Wadkin BGB 2500, BGB 3000 Instruction Manual

,

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

, I

I

I

rOR

SERVICE,

BUIISGRtEII

TLX.

SPARES

LODGE

TIIA"II'DEN,

Nr.

LANCASH I RE

GR!AT

TEL.

635032

A/ID

(COLNn

HQUO:,

COWl.

BRITAIN.

0282

(BURCOL-G)

TOOLING

LTD.,

•

86~310

CONTACT:-

,

BOOKNOB654

'I

1

I

PL£ASE

PL£ASE

WHEN

ORDERING

QUOTE fULL

INSERT

8GB

2500&3000

Belt Sander

SPARES

SERIAL

SERIAL

OR

REQ~STIHG

HUMBER

NUMBER

AND

OF

INDICATE

YOUR

MACHINE

SERVICE

MODEL

•

TYPE

HERE

• I

•

'J

'.

MODIFICATIONS

AS

IT IS

BURSGREEN

90011

OUR

MACH

SUPPLIED

ARE

MADE

CONSTANT

I IIES. I T IS

.ITH

POLICY

TltE

TO

THESE

TKERUORE

MACHIIIE

MANUAL.

BOOKS fROM TIME

TO

IMPROVE

BE

USED

THE

UIPOftTANT

AS

AN

INST

TO

TIME

DESIGN

THA

T TilE

RUCTION

Of

I

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

I

I

I

I

I

I

I

I

,

Woodwork

range

ding

M

any

to

WA

believe

table

followi

of

arrange

injuries

use

DKIN LTD

in

1.

2.

3 •

ing

machines

work

ments

the

guards

.•

supp

,

as

a

the

ir

ng

rules

The

operation

req

uirements

tio

ns

correctly

Safe

given

"Saf

(obtainable

and

Onl y

should

methods

ety

as

personnel

HEALTH

SAFETY

can be

of

wh

ich

against

t o

machinists

provided

ly

machinery

result

us

are

1974

in

in

advised

ope

of

e . I t

complied

of

.

All

.

o f

the

Hea

the

from

rate

&

OF

WOODWORKING

dangero

they

of

Use

by

trained

i t .

are

possible

are

or

thorough

is

the

w

the

machine

the

Woodworki

guar

ds should

working

lth

and

of

Her

Majesty'

wadk

capable

caused

to

adjust

designed for

t

user's

ith

only

Safety

Woodworking

i n

Ltd

in

SAFE

us

h

azards.

est

ing. mi

to

ensure

should

ng

shou

s

.

the

TY

if

improperly

,

requires

by

carelessness

them

responsibi

Machines

be u

l d

Work

Machines",

Stationery

safe

MACHINES

use

adequate

correctly.

maximum

n i mi z

safety

conform

sed and

be

Booklet

use

safe

es

lity

at

Regu

adjusted

adopted

Office)

of

a

the

to

No.

machine

d.

or

t y

t o

work:

the

l a-

as

4l ,

failure

which

risks

see

The

wide

safeguar-

they

inevi-

that

,

the

I

I

I

I

I

I

I

I

WAO

...

,

..

, .

5.

",N

.TO'

-

---,~-,-

Befor

the

machine

s hould

All

too

speed

SAFETY

ABOVE

ADVISE:

G"'

H N

e

making

have

ls

se

IS

OUR

RULES

011

THE

~ANE

'

......

should

ceased.

and

lect

ed

WATCHWORD

IN

HIS

SAFE

WO

.

"....

.

"

,'

a d

jus

cutters

must

OWII

USE

R K

S'

tments

be

stopped

must

be

~ppropriate

BUT

THE

INTEREST.

OF

OUR

000

LEICESTER

or

clearing

and all

be

securely

USER

MUST

WE

PRODUCTS

L H

OPf'

COMPLY

WOULD

.

'NGLANO

chips,

movement

for

BE

PLEASE:D

fixed

t he

WITH

T

ELEPHO

,,,

'''

too

THE

TO

..

.....

