,

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

20

'..

. I

l;

(~·S·l,v

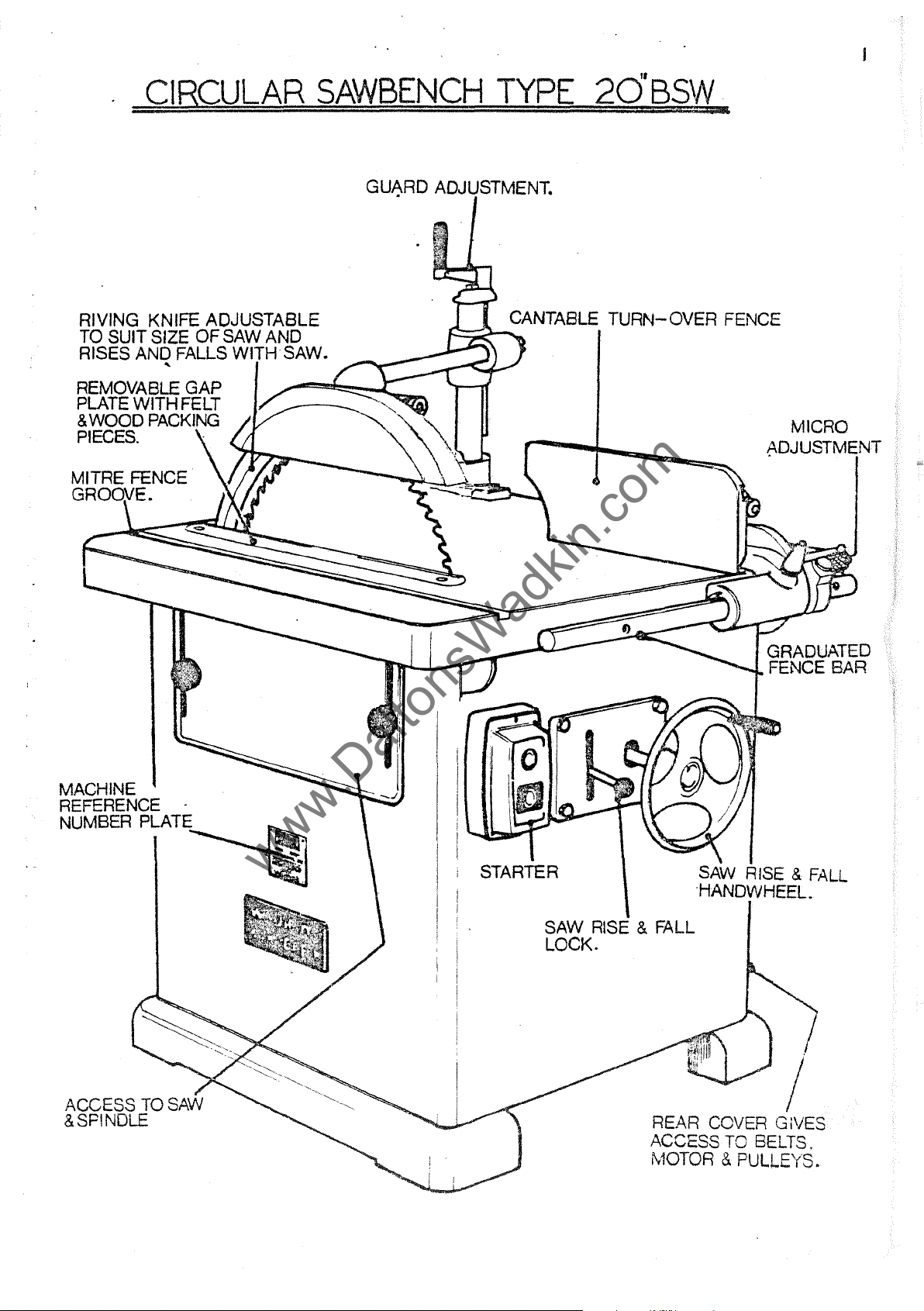

CIRCULAR

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

RIVING KNIFE ADJUSTABLE

TO SUIT SIZE

RISES AND FALLS WI . SAW.

REMOVABLE GAP

PLATE

& WOOD PACKING

PIECES.

WITH FELT

OF

SAW AND

"

SAWBENCH

TYP~

20'B§:tI

..

MICRO

~DJUSTMENT

MACHINE

REFERENCE

NUMBER

PLATE~

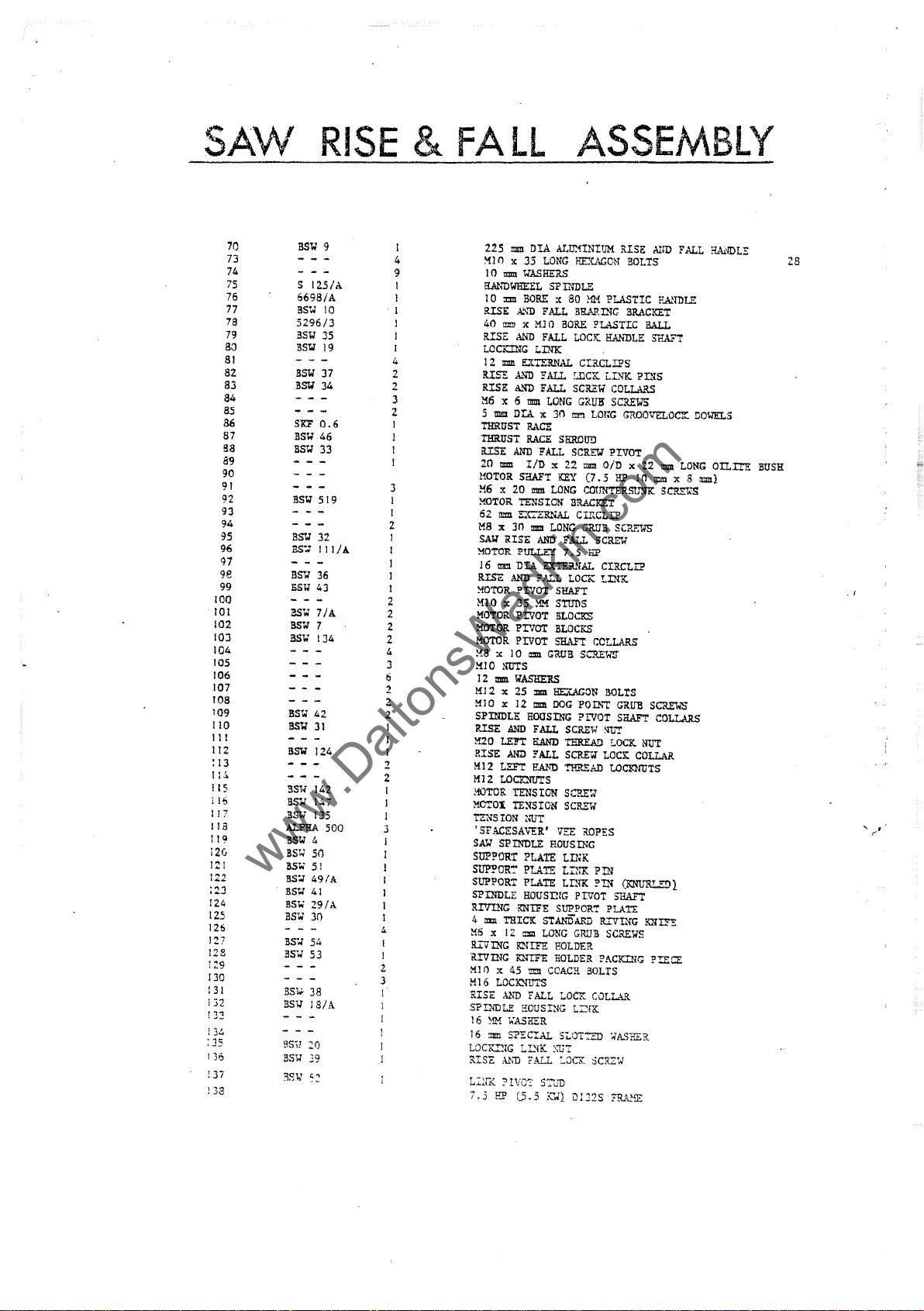

SAW RISE & FALL

, j LOCK.

I

REAR COVER GIVES

ACCESS TO BELTS.

MOTOR & PULLEYS.

2

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

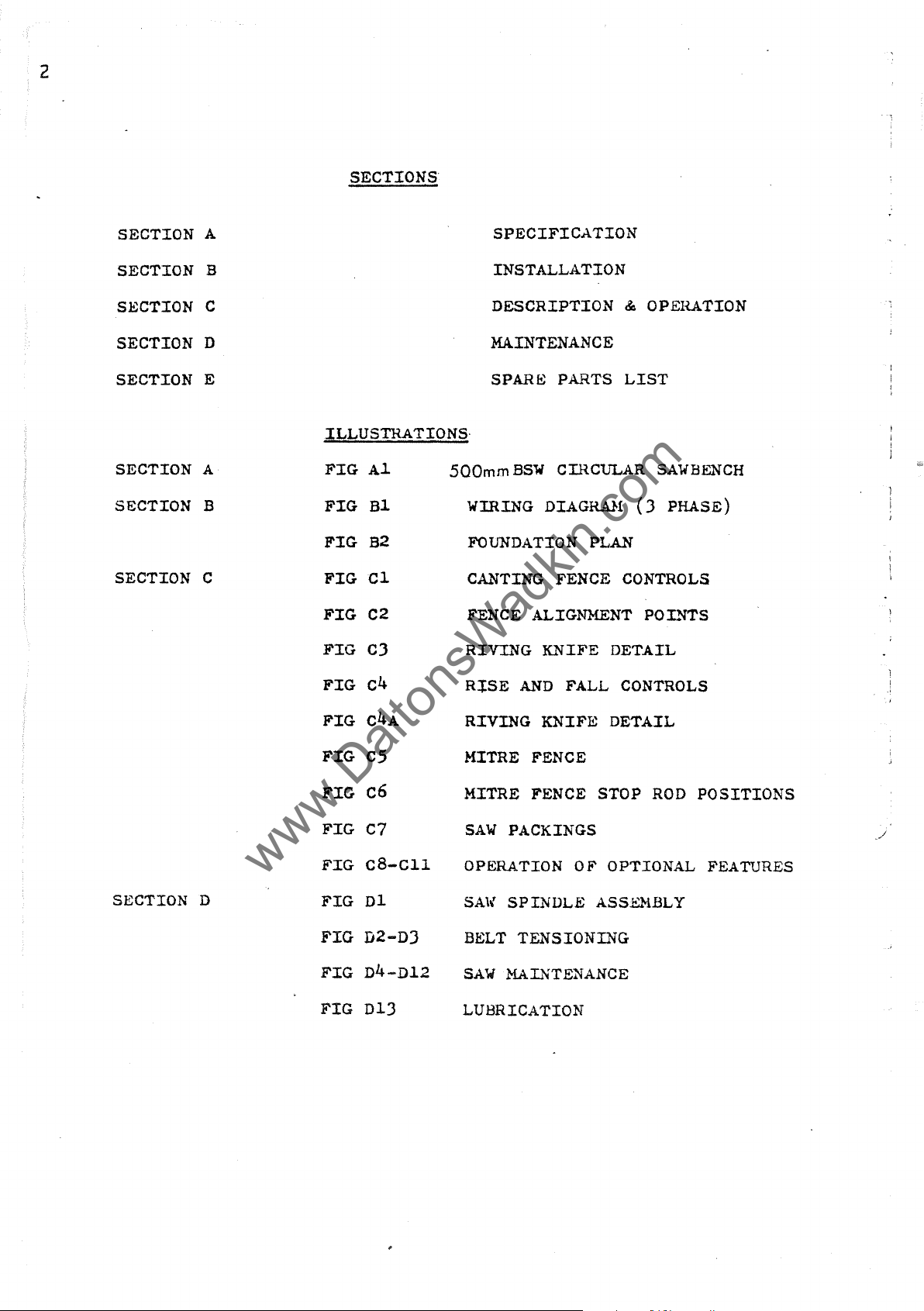

SECTIONS

SECTION A

SECTION B

Sl£CTION C

SECTION

D

SECTION E

SECTION A

SECTION B

SECTION C

ILLUSTRATIONS·

FIG

FIG

FIG

FIG

FIG

FIG

A~

B~

B2

C~

C2

C3

5QOmm

SPECIFICATION

INSTALLATION

&

DESCRIPTION

OP~{ATION

MAINTENANCE

SPARE PARTS

BSW

CIRCULAR

WIRING

DIAGRA.H

FOUNDATION

CANTING

FENCE

FENCE

ALIGNMENT

LIST

SAW

(3

PLAN

CONTROLS

POINTS

RIVING KNIFE DETAIL

BENCH

PHASE)

SECTION

D

FIG

FIG

FIG

FIG

FIG

FIG

FIG

FIG

FIG

FIG

c4

C4A

CS

c6

C7

cB-Cll

Dl

D2-D3

D4-D12

D13

R1SE

AND

FALL

CONTROLS

RIVING KNIFE DETAIL

MITRE

MITRE FENCE STOP

SAW

OPERATION

SA\{

BELT

SAW

FENCE

ROD

PACKINGS

OF

OPTIONAL

SPINDLE ASSEHBLY

TENSIONING

MAINTENANCE

LUBRICATION

POSITIONS

j

FEATURES

3

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Maximum

Maximum

Size

of

Table

Max.

