Wadkin BZL Operating Instructions Manual

---

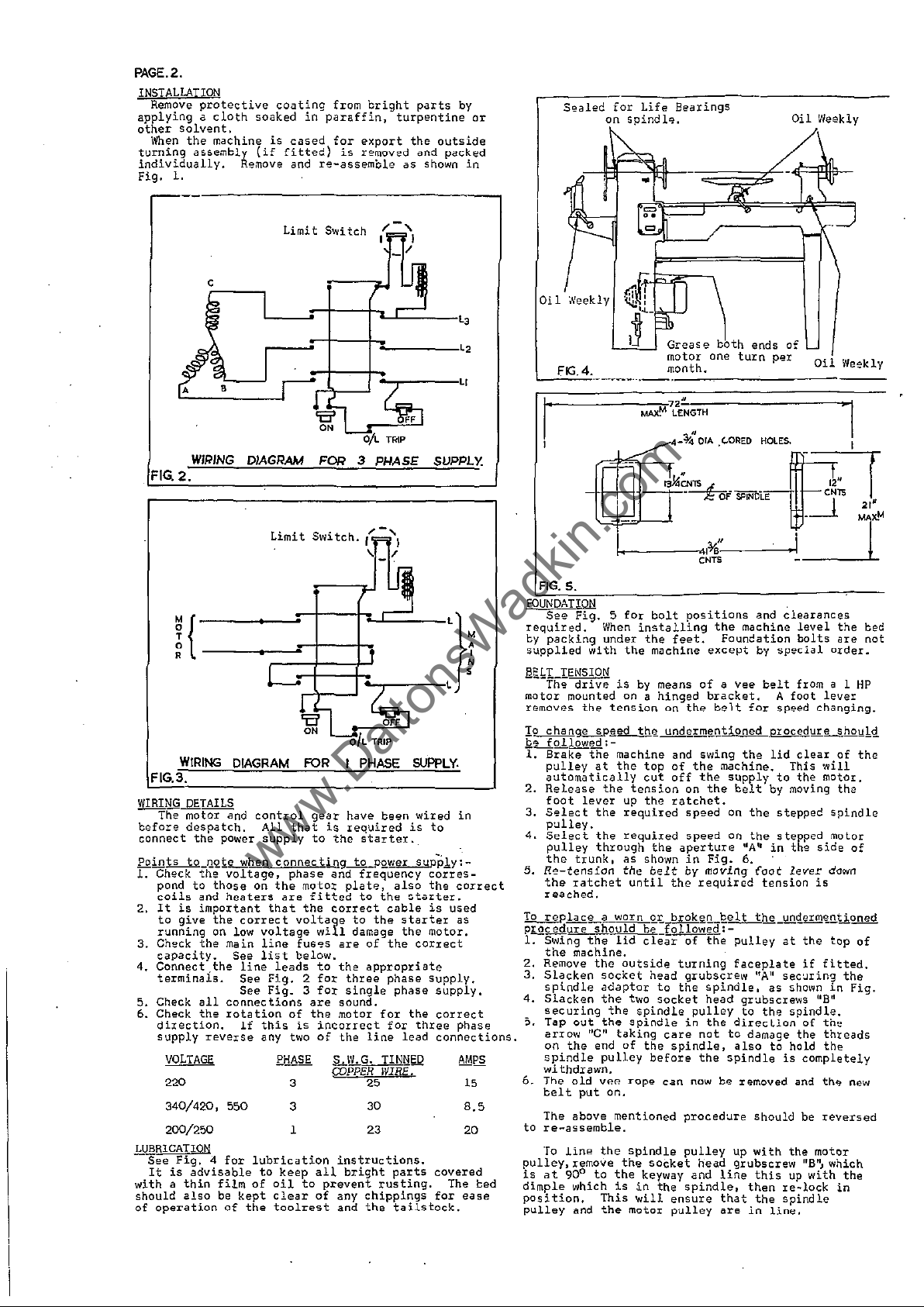

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-

---

_'-

...

_

~_

-

------

---

.

__

-=_

__

-_

"""-

-

-~

-

--~

_____

--.

.

--

----

-----

--

---

--

---.-

-_-

-~

~._"_

..

cc..

-,

--.- _

- - - - - -

-~

=.

__

7"._

~_

..

-~.

-."'-

~-"

_.-._-----

-..

_c.-_~_--'o.-'-_~_:'.-

-_

-O

__

~C"'_:__=-.

---

.

""'.

-7~

-

-=---.

--

--c

OI!ERATING

=-

AND

WOOD

MAINTENANCE

PARTS

TURNING

TYPE

INSTRUCTIONS

LIST

BOOK

LATHE

6"

BZL

PAGE.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

I.

TOOLREST.

TURNING

WOOD

BRAKE

STOP.

TURNING LATHE

AUTOMATIC

FACEPLA TE.

DIA

TYPE

TOOLRE5T.

6"

BZL

TURNING

FOOT

FOR

LEVER

BELT

TE~jSIC)NIING.

Height

Will

Height

Diameter

Width

Diameter

Speeds

Horse

Speed

Floor

Net

Gross

Shipping

of

take

from

turned

of

power

of

space

weight

weight...

centrest-..

between

floor

turned

turned

spindle

of

motor.

...

•••

dimensions.

'*

Note!

with

motor

centres

to

with

gap bed

over

•.•

.

..

Machine

over

.

..

••.

centres,.

gap bed

.•

handrest.

will

bed between

EQUIPMENT

5 P

Eel

FIe

swing a maximum

centres.