.... ~ ....

etc.,

and

ling

NE

...

the

o~n

,,,

_

.

..

,,

,~

"."""

,

7

6g11'

"""

..

t"

..

,

I

1

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

t

I

I

o

I

I

I

I

I

I

I

I

Ellewoe

EHe<u.e . o

Mul"'"",

RI", Ind

So""ln, belt len, .I, (±50mm)

Slndln,

Sandlnl

Slnd l

Slnd i

Th

Ou

N

Shlppln,

n,

", belt pull

rOl'

d~pth

><

u,,><. ion

et

..

~ICh'

..

nd,nl

len'th (BetW""

nd,n, widt

hei,h. und

fall

ubl

e ,,,o,or

belt

w,d, h

belt motOr

bell .p.ee

dl",en,lo

d. l'p<

ey di.m ..

(Double ,wan

out

n.

h (Bet

er

let.

""

.. ndln,

ed

""

Di>m ..

""

!>tl,

nO«)

or

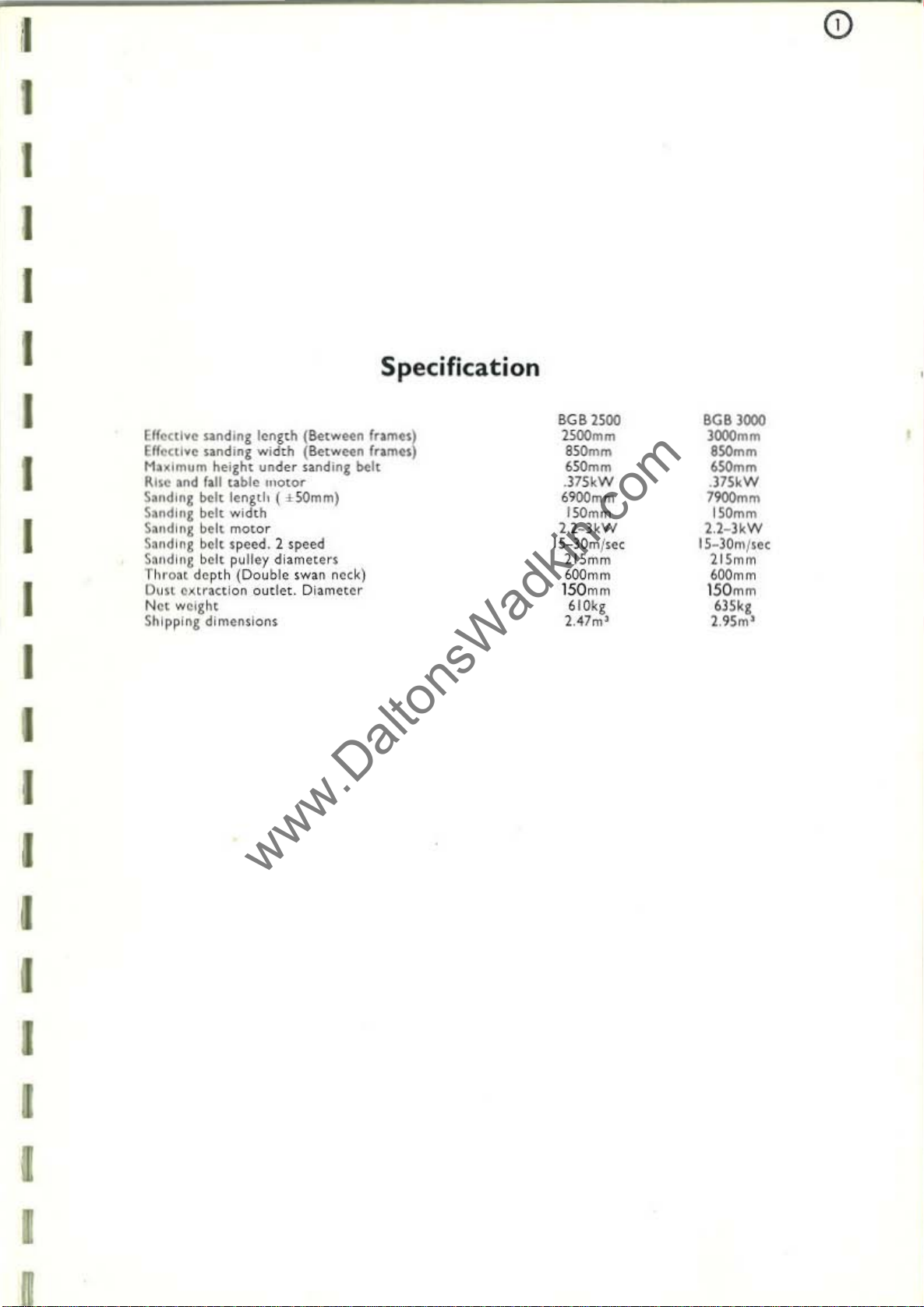

Specification

'rom

..

)

f

..

m

..

)

8GB

2500

""'mm

'

_m

''''''m

,)7S

kW

6'1OO

mm

150mm

}.

I_li<W

1S-30

",/

21S

mm

""

mm

150

mm

610k,

}.47""

,«

00''''''

""'mm

'_m

'_m

.)7SkW

"",,"m

"'mm

U-l

kW

15_)Oml'. (

l lSmm

""m

m

150

mm

6lSk,

].95",'

