Wadkin bursgreen User Manual

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

12"

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

HAND

FEED

I.

PLANER

TYPE

12"

BFT

..

PLANING..

HANDWHEEL. . .

TABLE

..

RISE.AND FALL.

PLANING.

Planing

Length

Speed

Cutting

Fence

Maximum depth of

Maximum de'tJth of

Rise

H.

Syn.

Height

Floor

.

Net

Gross

Sbipping

of

widtlt

timber

does

and

P.

of

speed

space

weight

weight

TABLE

capacity

of

tables

cutterblock

circle

: Length

Height

Will

of.timber

not

faU

driving

of

table

dimensions

LOCK

of

cutterblock

cant

to

rebate

rebate

overhanging

exceed

of

of

1"

tables

motor : 3phase

motor

from

floor

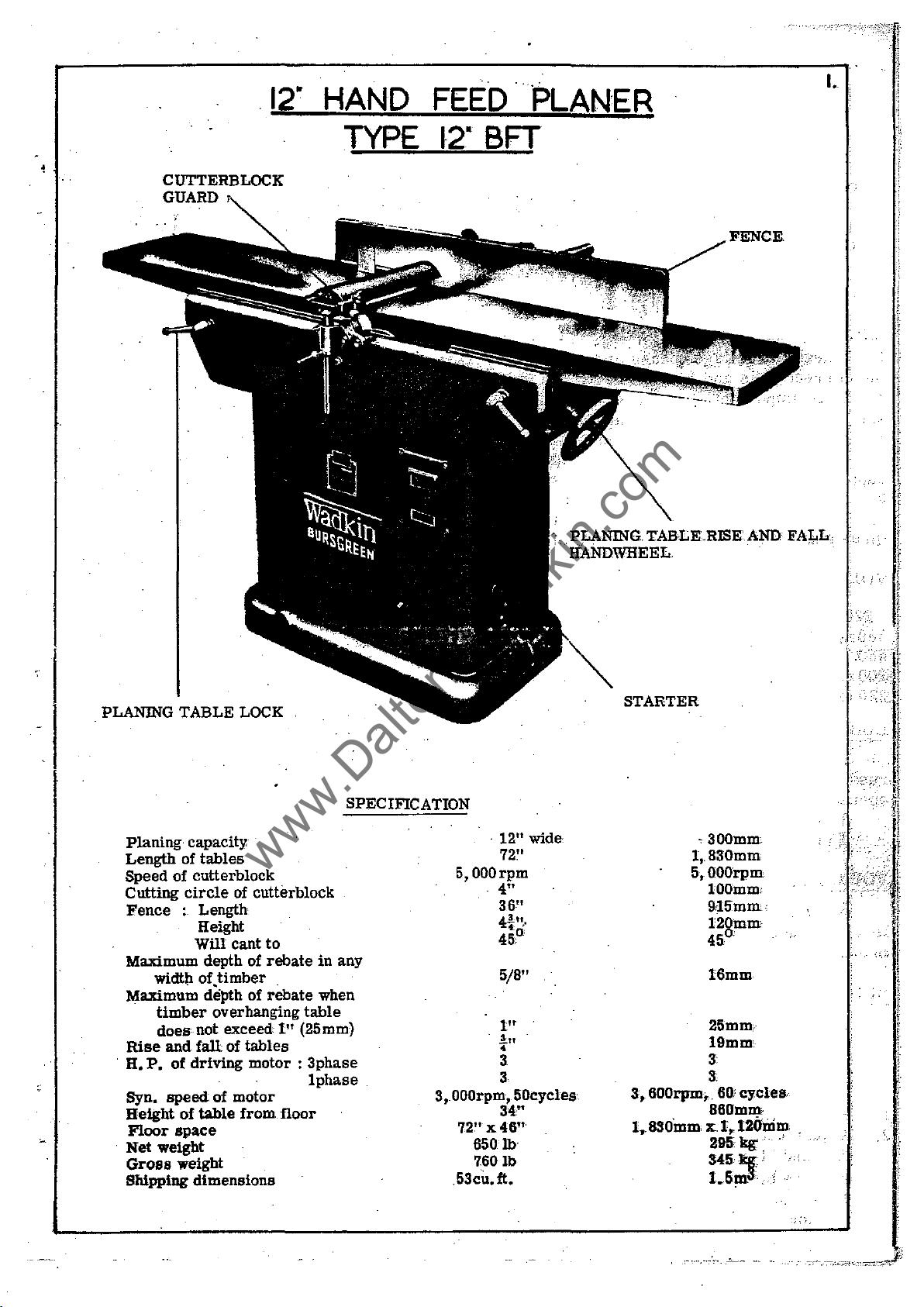

SPECIFICATION

in

any

when

table

(25mm)

Iphase

.

