Page 1

0203044en 005

02.2008

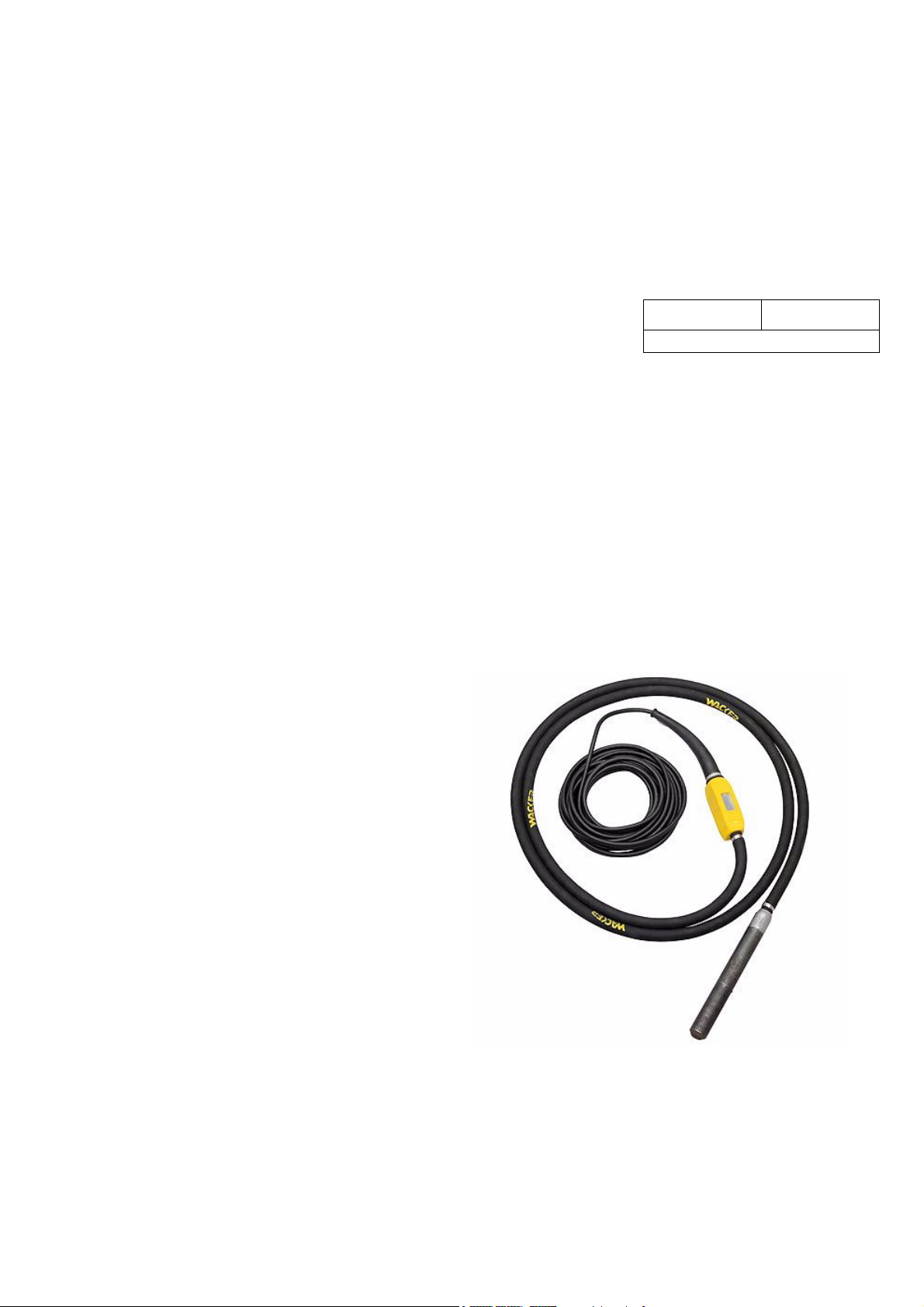

Internal vibrator

IREN

38, 40, 45, 57, 65

Operator's manual

Page 2

Page 3

Inhalt

IREN Contents

1 Foreword .................................................................................................................... 5

2 Introduction ...............................................................................................................6

2.1 Means of representation for this operator's manual ........................................... 6

2.2 WACKER representative .................................................................................... 7

2.3 Described machine parts.................................................................................... 7

3 Safety information .................................................................................................... 8

3.1 Principle.............................................................................................................. 8

3.2 Qualification of the operating personnel ........................................................... 10

3.3 Protective gear ................................................................................................. 11

3.4 Transport .......................................................................................................... 12

3.5 Operating safety ............................................................................................... 12

3.6 Safety during the operation of electric appliances............................................ 13

3.7 Maintenance..................................................................................................... 13

4 Scope of delivery ....................................................................................................14

5 Description ..............................................................................................................15

5.1 Application........................................................................................................ 15

5.2 Functionality ..................................................................................................... 15

5.3 Components and operator's controls................................................................ 16

6 Transport .................................................................................................................19

7 Operation .................................................................................................................20

7.1 Prior to starting the machine............................................................................. 20

7.2 Starting up ........................................................................................................ 21

7.3 Decomissioning ................................................................................................ 23

7.4 Cleaning ........................................................................................................... 23

