o

c

[

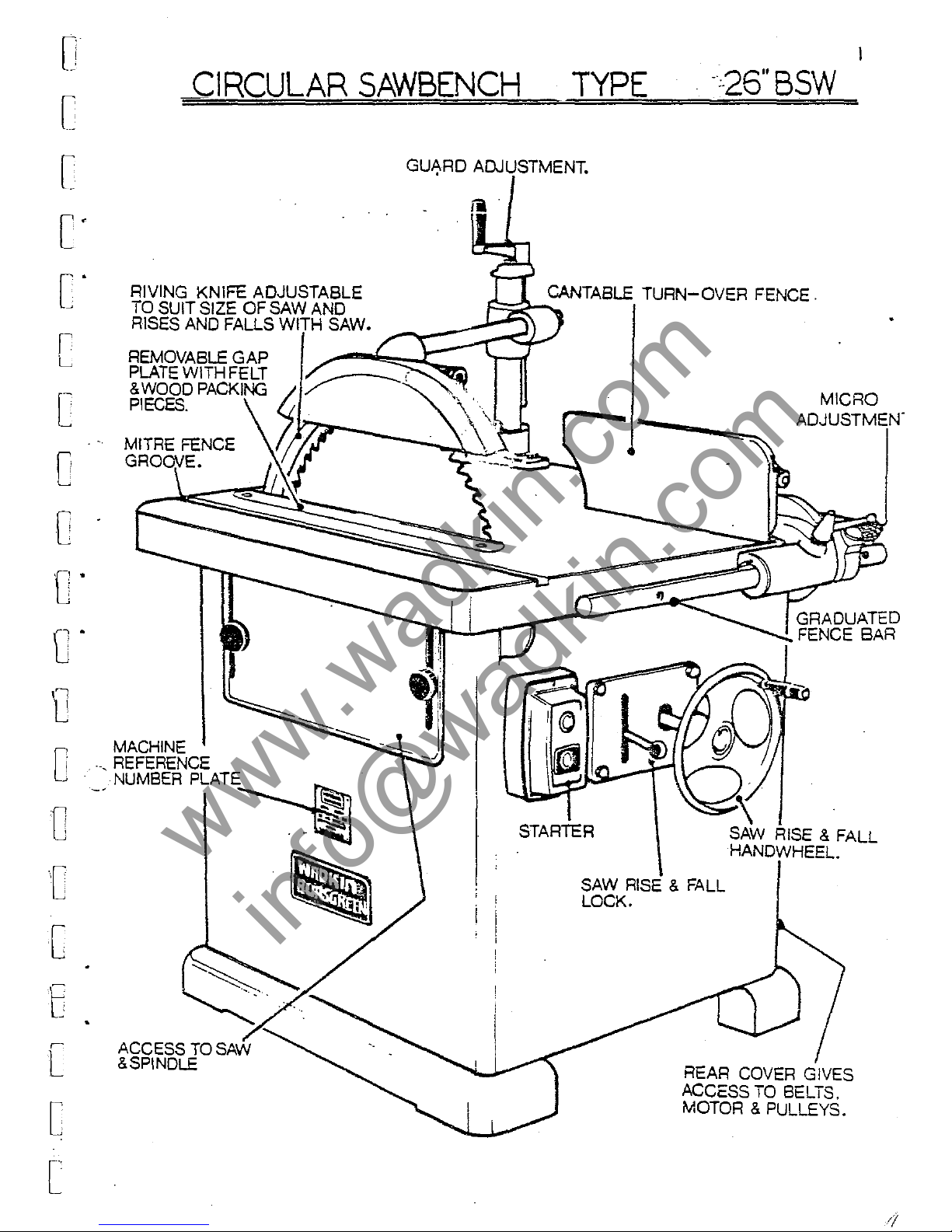

CIRCULAR

SAWBENCH

TYPE

-:-26"

BSW

c'

C'

r

L

c

o

o

tr

fJ"

RIVING KNIFE ADJUSTABLE

TO

SUIT SIZE OF SAW

RISES

AND

FALLS

IAln-U

REMOVABLE GAP

PLATE

WITH FELT

&

WOOD ,.."

.....

('\,,,"-'

PIECES.

MACHINE

0

1

.-,

REFERENCE

NUMBER

PLATE

o

r

[

t

[

[

[

ACCESS

TO

&SPINDLE

~

~

GU~RD

ADJUSTMENT.

CANTA8LE

TURN-OVER

FENCE.

F=:i-2-

.....

MICRO

ADJUSTMEN'

...

:cr=~-r~!!::::~~::::~~GRADUATED

FENCE BAR

STARTER

~

SAW

RISE

& FALL

HANDWHEEL.

SAW

RISE

& FALL

LOCK.

REAR

COVER

GIVES

ACCESS

TO

BELTS,

MOTOR & PULLEYS.

www.wadkin.com

info@wadkin.com

2

SECTION A

SECTION 5

SECTION C

SECTION

D

SECTION

E

SECTION A

SIi:CTION

5

SECTION C

,

, -,

SECTION D

'0

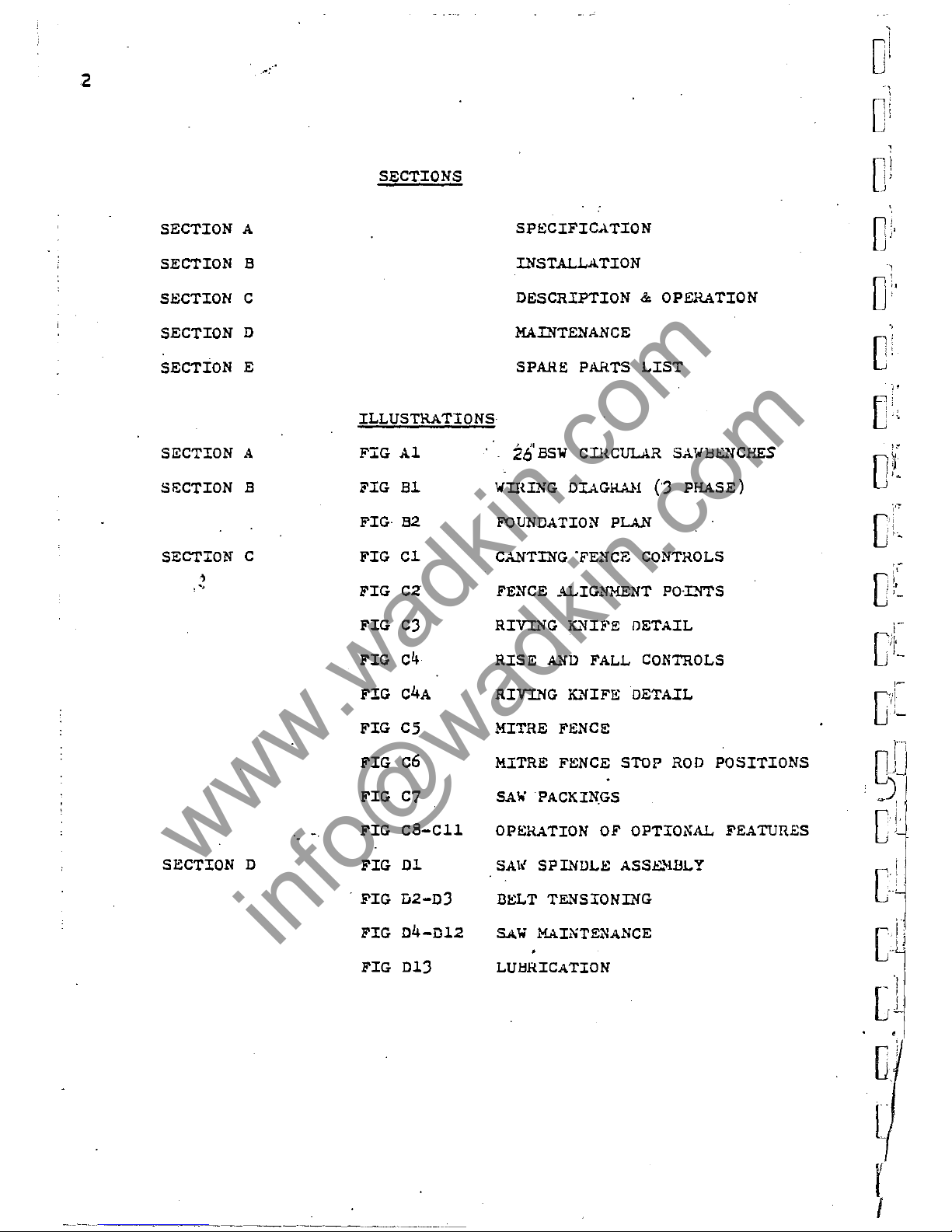

SECTIONS

ILLUSTRATIONS

FIG

Al

FIG

Bl

FIG

52

FIG

Cl

FIG

C2

FIG CJ

FIG

c4

FIG

C4A

FIG

CS

FIG

c6

FIG

C7

FIG

CS-Cll

FIG

Dl

, FIG D2-DJ

FIG

D4-D12

FIG D1J

SPECI:FICATION

INSTALLA.TION

DESCRIPTION & OPERATION

MAINTENANCE

SPAHE

PARTS

LIST

26'

BSW

CI!{CULAR

SAWl:l&'fCHES

WIHLXG

DIAGHA}l

(J

PHASE)

FOUNDATION

PLAN

CANTING

'FENCE

CONTROLS

FENCE

ALIGNMENT

PO'L'fTS

RIVING

K..'1H'E

DETAIL

RISE

~'1D

FALL

CONTROLS

RIVING

K..'1IFE

DETAIL

MITRE

FENce

MITRE

FENCE

STOP

ROD

POSITIONS

SA

....

PACKINGS

OPERATION

OF

OPTIONAL

FEATURES

SAI{

SPL'IDLE

ASSEl-lBLY

DELl' TENSIONL'IG

SAW

MAINTENANCE

LUl::IRICATION

,

O

i

Ii

,

,

C

l,!

"

->

0:'

1

Oi,

e:

'"

"

D

j

{'Oo

i'"

C

r

!'J

..

,-

i

.r

C

,I'

:

1-

.

