www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

Wadkin

INSTRUCTIONS

OVERHEAD

PRINCIPAL

Centre

Maximum

•

Size

Longitudinal

Transverse

Vertical

Vertical

foot

Spindle chuck

Speeds

Horse

Speed

Speed

Total

Floor

Approximate

Approximate

of

cutter

distance

of

main

table

traverse

motion by I\andwhee1

motion

motion of

lever.

of

cutter

power

of motol" in

of

motor

height

space

(allowing

of

bored

of

motor

in

net weight in

shipping

BORING

spindle

between

by

table

spindle

- No. 4

spindle

r.

p. m. on 50

r.

p. m. on

for

dimensions

AND

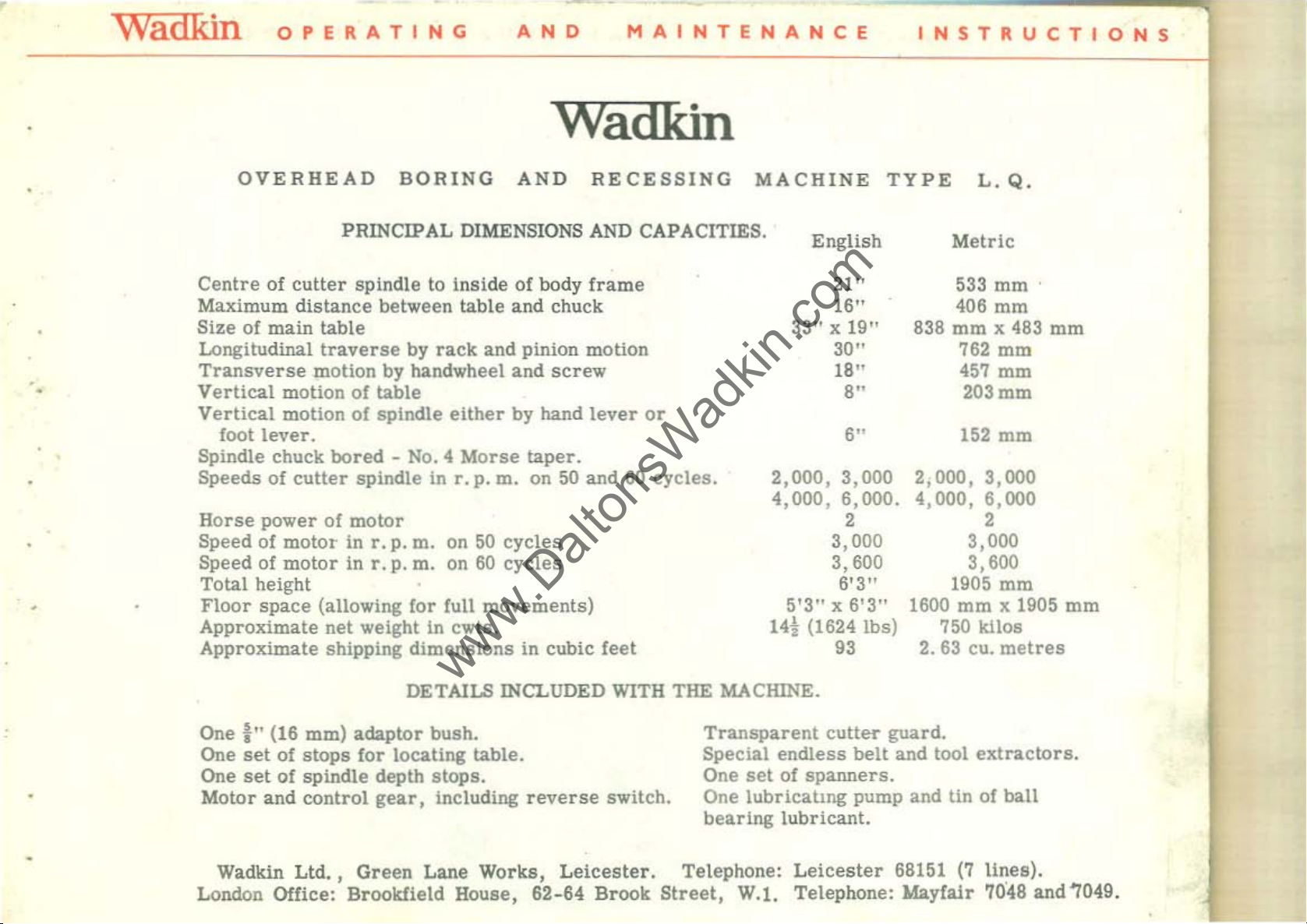

DIMENSIONS AND CAPACITIES.

to

inside

table

rack

of body

and

and pinion motion

and

either

in

r.p.m.

full

cwts.

Morse

by

hand

taper.

on 50

cycles

60

cycles

movements)

in

RECESSING

frame

chuck

screw

lever

and

cubic

feet

or

60

cycles.

MACHINE

English

21

16"

33" x 19"

30"

18"

8"

6"

2,000,

4,000, 6,000.

3,000

2

3,000

3,600

6'

5'3" x 6'3"

141 (1624

93

"

3 "

lbs)

TYPE

838

2,000, 3,000

4,000,6,000

L.

Metric

533

mm

406

mm

mm

x 483

762

mm

457

mm

203mm

152

mm

2

Q.