,

I

I

I

I

I

I

I

r

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

THE

MACHINE

lTEMS

PACKED

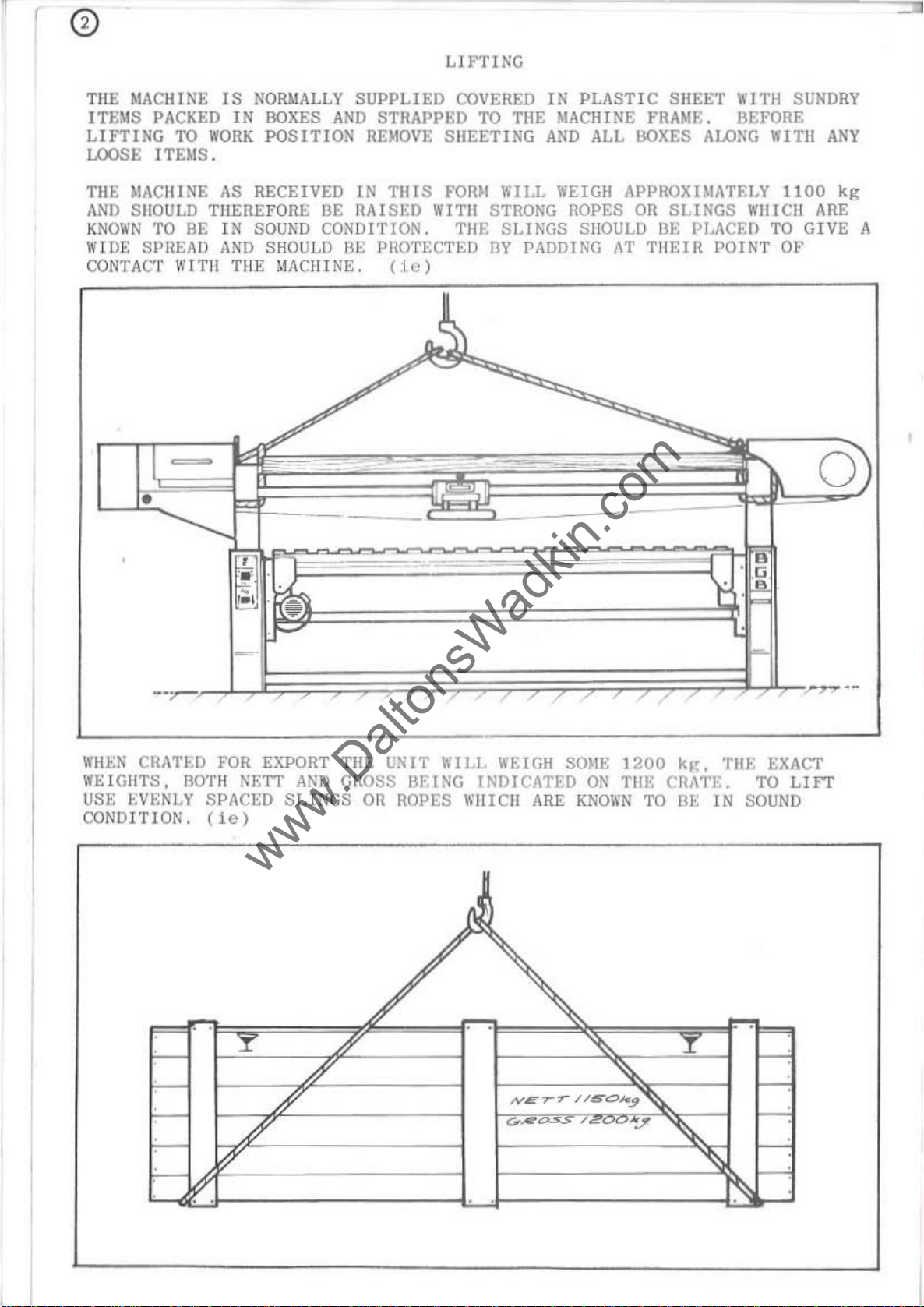

LIFTING

LOOSE ITEM

TilE

)!ACIIINE

ANI) SIlOULD THEREFORE BE

KN

OWN

TO BE

WID

E SPltEAO

CONTACT WITH T

TO

IS

IN

WORK

S.

AS

IN

AND

NORMALLY

BOXES

POSITI

RECEIVED IN

SOUND

SHOULD

HE

CONDITION.

MACHINE .

SUPPLIED

AND

STRAPPED

ON

REMO

TillS

RAISED

BE

PROTECTED

Uc)

LU'TI

COVERED

VE SH

FOIUl WIl.L WEIGH APPROXIMATELY 11

lUTE! STRONG ROPES OR

TilE

NG

IN

PLASTI C SHEET WI

TO

THE MACHINE FRAME. BEFORE

EETING

BV

AND

SLfKGS

PADDING

ALL

BOXES

SHOULD BE PI..ACED TO

AT

THEIR

ALOKG

SLINGS

POINT Ot'

TH

SUNDR

WITH

WIIICH ARE

ANY

00

kg

GIVE

o

Y

A

WHEN

W

USI::

CONDITION.

CRATW

EIGHTS,

EVENLY SPACED

FOR EXPORT

30TH

NETT

(ie)

