Wadkin CK90 Instruction Manual

CK90

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

HIGHSPEED

CROSS-CUT

INSTRUCTIO

N MANUAL

No 30331

SAW

1

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

CK90

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

HIGHSPEED

CROSS-CUT

MIC

No

T

EST

No

IN

STRUCT

ION l\lA!'<UAL

SAW

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

MANUFACTURERS E.C. DECLARATION

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

OF CONFORMITY

The followi

Third

Schedule

and Amendment No.

COMPANY

Wadkin Ultracare

Green Lane Road

Leicester

LE54PF

RESPONSIBLE PERSON

Mr J P Smith

MACHINE DESCRIPTION

TYPE

ng

machine has undergone ·Conformity Assessment· and has undergone

Party Examination by a Notified Body

lV

of

the Supply of Machinery (Safety) Regulations 1992

2063

LimHed

(Oi

rector

)

in

accordance with:-

High Speed Cross-Cur Saw

MODEL

DIRECTIVES COMPLIED WITH

Supply of

Amendment

Draught

ISO 9001 Part 1

Machine

Proposal CEN{TC 142

No.

2063 1994

ry

(Safety) Regulations 1992

CK90

NOTIFIED BODY

Ll

oyds Register

Lloyds Register House

Wellesley Road

29

Croydon,

CAO

2AJ

EC951000011

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

is

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

our

It

the

design

would remind

performance

going

fl1e

latest

and

policy

ana

to

pressl it

deve

suppliers

PREFACE

IMPORTANT

and

that

of

our

suppliers

capac

our

data contained herein are

opments

may

ity

of

customers

is

possible

to enhance p

vary

from

our

products.

that

that

those

while

due

erf

illus

to

constantly

With

the

dimensions

correct

to

the

incorporation

ormance,

trated.

this

in

mind

at the time

dimensions

review

we

and

of

of

This

is

certa in

shown

machine,

manual

shown

guards,

on

Fai

lure

is

written

to

illustrate

safety devices

particular

correctly

to comp'ly

as a general

the mam features.

and

illustrations

set and

with

invalidate the

work

ing

instructions

guarantee

guide.

For

machine

but

MUST

before

in

this

A typical machine

reason

parts

be

operating

manual may

of

may

fixed

clarity

not

to

be

the

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

BE

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

CAREFUL

THIS

MACHINE

IF

IMPROPERLY

Always use guards.

Keep clear until rotation has ceased.

Always

and

Read instruction manual before

in

accordance with good practice.

operating

ManulaCluredby:·

CAN

operate as

Of

maintaining machine.

BE

WADKIN PLC

Green

Leicester

LE54

England

DANGEROUS

USED

instructed

ins talling

Lane

Road

PF

phone

tax

no

no

;-0116 2769111

:-01162742310

CE

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

I

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

,

,

HEALTH AND SAFETY

n..,

CE

ma'"

on

tl1l:1

........:t>I

.... oig,,;!ie$

EC

deC

laration

indicating

lhal

accordance with

Sa1ety R&q.Iire<nenls

MacfIinI!ry (Solely)

Th

e 'requirements

machinery' in t

Regulations

satisfi

es

the

sa

lely

requ

maMaclure

r,uateh

the compIele

by

<;.iipabIe

or

its de$ign

01

safelY.

Persons

ur>de

Equi

these duties

!)u

irnpIi(;.;Itions

REGUlATION

Every

otqUipmern is

tie

or

In

,~~

and

which

which

any ackitiooal risk

work

Every

equipmefll

Which,

su~able

In

any respect which • Is reasonably fore

will

who

. t

he

pmen

t Ae oulatlo

t

the

uS",

empbylJ

su

~able

provided.

seleCli"ll

hoove

10

lI'e

risks

ui$t'"

1ha.t

eq.>ipmen1.

employe'

aoo

,

this regulalion

.lIect

llealh

01

COnlormity

the

machine

\he

Es~

01

ReQUIa1iOf1s

lor

he

Ger.eral Requi

ale

JlCt

on

ly that

relevam

ire

mell

eSsential

lS.

but also that

...... Cllfl'Ie. out

lests on

machine

or

being

inslallthl$

'PrOvision and Use cl W

is

!)i

should

01

the regulations.

5

~ne"u.

