Page 1

Operator’s Manual

5200009218

Direct-Fired Air Heater

HDR155

Type HDR155

Document 5200009218

Date 1115

Revision 03

Language EN

Page 2

Copyright notice

© Copyright 2015 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the

machine. Any other type of reproduction is prohibited without express

written permission from Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker

Neuson Production Americas LLC represents an infringement of valid

copyrights. Violators will be prosecuted.

Trademarks

Manufacturer

Original instructions

All trademarks referenced in this manual are the property of their

respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

This Operator’s Manual presents the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

HDR 155 Foreword

Foreword

This heater is designed and approved for use as a construction heater in

accordance with the following standards.

CSA B140.0-03 3rd Edition (R2008)

CSA B140.8-1967 (R2001)

UL 733 4th Edition (Rev. April 22, 2010)

CHECK WITH YOUR LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE

QUESTIONS ABOUT APPLICATIONS.

Other standards govern the use of fuel gases and heat producing products in

specific applications. Your local authority can advise you about these standards.

THE INSTALLATION OF THE UNIT SHALL BE IN ACCORDANCE WITH THE

REGULATIONS OF THE AUTHORITIES HAVING JURISDICTION.

In addition, as a standard practice for installation, Wacker Neuson recommends

referencing the current issue of CSA B139, Installation Code for Oil Burning

Equipment in Canada and NFPA 31 Standard for the Installation of Oil-Burning

Equipment in the USA.

WARNING

Risk of personal injury or machine damage from improper use.

f Before using the machine, read and understand all instructions and follow them

carefully.

f The manufacturer is not responsible for damages to goods or persons due to

improper use of this machine.

WARNING

Failure to comply with the precautions and instructions provided with this machine

can result in death, serious injury, and property loss or damage from fire, explosion,

burns, asphyxiation, carbon monoxide poisoning, and/or electric shock.

f Before using the machine, read and understand all precautions and instructions

that have been provided. Follow them carefully.

f Only persons who can understand and follow the precautions and instructions

should use or service this machine.

f Contact the manufacturer if you need assistance with operating the machine or

need replacement manuals or labels.

wc_tx003204gb.fm 3

Page 4

Foreword HDR 155

WARNING

Work site fire, burn, inhalation, and explosion hazards.

f Keep solid combustibles, such as building materials, paper, or cardboard at a

safe distance away from the machine as recommended by the instructions.

f Never use this machine in spaces which do or may contain volatile or airborne

combustibles, or products such as gasoline, solvents, paint thinner, dust particles, or unknown chemicals.

WARNING

Not for use in homes or recreational vehicles. Installing this machine in a home or

RV may result in fire, explosion, property damage, personal injury, or death.

f Operate the machine only for applications specified in Machine Description and

Intended Use.

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine model below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during installation,

operation, and maintenance of the machine.

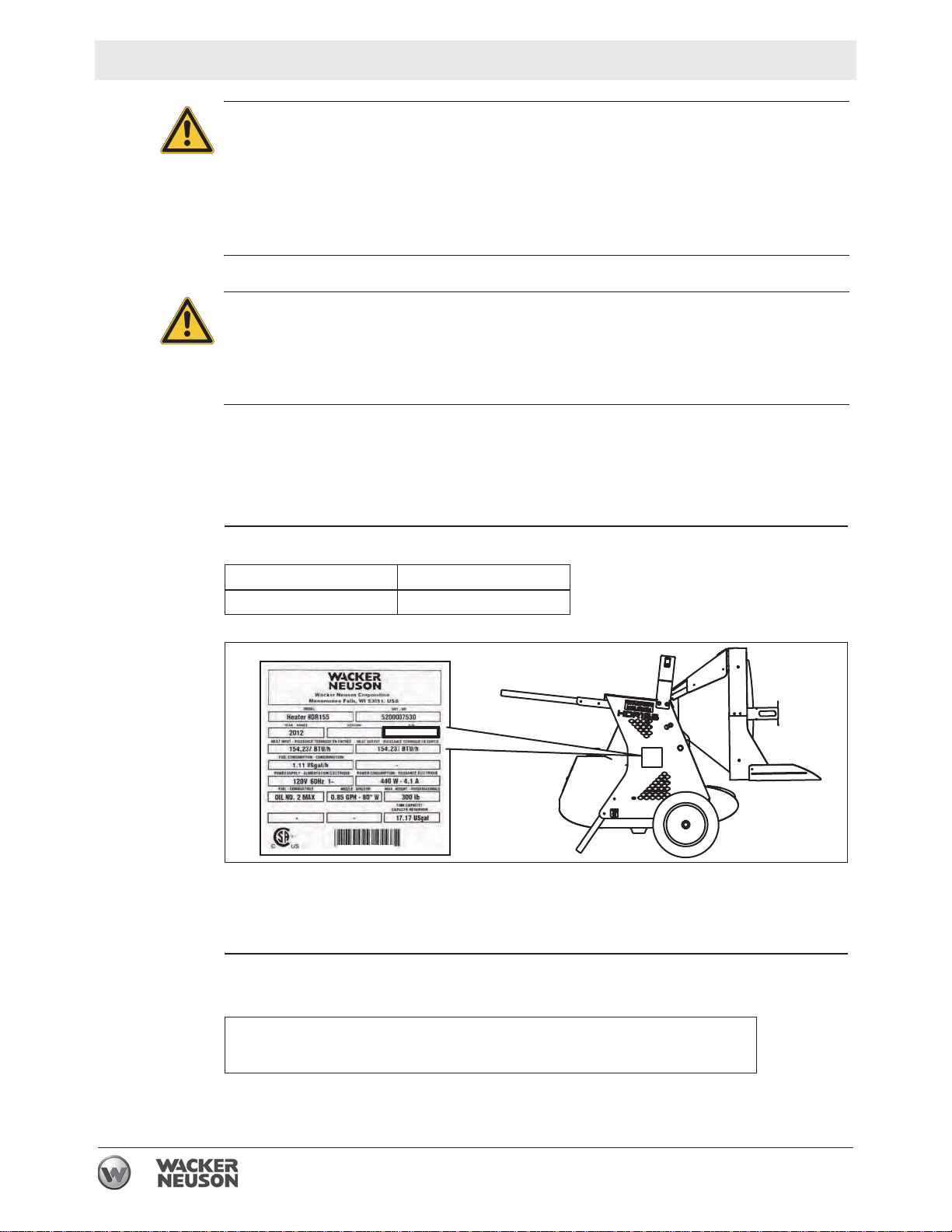

Machine

identification

Serial number

(S/N)

This manual covers the machine with the following item number:

Machine Item Number

HDR 155 5200007530

wc_gr010181

A nameplate listing the model number, item number, revision number, and serial

number is attached to this machine. The location of the nameplate is shown above.

For future reference, record the serial number in the space provided below. You will

need the serial number when requesting parts or service for this machine.

Machine

documentation

Serial Number:

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

4 wc_tx003204gb.fm

Page 5

HDR 155 Foreword

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson to

order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

Expectations

for

information in

this manual

Manufacturer’s

approval

This manual provides information and procedures to safely operate and main-

tain the above Wacker Neuson model(s). For your own safety and to reduce the

risk of injury, carefully read, understand, and observe all instructions described

in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change

any portion of this information without notice.

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker Neu-

son service center according to written instructions published by Wacker Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

wc_tx003204gb.fm 5

Page 6

Foreword HDR 155

6 wc_tx003204gb.fm

Page 7

HDR 155

Table of Contents

Foreword 3

1 Safety Information 9

1.1 Signal Words Used in this Manual ....................................................... 9

1.2 Machine Description and Intended Use ............................................. 10

1.3 Safety Guidelines for Operating the Machine ..................................... 11

1.4 Safety Guidelines for Operating Combustion Burners ....................... 14

1.5 Service Safety .................................................................................... 15

1.6 Safety Guidelines for Lifting and Transporting the Machine ............... 16

2 Labels 17

2.1 Label Locations .................................................................................. 17

2.2 Label Meanings .................................................................................. 18

3 Lifting and Transporting 22

4 Operation 23

4.1 Preparing the Machine for First Use ................................................... 23

4.2 Parts Included .................................................................................... 24

4.3 Assembling the Machine .................................................................... 25

4.4 Control / Component Locations .......................................................... 26

4.5 Adjusting the Heater Output Angle ..................................................... 27

4.6 Positioning the Machine ..................................................................... 28

4.7 Electrical and Grounding .................................................................... 30

4.8 Recommended Fuels and Fuel Blending Guide ................................. 31

4.9 Preliminary Checks ............................................................................ 31

4.10 Starting the Machine in Extremely Cold Weather ............................... 32

4.11 Starting the Machine .......................................................................... 33

4.12 Stopping ............................................................................................. 34

4.13 Operating Status Indicators ................................................................ 34

4.14 Installing and Using the Remote Thermostat ..................................... 35

5 Burner Setup 36

5.1 Removing and Installing the Burner Assembly ................................... 36

5.2 Setting Up the Burner ......................................................................... 37

5.3 Checking and Adjusting the Electrodes .............................................. 37

5.4 Replacing the Burner Nozzle .............................................................. 38

wc_bo5200009218_03TOC.fm

7

Page 8

Table of Contents

5.5 Adjusting the Air Damper ....................................................................39

5.6 Checking and Adjusting the Fuel Pressure .........................................40

HDR 155

6 Maintenance 42

6.1 Periodic Maintenance Schedule ..........................................................42

6.2 Inspecting and Cleaning the Machine .................................................43

6.3 Removing the Access Panel ...............................................................45

6.4 Replacing the Fuel Heater Filter ..........................................................46

6.5 Inspecting and Cleaning the Cadmium (CAD) Cell .............................47

6.6 Inspecting the Flame Head .................................................................48

6.7 Inspecting the Electrical Connections .................................................48

6.8 Long Term Storage .............................................................................49

7 Basic Troubleshooting 50

8 Technical Data 52

8.1 Machine ...............................................................................................52

8.2 Dimensions ..........................................................................................52

9 Schematics 53

9.1 HDR 155 ..............................................................................................53

8

wc_bo5200009218_03TOC.fm

Page 9

HDR 155 Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f To avoid death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000732gb.fm

9

Page 10

Safety Information HDR 155

1.2 Machine Description and Intended Use

Machine

description

Intended use

The HDR Heater is a direct-fired radiant heater. The machine operates on diesel

fuel. The machine consists of the following components:

Stainless steel combustion chamber

Blower

Single-stage burner

High-temperature shut-down device

Fuel tank

Safety tip switch

Fuel is consumed in a closed combustion chamber. Outside air is pulled into the

machine where it is heated. This clean, dry air is blown between the walls of the

combustion chamber to cool the machine. Access to the blower assembly is

protected by a guard fitted on the air inlet.

The HDR Heater is intended to provide heat on outdoor construction sites and in

other rugged applications. Do not use this machine indoors.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons on the work site. Machine

damage caused by misuse is not covered under warranty.

Optional

accessories

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may remain even after protective measures have been taken.

They are called residual risks. On this machine, they may include exposure to:

exhaust emissions

hot surfaces such as exhaust vents and fuel heater

fuel and fuel fumes when refueling

high voltages and arc flash

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

Wacker Neuson offers optional accessories for the machine. These accessories

include the following:

Remote thermostat

Contact your Wacker Neuson dealer for more information.

10

wc_si000732gb.fm

Page 11

HDR 155 Safety Information

1.3 Safety Guidelines for Operating the Machine

DANGER

Carbon monoxide. Using the machine indoors CAN KILL YOU IN MINUTES.

