Page 1

0114475 007

0300

Mobile Generator

Generador Móvil

G50

OPERATOR’S MANUAL

MANUAL DE OPERACÍON

G70

G85

0114475

Page 2

BELGIE

1730 ASSE-MOLLEM ASSESTEENWEG 17 Tel. (32) 02-4528509+07

4040 Herstal 4 Avenue

9800 Deinze Kortrijkse Steenweg 400 Tel. (09)-386 8529

B - 6041 Gosselies Rue Adrienne Bolland s/n Tel. 071-372450

ÇESKÁ REPUBLIKA

19402 PRAHA 9-HLOUBETIN KOLBENOVA 259 Tel. (0042) 2 862165

DANMARK

2690 KARLSLUNDE RØRGANGEN 6 Tel. 46 15 36 00

8200 Arhus N Randersvej 346 Tel. 86-231777

5250 Odense SV Holkebjergvej 56A Tel. 66-172170

ESPAÑA

28850 TORREJON DE ARDOZ (MADRID) POLIGONO INDUSTRIAL LAS MONJAS Tel. (34) 91-6757525 / 85

08780 PALLEJA (Barcelona) PRAT DE LA RIBA, 184 Tel. (93)-6632273

41700 Dos Hermanas (Sevilla) Poligono Industrial La Palmera Tel. (95)-4691129

46133 Meliana (Valencia) Calle Salvador Giner, 6 Tel. (96)-1492102

15890 Santiago de Compostela (La Coruña) Poligono Industrial el Tambre, Via Pasteur, 47a Tel. (981) 573366 / 67

CALLE PRIMAVERA 11

Nave 14 Tel. (95)-4691129

SUOMI

FIN 04250 KERAVA Peltomäenkatu 7 Tel. (358) 9-274 4740

FRANCE

77170 BRIE COMTE ROBERT 335, RUE GLORIETTE—ZAC DU TUBOEUF Tel. (33) 1-60623000

Aix en Provence 13540 Puyricard Tel. 4 42630526

Arras 62217 Beaurains Tel. 3 21235361

Bordeaux 33700 Merignac Tel. 5 56343346

Bourges 18390 St. Germain du Puy Tel. 2 48652015

Lyon 69740 Genas Tel. 4 78401384

Nancy 54180 Heillecourt Tel. 3 83565801

Rennes 35510 Cesson Sevigne Tel. 2 99321522

Toulouse 31270 Cugnaux Tel. 5 61075250

Kehl 77694 Kehl-Goldscheuer Tel. (0590) 9321

HUNGARIA

1106 BUDAPEST Kada u. 137 Tel. (36) 1-260 8668

IRELAND

DUBLIN 13 127A. BALDOYLE INDUSTRIAL ESTATE Tel. (00353) 01-8320218

ITALIA

40016 SAN GIORGIO DI PIANO (Bologna) Via Due Agosto, 1980, Strage di Bologna, 3 Tel. 39.05.665.566 - 665.1574

00125 ACILIA (Roma) Viale Enrico Ortolani, 262 Tel. 39 . 06 . 5219246

20041 Agrate Brianza (Mi) Via Archimede, 31 Tel. 39. 039.699 0136

NEDERLAND

3821 BJ AMERSFOORT COBOLWEG 1 Tel. 033 - 450 40 45

2984 BL Ridderker Glasblazerstraat 7 Tel. 0180 - 41 70 56

7418 EZ Deventer Arnbergstraat 9 Tel. 0570 - 63 00 87

5684 PS Best De Dintel 37 Tel. 0499 - 33 04 33

1704 RT Heerhugowaard Einsteinstraat 4d Tel. 072 - 574 20 78

9411 XN Beilen De Hanekampen 19 Tel. 0593 - 52 31 24

NORGE

1481 HAGAN TYRIVN. 7 Tel. (47) 0 6707-2330

POLSKA

05850 OŻARÓW MAZOWIECKI UL. KONOTOPSKA 4 Tel. (48) 22 722 20 59

62081 Wysogotowo k. Poznania ul. Kamienna 1 Tel. (061) 8143797

PORTUGAL

2785-S. Domingos De Rana Urbanização Industrial de Trajouce, Lote 1 Tel. (351) 21 4443561 / 87