12"

wide

72"

5, 000

rpm

4"

36"

4~tll

0

45.

5/8"

In

.!n

•

3

3

3,000rpm,50cycles

34"

x46

650

lb

7601b

n

72'"

53cu.ft.

STARTER

1,.

5,OOOrpm

3,

600rpm,

1

•.

630mm

,300mm

830mm

lOOmm

g.15mm

120mm

45°

16mm

25mm

19mm

3:

3:

..

60;

cycles,

860mm

x.

1,.

120mm

295 kg;.

345

kg

3

1.5m

.

,.

"'.

i

,

2.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

:rnSTALLATION

~RemoveproteGl:ive

turpentine

When

~r€movedandpack€d

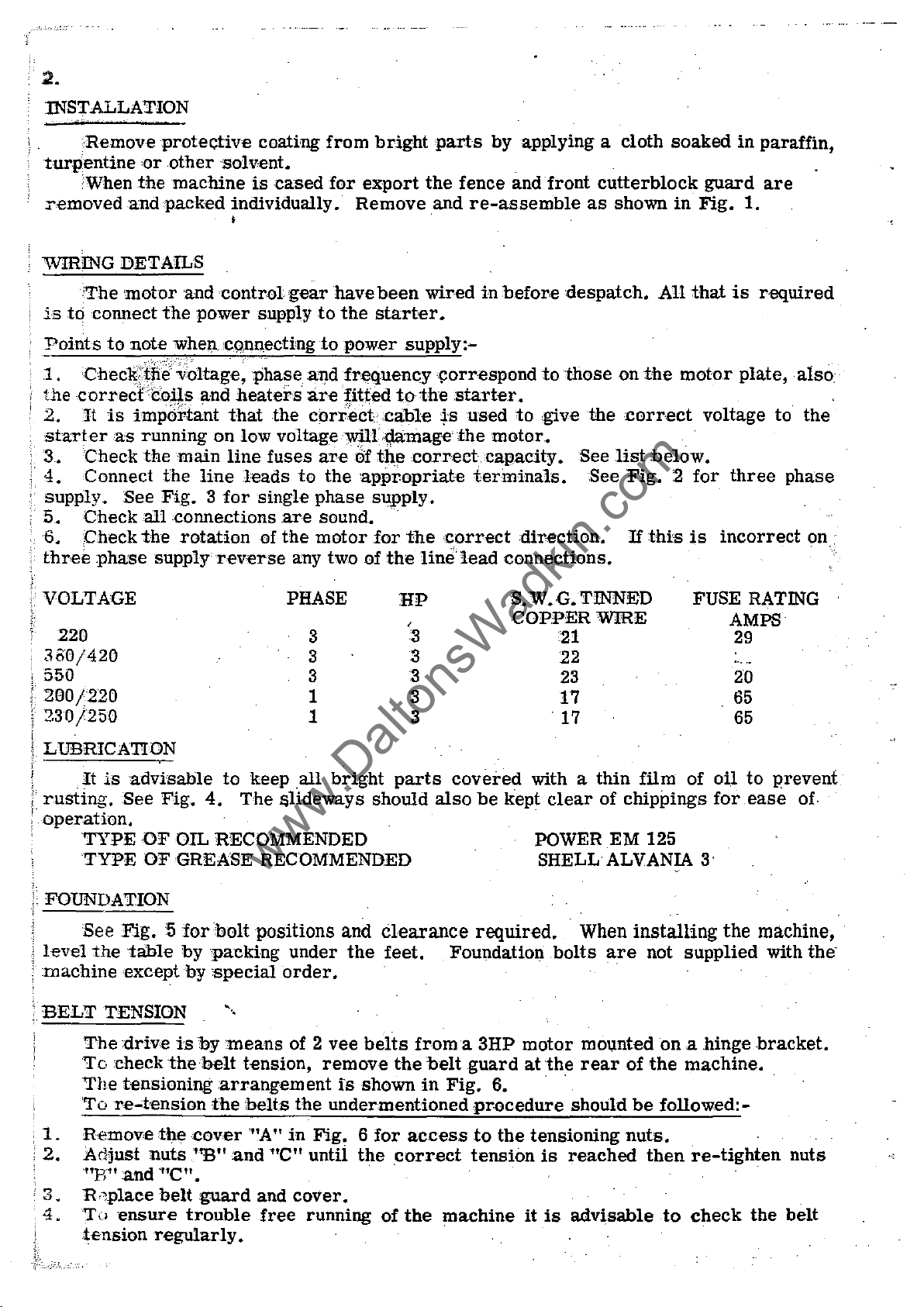

WIRING DETAILS

~The

is

to

connect

Points

motor

to

note

or

other

the

machine

and

the

power

whell,cq,lUl,ectingtopower

1.Chec~1:fi~;~ltage~

the

2.

start

3.

4.

~

supply.

5.

~

6.

three

correct

It

eras

Check

Connect

Check

Check

phase

cogs

is

important

running

the

See

all

the

supply

and

main

the

line

Fig. 3 for

connections

rotation

coating

sol

v€nt.

is

cased

individually.

,

control

gear

supply

phase

heaters

that

the

on

low

voltage')Vilr'l1amag€

line

fuses

leads

single

are

of

the

reverse

any two of

from

to

for

export

Remove

have

the

bright

the

been

wired

starter.

parts

fence

and

re-assemble

~

in

by

supply:-

alldfr~quency\!orrespond

are

fitted

carrect;cable

are

to

the

phase

sound.

motor

to

the

starter.

is

used

the

Of

thecorrecicapacity.

'appropriate

terminals.

supply.

for

the

'correct

the

line

lead

applying a

andiront

before

to

nespatch.

to

those

give

motor.

direction.

connections.

cloth

cutterblock

as

shown

on

the

the

correct

See

Hst

below.

See

Fig. 2 for

If

this

soaked

in

All

that

motor

is

in

paraffin,

guard

Fig.

are

1.

is

required

plate,also~

~

voltage

incorrect

three

to

the

phase

on ;

VOLTAGE

220

330/420

550

200/220

230/250

i

!.

