Wadkin BSW 26 inch Parts Manual

o

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

c

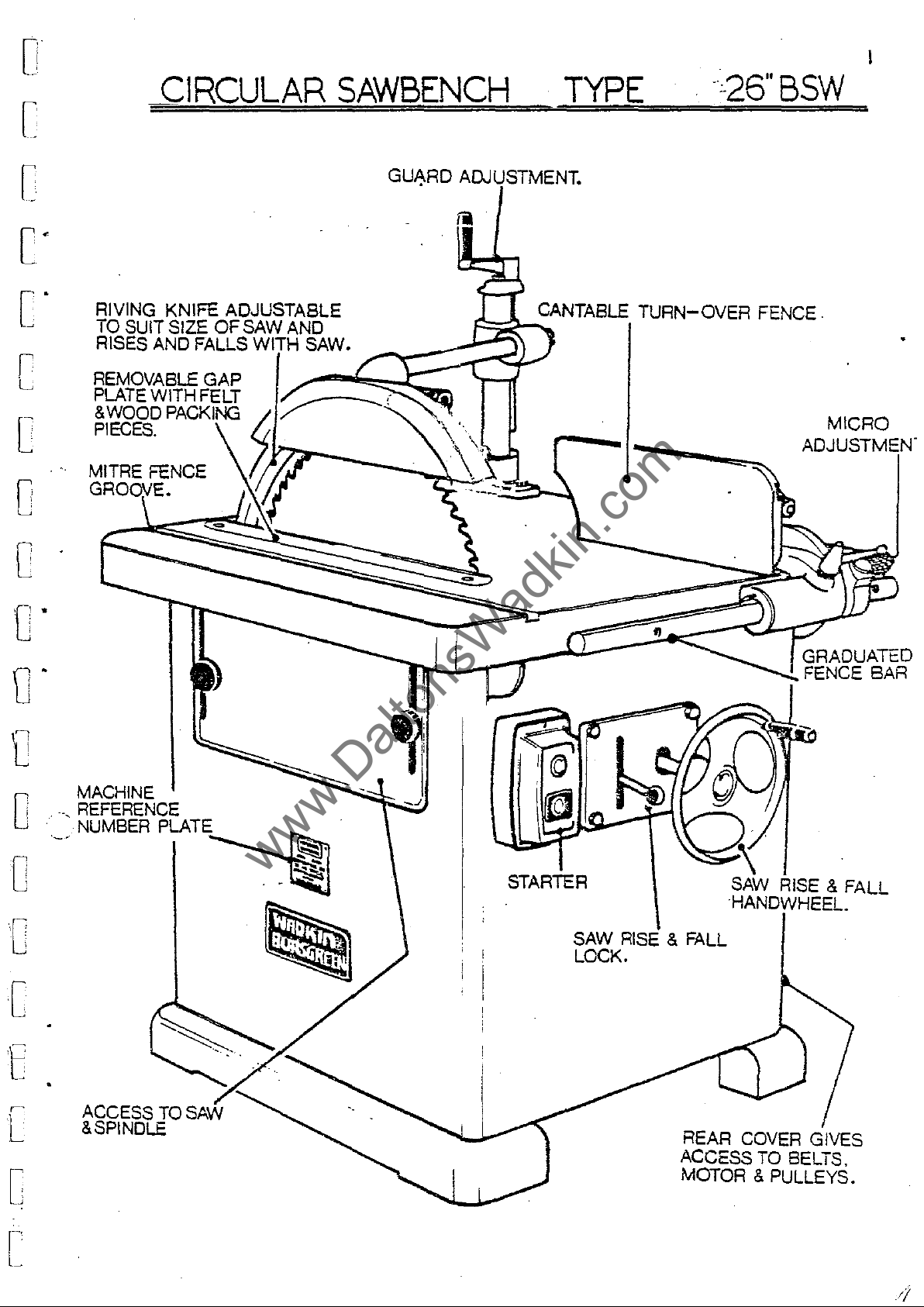

CIRCULAR

SAWBENCH

TYPE

-:-26"

BSW

[

c'

C'

r

L

c

o

o

RIVING KNIFE ADJUSTABLE

TO

SUIT SIZE

RISES

REMOVABLE GAP

PLATE

&

WOOD

PIECES.

AND FALLS

WITH FELT

PAC:KII\IG

OF

SAW

IAln-U

GU~RD

ADJUSTMENT.

F=:i-2-

CANT ABLE

.....

TURN-OVER

FENCE.

MICRO

ADJUSTMEN'

fJ'

fJ"

1

0

o

r

[

t

MACHINE

.-,

REFERENCE

NUMBER PLATE

~

~

:cr=~-r~!!::::~~::::~~GRADUATED

...

FENCE BAR

~

STARTER

SAW

LOCK.

RISE

& FALL

SAW

HANDWHEEL.

RISE & FALL

[

ACCESS

&SPINDLE

TO

[

[

REAR

ACCESS

MOTOR

COVER

GIVES

TO

BELTS,

& PULLEYS.

SECTIONS

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

,

i

Ii

O

,

,

l,!

"

C

.>

SECTION A

SECTION 5

SECTION C

SECTION

SECTION E

SECTION A

S8CTION 5

SECTION C

, -,

D

.~

ILLUSTRATIONS

FIG

Al

FIG

Bl

FIG

52

FIG

Cl

FIG

C2

FIG

CJ

SPECIFICATION

INSTALLATION

DESCRIPTION

MAINTENANCE

SPARE PARTS

26'

BSW

CIHCULAR

WIHL"IG

FOUNDATION

CANTING'FENCE

FENCE ALIGNMENT PO'L'lTS

RIVING

DIAGH.Ul

lL'IU'E DETAIL

& OPERATION

LIST

SAWl:l&"fCHES

(J

PHASE)

PLAN

CONTROLS

0;'

1

Oi,

e:

'"

"

j

('Oo

D

~'

!'J

..