10 determine whether

conSl"-"lion the machine Is

.feGled

machifle h

ns

1992',

ven

In

the lollQwjng extracl

be

l.miIiar

requirn,hat;

shal

so

col'IS

lrueted

10r

tr.e

purpose l

wo

ll< equipment, every

regard

work

10 lhe

10

he.~h

t

he

premises

equipment

and $afely

posed

$n.1 eMm"

;s

used only lor the operations lor

umler

cc

r>dilions lor w hich,

'su~_'

()(

salei)'

01

1$

is

tnaR/lactured in

Hea

me

"Supply or

1992

supply

01

,ement

lhe

heann

tile

ancl

po.o1

1nl"

ave

An

indication

..

~n

ensure

or

work

11>31

0<

ad<opled

wl'lich n is U

jng conditions

cl

or

un<lertal<ings in

Is 10

be

Dy

the

use

lh.1

means

any

su~3b1e

person.

'nal

an

drawn up

lh an:!

',

'/tlll . ant

01

The

machi

<le

aoo

,ne

ne<:essary

tillings

e~ioyer

serve:.

OOlie

orl<

lhe

lul

work

as

Sed

0<

s

01

s.

to

persons

...

ed

and

cl

lhal

wo'"

~

Is

in

se

eable

TI>e

P...,';s;"n

Regulalions a

10Iclws

:·

regulation 6 .

,egula tion 8 - information

r~ula:ion

111

018 :.

Atlefllion

W oodworI<rIg Machines AegulaHons

.....

hif;tI

are

Machinery (S;oI.ly)

Regulation

AeQJlalion. ,

Wll

ilst Ine pr

ulety

have

and B of

They

T""ing

and

aneeled

rests

legal dut;"s,

inckKIe:

reasonable

safely and

by

co-operating

sa

fely;

not

",Ie~ering

provided

Thft,

Ior

du',"

lupplemeflled

Ma

nagement

Regulations 1992, One

reQUirements

correctly all

employe r

t

ile

instructions t

use

the

~cms

~

ne!

U ••

lso

irduOe .(lQUirernents

mo;rnen~nc.

9 - training

is

","

awn

10

tho$e

not replaced

~tatlons

13

Cl

tile

W

,raining',

im

e duly Icr ens"ring

w~h

e~ers,

p.a~ic:t,ol;t~y

t

he

Hea~h

and

care

ttlal

wtlal

they

do

"rt

h tileit'

with or misusing anytllinQ

their

heattn,

on

.":pIo,.n

by

rego.tlalion 12

01

Hea~tI

;s

llI.iIt

wo

rlc

it

ems plo.ide!l by their

in

accordance

lley

rceeive to enable

safely,

01

Wall<

Equipm

8ne!

inS

truClions

'equi ... m,mts

Dy

the

~pIy

or

ott>er,

oodwork.ng Machinery

51

il applies,

l>ea

employe

und."

seetions

Salely

IOr

01

others w

or

e""icyer

WI'ly

and

emplOyees

..

i

m ... own

don

't

and weU,

5alety

01

t~

tM

al

WO<Ir.

ho

do;

Cn

heann

ha

...

the

51"<l1J1d

ir

training and

01

'97~

~h

es

Act.

hea~n

may

and

e,

IMrgn

01

il

Wor1<

new

use

lhem

..

as

the

01

eg;

and

100

be

the

to

nl

'

7

Noise

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

......

1'

can

""IY widely lrom machi'le

maochine

Pe

a shon

hear

levels can

dama

The Noise at

legal

10 hearing

There are lIl1

in r

depending on ItIe condilions

ncns

uposHl

l

imfI.

ing loss

10

ma

y

expe

.1Id

conliooous C

res.u

~

high noise levelS.

in permanen t hearing

o-.

Wo

ol<

Regu\;llions 1939 piace

a,liea

on

e

~~

ee

~Clion

eg

ulation 2;

The lirsl acllOn level:"

~

<uiy

_""I nt>i... exposuro (\.<

85dD(

A)

Tht secolId aClion It vel;"

a

daily

personal

~~,

The plale

a

pe

re

2Opa)

TM

the

Emis.sions

ItIe

Th

ese

aaion

ak

sor.md

upowre

e""sslon

I4!II1IIS

p&IIIQ.Otar

ievt!IS

ISO 7960 under

co";;t.,

Ih

ma

opefllLi:ln.

SPindle

n •.

~

highesl no

ny

lactors.

spHGS

lhe

Iype

noi

level

p,uwr

"'vel is obviouSly inlluenc

level

e

01

aU!he eqvipmem in li

Ior

~s

machine inslruaion manual.

are

ml!