8 Maintenance ............................................................................................................ 24

8.1 Maintenance schedule...................................................................................... 24

8.2 Maintenance work ............................................................................................ 24

9 Troubleshooting ...................................................................................................... 26

10 Disposal ...................................................................................................................27

10.1 Disposal of the machine ................................................................................... 27

3

Page 4

Contents IREN

11 Technical data ......................................................................................................... 28

11.1 IREN 38............................................................................................................ 28

11.2 IREN 40............................................................................................................ 29

11.3 IREN 45............................................................................................................ 30

11.4 IREN 57............................................................................................................ 31

11.5 IREN 65............................................................................................................ 33

11.6 Extension cable ................................................................................................ 35

EC Declaration of Conformity ................................................................................ 41

DIN EN ISO 9001 Certificate ................................................................................... 43

4

Page 5

1Foreword

This operator's manual contains information and procedures for the safe operation and maintenance of your WACKER machine. In the interest of your own

safety and to prevent accidents, you should carefully read through the safety information, familiarize yourself with it and observe it at all times.

This operator's manual is not a manual for extensive maintenance and repair

work. Such work should be carried out by WACKER Service or authorized specialists.

The safety of the operator was one of the most important aspects taken into consideration when this machine was designed. Nevertheless, improper use or incorrect maintenance can pose a risk. Please operate and maintain your

WACKER machine in accordance with the instructions in this operator's manual.

Your reward will be troublefree operation and a high degree of availability.

Foreword

Defective machine parts must be replaced immediately!

Please contact your WACKER representative if you have any questions concerning operation or maintenance.

All rights reserved, especially reproduction and distribution rights.

Copyright 2008 Wacker Construction Equipment AG

No part of this publication may be reproduced in any form or by any means, electronic or mechanical, including photocopying, without the expressed written permission of WACKER.

Any type of reproduction, distribution or storage on data media of any type and

form not authorized by WACKER represents an infringement of copyright and will

be prosecuted.

We expressly reserve the right to make technical modifications – even without

special notice – which aim at further improving our machines or their safety standards.

5

Page 6

Introduction

2 Introduction

2.1 Means of representation for this operator's manual

Warning symbols

This operator's manual contains safety imformation of the categories:

DANGER, WARNING, CAUTION, NOTICE.

They should be followed to prevent danger to life and limb or damage to equipment or improper service.

DANGER

This warning notice indicates hazards that result in serious injury or even death.

f Danger can be avoided by the following the actions mentioned.

WARNING

This warning notice indicates hazards that can result in serious injury or even

death.

f Danger can be avoided by the following the actions mentioned.

CAUTION

This warning notice indicates hazards that can result in minor injury.

f Danger can be avoided by the following the actions mentioned.

NOTICE

This warning notice indicates hazards that can result in material damage.

f Danger can be avoided by the following the actions mentioned.

Notes

Note: Complementary information will be displayed here.

Instructions

f This symbol indicates there is something for you to do.

1. Numbered instructions indicate that you have to carry out something in a defined

sequence.

This symbol is used for lists.

6

Page 7

2.2 WACKER representative

Depending on your country, your WACKER representative is your WACKER

Service, your WACKER affiliate or your WACKER dealer.

You can find the addresses in the Internet at www.wackergroup.com.

The addresses of the WACKER main locations are located at the end of this operator's manual.

2.3 Described machine parts

This operator's manual is valid for different machine parts from a product range.

Therefore some figures can differ from the actual appearance of your machine.

It is also possible that the descriptions include components which are not a part

of your machine.

Details for the described machine types can be found in the chapter Technical

Data.

Introduction

7

Page 8

Safety information IREN

3 Safety information

3.1 Principle

State of the art

This machine has been constructed with state-of-the-art technology according to

the recognized rules of safety. Nevertheless, when used improperly, dangers to

the life and limb of the operator or to third persons or damage to the machine or

other materials cannot be excluded.

Proper use

The machine may only be used for compacting fresh concrete. The vibrator head

has to be immersed in the fresh concrete.

The vibrator head may not be immersed into acidic or alkaline liquids.

Its proper use also includes the observance of all instructions contained in this

operator's manual as well as complying with the required service and maintenance instructions.

Any other use is regarded as improper. Any damage resulting from improper use

will void the warranty and the liability on behalf of the manufacturer. The operator

assumes full responsibility.

Structural modifications

Never attempt to modify the machine without the written permission of the manufacturer. Failure to do so will endanger your safety! In addition, this will void the

warranty and the liability on behalf of the manufacturer.

Requirements for operation

The ability to operate the machine safely requires:

Proper transport, storage and setup.

Careful operation.

Careful service and maintenance.

Operation

Operate the machine only as intended and only when in proper working condition.

Operate the machine in a safety-conscious manner with all safety devices attached and enabled. Do not modify or disable any safety devices.

Before starting operation, check that all control and safety devices are functioning properly.

Never operate the machine in a potentially explosive environment.

8

Page 9

IREN Safety information

Supervision

Never leave the machine running unattended!

Maintenance

Regular maintenance is required in order for the machine to operate properly and

reliably over time. Neglected maintenance work can make the machine dangerous to use.

