Grease

Grade

L.

6

Mobil

Flex

48

Shell

Alvania R3

Energrease

LS, 3

Maker'S

No.

Size

Number

Where

used

on

Per

Bore

x

OlD

x Width

Machine

Machine

Hoffmann

N3420

)

Made

specially

for

25

mm

x

52

mm

x 15

mm

1

Router

head

top

)

Wadkin

Ltd.

Hoffmann

N3243

\

Replacements

should

30

mm

x

62

mm

x 16

mm

1

Router

head

bottom

J

,

be

obtained

from

J

)

Wadkin.

Hoffmann

MS. 10

(Ball)

1"x2%"

x t"

1

Frequency

changer,

driving

end

Hoffmann

MS. 12

(Ball)

It"

x

3i"

x t"

1

Frequency

changer,

non

driving

end

Page

5

www.wadkin.com

info@wadkin.com

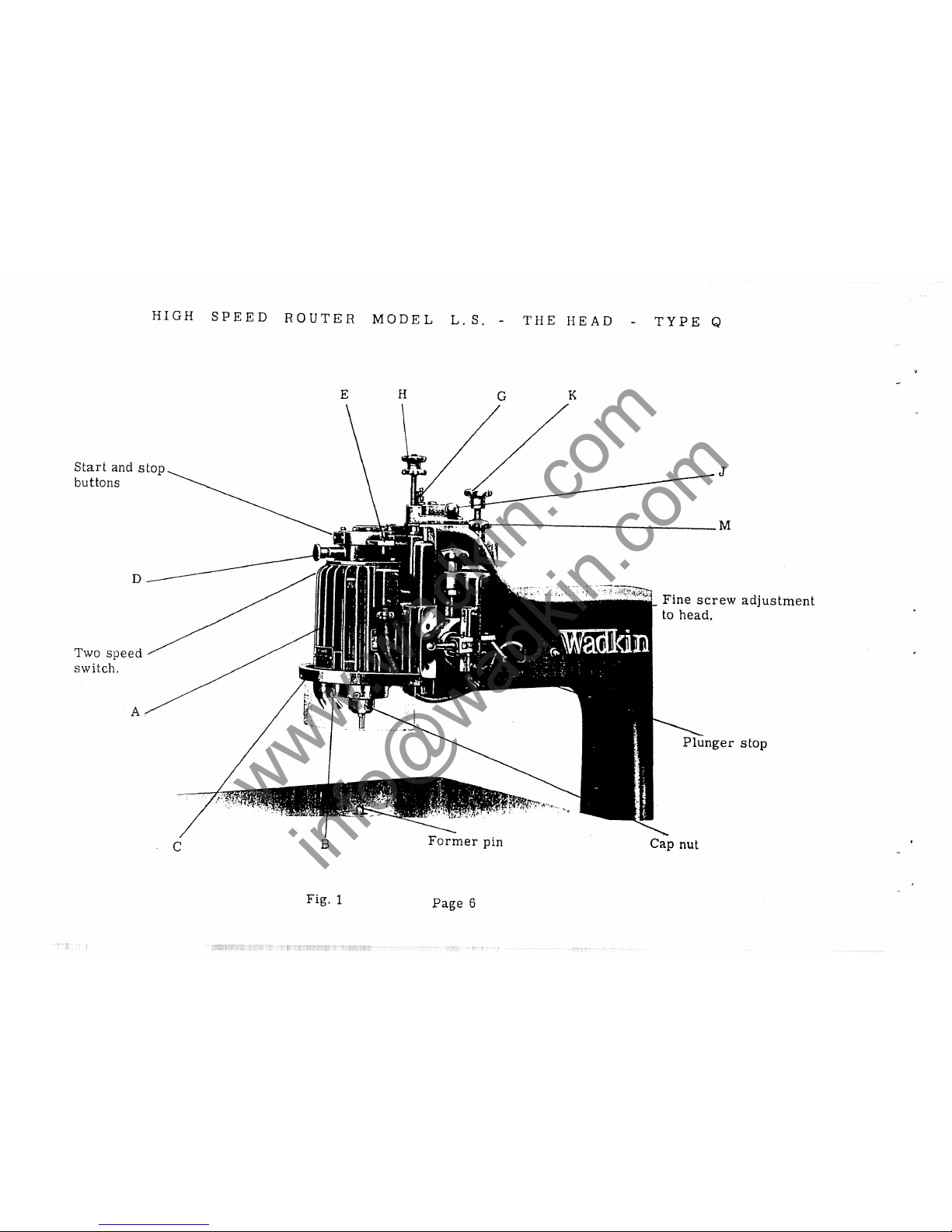

HIGH

SPEED

ROUTER

MODEL

L.

S.

-

THE

HEAD

TYPE

Q

Start

and

stop

buttons

D

Two

speed

switch.

A.

