-----

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-----<

I

BOOK

NOB556

CIRCULAR

PLEASE INSERT SERIAL

NUMBER OF MACHINE

MODIFICATIONS

AND IT IS IMPORTANT THEREFORE THAT

WITH

THE MACHINE SHOULD

ARE MADE

SAW

TO

THESE BOOKS FROM TIME

ONLY

BE

USEDAS A WORKING MANUAL

BENCH

THE BOOK SENT

TO

TIME

_

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

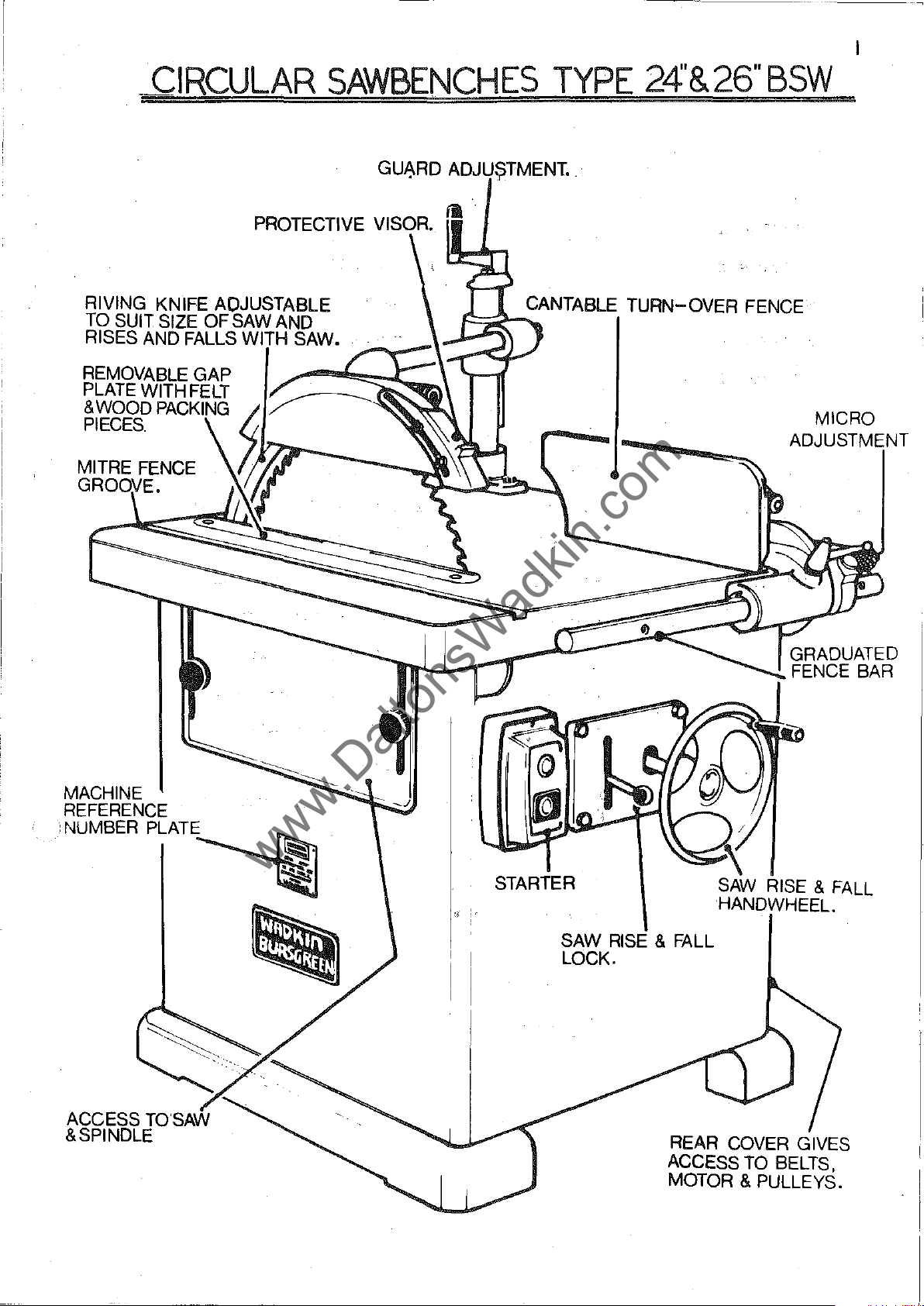

CIRCULAR

SAWBENCHES

TYPE

------

24'&26"BSW

RIVING KNIFE

TO

SUIT SIZE

AND

RISES

FALLS

~'"'--_-C_-:

lAIn

'MCLt:

...

:[I~-1r-JCr:::~~::::~~GRADUATED

..

~~

......

CANTABLE TURN-OVER FENCE

ADJUSTMENT

FENCE

MICRO

BAR

MACHINE

REFERENCE

-.NUMBER

PLATE~

\SI.

......

~

-.

STARTER

SAW

LOCK.

~\

RISE & FALL

REAR

ACCESS

MOTOR

SAW

HANDWHEEl.

RISE

COVER

TO

& PULLEYS.

GIVES

BELTS,

& FALL

2

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-------

-------------------------------------

. SECTIONS

SECTION A

SECTION B

SECTION C

SEc'nON

D

SECTION E

SECTION A

S8CTION B

SECTION C

ILLUSTRATIONS

FIG

Al

FIG

Bl

FIG

B2

FIG

Cl

FIG

C2

FIG CJ

SPECIFICATION

INSTALLATION

DESCRIPTION

MAINTENANCE

SPARE

24/26'

WDUNG

BSW

DIAGRAH

PARTS

CDWULAR

FOUNDATION

CANTING

FENCE

FENCE

ALIGNMENT

RIVING KNH'E

&

LIST

(J

PLAN

CONTROLS

DETAIL

OPERATION

SAWHENCHES

PHASE)

POINTS

SECTION

D

FIG

FIG

FIG

FIG

FIG

FIG

FIG

FIG

FIG

FIG

c4

C4A

CS

C6

C7

CS-Cll

Dl

D2-DJ

D4-D12

D1J

RISE

AND

FALL

RIVING KNIFE

"

MITRE

MITRE

SAW

FENCE

FI!;NCE

PACKINGS

OPI!;RATION

,!

SA\{

SPINDLI!;

DI!;LT

SAW

TENSIONING

MAINTENANCE

LUI.lIUCATION

CONTROLS

DETAIL

STOP

!

OF

OPTIONAL

ASSJ!:lolllLY

ROJ)

POSITIONS

,{

FEATURES

-,-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

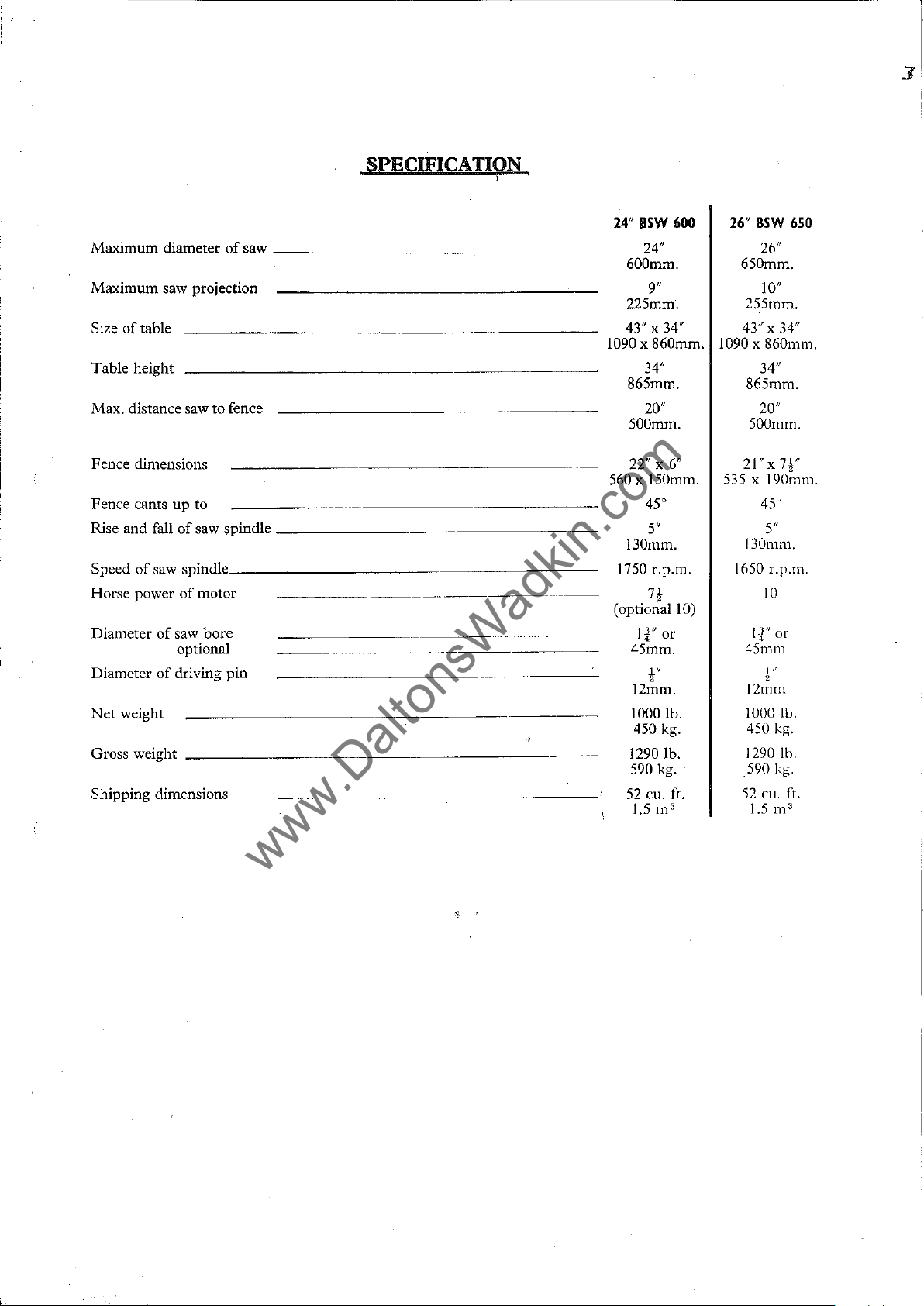

:1

Maximum

diameter

of

saw

Maximum saw projection

Size

of

table

Table

height

Max. distance saw to fence

Fence dimensions

Fence cants

Rise

and

Speed

Horse power

Diameter

Diameter

Net

weight

Gross weight

Shipping

up

fall

of

of

saw spindle

of

of

saw

optional

of

driving

dimensions

to

saw spindle

___________

motor

bore

pin

SPECIFICA

_________________

_________________

~.