3,000

3,600

1905

1600 mm x 1905 mm

750 klloe

2. 63 cu.

mm

metres

mm

DETAILS INCLUDED WITH THE MACHINE.

One i" (16

One

set

One

set

Motor

Wadkin

London Office:

of

of

and

mm)

stops

spindle

control

Ltd.,

adaptor

for

depth

gear,

Green

Brookfield

bush.

locating

stops.

Including

Lane

table.

reverse

Works, Leicester.

House,

62-64

switch.

Brook

Transparent

Special

One

One

bearing

Telephone:

Street,

endless

set

of

spanners.

lubricating

lubricant.

Leicester

W.

!.

Telephone:

cutter

belt

pump

guard.

and

tool

and tin of

68151 (7

Mayfair

extractors.

ball

lines).

70'48

and

"7049.

A

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

".

Points.

ball

bearing

on

boring

circular

top position and for

ot

her

must

grease

spindle

sllOe

point the

be

lowered

nipple Is

To lubr

at 3 points

must

icate

the

be

the

sptndle

until

tn

Handwheel to

tension of

belt.

regulate

o

To

lubr

spindle

lowered

through

o

2·

P

oints

locking handle

o 4 . P

each

shaft.

oints.

end

icate Circular

must

be

slightly

and Oilcan

hole.

. One

shaft.

I -

Point

of each handwheel

Inserted

on

""/-

slide

at

,

C=~

---"c

2 - P

oints

-

D

2 -

Points

treadle shaft.

on

motor.

on foot

B

3.

Points

on

raising

.",~,.'

Page 2

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

The machine Is despatched

This

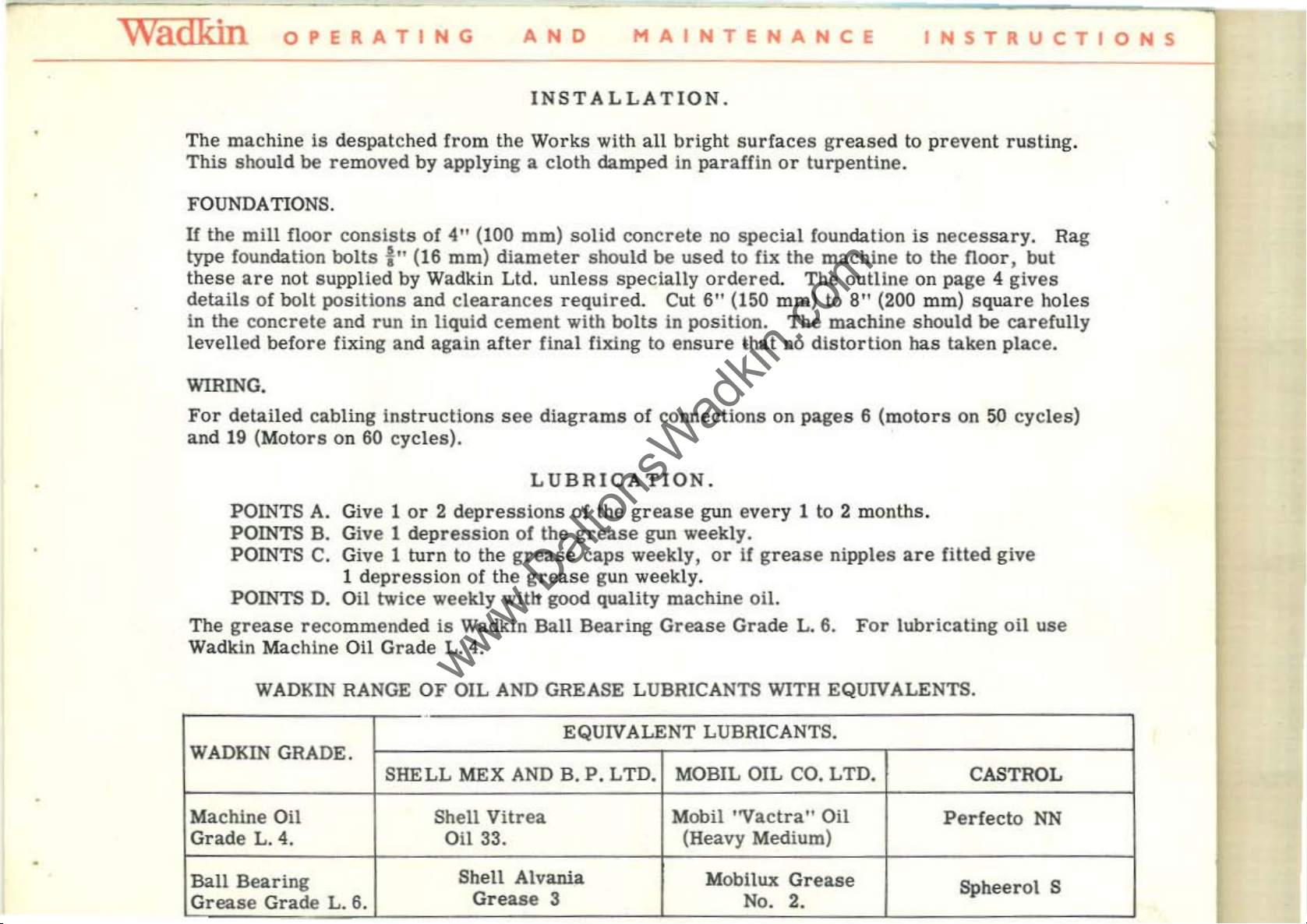

FOUNDATIONS.

