Page 1

Operator’s Manual

Indirect-Fired Air Heaters

HI 110D / HI 110HD D

HI 200D / HI 200HD D

HI 300D / HI 300HD D

EN

5000192822 06 0614

5000192822

Page 2

Copyright

notice

© Copyright 2014 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker Neuson Production

Americas LLC represents an infringement of valid copyrights. Violators will be

prosecuted.

Trademarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Original

instructions

This Operator’s Manual presents the original instructions. The original language of this

Operator’s Manual is American English.

Page 3

Foreword

Foreword

This heater is designed and approved for use as a construction heater in

accordance with the applicable standards of CSA. CHECK WITH YOUR LOCAL

FIRE SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT APPLICATIONS.

Other standards govern the use of fuel gases and heat producing products in

specific applications. Your local authority can advise you about these.

THE INSTALLATION OF THE UNIT SHALL BE IN ACCORDANCE WITH THE

REGULATIONS OF THE AUTHORITIES HAVING JURISDICTION.

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during installation,

operation, and maintenance of the machines.

Machines

covered by

this manual

This manual covers machines with the following item numbers:

Machine Item Number Machine Item Number

HI 110 D 0620915 HI 300 D 0620866

HI 110 HD 0620864 HI 300 HD D 0620867

HI 200 D 0620865, 5200011877

HI 200 HD 0620916, 5200011878

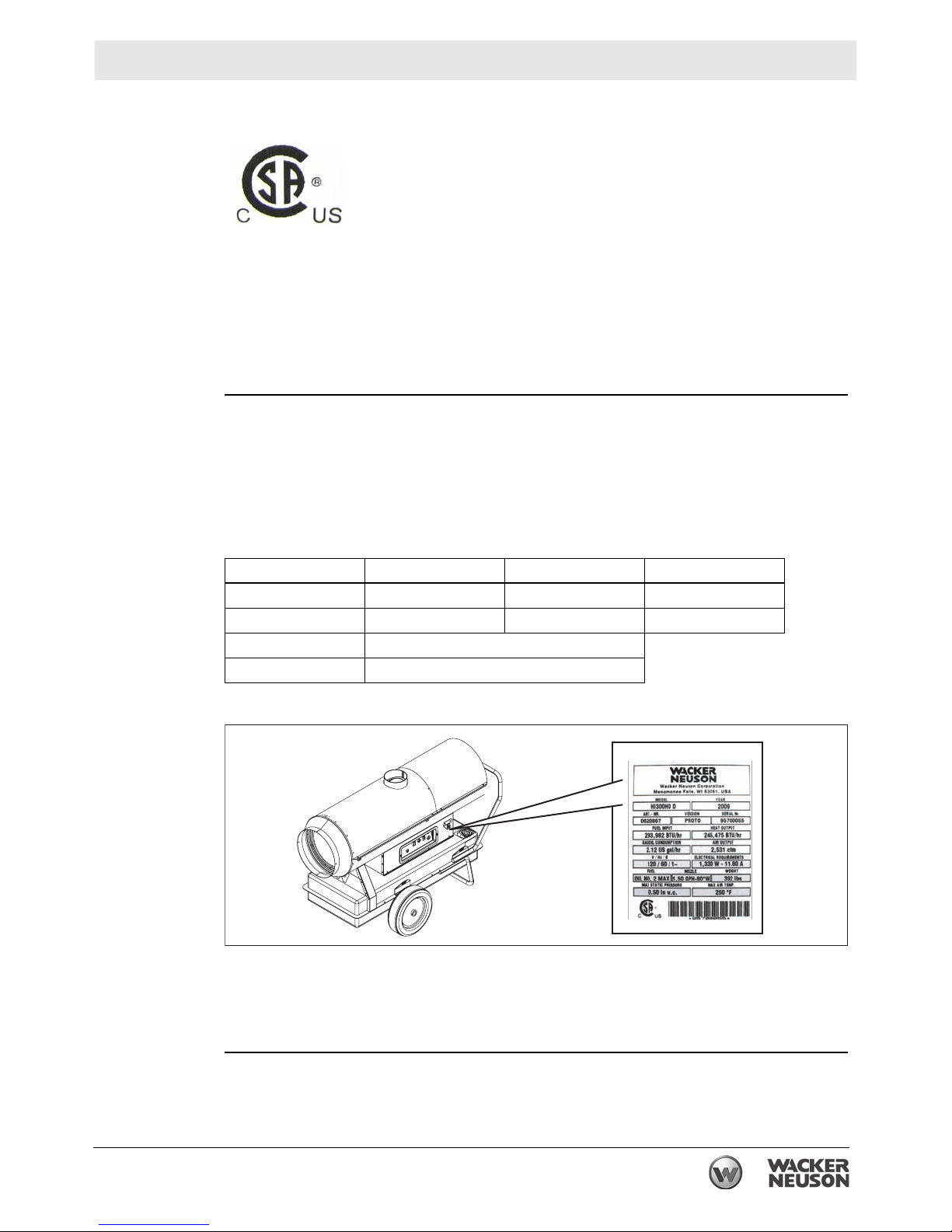

wc_gr012020

Machine

identification

Serial number

(S/N)

ghi_tx001445gb.fm 3

A nameplate listing the model number, item number, revision number, and serial

number is attached to this machine. The location of the nameplate is shown above.

For future reference, record the serial number in the space provided below. You will

need the serial number when requesting parts or service for this machine.

Page 4

Foreword

Serial Number:

Machine

documentation

Expectations

for

information in

this manual

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

Refer to the separate Repair Manual for detailed instructions on servicing and

repairing the machine.

If you are missing any of these documents, please contact Wacker Neuson to

order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change

any portion of this information without notice.

The illustrations, parts, and procedures in this manual refer to Wacker Neuson

factory-installed components. Your machine may vary depending on the

requirements of your specific region.

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

4 ghi_tx001445gb.fm

Page 5

HI 110 / 200 / 300

Table of Contents

Foreword 3

1 Safety Information 7

1.1 Signal Words Found in this Manual ...................................................... 7

1.2 Machine Description and Intended Use ............................................... 8

1.3 Operating Safety .................................................................................. 9

1.4 Safety Guidelines for Operating Combustion Burners ....................... 10

1.5 Service Safety .................................................................................... 11

2 Labels 13

2.1 Label Locations .................................................................................. 13

2.2 Label Meanings .................................................................................. 15

3 Lifting and Transporting 19

3.1 Lifting and Transporting the Machine ................................................. 19

4 Operation 20

4.1 Installing the Lift Brackets (if equipped) ............................................. 20

4.2 Installing the Wheels and Handle ....................................................... 21

4.3 Controls and Service Locations .......................................................... 22

4.4 Control Panel ...................................................................................... 24

4.5 Recommended Fuels and Fuel Blending Guide ................................. 25

4.6 Inspecting the Fuel Hose .................................................................... 26

4.7 Positioning the Machine ..................................................................... 27

4.8 Suggested Venting ............................................................................. 28

4.9 Installing the Heater Duct ................................................................... 30

4.10 Flex Ducting Options .......................................................................... 31

4.11 Connecting Power to the Machine ..................................................... 32

4.12 Pre-Starting Checks ........................................................................... 33

4.13 Starting the Machine .......................................................................... 34

4.14 Starting the Machine in Extremely Cold Weather ............................... 35

4.15 Stopping the Machine ......................................................................... 36

4.16 Burner Faults ...................................................................................... 37

4.17 Installing and Using the Remote Thermostat ..................................... 38

5 Accessories 39

5.1 Available Accessories ........................................................................ 39

wc_bo5000192822_06TOC.fm

5

Page 6

Table of Contents

HI 110 / 200 / 300

6 Burner Setup 40

6.1 Removing the Access Panel ...............................................................40

6.2 Removing and Installing the Burner Assembly ....................................41

6.3 Setting Up the Burner ..........................................................................42

6.4 Checking the Oil Burner Electrodes ....................................................44

6.5 Checking/Changing the Burner Nozzle ...............................................45

6.6 Adjusting the Fuel Pressure ................................................................46

6.7 Setting the Air Band ............................................................................47

7 Maintenance 48

7.1 Periodic Maintenance Schedule ..........................................................48

7.2 Inspecting the Heat Exchanger ...........................................................49

7.3 Changing the Fuel Heater Filter ..........................................................52

7.4 Inspecting and Cleaning the Cadmium (CAD) Cell .............................53

7.5 Cleaning the Fan Blades and Motor ....................................................54

7.6 Cleaning the Interior Shell ...................................................................55

7.7 Inspecting the Flame Head .................................................................56

7.8 Inspecting the Electrical Connections .................................................57

7.9 Cleaning the Machine ..........................................................................58

8 Basic Troubleshooting 59

9 Technical Data 60

9.1 Machine ...............................................................................................60

9.2 Dimensions - HI110D, HI110HD D ......................................................61

9.3 Dimensions - HI200D, HI200HD D ......................................................62

9.4 Dimensions - HI300D, HI300HD D ......................................................62

10 Schematics 64

10.1 Electrical Schematic - HI 110 D, HI 110 HDD .....................................64

10.2 Electrical Schematic - HI 200 D ...........................................................65

10.3 Electrical Schematic - HI 200 HDD .....................................................66

10.4 Electrical Schematic - HI 300 D ...........................................................67

10.5 Electrical Schematic - HI 300 HDD .....................................................68

6

wc_bo5000192822_06TOC.fm

Page 7

HI 110 / 200 / 300 Safety Information

1 Safety Information

1.1 Signal Words Found in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

To avoid death or serious injury from this type of hazard, obey all safety messages that

f

follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f

To avoid possible death or serious injury from this type of hazard, obey all safety messages that follow this signal word.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

To avoid possible minor or moderate injury from this type of hazard, obey all safety mes-

f

sages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

ghi_si000463gb.fm 7

Page 8

Safety Information HI 110 / 200 / 300

1.2 Machine Description and Intended Use

Machine

description

Intended use

The HI Heater is an indirect-fired air heater that operates on diesel fuel. The

machine consists of the following components:

Stainless steel combustion chamber and heat exchanger

Blower

Single-stage burner

High-temperature shut-down device

Fuel tank

Fuel is consumed in a closed combustion chamber. Room air or outside air

(depending on the application) is pulled into the machine where it is heated. This

clean, dry, hot air is then blown into the space to be heated by the blower. Access

to the blower assembly is protected by a guard fitted on the air inlet.

The HI Heater is intended to provide heat on outdoor or indoor construction sites (if

properly vented) and in other rugged applications.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons on the work site. Machine

damage caused by misuse is not covered under warranty.

Do not use this machine indoors without proper exhaust venting designed for

indoor use which meets all applicable regulations.

Optional

accessories

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may remain even after protective measures have been taken.

They are called residual risks. On this machine, they may include exposure to:

exhaust emissions

hot surfaces such as exhaust vents and fuel heater

fuel and fuel fumes when refueling

high voltages and arc flash

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

Wacker Neuson Corporation offers many optional accessories for the machine.

These accessories include the following:

Remote thermostat

Duct adapters (various sizes, available as kits, or individual ducts at lengths of

25 ft. or more).

Exhaust vents and elbows

Contact your Wacker Neuson dealer for more information.

8 ghi_si000463gb.fm

Page 9

HI 110 / 200 / 300 Safety Information

1.3 Operating Safety

Operator

training

Machine

condition

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only operate the machine when:

The heat exchanger is in proper working order.

All safety devices and guards are in place and in working order.

All controls operate correctly.

The machine is set up correctly according to the instructions in the Operator’s

Manual.

The machine is clean.

The machine’s labels are legible.

When operating the machine:

Do not modify or defeat the safety devices.

Do not use worn electrical cords.

Do not use faulty fuel supplies.

Guidelines for

operator

When operating the machine:

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

Wear protective clothing appropriate to the job site when operating the machine.

Wear safety glasses.

When operating the machine:

Do not operate a machine in need of repair.

Do not smoke near the machine.

Do not block the air inlet or outlet during machine operation.

Personal

Protective

Equipment

(PPE)

ghi_si000463gb.fm 9

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

Page 10

Safety Information HI 110 / 200 / 300

Machine

installation

guidelines

Work space

As a recommended installation practice, refer to the current issue of CSA B139,

Installation Code for Oil Burning Equipment in Canada and NFPA 31 Standard for

the Installation of Oil-Burning Equipment in the USA;

Never operate the machine in immediate proximity to flammable materials.

Minimum distances are specified in the Operation chapter under Positioning the

Machine.

A rough estimate of opening required for each gallon (US) of capacity is one

square foot for indirect-fired heater

When operating the machine:

Position the machine on a firm, noncombustible, level surface.

Keep the area immediately surrounding and underneath the machine clean,

neat, and free of debris and combustible materials.

Keep the area above the machine clear of debris that could fall on the machine.

Store the machine properly when it is not being used.

Keep unauthorized personnel, children, and pets away from the machine.

When operating the machine:

Do not connect ductwork between the exhaust outlet port and the supply air inlet

port.

Never operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

Do not position the electrical cords under the machine or over the top of the

machine.

1.4 Safety Guidelines for Operating Combustion Burners

When using the machine:

Clean up any spilled fuel immediately.

Replace the fuel tank cap after refueling the machine.

Refill the fuel tank in a well-ventilated area.

Make sure you have proper certification or licensing required by the locality,

state, or province in which the machine is being installed to work with Liquid

Petroleum (LP).

When using the machine:

DANGER

Exhaust gas from the burner contains carbon monoxide, a deadly poison. Exposure

to carbon monoxide can kill you in minutes.

f Never run the machine indoors or in an enclosed area unless the machine is

vented properly according to local and national codes.

Do not fill or drain the fuel tank near an open flame, while smoking, or while the

machine is running.

Do not smoke when refueling the machine.

10 ghi_si000463gb.fm

Page 11

HI 110 / 200 / 300 Safety Information

1.5 Service Safety

Licensing/

training/

Cleaning

Maintenance

guidelines

Only trained personnel should troubleshoot or repair electrical problems

occurring with the machine.

When cleaning and servicing the machine:

Keep the area around the burner free of debris such as leaves, paper, cartons,

etc.

Keep the machine clean and labels legible.

When cleaning the machine:

Do not clean the machine while it is running.

Never use gasoline or other types of fuels or flammable solvents to clean parts.

Fumes from fuels and solvents can become explosive.

When maintaining the machine:

Keep the fuel lines in good condition and properly connected.

Allow the burner to cool before maintaining the machine.

Re-install the safety devices and guards after repairs and maintenance.

Keep all electrical cords away from heat, oil, vibrating surfaces, and sharp

edges.

Inspect all electrical cords before each use and replace damaged cords.

Replacing

parts and

labels

Accessories,

safety devices

and

modifications

Personal

Protective

Equipment

(PPE)

When maintaining the machine:

When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those parts equivalent to the original in all types of

specifications, such as physical dimensions, type, strength, and material.

Replace worn or damaged components.

Replace all missing and hard-to-read labels.

Replace or repair electrical components with components that are identical in

rating and performance as the original component.

When using the machine:

Use only accessories/attachments that are recommended by

Wacker Neuson Corporation.

When using the machine:

Never operate the machine if any safety devices or guards are missing or

inoperative.

Do not defeat safety devices.

Do not modify the machine without the express written approval of the

manufacturer.

