Page 1

Operator’s Manual

Inverter Generator

GPi 3200 / GPSi 3200

GPi 4300 / GPSi 4300

0179740en 004 0311

0179740EN

Page 2

Copyright

notice

© Copyright 2010 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by W acker Neuson Corp oration

represents an infringement of valid copyrights. Violators will be prosecuted.

T ra d emarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Corporation

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Original

instructions

This Operator’s Manual presents the original instructions. The original language of this

Operator’s Manual is American English.

Page 3

Foreword

Machines

covered in

this manual

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models listed below. These instructions must be followed during

installation and maintenance of the generator (and battery, if equipped).

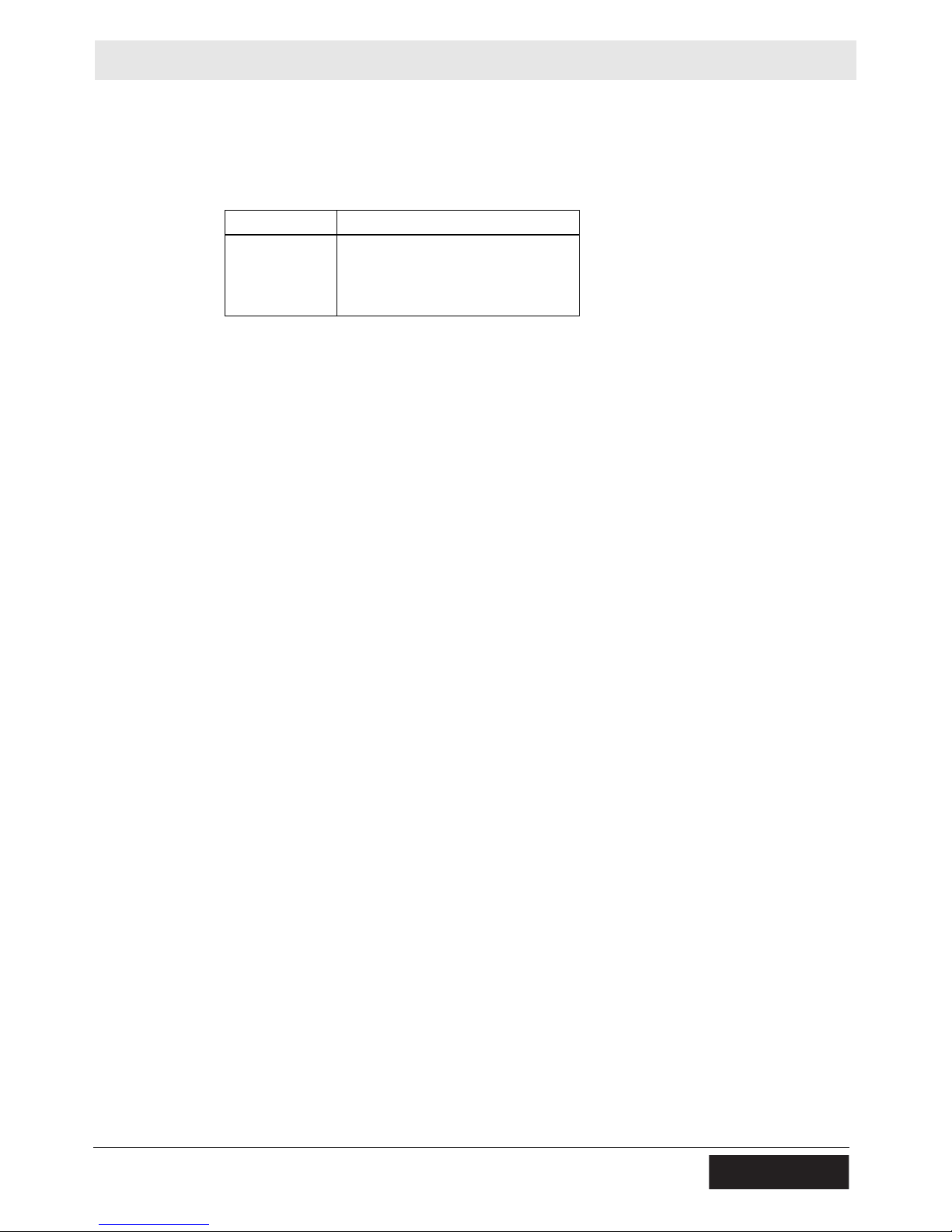

Machine Item Number

GPi 3200

GPSi 3200

GPi 4300

GPSi 4300

0620781, 0620779

0620780, 0620936

0620782, 0620784

0620783, 0620937

Machine

documentation

Expectations

for

information in

this manual

CALIFORNIA

Proposition

65 Warning

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing either of these documents, please contact Wacker Neuson

Corporation to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and main-

tain the above W acker Neuson model(s). For your own safety and to reduce the

risk of injury, carefully read, understand, and observe all instructions described

in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Corporation reserves the right

to change any portion of this information without notice.

Engine exhaust, some of its constituents, and certain vehicle components, contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

Laws

pertaining to

spark

arresters

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental discharge of sparks or flames from the engine exhaust. Spark arresters are qualified

and rated by the United States Forest Service for this purpose. In order to comply

with local laws regarding spark arresters, consult the engine distributor or the local

Health and Safety Administrator.

wc_tx001238gb.fm 3

Page 4

Foreword

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker Neu-

son service center according to written instructions published by Wacker Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

4 wc_tx001238gb.fm

Page 5

GPi 3200 / 4300 Table of Contents

Foreword 3

1 Safety Information 7

1.1 Signal Words Found in this Manual ...................................................... 7

1.2 Machine Description and Intended Use ............................................... 8

1.3 Safety Guidelines for Operating the Machine ....................................... 9

1.4 Operator Safety While Using Internal Combustion Engines ............... 11

1.5 Guidelines for Service Safety ............................................................. 12

1.6 Label Locations .................................................................................. 13

1.7 Machine Labels .................................................................................. 14

1.8 Safety and Warning Labels ................................................................ 14

2 Operation 17

2.1 Overview ............................................................................................ 17

2.2 Preparing the Machine for First Use ................................................... 17

2.3 Features and Components ................................................................. 18

2.4 Lifting and Transporting ...................................................................... 20

2.5 Wheel Brakes (if equipped) ................................................................ 20

2.6 Installation .......................................................................................... 21

2.7 Connecting and Maintaining the Battery ............................................ 22

2.8 Use of Extension Cords ...................................................................... 23

2.9 Power Requirements .......................................................................... 24

2.10 Control Panel ...................................................................................... 25

2.11 Customer Connections ....................................................................... 28

2.12 Grounding the Generator ................................................................... 29

2.13 Fueling the Machine ........................................................................... 30

2.14 Before Starting ................................................................................... 31

2.15 Starting the Generator (S Models) ..................................................... 32

2.16 Starting the Generator (Manual Start Models) ................................... 33

2.17 Using AC Power ................................................................................. 34

2.18 Using DC Power ................................................................................. 35

2.19 Stopping the Generator ...................................................................... 36

2.20 Emergency Shutdown Procedure ....................................................... 37

wc_bo0179740en_004TOC.fm 5

Page 6

Table of Contents GPi 3200 / 4300

3 Maintenance 38

3.1 Periodic Maintenance Schedule ..........................................................38

3.2 Detaching the Side Panels (S Models) ................................................39

3.3 Checking the Engine Oil ......................................................................40

3.4 Cleaning the Air Cleaner .....................................................................41

3.5 Cleaning and Checking the Spark Plug ...............................................42

3.6 Changing the Engine Oil .....................................................................43

3.7 Cleaning the Spark Arrester ................................................................44

3.8 Cleaning the Fuel Strainer ...................................................................45

3.9 Storing the Generator ..........................................................................46

4 Schematics 48

4.1 Electrical Schematic (S Models, non-CSA) .........................................48

4.2 Electrical Schematic Components (S Models, non-CSA) ....................49

4.3 Electrical Schematic (CSA) .................................................................50

4.4 Electrical Schematic Components (CSA) ............................................51

4.5 Electrical Schematic (Manual Start Models, non-CSA) .......................52

4.6 Electrical Schematic Components (Manual Start Models, non-CSA) ..53

4.7 Electrical Schematic (Manual Start Models, CSA) ..............................54

4.8 Electrical Schematic Components (Manual Start Models, CSA) .........55

5 Basic Troubleshooting 56

6 Technical Data 57

6.1 Engine .................................................................................................57

6.2 Generator Data ....................................................................................58

6 wc_bo0179740en_004TOC.fm

Page 7

GPi 3200 / 4300 Safety Information

1 Safety Information

1.1 Signal Words Found in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

To avoid death or serious injury from this type of hazard, obey all safety messages that

f

follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f

To avoid possible death or serious injury from this type of hazard, obey all safety messages that follow this signal word.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

To avoid possible minor or moderate injury from this type of hazard, obey all safety mes-

f

sages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000348gb.fm 7

Page 8

Safety Information GPi 3200 / 4300

1.2 Machine Description and Intended Use

This machine is a portable electric power source. The Wacker Neuson Inverter

Generator consists of a gasoline engine, a fuel tank, and an electric alternator and

inverter. Contr ols and recept acles are provided on a control pa nel mounted on the

side of the machine. As the engine runs, the generator convert s mechanical energy

into AC power and DC power. The operator connects loads to the AC power

receptacles or DC terminals.

This machine is intended for the purpose of supplying electrical power to

connected loads. Refer to the product specifications for the output voltage and

frequency of this generator, and for the maximum output power limit of this

generator.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following practices are some examples of misuse:

Connecting a load that has voltage and freque ncy requirements that are

incompatible with the generator output

Overloading the generator with a load that draws excess ive power during either

continuous running or start-up

Operating the generator in a manner that is inconsiste nt with all federal, state and

local codes and regulations.

Using the machine as a ladder, support, or work surface

Using the machine to carry or transport passengers or equipment

Operating the machine outside of factory spec ifications

Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may rema in even after protective measures have been t aken.

They are called residual risks. On this machine, they may include exposure to:

Heat, noise, exhaust, and carbon monoxide from the engine

Fire hazards from improper refueling techniques

Fuel and its fumes

Electric shock and arc flash

Personal injury from improper liftin g techniques

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

8 wc_si000348gb.fm

Page 9

GPi 3200 / 4300 Safety Information

1.3 Safety Guidelines for Operating the Machine

DANGER

Carbon monoxide. Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot

see or smell. If you can smell the generator exhaust, you are breathing CO. But

even if you cannot smell the exhaust, you could be breathing CO.

f NEVER use a generator inside homes, garages, crawlspaces, or other partly

enclosed areas. Deadly levels of carbon monoxide can build up in these areas.

Using a fan or opening windows and doors does NOT supply enough fresh air.

f ONLY use a generator outside and far away from windows, doors, and vents.