C

,-

,I'

i

.r

:

1-

C

SECTION D

'.

FIG

FIG

FIG

FIG

FIG

FIG

FIG

.

FIG

FIG

FIG

c4

C4A

CS

c6

C7

c8-Cll

Dl

D2-DJ

D4-D12

D1J

RISE

RIVING

MITRE

MITRE FENCE STOP

SA....PACKIN:GS

OPERATION OF OPTIONAL FEATURES

SAI{

DELT

SAW

LUBRICATION

~'1D

FALL

lL'IIFE DETAIL

FENCe

SPDIDLE

TENSIONL'iG

MAINTENANCE

CONTROLS

ASS~lBLY

ROD

POSITIONS

.1'1

Dd

, )

Cl

I

[

.~

• J

, .

Cl

L

~

[

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

[

3

[

[

[

[

c

Haximum

Maximum

Size

of

Table

Hax.

Fence

Fence

height:-------------------------------------------

distance

dimensions---------------------------------------

cants

SPECIFICATION

diameter

saw

projection----------------------------

table--------------------ll090

up

of

saw

-----------------

saw

to

fence--------------------------------

to----------------------------------

26"

650

rmn

10"

255

rmn

43" x 34"

x 860

34"

865

rmn

20"

SOO

rmn

21"

X

x 190

S35

o

4S

nun

7~1t

rmn

o

o

o·

[

[

[

Rise

and

fall

Speed

Horse

Diameter

Diameter

Net

Gross

Shipping

of

saw

power

of

of

weight----~---------------------------------------

weight

dimensions--------

of

saw

spindle------------------------------

spindle---

of

motor-------------------------------------

saw bore ___________________________________ _

driving

_

_________________________________

__________________

pin--------

_______

____________________________ _

~----------------

S"

130

rmn

16S0

rpm

10

45

rmn

12

rmn

1000

lb

4S0

kg

12901b

590 kg

52

cu.ft

1.5

m3

[

[-

L

4

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SECTION B

Cl

Installation:

Remove

"applyin~

Wiring:-

therefore

supply

POINTS

1 -

Check

2 _

It

correct

DAHAGE

J -

Check

1.

_

:;onnect

5

Check

6 _

Check

any

The

a

rrotor

to

TO

is

two

-

protective

cloth

all

the

NOTE

volta~e,

important

voltage

HOTOR.

main

line

all

spindle

of

soaked

and

that

starter,

WHEN

line

leads

connections

the

anti-ru~t

in

control

i~

required

or

CONNECTING

phasp.

that

to

fu~es

rotates

line

and

the

the

to

leAd

coating

paraffin

gear

i~olator

starter.

are

cnrrect

are

in

have

to

be

where

TO

POWeR

frequency

correct

of

correct

terminals

sound.

correct

connAct

or

other

been

done

SUPPLY.

cable

RUNNING

direction.

ion~.

from

fitted.

capacity.

bright

~olvent.

wired

i~

to

is

used

ON

(SEE

part~

in

before

connect

to

deliv

LOW

VOLTAGE

WIRING DIAGRAH).

If

not

by

de~patch,

the""main~

.. r

the

WILL

reverse

;

C

o

o

o

FAILURE

1 -

2 -

J -

4 -

;>"liJPPAGE flURIl'IG

1 -

~ -rtl~e5

Foundation:-

mounting

floor

cement.

artequate.

TO

Fuses

Isolator

Lock

Supply

Ov

..

rloarls

jf

automatic

The

and

For

START:-

1,1ave

switch

off

or

root

ha\'~

machine

into

rag

mounting

(see

blown

stop

available

OPBR4TTON

have

blown.

concrete,150

bolts

Fig.

ha~

tripned.

they

should

fitted,

BZ.)

or

button

~il1

on

have

not

been

(",her.

at

m"chlne.

&

~'AlL1]RS

r\,-set

be

levelled

to250

after

wood

not

heen

closed.

fitted)

11'

ll:l.nrl

after

square

which

~loors

fitted.

1V

i,ESTART:-

re-set,

and

coach

has

set

a

short

bolted

hola~

the

holes

bolts

not

been

hy

period.

down

should

dhould

will

rele~sed.

pressin~

firmly.

be

cut

be

found

be

!",ttrm.

For

in

run

the

with

o

1

0

1

0

j

C

c:

i

'

!_

J

0

b-

C

1

!"