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

ghi_si000463gb.fm 11

Page 12

Safety Information HI 110 / 200 / 300

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

12 ghi_si000463gb.fm

Page 13

HI 110 / 200 / 300 Labels

2 Labels

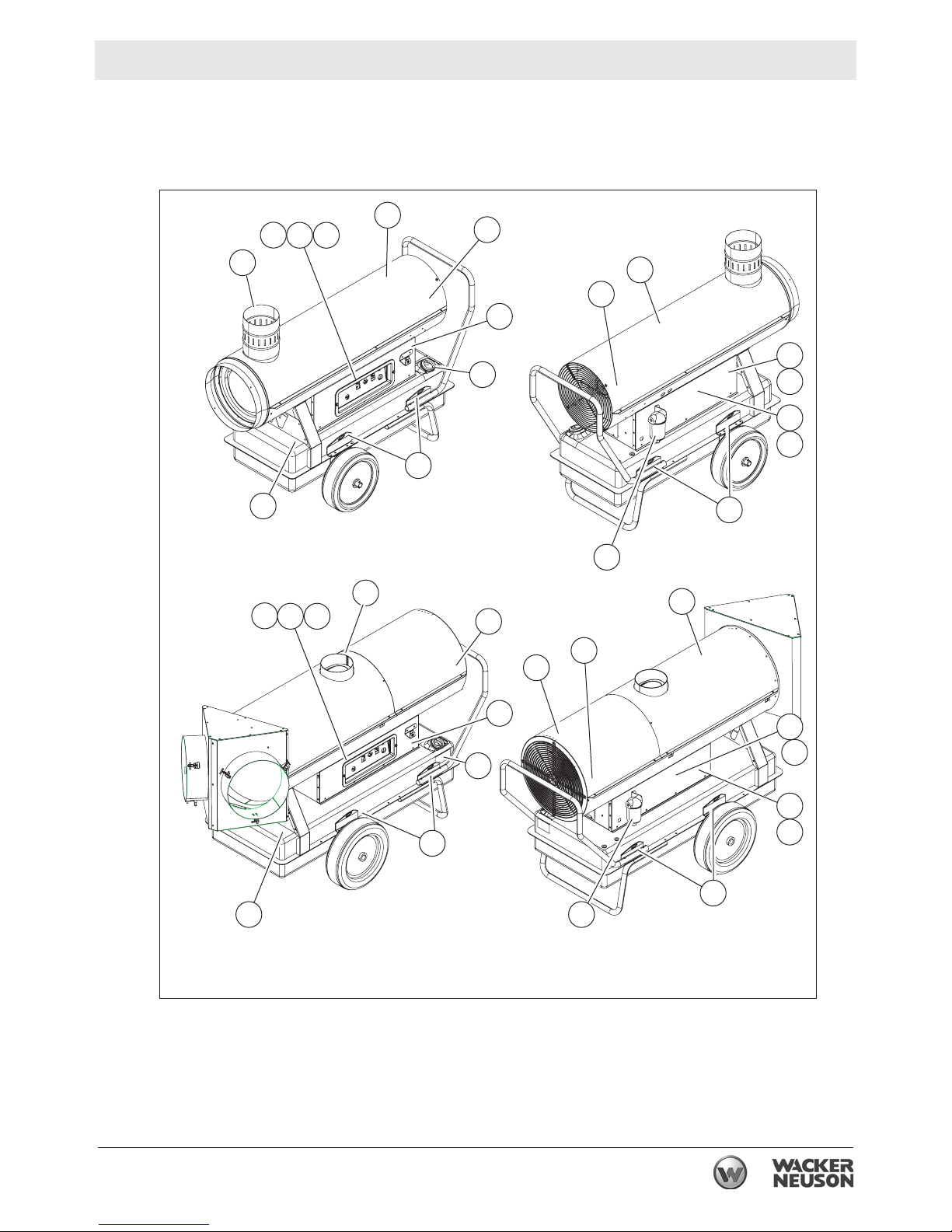

2.1 Label Locations

(4)

J

H

D G

A

B

G

B

P

K

E

H

L

N

C

F

HI 110

C

A

A

H

D

G

B

G

B

J

(4)

C

P

E

HI 200

L

N

K

H

C

AF

wc_gr009251

ghi_si000464gb.fm 13

Page 14

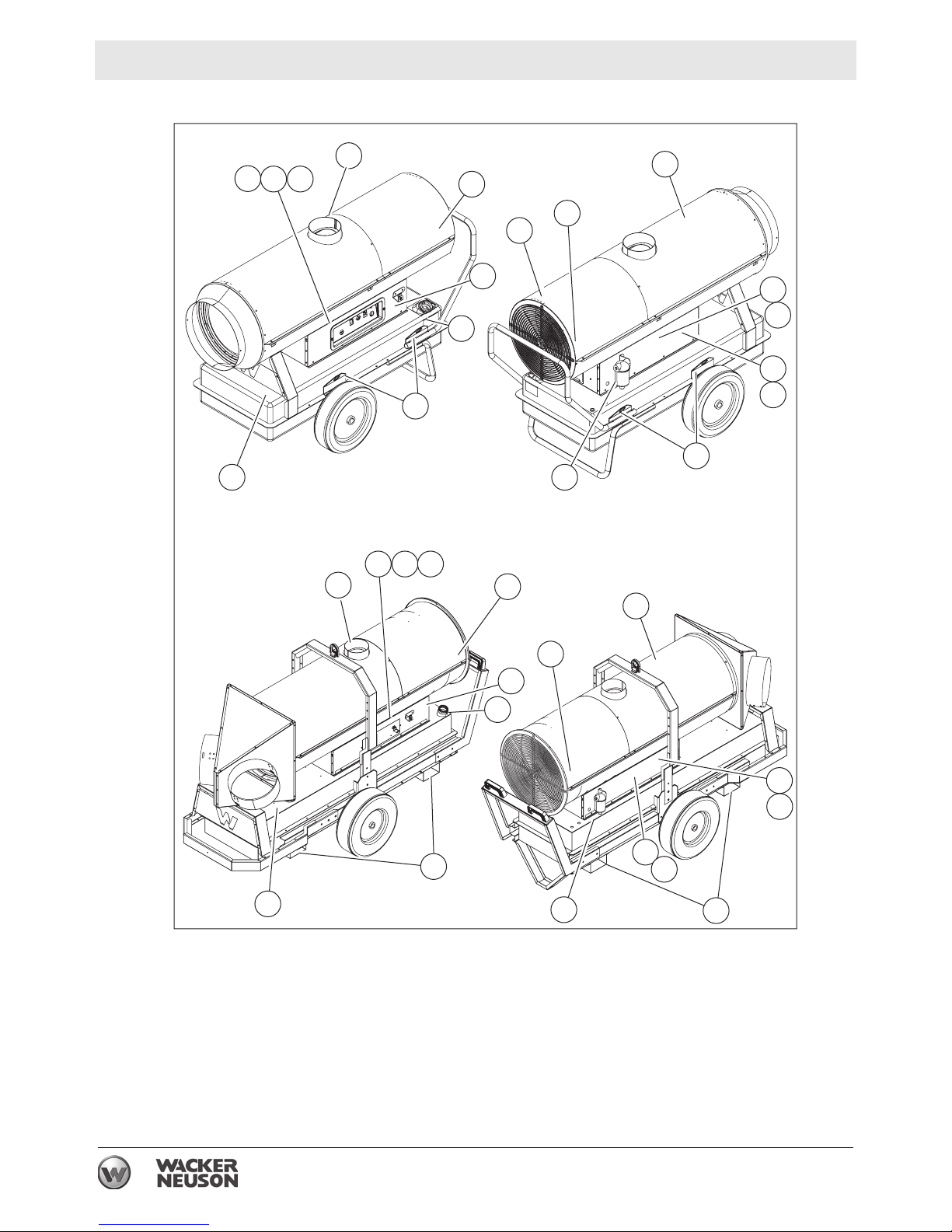

Labels HI 110 / 200 / 300

(4)

A

H

G

D

B

G

B

J

P

L

E

N

K

C

H

C

AF

HI 300

D

G H

A

B

J

(4)

B

P

E

H

K

L

C

F

HI 300 HD

A

N

C

wc_gr009252

14 ghi_si000464gb.fm

Page 15

HI 110 / 200 / 300 Labels

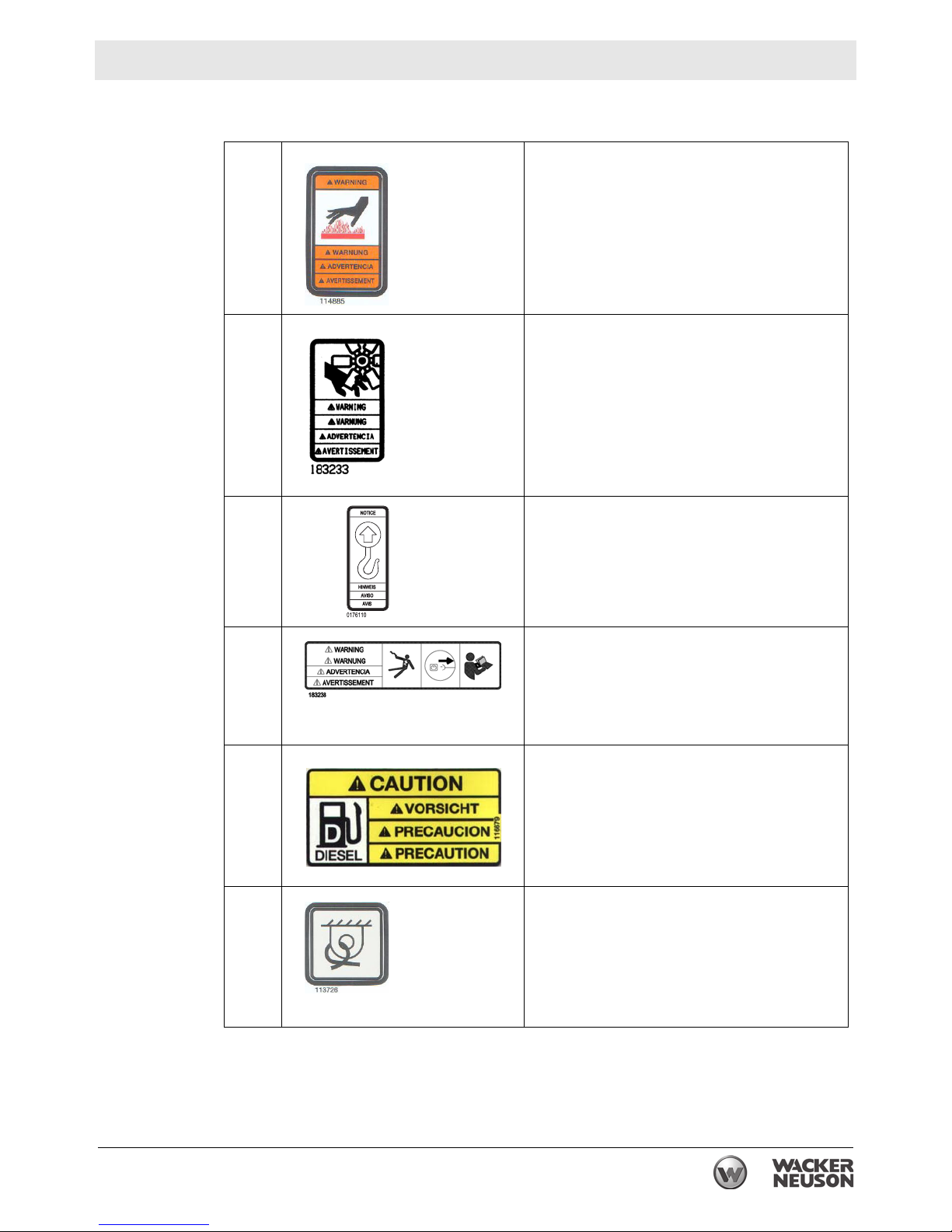

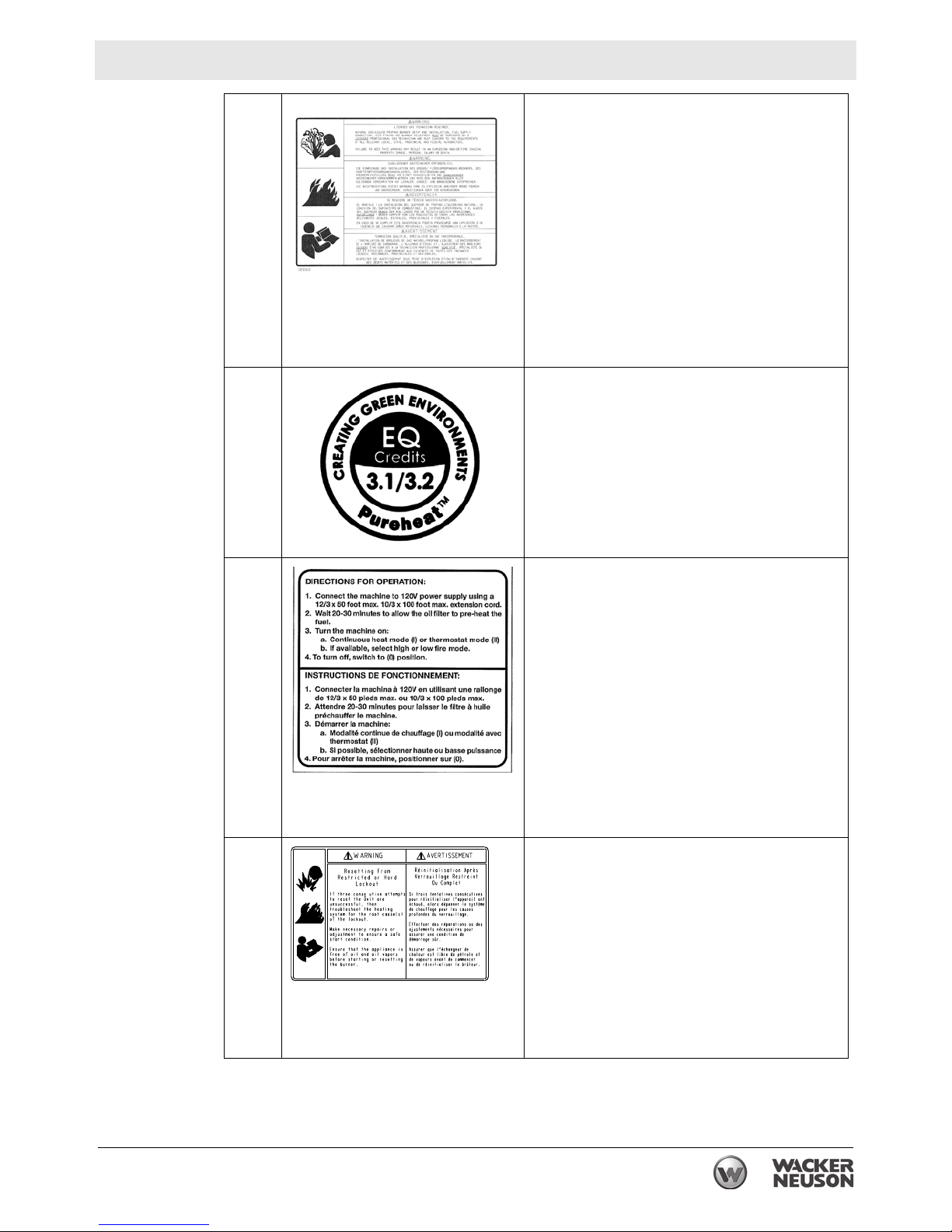

2.2 Label Meanings

1

A WARNING

Hot surface hazard!

B WARNING

Entanglement hazard. Rotating machinery.

Do not reach inside machine when engine is

running.

C NOTICE

Lifting point

D

WARNING!

Electric shock hazard.

Disconnect power before servicing.

Read Operator’s Manual.

ECAUTION

This machine uses diesel fuel.

F Tie-down point

ghi_si000464gb.fm 15

Page 16

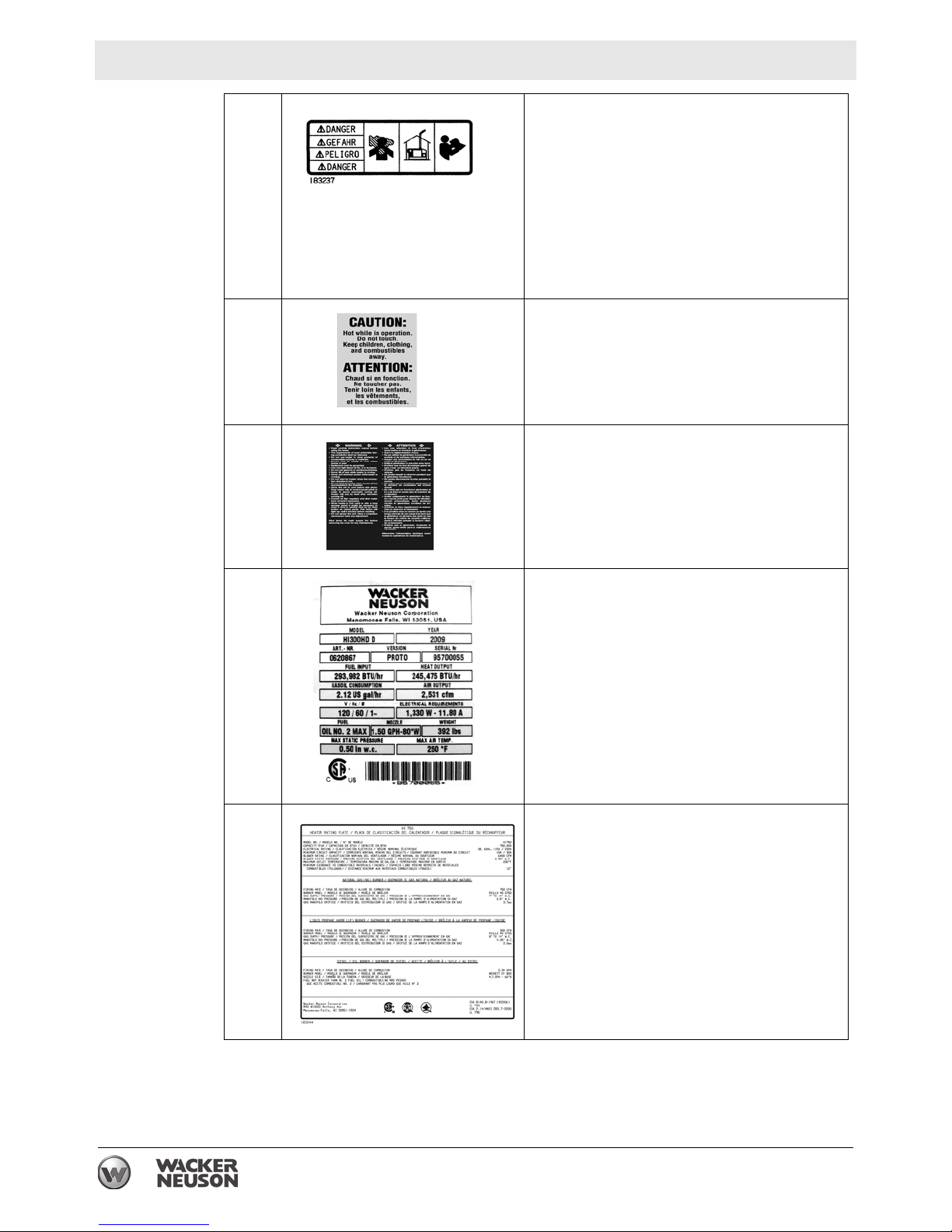

Labels HI 110 / 200 / 300

G

DANGER

Using a heater indoors can kill you in

minutes. Heater exhaust contains

carbon monoxide. This is a poison

you cannot see or smell. During

indoor operation, vent exhaust gas

outdoors. Refer to Operator's

Manual.