E

c

B

Fig. 1

H

G

K

___

J

~~~----------------

__

M

Page

6

Fine

screw

adjustment

to

head.

www.wadkin.com

info@wadkin.com

THE

HEAD.

The

cuEterhead

motor,

Fig,

1,

is

built

directly

onto a

nickel

chrome

steel

spindle

which

runs

on

precision

high

speed

bearings.

Blower

"B"

is

incorporated

in the

head

to

dislodge

chips

from

the

face

of the work.

Transparent

guard

"C",

which

can

be

swung

a way

for

easy

access

to the

cutter,

gives

full

protection

to

the

operator

without

obstructing

his

view

of

the job. A

quick

acting

brake

and

also a spindle

lock

for

use

when

cutter

changing

are

incorp-

orated.

The

brake

is

operated

by

pressing

the knob "Dti

after

the

motor

has

been

switched

off.

The

lock

is

operated

by

sliding

the

lOCking

bar,

tiE

tI

, INWARDS to

lock

the

spindle

and

OUT

to

unlock.

Care

should

be

taken

not to

start

the

machine

whilst

the

locking

bar

is

in

position.

MOVEMENT

OF

THE

HEAD.

The

head

is

brought

down

and

locked

by

means

of the fa

at

treadle

(see

Fig.

II). A

touch

on

the

auxiliary

toe

pedal

disengages

the

ratchet

holding the

head

which

is

counterbalanced

so

that

it

rises

out

of the

work

automatically

The

travel

of the

head

is

limited

by

stops

for

movement

both

up

and

down. A

range

of

four

stops,

"G",

controls

the

downward

movement.

Anyone

of

these

stops

may

be

selected

by

means

of the hand

lever

"J",

A

long

stop

screw

"H"

gives

a

wide

range

of

movement

to the head.

The

upward

movement

of

the

head

is

controlled

by

an

adjustable

stop

"K",

To

reduce

the

travel

of

the

head the

locking

handwheel

"M"

is

first

loosened

and

the

stop

then

screwed

in a

clockwise

direction,

the

locking

handwheel

being

tightened

again

afterwards.

To

increase

the

travel

of the

head

the

stop

is

screwed

in

an

anti-

clockwise

direction.

Page

7

www.wadkin.com

info@wadkin.com

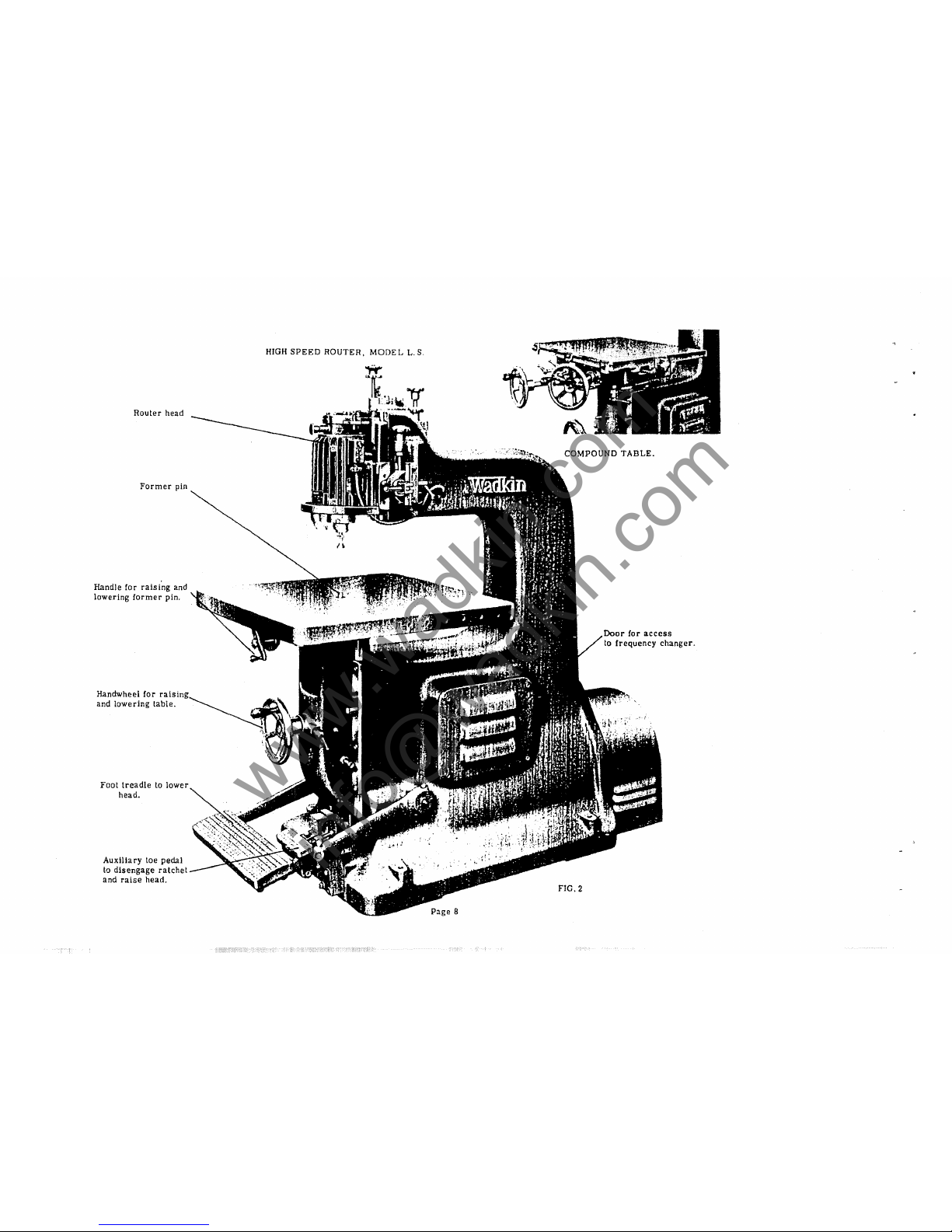

Router

head

Former

pin

Handle for

raising

and

lowering

former

pin.

Handwheel

for

raj

and

lowering

table.

Foot

treadle

to

lower

head.

Auxiliary

toe

pedal

to

disengage

ratchet

and

raise

head.

HIGH

SPEED

ROUTER,

MODEL

L.S.

COMPOUND

TABLE.

Door

for

access

to

frequency

changer.

FIG.2

www.wadkin.com

info@wadkin.com

c

B

aAL.L. PL.UNGf:.R GIves

THRe~

posrrloNS

TO

F01\Ml!./\

PIN.

I

E

D

Flg.4

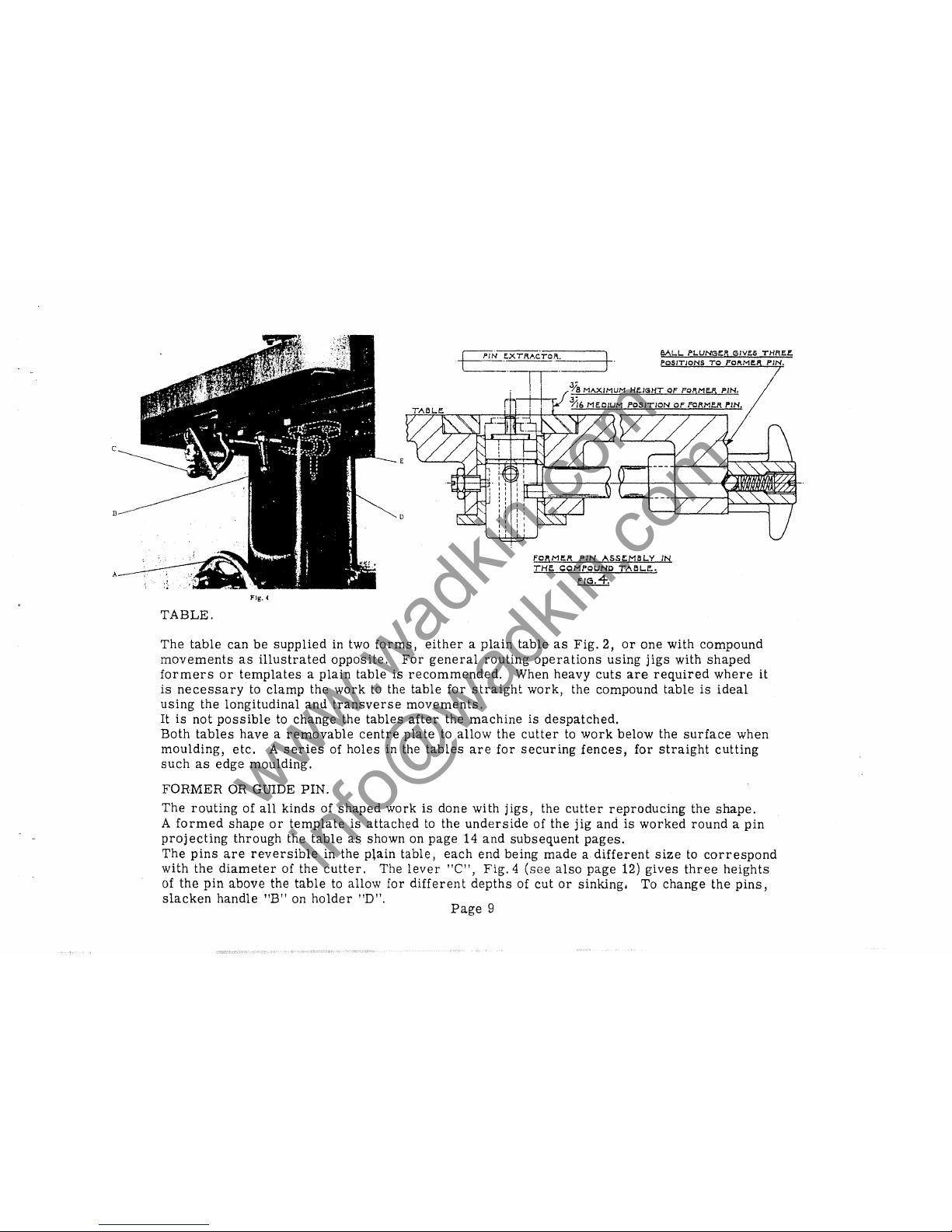

TABLE.

J'

7'8

MAXIMUM

HE.IGHT

OF

FO/\Me.t>.

PIN.

3"

YJ6

MEOIUM

POSITION

OF

FORMe.t>.

PIN.

fOI\ME.R.

PIN

6SSf:M5LY

IN

THE.

COMPOUND

Tt'l8LI!..

FI(3.4.

The

table

can

be

supplied

in two

forms,

either a plain

table

as

Fig.

2,

or

one

with

compound

movements

as

illustrated

opposite.

For

general

routing

operations

using

jigs

with

shaped

formers

or

templates a plain

table

is

recommended.

When

heavy

cuts

are

required

where

it

is

necessary

to

clamp

the

work

to the

table

for

straight

work,

the

compound

table

is

ideal

using

the

longitudinal

and

transverse

movements.

It

is

not

possible

to

change

the

tables

after

the

machine

is

despatched.

Both

tables

have a removable

centre

plate

to

allow

the

cutter

to

work

below

the

surface

when

moulding,

etc. A series