0

[

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

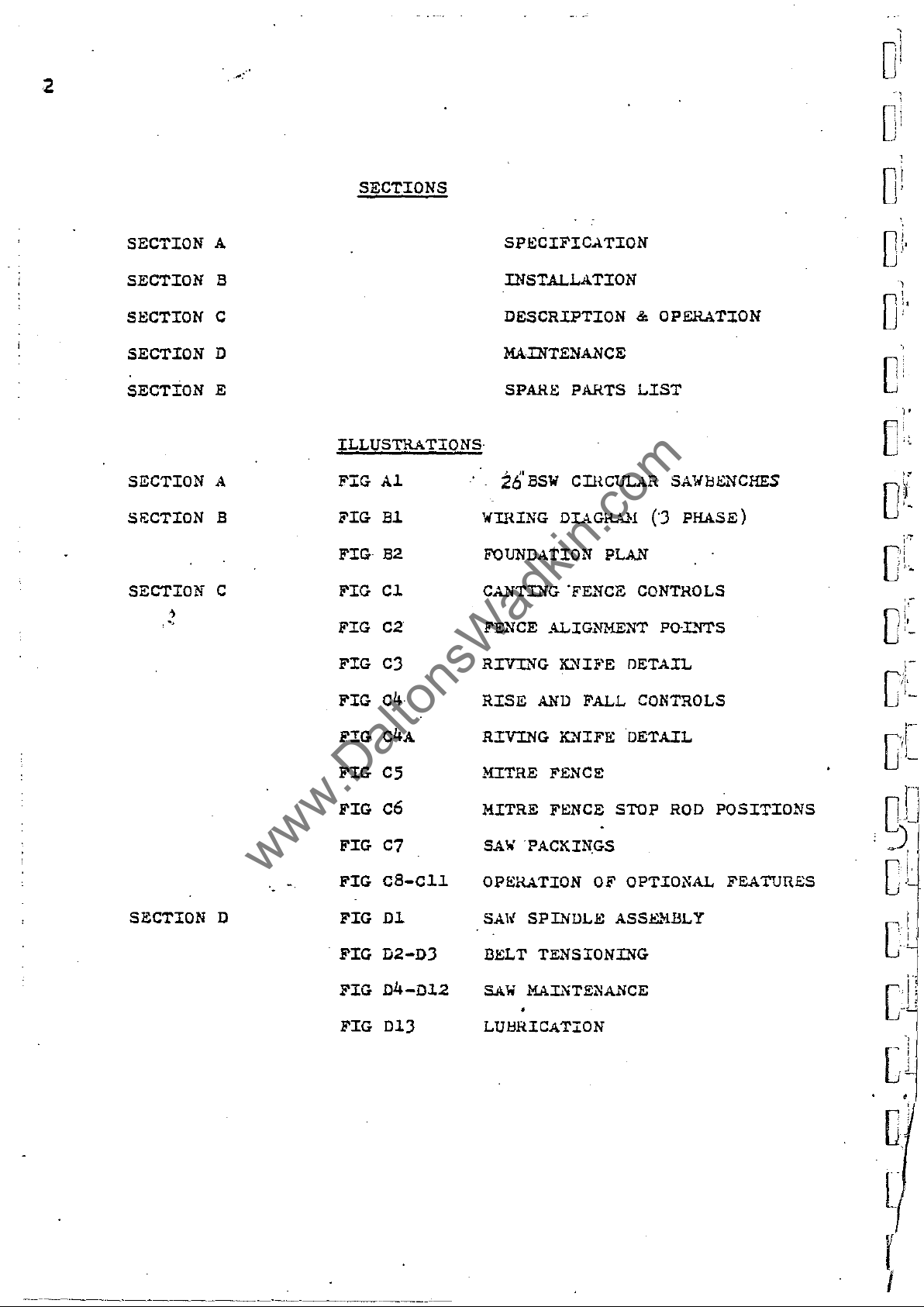

BROOK

RT3

STARTER(THREE

PHASE

5

DIAGRAM)

[

[:

c-

c-

c

[

[

c

-,

13

(11)h

14~

(12)

FOR

ANY

OTHER

SEPARATE

INSIDE

STARTER

SUPPLY

,

L1

L2 L3

LlNK'X'

BROWN

);