If

type

these

details

WIRING.

and

should

the mill floor

foundation bolts i" (

are

in the conc

levelled before fixing and again

For

detailed cabling

19

POINTS

POINTS

POINTS C. Give 1

POINTS

be

rem

oved by applying a cloth damped in paraffin

consists

not supplied by Wadkin Ltd.

of

bolt

positions

ret

e and run in liquid

Instructions

(Motors on

A.

B.

D.

60 cycles).

Give 1

Give 1

depression

1

Oil twice weekly with good quality machine oil.

from

of

4" (100 mm)

16

mm)

and

cle

or 2 depressions

depression

turn

to the

INST

the Works with

diameter

unless

aran

ces

required.

cement

after

see

of

grease

of the

with bolts in position. The machine should be

final fixing to

diagrams

LUBRICATION.

the

grease

A L

LATION.

all

solid

of the

grease

concrete

should

specially

of connections

grease

caps

weekly ,

gun weekly.

bright

be

used

Cut

ensure

gun weekly.

surfaces

00 special

to fix the machine to the floor, but

ordered

6"

(150 mm) to

that

gun

every

or

If

greased

or

turpentine.

foundation

. The

no disto

on

grease

outline

8"

rtion

pages 6 (motors

1 to 2 months.

nipples

to

prevent

is

necessary.

on page 4 gives

(200 mm)

has taken place.

are

square

on

50

fitted give

rusting.

Rag

hates

carefully

cycles)

grease

The

Wadkin Machine

WADKIN

WADKIN

•

Machine Oil

Grade

•

Ball

Grease

L.4

Bearing

rec

ommended

Oil Grade L. 4.

RANGE

GRADE.

.

Grade L. 6.

Is

OF

SHELL

Shell

Wadkin Ball

OIL

AND

MEX

Vitrea

Oil 33.

Shell Alvania

Greas

GREASE LUBRICANTS

AND

e 3

Bearing

EQUIVALENT LUBRICANTS.

B. P. LTD. MOBIL OIL

Grease

Mobil

(Heavy Medium)

Grade

WITH

"Vactra

MobUux

No.

L.

6.

CO.

·' Oil

Greue

2.

For

lubr

icating

EQUIVALENTS.

LTD.

Perfecto

Spheerol S

oil

use

CASTROL

NN

• •

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

~

~

-

•

•

"

•

-

~~

-

-

•

•

~8

""

""

<

"

• •

~

...

-

-

-

-•

-

•

,

-

...

-

;;:

-

•

~8

""

""

~

. 0

0 0

E~

< •

•

•

~

"

"

>.

"0

U

?

~

~5

."

P"'i

e 4

CD

o

;0

~

..

;0

~

[;l

C/l

Z

COl

s::

l-J

.

I

Z

III

•

:;!