________

nON

i

..

_----

.-._--

24"

_

1090

560 x 150mm.

_

~

1750 r.p.m.

(optional

BSW

600

24/1

600mm.

9"

225mm.

43" x 34"

x 860mm.

34"

865mm.

20"

500mm.

22/1

x 6"

45"

5"

130mm.

7!

1

&"

or

45mm.

l"

2

12mm.

1000 lb.

450 kg.

1290 lb.

590 kg.

52

eu. ft.

1.5

m'

1090 x 860mm.

535

10)

26"

BSW

26"

650mm.

10"

255mm.

43" x

34/1

865mm.

20"

500mm.

21"x

x 190mm.

45

130mm.

1650

10

If'

45111111.

~"

12mm.

1000 lb.

450 kg.

1290 lb.

590 kg.

52

eu. ft.

1.5 m

650

34/1

7r'

5"

Lp.m.

or

3

4

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

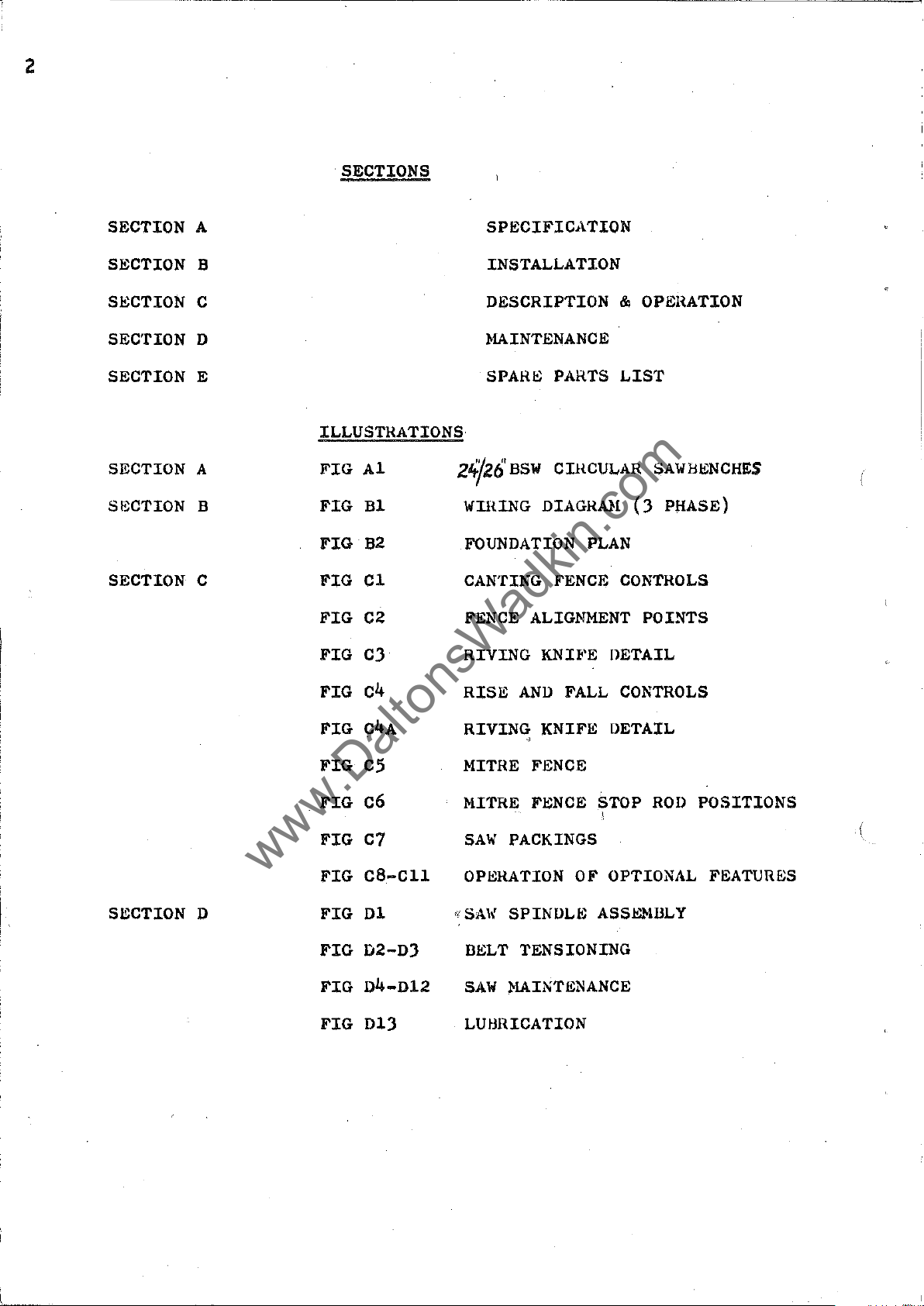

SECTION B

,

Installation:

Remove

'applyin~

a

Wiring:-

The

therefore

supply

POINTS

~

-

Check

2 -

It

motor

all

to

the

TO

NOTE

voltage,

is

important

correct

DANAGE

3 -

I, _

5 -

6

Check

Connect

Check

Check

any

main

all

two

-

protective

cloth

that

starter,

voltage

HOTOR.

line

connections

spindle

of

soaked

and

lVHEN

line

leads

rotates

the

anti-rust

in

paraffin

control

is

required

or

gear

isolator

CONNECTING

phasA

that

to

fuses

the

to

and

the

starter.

are

correct

are

in

line

lead

coating

or

have

to

be

been

done

where

TO

POWER

frequency

correct

cable

RUNNING

of

correct

termin"ls

sound.

correct

direction.

connections.

I

from

other

wired

is

fitted.

SUPPLY.

is

capacity.

bright

solvent.

in

to

connect

used

ON

LOW

(SEE

parts

before

to

delivAr

VOLTAGE

by

despatch,

the

mains

WILL

the

WIRING DIAGRA}I).

If

not

reverse

FAILURE

I -

2 -

J -

4 -

TO

Fuses

Isolator

Lock

Supply

have

off

SlOPPAGF; DUll

1 -

Ov',rloads

J f

automatJ.c

2.

-

FU:.ies

have

Foundation:-

The

machine

mounting

floor

cement.

adequate.

and

For

into

rag

(see

START:-

blown

switch

or

stop

~ot

available

ING

OPBRATTON

have

bJown.

concrete,

bolts

mounting

Fig.

ha9

tripped.

they

should

fitted,

B2.)

or

have

not

button

will

6"

on

wood

been

(when

at

mAchl.ne.

&.

FA

1'.'-S8L

be

levelled'

to

after

not

lLUHE

If

i,and

8"

floors

been

closed.

fitted)

TO

re-set,

after

and

square

which

cOBch

fitted.

has

l'(ESTART:-

a

short

bolted

holes

the

holes

bolts

not

set

period.

down

should

will

been

by

pressine:

"hould

released.

firmly.

be

cut

be

be

found

hutton.

For

in

the

run

with

-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-------------------

~ROOK

RT3

STARTERCTHREE

,

SUP,PlY

L1

l2

LINK'

X'

BROWN I LlNK'T'

_I

ORANGE

13

).

3

(11)6

~

--U---O-c ---0-

14

~

(12) 2 4 '

Ol.

2 4 6

(Tl)

A B C VIOLET

"-'--..:::...--,.~~

LINK W

BROWN

(r2)

MOTOR

ab

\ 5

21

(13~(j5)~

22

,6

n)

PHASE

33

-----0

14)

34(16)

95,(7)

O~

\--lPSTOP/RESET

98.

(9)

LlNK'ZI

96

DIAGRAM)

REMOTE

9r)

~6o-l

-{P

START

(8)

----

--------------------

5

"START.STOP"

BUTTONS

____

34t~TAR~3r5)

FOR

ANY

OTHER

SEPARATE

INSIDE

~

23"

(S8Smm)

STARTER

0(

TYPE

WIRING

DIAGRAM

BOX.

--

OF

STARTING

ENCLOSED

26~'

(666

mm)

-------

---

~

--------

SEE

~

..