HCAUTION

Hot while in operation. Do not touch. Keep

children, clothing, and combustibles away.

J Safety instruction label for diesel fuelled

heaters

K A nameplate listing the model number, item

number, revision number, and serial number

is attached to each unit. Please record the

information found on this plate so it will be

available should the nameplate become lost

or damaged. When ordering parts or

requesting service information, you will

always be asked to specify the model

number, item number, revision number, and

serial number of the unit.

L Heater rating plate

16 ghi_si000464gb.fm

Page 17

HI 110 / 200 / 300 Labels

M WARNING

Licensed gas technician required.

Natural gas / liquid propane burner setup and

installation, fuel supply connection, test

firing, and burner adjustment MUST be

performed by a LICENSED professional gas

technician and must conform to the

requirements of all relevant local, state,

provincial, and Federal authorities.

Failure to heed this warning may result in an

explosion and/or fire causing property

damage, personal injury, or death.

N Creating Green Environments

This product may help you earn credits

toward LEED® EQ 3.1 and 3.2 certification.

P DIRECTIONS FOR OPERATION:

1. Connect the machine to 120V power supply using a 12/3 x 50 foot max. 10/13 x

100 foot max. extension cord.

2. Wait 20-30 minutes to allow the oil filter to

pre-heat the fuel.

3. Turn the machine on:

a. Continuous heat mode (I) or

thermostat mode (II)

b. If available, select high or low fire

mode.

4. To turn off, switch to (0) position.

— WARNING

If three consecutive attempts to reset the

machine are unsuccessful, then troubleshoot

the heating system for the root cause(s) of

the lockout.

Make necessary repairs or adjustments to

ensure a safe start condition.

Ensure that the heat exchanger is free of

oil and oil vapors before starting or resetting the burner.

ghi_si000464gb.fm 17

Page 18

Labels HI 110 / 200 / 300

— Fork lift pocket

18 ghi_si000464gb.fm

Page 19

HI 110 / 200 / 300 Lifting and Transporting

3 Lifting and Transporting

3.1 Lifting and Transporting the Machine

Requirements

Background

Guidelines

Transport vehicle capable of carrying 1000 lbs (454 kg)

Crane or lift capable of carrying 1000 lbs (454 kg)

NOTICE: These machines are NOT designed to be towed with any vehicle.

WARNING

Crushing hazard.

f Only qualified riggers should attempt aerial lifting of this machine.

Follow the guidelines below when lifting and transporting this machine.

Remove all venting from the machine prior to lifting/transporting.

Cover all openings on the machine to avoid infiltration from road debris and dust.

Except for the HI 300HD, use all four lifting points on the sides of the machine

when using an aerial lifting rig.

When using an aerial lifting rig on the HI 300HD, use the designated lifting point

on top of the machine.

HI 300HD only: Use the designated fork pockets when transporting the machine

with a fork lift.

Use the manual transport handle when relocating the machine within the job site.

When tying down the machine, route tie-down straps or chains through the

lower frame only.

NOTICE: Do not route tie-down straps or chains over the top of the machine.

Doing so will damage the machine. Use only the designated tie-down locations.

ghi_tx001446gb.fm 19

Page 20

Operation HI 110 / 200 / 300

4 Operation

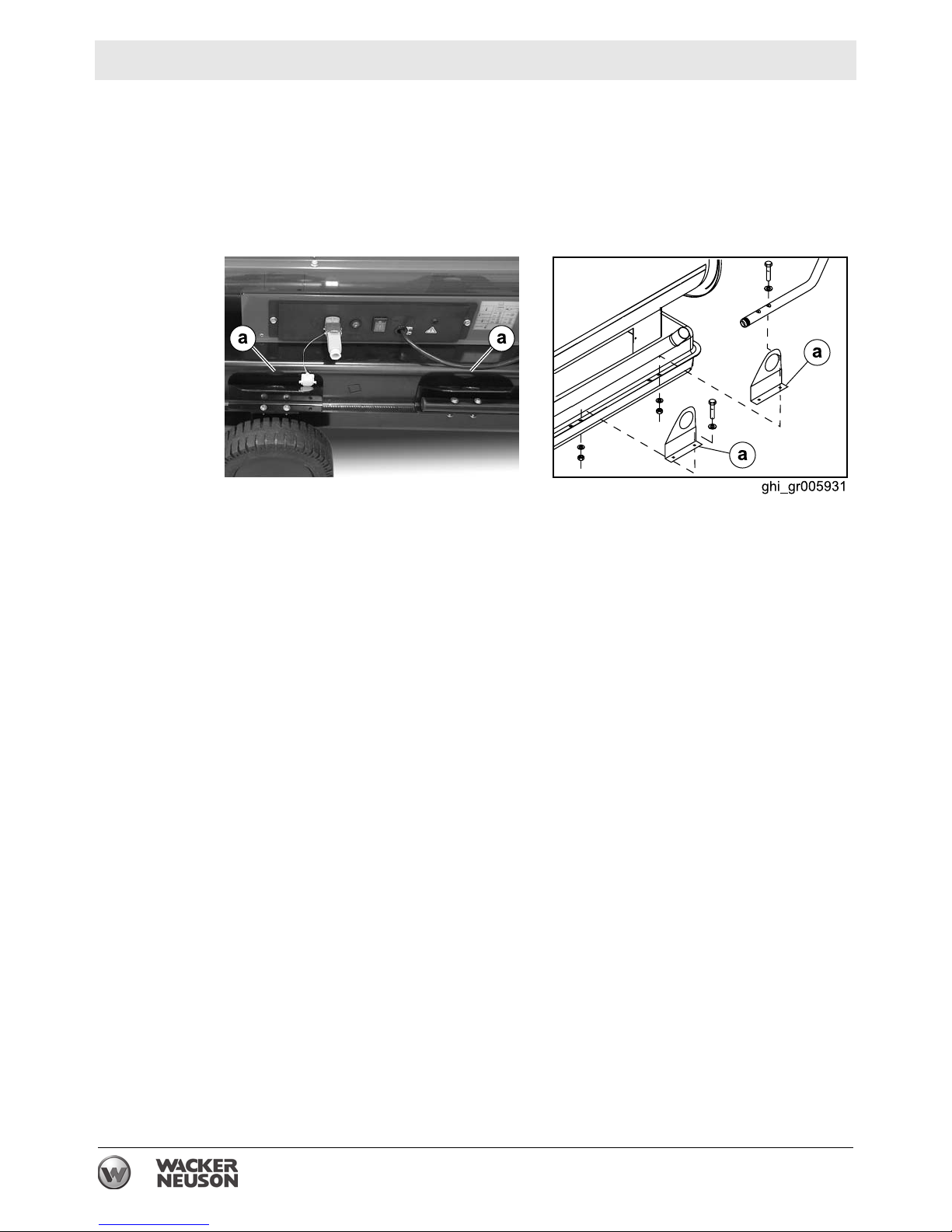

4.1 Installing the Lift Brackets (if equipped)

Before attempting to lift the machine, the lift brackets must be installed.

1. Remove the machine from the crate.

2. Intstall the four lift brackets

(a) as shown using the supplied bolts and washers.

20 ghi_tx001447gb.fm

Page 21

HI 110 / 200 / 300 Operation

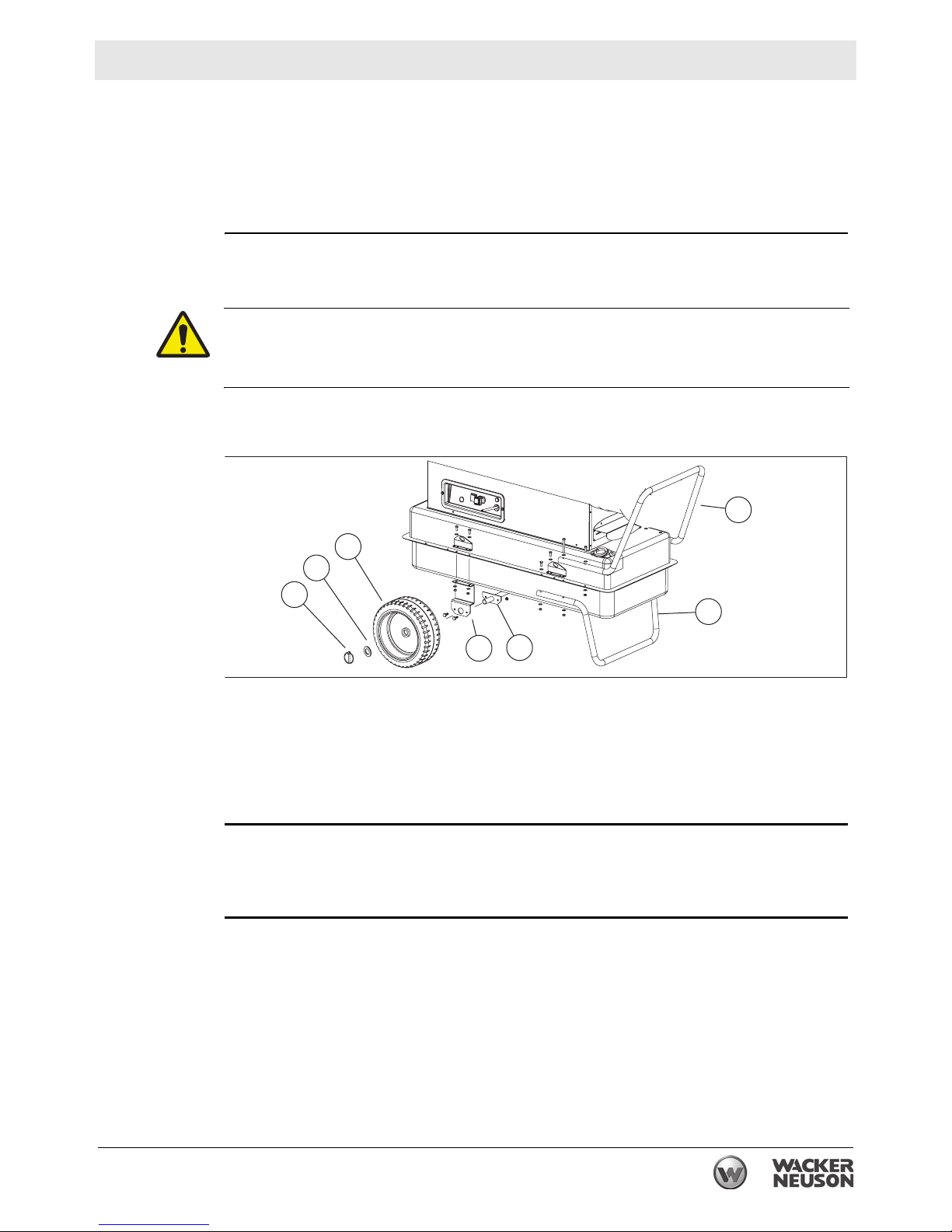

4.2 Installing the Wheels and Handle

Overview

Installing the

axle and

wheels

The axle, wheels, handle, and stand are shipped loose with the machine and must

be assembled before operation.

There are pre-drilled holes for all of the components to be assembled. Bolts,

washers, and nuts are provided.

Follow the procedure below to install the axle and wheels.

1. Lift the machine using appropriate lifting gear.

WARNING

Crushing hazard.

f Refer to chapter Lifting the Machine for instructions on proper lifting techniques.

2. Attach the two axle mounting brackets (a) to the sides of the fuel tank.

f

c

d

Atttaching the

handle and

stand

Result

e

g

b

a

wc_gr007779

3. Insert the ends of the axle (b) through the axle mounting brackets.

4. Place a wheel (c) and flat washer (d) on each end of the axle as shown.

5. Insert hitch pins (e) into the holes at each end of the axle to secure the wheels.

A

6. Align the holes in the handle (f) and stand (g) with the holes on the fuel tank

flange as shown.

7. Attach the handle and base support with bolts, washers, and nuts.

The machine has now been assembled. Lower the machine and proceed.

ghi_tx001447gb.fm 21

Page 22

Operation HI 110 / 200 / 300

3

4.3 Controls and Service Locations

HI 110D

j

HI 200

wc_gr00925

22 ghi_tx001447gb.fm

Page 23

HI 110 / 200 / 300 Operation

j

HI 300

j

HI 300 HD

Machine

components

ghi_tx001447gb.fm 23

Ref Description Ref Description

a Exhaust flue f Air inlet and fan guard

b Control panel g Access panel

c Manual transport handle h Fuel filter

d Fuel fill location j Manual holder

e Lift brackets (if equipped) — —

(Only on HI 200 HD and HI 300 HD models)

Page 24

Operation HI 110 / 200 / 300

4.4 Control Panel

Control panel

components

Ref Description Ref Description

a

Burner fault lamp and reset

d Power indicator

button (dual function)

b Mode switch (on-off-on)

See topic Starting the Machine.

c Thermostat receptacle — —

e Power cord

Symbols and

meanings

Symbol Meaning/function Symbol Meaning/function

RESET

Press and hold the button to

reset the machine when a

burner fault has occurred.

On

(Remote thermostat mode)

See topic Starting the

Machine

Power indicator

Illuminates when power is connected to the machine and the fuse is intact.

Thermostat connection point

On

(Continuous heat mode)

See topic Starting the Machine

24 ghi_tx001447gb.fm

Page 25

HI 110 / 200 / 300 Operation

4.5 Recommended Fuels and Fuel Blending Guide

Low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner

ignition failure and/or burner fuel pump damage. Always use the proper fuel for the

conditions.

Fuel Blend Guide

Lowest expected ambient

temperature °F (°C)

Below 5 (-15)

Generator powered Shore powered

50-50 blend of #2 diesel

and #1 diesel, plus

additives

OR

50-50 blend #2 diesel and

K1 kerosene, plus

additives

100% #1 diesel plus

additives

OR

100% K1 kerosene,

plus additives

70-30 blend of #2 diesel and #1 diesel, plus additives

5 to 25 (-15 to -4)

Above 25 (-4) Winter-blend diesel

70-30 blend of #2 diesel and K1 kerosene,

OR

plus additives

NOTICE: Do not use B20 or any other type of biodiesel fuel in this machine.

CAUTION

Fire hazard.

f Do not use gasoline, crankcase oil, or any oil containing gasoline.

ghi_tx001447gb.fm 25

Page 26

Operation HI 110 / 200 / 300

4.6 Inspecting the Fuel Hose

When

Replacement

hose

Visually inspect the fuel hose assembly each time before operating the heater.

WARNING

Fire and explosion hazards. A damaged hose may leak flammable fuel.

f Do not operate the heater if the hose has excessive abrasions, wear, or cuts.

Replace a damaged hose assembly with an equivalent as specified on the

machine label.

26 ghi_tx001447gb.fm

Page 27

HI 110 / 200 / 300 Operation

4.7 Positioning the Machine

DANGER

Exhaust gas from the burner contains carbon monoxide, a deadly poison. Exposure

to carbon monoxide can kill you in minutes.

f Never run the machine indoors or in an enclosed area unless the machine is

vented properly according to local and national codes.

WARNING

Fire hazard. Restricting air flow through the machine during operation can cause a

fire due to overheating components.

f Do not block the air inlet or outlet during machine operation.

NOTICE: Restricting the air flow through the machine during operation can cause

the machine and its components to overheat. To avoid damage, provide adequate

air flow through the machine while it is operating.

Guidelines

Proximity

restrictions

Observe the following guidelines when positioning the machine for operation.

Installer must be familiar with all applicable laws, codes, regulations, or other

restrictions regarding installation of Indirect-fired (IDF) heaters.

Machine must be on flat, firm surface.

Installation must adhere to proximity restrictions.