4785-S. Romao do Coronado Lg. do Soeiro, Apartado 2 Tel. (351) 22 982 7992 / 93

SVERIGE

24734 SÖDRA SANDBY SKATTEBERGAVÄGEN 13 Tel. (46) 046-57870

16170 Bromma Karlsbodavägen 17E Tel. 08-282860

41749 Göteborg Knipplekullen 3A Tel. 031-551362

SCHWEIZ

8305 Dietlikon Bahnhofstrasse 3 Tel. (41) 1-8353939

TURKIYE

81120 K. Bakkalköy-ISTANBUL Karaman Çiftligi Cad. No: 55 Tel. (90) 216 573 0621

35350 Üçkuyular-Izmir Mithatpasa Cad. No. 1189 Tel. (90) 232 259 8944

Ostim 06370 Ankara Alinteri Bulvari No. 210 Tel. (90) 312 385 6438/6439

Page 3

Item Number / Número de referencia:

0008229, 0008230, 0008231, 0008238, 0008239

0009006, 0009007, 0009008, 0009009, 0009010, 0009011

This manual is divided into the sections listed below:

Este manual está compuesto por las siguientes secciones:

G50/G70/G85

Operation

1A

Maintenance

2A

1C

Operación

2C

Mantenimiento

!

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust, some of its constituents, and certain

vehicle components contain or emit chemicals known to the

State of California to cause cancer and birth defects or other

reproductive harm.

(English)

(Español)

WARNING

1040SD70

This manual provides information and procedures to safely operate and maintain this WACKER model. For your

own safety and protection from injury, carefully read, understand and observe the safety instructions described

in this manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION

AT THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION

OF THIS INFORMATION WITHOUT NOTICE.

Este manual contiene información y procedimientos que son necesarios para operar y mantener esta máquina

WACKER. Para su propia seguridad y protección, lea por favor este manual cuidadosamente y observe todas las

instrucciones de seguridad descritas en este manual. LA INFORMACION CONTENIDA POR ESTE MANUAL FUE

BASADA EN LAS MAQUINAS FABRICADAS AL TIEMPO DE SU PUBLICACION. WACKER RESERVA EL

DERECHO DE CAMBIAR CUALQUIER PORCION DE ESTE MANUAL SIN AVISO PREVIO.