'U

III

r

p

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

• N 0

MAINTENANCE

INSTRUCTIONS

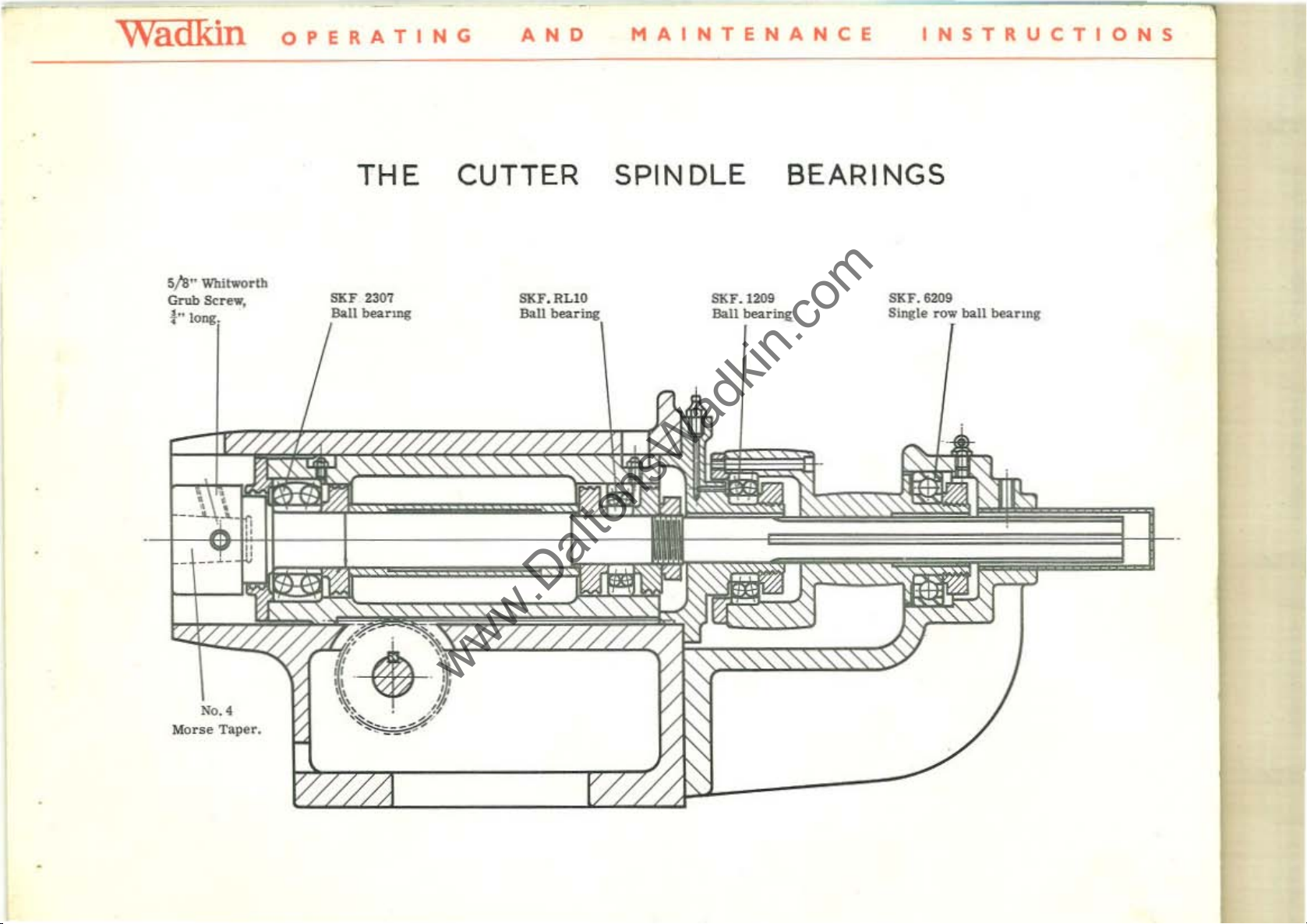

THE

CUTTER SPIN DLE BEARINGS

Sl(Y.l:lOll

BanbeariaC

NO

••

""'rn

Taper.

-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

...

..

~U

I "

..

~C1~

O

..

tlt

...

"'~

-l;~?;"!O:

~

:

...

,,

_°,,"0 -(

O~u

"I"':>I-

i.

i'III:)I'ti~3"

>

1

.......

"<>

f~"o(5"

..

':~if

i,luiil.J

ilZ

z3

..

"' _

.,2(

..

..

'

l~Z

..

I

Z

"

_ (

;1)10°'1'

lHoJ

t=~"~"O"Z

""'(

II'-OD.~"

..

Ol-IIZ

Z"u~«

_

....

-

0-'

~

"!'

...

..:"01·

0 0

..

~

0

10

;:

-

<I

... " ...

,,111""'2°

lol

-

-I-

"

;:l

l

11

"r

..

....

~0

~~~l~~~

~IL~

, .

• ,,_

_

",,:1:,,0

....

ill

~~~

.... " ..

. O·

~

.. 0

., ,'

'"9

•

5jj~D"

ifI'

....

It;JO

~

Ill",,,

,,""'I.t!!

!:

l

""Z~~1-

?;o.ir

"'Du

'1'(~Ot-

".rlq"·o·Ii<l"OO~"

)

~Zl1..

1,=1-0' ..

l;;i

~~~~~=>~H~~~~~

J.

..

..

I"

1.

o~j,I

.

1-...

11-

Zj

..

(11.1

""'""

..

·:.r

....

o

1.1"0("

0(0

..

&I'll

"~"l'

O~~W"

.. 0 ......

..

~;J

)"

.. 0 " W

d~""')

0

....

~:IIi;l·

..

lz

.

~

.,

....

1101

'1"

O~(l'~.~O

00"

..

..lOOWijt

"r;~U~

I ~

Fi."r

-

- ~

11':1-

,,1: ..

·

1I:

(~1·(1I~"

[

...

~"~J"OZ"~

11.1010.°)1-

I'(

J

0(

Z'l,·,

11

1

J~.

..

,,'.

....

1'

..

",,°oi

tt·-1r

..

".'

..

t-

(;11-

CI

"'..10

l<lrl.

00

3 i1"

U

...

(ll-lI

r

~..:

'"

011

(t-

..

011

Z 0

~

..

t-

1110

(1111

~

rZ

J

~~

H

«I-

oj:;Id:OO'!l

,,1.1°

(1.~:luOo

Z

"/::

oj(l.~-'

~~~~UZ':'

O!".~L-.

z

8~IHn~~~O

>,

.

.~~,

I(.J.J·

..

»(

....

~

...

O

1Il}~1

..

~·L..

Izb~.(<O:

...

0

~

~

1 -

__

-====":O~

±3

~

~

~

«'"

i I- t

J 0

..

rl

(

!;;~

I-

,

'

~

~

•

~

.

~

,.

>'

"

••

,.

..

O

~

"

z'o

'"

~i5

"I'

~.Il

r.,

,-~

~":---- - =i'

, " ,

-

..

- -_

..

-

~~

. /

>,

"

>,

>

J '

8 /

,

~

, u

~ ~

~

~

o

1J

i-

U • •

\'

L

. / '

___

---------,

I 0

_ _

_____

_

!

~

!

~

•

L ___ _ _ _

•

~

I

~II

• •

..

-----

~-----'

,

I

...

:<

~

.'

:l

~

-

"

l

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

INSTRUCTIONS

OPERATIONS FOR CU'fTlNG RIGHT HAND

PI'fOt

machine

to

phOi

round

Fix

alOpl '11" and

Fix

slop

"""mon.

down)

bring

Ar~e

stop

''0'',

continuaticm

suit

this

tabLe

hole

"F"

In

....