(1

Dd

, )

Cl

I

[

'~

• J

•

Cl

L

r

I

www.wadkin.com

info@wadkin.com

[

[

[

[

[

[

c

o

o

o·

D

D

[

[

[-

L

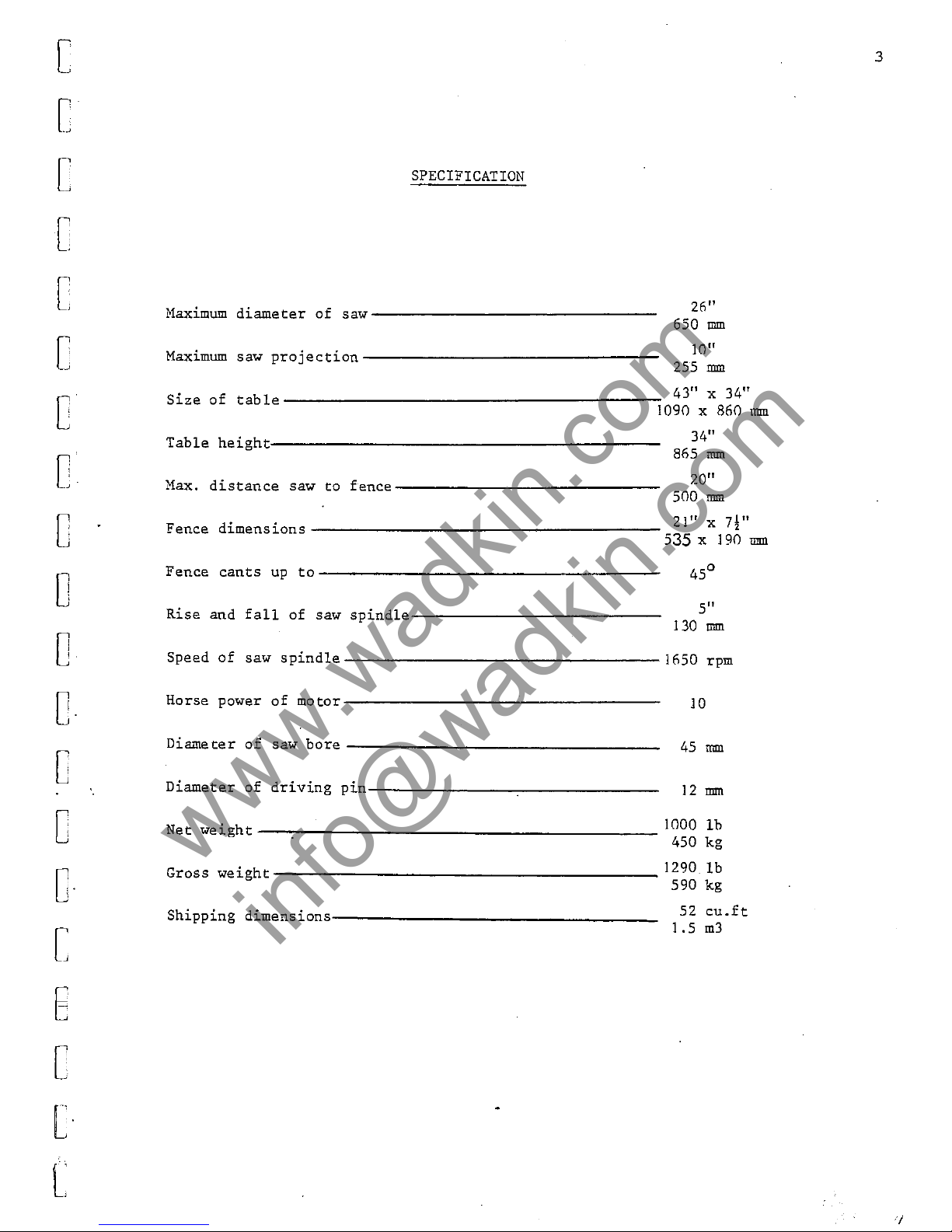

SPECIFICATION

Haximum

diameter

of

saw-----------------

Maximum

saw

projection----------------------------

26"

650

mm

10"

255

mm

43" x 34"

Size

of

table---------------------------------------~1090

x 860

lurn

Table

height-------------------------------------------

Max.

distance

saw

to

fence--------------------------------

34"

865

mm

20"

SOO

mm

21" X

7!"

Fence

dimensions---------------------------------------

S35

x 190

mm

Fence

cants

up

to----------------------------------

Rise

and

fall

of

saw

spindle------------------------------

45

0

5"

130

mm

Speed

of

saw

spindle----

_______________________________

16S0 rpm

Horse power

of

motor-------------------------------------

Diameter

of

saw

bore

___________________________________ _

Diameter

of

driving

pin--------

_______

~----------------

Net

weight----~---------------------------------------

10

45

mm

12

mm

1000

lb

4S0

kg

_

_________________________________

1290

lb

Gross

weight

590 kg

Shipping

dimensions--------

____________________________ _

52

cu.ft

1.5

m3

3

www.wadkin.com

info@wadkin.com

4

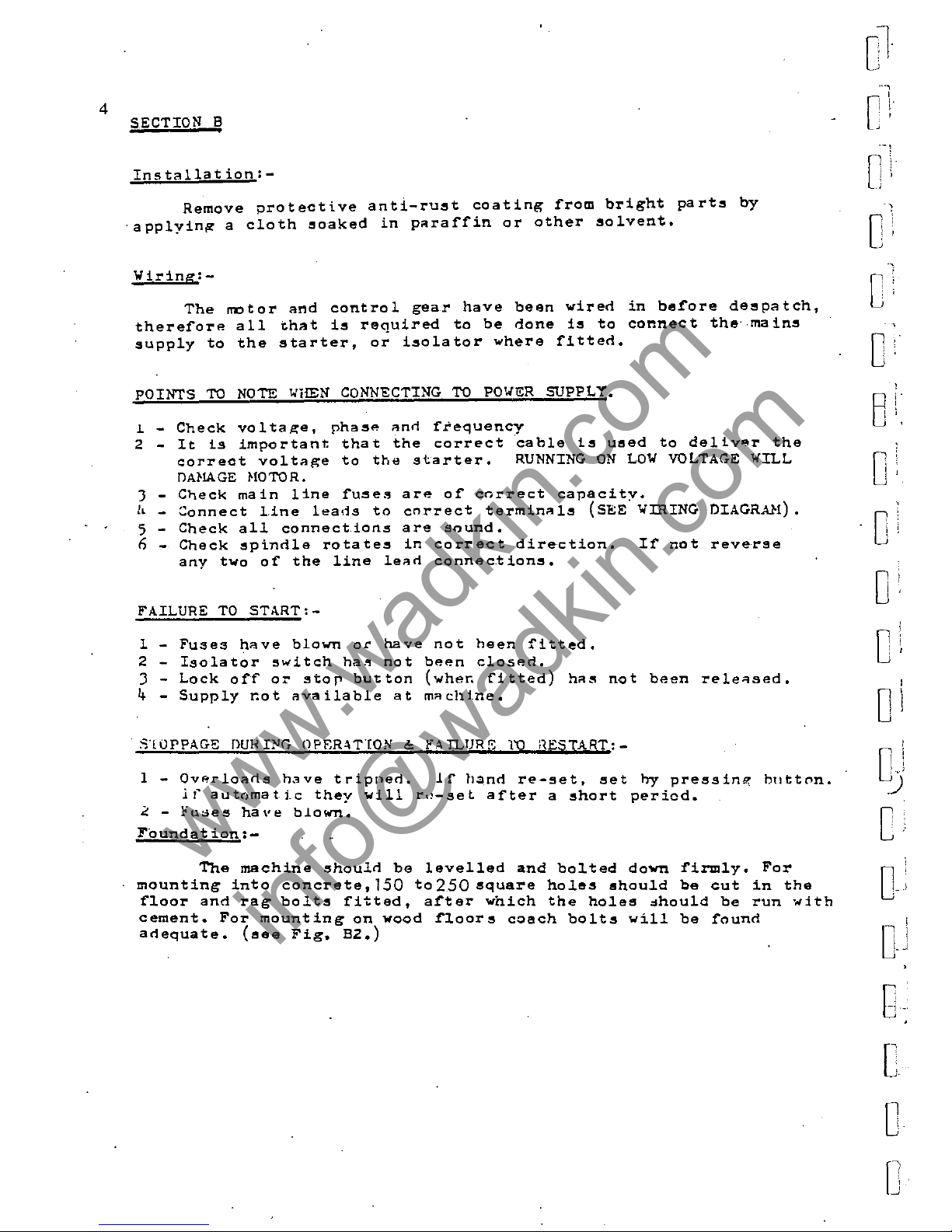

SECTION B

Installat

ion:-

Remove

protective

anti-rust

coating

from

bright

parts

by

'applyin~

a

cloth

soaked

in

paraffin

or

other

solvent.

Wiring:-

The

""tor

and

control

gear

have

been

wired

in

before

de"patch,

therefore

all

that

is

required

to

be

done

is

to

connect

the··mains

supply

to

the

starter,

or

isolator

where

fitted.

POINTS

TO

NOTE

WHEN

CONNECTING

TO

POWeR

SUPPLY.

1

-

Check

volta~e,

phase

and

frequency

2 _

It

is

important

that

the

correct

cable

is

used

to

deliv

.. r

the

correct

voltage

to

the

starter.

RUNNING

ON

LOW

VOLTAGE

WILL

rJAHAGE

HOTOR.

J -

Check

main

line

fuses

are

of

correct

capacity.

1.

_

:;onnect

line

leads

to

cnrrect

terminals

(SEE

Wlll.ING DIAGRAH).

5

Check

all

connections

are

sound.

6 _

Check

"pindle

rotates

in

correct

direction.

If

not

reverse

any

two

of

the

line

lead

connActions.

FAILURE

TO

START:-

1 -

Fuses

have

blown

of'

have

not

heen

fitted.

2 -

Isolator

switch

ha~

not

be"n

closed.

J -

Lock

off

or

stop

button

(~her.

fitted)

ha~

not

been

rele1sed.

4 -

Supply

r.ot

available

at

machine.

;>'liJPPAGE flURIl'IG (lPER4TTON & fAlLTJRS

1V

i1ESTART:-

1 -

Ovp.rloarls

have

tripned.

lf

I"'.nd

re-set,

set

hy

pressi"!?,

lmtt,m.

jf

automatic

they

will

r\,-set

after

a

~hort

period.

~ -rtl~e5

ha\'~

blown.