i

Page 4

G50/G80/G75

V

A

Hz

Ø

18300

REMOTE

START

REMOTE

START

INCHES

20

15

12

8

L1L2L3

18262

Off/0

On/I

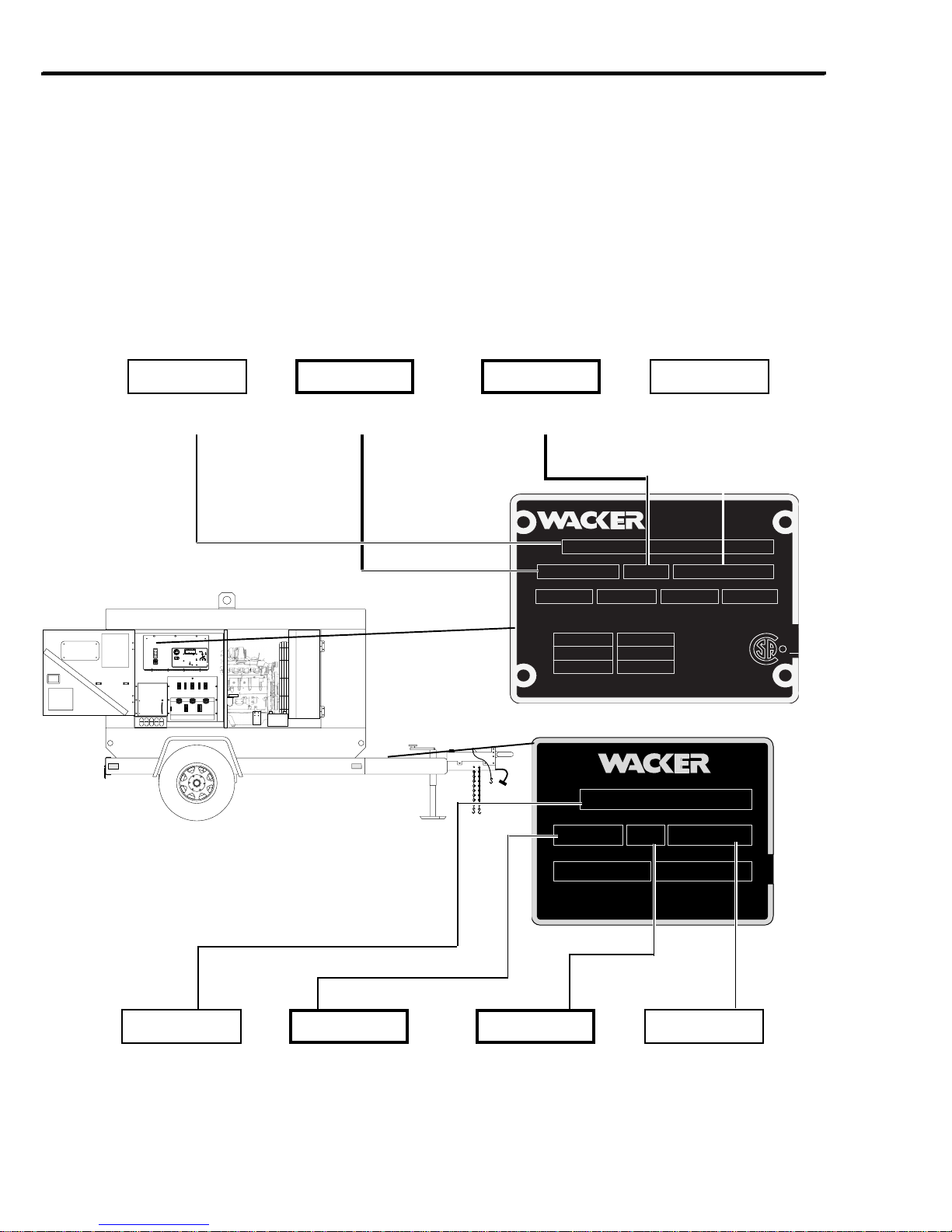

Nameplate

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is attached to each unit. Please

record the information found on this plate so it will be available should the nameplate become lost or damaged. When

ordering parts or requesting service information, you will always be asked to specify the model, item number,

revision number, and serial number of the unit.

Una placa de identificación con el modelo, número de referencia, nivel de revisión y número de serie ha sido añadida

en cada máquina. Favor de anotar los datos en la placa en caso de que la placa de identificación sea destruida o

perdida. En todos los pedidos para repuestos necesita siempre el modelo, el número de referencia, el nivel de

revisión y el número de serie de la máquina en cuestión.

My generator’s numbers are / Los números de mi generador son:

Model number

Modelo

Item Number

Número de referencia

1026SD80

My trailers’s numbers are /

Los números de mi remolque son:

Revision

Nivel de revisión

Model

G50

Item Number

0008229 101 5010101

kg

PRIME

3 phase

@ .8 P.F.

kW/

kVA

V

A

Model

MGT2S

Item Number

0008238

kg

Serial Number

Número de Serie

Wacker Corporation

Menomonee Falls, WI 53051 USA

Rev. Serial Number

1 phase

@ 1.0 P.F.

Rev.

101

lbs

MADE IN USA

rpm

MADE

IN USA

Serial Number

5010101

lbs

RATING

MENOMONEE FALLS, WI USA 53051

hz

For electrical

equipment only

Pour material

electrique

seulement

LR114631

R

116482

85647

Model number

Modelo

Item Number

Número de referencia

Nivel de revisión

ii

Revision

Serial Number

Número de Serie

Page 5

G50/G70/G85

111891

OF THESE U.S. PATENTS:

4643611; 4555238; 5564375; 5586630; 4419048

WACKER MACHINES PROTECTED BY ONE OR MORE

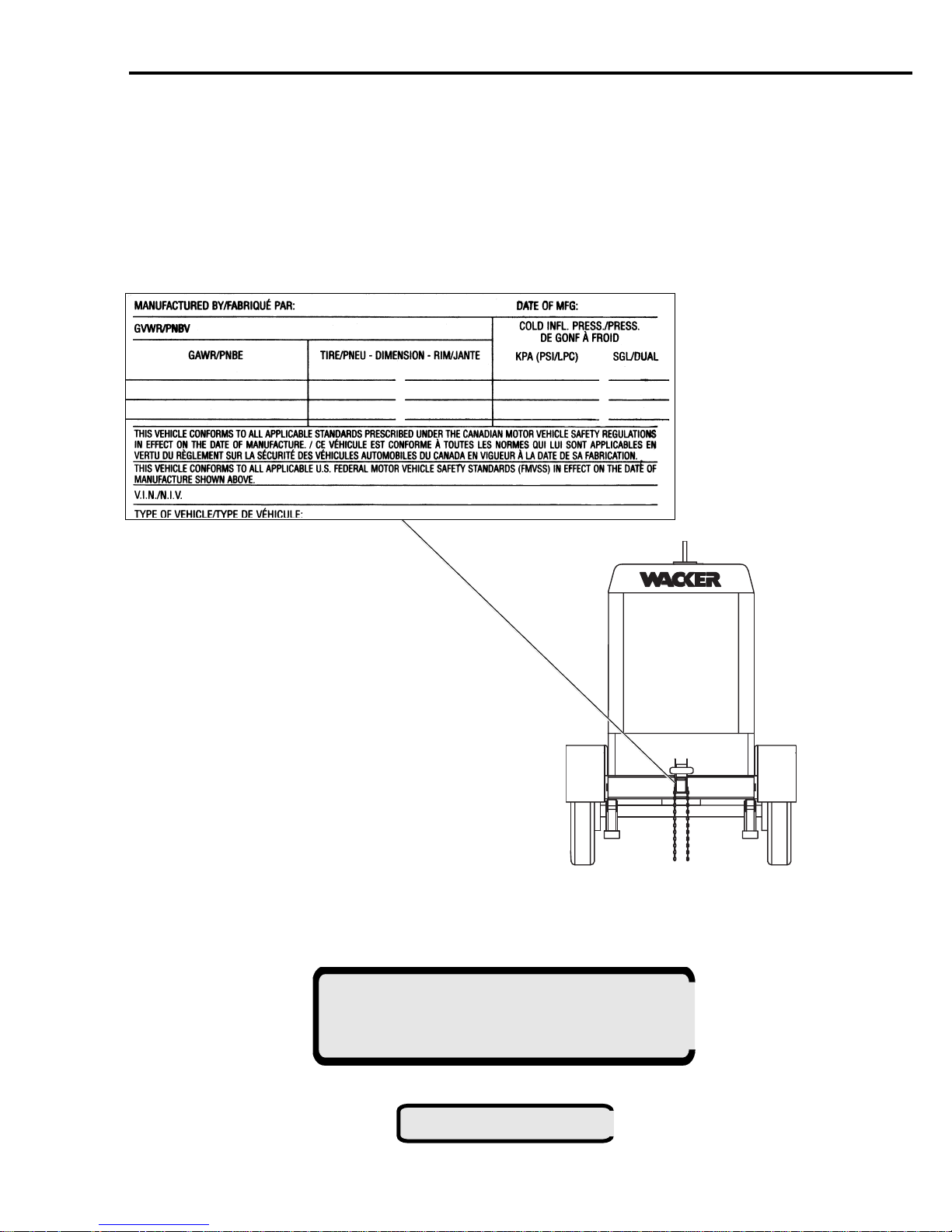

Certification Label (VIN Number)

Also attached to each unit is a Certification Label. This label specifies that the trailer conforms with all Federal

Motor vehicle standards in effect at the time of manufacture. It includes the Vehicle Identification Number (VIN)

for the trailer.

Cada unidad viene acompañada por una Etiqueta de Certificación. Esta etiqueta confirma que el remolque se ajusta

a todos los Estándares Federales para vehículos vigentes en el momento de la fabricación. La etiqueta incluye el

Número de Identificación del Vehículo (VIN) para el remolque.

1038SD61

This machine may be covered by one or more of the following patents:

Puede ser que las patentes a continuación sean válidas para esta máquina:

1029SD03

PATENT PENDING

iii

111545

Page 6

G50/G80/G75

Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immediately

inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying WACKER Corporation.

If NHTSA receives similar complaints, it may open an investigation; and if it finds that a safety defect exists in a group of

vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems

between you, your dealer, or WACKER Corporation.

To contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-800-424-9393 (or 366-0129 in Washington

DC area) or write to NHTSA, U.S. Department of Transportation, Washington, DC 20590. You can also obtain other

information about motor vehicle safety from the Hotline.

Informando sobre defectos en el sistema de seguridad de remolques

Ud. deberá informar de inmediato a la Administración Nacional de Seguridad para el Tráfico en Carreteras

(National Highway Traffic Safety Administration - NHTSA) si considera que su remolque tiene un defecto que

pudiera llegar a causar un accidente o que pudiera causar lastimaduras o conducir a la muerte. Además deberá

notificar además a la WACKER Corporation.