Arrange

CUller to

depth

.top

CU\

....

e<Ii;e

of

tQp

dlme",lo",

round

."

...

"L"

ltable

atop

,taTllne

to

lult

room

Qf

tread)

Bring

to rlf:l\t arid fill:

Fta:. S.

to

8ull

hole

"J"

Brine

11'11.

to

,Ive reqlrlred

to

live

pOmt u

and

tu!

on

tread.

and

on

Jig to

lab!e

~ltIon.

rl'q\llred

shown

II>e

f1UI

Pivot

eeUl"ll-out

normal

poslllon

FOll

STRlliG.

al

sull2ble"angle

fo......,.rd

F

ix

elamp

taper on

lencth

In

01

Fig.

paraUel

Jig

on

10

of

stair

again

CUTTING

and

arr~

In hole

rls"r

""""

4.

riser

noSing

"lop '·T "

string

(with

to s

uit

SUlr

piYOI

''C''

and

a.r~e

to tread.

and

and

measure

turn-over

and

cut

STAIR

~1

pin

stop

With

irud.

wedge

pitch

stop

..

1np

In

hole

"E"

"er ....

jig

Pivot

room

of

''0''

STRINGS.

to

be

cut u Fig.

"A"

dead

In !KIle

In

turn-over

In

DOrm.l.i

jig

00

on

trea<k

down)

under

''0''

to

atop

"""ltlon

to

atop

ri8er,

dlme",lon

and

Scribe

moVe

1. F

ill:

atlll ..

e~tre

gin

''C"' to

(wllIl \lIrn...over

"E"

"K",

,talr

of CIIller

required

brlnr

and

turn

Une

"N"

Fix

slrinll

flflre"'i

taper

Jig

stop

back

(which

pointer

alo",

jlf:

sph'ICIle.

on

tread.

10

normal

''0''

turn-Qver

Is

a

''N'' to

unUl

scrlbed

markl"i

"""od

OD

TO CUT LEFT

Pivot

"B"

pointer

to

riser,

machine

Fill.

line

"N"

out

Is

stop "E",

The

table

S.

Ar

at

tI>e

left

COincides with

necessary,

turn

back

pltcll

olllle

HAND

...

.-wnd

",e

band

STRING.

.top

end

polnler

To

cut

second

t"rn-onr stop

Ireacla

10

"S"

of

left

In

1Ia:

Is

and

hoLe

and

''N'',

and

now

controlled

fix

al

suitable

"I""

and

opposite

Clamp

remalnl"i

''0'',

cuI wedge

Slop "F"

band

down

by

turoonr

111IIe

tu

rn_OTer

and

treado

10

in

."Itable

room

suit

slop

arrange

and

risers

on

st~

stair str

pOaiUon

''0'',

turn_over

cut

Iread;

"0",

ln«

and

parallel

pivot

to

be

repeal

stop

"0"

In end

rlu

r ,

III

round

cui, Fill, 2,

to ItQp

opel"llllons u bef

of

110&1",

"F"

Fix

ill

no.l""

and

and

10

ore

tread,

cut

pivot

UIIltC

No

more

pivot

wedf!:e

round hole

tI>e

JIII

room

M.--_

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

10<

...

no. I

,,,,,.,,,,,,

................

""'"

..

,""

boo

-:..,

le

.

M_

...

....... , ...

""""

f!G. I

.........

.

... ...

,oIt_

boo

..

.

Wadkin 0

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

PER

A

TIN

G

AND

MAINTENANCE

INSTRUCTIONS

•

CUTTER

The following

of

cuts

that

can

included or

available

pages

10 to 15

be made u

for

EQU

sing

use

IPME

illus

the

with

NT

trate

the

variety

cutter

the machine .

equipment

•

Page

9

~"

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-

3" DU. COREBOX

CU'IT

ERS.

CORNER ROUNDING

_

l

r.

PA'ITERN

----CUTTERHOLDERS:-

CU'ITERS.

L.

P.305

r.

306.

C.B.I-t2

i" - I.

Spindle

SMALL COREBOX CU'ITERS.

L. P. 305,

Spindle

MEDIUM COREBOX CUTTERS.

1/16"

dia.

spud

L.

P.

43 C. B.

·

3"

dla.

speed

C.B.SO_S3

10 _

25

6,000

r.

p. m.

306

r.L.P.307

84_93

30

-75

&000-3000 R.

m/m

m/mdia.

P.

M.

dia

.

CUTTERS:-

W.H.C.70·72.

l/S"

-

f"

radiI.

Spindle

CORNER ROUNDING CUTTERS.

L. P. 307

Spindle

PATTERN CU'M'ERS.

speed

speeds

6,

000

r.

p. m.

P.C.80·9O

25 - 75 m/m

6000 _ 3000

dia.

r.p.

m.

Pag<>

10

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

t"

-

It'·

DIA. SOLID

OPERATING

..

ADJUSTA

BLE

AND

RECESSING CUTTERS,

MAINTENANCE

ROUTING

OR

RECESSING

INSTRUCTIONS

CIJ'ITERHEAD"

DOVETAIL CUTI'ERS.

.

2t"

dla.

J.

P. 94.

~~~~~t;

~

;:

~~~

--C~~~:i::._i

S;llndlt

ADJUSTABLE R£CEB5ll'IG

SplDdl.

SOLID RECESSI

I4

dla.

spM<I

e,

OGO

CUTTERS,

B.

