Wacker Neuson GP 3800A, GP 5600A, GP 6600A Repair Manual

www.wackergroup.com

Generator

GP 2500A

GP 3800A

GP 5600A

GPS 5600A

GP 6600A

GPS 6600A

REPAIR MANUAL

0160415en 001

0806

0160415EN

GP Repair Foreword

wc_tx000544gb.fm i

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or repair it. Basic operating and maintenance

procedures are described in the Operator’s Manual supplied with the

machine. Keep a copy of the Operator’s Manual with the machine at all

times. Use the separate Parts Book supplied with the machine to order

replacement parts. If you are missing either of the documents, please

contact Wacker Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to

the attention of the operator to prevent similar occurrences from

happening in the future.

This manual provides information and procedures to safely repair and

maintain the above Wacker model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. THE INFORMATION

CONTAINED IN THIS MANUAL IS BASED ON MACHINES

MANUFACTURED UP TO THE TIME OF PUBLICATION. WACKER

CORPORATION RESERVES THE RIGHT TO CHANGE ANY

PORTION OF THIS INFORMATION WITHOUT NOTICE.

This manual covers machines with Item Number:

0620009, 0620010, 0620011, 0620012, 0620013, 0620014, 0620015,

0620016, 0620041, 0620042, 0620043, 0620044, 0620045, 0620046,

0620047

Foreword GP Repair

wc_tx000544gb.fm ii

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

All rights, especially copying and distribution rights, are reserved.

Copyright 2006 by Wacker Corporation

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights, and

violators will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

WARNING

GP Repair Table of Contents

wc_br0160415en_001TOC.fm 1

1. Safety Information 4

1.1 Operating Safety .................................................................................. 5

1.2 Operator Safety while using Internal Combustion Engines .................. 7

1.3 Service Safety ...................................................................................... 8

1.4 Label Locations .................................................................................... 9

1.5 Safety and Operating Labels .............................................................. 10

2. Technical Data 14

2.1 Generator—GP 2500A ....................................................................... 14

2.2 Engine—GP 2500A ............................................................................ 15

2.3 Generator—GP 3800A, GP 3800A CAN ............................................ 16

2.4 Engine—GP 3800A, GP 3800A CAN ................................................. 17

2.5 Generator—GP/GPS 5600A/5600A CAN .......................................... 18

2.6 Engine—GP/GPS 5600A/5600A CAN ............................................... 20

2.7 Generator—GP/GPS 6600A/6600A CAN .......................................... 22

2.8 Engine—GP/GPS 6600A/6600A CAN ............................................... 24

3. Operation 25

3.1 Information Regarding Operation ....................................................... 25

3.2 Determining Power Requirements ..................................................... 25

3.3 Outdoor Installation ............................................................................ 27

3.4 Indoor Installation ............................................................................... 27

3.5 Recommended Battery (GPS only) .................................................... 27

3.6 Generator Derating ............................................................................. 28

3.7 Grounding the Generator ................................................................... 29

3.8 Control Panel ...................................................................................... 30

3.9 Control Panel—GP 3800 .................................................................... 31

3.10 Control Panel—GP 5600/GP6600 ...................................................... 32

3.11 Ground Fault Interrupt (GFI) ............................................................... 33

3.12 Twist-Lock Receptacles ..................................................................... 33

3.13 Engine Auto Idle ................................................................................. 34

3.14 Engine Speed ..................................................................................... 34

3.15 Voltage Selection ............................................................................... 35

3.16 To Start ............................................................................................... 36

3.17 To Stop ............................................................................................... 37

Table of Contents GP Repair

wc_br0160415en_001TOC.fm 2

4. Maintenance 38

4.1 Engine Maintenance ............................................................................38

4.2 Periodic Maintenance Schedule ..........................................................38

4.3 Engine Oil ............................................................................................39

4.4 Servicing Air Cleaner ...........................................................................40

4.5 Spark Plug ...........................................................................................41

4.6 Cleaning the Sediment Cup ................................................................42

4.7 Carburetor Adjustment ........................................................................42

4.8 Adjusting Engine Speed ......................................................................43

4.9 Storage ................................................................................................44

4.10 Transport .............................................................................................45

4.11 Electrical Schematic—GP 2500A ........................................................46

4.12 Components—GP 2500A ....................................................................47

4.13 Electrical Schematic—GP 3800A (0620010 rev. < 104) .....................48

4.14 Components—GP 3800A (0620010 rev. < 104) .................................49

4.15 Electrical Schematic—GP 3800A (0620010 rev. > 103) .....................50

4.16 Components—GP 3800A (0620010 rev. > 103) .................................51

4.17 Electrical Schematic—GP 3800A CAN (0620041 rev. < 104) .............52

4.18 Components—GP 3800A CAN (0620041 rev. < 104) .........................53

4.19 Electrical Schematic—GP 3800A CAN (0620041 rev. > 103) .............54

4.20 Components—GP 3800A CAN (0620041 rev. > 103) .........................55

4.21 Electrical Schematic—GP/GPS 5600A/6600A (rev. < 104) ................56

4.22 Components—GP/GPS 5600A/6600A (rev. < 104) ............................57

4.23 Electrical Schematic—GP/GPS 5600A/6600A (rev. > 103) ................58

4.24 Components—GP/GPS 5600A/6600A (rev. > 103) ............................59

4.25 Electrical Schematic (CAN)—GP/GPS 5600A/6600A (rev. < 104) .....60

4.26 Components (CAN)—GP/GPS 5600A/6600A (rev. < 104) .................61

4.27 Electrical Schematic (CAN)—GP/GPS 5600A/6600A (rev. >103) ......62

4.28 Components (CAN)—GP/GPS 5600A/6600A (rev. > 103) .................63

4.29 Engine Schematic (all)—GP/GPS 3800A/5600A/6600A .....................64

4.30 Engine Components (all)—GP/GPS 3800A/5600A/6600A .................65

5. Theory of Operation 67

5.1 Introduction ..........................................................................................67

5.2 Windings and Fields ............................................................................68

5.3 Voltage Regulation ..............................................................................69

5.4 Auto Idle Circuit ...................................................................................70

5.5 Anti-Afterfire Circuit .............................................................................71

GP Repair Table of Contents

wc_br0160415en_001TOC.fm 3

6. Troubleshooting 72

6.1 Troubleshooting Methodology ............................................................ 72

6.2 Checking Continuity ........................................................................... 74

6.3 Checking Resistance .......................................................................... 74

6.4 Checking Voltage ............................................................................... 74

6.5 Troubleshooting Flowcharts ............................................................... 75

6.6 No Voltage at Receptacles—Flowchart 1A ........................................ 76

6.7 No Voltage at Receptacles—Flowchart 1B ........................................ 77

6.8 Checking Voltage at Generator Terminal Strip ................................... 78

6.9 Checking Voltage at Plug—GP 2500A ............................................... 79

6.10 Checking Main and Rotor Windings ................................................... 80

6.11 No Voltage at Receptacles—Flowchart 1C ........................................ 82

6.12 Checking Main Circuit Breaker and Receptacle Circuitry ................... 84

6.13 Low Voltage at Receptacles—Flowchart 2A ...................................... 86

6.14 Checking Brushes .............................................................................. 87

6.15 Checking Excitation Winding .............................................................. 88

6.16 Checking AVR’s Sensing Wires—GP 2500A ..................................... 90

6.17 Checking AVR’s Sensing Wires ......................................................... 92

6.18 Confirming a Malfunctioning AVR ...................................................... 94

6.19 Checking and Installing the Voltage Selector Switch (VSS) ............... 96

6.20 High Voltage Troubleshooting—Flowchart 3A ................................... 98

6.21 Auto Idle Circuit Troubleshooting—Flowchart 4A ............................... 99

6.22 Checking Voltage to Auto Idle Solenoid ........................................... 100

6.23 Checking Auto Idle Circuitry Between Generator and Fuse ............. 102

6.24 Checking Auto Idle Circuitry Between Fuse and Auto Idle Unit ....... 104

6.25 Engine Backfires—Troubleshooting Flowchart 5A ........................... 105

6.26 Checking Anit-Afterfire Solenoid (AAS) Circuit ................................. 106

7. Disassembly/Assembly Procedures 109

7.1 Tools ................................................................................................. 109

7.2 Ordering Parts .................................................................................. 109

7.3 Reference Numbers ( ) ..................................................................... 109

7.4 Weight Block .................................................................................... 109

7.5 Replacing the Muffler ....................................................................... 110

7.6 Replacing the Fuel Tank .................................................................. 112

7.7 Replacing the Stator ......................................................................... 114

7.8 Replacing the Rotor .......................................................................... 116

7.9 Replacing the Engine ....................................................................... 118

Safety Information GP Repair

wc_si000169gb.fm 4

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

Note: Contains additional information important to a procedure.

