Page 1

Operator’s Manual

5100030216

Light Tower

LTV6K, LTV6L, LTV8K

60 Hz

Type LTV6K, LTV6L, LTV8K

Document 5100030216

Date

Revision

Language EN

0317

02

Page 2

Copyright notice

© Copyright 2017 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the

machine. Any other type of reproduction is prohibited without express

written permission from Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker

Neuson Production Americas LLC represents an infringement of valid

copyrights. Violators will be prosecuted.

Trademarks

All trademarks referenced in this manual are the property of their

respective owners.

Manufacturer

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Original instructions

This Operator’s Manual presents the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

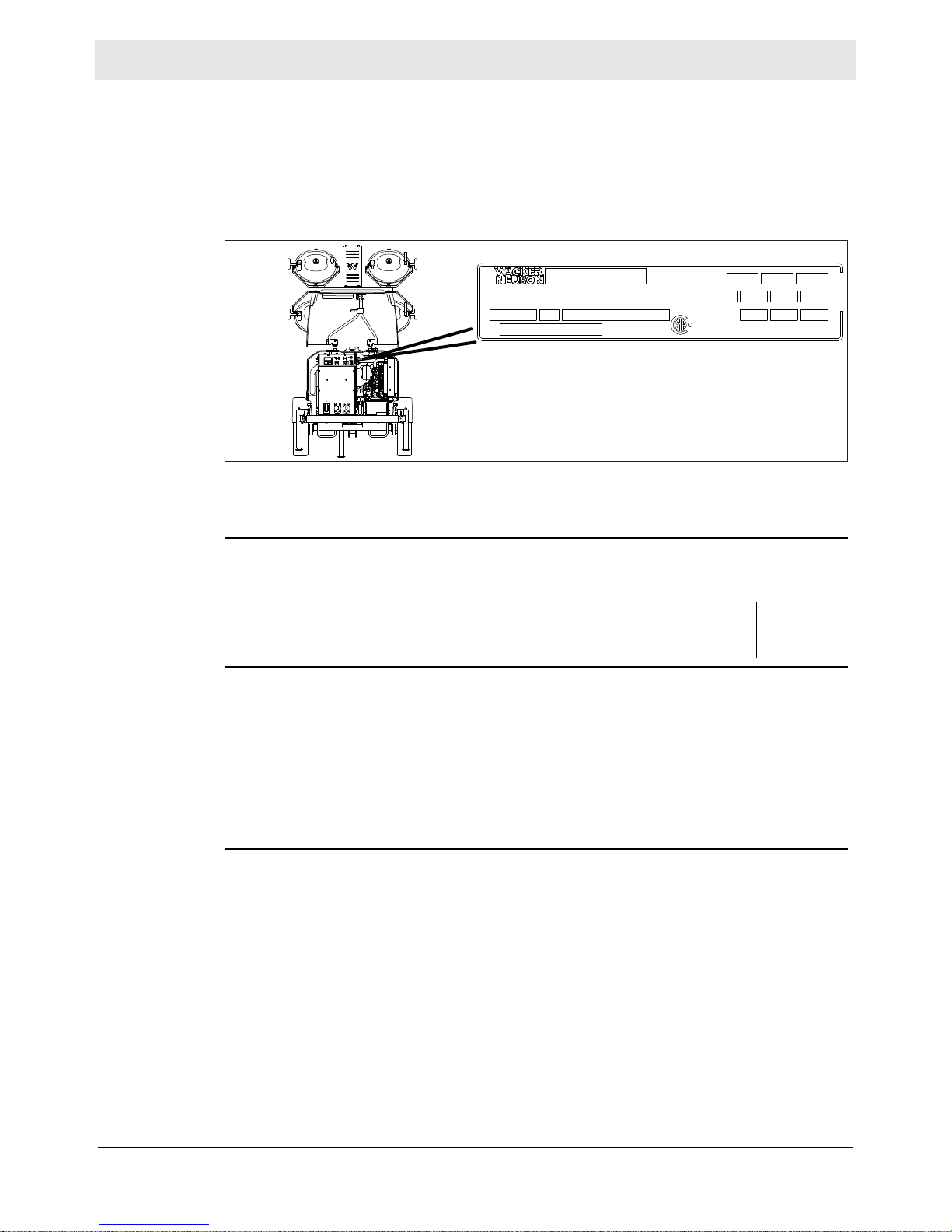

LTV

wc_gr013759

215429215429

R

51000314545100031454

For electrical

equipment only.

Pour material

electrique seulement.

lbs

Item No.

Type/Model

Serial No.

Rev.

MAX AMB 40~C

RPMhz

MON/YR

MADE IN USA

kW

kg

V

n

A

P.F .

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during inst allation,

operation, and maintenance of the machines.

Machine

identification

Serial number

(S/N)

Machine

documentation

Expectations

for

information in

this manual

A nameplate listing the model number, item number, revision number, and serial

number is attached to this machine. The location of the nameplate is shown above.

For future reference, record the serial number in the space provided below . You will

need the serial number when requesting parts or service for this machine.

Serial Number:

■ From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

■ Keep a copy of the Operator’s Manual with the machine at all times.

■ For spare parts info rmation, please see your Wacker Neuson Dealer, or visit the

Wacker Neuson website at http://www.wackerneuson.com/.

■ When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

■ This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

■ Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

■ The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to chan ge any

portion of this information without notice.

■ The illustrations, parts, and procedures in this manual refer to Wacker Neuson

factory-installed components. Your machine may vary depending on the

requirements of your specific region.

wc_tx004428gb_FM10.fm

3

Page 4

LTV

Manufacturer’

s approval

CALIFORNIA

Proposition

65 Warning

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

■ Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

■ Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

■ Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

■ Serious injury hazards to the operator and persons in the work area

■ Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

Combustion exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm.

Laws

pertaining to

spark

arresters

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose. In order to

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

4

wc_tx004428gb_FM10.fm

Page 5

LTV

Table of Contents

Foreword 3

1 Safety Information 9

1.1 Signal Words Used in this Manual ....................................................... 9

1.2 Machine Description and Intended Use ............................................. 10

1.3 Operating Safety ................................................................................ 11

1.4 Metal Halide Lamp Safety .................................................................. 13

1.5 Service Safety .................................................................................... 14

1.6 Operator Safety while Using Internal Combustion Engines ............... 16

1.7 Safety Guidelines for Lifting the Machine ........................................... 17

1.8 Safety Guidelines for Towing the Machine ......................................... 18

1.9 Reporting Safety Defects ................................................................... 19

2 Labels 20

2.1 Label Locations .................................................................................. 20

2.2 Label Meanings .................................................................................. 22

3 Lifting and Transporting 30

3.1 Lifting the Machine ............................................................................. 30

3.2 Preparing the Machine for Transport on a Truck or Trailer ................ 31

3.3 Before Towing Checklist ..................................................................... 32

3.4 Towing the Machine ........................................................................... 33

3.5 Trailer ................................................................................................. 34

3.6 Flip-up Tongue ................................................................................... 35

4 Machine Setup 36

4.1 Preparing the Machine for First Use ................................................... 36

4.2 Positioning the Machine ..................................................................... 37

4.3 Ground Connection ............................................................................ 38

4.4 Leveling the Trailer—Vertical Mast Light Towers ............................... 39

4.5 Refueling the Machine ........................................................................ 40

4.6 Aiming the Lights—Vertical Mast Light Towers .................................. 41

4.7 Manually Rotating the Light Bar ......................................................... 43

4.8 Raising the Tower—Manual Winch System ....................................... 44

4.9 Lowering the Tower—Manual Winch System .................................... 46

4.10 Raising the Tower—Power Winch System ......................................... 48

4.11 Lowering the Tower—Power Winch System ...................................... 50

wc_bo5100030216_02_FM10TOC.fm

5

Page 6

Table of Contents

5 Operation 52

5.1 Generator Derating ..............................................................................52

5.2 Control Panels and Receptacles—KUBOTA .......................................53

5.3 Control Panels and Receptacles—KOHLER .......................................54

5.4 Control Panel and Receptacles—DeepSea ........................................55

5.5 Machine Monitoring – DeepSea ..........................................................56

5.6 Alarms and Shut-Down Conditions – DeepSea ..................................58

5.7 Resetting the Maintenance Timers – DeepSea ...................................60

5.8 Before Starting ....................................................................................61

5.9 Starting, Operating, Stopping the Machine—KUBOTA .......................62

5.10 Starting, Operating, and Stopping the Machine—KOHLER ................64

5.11 Starting, Operating, Stopping the Machine—DeepSea .......................66

5.12 Auto Mode (Remote Run) ...................................................................68

5.13 Engine - Jump-Starting ........................................................................70

5.14 Emergency Shutdown Procedure ........................................................73

5.15 Using the Convenience Receptacles—60 Hz .....................................74

LTV

6 Factory-Installed Options 75

6.1 Cold Weather Package .......................................................................75

6.2 Engine Block Heater ............................................................................75

6.3 Battery Blanket ....................................................................................76

6.4 Oil Pan Heater .....................................................................................76

6.5 Fuel and Water Separator ...................................................................77

6.6 Positive Air Shutoff ..............................................................................77

6.7 Shore Power ........................................................................................77

7 General Maintenance 78

7.1 Preparing for Maintenance ..................................................................78

7.2 Periodic Maintenance Schedule ..........................................................79

7.3 Cleaning the Machine ..........................................................................80

7.4 Inspecting the Machine .......................................................................80

7.5 Maintaining the Trailer .........................................................................81

7.6 Maintaining the Battery ........................................................................82

7.7 Removing and Replacing Lamps ........................................................83

7.8 Long-Term Storage .............................................................................85

7.9 Machine Disposal and Decommissioning ............................................86

wc_bo5100030216_02_FM10TOC.fm

6

Page 7

LTV

Table of Contents

8 Engine Maintenance: Kubota D1005 / D1105 87

9 Engine Maintenance: KOHLER 90

10 Troubleshooting 95

11 Technical Data 97

11.1 Engine—KUBOTA .............................................................................. 97

11.2 Engine—KOHLER .............................................................................. 98

11.3 Generator ........................................................................................... 99

11.4 Machine ............................................................................................ 100

11.5 Radiation Compliance ...................................................................... 101

11.6 Dimensions—LTV6K, LTV8K, LTV6L .............................................. 101

12 Emissions Control Systems Information

and Warranty: KUBOTA

12.1 Emission Control System Background Information .......................... 102

12.2 Limited Defect Warranty for Wacker Neuson Emission Control

Systems ............................................................................................ 103

13 Emissions Control Systems Information

and Warranty: KOHLER

13.1 Emission Control System Background Information .......................... 106

13.2 Limited Defect Warranty for Exhaust Emission Control System ....... 107

102

106

wc_bo5100030216_02_FM10TOC.fm

7

Page 8

Table of Contents

LTV

wc_bo5100030216_02_FM10TOC.fm

8

Page 9

LTV Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

► Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

► To avoid death or serious injury from this type of hazard, obe

messages that follow this signal word.

y all safety

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

► To avoid possible death or serious injury from this type of hazard,

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

► To avoid possible minor or moderate injury from this type of hazard,

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

obey all safety

obey all

wc_si000704gb_FM10.fm

9

Page 10

Safety Information LTV

1.2 Machine Description and Intended Use

Machine

description

Intended use

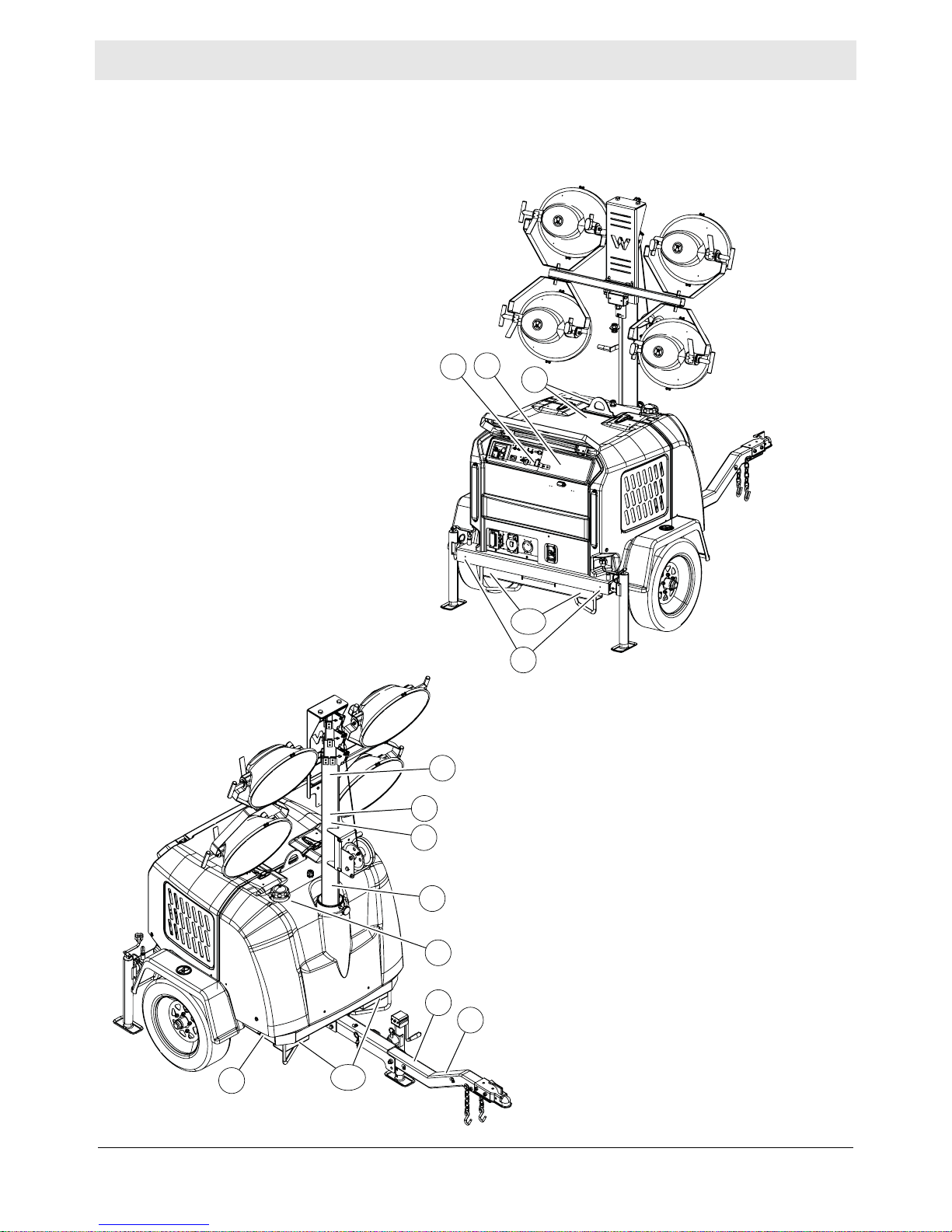

This machine is a mobile, trailer-mounted light tower. The Wacker Neuson Light

Tower consists of a trailer with a cabinet containing a diesel engine, a fuel tank, a

control panel, and an electric alternator. A telescoping tower with four metal halide

or LED lights is vertically mounted to the top of the cab inet. As the engine runs, the

generator converts mechanical energy into electric power. The metal halide or LED

lights run off this power. Receptacle(s) are also provided to power auxiliary loads.

