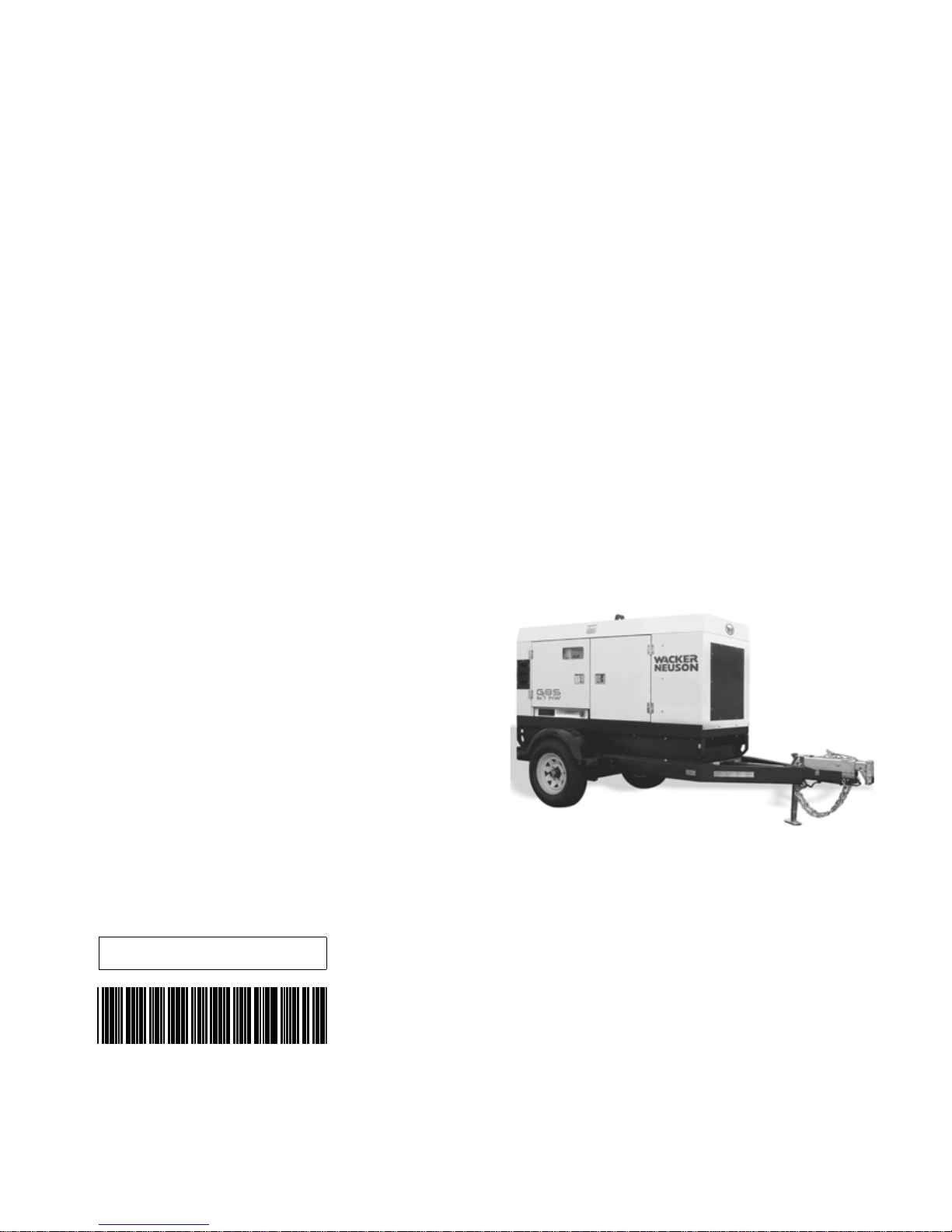

Wacker Neuson G 85 Repair Manual

Repair Manual

Mobile Generator

G 85

0171726en 004 0809

0171726EN

Copyright

notice

© Copyright 2009 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by W acker Neuson Corp oration

represents an infringement of valid copyrights. Violators will be prosecuted.

T ra d emarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Corporation

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

Mobile Generator Repair Foreword

This manual covers machines with Item Number:

0009369, 0009459, 0620003

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or repair it. Basic operating and maintenance

procedures are described in the Operator’s Manual supplied with the

machine. Keep a copy of the Operator’s Manual with the machine at all

times. Use the separate Parts Book supplied with the machine to order

replacement parts. If you are missing either of the documents, please

contact Wacker Neuson Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to

the attention of the operator to prevent similar occurrences from

happening in the future.

This manual provides information and procedures to safely repair and

maintain the above Wacker Neuson model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. The information contained in this

manual is based on machines manufactured up to the time of

publication. Wacker Neuson Corporation reserves the right to change

any portion of this information without notice.

3

Foreword Mobile Generator Repair

CALIFORNIA

Proposition 65 Warning:

Diesel engine exhaust, some of its constituents, and certain vehicle

WARNING

components contain or emit chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm.

Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

All rights, especially copying and distribution rights, are reserved.