TilE

AND

GIlOSS

SLINGS

UNIT

OH

WILL

BEING

ROPES \I'

WEIGH SOME

I NDICATED

HIel!

ARE

1200

ON

TlU; CHA1'E. TO

KNOWN

TO

k~.

BE

TilE

IN

EXACT

SOUN

LIFT

D

11

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

1.1

1)

WHEN

EDGES

2)

WHEN

STABILITY

LIFTING

WITH

USING POW

SUSPENEDED

SIGNS

3)

NEVER

1)

WflEN

IHOCK OR

COUPLE OF INCHES

5)

WlmHE

r:NSUH~:

OF

TILTING

llAISE

MOVING

LIFTING

SUCH

WITH

OLD

OF

LIFT.

AS

A LOAD

MACHINE

HorST,

FITMENTS

LIFTING

ROPE

TYPE

SACKING.

ER

HOISTS

LEVEL

LOWER

wr

BEFORE

OFF

HOOKS EYE BOLTS

LIFT

A

LOAD

AS

TH LOOSE

OR CRATE TO

MOVING

GROUND LEVEL.

ARE

SHOULD BE

POSS

IBLE. IF

OFF

AND

SECURED TO

NOTES

SLINGS

SLOWLY

READJUST

ITEMS

FOUNDATION

OFF

LOWER

OR

SP

PROTECT

FROM

GROUND

RAISED

ON

LI F

SLINGS.

UPON

ECIAL

TilE

IT.