The operator uses the control panel to operate and monitor the machine.

This machine is intended for the illumination of outdoor areas. This machine is also

intended for the purpose of supplying electrical power to connected loads. Refer to

the machine specifications for the output voltage and frequency, and for the

maximum output power limit of this machine.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty. The following are some

examples of misuse:

■ Connecting a load that has voltage and frequency requirements that are

incompatible with the machine output

■ Overloading the machine with a device that draws excessive power during

either continuous running or start-up

■ Operating the machine in a manner that is inconsistent with all federal, state,

and local codes and regulations

■ Using the machine as a ladder, support, or work surface

■ Using the machine to carry or transport passengers or equipment

■ Using the machine to tow other machines (unless factory equipped)

■ Using the machine as a hoist, or hanging items from the tower

■ Operating the machine outside of factory specifications

■ Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may rema in even after protective measures have been t aken.

They are called residual risks. On this machine, they may include exposure to:

■ Heat, noise, exhaust, and carbon monoxide from the engine

■ Heat from the lights

■ Ultraviolet radiation from the lights

■ Fire hazards from improper refueling techniques

■ Fuel and its fumes

■ Electric shock and arc flash

■ Personal injury from improper lifting the trailer tongue

■ Glare from lights (lights may blind drivers of nearby motor vehicles if the lights

are incorrectly positioned)

10

wc_si000704gb_FM10.fm

Page 11

LTV Safety Information

■ Typical hazards related to towing a trailer on roads and highways

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

1.3 Operating Safety

Operator

training

Operator

qualifications

Application

area

Before operating the machine:

■ Read and understand the operating instructions contained in all manuals

delivered with the machine.

■ Familiarize yourself with the location and proper use of all controls and safety

devices.

■ Contact Wacker Neuson for additional training if necessary.

When operating this machine:

■ Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

■ Have received instruction on how to properly use the machine

■ Are familiar with required safety devices

The machine must not be accessed or operated by:

■ Children

■ People impaired by alcohol, drugs or prescription drugs

Be aware of the application area.

■ Keep unauthorized personnel, children, and pets away from the machine.

■ Remain aware of changing positions and the movement of other equipment and

personnel in the application area/job site.

■ Identify whether special hazards exist in the application area, such as toxic

gases or unstable ground conditions, and take appropriate action to eliminate

the special hazards before using the machine.

Be aware of the application area.

■ Do not operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

Safety

devices,

controls, and

attachments

Only operate the machine when:

■ All safety devices and guards are in place and in working order.

■ All controls operate correctly.

■ The machine is set up correctly according to the instructions in the Operator’s

Manual.

■ The machine is clean.

■ The machine’s labels are legible.

To ensure safe operation of the machine:

wc_si000704gb_FM10.fm

11

Page 12

Safety Information LTV

■ Do not operate the machine if any safety devices or guards are missing or

inoperative.

■ Do not modify or defeat the safety devices.

■ Only use accessories or attachments that are approved by Wacker Neuson.

Safe

operating

practices

Personal

Protective

Equipment

(PPE)

Before

Starting

When operating this machine:

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

When operating this machine:

■ Do not operate a machine in need of repair.

■ Do not consume the operating fluids used in this machine. Depending on your

machine model, these operating fluids may include water, wetting agents, fuel

(gasoline, diesel, kerosene, propane, or natural gas), oil, coolant, hydraulic fluid,

heat transfer fluid (propylene glycol with additives), battery acid, or grease.

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

■ Be sure the machine is on a firm, level surface and will not tip, roll, slide, or fall

while operating.

■ Never connect the machine to other power sources, such as supply mains of

power companies.

■ Never use the machine if the insulation on the electrical cord is cut or worn

through.

■ Never raise the tower or operate the machine in high winds.

■ The tower extends up to 7 m (23 ft.). Make sure the area above the trailer is

open and clear of overhead wires and obstructions.

Operation

■ Keep the area under and around the lights clear of people while raising and

lowering the tower.

■ Do not move the machine while it is operating or while the tower is raised.

After Use

■ Stop the engine when the machine is not being operated.

■ Close the fuel valve on engines equipped with one when the machine is not

being operated.

■ Ensure that the machine will not tip over, roll, slide, or fall when not being

operated.

■ Store the machine properly when it is not being used. The machine should be

stored in a clean location out of the reach of children.

■ Lower the tower when not in use, or if high winds or electrical storms are

expected in the area.

12

wc_si000704gb_FM10.fm

Page 13

LTV Safety Information

■ The lamps become extremely hot during use! Allow the lamp and fixture to cool

10–15 minutes before handling.

1.4 Metal Halide Lamp Safety

Description

Operating

safety

The lamps provided with the machine are electric discharge lamps. They are

designed for use with metal halide ballasts only, and require time to reach full

brightness on initial startup and after a power interruption. These lamps comply

with FDA regulation performance standards 21 CFR 1040-30.

WARNING

Personal injury hazard. Broken or punctured lamps can cause serious skin burns

and eye inflammation from shortwave ultraviolet radiation.

► Do not operate the machine if a lamp is damaged.

► Replace damaged lamps immediately.

Replace damaged lamps according to the instructions in section Removing and

Replacing Lamps.

wc_si000704gb_FM10.fm

13

Page 14

Safety Information LTV

1.5 Service Safety

Service

training

Precautions

Before servicing or maintaining the machine:

■ Read and understand the instructions contained in all manuals delivered with

the machine.

■ Familiarize yourself with the location and proper use of all controls and

protective devices.

■ Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

■ Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

■ Do not allow untrained or improperly trained people to service or maintain the

machine. Personnel servicing or maintaining the machine must be familiar with

the associated potential risks and hazards.

■ Maintenance items that can be performed by the operator are listed in this

manual. Other repairs should be performed by a qualified technician. Repairs

can be hazardous if not performed correctly. Contact your Wacker Neuson

dealer service department for additional information or for repairs to your

machine.

When servicing or maintaining the machine:

■ Read and understand the service procedures before performing any service to

the machine.

■ All adjustments and repairs must be completed before operating the machine.

Do not operate the machine with a known problem or deficiency.

■ All repairs and adjustments shall be completed by a qualified technician.

■ Turn off the machine before performing maintenance or making repairs.

■ Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

■ Re-install the safety devices and guards after repair and maintenance

procedures are complete.

■ Before servicing the machine, make sure the engine start switch is turned to the

OFF position, the circuit breakers are open (off), and the negative terminal on

battery is disconnected. Do not perform even routine service (oil/filter changes,

cleaning, etc.) unless all electrical components are shut down.

■ Always turn off light circuit breakers and shut down engine before disconnecting

light fixtures or changing light bulbs.

Machine

modifications

When servicing or maintaining the machine:

■ Use only accessories/attachments that are approved by Wacker Neuson.

When servicing or maintaining the machine:

■ Do not defeat safety devices.

■ Do not modify the machine without the express written approval of Wacker

Neuson.

14

wc_si000704gb_FM10.fm

Page 15

LTV Safety Information

Replacing

parts and

labels

Cleaning

Personal

Protective

Equipment

(PPE)

■ Replace worn or damaged components.

■ Replace all missing and hard-to-read labels.

■ When replacing electrical components, use components that are identical in

rating and performance to the original components.

■ When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those p arts equivalent to the original in a ll types of

specifications, such as physical dimensions, type, strength, and material.

When cleaning and servicing the machine:

■ Keep machine clean and free of debris such as leaves, paper, cartons, etc.

■ Keep labels legible.

■ Clean with soapy water only.

When cleaning the machine:

■ Do not clean the machine while it is running.

■ Never use gasoline or other types of fuels or flammable solvents to clean the

machine. Fumes from fuels and solvents can become explosive.

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

■ Close-fitting work clothes that do not hinder movement

■ Safety glasses with side shields

■ Hearing protection

■ Safety-toed footwear

In addition, before servicing or maintaining the machine:

■ Tie back long hair.

■ Remove all jewelry (including rings).

wc_si000704gb_FM10.fm

15

Page 16

Safety Information LTV

1.6 Operator Safety while Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or

death.

► Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison.

Exposure to carbon monoxide can kill you in minutes.

► NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through items such as exhaust fans or hoses.

Operating

safety

Refueling

safety

When running the engine:

■ Keep the area around the exhaust pipe free of flammable materials.

■ Check the fuel lines and the fuel tank for leaks and cracks before starting the

engine. Do not run the machine if fuel leaks are present or the fuel lines are

loose.

When running the engine:

■ Do not smoke while operating the machine.

■ Do not run the engine near sparks or open flames.

■ Do not touch the engine or muffler while the engine is running or immediately

after it has been turned off.

■ Do not operate a machine when its fuel cap is loose or missing.

■ Do not start the engine if fuel has spilled or a fuel odor is present. Move the

machine away from the spill and wipe the machine dry before starting.

When refueling the engine:

■ Clean up any spilled fuel immediately.

■ Refill the fuel tank in a well-ventilated area.

■ Re-install the fuel tank cap after refueling.

■ Use suitable tools for refueling (for example, a fuel hose or funnel).

When refueling the engine:

■ Do not smoke.

■ Do not refuel a hot or running engine.

■ Do not refuel the engine near sparks or open flames.

16

wc_si000704gb_FM10.fm

Page 17

LTV Safety Information

1.7 Safety Guidelines for Lifting the Machine

When lifting the machine:

■ Make sure slings, chains, hooks, ramps, jacks, forklifts, cranes, hoists, and any

other type of lifting device used is attached securely and has enough weightbearing capacity to lift or hold the machine safely. See chapter Technical Data

for machine weight.

■ Remain aware of the location of other people when lifting the machine.

■ Only use the lifting points and tie-downs described in the Operator’s Manual.

■ Make sure the transporting vehicle has sufficient load cap acity and platform size

to safely transport the machine.

To reduce the possibility of injury:

■ Do not stand under the machine while it is being lifted or moved.

■ Do not get onto the machine while it is being lifted or moved.

wc_si000704gb_FM10.fm

17

Page 18

Safety Information LTV

1.8 Safety Guidelines for Towing the Machine

WARNING

Risk of severe injury or death. Improper trailer condition and towing technique can

lead to an accident.

► Obey the instructions below to reduce the risk of an accident.

When towing the machine:

■ Do not tow the machine if the towing vehicle’s hitch or the trailer’s coupler are

damaged.

■ Do not tow the machine if safety chains are damaged.

■ Do not tow the machine if any of the trailer’s lug nuts are loose or missing.

■ Do not tow the machine if the trailer’s tires have less than 1/16 inch (1.5 mm) of

tread.

■ Do not tow the machine if trailer tires are underinflated.

■ Do not tow the machine unless the trailer’s brakes are functioning properly.

■ Do not tow the machine if trailer lighting is not functioning properly.

■ Do not exceed the trailer manufacturer’s speed limitations of 89 km/h (55 mph).

When towing the machine:

■ Only tow the machine when the trailer’s lug nuts are properly torqued.

■ Only tow the machine when the trailer’s tires are properly inflated.

■ Only tow the machine when all trailer lights are functioning correctly.

■ Only tow the machine when the trailer’s safety chains are connected to the

towing vehicle in a crisscross pattern.

■ Maintain extra distance between the towing vehicle and other vehicles.

■ Avoid soft shoulders, curbs, and sudden lane changes.

■ Abide by all licensing requirements for your area.

If you have not driven a towing vehicle with a trailer before, practice turning,

stopping, and backing up the towing vehicle with the trailer in an area away from

traffic. Only drive the towing vehicle with the trailer when you are confident in your

ability to do so.

18

wc_si000704gb_FM10.fm

Page 19

LTV Safety Information

1.9 Reporting Safety Defects

If you believe your trailer has a defect which could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Wacker Neuson.

If NHTSA receives similar complaints, it may open an investigation; and if it finds

that a safety defect exists in a group of trailers, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in individual problems

between you, your dealer, or Wacker Neuson.