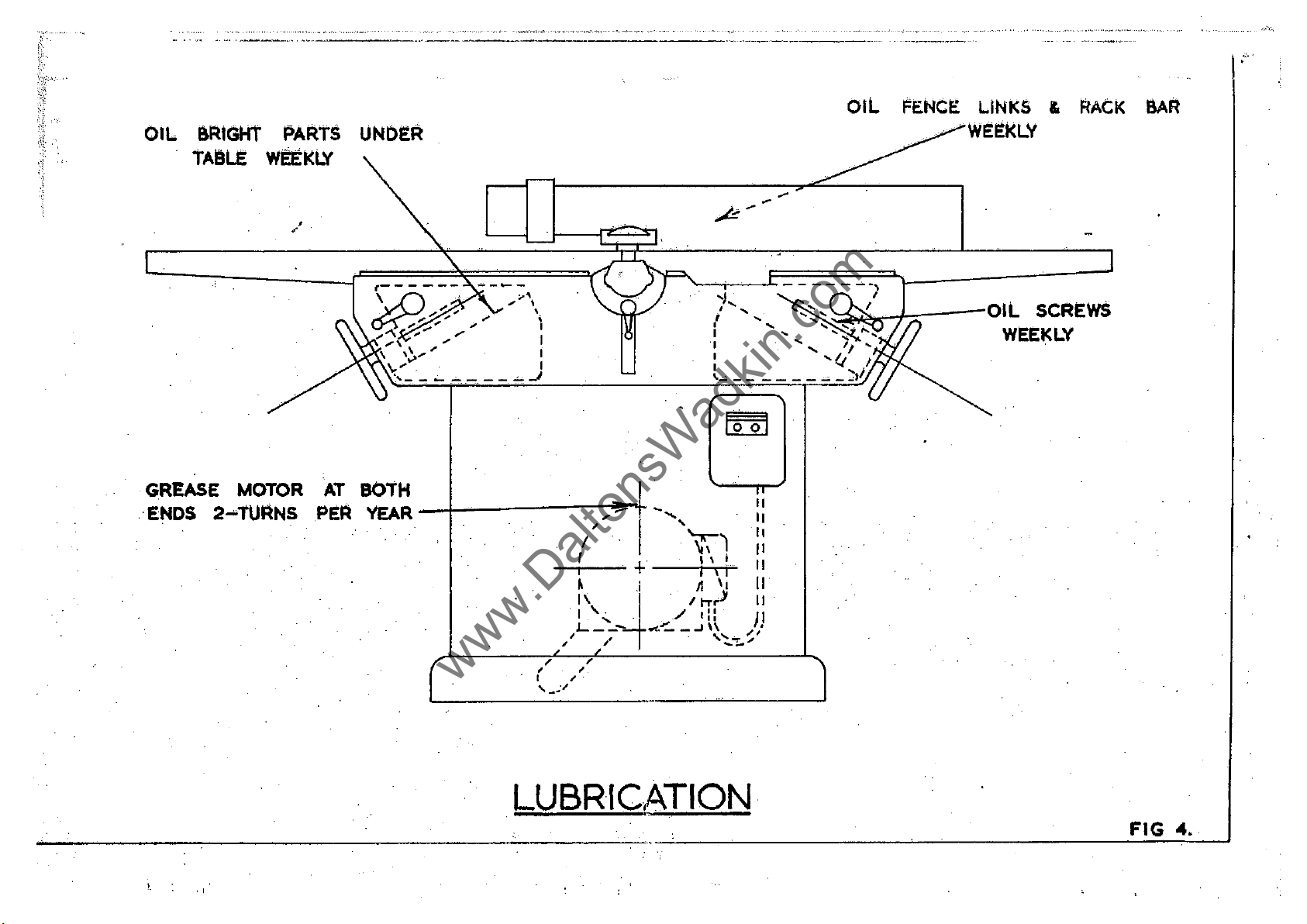

L1JBRICATION

, .

;'

.

1 FOUNDATION

1

It

is

rusting.

operation.

TYPE

TYPE

See

l.evel

the

machine

BELT

TENSION

The

To

check

The

advisable

See

Fig.

OF

OF

Fig. 5 for

table

except

drive

tensioning

Tore..;tension

PHASE

3

3

3

1

1

to

keep

.all

bright

4.

The

&lideways

OIL RECOMMENDED

GREASE RECOMMENDED

bolt

positions

by

by

is

by:means

the

belt

packing

special

-',

under

order.

of 2

tension,

remove

:arrangement

the

belts

the

should

and

Clearance

the

vee

belts

fs

shown

undermentioned

HP

,

'3

'3

3

'3

3

parts

feet.

from

the

covered

also

be

required.

Foundation

a BHP

belt

guard

in

Fig.

procedure

S.

W.G.TINNED

COPPER

'21

22

23

17

~

17

with a

kept

clear

POWER

SHELL ALVANIA

When

.bolts

motor

at

6.

the

.'

shouln

mounted

rear

WIRE

thin

film

of

chippings

EM

installing

are

of

be

FUSE RATING

AMPS

29

20

65

65

of

oil

to

prevent

for.ease

125

3'

the

machine,

not

supplied

with the'

on a .hingebracket.

the

machine.

followed:-

of·

.

,1.

,2.

3.

4.

Remove

Adjust

""E"

and

R

"place

To

'ensure

tension

the

cover

nuts

''E''

'nc

n • . . "

beUguard

trouble

'''A''

in

~and

nc"

and

cover.

free

Fig. 6 for

untii

the

running

access

correct

of

the

to

the

tension

machine

tensioning

is

it

is

regularly.

nuts.

reached

advisable

then

to

re-tighten

check

the

nuts

belt

A

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

cr--_

....