3su

cen

y

do

not ""enu,iIy

ise

level.

eg

nurrber

and

cond~ion

e1e.

rieroce

l

e~ra

<pcl$

10

preY,m

I4!

vets

01 oois

s.e

expos ure

01

2{lO

~SClIls

I'C

rHl

in

acr:ordaroce with

ain opec ilied

wn

i::h

is

DI

DI

DI

ev

en lor

ry

p

Mia

ure

to

rSama!/<!

e delined

...

(Ll

'''

(14!)d8

ed

provic!e<I

'~p,ese

influe

nced by

spO'>dI

es

_ piece.

10

use.

~igh

)

01

)

01

by

se

in

leSI

N

in

0,,,,

W

ood

wsl

can

be

ha'mful

;nhoItalion

01

l

uplosiv

Tile Control

Huttn R

and

okin comacl and conce ... r8tions

sman pan.cte$

e

mi

. tvre.

01

egula

tion.

In

the air can

Substances Hazardous to

(COSHH) 1989 pl.ace

duties on employe" to ........

ItIe

upo

su,e

oIl'is

a""toyees

lI

<uardous

whe

,. this

acleq.Ja

.....

adequal~

tely

10

hea

is

conu

co,.,.rol

~ h

1$

eit

nO

I reasonably p,acticable.

oIIed.

to

8<po

to a substance rwardous

secu,ed

01

where

by

measu,U

~rsonal

pi'oteclive equiproonL

the

mea

sure,

ollllr than

t

aken

tile parag,a ph above do not prevent

ade qu~le

haz aroous

adcl~ion

e"l'iOyer

SUCh

as will

sub~aoces

Instru<:!lons

M;tChi""'Y

Supply

provide

or equipmenl.

inlo,."...!ion is t

l

hl

controt or. expo

10

the

hei~h

or employees. then in

10 tack ing H

sha

lt

pn;IvOe thoSl!

su~able

personal

'oO&e

pro~

adequately c.onIrot

rwardou,

lor

manufa

01

Machine!')'

CO<tl>/ehlnsive "Instructions

ransmitttcllO

U$~

ctu,es

~

is

to hea'l>.

...

$3ltt

.n

macnir>e.

le

hea.h

Ionn

".

that:"

to sui)$tances

tler

prevellted

""re

of

e~

to

heafth

in

aeco,daroce w

su

'e

the

0'

10

sub

method

SNIt

proyi$lon

provide

sunces

s, t

.""""yen

~

the~

U poJ:U'1

requ ~ e

d

by

y Regubolions

101'

Use'

am

t!\:ill

lhe

pefson

using

by

an

Ie~ a

t

or,

ye es

be

ilh

hl

w!c

h

...

10

the

to

tnis

For

regvl~tlons

personat prot

delerlders. employers should

Pe'sonal

Regulations

and i.to'melion on ,eltv.,.,.

eClNe e'lUij)m(!N

r~l"

Protl!<:tive

\992.

E'lU;pme'" al

I.e

10 It\(!

Wo

ear

'"

IMPORTANT

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SAFETY PROCEDURES AND CONSIDERATIONS

To eflsure sa fe workiflg condition

01

operation

instructions give n within this

of !he machine and the safety aspects to be observed.

Note:

- Persons under the age of 18 years

POINTS TO NOTE BEFORE OPERATING

A)

OPERA

, }

You have r

and have bee n checked out

2)

The machine is supplied with

operated unless the sa

3)

CuttersJblades are the correct t

conditions, rotate in the correct direction of cut, are sharp and

4) Loose clothing is either removed

removed.

5} Adequa

6)

All dust

adequately.

this machine must ensure lhat they read and futly understand

during the course of training under the supervis ion of a trained operator.

TION OF THE MACHINE.

ead

and understand the operation and safety aspects of the machine

te

working space and lighting is provided,

e~tracti

on

equipment is switched on, properly adjust

s,

persons operating and assistiflg with the

manLJal

fe

guardings are in position and are functiona

and have received

mLJst

not operate the mach ine el(Cept

OR

by a qualilied supervisor.

lull sale guarding. The machine shall not be

ype,

suitable for the machine and working

or

securely fastened back and jewellery

sLJfficie

ASSISTt

nt

training in Ihe

NG

WITH

l.

correctly fitted.

ed

and worki

the.

LJse

THE

ng

7)

The machine is securely i

maflual

The machine should only

8)

and

particle

).

technological Characteristics similar to wood, and f

removal process

is

nst

alled (refer to installation section withifl this

be

used

lor

cutting wood or materials with physical

or

which the chip or

simila

r.