These openings can pull in generator exhaust.

f Even when you use a generator correctly , CO may leak into the home. ALW AYS

use a battery-powered or battery-backup CO alarm in the home.

f If you start to feel sick, dizzy, or weak after the generator has been running,

move to fresh air RIGHT AW AY. See a doctor. You could have carbon monoxide

poison.

WARNING

Machines operated improperly or by untrained personnel can be hazardous.

f Read the operating instructions contained in both this Operator’s Manual and

the engine operator’s manual.

f Familiarize yourself with the location and proper use of all controls.

f Inexperienced operators should receive instruction from someone familiar with

the machine before being allowed to operate it.

Operator

qualifications

Personal

Protective

Equipment

(PPE)

Before

starting the

machine

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

have received instruction on how to properly use the machine

are familiar with required safety devices

The machine must not be accessed or operated by:

children

people impaired by alcohol or drugs

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

Before starting this machine:

Follow starting and stopping instructions described in this manual. Know how to

operate and stop the generator before sta rting it.

Do not start a machine in need of rep air.

wc_si000348gb.fm 9

Page 10

Safety Information GPi 3200 / 4300

Make sure the machine is on a firm, level surface and will not tip, roll, slide, or fall

while operating.

Remove all tools, cords, and other loose items from the generator before starting it.

Electrical

safety

To increase electrical safety while operating this machine:

Do not operate the generator, or tools attached to the generator, with wet hands.

Do not use worn electrical cords. Severe electrical shock and equipment damage

may result.

Do not operate generator in standing water.

Make certain the machine is we ll-grounded and securely fastened to a go od earthen

ground per national and local regulations.

Do not overload the generator. The total amperage of the tools and equipment

attached to the generator must not exceed the load rating of the generator .

.

WARNING

Backfeed from the generator into the public power distribution system can seriously

injure or kill utility workers!

f Improper connection of generator to a building’s electrical system can allow

electrical current from the generator to backfeed into utility lines. This may re sult

in electrocution of utility workers, fire, or explosion.

f Connections to a building’s electrical system must be made by a qualified elec-

trician and comply with all applicable laws and electrical codes.

f If connected to a building’s electrical system, the generator must meet the

power, voltage, and frequency requirements of the equipment in the building.

Generator

vibration

Operating

safety

Generators vibrate in normal use. During and after the use of the gene rator , inspect

the generator as well as extension cords and power supply cords connected to it

for damage from vibration.

Have damaged items repaired or replaced as n ecessary.

Do not use plugs or or cords that show signs of damage such as broken or cra cked

insulation or damaged blades.

To increase operating safety while running this machine:

Do not operate the generator when open containers of fuel, paint, or other

flammable liquids are in the vicinity of the generator.

Do not place flammable material or liquids near the generator.

Do not operate the machine indoors.

Do not touch the hot engine, exhaust, or generator component s. Burns will result.

Always do the following:

Wear hearing protection when operating equipment.

Keep the machine at least one meter (three feet) away from structures, buildings,

and other equipment during use.

Keep the area immediately surrounding and underneath the machine clean, neat,

and free of debris and combustible materials. Make sure that the area overhead is

clear of debris that could fall onto or into the machine or exhaust compartment.

10 wc_si000348gb.fm

Page 11

GPi 3200 / 4300 Safety Information

Storing the

machine

Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

1.4 Operator Safety While Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or

death.

f Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Carbon monoxide. Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot

see or smell. If you can smell the generator exhaust, you are breathing CO. But

even if you cannot smell the exhaust, you could be breathing CO.

Refueling

safety

Operating

safety

When refueling the engine:

Do not smoke.

Do not refuel if the generator is sitting in a truck fitted with a plastic bed liner. Static

electricity can ignite the fuel or fuel vapors.

Do not refuel a hot or running engine.

Do not refuel the engine near an open flame.

When refueling the engine, always:

Refill the fuel tank in a well-ventilated area.

Replace the fuel tank cap after refueling.

When operating the generator:

Check the fuel lines and the fuel tank for leaks an d cracks before starting the en gine.

Do not run the machine if fuel leaks are present or the fuel lines are loose.

Do not run the engine near open flames.

Do not start the engine if fuel has spilled or a fuel odor is present. Move the

generator away from the spill and wipe the gene rator dry before starting.

Do not smoke while operating the machine.

wc_si000348gb.fm 11

Page 12

Safety Information GPi 3200 / 4300

1.5 Guidelines for Service Safety

WARNING

A poorly maintained machine can be a personal injury hazard.

f Follow the Periodic Maintenance schedule in this Operator’s Manual.

f Repair or replace any damaged or defective components immediately.

Personal

Protective

Equipment

(PPE)

Prerequisites

Ground

connection

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

Before servicing this machine:

Stop the engine.

If the engine has an electric starter, disconnect the negative terminal on the battery.

Attach a “DO NOT START” sign to the machin e. This will notify everyone that the

machine is being serviced and will reduce the chance of someone inadvertently

trying to start the machine.

The generator must be connected to a good earthen ground for proper operating

safety!

Ground the generator in accordance with the sta nd ards defined in national, state,

and local regulations.

Personal

injury

avoidance

Let the engine and muffler cool before transporting or servicing the machine.

Do not service the machine if your clothing or skin is wet.

Do not allow untrained personnel to service this machine. Only trained electrical

technicians should be allowed to service the electrical com ponents of this machine.

Service safety

Do not modify the machine without the express written approval of the ma nufacturer.

Do not allow water to accumulate around the base of the mach ine. If water is

present, move the machine and allow the machine to dry before servicing.

..

Replacing

parts and

labels

Replace worn or damaged component s.

Use only spare parts recommended by Wacker Neuson.

Keep the fuel lines in serviceable condition. Leaking fuel and fumes are extremely

explosive!

Replace all missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

Check all external fasteners at regular intervals.