Strictly observe the prescribed maintenance intervals.

Do not use the machine if it requires maintenance or repairs.

Malfunctions

If you detect a malfunction, you must shut down and secure the machine immediately.

Eliminate the malfunctions that impair safety immediately!

Have damaged or defective components replaced immediately!

For further information, refer to chapter Troubleshooting.

Spare parts, accessories

Only use spare parts and accessories from WACKER. Non-compliance will exempt the manufacturer from all liability.

Exclusion of liability

WACKER will refuse to accept liability for injuries to persons or for damage to

materials in the following cases:

Structural modifications.

Improper use.

Improper handling.

Use of spare parts and accessories not produced by WACKER.

Operator's manual

Always keep the operator's manual near the machine or near the worksite for

quick reference.

If you have misplaced the operator's manual or require an additional copy, contact your WACKER representative or download it from the Internet

(www.wackergroup.com).

Always hand over this operator's manual to other operators or to the future owner

of the machine.

9

Page 10

Safety information IREN

Country-specific regulations

Observe the country-specific regulations, standards and guidelines in reference

to accident prevention and environmental safety, for example those pertaining to

hazardous materials and wearing protective gear.

Complement the operator's manual with additional instructions taking into account the operational, regulatory, national or generally applicable safety guidelines.

Operator's controls

Always keep the operator's controls of the machine dry, clean and free of oil or

grease.

The function of the operator's controls must not be manipulated or rendered ineffective.

Cleaning

Always keep the machine clean and be sure to clean it each time you have finished using it.

Do not use gasoline or solvents. Danger of explosion!

Checking for signs of damage

Inspect the machine when it is switched off for any signs of damage at least once

per work shift.

Do not start the machine if there is visible damage or defects.

Have any damage or defects eliminated immediately.

3.2 Qualification of the operating personnel

Operator qualifications

Only trained personnel are permitted to start and operate the machine. The following rules also apply:

You are physically and mentally fit.

You have received instruction on how to independently use the machine.

You have received instruction in the proper use of the machine.

You are familiar with required safety devices.

You are authorized to start machines and systems in accordance with the

standards governing safety.

You have been assigned to work on the machine by your company.

Incorrect operation

Incorrect operation or misuse by untrained personnel can endanger the health

and safety of the operator and also cause machine and material damage.

10

Page 11

IREN Safety information

Operating company responsibilities

The operating company must make the operator's manual available to the operator and ensure that the operator has read and understood it.

Work recommendations

Please observe the recommendations below:

Work only if you are in a good physical condition.

Work attentively, particularly as you finish.

Do not operate the machine when you are tired.

Carry out all work calmly, circumspectly and carefully.

Never operate the machine under the influence of alcohol, drugs or medica-

tion. This can impair your vision, reactions and your judgment.

Work in a manner that does not endanger others.

3.3 Protective gear

Work clothing

Clothing should be appropriate, i.e. should be close-fitting but not restrict your

movement.

When on construction sites, do not wear long hair loosely, loose clothing or jewelry including rings. These objects can easily get caught or be drawn in by moving machine parts.

Personal protective gear

Wear personal protective gear to avoid injuries or health hazards:

Non-skid, hard-toed shoes.

Work gloves made of durable material.

Overalls made of durable material.

Hardhat.

Ear protection.

Ear protection

This machine generates noise that exceeds the country-specific permissible

noise levels (individual rating level). It may therefore be necessary to wear ear

protection. You can find the exact value in the chapter Technical Data.

WACKER recommends that you always wear ear protection.

11

Page 12

Safety information IREN

3.4 Transport

Switching off the machine

Before you transport the machine, switch it off and pull the plug out of the plug

receptacle. Allow the motor to cool down.

Transporting the machine

Secure the machine on the transport device against tilting, falling or slipping.

Restarting

Machines, machine parts, accessories or tools that were detached for transport

purposes must be re-mounted and fastened before restarting.

Only operate in accordance with the operating instructions.

3.5 Operating safety

Work environment

Familiarize yourself with your work environment before you start work. This includes e.g. the following items:

Obstacles in the work and traffic area.

Load-carrying capacity of the ground.

The measures needed to cordon off the construction site from public traffic.

The measures needed to secure walls and ceilings.

Options available in the event of an accident.

Starting the machine

Observe the safety information and warning notices located on the machine.

Never attempt to start a machine that requires maintenance or repairs.

Start the machine as directed in the operator's manual.

Avoid body contact with grounded components.

Vertical stability

Always make sure that you maintain a safe distance when working with the machine. This applies particularly when working on scaffoldings, ladders, etc.

Switching off the machine

Switch the machine off and pull the plug out of the plug receptacle: Before taking

a break or if the machine will not be used.

Before storing the machine, wait until it has completely stopped running.

Set or place the machine in such a way that it cannot tilt, fall or slip.

12

Page 13

IREN Safety information

Storage location

Store the machine after operation at a sealed off and dry location inaccessible to

children.

3.6 Safety during the operation of electric appliances

Specific regulations for electrical appliances

Observe the safety information provided in the brochure General Safety Rules

which is included in the scope of delivery of your machine.

Also observe the country-specific regulations, standards and guidelines in reference to accident prevention in connection with electrical equipment and machines.