DANGER

WARNING

CAUTION

GP Repair Safety Information

wc_si000169gb.fm 5

1.1 Operating Safety

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER

DISTRIBUTION SYSTEM CAN CAUSE SERIOUS INJURY OR

DEATH TO UTILITY WORKERS!

Improper connection of generator to a building's electrical system can

allow electrical current from the generator to backfeed into utility lines.

This may result in electrocution of utility workers, fire, or explosion.

Connections to a building's electrical system must be made by a

qualified electrician and comply with all applicable laws and electrical

codes.

If connected to a building's electrical system the generator must meet

the power, voltage, and frequency requirements of the equipment in

the building. Differences in power, voltage, and frequency

requirements may exist and improper connection may lead to

equipment damage, fire, and personal injury or death.

Familiarity and proper training are required for the safe operation of

equipment. Equipment operated improperly or by untrained personnel

can be dangerous. Read the operating instructions contained in both

this manual and the engine manual and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the equipment before

being allowed to operate the machine.

1.1.1 NEVER operate the generator when open containers of fuel, paint, or

other flammable liquids are near.

1.1.2 NEVER operate the generator, or tools attached to the generator, with

wet hands.

1.1.3 NEVER use worn electrical cords. Severe electrical shock and

equipment damage may result.

1.1.4 NEVER run the electrical cords under the generator, or over vibrating

or hot parts.

1.1.5 NEVER enclose or cover the generator when it is in use or when it is

hot.

1.1.6 NEVER overload the generator. The total amperage of the tools and

equipment attached to the generator must not exceed the load rating

of the generator.

1.1.7 NEVER operate the machine in snow, rain, or standing water.

1.1.8 NEVER allow untrained personnel to operate or service the generator.

The generator set should be set up by a trained electrician.

1.1.9 NEVER stand on the machine.

1.1.10 DO NOT stand under the machine while it is being hoisted or moved.

1.1.11 DO NOT attach equipment to the machine when it is suspended.

DANGER

WARNING

Safety Information GP Repair

wc_si000169gb.fm 6

1.1.12 ALWAYS store the equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the reach of

children.

1.1.13 ALWAYS position and operate the generator on a firm,

noncombustible, level surface.

1.1.14 ALWAYS transport the generator in an upright position.

1.1.15 ALWAYS keep the machine at least one meter (three feet) away from

structures, buildings, and other equipment during use.

1.1.16 ALWAYS keep the area immediately surrounding and underneath the

machine clean, neat, and free of debris and combustible materials.

Make sure that the area overhead is clear of debris that could fall onto

or into the machine or exhaust compartment.

1.1.17 ALWAYS remove all tools, cords, and other loose items from the

generator before starting it.

1.1.18 ALWAYS make certain the machine is well-grounded and securely

fastened to a good earthen ground per national and local regulations.

GP Repair Safety Information

wc_si000169gb.fm 7

1.2 Operator Safety while using Internal Combustion En gines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

warnings and safety guidelines could result in severe injury or death.

1.2.1 DO NOT run the machine indoors or in an enclosed area such as a

deep trench unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

1.2.2 DO NOT smoke while operating the machine.

1.2.3 DO NOT smoke when refueling the engine.

1.2.4 DO NOT refuel a hot or running engine.

1.2.5 DO NOT refuel the engine near an open flame.

1.2.6 DO NOT spill fuel when refueling the engine.

1.2.7 DO NOT run the engine near open flames.

1.2.8 DO NOT start the engine if fuel has spilled or a fuel odor is present.

Move the generator away from the spill and wipe the generator dry

before starting.

1.2.9 ALWAYS refill the fuel tank in a well-ventilated area.

1.2.10 ALWAYS replace the fuel tank cap after refueling.

1.2.11 ALWAYS check the fuel lines and the fuel tank for leaks and cracks

before starting the engine. Do not run the machine if fuel leaks are

present or the fuel lines are loose.

DANGER

Safety Information GP Repair

wc_si000169gb.fm 8

1.3 Service Safety

Poorly maintained equipment can become a safety hazard! In order

for the equipment to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary. If

the generator is experiencing problems or is being serviced, attach a

“DO NOT START” sign to the control panel to notify other people of its

condition.

1.3.1 DO NOT use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.3.2 DO NOT attempt to clean or service the machine while it is running.

1.3.3 DO NOT modify the equipment without the express written approval of

the manufacturer.

1.3.4 DO NOT allow water to accumulate around the base of the machine.

If water is present, move the machine and allow the machine to dry

before servicing.

1.3.5 DO NOT service the machine if your clothing or skin is wet.

1.3.6 DO NOT allow untrained personnel to service this equipment. Only

trained electrical technicians should be allowed to service the electrical

components of this equipment.

1.3.7 ALWAYS keep the machine clean and labels legible. Replace all

missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

1.3.8 ALWAYS replace the safety devices and guards after repairs and

maintenance.

1.3.9 ALWAYS let the engine cool before transporting or servicing it.

1.3.10 ALWAYS keep hands, feet, and loose clothing away from the moving

parts on the generator and engine.

1.3.11 ALWAYS turn the engine off before servicing the machine. If the

engine has electric start, disconnect the negative terminal on the

battery before servicing the machine.

1.3.12 ALWAYS keep the fuel lines in good condition and properly connected.

Leaking fuel and fumes are extremely explosive.