12 wc_si000348gb.fm

Page 13

GPi 3200 / 4300 Safety Information

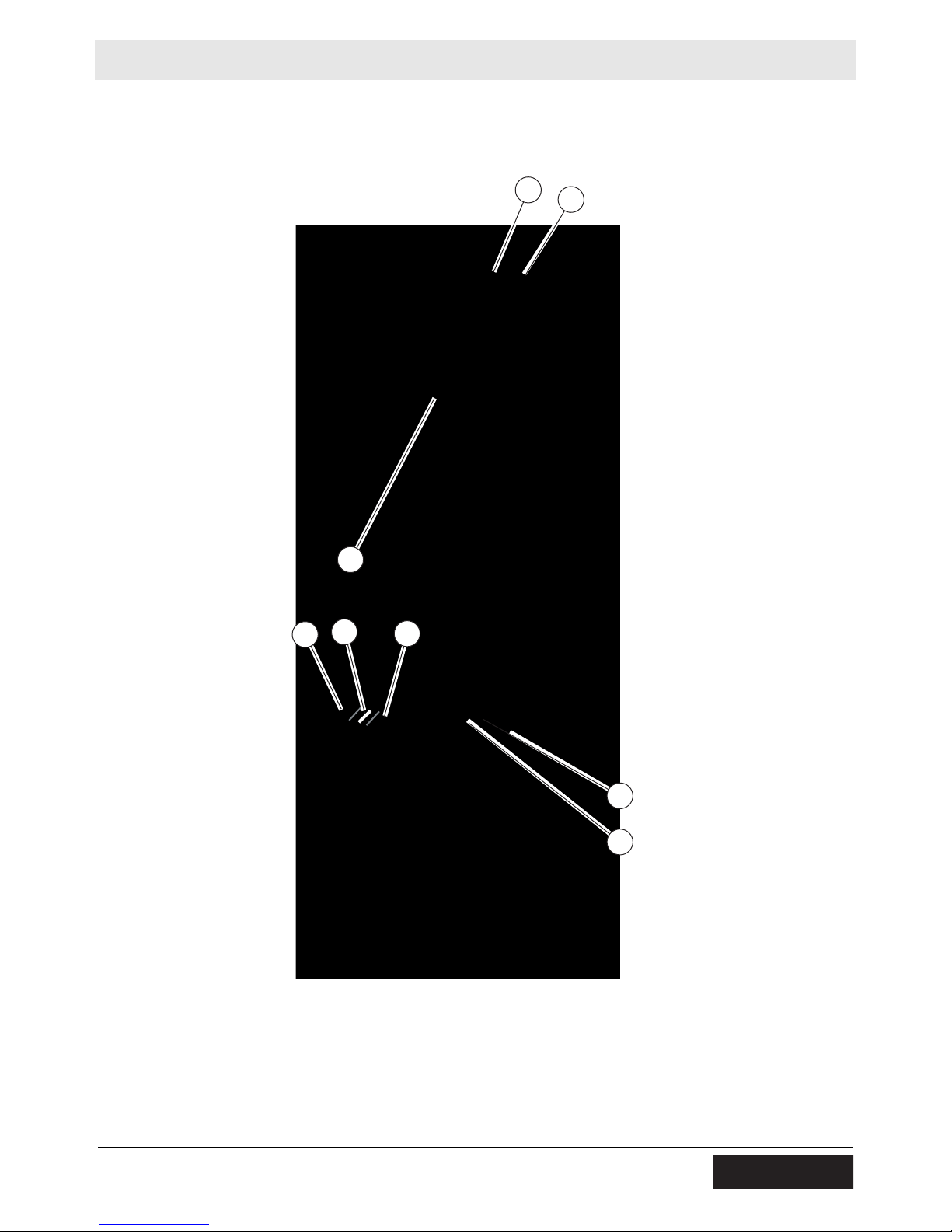

G

G

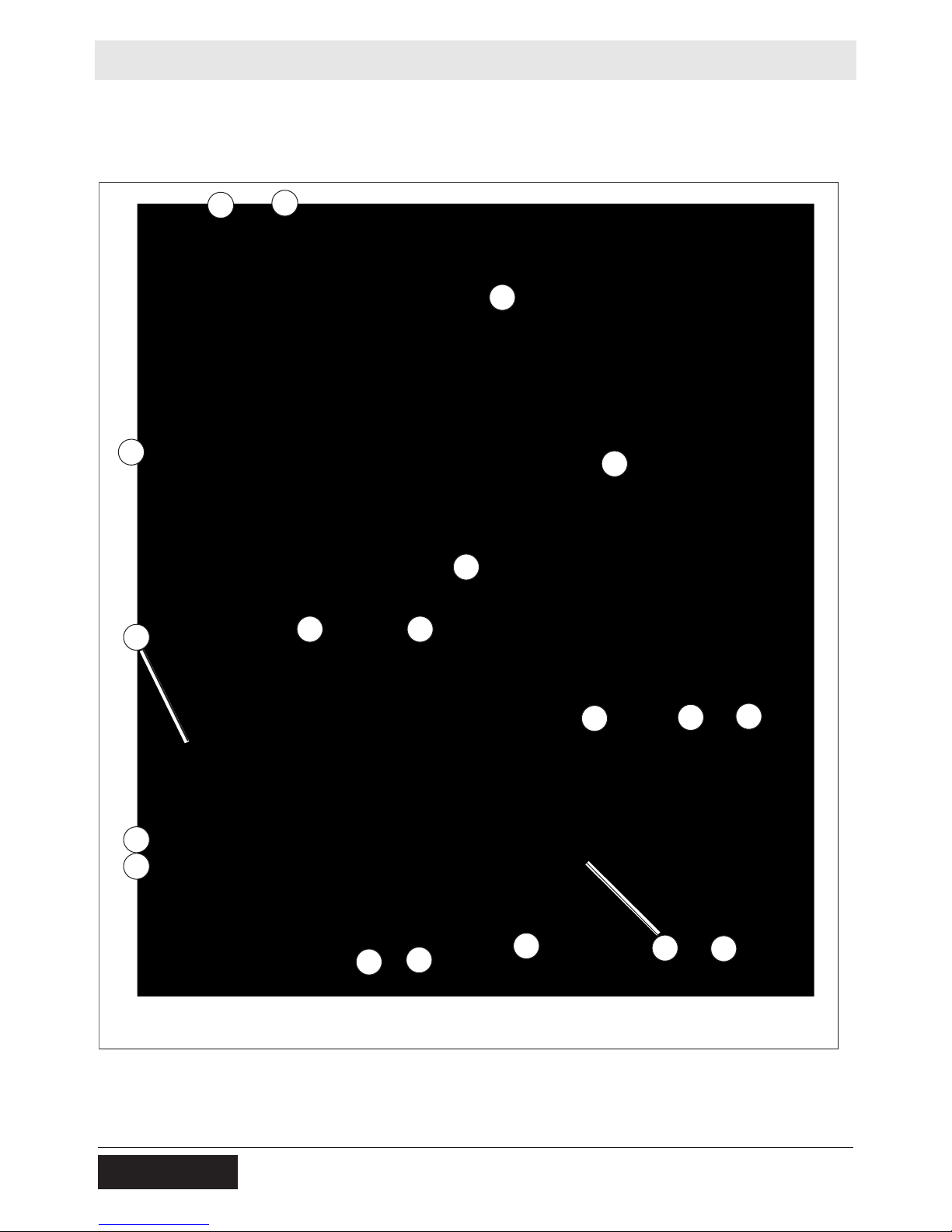

1.6 Label Locations

A

B

H

D

C

E

G

F

wc_si000348gb.fm 13

Page 14

Safety Information GPi 3200 / 4300

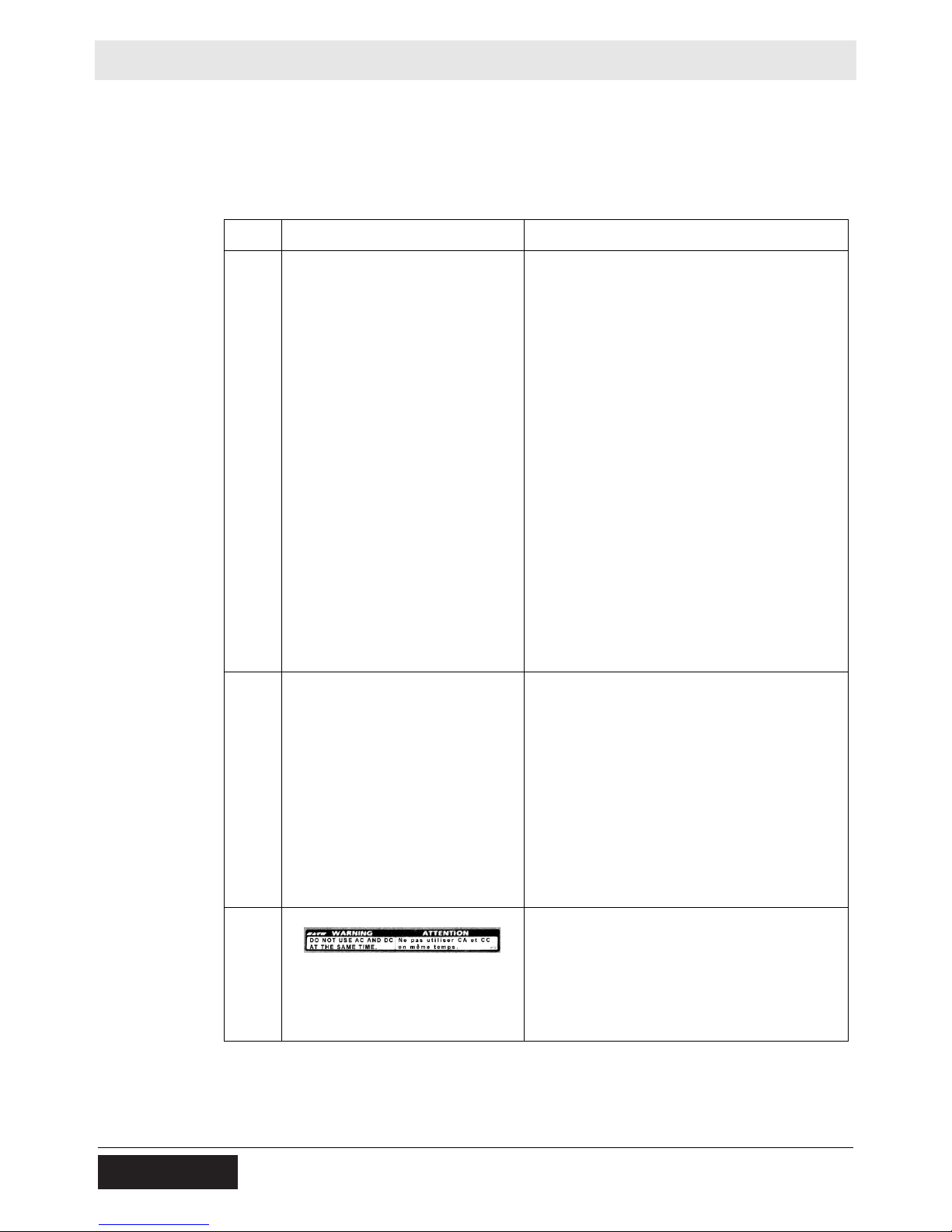

1.7 Machine Labels

Wacker Neuson machines use international pictorial labels where needed. These

labels are described below.

1.8 Safety and Warning Labels

Ref. Label Meaning

ADANGER

Using a generator indoors CAN KILL

YOU IN MINUTES. Generator

exhaust contains carbon monoxide.

This is a poison you cannot see or

smell.

NEVER use inside a home or garage,

EVEN IF doors and windows are

open.

Only use OUTSIDE and far away

from windows, doors, and vents.

B Do not connect the generator to a household

or commercial power source.

Keep open flames and sparks away from the

generator.

Attention!

Read the Operator’s Manual before

operating this machine.

Attention!

Stop the engine before refueling.

CWARNING

Do not use AC and DC at the same time.

14 wc_si000348gb.fm

Page 15

GPi 3200 / 4300 Safety Information

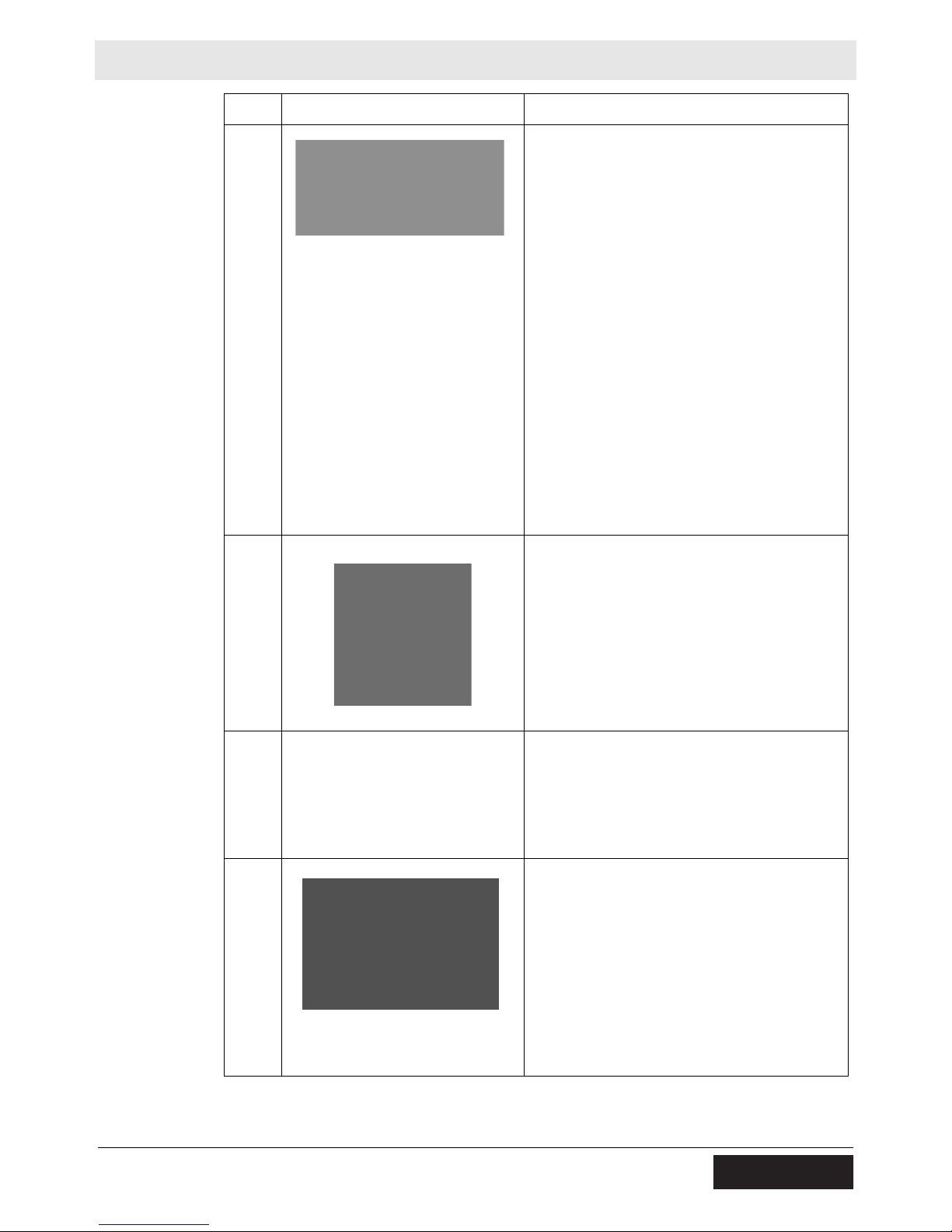

Ref. Label Meaning

D WARNING

To reduce the risk of injury, user must read

and understand instruction manual.