Install wedge blocks under the wheels to prevent movement.

The machine must be located a safe distance from any other structures, vehicles,

materials or other combustible surfaces. The following proximity restrictions apply

for all machine installations.

20 ft. (6 m) to air outlet

3 ft. (1 m) to air inlet and sides

5 ft. (1.5 m) to top

20 ft (6 m) from outlet to external fuel container

Note: Graphic is representative only. Your machine may vary.

ghi_tx001447gb.fm 27

Page 28

Operation HI 110 / 200 / 300

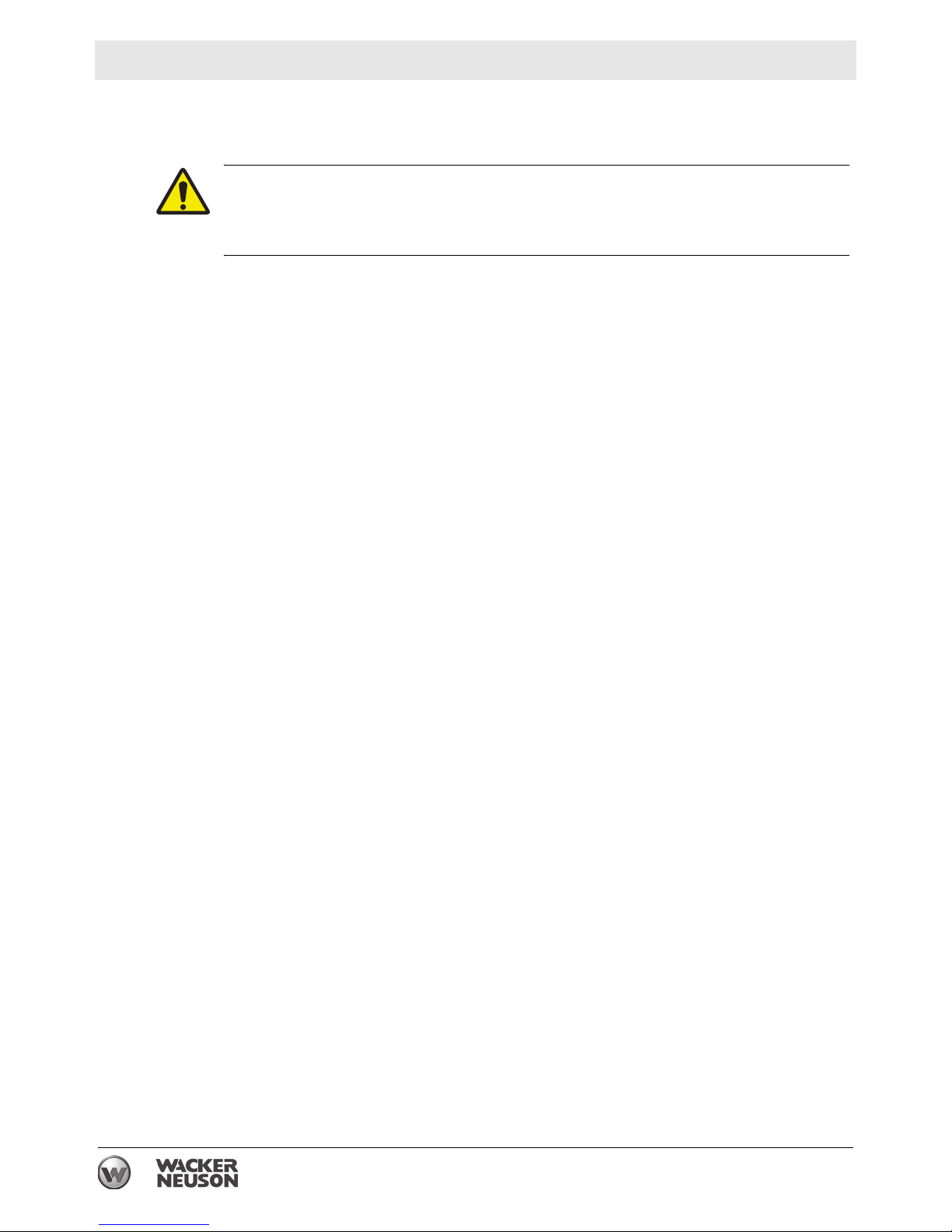

4.8 Suggested Venting

DANGER

Asphyxiation hazard.

Exhaust gas from the burner contains carbon monoxide, a deadly poison. Exposure

to carbon monoxide can kill you in minutes.

f Never run the machine indoors or in an enclosed area unless the machine is

vented properly according to local and national codes.

Overview

Before

installing the

machine

Duct

requirements

Machine

setup

The exhaust from indirect-fired heaters must be vented to a chimney or an exhaust

duct. Exhaust gases must rise in order to maintain a proper draft in the chimney or

exhaust duct.

Note: The information presented below is intended as a general reference guide.

Local and national code requirements supersede these suggestions.

Adhere to all local and national codes.

Adhere to all fire prevention regulations.

Consult all appropriate governing bodies or local contractor for venting and

fresh air requirements.

Make sure that the room or building to be heated has sufficient ventilation to

ensure that the machine has enough air to function properly.

Do not use B-vent exhaust pipes to vent an oil burning machine. Contact

Wacker Neuson Product Support for recommended alternatives.

Check local codes for appropriate vent piping materials.

Position the machine in a manner that avoids excessive vent bends (elbows),

and long horizontal runs.

Keep air inlets and outlets free from obstruction. Ensure that there are no bulky

objects or sheets/covers near or on the machine.

Routing the

vent piping

Route the venting pipes in a manner that avoids flammable materials.

Route the venting pipes in a manner that avoids contact with people.

Sufficient draft shall be created to assure safe and proper operation of the

machine (minimum 0.05 wc).

Avoid any 90° elbows or bends in at least the first 10 feet (3m) of exhaust ducts.

Terminat i ng

the vent

piping

When the machine is connected to a flue pipe, the flue pipe shall terminate in a

vertical section at least two feet (0.6m) long.

If exhaust is to be vented out the side of a building, as shown in the lower left

diagram, the end of the exhaust pipe should be vertical and at least 2 feet

(0.6m) long. A rain cap should be installed to avoid any potential downdraft or

back pressure on the exhaust system.

28 ghi_tx001447gb.fm

Page 29

HI 110 / 200 / 300 Operation

Note: The above venting diagram shows suggested venting layouts only. Consult

all appropriate governing bodies or local contractor for venting and fresh air

requirements.

ghi_tx001447gb.fm 29

Page 30

Operation HI 110 / 200 / 300

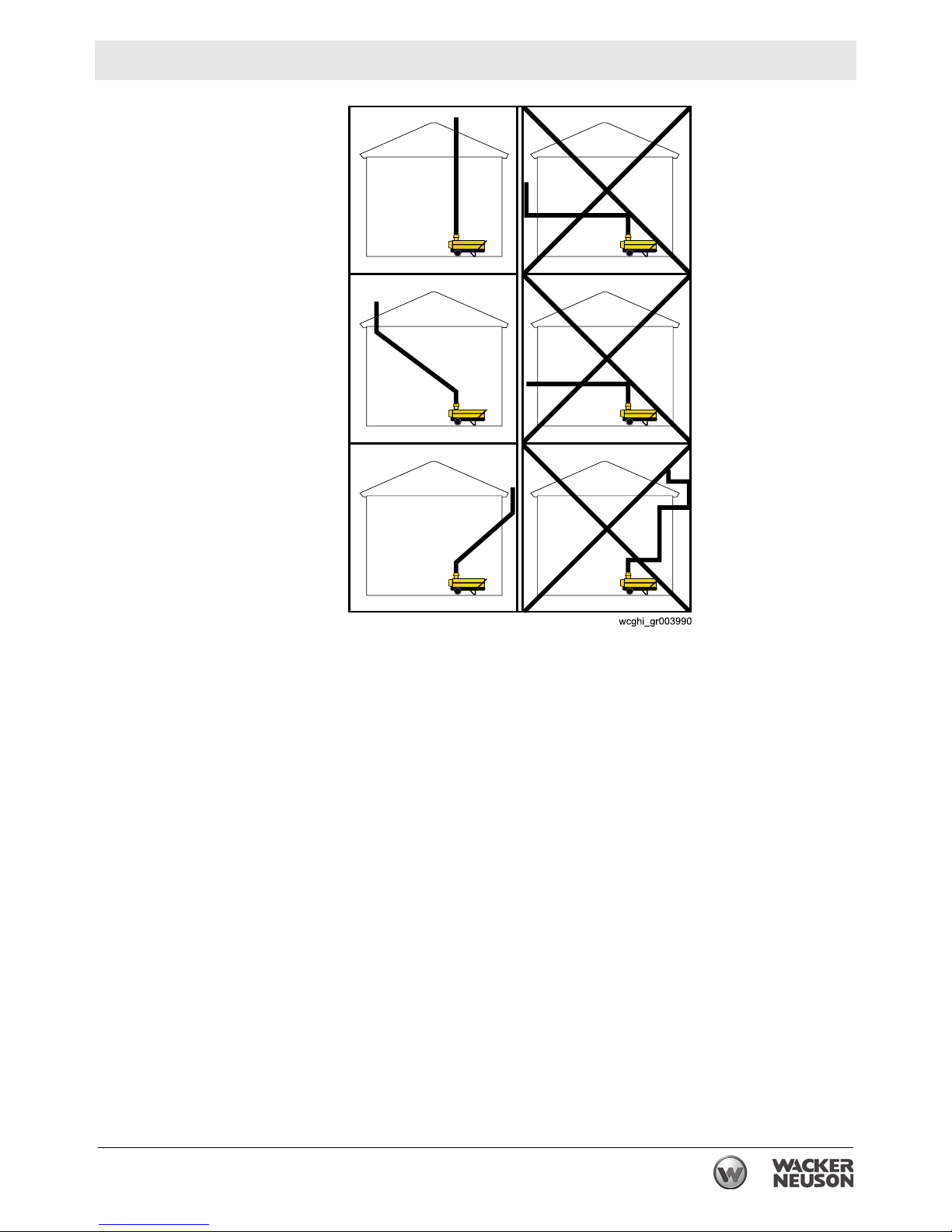

4.9 Installing the Heater Duct

Overview

Requirements

Procedure

Optional ducts can be connected to the air outlet. This allows warm air to be evenly

distributed throughout the heating area.

NOTICE: When using ducts, observe the static air pressure limits specified in

Technical Data.

Machine shut down and cooled

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

To install the ducts, carry out the following procedure.

1. Open the clamps (a).

2. Slide the duct (b) onto the duct adapter (c).

3. Close the clamp to secure the duct in place.

30 ghi_tx001447gb.fm

Page 31

HI 110 / 200 / 300 Operation

4.10 Flex Ducting Options

Refer to the chart below for the maximum allowable return and supply duct lengths

for your machine.

NOTICE: Do not exceed the maximum total lengths specified in the chart.

Exceeding these lengths, or blocking any of the duct openings, constricts the air

flow through the machine and may cause a high-temperature shut-down fault.

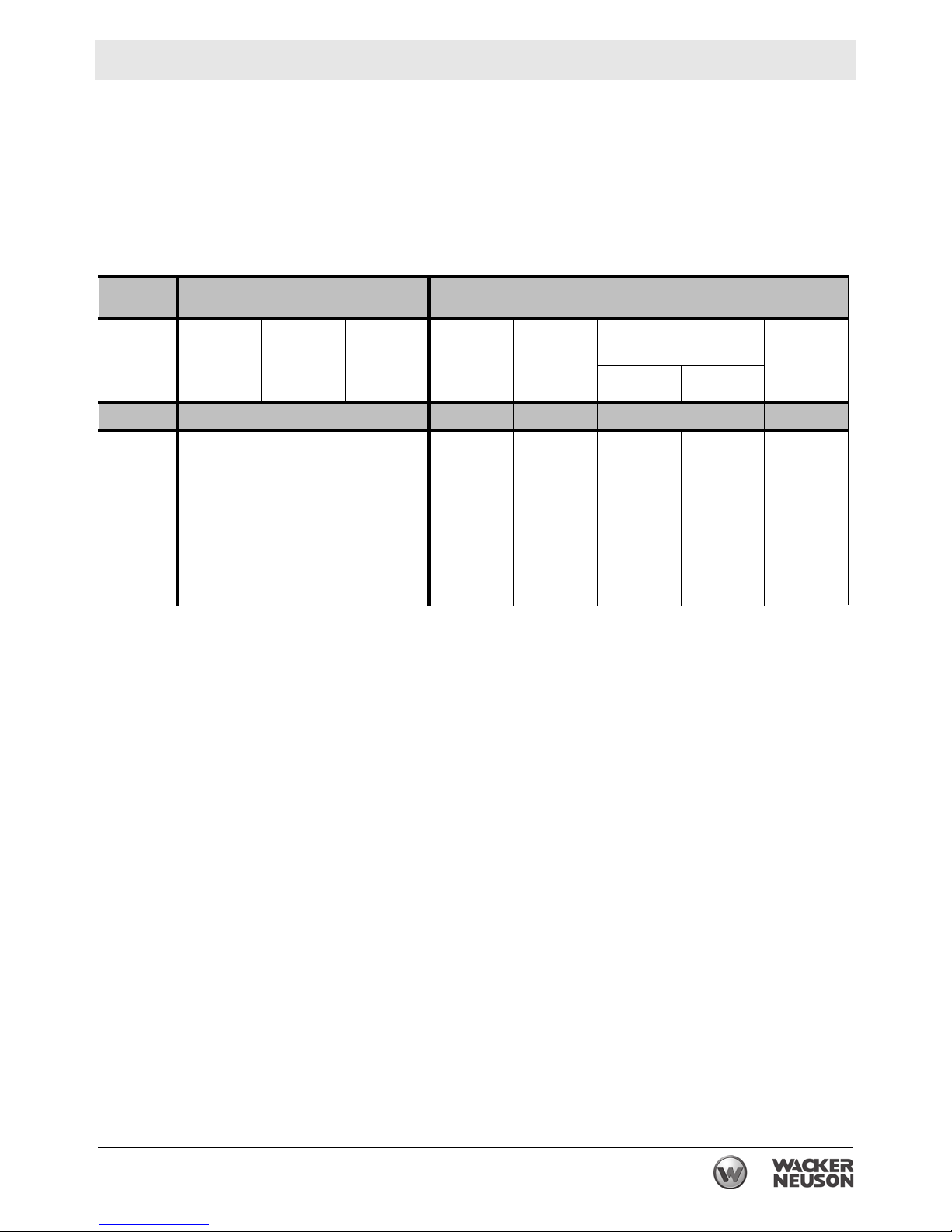

MODEL RETURN DUCTING SUPPLY DUCTING

—Return

adapter

HI 110

HI 200 14 in. 25 1 25 ft 25 ft

HI 200 2 X 12 in. 25 1 25 ft 50 ft

HI 300 16 in. 25 1 25 ft 25 ft

HI 300HD 2 X 12 in. 25 1 25 ft 50 ft

Return ductwork not available.

duct

Maximum

number of

25 ft. duct

sections

To ta l

combined

length

Supply

duct

adapter

12 in. 25 1 25 ft 25 ft

Length of

each duct

section

(ft)

Maximum duct sec-

tions per opening

Qty Length

Tot a l c o m -

bined

length

ghi_tx001447gb.fm 31

Page 32

Operation HI 110 / 200 / 300

4.11 Connecting Power to the Machine

Requirements

Extension

cords

Power source (115VAC)

Machine properly positioned

Operation mode switch in the OFF (0) position

]

WARNING

Fire hazard and electric shock hazard. The use of under-sized extension cords can

lead to fire and electric shock. Fire and electric shock can cause severe injury.

f Do not use under-sized extension cords.

Restrictions for extension cords:

Use only 3-wire type extension cords with heavy-duty plugs.

The maximum length of extension cord usage per circuit is 30 m (100 ft).

Use 12-gauge extension cords for lengths up to 15 m (50 ft).

Use 10-gauge extension cords for lengths up to 30 m (100 ft).

CAUTION

Burn hazard. The self-regulating fuel heater, located inside the fuel filter canister,

will initiate when power is connected to the machine. The surface of the fuel filter

canister may become very hot.

f Use caution when working with the fuel filter canister.

Procedure

Perform the procedure below to connect power to the machine.

1. Verify that the operation mode switch is in the OFF (0) position.

2. Connect the main power cord cord to a properly-rated power source.

Note: If the ambient temperature is below freezing, wait 10–30 minutes before

proceeding.

32 ghi_tx001447gb.fm

Page 33

HI 110 / 200 / 300 Operation

4.12 Pre-Starting Checks

Requirements

Checks

Machine properly positioned

Power connected to the machine

Before starting the machine, check the following items:

Item Task

Fuel sight gauge (if equipped) Check that the fuel tank is full (if applicable).

Fuel tank cap Check that the fuel tank cap (if applicable) is

secure.