8)

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

DURING

Wear suitable protective dothing e.g, approved eye protection. ear defenders

I )

and dust masks. Gloves

St

2)

3)

')

op

making adjustmen ts, cleaning or carrying

Ke

ep

not

allow the floor around the machine

Stop

potential malfunction or operator hazard.

machine

MACHININ

the machi

the floor area around lhe machine clean and free

t

he

machine and report immediately to a person in authority any actual or

unless qualified or

G:·

shal

l be worn when handli

ne

using the emergency stop or at Iha mains isolator before

ou

t maintenance.

to

be come

00

eu1l"1orised

to do so.

not

ng

sharp edge saws.

from

sl

ippery.

at1empt

10

repair or

wood reluse. Do

reC1ity

lhe

The operator must

')

Never by·pass inlerfocks.

6)

A push

7)

workpiece past the cuning

WARNIN

Failure to observe corree! opere!in\! procedures prior to

lhis machine can result in severe

DO NOT attempl

hat

t

st

ick or hand

G:-

reduces your alertness.

nol leave the machine running whitst unauended.

ted

pUSh

block must

bl

ade

.

in)Ury.

10

operale the machine while under the innuance of anything

be

used to t

eed

the trailing edge of a

and

during operation

01

CONTENTS

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SECTION 1 GENERA L INFORMATION

General Description

Foundalion and Machine Dimensions

NO

ise Emission Values

Machine crileria

Machine

Tooling cri teria

Operator Working Slations 1

Machine Specilications 1

Electrical Wiring Oiagrams 1

SECTION 2

SECTION 3

UNL OADING, UNPACKING, AND INST

Unloading

Unpacki

Cleaning

Location and loundation

Machine re-assembly

Supplies and Services

OPERATING INSTRUCTIONS

ng

Electrical supply

Exhaust connections

COiling

Page

1-1

1-1

1-'

1

-'

1

crileria

ALLATION

-,

1-'

-3

-5

-7

'-I

'-I

''-

,-,

,-,

'-3

I

I

SECTION 4

Salelyand

Machine Controls

Typical Machi

Trim Stop Adjustmenl 3-4

MAIN

Scheduled Mainlenance

Te

nsioninglAeplacing Motor Orive Belts

TensioninglAeplacmg Saw Spindle Drive Belts

Air Filler and Lubricalor Maintenance

Changing Saw Blades

Approved Lubricants ' -5

Safety Oevices

ne

TE

NANCE

Before operating the machine

During machining

Operation Cycle

week.l~

Month y

Yearly

Two yearly

3-1

3-1

3-1

3-'

3-3

4

-1

4-1

4

-1

4-1

4-1

4

-'

4-'

4-'

4-3

SECTION 5

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

ILLUSTRATED PARTS LIST

Main Body Assembly

and Spindle Assembly

Drive

Top Clamp Assembly

Stop Assembly

Trim

Saw Clamp Assembly

OuUeed Tab le Assembly

Pneumatic Assembly

5-3

~5

5-7

5-'