Quejas similares adicionales podrán conducir a una investigación por parte de la NHTSA. Si la NHTSA

determina que existen defectos en un grupo de vehículos, podrá ordenar que los mismos sean retirados de

circulación y que se inicie una campaña de reparaciones. Sin embargo, la NHTSA no deberá intervenir en

problemas individuales entre Ud., su Agente autorizado, o la WACKER Corporation.

Para tomar contacto con la NHTSA llame sin cargo alguno por línea directa al 1-800-424-9393 (ó 366-0129 en

el área de Washington, DC) o escriba a la NHTSA, U.S. Department of Transportation, Washington, DC 20590.

Haciendo uso de la línea directa recién mencionada Ud. también podrá obtener informaciones adicionales sobre

el tema de la seguridad de vehículos al utilizar la línea directa arriba mencionada.

Keep this manual or a copy of it with the machine. If you lose this manual or need an

additional copy, please contact WACKER Corporation. This machine is built with user

safety in mind, however, it can present hazards if improperly operated and serviced.

Follow operating instructions carefully! If you have questions about operating or

servicing this equipment, please contact WACKER Corporation.

Additionally, included with the machine for your convenience, are the following publications:

Power Tech 4.5L & 6.8L Owner’s Manual

John Deere Engine Warranty Registration

Magna Plus Generator Service Manual

Marathon Electric Authorized Service Station Listing

SE350 Voltage Regulator Instruction Manual.

Guarde este manual o una copia junto a la máquina. Por favor tome contacto con la WACKER

Corporation en el caso de perder este manual o si Ud. requiere una copia adicional. Esta máquina

ha sido construida teniendo en mente la seguridad del usuario - sin embargo podrán presentarse

situaciones peligrosas si la misma no es operada y mantenida correctamente. ¡Siga con atención

las instrucciones de operación! Por favor tome contacto con la WACKER Corporation en el caso

de tener preguntas sobre el modo de operación o servicio de este equipo.

Adicionalmente, y para su comodidad, incluimos con la máquina las siguientes publicaciones:

Manual del Operario Power Tech 4.5L & 6.8

Formulario de Garantía para motor John Deere

Manual de Mantenimiento del generador Magna Plus

Lista de Estaciones de Servicio Autorizadas Marathon Electric

Manual de Instrucciones para el Regulador de Voltaje SE350

iv

Page 7

G50/G70/G85

Operation

Table of Contents

1A

1.1 Safety Notes ............................................................................................. 1A-2

1.2 Operating Safety ....................................................................................... 1A-3

1.3 Operator Safety while using Internal Combustion Engines........................ 1A-3

1.4 Service Safety........................................................................................... 1A-4

1.5 Towing Safety ........................................................................................... 1A-5

1.6 Technical Data .......................................................................................... 1A-6

1.7 Labels ....................................................................................................... 1A-8

1.8 Label Locations ....................................................................................... 1A-10

1.9 Control Panels ........................................................................................ 1A-12

1.10 Generator Monitoring .............................................................................. 1A-14

1.11 Engine Monitoring ................................................................................... 1A-15

1.12 Engine Shutdown Faults ......................................................................... 1A-16

1.13 Current Overload Fault ........................................................................... 1A-17

1.14 Voltage Selector Switch .......................................................................... 1A-18

1.15 Emergency Stop Switch .......................................................................... 1A-18

1.16 Main Line Circuit Breaker........................................................................ 1A-18

1.17 Engine Start Switch ................................................................................. 1A-19

1.18 Voltage Adjustment Rheostat.................................................................. 1A-19

1.19 Warning Light .......................................................................................... 1A-19

1.20 Connection Lugs ..................................................................................... 1A-20

1.21 Ground Connection ................................................................................. 1A-20

1.22 Convenience Receptacles ...................................................................... 1A-21

1.23 Remote Run Terminal Block ................................................................... 1A-21

1.24 Panel Door Interlock Switch .................................................................... 1A-21

1.25 Terminal Connections ............................................................................. 1A-22

1.26 Before Starting ........................................................................................ 1A-23

1.27 Manual Start-up ...................................................................................... 1A-24

1.28 Running the Generator ........................................................................... 1A-25

1.29 Engine Power Correction Factors ........................................................... 1A-26

1.30 Shutting Down Generator........................................................................ 1A-27

1.31 Cold Weather Start-up ............................................................................ 1A-27

1.32 Lifting ...................................................................................................... 1A-27

1.33 Overnight Storage ................................................................................... 1A-27

1.34 Long-term Storage .................................................................................. 1A-27

1.35 Automatic/Remote Start-up ..................................................................... 1A-28

1.36 Remote/Transfer Switch ......................................................................... 1A-29

1.37 Towing .................................................................................................... 1A-30

1A-1

Page 8

1A OPERATION G50/G70/G85

1.1 Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION: Used without the safety alert symbol,

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note:

information important to a procedure.