A r

: : :

•.•

of

ION

50;1

600

780

42

12\.S"

•

~

eu,

{317

6"

36"

40"

18

8'2"

811'1

425,

16;"

lb.

lb.

ft.

11

800,

1500

mm}

1

1400,

r.p.m.

1270

2300

m.m

155

915

1015

460

215

215

x

270

350

1.2

mm

mm

mm

mm

mm

mm

r.p.m.

410

m.m

kg.

kg.

cU,m

•

PAGE.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

2.

applying a cloth

other

When

turning

individually.

Fig.

protective

solvent.

the

assembly

1.

machine

c

WIRING

FIG.

2.

soaked

is

(if

Remove

coating

fitted)

Limit

in

cased

and

re-assemble

from

bright

paraffin,

for

export

is

removed

Switch

parts

turpentine

the

and

as

L-rlr--t-UC='--l'

.---:-t---r"L---

DIAGRAM

Limit

FOR 3 PHASE

outside

packed

shown

SUPPLY.

by

1L

in

2

or

Sealed

FIG.

4.

for

Life

on

spindlt~.

Bearings

Grease

motor one

month.

both

ends

turn

per

of

Oil

Weekly

Oil

Weekly

WIRING

FIG.3.

WIRING~TAILS

The motor and

before

connect

Points

1. Check

2.

3.

4.

5. Check

6. Check

despatch.

the

to_QQ£e when

the

pond

to

and

is

important

give

the

all

the

reverse

those

the

on low

coils

It

to

running

Check

capacity.

Connect.the

terminals.

direction.

supply

power

voltage.

heaters

main

connections

rotation

VOLTAGE

220

340/420,

200/250

LUBRICATION

See

Fig. 4 for

It

is

with a thin

should

of

operation

advisable

film

also

be

550

of

DIAGRAM

control

on

correct

See

line

See

See

1f

lubrication

of

kept

the

FOR I PHASE

gear

All

that

supply

connectin9-1Q_PQ~er

phase

the

are

that

voltage

voltage

line

fU6~s

list

below.

leads

Fig.

Fig.

of

this

is

any

two

RHASE

3

3

1

to

keep

oil

clear

toolrest

is

to

and

motot

fitted

the

correct

will

to

2

fo~

3

fo~

are

the

incorrect

of

COPPER

all

to

prevent

of

the

li:.~G.

have been

required

starter.

frequency

plate,

to

to

damage

are

the

three

single

sound.

motor

the

instructions.

bright

any

chippings

and

the

SUPPLY.

wired

is

supplY:-

also

the

ctarter.

cable

the

starter

the

of

the

correct

appropriate

phase

phase

for

the

for

line

25

30

23

three

lead

TINtlED

WIRg.

parts

rusting.

tailstock.

in

to

corresthe

correct

is

used

as

motor.

supply.

supply,

correct

phase

connections.

AMPS

15

8.5

20

covered

The bed

for

ease

FIG.

S.

FOUNDATION

See

required.

by

supplied

llokLIENSIO~

motor mounted on a

removes

~o

&:L........Q....lowed:-

1.

2.

3,

4.

5.

To

pI.Q.cedure

1. Swing

2.

3.

4.

~.

6.

to

pulley,

is

dimple

position.

pulley

Fig. 5 for

with

drive

the

When

under

packing

The

cfhalngiL..§.pged

Brake

the

pu.lley

au.tomatically

Release

foot

Select

pulley.

Select

pulley

the

Re-tension

the

reached.

replac!L~Q.:Lbrok~!Le.elt

the

Remove

Slacken

spindle

Slacken

securing

Tap

arrow

on

spindle

wi

The

bel t put

The above mentioned

re-assemble.

To

at

at

the

lever

the

the

through

trunk.

ratchet

should

the

machine. .

the

socket

adaptor

the

out

the

"c"

the

end

pulley

thdrawn.

old

VP.P.

line

the

remove

900 to

which

This

and

the

bolt

installing

the

is

by

tension

th~

machine and swing

the

tension

up

required

required

as

the

until

lid

outside

two

the

spindle

spindle

taking

of

Tope can

on.

positions

the

feet.

machine

means

of

hinged

on

the

unde~!tQtioned

top

of

cut

the

shown

bl:!

clear

the

the

off

the

on

ratchet.

speed

speed

the

aperture

in

belt

by

the

required

_f.ollowed: -

of

turning

head

grubscrew

to

the

socket

pulley

in

care

not

spindle,

before

the

the

Fig.

moving

the

spindle.

head gr'Jbscrews liB"

the

now

procedure

spindle

the

the

is

will

motor

in

pulley

socket

keyway and

the

ensure

pulley

head

spindle,

the

Foundation

except

a Vee

bracket. A foot

helt

machine. This

supply

on

on

faceplate

direclion

to

also

spindle

be

lip

grubscrew

line

that

are

and

clearances

machine

for

the

belt

the

the

"A"

6.

pulley

to

damage

removed

then

in

level

the

bolts

by

special

belt

from a 1

speed

changing.

'procedure

lid

clear

to

the

by moving

stepped

stepped

in

the

side

(oot

lever

tension

the_llilq~enlioned

"A

as

the

at

l

sec'Jring

'

shown

spindle.

the

to

hold

is

is

the

if

of

completely

and

Should be

with

the

motor

this

the

liB", which

up

with

re~lock

spindle

lin~.

bed

are

not

order.

HP

lever

shou!.<:!

of

the

will

motor.

the

Spindle

molar

of

down

--

top

of

fitted.

the

in

Fig.

th~

threads

the

th~

new

reversed

the

in

Loading...

Loading...