Fence

Fence

distance

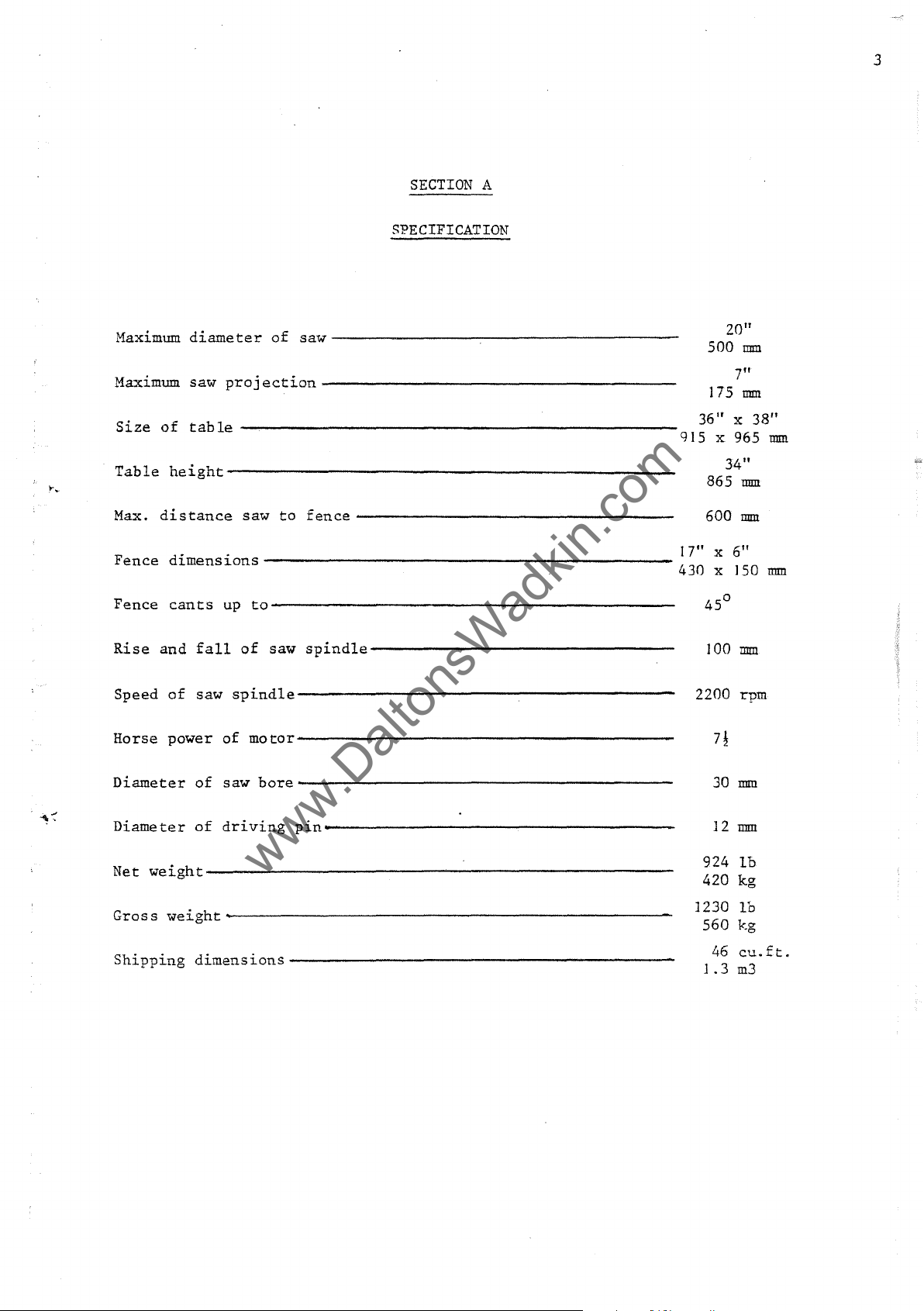

SECTION

SPECIFICATION

diameter

saw

table

height------------------------------------------------

dimensions-----------------------------------------------

cants

up

of

saw-----------------------------------------

proj

ection

-------------------------------------------------

saw

------------------------

to

fence

-----------------------

to----------------------------------------------

A

20"

500

175

36" x 38"

915

x 965

34"

865

600

17"

x

430 x

45°

mm

7"

mm

mm

mm

6"

150

mm

mm

Rise

Horse power

Diameter

Diame

Net

Gross

and

fall

of

saw

spindle-------------------------------

Speed

Shipping

of

saw

spindle------------------------------------------

of

motor-----------------------------------------

of

saw

bore--------------------------------------

ter

of

driving

weight---------------------------------------------------

weight---------------------------------------------------

dimensions---------------------------------------------

pin

------------------------------

100

mm

2200 rpm

7!

30

mm

12

mm

924

lb

420

kg

1230

lb

560

kg

46

cu.ft.

1.3

m3

4

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

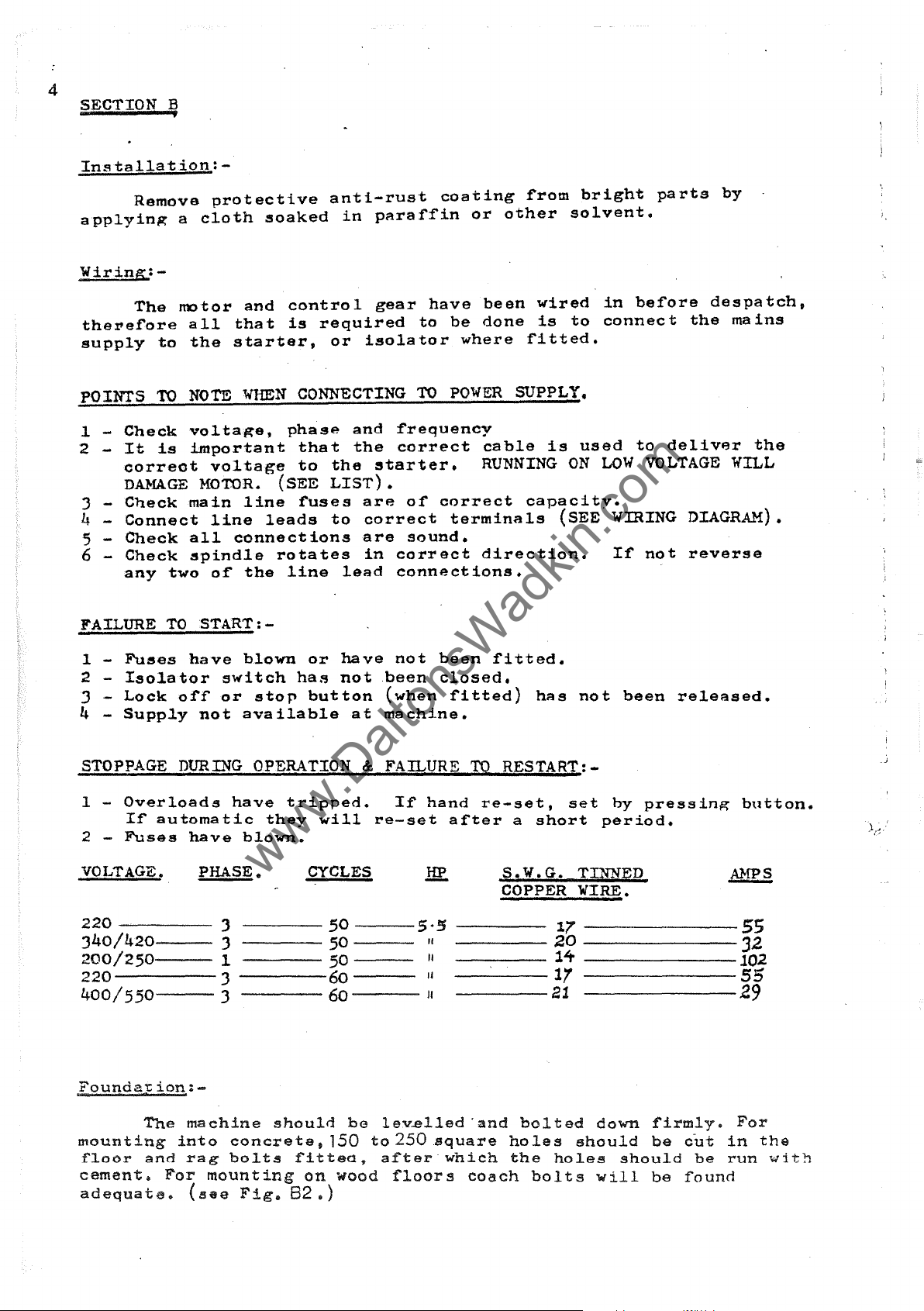

SECTION B

Installation:-

•

Remove

applying

Wiring,,:

The

there£ore

supply

POINTS

1 -

Check

2 -

It

correot

DAMAGE

j

Check

4 -

Connect

5 -

Check

6 -

Check

any

FAILURE

a

motor

all

to

the

TO

NOTE

voltage,

is

important

main

all

spindle

two

TO

protective

cloth

and

that

starter,

WHEN

voltage

MOTOR.

line

line

connections

o£

the

START:-

anti-rust

soaked

control

is

required

or

CONNECTING

phase

that

to

the

(SEE

leads

rotates

LIST).

fuses

to

line

in

isolator

and

the

are

correct

are

in

lead

coating

paraf£in

gear

starter.

have

to

TO

£requency

correct

of

correct

sound.

correct

connections.

or

other

been

be

done

where

POWER

cable

RUNNING

terminals

direction.

£rom

solvent.

wired

is

to

£itted.

SUPPLY.

is

ON

capacity.

(SEE

bright

in

connect

used

LOW

parts

be£ore

the

to

deliv~r

VOLTAGE

WIRING DIAGRAM).

If

not

reverse

by

despatch,

mains

the

WILL

1

Fuses

2

Isolator

3 -

Lock

4 -

Supply

STOPPAGE

I -

Overloads

If

automatic

2 -

Fuses

VOLTAGE.

220

340/420

200/250

220

400/550

,Foundat:ion:-

have

switch

o£f

or

not

DURING

have

have

PHASE.

3

j

1

j

3

blown

stop

available

OPERATION & FAILURE

blown.

tripped.

they

or

have

ha~

not

button

will

CYCLES

50

50

50

60

60

at

re-set

not

been

(when

machine.

I£

hand

l!!:

5-S

11

11

u

JI

been

closed.

fitted)

TO

re-set,

after

£itted.

has

RESTART:-

a

short

S.W.G.

COPPER

17'

.20

1-+

17

21

not

set

by

period.

TINNED

WIRE.

been

pressing

released.

button.

~

5S

32

102

55

29

The

machine

mounting

rloor

cement.

adequate.

and

into

rag

For

mounting

(see

should

concrete.

bolts

Fig.

82.)

150

fitted.

on

be

lev~lled'and

to250square

after

wood

floors

which

coach

bolted

holes

the

bolts

should

holes

down

should

will

firmly_

be

cut

be

be

found

For

in

run

the

with

-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

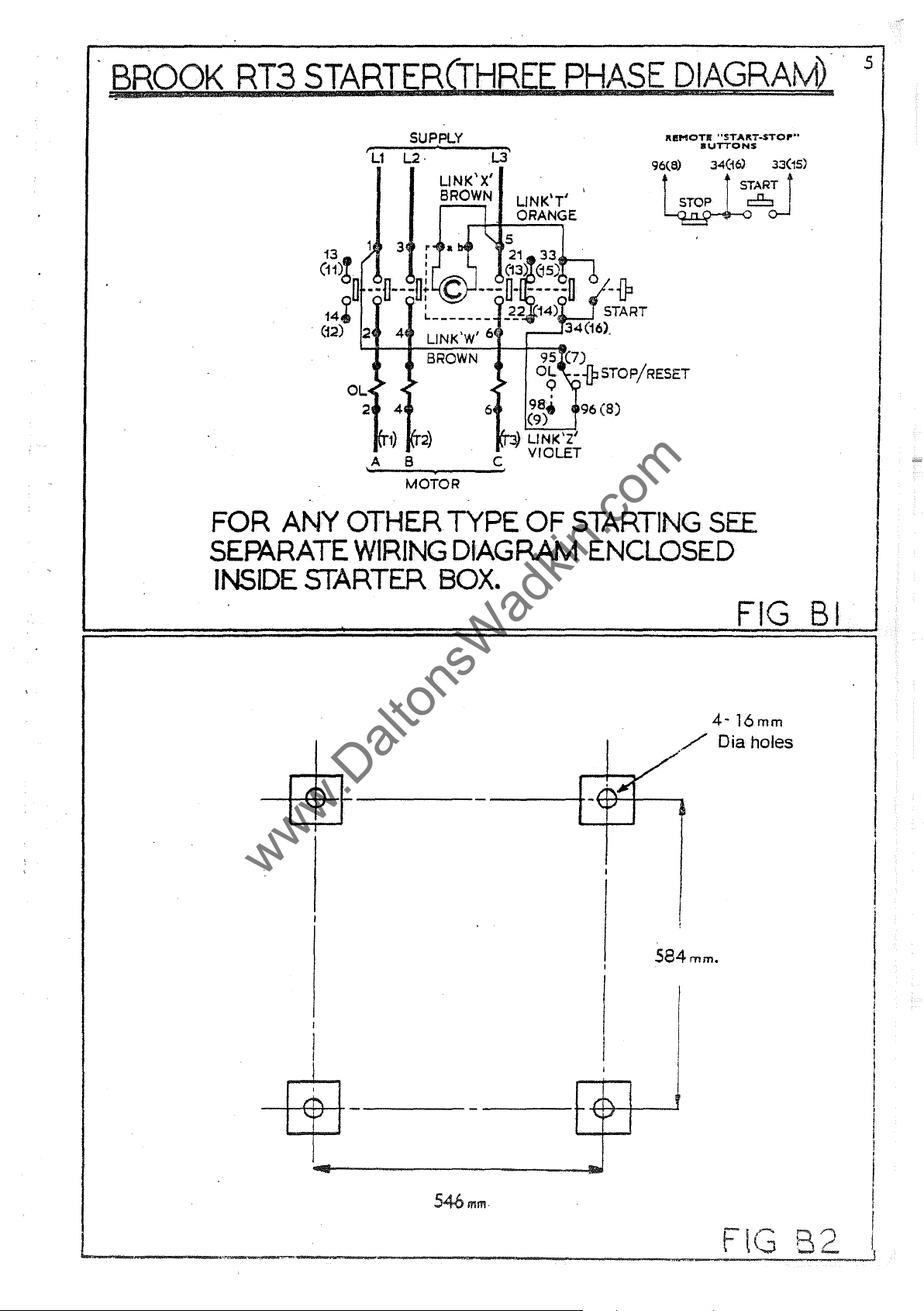

.t3BOOK

RT3

STARJER£THREE

PHhS

E

DIAGRAM).·

5

FOR

ANY

OTHER

SEPARATE

INSIDE

STARTER

SUP,PLY

r

L2

L1

,A

.L3'

LINK'X'

BROWN

B

•

MOTOR

TYPE

WIRING

BOX.

L1NK'T' I

ORANGE

C,

OF

STARTING

DIAGRAM

IU!,",OTI!

"STAftT·STO

IIUTTONS

SEE

ENCLOSED

..

••

I

I

!'\

j.I

FIG

4-16mm

/Diaholes

584mm.