WARNIN

G

GP Repair Safety Information

wc_si000169gb.fm 9

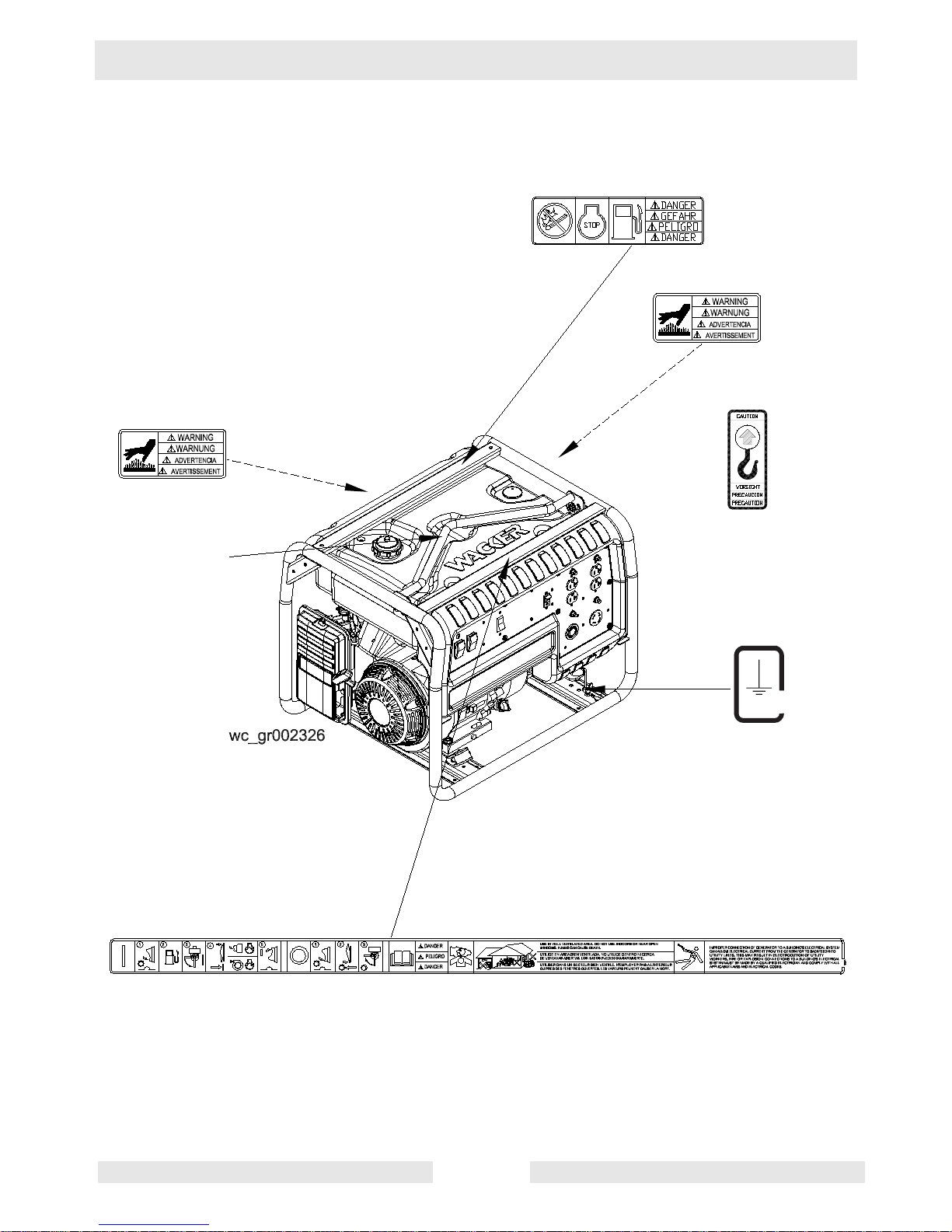

1.4 Label Locations

GND

88897

Safety Information GP Repair

wc_si000169gb.fm 10

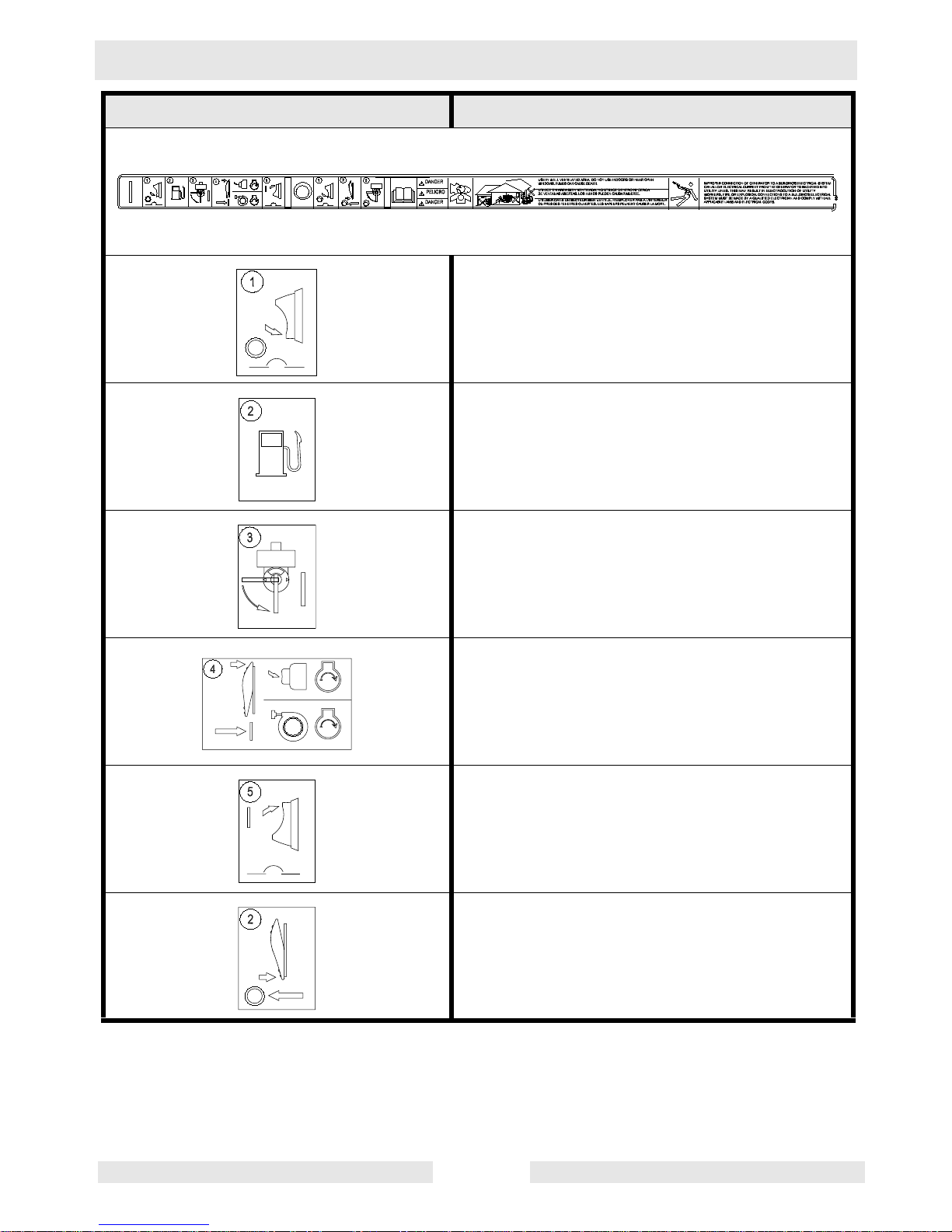

1.5 Safety and Operating Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

WARNING!

Hot surface!

CAUTION!

Read and understand the supplied Operator’s

Manuals before operating this machine. Failure to do so increases the risk of injury to yourself or others.

CAUTION!

Lifting point

Electrical ground

GND

88897

GP Repair Safety Information

wc_si000169gb.fm 11

Close main circuit breaker.

Check the fuel level.

Open the fuel flow valve.

Press engine switch to ON position.

GPS — Press ignition switch.

GP — Pull the rewind starter.

Open main circuit breaker.

Press engine switch to OFF position.