~-

FIG

--

BI

-----------+-I~t

I

5"

4 - 8 Dia holes

FIG

B2

6

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

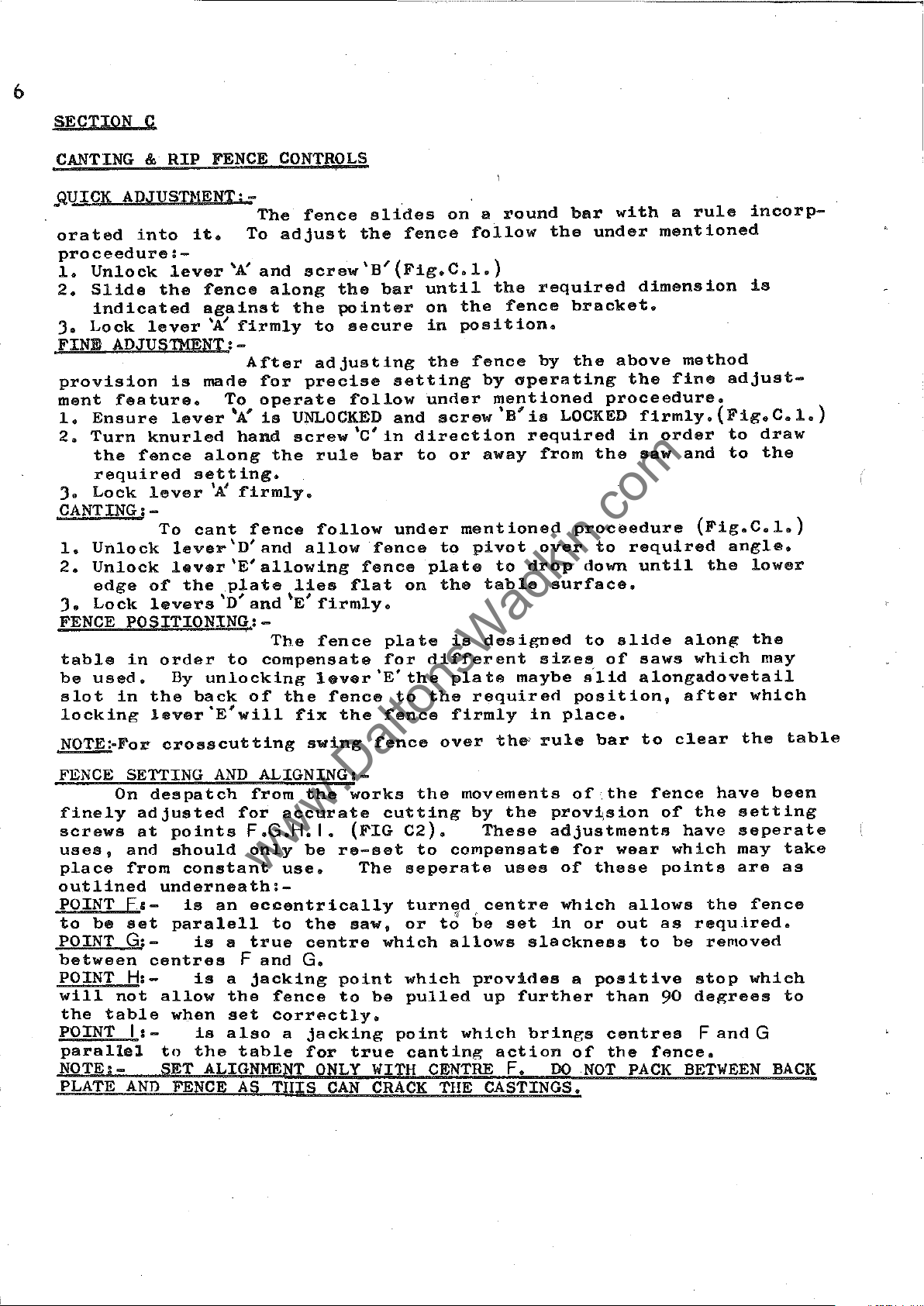

SECTION C

CANTING

.QUICK

orated

proceedure:-

1.

2.

J.

FINE

provision

ment

1.

2.

J.

CANTING:-

1.

2.

J.

FENCE

table

be

slot

locking

ADJUSn!ENT:-

Unlock

Slide

indicated

Lock

ADJUSIMENII-

feature.

Ensure

Turn

the

required

Lock

Unlock

Unlock

edge

Lock

POSITIONING:-

in

used.

in

&

RIP

FENCE

into

fence

it.

lever

the

fence

against

lever

knurled

lever

To

of

levers

order

the

lever'E'will

'A!

is

made

To

lever

along

setting.

'K

cant

lever'D'and

lever'E'allowing

the

\'

By

unlocking

back

The

To

'A:

and

along

firmly

After

for

operate

'A'

is

hand

the

firmly.

fence

plate

D

and

The

to

compensate

of

CONTROLS

fence

adjust

screw'B'(Fig.C.l.)

the

to

adjusting

precise

UNLOCKED

screw'C'in

rule

follow

allow

lies

",

E

firmly.

fence

lever

the

fix

the

the

pointer

secure

follow

fence

flat

fence

the

slides

bar

bar

fence

plate

for

'E'

fence

fence

until

on

in

the

setting

under

and

screw'B'ia

direction

to

under

plate

on

different

the

to

the

on a round

follow

the

the

fence

position.

fence

by

operating

mentioned

or

away

mentioned

to

pivot

to

the

table

is

designed

plate

firmly

maybe

required

bar

the

required

bracket.

by

the

LOCKED

required

from

proceedure

over

drop

in

down

surface.

to

sizes

s'lid

position,

place.

with

under

proceedure.

the

to

of

mentioned

dimension

above

the

firmly.(Fig.C.l.)

in

order

saw

required

until

slide

saws

alongadovetail

a

rule

method

fine

and

(Fig.C.l.)

the

along

which

after

incorp-

is

adjust-

to

draw

to

the

angle.

lower

the

may

which

NOTE:-For

FENCE SETTING

On

finely

screws

uses,

place

outlined

POINT

to

be

POINT

between

POINT H:-

will

the

table

POINT

parallel

NOTE:PLATE

despatch

adjusted

at

and

from

underneath:F&set

G:-

centres

not

allow

1:-

SET

AND

crosscutting

points

should

constant

is

paralell

is

is

when

to

FENCE

AND

ALIGNINGI-

from

for

F.G.H. I.

only

an

eccentrically

to

s

true

F

and

a

jacking

the

fence

set

correctly.

is

also

the

table

ALIGNMENT

AS

TIllS

swing

the

accurate

be

re-set

use.

the

centre

G.

point

to

a

jacking

for

ONLY

CAN

fence

works

cutting

(FIG

The

saw.

which

be

true

WITH

CRACK

over

the

C2).

to

seperate

turned

or

to

which

pulled

point

canting

CENTRE

THE

the'

movements

by

the

These

compensate

uses

centre

be

set

allows

provides

which

slackness

up

further

brings

action

F.

CASTINGS.

rule

bar

of

the

provi,sion

adjustments

for

wear

of

these

which

in

or

out

a

positive

than

centres

of

the

DO

NOT

to

fence

of

which

points

allows

as

to

90

fence.

PACK

clear

have

the

have

the

requ

be

removed

stop

degrees

F

and

BETWEEN

the

table

been

setting

seperate

may

take

are

as

fence

tred.