5,1 t

5· 13

5·15

SECTI

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

ON

1 GENERAL INFORMATION

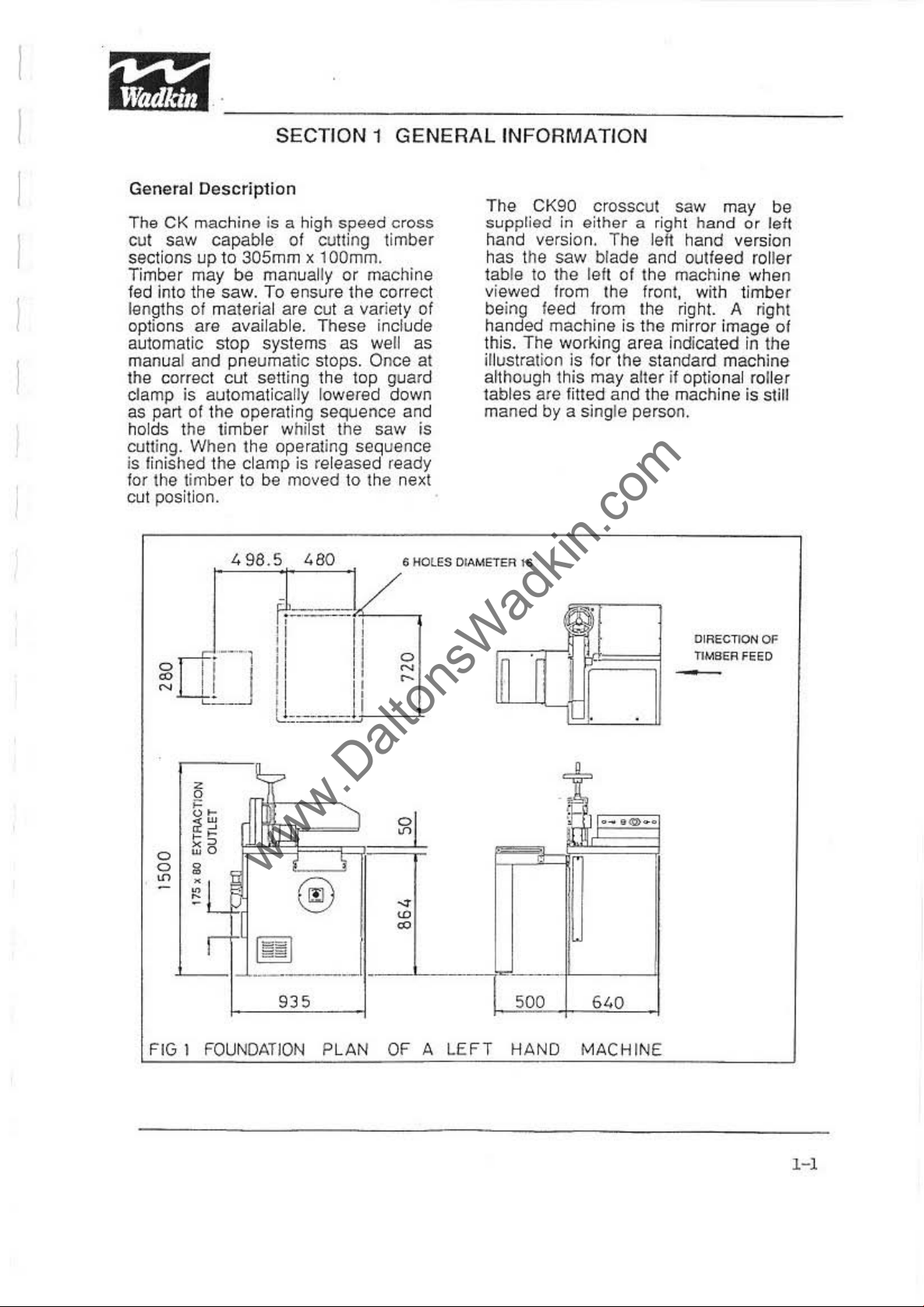

General De

The CK machine is " high speed cross

cut saw capable

sections

Timber may be manually or machi

fed into the saw. To ensure the

hs

lengt

options are availabl

automatic stop systems as

manual

the correct cut setting Ihe top guard

clamp is automatically lowered down

as part

ho

lds the timber whilst the saw is

cutting. When the operating sequence

is finiShed the clamp is

for

Ihe timber to

cut position.

script

up

to 305mm x 100mm.

of material are cut a variety

and

at the operating sequence and

,..--f j

---

~U

ion

01 cutting limber

cor

rect

e.

These include

we

ll as

pneumatic stops. Once

re

leased ready

be

moved to the next

,

4985

;

480

,

,

11

, I

, 1

1,

I ,

tJ.:::,--

/"

,

11

"

"

1 '

• I

,"