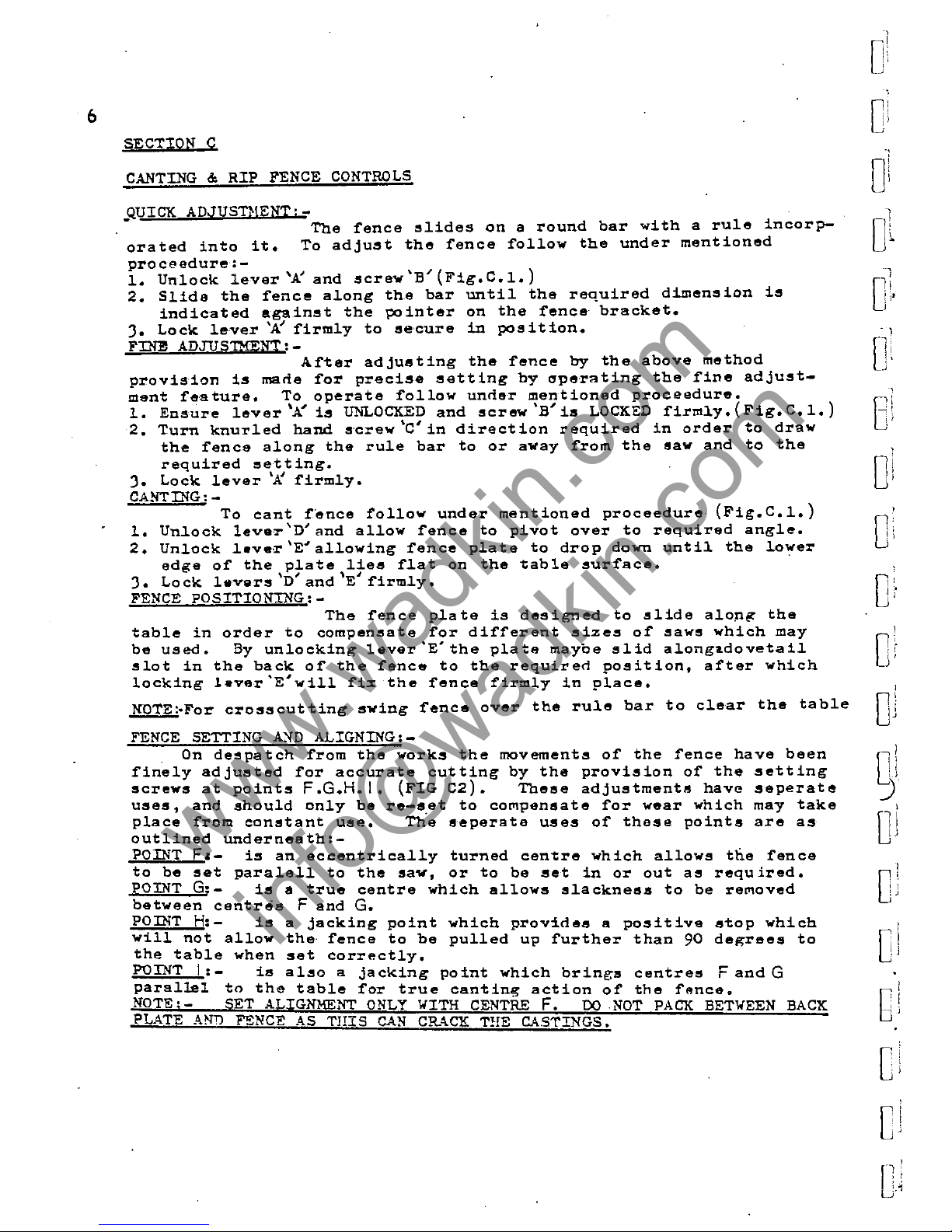

F'oundation:-

The

machine

should

be

levelled

and

bolted

down

firmly.

For

mounting

into

concrete,150

t0250

square

holes

should

be

cut

in

the

floor

and

rag

bolts

fitted,

after

which

the

hol

.. " ..

hould

be

run

·"ith

cement.

For

mounting

on

wood

floor"

coach

bolts

will

be

found

adequate.

(

..

ee

Fig.

B2.)

Cl

;

C

o

o

c

C

0

1

0

1

j

C

c:

0

' i

!_

J

[j-

[

fl

U·

www.wadkin.com

info@wadkin.com

[

[

[:

c-

c-

c

[

.,

[

c

o·

D'

C

D

'\

-'.

---/

0

C

D

E

[

[

[

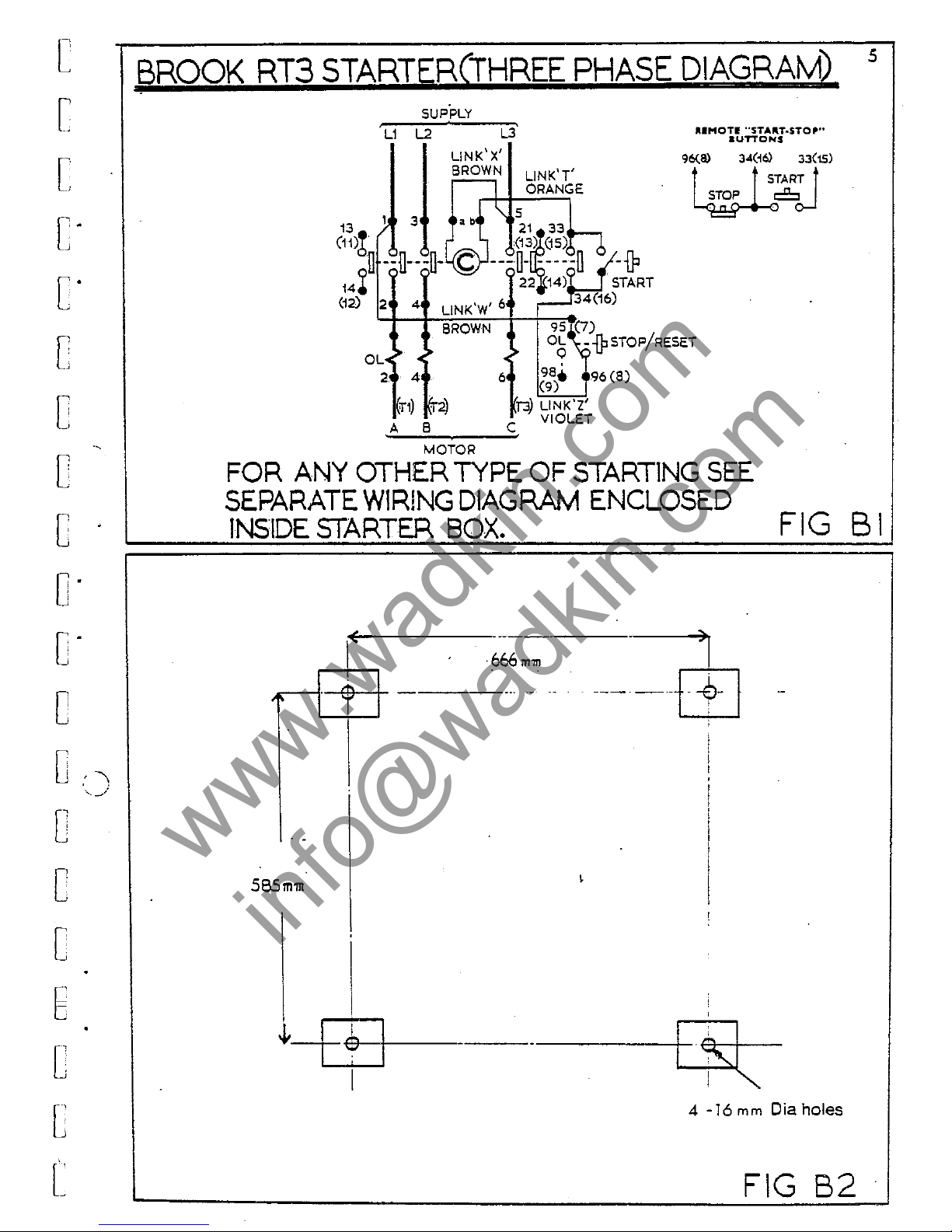

BROOK

RT3

STARTER(THREE

PHASE

DIAGRAM)

SUPPLY

,

L1

L2

L3

LINK'X'

BROWN

LlNK'T'

l ORANGE

"5

13

);

3 • b

21

33

(11)h

(13~e5)~

il

--n---o-

c

---0-

-----0

-{P

14~

22 14) .

START

(12)

2 4 LlNK'W' 6

34(16)

JI.IMOTI

"ST"'''T.STO'''

aUTTCNS

96(a)

34(~61

33(15)

t

_.___

t S

SlTAR.T

t

~°oJ

BROWN

9S~~7)

>

~

>

OL

-1PSTOP/RESET

OL~

~

•

~

2 4 6

98,

96(8)

(9)

j"3)

LlNK'Z'

A B C VIOLET

-=---~~~

MOTOR

FOR

ANY

OTHER

TYPE

OF

START1NG

SEE

SEPARATE

WIRING

DIAGRAM

ENCLOSED

5

INSIDE

STARTER

BOX.

FIG

B I

l

E

)1

·666

mm

...--l-e!-+

----

.... -

....

---·-+~-l

595 m 'Ill

i

,

-l-

I

I

I

I

~l

!

-

.

I

4 -16

mm

Dia holes

FIG

B2

www.wadkin.com

info@wadkin.com

b

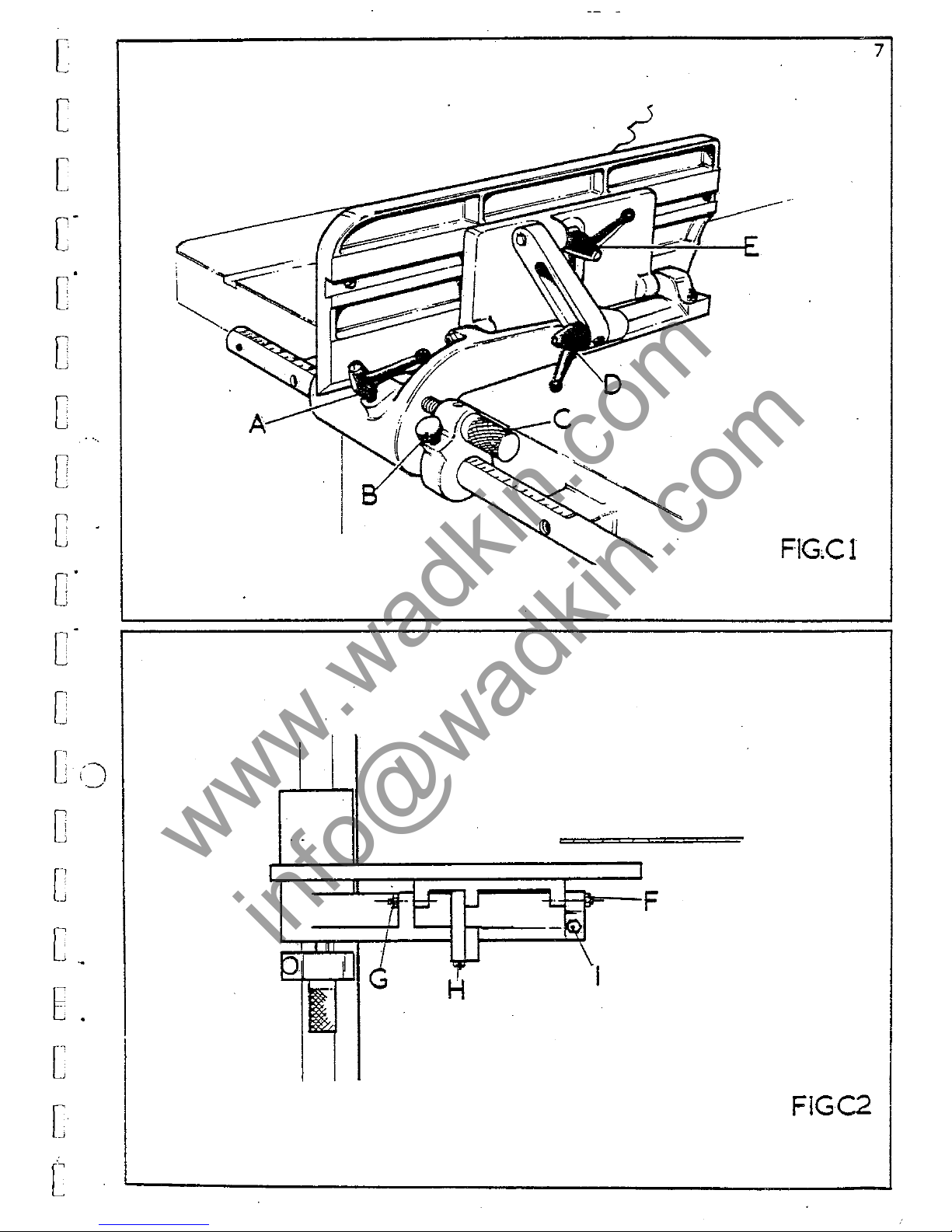

SECTION C

CANTING

&

RIP

FENCE

CONTROLS

QUICK

ADJUSTI!ENTi-

-

The

~ence

~lides

on a round

bar

with

a

rule

incorp-

orated

into

it.