which

to

G

BACK

7

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

FIG.Cl

FIGC2

8

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

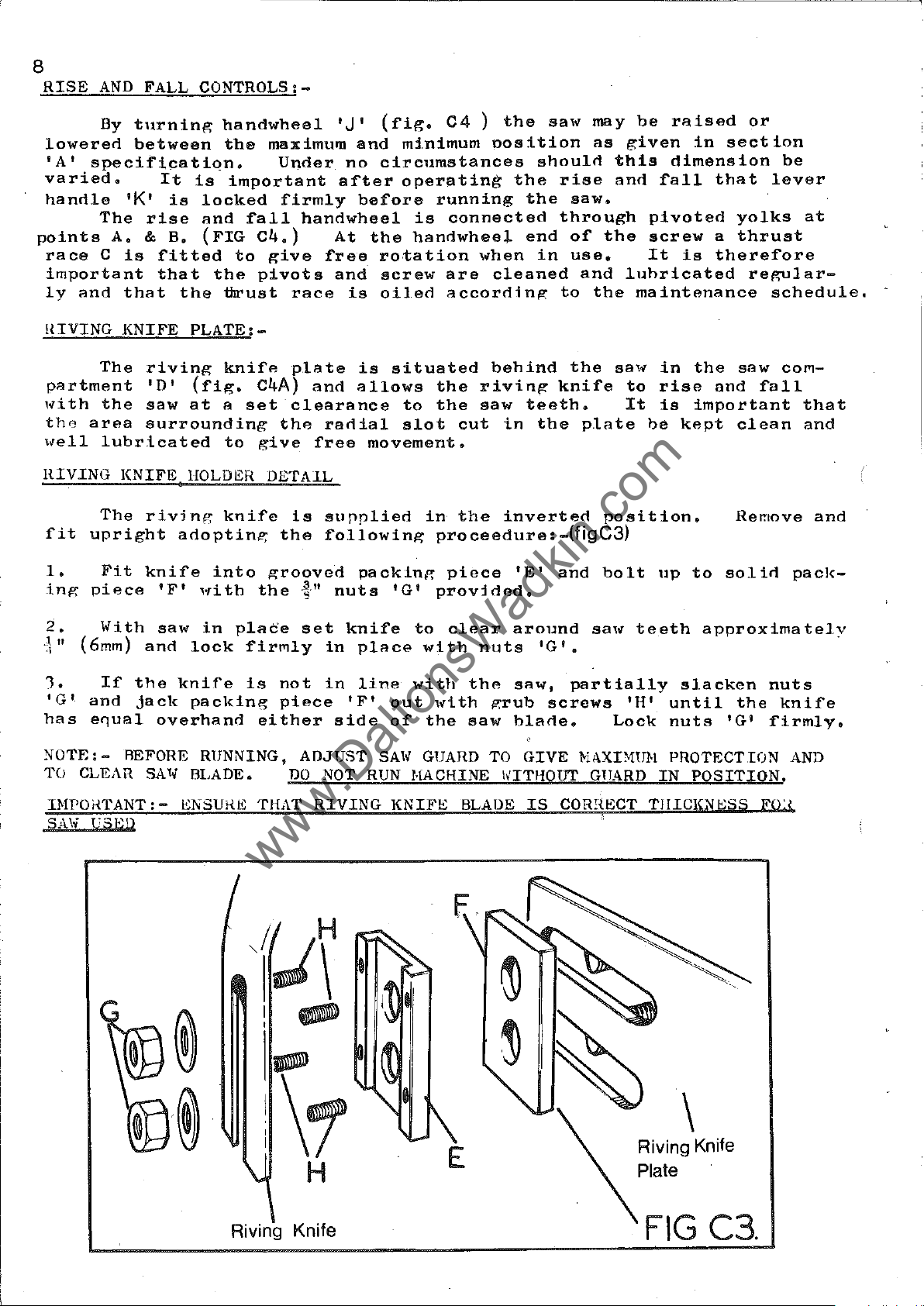

RISE

lo"ered

'A'

varied.

handle

points

race

important

ly

and

AND

FALL

By

turning

between

specification.

It

'K'

is

The

C

A.

is

that

rise

&

fitted

that

B.

the

CONTROLS:-

handwheel

the

maximum

Under.

is

important

locked

and

fall

(FIG

to

the

thrust

C4.)

give

pivots

firmly

handwheel

free

race

'J'

(fig.

and

no

circumstances

after

before

At

the

ro·tation

and

is

screw

oiled

C4

)

the

m1.nimum

operatin~

running

is

handwheel

position

connected

"hen

are

cleaned

accordinl"

the

sa"

should

the

end

in

may

as

rise

saw.

through

of

the

use.

and

to

the

be

r~ised

given

this

and

dimension

fall

pivoted

screw

It

luhricated

maintenance

in

is

or

section

that

a

therefore

lever

yolks

thrust

regular-

schedule.

be

at

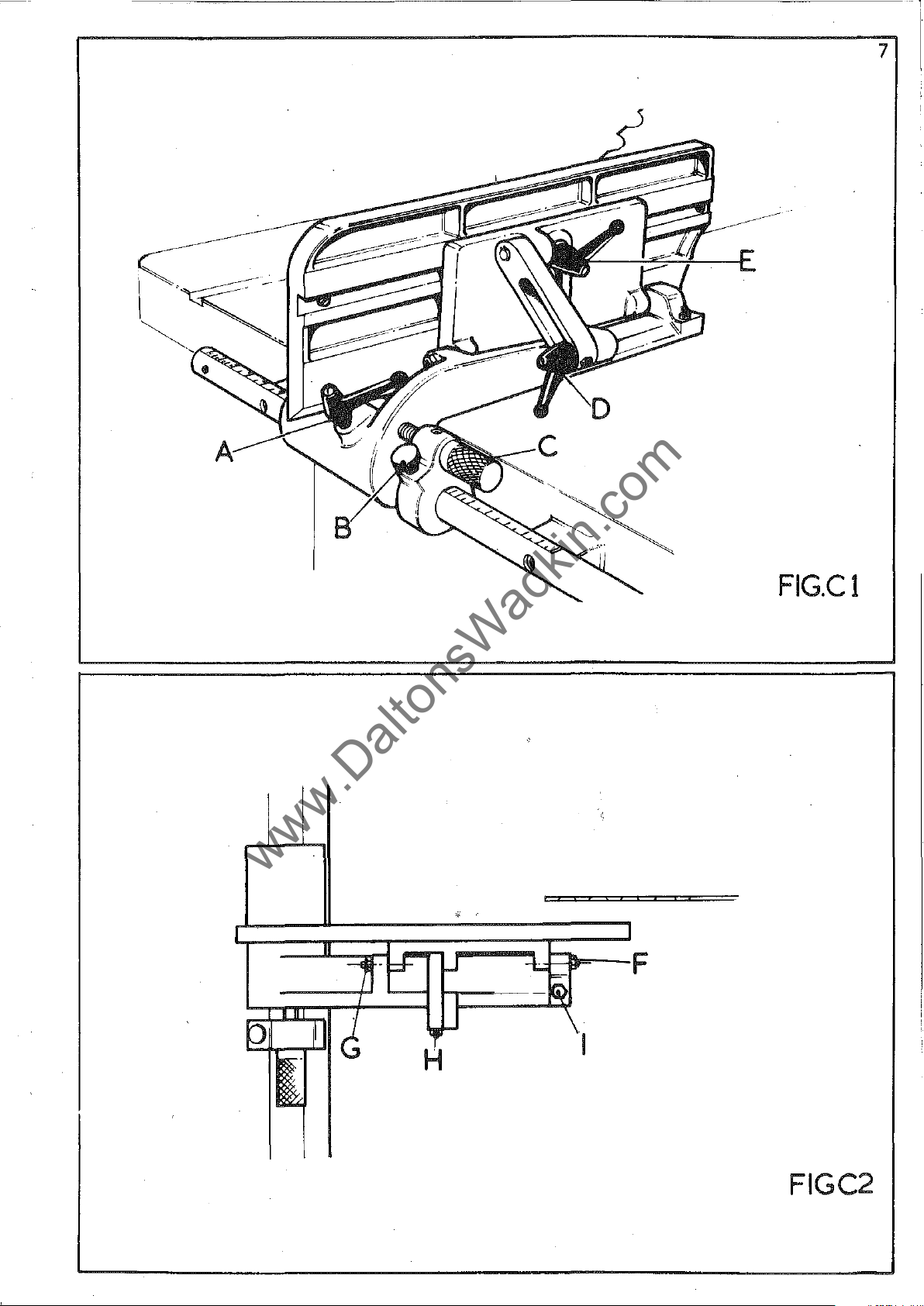

llIVING

p~rtment

with

the

\fell

HIVING

fit

1.

inp:

2.

.1"

.\

1.

'G'

has

NOTE:

TO CLEAR SA1,

KNIFE

The

the

area

lubricated

KNIFE

The

upright

Fit

piece

With

(6mm)

If

the

and

jack

e~u~l

- BEFORE

riving

'D'

saw

surrounding

rivjng

knife

'F'

saw

and

overhand

PLATE:-

knif"

(fig.

at

a

to

HOLD!;;"

knife

adoptinl';

into

with

in

plade

lock

knife

packing

RUNNING,

BLADE.

C4A)

set

the

give

DETAIL

the

grooved

the

firmly

is

not

piece

either

p1~te

and

clearance

radial

free

is

supplied

following

."

nuts

set

knife

in

in

'F'

side

ADJUST

DO

NOT RUN

is

situated

~llows

movement.

pack:ln,,,:

place

line

SAl,

the

to

the

slot

in

proceedure:

'G'

provided.

to

with

with

out

,dth

of

the

GUARD TO

HACHINE

piece

clear

rivinp:

saw

cut

the

nuts

the

saw

behind

teeth.

in

the

inverted

'E'

around

'G'

saw,

p;rub

I>ITHOUT

screws

blade.

GIVE

the

sa'"

knife

plate

position.

-(figC3)

and

bolt

sa"

•

partially

Lock

t<li\XDlUH

GTJARD

in

to

rise

It

is

be

up

teeth

'H'

until

nuts

PROTECTION

IN

the

saw

and

fall

important

kept

slacken

clean

Remove

to

solid

approximatelY

the

'G'

POSITION.

COI'1-

that

and

and

pack-

nuts

knife

firmly.

AND

INPOf{TANT:

SA\!

VSED

-

t;NSUf{~;

THAT

j~\

I.

®

-

.~

1\1

Riving Knife

RIVING

H

KNIFl;;

BLADE

E

IS

CORr{ECT

TJIICIGiESS

\

Riving Knife

Plate

F(U

-,

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-

J

A

K

FIGC4

FIGC4A

10

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

HOUNTING

SAliBLAOES:-

When

1.

2.

position.

J.

spindle.

4.

Check

especiAlly

Rpindle

the

').

fore

..!l..

NOTE:-

HUE TO THE

Isolate

Remove

Remove

Select

saw

Check

replacing

THPO.tTANT: -ENSURE

(ELECTRICS

the

checking

bore

IF

mounting

machine

table

spindle

blarle

hlade

where

and

that

the

L

Tlm

SAW

RUNNING

saws

insert

nut

required

is

in

it

will

that

pin

hole

the

saw

flange

SPINDLE

FL.\)IIGE

the

undermentioned

and

raise

(left

good

he

the

teeth

OR

OUT-OF-TRUE.

hand

depending

condition

gripped

fac~

centres

and

SA',[

of

point

locking

il.UNS

~'ACES

proceedure

the

saw

spindlp

thread)

on

and

by

the

hack

fit

correctly

towards

up

IN

COHRECT ClIRI,;CTION, f(8Fj<.;n

ARE NOT CLlCA'I

type

the

And

free

SAW

saw

the

f'irmly

of

from

ho"sing

front

work

dirt.

flange.

flange

onto

front

with

TillS

shoulrl

saw

which

is

those

of

the

CAN

be

into

flAnge

is

sawdust

Hount

clean

on

the

mAchine

spindle

TO

CAUSE

fOllowed:-

the

f'rom

to

be

and

saw

on

And

thAt

the

flange.

nut.