Exhaust gas contains carbon monoxide (CO). This is a deadly poison you cannot

see or smell. If you can smell the exhaust, you are breathing CO. Even if you

cannot smell the exhaust, you could be breathing CO.

f NEVER operate the machine inside an enclosed area, such as a home, tunnel,

or garage.

f ONLY use the machine outside and far away from windows, doors, and vents.

These openings can pull in exhaust.

f ALWAYS use a battery-powered or battery-backup CO alarm in nearby struc-

tures. Even when you use the machine correctly, CO may leak into nearby

structures.

f If you start to feel sick, dizzy, or weak after the machine has been running, move

to fresh air IMMEDIATELY. See a doctor. You could have carbon monoxide

poison.

Operator

training

Operator

qualifications

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

have received instruction on how to properly use the machine

are familiar with required safety devices

The machine must not be accessed or operated by:

children

people impaired by alcohol or drugs

Application

area

wc_si000732gb.fm

Be aware of the application area.

Keep unauthorized personnel, children, and pets away from the machine.

Remain aware of changing positions and the movement of other equipment and

personnel in the application area/job site.

Be aware of the application area.

Do not operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

11

Page 12

Safety Information HDR 155

Safety

devices,

controls, and

attachments

Safe

operating

practices

Only operate the machine when:

All safety devices and guards are in place and in working order.

All controls operate correctly.

The machine is set up correctly according to the instructions in the Operator’s

Manual.

The machine is clean.

The machine’s labels are legible.

To ensure safe operation of the machine:

Do not operate the machine if any safety devices or guards are missing or

inoperative.

Do not modify or defeat the safety devices.

Only use accessories or attachments that are approved by Wacker Neuson.

When operating this machine:

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

When operating this machine:

Do not operate a machine in need of repair.

Personal

Protective

Equipment

(PPE)

Machine

condition

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

Only operate the machine when:

The combustion chamber is in proper working order.

All safety devices and guards are in place and in working order.

All controls operate correctly.

The machine is set up correctly according to the instructions in the Operator’s

Manual.

The machine is clean.

The machine’s labels are legible.

When operating the machine:

Do not modify or defeat the safety devices.

Do not use worn electrical cords.

Do not use faulty fuel supplies.

Work space

Follow the guidelines below when placing the machine in the workspace.

Position the machine on a firm, noncombustible, level surface.

wc_si000732gb.fm

12

Page 13

HDR 155 Safety Information

Keep the area immediately surrounding and underneath the machine clean,

neat, and free of debris and combustible materials.

Keep the area above the machine clear of debris that could fall on the machine.

Do not position electrical cords under the machine or over the top of the

machine.

WARNING

Fire hazard. Do not move the machine while it is plugged in, even if power is lost.

f Turn off the machine, wait 10 minutes, disconnect power cord, and let it cool

completely.

While

operating the

machine

After use

Inspect the machine before startup, and monitor it regularly during operation.

Do not exceed the maximum heat output of the machine.

Disconnnect power from the machine.

Store the machine properly when it is not being used.

wc_si000732gb.fm

13

Page 14

Safety Information HDR 155

1.4 Safety Guidelines for Operating Combustion Burners

When using the machine:

Clean up any spilled fuel immediately.

Replace the fuel tank cap after refueling the machine.

Refill the fuel tank in a well-ventilated area.

Shut down the generator, if equipped, when refueling.

When using the machine:

DANGER

Carbon monoxide. Using this machine indoors CAN KILL YOU IN MINUTES.

Exhaust gas contains carbon monoxide (CO). This is a deadly poison you cannot

see or smell. If you can smell the exhaust, you are breathing CO. Even if you

cannot smell the exhaust, you could be breathing CO.

f NEVER operate the machine inside an enclosed area, such as a home, tunnel,

or garage.

f ONLY use the machine outside and far away from windows, doors, and vents.

These openings can pull in exhaust gas.

f ALWAYS use a battery-powered or battery-backup CO alarm in nearby struc-

tures. Even when you use the machine correctly, CO may leak into nearby

structures.

f If you start to feel sick, dizzy, or weak after the machine has been running, move

to fresh air IMMEDIATELY. See a doctor. You could have carbon monoxide

poisoning.

When refueling the machine:

Do not fill or drain the fuel tank near an open flame or while the machine is

running.

Do not smoke when refueling the machine.

Do not use gasoline, crankcase oil, or any oil containing gasoline.

14

wc_si000732gb.fm

Page 15

HDR 155 Safety Information

1.5 Service Safety

Service

training

Precautions

Before servicing or maintaining the machine:

Read and understand the instructions contained in all manuals delivered with

the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

Do not allow improperly trained people to service or maintain the machine.

Personnel servicing or maintaining the machine must be familiar with the

associated potential risks and hazards.

Follow the precautions below when servicing or maintaining the machine.

Read and understand the service procedures before performing any service to

the machine.

All adjustments and repairs must be completed before operation. Do not

operate the machine with a known problem or deficiency.

All repairs and adjustments shall be completed by a qualified technician.

Turn off the machine before performing maintenance or making repairs.

Machine

modifications

Replacing

parts and

labels

Cleaning

When servicing or maintaining the machine:

Use only accessories/attachments that are approved by Wacker Neuson.

When servicing or maintaining the machine:

Do not defeat safety devices.

Do not modify the machine without the express written approval of Wacker

Neuson.

Replace worn or damaged components.

Replace all missing and hard-to-read labels.

When replacing electrical components, use components that are identical in

rating and performance to the original components.

When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those parts equivalent to the original in all types of

specifications, such as physical dimensions, type, strength, and material.

When cleaning and servicing the machine:

Keep the machine clean and free of debris such as leaves, paper, cartons, etc.

Keep the labels legible.

When cleaning the machine:

Do not clean the machine while it is running.

wc_si000732gb.fm

15

Page 16

Safety Information HDR 155

Never use gasoline or other types of fuels or flammable solvents to clean the

machine. Fumes from fuels and solvents can become explosive.

Personal

Protective

Equipment

(PPE)

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

After Use

Stop the engine when the machine is not being operated.

Close the fuel valve on engines equipped with one when machine is not being

operated.

Ensure that the machine will not tip over, roll, slide, or fall when not being

operated.

Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

1.6 Safety Guidelines for Lifting and Transporting the Machine

When lifting the machine:

Make sure slings, chains, hooks, ramps, jacks, forklifts, cranes, hoists, and any

other type of lifting device used is attached securely and has enough weight-

bearing capacity to lift or hold the machine safely. See section Technical Data

for machine weight.

Remain aware of the location of other people when lifting the machine.

Only use the lifting points and tie-downs described in the Operator’s Manual.

Make sure the transporting vehicle has sufficient load capacity and platform size

to safely transport the machine.

To reduce the possibility of injury:

Do not stand under the machine while it is being lifted or moved.

Do not get onto the machine while it is being lifted or moved.

16

wc_si000732gb.fm

Page 17

HDR 155 Labels

2 Labels

2.1 Label Locations

M

I

D

E

L

G HFF

J

K

I

F

L

wc_gr010203

wc_si000733gb.fm

17

Page 18

Labels HDR 155

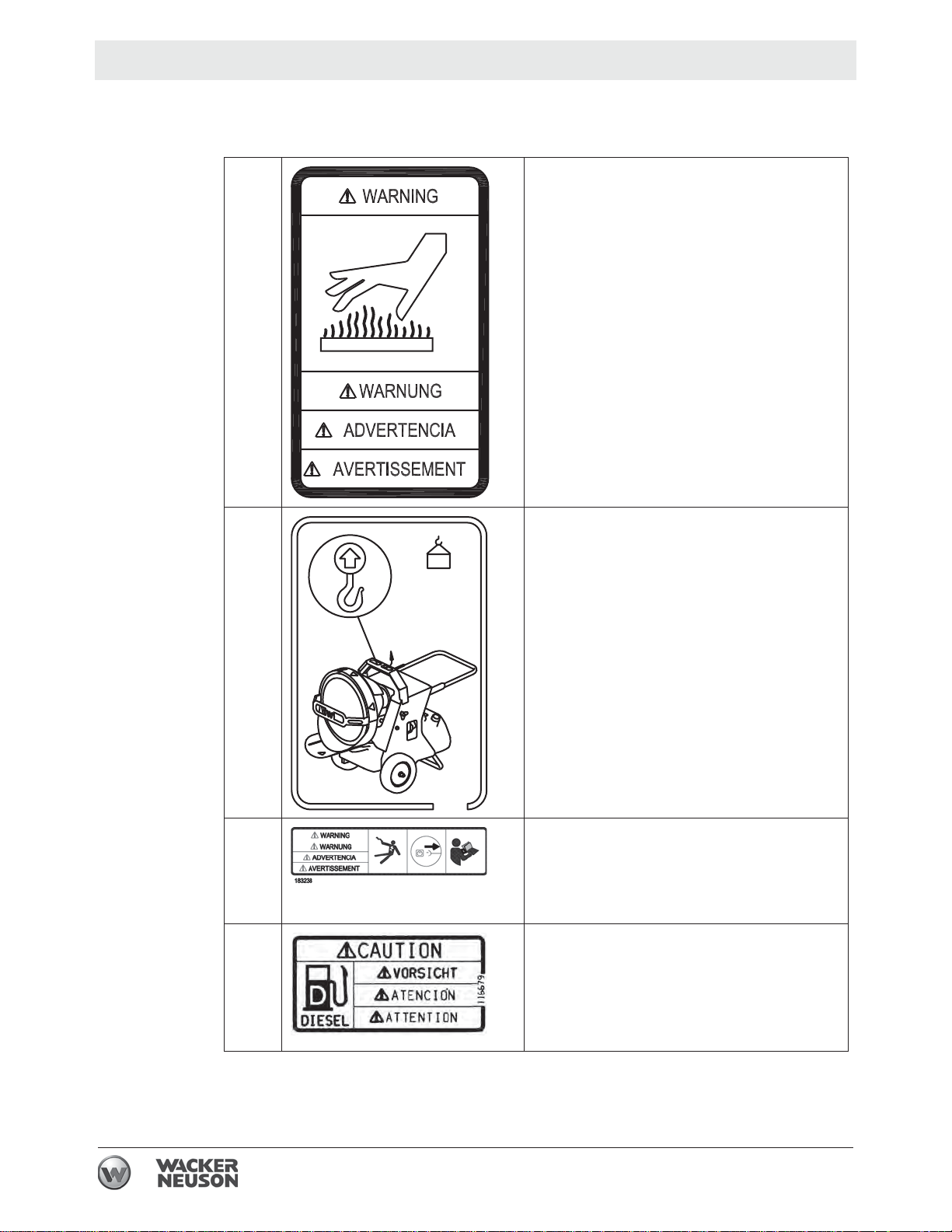

5200012779

2.2 Label Meanings

AWARNING

Hot surface

CNOTICE

Lifting point

136 kg

(300 LB)

DWARNING!

Electric shock hazard.

Disconnect power before servicing.

Read Operator’s Manual.

ECAUTION

This machine uses diesel fuel.

18

wc_si000733gb.fm

Page 19

HDR 155 Labels

113726

F Tie-down point.

113726

GDANGER

Asphyxiation hazard.

Using this machine indoors CAN KILL YOU

IN MINUTES. Burner exhaust and generator

exhaust (if the machine is equipped with a

generator) contains carbon monoxide. This is

a poison you cannot see or smell.

Never use inside an enclosed area even if

doors and windows are open.

Only use outside away from windows, doors,

and vents.

Read the Operator’s Manual before use.

HCAUTION

Hot while in operation. Do not touch. Keep

children, clothing, and combustibles away.

wc_si000733gb.fm

19

Page 20

Labels HDR 155

JWARNING

Read and understand the supplied Opera-

tor's Manual before operating this

machine.

The requirements of local authorities hav-

ing jurisdiction shall be followed.

Do not use heater in close proximity of

combustible surfaces or materials.