of

holes

in the

tables

are

for

securing

fences,

for

straight

cutting

such

as

edge

moulding.

FORMER

OR GUIDE

PIN.

The

rO\lting

of

all

kinds

of

shaped

work

is

done

with

jigs,

the

cutter

reproducing

the

shape.

A

formed

shape

or

template

is

attached

to

the

underside

of

the

jig

and

is

worked

round a pin

proj

ecting

through

the

table

a$

shown

on

page

14

and

subsequent

pages.

The

pins

are

reversible

in the

plain

table,

each

end

being

made a different

size

to

correspond

with

the

diameter

of

the

cutter.

The

lever

"C",

Fig.4

(see

also

page

12)

gives

three

heights

of

the

pin

above

the

table

to

allow

for

different

depths

of

cut

or

sinking.

To

change

the

pins,

slacken

handle

"B"

on

holder

"D".

Page

9

www.wadkin.com

info@wadkin.com

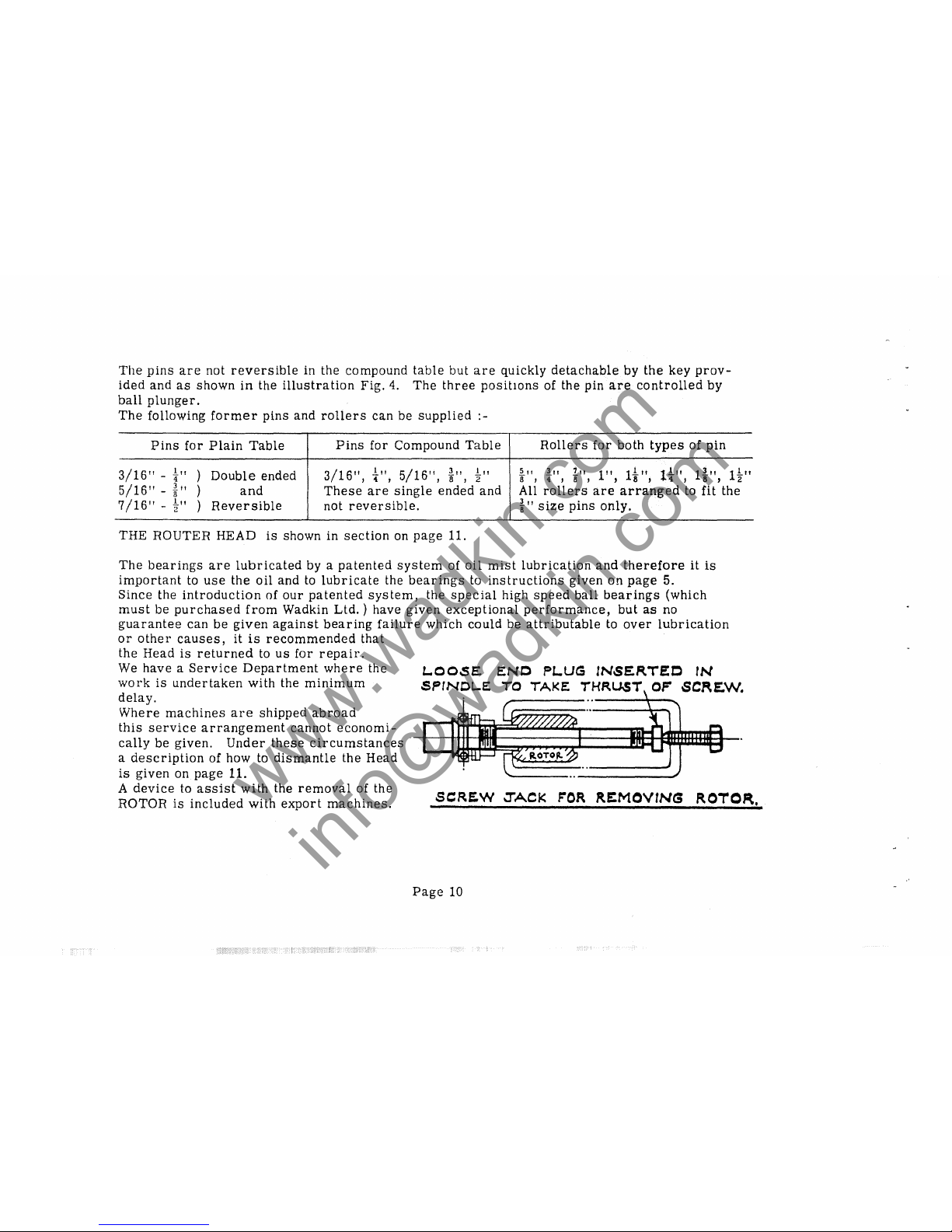

The

pins

are

not

reversible

in the compound

table

but

are

quickly

detachable

by

the

key

prov-

ided and

as

shown

in

the

illustration

Fig.

4.

The

three

positIOns of the

pin

are

controlled

by

ball

plunge

r.

The

following

former

pins

and

rollers

can

be

supplied

:-

Pins

for

Plain

Table

3/16"

-

tIt

5/16"

- i"

7/16"

-

~"

Double

ended

and

Reversible

Pins

for Compound

Table

3/1

6"

1.

"

5/16"

1.

t t

1..

, t

, 4 , , 8 , 2

These

are

single

ended

and

not

reversible.

THE ROUTER HEAD

is

shown in

section

on

page

11.

Rollers

for

both

types

of

pin

~II

1."

111

I"

11.11

11.11

1

1

"

11.11

S,ot,S,

,8,4,8,2

All

rollers

are

arranged

to

fit

the

~"

size

pins

only.

The

bearings

are

lubricated

by a

patented

system

of

oil

mist

lubrication

and

therefore

it

is

important

to

use

the

oil

and

to

lubricate

the

bearings

to

instructions

given

on

page

5.

Since

the

introduction

of

our

patented

system,

the

special

high

speed

ball

bearings

(which

must

be

purchased

from

Wadkin

Ltd.

) have

given

exceptional

performance,

but

as

no

guarantee

can

be

given

against

bearing

failure

which

could

be

attributable

to

over

lubrication

or

other

causes,

it

is

recommended

that

the Head

is

returned

to

us

for

repair.

We

have a Service

Department

where

the

work

is

undertaken

with

the

minimum

delay.

Where

machines

are

shipped

abroad

this

service

arrangement

cannot

economi-

cally

be

given.

Under

these

circumstances'

a

description

of how to

dismantle

the Head

is

given on

page

11.

A

device

to

assist

with

the

removal

of the

ROTOR

is

included

with

export

machines.

l..OOSE

ENC

PL.UG

INSERTEC

rN

SPINOLE:

TO

TAKE

"H~UST

OF

SCRE.W.

SCRE.W

JACK

rOR

RE:MOV1NG

ROTOR.

Page

10

www.wadkin.com

info@wadkin.com

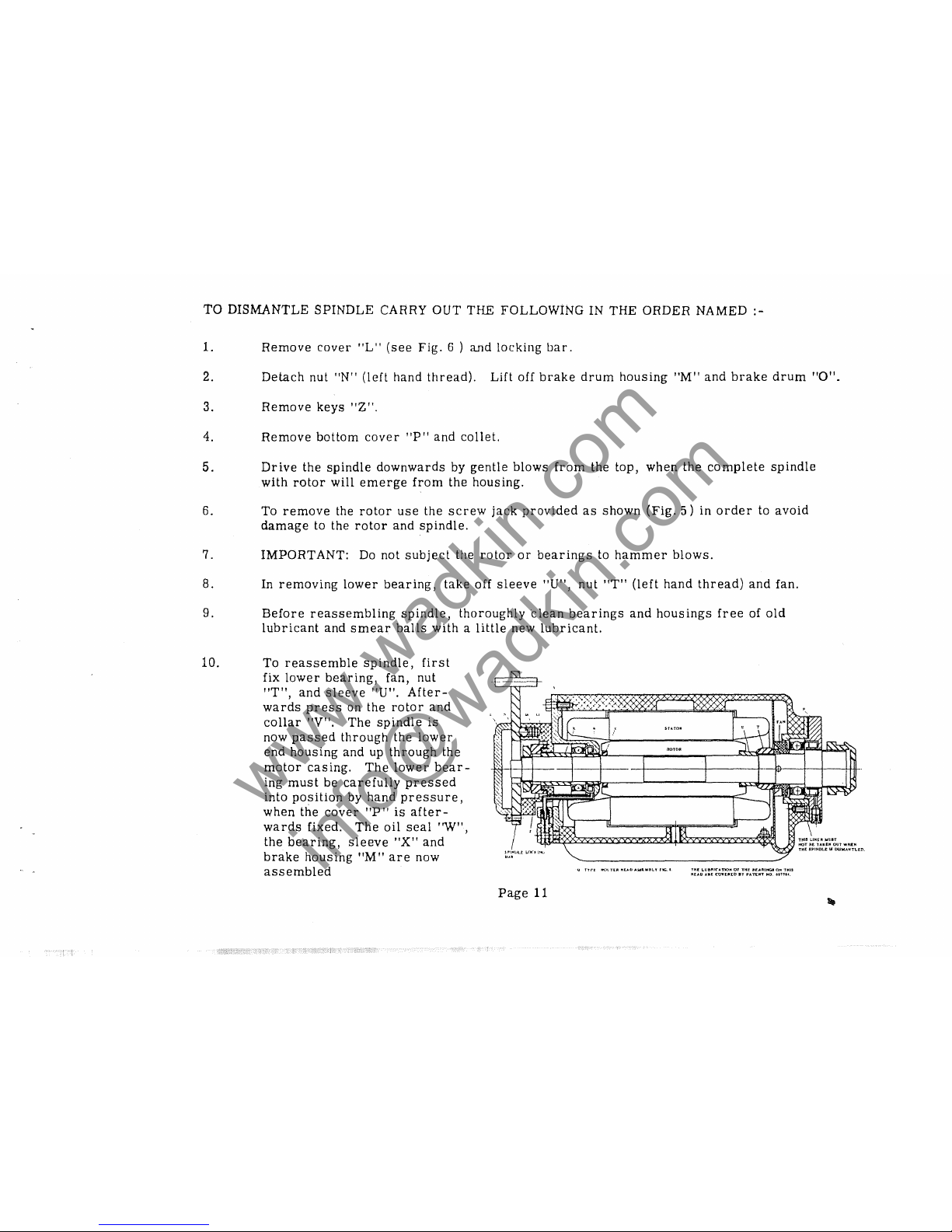

TO

DISMANTLE

SPINDLE

CARRY

OUT

THE FOLLOWING IN THE ORDER NAMED -

1.

Remove

cover

ilL"

(see

Fig.

6 )

and

locking

bar.

2.

Detach

nut

"N"

(left

hand

thread).

Lift

off

brake

drum

housing

"M"

and

brake

drum

"a".

3.

Remove

keys

"Z".

4.

Remove

bottom

cover

"P"

and

collet.

5.

Drive

the

spindle

downwards

by

gentle

blows

from

the top,

when

the

complete

spindle

with

rotor

will

emerge

from

the

housing.

6. To

remove

the

rotor

use

the

screw

jack

provided

as

shown

(Fig.

5)

in

order

to

avoid

damage

to the