SrXTIlJN

VIJlHATION

top

done.

,?,Um.

the

be-

MITHE

which

setting,

quick

the

mitre

(!'iI':.

rods

~nd

(fig.

FENCE

The

mitre

should

and

setting

Accurate

CS.)

The

hy

the

'0'

anrl

C6.)

(;C.1..p....Jt5)_(EXTRA.)

fence

rods

fence

be

a

positive

at

repetitive

are

two

slide

kept

firmly

clamps

is

clean.

900 and

held

the

fitted

stop

in

in

'D!

rorls

0

45

to

any

cutting

the

To

into

into

A

scale

'A'

is

the

position.

can

fence

adjust

the

the

groovp

is

provirled

incorporaterl

saw.

be

ohtAined

with

position

the

the

The

plastic

thumbscrews

stop

req'Jired

provided

to

in

the

by

USA

ro<ls

on

inrlicate

seale

hAnd'"heel

of

'C'

slAcken

~s

illustrHted

the

the

and

seo",

accurate

to

give

'B'

stop

the

C1A"'PS

t"hle,

locks

rods

stop

'C'

in

C

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

FIGC5

I1

MITRE

SLOT

----.

-

~'----'.

I

!

FIGC6

-

~

STOP

RODS

12

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

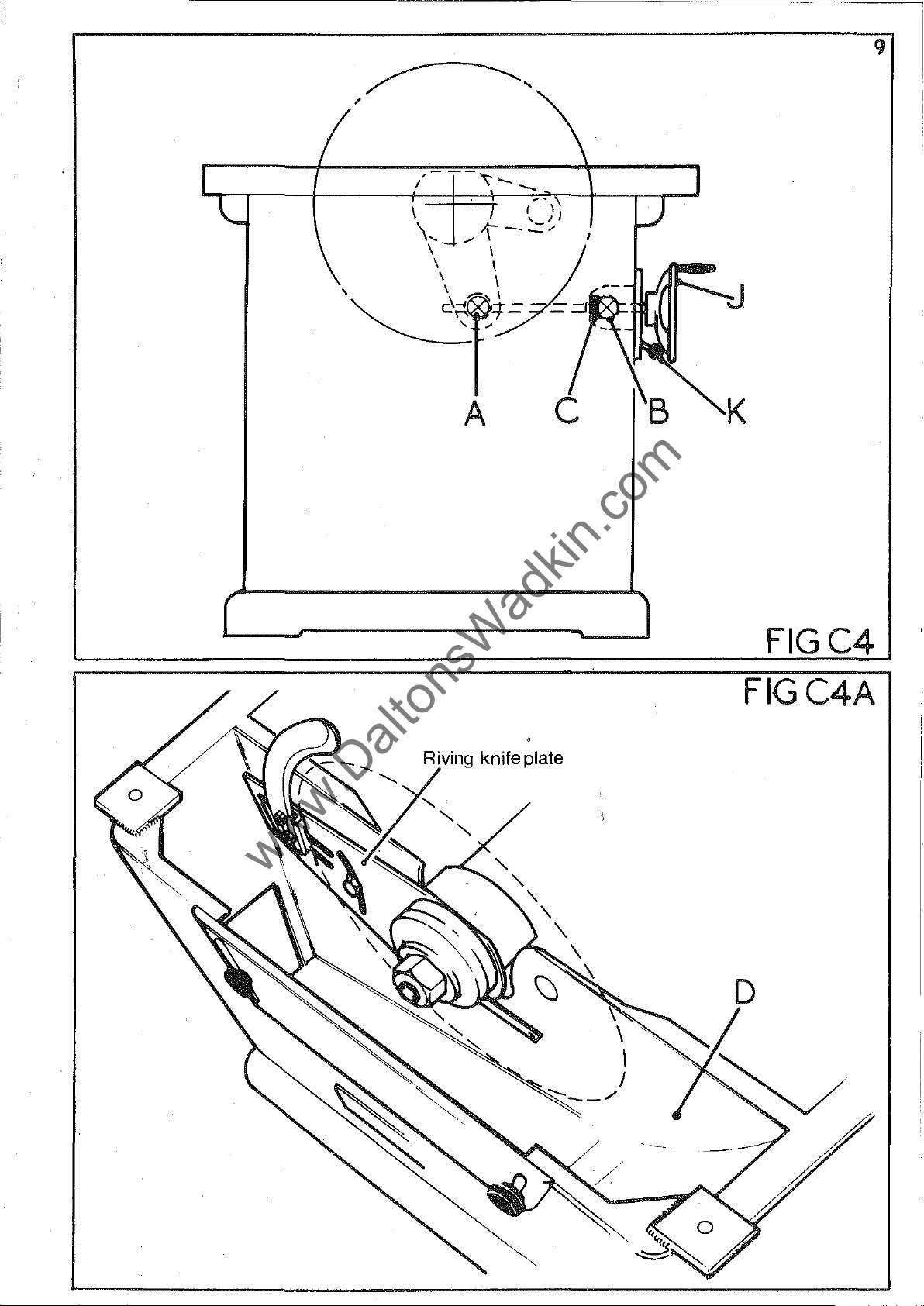

SAli

PACKING.

It

it

is

not

out-of-true

and

gap

packing

consequent

The

wood

retains

the

f'elt

strips

OPPOSITE.

he

amount

ouces

at

mouthpiece

underside

in

It

rene"eo,

The

heat

every

is

usual

intenoed

saws.

plate

must

loss

arrangement

the

f'elt

position.

close

)

shoulrl

ano

rrovision

of'

lubricating

and

opportunity,

is

not

of'

the

he

burning

to

provioe

th"t

The

to

steady

be

tight

of

tension

of'

a

packinl':

the

At

saw

noted

sho111(1

of'

this

idea

of'

the

length

tRhle

the

p;ap

thnt

not

the

oil,

whilst

the

a

the

"s

in

saw

extending

pieces

and

rear

and

he

felt

which

felt

sa'"

packing

of

fitting

saw,

this

the

packing's

in

to

of

provide

after

"110,,eo

inserts

not

runninp,'.

pieces

blade

but

"ill

blaoe.

place.

the

thA

some

with

be

used

pi-.ckinp,'

it

generate

beyono

front

g"p

a

p;uioe

to

allow

only

are

some

as

should

are

time,

in

the

Also

of'

plAte

for

fall

application

cleans

It

is

1uhricaterl.

form

"

R"uioe

piecAs

he

heat,

such

depth

wood

the

anrl

the

the

packinll's

into

the

therefore

noted

a

Il'ap

table

saw.

b"o

saw,

of

packing,

for

into

that

resulting

way

thRt

of

the

strips

plate

si.milar

(SEE

will

conrlition.

of' a s",,,11

hut

important

buckleo

the

table

the

in

"

saw

secured

support

nIAGHilHS

need

"Iso

but

or

a

hard-

teeth

to

the

wood

to

rethat,

NOTE:-

REPLACENENT LENGTHS OF

FELT

l'~7/'l6"

x

6"

.

Saw

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

~

I

-cr-

1---

I(~"'"

I

I

~L

I

I

I

I

I

I

lEE>

L_

FIGC7

Gap

plate

Saw

SECTION

~A

Saw

Felt

13

Table

~--

I

Hardw{)j

C)("~e=====:::::::=t==+~:f-.II

I

a:(B

LL-I-4~.~

I I

I

I I

Felt·~+======t=l~~

----,

I

I

®:a'

:

I

I

Gap Mouth

plate piece

... : ...

::+

/h/

" / 11-

EBI

.F

--17/Ndl.._I~ardwood

- - mouthpiece

",

/ I

X

Screw

SECTION

~aa~

Saw

/

-

'i1

/

I

"-

SECTION~

~CC

""...,....,..,.,.'-.r

l

If

I

Table

.-.

'1.""

J<

--1,/

,"

/

,/

14.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

B

PILLAIl

hanrlle

unlock

th"

correct

knit'e,

until

to

clear

the

guard

SAW

GUARD

'B'

(FIG

lever

unlock

correctly

timber

cover

FIG

To

re

CB)

'C'

anrl

position.

lever

positioned.

by

will

CB

ise

and

lower

To

position

slirle

'E'

approximately

hinge

To

and

the

centralize

up

slide

I.hen

and

the

the

guard

guard

in

over

gua

rd,

guard

pillar

the

back

operating,

(Jmm)

to

unlock

on

'0'

guard

or

To

reve"l

centre

until

to

forwarc1

ensure

gain

blade.

lever

clear

visor

access

witll

th"

aJong

'A'

the

guard

saw

'G'

to

anrl

and

bar

turn

saw,

is

riving

is

saw,

in

'F'

set

FIG

SPINOLE BRAKE:-

situated

brake

and

To

excessive

pillar

.md

placing

the

a

llow

of

C

11

next

pad

by

is

spring-loaded

tension

slackness

at

the

tensionccable

brake

rivet

the

heads -are

brake

special

to

the

means

the

cable,

spindle

pad

pad

to

pulley.(FIGC11)

This

rise

ot'

to

is

as

mentioned

it

is

below

wear

device

a

cable

relieve

turn

to

end

important

down

and

the

be

and

the

is

operated

fall

'B'

leading

tension

knurled

removed,

pull

above

that

surface

to

rivets

handwheel.