I

~

f-

-

-

I'

\;

~

BI

546

mm

-

6

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

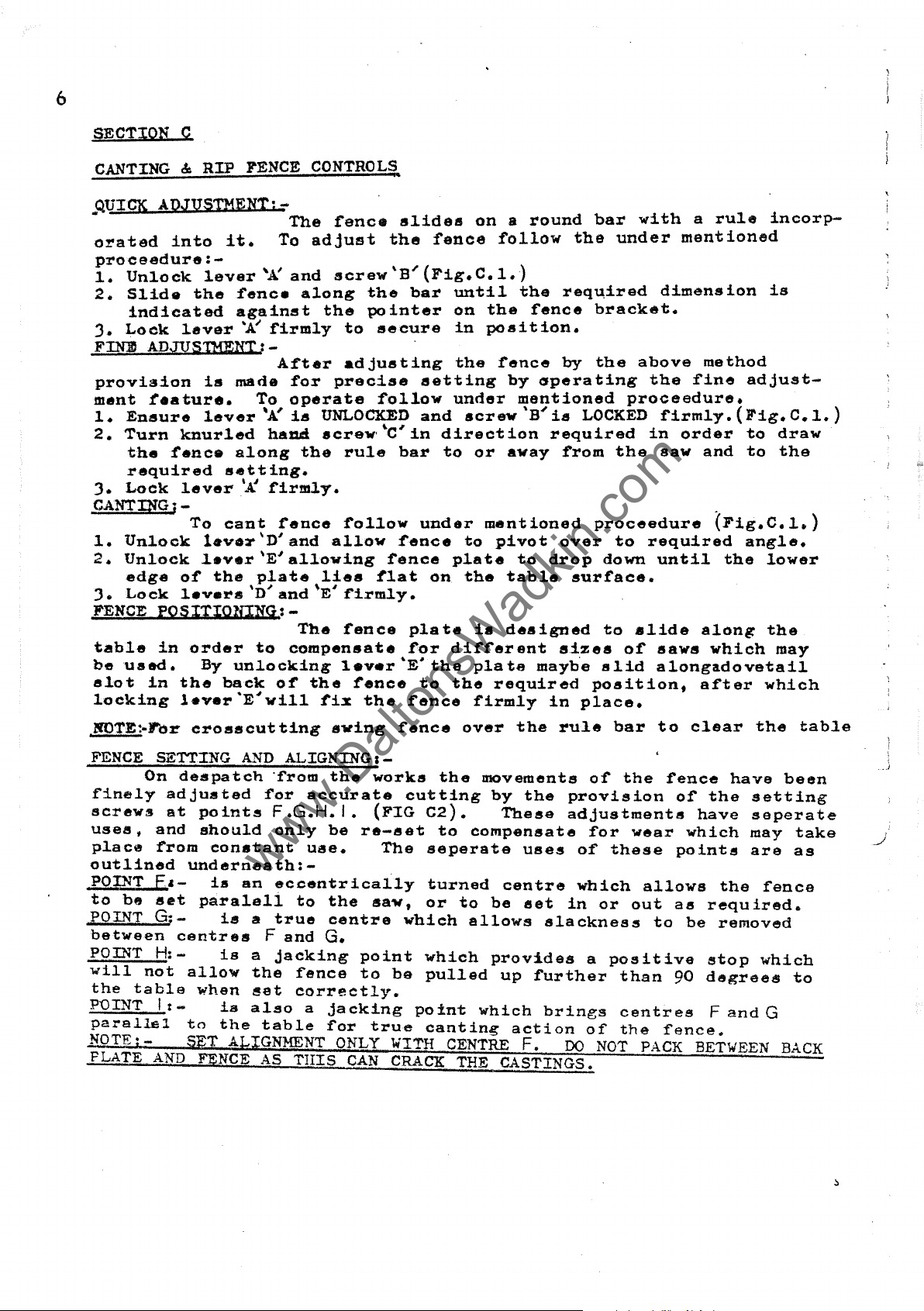

SECTION C

CANTING

&

RIP

FENCE

CONTROL~,

QUICK

ADJUSTMENT;-

•

orated

proceedure:-

L

Unlock

2.

Slide

indicated

3.

Lock

FINlD

provision

ment

1.

2.

3.

CANTING;-

1.

2.

3.

FENCE

table

be

slot

locking

ADJVS1HENI:-

reature.

Ensure

Turn

the

fence

required

Lock

Unlock

Unlock

edge

Lock

PQSIIIQltINq:-

in

used.

in

into

it.

lever

the

lever

is

lever

knurled

lever

To

tevor'D'and

lever'E'a11owing

of

the

levers

order

By

the

lever'E'Yill

"A:

fence

against

'A"

made

To

'A'

along

setting.

'K

cant

plate

D

" "

to

unlocking

back

The

To

adjust

and

along

the

£irm1y

After

for

operate

is

UNLOCKED

hand

firmly.

screw'

the

fence

lies

and

E

The

compensate

of

the

fix

£ence

screw'B

the

pointer

to

secure

adjusting

precise

follow

rule

follow

allow

flat

firmly.

fence

1.v.r

fence

the

slides

the

~

bar

'c'

in

bar

fence

fence

plate

for

'E'

fence

fenee

(Fig.

until

on

in

the

setting

under

and

direction

to

under

plate

on

di£ferent

the

to

the

on a round

follow

C.1.)

the

the

£ence

position.

fence

by

Gperating

mentioned

screw'B"is

or

away

mentioned

to

pivot

to

the

table

is

designed

pla

te

mayb'e

required

firmly

bar

with

the

under

req~ired

bracket.

by

the

above

proceedure.

LOCKED

required

from

over

drop

sizes

in

the

proceedure

to

down

surface.

to

of

slid

position.

place.

slide

a

rule

mentioned

dimension

method

the

fine

£irm1y.{Fig.C.1.)

in

order

saw

required

until

saws

alongadovetail

adjust-

to

and

to

.

(Fig.C.1.)

angle.

the

along

which

after

incorp-

is

draw

the

lower

the

may

which

N01'E:-J'br

FENCE SETTING

On

finely

screws

uses,

place

outlined

POINT

to

be

crosscutting

despatch

adjusted

at

points

and

should

from

underneath:-

F.,-

set

paraleli

constant

is

POINT G;-

between

POINT

will

the

POINT 1 t -

parallel

NOTFJ-

PLATE

H:-

not

table

AND

centres

is

allow

when

is

to

the

SET ALIGNMENT

FENCE

is

AND

ALIGNING: -

'from

for

F.G.H.I.

only

an

eccentrically

to

a

true

F

and

a

jacking

the

fence

set

correctly.

also

table

AS

THIS

swing

the

accurate

be

use.

the

centre

G.

a

jacking

for

ONLY

CAN

works

(FIG

re-set

The

say,

point

to

be

true

WITH

CRACK

fence

cutting

C2).

seperate

turned

or

which

which

pulled

point

canting

over

the

movements

to

compensate

to

allows

which

CENTRE

THE

the

by

the

These

uses

centre

be

set

slackness

prov1des

up

further

brings

action

F.

CASTINGS.

rule

DO

bar

o£

the

provision

adjustments

for

wear

of

these

which

in

or

out

a

positive

than

centres

of

the

NOT

to

fence

o£

points

allows

as

to

90

fence.

PACK

clear

have

the

have

which

the

required.