rotor

and

spindle.

7.

IMPORTANT:

Do

not

subject

the

rotor

or

bearings

to

hammer

blows.

8. In

removing

lower

bearing,

take

off

sleeve

"U",

nut

"T"

(left

hand

thread)

and

fan.

9.

Before

reassembling

spindle,

thoroughly

clean

bearings

and

housings

free

of

old

lubricant

and

smear

balls

with a little

new

lubricant.

10.

To

reassemble

spindle,

first

fix

lower

bearing,

fan, nut

1fT",

and

sleeve

"U".

After-

wards

press

on the

rotor

and

collar

"V".

The

spindle

is

now

passed

through

the

lower

end

housing

and

up

through

the

motor

casing.

The

lower

bear-

ing

must

be

carefully

pressed

into

position

by

hand

pressure,

when

the

cover

"P"

is

after-

wards

fixed.

The

oil

seal

"W",

the

bearing,

sleeve

"X"

and

brake

housing

"M"

are

now

assembled

Page

11

Q

T'rrr

1'10\

TUt

I'IU.b

ollOill"IIL'I'

fIG.'

'rrt[

LU81'1I('Ano".

or

THr

lI.f.:olRIIiGII

01'1

TMIS

"lA.C

"JI[

COYUI1D

IT

PATt.flfT

NO.

un

...

www.wadkin.com

info@wadkin.com

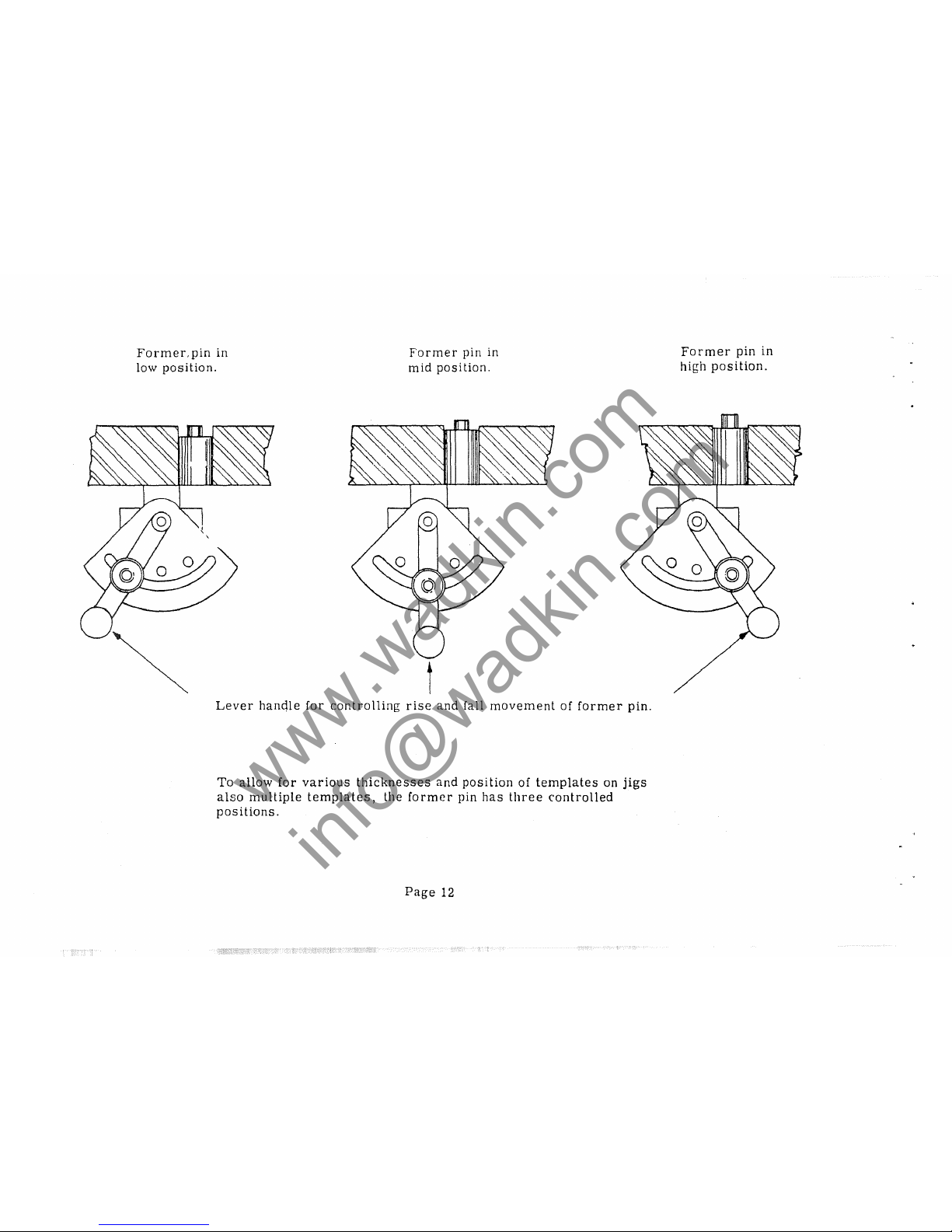

Former,

pin

in

low

position.

Former

pin in

mid

position.

t

Lever

hancHe

for

controlling

rise

and

fall

movement

of

former

pin.

To

allow

for

various

thicknesses

and

position

of

templates

on

jigs

also

multiple

templates,

the

former

pin

has

three

controlled

positions.

Page

12

Former

pin

in

hi~h

position.

www.wadkin.com

info@wadkin.com

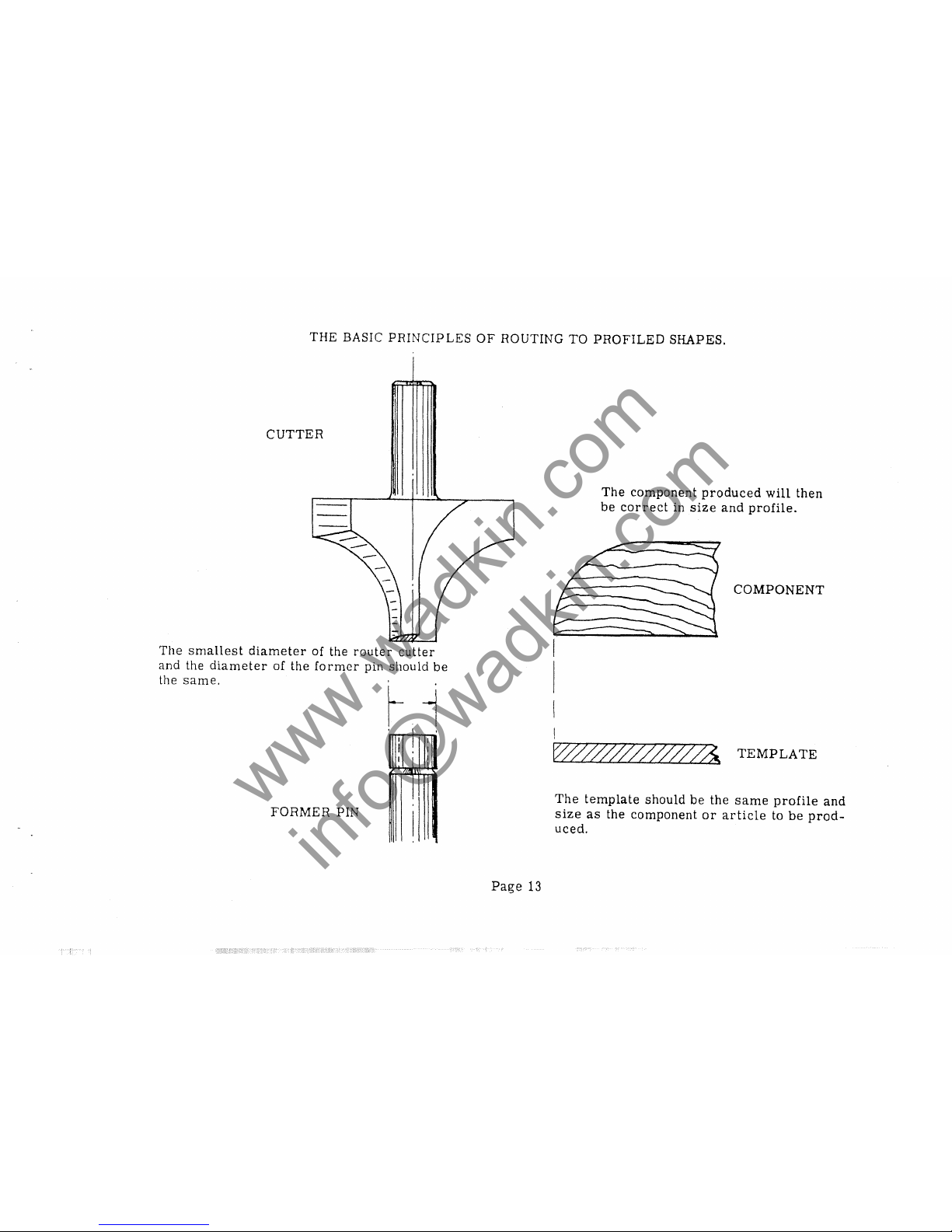

THE

BASIC

PRINCIPLES

OF

ROUTING

TO

PROFILED

SHAPES.

CUTTER

The

smallest

diameter

of the

router

cutter

and

the

diameter

of

the

former

pin

should

be

the

same.

_1

.

I

I

I

I I

I

~

FORMER

PIN

I

Page

13

The

component

produced

will

then

be

correct

in

size

and

profile.

COMPONENT

The

template

should

be

the

same

profile

and

size

as

the

component

or

article

to

be

prod-

uced.

www.wadkin.com

info@wadkin.com

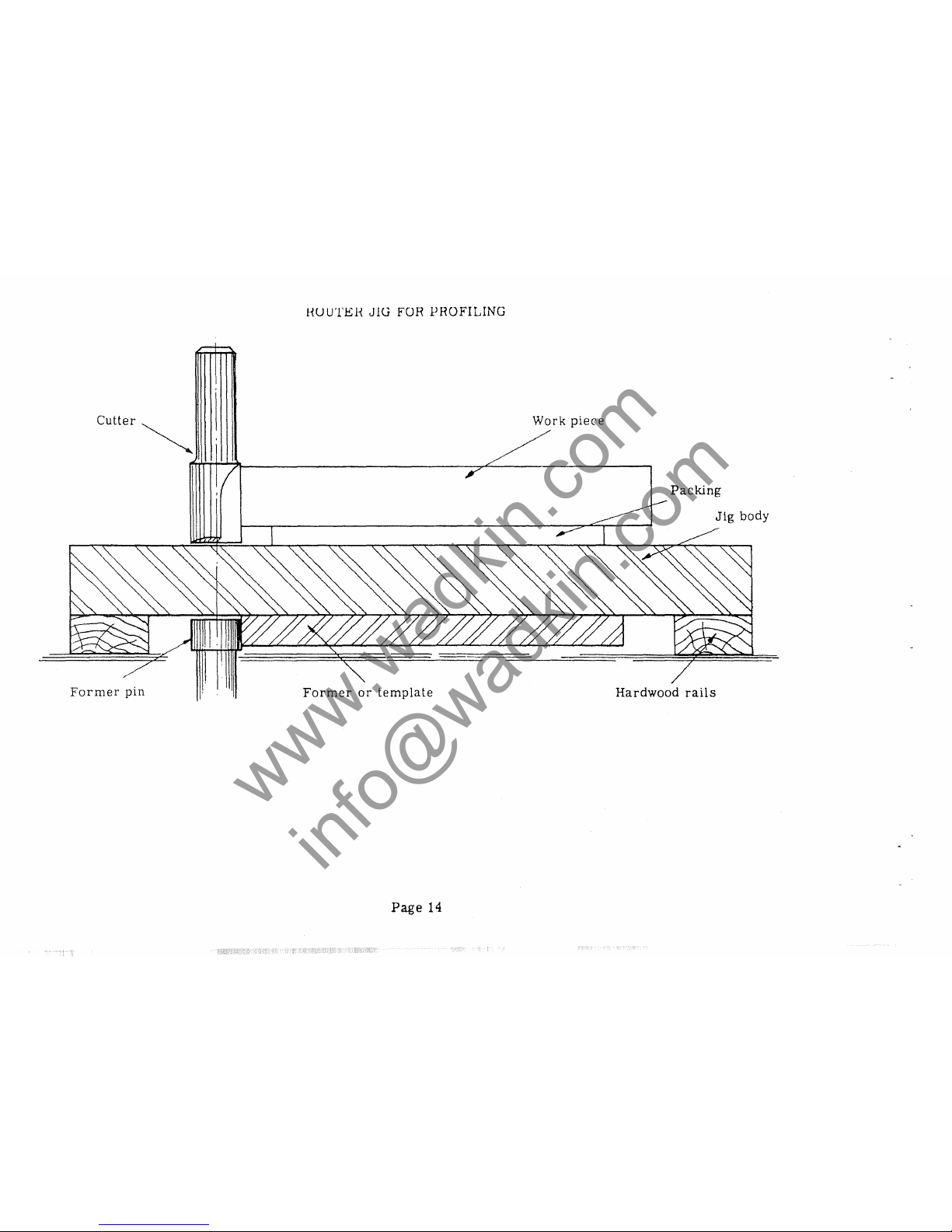

HU

UTEH

J lU FOR

1?

ROFILING

cutter~

Work

piece

Packing

Jig

body

Former

pin

Former

or

template

Hardwood

rails

Page

14

www.wadkin.com

info@wadkin.com

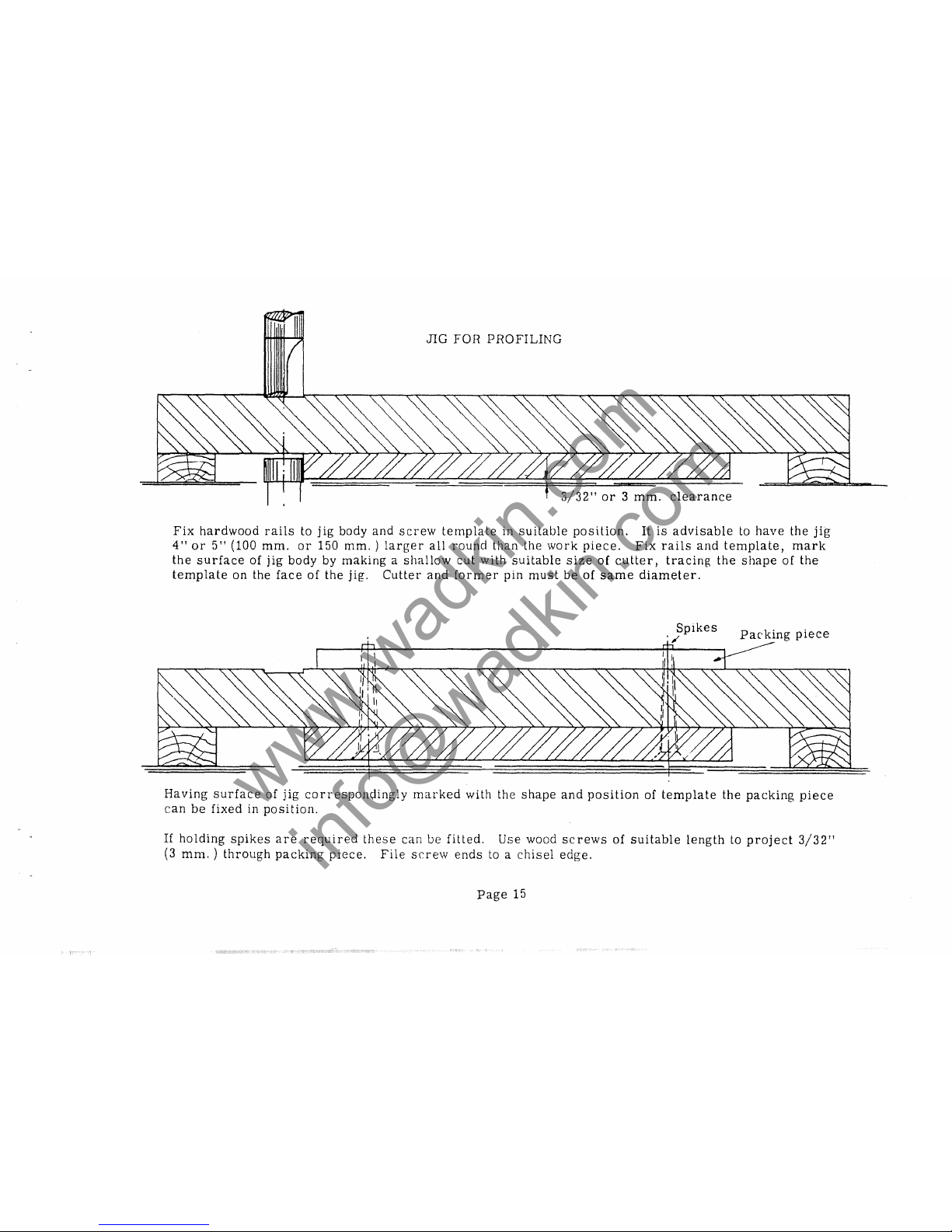

JIG

FOR

PROFILING

,

3/32"

or 3 mm.

clearance

Fix

hardwood

rails

to

jig

body

and

screw

template

in

suitable

position.

It

is

advisable

to

have

the

jig

4"

or

5"

(100

mm.

or

150

mm. ) larger

all

round

than

the

work

piece.

Fix

rails

and

template,

mark

the

surface

of

jig

body

by

making a shallow

cut

with

suitable

size

of

cutter,

tracing

the

shape

of

the

template

on

the

face

of

the

jig.

Cutter

and

former

pin

must

be

of

same

diameter.

Spikes

"

Packing

piece

Having

surface

of

jig

corresponc;lingly

marked

with

the

shape

and

position

of

template

the

packing

piece

can

be

fixed

in

position.

If

holding

spikes

are

required

these

can

be

fitted.

Use

wood

screws

of

suitable

length

to

project

3/32"

(3

mm. ) through

packing

piece.

File

SrT8W

ends

to a

chisel

edge.

Page

15

www.wadkin.com

info@wadkin.com

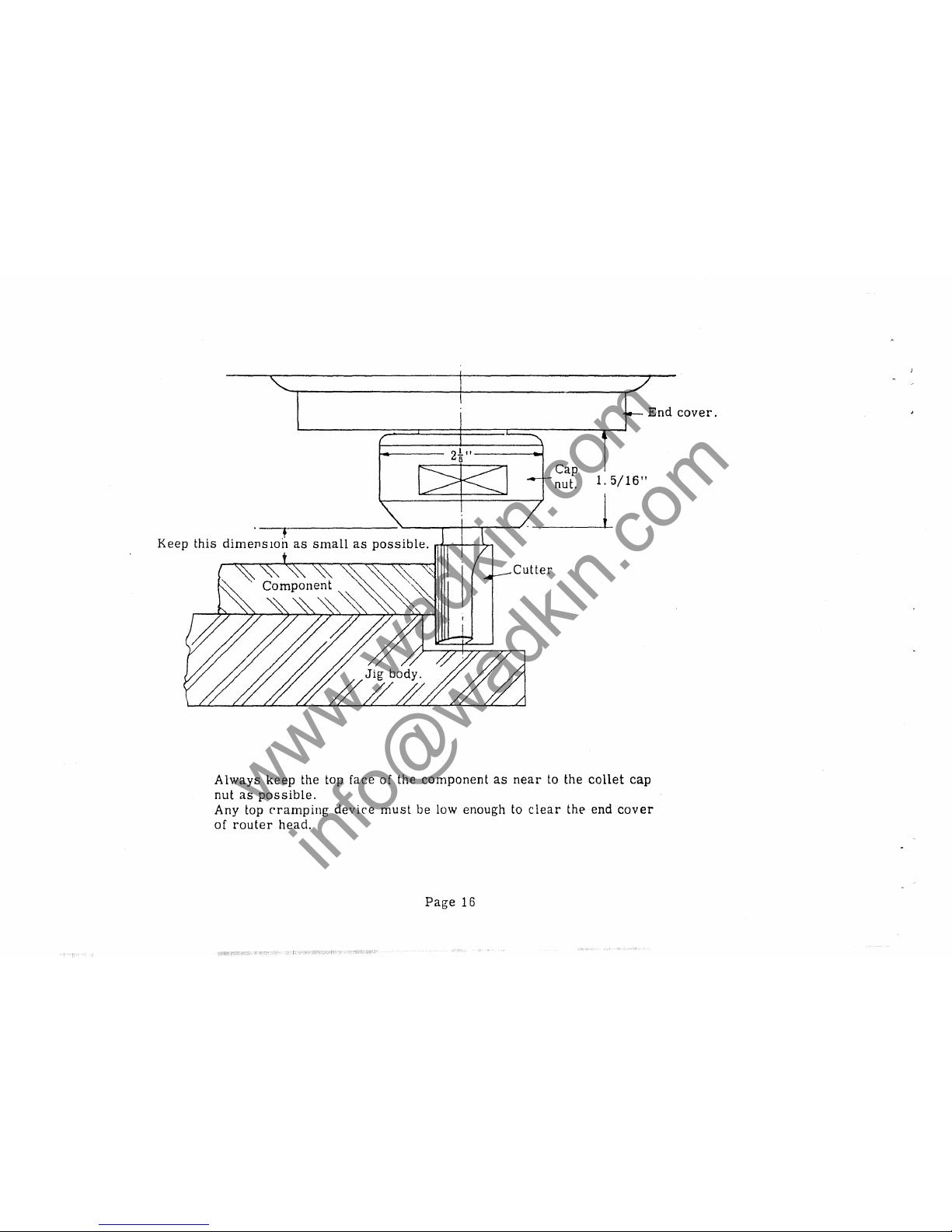

+

Keep

this

dimenSIOn

as

small

as

possible

.

..4-

____

--1.-.

Cutter

Cap

1.

5/16"

nut.

1

End

cover.

Always

keep

the top face of the

component

as

near

to the

collet

cap

nut

as

possible.

Any top