",hen

nut

unlock

cable

with

new

of

as

through,

knurled

the

this

from

from

hand

'C'

rivets

the

pad

the

It

the

pressure

on

grub

re-lock

screw.

are

material.

will

brake

is

connected

operating

the

lever.

screw

used

score

lever

is

grub

l¥hen

and

the

'A'

lever,

reljeved.

'D'

screw

that

Do

surt'ace

to

the

Where

on

the

re-

not

15.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SECTION

MAINTENANCE

"c"

16

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SECTION

During

to

replace

proceedure

1.

2.

).

4.

5.

6.

ISOLATF:

REHOVE G<\P

MACHINE.

SLACKEN AN]) RBHOVE

TENSION

WIND SAIl'

REMOVE COUNTERSUNK SCRE1; ANI)

IN

RE}iOYE KEY

RENOVB

HEHO

D.

-

the

worn

follow

PULLEY

CIRCLIP

YE

DUSTCAP

HAINTENANCE:-

operating

or

damaged'pnrts

the

undermention<~d

?-lAClllNE

PLATE,

STUDS

CARRIAGE

'C'

'D'

ELECTRICALLY

.\FTER

AND

AND

'F'

'H'.

life

SAl,

V-ROPES

PAC1CING HOTOR UT'

INTO

RENOVE.

DISTANCE

AND

of

AND

HIDWAY

HOTOH

the

(i.e.

BEFOaE

SA1~

SPDlDLE

FRON

POSITION.

I,ASHSR

PIF:CE

T8NSION

sawbench

ba,ll

instr\lctions.

PULLEYS

'E'.

races.)

ATTENPTING

FRONT

,\S

'A t AND

HRACKgT

it

may

be

fO\ln<1

To

un<1ertake

(SEE

AN·)

1\]\1)

HF:~IOVE

SH01{N

SLACKEN GRUB SCRE1,rS

'G'

FIG

ANY

WORK.

H~;AH

IN

COVERS FRON

TURNnUCKLB

(FIG

ANIl lJNSCHE1,

D

necessary

this

1.)

1'111':

AND

D.2.)

'H'

AND

8.

'.'.

10.

11.

A

re

*"

th e ri

for

tion.

WORKING

AND

UNSCfmw

To

thoroughly

the

SA

HEHClVE

t

L'

•

PLACE

SHA~'T

FRO}!

ING

TITH.OTlGIl

It

THE

FHON

re-assemble,

shoul<1

vi

nIT

motion

AT

T!lE

IV

FLANGE

SAt,

FLANGE

RIVING

A I{oODEN

THROUGH

HOPSING

TilE

'HTH

cleanerl

a.1so

kni

f'e

pla

of

FRONT

'J'.

KNIFE

DRIFT

Tlm

HOIJSING.

\HTIl

SHAFT

HA}IHER

reverse

out.

be

note<1

te

should

the

plate

OF

THg

'K'

(L.Jl.Tl{Hr;AD.)

PLATE*ANl)

ON

THE

TIlE

SA"

AND

RE-INSEaT

ANT)

mUI'''!'

above

thAt

only

"nrl

SAW

SPINDU~t

LINK,

PULU;Y

TIY

D01NG

EN')

TO

the·,

not

R8AIUNG

SHAFT

IlENOvg

proceedure

two

be t iroh t enprl

to

clamp

AND

EN])

locknuts

HENClVE NUT

UNSCHEW

OF

TlIE

TlIIS

ON

INTO

THB

eneurinr:

or

TilE

HOrSING

PllLLSY

pnour:;h

lock

A~,1l

SPI:-iDU:

Sf'INi)LE

IT.

..

on

T)llIVE

EW)

all

thp.

to

the

'I'

(L.H.THHEAD)

im)'IOVE

ANIl

KNUCl:ING

orie;inal

radi"l

provirle

plate

nUST

f)[(IVE

\HLL

THIS

nEAHING

in

CAP

'I'll"

!';hEHGE

BEAR-

SPINDU:

•

pFtrts

slot

a

flU

po"i-

in

id

e

17

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

'1

GJ

o

18

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

--------~~-----------

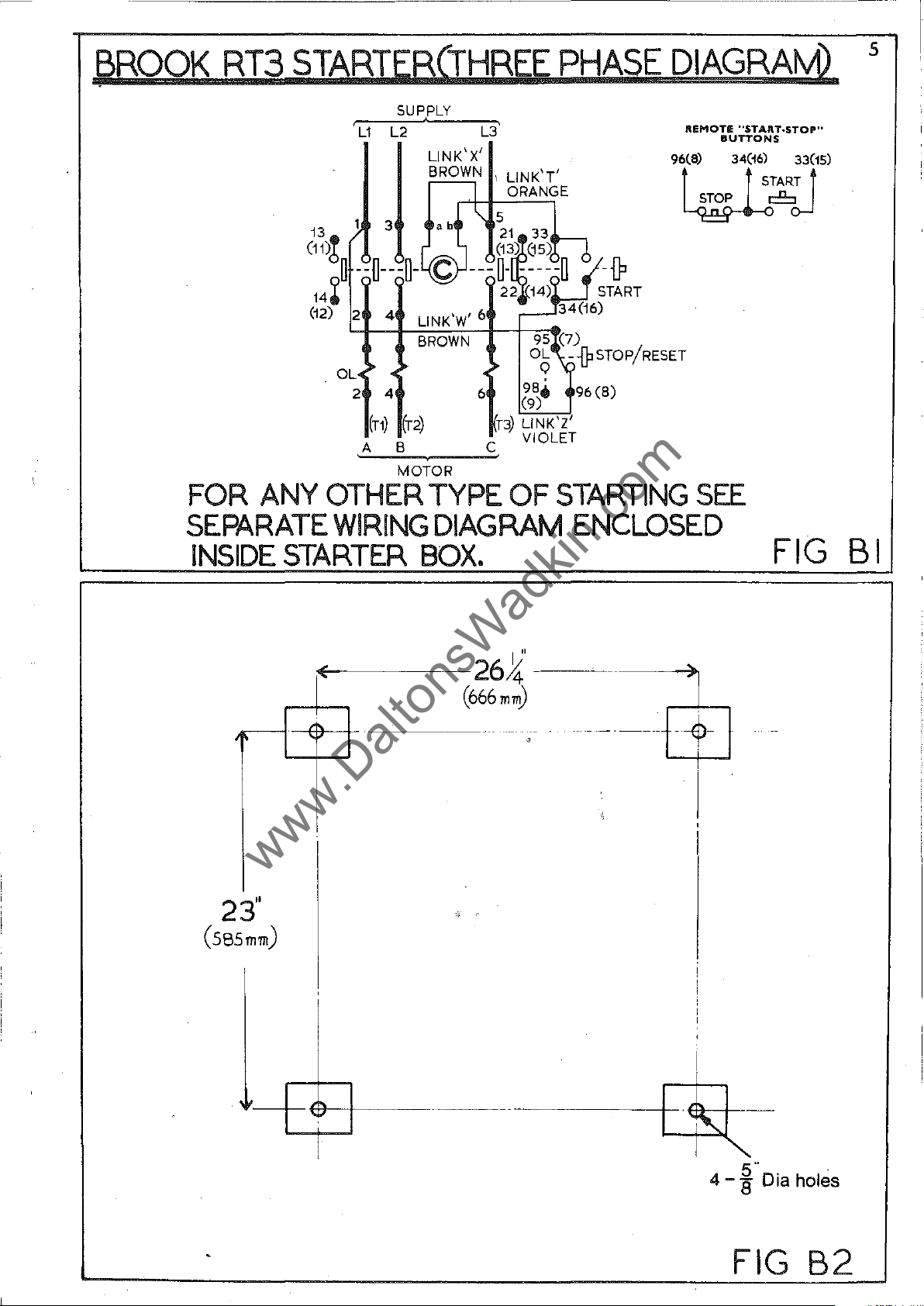

BELT

saw

maximum

correct

the

tioned

distance

the

of

applying

tion

defle

REPLACING

buckle

wards

TENSION:-

spindle

"running

proceedure.

By

belts.

the

pulleys

is

ct

ion.)

To

and

retension

is

efficiency

belt

turning

not

replace

of

the

a

force

greater

BELTS:-

thll"

tension

To

On

by

means

in"

turnbllckle

pullevs

achieve

(FIG

at

belts,

relievi.ng

as

all

mAchines

and

is

period.

(SEE

DJ.)

right

than

given

of'

four

life.of

maintained

FIG.

'A'

can

be

the

correct

and

angles

1/64"

decrease

tension

above.

the

ALPHA

these

To

tension

D.2.)

linking

increased

adjust

per

pulley

drive

at

and

inch

on

from

500,

helts,

all

the

the

tension,

with

central

of

centre

the

type

times

tension

to

the

span

belts

the

main

"V"

it

is

from

belts

provide

measure

turnbuckle

Along

-

(e.g.

distance

for

motorto

Belts.

important

new,

follow

studs,

greater

the

the

belt,

2J"

by

their

To

that

especially

the

the

tension

centre

until,

span

screwing

removal.

the

ensure

the

undermen-

centre

distance

whilst

the

deflec-

=

2'3/6h"

in

on

turn-

Aft

er-

POINTS

1.

2.

J.