To contact NHTSA, you may either contact the Vehicle Safety Hotline toll-free at

1-888-327-4236 (TTY: 1-800-424-9153); go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about your motor vehicle safety from

http://www.safercar.gov

wc_si000704gb_FM10.fm

19

Page 20

Labels LTV

2 Labels

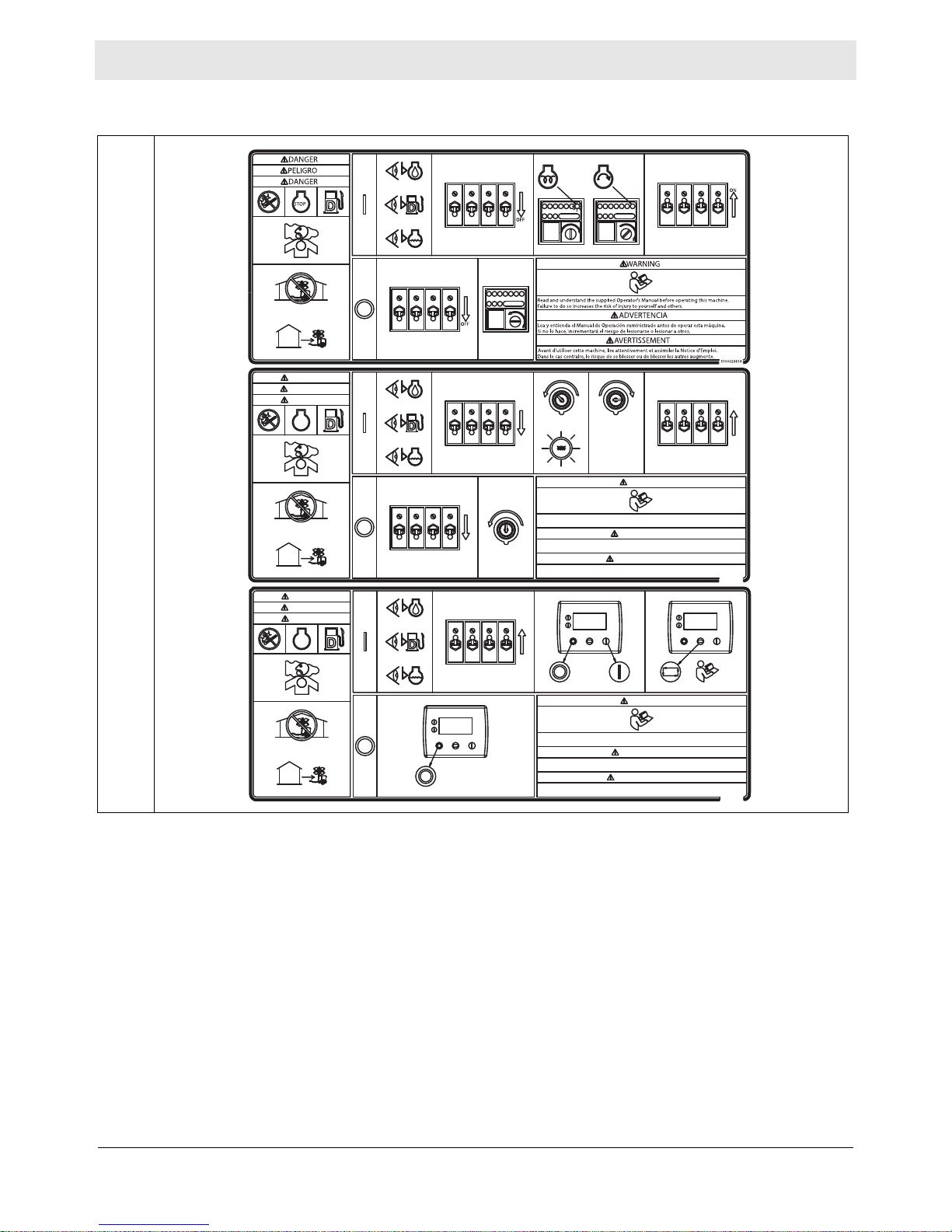

2.1 Label Locations

A

N

B

G

H

D,E

C

F

I

J

L

M

K

D,E

wc_gr013742

wc_si001039gb_FM10.fm

20

Page 21

LTV Labels

wc_gr013743

W

W

V

T

U

Q,S

wc_si001039gb_FM10.fm

21

Page 22

Labels LTV

AUTO

2.2 Label Meanings

A

DANGER

PELIGRO

DANGER

STOP

DANGER

PELIGRO

DANGER

STOP

START

OFF

15 SEC. MAX.

ARRANQUE

15 SEG. MAX.

DEMARRAGE

15 SEC. MAX.

WARNING

Read and understand the supplied Operator's Manual before operating this machine.

Failure to do so increases the risk of injury to yourself and others.

OFF

Lea y entienda el Manual de Operación suministrado antes de operar esta máquina.

Si no lo hace, incrementará el riesgo de lesionarse o lesionar a otros.

Avant d'utiliser cette machine, lire attentivement et assimiler la Notice d'Emploi.

Dans le cas contraire, le risque de se blesser ou de blesser les autres augmente.

ON

ADVERTENCIA

AVERTISSEMENT

AUTO AUTO

21

AUTO

ON

5100029814

WARNING

Read and understand the supplied Operator's Manual before operating this machine.

AUTO

Failure to do so increases the risk of injury to yourself and others.

Lea y entienda el Manual de Operación suministrado antes de operar esta máquina.

Si no lo hace, incrementará el riesgo de lesionarse o lesionar a otros.

Avant d'utiliser cette machine, lire attentivement et assimiler la Notice d'Emploi.

Dans le cas contraire, le risque de se blesser ou de blesser les autres augmente.

ADVERTENCIA

AVERTISSEMENT

5100031361

22

wc_si001039gb_FM10.fm

Page 23

LTV Labels

177123

5100031248

A See Operator’s Manual for light fixture information and troubleshooting.

BEFORE STARTING THE ENGINE:

1. Check levels of:

■ Engine oil

■ Fuel

■ Coolant

2. Move the circuit breakers to the OFF position.

TO START THE ENGINE:

1. On the engine control panel, turn the key switch to the PREHEAT position; the indicator light will

illuminate during preheating.

2. When the PREHEAT indicator light goes out, turn the key switch to the START position for a

maximum of 15 seconds.

3. When the engine is running, move the circuit breakers to the ON position.

TO SHUT DOWN THE MACHINE:

1. Move the circuit breakers to the OFF position.

2. Turn the key switch to the OFF position to stop the engine.

B NOTICE

Lifting point

C Insert jack locking pin before extending jack.

D,E Fork lift pocket

Tie-down point

F WARNING

Avoid crushing area.

wc_si001039gb_FM10.fm

23

Page 24

Labels LTV

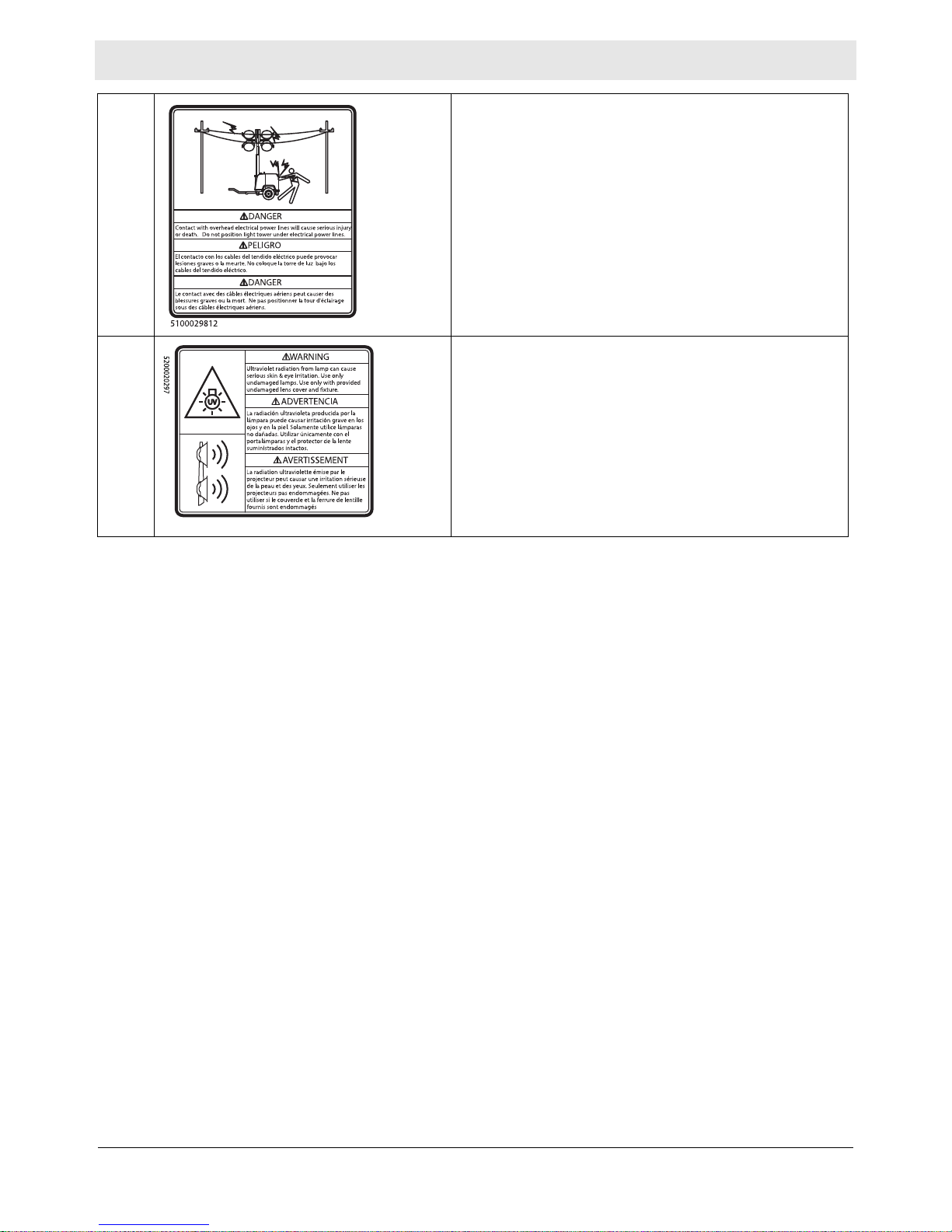

G DANGER

Contact with overhead electrical power lines will cause

serious injury or death. Do not position Light Tower

under electrical power lines.

H WARNING

Ultraviolet radiation from lamp can cause serious skin

and eye irritation. Use only with undamaged lamps. Use

only with provided undamaged lens cover and fixture.

24

wc_si001039gb_FM10.fm

Page 25

LTV Labels

SEULEMENT CARBURANT DE

SOUFRE ULTRA BAS.

5100031249

SOLAMENTE COMBUSTIBLE DE

ULTRABAJO CONTENIDO DE AZUFRE.

ULTRA LOW SULFUR FUEL ONLY

NOTICE

AVISO

AVIS

PELIGRO

DANGER

ULSD-S15

STOP

DANGER

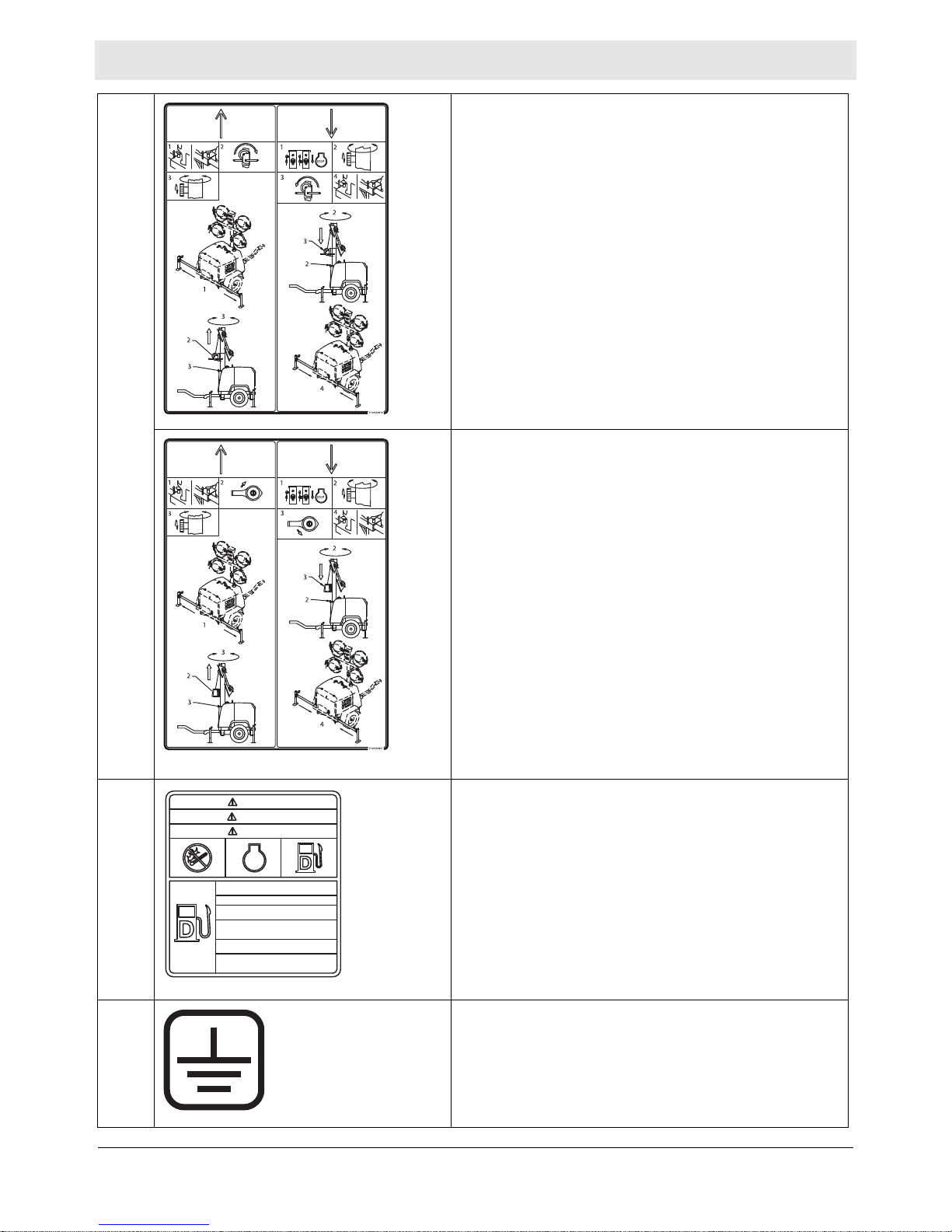

I Manual Winch

TO RAISE TOWER

1. Lift pins and extend outriggers

2. Raise tower with winch.

3. Loosen mast rotation knob to aim tower. Tighten

knob when tower is aimed.