Copyright 2009 by Wacker Neuson Corporation

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker

Neuson Corporation represents an infringement of valid copyrights,

and violators will be prosecuted. We expressly reserve the right to

make technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

4

MG Repair Table of Contents

1 Safety Information 9

1.1 Operating Safety ................................................................................ 10

1.2 Service Safety .................................................................................... 12

1.3 Operator Safety while using Internal Combustion Engines ................ 13

1.4 Towing Safety ..................................................................................... 14

1.5 Reporting Trailer Safety Defects ........................................................ 14

2 Theory of Operation 15

2.1 Basic Schematic ................................................................................. 15

2.2 Introduction ......................................................................................... 16

2.3 Terminology ........................................................................................ 18

3 Electrical Testing Techniques 22

3.1 Checking Continuity ........................................................................... 22

3.2 Checking Resistance .......................................................................... 22

3.3 Checking Voltage ............................................................................... 22

3.4 Probing ECM Plugs and Pins ............................................................. 23

4 ECM Background Information 24

4.1 ECM Handling Precaution .................................................................. 24

4.2 Normal Boot-up Sequence ................................................................. 25

4.3 Display Variables and Values ............................................................. 28

4.4 ECM Display Screens—Start Switch in Remote Position ................... 29

4.5 Additional Variables Monitored by the ECM ....................................... 30

4.6 Voltage Display Errors ........................................................................ 36

4.7 ECM Automatic Engine Shutdown Conditions ................................... 38

4.8 ECM Circuit Boards ............................................................................ 39

4.9 Control Wiring Numbering & Colors ................................................... 40

4.10 Removing and Installing the ECM ...................................................... 43

5

Table of Contents MG Repair

5 ECM/Sensor Troubleshooting 44

5.1 Checking Power to the ECM ...............................................................44

5.2 Checking Outgoing Power From the ECM ..........................................47

5.3 Checking Temperature Sender ...........................................................48

5.4 Fuel Sender Failure and Low Fuel Fault .............................................50

5.5 Calibrating ECM Voltage Display ........................................................51

5.6 Calibrating ECM AC Amperage Display ..............................................52

5.7 Calibrating ECM AC Frequency Display .............................................53

5.8 Calibrating ECM DC Display ...............................................................54

5.9 Checking the ECM CAN BUS Circuit ..................................................55

5.10 Checking the Main Circuit Breaker ......................................................56

5.11 ECM Plugs and Pins ...........................................................................57

6 John Deere Engines With ECU 59

6.1 John Deere Engines With ECU Background .......................................59

6.2 Locations of Engine Electrical Components ........................................60

6.3 Engine Electrical Components ............................................................61

7 Engine Starting Troubleshooting 62

7.1 Checking the Fuses .............................................................................62

7.2 Checking the Engine Control Module (ECM) ......................................63

7.3 Checking the Emergency Stop Switch ................................................64

7.4 Checking the Starter Relay .................................................................65

7.5 Checking the Starter Solenoid .............................................................66

7.6 Checking the Intake Heater Relay .......................................................67

7.7 Checking the Main Circuit Breaker ......................................................68

8 Output Voltage Troubleshooting 69

8.1 Checking the Emergency Stop Switch ................................................69

8.2 Checking the Lug Door Switch ............................................................70

8.3 Checking the Main Circuit Breaker ......................................................71

8.4 Checking the Voltage Adjusting Rheostat ...........................................72

8.5 Checking the Auxiliary Winding ...........................................................73

8.6 Checking the Exciter Stator .................................................................74

wc_br0171726en_004TOC.fm 6

MG Repair Table of Contents

8.7 Checking the AVR Sensing Wires ...................................................... 75

8.8 Flashing the Generator (checking the excitation system) .................. 76

8.9 Checking Stator Windings at the Lugs ............................................... 77

8.10 Checking the Rectifier Diodes—Thread-in Style ................................ 78

8.11 Checking the Rectifier Diodes—Solder-in Style ................................. 79

8.12 Checking the Main Rotor Winding ...................................................... 80

8.13 Checking the Exciter Rotor Winding ................................................... 81

8.14 Checking Stator Windings at the Voltage Selector Switch ................. 82

9 Disassembly/Assembly Procedures 84

9.1 Tools ................................................................................................... 84

9.2 Ordering Parts .................................................................................... 84

9.3 Reference Numbers ( ) ....................................................................... 84

9.4 Weight Block ...................................................................................... 84

9.5 Removing the Roof ............................................................................. 85

9.6 Preparing Unit for Generator Removal ............................................... 87

9.7 Replacing the Generator .................................................................... 89

9.8 Removing the AVR ............................................................................. 91

9.9 Installing the AVR ............................................................................... 92

9.10 Removing the Engine ......................................................................... 95

9.11 Installing the Engine ........................................................................... 97

9.12 Replacing the Fuel Tank .................................................................... 99

9.13 Replacing the Emergency Stop Switch (older) ................................. 101

9.14 Replacing the Emergency Stop Switch (newer) ............................... 103

9.15 Replacing the Diodes ....................................................................... 105

9.16 Replacing the Voltage Selector Switch (VSS) .................................. 107

9.17 G 50, G 70, G 85 VSS Wiring ........................................................... 109

10 Technical Data 110

10.1 Engine Data ...................................................................................... 110

10.2 Generator Data ................................................................................. 111

10.3 Trailer and Skid Data ........................................................................ 112

10.4 Dimensions ....................................................................................... 113

10.5 Engine Wiring Diagram—John Deere with ECU .............................. 114

10.6 ECU Wiring Diagram ...................................................................... 118

10.7 ECU Harness Connector .................................................................. 119

10.8 Generator Wiring Diagram ............................................................... 120

7

Table of Contents MG Repair

wc_br0171726en_004TOC.fm 8

G 85 Safety Information

G

1 Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

CAUTION

WARNIN

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

Electrocution hazard!

Electrocution or severe electrical shock hazards are present

throughout the generator any time the engine is running! Read all

safety notes contained in this section before operating or servicing this

equipment.

No one except a trained electrician, familiar with this equipment,

should attempt repairs to the generator! Test procedures which require

that the generator be running must be performed using extreme

caution.

This machine is built with user safety in mind; however, like any

electrical device it can present serious hazards if improperly operated

and serviced. Follow instructions carefully! Should questions arise

during operation or service of this equipment, contact Wacker Neuson

Corporation.

wc_si000356gb.fm 9

Safety Information G 85

1.1 O perating Safety

Familiarity and proper training are required for the safe operation of the

machine. Machines operated improperly or by untrained personnel

can be hazardous. Read the operating instructions contained in this

WARNING

1.1.1 NEVER operate the generator when open containers of fuel, paint, or

1.1.2 NEVER place flammable material or liquids near the generator.

1.1.3 NEVER operate the generator, or tools attached to the generator, with

1.1.4 NEVER use worn electrical cords. Severe electrical shock and

1.1.5 NEVER operate the machine indoors unless exhaust fumes can be

manual and the engine manual, and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the machine before

being allowed to operate it.

other flammable liquids are near.

wet hands.

equipment damage may result.

adequately ventilated.

1.1.6 NEVER overload the generator. The total amperage of the tools and

equipment attached to the generator must not exceed the load rating

of the generator.

1.1.7 NEVER allow untrained personnel to operate or service the generator.

The generator set should be set up by a certified electrician.

1.1.8 NEVER operate generator in standing water.

1.1.9 NEVER touch the hot engine, exhaust, or generator components.

Burns will result.

1.1.10 NEVER start a machine in need of repair.

1.1.11 Use the emergency stop button only in an actual emergency. DO NOT

restart the engine until the cause of the trouble has been determined

and fixed.

1.1.12 Wear hearing protection when operating equipment.

1.1.13 ALWAYS follow starting and stopping instructions described in this

manual. Know how to operate and stop generator before starting it.

1.1.14 ALWAYS make a walk-around inspection of the generator set before

starting it. Open side doors and visually inspect engine compartment

for obvious damage or the presence of foreign objects which might

affect operation.

1.1.15 ALWAYS keep the machine at least one meter (three feet) away from

structures, buildings, and other equipment during use.

1.1.16 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

wc_si000356gb.fm 10

G 85 Safety Information

1.1.17 ALWAYS keep the area immediately surrounding and underneath the

machine clean, neat, and free of debris and combustible materials.

Make sure that the area overhead is clear of debris that could fall onto

or into the machine or exhaust compartment.

1.1.18 Be sure the machine is on a firm, level surface and will not tip, roll,

slide, or fall while operating.

1.1.19 ALWAYS remove all tools, cords, and other loose items from the

generator before starting it.

1.1.20 ALWAYS make certain the machine is well-grounded and securely

fastened to a good earthen ground per national and local regulations.

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER

DISTRIBUTION SYSTEM CAN CAUSE SERIOUS INJURY OR

DEATH TO UTILITY WORKERS!

DANGER

Improper connection of generator to a building’s electrical system can

allow electrical current from the generator to backfeed into utility lines.

This may result in electrocution of utility workers, fire, or explosion.

Connections to a building’s electrical system must be made by a

qualified electrician and comply with all applicable laws and electrical

codes.

If connected to a building’s electrical system the generator must meet

the power, voltage, and frequency requirements of the equipment in

the building. Differences in power, voltage, and frequency

requirements may exist and improper connection may lead to

equipment damage, fire, and personal injury or death.

wc_si000356gb.fm 11

Safety Information G 85

1.2 S ervice Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

WARNING

1.2.1 NEVER perform even routine service (oil/filter changes, cleaning,

etc.) unless all electrical components are shut down. Before

servicing this machine, make sure the engine start switch is turned to

off “O”, the circuit breakers are open (off), the emergency stop switch

is closed (pushed in), and the negative terminal on battery is

disconnected. Attach a “DO NOT START” sign to the control panel.

This will notify everyone that the unit is being serviced and will reduce

the chance of someone inadvertently trying to start the unit. If the unit

is connected to a remote start or transfer switch, make sure the remote

switch is also off and tagged.

1.2.2 Ground Connection

The generator must be connected to a good earthen ground for

proper operating safety!

A central “equipment ground” is provided at the customer connection

lugs. This point is connected directly to the generator set base. All

other system grounds are connected to this central point. Ground the

generator in accordance with the standards defined in national, state,

and local regulations.

1.2.3 DO NOT attempt to open the radiator cap while the unit is running or

before the engine has cooled down. Severe burns may result!

1.2.4 DO NOT allow water to accumulate around the base of the machine.

If water is present, move the machine and allow the machine to dry

before servicing.

1.2.5 DO NOT service the machine if your clothing or skin is wet.

1.2.6 DO NOT allow untrained personnel to service this equipment. Only

trained electrical technicians should be allowed to service the electrical

components of this equipment.

1.2.7 Do not modify the machine without the express written approval of the

manufacturer.

1.2.8 DO NOT pressure wash the control panel, generator end, or any other

electrical components when cleaning the machine. Never allow water

to accumulate around the base of the generator set. If water is present,

DO NOT service!

1.2.9 ALWAYS replace the safety devices and guards after repairs and

maintenance.

1.2.10 ALWAYS let the engine cool before transporting or servicing the

machine.

wc_si000356gb.fm 12

G 85 Safety Information

1.2.11 ALWAYS remain aware of moving parts and keep hands, feet, and

loose clothing away from the moving parts of the machine.

1.2.12 ALWAYS replace all guards, fasten doors, and make sure all safety

devices operate properly after making repairs or servicing the

equipment.

1.2.13 ALWAYS keep hands, feet, and loose clothing away from the moving

parts on the generator and engine.

1.2.14 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

1.2.15 ALWAYS check all external fasteners at regular intervals.

1.2.16 ALWAYS make sure slings, chains, hooks, ramps, jacks, and other

types of lifting devices are attached securely and have enough weightbearing capacity to lift or hold the machine safely. Always remain

aware of the location of other people in the area when lifting the

machine.