LOAD

GRABS ARE

LOIID BEPORE

AROUND

LEVEL

IN

TilE

TING

POINT

nOWN

TilE

VIA

TO

CaHNERS

TO

AIR

TO BE

LOAD

OVERHEAD

WITHIN

PROVIDED

LIFTING

OR

SHARP

ASCERTAIN

SHOWS

A

.

IJ

I .

11

D

o

u

[]

6)

IlEFOIU;

CONDITION

SUSPECT

7)

1I'1lEN

S)

KEEP

9)

U~

:I'OIlE

I NSTltuCTIONS

10)

Jr.

A CHATE I S DAM

AND

USIN

G

ANY

. CUT OR FRAYED

LIN

KS SHOULD NEVER BE

OPF-LOADING

LOAD

LIFT

STATIONARY WHEN

LI

FTING

.

MACHINE ONLY.

ROPE ,

MACHINE

CHECK MACHINE

AGED

BELT SLING

ROPES,

OR

SUSPENDED,

TO THE

OR

CHAINS ENSURE

BELTS

USED.

CRATE , STAND WELL

OR

CRATE FOR

POINT

OR

00

WHERE

CHAINS

NOT ,\LLOI\'

ANY

IT

I S I

IT

WITH

CLEAR.

LOAD

SPF:CIAL

NSECURE,

IS

IN

SOUNIl

SPRAINED

TO SWING.