cramping

device

must

be low enough to

clear

the end

cover

of

router

head.

Page

16

www.wadkin.com

info@wadkin.com

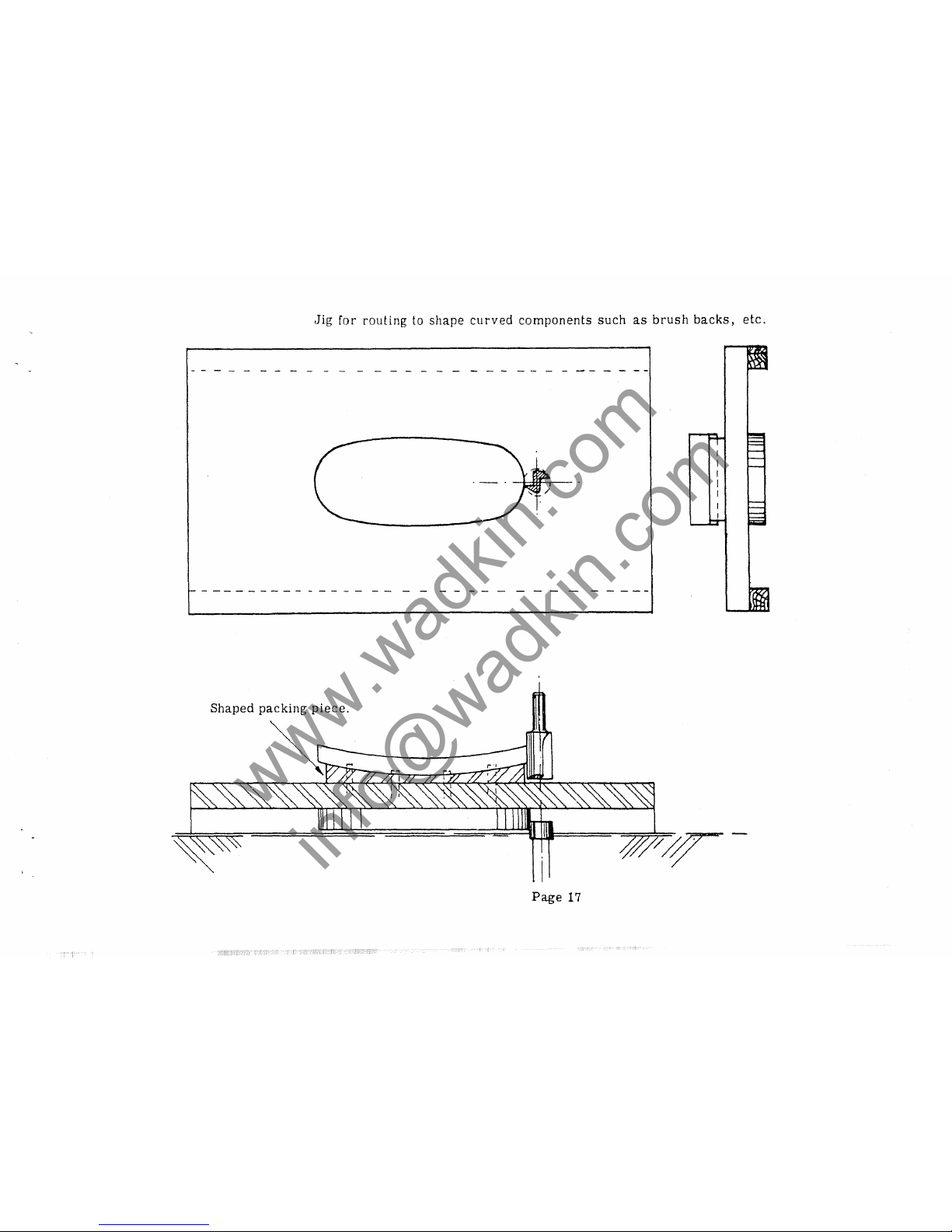

Jig

for

routing

to shape

curved

components

such

as

brush

backs,

etc.

Shaped

packing

piece.

Page

17

www.wadkin.com

info@wadkin.com

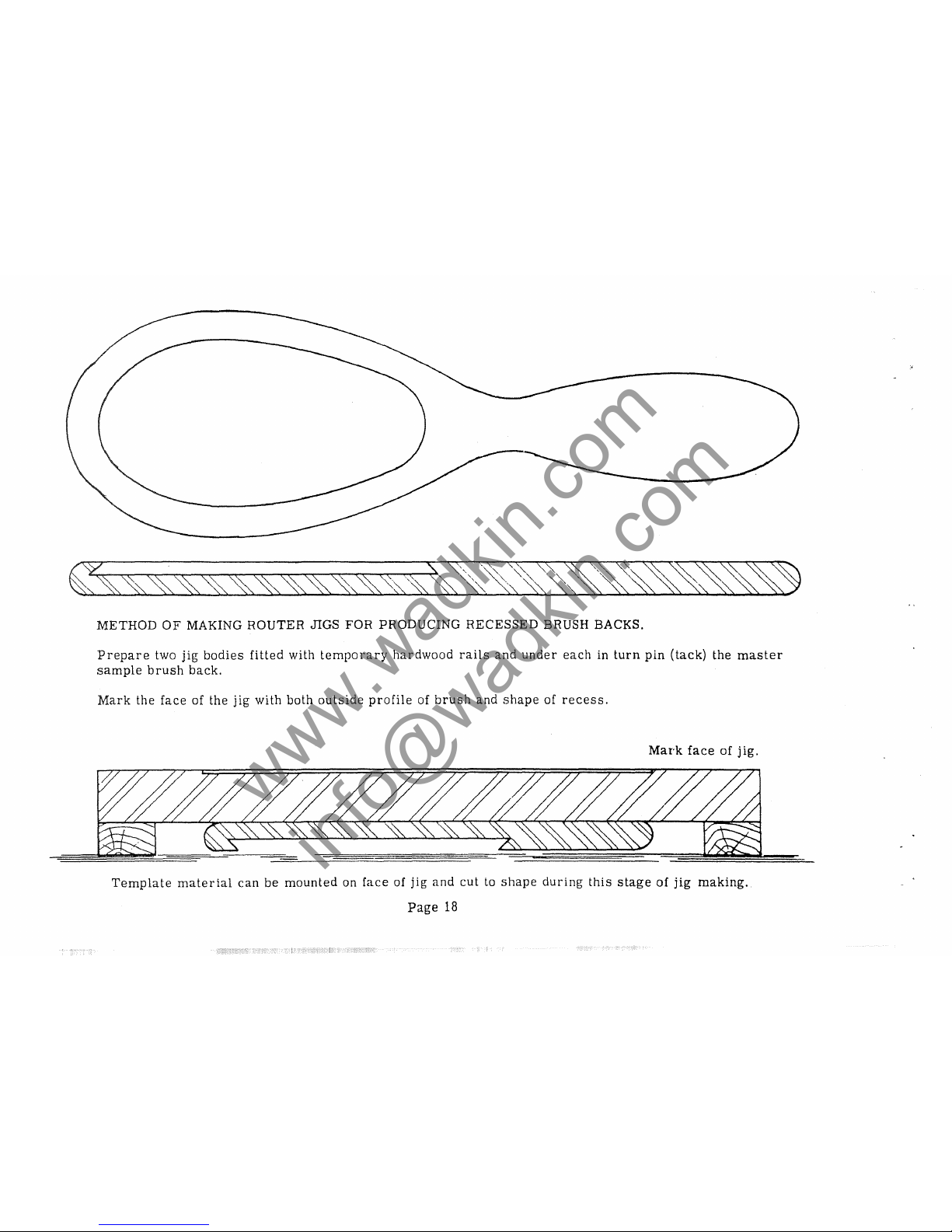

METHOD

OF

MAKING

ROUTER

JIGS

FOR

PRODUCING

RECESSED

BRUSH BACKS.

Prepare

two

jig

bodies

fitted

with

temporary

hardwood

rails

and

under

each

in

turn

pin

(tack)

the

master

sample

brush

back.

Mark

the

face

of

the

jig

with

both

outside

profile

of

brush

and

shape

of

recess.

Mark

face

of

jig.

Template

material

can

be

mounted

on

face

of

jig

and

cut

to

shape

during

this

stage

of

jig

making.

Page

18

www.wadkin.com

info@wadkin.com

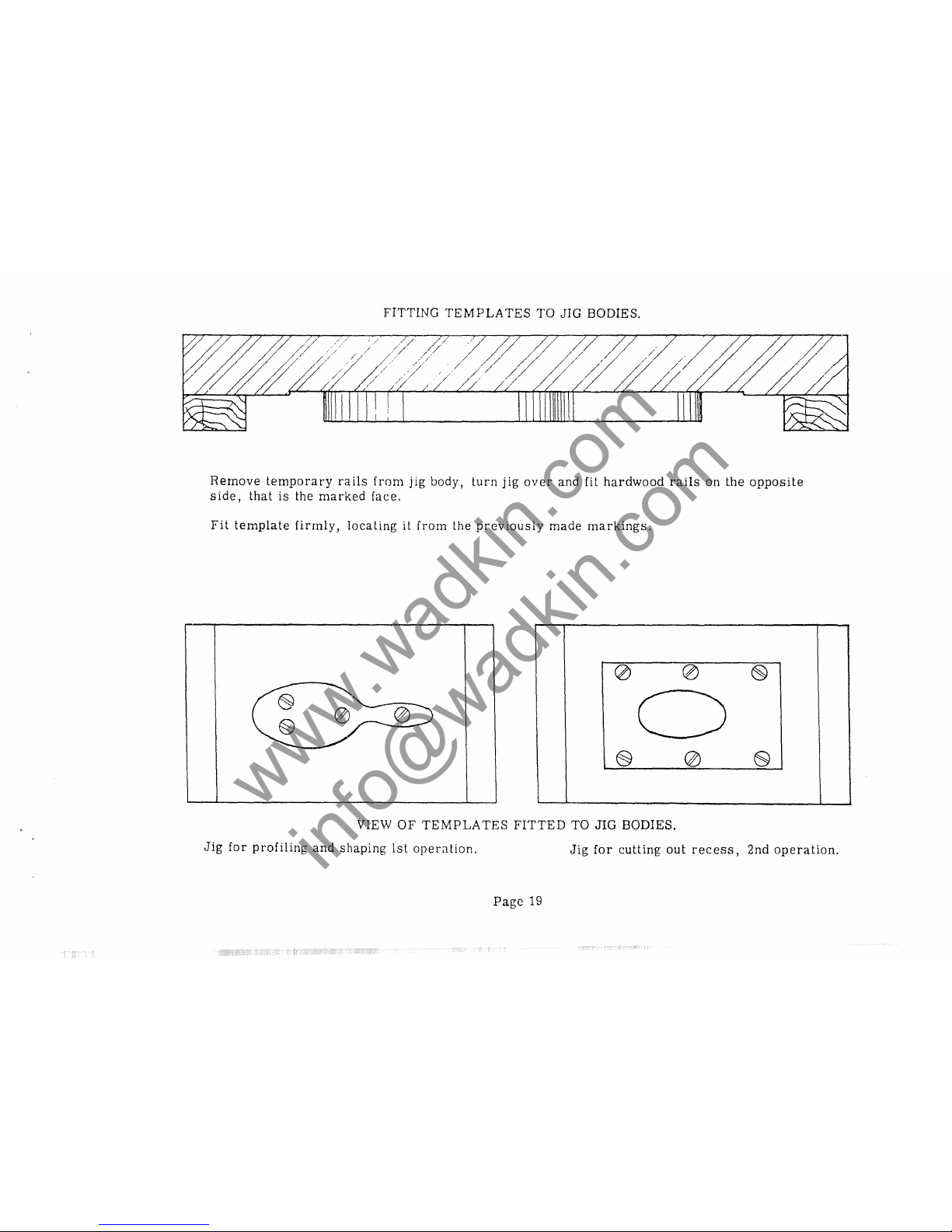

FITTING

TEMPLATES

TO JIG BODIES.

Remove

temporary

rails

from

jig

body,

turn

jig

over

and fit

hardwood

rails

on

the

opposite

side,

that

is

the

marked

face.

Fit

template

firmly,

locating

it

from

the

previously

made

markings.

0

0

6)

0

§

0

e

VIEW

OF

TEMPLATES

FITTED

TO

JIG

BODIES.

Jig

for

profiling

and

shaping

1st

operation.

Jig

for

cutting

out

recess,

2nd

operation.

Page

19

www.wadkin.com

info@wadkin.com

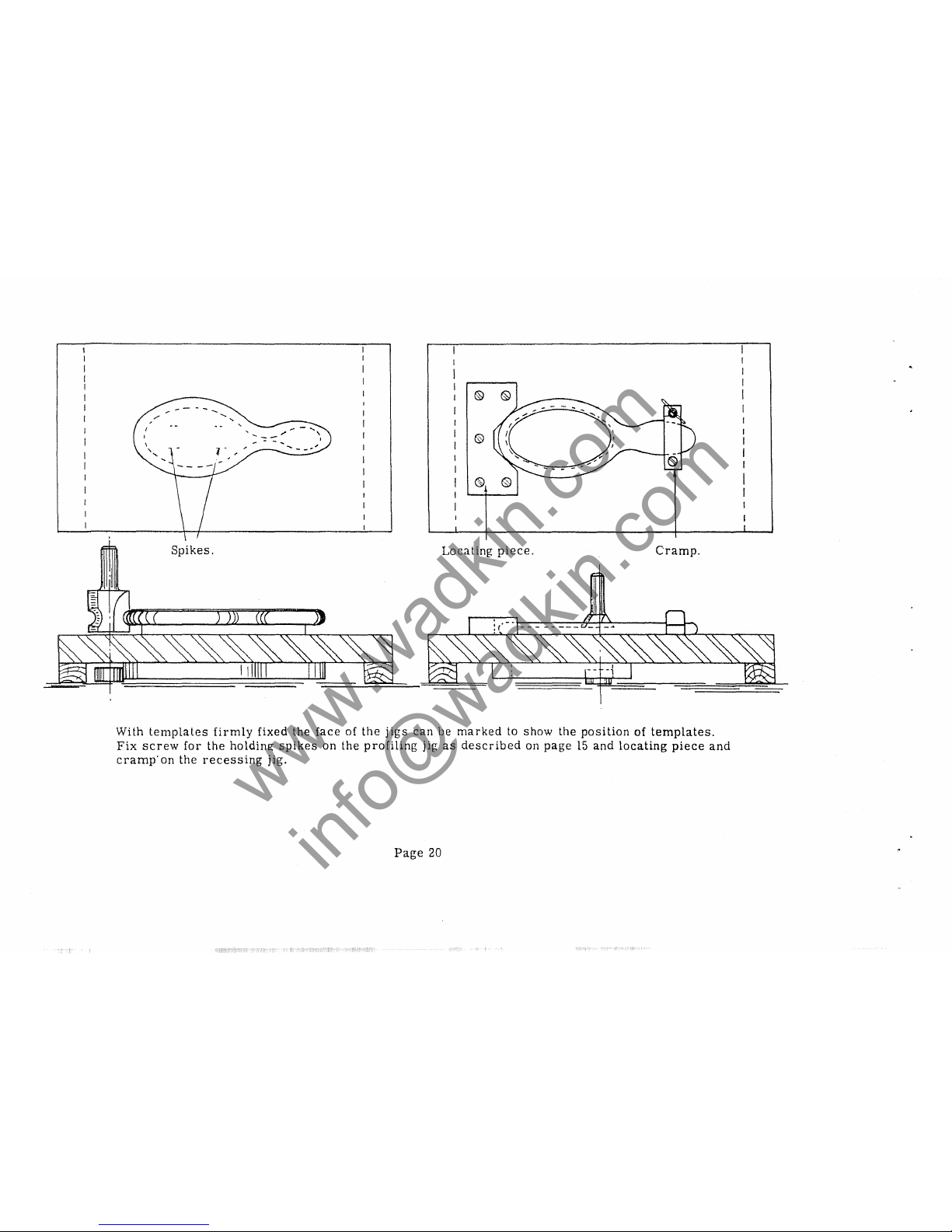

....

~

-

-'

Spikes.

Locating

piece.

Cramp.

With

templates

firmly

fixed

the

face

of

the

jigs

can

be

marked

to

show

the

position

of

templates.

Fix

screw

for

the

holding

spikes

on

the

profiling

jig

as

described

on

page

15

and

locating

piece

and

cramp'on

the

recessing

jig.

Page

20

www.wadkin.com

info@wadkin.com

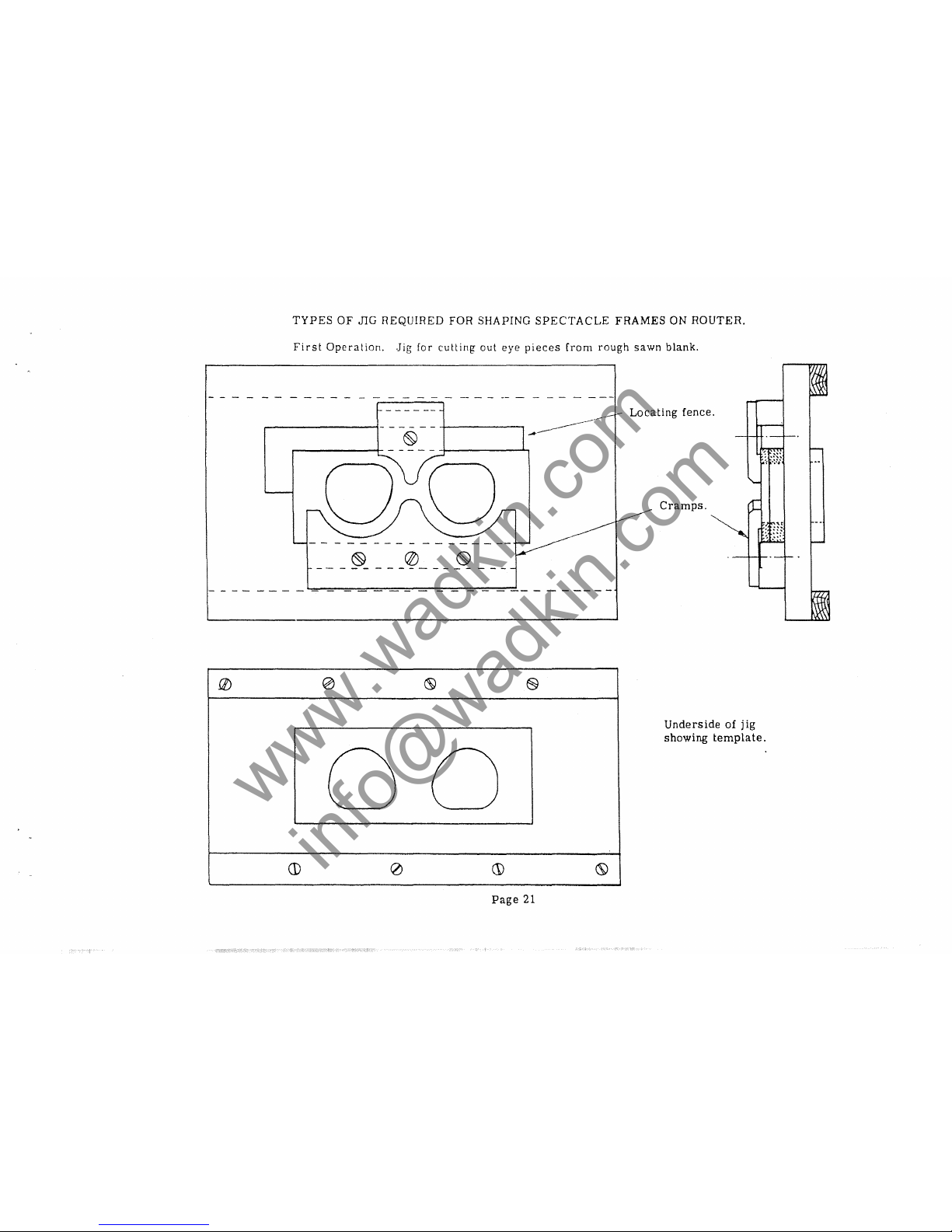

TYPES

OF

JIG

REQUIRED

FOR

SHAPING

SPECTACLE

FRAMES

ON

ROUTER.

First

Operation.

.Jig

for

cutting

out

eye

pieces

from

rough

sawn

blank.

------------------

..--------\-

- - - - -

+-----,

--------~-

@

r------_I_

- - - - -

-1------"-1

0

<8

(§)

§

0

0

CD

0

(j)

(S)

Page

21

Locating

fence .

Cramps.

Underside

of

jig

showing

template.

www.wadkin.com

info@wadkin.com

- - - - - - - - - - - - - - - - - - - - -

--

- - - - - - - - - - - -

-----

.

~.

'\-;2J

~age

22

Jig

for

shaping

outsides

of

spectacle

frames.

Locating

off

previously

cut

eye-pieces

.

www.wadkin.com

info@wadkin.com

--

...

®

Locating

pieces.

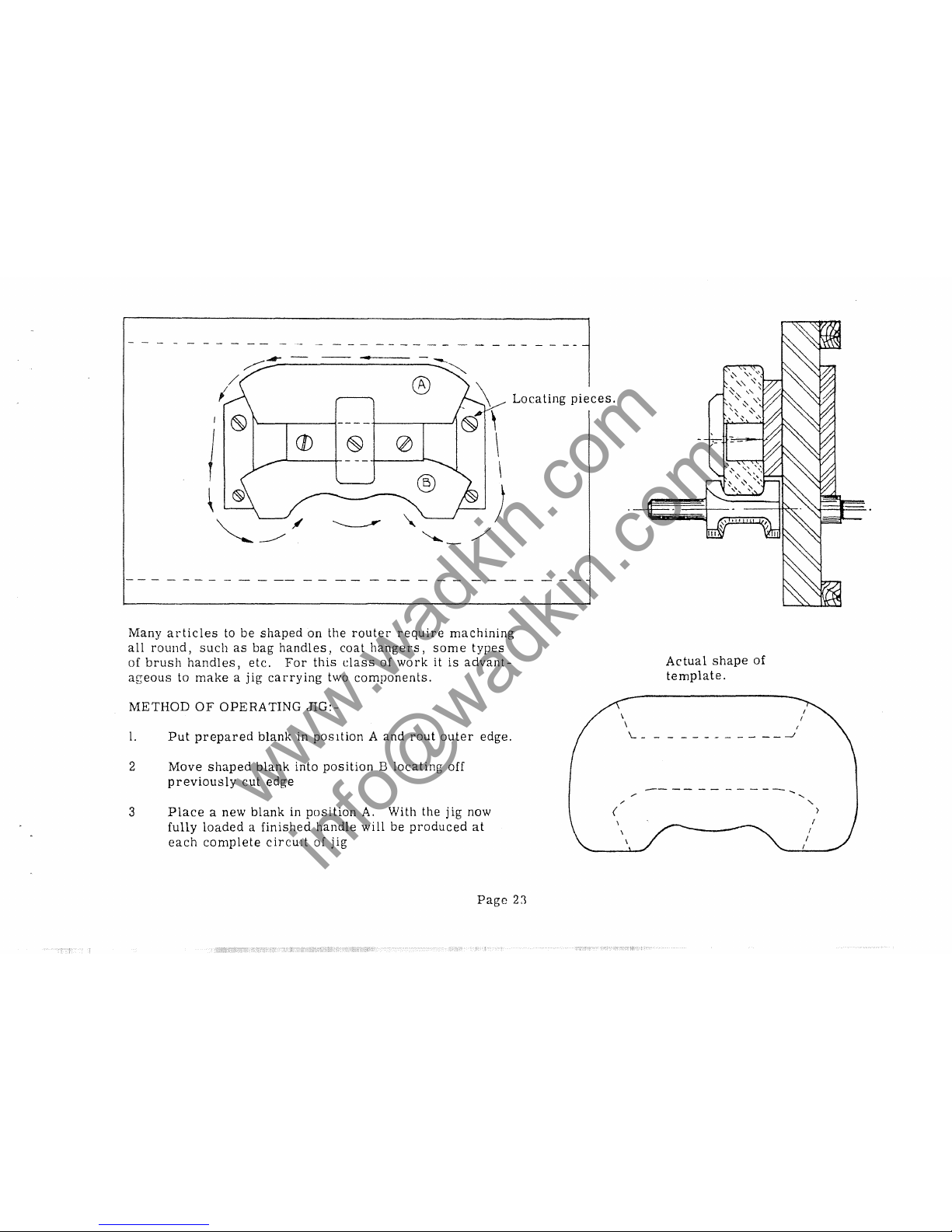

Many

articles

to

be

shaped

on

the

router

require

machining

all

round,

such

as

bag

handles,

coat

hangers,

some

types

of

brush

handles,

etc.

For

this

class

of

work

it

is

advant-

ageous

to

make a jig

carrying

two

components.

METHOD

OF

OPERATING

JIG:-

1.

Put

prepared

blank

in

position A and

rout

outer

edge.

2

Move

shaped

blank

into

position B locating

off

previously

cut

edge

3

Place

a new

blank

in

position

A.

With the

jig

now

fully

loaded a finished

handle

will

be

produced

at

each

complete

circUlt

of

jig

Page

2:1

(

\

\

'--

/

Actual

shape

of

template.

_________

--.-1

I

"-

"-

)

www.wadkin.com

info@wadkin.com

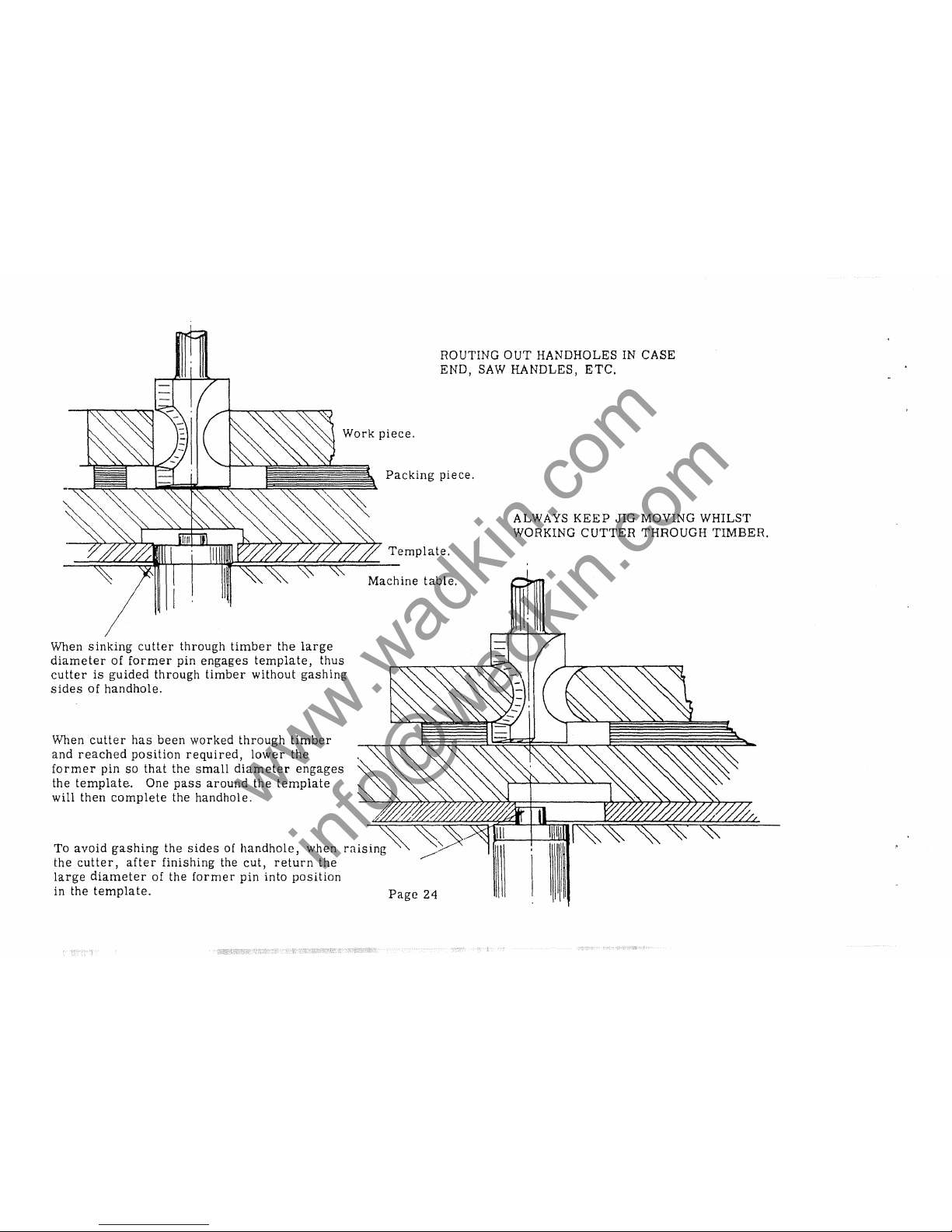

ROUTING

OUT

HANDHOLES

IN

CASE

END,

SAW

HANDLES,

ETC.

Packing

piece.

ALWAYS

KEEP

JIG

MOVING

WHILST

WORKING

CUTTER

THROUGH

TIMBER.

Template.