Contains additional

DANGER

Danger of Electrocution!

Danger of electrocution or severe electrical shock is present throughout the generator any time

the engine is running! Read all safety notes contained in this section before operating or

servicing this equipment.

No one except a qualified electrician, familiar with this equipment, should attempt repairs to the

generator! Test procedures which require that the generator be running must be performed

using extreme caution.

This machine is built with user safety in mind; however, like any electrical device it can present

serious hazards if improperly operated and serviced. Follow instructions carefully! Should

questions arise during operation or service of this equipment, contact WACKER Corporation.

1A-2

Page 9

G50/G70/G85 OPERATION 1A

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of electrical equipment! Equipment operated

improperly or by untrained personnel can be dangerous! Read the operating instructions and familiarize yourself with

the location and proper use of all instruments and controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the generator.

WARNING

NEVER operate generator when open containers

of fuel, paint, or other flammable liquids are near.

NEVER operate generator, or tools attached to the

generator, with wet hands.

NEVER use worn electrical cords. Severe electrical shock and equipment damage may result.

NEVER place flammable material or liquids near

generator.

NEVER operate generator indoors unless exhaust

fumes can be adequately ventilated.

NEVER overload generator. The total amperage of

the tools and equipment attached to the generator

must not exceed the load rating of the generator.

NEVER allow untrained personnel to operate or

service the generator. The generator set should

be set up by a trained electrician.

NEVER operate generator in standing water.

ALWAYS wear hearing protection when running

the unit with the doors open.

ALWAYS follow starting and stopping instructions

described in this manual. Know how to operate and

stop generator before starting it.

ALWAYS make a walk-around inspection of the

generator set before starting it. Open side doors

and visually inspect engine compartment for obvious damage or the presence of foreign objects

which might affect operation.

ALWAYS keep generator at least three feet (one

meter) away from structures, buildings and other

equipment during use.

ALWAYS keep generator out of reach of children

and pets.

ALWAYS keep the area immediately surrounding

the generator clean, neat and free of debris. Make

sure that the area overhead is clear of debris that

could fall onto or into the generator.

NEVER touch the hot engine, exhaust, or generator components. Burns will result.

NEVER start a generator under repair.

Use the emergency stop button only in an actual

emergency. DO NOT restart the engine until the

cause of the trouble has been determined and fixed.

BACKFEED FROM THE GENERATOR INTO THE UTILITY’S DISTRIBUTION SYSTEM

CAN CAUSE A SERIOUS INJURY OR DEATH TO UTILITY WORKERS!

Improper connection of generator to a building’s electrical system can allow electrical current from the generator

to backfeed into utility lines. This may result in electrocution of utility workers, fire or explosion. Connections to

a building’s electrical system must be made by a qualified electrician and comply with all applicable laws and

electrical codes.

ALWAYS position and operate generator on a firm,

level surface.

ALWAYS remove all tools and other loose items

from generator before starting it.

ALWAYS make certain generator is well-grounded

and securely fastened to a good earthen ground per

national and local regulations.

DANGER

1A-3

Page 10

1A OPERATION G50/G70/G85

1.3 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly

over a long period of time, periodic maintenance and occasional repairs are necessary. When servicing this

equipment always follow the instructions listed below.

WARNING

NEVER perform even routine service (oil/filter changes, cleaning, etc.)

unless all electrical components are shut down.

Before servicing this machine, make sure the engine start switch is turned to off “O”, the circuit breakers

are open (off), the emergency stop switch is closed (pushed in), and the negative terminal on battery is

disconnected. Attach a “DO NOT START” sign to the control panel. This will notify everyone that the unit is being

serviced and will reduce the chance of someone inadvertently trying to start the unit. If the unit is connected to

a remote start or transfer switch, make sure the remote switch is also off and tagged.