3 • b

il

--n---o-

2 4 LlNK'W' 6

>

OL~

2 4 6

A B C VIOLET

~~~~

c

BROWN

~

~

MOTOR

TYPE

WIRING

DIAGRAM

LlNK'T'

l ORANGE

"5

21

(13~e5)~

---0-

22 14) . START

>

• 9

j"3)

OF

BOX.

33

-----0

9S~~7)

OL

98,

(9)

LINK'Z'

-{P

34(16)

--jpSTOP/RESET

96(8)

START1NG

ENCLOSED

RlMOTI

96<a)

t

~6oJ

"ST"'''T.STO'''

aUTTCNS

34(~61

_.___

t S

S1TAR.T

SEE

33(15)

t

FIG

B I

o·

o·

0

D

'\

-'.

0

0

D

E

[

[

---/

.---+-e!-+

585'111'111

-l-

I

E

l

I

!

I

----._-

I

)1

-666

m,.

--

-.

- .

-----+~-l

i

,

-

.

I

~l

4 -16

mm

Dia holes

[

FIG

B2

SECTION C

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

o

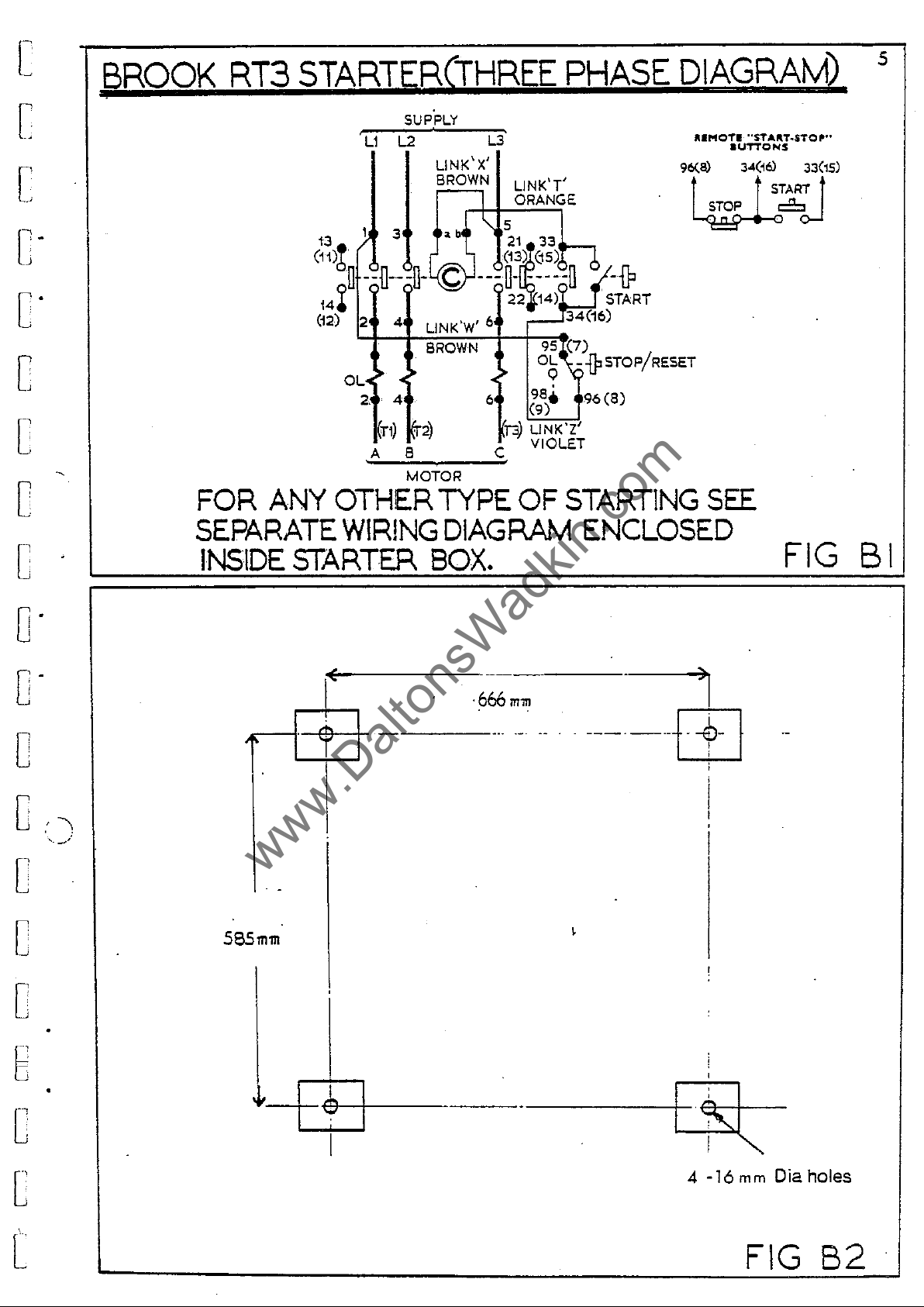

CANTING

9,UICK

orated

proceedure:-

1.

2.

J.

FINE

provision

ment

1.

2.

J.

CANTING,-

1.

2.

J.

FENCE

table

be

slot

locking

NOTE:.For

ADJUSTI!ENTj-

into

Unlock

Slide

indicated

Lock

ADJUSTMENT'-

feature.

Ensure

Turn

the

required

Lock

Unlock

Unlock

edge

Lock

POSITIONING,in

used.

in

&

RIP

FENCE

it.

lever

the

fence

against

lever

knurled

fence

lever

To

of

lavers

the

lever'E'will.

'A:

i~

made

lever

along

~etting.

'K

cant

leva·r

lever

the

order

By

unlocking

back

crosscutting

CONTROLS

The

To

adju~t

'A:

and

along

the

firmly

After

for

To

operate

'A'

is

UNLOCKED

hand

firmly.

'D'

'El

plate

\ I \ I

D

to

~crew

the

fence

and

allowing

lies

and

E

The

compen~ate

of

the

:fi~

fence

~crew

to

adjusting

precise

rule

follow

allow

firmly.

fence

lever

swing

~lides

the

'B'

the

bar

pointer

~ecure

follow

'C'

in

bar

fence

fence

flat

plate

for

'E"

fence

the

fence

fence

on a round

fence

(Fig.

~etting

and

direction

to

under

on

the

to

follow

C.l.)

until

on

the

in

position.

the

fence