~~~~~~~~~~~

When

sinking

cutter

through

timber

the

large

diameter

of

former

pin

engages

template,

thus

cutter

is

guided

through

timber

without

gashing

sides

of

handhole.

When

cutter

has

been

worked

through

timber

and

reached

position

required,

lower

the

former

pin

so

that

the

small

diameter

engages

the

template.

One

pass

around

the

template

will then

complete

the handhole.

To

avoid

gashing

the

sides

of

handhole,

when

the

cutter,

after

finishing

the

cut,

return

the

large

diameter

of the

former

pin

into

position

in the

template.

Machine

table.

Page

24

www.wadkin.com

info@wadkin.com

L

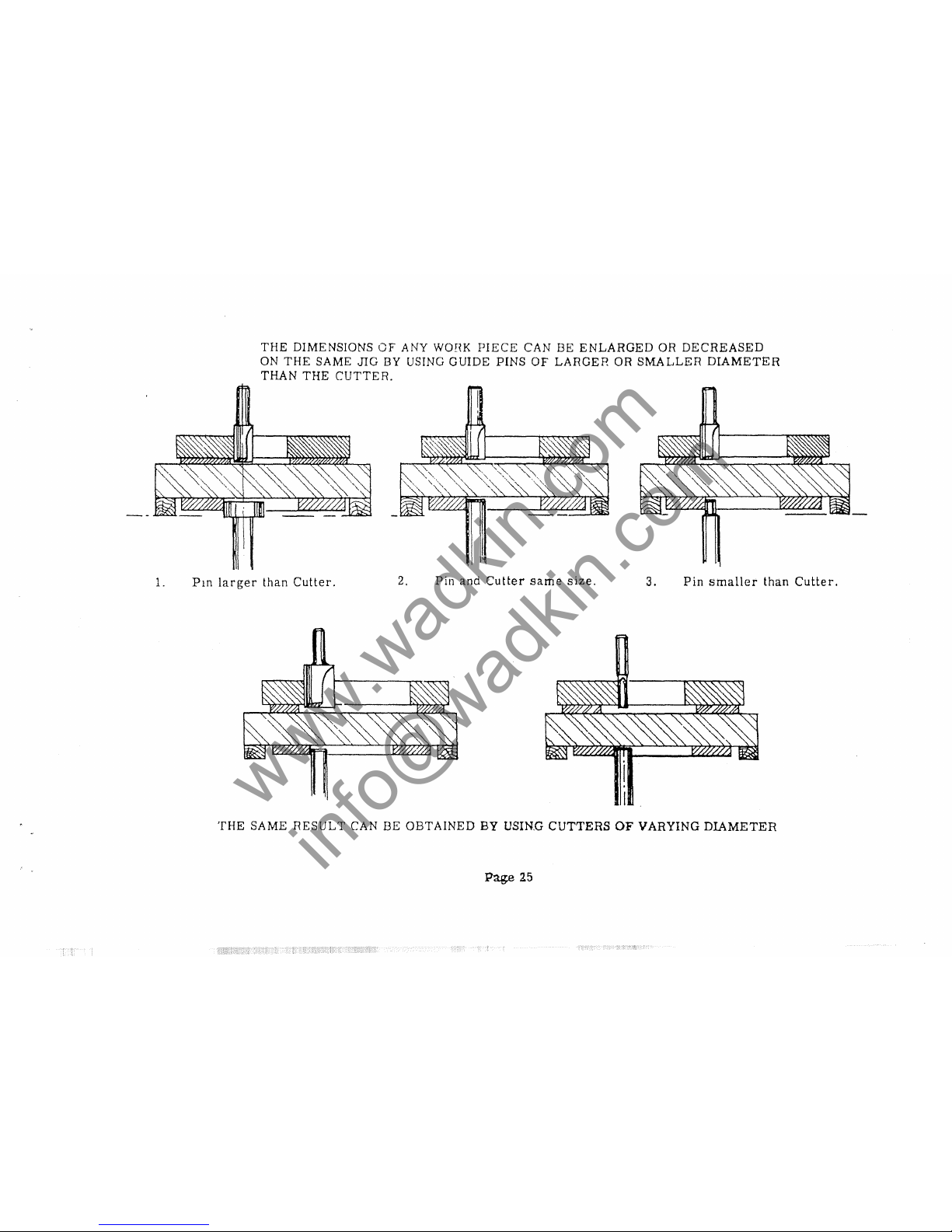

THE

DIMENSIONS

OF

ANY WOHK

PIECE

CAN

BE

ENLARGED

OR

DECREASED

ON

THE

SAME

JIG

BY USING

GUIDE

PINS

OF

LARGER

OR

SMALLER

DIAMETER

THAN

THE

CUTTER.