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

WARNING

1.3.1 Do not run engine indoors or in an area with poor ventilation unless

1.3.2 Do not fill or drain the fuel tank near an open flame, while smoking, or

1.3.3 Do not refuel a hot or running engine.

1.3.4 Refill the fuel tank in a well-ventilated area.

1.3.5 Do not touch or lean against hot exhaust pipes.

1.3.6 Replace the fuel tank cap after refueling.

1.3.7 Do not start the engine if fuel has spilled or a fuel odor is present. Move

1.3.8 Do not remove the radiator cap when the engine is running or hot. The

warnings and safety standards could result in severe injury or death.

exhaust hoses are used.

while the engine is running.

the generator away from the spill and wipe the generator dry before

starting.

radiator fluid is hot and under pressure and may cause severe burns!

wc_si000356gb.fm 13

Safety Information G 85

1.4 Towing Safety

Towing a large trailer requires special care. Both the trailer and vehicle

must be in good condition and securely fastened to each other to

reduce the possibility of an accident.

WARNING

1.4.1 ALWAYS check that the hitch and coupling on the vehicle are rated

equal to, or greater than, the trailer’s “gross vehicle weight rating”

(GVWR).

1.4.2 ALWAYS inspect the hitch and coupling for wear or damage. DO NOT

tow the trailer using defective parts.

1.4.3 ALWAYS make sure the coupling is securely fastened to the vehicle.

1.4.4 ALWAYS check the tires on the trailer for tread wear, inflation, and

condition. Replace worn tires.

1.4.5 ALWAYS connect the safety chains.

1.4.6 ALWAYS connect the breakaway cable safety hook to the bumper or

rear of the vehicle. DO NOT attach it to the hitch.

1.4.7 ALWAYS test the surge brakes on the trailer and the brakes on the

vehicle that will be used for towing.

1.4.8 ALWAYS make sure directional and trailer lights are connected and

working properly.

1.4.9 ALWAYS check that the lug nuts holding the wheels are tight and that

none are missing.

1.5 Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause a crash or

could cause injury or death, you should immediately inform the

National Highway Traffic Safety Administration (NHTSA) in addition to

notifying Wacker Neuson Corporation.

If NHTSA receives similar complaints, it may open an investigation;

and if it finds that a safety defect exists in a group of vehicles, it may

order a recall and remedy campaign. However, NHTSA cannot

become involved in individual problems between you, your dealer, or

Wacker Neuson Corporation.

To contact NHTSA, you may either contact the Auto Safety Hotline tollfree at 1-800-424-9393 (or 366-0129 in Washington DC area),

www.nhtsa.com, or write to NHTSA, U.S. Department of

Transportation, 400 7th Street SW, (NSA-11), Washington, DC 20590.

You can also obtain other information about motor vehicle safety from

the Auto Safety Hotline.

wc_si000356gb.fm 14

Mobile Generator Theory of Operation

2 Theory of Operation

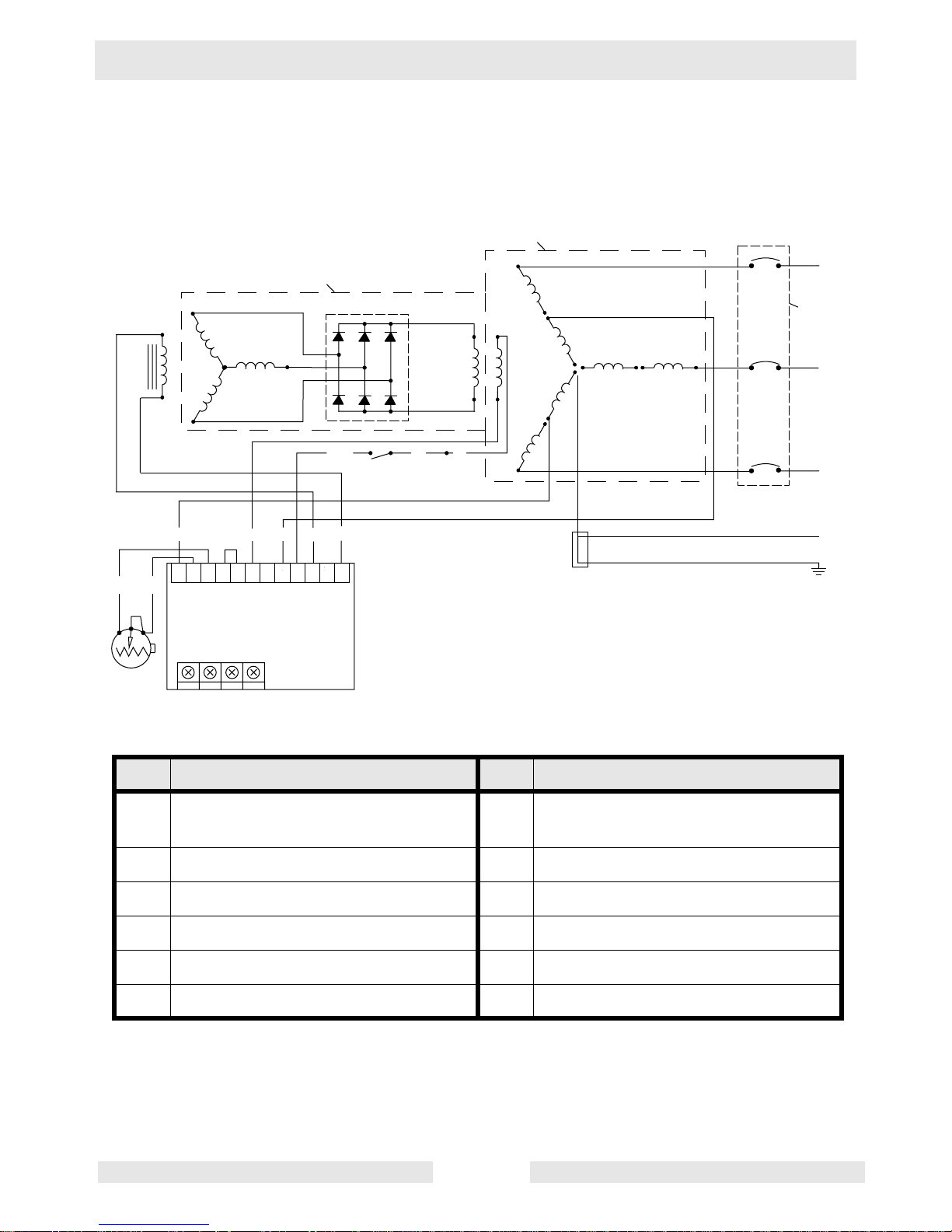

2.1 Basic Schematic

l

3-Phase AC out

c

T1

b

d

DC in

T2

T3

L1

h

a

LY

++–

DC out (exciter field)

BRGYL

BW

5C

j

AC in

n/a n/a

5B 7 5A 6 5 4A 4 3A 3 2 1

AMP HZ STAB

VOLT

e

–

L/W LR

k

AC sensing

g

i

T10

T9

T12

T11

T4

T8

f

Ref. Component Ref. Component

T7

T6

T5

L2

3-Phase

AC output

L3

N

GND

wc_gr003643

a Exciter stator winding g Automatic Voltage Regulator

b Rotor assembly h Main circuit breaker

c Exciter rotor winding i Auxiliary winding

d Rotating rectifier (diodes) j Voltage adjusting rheostat

e Main rotor winding k Lug door switch

f Main stator windings l Stator assembly

wc_tx001077gb.fm 15

(AVR)

