Page 1

0163721en 003

0708

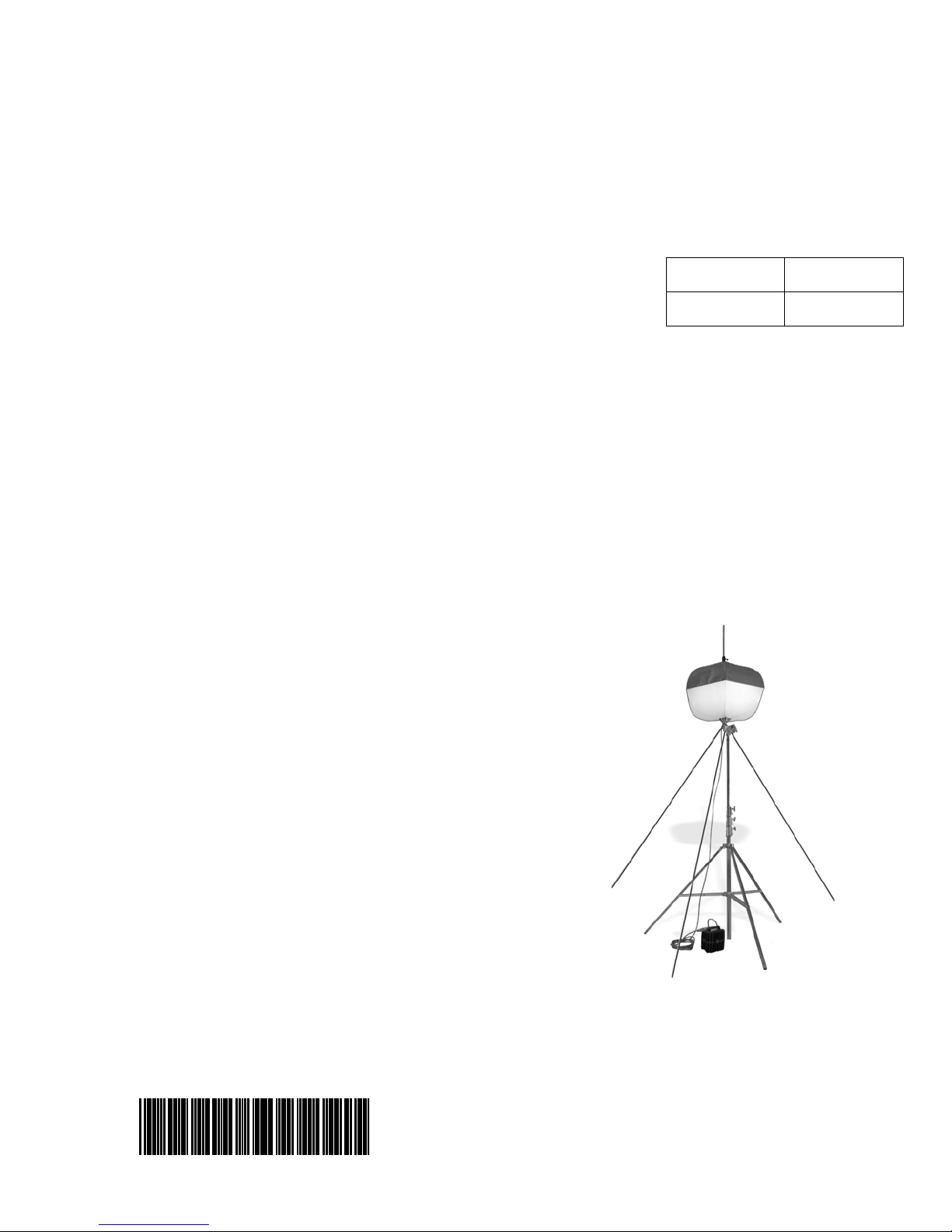

Indirect Lighting

System

LB 1

OPERATOR’S MANUAL

0163721EN

Page 2

Page 3

LB 1 Table of Contents

Foreword 4

1 Safety Information 5

1.1 Callouts Found in this Manual .............................................................. 5

1.2 Safety Guidelines for Operating the Machine ....................................... 6

1.3 Guidelines for Service Safety ............................................................... 7

1.4 Labels ................................................................................................... 8

2 Operation 9

2.1 Intended Use ........................................................................................ 9

2.2 Setting up the Balloon ........................................................................ 10

2.3 Setting up the Tripod .......................................................................... 11

2.4 Assembling the Balloon to the Tripod ................................................. 12

2.5 Turning ON/OFF the Light .................................................................. 14

2.6 Inspecting and Cleaning ..................................................................... 15

2.7 Changing the Bulb .............................................................................. 16

2.8 Troubleshooting .................................................................................. 18

2.9 Electrical Schematic ........................................................................... 19

3 Technical Data 20

3.1 Machine .............................................................................................. 20

wc_bo0163721en_003TOC.fm 3

Page 4

Foreword LB 1

Foreword

Machines

covered by

this manual

Operator’s

Manuals and

Parts Books

Expectations

for

information

in this

manual

This manual covers machines with Item Numbers: 0620340 & 0620341

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

Refer to the separate Repair Manual for detailed instructions on servicing and

repairing the machine.

If you are missing any of these documents, please contact Wacker Neuson Cor-

poration to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

Copyright

notice

Trademarks

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Corporation reserves the right to

change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2008 by Wacker Neuson Corporation.

This publication may be reproduced through photocopying by the original pur-

chaser of the machine. Any other type of reproduction is prohibited without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker Neuson Cor-

poration represents an infringement of valid copyrights, and violators will be

prosecuted.

All trademarks referenced in this manual are the property of their respective

owners.

wc_tx000887gb.fm 4

Page 5

LB 1 Safety Information

1 Safety Information