PlO

larger

than

Cutter.

2.

Pin and

Cutter

same

size.

3.

Pin

smaller

than

Cutter.

THE

SAME

RESULT

CAN

BE

OBTAINED

BY

USIN.G

CUTTERS

OF

VARYING

DIAMETER

Page

25

www.wadkin.com

info@wadkin.com

®

®

1

1 \

I I .

A.

Cutter

in top

position

and

former

pin

engaging

first

template.

D.

Head

lowered

to

serond

position

and

former

pin

raised.

C.

Head

lowered

to

bottom

position

and

former

pin

raised

to

engage

third

template.

Recesses

of

various

depths

such

as

those

in

Cutlery

trays,

Tap

and

Die

cases,

types

of

Brush

backs,

etc.,

can

be

worked

by

making a jig

with

multiple

templates.

Each

template

corresponding

to

the

recesses

of

one

depth.

Mount the

templates

in

one

pack

on

the

jig

body

and

raising

the

former

pin

by

the

hand

lever

on

the

front

of

the

machine

table -each

template

can

be

engaged

in

succession.

The

various

depths

of cut

are

pre-set

by

the

variable

stops

on the

router

head.

Page

26

www.wadkin.com

info@wadkin.com

-_._

..

Finished

article.

( )

(

)

( )

(

=

:)

First

template

itA

It

r--

- - - - - - -

--,

!

)

.........

- - - - - - - - - -

---"

( )

(

)

(

=

)

Second

template

"B"

Page

27

Section

across

tray.

First

depth.

Second

depth.

Third

depth

o

Details

of

templates

for

working

recesses

of

various

depths.

Third

template

'e

I

www.wadkin.com

info@wadkin.com

Track

of

cutter

1""--'

I

\

I

\

I

"-

/

\

I

" I

--"

Finished

component

spiked

to

locating

piece.

-

,

"-

\\

\\

-

"-

I

I

,/

Blank

Components

arranged

on

locating

pieces

around

jig.

'.

Templates

Plywood

surround

to

jig

body.

/

When

large

quantities

of any

small

artides

such

as

electric

light

ceiling

roseltes,

etc. , are

to

be

made,

it

is

often

advantageous

to

build a circular

jig

carrying a number

of

components.

By

using

this

type of

jig

the

operator's

position

in

relation

to the

machine

is

constant

and

excessive

move-

ments

of the

hands

avoided.

To

maintain

constant

production,

duplicate

jigs

can

be

used,

one

being

reloaded

whilst

operator

routs

with

second

jig.

This

eliminates

idle

machine

time.

Page

28

www.wadkin.com

info@wadkin.com

I

I

I

I

I

I

I I

, I

I'

I

I I

I :

Rauled

[ace

o[

wood.

Saw-rut.

Sm.l11

eirC'ubI'

'Jbjects

and

wheels

for

toys

can

be

made

by

sinking

cl

special

shaped

culler

inlo

the

surface

of

any

suitable

wood.

Saw

0[[

the

routed

[ace

lhen

the

wheels

will

fall

loose.

The

roulin€!

operation

can

then

be

repeated

on

the

stock

piece

of

wood

if

of

suitable

thickness.

Page

29

www.wadkin.com

info@wadkin.com

Standard

Cutterhead

LS.lb57H

Plywood

Machine

table

METHOD

OF

SCARFING

PLYWOOD,

ETC.,

ON A WADKIN

ROUTER.

Page

30

www.wadkin.com

info@wadkin.com

Two

strips

of

rubber

glued

to

face

of

jig

forming

both

vacuum

cavity

and

seal.

- - - - ---- -

~""iiiiiiiiiiiiiii

....

,

\

Taper

connection

with

valve

to

enable

suction

to

be

turned

on

and

off

at

will.

----------------------------~-

-----------

Hole

bored

in

end

of

jig

to

connect

with

hole

bored

from

face

of

jig,

JIG

BODY

Plastic

C'omponents,

draughtsmen

I s

protractors,

or

any I i[:';ht

article

reqUlrmg

routing

all

round

can

be

pI'oduced

by l1lukinp; a jIg

whereby

Lhe

components

are

held

by

suction.

Two

rubber

strips

are

glued

to

face

of

jig

confol'ming

to

Lhe

profile

of

the

component.

Place

the

blank

component

on

the

rubber

and

exhaust

Lhe

a

ir

from

between

the

strips.

Blank

will

now

be

held

firmly

during

routing.

Page

31

www.wadkin.com

info@wadkin.com

Type

of

jig

required

for

shaping

and

moulding

curved

chair

backs,

etc.

Shaped

table

cramped

to

router

table.

Cradle

to

carry

curved

chair

back.

Page

32

I I

I

'~

Former

pin

Front

of

router

table.

/'

/ )

/ I

/ /

/

,,/

/

www.wadkin.com

info@wadkin.com

i"'----

I

I

f~~

®

~

~

~;~

,

....-

......

I

@

$

\

~

I

'\

'-

\

eed

in

from

Front

of

router

table.

\

\

F

this

side.

Pressure

fence.

Position

of

cutter.

Simple

type

of

pressure

ience

to

enable

small

mouldings,

beads,

etc.,

and

lhicknessing

to

be

worked

on

Router.

Page

33

,..

\\

\

-

-

\

--

~

\

/

Fixed

fence.

Board

carrying

fences

clamped

to

router

table.

Front

of

machine,

www.wadkin.com

info@wadkin.com

,

,

)--

I

-,

--

-----1

,

,

Hardwood

'frame

around

composition

or

aluminium

jig

body.

)-

- - - - - - -

'-

- - - - - -

I

- - - - - - - - - - - - - - -

---"""

"

,

Light

alloy

component

supporting

posts.

Light

alloy

components

can

be

profiled

to

shape

by using a

jig

made on

principle

shown. The

supporting

posts

going

right

through

jig

body,

tracking

up both

template

and

component,

the

template

having

exactly

the

same

profile

and

tooling

holes

as

component.

Page

34

www.wadkin.com

info@wadkin.com

ECCENTRIC

CHUCKS

For

slotting,

small

morlices,

grooving,

etc.,

where

constant

cuttlDg

dIameter

is

important,

the

u~e

of

a.n

eccentric

chuck

is

advised.

The

cutters

are

only

sharpened

inside

the

flute.

Providl!1g

the

cutting

edge

is

always

set

in

position,

between

lhe

300 and

500 marks

as

shown

111

diagram,

the

effective

cutting

diameter

will

never

derrease.

It

is

important

that

the

right

combinations

of

cutter

and

chuck

as

set

out

on

the

chart

are

maintained.

If

nol,

cutter

burning

and

poor

work

will

result.

Eccentric

chucks

must

be

balanced

carefully.

SIZE

OF

DIAMETER

OF

CUTTER

EFFECTIVE

CUTTING

DIAMETERS

CHUCK

1/32

1

5/32 3/16

5/32

3/16

7/32

B

3/64

1

5/32 3/16 7/32 11/64 13/64

15/64 17/64

"8

1/16 3/16 7/32

1

5/16

1

9/32

5/H5

3

4"

4"

"8

3/32

1

5/16

:I

11/32

13/32 15/32

4"

"8

1

5/16

J

13/32 7/16

7/16

1

17/32

9/16

"8

"8

'2

5/32

J

13/32 7/16 15/16

17/32 9/16 19/32

5

"8

8"

DIMENSIONS

OF

CUTTERS

FOR

ECCENTRIC

CHUCKS.

-4£1

'

f'··

. . A

,

A

1..

..

5/32"

3/16"

7/32"

1..11

5/16"

1"

13/32

"

7/16"

15/32"

1.."

8

4

8

2

B

31/32"

31/32"

31/32"

31/32"

1.3/16"

1i"

It"

It"

It"

It"

It"

C

9/16"

9/16"

E.11

E.11

111

7/8"

1

k"

1

t"

1.

3/16"

1.

3/16"

It"

8 8

<I

Page

35

r11>

I

www.wadkin.com

info@wadkin.com

Eccentric

chuck.

-I-

Size

of

chuck

ViS

stamped

here.

_--Ml.LL.fo..l.li\ll'----.

ctt· 0

. 3p

To find the

cutting

diameter

of

any

respective

chuck

and

cutter,

add

the

chuck

size

tD

the

diameter

of the

cutter.

The

cutting

edge of the

cutter

must

be

either

on

or

between

the

lines

marked

300-50

0

to

ensure

cutter

clearance

and

the

best

cutting

angles.

With

cutter

so

set a chuck

marked

1/16"

and a cutter

t"

diameter

will

cut

5/16"

diameter.

Page

36

500 Line

300 Line

Correct

setting

of

cutter

in

chuck

500 Line

300 Line

Incorrect

500 Line

300 Line

Incorrect

www.wadkin.com

info@wadkin.com

It

is

importallt

that

an

eccentric

chuck

should

be

balanced

every

time

the

cutter

is

changed.

The

cutter

being

set

in

its

correct

cllLtin~

position

before

the

balance

operation

is

carried

out.

Dalallcil1[,("

plate

is

levelled

by

means

of

three

adjustable

sne'.vs.

Then

tile

ciluck

is

Inserted

in

the

balancing

roller

alld

tile

('orrect

balance

IS

obtained

by

inserting

or

withdraw-

in~

lJalaIlcil1~

screws.

When

the

chuck

is

perfectly

in

balance

the

roller

wi

II

come

to

rest

in

any

position.

The

pbte

can

be

levelled

by

testing

with

the

balancing

roller

only,

or

spirit

level.

Great

care

must

be

taken

with

the

11)11cr,

never

allowing

the

rims

to

be

bruised.

Page

37

www.wadkin.com

info@wadkin.com

Rebating

across

or

with the

grain.

3/16"

,.

taximum

depth

of

cut when

edging

shaped

work

rrr-r-r"',"-,-j--'>-lo~-rTl111

I

~

2".

For

this

class

of

routing

3/16"

is

the

. .

l'

maximum

amount

of wood

to

I

remove

continuously.

2"

50

m/m

\

EXAMPLES

OF

EXTREME

CUTS

POSSIBLE

ON

WADKIN

ROUTER.

t"

3

m/m

Maximum

dimension

of

moulding on

Router.

www.wadkin.com

info@wadkin.com

'.',

r

!

f,

··--F

, ,

~

'::~

,

--t

'-'\.

;'

-

~~

r'

..

,

t-

u

~'

~

n

~~>----:..~,

_

~

__

~L

19/16"1

:.-

--.,J

Ma.x:mum

sIzes

double

rebate

Maximum

size

of

groove

Smallest

broove

possible

EXAMPLES

OF

EXTREME

CUTS

POSSIBLE

ON

WADKIN

ROUTERS.

Maxi

mum

size

of

flute

Maximum

and

mmimum

sizes

of

dovetail

grooves

r

Maximum

and

minimum

sizes

of

nosin~

(rounding)

cutters

Type

23.

www.wadkin.com

info@wadkin.com

A

Spring

Pressure

Cramp

can

be

fitted

to

the

Router

Head to

ensure

that

hardwood

components

are

pressed

onto the jig.

Also

preventing

the

component

lifting

off the

spikes.

The

spring

pressure

helps

to

provide

accurate

routing.

Applicable

when

routing

thin plywood,

veneers,

plastics,

and

hardwood

components

which

are

held

to the

jig

by

spikes.

Page

40

)'fj'IiJ'1

Cramp

www.wadkin.com

info@wadkin.com

Double

Edged

Cutters -Panel

Type

4.

Relief

or

clearance

always

increasing

from

the

'\

cutting

edge

Face

Cutter

as

sent

out

by

Wadkin

Ltd.

Hump

behmd

cutting

edge.

Cutter

incorrectly

ground

and

honed.

'VCutting

edge.

Face

ground.

straight.

Single

Edge

Cutters-Spoon

Type

1.

Incorrect

grinding

will

result

in

cutter

breakage

and

bad

work.

Relief

restored.

Cutter

regl'ound

correctly.

Page

41

www.wadkin.com

info@wadkin.com

CUTTER

GRINDING

To

obtain

consistently

good

work

from

high

speed

routing

it

is

essential

that

the

cutters

are

kept

sharpened

and

ground

correctly.

This

can

only

be

assured

when

suitable

equipment

is

available.

The

ideal

grinder

for

this

purpose

is

the

Universal

Type

N.

H.

shown left. Not only

will

this

machine

deal

with

all

router

cutters,

but

it

is

indispensable

for

maintaining

every

type of

cutter

equipment

used

in a woodworking

plant,

excluding

long

planer

knives.

NOTE -

Where a suitable

grinder

is

already

installed

we

can

supply

the

set

of

fixtures

for

router

cutters

as

used

on

this

machine.

Where

the

amount

of

cutter

gylnding

does

not

justify a Un

iversal

Grinder

we

recommend

the

N.

U.

type

machine

'shown

right.

This

machine

has

been

specially

designed

for

router

cutters.

It

is

self-contained

and

provided

with a

precision

grinding

spindle.

Table

has

movement

in

three

directions

and

is

designed

to

take

fixtures

for

handling

all

types

of

rou

ter

cutters.

Whilst

we

strongly

recomm-

end

the

use

of a

separate

grinder,

where

the

number

of

cutters

to be

maintained

does

not

justify

either

of the

above

machines,

we

can

supply

the

fixture

shown

left

for

use

on the

Router

itself.

In

this

case

it

is

essential

to

use

the

Router

with

speed

18,000

r.

p.

m.,

this

lower

speed

being

necessary

for

the

grinding

wheels.