by

under

~crew

or

away

mentioned

to

pivot

plate

the

table

is

designed

different

plate

the

required

firml.y

over

bar

the

the

required

fence

by

operating

mentioned

'B'is

to

the

LOCKED

required

from

over

drop

~urface.

~izes

maybe

in

pl.ace.

rul.e

with

under

dimen~ion

bracket.

the

above

the

proceedure.

firmly.

in

the

saw

proceedure

to

required

down

to

slid

position,

of

bar

until

slide

saws

along

to

a

rule

mentioned

method

fine

order

cl.ear

adju~t

(Fig.

to

and

to

(Fig.C.l.)

angle.

the

alon~

which

..

dovetail.

a:fter

incorp-

is

C.l.

draw

the

lower

the

may

which

the

)

table

l

O

-,

1

Cl:·

~,

·:·

It

6

1

, 1

0.

,

,

"

0·

,

I'

.1

0

I

Or

FENCE

finely

screws

uses,

pl.ace

outlined

POINT

to

be

POINT

between

POINT

wil.l.

the

table

POINT

parallal

SETTING

On

despatch

adjusted

at

points

and

should

from

underneath:-

F.-

set

paral.el.l

G;-

centres

H,-

not

all.ow

when

I;

-

to

A~D

for

constant

is

an

i .. a

F

is

a

the

~et

ie

al~o

the

tabl.e

ALIGNING,-

:from

the

accurate

F.G.H.I.

onl.y

eccentrical.ly

true

jacking

be

u ..

e.

to

the

centre

and

G.

fence

correctly.

a

jacking

for

re-eet

point

to

works

cutting

(FIG

The

sav,

which

be

true

the

movements

by

the

C2).

to

~eperate

turned

or

which

pull.ed

point

cant

Theee

co~pen~ate

u~es

centre

to

be

~et

al.lows

provides

up

of

provision

adjustments

for

of

which

in

sl.acknesa

a

further

the

fence

wear

the~e

al.lows

or

out

to

positive

than

have

of

the

have

which

point

as

90

..

the

required.

be

re~oved

~top

degrees

F

and

been

~etting

seperate

may

are

take

as

fence

which

to

G

)

@

Cl

f

i J

O

I

~.I

Ul

nf

Uj

,

··!,

; :

C