Theory of Operation Mobile Generator

2.2 Introduction

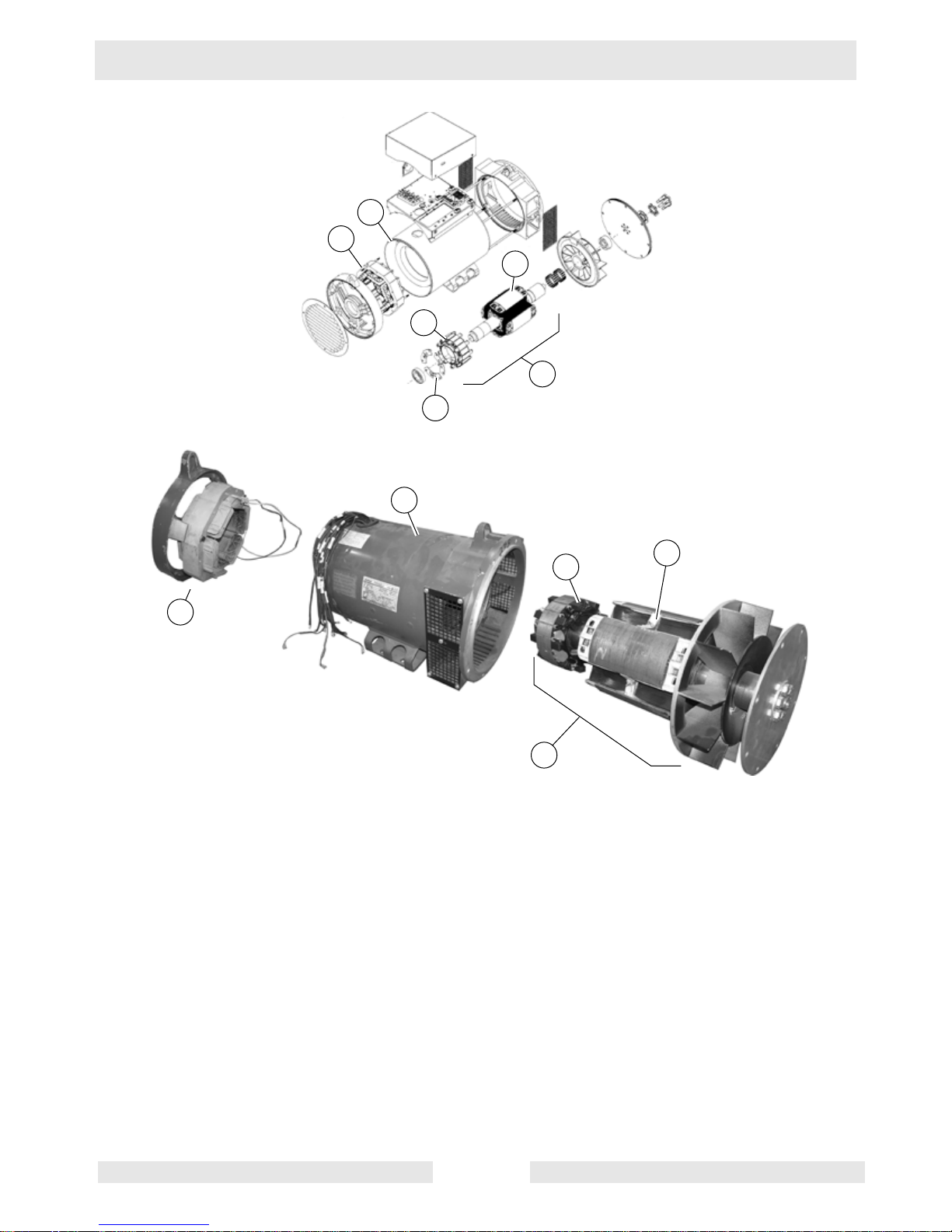

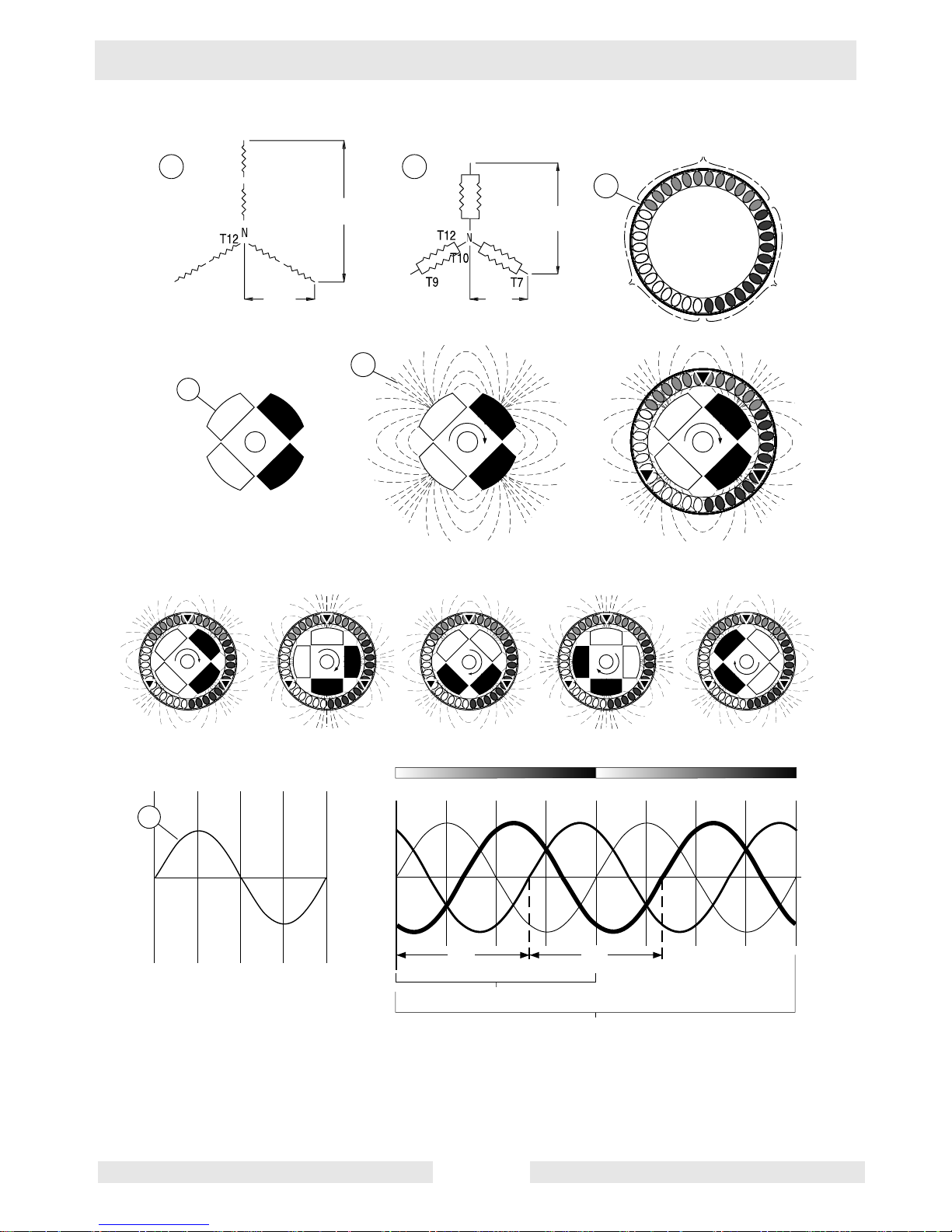

See Graphic: wc_gr003303

A generator set is a transducer, which means it converts energy from

one form (heat) into another (electrical). The two main components of

a generator set are the prime mover (engine) and the generator

assembly. The engine converts heat into rotating mechanical energy

which is then converted by the generator assembly into electrical

energy. The generator does so through the principle of

electromagnetic induction. This principle states that when a coil of wire

(also known as a winding) is passed through a magnetic field, a

voltage is induced in the winding. The amount of voltage depends on

three factors: 1) the speed of the coil cutting through the magnetic field

(it does not matter which is moving—either the magnetic field or the

winding); 2) the strength of the magnetic field; and 3) the amount of

turns of wire in the winding. The principle also works in reverse; that is,

if voltage and current are present in a coil of wire, a magnetic field is

produced. It is important to understand this basic theory to understand

how the generator functions.

The typical brushless generator assembly consists of a stator

(stationary element), a rotor (rotating element), a voltage regulator

(voltage control device), and a rectifier assembly (current control

device). The rotor can function as either the magnetic field or the

winding. Likewise, the stator can function as either the magnetic field

or the winding, depending on the application. In Wacker Neuson

generators there are two stators (a and b) and a single rotor assembly

(c). The rotor assembly is made up of two halves—the exciter (d) and

the main (e). Three windings make up the exciter half and a single

winding makes up the main rotor half. There are three distinct stator

windings—the exciter, the main, and the auxiliary. The exciter stator

winding (a) is a stand-alone winding. The main and auxiliary windings

are housed within the large stator housing (b).

The exciter stator is the generator’s source of residual magnetism. As

the engine spins, the exciter rotor portion of the rotor assembly spins

inside the exciter stator, an AC voltage is induced in the exciter rotor.

This AC voltage is rectified into DC by the diodes (f) connected to the

rotor assembly. The DC voltage flows through the main rotor winding,

creating a magnetic field. Voltage is then induced in the main stator

windings and the auxiliary winding. The voltage induced in the main

stator windings provides the voltage to the lugs and the receptacles.

The voltage induced in the auxiliary winding is used to power the

voltage regulator.

wc_tx001077gb.fm 16

Mobile Generator Theory of Operation

b

a

e

d

c

f

b

d

e

a

c

wc_gr003303

wc_tx001077gb.fm 17

Theory of Operation Mobile Generator

2.3 Terminology

See Graphic: wc_gr003315

To understand the terms “phase”, “leg”, “line-to-line”, and “line-to-

neutral”, review the following information.

• The main stator (a) consists of three separate groups of windings.

These groups of windings are referred to as legs. The legs are

labeled L1, L2, and L3. Each leg includes two individual windings. The

ends of these windings are labeled T1, T2, T3, and so on, up to T12.

• Each individual winding has the same resistance (0.2 Ohms). The

voltage selector s witch determines how the windings are connected—

in series or parallel. In series, the total voltage of a leg is equal to the

sum of the voltages induced across both windings. In parallel, the

total voltage of a leg is equal to the voltage induced across either

winding (only one).