To

adjust

the

~ence

~ollow

the

under

mentioned

proceedure:-

1.

Unlock

lever

'A'

and

"crew

'B'

(Fig.

C.1.)

2.

Slide

the

~ence

along

the

bar

until

the

required

dimension

is

indicated

against

the

pointer

on

the

~ence

bracket.

J.

Lock

lever

'K

~irm1y

to

~ecure

in

position.

FINE

ADJUSIMENT:-

A~ter

adjusting

the

~ence

by

the

above

method

provision

is

macie

~or

precise

setting

by

operating

the

~ine

adjust-

ment

~eature.

To

operate

~ollow

uncier

mentioned

proceedure.

1.

Ensure

lever

'AI

is

UNLOCKED

and

~crew'Blis

LOCKED

~irm1y.(Fig.C.1.)

2.

Turn

knurled

hand

~crew

'C'

in

direction

required

in

order

to

draw

the

~ence

along

the

rule

bar

to

or

away

~rom

the

saw

and

to

the

required

eetting.

J.

Lock

lever

'J:

~irm1y.

CANTING:-

To

cant

~ence

~ollow

under

mentioned

proceedure

(Fig.C.1.)

1.

Unlock

leva·r

'D'

and

allow

~ence

to

pivot

over

to

required

angle.

2.

Unlock

1.ve·r

'E'

allowing

~ence

plate

to

drop

down

until

the

lower

edge

o~

the

plate

lies

~lat

on

the

table

sur~ace.

\

~

\

~

J.

Lock

1avers

D

and

E

~irm1y.

FENCE

POSITIONING:-

The

~ence

plate

is

de~igned

to

slide

alOng

the

table

in

order

to

compensate

~or

di~~erent

sizes

o~

"aw~

which

may

be

used.

By

unlocking

lever

'E'

the

p1at

..

maybe

slid

a10nglldovetai1

~lot

in

the

back

o~

the

~ence

to

the

requiren

position,

a~ter

which

locking

lever'E'wi11

~i~

the

~ence

~irm1y

in

place.

NOTE:'!'or

crosscutting

swing

~ence

over

the

rule

bar

to

clear

the

table

FENCE SETTING

A~D

ALIGNING:-

On

de~patch

~rom

the

works

the

movement~

o~

the

~ence

have

been

~ine1y

adjusted

~or

accurate

cutting

by

the

provision

o~

the

setting

screws

at

points

F.G.H.I.

(FIG

C2).

These

adjustments

have

seperate

uses,

and

should

only

be

re-eet

to

co~pensate

~or

wear

which

may

take

place

~rom

constant

use.

The

seperate

uses

o~

these

points

are

as

outlined

underneath:-

POINT

F.-

is

an

eccentrically

turned

centre

which

allows

the

~ence

to

be

~et

para1e11

to

the

sav,

or

to

be

set

in

or

out

ae

required.

POINT

G;-

is

a

true

centre

which

allows

slackness

to

be

re~oved

between

centres

F

and

G.

POINT

H:-

is

a

jacking

point

which

provines

a

positive

stop

which

will

not

allow

the

~ence

to

be

pulled

up

~urther

than

90

degrees

to

the

table

when

set

correctly.

P'OINT

I;

-

is

a1,,0

a

jacking

point

centres

F

and

G

parallel

to

the

table

~or

true

cant

o

O

l

"

1

Cl:·

6

·:·

~,

It

0.

1

, 1

,

0·

"

,

0

,

I'

.1

I

Or

)

@

Cl

O

f

i J

I

~.I

Ul

nf

Uj

,

[

...

t,

; :

,

I

',

.'

; i

J.1

www.wadkin.com

info@wadkin.com

[

7

[

[

C-

C

C

[

0

c

.

FIG-Cl

O·

0

C

C

lOO)

.-./

0

['

-'

[

J

E

.

[

[

FlGC2

[

www.wadkin.com

info@wadkin.com

8

RISE

AND

FALL

CONTROLS:-

By

turning

handwheel

'J'

(fig.

C4 ) the

"aw

may

be

r>lised

or

lowered

between

the

maximum

and

minimum

oosition

AS

given

in

section

'A'

specification.

Under

no

circumstances

should

this

dimension

be

varied.

It

is

important

after

operating

the

rise

and

fall

thAt

lever

handle

'K'

is

locked

firmly

before

running

the

saw.

o

0

'",1

, )

.,

"

The

rise

And

fall

hanrlwheel

is

connected

through

pivoted

yolks

at

1

points

A.

&

B.

(FIG

c4.)

At

the

hanrlwheel

end

of

the

screw

a

thrust

Oil'

race

C

is

fitted

to

give

free

ro,tation

when

in

use.

It

is

therefore

J

important

that

the

pivots

and

"crew

are

cleaned

and

luhricated

regular-

,

ly

and

that

the

tiru"t

race

is

oiled

Accorrlin".

to

the

maintenance

sCheduleD!'

!tIVING

KNIFE

PLATE:-

The

riving

knif

..

pIa

te

is

situated

behind

the

"a'"

in

the

saw

co",-

pa'rtment

'0'

(fig.

C4A)

and

allows

the

riving

knife

to

rise

anrl

fall

with

the

"aw

at

a

set

clearance

to

the

saw

teeth.

It

is

important

that

th",

area

s,urrounding

thA

radial

"lot

cut

in

the

p.lflte

'be

kApt

clean

>lnd

well

lubricated

t'o

give

free

movement.

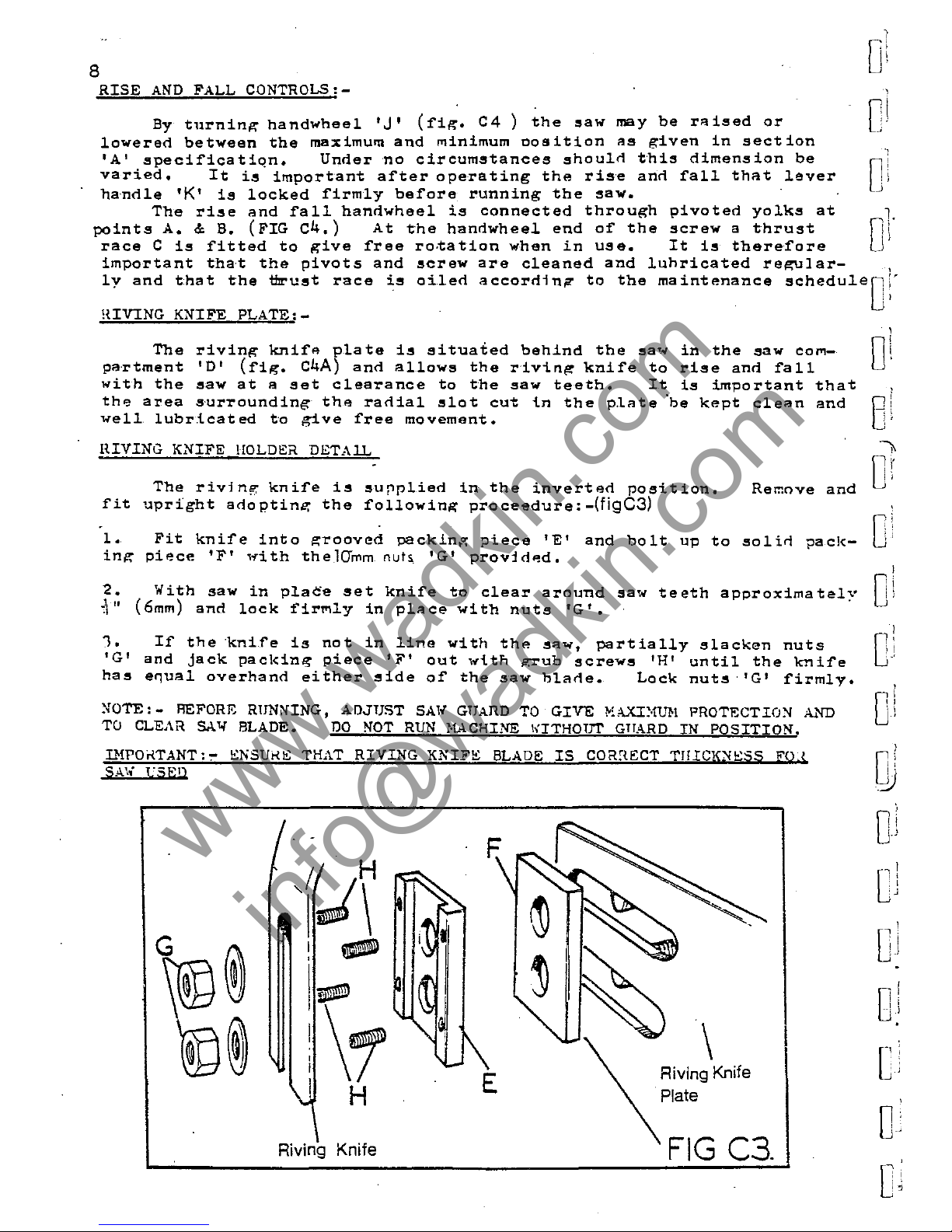

HIVING

KNIFE

HOLDEi1.

DETAIL

The

riving

knife

is

"urplied

in

the

invertAd

position.

fit

upright

adoptine:

the

following

proceedure:

-(figC3)

Remove

and

1.

Fit

knife

into

groovt!rl

packln,,,:

piece

'E'

and

bolt

up

to

solid

1'acl<-

ing

piAce

'F'

'~ith

thelO'rrom

nuts

'G'

prov:ldAd.

2.

J'II

.,

1.

'G'

ha"

With

saw

in

plaee

set

knife

to

clear

around

saw

teeth

approximatelY

(6mm)

and

lock

firmly

in

plAce

with

nuts

'G'.

If

the

'knife

is

not

in

line

with

th

..

sa""

partially

slacken

nuts

and

jack

packing

piece

'F'

out

,~ith

/7,rub

screw"

'H'

until

the

knife

e~ual

overhand

either

side

of

the

saw

blade.

Lock

nuts"G'

firmly.

XOTE:

- REFORI':

RUNNING,

ADJUST

SAl

..

GUARD

TO

GIVE

~,AXD1UN

PROTECTIO:-l

AND

TU

CLEAR

SA'!.f

BLADE.

no

NOT

RUN

K4.CHINE IGTHOUT

GTTARD

IN

POSITION.

U!PO!{TANT:,.

ENSU!{E THAT

RIVING

KNIFl!:

BLADE

IS

COR,\ECT TrrrCK±'fE§S

FO!

SA"·

rSEI)

G

,(~\

®

-

-

~

\1

\

E

Riving Knife

H

Plate

Riving Knife

FIG

C3,

Ol

B

',r

· .

·

,

"

0

','

, I

! i

0

'

· .

\ i

•

!

0

1

11

I

0\

O

,,!

i \

C

i

:V

0

·;

u

,]

[jJ

QJ

C

"

:

, j

•

0;

www.wadkin.com

info@wadkin.com

[

[

c

[

' .

-'

c-

c

[

c

C

0-

c-

C

[-':

c

[

[

6

[

[

[

... ~.J

9

A

.