Operation mode switch Check that the operation mode switch is in the

OFF position.

Main control panel Check that proper power supplies have been con-

nected at the main control panel. See topic

Connecting Power to the Machine.

Remote thermostat (if installed) Check that the remote thermostat has been cor-

rectly installed. See topic Installing the Remote

Thermostat or Thermostat Receptacle Plug.

Ducts and duct adapters Check that all ducts and duct adapters have been

properly installed. See topic Installing the Heater

Duct.

Result

The machine is ready to turn on.

ghi_tx001447gb.fm 33

Page 34

Operation HI 110 / 200 / 300

4.13 Starting the Machine

Requirements

Procedure

Machine properly positioned

Power connected

Pre-Starting Checks completed

To start the machine, follow the procedure below.

1. Select an operation mode.

a. Continuous heat mode (I)

b. Thermostat mode (II)

0

wc_gr007558

Operational

sequence

Nozzle heater

The following sequence of events will occur.

1. The blower will start.

Note: HI 200 HD and HI 300 HD machines are equipped with an additional heater

that warms the nozzle to the required operating temperature.

2. The burner will start firing.

If a remote thermostat is not being used, the burner will fire continuously.

In applications in which the remote thermostat is being used, the burner will fire

until the air temperature of the application area reaches the target temperature

set by the remote thermostat. At that time, the burner will shut off, but the blower

will continue to operate. When the air temperature of the application area falls

below the target temperature set by the remote thermostat, the burner will refire.

The process continues as long as there is fuel for the burner.

34 ghi_tx001447gb.fm

Page 35

HI 110 / 200 / 300 Operation

4.14 Starting the Machine in Extremely Cold Weather

Background

Preheating

the fuel

In temperatures below 32°F (0°C), it may be necessary to preheat the fuel inside

the fuel filter canister. The fuel filter canister is equipped with a low-wattage heating

element specially designed for this purpose.

HI 200 HD and HI 300 HD machines are also equipped with a thermostatically

controlled nozzle heater as described below.

.

WARNING

Burn hazard. The external surface of the fuel filter may be hot.

f Wear safety gloves when handling the fuel filter.

Note: Excess heating may increase the need for maintenance. See topics

“Replacing the Fuel Filter” and “Replacing the Burner Nozzle”.

To preheat the fuel, carry out the following procedure.

1. Connect power to the machine. See topic Connecting Power to the Machine.

2. Wait up to 30 minutes—longer for colder temperatures.

3. Start the machine. See topic Starting the Machine.

Note: In extreme wind, the machine may need to be temporarily blocked from the

wind in order to start.

Troubleshooting

Nozzle heater

4. If the burner does not start on the first attempt, allow the power-on sequence to

cycle again.

5. If, after the second power-on sequence completes, the machine will not fire,

move the power switch to the OFF position.

6. Wait another 20-30 minutes and attempt to start the machine again.

The burner may not fire immediately on startup if the nozzle is cold. HI 200 HD and

HI 300 HD machines are equipped with an additional heater that warms the nozzle

to the required operating temperature.

ghi_tx001447gb.fm 35

Page 36

Operation HI 110 / 200 / 300

4.15 Stopping the Machine

Procedure

Shutdown

sequence

Follow the procedure below to stop the machine.

WARNING

Electric shock hazard. Electric power is still active at the blower even when the

machine is turned OFF.

f Remove all electric power to the machine before servicing the machine.

1. Turn the operation mode switch to the OFF (0) position (c).

0

The following sequence of events will occur after turning the machine off.

1. The burner will shut down.

2. The blower will stop when the machine is sufficiently cool.

36 ghi_tx001447gb.fm

Page 37

HI 110 / 200 / 300 Operation

4.16 Burner Faults

The burner fault lamp / reset button (a) is illuminated while the machine is

operating. The lamp is green during normal operation.

Burner fault

A burner fault occurs if the burner does not start after two failed attempts to start or

restart upon shutdown. The lamp will turn red.

f To clear a burner fault, press and hold the burner fault lamp / reset button for

2–3 seconds until the lamp goes out.

f Re-start the machine.

f If the burner fault re-occurs, see Basic Troubleshooting.

WARNING

If three consecutive attempts to reset the machine are unsuccessful, then troubleshoot the

heating system for the root cause(s) of the lockout.

f Make necessary repairs or adjustments to ensure a safe start condition.

f Ensure that the heat exchanger is free of oil and oil vapors before starting or resetting

the burner.

ghi_tx001447gb.fm 37

Page 38

Operation HI 110 / 200 / 300

4.17 Installing and Using the Remote Thermostat

Requirements

Procedure

Remote thermostat

Pre-starting checks complete

Follow the procedure below to install and use the remote thermostat.

1. Remove the protective cap (a) from the control panel receptacle.

2. Connect the remote thermostat (b) to the control panel receptacle (c).

3. Set the sensor end (d) within the area to be heated.

4. Adjust the target temperature with the dial (e).

b

a

d

Result

Thermostat

adapter

e

c

b

wcghi_gr007405

The machine will now be controlled by the remote thermostat.

An adapter is available to convert the proprietary thermostat connection to an

Edison plug style connection for use with commonly available thermostats. This

adapter can be purchased using Wacker Neuson part #5200007098.

NOTICE: The thermostat adapter is designed for use ONLY with a thermostat. To

avoid damaging the machine, do not plug any other equipment into the thermostat

adapter.

38 ghi_tx001447gb.fm

Page 39

HI 110 / 200 / 300 Accessories

5 Accessories

5.1 Available Accessories

Introduction

Wacker Neuson Corporation offers many optional accessories for this machine.

These accessories are described below. Contact your local Wacker Neuson dealer

or visit www.wackerneuson.com for ordering information.

Item Description/Purpose

Remote thermostat Allows the user to remotely control the target

temperature

Exhaust pipe An insulated exhaust pipe that offers a method of

directing exhaust away from the application area

Inlet and outlet covers Vinyl covers that protect the interior of the machine

from the elements during transport or storage

Duct adapters—various sizes Various sizes of detachable inlet and outlet adapters

Flexible ducts—various sizes Vinyl ducts that offer a method of directing inlet and

outlet air

Exhaust support bracket Bracket to support exhaust vents

Exhaust vent rain cap Metal cap to protect exhaust pipes from the elements

ghi_tx001448gb.fm 39

Page 40

Burner Setup HI 110 / 200 / 300

5

6 Burner Setup

6.1 Removing the Access Panel

Requirements

Overview

Procedure

Machine shut down and cooled

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Your machine is equipped with a removable access panel. The access panel must

be removed in order to maintain and repair certain machine components such as

the burner, electric motor, and fuel pump.

Follow the procedure below to remove the access panel.

1. Shut down the machine and allow it to cool.

2. Disconnect the power cord from the power source.

3. Remove the screws that fasten the access panel (g).

Note: There are six screws to remove on the HI 110; four screws to remove on the

HI 200 and HI 300.

g

g

4. Remove the access panel and set it aside.

5. Perform the required maintenance.

6. When maintenance is complete, reinstall the access panel and fasten it with the

screws.

wc_gr00738

40 ghi_tx001449gb.fm

Page 41

HI 110 / 200 / 300 Burner Setup

6.2 Removing and Installing the Burner Assembly

Requirements

Procedure

Removal

Machine shut down and cooled

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Before performing any maintenance on the burner assembly, it must be removed

from the machine. To remove or install the burner assembly perform the following

procedure.

1. Shut down the machine and allow it to cool.

2. Disconnect the power cord from the power source.

3. Remove the access panel. See topic Removing the Access Panel.

e

d

Installation

c

b

wc_gr007378

4. Remove the screw (d) to disconnect the ground wire (c) from the burner

assembly (b).

5. Rotate the burner assembly counter-clockwise and remove it from the flame

head and air tube assembly (e).

6. Perform the required maintenance.

Note: Refer to the maintenance procedures in this manual.

7. Reinstall the burner assembly. Refer to the steps below to install the burner

assembly.

1. Place the burner assembly into the flame head and air tube assembly.

2. Rotate the burner assembly clockwise to lock it into place.

3. Install the ground wire using the screw (d).

4. Reinstall the access panel.

ghi_tx001449gb.fm 41

Page 42

Burner Setup HI 110 / 200 / 300

6.3 Setting Up the Burner

Factory

settings

Machine Nozzle size Fuel pressure Air band setting

gph psi bar Diesel Winter blend

HI 110 D 0.55 x 80W 217 15 3.0 2.0

HI 110 HD D 0.55 x 80W 217 15 3.0 2.0

HI 200 D 1.10 x 80W 181 12.5 3.8 3.0

HI 200 HD D 1.10 x 80W 181 12.5 3.3 2.6

HI 300D 1.50 x 80W 200 13.8 6.8 3.4

HI 300HD D 1.50 x 80W 200 13.8 3.5 3.2

Background

Tools required

Mandates

When

The burner consists of several different components and subsystems. Each of these

components or subsystems must be operating correctly for the burner to function properly.

The following tools are required to adjust the burner:

High-quality combustion analyzer

Smoke spot tester

Fuel pressure test gauge

General hand tools

Adjustments made shall be done so that the machine conforms to the require-

ments of local, state, and federal codes and authorities.

Adjustments shall be made at the job site.

Adjust the burner:

Before operating the machine at elevations 305 m (1,000 ft) above or below the

location of where the last adjustments were made

Before starting at a new job site

After any burner maintenance or repair has been performed

If burner performance is in question

Procedure

Follow the procedure below to set up the burner.

1. Shut down the machine.

2. Set the burner electrodes.

(See topic Checking and Adjusting the Oil Burner Electrodes.)

3. Check the burner nozzle.

(See topic Checking/Changing the Burner Nozzle.)

4. Set the air band.

(See topic Setting the Air Band.)

5. Start the machine and the burner.

6. Check/set the fuel pressure.

(See topic Adjusting the Fuel Pressure.)

42 ghi_tx001449gb.fm

Page 43

HI 110 / 200 / 300 Burner Setup

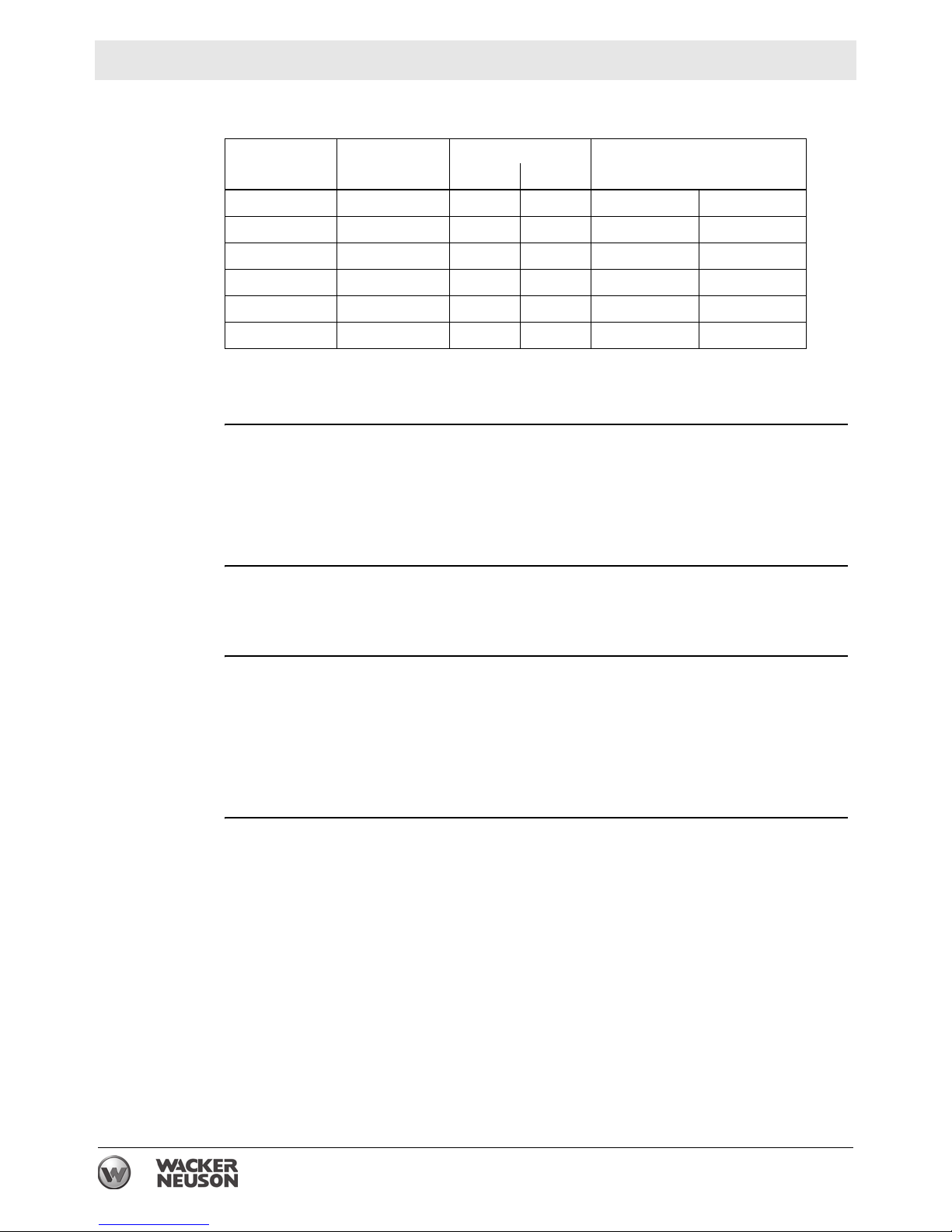

7. Conduct a smoke spot test. Follow the smoke spot tester manufacturer’s

instructions and the general guidelines below.

HI Heater

ghi_gr007395

Use the access hole in the exhaust stack.

Several samples should be taken as the heater warms.

The final sample should be taken just before the heater reaches 71°C (160°F).

8. Analyze the combustion. Follow the combustion analyzer manufacturer’s

instructions and the general guidelines below.

Use the access hole in the exhaust stack.

Take several samples as the heater warms.

Take the final sample just before the heater reaches 71°C (160°F).

9. Re-adjust the air band, if necessary, until the smoke spot test and combustion

analysis are within the following parameters:

O

content: 3–5%

2

Smoke spot: less than 1

Result

ghi_tx001449gb.fm 43

The burner has now been set.

Page 44

Burner Setup HI 110 / 200 / 300

6.4 Checking the Oil Burner Electrodes

Requirements

When to

inspect

Procedure

Machine shut down

Power disconnected

Burner cool

Inspect the electrodes on your machine every two weeks or after every 50 hours of

operation. The condition of the electrodes will drastically affect your machine’s

ability to fire efficiently.

Remove the burner assembly and inspect the condition of the electrode tips (a).

Refer to the table below to determine the condition of the electrode tips.

a

b

a

c

wc_gr007619

Condition Task

None; ok as-is

None; ok as-is

Replace

The electrodes should be replaced if they are worn or damaged. Contact your

Wacker Neuson dealer for replacement electrodes.

44 ghi_tx001449gb.fm

Page 45

HI 110 / 200 / 300 Burner Setup

ghi_g

6.5 Checking/Changing the Burner Nozzle

Prerequisites

When

Removing the

nozzle

Installing the

nozzle

Machine shut down and cool to the touch

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Replace the burner nozzle annually, or if it is damaged.

To replace the burner nozzle, carry out the following procedure.

1. Remove the burner. See topic Removing and Installing the Burner Assembly.

2. Place an adjustable wrench on the large fitting (a) on the nozzle base (c).

3. Place another adjustable wrench on the nozzle (b).

4. Rotate the nozzle counter-clockwise and remove it from the assembly.

5. Install the new nozzle (b) onto the nozzle base (c).

6. Tighten the nozzle (b) using an adjustable wrench. Rotate the wrench

clockwise.

7. Reinstall the burner assembly. See topic Removing and Installing the Burner

Assembly.

b

a

c

ghi_tx001449gb.fm 45

r007408

Page 46

Burner Setup HI 110 / 200 / 300

9

6.6 Adjusting the Fuel Pressure

Requirements

Background

When to

check

Procedure

Machine shut down and cool to the touch

Power disconnected

Fuel pressure gauge

The information below will show you how to check the fuel pressure on your

machine. Incorrect fuel pressure will result in too much fuel, or too little fuel, to be

supplied to the burner. This will cause the machine to smoke during operation.

Check the fuel pressure if the machine emits smoke during operation.

To check and/or adjust the fuel pressure, carry out the following procedure.

1. Remove the access panel. See topic Removing the Access Panel.

2. Disconnnect one of the wires from the solenoid valve (a).

3. Remove the threaded plug (b) from the pressure test port (c) using a hex key

wrench. Set the plug in a safe location to be re-installed later.

a

4. Install a pressure gauge with adapter (d) in the pressure test port.

5. Start the machine. See topic Starting the Machine.

6. With the machine running, verify the fuel pressure setting during the preventilation period (approximately 15 seconds). Refer to the Technical Data

charts in this manual for the correct settings.