"

[

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

[

[

C-

O

0

C

7

0

C

O·

0

C

lOO)

C

.-../

0

['

-'

.

FIG-Cl

[

J

E

.

[

[

[

FlGC2

8

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

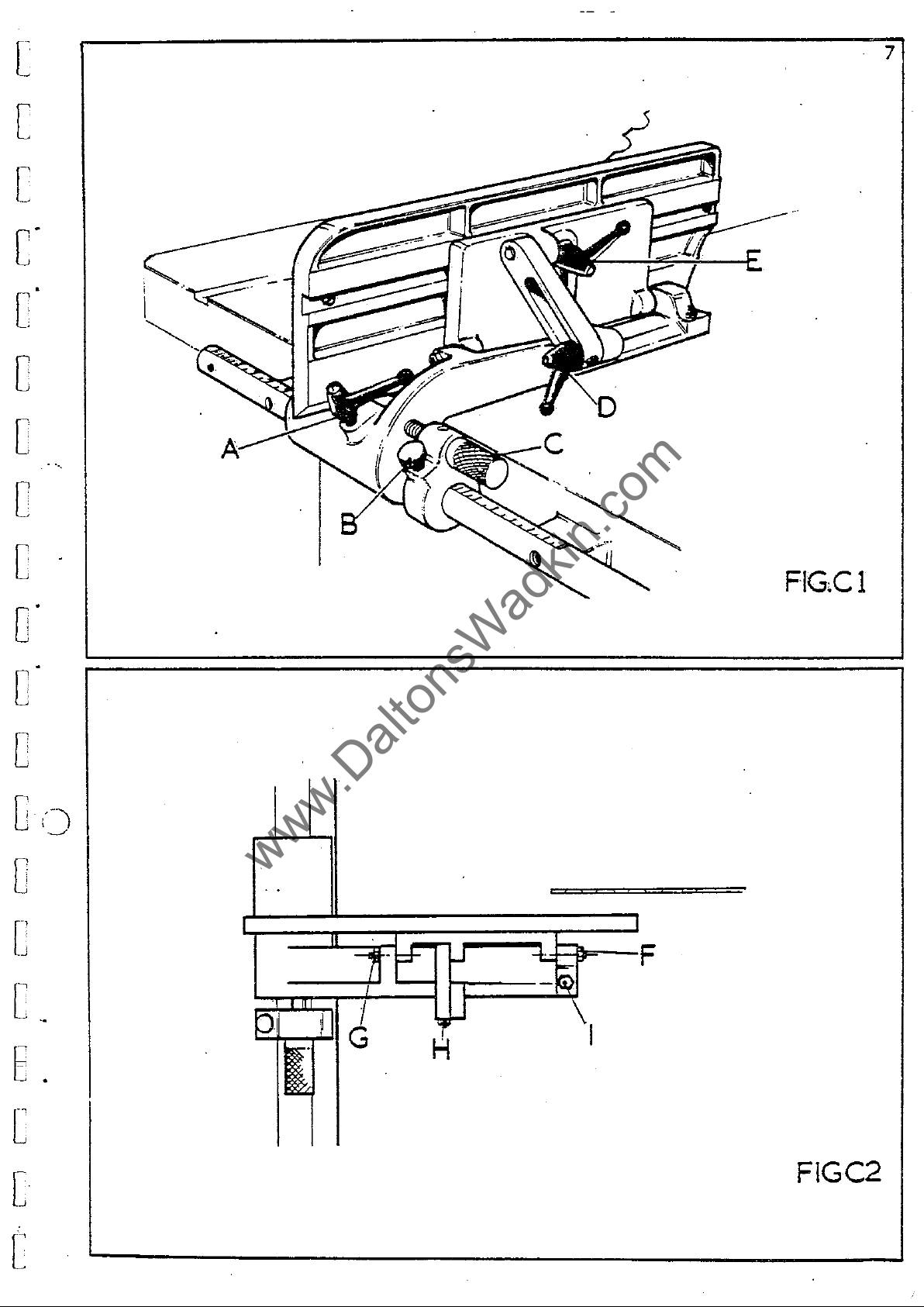

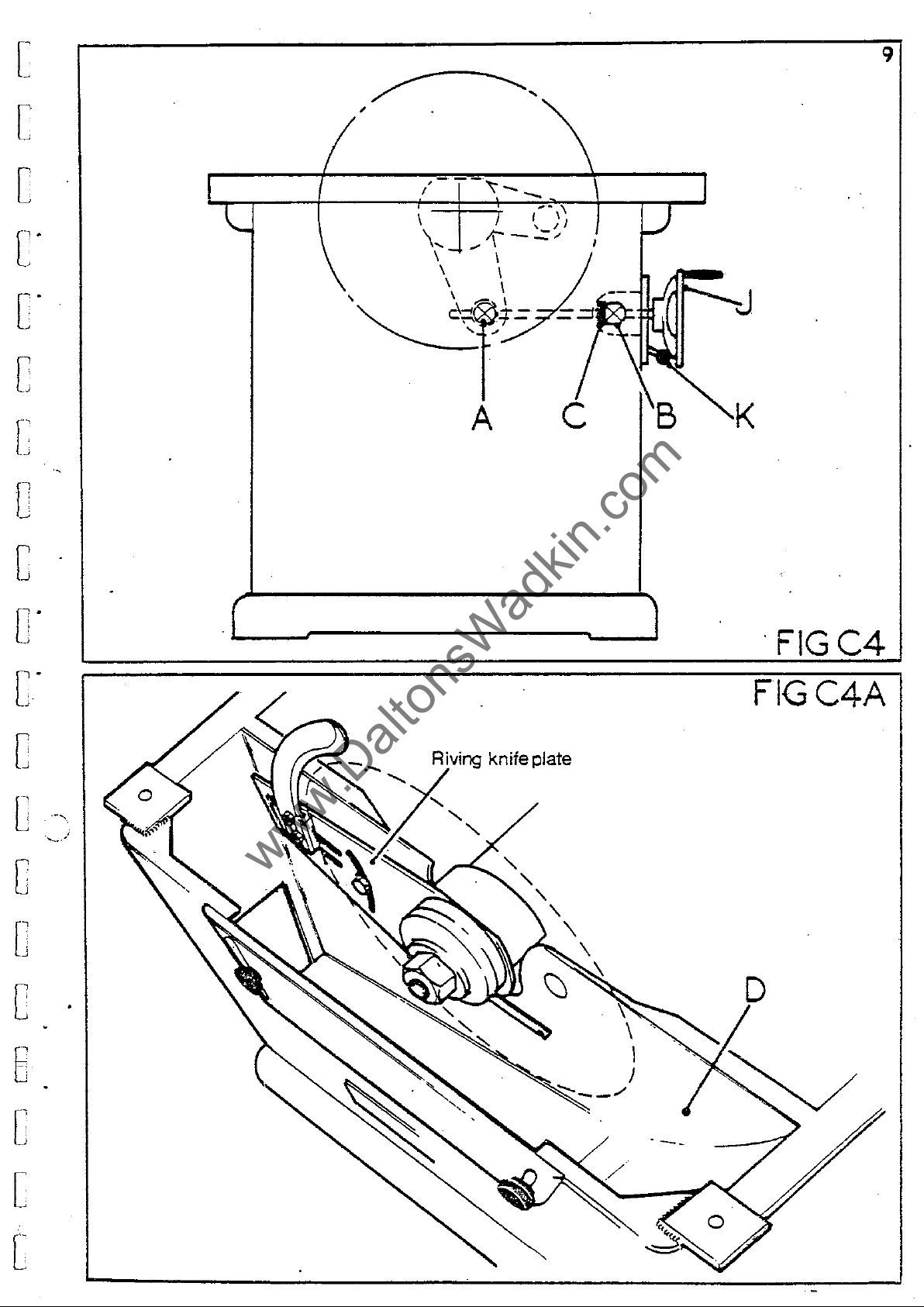

RISE

lowered

'A'

varied.

handle

points

race

important

11"

and

AND

FALL

By

turning

between

specification.

It

'K'

is

The

C

A.

&

is

that

rise

B.

fitted

that

the

CONTROLS:-

handwheel

the

maximum

Under

is

important

locked

and

(FIG

to

the

wu"t

firmly

fall

C4.)

give

pivots

'J'

no

after

handwheel

At

free

and

race

is

(fig.

and

minimum

circumstances

operating

before

is

the

handwheel

ro,tation

"crew

oiled

C4

)

running

connected

when

are

accordin

the

ooaition

should

the

the

end

in

cleaned

....

saw

rise

saw.

through

of

use.

and

to

may

as

this

and

the

the

given

luhricated

be

r~ised

in

dimension

fall

pivoted

screw

It

maintenance

is

that

a

therefore

or

section

lever

yolks

thrust

regular-

be

at

sCheduleD!'

o

, )

,···1

.,

0

.,

1

Oil'

J

,

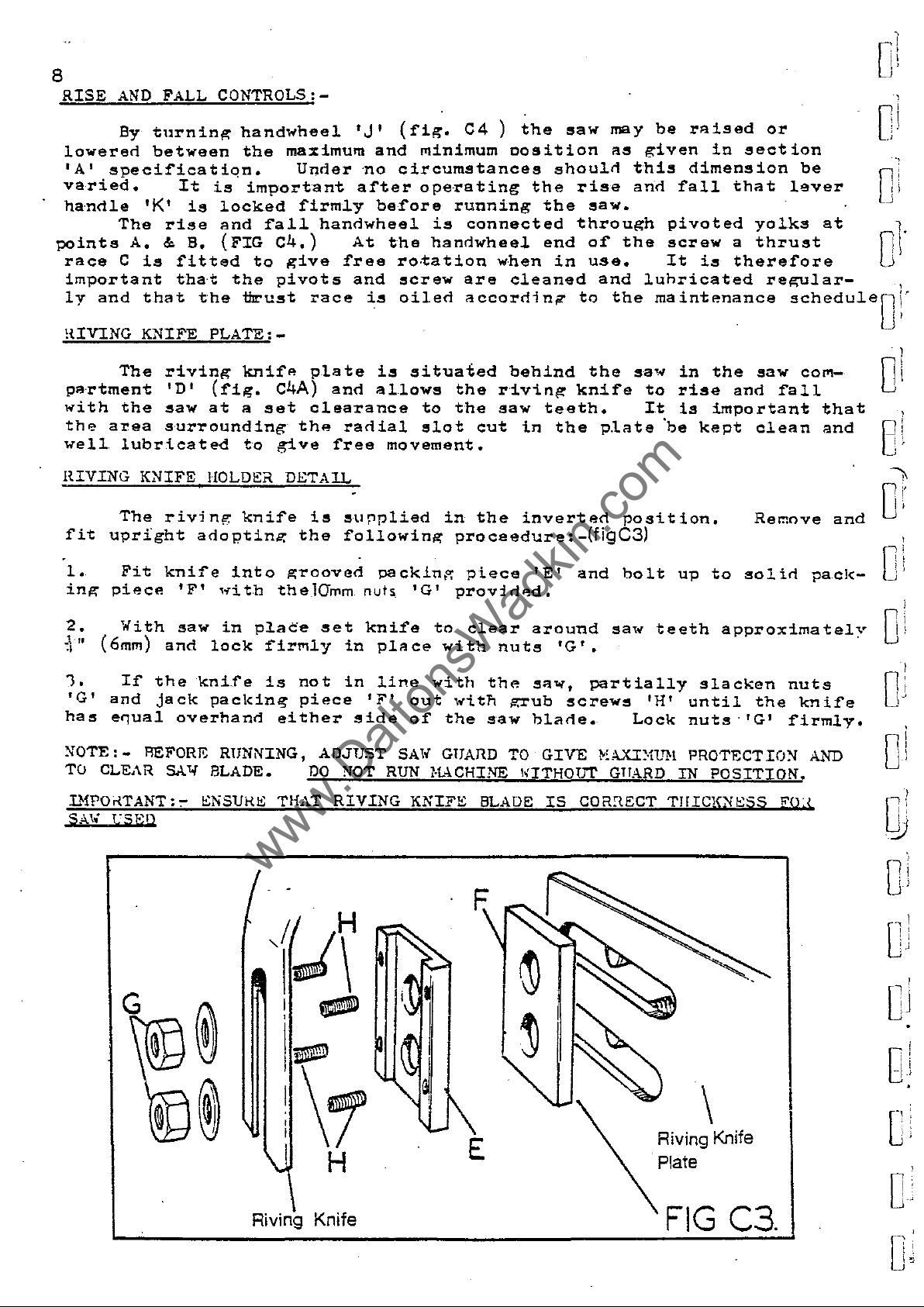

!UVING

partment

,.,i

th

th",

well

HIVING

fit

1.

ing

2.

J'II

.,

1.

'G'

ha"

XOTE: - REFORE RUNNING,

TO

KNIFE

The

the

area

lubr:lcated

KNIFE

The

upright

Fit

piece

With

(6mm)

If

the

and

CLEAR SA"f BLADE.

jack

e.,u~l

PLATE:-

riving

'0'

saw

s·urrounding

riving

knife

'F'

saw

and

'knife

overhand

knife

(fig.

at

a

t·o

HOLDER

knife

adcptinO':

into

'~ith

in

lock

packing

set

place

firmly

is

c4A)

give

DETAIL

g-roovad

thelGmm

either

plate

and

clearance

the

radial

free

i"

"uflplied

the

following

set

in

not

piece

ADJUST

DO

in

NOT

is

allows

movement.