1.1 Callouts Found in this Manual

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f Obey all safety messages that follow this symbol to avoid injury or death.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f Obey all safety messages that follow this symbol to avoid possible injury or

death.

CAUTION indicates a situation which, if not avoided, could result in minor or moderate injury.

f Obey all safety messages that follow this symbol to avoid possible minor or

moderate injury.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

wc_si000219gb.fm 5

Page 6

Safety Information LB 1

1.2 Safety Guidelines for Operating the Machine

Operator

training

Work area

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson Corporation for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

When setting up the machine:

Keep the area immediately surrounding the machine clean, neat, and free of

debris.

When lighting traffic routes, always place one of the three support ropes at a

right angle to the traffic route to ensure that the machine does not fall into the

traffic route.

Cordon off the area around the tripod in areas with crowds of people.

Clearly mark support ropes so that the support ropes do not pose a hazard for

passersby.

Keep plugs and receptacles dry.

Keep a distance of at least one meter (3 feet) between the balloon and any

flammable material such as wood or plastic.

Keep the machine at least 5.5 m (16 ft.) from pools and spas.

Be sure the machine is on a firm, level surface and will not tip, roll, slide, or fall.

Make sure the area above the balloon is open and clear of overhead wires and

obstructions. High voltage cables should be at least 50 meters (160 feet) linear

distance away from the tripod. Overhead electric lines should be kept at least

2.5 meters (8 feet) away from the balloon.

When operating this machine:

Do not allow water to accumulate around the base of the machine. If water is

present, move the machine.

Do not operate the machine in areas where leaks of combustible substances

such as gasoline and natural gas may occur.

Do not use with extension cord near water or where water may accumulate.

Guidelines for

operating

wc_si000219gb.fm 6

When operating this machine:

Use on GFCI-protected circuits only.

Replace a damaged balloon cover before use.

Lower the tripod and collapse the balloon after use.

Page 7

LB 1 Safety Information

When operating this machine:

Do not start a machine in need of repair.

Do not use the machine if the insulation on the electrical cord is cut or worn

through.

Do not operate the light without the balloon.

1.3 Guidelines for Service Safety

Precautions

Accessories,

safety devices

and

modifications

When maintaining this machine:

Read and understand the service procedures before performing any service to

the machine.

All adjustments and repairs shall be completed before operating the machine.