Label Meaning

Safety Information GP Repair

wc_si000169gb.fm 12

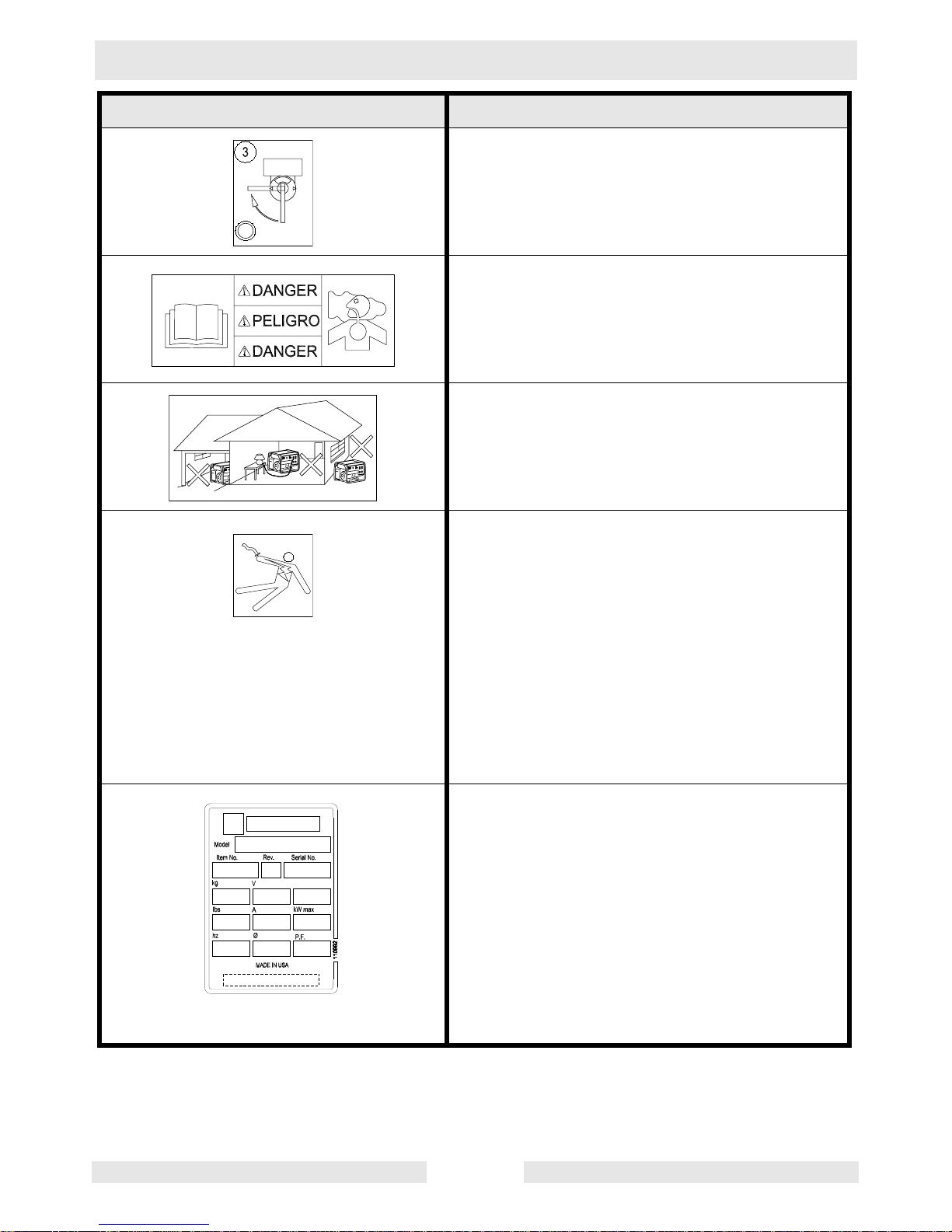

Close the fuel flow valve.

DANGER!

Asphyxiation hazard. Read the operator’s

manual for instructions.

Use in a well-ventilated area. Do not use

indoors or near open windows. Fumes can

cause death.

WARNING!

To reduce the risk of electrical shock, read the

operator’s manual. Improper connection of the

generator to a building’s electrical system can

allow electrical current from the generator to

backfeed into utility lines. This may result in

electrocution of utility workers, fire or explosion. Connections to a building’s electrical system must be made by a qualified electrician

and comply with all applicable laws and electrical codes.

A nameplate listing the model number, item

number, revision number, and serial number is

attached to each unit. Please record the information found on this plate so it will be available

should the nameplate become lost or damaged. When ordering parts or requesting service information, you will always be asked to

specify the model number, item number, revision number, and serial number of the unit.

Label Meaning

GP Repair Safety Information

wc_si000169gb.fm 13

This machine may be covered by one or more

patents.

DANGER!

No sparks, flames or burning objects near

machine.

Shut off the engine before refueling.