packin!,:

nuts

knife

place

line

'F'

side

RUN

situaied

the

to

the

slot

in

proceedure:

'G'

prov:lded.

to

with

with

out

,~itn

of

the

SAl,

GUAnO

K~CHINE

cut

the

piece

clear

the

saw

behind

riving

saw

in

inverted

'E'

around

nuts

sa""

..:rub

blade.

TO

GIVE

IGTHOTlT

knife

teeth.

the

and

'G'.

screw"

the

"a'"

to

It

plate

-(figC3)

saw

partially

~,AXIXUH

GTTARD

'be

position.

bolt

teeth

'H'

Lock

in

the

saw

rise

is

up

IN

and

important

kept

slackan

until

nuts'

PROTECTIO!'l

clean

Remove

to

solid

approximatel::

the

'G'

POSITION.

CO<'l-

fall

1'acl<-

nuts

knife

firmly.

AND

that

and

and

Ol

, ,

,·i

, ,

O

. I

'·'

"

! i

0

, ,

'

\ i

0

1

!

,

11

0

I

0\

i \

'·1

0

DIPOi-{TANT:,.

SA"·

rSEI)

G

ENSUi-{E

THAT

,(~\

®

-

~

Riving Knife

\1

RIVING

-

H

KNIFE

BLADE

E

IS

COR,\ECT

TlfrCKflESS

\

Riving Knife

Plate

FIG

C3,

FO!

:

0

..

:V

·1

u

0

-,1

[jJ

DJ

-'

:

, j

C

,

0;

o

[

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

[

c

' .

[

-'

9

c-

c

[

o

C

0-

C-

C

A

I'<;V'r'V1 knife plate

J

K

. F1GC4

FIGC4A

[-':

... ~.J

c

[

[

6

[

[

[

10

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

HaUNTING

1.

SAWBLADES:-

When

Isolate

mount

machine

in..;

saws

the

und

erment

iancd

proceedure

sho

"In

be

.

t'ollo",ed:-

o

, ,

)

,

0'

j

.,

,

0;

2.

position.

3.

spindle.

4.

Check

especially

:'!pind1e

the

~.

fore

',OTE:-

DUE

which

setting,

quick

the

Remove

Remove

Select

saw

Chack

re·p1ac!nl?,

IHPO.<TA

...1!

ELECTRICS

TO

The

mitre

the

checki.ng

bore

..

'1T:-

IF

THE

mitre

should

and

s"tting

table

spindle

b1ane

h1ane

where

and

that

ENSURE

is

it

that

pin

the

the

insert

nut

required

in

good

will