FIG

C4

FIGC4A

I-<iv,...., knife plate

www.wadkin.com

info@wadkin.com

10

o

HOUNTING

SAWBLADES:-

When

mount

in..;

saw"

the

llndermentiancd

proceedure

sho"ld

be

.

0'

, ,

,

)

t'ollo",ed:-

j

1.

Isolate

machine

2.

Remove

table

insert

and

raise

the

SRW

sr~nrllR

hOl1sin~

into

the

top

position.

3.

Remove

spindle

nut

(left

hand

thread)

~nd

front

saw

fl~nKe

from

spind

1 e •

4.

Select

blade

required

depending

on

tYro

of

work

wh

ich

is

to

be

done.

Check

the

hlade

is

in

good

condition

and

free

from

dirt,

sawdust

and

,-;::um.

especiAlly

where

it

will

he

gripped

by

the

saw

flan,o:e.

Hount

saw

on

the

~pindle

checking

that

the

face

of

the

hack

saw

flange

is

clean

~nd

thRt

the

saw

b6re

and

pin

hole

centres

fit

correctly

onto

those

on

the

flange.

~.

Ch",ck

that

the

saw

teeth

poi.nt

towards

the

front

of

the

,""chine

be-

fore

re·placin/?,

the

flanl1:'"

Rnd

loekin"

UP

firmly

with

the

spindlp.

nut.

IHPO.nA.l'lT:-

ENSURE

SPINDLE

;lUNS

IN

COaRECT

'lIRo;CTIOI'.

R:::Ft:R TO

Sr~CT

...1!

ELECTRICS

L

'{QTE:-

IF

TllI,

FL.\:-IGE

OR

5,\1.:

FACES

ARE

'lOT

CL8A'I

THIS

CAN

C,\:"SE

VIJHV.1'IO~

DUE

TO

THE

SAW

RUN:-IING

OUT-QF-TRliF..

}I

ITHE

FENC:; (

!if.:

~

j)

.-t

E'URA.

)

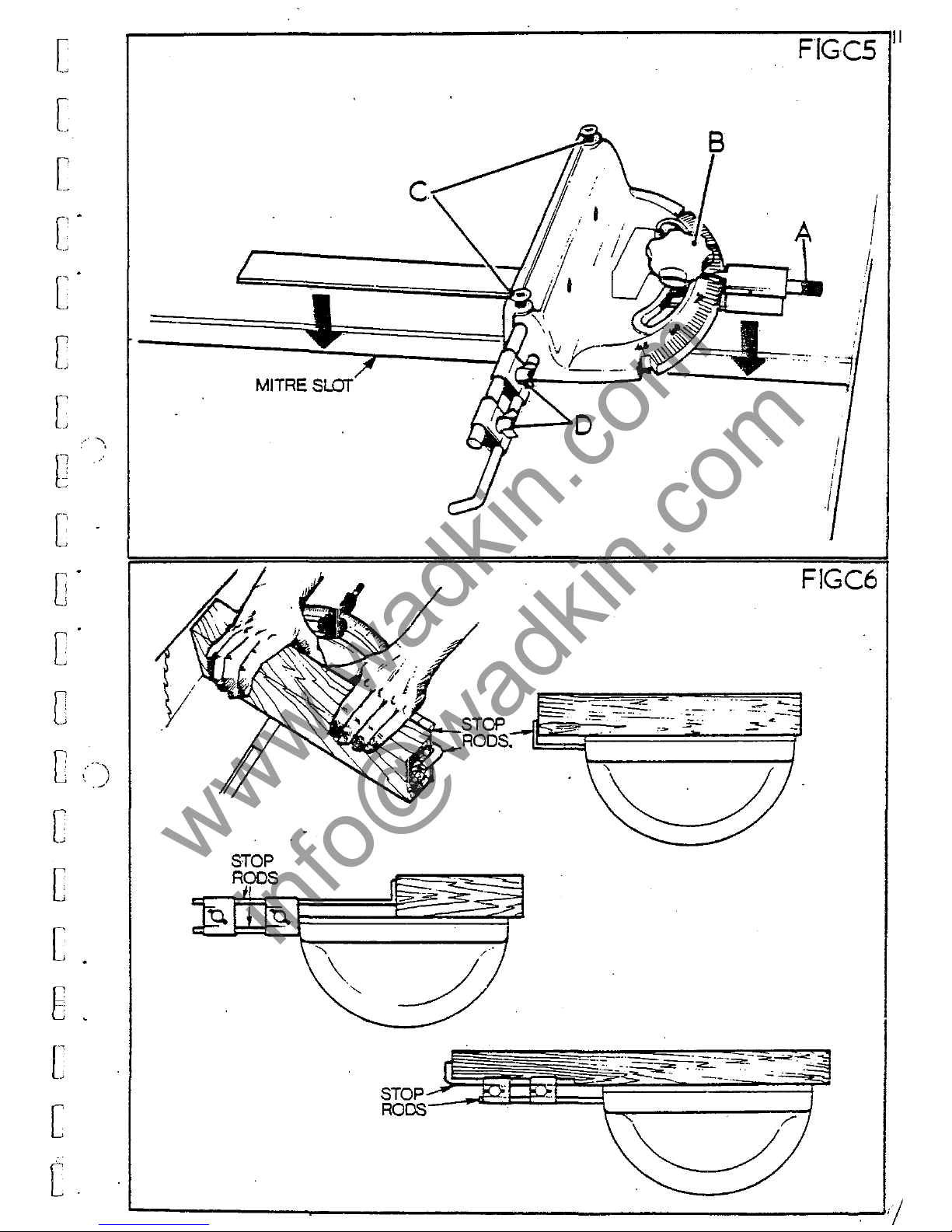

The

mitre

fence

is

fitted

into

the

/?,rOOY"

provided

on

the

S"N

t"hle,

Nhieh

should

he

kert

clean.

A

scale

is

proyided

tn

indicate

accurate

setting,

and

a

positlve

stop

'A'

is

incorporated'

in

the

sr.ale

to

I;iv"

quick

sPotting

al;

qOO

and

4S

0

to

the

saw.

Th"

rlastic

""nd"heel

'fi'

locks

the

mitre

fence

firmly

in

any

position.

Accurate

repetitive

cutting

~an

he

obtAined

hy

USP

of

th"

stop

rods

(fil1:.

CS.)

The

rods

are

held

in

the

fence

with

the

thumbscrews

'C'

and

the

stop

rods

hy

the

two

clamps

'D!

Tb

adjust

the

stor

rods

sl~cken

cl~"'ps

'c'

~nd

'D'

and

slide

the

rods

into

th",

position

reqlJired

as

illustrRted

in

(fi~.

C6.)

.

,.,

,

0

1

[1

:

O·

i

, .

I'

i

0

:

y

I

D

·!

[,j

O

"l.

, ,

(_1

oJ

gJ

[

"

.'.

' ,

i J

j

I

C

"

, ,

, :

D·

www.wadkin.com

info@wadkin.com

[

[

[

[

' .

.

~

c·

c

[

c

[

o·

c

c

c ,

..

_"

;

.....

'

C

·

-'

[

[

E

[

[

c.

MITRE

SlOT

STOP

RODS

B

~.--.-

-.

.F"

FIGCS

11

I

I

,

I

FIGC6

www.wadkin.com

info@wadkin.com

12

SA\;

PACKING.

It

is

usual

to

provirle

a

saw

hl"de

with

some

form

cjf

packinr;,

hut

it

is

not

intenrled

that

this

packing

be

userl

as

a

~uirle

for

bucklerl

or

ou~-of-true

sa*s.

The

idea

of

fitting

packin~

piec~s

into

the

tahle

and

gap

plate

is

to

steady

the

saw,

but

it

should

he

noted

that

the

packing

must

not

be

tight

"s

this

will

,o:enera

te

heat,

resulting

in

"

consequent

lo~s

or

ten~ion

in

the

blarle.

The

arrangement

of

the

saw

pAckings

"re

in

such

a

way

that

a

h"rd-

wood

mouthpiece

of

"

lene;th

extending

beyond

the

depth

of

the

saw

teeth

retains

the

felt

packin/!:

pieces

in

pl"ce.

Also

wood

strips

secured

to

the

underside

of

the

tahle

and

to

the

front

of

the

I';"p

plate

support

the

felt

in

position.

At

the

rear

of

the

gap

plnte

anrl

tahle

similar

wood

strips

close

the

~aw

p:ap

and

provide

a

/,:llirle

for

the

saw.

(SEE

DIAlSH,\NS

OPPOSITE.

)

It

shoulrl

he

noterl

thAt

after

some

time,

the

p"ckings

will

need

to

he

renewecl,

ancl

shol1lrl

not

he

"llowerl

to

fall

into

b"rl

cnnrlitif)n.

The

provision

of

the

felt

inserts

allow

applicatinn

of

"

s,",all

amount

of

luhricatin,o:

oil,

which

not

only

cl""n"

the

s"w,

hut

"Iso

re-

rluces

he"t

and

burning

whilst

runnin.o:.

It

is

th"refore

import"nt

that,

at

every

opportunity,

the

felt

pieces

are

luhricaterl.

"

NOTE,-

REP1...ACE~!EYl'

LENGTHS OF EELT

12 x 11 x 150

[J

I

0

1

)

D.

!

I:

,

I

ii

0

"

, '

0

1

q-

!

0

1"

I i

i-l

Dl

OJ

~

O

il

\-

0

'

!

I i

u

0-1

o

L

www.wadkin.com

info@wadkin.com

[

[

[

c:-

C"

c

[~

c

[

c-

C"

c

c·~)

c

[

[

E

[

[

[

'

~~

Hardwood

Saw

~

I

lA

.-p

Li..-4\mtHtiti

1

I

I

-

~====:::::t-WmJt_

:

,I

i

I 1

I [

I~J

--..,

[

[

.""'V".Jk====ti~Pf""

:1

Hardw 1

:(f)

~le

Bt.L~H--.~

I

1

[

Felt~J:=====t=t:~

FI

SECTION,

AA

Saw

'"---Screw

SECTION,

'BB

Saw

SECTICN,

'CC

13

www.wadkin.com

info@wadkin.com

I

....

B

E

A

.-'/

./

FIG

CS

FIG

C

11

SPINDLE

ERAKE:_

This

device

is

operated

from

the

brake

lever

'A'

situated

next

to

the

rise

and

1'all

handwheel.

It

is

connected

to

the

brake

pad

by

means

of

a

cable

'B'

leading

from

the

operating

lever,

and

is

spring-loaded

to

relieve

tension

when

hand

pressure

is

reljeved.

To

tension

the

cable,

turn

the

knurled

nut

'C'

on

the

lever.

Wher~

e'xee!!~ive

~laekness

is

to

be

removed,

unlock

the

grub

screw

'D'

on

the

pillar

at

the

spindle

end

and

pull

cable

through,

re-lock

grub

screw

and

tension

cable

as

mentioned

above

with

knurled

scre~.

When

re-

placing

brake

pad

it

is

important

that

new

rivets

are

used

and

that

the

rivet

heads"are

below

the

sur1'ace

01'

the

pad

material.

Po

not

allo~

brake

pad

to

wear

down

to

rivets

as

this

will

score

the

sur1'ace

01'

the

special

pulley.(FIGC11}

i!

u

)

[

' '

I:

, '

.