Extension cable

The machine may only be operated with undamaged extension cables!

Only use extension cables with grounded conductor and correct connection of

the grounded conductor to the plug and coupling (not for 42 V machines).

Only use extension cables which are suitable for use at construction sites: Average rubber hose H05RR-F or better – WACKER recommends H07RN-F or a

country-specific equivalent design.

Immediately replace damaged extension cables (e.g. tears in the sheathing) or

loose plugs and couplings.

Protecting the power cable

Do not use the power cable to pull or lift the machine.

Do not unplug the power cable by pulling on the cable.

Protect the power cable from heat, oil and sharp edges.

If the power cable is damaged or the plug is loose, have it replaced immediately

by your WACKER representative.

3.7 Maintenance

Maintenance work

Service and maintenance work must only be carried out to the extent described

in these operating instructions. All other procedures must be performed by your

WACKER representative.

For further information, refer to chapter Maintenance.

Disconnecting the machine from the electric power supply

Before carrying out service or maintenance work, pull the plug out of the plug receptacle in order to disconnect the machine from the electric power supply.

13

Page 14

Scope of delivery IREN

4 Scope of delivery

The internal vibrator is delivered completely mounted and will only be ready for

operation in combination with a three-phase inverter.

The scope of delivery includes:

Machine.

Operator's manual.

Parts book.

General safety instructions.

14

Page 15

IREN Description

5 Description

5.1 Application

The machine is designed to compact fresh concrete in formworks and on even

surfaces.

IREN GV

The machine is protected from damage of the formworks by the rubber seal cap

(GV).

IREN ...k

The machine is especially suited for compacting fresh concrete on even surfaces

with low layer thickness. The short construction (...k) enables the complete immersion of the vibrator head, which results in a more efficient cooling of the vibrator head.

IREN ST

The machine is especially suited for better guidance and positioning in areas of

the formwork which are difficult to reach.

IREN lifting point

The machine is especially suited for compacting fresh concrete in work areas

which are inaccessible.

The machine is equipped with an additional steel cable to increase the safety

(higher traction force).

5.2 Functionality

Principle

The machine is an internal vibrator which creates high-frequency vibrations in

the vibrator head.

Concrete is deaerated and compressed in the effective range of the vibrator

head when the vibrator head is immersed into the fresh concrete.

The fresh concrete is simultaneously cooling the vibrator head.

Note: The concrete is being compressed for as long as bubbles of air arise.

15

Page 16

Description IREN

Thermal overload switch

The machine is protected against overheating by a thermal overload switch,

which will deactivate the machine in the case of overheating.

After cooling, the machine has to be deactivated and activated again.

Note: If there is no ON/OFF switch on your machine, you need to switch off

the inverter and switch it on again.

Vibrator head

In the vibrator head, an electric motor turns an eccentric weight at approx.

12,000 rpm (200 Hz) and thus generates vibrations.

These vibrations will cause the vibrator head to execute precessions.

5.3 Components and operator's controls

IREN

Item Description Item Description

1 Vibrator head 5 Plug

2 Protective hose 6 ON/OFF switch

3 Switch housing 7 Lower tube

4 Power cable

IREN without ON/OFF switch

Item Description Item Description

1 Vibrator head 4 Plug

2 Protective hose 5 Lower tube

3 Power cable

16

Page 17

IREN Description

IREN GV

Item Description Item Description

1 Vibrator head 5 Plug

2 Protective hose 6 ON/OFF switch

3 Switch housing 7 Lower tube

4 Power cable 8 Rubber seal cap

IREN with lifting point

Item Description Item Description

IREN ST1

Item Description Item Description

1 Vibrator head 4 Plug

2 Protective hose 5 Lifting point

3 Power cable 6 Lower tube

1 Vibrator head 5 Power cable

2Pipe 6Plug

3 Protective hose 7 ON/OFF switch

4 Switch housing 8 Lower tube

17

Page 18

Description IREN

IREN ST2

Item Description Item Description

1 Vibrator head 5 Power cable

2Pipe 6Plug

3 Connecting cable 7 ON/OFF switch

4 Switch housing 8 Lower tube

IREN ST3

Item Description Item Description

1 Vibrator head 4 Plug

2 Pipe 5 Lower tube

3 Power cable

IREN ST4

Item Description Item Description

1 Vibrator head 4 Power cable

2Pipe 5Plug

3 Protective hose 6 Lower tube

18

Page 19

IREN Transport

6Transport

WARNING

Hot vibrator head!

Touching it can cause burns.

f Only touch the vibrator head once the engine has cooled down.

Transporting the machine

1. Switch off the machine via the ON/OFF switch.

Note: If there is no ON/OFF switch on the machine, switch off the machine

via the ON/OFF switch of the inverter.

2. Wait until the machine has come to a complete standstill.

3. Turn off the inverter.

4. Disconnect the machine from the inverter.

5. Place the machine on or into a suitable means of transport.

6. Roll up the power cable.

Note: Do not kink the power cable!

7. Secure the machine against falling or sliding.

Note: Due to its length, IREN ST may protrude over the means of transport.

Observe the valid road traffic regulations and secure the machine with

a mandatory warning sign, if required.