Ensure fresh air supply to space where

heater is used.

Equipment must be grounded.

Use only light diesel oil No. 2 or kerosene.

Do not use gasoline or crankcase drain-

ing.

Do not fill the tank while the unit is operat-

ing.

Never pull electrical socket while heater is

running.

Do not start the heater when the combus-

tion chamber is hot.

Do not start the heater when excess oil

has accumulated in the chamber.

Allow unit to cool before shutdown. Stop

heater only at control panel switch in order

to ensure automatic cooling off. Heater will

stop by itself after automatic cooling off.

Clean fuel filter regularly and drain water

from fuel tank if necessary.

When heater is first used after a long stor-

age period it might be necessary to reset

the machine once or several times by the

reset button. The button will light up; wait

two minutes before resetting.

Do not tamper with the unit. Have a com-

petent serviceman make any adjustments.

Unplug machine before removing the

cover for any maintenance.

OCAUTION

Floor guard must be fully extended before

operating heater.

Minimum clearances from combustible material must be:

30" from side and rear (air inlet) of heater.

80" from surfaces above heater.

40" from air outlet of heater

20

wc_si000733gb.fm

Page 21

HDR 155 Labels

5200012778

˚

PCAUTION

CAUTION

ATTENTION

Burn hazard. The front of the machine gets

very hot during operation. Do not touch the

1010˚

front of the machine when adjusting.

wc_si000733gb.fm

21

Page 22

Lifting and Transporting HDR 155

3 Lifting and Transporting

Requirements

Transport vehicle capable of carrying 180 lbs (81.6 kg)

Crane or lift capable of carrying 180 lbs (81.6 kg)

NOTICES Do not tow this machine.

Do not route tie-down straps or chains over the top of the machine.

Fuel may leak from the fuel tank cap during transport. Clean up any leaked fuel

before using the machine.

WARNING

Crushing hazard.

f Only qualified riggers should attempt aerial lifting of this machine.

Guidelines

Follow the guidelines below when lifting and transporting this machine.

Turn off the machine, disconnect the power cord, and let it cool completely.

Cover all openings on the machine to avoid infiltration from road debris and dust.

When using an aerial lifting rig, use the designated lifting point (b) on top of the

machine.

Use the manual transport handle when relocating the machine within the job site.

When tying down the machine, route tie-down straps or chains through the

lower frame only.

Use only the designated tie-down locations (a).

Note: There is one tie-down located behind each wheel.

b

a

wc_gr010034

22

wc_tx003205gb.fm

Page 23

HDR 155 Operation

4 Operation

DANGER

Carbon monoxide. Using the machine indoors CAN KILL YOU IN MINUTES.

Exhaust gas contains carbon monoxide (CO). This is a deadly poison you cannot

see or smell. If you can smell the exhaust, you are breathing CO. Even if you

cannot smell the exhaust, you could be breathing CO.

f NEVER operate the machine inside an enclosed area, such as a home, tunnel,

or garage.

f ONLY use the machine outside and far away from windows, doors, and vents.

These openings can pull in exhaust.

f ALWAYS use a battery-powered or battery-backup CO alarm in nearby struc-

tures. Even when you use the machine correctly, CO may leak into nearby

structures.

f If you start to feel sick, dizzy, or weak after the machine has been running, move

to fresh air IMMEDIATELY. See a doctor. You could have carbon monoxide

poison.

4.1 Preparing the Machine for First Use

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

wc_tx003206gb.fm

23

Page 24

Operation HDR 155

4

4.2 Parts Included

Q

X

W

R

S

U

T

V

ABCDEFGHI LMNO

Ref. Qty. Description Ref. Qty. Description

A*

B*

C*

D* 4

E* 4

F* 4

G* 4

H* 2

I* 4

L* 4

M* 4

4Bolt

8 Washer

4 Lock nut

Allen-head screw

Lock washer

Washer

Screw

Locking pin

Washer

Hexagonal bolt

Wing nut

N* 4

O* 4

P1

Q

R

S

T

U

V

W

X

Washer

Bolt with washer

Assembly diagram

1 Front guard

1 Lift bar

1Handle

2 Wheel

1Foot suport

1Axle

1 Floor guard

1 Bottom guard

P

wc_gr01057

*Included in hardware bag.

24

wc_tx003206gb.fm

Page 25

HDR 155 Operation

4.3 Assembling the Machine

Requirements

Procedure

Standard tools

Extra person or a lifting device capable of supporting the weight of the machine

Perform the procedure below to assemble the machine.

1. Install the handle (S) using the bolts (A), washers (B), and lock nuts (C).

2. Install the lift bar (R) using the allen-head screws (D), lock washers (E), and

washers (F).

3. Install the front guard

4. Install the floor guard (W) using the wing nuts (M) and washers (N).

5. Install the foot support (U) using the screws (G).

6. Slide the axle (V) through the holes on both sides of the machine and secure it

using the hexagonal bolts (L).

7. Install washers (I) on both ends of the axle then slide the wheels (T) onto the

shaft. Secure the wheels using the remaining washers (I) and locking pins (H).

(Q)

and bottom guard

R

(X)

using the bolts with washers

S

C

B

(O)

.