E,go _ 901,

B.£.70

'PHd

.14,

6,000

NG

CUTTERS.

r. p. m.

i-

-

t··

-

r.

p. m.

IJ"dla.

Ij"<lia.

~~~

:

j!

j_~~-I(...l~rUTI'ER

·

/j~I---_coE~;~

C~nlre

Spin,U,

ROUTING OR RECESSING

r,

_---

, . L. P. 295

ADAPTOR BUSII:-

7/18" " 1/8"

~or

boosU'le.

Spindle speed 6,000 r . p. m.

.qua

...

Or

. 22?A,

4.000

dla.

(1

I"OUDd

J.P.94

J.P.94Il

2Z7C,

r.

p. m.

.

1 "

!2

.tee

J.P

J.P.227B,

culter,_ J. P.

epee<!

CU

TTERHEAD

W.H.D.S06S2.

S;-

cum",

dav,tall

DOVETAIL CUTTERS.

corne r:_

....

J,

P. He.

ID/m

..

lor loo.se

dta

. )

i" - :.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

5/8"

DIA.

SORlNG"

SLOTTING CUTTE

RS.

SOLID TRENCHlNG CUTT E

RS"

TW

O_FLUTED CENTFlE Bl'l'S.

•

'._----- AD

!-.

•

,

,

~'

. ,

':

,i.

_-

/

1

,

"

APTOR

L.

p.

:m _ 296 .

'7f-CUTTERS,

B. E.

11

Spindle

THREE

SLOTTING CUTTERS.

CUTTERHO

L. P

.305"

BUSHES,-

square

-

I~

,

t"

spHd

8, 000 r .

WIN

G BORING

LDE

RS:_

306.

oou:_

-

I"

<!la.

p.

..

m.

,

~~

-j~

;, L. P

_-AD

APTOR

CUTTERS, clothe.

L. P. 425 - 432,

Sp

SOLID TRENCHlNG CUTTE

or

.H5

will

indle

self

up

10

BUSH:_

.

IXI

I sl.nk.

speed

BUS

- 296,

cenl

t··

<!la.

6,000

HES:-

rJ.tc

peg

t,·

cbo.lc

- I

r.

k

I

ype

t"

p.

,

<!la..

m.

RS.

UTTERS:-

W

.H.C.I-3,

SpIDdl

, speed 6000 " 4000 r . p.

SORlNG

"SLOTTING

1" _ 2. S

/S·

·dJ

a.

m.

CUTTERS.

Page

12

_---I

.

-C

":~~:.

.

~

..

:6.

t"

Spindle speed 3000 _

TWO-FLUTED

_ f" dla.

CENTRE BITS.

l1OOO

r.

p.

m.

I

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Wadkin

OPERATING

AND

MAINTENANCE

,

INSTRUCTIONS

MORSE PATIE

RN

TWtST"

Or

CLEAN-CUT BITS.

BUSHES:-

- :t98,

uU

cent ..

l",

to

i"

dla

,

ahanl<.o.

~.

SpIDdle

MORSE

8peed

:woo

PATTERN TWIST

chuck up

• eooo

r.

p:

mTS.

m.

~~~~

~

~

~

TAPER"

PARALLEL PORTHOLE CUTTERS,

DRILLS"

,

COUNTERSlNKS.

______

ADAPTOR BUSHES:_

i i"'-- L.P.:I;9S

l·

ldd

~

CUTTERS:-

_----·",,,

l

J~

lt·

l

~~~~~~SpIr.dle

.1 /

. :

,I

W.

H.

Po.raU"L

W.H.C.U3-117

TAPER

REVERSIBLE

10

Z96

C. 102 - 104 'l/

. pe.ed

..

6,000

PARALLEL

CUTTERS.

U" -1/1"

t"-I

"dIa.

r.

p.

m.

PORTHOLE

dla.

or

self

centrl"ll

;;;,~.

CLEAN_CUT

speed

PLYWOOD.

chuck.

SOOO _ l1OOO

BiTS FOR

use

r.

p

.....

ON

L. P.:I;94 " ::95

Or

Kif

t"

centring

dla.

chuck up to

shanks.

w:~';!,.~~,

c:.::.:,;:.:';

COUI'ITERSlNK:-

DRILL WlTH COUNTt:RBOIU

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

I"

SQU

....

RE CUTTERBLOC

K.

GROOVUI"G SAWS"

FRE

NCH SPI

NDLE.

Or

to.

MM

dla.

BUSHES

-'"

c..,trLoc

eIwIQ.

:-

ctN.:k

..

to

t;H. ___

- -

"ENCH

CUTTERS:-

CIIU~ra

SpLndk

SPINDLE

L.P.I87.

to

auLt

cu.tom~r

requLn_"~.

~

4

,000

t

.

r.p.m.

Spi".,Le

,

_2000r.p.m.

,

L. P. 188.

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

,

INSTRUCTIONS

•

SLOTTED

COLLARS, CUTTERS h SCREWED SPIND L

J\,

-

•

,

•

,

,

,

,

,

•

,

•

,

,

, ,

,

•

I

"-

,

•

,

•

,

•

,

,

,

,

,

---

--

./.

r

WED

SCRE

L.P.lsa.

$PAC

ING COLLARS

Z.1,2&3.

Q.

S

LOTTED

L.

SPINDLE;_

COLLARS

P.199

E.

.

ADJUSTABLE TRENCIllNG h

---

_

l

,

__

-

=

:::2

~

~tl;;;:f~::

:

_

----CUTT

L

--CU

PANEL

C

UTT

L.

TTERS:-

Shaped

suit

Spindle apeed4,OOO r

PANEL

L.

RAISING CUTTERS.

ERHEAD

P.412.

customeu

ERHEAO;.

P.

:-

cut

ters

RAISING

412.

supplied to

requlrementl!.

.p.m.

HEAD.

•

SMA

LL

FILLET

W.

H.

C.

130 _ 135.

Spindle

speed

CUTTERS,-

3/8"

3,000

r.

p. m.

- I"

rad.

CUTTERS:_

L.

P.