19

Page 20

Operation IREN

7 Operation

WARNING

Improper handling can result in injury or serious material damage.

f Read and follow all safety instructions of this operator's manual, see chapter

Safety information.

7.1 Prior to starting the machine

After unpacking, the machine is ready for operation.

Plug

The machine comes with a country-specific plug as a standard equipment.

Carrying out checks

f Check if mains or power distribution on the construction site have the correct

operating voltage (see nameplate of the machine or chapter Technical Data).

f Check if mains or power distribution on the constructions site are protected

in accordance with current standards and regulations.

f Check protective hose and power cable for damage.

20

Page 21

IREN Operation

7.2 Starting up

Connecting the machine to the power supply

The machine may only be connected to a three-phase inverter, connection values see chapter Technical Data.

NOTICE

Electrical voltage.

Incorrect voltage can cause damage on the machine.

f Check if the voltage of the current source corresponds with the information

of the machine, see chapter Technical Data.

WARNING

Electrical voltage.

Danger of electrocution!

f Only use extension cables for which grounded conductors are connected to

the plug and the coupling (only for machines of class rating I).

1. Turn off ON/OFF switch.

Note: When the ON/OFF switch is pressed, the machine starts to run immediately at the connection. The machine can strike out and may injure persons

or be damaged.

2. If required, connect the machine to a permitted extension cable.

Note: See chapter Technical data for the permitted lengths and cross-section

areas of extension cables.

3. Connect the power cable or extension cable to the inverter.

Switching IREN on

1. Use the protective hose to hold the machine near the vibrator head.

2. Switch on the machine via the ON/OFF switch.

Switching IREN with lifting point on

1. Use lifting point to attach machine to the safety load hook of the crane.

2. Switch on the machine via the ON/OFF switch of the inverter.

Note: Please also refer to the operator's manual of the inverter.

Switching IREN ST 1/2 on

1. Use the pipe to hold the machine near the vibrator head.

2. Switch on the machine via the ON/OFF switch.

21

Page 22

Operation IREN

Switching IREN ST 3/4 on

1. Use the pipe to hold the machine near the vibrator head.

2. Switch on the machine via the ON/OFF switch of the inverter.

Note: Please also refer to the operator's manual of the inverter.

Compacting fresh concrete

1. Quickly immerse the vibrator head in the fresh concrete, hold it for several

seconds and slowly pull it out again.

2. Immerse the vibrator head in all areas of the formwork and compact the fresh

concrete.

Note:

Compact especially intensively in corner areas and the formwork because of

the high reinforcement.

Make sure that the vibrator head does not touch the reinforcement. Damages

can occur both on the vibrator head and also on the concrete, if it is already

in the curing process.

The holding time of the vibrator head in the concrete depends on the diame-

ter of the vibrator head, the consistency of the concrete and the layer thickness.

Indications that the concrete is sufficiently compacted:

The concrete no longer sets.

Air bubbles no longer or rarely rise.

The sound of the vibrator head is not changing anymore.

22

Page 23

IREN Operation

7.3 Decomissioning

Switching off the machine

NOTICE

The vibrator head moves if it is turned on and not immersed in the fresh concrete.

Danger of injury or danger of damage to property by uncontrolled vibrator head.

f Switch the machine off before you put it down.

NOTICE

The vibrator head heats up if it is turned on and not immersed in the fresh concrete.

Hot surface can cause burns!

Damage to the machine with excessive wear!

f Do not operate the machine with the internal vibrator not immersed in the

fresh concrete.

1. Slowly remove the machine from the fresh concrete; hold the vibrator head in

2. Switch off the machine via the ON/OFF switch.

3. Turn off the inverter.

4. Wait until the machine has come to a complete standstill.

5. Put down the machine slowly.

6. Disconnect the machine from the inverter.

7.4 Cleaning

Cleaning the machine

f Clean the machine with water after each use.

Note: You can remove concrete residuals by immersing the running machine

the air.

Note: If there is no ON/OFF switch on the machine, switch off the machine

via the ON/OFF switch of the inverter.

Do not kink the protective hose and power cable!

into gravel.

23

Page 24

Maintenance IREN

8 Maintenance

WARNING

Improper handling can result in injury or serious material damage.

f Read and follow all safety instructions of this operator's manual, see chapter

Safety information.

8.1 Maintenance schedule

Note: The time intervals mentioned here are reference values for normal op-

eration. For extreme operation, e.g. continuous use, the service intervals should be halved.

Task Daily be-

Visual inspection of all parts

for damage.

Check the wear dimensions.

Change oil in vibrator head.

Notify your WACKER contact in case of maintenance work which you cannot or

may not complete yourself.

8.2 Maintenance work

Visual inspection for damage

WARNING

A damaged machine part, protective hose or power cable can result in personal

injury caused by electric current.

f Do not operate a damaged machine!

f Have a damaged machine repaired immediately.

fore operation

Every

100 hrs.

24

Page 25

IREN Maintenance

Checking the machine

f Check all machine parts for damage.

Machines with ON/OFF switch:

f Check the tightness of the switch diaphragm.

Check wear dimensions of the vibrator head

Wear dimensions:

Minimum diameter of lower tube øL

Minimum diameter of vibrator head øL

Length of vibrator head L

L

Wear is highest at the immersed end of the vibrator head.