B

A

O

Q

F

E

D

X

G

W

T

N

N

U

V I

MM

L

ABCDEFGHI LMNO

I

H

wc_tx003206gb.fm

wc_gr010572

25

Page 26

Operation HDR 155

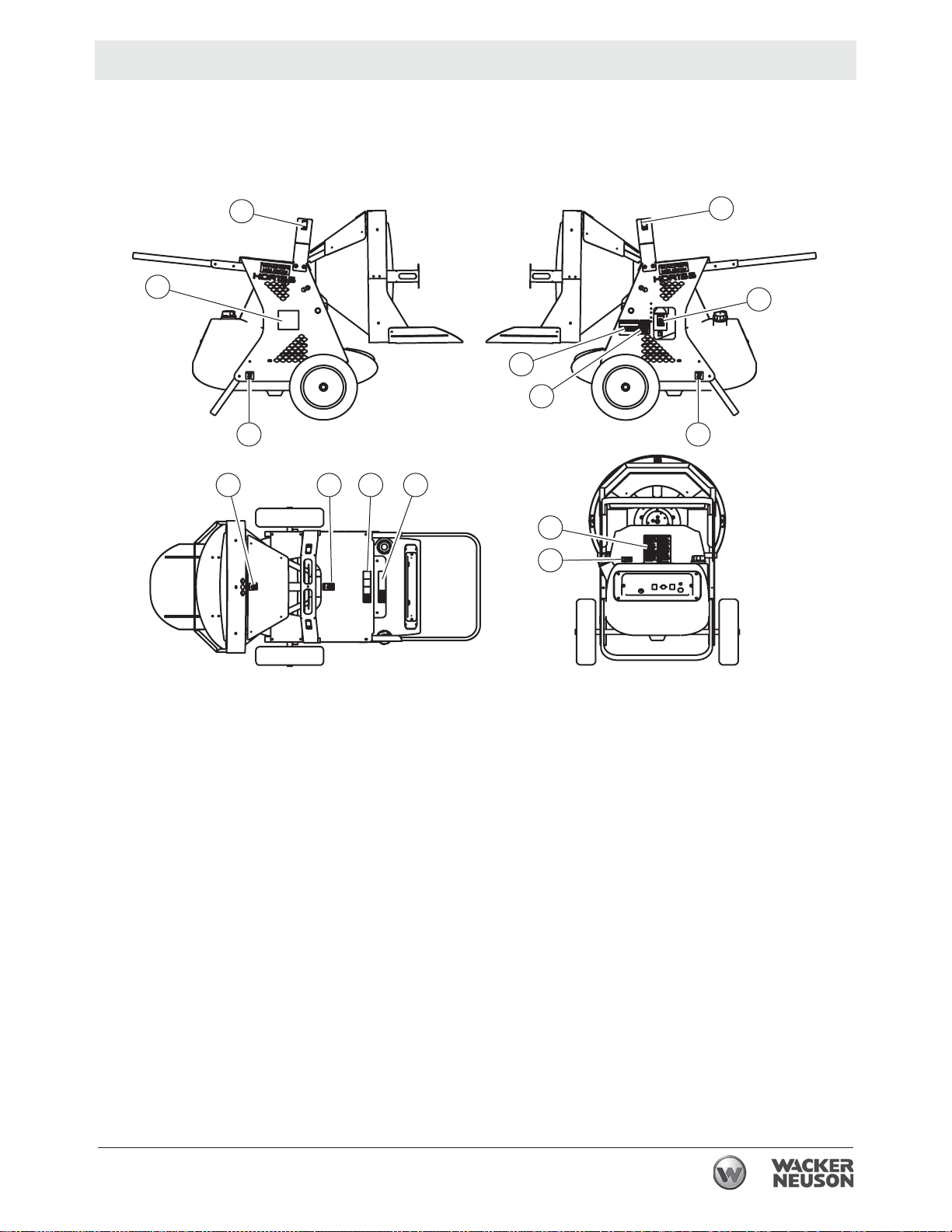

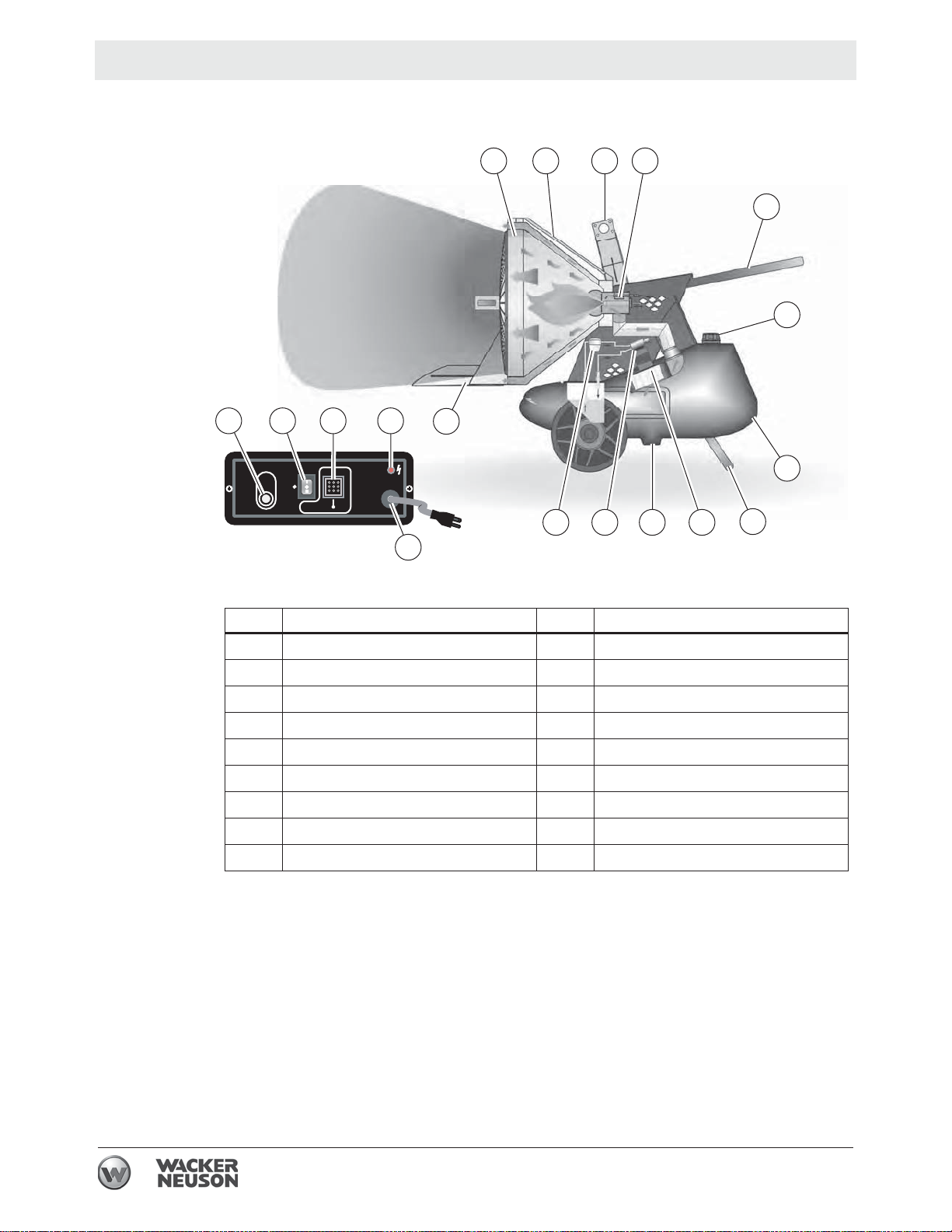

4.4 Control / Component Locations

a b c d

e

f

r q p o

ON

RESET

ON

m

l k

j i

h

n

wc_gr009909

Ref Description Ref Description

a Combustion chamber j Drain plug

b Upper guard k Fuel pump

c Lifting device l Fuel filter

d Burner (flame head) m Lower (floor) guard

e Transport handle n Power cord

f Fuel tank cap o Power indicator

g Fuel tank p Thermostat receptacle

h Support q Operation mode switch

i Fan r Burner fault lamp and reset button

g

26

wc_tx003206gb.fm

Page 27

HDR 155 Operation

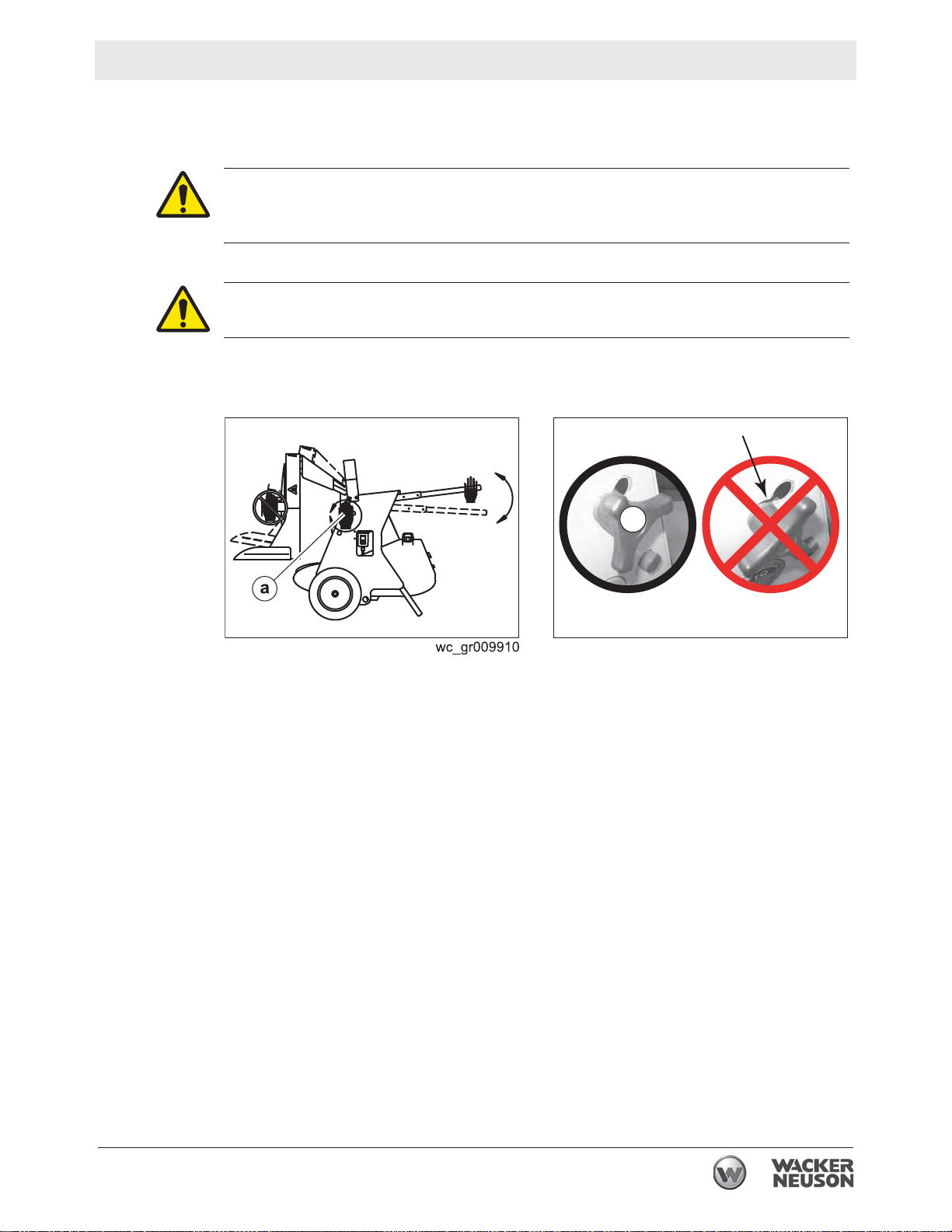

4.5 Adjusting the Heater Output Angle

Requirement

Procedure

Heater on a level surface.

CAUTION Pinch hazard. Several areas of the machine present pinching hazards if

not properly alligned and secured.

f Be sure to align and secure the machine properly when adjusting.

CAUTION Burn hazard. The front of the machine gets very hot during operation.

f Do not touch the front of the machine while adjusting.

Follow the procedure below to adjust the heater ouput angle.

1. Loosen the locking handles (a).

o

10

a

wc_gr010069

2. Tilt the heater up or down (maximum 10°) until the desired angle is achieved.

3. Tighten the locking handles (a) only when allignment is correct.

wc_tx003206gb.fm

27

Page 28

Operation HDR 155

4.6 Positioning the Machine

DANGER

Carbon monoxide. Using the machine indoors CAN KILL YOU IN MINUTES.

Exhaust gas contains carbon monoxide (CO). This is a deadly poison you cannot

see or smell. If you can smell the exhaust, you are breathing CO. Even if you

cannot smell the exhaust, you could be breathing CO.

f NEVER operate the machine inside an enclosed area, such as a home, tunnel,

or garage.

f ONLY use the machine outside and far away from windows, doors, and vents.

These openings can pull in exhaust.

f ALWAYS use a battery-powered or battery-backup CO alarm in nearby struc-

tures. Even when you use the machine correctly, CO may leak into nearby

structures.

f If you start to feel sick, dizzy, or weak after the machine has been running, move

to fresh air IMMEDIATELY. See a doctor. You could have carbon monoxide

poison.

CO Alarms

WARNING

Fire hazard. Do not move the machine while it is plugged in, even if power is lost.

f Turn off the machine, wait 10 minutes, disconnect the power cord, and let it cool

completely.

WARNING

Fire hazard. Machines positioned on a hill or an incline may slide, break away or

roll over.

f Do not position the machine on a hill or an incline.

WARNING

Explosion and fire hazard. Risk of severe injury or death.

f Do not operate the machine near flammable vapors, fuels, or combustibles.

Because this machine produces carbon monoxide (CO), Wacker Neuson

recommends that CO alarms be installed in all structures in close proximity to the

machine. CO alarms provide an extra measure of protection against this poison

that you cannot see or smell.

Install battery-operated CO alarms or plug-in CO alarms with battery backup,

according to the manufacturer’s instructions. CO alarms should be certified to the

requirements of the latest safety standards (UL 2034, IAS 6-96, or CSA 6.19.01).

Test the CO alarm batteries monthly.

This procedure continues on the next page.

wc_tx003206gb.fm

28

Page 29

HDR 155 Operation

Continued from the previous page.

Requirements

Guidelines

Tip-over

protection

Position the machine:

So that burner exhaust will not enter nearby structures.

So that the machine does not block traffic.

So that the machine is not close to any combustibles or flammable vapor.

So that the machine is not exposed to high levels of dust or airborne debris.

So that all of the machine’s access doors/panels may be accessed.

So that the cord does not pose a tripping hazard, and so the cord cannot be

damaged by machines or other equipment on the job site.

So that the machine is not sitting in pooled water or deep snow.

Machine must be on flat, firm surface.

Observe the following guidelines when positioning the machine for operation.

Installer must be familiar with all applicable laws, codes, regulations, or other

restrictions regarding installation of direct-fired radiant heaters.

Install wedge blocks under the wheels to prevent movement.

Installation must adhere to proximity restrictions.

This machine features tip-over protection. Operation is disabled if the machine tips

past thirty five degrees from the horizontal. Return the machine to a horizontal

position to resume operation.

Proximity

restrictions

The machine must be located a safe distance from any other structures, vehicles,

materials or other combustible surfaces. The following proximity restrictions apply

for all machine installations.

30" (0.76 m) from side and rear (air inlet) of heater

80" (2.03 m) from surfaces above heater

40" (1.02 m) from air outlet of heater

20' (6 m) from outlet to external fuel container

wc_tx003206gb.fm

29

Page 30

Operation HDR 155

4.7 Electrical and Grounding

WARNING

Fire and electric shock hazards. The use of an innappropriate power supply, or

undersized extension cords, can lead to fire and electric shock. Fire and electric

shock can cause severe injury.

f Before use, ensure that the machine is properly connected to an appropriate

power source and grounded per the requirements provided below.

f Do not use undersized extension cords.

Electrical

requirements

Grounding

requirements

Ensure that the machine is connected to a reliable, consistent source of electric

power.

The electric power source must be grounded per the requirements below and

connected to a freely accessible circuit breaker.

Ensure that extension cords (if used) are properly sized for the installation. Do

not use worn, bare, or frayed cords!

Restrictions for extension cords:

Use only 3-wire type extension cords with heavy-duty plugs.

The maximum length of extension cord usage per circuit is 30 m (100 ft).

Use 12-gauge extension cords for lengths up to 15 m (50 ft).

Use 10-gauge extension cords for lengths up to 30 m (100 ft).

Electrical grounding must comply with the National Electric Code ANSI/NFPA 70

or the CSA C22.1 Canadian Electrical Code, Part 1.

CAUTION

Burn hazard. The self-regulating fuel heater, located inside the fuel filter canister,

will initiate when power is connected to the machine. The surface of the fuel filter

canister may become very hot.

f Use caution when working with the fuel filter canister.

Connecting

power

Perform the procedure below to connect power to the machine.

1. Verify that the operation mode switch is in the OFF (0) position.

2. Connect the main power cord cord to a properly-rated power source.

Note: If the ambient temperature is below freezing, wait 10–30 minutes before

proceeding.

wc_tx003206gb.fm

30

Page 31

HDR 155 Operation

4.8 Recommended Fuels and Fuel Blending Guide

Low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner

ignition failure and/or burner fuel pump damage. Always use the proper fuel for the

conditions.