be

removed

stop

degrees

F

and

BETWEEN

the

table

been

setting

seperate

may

take

are

as

fence

which

to

G

BACK

,.I

~

7

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

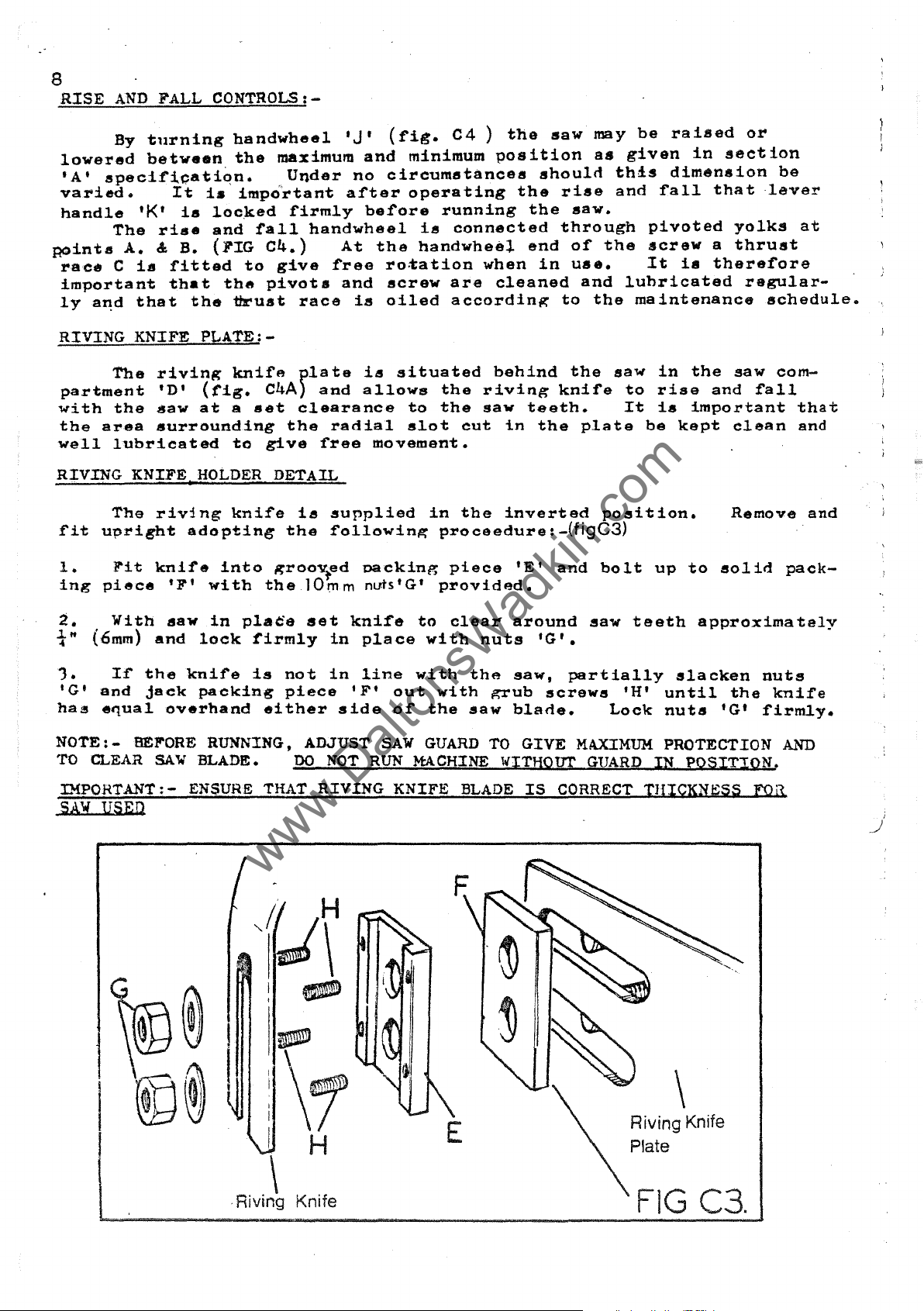

FIG.Cl

IGC2

8

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

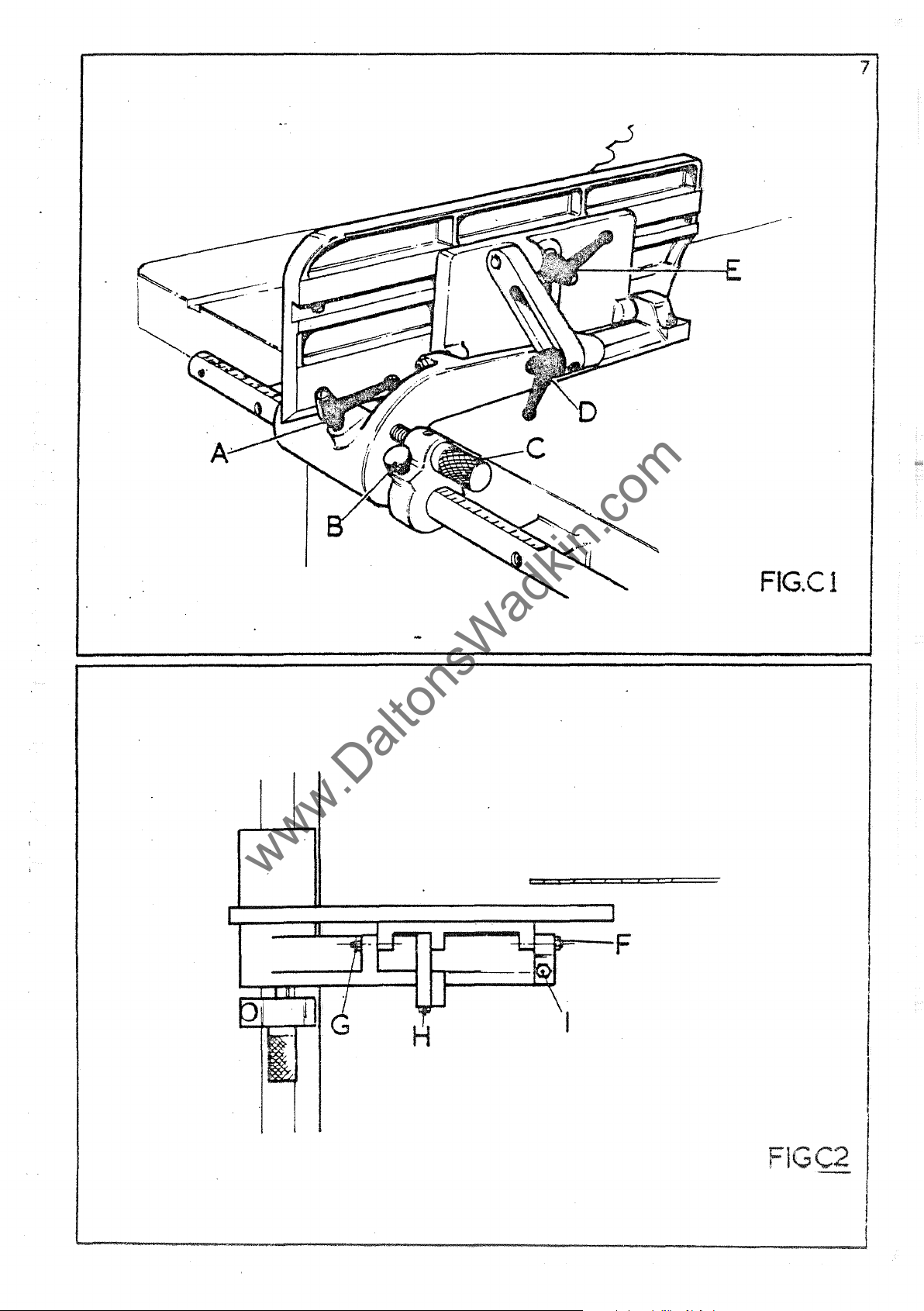

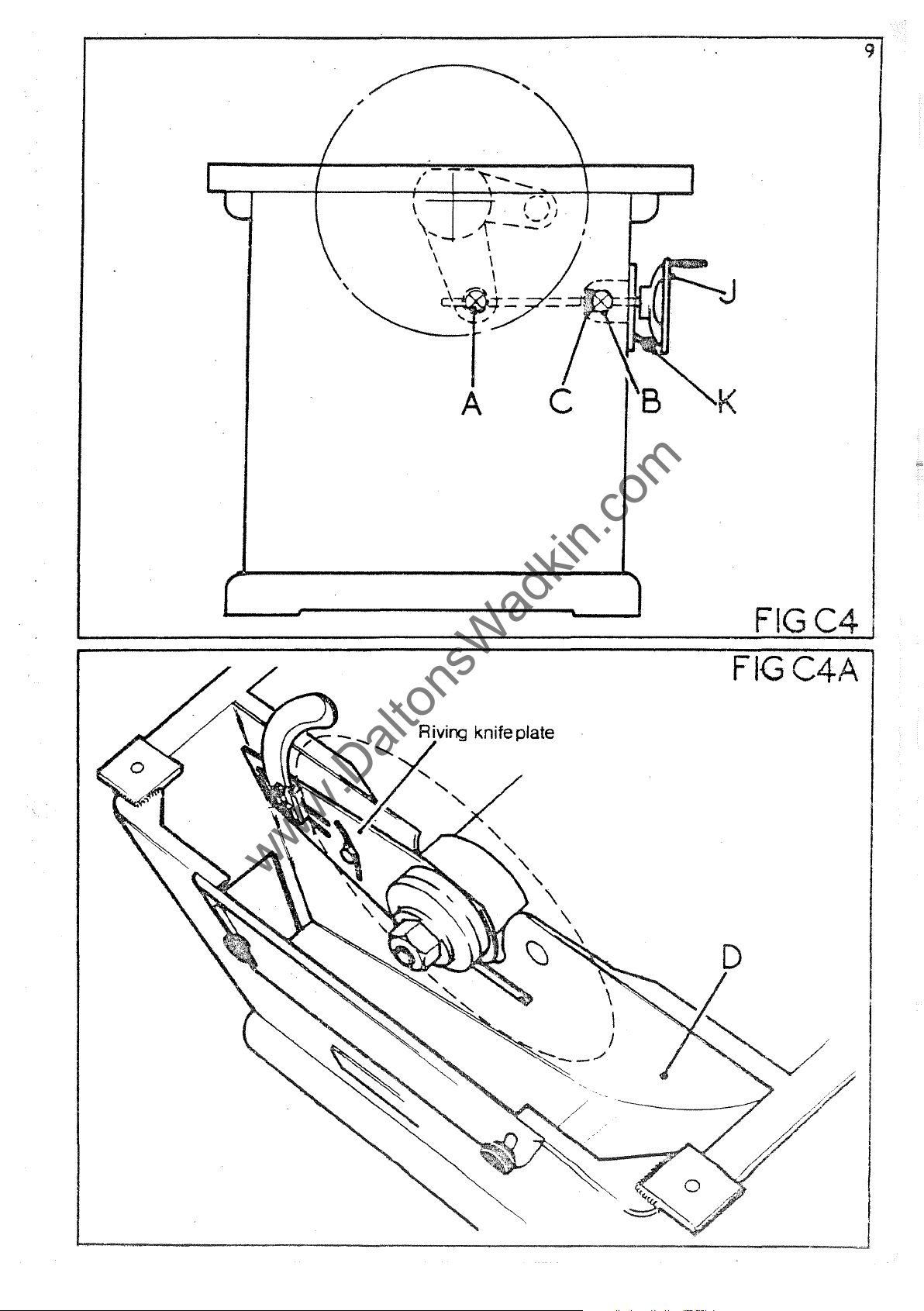

RISE

lowered

'A'

varied.

handle

~ints

race

important

ly

AND

By

specificati~n.

The

C

a~d

FALL CONTROLS:-

turning

between

It

'K'

is

rise

A. & B.

is

fitted

that

that

i.

loc.ked

and

(FIG

the

handwheel

the

imp~~tant

th~

tirust

maximum

fall

04.)

to

give

pivots

Under

firmly

handwheel

At

free

and

race

'J'

(fig.

and

minimum

no

circumstances

after

is

operating

before

the

ro~ation

screw

oiled

04

)

running

is

connected

handwheel

when

are

according

the

saw

position

shoulrl

the

the

end

in

cleaned

may

as

rise

saw.

through

of

the

use.

and

to

the

be

raised

given

this

and

dimension

fall

pivoted

screw

It

is

luhricated

maintenance

in

section

that

yolks

a

thrust

therefore

or

be

lever

at

regular-

schedule.

RIVING

The

partment

with

the

well

RIVING

:fit

1.

ing

2.

~"

).

'G'

has

NOTE:TO

the

area

lubricated

The

upright

~it

piece

With

(6mm)

If

and

equal

CLEAR

KNIFE

KNIFE,HOLDER DETAIL

the

jeck

BE~ORE

PLATE:-

riving

ID'

saw

surrounding

riv1ng

knife

'P"

saw

and

overhand

SAW

knife

(fig.

at

a

to

knife

adopting

into

with

in

place

lock

knife

packing

RUNNING, ADJUST

BLADE.

plate

C4A}

set

clearance

the

give

is

the

groov~d

the

lOr:nm

set

firmly

is

not

piece

either

DO

and

radial

free

supplied

f'ollowing

in

in

NOT

is

allows

movement.

oacking

nLJ.ts'G'

knife

place

line

'F'

side

SAW

RUN

situated

the

to

the

slot

in

proceedure:

provided.

to

with

with

out

with

of'

the

GUARD

MACHINE

riving

saw

cut

the

piece

clear

nuts

the

saw

behind

teeth.

in

the

inverted

'E'

around

'G'.

saw,

grub

blade.

TO

GIVE

WIT!iOt!l'

the

knife

plate

-(figC3)

and

saw

partially

screws

MAXIMUM

GUARD

saw

to

rise

It

is

be

position.

bolt

up

teeth

'H'

Lock

IN

in

the

saw

and

fall

important

kept

slacken

until

nuts

PROTECTION

POSITION.

clean

Remove

to

solid

approximatelv

the

'G'

com-

that

and

and

pack-

.

nuts

knif'e

firmly.

AND

IMPORTANT:-

SA\l USED

~

(@@

ENSURE

®

THAT

, H

'(:J\

.-

-

:\1

I H

\

. Riving

Knife

RIVING

KNIFE

BLADE

E

IS

CORRECT

IHICKNl:tSS

FOR

i

)

9

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

FIGC4 '

FIGC4A

10

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

JtIOUNTING SA WBLAnES : -

When

1.

2.

Isolate

Remove

position.

J.

Remove

spindle.

4.

Check

Select

the

especially

spindle

the

saw

'5.

fore

.JL

NOTE:-

DUE

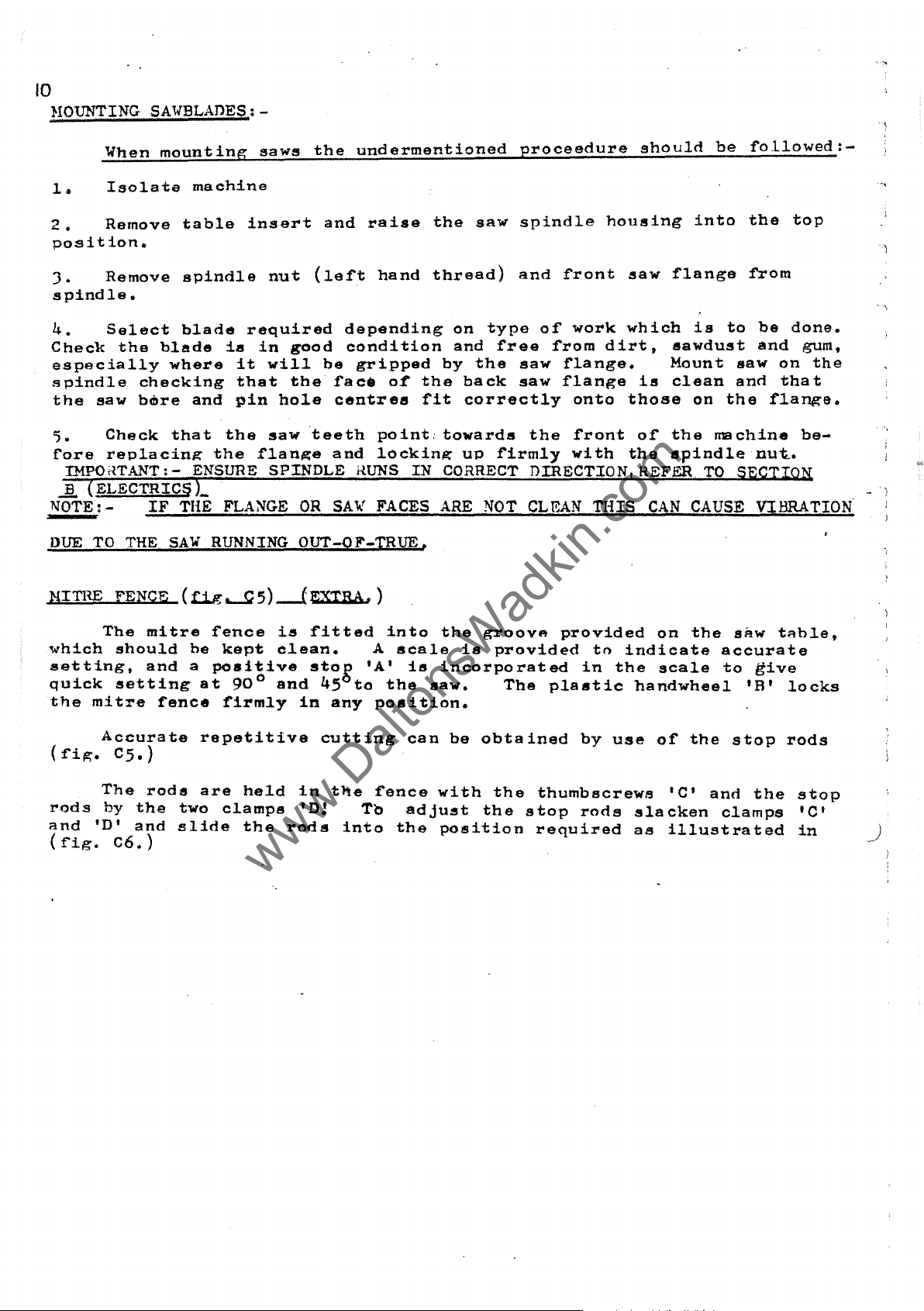

NITHE

Check

replacing

IMPOrtTANT:-

(ELECTRICS

TO

THE

FENCE

mounting

machine

table

spindle

blade

blade

where

checking

bmre

and

that

ENSURE

L

IF

THE FLANGE

SAW

(llg......Q

saws

insert

nut

required

is

in

it

will

that

pin

hole

the

saw

the

flange

SPINDLE

RUNNING

5)

-f

the

undermentioned

and

raise

(left

hand

depending

good

the

condition

be

gripped

face

o£

centres

teeth

OR

OUT-OF-TRUE.

EXTRA, )

and

HUNS

SAW

point:

locking

FACES ARE

the

thread)

by

the

fit

towards

IN

CORRECT

saw

on

type

and

free

the

back

correctly

UP

firmly

NOT

proceedure

spindle

and

front

of

work

from

saw

flange.

saw

flange

onto

the

front

with

DIRECTION,REFER

CLEAN

THIS

should

housing

saw

which

dirt,

is

those

of

the

CAN

be

fol1owed:-

into

flange

is

sawdust

Mount

clean

on

the

spindle

CAUSE VIBRATION

the

from

to

saw

and

the

me

chine

TO

S~CTIQ~

top

be

done.

and

on

that

flange.

be-

nu~.

gum.

-,

the

- I

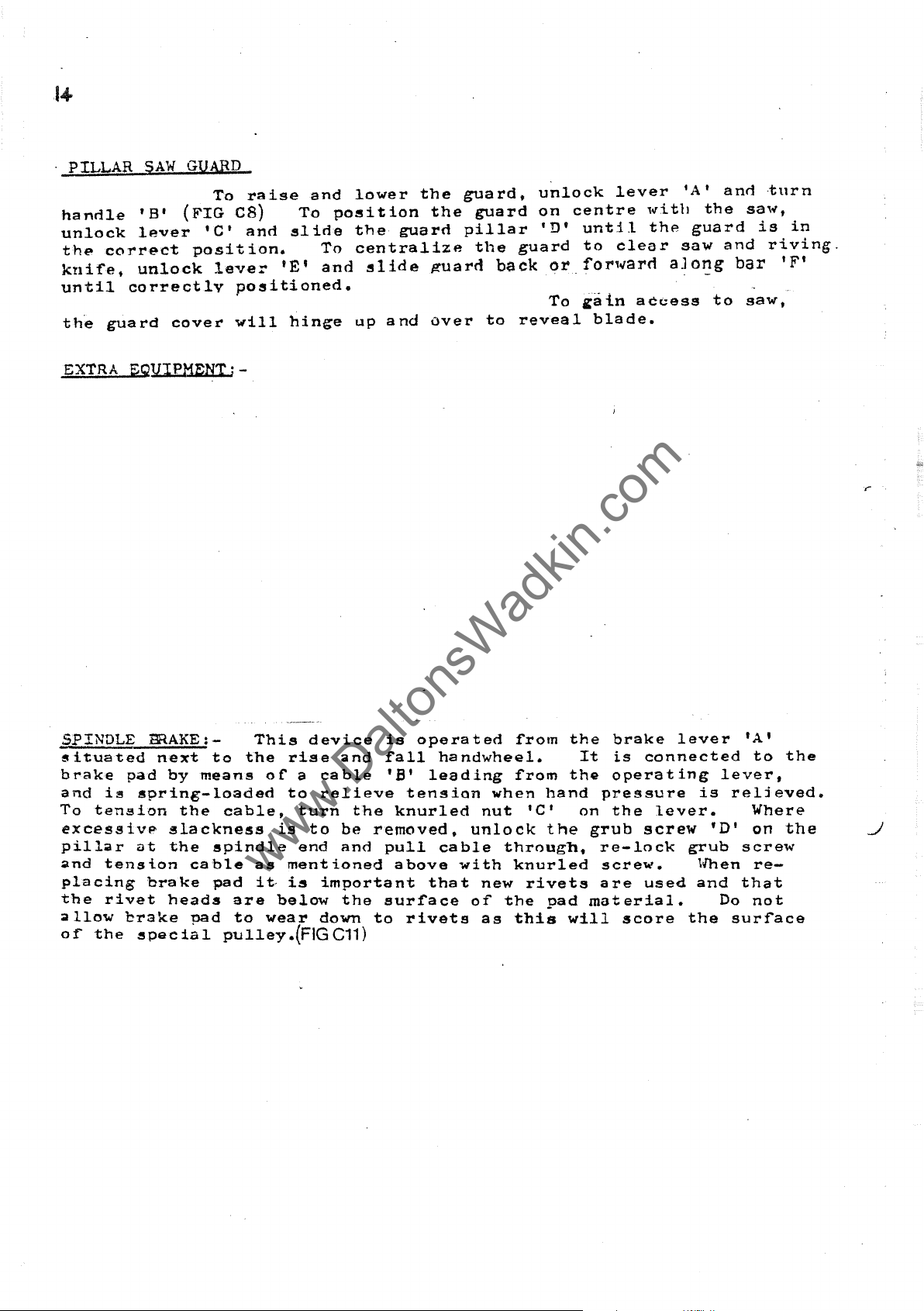

which

setting,

quick

the

mitre

(:fig.

rods

and

'D'

(:fig.

The

mitre

should

and

setting

fence

Accurate

CS.)

The

rods

by

the

and

C6.)

fence

he

kept

a

positive

at

repetitive

are

two

slide

900 and

firmly

held

clamps

the

is

fitted

clean.

stog

in

in

'D!

rods

'A'

45

to

any

cutting

the

Tb

into

into

A

scale

is

the

saw.

position.

can

:fence

adjust

the

the

grOOVA

is

provided

incorporated

The

be

obtained

with

the

the

stop

position

provided

to

indicate

in

the

p1sstic

by

use

thumbscrews

rods

required

on

the

scale

handwhee1

of

the

'C'

and

slacken

as

illustrated

saw

accurate

to

give

'B'

stop

the

clamps

t~blet

locks

rods

stop

'Cl

in

)

FfGCS

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

11

MITRE

SlOT

12

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SAW

PACKING.