7. After the pre-ventilation period, the absence of a flame will cause the machine to

stop in safety mode. Press the reset button to enable re-start if the fuel pressure

needs adjustment.

ghi_gr00737

46 ghi_tx001449gb.fm

Page 47

HI 110 / 200 / 300 Burner Setup

9

Adjusting fuel

pressure

8. Adjust the fuel pressure if necessary using the adjusting screw (e) and re-check

the settings. Repeat steps 4–6 to re-check the settings.

NOTICE: Do not adjust the fuel pressure to a setting outside the safe operational

parameters.

9. Remove the pressure gauge (d) from the pressure test port (c).

10.Re-install the threaded plug (b) into the pressure test port (c).

11.Re-connect the solenoid wire.

12.Close the access panel and re-install the two bolts (a) that secure the panel.

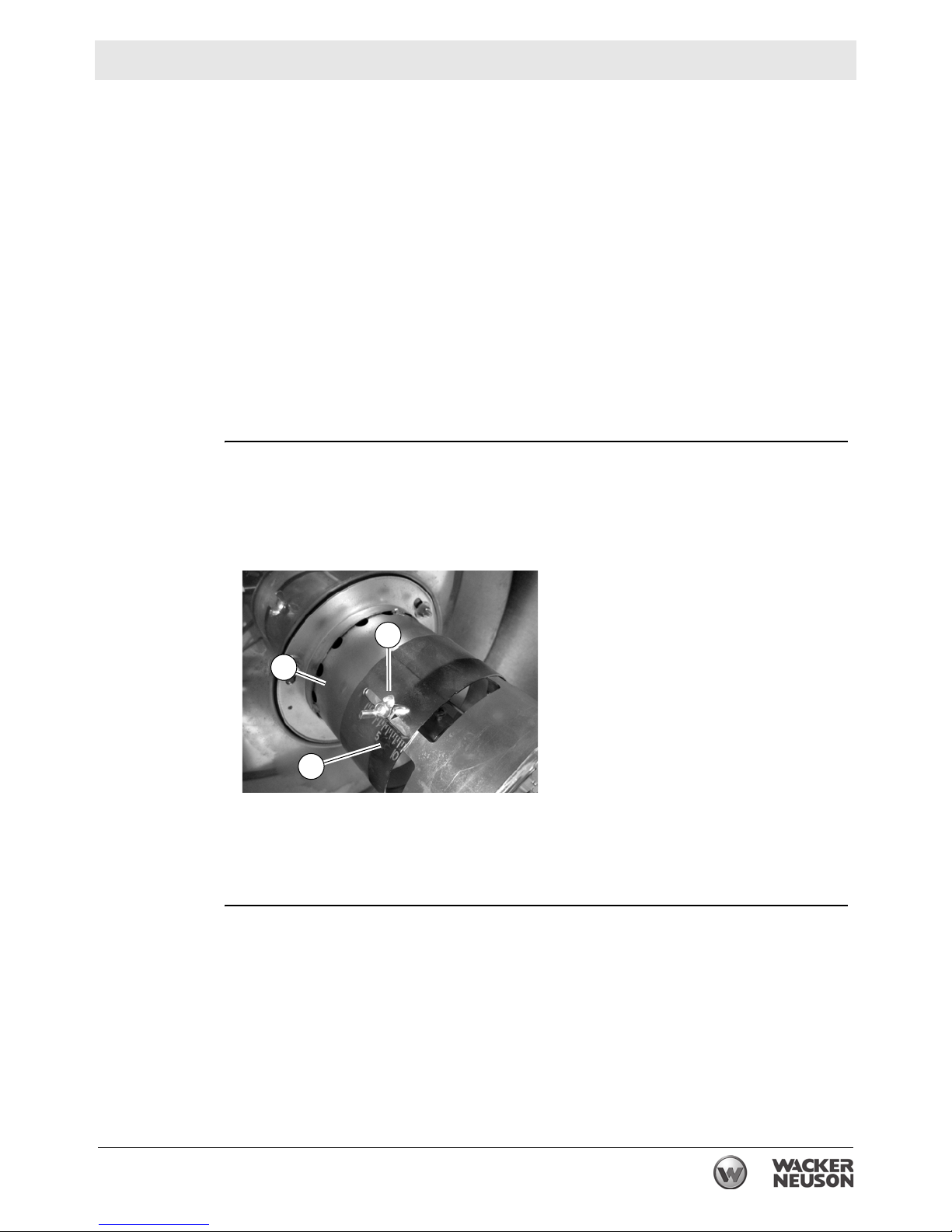

6.7 Setting the Air Band

Requirements

Procedure

Machine shut down

Power disconnected

Perform the procedure below to set the air band.

1. Shut down the machine and allow it to cool.

2. Disconnect the power cord from the power source.

3. Remove the access panel. See topic Removing the Access Panel.

Result

a

b

c

ghi_gr00740

4. Loosen the wing nut (a) and slide the air band (b) as needed. The front edge

should line up with the graduations (markings) on the flame head (c).

5. Tighten the wing nut.

The air band has now been set.

ghi_tx001449gb.fm 47

Page 48

Maintenance HI 110 / 200 / 300

7 Maintenance

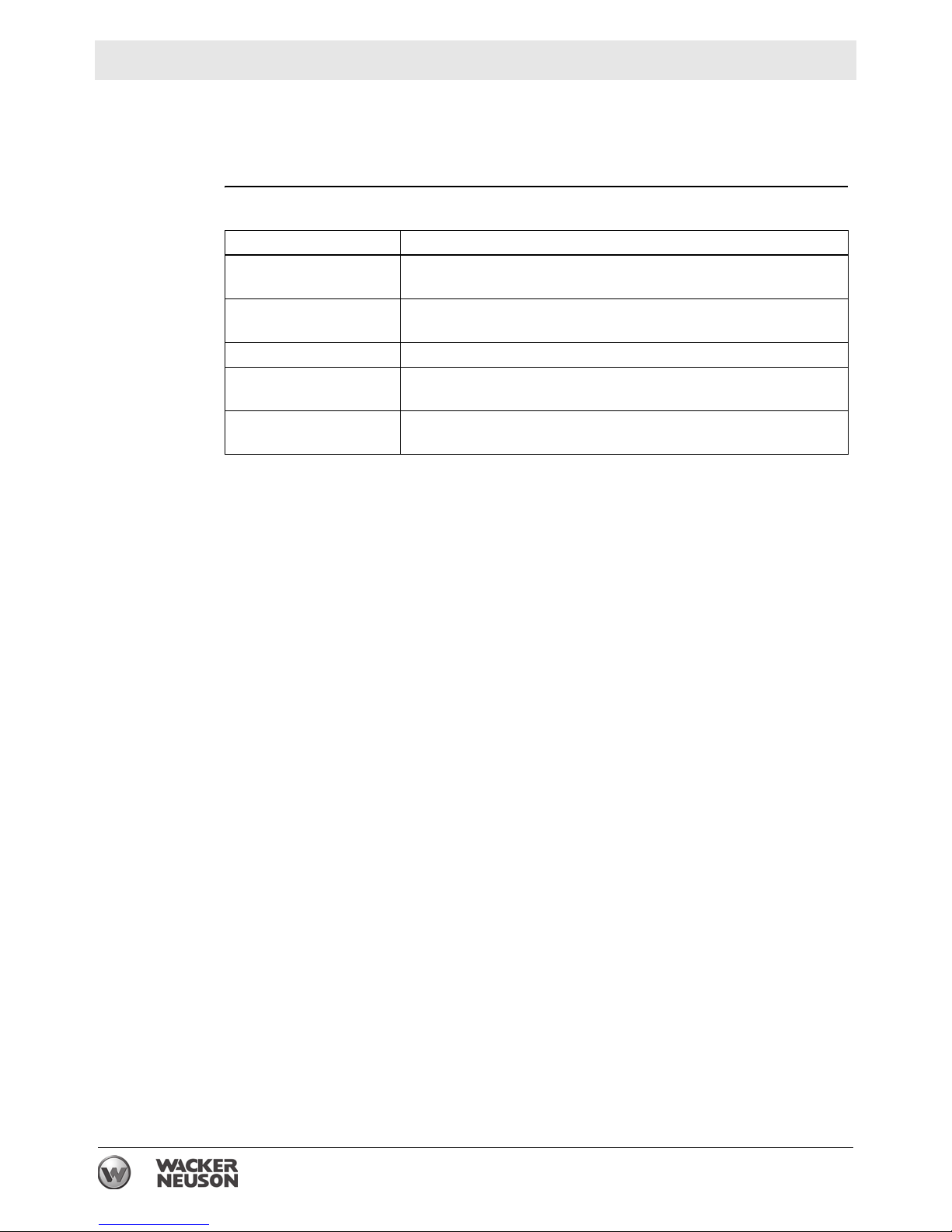

7.1 Periodic Maintenance Schedule

Interval*

(hours of service)

Daily 2 Weeks 6 Months Yearly

Task

Inspect the heater.

Inspect the hose assembly.

Check fuel level and

pressure.

Clean the machine.

Clean the fuel filter.

Clean the fan and the

interior shell.

Clean and check/adjust

burner electrode settings.

Inspect the heat exchanger.

Inspect electrical

components.

Inspect the blower motor

and belts. Replace the belt

if necessary.

--- (50) (1000) (1200)

Replace the burner nozzle.

Replace the fuel heater

filter.

Maintain the heater

weldment.

Inspect and test the burner. As needed or upon changing job sites;

see chapter Burner Setup.

Inspect burner electrodes;

replace if necessary.

*

Use whichever comes first, calendar time or service hours.

As needed or upon changing job sites;

see chapter Burner Setup.

48 ghi_tx001450gb.fm

Page 49

HI 110 / 200 / 300 Maintenance

7.2 Inspecting the Heat Exchanger

Introduction

Reasons for

inspection

When

The heat exchanger consists of the combustion chamber and an outer shell. As

intake air flows over the hot combustion chamber, it collects heat. The heated

intake air is then blown out of the supply ducts.

A cracked or damaged heat exchanger is hazardous! Poisonous carbon monoxide

gas can escape from the heat exchanger and enter the clean air stream.

Combustible gases may also ignite the surrounding insulation material, causing a

fire.

To ensure a safe operating condition, the heat exchanger must be inspected

regularly for damage.

DANGER

Asphyxiation hazard. Gases escaping from a cracked or damaged heat exchanger

contain carbon monoxide (CO). This is a poison you cannot see or smell. CO can

kill you in minutes!

f Do not operate the machine if it has a cracked or damaged heat exchanger.

Inspect the heat exchanger at least twice a year as part of the regularly scheduled

maintenance program.

Inspect the heat exchanger more often if any of the following conditions exist:

The machine has been transported over extremely rough roads or terrain.

The machine / transport vehicle has been involved in an accident.

The machine has been dropped.

There is visible damage to the heater shell.

The burner has been improperly adjusted and is over-firing.

There is doubt about whether regularly scheduled maintenance has been

performed.

The safety systems have been bypassed by improper or modified wiring.

NOTICE: If the machine wiring has been altered, correct the wiring before

operating the machine.

Requirements

Power disconnected from the machine.

Machine cool. Do not inspect a hot heat exchanger.

Assistant to aid in the inspection

Lifting equipment

Shop light or flash light

Inspection mirror

This procedure continues on the next page.

ghi_tx001450gb.fm 49

Page 50

Maintenance HI 110 / 200 / 300

Continued from the previous page.

Access

procedure

Follow the procedure below to access the heat exchanger.

1. Remove the access panel (a). (See Removing the Access Panel.)

d

a

a

c

c

b

c

e

wc_gr008456

2. Loosen the three nuts (b) securing the burner tube assembly (c). Rotate and

remove the burner tube assembly.

3. Remove the cover (d) from HI 200 and HI 300 machines.

4. Remove the bolts that secure the heat exchanger (e) to the lower shell.

5. Lift the heat exchanger out for visual inspection by either of the following

methods:

Use a hoist with non-marring straps and approved rigging devices

Use a team of four people to lift the heat exchanger by hand, using safe lifting

practices and techniques.

The heat exchanger can now be inspected.

This procedure continues on the next page.

50 ghi_tx001450gb.fm

Page 51

HI 110 / 200 / 300 Maintenance

Continued from the previous page.

Inspection

procedure

Follow the procedure below to inspect the heat exchanger.

1. Using a strong light and inspection mirror, inspect the outer shell of the

combustion chamber for cracks or separations.

2. Inspect welded areas.

3. Use the light and mirror to examine the interior of the combustion chamber for

cracks or separations. Also, inspect the burner tube assembly mounting surface

(f) for damage.

g

f

wc_gr008458

4. Have an assistant shine the light over the exterior shell of the combustion

chamber while you peer through the burner mounting hole (g). Look for signs of

light inside the combustion chamber.

Results

Reassembly

Do not use the machine if any of the following conditions exist. Contact Wacker

Neuson Product Support for assistance.

Cracks or separations are discovered in the heat exchanger

Soot is vislble on the exterior (air side) of the heat exchanger

There are cracks or damage to the burner tube assembly mounting surface.

Note: Light surface rust is normal.

Follow the procedure below to reassemble the machine after inspecting the heat

exchanger.

1. Reinstall the heat exchanger.

2. Reinstall the cover (HI 200 / HI 300 only).

3. Reinstall the burner tube assembly.

4. Reinstall the access panel.

The machine has now been reassembled.

ghi_tx001450gb.fm 51

Page 52

Maintenance HI 110 / 200 / 300

7.3 Changing the Fuel Heater Filter

Prerequisites

Procedure

Machine shut down

Power disconnected

Burner cool

CAUTION Hot surface hazard.

The external surface of the fuel filter canister may be hot.

f Allow the machine to cool before servicing.

WARNING Hot fluids.

The fuel inside the fuel filter canister may be hot.

f Wear safety glasses.

Follow the procedure below to change the fuel heater filter.

1. Disconnect the power, shut down the machine, and allow it to cool.

2. Remove the screw that secures the cover to the housing (a).

3. Remove the filter (b).

4. Inspect the O-ring (c). Replace it if it is cracked, damaged, or deformed.

5. Install the new filter.

6. Reinstall the cover.

Result

The procedure to replace the fuel heater filter is now complete.

52 ghi_tx001450gb.fm

Page 53

HI 110 / 200 / 300 Maintenance

0

7.4 Inspecting and Cleaning the Cadmium (CAD) Cell

Prerequisites

When

Machine shut down and cool to the touch

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Inspect and clean the CAD cell as needed, or while performing other scheduled

maintenance procedures.

To inspect and clean the CAD cell, carry out the following procedure.

1. Remove the access panel. See topic Removing the Access Panel.

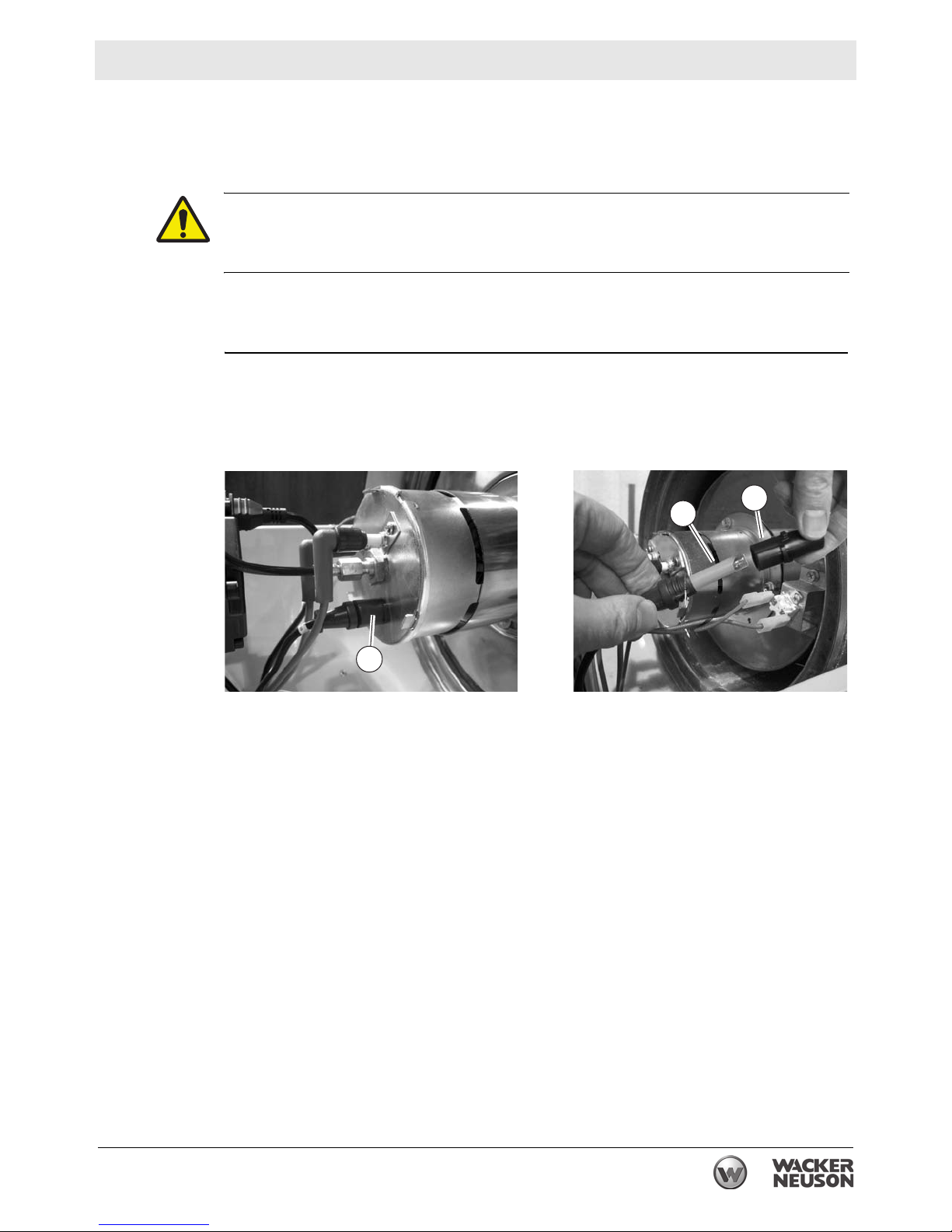

2. Twist and pull out the plastic protective holder

(1) off the base of the burner

assembly. The CAD cell (2) is inside this plastic holder.