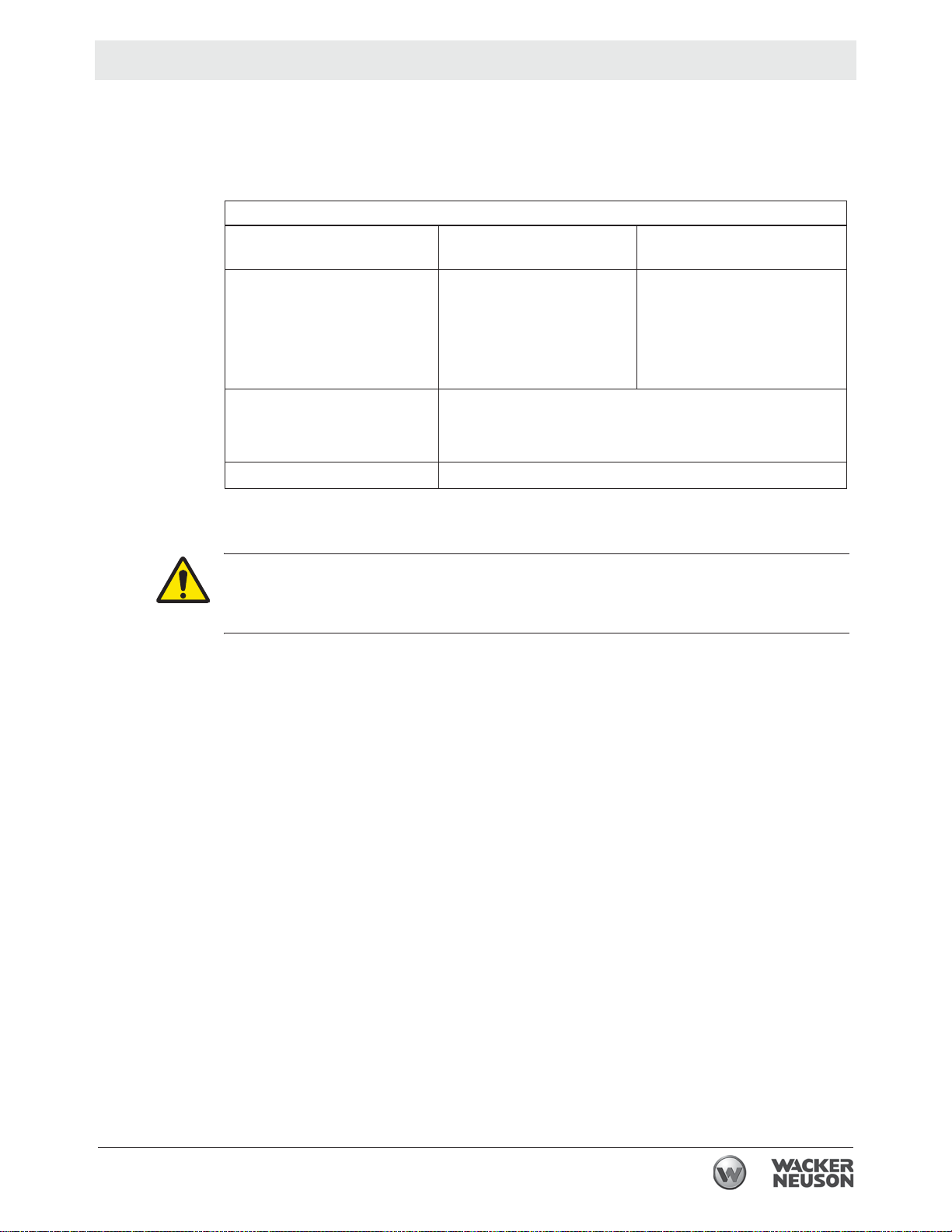

Fuel Blend Guide

Lowest expected ambient

temperature °F (°C)

Below 5 (-15) 50-50 blend of #2 diesel

Generator-powered Shore-powered

100% #1 diesel plus

and #1 diesel, plus

additives

OR

50-50 blend #2 diesel and

K1 kerosene, plus

additives

additives

OR

100% K1 kerosene,

plus additives

5 to 25 (-15 to -4) 70-30 blend of #2 diesel and #1 diesel, plus additives

Above 25 (-4) Winter-blend diesel

NOTICE: Do not use B20 or any other type of biodiesel fuel in this machine.

CAUTION

Fire hazard.

f Do not use gasoline, crankcase oil, or any oil containing gasoline.

4.9 Preliminary Checks

Checks

Before starting the machine, check the following items.

Fuel tank full

Fuel tank cap secure

Operation mode switch in the OFF position

Power supply connected

Remote thermostat (if applicable) installed

Lower (floor) guard fully extended

Reset button illuminated green

Note: If the button is illuminated red, it must be pressed to reset the machine.

OR

70-30 blend of #2 diesel and K1 kerosene,

plus additives

wc_tx003206gb.fm

31

Page 32

Operation HDR 155

4.10 Starting the Machine in Extremely Cold Weather

Cold weather

Preheating

the fuel

Troubleshooting

In temperatures below 32°F (0°C), it may be necessary to preheat the fuel inside

the fuel filter canister. The fuel filter canister is equipped with a low-wattage heating

element specially designed for this purpose. See below for instructions.

.

WARNING

Burn hazard. The external surface of the machine and fuel filter may be hot.

f Wear safety gloves when handling the machine components.

Note: Excess heating may increase the need for maintenance. See topics

“Replacing the Fuel Filter” and “Replacing the Burner Nozzle”.

To preheat the fuel, carry out the following procedure.

1. Connect power to the machine. See topic Connecting Power to the Machine

(Preheating).

2. Wait 20–30 minutes—longer for colder temperatures.

3. Start the machine. See topic Starting the Machine.

Note: In extreme wind, the machine may need to be temporarily blocked from the

wind in order to start.

1. If the burner does not start on the first attempt, allow the power-on sequence to

cycle again.

2. If, after the second power-on sequence completes, the machine will not fire,

move the power switch to the OFF position.

3. Wait another 20–30 minutes and attempt to start the machine again.

32

wc_tx003206gb.fm

Page 33

HDR 155 Operation

4.11 Starting the Machine

Requirements

Procedure

Machine properly positioned

Power connected

Pre-starting checks completed

WARNING

Burn hazard. The external surface of the machine and fuel filter may be hot.

f Wear safety gloves when handling the machine components.

To start the machine, follow the procedure below.

1. Select an operation mode.

a. Continuous heat mode (I)

b. thermostat mode (II)

ON

ON

ON

RESET

ON

Operational

sequence

ON

ON

wc_gr010009

The following sequence of events will occur.

1. The burner blower will start.

2. The burner will start firing.

In applications in which the remote thermostat is not being used (I), the

burner will fire continuously.

In applications in which the remote thermostat is being used (II), the burner

will fire until the air temperature of the application area reaches the target

temperature set by the remote thermostat. At that time, the burner will shut

off. When the air temperature of the application area falls below the target

temperature set by the remote thermostat, the burner will refire. The process

continues as long as there is fuel for the burner.

wc_tx003206gb.fm

33

Page 34

Operation HDR 155

4.12 Stopping

Procedure

Follow the procedure below to stop the machine.

WARNING

Electric shock hazard. Electric power is still active at the blower even when the

machine is turned OFF.

f Remove all electric power to the machine before servicing the machine.

1. Turn the operation mode switch to the OFF (0) position (c).

Shut-down

sequence

The following sequence of events will occur after turning the machine off.

1. The burner will shut down.

2. The blower will stop when the machine is sufficiently cool.

4.13 Operating Status Indicators

Overview

Two lamps (a, g) on the control panel display the operating status of the machine.

ON

c

ON

Burner fault

lamp

Power

indicator

ga

ON

RESET

ON

wc_gr010010

The burner fault lamp / reset button (a) is illuminated while the machine is

operating.

If the burner fault lamp / reset button is green, the machine is operating

normally.

If the burner fault lamp / reset button is red, the machine is in a burner lock-out

state. The burner lock-out must be cleared before machine operation can

resume.

To clear a burner lock-out, press and hold the burner fault lamp / reset button until

the lamp goes out.

The power indicator (g) illuminates if the supply power is present.

See Basic Troubleshooting or contact Wacker Neuson for additional help if

necessary.

34

wc_tx003206gb.fm

Page 35

HDR 155 Operation

c

4.14 Installing and Using the Remote Thermostat

Requirements

Procedure

Remote thermostat

Pre-starting checks complete

Follow the procedure below to install and use the remote thermostat.

1. Remove the thermostat receptacle plug (a) from the control panel receptacle.

2. Connect the remote thermostat (b) to the control panel receptacle (c).

3. Set the sensor end (d) within the area to be heated.

4. Adjust the target temperature with the dial (e).

b

a

d

Thermostat

adapter

e

wcghi_gr007373

An adapter is available to convert the proprietary thermostat connection to an

Edison plug-style connection for use with commonly available thermostats. This

adapter can be purchased using Wacker Neuson part #5200007098.

NOTICE: The thermostat adapter is designed for use ONLY with a thermostat. To

avoid damaging the machine, do not plug any other equipment into the thermostat

adapter.

wc_tx003206gb.fm

35

Page 36

Burner Setup HDR 155

5 Burner Setup

5.1 Removing and Installing the Burner Assembly

Requirements

Procedure

Removal

Machine shut down and cool

Machine properly positioned

CAUTION Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Before performing any maintenance on the burner assembly, it must be removed

from the machine. To remove or install the burner assembly, perform the follwing

procedures.

1. Shut down the machine and allow it to cool.

2. Disocnnect the power cord.

3. Remove the access panel. See Removing the Access Panel.

d

c

e

e

b

Installation

b

wc_gr010072

4. Remove the screw (d) to disconnect the ground wire (c) from the burner

assembly (b).

5. Rotate the burner assembly counter-clockwise and remove it from the flame

head and air tube assembly (e).

6. Perform the required maintenance.

Note: Refer to the maintenance procedures in this manual.

7. Reinstall the burner assembly. Refer to hte steps below to install the burner

assembly.

1. Place the burner assembly into the flame head and air tube assembly.

2. Rotate the burner assembly clockwise to lock into place.

3. Install the ground wire using the screw (d).

4. Reinstall the access panel.

36

wc_tx003210gb.fm

Page 37

HDR 155 Burner Setup

5.2 Setting Up the Burner

Factory

settings

5.3 Checking and Adjusting the Electrodes

Machine Nozzle size Fuel pressure

psi bar

HDR 155

0.85 (80ºW) gph

174 12

Air damper

2

Requirements

When to

inspect

Procedure

Machine shut down

Power disconnected

Burner cool

Inspect the electrodes on your machine every two weeks or after every 50 hours of

operation. The condition of the electrodes will drastically affect your machine’s

ability to fire efficiently.

Perform the procedure below to inspect or adjust the electrodes.

1. Remove the burner assembly. See topic Removing and Installing the Burner.

2. Inspect the condition of the electrode tips (a). Replace any damaged or worn

electrodes.

3. Verify the electrode gap is set to the recommended measurement.

wc_tx003210gb.fm

wc_gr010078

Refer to the table below to determine the condition of the electrode tips.

Condition Task

None; ok as is

None; ok as is

Replace

37

Page 38

Burner Setup HDR 155

5.4 Replacing the Burner Nozzle

When

Requirements

Procedure

Replace the burner nozzle annually, or if it is damaged.

Machine shut down and cool to the touch

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

To replace the burner nozzle, perform the following procedure.

1. Remove the burner. See topic Removing and Installing the Burner Assembly.

2. Loosen the screw (d) and remove the turbulator (c).

3. Place an adjustable wrench on the nozzle base (a).

4. Place another adjustable wrench on the nozzle (b).

5. Rotate the nozzle counter-clockwise and remove it from the assembly.

Result

6. Install the new nozzle (b) onto the nozzle base (a).

7. Tighten the nozzle (b) using an adjustable wrench. Rotate the wrench

clockwise.

8. Re-install the turbulator (c) and tighten the screw (d).

9. Reinstall the burner assembly. See topic Removing and Installing the Burner

Assembly.

The burner nozzle has been replaced.

wc_tx003210gb.fm

38

Page 39

HDR 155 Burner Setup

5.5 Adjusting the Air Damper

When

Factory

settings

Effects

Procedure

Adjust the air damper when burner performance is in question.

Air damper: 2

Note: This parameter is factory-set.

The air setting has the following effects on combustion.