6

0

N

N

ne

of

al

IfOlES

,

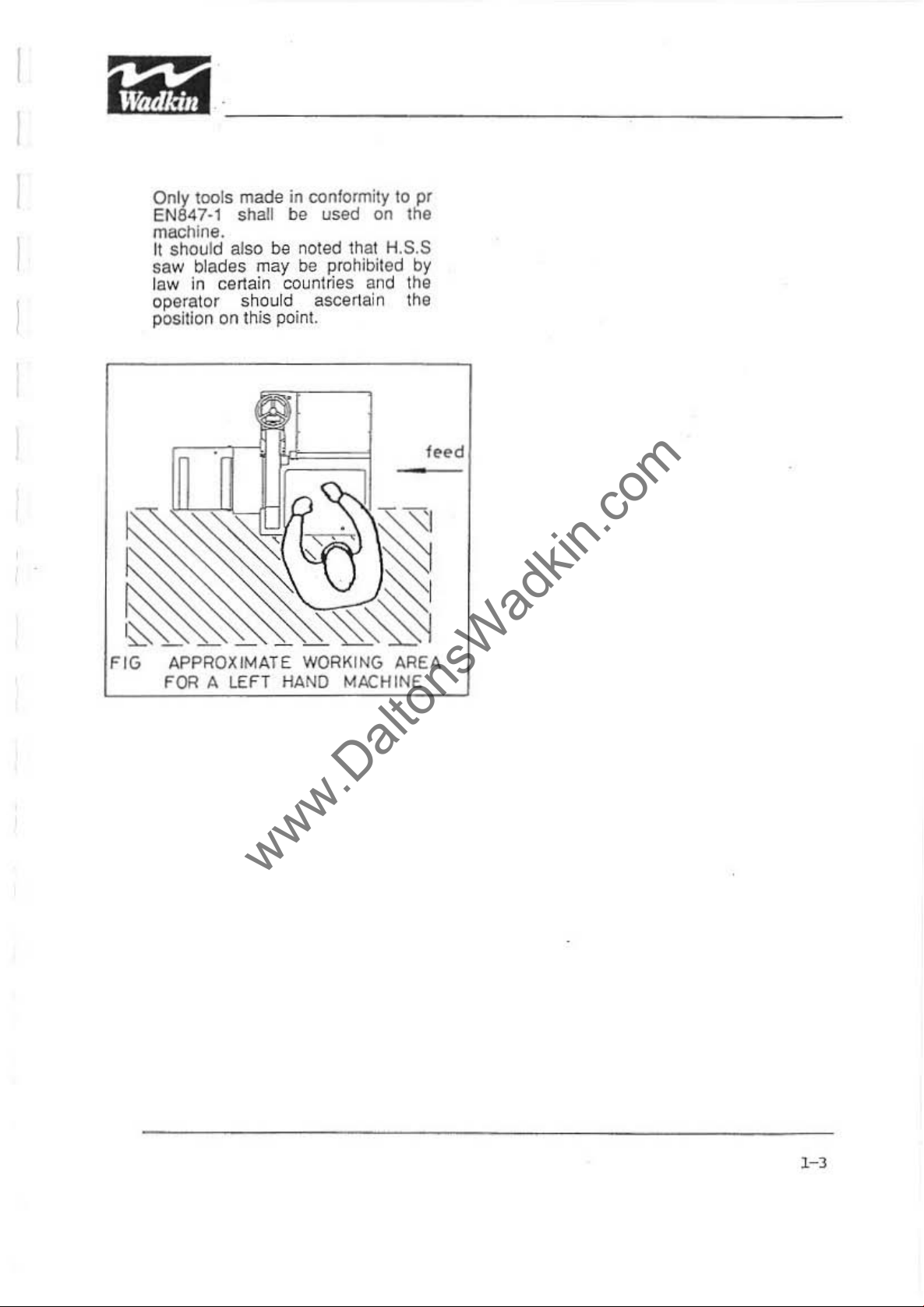

The

supplied in ei

hand version. The

has the saw blade and outfeed roller

table to Ihe left

viewed from

bei

handed machi ne

thi

illustralion

although this

tables

maned

O

I~

..

ETER

CK90 crosscut saw may

the, a right hand

lel! hand version

of

Ihe machine when

Ihe front, with timber

ng

feed from the right. A righl

is the mirror image

S.

The working area indicated in the

is

for the standard machine

may

alter if optional roller

are

titled and the machine is Slill

by a singlo person.