All adjustments and repairs shall be done by a qualified technician.

Turn the machine off before performing maintenance or making repairs.

When maintaining this machine:

Never allow a machine with a known problem or deficiency to be operated.

Repair or maintain the machine immediately after detecting a problem.

When maintaining this machine:

Use only accessories or attachments that are recommended by Wacker Corpo-

ration.

When maintaining this machine:

Do not defeat safety devices.

Do not modify the machine without the express written approval of the

manufacturer.

Replacing

parts and

labels

wc_si000219gb.fm 7

When maintaining this machine:

Use only spare parts recommended by Wacker Neuson Corporation.

Replace all missing and hard-to-read labels.

Page 8

Safety Information LB 1

1.4 Labels

wc_si000219gb.fm 8

Page 9

LB 1 Operation

2 Operation

2.1 Intended Use

Intended use

Local

regulations

The LB 1 is intended to illuminate work areas. The end user assumes all responsibility for operating the machine safely and within its specified parameters.

Consult with local authorities to determine regulations limiting noise and light emissions in the work area. Be sure to abide by these regulations when using the

machine.

wc_tx000741gb.fm 9

Page 10

Operation LB 1

2.2 Setting up the Balloon

Prerequisites

Procedure

Balloon

Light fixture with bulb

Follow the procedure below to set up the balloon.

1. Remove the light from the transport cylinder.

2. Remove the light from the transport bag.

WARNING

Electric shock hazard. Electric shock can cause serious injury or death.

f Never connect the light to its power source and never turn it on until it has been

fully unpacked and assembled to the tripod!

3. Hold the black handle with one hand and pull the stop bolt (a) with the other

hand while slowly pushing the handle downward (b). Push forcefully during the

last 5 mm (0.20 in.), as the seals provide some resistance.

The balloon is fully expanded when the stop bolt clicks into the lowest tension position.

4. Check that the hook and loop (Velcro) seal is closed all around and that the

white, translucent lower balloon cover shows no signs of serious damage. If the

translucent lower cover is damaged, repair or replace it.

The balloon is now ready to be assembled to the tripod.

wc_tx000741gb.fm 10

Page 11

LB 1 Operation

2.3 Setting up the Tripod

Prerequisites

Procedure

Tripod

Follow the procedure below to set up the tripod.

WARNING

Electric shock hazard. Electric shock can cause serious injury or death.

f Never connect the light to its power source and never turn it on until it has been

fully unpacked and assembled to the tripod!

1. Unfold the tripod legs.

b

6 cm

(2 in.)

2. One of the legs has its own locking clamp (a). If the ground is not level, loosen

this clamp and adjust the length of the leg so that the mast is vertical.

3. The mast should not touch the ground. Adjust the mast so that it is at least 6 cm

(2 inches) from the ground.

4. Adjust the braces (b) so that they are parallel to the ground.

The tripod is now ready for the balloon.

wc_tx000741gb.fm 11

Page 12

Operation LB 1

2.4 Assembling the Balloon to the Tripod

Prerequisites

Procedure

Tripod

Follow the procedure below to assemble the balloon to the tripod.

WARNING

Electric shock hazard. Electric shock can cause serious injury or death.

f Never connect the light to its power source and never turn it on until it has been

fully unpacked and assembled to the tripod!

1. Lift the balloon and insert the end of the round shaft into the tripod receptacle

(a). Tighten the receptacle clamp.

b

c

a

wc_gr005065

2. Ensure that each carabiner (b) moves freely and is not jammed.

3. Each of the three support ropes (c) is provided with a loop on both ends. Attach

a support rope to each carabiner. Let the free ends of the ropes hang loosely for

the moment.

This procedure continues on the next page.

wc_tx000741gb.fm 12

Page 13

LB 1 Operation

Continued from the previous page.

CAUTION

Pinch point. Fingers or hands could get pinched between the telescoping sections

of the tripod mast.

f Use care when raising and lowering the tripod mast.