1

2

1

ghi_gr00737

3. Inspect the CAD cell for cleanliness. Be sure the cell is free of debris or soot.

4. Clean the CAD cell if necessary.

NOTICE: Do NOT use solvents or liquids to clean the CAD cell. Use a soft dry

cloth to clean the CAD cell.

5. Reinstall the plastic protective holder onto the base of the burner assembly.

ghi_tx001450gb.fm 53

Page 54

Maintenance HI 110 / 200 / 300

7.5 Cleaning the Fan Blades and Motor

Prerequisites

When

Machine shut down and cool to the touch

Power source disconnected

WARNING

Electric shock hazard. Electric power is still active at the blower even when the

machine is turned OFF.

f Remove all electric power to the machine before performing this procedure.

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Clean the fan blades and motor prior to the first seasonal use, every 1200 hours or

annually, or as needed.

To clean the fan blades and motor, carry out the following procedure.

1. Remove the fan guard (f). There are four screws that secure the fan guard.

f1

f

HI 110D

HI 110D

HI 200 / HI 300

HI 200 / HI 300

g

m

ghi_gr007380

2. Remove the the access panel (g). See topic Removing the Access Panel.

This procedure continues on the next page.

54 ghi_tx001450gb.fm

Page 55

HI 110 / 200 / 300 Maintenance

3. Inspect and, if necessary, clean the motor (m) using compressed air.

4. Clean the fan blades using a stiff brush.

5. Reinstall the internal access panel.

6. Reinstall the fan guard.

7.6 Cleaning the Interior Shell

Prerequisites

When

Machine shut down and cool to the touch

Power source disconnected

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Clean the interior shell prior to the first seasonal use, every 1200 hours or annually,

or as needed.

To clean the interior shell, carry out the following procedure.

1. Remove the fan guard. See topic Cleaning the Fan Blades and Motor.

2. Remove the internal access panel. See topic Removing the Internal Access Panel

.

3. Inspect and clean the interior shell using compressed air.

4. Re-install the internal access panel.

5. Re-install the fan guard.

ghi_tx001450gb.fm 55

ghi_gr007381

Page 56

Maintenance HI 110 / 200 / 300

2

7.7 Inspecting the Flame Head

Requirements

When

Procedure

Machine shut down and cool to the touch

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Inspect the flame head prior to the first seasonal use, during regular maintenance,

and as needed.

To inspect the flame head (a), carry out the following procedure.

1. Remove the access panel. See topic Removing the Access Panel.

2. Remove the burner assembly. See topic Removing and Installing the Burner

Assembly. The flame head is attached.

a

a

ghi_gr00738

3. Inspect the flame head for the following:

Wear. Replace if necessary.

Cleanliness. Clean the flame head if necessary.

Thermal stress. Replace if necessary.

4. Re-install the burner assembly. See topic Removing and Installing the Burner

Assembly.

56 ghi_tx001450gb.fm

Page 57

HI 110 / 200 / 300 Maintenance

7.8 Inspecting the Electrical Connections

After disconnecting the power cord, check all electrical connections for the

following:

Proper connections. Be sure that all connections are complete and tight.

Corrosion. Clean or replace if necessary.

Damaged wires/connectors. Replace if necessary.

Proper ground.

ghi_tx001450gb.fm 57

Page 58

Maintenance HI 110 / 200 / 300

7.9 Cleaning the Machine

Requirements

General

cleaning

Machine shut down

Machine cool

Clean the following areas to ensure proper operation.

Item Method/task

Burner Remove all dirt and debris. Ensure that the air intake area is

unobstructed.

Hoses, connectors,

and couplings

Trailer (if equipped) Clean with compressed air: 50 psi maximum.

Covers/machine

exterior

Air inlets/ouputs Remove all dirt and debris. Ensure that the air intake area is

Wipe clean with cloth.

Wipe clean with cloth.

unobstructed.

58 ghi_tx001450gb.fm

Page 59

HI 110 / 200 / 300 Basic Troubleshooting

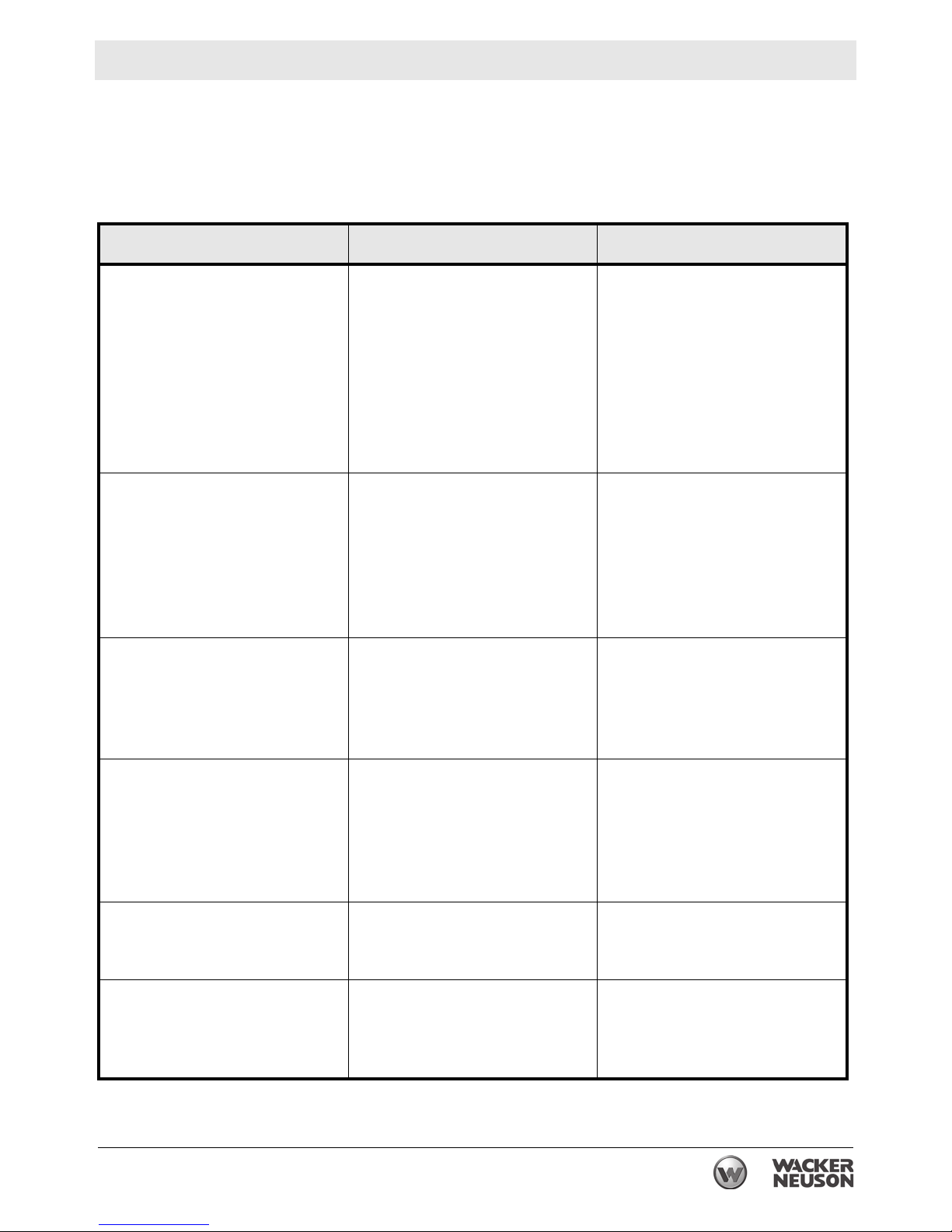

8 Basic Troubleshooting

Note: The following symptoms and remedies are some of the more common

issues that have arisen during the history of these machines. These do not represent all the possibilities. If you need advanced troubleshooting assistance, please

contact Wacker Neuson Product Support.

Symptom Possible Causes Remedy

The burner does not start • The remote thermostat or

thermostat plug is not

inserted correctly.

• Faulty cable or power

supply

• The over temperature limit

has tripped

• The burner is in lock-out

mode.

The burner starts, the flame

does not ignite, the unit locks

out

•No fuel

• Worn burner nozzle

• Faulty electrodes

• Cad cell detecting external

light.

• Cad cell defective

• Burner control defective

The burner starts, flame

ignites, but the unit locks out

• Incorrect fuel pressure

• Worn burner nozzle

• Incorrect air lock setting

• Cad cell defective

• Burner control defective

• Insert the remote

thermostat or thermostat

plug.

• Check cable and power

supply

• Press the reset button.

• Fill fuel tank

• Replace burner nozzle

• Replace electrodes

• Check the Cad cell

enclosure

• Increase fuel pressure

• Replace burner nozzle

• Re-adjust air lock setting

The burner ignites but the

performance is poor

Black smoke from vent pipe • Insufficient combustion air

The machine stops due to

pressure switch fault

ghi_tx001468gb.fm 59

• Worn burner nozzle

• Clogged fuel filter

• Air leaks in the fuel lines

• Insufficient oil pressure

• Insufficient ventilation air

• Overheat condition

• Faulty pressure switch

• Incorrect nozzle

• Wrong fuel pressure

• Replace burner nozzle

• Replace the fuel filter

• Inspect the lines for leaks;

replace if necessary

• Remove any obstructions

from the air inlet and outlet

areas.

• Contact Wacker Neuson

Product Support

Page 60

Technical Data HI 110 / 200 / 300

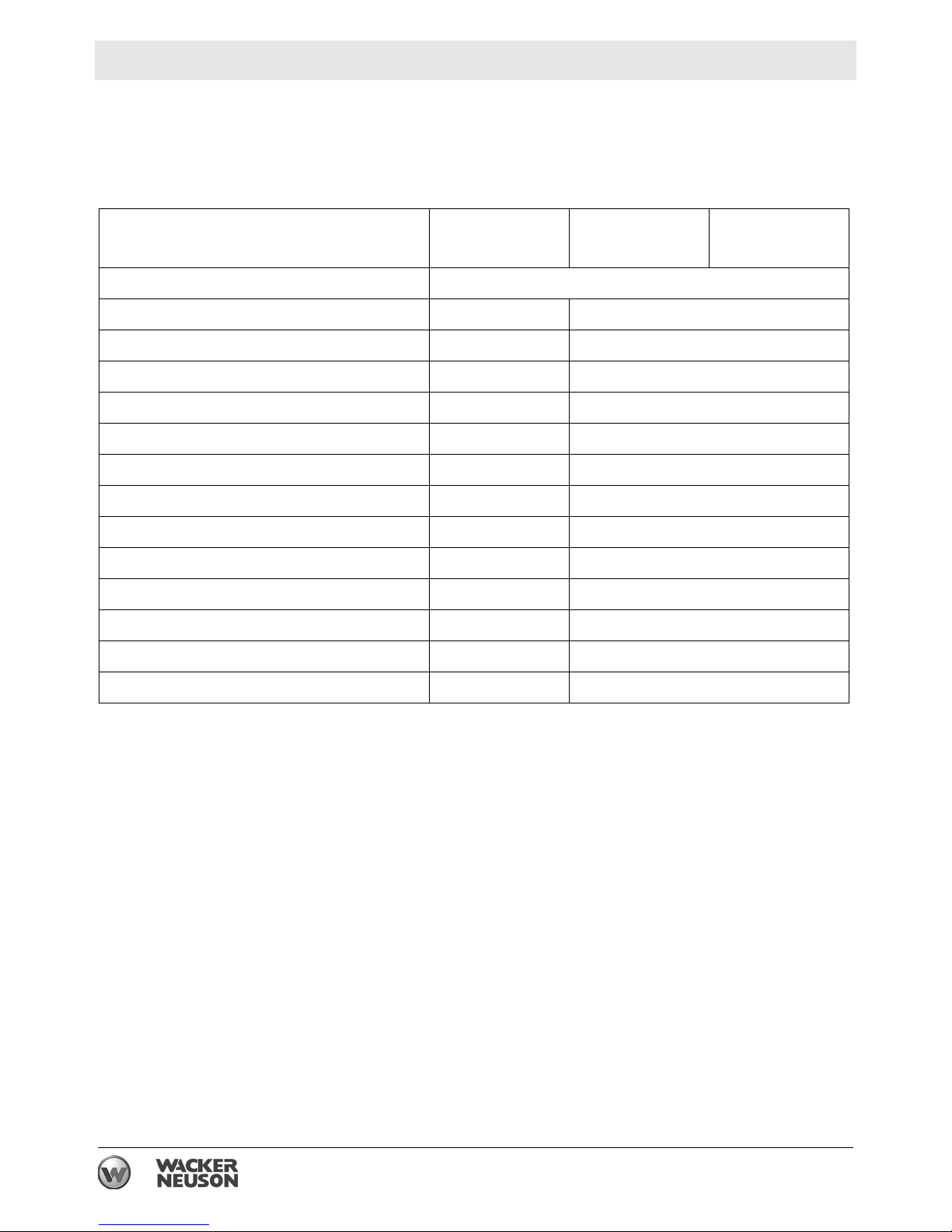

9 Technical Data

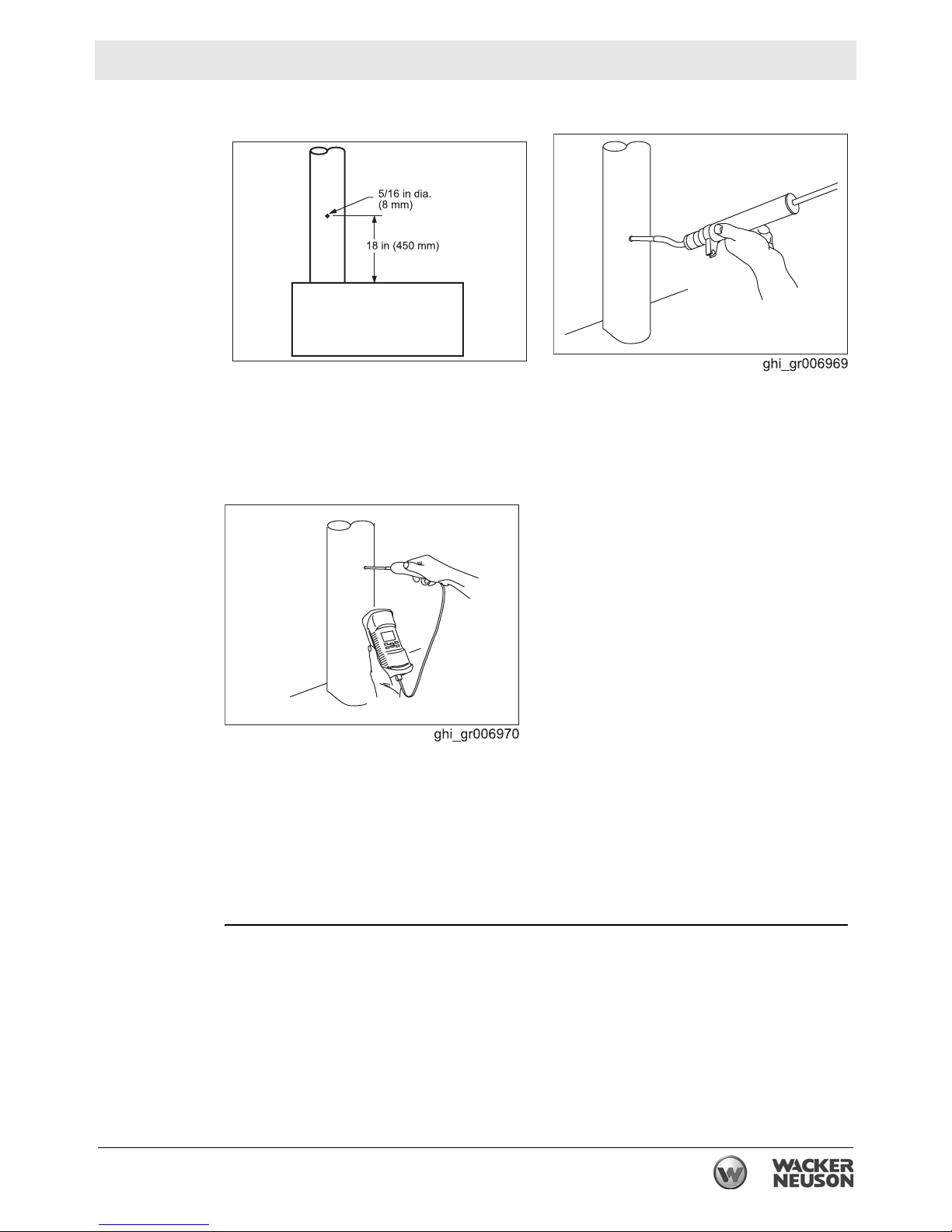

9.1 Machine

Model

Units

Heat input BTU/hr 112,141 204,873

Heat output BTU/hr 92,516 173,117

Fuel consumption L (gal)/hr 3.1 (0.81) 5.6 (1.48)