• Each leg (L1, L2, and L3) is physically 120° from each other.

• The main rotor (b) functions as a rotating magnetic field. It has four

poles, two of which function as North and the other two as South.

• “Flux” is a term used to describe the amount of magnetic field in a

given area. The term “lines of flux” refers to the direction of the attraction of the magnetic fields—North to South. The point where these

lines of flux are closest to 90° is the point where the magnetic field is

the strongest, i.e., at either pole. The lines of flux (c) of the main

rotor’s magnetic field are as shown. When the windings of the stator

cut these lines of flux, voltage is induced in them. The amount of

induced voltage is greatest at the position where the stator winding is

perpendicular to the lines of flux, i.e., when the rotor is in such a position that the windings of a leg are centered over one of the four magnetic poles.

• When the two windings of each leg are connected in series, this is the

high-wye configuration (e). The v oltage induced in this configuration is

277V per leg. When the two windings of each leg are wired in parallel,

this is the low-wye configuration (f). The voltage induced in this configuration is 139V per leg. (It is adjusted to a usable 120V by the control panel rheostat.)

• The amount of voltage induced in each leg over time can be graphed.

This graph yields a sine wave (d). It represents the repeating event

(cycle) of the induced positive voltage of the North pole followed by

the induced negative voltage of the South pole. Since the rotor has

four magnetic poles, this cycle occurs twice per re v olution of the rotor.

• The engine spins the rotor at 1800 rpm which equals 30 revolutions

per second (rps) (1800 ÷ 60 = 30). The number of revolutions per second multiplied by the cycles per revolution (cpr) equals the cycles per

second (Hertz). Thus, 30 rps x 2 cpr = 60 Hz.

wc_tx001077gb.fm 18

Mobile Generator Theory of Operation

a

e

e

ye

6

5

8

9

0

3

(480V)

(208V)

3

5

8

6

(

)

(

)

3

3

S1

High Wy

L

N1

S1

L3

Low W

T

-

T

T1

T

T

-

277V

T

L

T

-

T

-

120V

T

L3

T

c

L1

L2

L1

b

N1

L3

S2

N2

180˚45˚

N2

S2

L2

L1

S1

N1

L2

L1

0˚

S2

N1

S1

S2

N2

L2

L3

N2

L1

N1

N2

S2

L2

S1

S1

L3

N1

N2

S1

90˚

L1

N1

S2

S2

N2

L2

L3

N2

135˚

L1

S1

L3

S1

N1

S2

L2

0˚ 45˚ 90˚ 135˚ 180˚

d

L1

wc_tx001077gb.fm 19

N1–S1 N2–S2

45˚ 90˚ 135˚ 180˚0˚ 225˚ 270˚ 315˚ 360˚

L2

L1

L3

120˚ 120˚

1 Hz

1 Rev

wc_gr003315

Theory of Operation Mobile Generator

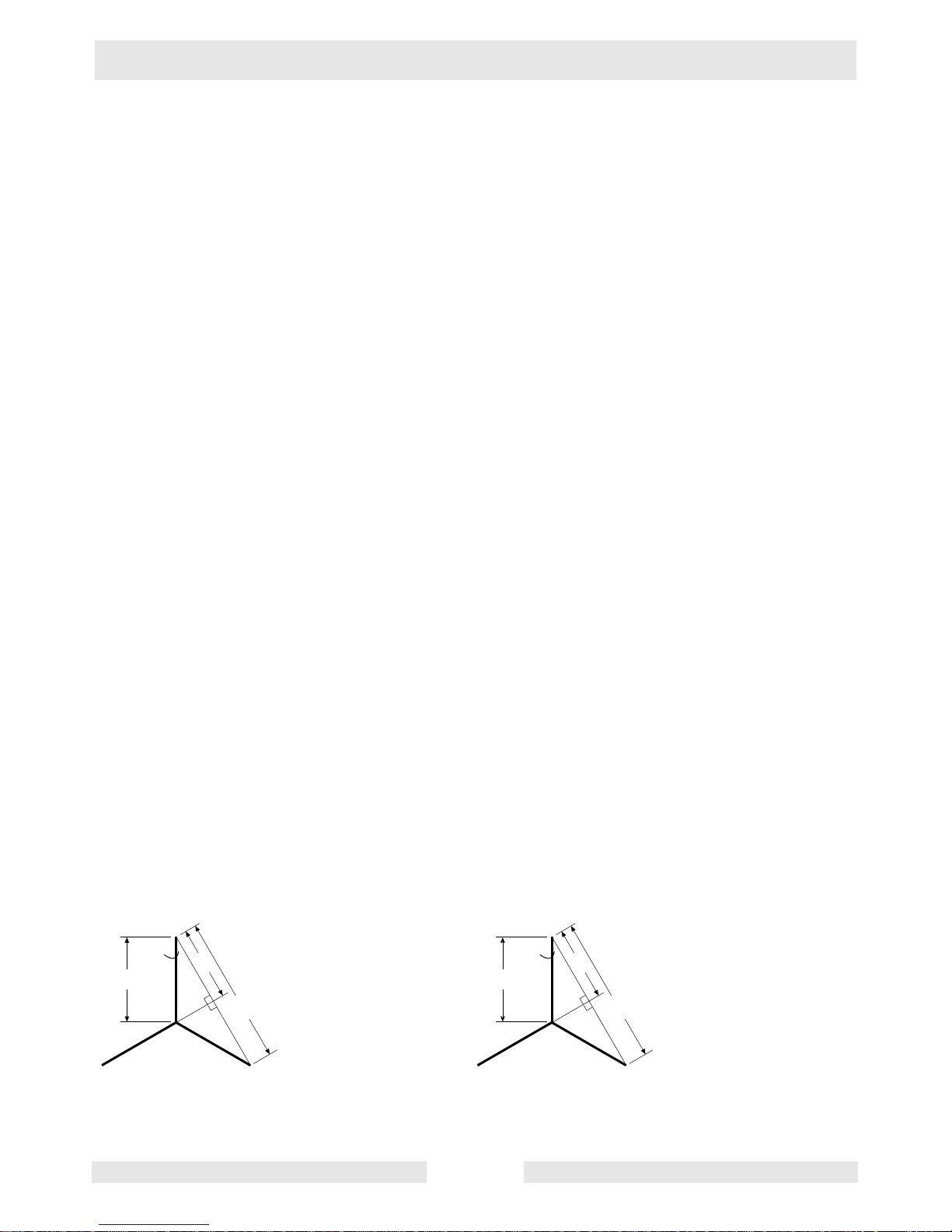

• Since the legs are mechanically 120° apart, as the rotor spins, time

elapses between the moment when one leg reaches its largest voltage potential and the moment when the next leg reaches its largest

voltage potential. Thus, no two legs reach their largest voltage potential at the same moment in time, and their corresponding sine waves

are 120° apart. In other words, the voltages induced in each leg are

120° out of phase with each other.

• Although the largest amount of voltage induced in any single leg in

the high-wye configuration is 277V, the voltage induced in a second

leg (either of the other two legs) at that same moment can be tapped

and combined with the 277V of the first leg to create the maximum

voltage available from the generator. The amount of voltage in the

second leg is less than its largest potential because of the position of

the rotor’s magnetic field—it is less than perpendicular to the second

leg. The amount of voltage induced is approximately 73% (203V) of

its potential (see graphic wc_gr003317). Thus, 277V + 203V = 480V,

which is the maximum voltage available from the generator. In the

low-wye configuration, the largest usable voltage potential in any leg

is 120V; adding the 73% of any second leg (88V), yields the maximum voltage potential for the low-wye configuration—208V.

277

30˚

120˚

120˚

60˚

60˚

• Any measurement between the end of a leg and neutral is know as

line-to-neutral (L-N) voltage. Any measurement between the end of

one leg to the end of another leg is known as line-to-line (L-L) voltage.

Any combination of L-N or L-L voltages are 120° out of phase with

each other. For example, L1–N is out of phase with L2–N; L2–N with

L3–N; L3–N with L1–N. Likewise, L1–L2 is out of phase with L2–L3;

L2–L3 with L3–L1; and L2–L3 with L1–L2.

• A three-phase event exists when a three-phase load is attached to the

generator. The three-phase load uses both the voltage and current

from each phase produced by the generator simultaneously. Positive

current produced by the voltage from each leg flo ws to corresponding

legs of the load.