the

hole

saw

f'lanl?,a

SPINDLE

(left

teeth

L

'I'll!, FL.\:-IGE OR S/\I.:

SAW

fence

RUN:-IING

fence

he

kept

a

positive

at

qOO

firmly

OUT-OF-TRUF.,

is

fitten

clean.

stop

and

in

and

raise

depending

conditi.on

he

gripped

face

centr

and

;<UNS

0

4S

to

any

the

sa",

hand

poi.nt

lock!n"

FACES

A

'A'

position.

thread)

on

ann

by

the

of'

the

hack

es . f'i t correctly

towards

UP

IN

COaRECT

ARE :-101'

into

the

the

scale

is

incorporated'

saw.

is

sr-i.ndl"

"nd

front

tYro

/?,roov"

of

work

free

t'irm.ly

provined

from

s"w

flange.

saw

flange

onto

the

front

with

'lIR"~CTIor;.

CL8A'I

providen

in

Th"

pl"stic

hOllsing

saw

which

dirt,

those

the

T1[IS

tn

innicate

the

into

flan~e

is

sawnust

Hount

i.s

clean

on

of

the

spindlp.

R;;;Fr~

CAN

""nnwheel

on

scale

TO

CA::SE

the

tbe

top

t'rom

to

be

done.

ann

,-;::urn.

saw

on

and

that

th e f'lanl"e.

machine

nut.

Sr~CT

VIJH1.A1'IO~

S""

accurate

to

'B'

be-

t"hle.

l;iv8

locks

the

0\'

..,

,

1

0

l1

:

i

, .

I'

O·

i

:

y

0

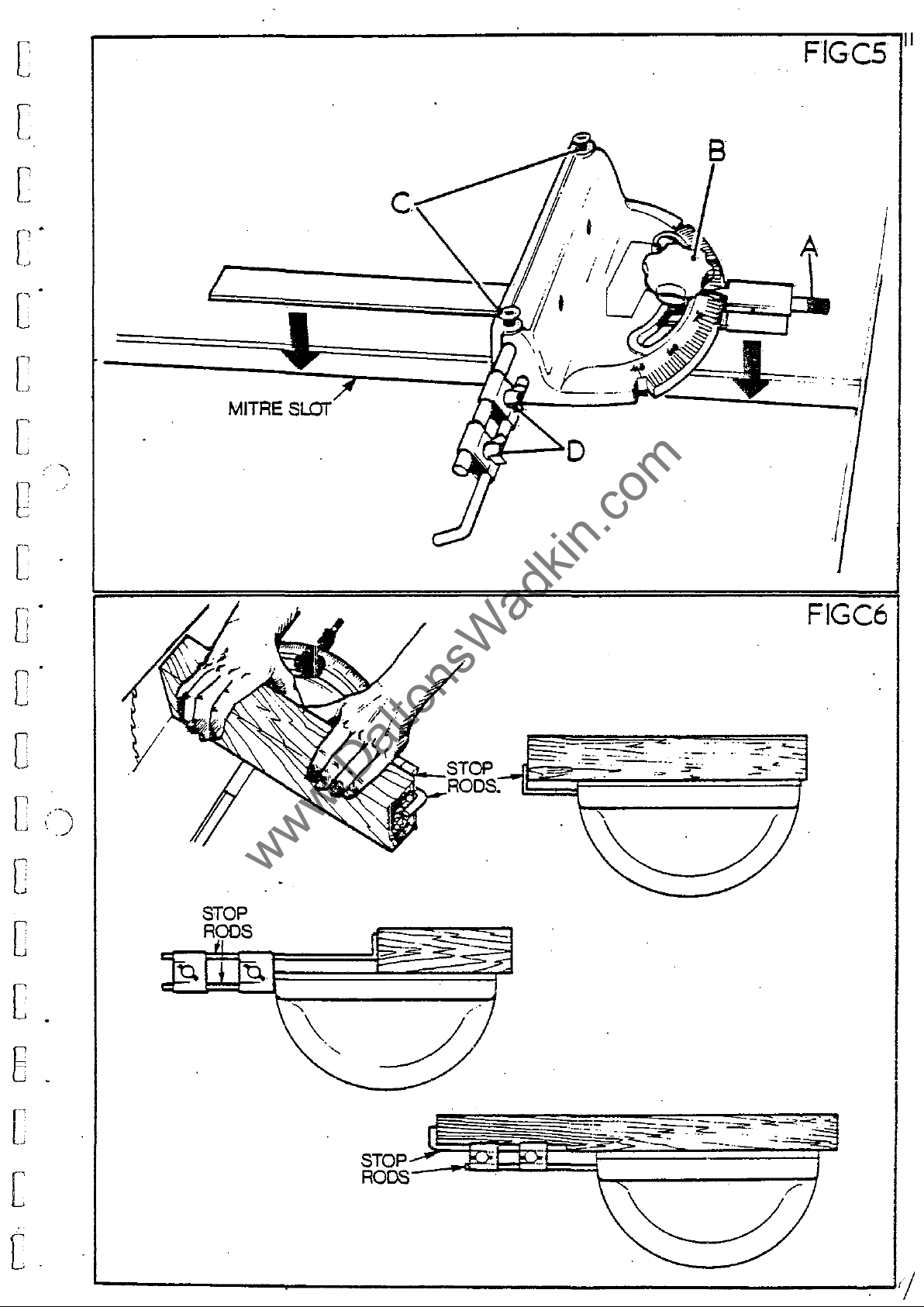

(fil':.

rods

"nd

(fi/r.

Accurate

C5.)

The

hy

the

'D'

ann

C6.)

rods

repetitive

are

two

sline

held

clamps

the

in

'D!

rons

cutting

the

Tb

into

'can

fenca

tha

he

with

adjust

po~ition

obtainen

the

the

sto!"

hy

us

..

of

thumb~crew~

rons

reqlJired

'c'

sl"cken

,,~

illustr"ted

the

stop

an~

cl"",ps

the

rods

stop

'C'

in

1

·!

[,j

D

, ,

"l.

(_1

O

oj

gJ

[]l

I

, .

"

, :

C

D·

[

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

[

[

' .

[

.

~

c·

c

[

MITRE

SlOT

B

FIGCS

I

I

11

c

[

o·

c

c

..

· ;

C

;

[

[

-';

.....

'

STOP

RODS

~.--.-

-.

.F"

,

I

FIGC6

[

E .

[

[

c.

Loading...

Loading...