TO LOWER TOWER

1. Turn off breakers and engine.

2. Loosen mast rotation knob an d rotate tower forward.

Tighten knob when tower is facing forward.

3. Lower tower with winch.

4. Lift pins and retract outriggers.

Power Winch

TO RAISE TOWER

1. Lift pins and extend outriggers

2. Raise tower with switch.

3. Loosen mast rotation knob to aim tower. Tighten

knob when tower is aimed.

TO LOWER TOWER

1. Turn off breakers and engine.

2. Loosen mast rotation knob and rotate tower forwa rd.

Tighten knob when tower is facing forward.

3. Lower tower with switch.

4. Lift pins and retract outriggers.

J Ultra low sulfur fuel only

K Electrical ground

wc_si001039gb_FM10.fm

25

Page 26

Labels LTV

5100031166

WARNING

ADVERTENCIA

AVERTISSEMENT

WARNING

ADVERTENCIA

AVERTISSEMENT

5

3

85 lb-ft

115 Nm

4

2

1

5100031252

ADVERTENCIA

WARNING

ADVERTENCIA

WARNING

AVERTISSEMENT

AVERTISSEMENT

5

3

85 lb-ft

115 Nm

4

2

1

L

WARNING

(On trailer, if equipped)

Lights can prevent trailer from being hit by other vehicles. You must:

1. CONNECT trailer and tow vehicle electrical connectors.

2. CHECK all lights: tail lights, turn signals, and brake lights.

3. DO NOT TOW if lights are not working.

WARNING

Tire, wheel or lug nut failure can cause loss of control. Before towing, you must CHECK:

1. Tire pressure and tread.

2. Tires and wheels for damage.

3. Lug nuts for tightness. Lug nuts should be tighte ned to 85 f t-lbs. For new and remounted wheels,

re-tighten lug nuts at the first 10, 25, and 50 miles of driving.

26

wc_si001039gb_FM10.fm

Page 27

LTV Labels

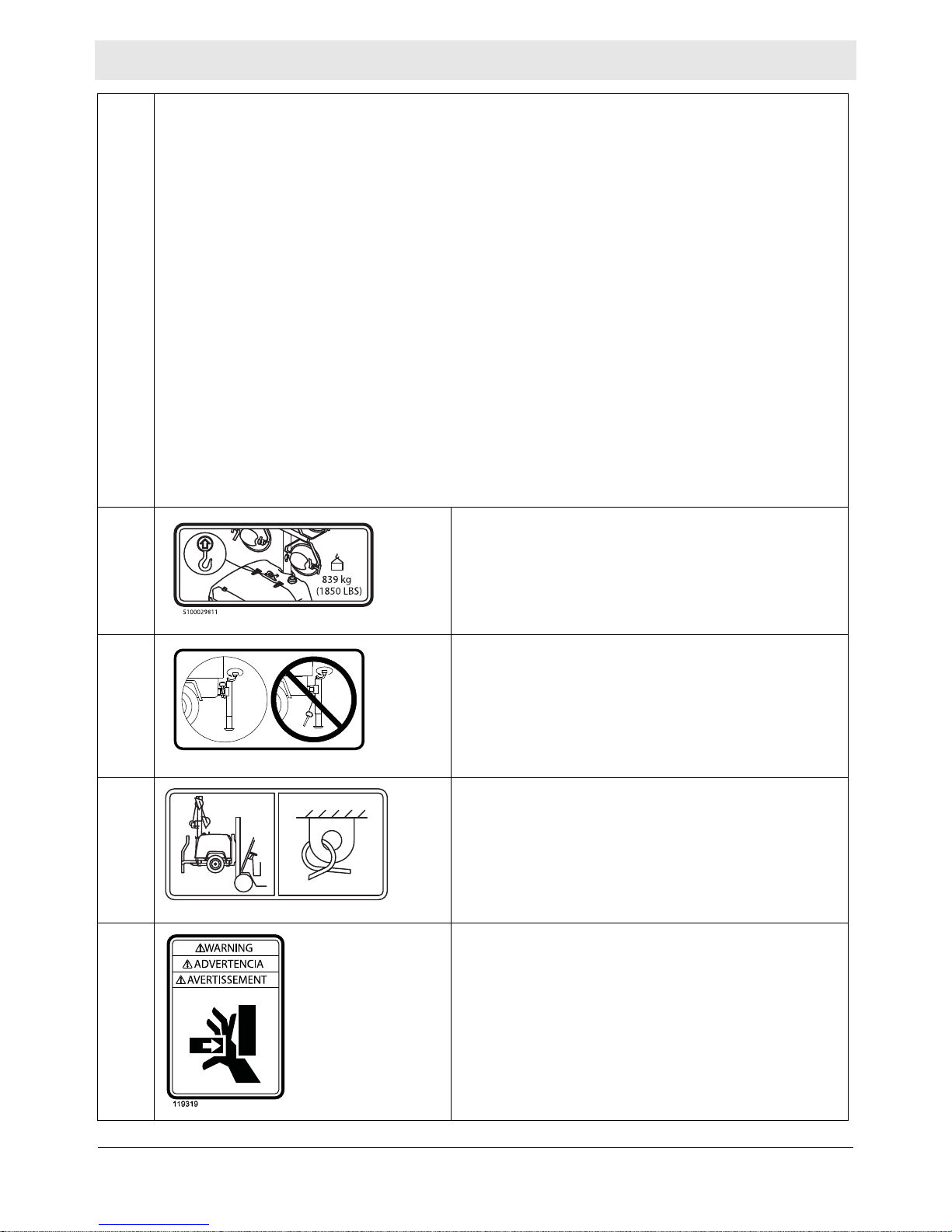

839 kg

(1850 LBS)

WARNING

AVERTISSEMENT

ADVERTENCIA

5100031165

WARNING

AVERTISSEMENT

ADVERTENCIA

839 kg

(1850 LBS)

WARNING

ADVERTENCIA

AVERTISSEMENT

5100031251

ADVERTENCIA

WARNING

AVERTISSEMENT

5100029813

160604160604

M

WARNING

(On trailer, if equipped)

Uncoupling will cause trailer to come loose from tow vehicle. You must:

1. CHECK that ball LOAD RATING is same as or greater than coupler LOAD RATING.

2. CHECK that ball SIZE is same as coupler.

3. CLOSE COUPLER CLAMP on ball.

4. LIFT coupler upwards to test that it will not separate from ball.

5. LOCK coupler clamp with pin or padlock.

WARNING

(On trailer, if equipped)

ALWAYS use safety chains. Chains hold trailer if connection fails. You must:

1. CROSS chains underneath coupler.

2. ALLOW slack for trailer to turn.

3. ATTACH chain hooks securely to tow vehicle.

N Light cover

P (if equipped)

wc_si001039gb_FM10.fm

Skid drain access point

27

Page 28

Labels LTV

Operation of This Equipment May Create Sparks That Can

Start Fires Around Dry Vegetation. A Spark Arrestor May be

Required. The Operator Should Contact Local Fire Agencies

For Laws or Regulations Relating to Fire Prevention

Requirements.

Choque eléctrico y arco voltaico de cortocircuito pueden

causar heridas personales o muerte. Dispositivo de

almacenaje eléctrico en el interior. Para trabajos de

mantenimiento o para abrir la caja eléctrica consulte

a un electricista capacitad

Électrochoc et arc de court-circuit peuvent résulter en

blessures graves ou mort. Dispositif électrique de stockage

à l'intérieur. Contacter un électricien qualié pour réparer

ou ouvrir le boitier électrique.

AVERTISSEMENT

Electric shock and arc ash can cause serious

injury or death. Electrical storage device

within. Contact a qualied electrician for

service or to open electrical box.

Per CAL. PRC. CODE ÿ 4442.6(a)

WARNING

ADVERTENCIA

5100031250

WARNING

UTILITY 159116UTILITY 159116

U.S.PAT.Nos.: 6012285, 6471476, U.S.PAT.Nos.: 6012285, 6471476,

D416858, D454357 OTHER U.S. AND D416858, D454357 OTHER U.S. AND

FOREIGN PATENTS PENDINGFOREIGN PATENTS PENDING

178775178775

ADVERTENCIAADVERTENCIA

AVERTISSEMENTAVERTISSEMENT

WARNINGWARNING

114891114891

AVERTISSEMENTAVERTISSEMENT

WARNINGWARNING

ADVERTENCIAADVERTENCIA

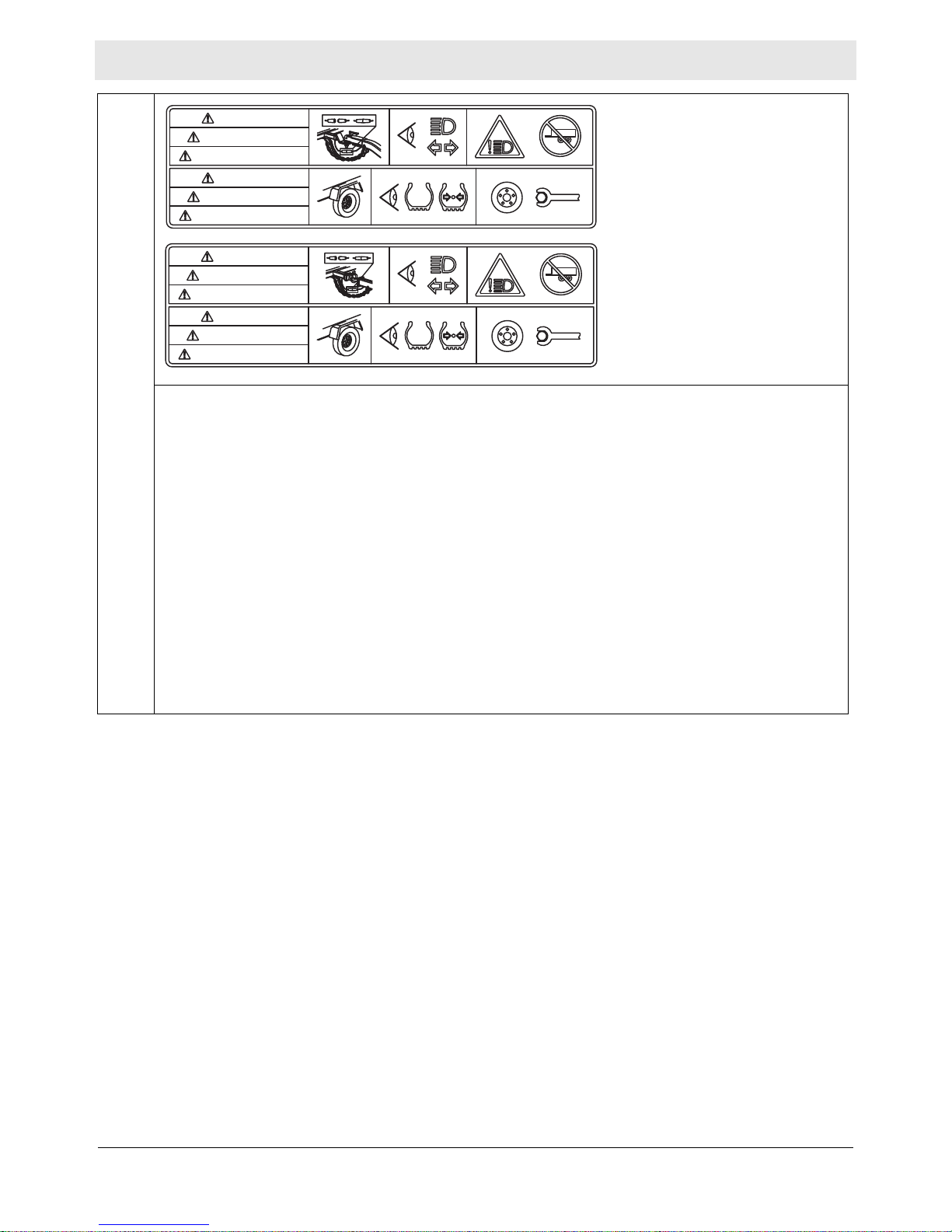

Q WARNING

Electric shock and arc flash can cause serious injury or

death. Electrical storage device within. Contact a

qualified electrician for service or to open electrical box.

WARNING

Operation of this equipment may create sparks that can

start fires around dry vegetation. A spark arrester may

be required. The operator should contact local fire

agencies for laws or regulations relating to fire

prevention requirements.

S This machine may be covered by one or more patents.

T WARNING

■ Pressurized contents. Do not open when hot!

■ Pinching / cutting hazards.

■ Rotating machinery.