.J

Cl

1

fl

t

L~

Bi

- ,

Di

o

o

o

Ol

)

~j

fJ!

I

n

J

0

,

\ r

r~

c

www.wadkin.com

info@wadkin.com

r

[

[

[-

r~·

.

[

[

r:

[ .

[.

c-

[

[,'

, ,

[

[

[

E

[

[

L

.j

1$.

S:ECTION

"c"

MAINTENANCE

(/

www.wadkin.com

info@wadkin.com

\

16

SECTION

D.

-

HAINTENANCEj-

During

th9

op9rating

life

of

the

~awbench

it

may

be

fOllnel

necess<'lry

..

,

to

replace'worn

or

damaged

pRrts

(Le.

ball

race~.)(

1'0

unrlertak)e

this

n.,l

proceedure

follow

the

undermention

..

<l

instrllctinn~

•

.sEE

FIG

D

1.

lJ

1.

2.

3.

ISOLATl':

MACHINE

ELECTRICALLX

BEFOj(E

AITEHPJING

ANY

·'ORK.

RENon

GA.P

PLATE,

SAl.

AND

SAW

SPINDLE:

FRONT

,\N')

RF:J\R

COVERS

FRO~r

TilE

MACHINE.

SLACKEN

ANn

HENon

V_ROPES

FRON

PULLEYS

A.1W

nRHOYE

TURNnTJCKLE AND

TENSION

STUDS

.\FTER

PACKING

HOTOR UP

;\S

SH01JN

IN

(FIG

D.2.)

4.

'.HND

SAW

CARRIAGE

INTO

HIDWAY

POSITION.

6.

8.

n

..

10.

11.

REHOVE COUNTERSUNK SCRE1.

AND

\{

ASHBR '

A'

ANn SLACKBN

GH1JB

SCREWS

'R'

IN

PULLEY

'C'

AND

REHOVE.

RE}IOVE KEY

'D'

AND

DISTANCE

PIP-CE

'E'.

RE:HOVE

CIRCLIP

'F'

AXn HOTOR

TI::NSION

BRACKET

'G'

ANIJ

1JN~CnE:1{

Ai'!D

REHO

YE

DUSTCAP

'H'.

WORKING

AT

TilE

FRONT

OF

THE

SAW

SPINDLE,

HE:·l0VE

NUT

'I'

(L.H.THHEAD)

AND

SA"

FLANGE

'J'.

UNSr.:REW

SAlo/

FLANGE

'K'

(L.IJ.THH$A1).)

HEHOVE

RIVING

KNIFE

PLATE*A.'In

LI~,

A.'!D

UNSCHEW '\:'\1l REHOVli:

DUST

CAP

1

L'

•

PL~CB

A \.OOOEN

DRIFT

ON

THE

PULLEY

E:Xn

OF

THP.

Sl'I:'<nLr;

~m

fJltIVE

THI,

SHAFT 'THROUGH

THE

HOUSING.

11Y

OOlNG

TIiIS

TlIR

SPINDLE

IHLL

!':hEHGE

FRON

THE

H01'SI:-l'G

\;JTlI

TIlE

SAl{

EN!)

REAIU.'IG

ON

IT.'JIUVE

THI::;

m;AR-

ING

PItON

THE

SHAFT

AND

RE-INSERT

SHAFT

INTO

HOL"SIXG lGWC1:T.NG

Sf'INDU:

TlTilOlIGH

''iITH

HANHER

ANT)

DRIFT

1'0

I~E}IOVE

THE

PlTLLSY EN':)

nEARING.

[

11

J '

0

1

SI

Dj

U

-l

i

, ,

Or

0

,\

I J

1'0

re-a~~e",ble',

rever"e

above

proc"

..

<lut"e

ensur1.n.:

all

ori",inal

p"rts

D.J'I

are

thoroup.:hly

cleanerl

out.

* ' ,

It

shoulrl

al~o

be

note<l

th"t

the

two

locknuts

on

thp.

rarli"l

s~ot

in

the

rivinp;

knife

plate

~hould

onlv

be

tirhtenp.rl

9nnu,[h

to

prClvirle

a

=i<l

..

Qj!

for

the

motion

of

the

plate

"nrl

not

to

clamp

or

lock

the

pl"te

in

oo"i-

)

ti.on.

DJ

W

o

[

o

www.wadkin.com

info@wadkin.com

r

[

[

r·

c

c·

r

e

c

[

C"

C"

C

[

(-\

[

[

[

E

[

[

[

j.

17

'1

GJ

o

www.wadkin.com

info@wadkin.com

18

BELT

TENSION:-

On

all

",,,chine~the

drive

from

the

",ain

motorto

the

,.'aw

spindle

is

by

means

of

four" ALPHA

500

type

"V"

Belts.

To

ensure

maximum

effi

ciency

and

life,

of

the'se

belts,

t.t

is

importa

nt

tha

tthe

correct

belt

tensi'on

is

maintained

at

all

times

from

new,

especia'lly

in

the

"running

in"

period.

To

tension

the

belts

folIo\{

the

undermen-

tioned

proceedure.

(SEE

FIG.

0.2.)

By

turning

turnhuckle

'A'

linking

the

tension

studs,

the

centre

distance

of

the

pullevs

can

he

incre"sed

to

provide

greater

tension

on

the

belts.

To

achieve

the

correct

tension,

m~asure

the

centre

distance

of

the

J)ulleys

(FIG

DJ.)

and

adjust

with

the

turnbuckle

until,

whilst

apl'lying

a

force

at

right

aneles

and

centr'll

'11ong

the

belt,

'the

deflec-

tion

is

not

greater

than

O'S

per

25-.mmot'

s,pan

-(e.g.S84

sl'an

=

11Smm)

de,flection.)

REPLACING

BELTS:-

[J

r,i

1]1

O

J

; ,

f

-l

I,

e

To

replace

belts,

decrease

pulley

centre

distance

by

screwing

buckle

and

thu"

relievi.n~

tension

on

the

belts

for

their

removal.

I<a'rds

retension

as

giv,m

above.

turn-

nt

AfterlJ

POINTS

TO

NOTE WlIE);

HAINTAINING

BELT

nRIVES:-

1.

2.

).

4.

5.

6.

ALWA

YS

HAINTAIN

COimECT

BELT

TENSION

Q

REPL,\CE

1¥OHX

m:LTS

WITH SANE

TYPE

AS

SPEClFIED.

AU1AYS

REPLACE

'mllN

OH.

D.tHAGED BELTS

INMEDIATELY.

ENSURE

pm

LEYS

Ai{E

COtl.HECTLY

ALIGl\ED.

DO

NOT

PRISE

HELTS OVER

P'ULLI!."YS

1iITIl

SCHE1i

DRIVERS

Oll.

OTHER SHARP

IMPLEMENTS AS

TInS

CA:,

DAMAGE

BF;LTS.

ENSTTRE

PULLEY

GHOOVES

AND

BELTS

AHE CLEAN

AND

REl-tOVE

A:-IY

(JIL,

RUST

OR

DUTIRS

'.l!ICIl

ARE

PRESENT.

O

,!

I'

(ll

u!

0

1

,

Di

0

1

I I

i-l

I

DJ

Q

I

, I

-J-~

0

1

C

[

www.wadkin.com

info@wadkin.com

[

[

[

[

[

[

[ ,

[

[

[

c

[

[

[

[

[

t

[

[

[

·

·

·

·

,

.,

'

........

7

Method

of

pacl<.ing.up

motOr

for

remcval of

tension screws as

outlined in section

01

I

I

(~~--t--t---A

I

I

I

I

I

FORCE

FIG

02

FIG

03

DEfLECTION

O°,5mm

PER

25mm

OF

SPAN

19

www.wadkin.com

info@wadkin.com

20

SAW

HAINTENANCE:-

Efficient

operation

of

a

ctrcu~ar

saw

depends

on

true

runnine

of

the

saw

~pindle,

and

the

saw

flanges

being

perfectly

square

to

the

axis

of

the

spindle.

Th"

saw

must

also

run

at

the

correct

peripheral

speed

to

ensur~

straieht

cutting.

HANGING:

-

'RanginR

down'

should

he

done

on

a

new

saw

or

any

saw

after

the

fourth

or

fift'h

sharpening.

To

range

dow·n,

feed

a

square-edged

abra-

sive

block

in

a

wood,,"

holder

(FIG

04.)

lightly

against

the

saw

teeth

whils't

running.

The

saw

should

then b ..

removed

and

the

tops

of

the

teeth

filed

lip,htl'Y

to

remOve

the

rangin~

marks.

SAW

SiiARPENING:-

Do

not

run

a

saw

when

blunt.

To

re-sharpen

by

.hand,

hold

the

saw

in

a

vice

as

shown

in

(FIG

D5.)

1ii.th

rip

saw

teeth,

chisel

edges

and

sq,,"re

faces

are

required

(FIG

06.)

Sharpen

hy

e'ivjn1"

each

tooth

an

equal

number'

of

strokes

with

a

flat

file.

At

the

same

time,

file

the

gullet

of

the

s"w

in

the

s'ame'

manner,

takinp;

care

to

keep

the

gullet

well

rounded.

1;

Lt'h

cross

cut

saw.s

points

are

needed

with

hack

and

front

l>evels

as

in

(FIG.

D7.)

In

the

course

01

repeated

filing,

saws

lose

their

original

s·h"p

..

and

the

gulle·ts·

become

shallow.

To

restore

the

original

profile,

it

i..

ne·cess·ary

to

grind

the

saw

on a saw-sharpen

in",

machine.

SETTING:-

The

a",ount

of

set

should

be

sufficient

to

give

clearance

to

the

saw

body

so

th"rei~

freedom

fr~m

friction.

Saw

teeth

are

generally

'spring

set'

(i.e.)

the

teeth

are

bent

alternately

to

the

right

or

left

as

shown

in

(FIG

OS)

For

good

sawinp;,

this

amount

of

set

should

he

e<"Jual

at

each

side

or

els.e

the

saw

will

run

to

one

side.

To

check

the

set,

cut

into

a

piece

of

timber

where

the

result

"hould

he

a

small,

even

triangle,

as

seen

in

(FIG.

D9)

The

aMount

"1

set

varies

according

to

the

t.imher

being

cut,

hut

is'

usu"lly,

.Jmm

- 4mm,

.

We

can

supply

a

sm"ll

machine

for

precisely

settin",

saws

as

shown

in

(FIG

010)

This

device

will

accept

saws

up

to

J6"

in

diameter,

and

indicates

the

amount

o~

set

by

micrometer

dial.

For

hand

setting,

small

devi.ces

can

he

supplied

where

it

is

felt

that

the

nl1mher

of

saws

used

does

not

warrant

a

machine

(SI';':

~'IGs.Dll

&:

012.)

45

mm

Bore

STANDARD

S.A.W

AND

PIN HOLE CENTRES

15

mm

Bore

"1

[]I

n,!

u

or

[

ll

J:

01

ru

01

[

11

JJ

0

,

u

DJ

[

~

, :

www.wadkin.com

info@wadkin.com

[

[

r

~

[-

['

[

L

C

[

c-

c-

r"

L.

[,

[

C

[

E

[

[

[

l t

".j

-

-------.-.--.--~

-

.. , ...... ___

-t

_

...