Label Meaning

Technical Data GP Repair

wc_td000169gb.fm 14

2. Technical Data

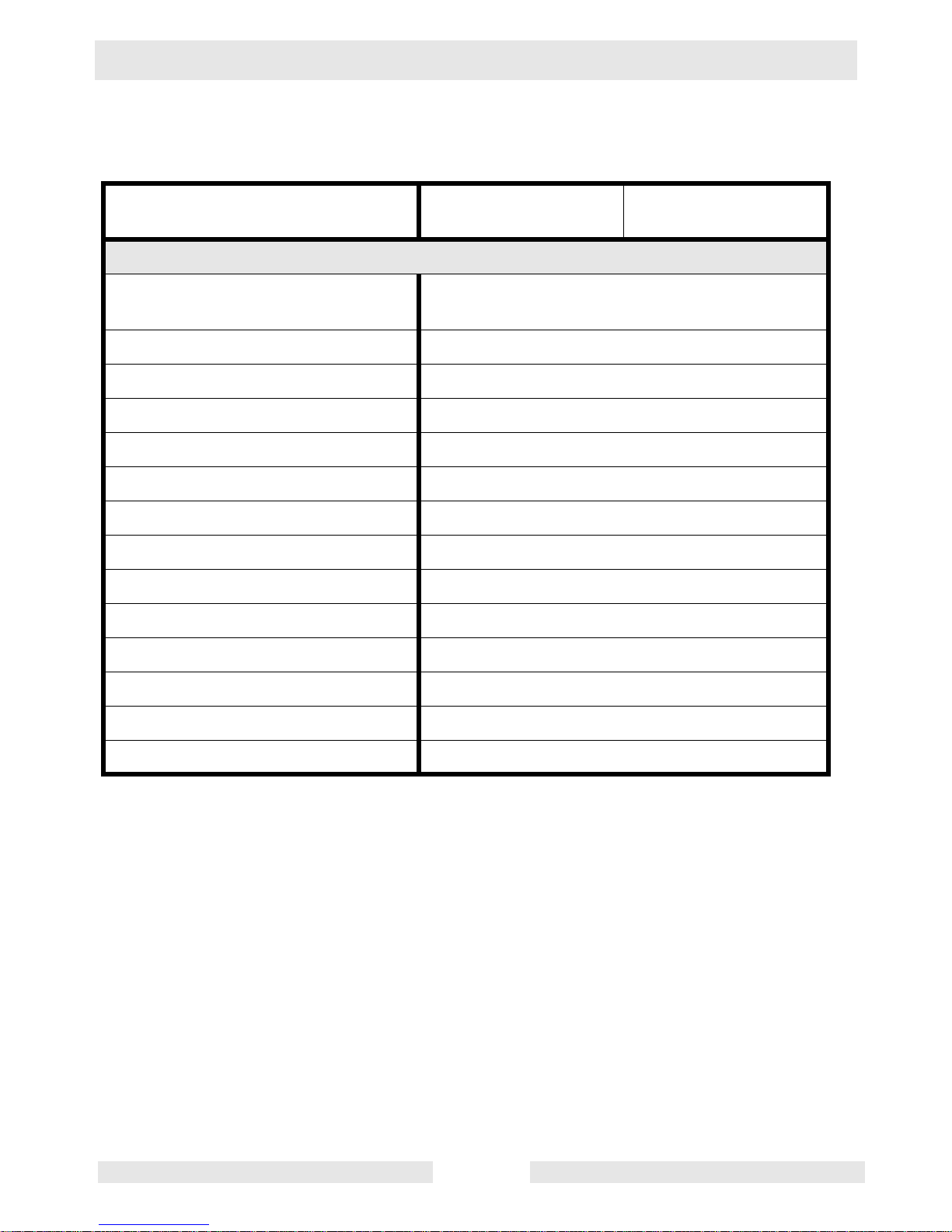

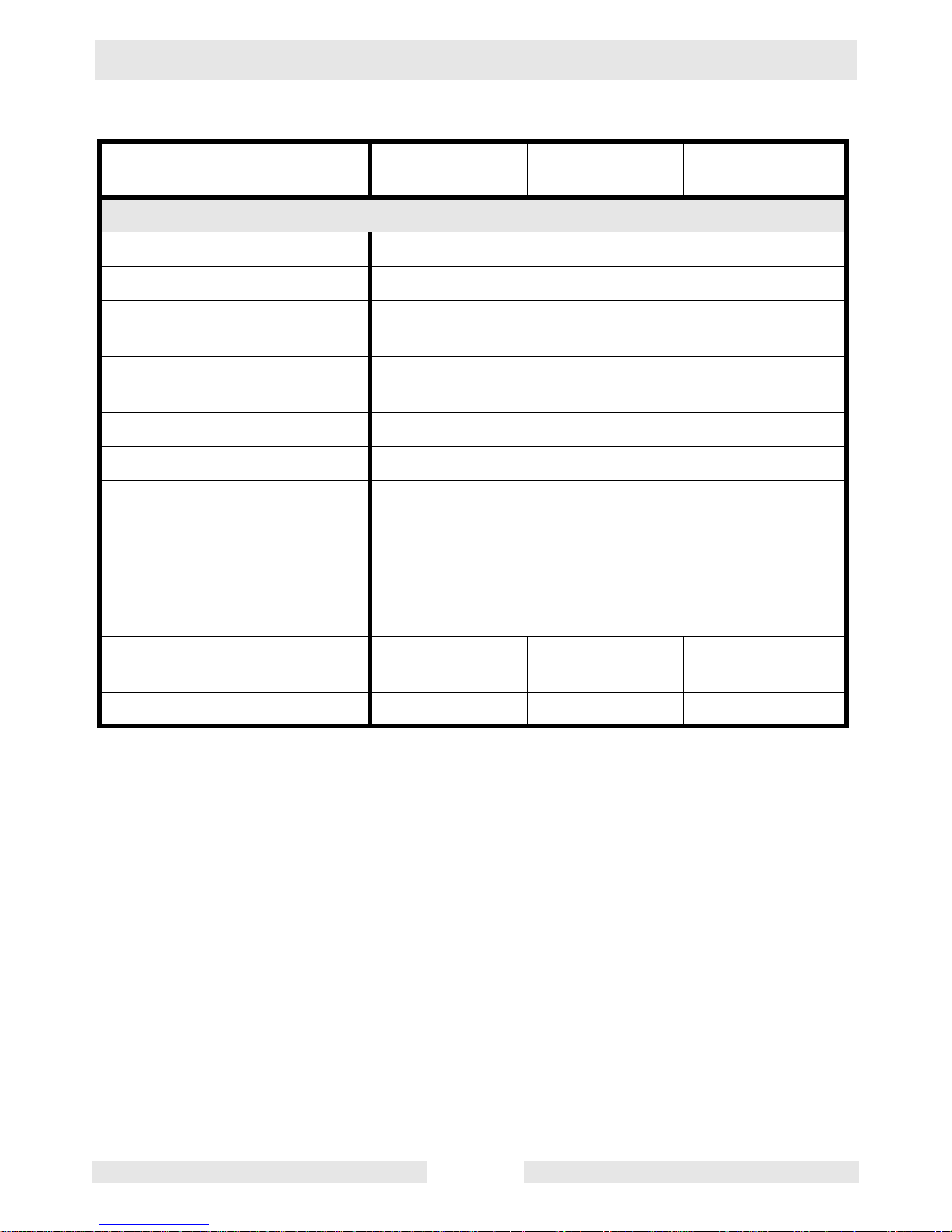

2.1 Generator—GP 2500A

Item No. GP 2500A

0620009

Generator

Maximum Output

W

2500

Continuous Output

W

2250

Type Single voltage, single phase,

Auto voltage regulator system

AC Voltages Available

volts

phase

120

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

125V GFI duplex

125V duplex

amp

amp

20

20

Main Circuit Breaker

amp

20

L x W x H

mm (in.)

565 x 435 x 445 (22.3 x 17 x 17.5)

Weight (dry)

Kg (lbs.)

44.5 (98)

GP Repair Technical Data

wc_td000169gb.fm 15

2.2 Engine—GP 2500A

Item No. GP 2500A

0620009

Engine

Engine Make Honda

Engine Model GX 160 K1VX

Rated Power

kW (Hp)

4.1 (5.5)

Spark Plug BPR6ES / W20EPR-U

Electrode Gap

mm (in.)

0.7–0.8 (0.028–0.031)

Operating Speed (Max.)

rpm

3600

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD, or SC

Engine Oil Capacity

l (qts.)

0.6 (0.7)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

12 (3)

Fuel Consumption

l (qts.)/hr.

1.7 (1.8)

Running Time - full load

hrs.

7

Technical Data GP Repair

wc_td000169gb.fm 16

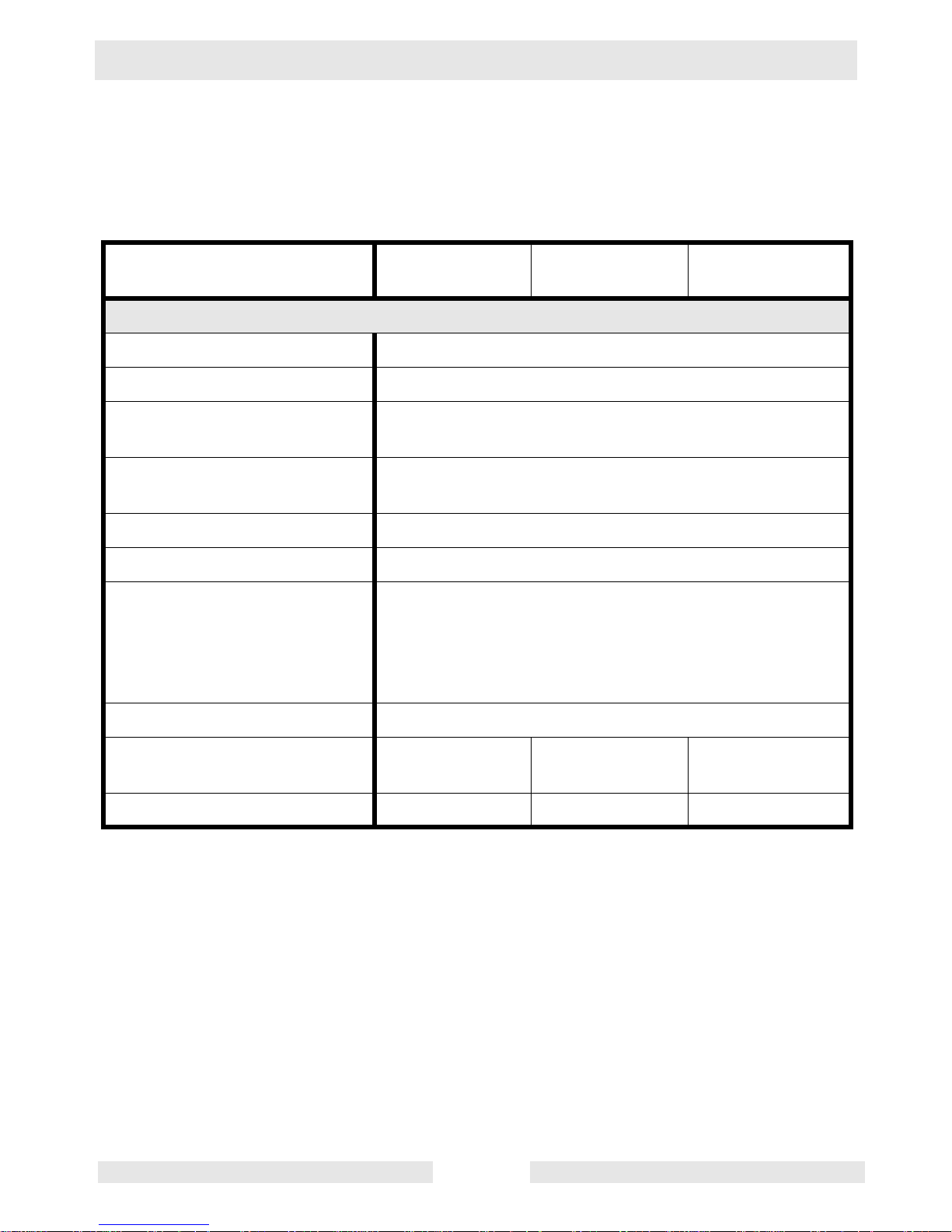

2.3 Generator—GP 3800A, GP 3800A CAN

Item No. GP 3800A

0620010

GP 3800A CAN

0620041

Generator

Maximum Output

W

3800

Continuous Output

W

3400

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages Available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

125V GFI duplex

125V GFI duplex

125V twist-lock

125V/250V twist-lock

amp

amp

amp

amp

20

20

30

20

Main Circuit Breaker

amp

2-pole, 16 amp each pole

L x W x H

mm (in.)