Sine 60 = 0.866

Sine 60 = a/277

a

2(a)

0.866 = a/277

277 x 0.866 = (a/277) x 277

240 = a

2(a) = 480

480 – 277 = 203

203/277 = 0.73 = 73%

120

30˚

120˚

120˚

60˚

a

2(a)

60˚

Sine 60 = 0.866

Sine 60 = a/120

0.866 = a/120

120 x 0.866 = (a/120) x 120

104 = a

2(a) = 208

208 – 120 = 88

88/120 = 0.73 = 73%

wc_tx001077gb.fm 20

wc_gr003317

Mobile Generator Theory of Operation

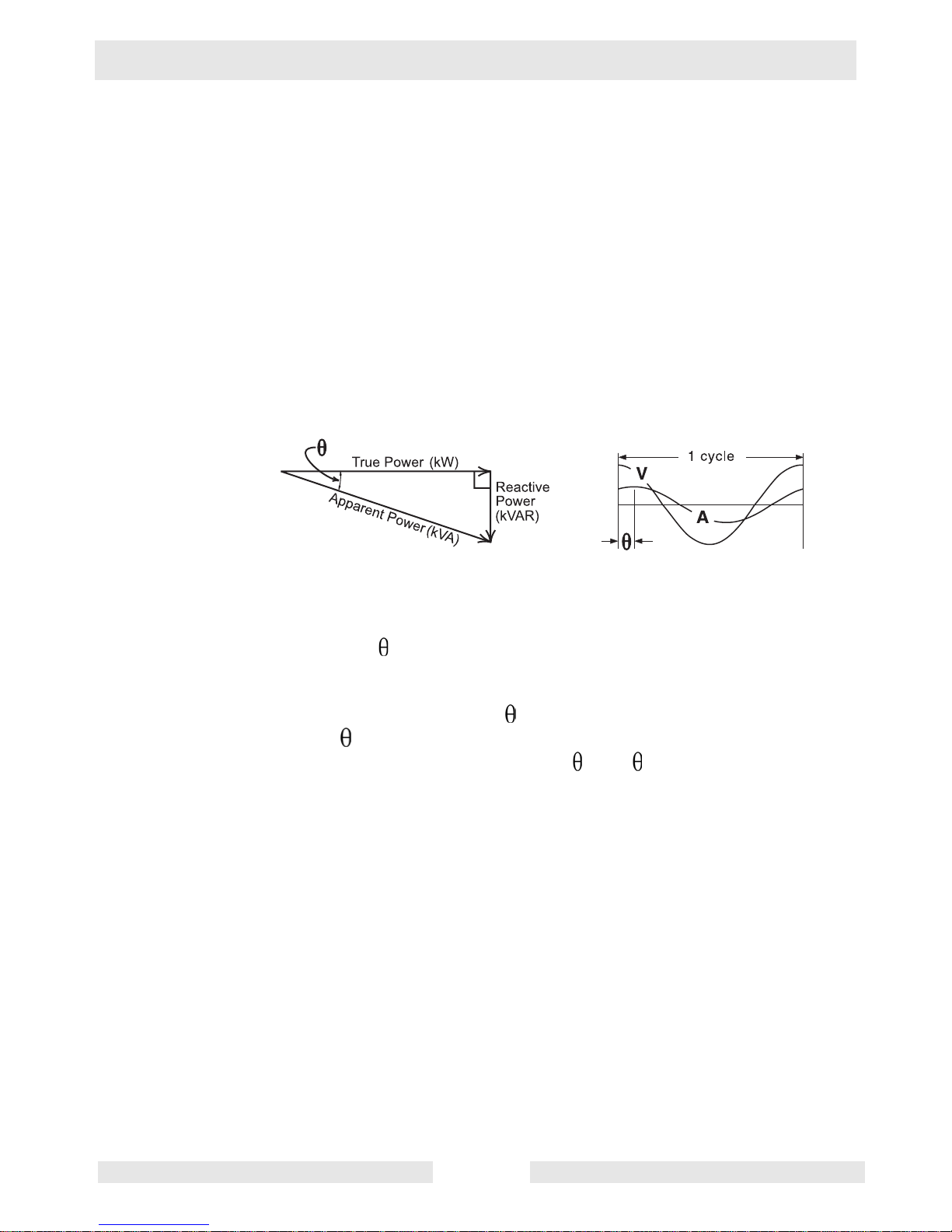

• Wacker Neuson generators are designed to accommodate various

loads and multiple power factors. Power factor is the relationship

between power supplied to the load (ref erred to as apparent power in

kVA) and true power (pow er used by the load (kW). It is expressed

mathematically by the equation: power f actor = true powe r ÷ apparent

power. The power factor is determined by the type of load—inductive

or resistive. In resistive loads, such as heaters, the power factor is

typically 1. In inductive loads, such as motors and tr ansformers, the

power factor is always less than 1. In inductive loads, a portion of the

supplied power is converted to a magnetic field and not used by the

load. This unused power is known as reactiv e po wer. The relationship

between apparent power, true power, and reactive pow er is illustrated

in the power right triangle below.

Reactive pow er and true power are always represented 90° from

each other. In the power right triangle, the angle formed by the hypotenuse (apparent power) and the adjacent side (true power) is referred

to as theta ( ). Theta is derived from the separation in the sine w a v es

of voltage and current. In inductive circuits, current lags the voltage

due to such factors as coil length, coil material, and frequency. From

trigonometry, the cosine of = adjacent side ÷ hypotenuse. Since

cosine and pow e r factor are calculated in the same manner, power

factor is often referred to as cosine (cos ).

• Single-phase receptacles are tapped off the legs in a manner that

keeps the generator balanced. That is, v oltage supplies to the v arious

single-phase outlets originate from different legs of the generator (L1

and L3), not from the same leg. When tapping single-phase loads

from the lugs, care must be taken so that the generator does not

become unbalanced. Attach equal loads to each leg if you are running

the generator in this manner.

wc_tx001077gb.fm 21

Electrical Testing Techniques Mobile Generator

3 Electrical Testing Techniques

3.1 Checking Continuity

Conduct continuity tests when the engine is shut down.

When checking continuity, use the Ohm setting on your multimeter.

Place a lead of the multimeter on one end of the wiring or component

and the other lead on the opposite end. If your meter reads “OL” or

“OPEN”, there is no continuity and the wiring or component must be

repaired or replaced.

Note: Some multimeters also have an audio signal setting for

determining continuity. This setting may also be used.

• If your meter reads less than 1.0 Ohm, or the audio signal

sounds, the wiring or component has continuity and should be

OK.

• If your meter reads more than 1.0 Ohm, the wiring is faulty and

must be repaired or replaced.

3.2 C hecking Resistance

Conduct resistance checks when the engine is shut down.

Use the Ohm setting on your multimeter.

Conduct resistance checks when the machine is as close to 21°C

(70°F) as possible. Higher temperatures can affect resistance values.

Most digital multimeters have some internal resistance. To obtain your

multimeter’s internal resistance, simply cross the two leads of your

multimeter and read the display. When conducting a resistance check,

subtract your multimeter’s internal resistance from the value you

measure to obtain the true resistance of the component you are

checking.

3.3 Checking Voltage

Conduct voltage checks when the engine is running.

Use the Volt setting on your multimeter. To prevent damage to your

instrument, start with the highest scale available on your multimeter.

Adjust to a lower scale as readings dictate.

Use extreme caution when checking voltage to reduce the risk of

electric shock.