It

it

is

out-of-true

and

gap

packing

consequent

The

wood

retains

the

felt

strips

OPPOSITE.

be

amount

duces

at

mouthpiece

underside

in

It

renewed.

Tbe

every

is

usual

not

intended

plate

must

loss

arrangement

the

position.

close

)

should

provision

of

lubricating

heat_and

opportunity,

saws.

is

not

felt

of'

the

and

burning

to

to

be

of

of

packing

the

saw

be

noted

should

provide

that

The

steady

tight

tension

of

a

length

table

At

the

gap

not

of

the

oil,

whilst

the

this

idea

as

the

pieces

and

that

felt

which

felt

a

saw

packing

of

£itting

the

saw,

this

in

the

saw

packings

extending

in

and

to

rear

be

of

provide

af'ter

allowed

inserts

running.

pieces

blAde

will

blade.

place.

the

the

some

not

be

but

beyond

front

a

to

allow

only

are

with

used

packing

it

should

generate

are

Also

of

gap

plate

guide

time,

f'al1

cleans

It

is

lubricated.

some

as

in

the

f'or

application

form

a

guide

pieces

he

heat,

such

depth

wood

the

gap

and

the

the

packings

into

bad

the

theref'ore

of

for

into

noted

resulting

a

way

of

strips

pla

table

saw.

condition.

of

saw,

important

packing,

buckled

the

that

that

the

saw

secured

te

support

similar

(SEE

will

a

small

but

also

but

or

table

the

in

a

a

hard-

teeth

to

the

wood

DIAGRANS

need

to

re-

that,

NOTE;-

REPLACE!oLENT

LENGTHS

OF

FELT

12

x

11

x

100

mm

..

J

I

J

I

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

I

I

I

I

I~

L_

Saw

~

FIGC

Saw

13

SECTION

AA

Saw

Felt

--..,

I

H~

~~~======~-+~~-:

I

I

-h-'-tH-t_tt)+.~

I

I

Felt--==F=======Cldtl

I

S.,w

t

I

I

I

I

tt11

. I

~arrl

-

-lnOUthpiece

..

.ood

Screw

SECTION

'\

a~

Saw

SECTla~

" ,

/f

j

UI

I

I

I

I

1+

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

.

PILLAR

handle

unlock

the

kni"fe,

until

the

SAW

'B'

lever

correct

unlock

correctly

guard

GUARD

(FIG

'Cl

position.

cover

To

raise

CS)

and

lever

positioned.

will

To

slide

'E'

hinge

and

poeition

To

and

lower

the

guard

centralize

slide

up

and

the

the

j!'uarrl

over

guard,

guard

pillar

the

back

to

unlock

on

'D'

guard

or

To

reveal

lever

centre

until

to

clear

fOl"l.,arn

~a{n

blade.

,,,itll

the

aJor:g

access

'A'

guard

saw

anrlturn

the

and

bar

to

sa,,,,

is

riving.

saw,

in

'F'

EXTRA

SPINDLE

situated

brake

and

is

To

ten~ion

excessivp

pill~r

..

nd

tens

placing

the

rivet

allow

of"

the

EQVIPMENTi-

BRAKE

pad

spring-loaded

next

by

the

:-

to

means

cable,

slackness

ut

the

spindle

i.on

cable

brake

brake

:!Special

pad

heads

pad

pulley.(FIGC11)

the

are

to

This

0 f a

is

as

it·

below

wear

device

rise

ca

to

relieve

turn

to

end

ment

ie

important

down

and

ble

the

be

and

ioned

the

is

opera

rall

'B'

leading

tension

knurled

removed,

pull

above

that

surrace

to

rivets

ted

"from

handwheel.

rrom

when

nut

unlock

cable

with

new

or

as

through,

knurled

the

thi~

hand

'Cl

the

rivets

oad

the

It

the

pressure

on

grub

re-lock

screw.

are

material.

will

brake

is

opera t ing

the

lever

connected

lever.

screw

grub

used

score

the

lever

is

'D'

'Yhen

and

Do

lA'

to

the

f

reljeved.

Where

on

the

screw

re-

that

not

surlace

15

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

FIG

CB

••

38mm

:-:

Rad

FIGCIO

FIG

Cl

I

-

!-~iilli!~-

~------------560mm----------~

B

Rad

38mm

",/

Size of

to suit'sefand

position

saw unit.

cut-out

of

wobble

\

\

16

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

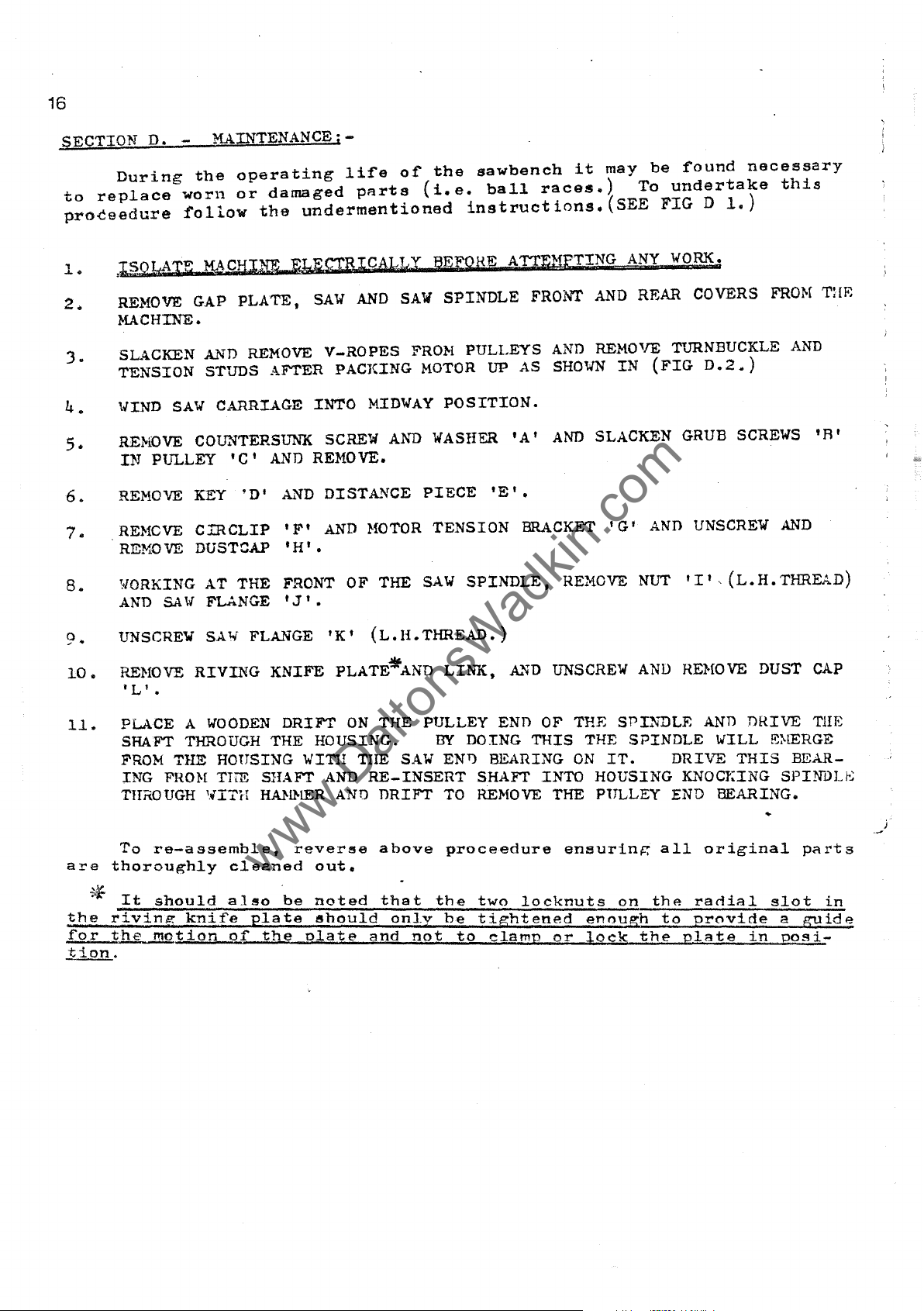

SECTION

During

to

replace

proceedure

1.

2.

,I,§QMIE

REMOVE GAP

MACHINE.

J.

4.

5.

6.

7.

8.

SLACKEN

TENSION

'/IND

REI-lOVE

IN

REMOVE

REHCVE

REMOVE

WORKING

AND

D.

-

MAINTENANCEj-

the

operating

worn

or

follow

MA

CHINE_EJ~IEcrRl.CALLX

AND

STUDS AFTER

SAW

CARRIAGE

COUNTERSUNK SCREW

PULLEY

SA

'C'

KEY

CIRCLIP

DUSTCAP

AT

THE

W FLANGE I J I •

damaged

the

PLATE,

REMOVE

AND

'D'

~~D

'Ft

'H'.

FRONT

life

of

pArts

undermentioned

SAW

AND

SAW

V-ROPES

PACKING

INTO

REMOVE.

DIST~~CE

AND

OF

FROM

MIDWAY

AND

}fOTOR

THE

the

sawbench

(i.

e.

ball

races.)

instructions.

BEFQHE A TTlillW

SPINDLE

PULLEYS

MOTOR

POSITION.

WASHER

PIECE

TENSION

SAW

SP1NDLE.

FRONI'

UP

AS

'A'

'E'.

BRACKET I G I

it

may

be

found

To

undertake

(SEE

NG

AND

AND

REMOVE TURNBUCKLE AND

SHOWN

AND

SLACKEN GRUB SCREWS

REMOVE NUT

FIG D 1.)

ANY

WORK",;

REAR COVERS

IN

(FIG

AND

0.2

UNSCREW

III,(L.H.THREAD)

necessary

this

FROt-{

..

)

AND

Tal':

'R

t

10.

11.

are

'*

the

for

tion.

UNSCREW

RENOVE

'L'

.

PLACE A

SHAFT THROUGH

FROM

ING

THROUGH

To

re-assemble,

SAW

RIVING

WOOD&~

THE HOUSING

FHO:t-[

THE

'HTH

thoroughly

It

should

rivin~

the

motion

also

knife

of'

FLANGE

KNIFE

DRIFT

THE

SHAFT

HANHER AN!)

reverse

cleaned

.

be

plate

the

'Kt

PLATE*AND

ON

HOUSING.

WInl

TIlE

AND

out.

noted

should

elate

(L.B.THREAD.)

LINK,

THE

PULLEY

BY

DOING

SAW

ENT)

RE-INSERT

DRIFT

above

that

on].v

and

TO

proceedure

the

be

not

to

A.~D

UNSCREW

END OF THE

THIS

BEARING

SHAFT

REMOVE

two

INTO

THE PULLEY END

locknuts

tightened

clamp

or

SPINDLE

THE

ON

IT.

HOUSING

ensuring

on

enouLh

lock

AND

REHOVE DUST

SPINDLE

DRIVE

KNOCJ=ING

all

th~

to

the

plate

AND

WILL

THIS

BEARING.

original

radial

provide

CAP

DRIVE

TIlE

~~~RGE

BEAR-

SPINI)Li~

parts

slot

a

gyide

in

posi-

in

-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

o

'--t)

18

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

BELT

saw

maximum

correct

the

tioned

distance

the

of

applying

tion

def'lection.)

REPLACING

buckle

,,.,arde

POINTS

TENSION:-

On

spindle

"running

proceedure.

By

belts.

the

~ulley3

is

To

and

retension

TO

the

standarn

is

by

means

e~ficiency

belt

tension

in"

turning

of

a

force

not

BELTS,.:-

replace

thus

NOTE

turnbuckle

the

pulleys

To

achieve

(FIG

greater

belts,

relieving

as

WHEN

at

machine

of

and

life.of

is

maintained

period.

(SEE

given

HAINTAINING BELT

D3.)

right

than

FIG.

can

the

and

0-5mm

decrease

above.

the

three

~n~Jes

To

D.2.)

'A'

be

correct

adjust

ALPHA

these

linking

increased

per25mrrrof

tension

drive

tension

ar.~

pulley

at

tension,

with

on

the

DRIVES:-

from

500

type

belts,

all

the

the

to

the

central

centre

belts

the

it

times

belts

tension

provide

measure

turnbuckle

Along

span

5.

SHP

"V"

Belts.

is

important

~rom

follow

-

(e.g.584·

distance

for

their

motor

new,

studs,

greater

the

the

especially

the

the

centre

until,

belt,

span:::

by

screwing

removal.

(4KW')

To

ensure

that

undermen-

centre

tension

whilst

the

to

the

the

in

on

distance

deflec-

Tl-5mm

turn-

After-

1.

.2.

J.

4.

5.

6.

ALWAYS

REPLACE

ALl-lAYS

ENSURE

DO

IMPLEM~NTS

ENsrJ!1E PULLEY

RUST

NOT

OR

MAINTAIN

WOHN

REPLACE

pm

.LEYS

PRISE

AS

BURRS

CORRECT

m'::LTS

WORN

ARE

BELTS

THIS

GROOV'ES

'mIcn

WITH

OR

CO

RH.ECTL

OVER

CAN

AND

ARE

BELT TENSION •

SAME

D.\J.tAGED

PULLEYS lfITH SCREli DRIVERS

DAMAGE

PRESENT.

TYPE AS

BELTS DtMEDIATELY.

Y ALIG!\ED.

BELTS.

BELTS

ARE

SPECIFIED.

CLEAN

AND

RE}10VE

OR

OTHER

k"fY

OIL,

SHARP

GREASE

j

u---+--t---A

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

19

Method

motbr

tension screws

outlined in section

of

packing up

for remcNal of

as

D1

I

FIG

FIG

DEElnECTION

__

O·5rnm

OF

PE R 25

SPAN

mm

D2

D3

__

.

20

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SA~

MAINTENANCE:-

Effici8nt op6rat1on of a

the

say

of

the

spindle.

to

ensure

BANGING;-

'Ranging

fourth

sive

whilst

teeth

SAW

in

square

equal

gu11At

rounded.

~ve18

their

original

machine.

or

block

running.

riled

SRARPENING:-

Do

a

vice

faces

number

of

as

original

spindle,

straight

down'

rifth

in a wooden

lightly

not

run

as

shown

are

of

the

saw

With

in

{FIG.

profile,

and

sharpening.

a

required

strokes

crosI!

the

The

cutting.

should

The

to

saw

in

in

the

D7.)

shape

it

and

is

saw

saw

must

be

holder

eaw

should

remove

when

(FIG

with

same

cut

saws

In

the

necessary

flanges

done

blunt.

D5.)