Exhaust gas contains poisonous carbon

monoxide.

Do not use in poorly ventilated area.

The operator may suffer severe elecrtric

shock.

Do not touch with wet hands.

The operator may suffer burns.

Do not touch hot muffler.

Potent ial da ng e r of ex plos ion or fire.

Stop engine during fuel supply. Keep

flammable things away.

Be careful not to spill fuel during refueling.

Use unleaded gasoline only.

Keep open flames away from the

generator.

Do not operate in rain or snow.

Do not connect to a household circuit.

E WARNING

Hot surface! Do not touch.

DANGER

Risk of carbon monoxide poisoning.

Keep a safe distance away from the

machine.

F This equipment does not meet California

EVP emission regulations for small off-road

engines.

G WARNING

Improper connection of the generator to a

building’s electrical system can allow

electrical current from the generator to

backfeed into utility lines. This may result in

electrocution of utility workers, fire, or

explosion. Connections to a building’s

electrical system must be made by a

qualified electrician and comply with all

applicable laws and electrical codes.

wc_si000348gb.fm 15

Page 16

Safety Information GPi 3200 / 4300

Ref. Label Meaning

H

A nameplate listing the model

number, item number, revision

number, and serial number is

attached to each unit. Please record

the information found on this

nameplate so it will be available

should the nameplate become lost or

damaged. When ordering parts or

requesting service information, you

will always be asked to specify the

model number, item number, revision

number, and serial number of the

unit.

16 wc_si000348gb.fm

Page 17

GPi 3200 / 4300 Operation

2 Operation

DANGER

Carbon monoxide. Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot

see or smell. If you can smell the generator exhaust, you are breathing CO. But

even if you cannot smell the exhaust, you could be breathing CO.

f NEVER use a generator inside homes, garages, crawlspaces, or other partly

enclosed areas. Deadly levels of carbon monoxide can build up in these areas.

Using a fan or opening windows and doors does NOT supply enough fresh air.

f ONLY use a generator outside and far away from windows, doors, and vents.

These openings can pull in generator exhaust.

f Even when you use a generator correctly , CO may leak into the home. ALW AYS

use a battery-powered or battery-backup CO alarm in the home.

f If you start to feel sick, dizzy, or weak after the generator has been running,

move to fresh air RIGHT AW AY. See a doctor. You could have carbon monoxide

poison.

2.1 Overview

Generator

application

This generator is an exceptionally quiet and compact machine desig ned to provide

single phase power for construction, commercial, and residential applications.

State-of-the-art inverter technology ensures a consistent flow of clean and stable

power suitable for operating not only tools, but also delicate electronic equipment.

Safety notices

Do not exceed the power output of the generator . Damage to tools or generator

can occur. Refer to Technical Data.

When using the generator as a stand-by or substitute power supply, make sure

the voltage and phase rotation of the line connections match those of the main

lines. Failure to match phase rotation and voltage may cause equipment

connected to the generator to operate incorrectly! This could create unsafe

operating conditions.

Do not exceed the rated current limit of any receptacle.

2.2 Preparing the Machine for First Use

Preparing for

first use

To prepare your machine for first use:

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

wc_tx001239gb.fm 17

Page 18

Operation GPi 3200 / 4300

2.3 Features and Components

l

A

S

B

C

D

E

F

H J

Q

R

G

P

O

K

E

L

M

N

wc_gr006662

18 wc_tx001239gb.fm

Page 19

GPi 3200 / 4300 Operation

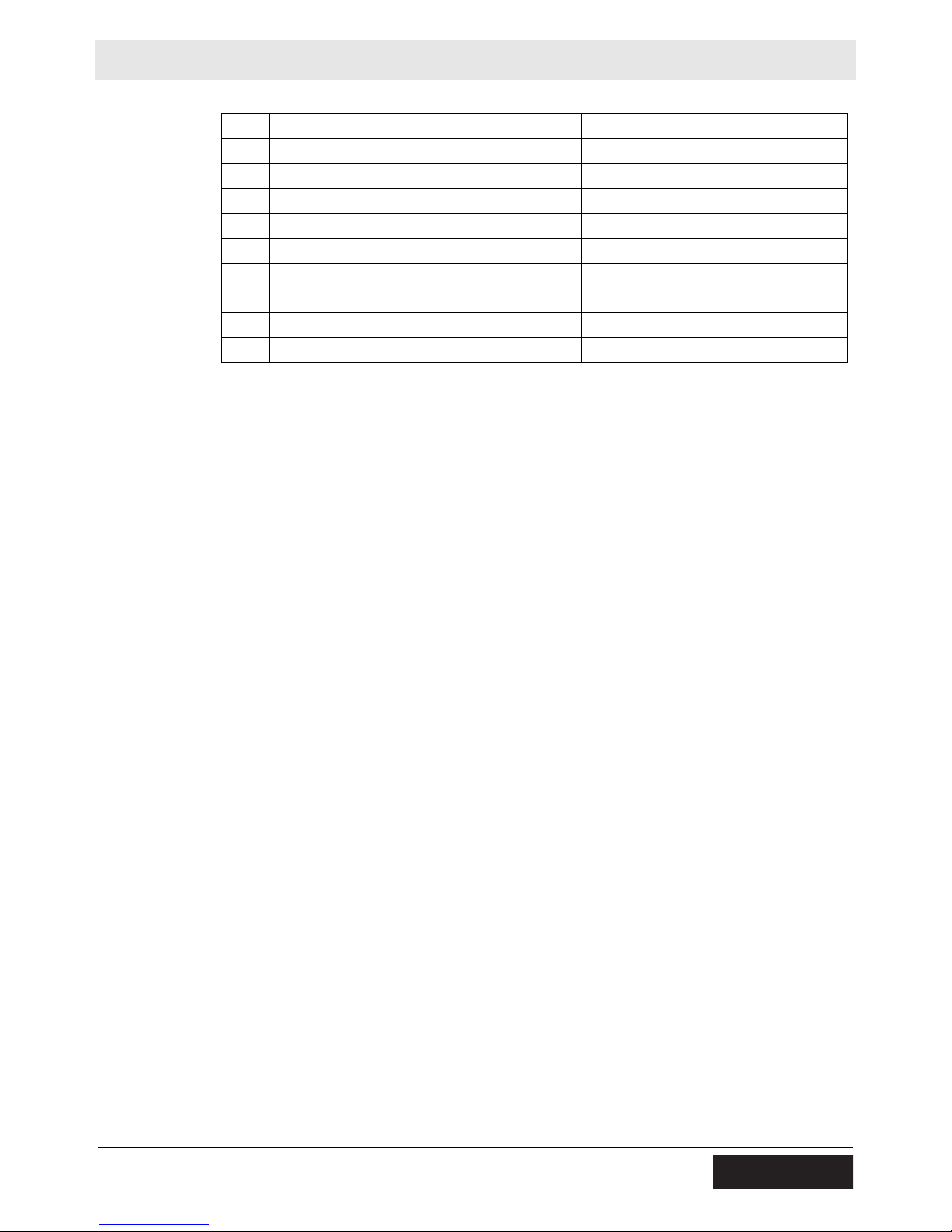

Ref. Description Ref. Description

A Control panel K Spark plug cap

B Fuel tank L Air cleaner

C Fuel gauge M Fuel strainer

D Right side panel (if equipped) N Battery (if equipped)

E Oil drain plug O Oil filler / gauge

F Recoil starter P Left side panel (if equipped)

G Wheel brake (if equipped) Q Exhaust outlet

H Fuel tank cap R Spark arrester

J Frame S Rear cover

wc_tx001239gb.fm 19

Page 20

Operation GPi 3200 / 4300

2

2.4 Lifting and Transporting

Lifting the

Machine

Transporting

the Machine

This generator, while compact, is heavy enough to cause injury if proper lifting

techniques are not used. Observe the following guidelines when lifting the

generator.

Do not attempt to lift and carry the generator unassisted. Use appropriate lifting

equipment such as slings, chains, hooks, ramps, or jacks.

Make sure lifting equipment is attached securely and has enough weight-

bearing capacity to lift or hold the generator safely.

Remain aware of the location of other people nearby when lifting the generator.

Observe the following guidelines when transporting the generator to and from the

job site.

Allow the engine to cool before transporting the generator.

Drain the fuel tank.

Close the fuel valve.

Ensure that the generator is securely strapped down in the transport vehicle to

prevent it from sliding or tipping.

Do not refuel the generator in or on the transp ort vehicle. Move the generator to

its operating location and then fill the fuel tank.

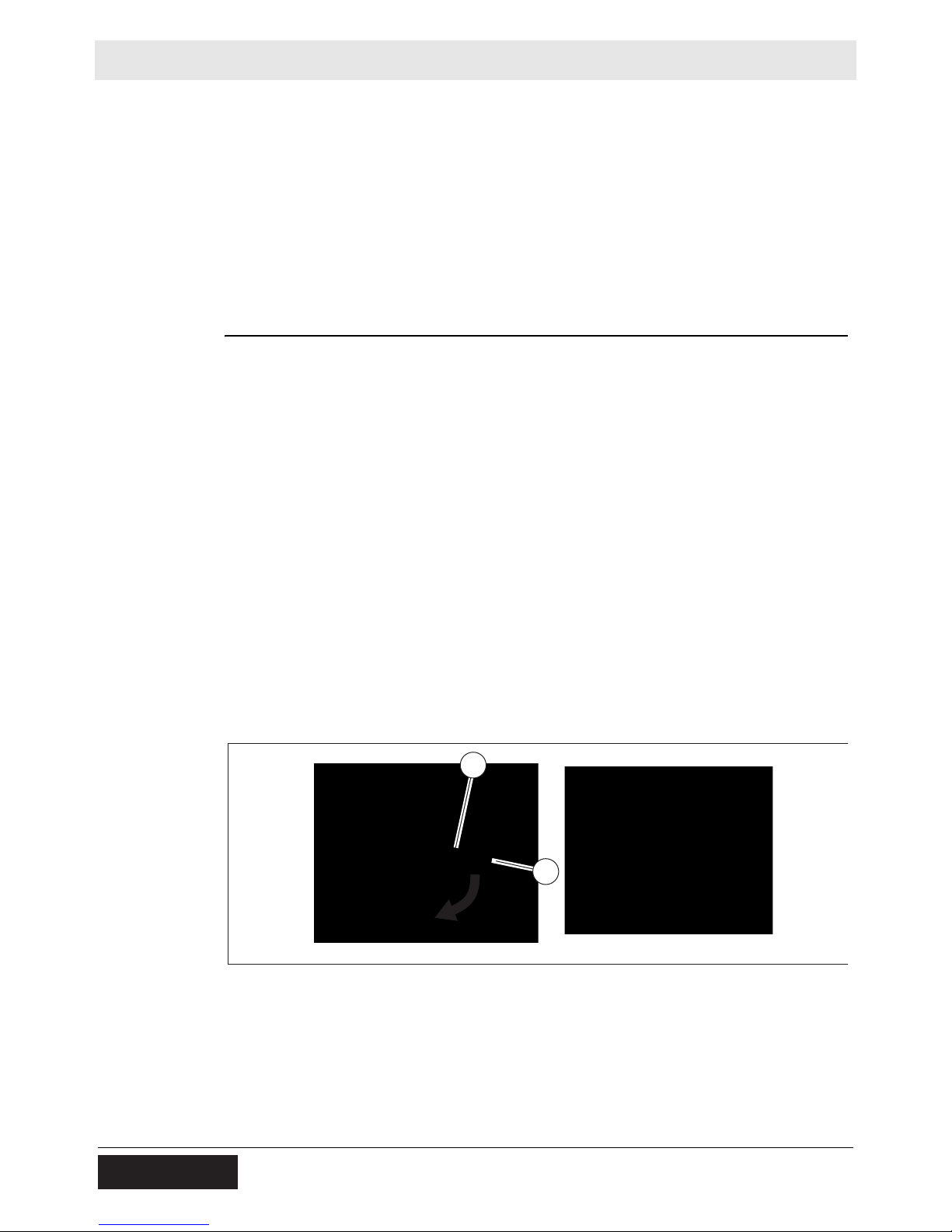

2.5 Wheel Brakes (if equipped)

Description

Locking and

unlocking the

wheels

The two rear wheels on your generator (if equipped) feature spring-operated

brakes (g) . These brakes help to prevent the generator from unintentional

movement. Lock both rear wheels after the generator has been placed in its

operating position.