L

Machine

type

IR... 30 28 (30) 347 (353) — *

IR... 38 33 (38) 338 (345) 36 (38) 218

IR... 45 38 (45) 372 (382) 42 (45) 333

IR... 57

IR... 57k

IR... 65 52 (65) 475 (490) 58 (65) 322

* Vibrator head does not comprise 2 parts.

Dimensions for vibrator head and lower tube

[mm]

øL

L

50 (58) 390 (400)

L

L

320 (330)

øL L

54 (58)

54 (58)

— *

253

213

Dimensions in bold are wear dimensions.

Dimensions in brackets are original dimensions of new machines.

Let the lower tube be exchanged by your WACKER contact if the wear dimensions are reached at a certain point.

Changing the oil in the vibrator head

Take the machine to your WACKER contact to change the oil in the vibrator

head.

25

Page 26

Troubleshooting IREN

9 Troubleshooting

Potential faults, their causes and remedies can be found in the following table.

Malfunction Cause Remedy

Vibrator head does not vibrate. No line voltage. - Connect the plug to the in-

verter.

- Check power cable for damage, replace if defective.

Noticeable sound, vibrator head

runs with reduced power.

Vibrator head has switched off

due to excess temperature.

- ON/OFF switch defective.

- Inverter defective.

- Mechanical defect in the vibrator head.

One of the thermal overload

protections has switched off

(two phase operation).

Deactivate the machine and allow the vibrator head to cool

down.

Have the machine repaired.

Have the machine repaired.

Notify your WACKER contact in case of malfunctions you cannot or may not remedy yourself.

26

Page 27

IREN Disposal

10 Disposal

10.1 Disposal of the machine

Your machine contains many valuable raw materials which should be disposed

and recycled in an environmentally friendly manner.

During disposal of the machine observe the country-specific rules and regulations, e.g. the European Directive for obsolete electrical and electronic devices.

Do not dispose of the machine in household rubbish. It

must be disposed at a recycling facility.

27

Page 28

Technical data IREN

11 Technical data

11.1 IREN 38

Designation Unit IREN 38 IREN 38/115 IREN 38/250

Item no. 0007895

0008513

0008514

0008515

0008433

0008578

0008665

0008671

0008676

Rated voltage V 42 115 250

Rated frequency Hz 200

Rated power consumption kW 0.41

Rated current consumption

Diameter of vibrator head mm (in) 38 (1.5)

Length of vibrator head mm (in) 345 (13.6)

Vibration range mm (in) 1.9 (0.07)

Class rating III I

Protection class *

A7 3.1 1.4

0008469 0008470

0008627

IP67

Oil specification SAE 0W-30 (API SF or superior)

3

Oil quantity cm

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a distance of 2 m (6.6 ft)

from the lower tube, freely suspended in the air, at nominal speed.

hv

**

dB(A) 79

m/s

3)

(in

2

8 (0.49)

0.7

28

Page 29

IREN Technical data

11.2 IREN 40

Designation Unit IREN 40/048/240

Item no. 0610221

Rated voltage V 48

Rated frequency Hz 240

Rated power consumption kW 0.41

Rated current consumption

Diameter of vibrator head mm (in) 38 (1.5)

Length of vibrator head mm (in) 345 (13.6)

Vibration range mm (in) 1.9 (0.07)

Class rating III

Protection class *

Oil specification SAE 0W-30 (API SF

Oil quantity cm

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a dis-

tance of 2 m (6.6 ft) from the lower tube, freely suspended in

the air, at nominal speed.

hv

**

A6.2

IP67

or superior)

3

(in3)8 (0.49)

dB(A) 79

m/s

2

0.7

29

Page 30

Technical data IREN

11.3 IREN 45

Designation Unit IREN 45 IREN 45/

048/240

Item no. 0007896

0008510

0008511

0008512

0008474

0008434

0008664

0008670

0008675

Rated voltage V 42 48 115 250

Rated frequency Hz 200 240 200

Rated power consumption

Rated current consumption

Diameter of vibrator head mm (in) 45 (1.8)

Length of vibrator head mm (in) 382 (15)

kW 0.58

A10 8.8 4 1.85

0008592 0008471 0008472

IREN 45/115 IREN 45/250

0008626

Vibration range mm (in) 2.3 (0.09)

Class rating III I

Protection class *

Oil specification SAE 0W-30 (API SF or superior)

Oil quantity cm

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a distance of 2 m (6.6 ft) from the lower

tube, freely suspended in the air, at nominal speed.

hv

**

3

(in3)8 (0.49)

dB(A) 79

2

m/s

IP67

1.7

30

Page 31

IREN Technical data

11.4 IREN 57

Designation Unit IREN 57 IREN 57k IREN 57/

048/240

Item no. 0007820

0008346

0008430

0008435

0008504

0008505

0008506

0008662

0008668

0008673

0008903

0008904

0008905

Rated voltage V 42 48

Rated frequency Hz 200 240

Rated power consumption kW 1.05 0.76 1.05 0.76

Rated current consumption

Diameter of vibrator head mm (in) 58 (2.3)