'6

D'RECTION

ll""ERFE.O

or

be

teft

of

OF

FIG 1

FOUNOATION PLAN

OF

A

LE

FT

HAND MACH I

NE

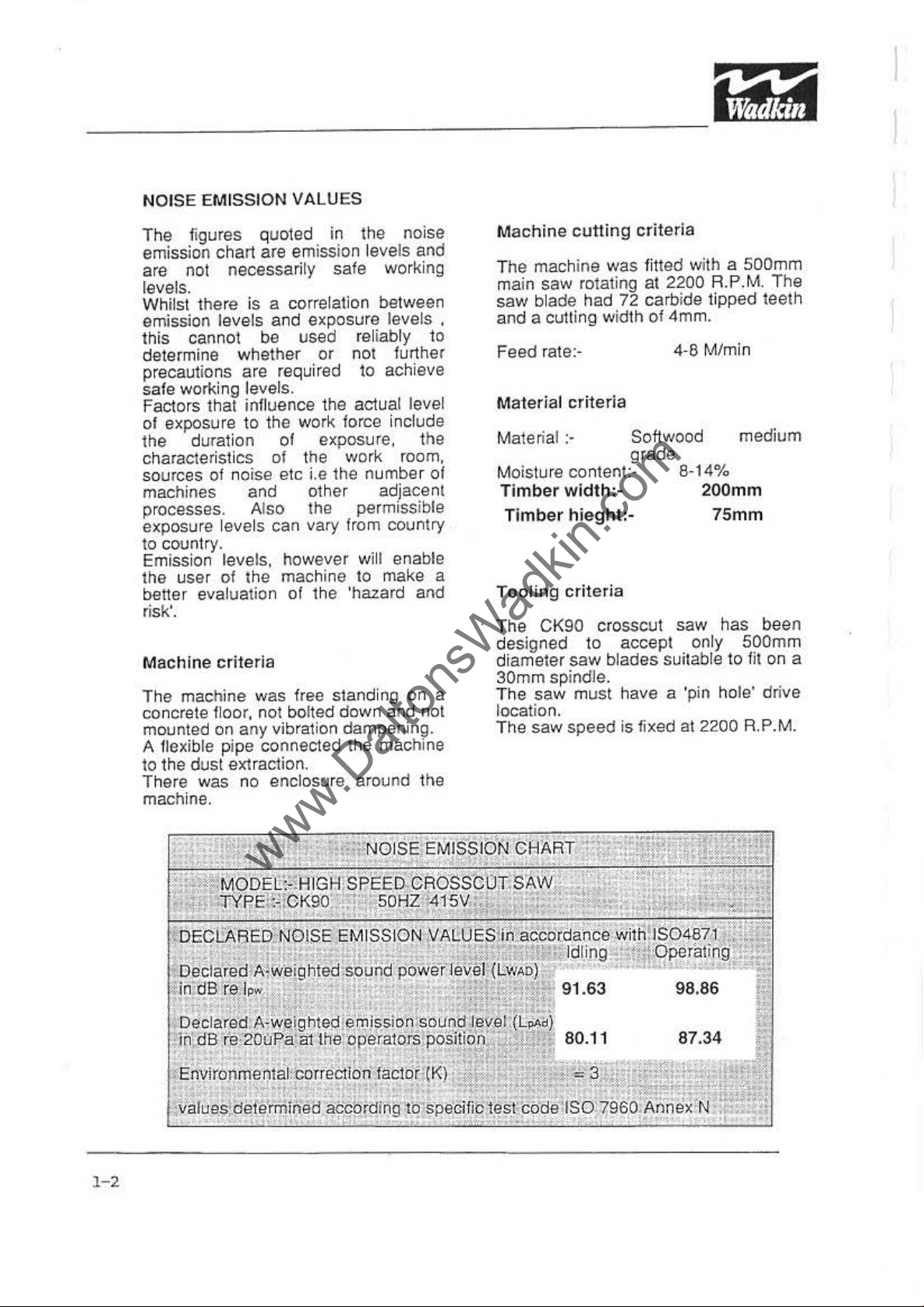

NOISE EMISSION

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

The figures quoted in the

emission chart are emissi

are not necessarily safe worki

levels.

Whilst there

emission

this cannot

determine wheth

precautions are required

safe

Factors th

of exposure to the work fo

the duration of exposure. the

characteristi

sources of noise etc i.e the number

machines and other adjacent

processes.

exposure levels can valy from country

10

country.

Emission

the user at the machine to make a

better evaluation of the

risk'.

chine

Ma

The mac hine was free standi

co ncrete floor.

mounted on any vibration dampening.

A flexible pipe connected the machine

to the dust

There was

machine.

levels and exposure l

workin

g levels.

at

influence the actual level

cs

levels, however will enable

criteria

extraction.

no

VALUES

nO

ise

on

levels and

ng

is

a correlation between

evels.

be

used

er

of t

he

Also the permIssible

no\ bolted down and not

enclosure around the

reliab

ly to

or not further

\0

achieve

rce include

work

'hazard and

ng

fOam,

01

on a

Mac

hine

culling

The mach

main saw rOlating

saw blade had

and a culling width

Feed

Mal

erial

Material

Moislu

T

imber

Timber hieght:-

Tooling

The CK90 crosscut saw

designed

dr

ameler saw blades suilable

30mm spindle.

The saw must have a 'pin hole' drive

location.

The saw speed is fixed

ine was fitted with a 500mm

rat

e:-

criteria

:-

re

contenl:- 8-14%

width;-

crileria

10

criteria

al

2200 R.P.M. The

72

carbide tipped teeth

at

4mm.