To lock the wheel, press the brake tab (g1) until the brake snaps in place

against the wheel.

To unlock the wheel, lift the brake tab.

g

g1

wc_gr00684

20 wc_tx001239gb.fm

Page 21

GPi 3200 / 4300 Operation

2.6 Installation

Locating the

generator

Follow the practices below when choosing an appropriate location for the

generator.

Place the generator in an area where it will not be exposed to rain, snow, or

direct sunlight.

Position the generator on firm, level ground so that it will not slide or shift.

Position the engine exhaust away from areas where people may be present.

The surrounding area must be free from water and moisture. All components

must be protected from excessive moisture.

NOTICE: The generator has a built-in forced air cooling system, and may beco me

overheated if it is enclosed. Therefore, do not enclose the generator or cover it with

a box.

wc_tx001239gb.fm 21

Page 22

Operation GPi 3200 / 4300

2.7 Connecting and Maintaining the Battery

Location and

description

An automotive-style battery (n) is installed on the machine. The battery is located

next to the air cleaner.

n

wc_gr006680

WARNING

Explosion hazard. Batteries can emit explosive hydrogen gas.

f Keep all sparks and flames away from the battery.

f Do not short-circuit battery posts.

Battery

connections

Maintaining

the battery

WARNING

Battery fluid is poisonous and corrosive.

f In the event of ingestion or contact with skin or eyes, seek medical attention

immediately.

To connect the battery:

Connect the positive (+) battery cable to the battery.

Connect the negative (-) battery cable to the battery.

To disconnect the battery:

Stop the engine.

Place all electrical switches in the OFF position.

Disconnect the negative (-) battery cable from the battery.

Disconnect the positive (+) battery cable from the battery.

Follow the battery manufacturer’s maintenance recommendations.

Keep battery terminals clean and connections tight.

When necessary, tighten the cables and grease the cable clamps with

petroleum jelly.

Maintain the battery at full charge to improve cold weather starting.

Precautions

Observe the following precautions to prevent serious damage to the electrical

system.

22 wc_tx001239gb.fm

Page 23

GPi 3200 / 4300 Operation

Do not disconnect the battery while the machine is running.

Do not attempt to run the machine without a battery.

Do not attempt to jump-start the machine.

In the event that the machine has a discharged battery, either replace the

battery with a fully charged battery or charge the battery using an appropriate

battery charger. See Technical Data for the equivalent battery specification.

Dispose of waste batteries in accordance with local environmental regulations.

2.8 Use of Extension Cords

When a long extension cord is used to connect an appliance or tool to the

generator , a volt age loss occurs—the longer the cord, the greate r the volt ag e loss.

This results in less voltage being supplied to the appliance or tool and increases

the amount of current draw or reduces performance. A heavier cord with a larger

wire size will reduce the voltage loss.

WARNING

Electric shock hazard. Damaged extension cords can cause electrical shock,

resulting in serious injury or death. DO NOT use worn, bare, or frayed cords.

f Replace damaged cords immediately.

Use the chart below as a guide for selecting proper cable size.

Current Load in Watts Maximum Cable Length in Feet

(Amps) 120V 240V #10 #12 #14 #16

2.5 300 600 1000. 600 375 250

5 600 1200 500 300 200 125

7.5 900 1800 350 200 125 100

10 1200 2400 250 150 100 -

15 1800 3600 150 100 65 -

20 2400 4800 125 75 50 -

Use only extension cords rated for outdoor use and equipped with a third-wire

ground.

NOTICE: Operating equipment at low voltage can cause it to overheat.

wc_tx001239gb.fm 23

Page 24

Operation GPi 3200 / 4300

2.9 Power Requirements

Application

About power

requirements

Approximate

starting power

requirements

This generator is designed to operate single-phase, 60 Hz equipment running at

120 VAC. It also provides DC power strictly intended for charging 12V automotive

style batteries.

Check the nameplate or label provided on tools and equipment to make sure their

power requirements are met by the power output of the gene rator. If the wattage is

not given for a particular tool or piece of equipment, contact the tool manufacturer

for wattage requirements.

NOTICE: Do not exceed the continuous rated output of the generator. Damage to

tools or generator can occur. See Technical Data.

Some pieces of equipment and tools require a surge of current when starting. This

means that the amount of power needed to initially start the equipment is larger

than the power required to keep it running. The generator must be capable of

supplying this "surge" current. Other equipment may require more power than is

actually stated on its nameplate.

The information in the following chart is offered only as a general guideline to help

you determine power requirements for different types of equipment. Contact your

nearest Wacker Neuson dealer, or the manufacturer or dealer of the tool or

equipment, with questions regarding power requirements.

Equipment type Wattage needed to start Comments

Incandescent lights

Appliances such as

irons and hot plates

Fluorescent and

mercury lamps

Electrical motors

Certain electrical tools

Most electrical tools 1.2–3 times their stated wattage

Submersible pumps

Air compressors

Other equipment Calculate by multiplying its

Same wattage as is stated on

their nameplates

1.2–2 times their stated wattage

Depends on motor type and use

3–5 times their stated wattage

voltage and amperage

requirements

These have resistivetype heating elements.

Volt s x Amps = Watts

24 wc_tx001239gb.fm

Page 25

GPi 3200 / 4300 Operation

e

AC 120V

2.10 Control Panel

GPi 3200

GPi 4300

GPSi 3200

GPSi 4300

a

b c j k l

m

defh

a

b c j k l

nopq

m

defgh

nopq

GPi 3200

(CSA)

GPi 4300

(CSA)

a

c j k l

m

h

a

d

c j k l

nopq

m

gh

d

nopq

wc_gr006675

wc_tx001239gb.fm 25

Page 26

Operation GPi 3200 / 4300

Ref. Description Ref. Description

a Multi monitor k Operation hour indicator light

b AC receptacles, 20A l Voltage indicator light

c AC receptacle, 30A m Frequency indicator light

d Ground lug n LED display changeover switch

e DC terminals o Auto-power saving switch

f DC circuit breaker p Auto-power saving indicator

g Key switch q

h Engine switch r AC circuit breaker

jLCD

Engine oil level warning indicator light

Multi monitor

(a)

AC

receptacles

(b, c)

Ground lug (d)

DC terminals

(e)

DC circuit

breaker (f)

Key switch (g)

The multi monitor (a) displays the status of various machine functions while the

generator is operating.

AC power is supplied through two 20A receptacles (b) and a 30A twist-lock

receptacle (c). Use only grounded, three-leg electrical plugs when connecting AC

equipment to the machine.

The ground lug (d) is the terminal for grounding the generator. See topic Ground

Lug for more information.

The generator provides DC power for charging batteries. The red terminal is

positive (+); the black terminal is negative (-). See topic Using DC Power.

The DC circuit breaker

(f)

shuts off the electrical current when the curren t exceeds its

limit, or a malfunction occurs in a piece of equipment connected to the generator.

The DC circuit breaker has activated when the button pops out.

To reset the DC circuit breaker, press the button.

The key switch (g) is used to start and stop the engine. See topic Starting the

Generator (Electric Start).

Engine switch

(h)

The engine switch (h) controls the function of the choke and the fuel valve. There

are three positions:

Symbol Meaning Description

Choke valve is

closed

Normal operating

position

Fuel valve is

closed

Turn the switch to this position when starting a cold

engine.

Turn the switch to this position after the engine starts.

Note: A warm engine can be started with the switch in

this position.

Turn the switch to this position to stop the engine.

26 wc_tx001239gb.fm

Page 27

GPi 3200 / 4300 Operation

LCD (j)

LCD

changeover

switch (n)

and indicator

lights

Auto-power

saving switch

(o) and

indicator light

Engine oil

level warning

indicator light

(q)

The LCD (j) displays machine operating status such as voltage, frequency, and

operating hours. The LCD also displays O_Lod when the generator is in an

overload condition.

The green LCD changeover switch (n) allows the operator to cycle through the

various machine status modes described above.

Operating hours are displayed when the machine starts. The red operator hour

indicator light (k) illuminates.

Pressing the LCD changeover switch after starting changes the LCD display to

voltage. The red voltage indicator light (l) illuminates.

Pressing the LCD changeover swiitch a second time changes the LCD display

to frequency. The red frequency indicator light (m) illuminates.

Pressing the LCD changeover switch a third time changes the LCD display back

to operating hours. The red operator hour indicator light (k) illuminates.

When pressed, the red auto-power saving switch (o) activates the auto-power

saving function. The green auto-power saving indicator light (p) illuminates.

When the engine oil level falls below the specified operating level, the indicator

light (q) illuminates and the engine stop s. The oil level is detected by an interna l oil

sensor.

AC circuit

breakers (r)

An AC circuit breaker

(r)

shuts off the electrical current whe n the current exceeds its

limit, or a malfunction occurs in a piece of equipment connected to the generator.

An AC circuit breaker has activated when the toggle switch moves to the OFF

position.