ALWA

REPLACE

ALtrAYS RF:PLACE

4.

5.

6.

TO

NOTE

YS

HAINTAIN

\VOIt"

ENSURE

DO

IMPLEHENTS

ENSFRE

RUST

PUlLEYS

NOT

PRISE

PULLEY GHOOVES

OR

BURRS 1.11lCIl ARE

WHEN

HAINTAINING

COimECT

BELTS

11'OHN

ARE CORl{ECTLY

BELTS OVER

AS

THIS

BELT

BELT

WITH SAl'lE

OH

D.\HAGED BELTS

PULU~YS

CA?

DAMAGE

AND

BELTS

PHES~~NT.

DRIVES:-

TENSION.

TYPE

ALIGl\ED.

AS

\HTH

BF;LTS.

AHE

SPECIFIED.

IHHEDIATELY.

SCHEl,

CLE:AN

DRIVERS

,

AND

OR OTHER SHARP

REMOVE

ANY

OIL,

GREASl')

~--+--t---A

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

19

Method of packing up

motor for removal of

tension screws as

outlined in sectionDl

I

FORCE

FIG

FIG

DEFLECTION

1f640F

PER

AN

INCH

INCH

OFSPAN

D2

D3

20

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

SAW

MAINTENANCE:-

Efficient

the

saw

of

the

to

ensure

HANGING:-

'Ranl':inF,

fourth

sive

whilst

teeth

SAW

in

sqll"re

equal

gullet

rounrleo.

:bevels

their

original

machine.

block

filao

SI1ARPENING:-

Do

a

vice

number

original

spindle,

spindle.

straight

or

fifth

in

running.

not

as

faces

of

the

Wi.th

as

in

profile,

operation

and

The

cutting.

down'

a

li~htly

run

shown

ara

of

saw

(FIG.

sha

woooen

The

a

saw

required

strokes

in

cross

shape

it

shoulo

rpen

in

D7.)

the

to

sew

ing.

holoer

saw

remove

when

(FIG

the

cut

and

i"

of

a

saw

flanges

must

he

done

shoulo

blunt.

05.)

(FIG

with

necessary

same

saws

In

the

a

the

gullets

circular

also

on

To

range

(FIG

then

the

ranging

With

D6.)

flat

manner,

points

course

to

being

run

a

D4.)

To

file.

become

saw

at

new

down.

lightly

be

removed

re-sharpen

rip

Sharpen

taking

are

of

grind

depends

perfectly

the

saw

feed

marks.

saw

At

care

needed

repeated

shallow.

the

correct

or

al':ainst

anrl

teeth,

hy

the

saw

on

true

square

any

saw

a

square-edged

the

by

hand,

chisel

".ivine:

same

to

keep

with

filing,

on

hack

a

running

to

the

peripheral

after

the

saw

tops

e"ch

time,

To

saw-sharpening

holrl

eoges

tooth

the

anrl

saws

restore

of

file

gullet

front

speed

the

abra-

teeth

the

the

lose

the

of

axis

saw

anrl

an

the

well

SETTING:-

The

body

spt'

in

side

a

seen

being

in

indicates

that

&

so

(Le.)

(FIG

or

piece

in

cut,

1,e

(FIG

For

the

D12.)

a,"ount

there

DS)

else

of

timber

(FIG.

hut

CAn

DID)

the

hand

number

is

the

For

the

D9)

supply

This

amount

setting,

3"

14

Bore

of

freedom

teeth

saw

where

is

of

set

are

good

will

The

usually

a

small

device

of

saws

shOUld

from

bent

sawing,

run

the

a[,lOunt

010"

machine

wi

set

small

used

be

friction.

alternately

this

to

result

of

to

11

a

by

micrometer

devi.ces

does

sufficient

amount

one

side.

shoulo

set

015"

for

ccept

can

not

Saw

be

varies

(.3mm:

precisely

saws

dial.

be

warrant

to

teeth

to

the

of

set

To

a

according

.4mmJ

up

to

supplieo

a

give

rip,-ht

shoulo

check

small,

setting

36,"

machine

clearance

are

generally

or

he

the

even

to

saws

in

diameter.

where

(SI':E

to

the

'spring

left

set,

triangle,

the

it

as

shown

erll",l

~'IGs.Dll

at

cut

t.imher

as

shown

and

is

felt

into

saw

each

as

16 Bore

STANDARD

PIN HOLE CENTRES

SAW AND

~"

8

CNT

9"

FIGD4

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

FIGD5

FIGD6

Clearance

angle15°

Hook1

RIP SAW

FIGD7

Clearance

angle 43

CROSSCUT SAW

0

===i~1~~l===d~~s=e:~~5~f:~~

Saw cut Set

Area of tooth

shown shaded

FIGD8

set-over

---....-""

~.-=~~

l .. ...::

.~

FIGD9

FIGDII

FIGDIO

FIG

10

I I

_18--"'_,..,j1

DI2

11..-.

___

15

2~0

FIG Dl3

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

LUBRICATION

DIAGRAM

RI

Cl

7"_:::::::=-i~'"

_-..-----r-r-'I.-.

I

1111

1-

l

,.,.

A~

__

,

v~\""

---\=:

i~,~

......

-

\--

i

I

\ 1

\

-1

....

-

"\-I.

L\,

1I.'"

.......

__

~t~

\"

_ -,-

-

~

A-

B-Oil

C-"THRUST

D-Grease-two

Oil

and

weekly.

each end per year.

"

clean weekly.

RAC(oil

weekly.

shots

A

A

A

10

A

/},

<?--'--

/

/./}/

,:,(

J ,

\ I

',-

__

.........

\

/9'--D

Dust Outlet

8x5

I L i

I -

I l

I I

I I

I I

__

I

----

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

23

SECTION

SPARE

PARTS

11

E

LISTS

"

24

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

REF.

NO.

1

2

3

4

5

6

7

~8

10

11

12

13

14

15

16

17

PLEASE

9

18

19

20

21

22

23

24

25

26

27

28

29

30

MW

75~.

BSW

750.

BSw75Z.

BSX

12.

BSW

751.

BSW

137.

BSW

27.

STATE

BZG

70.

MAIN

1

1

1

1

2

1

1

1

VOLTAGE,

1

2

2

8

4

4

2

2

2

2

?

8

2

2

1

2

2

2

1

2

3

2

PHASE,

BASE

&

FREQUENCY.

ASSEMBLY

MAIN

TABLE

GAP

SPINDLE

BASE

FRCNT

BASE

BROOK

WADKIN

REAR

FRONT

No. 10

~"

~"

~"

i"

211

i"

PLASTIC

~"

il:"

il:"

SPRING

~"

DZUS

t"

DZUS

f'

2BA

3/16"

BASE.

PLATE.

FEET.

COVER.

RT 3 STARTER.

WOOD

WOCD

WHIT

WASHERS.

DIA X 1"

WHIT

WHIT

WASHERS.

WHIT

WHIT

WASHERS.

WHIT

AJW6-55

EX'l'ERNAL

s6-275

DIA

X

WHI'f

DESCRIPTION.

PULLEY

COVER.

BURSGREEN

SAW

WOODSCREWS.

X 1i"

X

i"

X 1i"

HANDWHEELS

X 1"

X

~"

GUARD

NUTS.

BRASS

~"LOlJG

COVER.

PACKINGS.

SAW

PACKINGS.

LONG

LONG

LONG

LONG

LONG

LONG

CLIP.

WWG

CIRCLIP.

SPRING.

RIVETS.

HOUND

X

t."

LONG

NAMEPLATE.

DOWELS.

HEXAGON

HEXAGON

)

)

HEXAGON

RCUND

STUDS.

REF:

NUT.

HEAD

COUNTERSUNK

BOLTS.

HEAD

6687/B.

BOLTS.

BOLTS.

SCRE'IS.

SCRE'IS.

SCREW;

WHEN

ORDERING

MACHINE.

SPARE

PARTS

PLEASE

QUOTE

PART

NUMBER

AND

SERIAL

NUMBER

OF

~"

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

___

------.c

••

..

-~

?---2

4

i

'3

, \

~

~~--

~

C

C

,

(,'

\;l

, .

~

c"

0

:[

1----

~

-8

\

20

5

26

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

SAW

BSW759.

BSW

80.

1

BS1

760.

BSW

5.

BSS

57.

'BSW

519.

BSW

761.

BSX

?/A.

BSW

61/A.

BSX

19

SPINDLE

llQ..

ASSEMBLY

£IT.

1

1

1

1

1

1

2

1

2

1

2

1

1

1

1

1

1

1

1

1

1

2

1il:"

WHIT

FRON'r

SAW

DRIVING

REAR

HOUSING

5/16"

5/16"

5/16"

SKF

6308

RBAR

5/16"

HOTCH

2;!-"

EXTERNAL

PULLEY

SPINDLE

5/16"

5/16"

;!-"

WHIT

SCREI,

SPINDLB

~"

SQUARE

KEY.

SPINDLE.

KINGFISHER

FORM

SAIl

SAl,

FLANGE.

FRONT

WHIT

WHIT

WHIT

SINGLE

HOUSING

WHIT

TENSION

DISTANCE

PULLEY.

WHIT

WHIT X 1il:"

X 1"

•

PULLEY

DESCRIPTION.

L.H. 7

FLANGE.

PEG.

DUiiTCAP.

X

3f;"

LOCKNUTS.

X

3t:"

DUSTCAP.

COUNTERSUNK

BRACKET'.

CICLIP.