~~~~~~~~~~~

~

Spindle

................

TRENCHING

speed

"

4,000

417. 1.

L.

P.

415.

L.

P.

418. 1. 1/

L. P. 418. 1.

r.p.m

-~-

..

~

1/8"

.....

~ ~

3/8"

VS"

.

- I

• I

:"

8'

_

• 2".

..

----

t".

1~".

TYPICAL

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERA

TlO

NS

ON

THE

MA

CHINE.

The following

It

should

the

cont

worked

illus

per

o

regulate

panel,

be

vari

ous

movements -

rols

the leng th of the

IrH

trati

on

ation

being

the width and length

and co

page.

,how

the shaj)f!S that can

noted that once the

slralghlllne,

travel

hand.

show.

a panel sinking

performed.

ntr

ol the depth of cut.

WQrk

only of the

StO)l3

of

be

generated

uSing the

Is fixed on the table and the cut

angular, circular, etc. are

work

past

the

culler,

and

varlous

ter

accurately

pre

cision

apart

feed movements on the machine.

functions

from

pOsition

Ihls

ed

with

01

the machine. The

the

vari

ous

shapes

respect

are

to the

WQrk,

operator

nol In any

way

A panel

that

crou

2 ~ "

x

9"

1& the maximum

may be cut

at

and longi tudinal

one

settlng

using

traverae.

Page

16

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

AND

MAINTENANCE

INSTRUCTIONS

Boring a

number

traverse

ate

location for

series

of

stops

to give quick and

of

holes

on

longitudinal

repetition

using

aCCUI"-

work.

a

Producing

radius

radius

This

lever

pin

•

and

pal

table

fitted

which

provides

angles.

circular

and

segmental

by

means

Is

with

engages

of

contro

spring

stops

work

auxiliary

lled

holes

for

up to

work

by hand

plunger

In

all

6"

12"

table.

table

princi-

I

G

Illustration

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

rotated

to 45°

shows main table

for

cutting

stair

,

I

I

I

strings

longitudinal

by

use

of

cross

traverse

and

motions.

Using

l

ocked

hand

l

fences and

work

past

may

cutters.