Higher O

percentage (excess air settings) lowers soot production but raises

2

stack temperature and reduces efficiency: lean mixture.

Lower O

percentage (inadequate air settings) increases efficiency and lowers

2

stack temperature but may cause soot build-up: rich mixture.

Follow the procedure below to adjust the air damper.

1. Initial setting of the air damper should be performed with the machine shut

down.

2. Remove the burner. See topic Removing and Installing the Burner Assembly.

3. Loosen the screws (a).

Result

wc_tx003210gb.fm

4. Using the position pointer (b) to determine position, rotate the air damper

to a higher number to decrease air volume.

to a lower number to increase air volume.

5. Tighten the screws (a).

6. After the air damper has been adjusted, reinstall the burner. See topic

Removing and Installing the Burner Assembly.

The air damper has now been adjusted.

39

Page 40

Burner Setup HDR 155

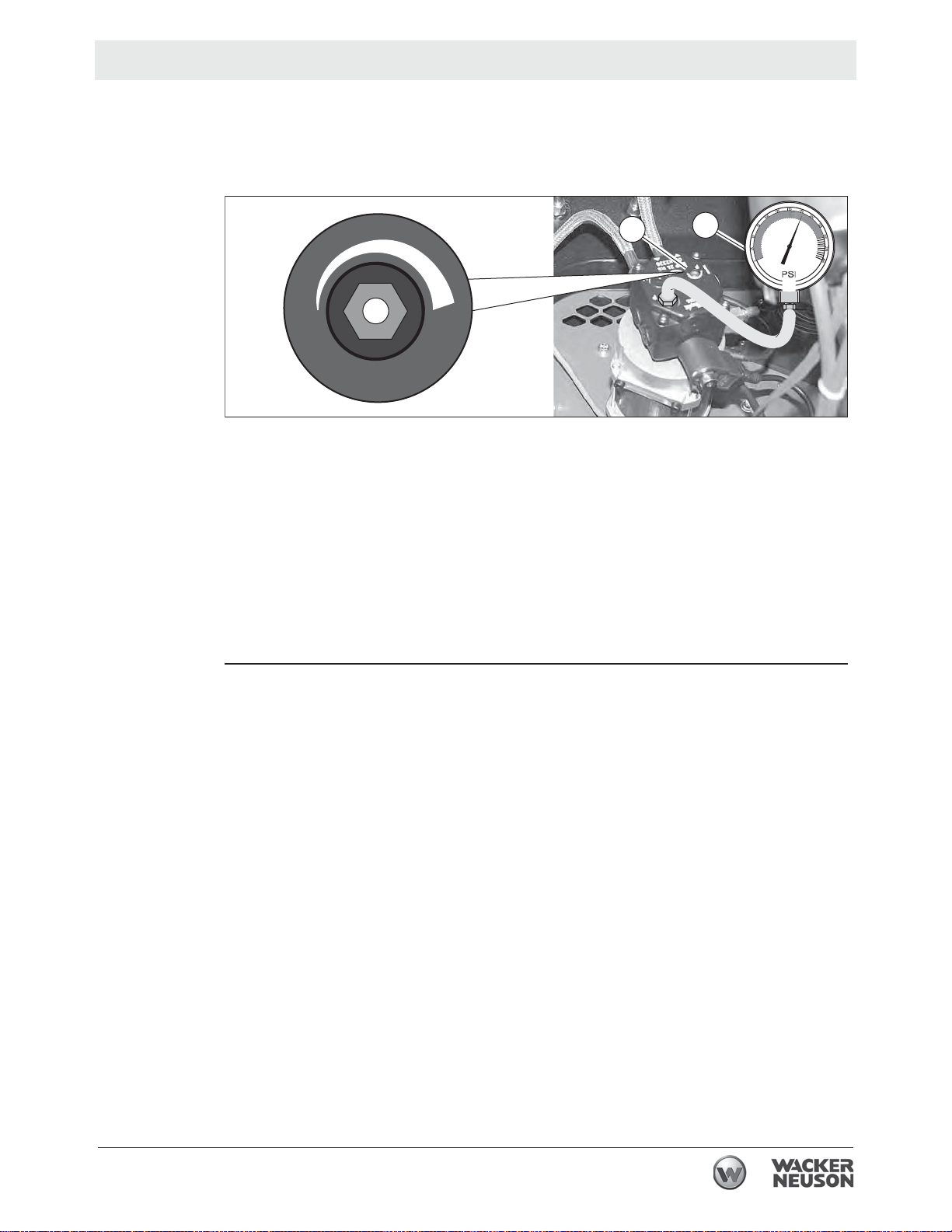

5.6 Checking and Adjusting the Fuel Pressure

When

Requirements

Background

Procedure

Check the fuel pressure if the machine emits smoke during operation.

Machine shut down and cool to the touch

Power disconnected

Fuel pressure gauge

The information below will show you how to check the fuel pressure on your

machine. Incorrect fuel pressure will result in too much fuel, or too little fuel, to be

supplied to the burner. This will cause the machine to smoke during operation.

To check and/or adjust the fuel pressure, carry out the following procedure.

1. Remove the access panel. See topic Removing the Access Panel .

2. Disconnnect the wire from the solenoid valve (a).

3. Remove the threaded plug (b) from the pressure test port using a hex key

wrench. Set the plug aside to be re-installed later.

d

d

c

b

a

wc_gr010075

4. Install a pressure gauge with adapter (c) in the pressure test port.

5. Start the machine. See topic Starting the Machine.

6. Observe the fuel pressure setting during the first 15 seconds of operation. Refer

to topic Technical Data for the recommended settings.

If Then

The fuel pressure needs adjustment,

The fuel pressure is within specifications skip to step 10.

Note: The machine will shut down at this point and enter safety lock-out mode.

This procedure continues on the next page.

continue to step 7.

40

wc_tx003210gb.fm

Page 41

HDR 155 Burner Setup

Continued from the previous page.

7. Adjust the fuel pressure using the adjusting screw (d).

Clockwise increases fuel pressure

Counter-clockwise decreases fuel pressure

d

_

d

+

c

P

wc_gr010095

NOTICE: Do not adjust the fuel pressure to a setting outside the operational

parameters.

8. Press the reset button.

9. Repeat steps 5–6 to re-check the settings.

10.Remove the pressure gauge (c) from the pressure test port and re-install the

threaded plug (b).

11.Re-connect the solenoid wire.

12.Re-install the access cover.

Result

The fuel pressure has been adjusted.

wc_tx003210gb.fm

41

Page 42

Maintenance HDR 155

6 Maintenance

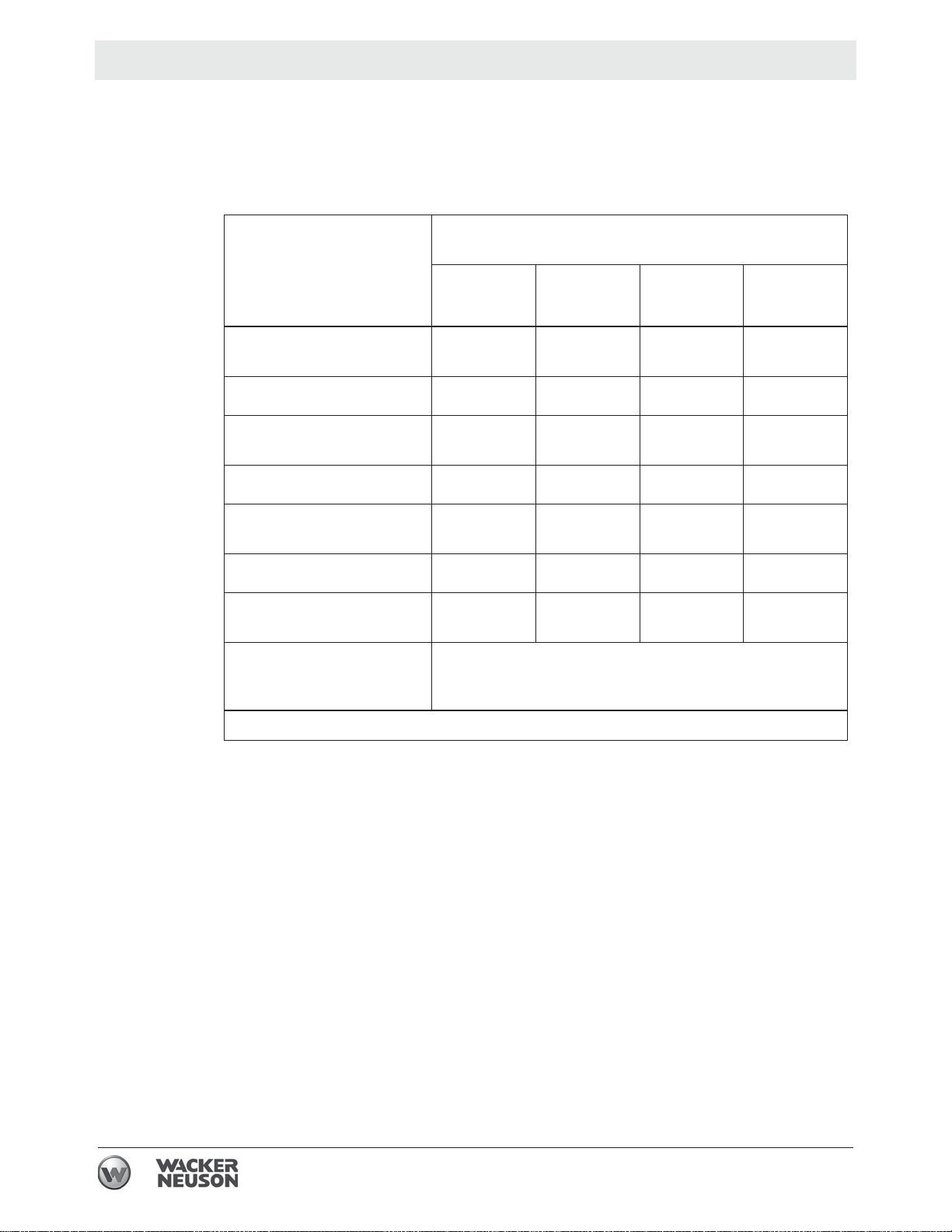

6.1 Periodic Maintenance Schedule

Interval*

(Hours of service)

Daily 2 Weeks 6 Months Yearly

Task

Inspect and clean the

machine.

Inspect the fuel hoses.

Check fuel level and

pressure.

Clean the fuel filter.

Inspect electrical

components.

Replace the burner nozzle.

Replace the fuel heater

filter.

Clean and check/adjust

burner electrode settings;

replace if necessary.

Use whichever comes first, calendar time or service hours.

*

--- (50) (1000) (1200)

33

3

3

3

3

3

3

As needed or upon changing job sites;

see chapter Burner Setup.

42

wc_tx003207gb.fm

Page 43

HDR 155 Maintenance

6.2 Inspecting and Cleaning the Machine

When

Requirements

Every 50 hours or as needed.

Machine shut down

Machine cool

Machine properly positioned

DANGER

Fire and explosion hazard. Residue from flammable materials such as solvents or

gasoline could ignite and cause a fire or an explosion.

f Do not use flammable materials or solvents to clean the machine.

WARNING

Electric shock hazard. A machine with power connected can cause electric shock.

f Unplug the machine before servicing.

CAUTION

Hot surface hazard. The external surface of the machine or fuel filter canister may

be hot.

f Allow the machine to cool before servicing.