A 17.3 13 15.2 11.4

0007821

0008437

0008507

0008508

0008509

0008663

0008669

0008674

0008591 0008590

IREN 57k/

048/240

Length of vibrator head mm (in) 400 (15.8) 330 (13) 400 (15.8) 330 (13)

Vibration range mm (in) 2.1 (0.083) 1.9 (0.075) 1.8 (0.070) 1.4 (0.055)

Class rating III

Protection class *

Oil specification SAE 0W-30 (API SF or superior)

Oil quantity cm

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a distance of 2 m (6.6 ft) from the lower

tube, freely suspended in the air, at nominal speed.

hv

**

3

(in3) 12 (0.73)

dB(A) 79

2

m/s

IP67

2.2

31

Page 32

Technical data IREN

Designation Unit IREN 57/

115

Item no. 0008465 0008460 0008479 0008466

Rated voltage V 115 240 250

Rated frequency Hz 200 180 200

Rated power consumption kW 1.05 0.76 1.05 1.05 0.76

Rated current consumption

Diameter of vibrator head mm (in) 58 (2.3)

Length of vibrator head mm (in) 400 (15.8) 330 (13) 400 (15.8) 400 (15.8) 330 (13)

Vibration range mm

Class rating I

Protection class *

Oil specification SAE 0W-30 (API SF or superior)

Oil quantity cm

A 6.5 4.8 3.1 3.0 2.2

2.1

(in)

3

(0.083)

(in3) 12 (0.73)

IREN

57k/115

1.9

(0.075)

IREN 57/

240/180

2.1

(0.083)

IP67

IREN 57/

250

0008624

2.1

(0.083)

IREN

57k/250

0008461

0008625

1.9

(0.075)

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a distance of 2 m (6.6 ft) from the lower

tube, freely suspended in the air, at nominal speed.

hv

**

dB(A) 79

m/s

2

2.2

32

Page 33

IREN Technical data

11.5 IREN 65

Designation Unit IREN 65 IREN 65/048/

240

Item no. 0007847

0008498

0008443

0008436

0008660

Rated voltage V 42 48 115

Rated frequency Hz 200 240 200

Rated power consumption kW 1.6 1.6

Rated current consumption

Diameter of vibrator head mm (in) 65 (2.6)

Length of vibrator head mm (in) 590 (23.2)

Vibration range mm (in) 2.5 (0.1)

Class rating III I

Protection class *

A25229.5

0008747 0008467

IP67

IREN 65/115

Oil specification SAE 0W-30 (API SF or superior)

Oil quantity cm

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a distance of 2 m (6.6 ft)

from the lower tube, freely suspended in the air, at nominal speed.

hv

**

3

(in3) 12 (0.73)

dB(A) 79

m/s

2

3.4

33

Page 34

Technical data IREN

Designation Unit IREN 65/240/180 IREN 65/250

Item no. 0008480 0008468

0008622

Rated voltage V 240 250

Rated frequency Hz 180 200

Rated power consumption kW 1.6

Rated current consumption

Diameter of vibrator head mm (in) 65 (2.6)

Length of vibrator head mm (in) 490 (19.2)

Vibration range mm (in) 2.5 (0.1)

Class rating I

Protection class *

Oil specification SAE 0W-30 (API SF or superior)

Oil quantity cm

Sound pressure level at

operator's station

Total vibration value of the

acceleration a

* According to DIN EN 60529.

** Determined according to DIN EN ISO 5349, measured at a distance of 2 m

(6.6 ft) from the lower tube, freely suspended in the air, at nominal speed.

hv

**

A4.4 4.2

IP67

3

(in3) 12 (0.73)

dB(A) 79

m/s

2

3.4

34

Page 35

IREN Technical data

11.6 Extension cable

WARNING

Electrical voltage.

Danger of electrocution!

f Only use extension cables for which grounded conductors are connected to

the plug and the coupling (only for machines of class rating I).

Please refer to the following table for the required cross-section area of cable for

a designated extension.

Note: Refer to the nameplate or the chapter Technical data (via the item

number) for the type designation and voltage rating of your machine.

Machine Voltage

[V]

IREN 38 42 < 29 2.5

48 < 37 2.5

115 < 109 1 . 5

250 < 150 1.5

IREN 40 48 < 37 2.5

IREN 45 42 < 20 2.5

48 < 26 2.5

Extension

[m]

< 45 4

< 58 4

< 150 2.5

< 58 4.0

< 31 4

< 46 6

Cross-section

area of cable

[mm

2

]

< 41 4

115 < 85 1.5

< 139 2.5

250 < 150 1.5

35

Page 36

Technical data IREN

Machine Vol tage

[V]

IREN 57 42 < 11 2.5

48 < 15 2.5

115 < 52 1.5

240 < 150 1.5

250 < 150 1.5

IREN 57k 42 < 15 2.5

Extension

[m]

< 18 4

< 26 6

< 42 10

< 23 4

< 34 6

< 85 2.5

< 24 4

Cross-section

area of cable

[mm

2

]

< 35 6

< 56 10

48 < 20 2.5

< 31 4

< 45 6

115 < 70 1.5

< 116 2.5

240 < 150 1.5

250 < 150 1.5

36

Page 37

IREN Technical data

Machine Voltage

[V]