LIFTING

UNPACK

Oil

/1

I1

11

11

n

11

lnsta

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

llation.-

Remove

applying

Wiring:_

t he r

efore

supply

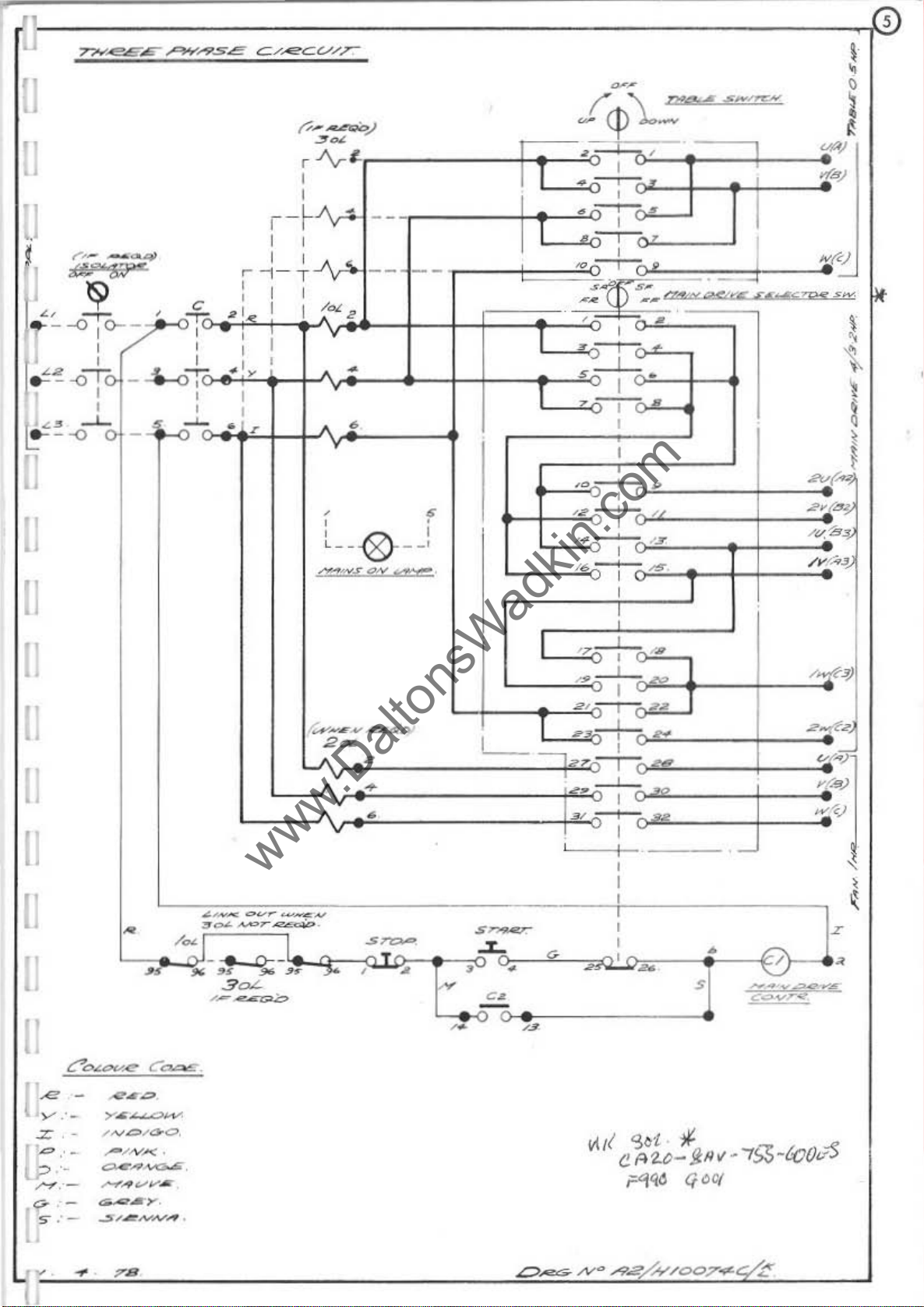

POINTS

1

Check

2 -

It

corre

DANAG£

3 •

Check

4

Connect

5

Check

6 CheCk s

two

FAILURE

1

Fuse

2 I s

3

Lock

4

Supply not

The

to

TO

is

olator

a

motor

ct

of

TO

s ha

orf

proteetive

cloth

all

the

NOTE WHEN CONNECTING

voltage,

important

voltage

MOTOR.

maln

lino lea

all

plndle

the

START:-

ve

soaked

and

that

star

connections

swi

or

ter

line

rotates

line

blown

t c h

stOp button

availab

ant

control

is

r e

, o r

phase

tha

t

to

the

fuses

ds

to

le

ad

or

has not

le

i-ru

in

paraffi

gear

quired

isolator

and

the

starter.

are of

correct

are

in

eonnect

have

at

frequency

correct

correct

not

been

(when

ma c

st

to

TO

so

hine.

coa

n o r

have

be

where

POWER

eo

rre

termina

und.

i o

ns.

been

e l

osed

fit

ting

been

done

cable

RUNNING

direetion.

ted)

fr

other

fitted

SUPPLY: -

.

e t c a

ls

fitted

.

om

solvent

wired

i s

to

Is

ON

paeity.

(S

.

has

brigh

used

EE

not

t

parts

.

In

befo

r e

eo

nne

e t

the

.

to

delive

LOW VOLTA

WIRING DIAGRAM).

I f

not

been

GE WILL

re

released.