with

be

fed

table

by

Page

I

•

18

Wadkin

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OPERATING

•

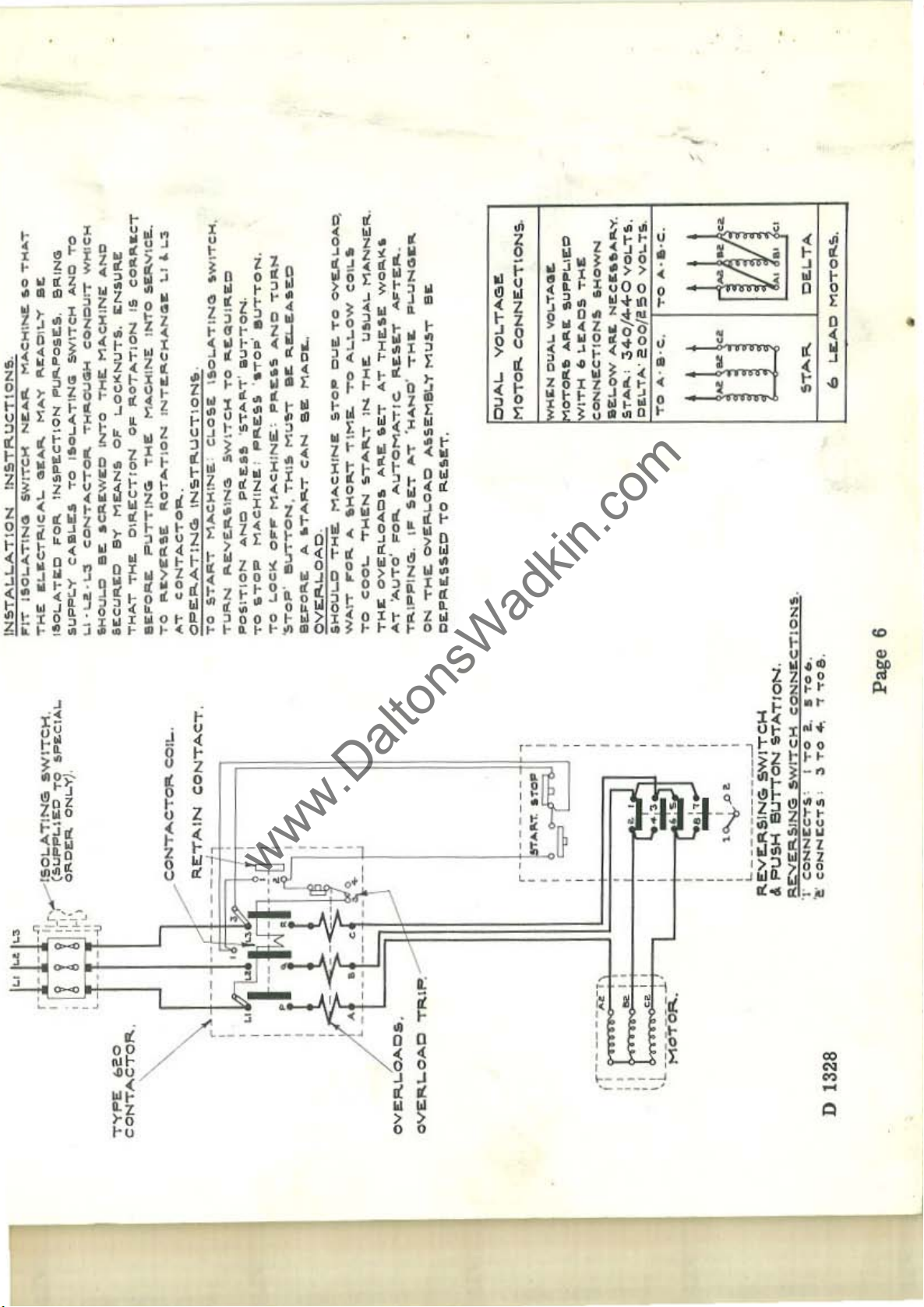

ON'-V)

AND

MAINTENANCE

so

'THAT

,,"£.AOI<-V

1'>

"'''"pca ....

DISCONNECT

MA(l,NItT'C

WHIC...,

MACHIN!;

... O(:kNU"'

1"'1ACJ04

C"""-"YlN&

I5,..AI\TE

OF

T'

lO-OTATION

INIt"

,.,OTATI'ON

....

: M ....

TM.I:

'.

01-"''1'"11:'0

&"""1"

~1'l"C'"

..

T ....

!lHOU1...C

"'''10

.....

"",AMI:

THE

.....

I!NSU"E

CHI

N£

LN-rE!'l..C.

IU

..

ECTIO.ICA",

.11.11"'''''''0'

"'TE"

8E.

&E

el,l

HeLl[

JrOJit

C ....

~1o

"1'"104

1$

CO'"'''EeT

INTO

......

INSTRUCTIONS

00£:

...

1'1.

MA'"

1"0"

",ND"-O

TIot""u.'"

SC,.,rwED

~D

" _

...

"

LN

eAat.E~

8V

OV'C

TIoIE

TO

,.. TI-II!:

':"'Vlel:

NOOI;

!I"I!:CTION

U~U!-I-;)

eoNO

I

NTO

MEAN"

EO

C.ONOUIT

TH!:

D"

eE.FORE

, TCI

1...1

",NO

TO

MAOoN

'I:

fO.S:VC"

Mool.CH.lNIt

,..,

....

AT

... IT

.,.'"'£

OJ"

IN

THE'.

II!:"nc

C.T

l0N

P'UTTING

1..3 .

•

a.:

,"1

..

E.

\

\

•

I

•

D

I"<;()NN&C"T

BUTT

I!oUTTON. TO

TuRN

""11:1-1.

ON.

'STOP'

.......

OVERLOAD

SHOULO

OVE:J'lI..OAO

,",-...,~1E'fII,

•• .

GP.OUNO

~~:~:~

••

".

(

!oWITeH

TO

$'1'01"

L.OCK

BU"!"'r

'0

BI:FOFl.E

.

T}oj£

MAC:I·UNr.

JIlf:!!>I:T

0'"

:

;~.;

M .... Cl--lJNE .

THJ;:

1..1

A3

A3

I"'IACIoIIN

OFI'

ON,

A $TAP..T

....

TO

I..

t

"'0

TO

LI

TO

1..

1 T O

TO

"NO

M,",CH1NE'

'1"),<1.

!oTOP

1103,

Lit

BI! , 1..2.

a:!,

B3

A3.

I..I!

ca.

I.&.

&3.

B3

PP.

E :

MU

c:

CWE:

TO

TO

T O C;J.

TO

TO

TO

E$$

... T

....

'~,T"'''T

'""It!.

N

"'3,

ea,

&3.

""Illi!t

BE

BE M ....

TO

1..3

1..3

alt

,

<::3.

'.-rep"

T

1..3 T O ....

1..::1

Hr.

TO

TO

TO

''

....

N'O

O£..

<:3.

C3-

Ar..

1

It

.

•

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

...

blow

chips

Wadkin

No

motor

duct

or

control

the

re.ultant

Similnly,

the machine

for blowing down

in

bener

breakdown.

Bl

owers

for

Please

any

voltage

sute

i«umuluion.

and

un

away

and

harmful

dirt

with

Electric

un

run

at

its maximum efficiency

gur

covered with dust ind dirt. Sooner or later

overheuing will

un Interfere with its efficiency.

all

Woodwork

usler

be

volu.ge when ordering.

running, in

supplied for single phase A.c.

up

to 250.

ouse

serious trouble.

of chips and dust. in

ing

Mach

Increued

dust,

a

Blower

with

it.

the

meclQnial

A.

few

minutH

inery

will

be

amply repaid

life, and freedom

or

Direct

v~ntilatin&

parts

of

a week

from

Current

•

•

l

Loading...

Loading...