685 x 530 x 520 (27 x 21 x 20.5)

Weight (dry)

Kg (lbs.)

73 (160)

GP Repair Technical Data

wc_td000169gb.fm 17

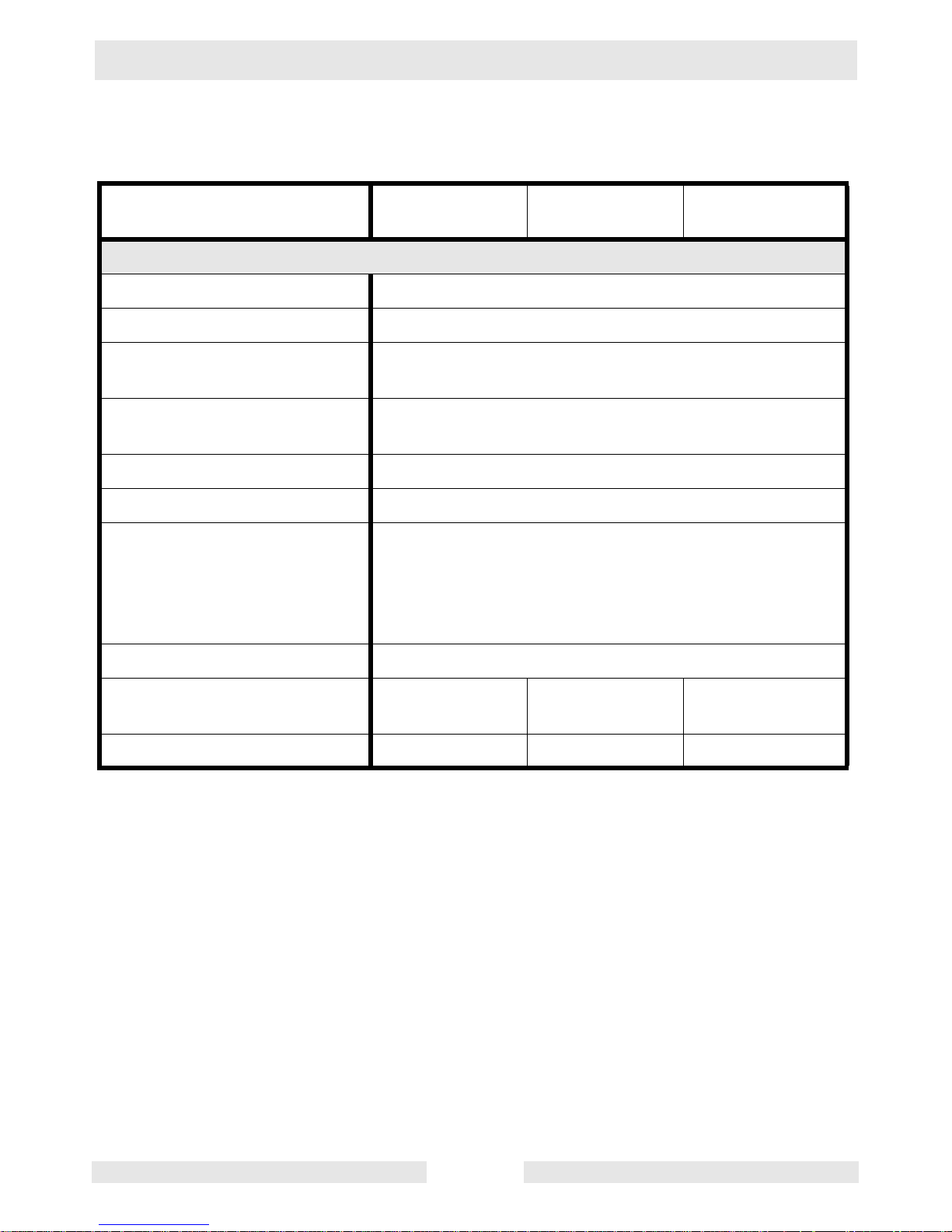

2.4 Engine—GP 3800A, GP 3800A CAN

Item No. GP 3800A

0620010

GP 3800A CAN

0620041

Engine

Engine Type Single cylinder, 4-cycle,

air-cooled, gasoline engine

Engine Make Honda

Engine Model GX 240

Rated Power

kW (Hp)

6 (8)

Spark Plug BPR6ES / W20EPR-U

Electrode Gap

mm (in.)

0.7–0.8 (0.028–0.031)

Operating Speed (max.)

rpm

3600

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD or SC

Engine Oil Capacity

l (qts.)

1.1 (1.2)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

19.5 (5.2)

Fuel Consumption

l (qts.)/hr.

2.4 (2.5)

Running Time

hrs.