by

des

main

r t

verse

pat

ch,

s

he

any

1

STOPPAGE

1

OverloadS

If

2

Fuses

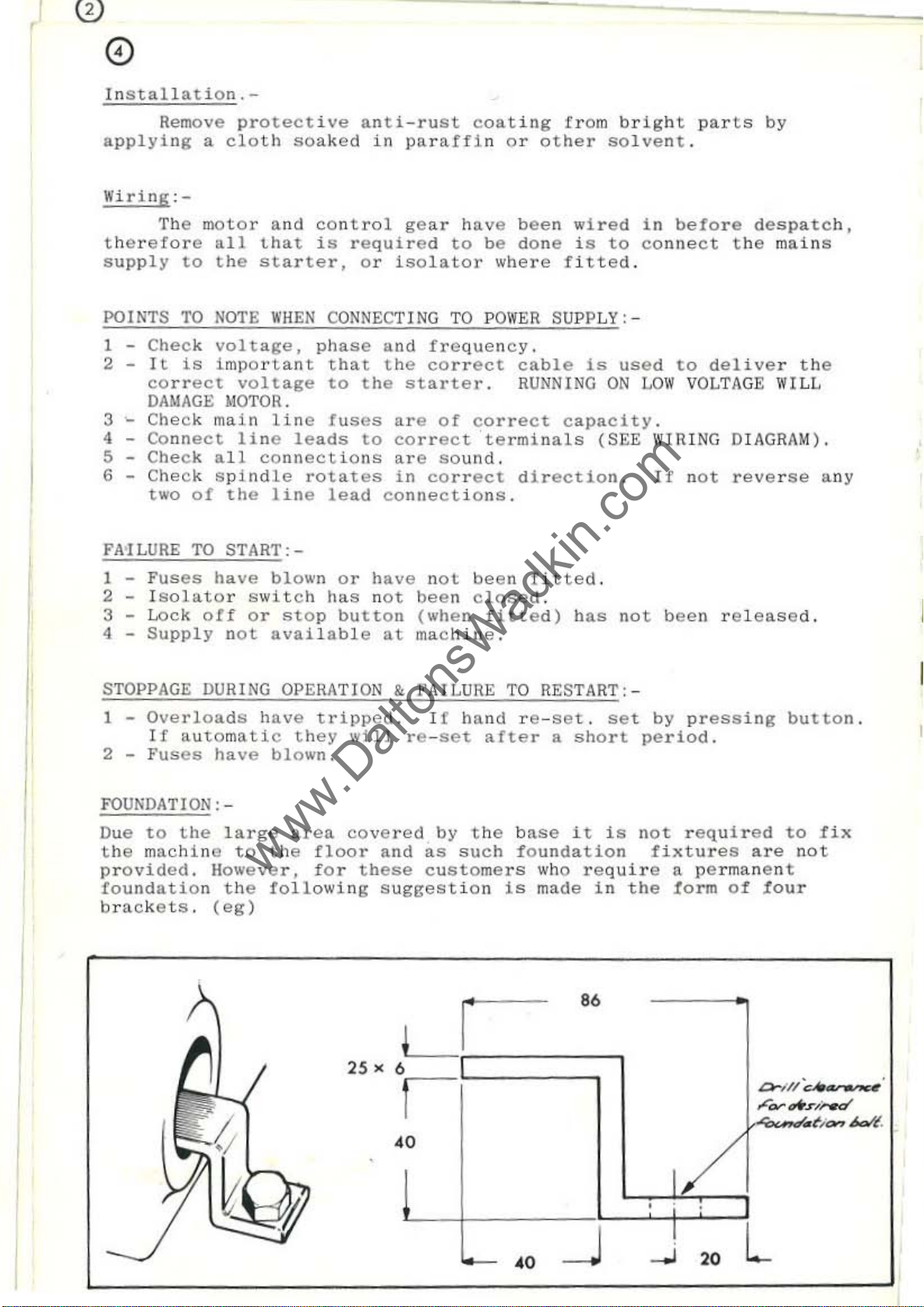

FOUNDATION:

Due

provided.

brackets.

to

the

machin

foundati

DURING

automatic

the

on

have

have

large

e

However,

the

(eg)

to

blown.

the

followi

OPERA

tripped

t h

ey

area

floor

fo r

TlON

covered

ng

&0

will

and

these

sugges

,

".

fAILURE

. I f

re-set

hand

after

by

t he b

as

such

eustomers

ti

o n

LI

I

TO

RESTART:-

r e -set.

a

ase

f o

undation

who require

Is

ma

de

set by pressing

short

it

86

period.

is

not required

fix

in

the

a

form

t ures

permanent

are

of

button.

to

not

lour

Drl//~

...........

.rN-N

~,.

fix

,

.....

4.a/{

1

.

"

'--

,.

~

1/

!

-'

2.

L

11

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

"

cl

11

11

I!

11

11

11

,.

C"_

'------'.'<;--;--

,

,..

--L-

. J

L-

, I

n-Q,,""-----I--

•

•

.~

r-'

'"

.L

-

CO

0

•

•

"

.-

• •

c

~

..