U Coolant overflow bottle only, not a return system.

V WARNING

Disconnect battery before servicing.

Read the Operator’s Manual.

wc_si001039gb_FM10.fm

28

Page 29

LTV Labels

AVERTISSEMENTAVERTISSEMENT

52000058905200005890

ADVERTENCIAADVERTENCIA

WARNINGWARNING

MANUFACTURED BY/FABRIQUÉ PAR: A

DATE: B GVWR/PNBV: C

GAWR/PNBE (ALL AXLES) TIRE/PNEU RIM/JANTE KPA (PSI/LPC) SGL/DUAL

D E F G H

THIS VEHICLE CONFORMS TO ALL APPLICABLE STANDARDS PRESCRIBED UNDER THE CANADIAN

MOTOR VEHICLE SAETY REGULATIONS IN EFFECT ON THE DATE OF MANUFACTURE. /CE

VÉHICULE EST CONFORME À TOUTES LES NORMES QUI LUI SONT APPLICABLES EN VERTU DU

RÉGLEMENT SUR LA SÉCURITÉ DES VÉHICULES AUTOMOBILES DU CANADA EN VIGUEUR À LA

DATE DE SA FABRICATION.

THIS VEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY

STANDARDS (FMVSS) IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE

V.I.N./N.I.V. I TYPE/TYPE DE VEHICULE: J

COLD INFL. PRESS./PRESS.

DE GONF À FROID

174993

W WARNING

Explosion hazard.

■ Do not use evaporative starting fluids such as ether

on this engine.

■ The engine is equipped with a cold starting aid. Using

evaporative starting fluids can cause an explosion

which can cause engine damage, personal injury, or

death.

■ Read and follow the engine starting instructions in this

Operator's Manual.

— (if equipped)

Notification of National Association of Trailer

Manufacturers (NATM) compliance

—

(On trailer, if equipped)

Certification Label (VIN Number)

Also attached to each unit is a Certification Label. This label specifies that the trailer conforms with

all Federal Motor Vehicle Standards in effect at the time of manufacture. The label includes the

Vehicle Identification Number (VIN) for the trailer.

wc_si001039gb_FM10.fm

29

Page 30

Lifting and Transporting LTV

c

d

wc_gr013769

e

a

b

d

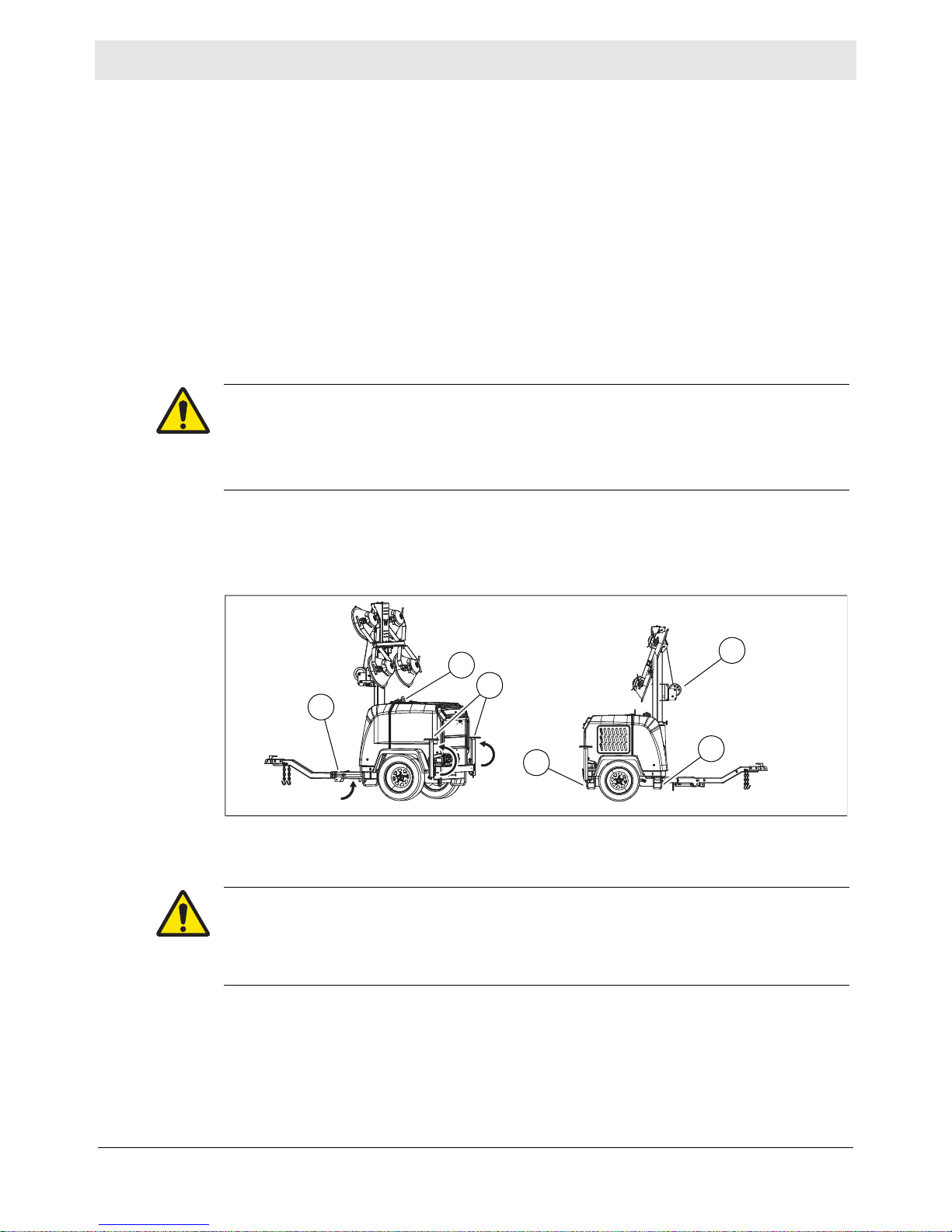

3 Lifting and Transporting

3.1 Lifting the Machine

Requirements

Procedure

■ Properly rated lifting equipment (crane or hoist). See Chapter Technical Data.

■ Machine stopped.

■ All doors and access covers closed and secured.

■ Tower is completely lowered.

■ The winch (e) and lights are facing foward.

■ Outriggers have been returned to their travel position.

■ Outrigger bars and jacks are locked in place.

■ Outrigger jacks (c) are completely cranked in and rotated 180°.

WARNING

Crushing hazard. You may be crushed if the lifting devices fail.

► Never stand under, or get onto, the machine while it is being lifted or moved.

► Use only the designated lifting points to lift the machine.

Perform the procedure below to lift the machine.

1. Attach the lifting equipment to the lifting eye (b) on the machine using hooks,

shackles, and chains or insert forks into the fork pockets (d).

2. Lift the machine a small distance.

WARNING

Crushing hazard. An unstable machine may cause the lifting devices to fail. You

may be crushed if the lifting devices fail.

► Check for stability before continuing.

3. Check for stability. If necessary, lower the machine, reposition the lifting device,

and lift the machine a small distance again.

4. Continue lifting the machine as necessary.

wc_tx004429gb_FM10.fm

30

Page 31

LTV Lifting and Transporting

3.2 Preparing the Machine for Transport on a Truck or Trailer

Requirements

Checklist

■ Machine stopped.

■ Flatbed truck or trailer capable of supporting the machine’s weight.

■ Chains, hooks, or straps capable of supporting the machine’s weight.

WARNING

Crushing hazard. Improperly securing the machine can lead to a crushing hazard.

► Use only the designated tie-down points to secure the machine to a truck or

trailer.

Before transporting the machine, check the following items:

Machine

All doors and access panels of the machine are closed.

All electrical connections are disconnected from the machine.

The generator is shut down.

The tower is completely lowered.

The outriggers are in the travel position.

The outrigger bars and jacks are locked in place.

The tongue jack is in the travel position.

Loading and transporting equipment

The transport vehicle or trailer can support the weight of the machine.

The wheels of the transport vehicle or trailer are chocked during the loading

process.

The transport vehicle or trailer is clean and free of grease, oil, ice, and other

loose material.

Do not use the machine’s trailer jack to support the trailer tongue during

transporting.

Check that any ramps used in the loading process:

■ Can support the weight of the machine

■ Are clean and free of grease, oil, ice, and other loose material.

■ Are securely connected to the transport vehicle or trailer.

■ Are of sufficient length to keep the loading angle 15° or less.

In addition:

The loading area is flat and the ground is stable.

The overall height of the machine once loaded. Plan your travel route so that

there will be adequate clearance for overpasses, road signs, buildings, etc.

Check local regulations regarding transporting and obey these regulations.

wc_tx004429gb_FM10.fm

31

Page 32

Lifting and Transporting LTV

3.3 Before Towing Checklist

For trailer machines only.

Before towing the machine, check the licensing requirements for trailers in your

area. Check the following items:

Machine

All doors and access panels of the machine are closed.

All electrical connections are disconnected from the machine.

The generator is shut down.

The tower is completely lowered.

The outriggers are in the travel position.

The outrigger bars and jacks are locked in place.

The tongue jack is in the travel position.

Hitch and coupler

The towing vehicle and hitch have a rating equal to or greater than the GVWR of

the machine. See Technical Data.

The hitch of the towing vehicle and coupler of the trailer are compatible.

The condition of both the coupler and the hitch.

That all fasteners on the coupler are secure.

That the coupler has fresh grease applied to it.

Wheels

That all lug nuts are in place and are properly torqued.

The tread wear of the tires.

That the tires are inflated to the proper pressure.

Trailer operation

The directional and running lights on the trailer function correctly.

The safety chains of the trailer are connected to the towing vehicle using a

crisscross pattern.

32

wc_tx004429gb_FM10.fm

Page 33

LTV Lifting and Transporting

3.4 Towing the Machine

WARNING

Risk of severe injury or death. Improperly torqued lug nuts can lead to loss of

wheels. Loss of wheels can cause an accident, severe injury or death.

► Tighten the lug nuts to the proper torque before towing the machine.

NOTICE: Wacker Neuson recommends a maximum towing speed of 88 km/h

(55 mph) on highways and paved roads and 16 km/h (10 mph) on rugged roads

and terrain.

Procedure

Perform the procedure below when towing the machine.

1. Read and follow the towing safety guidelines. See topic Safety Guidelines for

Towing the Machine.

2. Complete the shut-down procedures.

3. Adjust the amount of fuel in the machine to approximately 70% capacity to avoid

fuel spillage.

4. Complete the Before Towing Checklist. See topic Before Towing Checklist.

5. Connect the machine to the towing vehicle and connect the lights.

6. Rotate the trailer and tongue jacks to a horizontal position.

7. Tow the machine as needed.

wc_tx004429gb_FM10.fm

33

Page 34

Lifting and Transporting LTV

c

a

a

c

b

b

wc_gr011629

3.5 Trailer

Background

Licensing

requirements

Coupler

maintenance

The machine’s trailer is equipped with safety chains (a), tongue jack (b), lights, and

a coupler (pintle or ball-type) (c).

■ In most states, large trailers must be registered and licensed by the State

Department of Transportation. Before towing, be sure to check licensing

requirements.

■ Drivers towing trailers may be required to carry a commercial driver’s license

(CDL). Check your local and state licensing regulations before towing the

generator.

■ A film of grease on the coupler will extend coupler life and eliminate squeaking.

Wipe the coupler clean and apply fresh grease each time the trailer is towed.

Towing safety

■ When towing, maintain extra space between vehicles and avoid soft shoulders,

curbs and sudden lane changes. If you have not pulled a trailer before, practice

turning, stopping, and backing up in an area away from heavy traffic.

Do not exceed 55 mph when towing a trailer.

34

wc_tx004429gb_FM10.fm

Page 35

LTV Lifting and Transporting

wc_gr014010

d

3.6 Flip-up Tongue

Background

Procedure

The flip-up tongue allows the machine to be stored in a smaller space than a

machine with a conventional tongue.

Perform the procedure below to raise the flip-up tongue to the storage position.