To reset an AC circuit breaker, move the toggle switch to the ON position.

wc_tx001239gb.fm 27

Page 28

Operation GPi 3200 / 4300

RESET

TEST

RESET

TEST

2.11 Customer Connections

Description

Testing GFI

operation

The generator is equipped with:

one 120V 20A duplex receptacle (b) with a ground fault circuit interrupt (GFI)

one 120V 30A twist-lock receptacle (c)

one pair of DC terminals (e) exclusively intended for charging 12V automotive-

style batteries. See Using DC Power for more information.

c

b b1 b2

TEST

RESET

e

RESET

b1

TEST

b2

b

e

c

wc_gr006677

The GFI cuts power to the receptacle when a ground fault occurs to a piece of

equipment attached to the generator. Follow the procedure below to test the GFI

for proper operation every time the generator is used.

1. Disconnect all equipment from the generator.

2. Start the generator.

3. Push the black TEST button (b1) on the recept acle. Pushing the TEST button in

cuts power to the receptacle and causes the red RESET button (b2) to pop out.

NOTICE: If the RESET button does not pop out, the GFI is not working. Do not

operate the generator until the problem can be corrected.

4. Push the RESET button to restore power to the receptacle.

If the RESET button pops out during operation, stop the generator and check the

equipment attached to the generator for defects.

28 wc_tx001239gb.fm

Page 29

GPi 3200 / 4300 Operation

2.12 Grounding the Generator

Location

Function

The ground lug (d) is located to the right of the DC terminals.

d

d

w

wc_gr006664

This ground connection is used for electrically grounding the generator when

necessary to comply with the National Electrical Code and other federal, state, and

local regulations. For grounding requirements in you r area, consult with a qualified

electrician, electrical inspector, or local agency having jurisdiction over electrical

compliance.

If the generator is used at a construction site, there may be additional

regulations which must be observed.

In some areas, generators are required to be registered with local utility

companies.

Connection

Connect the ground lug to a good earthen ground for proper operating safety in

compliance with NEC and local standards. The following options may be used:

Connect the ground lug to a grounding spike (w) and drive the grounding spike

into the earth.

Connect the ground lug to an existing grounded conductor.

wc_tx001239gb.fm 29

Page 30

Operation GPi 3200 / 4300

2.13 Fueling the Machine

Fuel filler cap

The fuel filler cap (C) is located on top of the fuel tank. Turn the fuel filler cap

counter-clockwise to open; clockwise to close.

C

C1

C2

C2

wc_gr006665

WARNING

Fire/burn hazards. Gasoline is flammable and can ignite or explode.

f Keep all open flames, sparks, and cigarettes away from the machine while refu-

eling.

f Do not refuel if the generator is sitting in a truck fitted with a plastic bed liner.

Static electricity can ignite the fuel or fuel vapors.

f Do not refuel when the engine is running or hot.

Filling the fuel

tank

Using

gasoline /

ethanol

blends

Follow the guidelines below when filling the fuel tank.

Turn the engine switch (h) to STOP before refueling.

Refuel only with clean, fresh unleaded gasoline.

Add fuel through the fuel filter (C1), making sure that dirt or water do not enter

the fuel tank.

Fill only until the fuel level reaches the “F” mark on the fuel level gauge (C2). Do

not overfill!

Close the fuel filler cap tightly and clean up spilled fuel before operating the

machine.

This portable generator is not for use with gasoline / ethanol blends with over 15%

ethanol.

30 wc_tx001239gb.fm

Page 31

GPi 3200 / 4300 Operation

2.14 Before Starting

DANGER

Carbon monoxide. Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot

see or smell. If you can smell the generator exhaust, you are breathing CO. But

even if you cannot smell the exhaust, you could be breathing CO.

Explanation

Exterior

checks

Before putting the generator into service, review each item on the following

checklist. It is important to make sure that the machine is set up properly to reduce

the possibility of malfunction.

WARNING

Personal injury hazard. Failure to follow the listed procedures may cause injury to

personnel or damage to the generator.

f Make sure that all persons setting up the generator are certified or fully trained

on the installation and operation of the generator.

Before starting the generator:

check for damage that may have occurred during towing or travel to the jobsite

check for fuel leaks

check for loose or missing fasteners

make sure the exhaust pipe is not clogged with debris

make sure that the generator is level

make sure the generator is not resting on against any adjacent wiring

make sure that the generator air vents are not blocked

make sure that the generator is grounded to a good earthen ground per local

regulations and NEC standards

Internal and

pre-operation

checks

wc_tx001239gb.fm 31

check engine oil and fuel levels—fill as required

determine voltage needs

review and follow safety instructions found in the front of this Operator’s Manual

Page 32

Operation GPi 3200 / 4300

2.15 Starting the Generator (S Models)

CAUTION

Personal injury or machine damage hazards. S t arting the generator with equipme nt

attached can damage the generator or the equipment. Unexpected equipment

start-up can cause personal injury.

f Disconnect all equpment from the generator before starting it.

Starting

procedure

Follow the procedure below to start the machine.

1. Turn the engine switch (h) to the CHOKE position (or the RUN position if the

engine is warm or the ambient temperature is high).

n

h

g

wc_gr006666

2. Insert the starting key into the key switch (g).

3. Turn the starting key clockwise to the “I” (ON) position, then farther to the

START position. The engine will start.

NOTICE: To avoid machine damage, do not engage the starter motor continuously

for more than five seconds. If the engine fails to start, return the starting key to the

ON position, wait approximately 10 seconds, and then try again.

Do not turn the key switch to the START position when the engine is running.

4. If you started the engine with the engine switch in the CHOKE position, allow the

engine to run for 20–30 seconds and then turn the engine switch to the RUN

position.

5. Use the LED changeover switch (n) to switch to display voltage on the LCD. A

reading of 120V indicates that the generator is operating properly.

Trou bles h ooting

If the engine does not start after several attempts, repeat the st arting procedure

with the engine switch turned to the RUN position.

Try starting the machine manually. See Starting the Generator (Manual Start

Models).

If the engine still does not start, refer to the Troubleshooting chapter.

32 wc_tx001239gb.fm

Page 33

GPi 3200 / 4300 Operation

2.16 Starting the Generator (Manual Start Models)

CAUTION

Personal injury or machine damage hazards. S t arting the generator with equipmen t

attached can damage the generator or the equipment. Unexpected equipment

start-up can cause personal injury.

f Disconnect all equpment from the generator before starting it.

Starting

procedure

Follow the procedure below to start the machine.

1. Turn the engine switch (h) to the CHOKE position (or the RUN position if the

engine is warm or the ambient temperature is high).

n

h

f

wc_gr006840

2. Pull the recoil starter (f) slowly until you feel resistance.

3. After you feel resistance, return the recoil starter to its original position and pull

quickly. The engine will start.

4. If you started the engine with the engine switch in the CHOKE positio n, allow the

engine to run for 20–30 seconds and then turn the engine switch to the RUN

position.

5. Use the LED changeover switch (n) to switch to display voltage on the LCD. A

reading of 120V indicates that the generator is operating properly.

Troubleshooting

If the engine does not start after several attempts, repeat the starting procedure

with the engine switch turned to the RUN position. If the engine still does not start,

refer to the Troubleshooting chapter.

wc_tx001239gb.fm 33

Page 34

Operation GPi 3200 / 4300

7

AC 120V

NEUTRAL BONDED TO FRAME

RESET

TEST

OFF

OFF

TOTAL 2.8kVA

NEUTRE MIS A LA MASSE

A LA CARCASSE DU MOTEUR

2.17 Using AC Power

Prerequisites

Engine switch

position

Verify that the engine is operating.

Verify that the voltage displayed on the LCD (j) is approximately 120V.

Turn off the equipment to be connected to the generator.

Confirm that the equipment to be connected to the generator does not exceed

the maximum rated power output and specifed amperage.

WARNING

Electric shock hazard. Failure to properly ground the generator could lead to

electrical sparks, especially if the connected electrical equipment is grounded.

f Make sure the generator is properly grounded. See Grounding the Generator.

Leave the engine switch (h) in the RUN position while the machine is operating.

br

AC 120V

OFF

OFF

TEST

RESET

TOTAL 2.8kVA

NEUTRAL BONDED TO FRAME

NEUTRE MIS A LA MASSE

A LA CARCASSE DU MOTEUR

c

j

Connecting

equipment

Overload fault

Circuit

breaker

activation

Disconnecting

equipment

h

wc_gr00666

1. Insert the equipment plug into the 20A GFI receptacle (b) or the 30A twist-lock

receptacle (c).

Note: To use the 30A twist-lock receptacle, insert the plug into the receptacle and

turn it clockwise to the LOCK position.

2. Turn on the power switch for the equipment.

Excessive current draw on the generator will cause an overload fault. When this

fault occurs, AC power is cut off and O_Lod displays on the LCD.

To clear an overload fault, stop the engine immediately and remedy the overload

condition. Then re-start the engine.

If equipped, your machine’s circuit breakers

(r)

shut off the electrical current when the

current exceeds its limit. Circuit breakers also activate if a malfunction occurs in a

piece of equipment connected to the generator.

Reset circuit breakers by returning the toggle switches to the ON position.

Stop the machine and identify the cause if a circuit breaker activates repeatedly.

1. Turn off the power switch for the equipment.

2. Remove the plug from the 20A GFI receptacle or the 30A twist-lock receptacle.

Note: To remove the plug from the 30A twist-lock receptacle, first turn the plug

counter-clockwise to unlock it.

34 wc_tx001239gb.fm

Page 35

GPi 3200 / 4300 Operation

8

2.18 Using DC Power

Overview

Prerequisites

The DC terminals (e) are to be used only for charging 12V batteries. Maximum

available power is 12V–8.3A (100W).

WARNING

Risk of machine damage and electric shock.

f Do not use AC power and DC power at the same time.

Verify that the engine is operating.

Verify that the voltage displayed on the LCD (j) is approximately 120V.

Verify that nothing is connected to the AC outlets.

Make sure that the charging cables to be used are rated for 12V and the

maximum CCA rating of the battery.

WARNING

Personal injury hazard. Battery acid is corrosive to metallic surfaces and harmful to

human skin.

f Wear protective clothing, goggles and gloves when working near batteries.

f If battery acid contacts the skin or eyes, rinse immediately with clear water and

seek immediate medical attention.

Engine switch

position

WARNING

Explosion hazard. Explosive hydrogen gas is discharged through battery vent holes

during the charging process.

f Do not use open flames or smoke near batteries.

f Do not place metallic objects on or near the b attery terminals. Metallic object s in

contact with both poles of the battery will generate extreme heat and potentially

ignite explosive battery gases.

Leave the engine switch (h) in the RUN position while the generator is operating.

j

f

e2

e1

h

e

wc_gr00666

wc_tx001239gb.fm 35

Page 36

Operation GPi 3200 / 4300

Connecting

and charging

a battery

Disconnecting

the battery

If the DC

circuit breaker

activates

Follow the procedure below to connect and charge a battery.

1. Connect the positive terminal (e1) (red) on the generator to the positive (+)

battery terminal.

2. Connect the negative terminal (e2) (black) on the generator to the negative (-)

battery terminal.

3. Charge the battery for the recommended length of time prescribed by the

battery manufacturer.