-2"".-,.-.

•.

FIG

04

FIG06

Hook

Top bevel

a

gle10

0

RIP SAW

==s;}~.

:::::::z:;;;

:fls=e:=~

:::::;;:s~f8~dY

J • I +

saw

Saw cut . Set

Area

of

tooth

set-over

shown shaded

--~

FIG

08

FIG

010

FIG

05

FIG

07

FIG

09

F!GDII

10

18'

FIG

012

Clearance

angle

43

0

CROSSCUT SAW

----

1 I

I I

" .

15

20

www.wadkin.com

info@wadkin.com

FIG

013

c::-::J

L.

..

.-e

',.1,

.

LUBRICATION

DIAGRAM

-'I,..

,

----

I

llll

A4

i--t-L

__

{r.'.I

,-----V-:

\

1-

1

~~\'I

c

\ I

\ I

0"">+--

(,.n--

-----"'i:

--?,

(y

->-... .......

/ \

/)/

\

~J

J

,

"--D

'-

./

....

C_J

£---,-~

f-_

...

J

L

__

f__

_J

L _ c

1,_J

\t;=_l

L

__

'

't_

A-

Oil

and

clean weekly.

B-Oil

weekly.

C-"THRUST

RACE:'oil

weekly.

D-Grease-two

shots

each

end per

year.

t

Dust Outlet

20Qx130

I -

I l

I I

I

I

I I

t I L

__

i

Q:

L J

(.-1

!---

~.

L_.J

c::=J

[]jCL..J

r=J

.---

1

-----,

".

,-

~

A---.I.

.A

l.w..J

L-_._j

-.----;

l :J

c::J

~--

)

r----1

l

___

.

..-l

...

_.)

www.wadkin.com

info@wadkin.com

[

[

[

c-

C"

c

c

c

[ .

C

[

[.

.

[~

[.

[.

[

E

[.

[.

[

23

u "

SECT'ICN

E

SPARE

PARTS

LISTS

www.wadkin.com

info@wadkin.com

1

24

ot

-,

MAIN

BASE

ASSEMBLY

et

,

0

1

i I

'REF

PART

NO.

NO.

NO.

OFF

DESCRIPTION

O!

I

BS\,

753

MAIN

BASE

,

2

BSI'

750

I

TABLE

3

BSW

752 I

GAP

PLATE

ni'

, i

4

BSX

12

I

SPINDLE

PULLEY

COVER

5

BSW

751 2

BASE

FEET

6

BSW

137 I

FRONT

COVER

7

BSW

27

BASE

COVER

Ol

;

(8

BROOK

RT 3 STARTER}

(

PLEASE

STATE

VOLTAGE,

PHASE & FREQUENCY

1

9 I

WADKlll

BURSGREEN

NA'!EPLATE

1

['1'

· ,

1

:,

10 2

REAR

\,000

SAW

PACKrnGS

I I

2

FRONT

WOOD

SAW

PACKJi~GS

12 8

No.

10

WOODSCREHS

13

4

MI2 x

30

mm

LONG

HL~AGON

BOLTS

D:

14

4

12

mm

WASHERS

15

2

10

mm

DIA x

25

mm

DOWELS

16

2

M8 x IS

!IIIll

ROUND

HEAD

SCREWS

,

D"

I I

· .

17

4

MIO

x 35

mm

LONG

SCREWS

20

8

MIO x 25

DlII'

HEXAGON

BOLTS

21

2

116

x I 0

nnn

HEXAGON

BOLTS

22 2 6

mm

WASHERS

Q!

\ :

, ,

I

23

BZG

70 I SPRING

GUARD

CLIP

24

2

M6

NUTS

25 2

WING

NUTS

Oi,

26 2

10

nnn

EXTERNAL

CIRCLIP

I

27

I

M8 x IS

mm

LONG

ROUNDHEAD

SCREWS

28

2

1/8"

DIA

BRASS

RIVETS

29

3

'

2BA

x 20

nnn

LONG

SCRElfS

0:

,I,

30

2 DRIVEPINS

!

D'

, ,

!-~j,

,

WHEN

ORDERING

SPARE

PARTS

PLEASE

QUOTE

PART

NUMBER

AND

SERIAL

NUMBER

OF

MACHINE

0

· ,

!,-),

,

0:

, ,

'--"

, I

Di

:-~.

(

· '

, ;

,

>~

C

!

..

;

C

' ,

'-

;

L

.

''l

www.wadkin.com

info@wadkin.com

'[

www.wadkin.com

info@wadkin.com

\0

r

L

re

f"

~

C·

TI

t

[

(--

.J

i"

6~

-------.2

. -.

..

._..-,..--.,----

'~

.

~

~.

---

-..

-,-.,

4

0

~'

,

,

8

L

[

C

t

l

[

5

REF

NO.

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

SAW

SPINDLE

ASSEMBLY

PART

NO.

BSW

759

BSH

80

BSW

760

BSH 5

BSS

57

BSW

519

BSW

761

BSX

7/

A

BSH

61/A

BSX

19

NO.

OFF

I

I

I

2

I

2

I

2

I

I

I

I

2

DESCRIPTION:

32

mm

FORM

L.

H.

NUT

FRONT

SAW

FLANGE

SAW

DRrvING

PEG

REAR

SAH FLANGE

HOUSING FRONT DUSTCAP

M6 x 88

mm

STUD

M6

LOCKNUTS

M6 x 92

mm

STUD

SKF

6308

SINGLE

ROW-

BEARINGS -

REAR

HOUSING DUSTCAP

M6 x 18

mm

COUNTERSUNK SCREHS

MOTOR

TENSION

BRACKET

62

nun

EXTERJ.'!AL

CIRCLIP

PULLEY

DIST~~CE

PIECE

SPINDLE PULLEY

M6 x 25

mm

ALLEN

GRUB

SCREW

M6 x 30

tmn

ALLEN

GRUB

SCRE1{

MI

2 x

25

mm

COUNTERSUNK

'SELF

LOK'

SPINDLE

PULLEY

WASHERS

10

mm

SQUARE

x

40

MM

SINGLE

ROUND

SPINDLE

KINGFISHER

NO.2

GREASE CUPS

NOTE: PART NO. BSH

519

IS

ALSO USED

ON

RISE

~~

FALL UNIT (SEE PAGE

29

PART NO.

92}

WHEN

ORDERING SPARE PARTS PLEASE

QUOTE

PART

NU~BER

AND

SERIAL

NUMBER

OF

MACHINE

O

i .

26

),

ENO

D

•

.

~

;

)

,

D

':'

~

,

0

1.,.

i:

i,

,

FiY

0.

"

'1

i;

, J

L

-:

"

[;

www.wadkin.com

info@wadkin.com

['

www.wadkin.com

info@wadkin.com

C'

r

L

__

r

c·

-

C

[

[

K-

-A.

0

--A.

-

.

.~;t

0')

-"@

~

--A.

--A.

r

~

C

C

[

c

[

[--

-\,"""

:~\

\ i

~>

8-

t----~

LU1

o

I

kJ

f:{]1

01

-A'

'

I

70

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

I I I

112

113

I 14

I

15

116

I 17

I I 8

I

19

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

m

137

138

(SPZ

SAW

RISE

&

FALL

ASSEMBLY

BSW

9

S

125/

A

6698/A

BSW

10

5296/3

BSW

35

BSW

19

BSW

37

BSW

34

SKI'

0.6

BSW

46

BSW

33

BSW

519

BSS

25

BSX

8/A

BSW

756

BSW

43

BSW

7/A

BS\, 7

BSW

134

BSW

42

BSW

31

BSW

124

BSW

142

BSW

147

BSW

135

1270)

ALPHA

500

BSW

4

BSW

50

BSW

51

BSW

49/A

BSX

18

BSI{

754/A

BSX

23

BSW

29

BSW

28

BSI{

159

BSW

38

BSW

18

BSW

20

BSW

39

BSW

62

225

nun

DLA

ALUMINIU:I

RISE

AND

FALL

HANDLE

4

Ml0

x 35

mm

HEXAGON

BOLTS

9 1 0

mm

I{ASHERS

1

HANDllliEEL

SPINDLE

, 10

mm

BORE

x 80

"ill

PLASTIC

HANDLE

RISE

AND

FALL

BEARING

BRACKET

en

0 x

40

l1IIil

BORE

PLASTIC

BALL

RISE

AND

FALL

LOCK

HJL~LE

SHAFT

I

LOCKING

LINK

4 12

mm

EXTERl'<AL

CIRCLIPS

2

RISE

AND

FALL

LOCK

LINK

PINS

2

RISE

AND

FALL

SCREW

COLLARS

3

M6

x 6

mm

GRUB

SCREWS

2 5

mm

x 30

mm

GROOVELOCK

DOWELS

1

THRUST

RACE

1

THRUST

RACE

SHROUD

1

RISE

AND

FALL

SCREW

PIVOT

1 20

1!I[!l

x 22 x 22

rrnn

OllITE

BUSH.

MOTOR

SHAFT

KEY

(pLEASE

QUOTE

MACRINE & MOTOR

HP)

3

M6 x 20

mm

COUNTERSUNK

SCREWS

I

MOTOR

TENSION

BRACKET

I

62

rrnn

EXTERNAL

CTRCL

IP

2

M8 x 30

mm

GRUB

SCREWS

I

SAW

RISE

AND

FALL

SCREW

1

MOTOR

PULLEY

10

HP

(STANDARDl

1 I 6

rrnn

E;.'l:TERNAL

C IRCLIP

1 RISE

AND

FALL

LOCK

LL'lK

1

MOTOR

PIVOT

SHAFT

2

Ml0

x 35

rrnn

STUDS

2

MOTOR

PIVOT

BLOCKS

2

MOTOR

PIVOT

BLOCKS

2

MOTOR

PIVOT

SHAFT

COLLARS

4

MIO

x 10

1!I[!l

GRUB

SCREW'S

3

MIO

NUTS

6 1 2

mm

WASHERS

2

M12

x 25

rrnn

HEXAGON

BOLT

S

2

MIO

x 12

mm

DOG

POINT

GRUBS

CREWS

2 SPINDLE

HOUSING

PIVOT

SHAFT

COLLARS

1 RISE

AND

FALL

SCREW

NUT

1

M20

LEFT

HAND

THREAD

LOCKNUT

1

RISE

AND

FALL

SCREW

LOCK

COLLAR

2

M12

LEFT

HAND

THREAD

LOCKNUTS

2

M12

LOCKNUTS

1

MOTOR

TENSION

SCREW

1

MOTOR

TENSION

SCREW

1 TENSION

NUT

4 '

SPACES

AVER ' VEE

ROPES

SAW

SPINDLE

HOUSING

SUPPORT

PLATE

LINK

SUPPORT

ELATE

LINK

PIN

SUPPORT

PLATE

LINK

PIN

(KNURLEDl

1 SPINDLE

HOUSING

PIVOT

SHAFT

1 RIVING KNIFE

SUPPORT

PLATE

1

STANDARD

RIVING KNIFE

4

M6

x 1 2

1Il!Il

GRUB

SCREI{S

RIVING KNIFE

HOLDER

1 RIVING KNIFE

HOLDER

PACKING

PIECE

2

MIO

x 45

mm

COACH

BOLTS

3 MI6

LOCKNUTS

1

J

1

J

RISE

k'<D

FALL

LOCK

COLLAR

SPINDLE HOUSlllG LINK

16

mm

1,ASHER

16

mm

SPECIAL

SLOTTED

WASHER

LOCKING

LINK

NUT

RISE

AND

FALL

LOCK

SCREW

LINK PIVOT

STUD

BROOK

MOTOR

STANDARD

10

HP

D132S

FBJll~

2[<;1,

it

!\

.J

D

','i

, ,

. ,

8

"

, '

_,

I.