IREN 65 42 < 8 2.5

48 < 16 4

115 < 35 1.5

240 < 150 1.5

250 < 150 1.5

Extension cable for the US market:

Machine Voltage

[V]

Extension

[m]

< 12 4

< 18 6

< 29 10

< 23 6

< 58 2.5

Extension

[ft]

Cross-section

area of cable

[mm

Cross-section

area of cable

[AWG]

2

]

IREN 38 42 < 49 16

< 79 14

< 125 12

< 194 10

48 < 66 16

< 102 14

< 157 12

< 243 10

115 < 315 1 6

< 492 14

250 < 492 16

37

Page 38

Technical data IREN

Machine Vol tage

[V]

IREN 40 48 < 66 16

IREN 45 42 < 36 16

48 < 46 16

115 < 243 1 6

Extension

[ft]

< 102 14

< 157 12

< 243 10

< 56 14

< 85 12

< 135 10

< 72 14

< 112 12

< 171 10

Cross-section

area of cable

[AWG]

< 384 14

< 492 12

250 < 492 16

IREN 57 42 < 33 14

< 49 12

< 79 10

48 < 43 14

< 66 12

< 98 10

115 < 151 1 6

< 236 14

< 367 12

< 492 10

240 < 492 16

250 < 492 16

38

Page 39

IREN Technical data

Machine Voltage

[V]

IREN 57K 42 < 43 14

48 < 56 14

115 < 203 1 6

240 < 492 16

250 < 492 16

IREN 65 42 < 36 12

Extension

[ft]

< 66 12

< 105 10

< 85 12

< 132 10

< 318 14

< 492 12

< 52 10

Cross-section

area of cable

[AWG]

48 < 46 12

< 69 10

115 < 102 1 6

< 161 14

< 249 12

< 387 10

240 < 466 16

250 < 492 16

Example

You utilize an IREN 57/115 and want to use an extension cable with a length of

80 m (262 ft).

The machine has an input voltage of 115 V.

According to the table, the extension cable must feature a cross-section area of

2.5 mm

2

(AWG 12).

39

Page 40

Technical data IREN

40

Page 41

EC Declaration of Conformity

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München certifies that the

construction machines:

Category

Internal vibrator

Typ e IREN 30 IREN 38 IREN 40 IREN 45 IREN 57 IREN 65

Machine

type number

0008958

0610004

0610016

0610017

0610018

0610065

0610066

0610067

0610068

0007895

0008433

0008469

0008470

0008513

0008514

0008515

0008578

0008627

0008665

0008671

0008676

0610221 0007896

fulfill the requirements of the following directives:

98/37/EC

2004/108/EC

EN 61000

2006/95/EC

0008434

0008471

0008472

0008474

0008510

0008511

0008512

0008592

0008626

0008664

0008670

0008675

0007820

0007821

0008346

0008430

0008435

0008437

0008460

0008461

0008465

0008466

0008479

0008504

0008505

0008506

0008507

0008508

0008509

0008590

0008591

0008624

0008625

0008662

0008663

0008668

0008669

0008673

0008674

0008903

0008904

0008905

0007847

0008436

0008443

0008467

0008468

0008480

0008498

0008622

0008660

0008747

Dr. Stenzel

Head of Research and Development

Page 42

Page 43

Prüf- und Zertifizierungsinstitut

VERBAND DER ELEKTROTECHNIK

ELEKTRONIK INFORMATIONSTECHNIK e.V.

C E R T I F I C A T E

Registration-Number: 6236/QM/06.97

This is to certify that the company

Wacker Construction Equipment AG

Wacker-Werke GmbH & Co. KG

DIN EN ISO 9001 Certificate

at the following locations

Head Office Munich

Preußenstraße 41

80809 Munich

Production plant Reichertshofen

Karlsfeld logistics centre

Sales regions with all branches all over Germany

has implemented and maintains a

Qality Management System for the following scope:

Machine manufacture

Construction machines

This Q System complies with the requirements of

DIN EN ISO 9001:2000

and the requirements of the German and international Road Traffic Act.

This Certificate is valid until 2009-06-05.

VDE Testing and Certification Institute

Certification

Date: 2006-05-30

63069 Offenbach, Merianstraße 28

Telefon: +49 (0) 69 83 06-0, Telefax: +49 (0) 69 83 06-555

E-Mail: vde-institut@vde.com

The VDE Testing and Certification Institute is accredited by DAR Accreditation

Bodies according to DIN EN ISO 17020 and DIN EN ISO 45012 and notified in the EU

under ID.No. 0366.

, http://www.vde-institut.com

TGA-ZM-09-92-00

KBA-ZM-A 00021-97

Page 44

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München – Deutschland – Tel.: +49-(0)89-354 02-0 – Fax: +49-(0)89-354 02-390

Wacker Corporation – P.O. Box 9007 – Menomonee Falls, WI 53052-9007 – USA – Tel.: +1(1)262-255-0500 – Fax: +1(1)262-255-0550 – Support: 800-770-0957

Wacker Machinery (HK) Ltd.– Skyline Tower, Suite 2303, 23/F – 39 Wang Kwong Road, Kowloon Bay – Hong Kong – Tel.: +852-3188-5506, Fax: +852-2406-6021

Page 45

Page 46

Loading...

Loading...