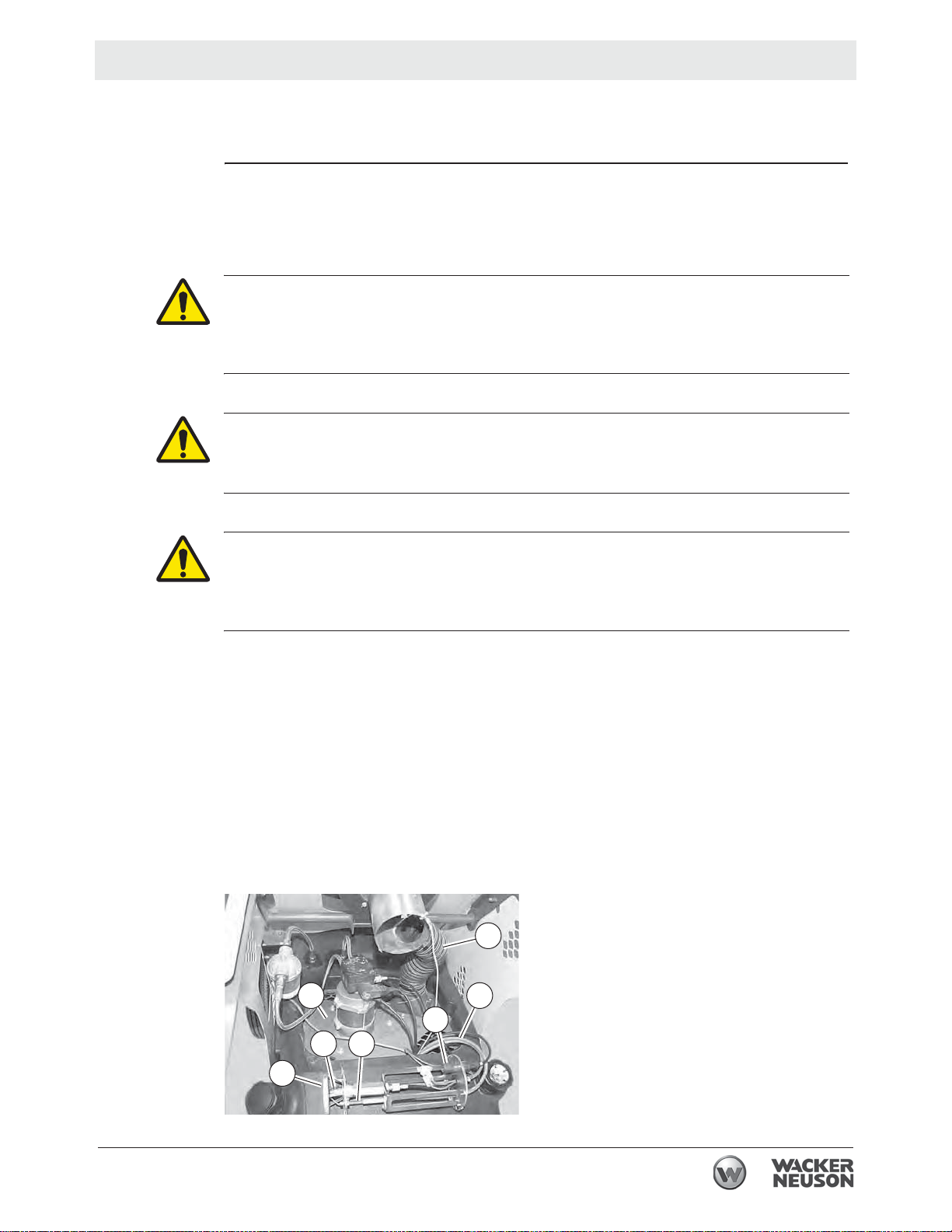

The following internal components of the machine require regular cleaning to

maintain optimum performance.

Enclosure (all areas must be free of dirt and debris)

Ventilator (b)

High-tension connectors (c)

CAD (Cadmium) cell (d)

Flame head (e)

Electrodes (f)

Burner nozzle (g)

Air tube (h)

h

b

c

d

g f

e

wc_tx003207gb.fm

wc_gr010098

43

Page 44

Maintenance HDR 155

Procedure

Result

Perform the procedure below to clean the interior components of the machine.

1. Remove the access cover. See topic Removing the Access Panel.

2. Use compressed air to clean the enclosure and ventilator (b).

3. Inspect and clean the high-tension connnectors and wires (d). Replace any

damaged or worn components.

4. Remove the burner assembly. See topic Removing and Installing the Burner

Assembly.

5. Check/clean the CAD cell. See topic Inspecting and Cleaning the CAD Cell.

6. Check electrodes. See topic Checking and Adjusting the Electrodes.

7. Check the burner nozzle. See topic Replacing the Burner Nozzle.

The machine has been cleaned.

44

wc_tx003207gb.fm

Page 45

HDR 155 Maintenance

6.3 Removing the Access Panel

Requirements

Overview

Procedure

Machine shut down and cool

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Your machine is equipped with removable access panels. The access panels must

be removed in order to maintain and repair certain machine components such as

the burner, electric motor, and fuel pump.

Follow the procedure below to remove the access panel.

1. Shut down the machine and allow it to cool.

2. Disconnect the power cord from the power source.

3. Remove the four bolts that fasten the lift bar (a), remove the lift bar, and set it

aside.

4. Remove the four screws (b) that fasten the access panel (c), remove the panel

and set it aside.

c

b

a

wc_gr010071

5. Perform the required maintenance.

6. When maintenance is complete, re-install the access panel and fasten it with the

screws.

wc_tx003207gb.fm

45

Page 46

Maintenance HDR 155

6.4 Replacing the Fuel Heater Filter

Requirement

Procedure

Machine shut down and cool

CAUTION Hot surface hazard.

The external surface of the fuel filter canister may be hot.

f Allow the machine to cool before servicing.

WARNING Hot fluids.

The fuel inside the fuel filter canister may be hot.

f Wear safety glasses.

Follow the procedure below to change the fuel heater filter.

1. Shut down the machine and allow it to cool.

2. Remove the screw that secures the cover to the housing (a).

Result

wc_gr010015

3. Remove the filter (b).

4. Inspect the O-ring (c). Replace it if it is cracked, damaged, or deformed.

5. Install the new filter.

6. Re-install the cover.

The procedure to replace the fuel heater filter is now complete.

wc_tx003207gb.fm

46

Page 47

HDR 155 Maintenance

0

6.5 Inspecting and Cleaning the Cadmium (CAD) Cell

Requirements

When

Machine shut down and cool to the touch

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Inspect and clean the CAD cell as needed, or while performing other scheduled

maintenance procedures.

To inspect and clean the CAD cell, carry out the following procedure.

1. Remove the access panel. See topic Removing the Access Panel.

2. Twist and pull out the plastic protective holder (1) off the base of the burner

assembly. The CAD cell (2) is inside this plastic holder.

1

2

Result

1

ghi_gr00737

3. Inspect the CAD cell for cleanliness. Be sure the cell is free of debris or soot.

4. Clean the CAD cell if necessary.

NOTICE: Do not use solvents or liquids to clean the CAD cell; use a soft dry cloth.

5. Reinstall the plastic protective holder onto the base of the burner assembly.

The CAD cell is now clean.

wc_tx003207gb.fm

47

Page 48

Maintenance HDR 155

2

6.6 Inspecting the Flame Head

Requirements

When

Procedure

Machine shut down and cool to the touch

Machine properly positioned

CAUTION

Hot surface hazard. The machine surfaces may be hot.

f Allow the machine to cool for a minimum of ten minutes before touching it.

Inspect the flame head prior to the first seasonal use, during regular maintenance,

and as needed.

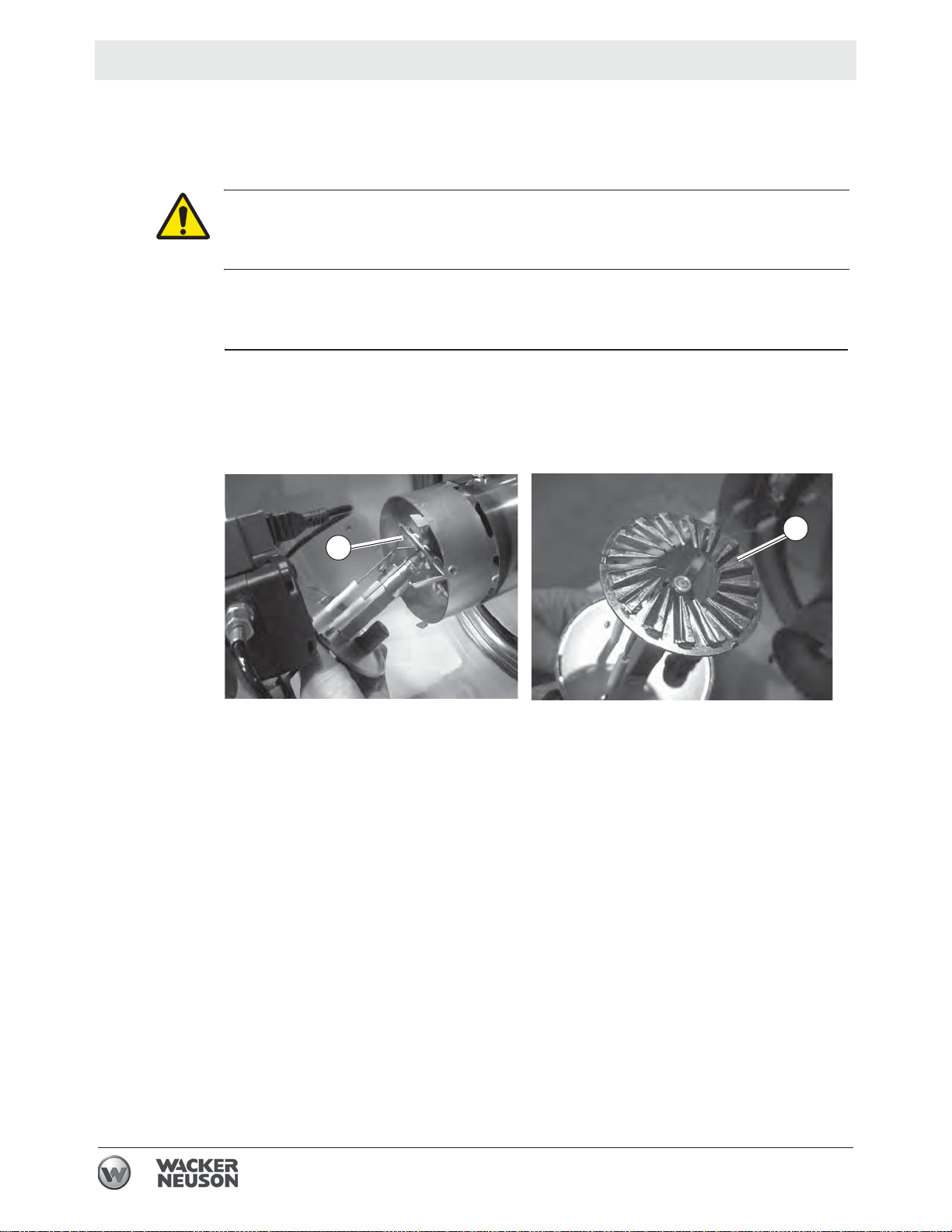

To inspect the flame head (a), carry out the following procedure.

1. Remove the access panel. See topic Removing the Access Panel .

2. Remove the burner assembly. See topic Removing and Installing the Burner

Assembly. The flame head is attached.

a

a

3. Inspect the flame head for the following:

Wear. Replace if necessary.

Cleanliness. Clean the flame head if necessary.

Thermal stress. Replace if necessary.

4. Re-install the burner assembly. See topic Removing and Installing the Burner

Assembly.

6.7 Inspecting the Electrical Connections

After disconnecting the power cord, check all electrical connections for the

following:

Proper connections. Be sure that all connections are complete and tight.

Corrosion. Clean or replace if necessary.