{

11

'"

D

,!

, (Ii

0

1

! i

0

'

r

, :

~-}

C

l

;

J'

0

',:

, ,

:.J

,

"

, I

[

i

,J'

www.wadkin.com

info@wadkin.com

L

www.wadkin.com

info@wadkin.com

[

[

.

~,

c'

\25

.'

[

D

[

[

r

u " J

D

L

[

\2\

On

9(

__

(

E-

___

.

.J

11

I i '

I,

i !

I I

! :

, .

, ,

,

t

r

u

REF.

NO.

160

161

162

163

164

165

166

167

16i!

169

170

17I

• 172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

19

I

CANTING

PART

NO.

BSX

10

BSW

8

BSW

14

BSW

83

BSW

66

BSW

65

BSW

16

BSW

17

BSW

57/A

BSW

123

BSW

58

BSW

526

BSW

63

BSW

57

BSW

12

BSW

56

BSS

88.

NO.

OFF

I

3

I

I

I

I

1

3

I

I

I

I

1

I

I

I

I

1

2

FENCE

ASSEMBLY

DE

SCRIPTION

FRONT

FENCE

PLATE

26"

BSW

M6

x 6

mm

CHEESE

HEAD

SCREloIS

DOVETAIL

BOLT

BACK

FENCE PLATE

M6 x ]0

mm

GRUB

SCREW

12

mm

WASHER

M12

LEVER

LOCKHANDLE

TURNOVER

BRACKET

SCREW

MI0

LOCKNUTS

FENCE

PIVOT

SCREW

(ECCENTlKI:C

1

FENCE

PIVOT

SCREW

(TRUE

1

M8

x I 2

mm

GRUB

SCREW

M8

LOCKNUT

FENCE

CANTING

LINK

10

mm

EXTERNAL

CIRCLLF

FENCE

LINK

PIVOT

PIN

M12

LEVER

LOCK

HANDLE

M6

x 6

mm

GRUB

SCREW

BRASS

LOCKING

PAD

M12 x

50

nnn

STUD

16

nnn

EXTER..'1AL

CI:RCLLF

FINE

ADJUSTMENT

SCREW

COLLAR

THUMB

SCREW

FINE

ADJUSTMENT

BRACKET

FINE

ADJUSTNENT

SCREW

BRASS

LOCKING

PAD

12

mm

WASHER

M12

LEVER

LOCK

HANDLE

TURNOVER

BRACKET

RULE

POINTER

METRIC

RULE

BAR

MI0 x

30

mm

ALLEN

SCREWS

,

WHEN

ORDERING

SPARE

PARTS

PLEASE

QUOTE

PART

NUMBER

AND

SERI:AL

NUMBER

OF

THE

MACHINE

"

Cl

"

0

"',

:

, ,

,

0:'

,

G

i'

[

Oi

n

·

:

~_~J,

0

,

i

! !

:

__

-.l

r:

1

L'·-'

[J

[,

www.wadkin.com

info@wadkin.com

[

c

[

[

o

[

L

[~

[ .

[

o

o

Q

",

[

J

,

o

[

6

' , .

[

C·

l~

'-}

31

160

•

191~~

www.wadkin.com

info@wadkin.com

REF.

~O.

200

201

202

203

204

205

206

207

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

PILLAR

PART

NO.

BSX

22

STOCK

BSW

57

BSW

764

BSW

763

BSW

71

BSW

82

BSW

69

BSW

70

S 125 / A

6698/A

BSW

77

BSX

21

BSW

68

BSX

20

BSW

67

BSW

78

NO.

OFF

3

I

2

I

1

1

I

1

1

3

3

1

1

]'

I

I

I

GUARD

ASSEMBLY

DESCRIPTION

MIO

LOCKNUTS

10

mm

SPRING \,ASHER

10

mm

WASHER

SAW

GUARD

SRAFT

Ml0

TEE

LOCK

HANDLE

BRASS

LOCKING

PAD

SAW

GUARD

REAR

COVER

SAW

GUAlID

BRACKET

FOR

SAW

GUARD

5

mm

x

37

mm

GROOVELOCK

DOWEL

6

mm

x 50

mm

GROOVELOCK

DOWEL

MS

x I 2

mm

SQUARE

HEAIl

BOLT

MS

LOCKNUT

M12

LEVER

LOCK

HANDLE

LOCKING

KEY

SAW

GUARD

RISE

AND

FALL

CAP

12

mm

WASHERS

M12

x 37

rrnn

HEXAGON

BOLTS

5

mm

x 25

mm

GROOVELOCK

DOIVEL

GUARD

RISE

Al'ID

FALL

HANDLE

ARM

GUARD

RISE

AND

FALL

HANDLE

SPINDLE

PLASTIC

GUARD

RISE

AND

FALL

HANDLE

SAW

GUARD

RISE

AND

FALL

SCREW

COLLAR

M12

x 45

mm

SQUARE

IlEAD

LOCK

BOLT

SAW

GUARD

RISE

Al'ID

FALL

SCREW

SAW

GUARD

RISE

AND

FALL

BOSS

SAW

GUARD

COLUMN

M6 x 10

mm

GRUB

SCREW

SAW

GUARD

BASE

CASTING

SAW

GUARD

SUPPORT

Afu~

32

~

Oi

J

-,

C

,

I

,

-0

0

i

!

0

\

:

"

0

:

0

[~

,

C

i :

c '

,

0

,

,

0

i

,

i

0

I

I

. ,

et

,J

J

DJ

L.J

~

0·:

['

, i

u

Cl

J

I

[j

C

[

[

www.wadkin.com

info@wadkin.com

o

[

c

c

o

o

o

c

o

o

o

o

D

·

..

,

/ 1

'._/

o

o .

C

B

C

C

r~

33

221

222

223

225~

220

224~

U

219

___

~-=;:==5i::::r202

218

""'''

~;;:.,

=-200

215

.

216

.'

.

c;::)=a

'qn

'Xi

C?

214~~

217--y

226

213--.

~

233 0

!)

212

I I

.

"--.-.~

"\

I \

202

",

. .

----.."

\ .

'.

. \

204

201

, . 205

206

207

200

230

229

...

2

21-====-

'"=~

22Q..=:::::::::::~~j,

232

222

227

228

www.wadkin.com

info@wadkin.com

SPINDLE

BRAKE

ASSEMBLY

290

1

20"

BSW

BRAKE

CABLE

291

BSW

131

1

BRAKE

POST

292

2

M5

LOCKNUTS

293

1

12

mm

WASHER

294

1 MJ2

NUT

295

1

M6 x 10

mm

GRUB

SCREW

296

BSl-l

148

1

BRAKE

STOP

SCREW

297

1 46

mm

llRAKE

RETURN

SPRING

298

BSW

145

1

PAD

ALIGNMENT

SPRING

299 2

116

LOCKNUTS

300 2

M8

LOCKNUTS

301

I

M8

SPECIAL

WASHER

302

I

22 x 10

x 12

mm

OILITE

BUSH

303

BSW

132 I

BRAKE

ARM

304

BSW

129

I

BRAKE

PIVOT

PIN

305

I07.PA

7/8

RH

1

BRAKE

LEVER

COMPLETE

. 306

BSW

128

1

BRAKE

LEVER

ARM

307

1

M8 x 12

mm

GRUB

SCRE1'[

308

BSW

125

I

SPECIAL SPINDLE

PULLEY

FOR

BRAKE

309

1

M8 x 16

mm

GRUB

SCREW

310 1

M6 x 50

mm

COUNTERSUNK

SCREW

31

I

2 3

mm

COPPER

RIVETS

312

BRAKE

LINING

FOR

20"

BSW

313

BSW

133

BRAKE

PAD

BACKPLATE

WHEN

ORDERING

SPARE

PARTS

PLEASE

QUOTE

PART

NUMBER

ru1U

SERL~

NL~BER

OF

MACHINE

l

I'

0

',

,

11

34

i I

[

' ,

i'

C

l

: i

I

.0

1

DJ

0

1

iJ

,

[U

01

1 I

DJ

cJ

[

www.wadkin.com

info@wadkin.com

o

o

c

~

LJ

o

o

D

..

o .

o .

o

. .

o

n

n

D.

B .

.

n

u

o

u

J".

29~

306

304

1-307

309~

www.wadkin.com

info@wadkin.com

36

RECCMMENCEC

SPARE

PARTS.

PART

QTY

SPINDLE BEARINGS

-

2

RISE a FALL SCREW THRUST RACE

I

VEE-BELTS

4-

FELT SAW PACKINGS

2-

ELECTRICS.

380,440-3Ph-SOCy~

FIXED

a.MOVING CONTACTS

I SET

NO VOLTCOIL

I

OVERLOAD UNIT

UI6

I

FIXED a MOVING CONTACTS

'.:seT

NO VOLT COIL

I

OVERLOAD UNIT

I

TIMER

I

STANDARD STOCK SAWS

BC2S

BCS1

BC2S

sese

BC

27

BC

:32

BC

124

se

125

SC

127

24"

(610mm) DIAMETER ALLOY CROSSCUT

SAW.

26" (660 mm) DIAMETER ALLOY CROSSCUT

SAW.

24"

(610mm) DIAMETER GENERAL

PURPOSE ALLOY RIP

SAW.

26"(660mm) DIAMETER GENERAL

PURPOSE ALLOY RIP

SAW.

24"

(610mm) DIAMETER CHROME PLATED

RIP

SAW.

26'(660mm)

DIAMETER CHROME PLATED

RIP

SAW.

24'

(610mm) DIAMETER TUNGSTEN CARBID

TIPPED RIP

SAW.

6'(660mm) DIAMETER TUNGSTEN CARBIDE

TIPPED RIP

SAW.

2O'(SOOmm)

DIAMETER TUNGSTEN CARBIDE

TIPPED RIP

SAW.

REF

S.KF.6308

11

0'6

ALPHASOO

12xUxlSO

--.-;;>-::--,--

BROOK-RT3 STARTER

• •

•

•

•

•

••

• •

• •

BROOK

RY.D.

STARTER

11

••

• •

••

• •

11

••

· ,

11

"

,

DI

[I!

[

11

I'

0

1

'

l"

[li

-l

0

1

Di

i

Cl

,

0

':

i-'

o

,

ni

L'i

0

··1

, ,

C

l

. f

0

,1

:'J

[

I

u

C

' ,

!

--~

l.·

j

.J

OTHER TYPES OF SAWS FOR CUTTING PLASTICS a PLYWOOD ARE AVAILABLE, DETAILS

['.

OF WHICH CAN BE APPLIED FOR OR

BE

SEEN

IN

THE

wacikin

SMALL TOOLS CATALOGUE·

www.wadkin.com

info@wadkin.com

Loading...

Loading...