When the battery is fully charged:

1. Disconnect the cable from the negative ( -) terminals of th e battery and the ge nerator.

2. Disconnect the cable from the positive (+) termin als of the ba ttery an d the gene rator.

The DC circuit breaker (f) may activate while a battery is charging. This may occur

for either of the following reasons:

Defective battery—check the battery before replacing the DC breaker

Excessive current draw from a large capacity battery or a totally discharged

battery—use an AC battery charger to charge the battery instead of the generator.

2.19 Stopping the Generator

Before

stopping

Stopping

procedure

Inform other personnel on the jobsite that power is being turned of f. Make sure that

the power shutdown will not create any hazards by turning off devices such as

pumps, heaters, or lights that may need to be kept on.

To stop the generator:

1. Switch off and disconnect all equipment from the generator.

2. Allow the generator to run at no load for approximately 3 minutes.

3. Turn the engine switch (h) to the STOP position.

h

g

4. (Electric start models only): Turn the key switch (g) to the “O” (STOP) position.

wc_gr006678

36 wc_tx001239gb.fm

Page 37

GPi 3200 / 4300 Operation

2.20 Emergency Shutdown Procedure

Procedure

If a breakdown or accident occurs while the machine is operating, follow the

procedure below:

1. Stop the engine.

2. Turn off the fuel supply.

3. Disconnect tools from the machine.

4. Allow the machine to cool.

5. Contact the rental yard or machine owner for further instructions.

wc_tx001239gb.fm 37

Page 38

Maintenance GPi 3200 / 4300

3 Maintenance

3.1 Periodic Maintenance Schedule

The table below lists basic machine and engine maintenance. Tasks designated

with check marks may be performed by the operator . Tasks designated with square

bullet points require special training and equipment.

Refer to the engine owner’s manual for additional information.

Clean generator enclosure

Check for loose or missing fasteners

Check engine oil level and refill as needed

Check AC receptacles for dirt or blockage;

test GFI

Check DC terminals for damage or dirt

Check engine switch and multi monitor for

proper operation

Clean spark plug

Clean air cleaner

Change engine oil

Clean spark arrester

Replace air cleaner element

Clean fuel strainer

Clean and adjust spark plug and electrodes

1

Every

8 hours

(daily)

3

3

3

3

3

3

Every

50 hours

(weekly)

Every

100 hours

(biweekly)

Every

200 hours

(monthly)

Every

500 hours

Every 1000

hours

Replace spark plug

Remove carbon from cylinder head

Check and adjust valve clearance

Clean and adjust carburetor

Clean and replace carbon brushes

Replace fuel lines

Overhaul engine

Check generator rotor

Check generator stator

Replace engine mount

3

2

1 Perform initial oil change after first 20 hours of operation.

2 Refer to the engine service manual or consult an authorized Wacker Neuson service center

3 Replace yearly

2

2

2

38 wc_tx001240gb.fm

Page 39

GPi 3200 / 4300 Maintenance

3.2 Detaching the Side Panels (S Models)

Description

Removing the

left side panel

Electric start machines are equipped with two sound attenuation panels. The

panels remain in place during normal operation. The left side panel (p) must be

detached and removed to perform routine maintenance.

Follow the procedure below to detach and remove the left side panel.

p1

d

p

1. Using a flat bladed screwdriver, loosen the two mounting screws (p1) at the top

of the panel.

Note: It is not necessary to completely remove the mounting screws. Loosen the m

only until the screws spin freely.

2. The bottom edge of the panel rests in a metal channel (p2). Grasp the rubber

seal at the top edge of the panel and pull the panel away from the generator

body.

p

p2

wcgr006841

Detaching the

right side

panel

3. Remove the panel by lifting it out of the channel in the direction of the white

arrow.

The right side panel (d) cannot easily be removed from the generator because of

the recoil starter. However, the right side panel can be detached if necessary by

following steps 1 and 2 above.

Re-attach the panels when maintenance work is complete.

wc_tx001240gb.fm 39

Page 40

Maintenance GPi 3200 / 4300

3.3 Checking the Engine Oil

When

Prerequisites

Procedure

Check engine oil daily before starting the engine, or more than 5 minutes after

stopping the engine.

Engine is stopped

Machine is on a level surface

Fresh oil is available (see Technical Data for type and quantity)

WARNING

Burn hazard. The engine and exhaust pipe become extremely hot during operation.

f Stop the engine and allow the machine to cool before checking the engine oil.

Follow the procedure below to check the engine oil level.

1. The oil filler cap (O) with level gauge is located at the rear of t he machine b elow

the engine exhaust pipe.

O

O1

O2

wc_gr006663

2. Unscrew and remove the oil filler cap from the oil fill port.

3. Wipe the level gauge clean and insert it into the oil fill port.

4. Remove the level gauge from the oil fill port and check the oil level. The oil level

should fall between the upper and lower marks (O1, O2).

5. If the oil level is too low, add oil until the level reaches the upper mark (O1).

6. Re-install the oil filler cap and tighten it securely.

Note: Change the oil if it appears dark, dirty, or contaminated. See “Changing the

Engine Oil.”

40 wc_tx001240gb.fm

Page 41

GPi 3200 / 4300 Maintenance

3.4 Cleaning the Air Cleaner

When

Prerequisite

Description

Procedure

Clean the air cleaner every 50 hours of operation.

Engine is stopped and cool to the touch

The air cleaner assembly consists of two urethane forms housed inside the air

cleaner body. A clean air cleaner prevents dirt from entering and damaging the

engine.

WARNING

Burn hazard. The engine and exhaust pipe become extremely hot during operation.

f Stop the engine and allow the machine to cool before cleaning the air cleaner.

Follow the procedure below to clean the air cleaner.

L1

L2

L

wc_gr006670

1. The air cleaner assembly (L) is located on the right side of the machine behind

the control panel. Unhook and remove the air cleaner body cover (L1).

2. Remove the urethane forms (L2) from the air cleaner body.

3. Rinse the urethane forms with clean water. Squeeze out excess water (do not

twist) and dry the urethane forms thoroughly.

4. Wipe the inside of the air cleaner body with a clean, dry cloth.

5. Re-install the urethane forms inside the air cleaner body.

6. Re-install the air cleaner body cover.

wc_tx001240gb.fm 41

Page 42

Maintenance GPi 3200 / 4300

3.5 Cleaning and Checking the Spark Plug

When

Prerequisite

Removing and

cleaning the

spark plug

Clean the spark plug and check the electrode gap every 200 hours of operation

(monthly).

Engine is stopped and cool to the touch

WARNING

Burn hazard. Engine and exhaust pipe become extremely hot during operation.

f Stop the engine a nd allow the machine to cool before cleaning and adjusting the

spark plug.

Follow the procedure below to remove and clean the spark plug.

1. The spark plug cap (K) is located on the side of the engine behind the air

cleaner.

K1

K2

K

Checking the

electrode gap

Re-installing

the spark plug

K

wc_gr006676

2. Disconnect the spark plug cap from the spark plug (K2).

3. Using the provided spark plug wrench (K1), unscrew and remove the spark

plug.

4. If the electrode is covered with carbon deposits, use a wire brush or spark plug

cleaner to remove the carbon.

NOTICE: If the spark plug is cracked or damaged, replace it. See Technical Data.

5. The electrode gap should measure between 0.6 to 0.7 mm (0.024 to 0.028 in.).

Adjust the gap if necessary.

6. Re-install the spark plug and tighten it securely.

NOTICE: A loose spark plug can become very hot and may cause engine dam-

age. Make sure that the spark plug is properly seated and tightened.

7. Re-connect the spark plug cap.

42 wc_tx001240gb.fm

Page 43

GPi 3200 / 4300 Maintenance

3.6 Changing the Engine Oil

When

Prerequisites

Changing the

engine oil

Change the engine oil after the first 20 hours of operation, and every 50 hours

thereafter.

Engine is stopped, but still warm

Machine is on a level surface

Fresh engine oil (see engine operator’s manual)

Plastic cloth and a container of sufficient volume to collect drained oil

Note: Collect, store and dispose of drained oil in accordance with current environmental protection regulations.

WARNING

Burn hazard. Engine and exhaust pipe become extremely hot during operation.

f Stop the engine and allow the machine to cool before changing the engine oil.

Follow the procedure below to change the engine oil

1. Place a plastic cloth and a collection container beneath the machine.

2. Unscrew and remove the oil filler cap (O) from the oil fill port.

O

E

wc_gr006669

3. The oil drain plug (E) is located at the base of the engine. Unscrew and remove

the oil drain plug. Drain the oil into a suitable container.

4. Re-install the oil drain plug.

5. Add new engine oil to the upper line of the level gauge on the oil filler cap. When

the proper oil level is reached, re-install the oil filler cap. See Checking the

Engine Oil.

wc_tx001240gb.fm 43

Page 44

Maintenance GPi 3200 / 4300

3.7 Cleaning the Spark Arrester

When

Prerequisite

Description

Procedure

Clean the spark arrester after every 100 hours of operation.

Engine is stopped and cool to the touch

The spark arrester is a cylindrical metal e lement fastened inside the exhaust outlet.

If the spark arrester is not cleaned regularly, it will become clogged with carbon

deposits and impair engine performance.

Engine exhaust gases will not flow.

Engine output will be reduced.

More fuel will be consumed.

Starting will become difficult.

CAUTION

Personal injury hazards. The spark arrester screen is made of stiff metal wire.

Sharp wire ends can puncture or cut skin. Carbon dust can get into eyes.

f Wear protective gloves and eye protection when cleaning the spark arrester.

Follow the procedure below to clean the spark arrester.

s

r

r2

r

r4

r5

q

r3

wc_gr006679

1. Remove the four flange bolts from the rear cover (s), and remove the rear cover.

2. Remove the nut (r2) and screw (r3) from the tail screen cover (r4), and remove

the tail screen cover.

3. Remove the tail screen (r5) and spark arrester (r) from the exhaust outlet (q).

4. Use a stiff brush to remove carbon deposits from the spark arrester screen.

NOTICE: Avoid damaging the spark arrester screen during the cleaning process.

5. Inspect the spark arrester screen for holes or cracks. If the screen is damaged,

replace it.

6. Re-insert the spark arrester screen into the exhaust outlet.

7. Re-install the tail screen and tail screen cover, and fasten with the nut and

screw.

8. Replace the rear cover and re-install the flange bolts.

44 wc_tx001240gb.fm

Page 45

GPi 3200 / 4300 Maintenance

3.8 Cleaning the Fuel Strainer

When

Prerequisite

Description

Procedure

Clean the fuel strainer monthly, or after every 200 hours of operation.

Engine is stopped and cool to the touch.

The fuel strainer (M) removes dirt and water from the fuel before it enters the

carburetor. Water and sediment collect in the fuel strainer cup (M1).