8.2

Technical Data GP Repair

wc_td000169gb.fm 18

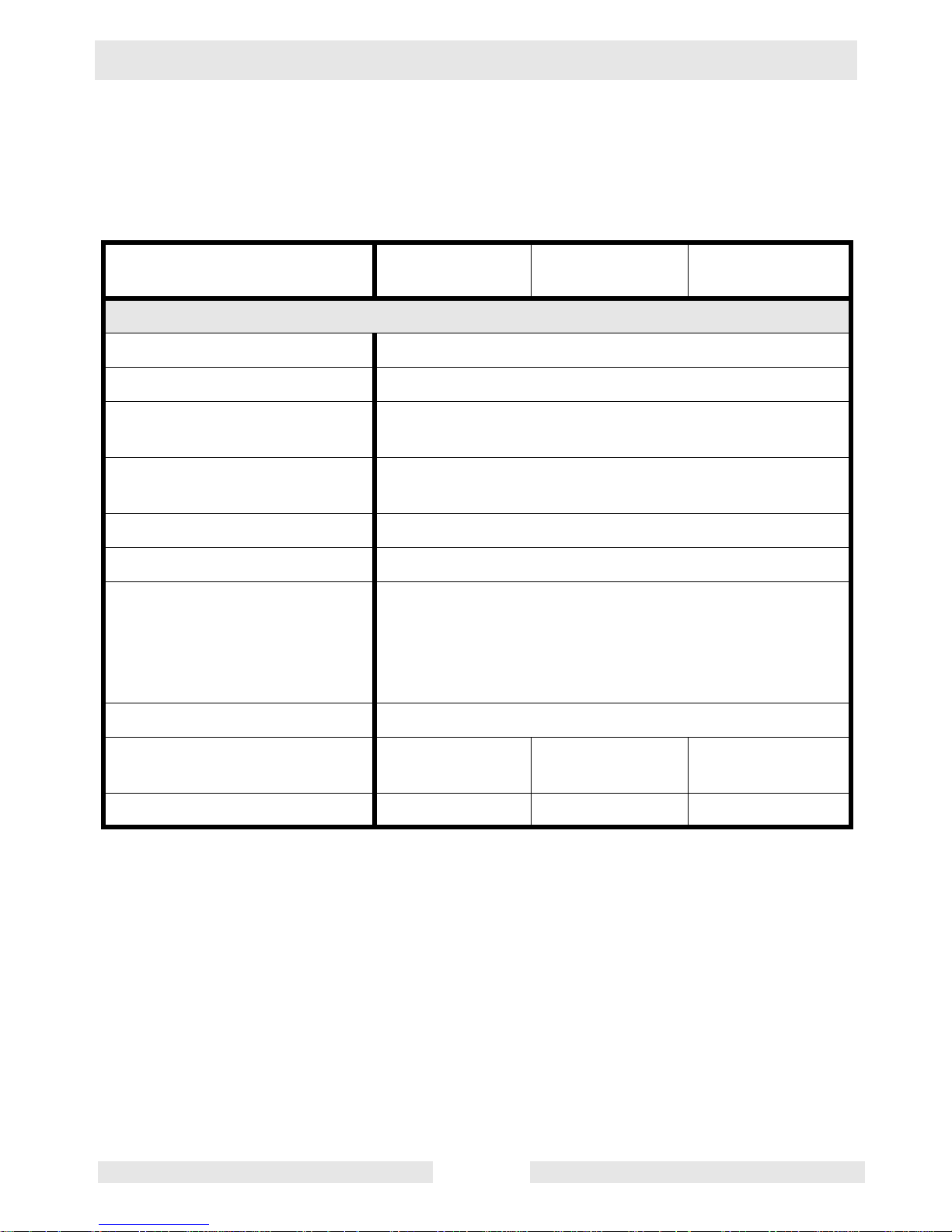

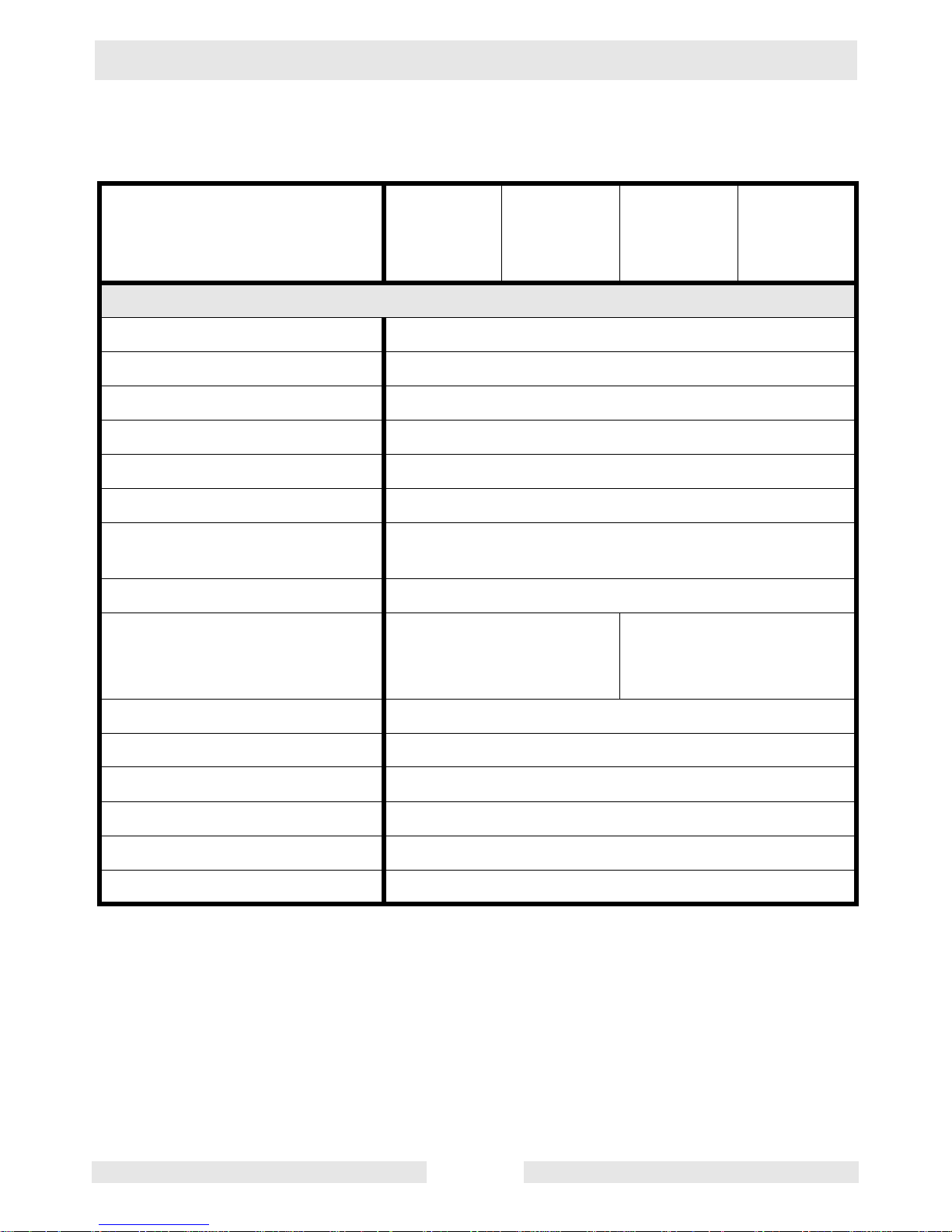

2.5 Generator—GP/GPS 5600A/5600A CAN

Item No. GP 5600A

0620011

GP 5600A

0620012

GPS 5600A

0620013

Generator

Maximum Output

W

5600

Continuous Output

W

5000

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages

Available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

125V GFI duplex

125V GFI duplex

125V twist-lock

125V/250V twist-lock

amp

amp

amp

amp

20

20

30

30

Main Circuit Breaker

amp

2-pole, 23 amp each pole

L x W x H

mm

(in.)

685 x 530 x 520

(27 x 21 x 20.5)

1005 x 685 x 660

(39.5 x 27 x 26)

870 x 530 x 520

(34.3 x 21 x 20.5)

Weight (dry)

Kg (lbs.)

84 (186) 94 (208) 91 (201)

GP Repair Technical Data

wc_td000169gb.fm 19

Item No. GP 5600A CAN

0620042

GP 5600A CAN

0620043

GPS 5600A CAN

0620044

Generator

Maximum Output

W

5600

Continuous Output

W

5000

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages

Available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

125V GFI duplex

125V GFI duplex

125V twist-lock

125V/250V twist-lock

amp

amp

amp

amp

20

20

30

30

Main Circuit Breaker

amp

2-pole, 23 amp each pole

L x W x H

mm

(in.)

685 x 530 x 520

(27 x 21 x 20.5)

1005 x 685 x 660

(39.5 x 27 x 26)

870 x 530 x 520

(34.3 x 21 x 20.5)

Weight (dry)

Kg (lbs.)

84 (186) 94 (208) 91 (201)

Technical Data GP Repair

wc_td000169gb.fm 20

2.6 Engine—GP/GPS 5600A/5600A CAN

Item No. GP 5600A

0620011

0620012

GP 5600A

CAN

0620042

0620043

GPS 5600A

0620013

GPS 5600A

CAN

0620044

Engine

Engine Type Single cylinder, 4-cycle,

air-cooled, gasoline engine

Engine Make Honda

Engine Model GX 340 K1

Rated Power

kW (Hp)

8.2 (11)

Spark Plug BPR6ES / W20EPR-U

Electrode Gap

mm (in.)

0.7–0.8 (0.028–0.031)

Operating Speed

(Max.)

rpm

3600

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Battery

type

rating

size (in.)

N/A

Y50-N18L-A

12V – 20 Amp-hour

8-

1

/8 x 3-9/16 x 6-7/

16

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD, or SC

Engine Oil Capacity

l (qts.)

1.1 (1.2)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

19.5 (5.2)

Fuel Consumption

l (qts.)/

hr.

3.2 (3.4)

Running Time

hrs.