Efficiency % 82.5 84.5

Noise level at 1 m dB (A) 74 77

Power requirement VAC/Hz 120/60 120/60

Electrical current Ampere 15 15

Weight (no fuel) kg (lb) 80 (176) 109 (240)

Height mm (in.) 978 (38.5) 983 (38.6)

Length mm (in.) 1219 (48) 1661 (65.4)

Width mm (in.) 610 (24) 762 (30)

Flue diameter mm (in.) 152.4 (6) 152.4 (6)

HI 110D

HI 110HD D

HI 200D

HI 200HD D

Fuel tank capacity L (gal) 67.4 (17.8) 105 (27.74)

60

wc_td000400gb.fm

Page 61

HI 110 / 200 / 300 Technical Data

Model

Units

Heat input BTU/hr 293,982 293,982

Heat output BTU/hr 245,475 245,475

Fuel consumption L (gal)/hr 8 (2.12) 8 (2.12)

Efficiency % 83.5 83.5

Noise level at 1 m dB (A) 75 75

Power requirement VAC/Hz 120/60 120/60

Electrical current Ampere 15 15

Weight (no fuel) kg (lb) 160 (352) 202.8 (447)

Height mm (in.) 1270 (50) 1321 (52)

Length mm (in.) 1740 (69) 2134 (84)

Width mm (in.) 762 (30) 864 (34)

Flue diameter mm (in.) 152.4 (6) 152.4 (6)

Fuel tank capacity L (gal) 134.8 (35.6) 216.1 (57.1)

HI 300D

HI 300HD D

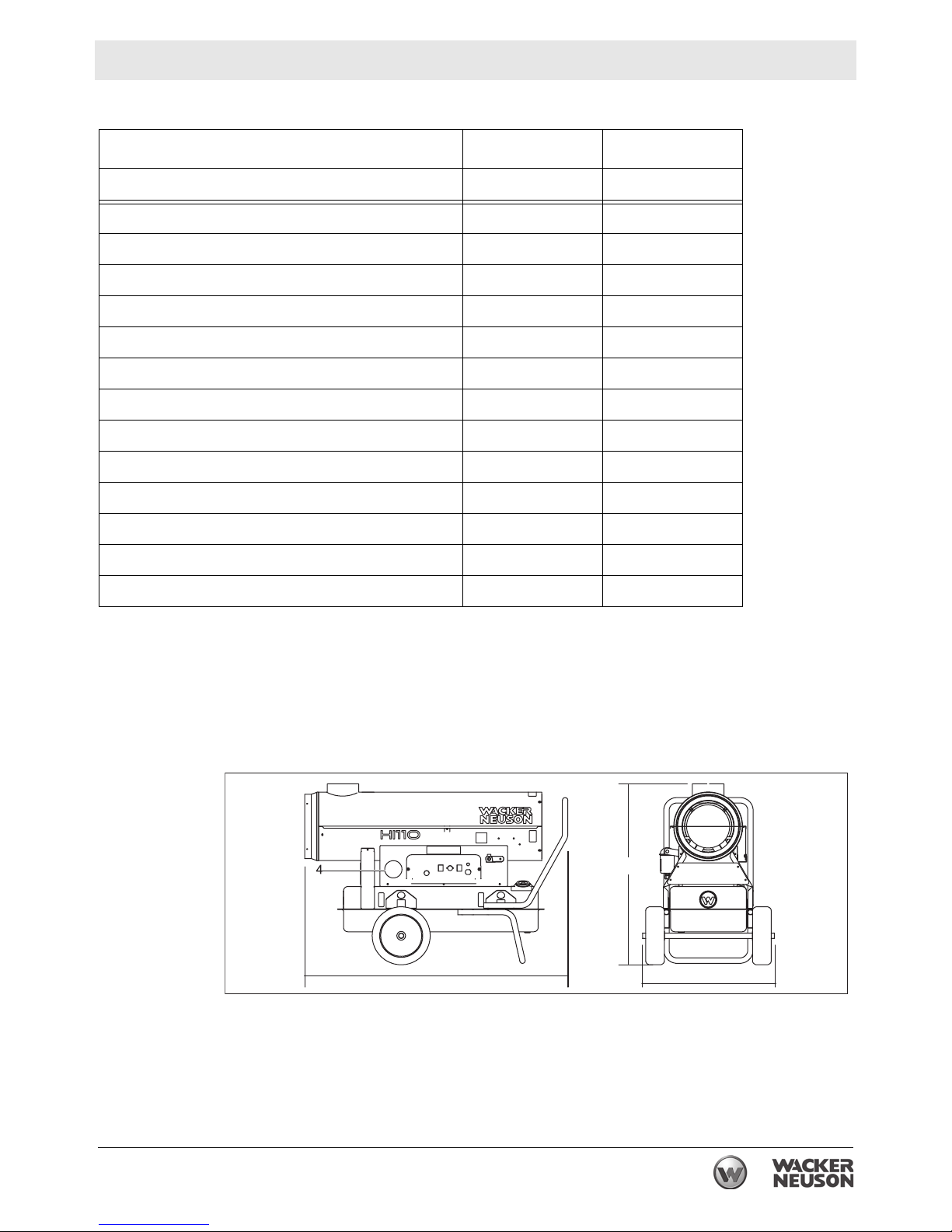

9.2 Dimensions - HI110D, HI110HD D

in. (mm)

48 (1219)

wc_td000400gb.fm

61

38.5 (978)

24 (610)

wc_gr012068

Page 62

Technical Data HI 110 / 200 / 300

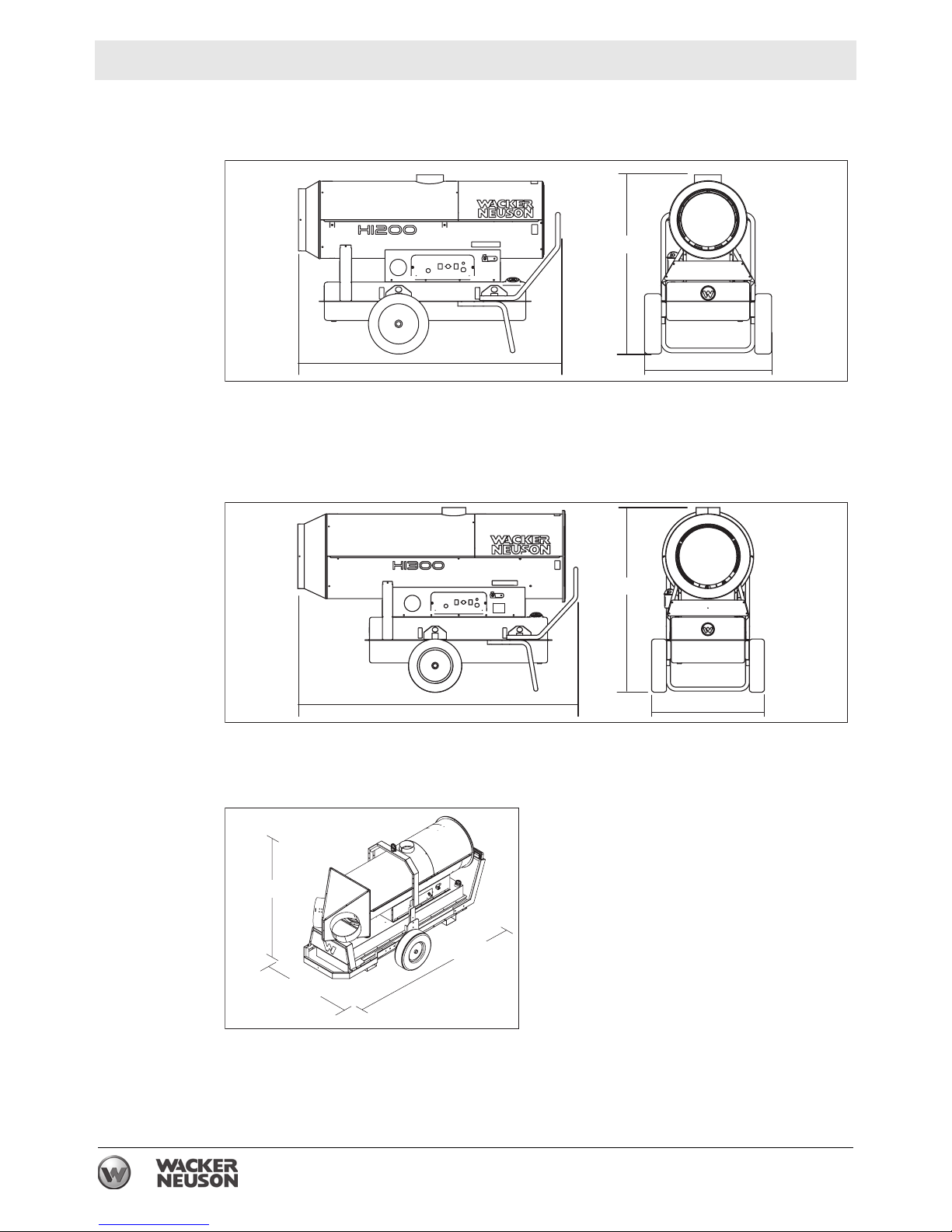

9.3 Dimensions - HI200D, HI200HD D

in. (mm)

38.6 (983)

65.4 (1661)

9.4 Dimensions - HI300D, HI300HD D

in. (mm)

69 (1740)

in. (mm)

30 (762)

wc_gr012069

50 (1270)

30 (762)

wc_gr012070

52 (1321)

34 (864)

84 (2134)

wc_gr012071

wc_td000400gb.fm

62

Page 63

HI 110 / 200 / 300 Technical Data

wc_td000400gb.fm

63

Page 64

Schematics HI 110 / 200 / 300

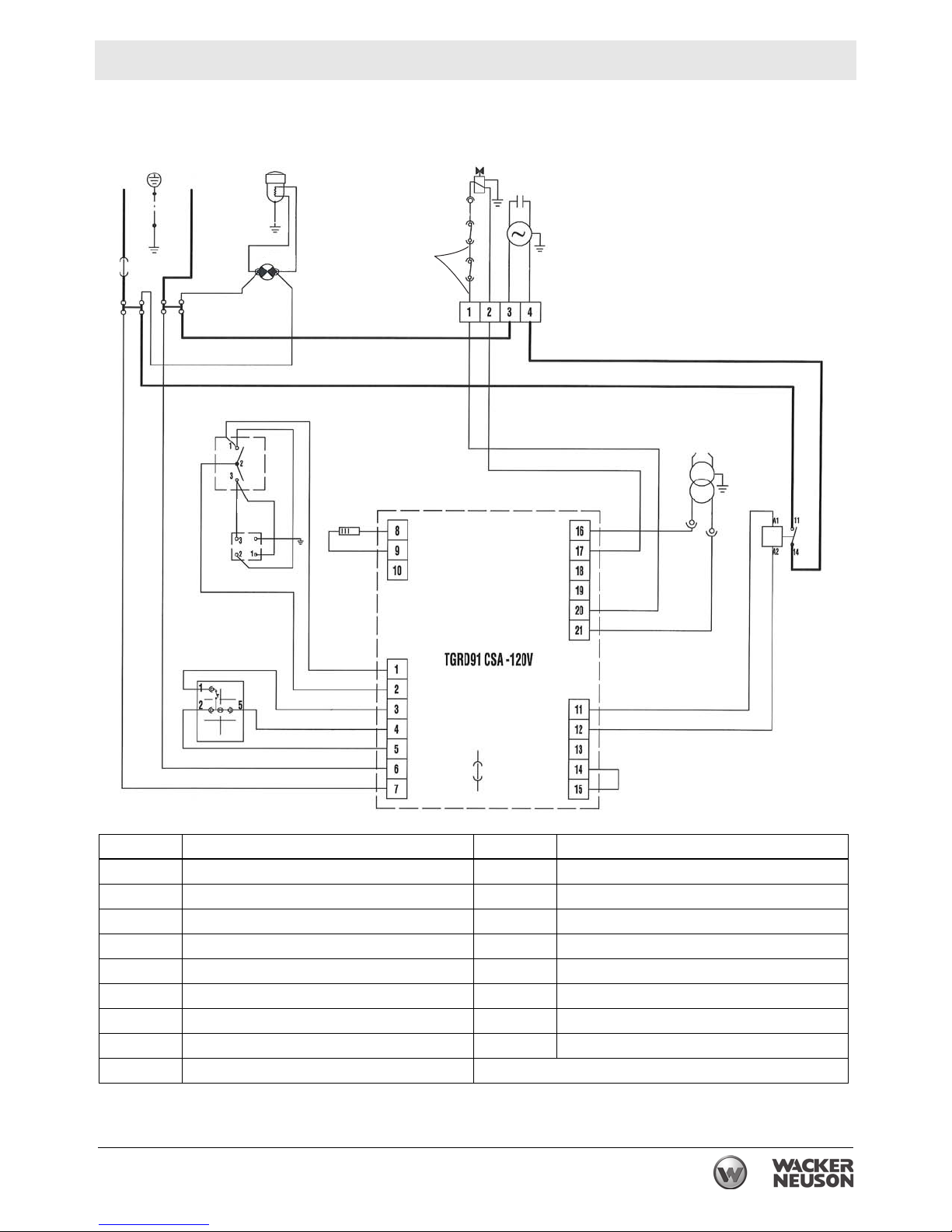

10 Schematics

10.1 Electrical Schematic - HI 110 D, HI 110 HDD

12

7

LN

3

5

13

WH

BK

RD

BK

WH

BK

BK

6

14

WH

WH

BK

RD

7

RD

2

WH

11

8

RD

9

4

J4

J3

10

BK

RD

RD

YL

GY

BU

WH

TGRD91 CSA 120V

J1

1

WH

BK

J2

wc_gr012018

No. Description No. Description

1 Fuse 8 Control switch

2 Overheat thermostat 9 Room thermostat plug

3 Solenoid valve 10 Control box

4 CAD cell 11 Air pressure switch

5 Capacitor 12 Heated fuel filter (optional)

6 Fan motor 13 Reset switch/lockout indicator

7 Electric pilot lamp 14 High voltage transformer

64

wc_tx003764gb.fm

Page 65

HI 110 / 200 / 300 Schematics

10.2 Electrical Schematic - HI 200 D

1

BK

BR

WH

14

3

4

12

BU

6

WH

7

BK

BK

BK

2

WH

WH

11

J3

BK

BK

13

PE

N

RD

WH

8

WH

BK

L

9

RD

5

10

J4

RD

RD

15

WH

BK

No. Description No. Description

1 Fuse 10 Room thermostat plug

2 High voltage transformer 11 Relay

3 Overheat thermostat 12 Control box

4 Solenoid valve 13 Heated fuel filter

5 CAD cell 14 Air pressure switch

6 Capacitor 15 Reset switch / lockout indicator

7 Fan motor 16 Resistance heater coil*

8 Electric pilot lamp 17 Nozzle line heater*

9 Control switch *Used on HD models only

YL

GY

BU

J1

J2

1

WH

BK

BK

wc_gr012019

wc_tx003764gb.fm

65

Page 66

Schematics HI 110 / 200 / 300

10.3 Electrical Schematic - HI 200 HDD

BR

BK

1

BK

GY

L

PE

N

13

WH

BU

WH

BR

RD

8

BR

WH

14

3

4

8

6

7