(FIG

a

the

gullets

circular

being

also

To

(FIG

the

D6.)

flat

manner,

points

run

on a new

range

04.)

then

ranging

To

With

file.

course

become

to

grind

saw

depends

perfectly

at

the

saw

down,

lightly

be

removed

marks.

re-sharpen

rip

saw

Sharpen

taking

are

needed

01

repeated

the

correct

or

feed

against

and

teeth,

hy

giving

At

the

care

with

shallow.

ssw

on

true

square

any

Baw

a

square-edged

the

by

hand,

chisel

same

to

keep

back

filing,

To

on a saw-sharpening.

running

to

peripheral

after

the

saw

tops

holo

edges

each

time,

tooth

the

and

saws

restore

the

the

teeth

of

the

file

gullet

front

of

axis

speed

abra-

the

saw

and

an

the

well

lose

the

SETTING:-

The

body

set I (Le.)

in

side

a

seen

being

in

indicetes

that

&

so

(FIG

or

piece

in

cut,

We

(FIG

For

the

D12.)

amount

there

D8)

else

er

timber

(FIG.

but

can

DlO)

the

hand

nnmber

32

ml1l Bore

is

the

teeth

For

the

D9)

is

supply

This

amount

setting,

or

01

set

~reedom

are

good

saw

will

where

The

uaua1ly,

a

small

device

o~

saws

should

from

bent

sawing.

run

the

aMount

machine

will

set

small

used

be

sufficient

~riction.

alternately

this

to

one

result

by

devices

does

should

of

SAt.

for

accept

micrometer

not

amount

side.

varies

.3mm-.4mm.

precisely

saws

can

warrant

to

give

Saw

teeth

to

the

or

set

To

check

be a small,

according

up

to

dial.

be

supplied

a

machine

clearance

are

right

should

setting

36"

where

generally

or

the

even

to

in

diameter,

(SgE

left

be

equal

set,

triangle,

the

saws

it

to

the

'spring

as·

at

cut

timber

as

shown

and

is

felt

FIGs.Dl1

saw

shown

each

into

as

STANDARD SAW AND

PIN

HOLE

CENTRES

r

I

-.:s

-5

CNT

mm

-----

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-_._----

21

FIG

FIGD6

Area of tooth

~.

FIG

D4

__

-----------

Clearance

angle15°

,br.,

:aw ' cu:net

set-over

shown shaded ---....... ..

<:it:

08

Top

a gle10

RIP

SAW

4~

bevel

0

saw

FIGD7

FIG

09

Clearance

angle

43°

CROSSCUT

SAW

FIG

FIG

DIO

IG

011

Dl2

10

15

",.

20

FIG DI3

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

LUBRICATION

A - Oil and clean weekly.

DIAGRAM

~

_---r-

-~

- i

/)/

~J

4~_~

. I

\

/),

U/"

-'--

/ "

\ J

"'~-.

I

t--

\

I

~.."

'\-t-

L\.,,@

\

\

-=-=

".,

'}

\J::I

B-Oil

C-"THRUST

D-Grease-two

weekly'

each

end

r

DLJst

Outlet

230x1l5.

RACE:'

shots

per

year.

oil weekly.

A

A

" "'-D

.......

Lt

'"

.,/

~

\-..

300.

23

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

.--

S

SPARE

eTION

PARTS

11

LISTS

11

E

24

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

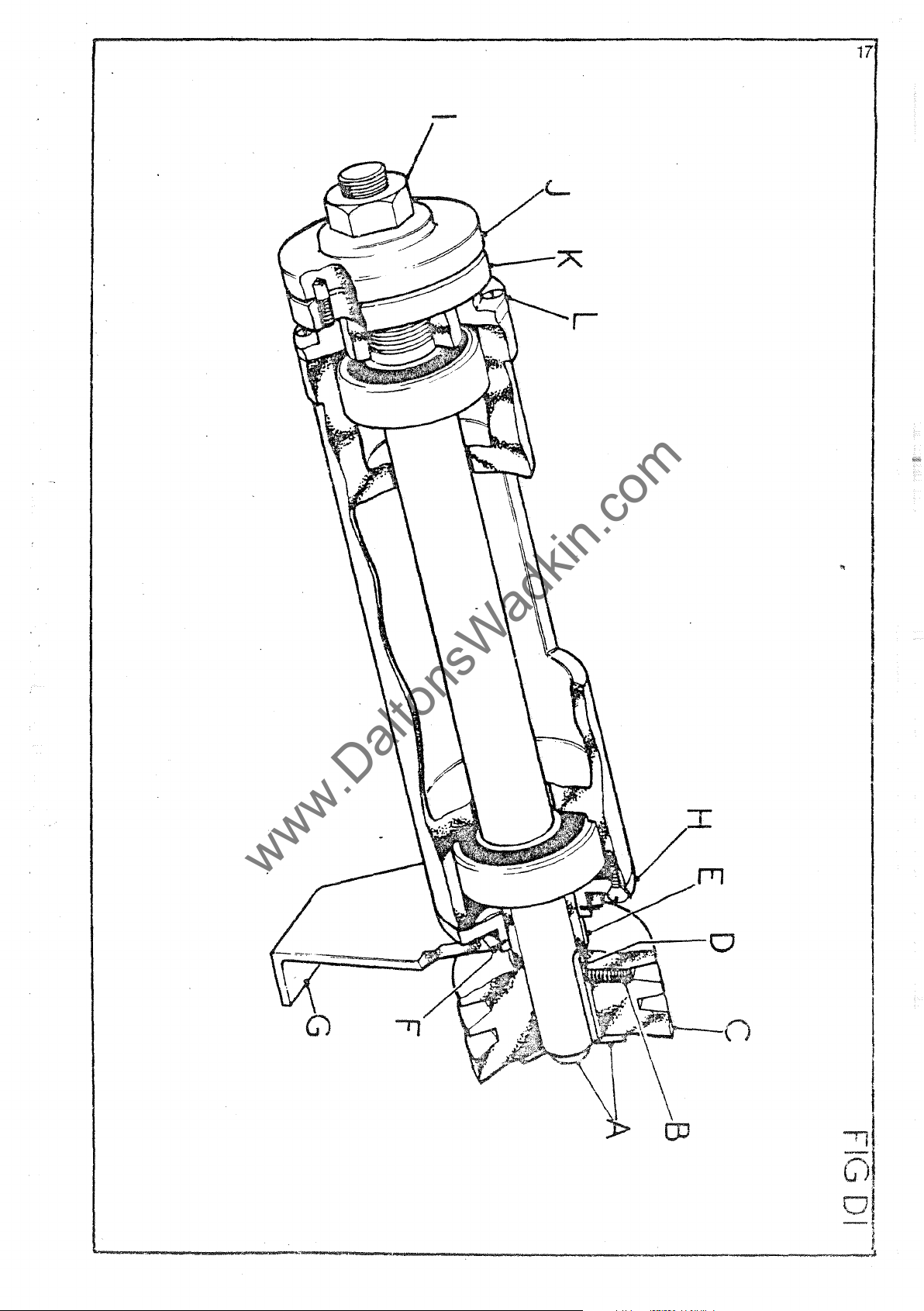

REF.

NO-:-

1

2

3

4

5

6

7

(8

(

9

10

11

12

13

14

15

16

17

20

21

22

23

25

26

27

28

29

30

PART

NO.

BSW

BSW

BSW

BSX

BSW

BSW

BSW

PLEASE

BZG

MAIN

NO.

OFF

1

2

3

12

11

137

27

STATE

70

VOLTAGE,

BASE

1

1

1

2

1

1

1

PF..ASE & FREQUENCY

1

2

2

8

4

4

2

2

4

8

2

2

)

2

2

2

1

2

3

2

ASSEMBLY

DESCRIPTION

BASE

HAIN

TABLE

GAP

SPINDLE

BASE

FRONT

BASE

BROOK

WADKIN

REAR

FRONT

No.IQ

M12 x

1 2

10

M8 x 15

MIO x 35

MIO x 25

M6 x ]0

6

SPRING

M6

WING

I

()

M8 x 15

1/8"

2BA x

DRlVEPINS

(STANDARD)

PLATE

FEET

COVER

COVER

RT

BURSGREEN

WOOD

WOOD

WOODSCREWS

30

mm

WASHERS

mm

DIA

mm

WASHERS

GUARD

NUTS

NUT

mm

EXTER..l\lAL

DIA

20

PULLEY

3 STARTERl

SAW P ACKINGS

mm

x

mm

mm

mm

mm

mm

BRASS

mm

COVER

SA\{ P ACKINGS

LONG

25

mm

LONG

ROUND

LONG

LONG

LONG

HEXAGON

CLIP

CIRCLIP

LONG

ROUND

RIVETS

LONG

1

N.M1EPLATE

HEXAGON

LONG

DOWELS

HEAD

SCRE~-1S

HEXAGON

HEAD

SCRE1TS

BOLTS

SCREw"S

BOLTS

BOLTS

SCREWS

"mEN

ORDERING

SP

A.1lli

PARTS

PLEASE

QUOTE P ,,\RT

N1JM:BER

k'l:D

SERIAL

NlJMBER

OF

HACHINE

4

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

\7

6

\

5

26

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

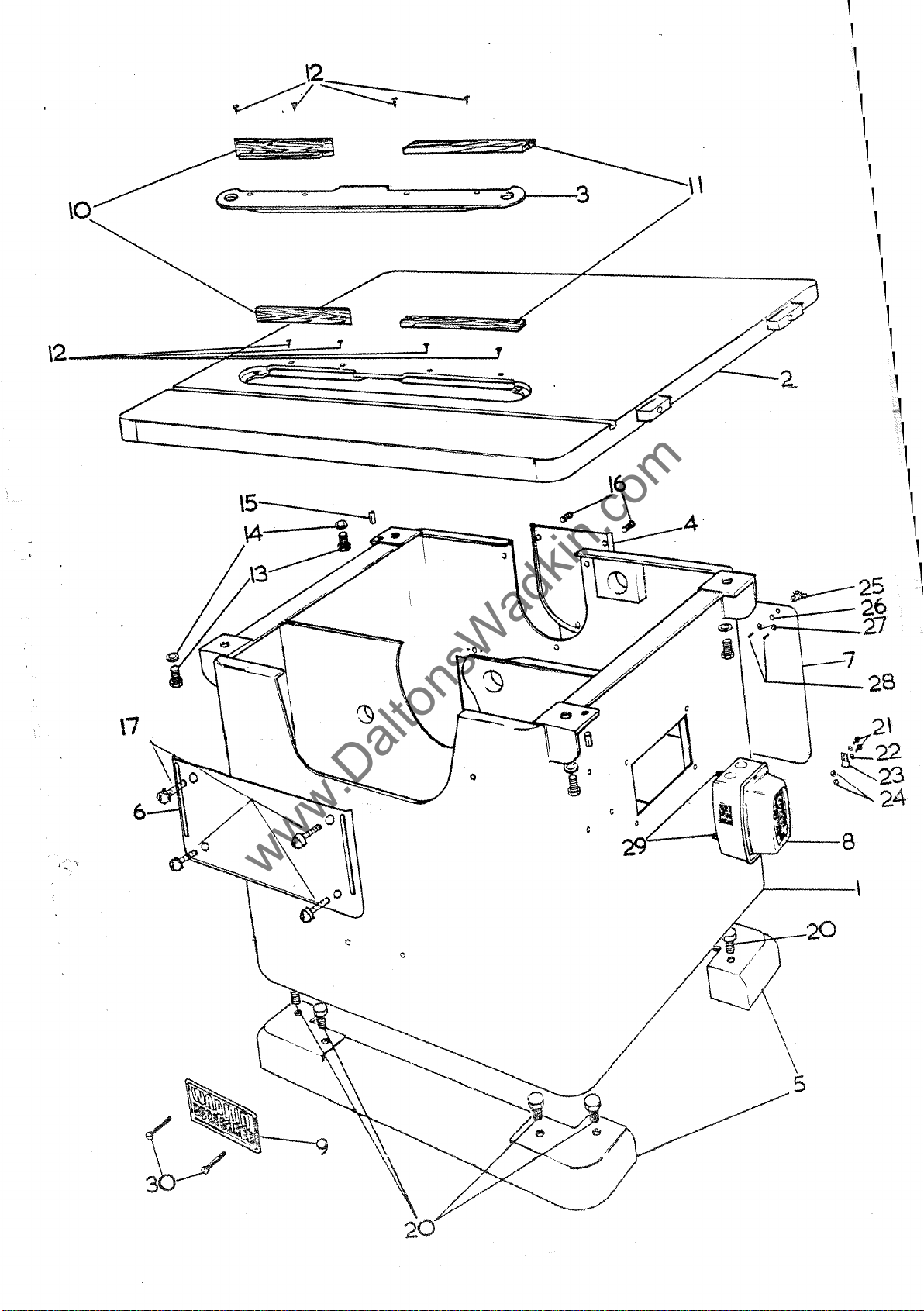

REF

NO.

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

c;-

-

-'-

56

57

58

59

60

61

SAW

PART

NO.

BSW

25

BSW

80

BSW

24

BSW

5

BSS

57

BSW

519

BS"W

761

BSW

21

lA

BSW

61

lA

BSW

40 1

SPINDLE

NO.

OFF

I

I

1

1

1

1

2

1

2

1

2

1

1

1

1

1

I

1

1

1

2

DESCRIPTION

M32

FRONT

SAW

REAR

HOUSING

H6

M6

M6 x 92

SKF

REAR

M6 x 18

MOTOR

62

PULLEY

SPINDLE

M6

M6 x 30

M12 x 25

SPINDLE

10

KEY

SPINDLE

KINGFISHER

ASSEMBLY

FORM

L.H.

NUT

SAW

FLANGE

DRIVING

S.,l\.W

x:

88

LOCKNUTS

6308

HOUSllTG

TE~SION

rrnn

EXTERNAL

x:

25

rrnn

SQUARE

PEG

FL.AJ.'~GE

FRONT

rrnn

rrnn

rrnn

DISTANCE

PULLEY

rrnn

ID.!ll

rrnn

PULLEY

DUSTCAP

LONG

SINGLE

COUNTERSUNK

LONG

LONG

NO.2

STUD

STun

Rmol

DUSTCAP

BRACKET

CIRCLIP

PIECE

ALLEN

ALLEN

COUNTERSUNK

i.J'ASHERS

x

4n

rrnn

GREASE

BEARllTGS

SCREWS

GRUB

GRUB

'SELF

LONG

SINGLE

CUPS

SCREW

SCREW

LOK'

ROv~~

F1ITD

NOTE:

wOEN

PART

NO.

ORDERING

BSW

SPARE

519 IS

PARTS

ALSO

USED

PLEASE

ON

QUOTE

RISE

PART

AND

FALL

NUMBER

UNIT

AND

(SEE

SERIAL

PAGE

NUMBER

29,

PART

OF

MACHINE.

NO.

92)

42

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

43

---------------------------------------------

44 45 46 49

ET<'\

mIPillDmUIIlllJmmmmIDllJl)JDl)J

o

',:::':;';<>'

'j

,

...