1. Remove the pin behind the tongue jack (a).

b

a

c

Towing

wc_gr014009

2. Rotate the tongue into the storage position (b) and insert the pin (c).

3. Install cotters (d) in all the pins.

Reverse the procedure when preparing the tongue for towing.

wc_tx004429gb_FM10.fm

35

Page 36

Machine Setup LTV

4

Machine Setup

4.1 Preparing the Machine for First Use

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

36

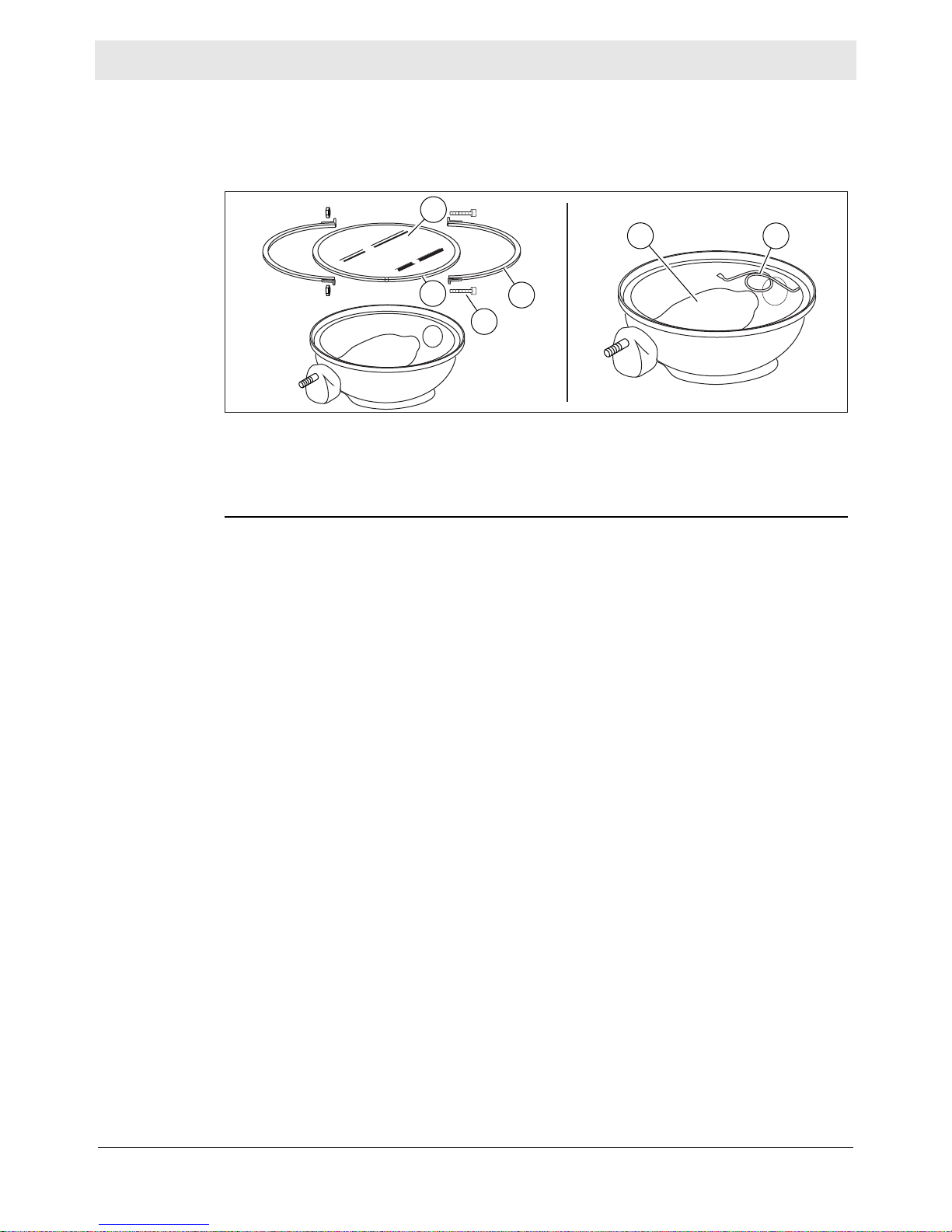

wc_tx004430gb_FM10.fm

Page 37

LTV Machine Setup

4.2 Positioning the Machine

DANGER

Asphyxiation hazard. Exhaust gas from the machine contains carbon monoxide, a

deadly poison you cannot see or smell. Exposure to carbon monoxide can kill you

in minutes.

► Position the machine so that exhaust will not enter any nearby structures.

WARNING

Fire hazard. Do not move the machine while it is running.

► Shut down the machine before moving or repositioning it.

WARNING

Electric shock hazard. The tower extends up to 7 m (23 ft.) and could contact

overhead wires or obstructions.

► Position the trailer on a firm, flat surface clear of overhead wires and

obstructions.

CO Alarms

Requirements

WARNING

Fire hazard. Machines positioned on a hill or an incline may slide, break away or

roll over.

► Do not position the machine on a hill or an incline.

WARNING

Explosion and fire hazard. Risk of severe injury or death.

► Do not operate the machine near flammable vapors, fuels, or combustibles.

Because this machine produces carbon monoxide (CO), Wacker Neuson

recommends that CO alarms be installed in all structures in close proximity to the

machine. CO alarms provide an extra measure of protection against this poison

that you cannot see or smell.

Install battery-operated CO alarms or plug-in CO alarms with battery backup,

according to the manufacturer’s instructions. CO alarms should be certified to the

requirements of the latest safety standards (UL 2034, IAS 6-96, or CSA 6.19.01).

Test the CO alarm batteries monthly.

Position the machine so that:

■ machine exhaust will not enter nearby structures.

■ the machine does not block traffic.

■ the machine is not near any combustible material or flammable vapor.

■ all of the machine’s access doors/panels may be accessed.

■ the area to be illuminated is at or below the level of the lights.

■ there is room around the machine for the outriggers to be extended.

wc_tx004430gb_FM10.fm

37

Page 38

Machine Setup LTV

4.3 Ground Connection

Location

Function

A ground connection (a) is located on the trailer frame.

a

wc_gr013762

This ground connection is used for electrically grounding the Light Tower when

necessary to comply with the National Electrical Code and other federal, state, and

local regulations. For grounding requirements in your area, consult with a qualified

electrician, electrical inspector, or local agency having jurisdiction over electrical

compliance.

■ If the Light Tower is used at a construction site, there may be additional

regulations which must be observed.

Internal

grounding

■ The exposed, conductive, noncurrent-carrying components that could become

energized (e.g., engine, generator housing, control panel, and trailer) are

bonded (connected to the machine’s frame.

■ The grounding wires of the machine’s power outputs (receptacles) are bonded

(connected) to the machine’s frame.

■ The neutral of the generator stator winding is bonded (connected) to the

machine’s frame.

38

wc_tx004430gb_FM10.fm

Page 39

LTV Machine Setup

4.4 Leveling the Trailer—Vertical Mast Light Towers

WARNING

Tipping and falling hazard. Failure to level the trailer or extend the outriggers will

reduce the stability of the unit.

► Level the trailer and extend the outriggers before raising the tower. The

outriggers must remain extended while the tower is up.

Procedure

Perform the procedure below to level the trailer.

1. Pull the locking pin on the tongue jack (a) and rotate the tongue jack down 90°

as shown. Reinsert the pin once the jack is in position.

b

e

d

c

2. Block or chock the trailer wheels (b).

3. Crank the tongue jack (a) down to raise the trailer tongue off the vehicle.

4. Pull the outrigger lock pins (c) to release the outriggers. Pull both outriggers (d)

out until you feel the lock pin snap into place.

5. Pull the locking pins on the outrigger jacks (e). Rotate the jacks down 180°.

Reinsert the pins once the jacks are in position.

c

d

e

a

wc_gr013324

6. Extend the jack(s) on the highest side(s) of the trailer until they rest firmly on the

ground. Extend the remaining jacks until the trailer is level.

wc_tx004430gb_FM10.fm

39

Page 40

Machine Setup LTV

wc_gr01374

DD

a

50 mm

(2 in)

4.5 Refueling the Machine

Requirements

Procedure

■ Machine shut down

■ Engine cool

■ Machine/fuel tank level with the ground

■ Fresh, clean fuel supply

Perform the procedure below to refuel the machine.

WARNING

Fire hazard. Fuel and its vapors are extremely flammable. Burning fuel can cause

severe burns.

► Keep all sources of ignition away from the machine while refueling.

► Refuel only when the machine is outdoors.

► Clean up spilled fuel immediately.

1. Remove the fuel cap (a).

Result

2. Fill the fuel tank, allowing a minimum of 50 mm (2 in.) expansion space between

the fuel level and the top of the tank.

CAUTION

Fire and health hazard. Fuel expands when heated. Expanding fuel in an ove r-filled

tank can lead to spills and leaks.

► Do not fill the fuel tank completely.

3. Re-install the fuel cap.

The procedure to refuel the machine is now complete.

wc_tx004430gb_FM10.fm

40

Page 41

LTV Machine Setup

wc_gr013746

a

a

a

b

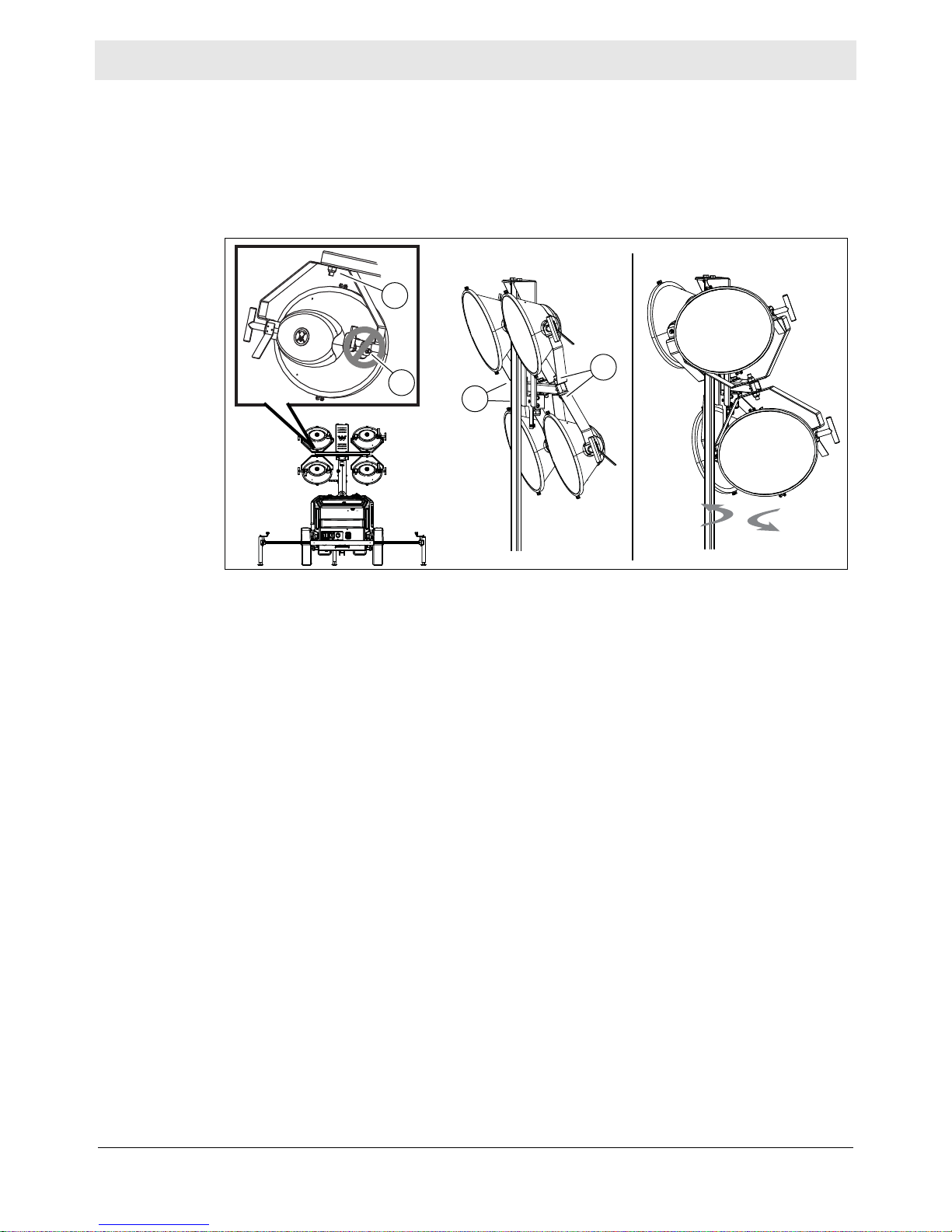

4.6 Aiming the Lights—Vertical Mast Light Towers

Overview

Requirements

Aiming the

light fixtures

■ Each individual light fixture can be independently aimed up, down, left, or right.

There are four total light fixtures on each machine.

■ This procedure is not for rotating the lights as a single unit while the tower is

raised. This procedure requires the tower is lowered and the machine is

stopped. To rotate the lights, see topic Rotating the Lights.

Before adjusting the lights, make sure that the following conditions have been met.

■ Machine is stopped

■ Tower is completely lowered

■ Lights are cool to the touch

Aiming Up or Down

Perform the procedure below to aim an individual light fixture up or down.

1. Loosen the T-handle (a) and aim the light up or down.

NOTICE: Do not loosen the nut (b). Damage to the light fixture may occur.

2. Tighten the T-handle (a) when the light is aimed properly.

3. Repeat steps 1–3 for each remaining light fixture, if desired.

This procedure continues on the next page.

wc_tx004430gb_FM10.fm

41

Page 42

Machine Setup LTV

wc_gr013747

c

c

c

b

Continued from the previous page.

Aiming Left or Right

1. Grasp the light fixture and aim it to the left or right. If necessary, loosen the

bracket nut (c) to allow movement of the fixture.

NOTICE: Do not loosen the nut (b). Damage to the light fixture may occur.

2. If loosened, tighten the bracket nut (c) when the light is aimed properly.

Note: The bracket nut (c) should be only tight enough so that slight resistance is

present when aiming the fixture.

3. Repeat steps 1–2 for each remaining light fixture, if desired.

42

wc_tx004430gb_FM10.fm

Page 43

LTV Machine Setup

wc_gr013767

a

4.7 Manually Rotating the Light Bar

Overview

Procedure

The operator can rotate the light bar 360° while the tower is lowered.

Perform the procedure below to rotate the light bar.

1. Loosen out the locking knob (a).

2. Rotate the light bar to the desired position.

3. Tighten the locking pin (a).

Note: Before towing, aim the light bar forward. Be sure the locking pin seats into a

hole in the light bar. Holes are positioned at 90° angles.

wc_tx004430gb_FM10.fm

43

Page 44

Machine Setup LTV

4.8 Raising the Tower—Manual Winch System

Background

Requirements

The Light Tower includes a telescoping winch for raising the towe r. The winch is an

automatic brake-type winch that automatically brakes when the handle is released.

The handle must be rotated to wind in the cable as well as to unwind the cable.

■ Engine is stopped

■ Light Tower is located on a firm, flat surface clear of overhead wires and

obstructions

■ Winch cables are in serviceable condition and resting properly in pulleys

■ Light tower has been leveled, with all outriggers extended and locked

WARNING

Electric shock hazard! Do not use the Light Tower if insulation on any of the

electrical cords is cut or worn through. Bare wires in contact with the metal frame of

the trailer or tower can cause electrocution.