4-8 Mlmin

Softwood mediu m

grade

200mm

75mm

has

been

accep t

on

ly 500

10

fit on a

at

2200 R.P.M.

mm

91.63

80

.11

I

98.86

87.34

Only \oolS made in conformity to

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

EN847·1 shall be used

machine.

It

should also be noted that H.S.S

saw blades may

law

in

certain

operator should ascerta

position on this poin

be

countries and

t.

pro

hibited by

in

on

pr

the

the

th

e

f iG APPROXIMATE WORKING AREA

F

OR

A LEFT HAND M.ocHINE

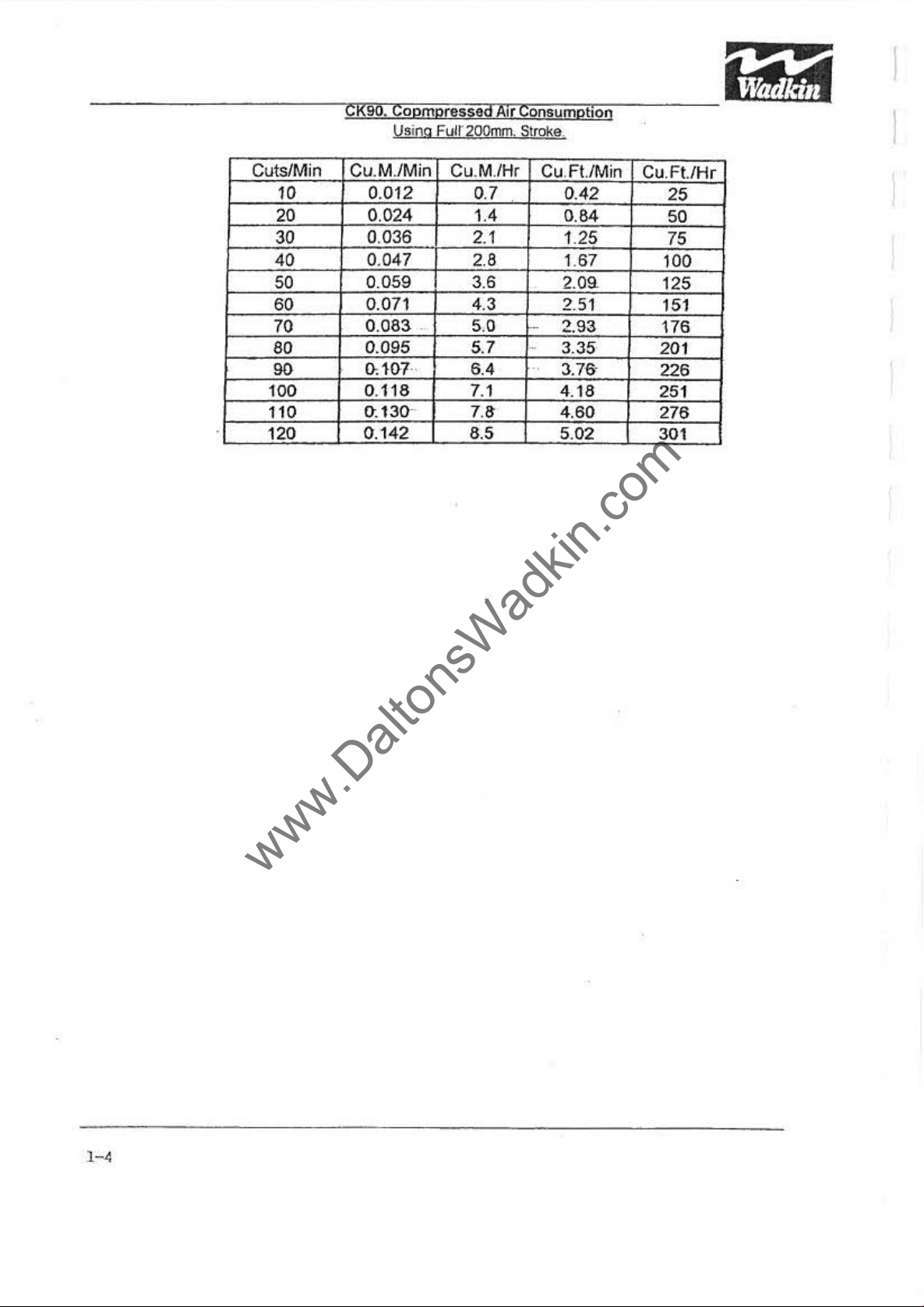

U~iOQ

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Eulr

2OO!Im

Stroke

Loading...

Loading...