~Ullml!!lmnlllilllrlllmmmll!l)

6~

47 46

@

:

@/J

59

6/

::.J-SI

B

,

CC

60

-----7.,..-

.:

;

,,-\

SAW

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

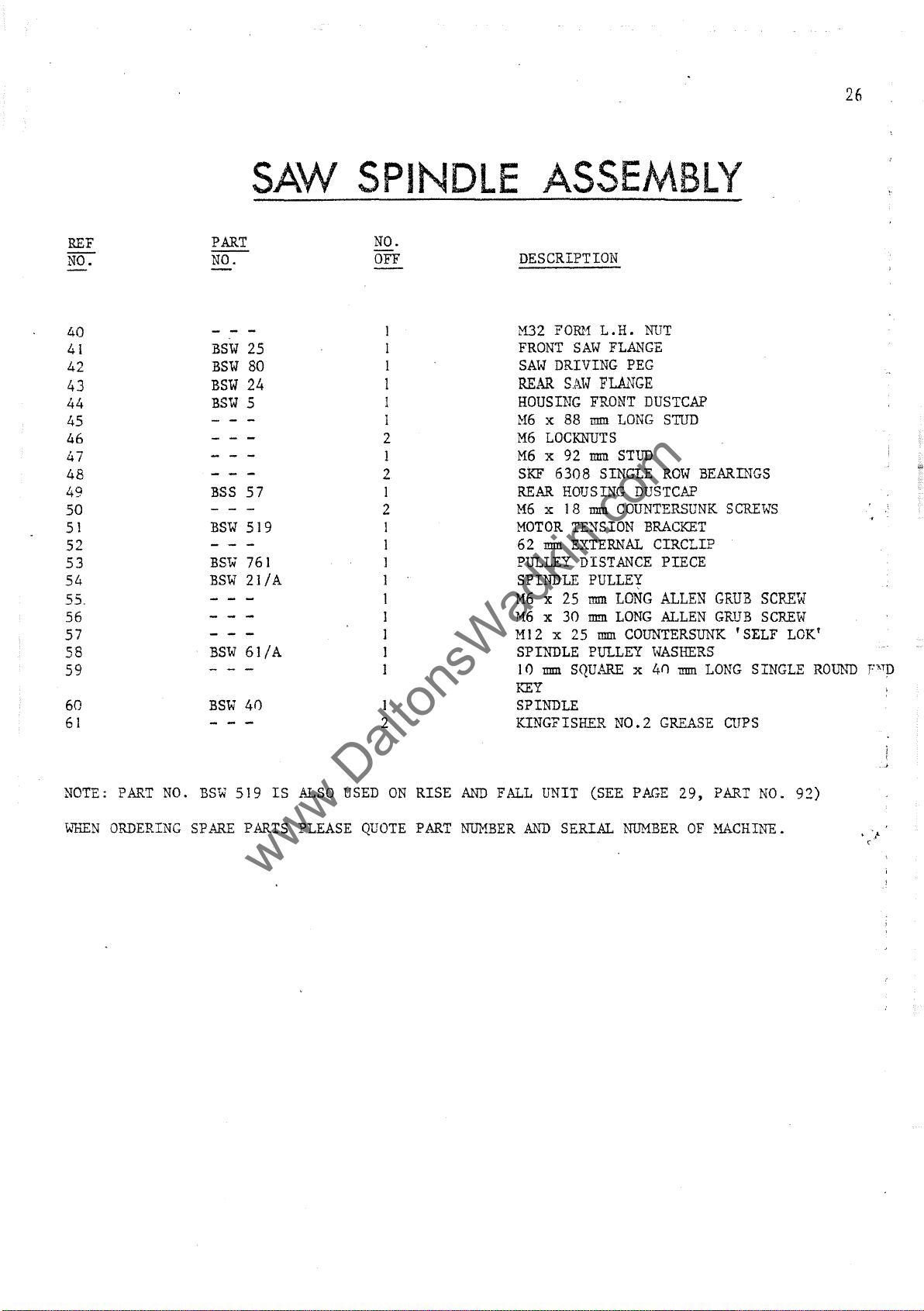

RISE

&

FALL

ASSEMBLY

86

87

a8

89

90

91

92

93

94

95

96

91

98

99

100

101

102

103

104

105

106

107

108

109

110

11

112

: 13

ll~

!

15

i 16

117

lIB

119

120

121

122

;23

124

125

126

127

122

130

131

i32

!3~

!34

:35

136

Di

138

77

78

79

80

81

82

83

84

85

t

70

73

74

75

76

BSW

S

6698/A

asw

5296/3

BS""

BS""

SSW

asw

SKF

BSW

BSt;!

SS""

BSW

SS::

S$''/ 36

5SW

BSW

BS'W'

SSW

SS""

BSW'

SSW

BSW

asw

asw

ALPHA

SSW

BSW

BSW

SS"

BS

..

SSW

aSW)O

BS"

BS" 53

BS~

5S;; J

BSi!

:0

BSW

39

125/

37

34

0.6

46

33

519

32

Ill/A

43

7/A

7

134

42

31

124

142

147

135

4

SO

51

49(A

41

29/A

54

38

8/A

9

10

35

19

500

I

4

A

9

1

1

4

2

2

3

2

1

J

3

I

1

2

1

1

1

1

1

2

2

2

2

4

3

6

2

2

2

I

J

1

2

2

3

4

I

I

2

3

225

mm

DrA Attr.nNIUM !USE

'HO x 35

10

ElANDWIl'.EIL

1 0 """

RISE A

40

RISE

LOo:::mG

12

RL"E

RISE

M6

5

mm

ntRUST

ntRUST

RISE

20

HOTOR

M6 x 20

XOTOR

62 = L{

M8 x

SAW

XOTOIt

J 6

RISE

MOTOR

M]O x 35

MOTOR

MOTOR

MOTOR

!{8

:,

MI0

] 2

mm

LONG

mm

WASHERS

SP

INDLE

BORE

x 80

..

'\'D

FALL

J!ll!J

x

MJ 0 BORE

AND

FALL

LINK

mm

EXTERNAL CIRCLIPS

A.'ID

FALL

AND

FALL

x 6

mm

LONG

DU x 30

RACE

RACE

SHROUD

AND

FALL

mm

VD

le 22

5aAFT

KEY

mm

LONG

RISE

!!ll.11

NUTS

30

AND

lOam

TENSION

PULlEf

DU

PIVOT

PIVOT

PIVOT

PIVOT

IlASI!:EllS

•

.:.R..'<AL

mm

LONG

AND

n:nR.'.iJ..

;;

ALL

l1M

GRUB

BRACKET

FALL

7.5

LOCK

SHAFT

StuDS

BLOCKS

BLOCKS

SHA.."T

HEUGCN

MM

B1U.RING

LOCK.

f..nCK

SCREW

GRUH

mm

LOt;'G

SCRnT PIVOT

mm

(7. 5 HP

COfJN'!ERSIDl1C

crr-CLIP

GRUB

liP

SCREW

M12 x 25 ~ HEXAGON

MI0

le

12

mm

DOG

SPINDLE

RISE

M20

RISE

M12

M 1 2

MOTOR

MCTOX

1'ZNS

'SFACESAVER'

SAl.'

SUP?OR'!

SUPPOR:"

SUPPORT

SPINDLE

RIVING KNIFE SUPPOR':

4 = THICK

M6

R..:.--VING

ltIVING KNIFE

!flO

Ml6

RISE

SPL'IDLE

16 ~ I;ASHER

16

LOCK.!!IG

L:~l:K

7.5

AND

LEn

AND

LEFT

LOCK:NtJ'!S

TENSION

n~SION

ION

SPINDLE

x

12

KNIFE

le 45 =

LOClQIUTS

A.'m

:mn

S?ECIAL

LL'IK

? 1

VO:'

HP

lS.5

HOUSING

:"UT

PLATE

PLArE

PLATE

HOUSING

mm

FALL

HOUSING

PaTh'"!'

PIVOT

FALL

SCReW

!UND

TE:REA!l

'!!

ALL

Scru:-w

RAND

TIll'-1':AD

SCP.EW

SCREe

vu:

ROPES

ROUSING

tTh1<

LnlK

LINK

PIVOT

STMtiiARD

LONG

GRUB

EOLDER

HOLDER

COACH

LOCK

L~nc

S-;"OT:tJ) ;;'ASi1ER

~:UT

S:::WD

i(';lL

D1J2S

..

BOLTS

Alm

BOLTS

PLASTIC

PLASTIC

HANDLE:

LINK.

COLLARS

SCREWS

OiD x

SCREW

CIRCLIP

LINK

CC!.LAR5

BOLtS

:m'!

LOCK

LOCK

tOcnroTS

PIN

pm

PLAn:

R..:.--VL'fG

SCREWS

PAo:::mG l'!:ECE

COLLAR

FRA..'iE

P.A!TDLE

BRACKET

BAll

stIA.:'"'1'

PINS

GROOVELOC:r

22

U1

n:m

SCl'.EYS

GRUB

SCR..."1oIS

SRAFT

COLL.l.RS

NUT

COLLAR

(KNURUDl

SHAFT

KNITE

FALL

DOWELS

IllIII

LONG

x 8

=1

SCRl!:101S

!1.A.lDLE

OTL:I:'!E

28

BUSH

, r

, ,

\25

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

~

1

1

1

1

1

1

1

1

30

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

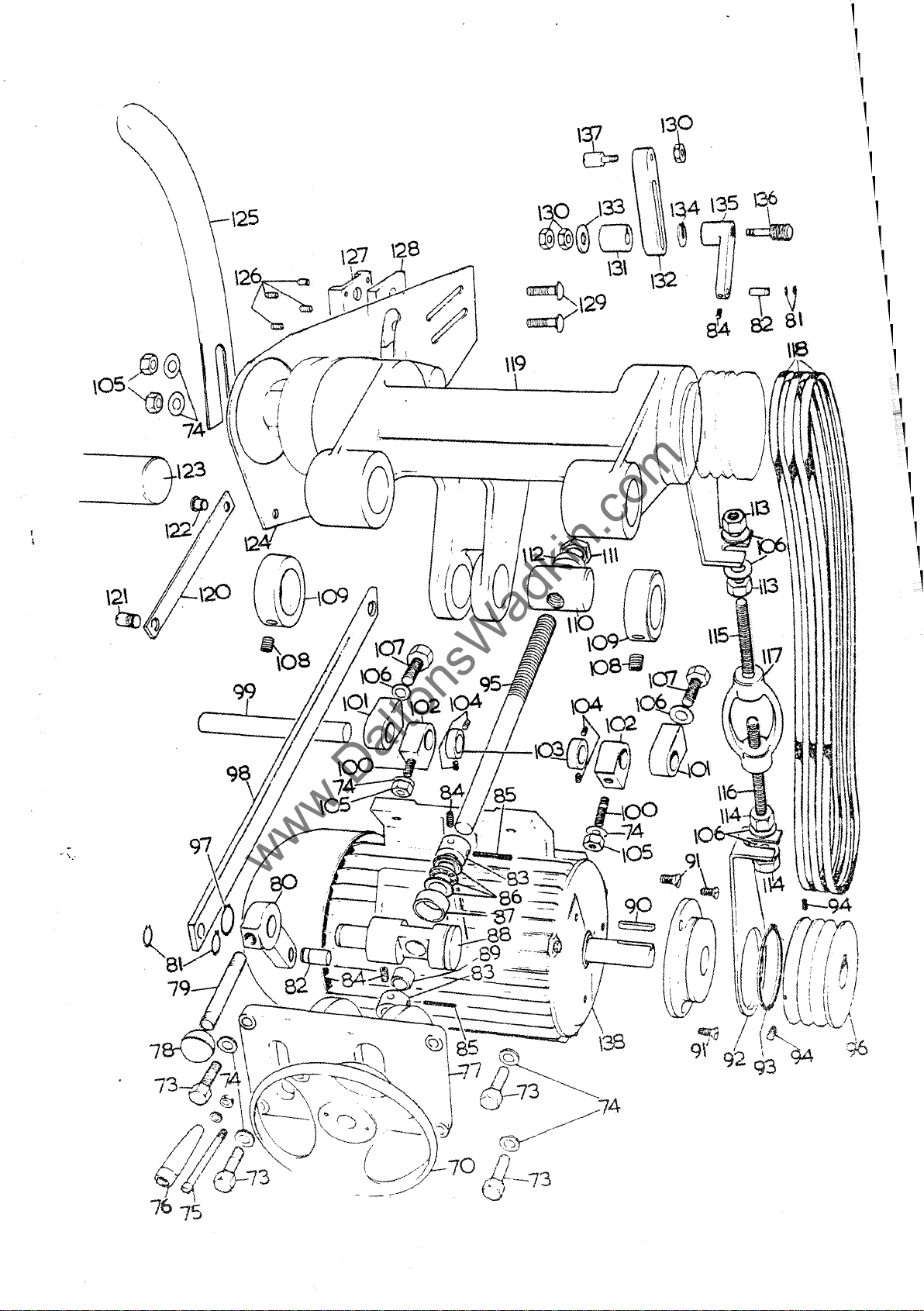

CANTING

REF

NO.

160

161

162

163

164

165

166

167

168

169

170

171 1 M8 x 12

PART

Ne:"""

BSW

15

BSW

8

BSW

14

BSW

83

BSW

66

BSW

65 I

172

173

174

175

176

BSW

BSW

16

17

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

BSW

57/A

BSW

r23

BSW

58

BSW

526

BSW

63

BSW

57

BSW

12

BSW

56

BSW

139 1

NO.

OFF

1

3

1

1

1

1

1

1

3

1

I

1

1

1

1

1

1

1

1

1

2

fENCE

DESCRIPTION

FRONT

'116

x 6

DOVETAil.

BACK

FENCE

M6

x J n

1 2

mm

MJ

2

LEVER

TURNOVER

MIO

LOCKNUTS

FENCE

FENCE

M8

LOCKNUT

FENCE

10

:mm

FENCE

MI6

LEVER.

M6

x 6

BRASS

MJ2 x 50

mm

] 6

FINE

ADJUSTMENT

THlJ}fB

FINE

ADJUSTMENT

FINE

ADJUSTMENT

BRASS

12

mm

M12

LEVER

TURNOVER

Rt"LE

POINTER

METRIC

MJ

0 x

ASSEMBLY

FENCE

mm

WASHER

PIVOT

PIVOT

CANTING

EXTER..,,{AL

LINK PIVOT

mm

LOCKING

EXTER.1IiAL

SCREiv

LOCKING

WASHER

RlJLE

30

PLATE

CHEESE

BOLT

PLATE

mm

GRUB.

SCREW

LOCK

HANDLE

Br~~CKET

SCREW

SCREW

mm

GRUB

SCREW

LINK

ClRCLIP

LOCK

HANDLE

GRUB

SCREW

PAD

mm

STUD

CIRCLlP

SCREW

BRACKET

SCRE1<l

PAD

LOCK

HANDLE

BRACKET

BAR

mm

ALLEN

SCREWS

HEAD

SCREW

(ECCENTRIC).