► Repair or replace the cord before using the machine.

WARNING

Electrocution hazard.

► Do not position the Light Tower under electrical power lines.

WARNING

Tipping/falling hazards. Certain actions may cause the tower to fall or the Light

Tower to tip over.

► Do not raise the tower or operate the Light Tower in high winds.

► Do not touch the winch pawl while the tower is raised!

► Do not pull the vertical tower locking pin while the tower is raised.

WARNING

Personal injury hazard. Bystanders can be struck by the tower as it is being raised

or lowered.

► Do not allow anyone to stand near the front of the machine while raising or

lowering the tower.

This procedure continues on the next page.

44

wc_tx004430gb_FM10.fm

Page 45

LTV Machine Setup

wc_gr013770

a

Continued from the previous page.

Reference

graphic

Procedure

NOTICES

Raising the

tower

Perform the procedure below to raise the tower.

■ Do not attempt to raise the tower if the winch is damaged or not operating

properly, or if the winch cables are worn or damaged.

■ The tower and light bar can be rotated 360°. If you wish to position the light bar

so the lights illuminate to the left, to the right, or to the rear, the light bar should

be rotated when the tower is fully lowered. See topic Manually Rotating the Light

Bar.

1. Check the operation of the telescoping winch (a) by rotating its handle 1/4 turn

clockwise (“cable in” direction). The winch pawl must engage the winch gear

teeth. When operating properly, the winch pawl will make a “clicking” sound

when its handle is rotated clockwise.

2. Continue rotating the winch handle until the tower is at the desired height. Do

not overcrank the winch when the tower is fully extended.

wc_tx004430gb_FM10.fm

45

Page 46

Machine Setup LTV

4.9 Lowering the Tower—Manual Winch System

Requirements

Procedure

■ Lights are turned off

■ Engine is stopped

■ Outriggers are extended and locked in place

WARNING

Tipping/falling hazards. Certain actions may cause the tower to fall or the machine

to tip over.

► Do not raise the tower or operate the Light Tower in high winds.

► Do not touch the winch pawl while the tower is raised!

Perform the procedure below to lower the tower.

WARNING

Personal injury hazard. Bystanders can be struck by the tower as it is being raised

or lowered.

► Do not allow anyone to stand near the front of the machine while raising or

lowering the tower.

1. Turn the handle on the telescoping winch (a) counterclockwise (“cable out”

direction) until the tower is lowered completely.

a

b

This procedure continues on the next page.

wc_gr013771

wc_tx004430gb_FM10.fm

46

Page 47

LTV Machine Setup

Continued from the previous page.

2. If the light bar has been rotated, loosen the locking knob (b) and rotate the tower

so the light bar and winch are facing toward the trailer tongue. See topic

Manually Rotating the Light Bar.

3. If the lights have been aimed vertically or horizontally, return them to a position

parallel to the light bar . See topic Aiming the Ligh ts—Vertical Mast Light Towers.

wc_tx004430gb_FM10.fm

47

Page 48

Machine Setup LTV

4.10 Raising the Tower—Power Winch System

Background

Requirements

The Light Tower includes a telescoping winch for raising the tower.

■ Machine is shut down

■ Light Tower is located on a firm, flat surface clear of overhead wires and

obstructions

■ Winch cables are in serviceable condition and resting properly in pulleys

■ Light Tower has been leveled, with all outriggers extended and locked

WARNING

Electric shock hazard! Do not use the machine if insulation on any of the electrical

cords is cut or worn through. Bare wires in contact with the metal frame of the trailer

or tower can cause electrocution.

► Repair or replace the cord before using the machine.

WARNING

Electrocution hazard.

► Do not position the Light Tower under electrical power lines.

WARNING

Tipping/falling hazards. Certain actions may cause the tower to fall or the machine

to tip over.

► Do not raise the tower or operate the Light Tower in high winds.

► Do not pull the vertical tower locking pin while the tower is raised.

WARNING

Personal injury hazard. Bystanders can be struck by the tower as it is being raised.

► Do not allow anyone to stand near the front of the machine while raising the

tower.

This procedure continues on the next page.

wc_tx004430gb_FM10.fm

48

Page 49

LTV Machine Setup

Continued from the previous page.

Procedure

NOTICES

Raising the

tower

Perform the procedure below to raise the tower.

■ Do not attempt to raise the tower if the winch is damaged or not operating

properly, or if the winch cables are worn or damaged.

■ The tower and light bar can be rotated 360°. If you wish to position the light bar

so the lights illuminate to the left, to the right, or to the rear, the light bar should

be rotated when the tower is fully lowered. See topic Manually Rotating the Light

Bar.

1. Check the operation of the telescoping winch (a). Turn the telescope rotary

switch (b) on the control panel to the up position.

b

a

2. Continue to hold the telescope rotary switch until the tower is at the desired

height. Release the switch when the tower is at the desired height.

wc_tx004430gb_FM10.fm

wc_gr013772

49

Page 50

Machine Setup LTV

wc_gr013773

a

b

4.11 Lowering the Tower—Power Winch System

Requirements

Procedure

■ Lights are turned off

■ Engine is stopped

■ Outriggers are extended and locked in place

WARNING

Tipping/falling hazards. Certain actions may cause the tower to fall or the machine

to tip over.

Perform the procedure below to lower the tower.

WARNING

Personal injury hazard. Bystanders can be struck by the tower as it is being raised

or lowered.

► Do not allow anyone to stand near the front of the machine while raising or

lowering the tower.

1. Hold the rotary switch (b) in the down position (“cable out” direction) until the

tower is completely lowered.

This procedure continues on the next page.

wc_tx004430gb_FM10.fm

50

Page 51

LTV Machine Setup

Continued from the previous page.

2. If the light bar has been rotated, loosen the locking knob (a) and rotate the tower

so the light bar and winch are facing toward the trailer tongue. See topic

Manually Rotating the Light Bar.

3. If the lights have been aimed vertically or horizontally, return them to a position

parallel to the light bar . See topic Aiming the Ligh ts—Vertical Mast Light Towers.

wc_tx004430gb_FM10.fm

51

Page 52

Operation LTV

5 Operation

5.1 Generator Derating

Description

Derating

percentage s

All generator sets are subject to derating (reduced power output) depending on the

altitude and ambient temperature. Derating should not affect the operation of the

floodlights, although it will reduce the available reserve power to the receptacle.

Power ratings are typically reduced by the following percentages:

■ 3% per 300 m (1000 ft.) elevation above sea level

■ 2% per 5.5°C (10°F) increase in ambient temperature above 25°C (78°F).

52

wc_tx004431gb_FM10.fm

Page 53

LTV Operation

wc_gr013749

a

b d

c

a

b

c

e

f

6K 8K

6K

g

h

j

k

m m

n

8K

n

p

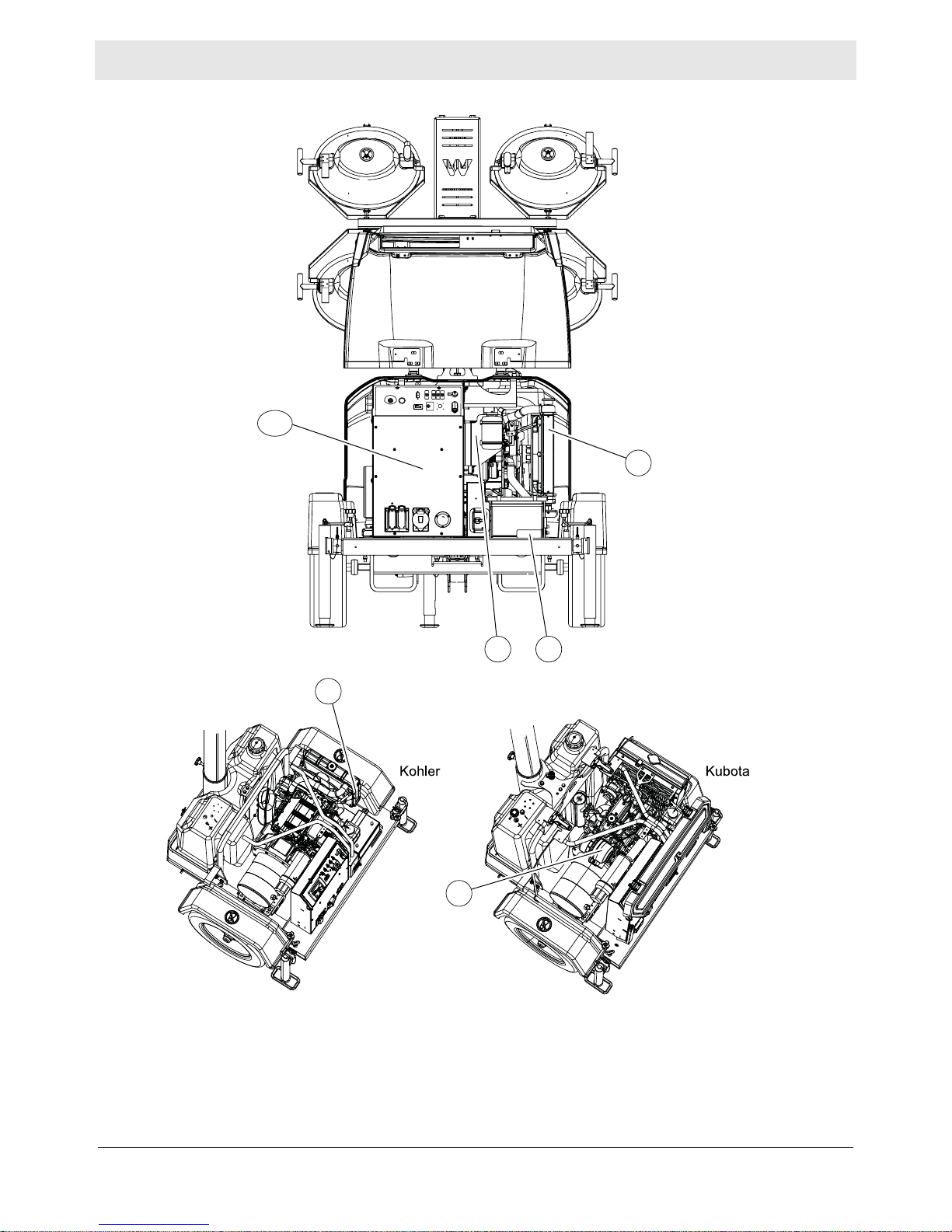

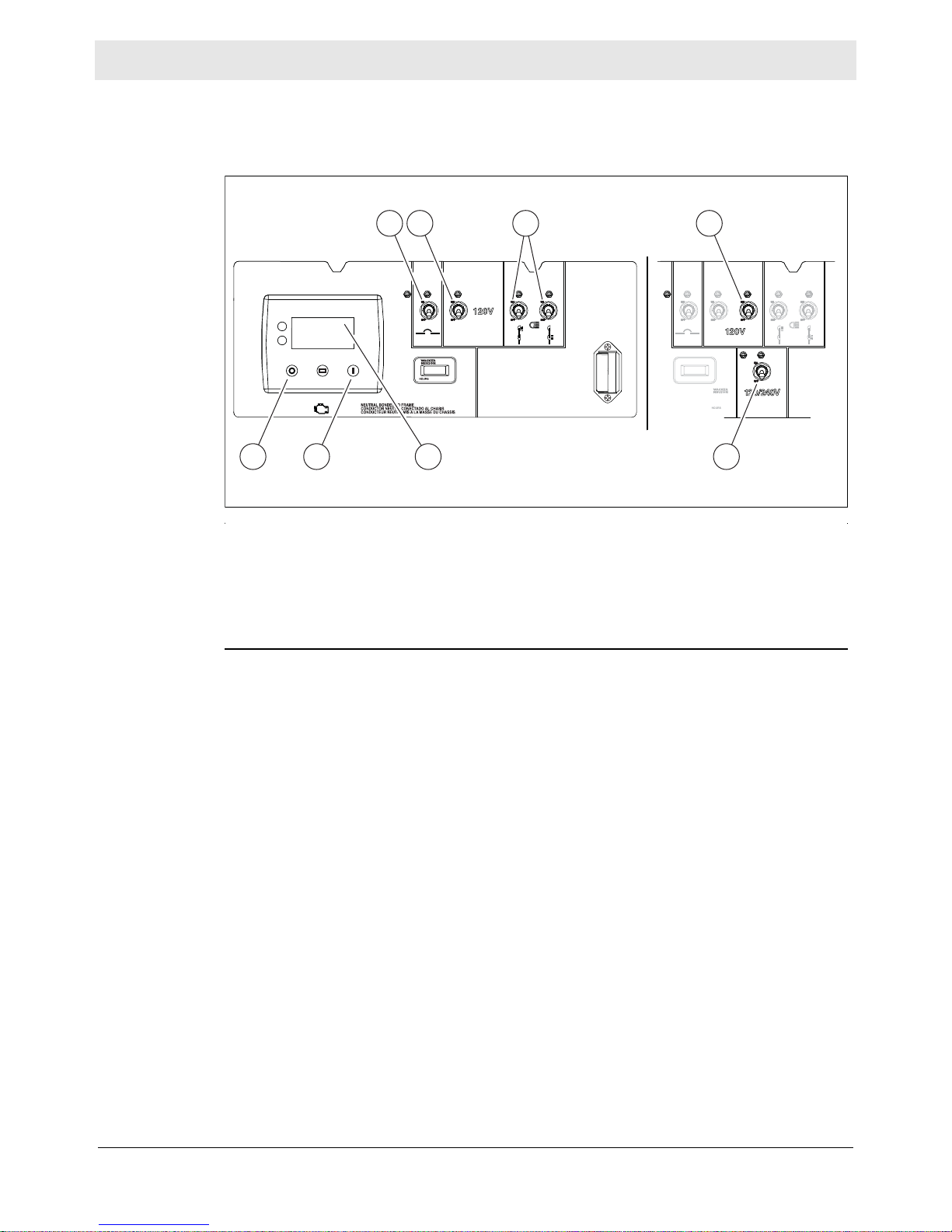

5.2 Control Panels and Receptacles—KUBOTA

Ref. Description Ref. Description

a 33A main circuit breaker (8K)