4. The recommended installation height for the tripod is 4–5 meters (approximately

12 –15 feet). Loosen the mast clamps on the tripod and adjust the height of

each section as desired. Tighten all mast clamps securely.

5. Three metal stakes (d) are provided with the LB 1. Pound each into a suitable

ground location and loop the free ends of the support ropes around them to

anchor the machine. Make sure that the ropes are taut.

CAUTION

Tripping hazard! Passersby may accidentally trip over the support ropes or walk

into them. This may lead to personal injury.

f Attach brightly-colored ribbons to the support ropes to increase visibility.

The LB 1 is now ready for operation.

wc_tx000741gb.fm 13

Page 14

Operation LB 1

2.5 Turning ON/OFF the Light

Prerequisites

Turning on

Ballast and power source

LB 1 assembled

Follow the procedure below to turn on the light.

1. Connect the plug (a) of the light cord into the ballast (b). If in doubt which way

the plug should be installed, install it so that the screw (d) is facing up.

2. Secure the plug to the ballast with the clamp (c). Then, plug the ballast into the

GFCI-protected circuit. The bulb will reach full power in 4–5 minutes.

Note: After being turned off, the lamp requires a 7–10 minute cool-down period

before it will re-start.

.

Turning off

WARNING

Electric shock and trip hazard!

f Do not allow pedestrians or vehicular traffic to cross over the electrical cords.

The cords could be damaged, cut, or tripped over.

CAUTION

Electric shock hazard! The ballast choke is compensated with a capacitor. The

capacitor may produce a small spark or electric shock when discharging.

f Disconnect the ballast from the power source before disconnecting the light

from the ballast.

Note: The capacitor charge conforms with ENEC/VDI and UL regulations. Due to

the discharge resistance at the capacitors, the capacitor is discharged within a

defined period of time (approximately 30 seconds).

Follow the procedure below to turn off the light.

1. Unplug the ballast from the voltage source (GFCI-protected circuit). After

approximately 30 seconds, unplug the light from the ballast.

2. Allow the lamp to cool 10 minutes, then collapse the balloon and the tripod.

Note: Always collapse the balloon and the tripod after each use of the light.

wc_tx000741gb.fm 14

Page 15

LB 1 Operation

2.6 Inspecting and Cleaning

Inspecting

Cleaning

Inspect the following components each time you unpack the LB 1:

Make sure that no electrical cords are damaged. If any electrical cords are

defective or damaged or if the grounding plug is broken or shorted-out, have a

specialist repair it.

Inspect the bulb for cracked glass.

Make sure the bulb is properly screwed into the socket.

Inspect the lower and upper covers for damage. Do not operate the balloon

with a defective cover.

Follow the instructions below for cleaning the machine:

If the balloon should become damp during use, let it dry thoroughly before

returning the balloon to its transport cylinder. Otherwise, it will become musty in

storage.

If the cover (upper/lower) is dirty, wipe it with a weak solution of liquid dish soap

and water.

NOTICE: Do not use solvents to clean the balloon cover!

NOTICE: Never use a pressure washer to clean the machine.

wc_tx000741gb.fm 15

Page 16

Operation LB 1

2.7 Changing the Bulb

Prerequisites

Removal

Leather gloves and eye protection

New bulb

Follow the procedure below to remove the bulb.

WARNING

Cutting hazard. Broken glass from the bulb can cause severe cuts.

f Always wear leather gloves and eye protection when changing the bulb.

Note: Yellow-brown condensing particles with free or enclosed metal drops inside

the bulb are normal. The bulb is damaged and in need of replacing if the inner part

of the bulb is deformed by heat or if the inner or outer bulbs show cracks or cuts.

Removal:

1. Turn off the generator, unplug the light, and allow the bulb to cool at least 15

minutes.

2. Remove the balloon from the tripod.

3. Expand (open) the balloon. See section Setting up the Balloon.

4. Mount the balloon in a bench-top vise or other similar location that can hold the

balloon securely and provide accessibility.

5. Separate the upper (a) from the lower portion (b) of the balloon by separating

the hook-and-loop tape (Velcro

®

). Limit the opening to one or two sections.