6

GP Repair Technical Data

wc_td000169gb.fm 21

Notes

Technical Data GP Repair

wc_td000169gb.fm 22

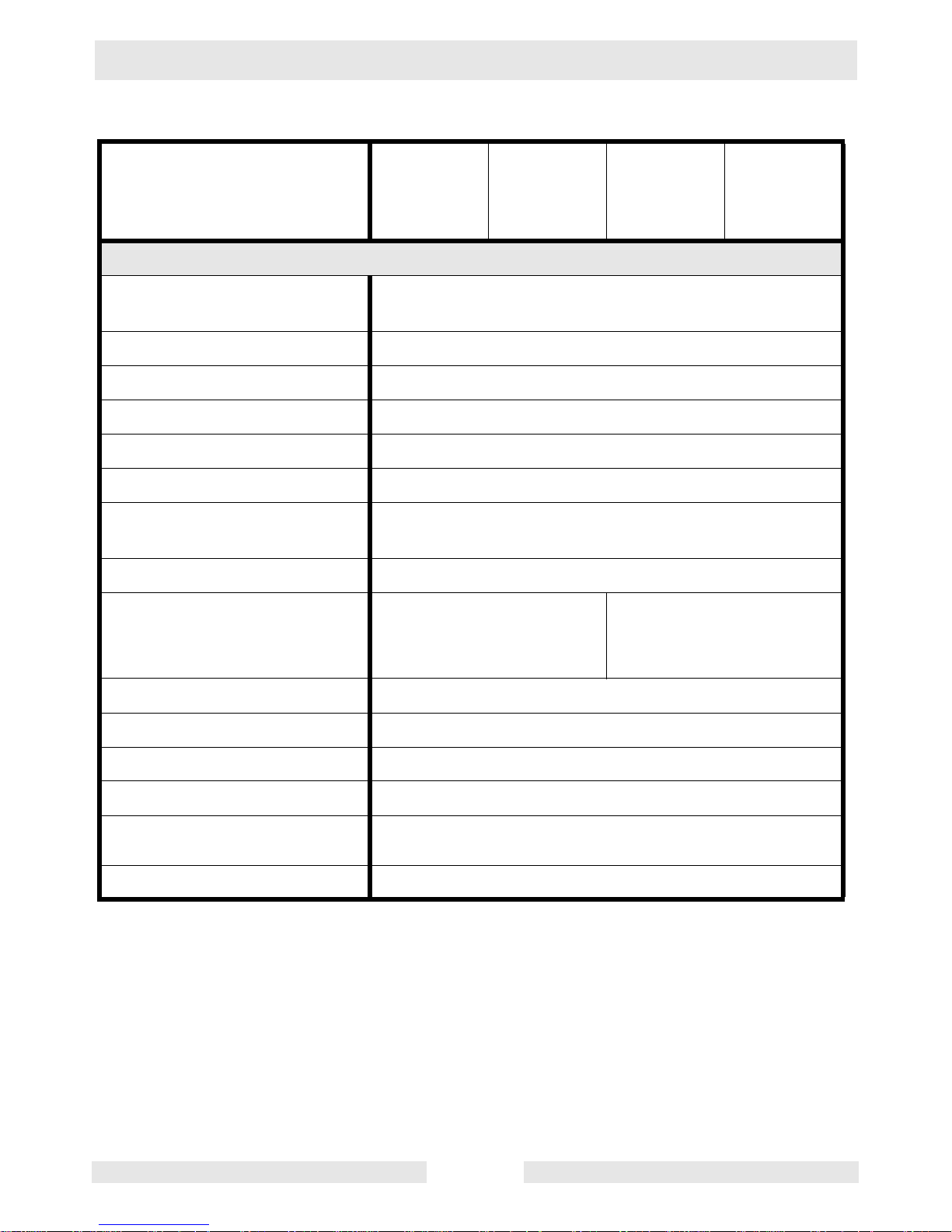

2.7 Generator—GP/GPS 6600A/6600A CAN

Item No. GP 6600A

0620014

GP 6600A

0620015

GPS 6600A

0620016

Generator

Maximum Output

W

6600

Continuous Output

W

6000

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages

available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

125V GFI duplex

125V GFI duplex

125V twist-lock

125V/250V twist-lock

amp

amp

amp

amp

20

20

30

30

Main Circuit Breaker

amp

2-pole, 27 amp each pole

L x W x H

mm

(in.)

685 x 530 x 520

(27 x 21 x 20.5)

1005 x 685 x 660

(39.5 x 27 x 26)

870 x 530 x 520

(34.3 x 21 x 20.5)

Weight (dry)

Kg (lbs.)

87 (192)

96.6 (213)

94 (207.5)

GP Repair Technical Data

wc_td000169gb.fm 23

Item No. GP 6600A CAN

0620045

GP 6600A CAN

0620046

GPS 6600A CAN

0620047

Generator

Maximum Output

W

6600

Continuous Output

W

5500

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages

available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

125V GFI duplex

125V GFI duplex

125V twist-lock

125V/250V twist-lock

amp

amp

amp

amp

20

20

30

30

Main Circuit Breaker

amp

2-pole, 27 amp each pole

L x W x H

mm

(in.)

685 x 530 x 520

(27 x 21 x 20.5)

1005 x 685 x 660

(39.5 x 27 x 26)

870 x 530 x 520

(34.3 x 21 x 20.5)

Weight (dry)

Kg (lbs.)

87 (192)

96.6 (213)

94 (207.5)

Technical Data GP Repair

wc_td000169gb.fm 24

2.8 Engine—GP/GPS 6600A/6600A CAN

Item No. GP 6600A

0620014

0620015

GP 6600A

CAN

0620045

0620046

GPS 6600A

0620016

GPS 6600A

CAN

0620047

Engine

Engine Type Single cylinder, 4-cycle, air-cooled, gasoline engine

Engine Make Honda

Engine Model GX 390

Rated Power

kW (Hp)

9.7 (13)

Spark Plug Champion RN10Y

Electrode Gap

mm (in.)

0.7–0.8 (0.028–0.031)

Operating Speed

(Max.)

rpm

3600

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Battery

type

rating

size (in.)

N/A

Y50-N18L-A

12V - 20 Amp-horo

8-

1

/8 x 3-9/16 x 6-7/

16

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD, or SC

Engine Oil Capacity

l (qts.)

1.1 (1.2)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

19.5 (5.2)

Fuel Consumption

l (qts.)/hr.

3.9 (4.1)

Running Time

hrs.

5

GP Repair Operation

wc_tx000545gb.fm 25

3. Operation

3.1 Information Regarding Operation

The information regarding the operation of the machine included in this

manual is condensed. Refer to the Operator’s Manual for complete

operating instructions. Always read, understand, and follow the

procedures in the Operator’s Manual when operating the machine.

3.2 Determining Power Requirements

This generator is designed to operate single-phase, 60 Hz appliances

running at 120 VAC or 240 VAC. Check the nameplate or label

provided on tools and appliances to make sure their power

requirements match the power output of the generator.

Some appliances and tools require a surge of current when starting.

This means that the amount of power needed to initially start the

equipment is larger than the power required to keep it running. The

generator must be capable of supplying this “surge” current. Other

types of appliances require more power than is actually stated on their

nameplate.

The information in “Approximate Starting Power Requirements” is

offered only as a general guideline to help you in determining power

requirements for different types of equipment. Check with your nearest

Wacker Dealer, or contact the manufacturer or dealer of the tool or

appliance, with questions regarding its power requirements.

CAUTION: If a tool or appliance does not reach full speed within a few

seconds when switched on, turn it off immediately to avoid damage.

Approximate Starting Power Requirements:

• Incandescent lights and appliances such as irons and hot plates, which

use a resistive-type heating element, require the same wattage to start

and run as is stated on their nameplates.

• Fluorescent and mercury lamps require 1.2–2 times their stated

wattage to start.

• Electrical motors and many types of electrical tools often require a

large starting current. The amount of starting current depends on the

type of motor and its use.

• Most electrical tools require 1.2–3 times their stated wattage for

starting.

• Loads such as submersible pumps and air compressors require a very

large force to start. They need as much as 3–5 times the wattage

stated on the nameplate in order to start.

Operation GP Repair

wc_tx000545gb.fm 26

If the wattage is not given for a particular tool or appliance, it can be

calculated by multiplying its voltage and amperage requirements:

Single Phase: VOLTS x AMPS = WATTS

Three Phase: VOLTS x AMPS x 1.732 x 0.8 = WATTS

Loading...

Loading...