50A main circuit breaker (6K)

b 33A GFI circuit breaker (8K)

25A GFI circuit breaker (6K)

c 30A lights circuit breaker k 30A receptacle breaker

d Tower winch rotary switch (optional) m 20A GFI receptacle

e Key switch n 30A receptacle

f Glow plug indicator p Shower power inlet

g Hour meter

h Shore power switch

(optional for 6K)

j Control panel light

(standard for 8K)

(optional for 6K)

wc_tx004431gb_FM10.fm

53

Page 54

Operation LTV

wc_gr013750

h

g

f

e

dcba

j m

k

n

o

p q

r s

t

u

v

5.3 Control Panels and Receptacles—KOHLER

Ref. Description Ref. Description

a Low fuel indicator (not used) m Tower winch rotary switch (optional)

b Safety shut-down indicator n 20A GFI circuit breakers (optional)

c Low oil pressure shut-down

indicator

d High coolant temperatur e shut-

down indicator

e Alternator indicator q Key switch

f Auxiliary lights (not used) r Hour meter

g Glow plug indicator s Control panel light

h 50A main circuit breaker t 20A GFI receptacle

j 20A GFI circuit breaker u 30A receptacle (optional)

k 30A lights circuit breaker v Shore power inlet (optional)

o Air filter restriction indicator

p Auxiliary lights (not used)

54

wc_tx004431gb_FM10.fm

Page 55

LTV Operation

wc_gr013748

c

b

a

d

f

e c

d

e

g

h

j

6K 8K

6K

k

m

n

o

p

o

p

8K

5.4 Control Panel and Receptacles—DeepSea

Ref. Description Ref. Description

a Menu navigation buttons (up/down) h Auto start button

b Controller display j Start button

c 25A main circuit breaker (6K)

33A main circuit breaker (8K)

d 20A GFI circuit breaker m Control panel light

e 30A lights circuit breaker n 30A receptacle breaker

f Tower winch rotary switch (optional) o 20A GFI receptacle

g St op/reset button p 30A receptacle

k Hour meter

(standard for 8K)

wc_tx004431gb_FM10.fm

55

Page 56

Operation LTV

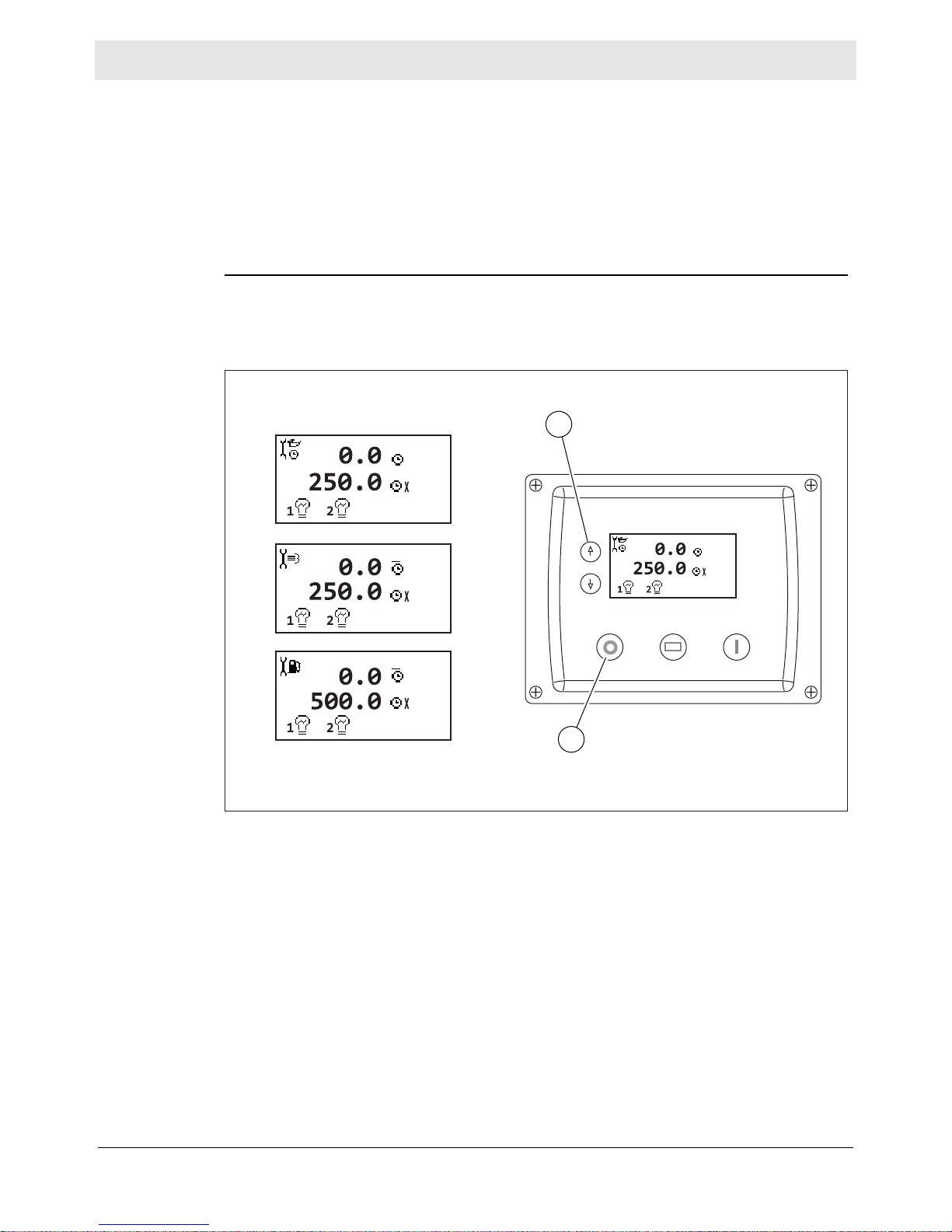

wc_gr012363

wc_gr012362

wc_gr012361

wc_gr012364

wc_gr012356

5.5 Machine Monitoring – DeepSea

Description

Engine and generator information is displayed on the the LCD panel The user can

scroll through the screens to monitor machine parameters.

V olt s “V”- Displays the AC outpu t volt age being produced by the

generator.

V olt s “V”- Displays the AC outpu t volt age being produced by the

generator.

Hertz “Hz” - Displays output frequency. This gauge should read

approximately 60 Hz under a no-load condition. If the frequency

is too high, check the engine rpm.

Displays the engine rpm.

Displays the metered usage of the machine in hours (h) and

minutes (m).

wc_tx004431gb_FM10.fm

56

Page 57

LTV Operation

Displays the available voltage of the battery.

wc_gr012357

Displays the maintenance interval as well as the time remaining

until maintenance is required.

Each parameter is displayed on a separa te screen:

■ Oil change

■ Air filter

■ Fuel filter

wc_gr012360

wc_tx004431gb_FM10.fm

57

Page 58

Operation LTV

wc_gr012354

a

b

c

d

e

wc_gr012355

f

g

h

j

i

k

n

l

5.6 Alarms and Shut-Down Conditions – DeepSea

Background

Warning

alarms

The Light Tower controller monitors variables of engine and machine function. The

Light Tower controller has two types of alarms: warning alarms and shut-down

alarms.

Warnings are non-critical alarm

conditions that do not affect the operation

of the generator system. They serve to

draw the operator’s attention to an

undesirable condition. Warning alarms

are self-resetting when the fault condition

is removed.

Warning alarms include:

a.Generator over-frequency

b.Generator under-frequency

c.Time to maintenance-oil

d.Time to maintenance-air filter

e.Time to maintenance-fuel filter

During a warning alarm condition, the

LCD panel displays the type of warning

alarm. The machine is not shut down.

Shut-down

alarms

Shut-down alarms are latching alarms

and stop the generator. Shut-down

alarms include:

f. High coolant temperature

g.Low oil pressure

h.Overspeed

i. Underspeed

j. Generator over-frequency

k.Generator under-frequency

l. Overcrank

m.Low coolant level (if equipped)

n.Emergency stop

During a shut-down alarm condition, the

LCD panel displays the type of alarm that

caused the machine shutdown. Remove

the fault condition, then press “Stop”.

This procedure continues on the next page.

58

wc_tx004431gb_FM10.fm

Page 59

LTV Operation

Continued from the previous page.

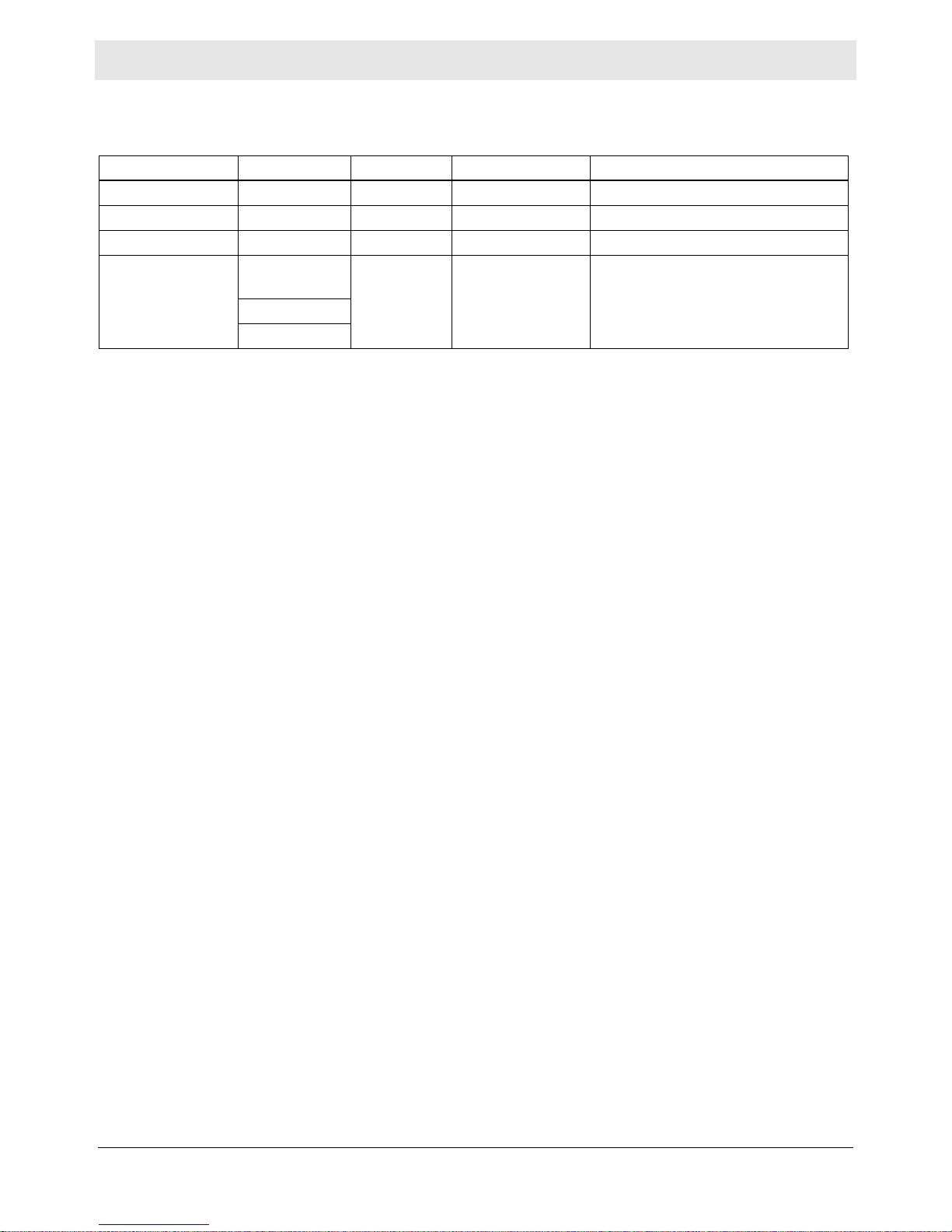

Alarm and Shutdown limits

Variable Normal Warning Shutdown To Reset

Overspeed 60 Hz 63 Hz 66 Hz Press “Stop”.

Underspeed 60 Hz 57 Hz 55 Hz Press “Stop”.

Overcrank — — After 3 attempts Press “Stop”.

Time to maintain:

■ Oil

■ Air

■ Fuel

750 hours

250 hours

500 hours

0 hours —

Navigate to the applicable

maintenance screen and press and

hold “Stop” for 10 seconds.

wc_tx004431gb_FM10.fm

59

Page 60

Operation LTV

b

a

wc_gr012367

5.7 Resetting the Maintenance Timers – DeepSea

Background

Procedure

The maintenance timers are preset on the controller. When the timer expires, the

alarm will display in the upper right corner of the screen. The maintenance timers

are preset as follows:

■ Oil change interval: 750 hours

■ Air filter change interval: 250 hours

■ Fuel filter change interval: 500 hours

After the required maintenance has been completed, perform the following

procedure to reset a maintenance timer.

1. Use the up and down arrows (a) to navigate to the applicable screen.