22 wc_tx000699gb.fm

Mobile Generator Electrical Testing Techniques

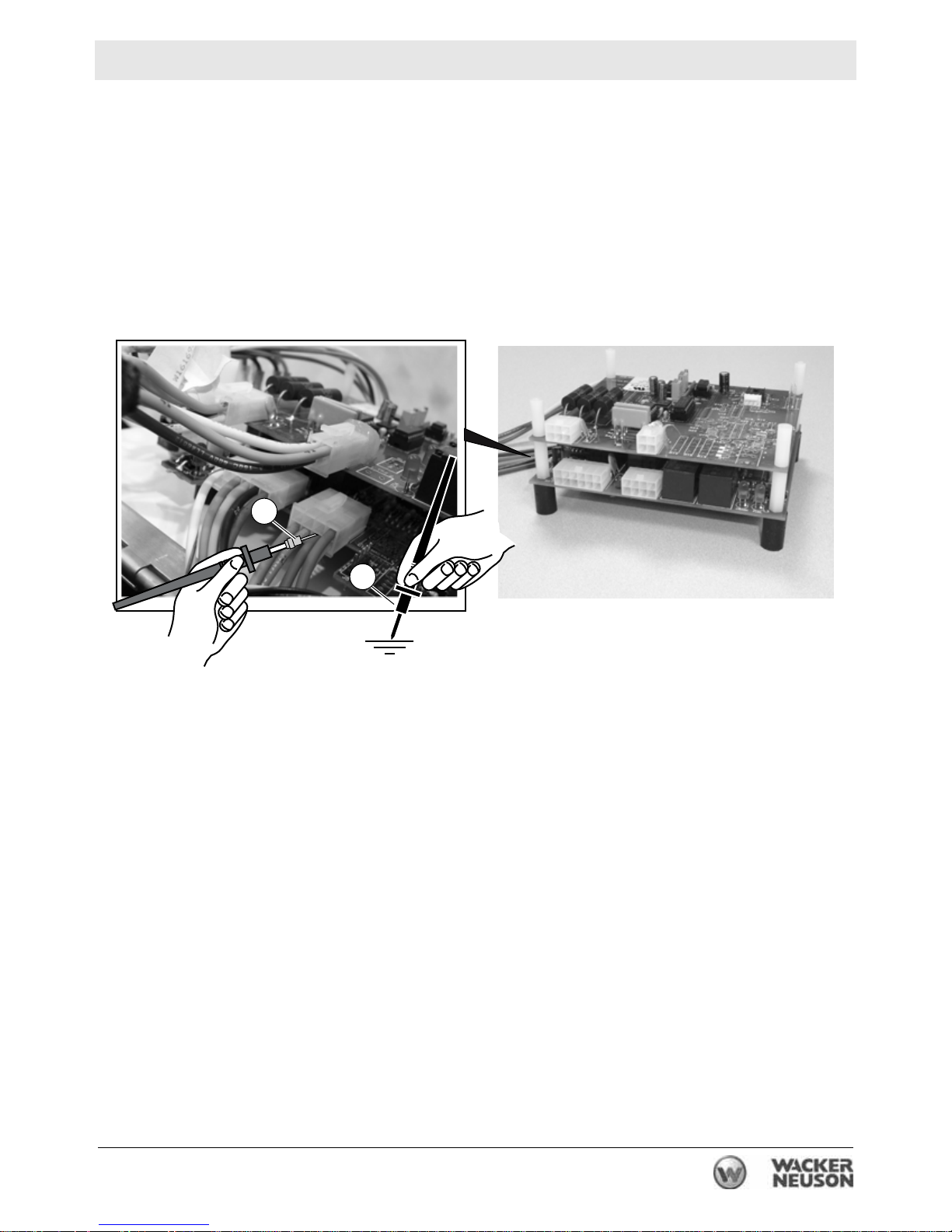

3.4 Probing ECM Plugs and Pins

See Graphic: wc_gr002926

To measure the voltage at an ECM pin, attach an appropriate

extension (a) to the positive probe on your multimeter. Slide the

positive probe into the plug along the wire of the pin to be tested. Use

care when testing this way so you don’t damage the wire, plug, or

ECM. Find a suitable ground on the machine’s frame for the negative

probe (b) of your multimeter.

6

5

4

3

2

1

12

11

10

9

8

6

5

4

3

2

a

4

3

2

1

7

8

7

6

1

5

4

3

2

1

b

wc_gr002926

wc_tx000699gb.fm 23

ECM Background Information Mobile Generator

4 ECM Background Information

4.1 ECM Handling Precaution

See Graphic:wc_gr003355

NOTICE: Use care when working on or around the ECM. The ECM

may be damaged or it may malfunction if it is accidentally hit by your

hand or a tool. Do not touch the pins (a) of the ECM because the AC

board of the ECM may malfunction.

a

wc_gr003355

24 wc_tx000713gb.fm

Mobile Generator ECM Background Information

4.2 Normal Boot-up Sequence

During the boot-up sequence, the ECM scrolls through several

screens before it settles into displaying the run screen. There are two

different boot-up sequences depending on size of the generator and

options included on the generator. Both of the boot-up sequences are

listed below. When checking the boot-up sequence of your generator,

be sure you are checking the one that matches your generator.

G 25, G 50, G 70, G 85 (9310)

ECM Display Description

Start of the boot-up sequence. The ECM shows that the

glow plugs are on. The LED near the stop icon also illu-

Glow Plugs

On

minates. Note that the glow plugs are only on during the

first of the three starting cycles.

Starting Engine

Time to Service

250

480 P2 0 61.5

71 75% 87 12.7

The ECM displays this screen when the starter is cranking the engine.

The ECM displays the countdown time , in hours, until the

next scheduled service. The timer starts at 250 and

counts down to 0.

At this point, the ECM displays the running values of the

generator.

Note: The ECM display scrolls through each phase (P1,

P2, P3) if in the 3-phase mode, or L1, L3, and L1 + L3 if

in the single-phase mode.

wc_tx000713gb.fm 25

ECM Background Information Mobile Generator

G 85 (9305), G 125, G 160

ECM Display Description

Start of the boot-up sequence. The ECM display reads

“Initializing” and shows the model of the generator. If the

Initializing

G 85

Time to Service

250

Cranking 1 of 3

model displayed does not match the model of the generator, call Wacker Neuson Service.

The ECM displays the countdown time until the next

scheduled service. The timer starts at 250 and counts

down to 0.

The ECM displays this screen during the first cranking

cycle.

80 P2 0 60.0

71 75% 87 12.7

Under Frequency

Enabled

480 P2 0 60.0

71 75% 87 12.7

Engine Protection

Enabled

The ECM displays this screen as soon as the engine

starts. Note that some of the values such as voltage, ma y

not be up to their running values at this stage of the

sequence.

The ECM displays this screen to let the operator know

that the under frequency system (engine speed) has

been enabled.

At this point in the sequence, the ECM displays running

values.

The ECM displays this screen to let the operator know

that the engine protection system has been enabled.

26 wc_tx000713gb.fm

Mobile Generator ECM Background Information

The ECM displays the A C configuration as determined by

AC Configuration

Alt Protection

Enabled

Rated Volts L to L

480 P2 0 60.0

71 75% 87 12.7

the position of the voltage selector switch (VSS).

The ECM displays this screen to let the operator know

that the alternator protection system has been enabled.

The ECM displays the line-to-line voltage . (This screen is

shown for 3-phase VSS positions only.)

At this point, the ECM displays the run screen and the

values for the main generator variables: voltage, phase*

(leg), amperage, hertz (For generators with engines that

include ECUs, the Hz reading will be 60.0. For all others

the reading will be 61.5.) The ECM will also display the

values for the main engine variables: oil pressure, fuel

tank quantity, engine temperature, and battery voltage.

*Note: The ECM displa y scrolls through each phase (P1,

P2, P3) if in the 3-phase mode, or L1, L3, and L1 + L3 if

in the single-phase mode.