, J

T

/i

O

"'~"--

,

I

,

,

,

,

-

/"(3)

-

---1-..:::;

r·

.

~

'

0

...

)

'O

"','4'

~

i)

,

,

(

I

•

,

I

'1

I '

..a

-

"cl=

' Y _

It

.-=-

)'

& <

'0'

,,,,,

:;,,0-

,,-/N.-.;

CWl'A • .........-

_""v""

~ky

$,,'-""""'

~

. ,

0.

,

''' .

• •

1

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

~

0

ABRAS

For

be

machine

BELT DIMENSIONS

8GB 2500

BGB

The

must

REMOVAL,

To

ad

1 . Remove

2.

IVE BELTS

tr

ansp

lt

fitted

will

:-

3000

above

be

:-

given

remove

opted

s w

Turn -hand

possible

oversanding

pulley,

are

.

ing

open

tllerefore,

not

ortatio

and

be

6900

7900

dimensions,

when

REPLACEMENT AND

and

repla

belt

du

lever

to

the

belt

fitted

n r

as

packed

mm

rmI

guard

st

lift

table

bel

t

with

easo

ns

s u

ch

any

in

separate

(22'

(25'11")

plus

I")

the

re-orderin

TRACKING

ce

abrasive

cover

hood

C

may

tn

belt

.

wtll

gu

ard

clockWise

from

On

machines

require

require

this

the

belts

x

x

g

A

featu

trom

machine

ordored

boxes

150

mm

150

mm

machine

belts.

OF

belts

idler

B

at drive

direction

pulleys

with

li

ft

slackeni

re.

will

to

affixed

n

)

(6

(6")

model

SANDING

the

fo

pulley

pulley

and

over

sanding

ing

over

ng

f u

be

sup

plied

be supplied

to

type

llowin

to

rther

and

B~;L'I'S

g

cnd

cn

d.

Slacken

wooden

discs

disc

without

the

trame

serial

procedure

of

machine

be

fence

fitted

back

than

plate,

machines

with

l t

the

the

.

number

should

and

until

on

the

to

drive

which

it

be

is

3.

Before

replacement

(l.e.)

RUNNING WITH

4.

To

replace

re-tension

(DO

NOT

TRACKING

It

may

a

bel t that

order

to

'run-

TO UNDERTAKE

ADOPTED.

1.

Remove

tensio

not

fully

2.

Rota

t e

nut

E.

3.

St

ill

ls

ce

ntral

sc

rew D and

reUt.ting,

beit

fr

ee

from

WORN OR

belt,

by

turning

OVERTENSION,

be

found

the

that

n b

rotat.ing

off

idler

olt

t.ensioned

idler

the

'.

on

nut

belt

THIS

pulley

t o

pulley

width

it

is

culs,

reverse

that

t.rack

OPER

polnt

pulley.

E.

is

important

checked

cracks

DEFECTIVE

hand

SEE

after

or

runs

ATION THE FOLLOWING PROCEDURE SIlOULD BE

guard

where

as

it

by

hand

turn

of

pulley

and

or

pro

ced

lever

POINT

replacement

running

equally

cover

all

would

and

sc

drivo

that

found

toars

BELTS

ure outlined

C

In

X).

alignment

over

and

Slackness

be

whilSt.

rew

}'

the

to

.

CAN

anti-clockwise

Or

each

by

for

use

ln eith

face

conditjon

be

in

good

BE DANGEROUS.

In

point.

during

requires

pulley

turning

i s

rotat.lng

.

removed

under

e r

direct

A~

this

t he

slacken

of

cond;tion

(2)

dl

the

running

running

ndjustment.

and

does

handlever

but.

i o n

pOint

rection

the

and

not

belt

conditio

screw

until

re-lock

life

C

Is

D

belt

in

te

and

of

nd

ns.

I

I

I

I

I

I

I

4 .

Replace

Is

4 6

point

X.

all

covers

mm

clearance

and

tension

between

belt

shoulder

by

turning

on

sh

handle

alt

and

C

cas

until

tin

g

t

here

at

~

Loading...

Loading...