This procedure continues on the next page.

wc_tx000741gb.fm 16

Page 17

LB 1 Operation

Continued from the previous page.

6. Disconnect the snaps and remove the burst cage (c).

7. With a gloved hand, unscrew the bulb (d) and remove it.

Installation

Follow the procedure below to install a new bulb.

1. With a gloved hand, screw the bulb into the light fixture.

NOTICE: Avoid touching the bulb with your bare hands. Oils from your skin may

shorten bulb life.

2. Re-install the burst cage.

3. Reconnect the lower and upper portions of the balloon with the hook-and-loop

tape (Velcro

®

).

The procedure to change the bulb is now complete.

wc_tx000741gb.fm 17

Page 18

Operation LB 1

2.8 Troubleshooting

Problem Reason Remedy

Balloon does not open. The stop bolt is not pulled

out before attempting to

push the black hand grip

downward.

Bulb does not light. Power supply has incorrect

voltage or frequency.

Damaged or loose bulb. Check bulb.

Loose plug. Ensure that all plugs are

Faulty, damaged, or burned

bulb socket.

Faulty or damaged ballast. Replace ballast.

Light shuts off and/or

restarts during operation

Defective electrical network.

Deviation in frequency by

more than ±10Hz.

Pull out the stop bolt and

attempt to push down

again.

If the balloon still does not

open, hold the aluminum

bell, rotate the black hand

grip left or right, pull out the

stop bolt and attempt to

push down again.

Check power supply.

properly seated and locked.

Replace socket.

Check power supply.

Check power supply.

Light flickers during operation

Deviation in frequency by

more than ±10Hz.

Power supply unstable or

insufficient.

Generator’s condenser may

be worn out.

Too many other machines

using the same generator.

Check power supply.

Check power supply.

Check generator.

Check generator.

wc_tx000741gb.fm 18

Page 19

LB 1 Operation

2.9 Electrical Schematic

Ref. Description Ref. Description

1 Power source 5 Lamp

2 Power source plug and cord 6 Transformer

3 Ballast box 7 Capacitor

4 Ballast plug 8 16A fuse

wc_tx000741gb.fm 19

Page 20

Technical Data LB 1

3 Technical Data

3.1 Machine

Item Number 0620340 0620341

Dimensions (l x w x h) mm (in.) 1960 x 1960 x 2622

(77.2 x 77.2 x 103.2)

Working height:

minimum

maximum

Weight kg (lbs.) 21 (46.3)

Diameter mm (in.) 900 (35.4)

Lamp type -- Metal halide

Lamp output Watt 1000

Luminous flux lm 99,0000

m (ft.)

m (ft.)

2.6 (8.6)

6.2 (20.3)

AC voltage V 230 115

Starting current Amp 7.4

Steady-state current Amp 4

Frequency Hz 50

Plug type -- Schuko

Cord length:

balloon to ballast

ballast to generator

Ambient temperature range °C (°F) -30 – +40 (-22 – +104)

m (ft.)

m (ft.)

7 (23)

3 (9.8)

wc_td000261gb.fm 20

Page 21

EC DECLARATION OF CONFORMITY

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München hereby certifies that

the construction equipment specified hereunder

Category

Light Balloon

has been produced in accordance with the following standards:

98/37/EG

2006/95/EG

2004/108/EG

EN 55015

EN 61000-3-2

EN 61000-3-3

EN 61547

Typ e LB 1

Item number of equipment

0620340

0620341

Dr. Stenzel

Leiter Forschung und Entwicklung

Page 22

Wacker Construction Equipment AG · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-3 54 02 - 0 · Fax: +49 - (0)89-3 54 02-3 90

Neuson Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : (262) 255-0500 · Fax: (262) 255-0550 · Tel. : (800) 770-0957

Wacker

Wacker Asia Pacific Operations · Skyline Tower, Suite 2303, 23/F · 39 Wang Kwong Road, Kowloon Bay, Hong Kong · Tel. +852 2406 60 32 · Fax: +852 2406 60 21

Loading...

Loading...