wc_tx000713gb.fm 27

ECM Background Information Mobile Generator

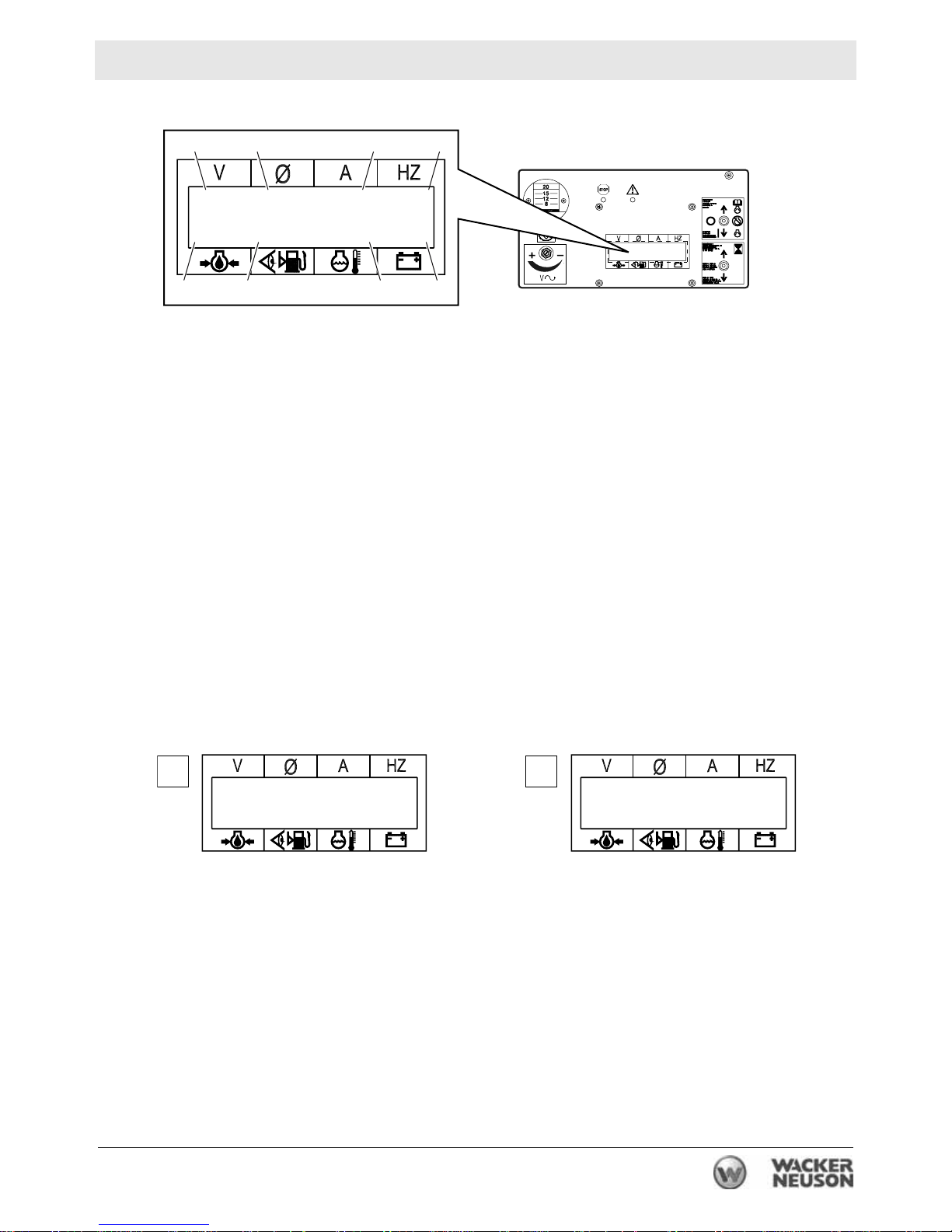

4.3 Display Variables and Values

See Graphic: wc_gr002944

• Generator Variables

The values shown in the top line of the ECM display are all variables

from the generator side of the machine. They are:

(1) voltage (V)

(2) phase (Ø) (or leg for single phase)

(3) amperage (A)

(4) frequency (Hz)

• Engine Variables

The values shown in the lower line of the ECM display are all variables

from the engine side of the machine. They are:

(5) engine oil pressure (psi)

(6) fuel tank quantity (shown in percentage of capacity)

(7) engine temperature (°F)

(8) battery voltage (V)

• Blinking Values

When a value on the ECM display blinks on and off, it signifies that the

variable (temperature, fuel capacity, etc.) is in a pre-alarm state. For

example, the value for the temperature reading will blink when the

temperature of the generator is below 23°C (74°F). This simply

signifies that the manifold heater (or glow plugs) will be energized to

aid in engine starting. The fuel capacity reading will blink when it is

below 25%. This tells the operator that the generator will be requiring

fuel soon. See Section Additional Variables Monitored by the ECM.

Note: If your generator has a block heater, the temperature reading

should not blink. If it does, check the block heater to make sure it is

functioning properly.

• ND (No Data), 0 (zero), or Blank Values

When a value on the ECM display reads ND, 0 (zero), or is blank, it

signifies that there is no data available for the variable.

28 wc_tx000713gb.fm

Mobile Generator ECM Background Information

1

2

3 4

481 P2 0 60.0

71 24% 87 12.7

5

678

wc_gr002944

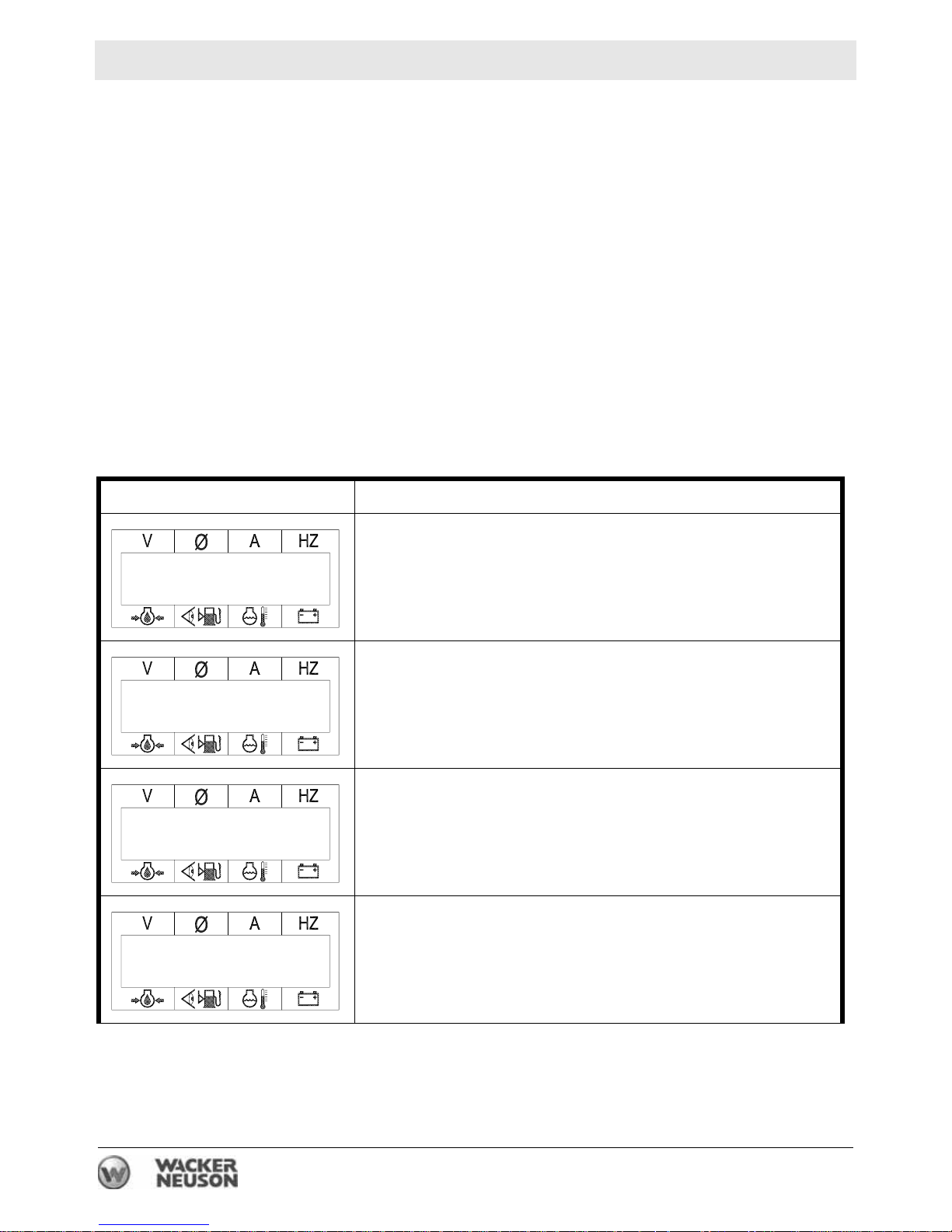

4.4 ECM Display Screens—Start Switch in Remote Position

See Graphic: wc_gr002943

When the start switch is placed in the REMOTE position, the following

screens are displayed.

4.4.1 “Initializing”

The ECM display reads “Initializing” and shows the model of the

generator. If the model displayed does not match the model of the

generator, call Wacker Neuson Service.

4.4.2 “Unit in Auto”

The ECM displays “Unit in Auto” and the values for oil pressure,

percentage of fuel remaining, engine temperature, and voltage of the

battery.

12

Initializing

G85

Unit in Auto

0 50% 74 12.7

wc_gr002943

wc_tx000713gb.fm 29

ECM Background Information Mobile Generator

4.5 Additional Variables Monitored by the ECM

Holding the toggle switch in the HOURS/RESET position allows the

operator to view additional variables monitored by the ECM. It also

allows the time-to-service countdown timer to be reset. To reset the

countdown timer, hold the toggle switch in the HOURS/RESET

position for approximately 30 seconds or until all the screens have

been scrolled through twice. There are three different sets of additional

variables. Each of the following categories of generators has its own

unique set: standard, those generators with cold weather packages or

custom features, and those with the John Deere engine that includes

the electronic Engine Control Unit (ECU). All three sets of additional

variables are listed below, along with typical no load values. Note: The

values from your generator may differ slightly from those shown here.

G 25, G 50, G 70, G 85 (9310) Standard Models

ECM Display Description

Running Time

0.6

Time to Service

250

FOR SALES AND

SERVICE CONTACT

YOUR LOCAL

WACKER DEALER

The display shows the amount of time, in 1/10 hour segments, that the engine has been running.

The display shows the amount of time left until service on

the machine is required. To reset the timer to 250 hours,

hold the Hours/Reset toggle switch in the up position until

all the screens have been scrolled through twice.

Some ECMs include this message.

Some ECMs include this message.

30 wc_tx000713gb.fm

Loading...

Loading...