Page

42

www.wadkin.com

info@wadkin.com

INSTRUCTIONS

FOR

GRINDING

WADKIN

ROUTER

CUTTERS

A

sharp

and

properly

ground

cutter

is the key to good

routing.

It

is

important,

t.herefore,

that

the

operator

should

understand

exactly

what

he,

is

doing

when

sharpening

cutters.

Detailed

instructions

in the

grinding

of

all

types

of

router

cutters

are

given

on

the

following

pages,

and

if

read

carefully

and the

instructions

carried

out

will

ensure

trouble

free

running

and

high

production.

Page

43

www.wadkin.com

info@wadkin.com

WOODWORKING

CUTTERS.

CHOICE

OF

THE CORRE CT CUTTER.

In

order

to

get

the

best

results

from

routing

it

is

essential

to

use

the

proper

cutter

for

each

operation.

Straight

cutters

from

1/16"

diameter

to

1~"

diameter

are

available

in

varying

lengths.

A wide

range

of

shaped

cutters

can

be

supplied,

also

built-up

cutters

for

tonguing

and

grooving,

moulding,

etc. I circular

cutterblocks

and moulding

blocks.

Illustrations

show

some

of the

principal

types

in the

range.

TYPE

52

Panel

:Cutter

Head

TYPE

53.

Tonguing

and

Grooving

Arbor

"

,

TYPE 4

Double edge

Panel

Bit

TYPE

21

TYPE

1

Spoon

Bit

Solid

Profile

TYPE

55

Cutter

Circular

Block

When in doubt,

always

consult

Wadkin Ltd.

for

advice

and

recommendations.

More

information

on

cutter

types

can

bE;)

obtained

under

the following

References

:-

Cutters

for

Wood,

Plastics,

Synthetic Bonded

Ply.

Book No. 713

Router

operation,

Design

of Jigs'

and

Fixtures,

etc.

BookNo.716

THE AIM

OF

CUTTER SHARPENING.

The

primary

object

of

cutter

sharpening

is

to

restore

the cutting edge

at

the

correct

cutting

angle-,and

'ensure

correct

clearance

behind the cutting edge.

Relief

or

clearance.

Correctly

honed and

ground

cutter.

\, _ Face

not

straight.

Hump behind

cutting edge.

Incorrectly

honed

cutter,

Page

44

Worn

cutter

correctly

ground

and honed,

-~"»--

"j

-"

-Incorrectly

honed,

rubbing

on the

back.

.

Dotted

line

indicates

necessary

grinding

to

restore

cutting

edges.

www.wadkin.com

info@wadkin.com

THE

IMPORTANCE

OF

MACHINE

GRINDING.

The

key

to

high

quality

rouling

is

Cl

cutter

wilh clea:n

sharp

edges

and

smooth

continuous

relief.

In

order

to

maIntain

the

correct

cutting

angle

and

clearance,

machine

grinding

is

essential.

Experience

has

shown

that

free-hand

grinding

does

not

give

the

clean

smooth

edge

essential

for

good

cutting,

and

the

result

is

nothing

like

the life of a

machine

ground

cutter.

Another

import-

ant

point

is

that

it

is

almost

impossible

to

gr

ind

equal

amounts

from

both

edges

free-hand.

Mechanical

grinding

ensures

that

both

edges

of a

cutter

are

identical,

also

the

minimum

amount

of

metal

is

removed

at

each

regrind,

thus

making

sure

of

longer

life

from a cutter

than

when

most

carefully

free-hand

ground.

GRINDING

MACHINE,

TYPE

N.

U.

This

is

the

Grinding

Machine

generally

supplied

for

grinding

router

cutters

(see

illustration

on

Page

42).

It

has a spindle

speed

of

4,750

r.

p. m. and

is

prOVided

with

rise

and

fall,

and

also

traverse

movement

to the

table.

With the

aid

of the

three·

attachments

shown

overleaf,

most

types

of

cutters

for both

metal

and

wood

routing

can

be

dealt

with.

The

class

of

work

being

done

will

dIctate

the

attachments

needed,

but for wood

cutters

the

S.

F.

A.

attachment

is

essentlal,

and

the

P.

R.

F.

is

very

useful

for

regrinding

the

relief

on

straight

panel

cutters.

For

sheet

dural,

alclad

and

brass

the

D. G

A.

and

P.

R.

F.

attachments

are

essential.

Where

an

existing

Tool

Room

Grinder

of

suitable

type

and

having a speed

of

not

less

than

5000

r.

p.

m.

is

available,

the

grinding

attachments

only

are

needed.

In

such

cases

the

user

would

need

to

make a spindle

extension

arbor

to

suit

his

machine.

Page

45

www.wadkin.com

info@wadkin.com

GRINDING

ATTACHMENTS

ATTACHMENT

S.

F.A.

to

be

used

for

grinding

stra

ight

fluted

cutters

of

all

types,

also

ending

up

panel

cutters

and

Spoon

Bits.

This

attachment

will

generally

be

used

for

profiling

cutters

and

spoo"n

bits.

It

is

also

suitable

for

tungsten

carbide

cutters.

ATTACHMENT

D.G.A.

to

be

used

for

grinding

the

flutes

(spiral

or

straight)

of

all

alclad

or

dural

cutters

used

on

SHEET

WORK.

ATTACHMENT

P.

R.

F.

to

be

used

for

regrinding

the

eccentric

relief

on

panel

cutters;

suitable

for

dural,

alclad

and

brass

cutters,

after

loss

of

clearance

due

to

con-

tinuous

honing.

Page

46

Grinding

wheels

supplied

with

GRINDING

ATTACHMENTS.

FOR

ATTACHMENT

S.

F.

A.

ONLY

139

2"

diameter

~tI

FLAT

face

i"

Bore

2t"

diameter

1

It

CUP

i"

Bore

141

2t"

diameter

1"

DISH

f"

Bore

FOR

ATTACHMENT

D.

G.

A.

and

S. F.

A.

137

1jS

FOR

ATTACHMENT

S.F.A.

2"

diameter

137

3/16"

ROUND

edge

~

It

Bore

2

It

diameter

138 tit ROUND

edge

i

It

Bore

FOR

ATTACHMENT

P.

R.

F.

86R

Rougher

87 R

Finisher

146

These

wheels

are

used

for

grinding

chipped

ed~es

of

Tungsten

Carbide

Cutters.

Both

are

2t

lt

diameter,

1"

dish,

~"bore.

2t"

diameter

1

It

CUP

~"

Bore

www.wadkin.com

info@wadkin.com

LAPS FOR TUNGSTEN CARBIDE

TIPPED

ROUTER CUTTERS.

Diamond

lap

wheel

for

use

on

Attach-

ment

S.

F.

A.

and

used

for lap

finish-

ing

Tungsten

Carbide

Tipped

Cutters

after

regrinding

with

wheels

86R

and

87R.

145

.------:t:,==~

__

.,0<

__

~

..-.---

,...

s='--

~~

,"

Diamond

Impregnated

for

Hand Lap

honing

Tungsten

Carbide

Tipped

Cutters.

Also a similar

hone of

solid

material

in fine and

medium

grain

can

be

supplied.

Carborundum

Slip

Stones

for

High

Speed

Steel

Router

Cutters

No.183.

4%"

x 1;f"

xi"

-

3/16"

No.177.

4t"

x

n-!!

x

t"

-

1/16"

WHEEL

DRESSER DIAMOND',PART NO.

P.

R.

F.

37.

uRed

for

dressing

all

types

of

grinding

wheels,

excepting

the

Diamond

Lap Wheel,

No.145.

REGRINDING STRAIGHT

FLUTED

CUTTERS

OF

ALL

TYPES,

ON

ATTACHMENT

S.

F.

A.

LOC

U~JG

BOLT

FOR

CANTlNG

ARBOR

1.

MAX

BORE

Of

CHUCK

RADIAL

ADJUSTING SCREW

STOP

LEVER

FOR

INDEX

PLATE

-----(

COMBI~I[D

LOCKlt~G

BOLT

fOR

SWIVELLING

ARBOR

BRACKET

"ND

SECURING

BASE

TO

TABLE

ARBOR

HANDWHEEL

TYPES

OF

CUTTERS

MOST COMMONLY GROUND

ON

TIllS

ATTACHMENT

:-

--~

I

I

-

-1

Page

47

I

I

"

SPOON BITS.

Use

grinding

wheels

Nos. 137

and

138.

After

grinding

the

flute

I

it

will

be

necessary

to

stone a flat

on

the

cutting

edge

of

this

type

of

cutter

to

obtain

more

clearance.

The

out-

side

diameter

should

not

be

ground.

PANEL

ROUTER

CUTTERS

OR

SOLID

SHAPED

CUTTERS

Use

grinding

wheels

Nos.

140

and

141.

After

setting

up

as

described

opposite

both

flutes

should

be

ground

at

the

one

setting.

After

several

regrinds

of

the

flutes

it

becomes

necessary

on

this

type

of

cutter

to

give

more

clearance

on

the

back

of

the

cutting

edge

. (See

pages

48

and

49. )

www.wadkin.com

info@wadkin.com

TO

SET

UP FOR GRINDING

FLUTES.

First

bring

the

cutter

flute into

correct

relation

with

wheel.

Adjust

the

stap

on

machine

table

to

suit

length of flute

to

be

ground.

Use

table

move-

ment

to

grind

the

flute

taking

light

cuts.

To

put

on any

cut

use

the

radial

adjusting

screw,

thus

maintaining a correct

cutting

angle.

Both

flutes

should

be

ground

after

each

adjustment

to

ensure

that

each

is

ground

identically.

TO

SET

UP

FOR

GRINDING THE END OF THE

CUTTER.

First

turn

attachment

round

at

right

angles

to

grinding

wheel

and

lock

up.

Bring

cutter

into

correct

relation

with

wheel

and

adjust

stop.

Take

light

cuts

by

using

table

movement.

The

remaining

face

can

be

brought

into a

similar

position

by

using

Index

plate.

Use

grinding

wheels

140

and

141.

PERIPHERAL

RELIEVING

OR REGRINDIN G CLEARANCE

OF

PANEL

CUTTERS

ON .

ATTACHMENT

S.

F.

A.

The

best

results

on

relief

grinding

are

obtained

by

using

the

attachment

P.

R.

F.,

as

described

on

pages

49

to 53.

This

method

is

illustrated

for

operators

who

have

the S.

F.

A.

Attachment

only,

but

it

should

be

stressed

that

the

results

obtained

will

not

be

as

good

as

with

the

P.

R.

F.

Page

48

Fig.l

Shows a new

panel

cutter

with

plenty

of

clearance.

Fig.2

Shows the

same

cutter

after

several

regrinds

with

no

clearance.

www.wadkin.com

info@wadkin.com

PERIPHERAL

RELIEVING

ON

ATTACHMENT

S.

F.

A.

Cutter

is

moved

across

the wheel

by

table

move-

ment

as

for

grind-

ing the

flutes.

Take

light

cuts.

1st

stage

2nd

Stage

Fig.4.

Fig.

3

Use

wheel

No. 140

or

141

Using

same

wheel.

GRINDING

OF

SHAPED

CUTTERS

TYPE

NOS.

9, 11, 12, 32.

Shaped

cutters

must

only

be

ground

in the flute and

must

never

be

ground

on

the

straight

relief,

unless

the

shape

or

profile

of the

cutter

is

being

altered.

This

operation

is

done on the

S.

F.

A.

Attachment,

using

wheel

No. 141.

The

method

is

illustrated

right

and

described

on

page

48.

PERIPHERAL

RELIEVING

OF

PANEL

CUTTERS

ON

ATTACHMENT

P.

R.

F.,

ALSO SUITABLE

FOR

RELIEVING

OF

TWO-EDGED CUTTERS FOR SHEET DURAL, ALCLAD

AND

BRASS.

This

Attachment,

mounted

on

our

N.

U.

Grinder

has

been

designed

to

obviate

the

poor

results

obtained

when

operating

Routing

Machines

due

to

the

outside

relief

of

cutters

being

improperly

honed,

and

in

some

cases,

hand

ground.

It

consists

of a

base

plate,

on which is

pivoted a platen

carrying a swivelling

bracket,

on

which

in

turn

is

carried

the

spindle

head

which

can

also

swivel.

Both

the

swivelling

units

are

graduat

ed

and

the

control

knob

for

pivotrng

has

also a graduated

dial.

The

work

spindle

is

on the

eccentric

principle,

provision

being

made

to

vary

the

eccentricity

(or

radius

of

relief).

GRINDING

OF

GROOVING CUTTERS

TYPES

41

- 53.

These

cutters

must

never

be

ground

in

the

flutes

because

of the

loss

of width

which would quickly

result,

due

to

side

relief

of

cutting

edges.

Resharpen

these

cutters

by

grinding

on the

outside

face,

using

the

S.

F.

A.

Attachment.

Grinding

of

cutters

for

Flat

Knife

Chuck

No. 50,

Expanding

Cutter

head

No. 51,

Panel

Cutterhead

No. 52,

Circular

Block

No.

55.

For

resharpening

these

cutters

it

is

recommended

that

the

knives

be

removed

from

the

block

and

ground

freehand

on a

moulding

iron

grinder.

www.wadkin.com

info@wadkin.com

For

holding

the

cutters,

bushes

i"

and

i"

bore

are

provided;

these

have

two

lines

engraveq.

at

180

0

J

each

line

in

turn

being

brought

into

alignment

with a

zero

line

on the

spindle

nose

J thus

enabling

both

edges

of

the

cutter

to

be

ground

at

one

setting.

An

approximate

position

to

place

the

cutter

radially

is

also

indicated

by

another

line

on the

no

se

of

each

bush,

one

of the

cutter

edges

being

placed

opposite

this;

this

position

can only

be

approximate

as