Damaged wires/connectors. Replace if necessary.

Proper ground.

ghi_gr00738

48

wc_tx003207gb.fm

Page 49

HDR 155 Maintenance

6.8 Long Term Storage

Introduction

When

Preparing for

storage

Stabilizing the

fuel

Extended storage of equipment requires preventative maintenance. Performing

these steps helps to preserve machine components and ensures the machine will

be ready for future use. While not all of these steps necessarily apply to this

machine, the basic procedures remain the same.

Prepare your machine for extended storage if it will not be operated for 30 days or

more.

Follow the procedures below to prepare your machine for storage.

Complete any needed repairs.

After completing the procedures listed above, fill the fuel tank completely and add a

high-quality stabilizer to the fuel.

Choose a stabilizer that includes cleaning agents and additives designed to

coat/protect the cylinder walls.

Make sure the stabilizer you use is compatible with the fuel in your area, fuel

type, grade and temperature range. Do not add extra alcohol to fuels which

already contain it (for example, E10).

Use a stabilizer with a biocide to restrict or prevent bacteria and fungus growth.

Add the correct amount of stabilizer per the manufacturer’s recommendations.

Storing the

machine

Perform these remaining steps to store your machine.

Wash the machine and allow it to dry.

Move the machine to a clean, dry, secure storage location. Block or chock

wheels to prevent machine movement.

Use touch-up paint as needed to protect exposed metal against rust.

Cover the machine. Tires and other exposed rubber items should be protected

from the weather. Either cover them or use a readily available protectant.

wc_tx003207gb.fm

49

Page 50

Basic Troubleshooting HDR 155

7 Basic Troubleshooting

Note: The following symptoms and remedies are some of the more common

issues that have arisen during the history of these machines. These do not

represent all the possibilities. If you need advanced troubleshooting assistance,

please contact Wacker Neuson Product Support.

Problem Cause Remedy

Motor does not start, no

ignition

Motor starts, no ignition, or

cuts out

Electrical current is not

present

Control setting is below

ambient temperature (main,

thermostat, or other control)

Thermostat or other control

is malfuntioning

Electric motor is malfuntioning

Electric motor bearings are

malfuntioning

Condenser is malfunctioning

Electric igniter is malfuntioning

Check the electrical supply

connection.

Check proper positioning

and functioning of switch.

Check fuse.

Check setting of heater

control. If thermostat, make

sure selected temperature

is higher than room temperature.

Replace control device.

Replace electric motor.

Replace electric motor.

Replace condenser.

Check connection of hightension leads to electrodes

and transformer.

Check electrodes setting.

Check electrodes for cleanliness.

Replace high-voltage transformer.

Burner controller is malfuntioning

CAD cell is malfuntioning Replace photocell.

Fuel supply is insufficient Check condition of motor-

Replace control box.

pump plastic coupling.

Check fuel line system

including fuel filter for possible leaks.

Clean or replace oil nozzle.

wc_tx003208gb.fm

50

Page 51

HDR 155 Basic Troubleshooting

Problem Cause Remedy

Motor starts, heater emits

smoke

Heater does not stop Solenoid malfuntioning Replace solenoid coil or

Air supply is insufficient Make sure air inlet and out-

let are unobstructed.

Check setting of combustion air flap.

Clean burner disc.

Air supply is overly sufficient

Fuel is contaminated Replace fuel.

Air leaks present in fuel circuit

Fuel supply is insufficient at

burner

Fuel supply is overly sufficient at burner

Check setting of combustion air flap.

Clean or replace oil filter.

Check fuel line and filter for

possible leaks.

Check pump pressure.

Clean or replace fuel nozzle.

Check pump pressure.

Replace nozzle.

entire solenoid.

wc_tx003208gb.fm

51

Page 52

Technical Data HDR 155

F

8 Technical Data

8.1 Machine

Model HDR 155 - 5200007530

Units

Max. heat output BTU/h 154,000

Fuel pressure psi 174

Fuel consumption gal/h (L/h) 1.1 (4.16)

Power supply

Power consumption W 440

Fuel tank capacity gal/L 17.17 (65)

Noise level at 1m dBA 72

Weight lb(kg) 180 (81.6)

8.2 Dimensions

/V/Hz

1/120/60

52

wc_td000542gb.fm

Page 53

HDR 155 Schematics

9 Schematics

9.1 HDR 155

13

YL

5

GY

BU

wc_gr012088

Ref Description Ref Description

1 Fuse 8 Control

2 Overheat thermostat 9 Remote thermostat plug

3 Solenoid valve 10 Control box

4 CAD cell 11 Heated fuel filter

5 Capacitor

6 Fan motor

7 Electric pilot lamp

12 Tip switch

13 Reset switch

——

Wire Colors

BK Black RD Red YL Yellow OR Orange

GN Green TN Tan BR Brown PU Purple

BU Blue VIO Violet CL Clear SH Shield

wc_tx003209gb.fm

PK Pink WH White GY Gray LB Light blue

53

Page 54

Page 55

Page 56

Important: For spare parts information, please see your Wacker Neuson Dealer, or visit the

㔜せ

䠃㾷

Wacker Neuson website at http://www.wackerneuson.com/.

Wichtig! Informationen über Ersatzteile erhalten Sie von Ihrem Wacker Neuson Händler oder

besuchen Sie die Wacker Neuson Website unter http://www.wackerneuson.com/.

Important : Pour des informations sur les pièces détachées, merci de consulter votre

distributeur Wacker Neuson, ou de visiter le site Internet de Wacker Neuson sur

http://www.wackerneuson.com/.

Importante : Para saber más sobre las piezas de repuesto, póngase en contacto con su

distribuidor de Wacker Neuson o acceda al sitio web de Wacker Neuson en

http://www.wackerneuson.com/.

Importante : Per informazioni sui pezzi di ricambio, contattare il rivenditore Wacker Neuson o

visitare il sito di Wacker Neuson all’indirizzo www.wackerneuson.com.

Viktigt : För information om reservdelar, kontakta din Wacker Neuson-leverantör eller besök

Wacker Neusons webbplats på http://www.wackerneuson.com/.

Tärkeää : Pyydä varaosatietoja Wacker Neusoni n j ällee nmyyj äl tä tai vieraile Wacker Neusonin

web-sivustolla osoitteessa http://www.wackerneuson.com/

Viktig : For informasjon om reservedeler, vennligst kontakt din Wacker Neuson-forhandl er , ell er

besøk Wacker Neusons nettside på http://www.wackerneuson.com/.

Vigtigt : Hvis du ønsker oplysninger om reservedele, bedes du kontakte din Wacker Neuson

forhandler eller besøg Wacker Neuson websiden på http://www.wackerneuson.com/.

Belangrijk! Neem contact op met uw Wacker Neuson dealer of bezoek de website van Wacker

Neuson op http://www.wackerneuson.com/ voor meer informatie over reserveonderdelen.

Importante : Para obter informações sobre as peças sobresselentes, consulte o seu

fornecedor da Wacker Neuson ou aceda ao site Web da Wacker Neuson em

http://www.wackerneuson.com

WaĪne : W celu uzyskania informacji na temat czĊĞci zamiennych skontaktuj siĊ z

przedstawicielem firmy Wacker Neuson lub skorzystaj z witryny internetowej

http://wackerneuson.com/.

DĤležité upozornČní! Pro informace o náhradních dílech, prosím, kontaktujte svého Wacker

Neuson dealera, nebo navštivte webové stránky http://www.wackerneuson.com/.

FONTOS: A pótalkatrészekre vonatkozó informá ciókért kérjük, forduljon Wacker Neuson

kereskedĘjéhez vagy látogasson el a Wacker Neuson weboldalára a következĘ címen:

http://www.wackerneuson.com/.

ȼɚɠɧɨ! Ⱦɥɹ ɨɡɧɚɤɨɦɥɟɧɢɹ ɫ ɢɧɮɨɪɦɚɰɢɟɣ ɨ ɡɚɩɚɫɧɵɯ ɱɚɫɬɹɯ, ɩɨɠɚɥɭɣɫɬɚ, ɨɛɪɚɬɢɬɟɫɶ ɤ

ɦɟɫɬɧɨɦɭ ɬɨɪɝɨɜɨɦɭ ɩɪɟɞɫɬɚɜɢɬɟɥɸ ɤɨɦɩɚɧɢɢ Wacker Neuson ɢɥɢ ɩɨɫɟɬɢɬɟ ɜɟɛ-ɫɚɣɬ

http://www.wackerneuson.com/.

ȈȘȝĮȞIJȚțȩ

: īȚ

Į ʌȜȘȡȠijȠȡȓİȢ ıȤİIJȚțȐ ȝİ IJĮ ĮȞIJĮȜȜĮțIJȚțȐ, ȝȚȜȒıIJİ ȝİ IJȠȞ ĮȞIJȚʌȡȩıȦʌȩ ıĮȢ IJȘȢ

Wacker Neuson, Ȓ İʌȚıțİijșİȓIJİ IJȠȞ ȚıIJȩIJȠʌȠ http://www.wackerneuson.com/.

Važno : Za rezervne dijelove obratite se svom Wacker Neuson prodavaþu ili posjetite mrežne

stranice tvrtke Wacker Neuson: http://www.wackerneuson.com/.

Önemli : Y edek parça bilgileri için Wacker Neuson Bayinize bakÕn veya Wacker Neuson web

sitesini ziyaret edin. http://www.wackerneuson.com/

㒊ရࡢሗࡘ࠸࡚ࡣࠊ࣡ࢵ࣮࢝ࣀࢯࣥࢹ࣮࣮ࣛ࠾ၥ࠸ྜࢃࡏ㡬ࡃࠊ࣡ࢵ

࣮࢝ࣀࢯ࢙ࣥ࢘ࣈࢧࢺ KWWSZZZZDFNHUQHXVRQFRP ࢆࡈぴࡃࡔࡉ࠸ࠋ

ᴿީ༽Ԭؗᚥθ䈭䈘ᛞⲺ့ށ䈰ἤ㔅䬶ᡌ䇵䰤့ށ䈰ἤ㖇ㄏφ

KWWSZZZZDFNHUQHXVRQFRPȾ

Important : Pentru informaĠii referitoare la piesele de schimb, vă rugăm să vă adresaĠi

distribuitorului Wac k er Neuson sau să vizitaĠi site-ul web Wacker Neuson la adresa

http://www.wackerneuson.com/.

ȼɚɠɧɨ : Ɂɚ ɢɧɮɨɪɦɚɰɢɹ ɨɬɧɨɫɧɨ ɪɟɡɟɪɜɧɢ ɱɚɫɬɢ, ɦɨɥɹ, ɨɛɴɪɧɟɬɟ ɫɟ ɤɴɦ ɦɟɫɬɧɢɹ ɞɢɥɴɪ

ɧɚ W

acker Neuson ɢɥɢ ɩɨɫɟɬɟɬɟ ɭɟɛɫɚɣɬɚ ɧɚ Wacker Neuson ɧɚ ɚɞɪɟɫ

http://www.wackerneuson.com/.

Wacker Neuson Produktion GmbH & Co. KG, Preußenstraße 41, D-80809 München,

Wacker Neuson Production Americas LLC, N92W15000 Anthony Ave., Menomonee Falls, WI. 53051

Wacker Neuson Limited - Room 1701–03 & 1717–20, 17/F. Tower 1, Grand Century Place, 193 Prince Edward

Road West, Mongkok, Kowloon, Hongkong. Tel: (852) 3605 5360, Fax: (852) 2758 0032

Tel.: +49-(0)89-3 54 02-0 Fax: +49 - (0)89-3 54 02-390

Tel.: (262) 255-0500 Fax: (262) 255-0550 Tel.: (800) 770-0957

Loading...

Loading...