WARNING

Fire/burn hazards. Gasoline is flammable and can ignite or explode.

f Keep all open flames, sparks, and cigarettes away from the machine while

cleaning the fuel strainer.

f Do not clean the fuel strainer while the engine is running or hot.

Follow the procedure below to clean the fuel strainer.

M3

M

M2

M1

wc_gr006673

1. Using a wrench, remove the fuel strainer cup, gasket (M2), and screen (M3)

from the generator.

2. Empty collected water and sediment from the fuel strainer cup.

3. Using a clean dry cloth, wipe any remaining water and sediment from the

screen, the gasket, and the inside of the fuel strainer cup.

4. Re-assemble and re-install the fuel strainer. Tighten securely to prevent fuel leaks.

wc_tx001240gb.fm 45

Page 46

Maintenance GPi 3200 / 4300

3.9 Storing the Generator

When

Tasks

Prerequisites

Follow the procedures described below if you intend to take your generator out of

service and store it for at least six months.

The following tasks must be performed in order to prepare the generator fo r storage

1. Drain fuel from the fuel tank.

2. Drain fuel from the carburetor.

3. Change the engine oil.

4. Check for loose or missing fasteners; tighten or replace as needed.

5. Clean the machine.

6. Store the machine.

Engine is stopped and cool to the touch

Machine is on a level surface

Fresh engine oil (see engine operator’s manual)

Clean, dry shop cloths

Plastic cloth and containers of sufficient volume to collect drained fuel and oil

Note: Collect, store and dispose of drained fuel and oil in accordance with current

environmental protection regulations.

:

Draining the

fuel tank

WARNING

Fire/burn hazards. Gasoline is flammable and can ignite or explode.

f Keep all open flames, sparks, and cigarettes away from the machine while

draining the fuel tank and carburetor.

f Do not drain fuel while the engine is running or hot.

Follow the procedure below to drain the fuel tank.

M

M4

wc_gr006814

1. Place a plastic cloth and a collection container beneath the machine.

2. Locate the fuel line (M4). Pinch the fuel line with locking pliers or a hose pincher

and disconnect it from the fuel strainer (M).

3. Open the fuel line and drain fuel into the collection container.

46 wc_tx001240gb.fm

Page 47

GPi 3200 / 4300 Maintenance

4. Reconnect the fuel line to the fuel strainer.

5. Dispose of drained fuel.

Draining the

carburetor

6. Place a plastic cloth and a collection container beneath the machine.

a

a

wc_gr006674

7. Locate the fuel drain screw (a). The screw is either recessed or exposed

depending on your machine model.

8. Unscrew and remove the fuel drain screw. Fuel will drain from the attached

plastic tube.

9. Collect and dispose of drained fuel.

Change the

engine oil

Check

fasteners

Clean the

machine

Store the

machine

10.Re-install the fuel drain screw.

See Changing the Engine Oil.

Check the machine for loose or missing fasteners. Tighten or replace as needed.

11.Using a clean, dry shop cloth, wipe the outside of the machine thoroughly to

remove dust and contaminants.

12.Spray the machine with a protectant such as Armor-All®.

NOTICE: Do not use water to clean the machine! Water is corrosive and can per-

manently damage the machine and operating electronics.

13.Store the machine in a well-ventilated, low humidity area.

wc_tx001240gb.fm 47

Page 48

Schematics GPi 3200 / 4300

4 Schematics

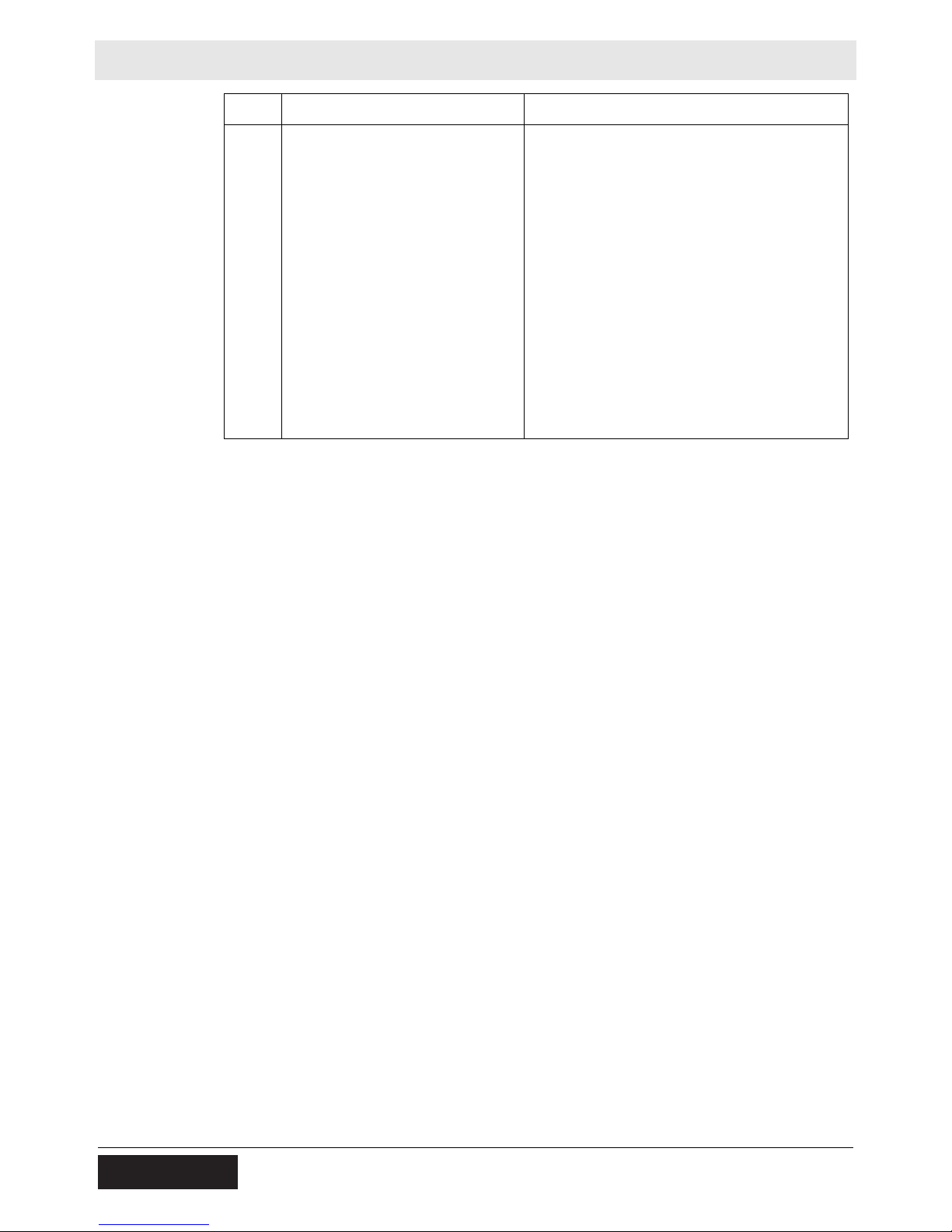

4.1 Electrical Schematic (S Models, non-CSA)

B

E

F

G

H

D

N

J

C

K

L

M

O

A

V

S

T

W

U

P

Z

R

Q

X

Y

wc_gr006681

48 wc_tx001241gb.fm

Page 49

GPi 3200 / 4300 Schematics

4.2 Electrical Schematic Components (S Models, non-CSA)

Component Component

A Engine O Monitor control unit

B Generator P Engine switch

C Control panel Q AC receptacle, 120V 20A

D Diode rectifier R Ground terminal

E Coil (1) S Stepping motor

F Coil (2) T Oil level sensor

G Coil (3) U Ignition coil

H Main coil V Starting motor

J DC circuit breaker W Battery

K DC output terminal X Fuse, 10A

L Diode rectifier Y Relay

M Key switch Z AC receptacle, 120V 30A

N Inverter and engine control unit AA Circuit breaker

Wire Colors

Blk Black Brn Brown Org Orange

Blk/W Black/White Brn/W Brown/White Gry Gray

Blu Blue Grn Green R Red

LBlu Pink Grn/W Green/White W White

Y Yellow W/Blk White/Black Grn/Y Green/Yellow

Pur Purple

wc_tx001241gb.fm 49

Page 50

Schematics GPi 3200 / 4300

4.3 Electrical Schematic (CSA)

B

E

F

G

H

S

D

N

J

C

K

L

M

O

A

T

V

W

U

P

X

AA

AA

Y

Z

(AA)

Q

R

wc_gr007295

50 wc_tx001241gb.fm

Page 51

GPi 3200 / 4300 Schematics

4.4 Electrical Schematic Components (CSA)

Component Component

A Engine O Monitor control unit

B Generator P Engine switch

C Control panel Q AC receptacle, 120V 20A

D Diode rectifier R Ground terminal

E Coil (1) S Stepping motor

F Coil (2) T Oil level sensor

G Coil (3) U Ignition coil

H Main coil V Starting motor

J DC circuit breaker W Battery

K DC output terminal X Fuse, 10A

L Diode rectifier Y Relay

M Key switch Z AC receptacle, 120V 30A

N Inverter and engine control unit AA Circuit breaker

Wire Colors

Blk Black Brn Brown Org Orange

Blk/W Black/White Brn/W Brown/White Gry Gray

Blu Blue Grn Green R Red

LBlu Pink Grn/W Green/White W White

Y Yellow W/Blk White/Black Grn/Y Green/Yellow

Pur Purple

wc_tx001241gb.fm 51

Page 52

Schematics GPi 3200 / 4300

4.5 Electrical Schematic (Manual Start Models, non-CSA)

B

E

F

G

H

S

D

J

N

Z

C

K

M

O

R

A

T

U

Q

P

wc_gr006848

52 wc_tx001241gb.fm

Page 53

GPi 3200 / 4300 Schematics

4.6 Electrical Schematic Components (Manual Start Models, non-CSA)

Component Component

A Engine K DC output terminal

B Generator M Micro switch

C Control panel N Inverter and engine control unit

D Diode rectifier O Monitor control unit

E Coil (1) P Engine switch

F Coil (2) Q AC receptacle, 120V 20A

G Coil (3) R Ground terminal

H Main coil U Ignition coil

J DC circuit breaker Z AC receptacle, 120V 30A

Wire Colors

Blk Black Brn Brown Org Orange

Blk/W Black/White Brn/W Brown/White Gry Gray

Blu Blue Grn Green R Red

LBlu Pink Grn/W Green/White W White

Y Yellow W/Blk White/Black Grn/Y Green/Yellow

Pur Purple

wc_tx001241gb.fm 53

Page 54

Schematics GPi 3200 / 4300

4.7 Electrical Schematic (Manual Start Models, CSA)

B

E

F

G

H

S

D

Org

Gry

Brn

Brn

W

W

Grn/Y

R

W

Blu

Grn

Blu

Pur