(TRlJ"E)

PIN

COLLAR

SCR-VWS

,

WHEN

DRDERING

SPARE

PARTS

PLEASE

QUOTE

PART

NUMB.ER

AND

SERIAL

NlJMBER

OF

THE

}~CHINE

160

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

31

191--/

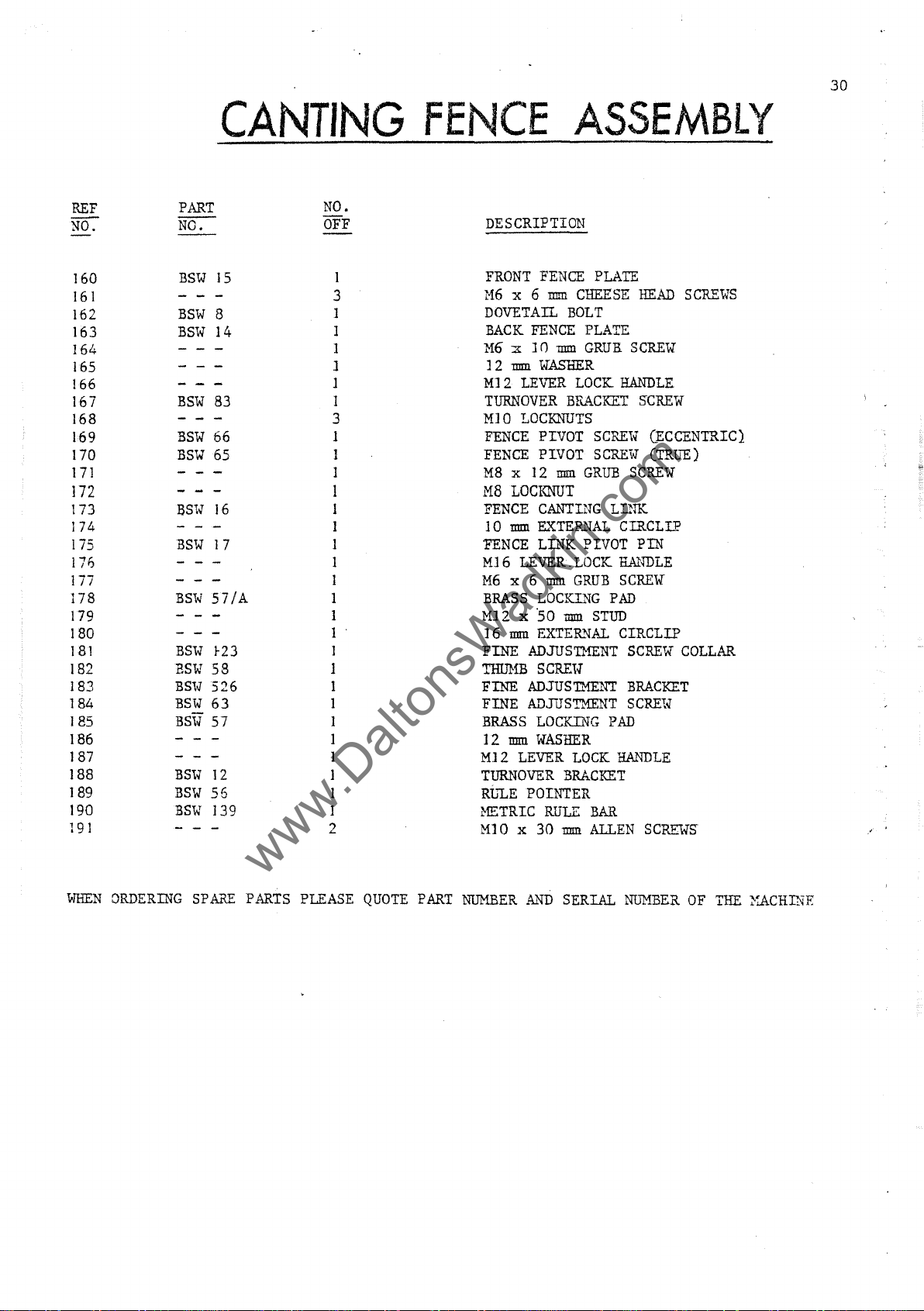

PILLAR

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

GUARD

ASSEMBLY

"

3

"

REF.

ND.

200

201

202

203

204

205

206

207

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

PART

NO:-

BSW

79

STOCK

BSW

57

BSW

73

BSW

72

BSW

71

BSW

12]

BSW

82

BSW

69

BSW

70

S12S/A

6698/A

BSW

77

BSW

76

BSW

68

BSW

75

BSW

67

BSW

7S/A

NO.

OFF

3

J

2

J

1

1

1

]

J

]

1

I

3

3

1

I

1

1

1

1

I

1

1

1

I

1

DESCRIPTION

MIO

LOCKNUTS

] 0

mm

SPRING

1 0

1IIID.

WASEER

SAW

GUARD

MI

()

TEE

LOCK

BRASS

SAW

SA~{

BRACKET

BRACKET

5

6

M8

MS

M] 2 LEVER

LOCKING

SAW

] 2

M12 x 37

5

GUARD

GUARD

PLASTIC

SAW

M12 x 45

SAW

SAW

SAW

M6

SAW

SAW

LOCKING

GUARD

GUARD

mm

x 37

mm

x

50

x ] 2

LOCKNUT

GUARD

mm

WASHERS

mm

x 25

RISE

RISE

GUARD

GUARD

GUARD

GUARD

x 1

()

GUARD

GUARD

FOR

FOR

mm

KEY

mm

GUARD

mm

mm

WASHER

SHAFT

HANDLE

PAD

REAR

COVER

SAW

GUARD

SAW

GUARD

mm

GROOVELOCK

mm

GROOVELOCK

SQUARE

LOCK

H.Mil)LE

RISE

)..Nl)

HEXAGON

mm

GROOVELOCK

k~

FALL

AI.'ID

FALL

RISE

RISE

AND

SQUARE

RISE

AND

RISE

AND

COLUMN

GRUB

BASE

SLTPORT

SCREW

CASTING

ARM

HEAD

FALL

BOLTS

HANDLE

HANDLE

AND

FALL

HEAD

FALL

FALL

(LARGE

DOWEL

DOiJEL

BOLT

CAP

DOWEL

ARM

SPTh'DLE

FALL

SCREW

LOCK

SCREW

BOSS

TABLE}

HKNDLE

COLLAR

BOLT

240

241

242

243

244

245

246

247

243

240

250

251

252

2.5

254

'55

256

257

258

259

MITRE

A-I026/220

A-I026/226

ETS

30

5103-25

Z4 2

A-I026/227

A-1026/174

D-I026/219

3

B1026/69

B-I026/69

A-I026/68

A-1026/73

FENCE

2

1

I

I

I

> 2

1

J

2

4

2

2

ASSE/v\BlY

MITRE

MITRE

PLUNGER

PLUNGER

M5

8

PLUNGER

MS

S

MS

H6

MITRE

PIVOT

~fITRE

MITRE

i'fITP~

~6

MITRE

MITRE

H6

FENCE

FENCE

x 1 0

mm

LONG

x

45

mm

IvASHER

x 37

THUMB

FENCE

PDI

FENCE

FENCE

::ENCE T&3LE

\{ING

FENCE

FENCE

x 20 1I!Ill

PLUNGER

LOCATION

SPRING

CIRCLIP

mm

SCREWS

SELF TAPpmG

BRACKET

HM

mm

SCREIV'S

FOR

NUTS

COACH

COVER

DIA

PLASTIC

FOR

MITRE

STT..::J

BODY

HITRE

STOPROD

STOPROD

STOP

STOP

PLATES

HAT::::

BRACKET

PIN

FENCE

FENCE

(CRANKED}

(STRAIGHT)

S7RIP

BOLTS

SCREWS

RAl.'ID1:{HEEL

SPRTI~GS

33

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

221

220

215 216

214~~

2f2---::-2_

/~~\

.

131

_-;-=-·

--

. • G

.'

-..--

~

\'

207

233 0

i

206

217-?

cr---_

\"1\

204

205

222 223

219____

218.

~

~

re

225~

224~U

,

~.

!

.,

~5

9 '

226

~

I

222

2b;~>JJ

202

201

229

200

230

227

228

;

..

246

247-9

245

~!~~

--""'.

248-© i\lto--250

249-D

242~

j.

241

240

~---~-_6:~~~~====~

.

251

232

~

256

257

258

259

255

I

-

_"

231

253;

254

256 258

~-259

257

34

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

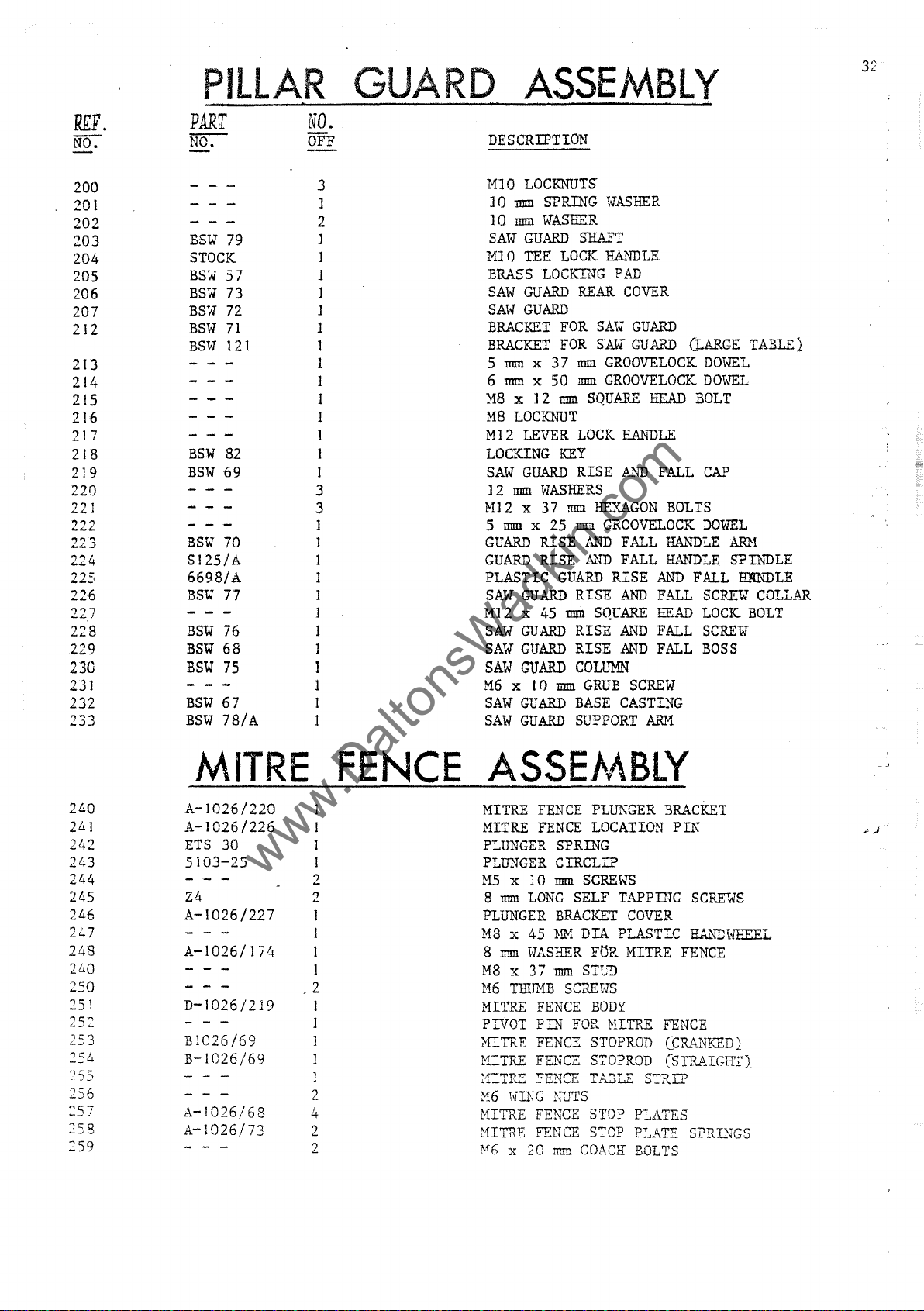

SPINDLE

REF

NO.

290

291

292

293

294

295

<;,296

297

298

299

300

301

302

303

304

305

306

307

308

309 1

310

311

312

J.>-313

PAR:1:

NO.

/ "

:;~f~

ro-;v2l

BSW

131

BSW

148

BSW

145 1

BSW

132

BSW

129

107.PA

BSW

BSW

BSW

7/8

128

125

133

RH

NO.

OFF

1

1

2

]

]

]

1

]

2

2

1

1

1

I

1

1

]

I

"2

BRAKE

PESCRIPTION

20"

BSW

BRAKE

BRAKE POST

MS

LOCKNUTS

]2

mm

WASHER

MJ2

NUT

M6 x ] 0

BRAKE

46

mm

P

AD

M6

MS

MS

22

nnn

BUSH

BRAKE

BRAKE

BRAKE

BRAKE

x

M8

SPECIAL SPINDLE PULLEY

M8 x ] 6

M6 x 50

3

nnn

BRAKE

BRAKE

mm

STOP

BRAKE

ALIGNMENT SPRING

LOCKNUTS

LOCKNUTS

SPECIAL

DID

ARM

PIVOT

LEVER COMPLETE

LEVER

12

mm

mm

mm

DrA

COPPER

LINING

PAD

ASSEMBLY

CABLE

GRUB

SCREW

SCREW

RETURN

WASHER

x

10

PL~

ARM

GRUB

GRUB

COUNTERSUNK

FOR

BACKPLATE

mm

I/D

SCREW

SCREW

RIVETS

20"

SPRING

x ] 2

FOR

SCREW

BSW

mm

LONG

BRAKE

OILITI

WHEN

ORDERING

SPARE

PARTS PLEASE

QUOTE

PART

NUMBER

AND

SERIAL

NUMBER

OF

MACHINE

35

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

29~

291

,-295

296

30

-

304

...

__

----306

1i-307

309

36

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

~SCOMMENCEC

PART

SPINDLE BEARINGS

RISE & FALL

VEE-BELTS

FELT SAW PACKINGS

ELECTRICS

FIXED & MOVING CONTACTS

NO VOLTCOIL

OVERLOAD UNIT

FIXED & MOVING CONTACTS

NO

VOLT

OVERLOAD UNIT

TIMER

SCREW

380L440-3Ph

COIL

THRUST

-50Cy£..

UI6

RACE

SPARE

aTY

2

1

3

2

1

Set

-1

1

3 Sets

1

1

1

s.K.F.6308

ALPHA

1 2 x

BROOK RT3 STARTER

I I

I •

BROOK

I I

I I

11

11

11

PARTS

REF

0-6

500

x lOOm m

I • I •

• I

RY-D.

• I

I1

11

,

• I

STARTER

• I

..

It

..

STANDARD

20·(500mm) DIAMETER ALLOY CROSSCUT

BC21

BC20

,

BC22

BC

123

SAW.

20<

ALLOY

2d(

500mm)

RIP SAW.

20"(500mm) DIAMETER TUNGSTEN CARBIDE

TIPPED RIP

-

500mm)

RIP

STOCK

DIAMETER GENERAL PURPOSE

SAW.

DIAMETER CHROME PLATED

SAW.

SAWS.

_J

OTHER TYPES OF SAWS

OF WHICH CAN

BE

FOR

CUTTING PLASTICS & PLYWOOD ARE AVAILABLE DETAILS

APPLIED FOR OR BE SEEN

IN

THE

waaKin

SMALL TOOLS

,

CATALOGUE.

Loading...

Loading...