LIIIK

....---

ON

M

o

T

o

R

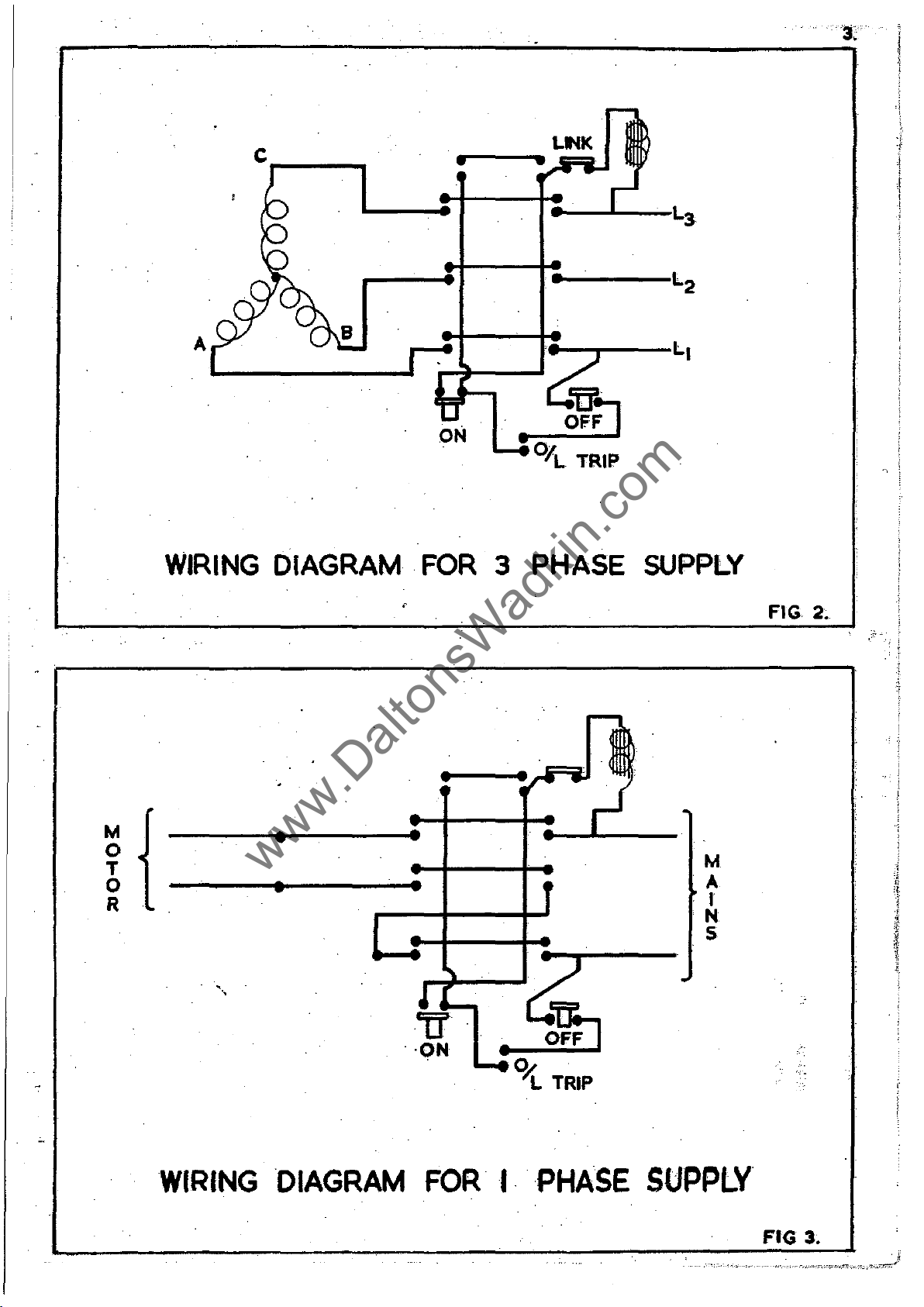

WIRING

.

"\

DIAGRAM·

•

•

•

•

FOR

•

3 PHASE

SUPPLY

M

A

. I

N

S

FIG

2~

WIRING

DIAGRAM

FORI··

PHASE

SUPPLY

FIG 3.

·

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

...

---

.......

----

..

-.--.

._---------_

.....•

_---.-----

...

--

...

-

\

.'

OIL

GREASE

ENDS 2

aRIGHt

TABLE

PARTS

wEEKLY

MOTOR

.....

TUANSPEA

AT

UNDER

BOtH

YEAR

-+------,~"I-

, '

-,

/ \\1::

r + 1\:

~

1\

"",

L

" /

, ,

, ,

I , .

,-~.'"

__

.i

4

-

-

..:'.~_.J\\

./

A

lIT

I::

I,

..

)

~/

''':::..'''!..

....

::

11

11

11'

JI

OIL

FENcE LINKS &

WEEKLV

RACK

BAR

LUBRICATION·

FIG

04

•.

Loading...

Loading...