X 1"

COUNTERSUNK 1 SELF

WASHERS.

X 1i"

UO

2

LONG

GREASE

T.P./

LONG

STUD.

ROW

J3BAHINGS.

PIECE.

LONG

ALLEN

LONG

SINGLE

STUD.

SCHBVlS

ALLEN

CUPS.

NUT.

i"

GRUB

GRUB

LOK

ROUND

LONG.

SCREW.

SCREW.

1

11'JD

'NOTE:

PART

WHEN

OF

MACHINE.

PART

NO.

ORDERING

NO.

HEF:

BSW

519 IS

92.

SPI\RIC

PAHTS

ALSO

USED

PLICASE

ON

i/.UOTE

RISE

PART

AND

FALL

r;NHBER

UNIT

AND

SEE

SERIAL

PIIGE29

NUHBBR

40

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

41

42

4344

~

~

61

".,.

• 0

\-\\\

\!

J

! /

/ /

...

rn:

!!Ill

!!IIIII

)))

f!j/

11

!Ill i III

1111

1111

!iI!iiilllll

47 46

~

JO~~3

~~

.~

-.le

\-51

6/

~

1t55

~

56

~

60

"*

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

See

add!

6:

1011$

10

clrauuinq

28.

SAW

70

71

72

73

74

75

76

77

71l

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

6

(9

97

98

99

100

101

102

103

104

105

10(,

1\~r7

108

10~

11

111

112

11)

114

115

116

117

(SPZ

118

119

120

121

122

123

124

125

126

127

121l

129

130

131

132

133

134

135

136

137

138

1270)-ALPHA

BSW

9.

S

125/A

6698/A

MW

10

5296/3

MW

35

MW

1 9

MW

37

BSW

34

SKF

0.6

BSW

41)

BSW

33

- - - 1

MOTOR

- _ _ 3 i!:"

MW

BSS

MW1')O---1--24"BSW--fIOTOR

MX

MW7S6

BSW

BSW

BSW

BSW

BSW

IlSW

BSW

BS\>!

BSW

BSW

llSW

BSW

BSW

BSX

BSW

BSX

MW

MW

,BSli/

MW

M\v

MW

BSW

MW

BROOK

(

11

SHAFT

519

2')

SjA

43

7/A

7

134

42

31

142

147

135

500

4

50

51

49/A

is'

754/A

2J

29

28

159

38

18

20

39

62

MOTOR

STANDARD

!I

RISE&FALL

1

1

2

4

9

1

1

1

1 1i!:i. DIA X i"

1

1

4

2

2

3 i!:"

2

1

1

1

KEY

(PLlo:ASE

1

1

2

1

1-

1

1

1

2

2

2

2

4

3

h

?

2 i"

2 SPINDLE

1

1

1

2

2

1

1

1 j)EtlSION

4-

1

1 SUPPORT PLATE

1 SUPPORT PLATE LINK

1 SUPPORT PLATE LINK

1 SPINDLE

1 RIVING KNIFE SUPPORT PLATE.

1

4

1 RIVING KNIFE

1 RIVING KNIFE

2

3

1

1

1

1

1

1

1

11

~UOTE

26"

BSW

24"BSW

26"BSW

7.5

10

HP

ASSEMBLY

9"

DIA

ALLUMINIUM

RISE

& FALL INDICATOR PLATE.

t"

DIA

BRASS

t"

,IHIT

X 1i!:"

i"

WASHlo:RS.

HANDWHEEL

i"

BORE X 2i"

RISE & FAIL

RISE & FAIL

LOCKING

~"

EXTERNAL

RISE

RISE

WHIT

3/16"

THRUST

TH1<UST

RISE

& FALL

~"

I/D

MACHINE & MOTOR

WHIT

MOTOH

2~"

EXTERNAL

5/16"

SAW

RISE

""

t"

DIA

RISE

& FALL

MOTOR

~"

WHIT X 11"

MOTO?

MUTOR

M01'OR

5/16"

i"

\IHIT NUTS.

r"

WASHERS.

2"

WHIT X 1"

WHIT

RISE & FAIL

~"

WHIT

RISlo:

& FALL

~"

WHIT

~"

\/lIlT

fIOTOR

11

"SPACESAVER" VEE-ROPlo:G.

SAW

SPINDLlo: HOUSING.

STANDARD

3/16"

i"

WHIT

fi"

WHIT

RISE

& 'FALL

SPINDLb

~"

I'IASHER.

Jl"

SPECIAL

LOCKING

RISE & FAIL

LINK

PIVOT STUD.

D132S

FHAME,AITERNATIVE

SPINDLE.

LINK.

& FALL

& FALL SCREII COLLARS.

X

~"

DIA X 1i!:"

RAGE.

RACE

X

~"

X

1."

TENSION BRACKrJr.

X

11!:"

AND

PULLEY?-5HP (STANDARD)

EXTlo:RNAL

PIVOT SHAFT.

PIVOT BLOCKS.

PIVO~'

PIVOT

WHIT

X

X

~"

HOUCiING

U:FT

LEF"r

LOCKNUTS.

TENSION

11 11

nUT.

HOUSING

RIVING KNIFE •

\IllIT X

X

1~"

LOCKNUTS.

HOUSING

SLOTTlo:D

LINK NUT.

R1SE &

RIVlo:TS.

LONG

Hlo:XAGON

PLASTIC

BEARING BRACKET.

WHIT

LOCK

CIRCLIPS

LOCK

LONG

LONG

SHROUD.

SCRlo:,1

OlD

X if"

HP,~

LOllG

CIRCLIP.

LONG

WHIT

FAIL

10

,0 HP(STANDARD).

CIRCLIP

LOCK

LINK.

LONG

BLOCKS.

SHAFT

i"

LONG

LONG

LONG

PIVOT

SCREW

HAND,

SCRr;W'LOCK

HAND

SCREW.

LINK.

PIVOT SHAFT.

~"

LONG

HOLDER.

HOLDER

LONG

LOCK

COLLAR.

LINK.

LOCK

SCREW.

HANDLE.

BOR;;

PLASTIC BALL.

HANDLE

LINK

GRUB

PIVOT.

- - - - - - - - •

COUNTI>R!iUNK

SCREW.

STUDS.

COLLARS.

HEXAGON

IXlG

NUT.

THREAD

THREAD

PIN.

PIN

COACH

WASHER.

SHAFT.

TYPE

PINS.

SCR1'WS.

GROOVELOCK

LONG

GRUB

TYPE

CHUB

POINT

SHA"FT

LOCKNUT.

COLLAR.

LOCKNUTS.

(KNURLED).

GHUB

PACKING

BOLTS.

10

HP)

FAIL

HANDLE.

BOLTS.

1300.

OILITE

SCREIIS.

SCREWS.

11

10·0

1400.

SCR);IIS.

KOLTS.

GRUB

CULLARS.

SCREvIS.

PHCE.

DOWELS.

BUSH.

HP.

SCHEWS

29

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

ft

105

@\

~~

74

123

-=n-

122~

()

125

10

~129

~

119

1&

133

131

0

I~O

132

0

0

8~

ad.

c;:m

ak

~I

30

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

REF.

NO.

60

0

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

CANTING

PART

NO.

BSS

40

BSX

10

BSW

8 1

BSW

14

BSW

83

BSW

66

BSW

65

BSW

16

BSW

17 1

BSW

57/A

BSW

123 1

BSW

58 1

BSW

526 1

BSW

63

BSW

57

BSW

12

BSW

56

BSS

81l

lJQ..

OFF

1

3

3

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

FENCE

I

FRONT

FRONT

~"

DOVETAIL

BACK

1."

t"

t"

TURNOVER

i"

FENCE

FENCE

5/16"

5/16"

FENCE

i"

FENCE

~1iWHIT

3/16

BRASS

t"

i"

FINE

THUMB

FINE

FINE

BRASS

t"

t"

TURNOVER

RULE

IMPERIAL/METHIC

i"

ASSEMBLY.

DESCRIPTION.

FENCE

FENCE

WHIT X 1."

FENCL

WHIT

WASHER.

WHIT

WHIT

PIVOT

PIVOT

WHIT

WHIT

CANTING

EXTERNAL

LINK

11

WHIT

LOCKING

,/HIT

EXTERNAL

ADJUSTMENT

SCREW.

ADJUSTMENT

ADJUSTMENT

LOCKING

WASHER.

WHIT

POINTER.

WHIT X 11."

PLATE.

PLATE.

LONG

BOLT.

PLATL.

X

~"

LONG

LEVER

BRACKET

LOCKNUTS.

LEVER

X 2"

LEVER

BRACKET.

LOCK

SCREW.

SCREW

SCREW

X

t"

LONG

LOCKNUT.

LINK.

CIRCLIP.

PIVOT

X

PIN.

LOCK

t"

LONG

PAD.

LONG

CIRCLIP.

SCREW

BiiACKET.

SCREW.

PAD.

LOCK

RULE

LONG

24

" )

26"

CHEBSE

GRUB

HANDLE.

(ECCENTRIC).

(TRUE).

GRUB

HANDLE.

GRUB

STUD.

HANDLE.

BAR

ALLEN

BSW·

BSW

HEAD

SCRE'I.

SCREW.

SCREIJ.

COLLAH.

SCREWS.

.

SCRElvS.

NOTE:-

WHEN

OHDERING

SERIAL

SPARE

NUMBER

OF'

PARTS

THE

MACHINE.

PLEASE

QUOTE

PART

NUMBER

AND

Loading...

Loading...