WARNING

Ground Connection

The generator must be connected to a good earthen ground for proper operating safety!

A central “equipment ground” is provided at the customer connection lugs. This point is connected directly to the

generator set base. All other system grounds are connected to this central point. Ground the generator in

accordance with the standards defined in national, state and local regulations.

WARNING

DO NOT attempt to open the radiator cap while the

unit is running or before the engine has cooled

down. Severe burns may result!

DO NOT allow water to accumulate around the base

of the generator set. If water is present, move the

generator and allow it to dry before servicing.

DO NOT service generator if clothing or skin is wet.

DO NOT allow untrained personnel to service this

equipment. Only trained electrical tech-nicians should

be allowed to service the electrical components of

this equipment.

DO NOT modify the equipment without ex-press

written approval from WACKER Corporation.

When cleaning the unit, DO NOT pressure wash

the control panel, generator end, or any other

electrical components. Never allow water to accumulate around the base of the generator set. If

water is present, DO NOT service!

ALWAYS replace all guards and safety devices

immediately after servicing.

ALWAYS let engine cool before transporting or servicing.

ALWAYS remain aware of moving parts and keep

hands, feet and loose clothing away from moving parts

on generator and engine.

ALWAYS replace all guards, fasten doors and make

sure all safety devices operate properly after making

repairs or servicing the equipment.

ALWAYS keep hands, feet, and loose clothing

away from moving parts on generator and engine.

Stay especially clear of fan blade and use care to

avoid having tools or parts drop into blade.

ALWAYS replace all missing and hard-to-read

labels. Labels provide important operating

instructions and warn of dangers and hazards.

Check and tighten all external fasteners at regular

intervals.

Make sure slings, chains, hooks, ramps, jacks, and

other types of lifting devices are attached securely

and have enough weight-bearing capacity to lift or

hold the equipment safely. ALWAYS remain aware

of the position of other people around you when

lifting the generator.

1A-4

Page 11

G50/G70/G85 OPERATION 1A

1.4 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation and fueling! Failure to follow the safety

guidelines described below could result in severe injury or death.

DANGER

DO NOT run engine indoors or in an area with

poor ventilation unless exhaust hoses are used.

DO NOT fill or drain fuel tank near an open flame,

while smoking, or while engine is running.

DO NOT fill fuel tank in an enclosed area with poor

ventilation.

DO NOT touch or lean against hot exhaust pipes.

DO NOT operate with the fuel tank cap loose or

missing.

DO NOT add fuel to a hot or running engine.

DO NOT start engine if fuel has spilled or an odor

of fuel is present. Move generator away from the

spill and wipe generator dry before starting.

DO NOT operate with the fuel tank cap loose or

missing.

DO NOT remove engine coolant cap while engine

is hot.

1.5 Towing Safety

Towing a large trailer requires special care! Both the trailer and vehicle must be in good condition and securely fastened

to each other to reduce the possibility of an accident.

WARNING

ALWAYS check that the hitch and coupling on the

vehicle are rated equal to, or greater than, the trailer's

“gross vehicle weight rating” (GVWR).

ALWAYS connect breakaway cable safety hook to

the bumper or rear of the vehicle. DO NOT attach to

hitch.

ALWAYS inspect the hitch and coupling for wear or

damage. DO NOT tow trailer using defective parts!

ALWAYS make sure the coupling is securely fastened to the vehicle.

ALWAYS check tires on trailer for tread wear, inflation, and condition. Replace worn tires.

ALWAYS connect the safety chains.

If you believe your trailer has a defect which could cause a crash or could cause injury or death, you should

immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying WACKER

Corporation.

If NHTSA receives similar complaints, it may open an investigation; and if it finds that a safety defect exists in

a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in

individual problems between you, your dealer, or WACKER Corporation.

To contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-800-424-9393 (or 366-0129 in

Washington DC area) or write to NHTSA, U.S. Department of Transportation, Washington, DC 20590. You can

also obtain other information about motor vehicle safety from the Hotline.

ALWAYS test surge brakes on trailer and the brakes

on vehicle that will be used for towing.

ALWAYS make sure directional, backup, and trailer

lights are connected and working properly.

ALWAYS check that lug nuts holding wheels are tight

and that none are missing.

Reporting Trailer Safety Defects

1A-5

Page 12

1A OPERATION G50/G70/G85

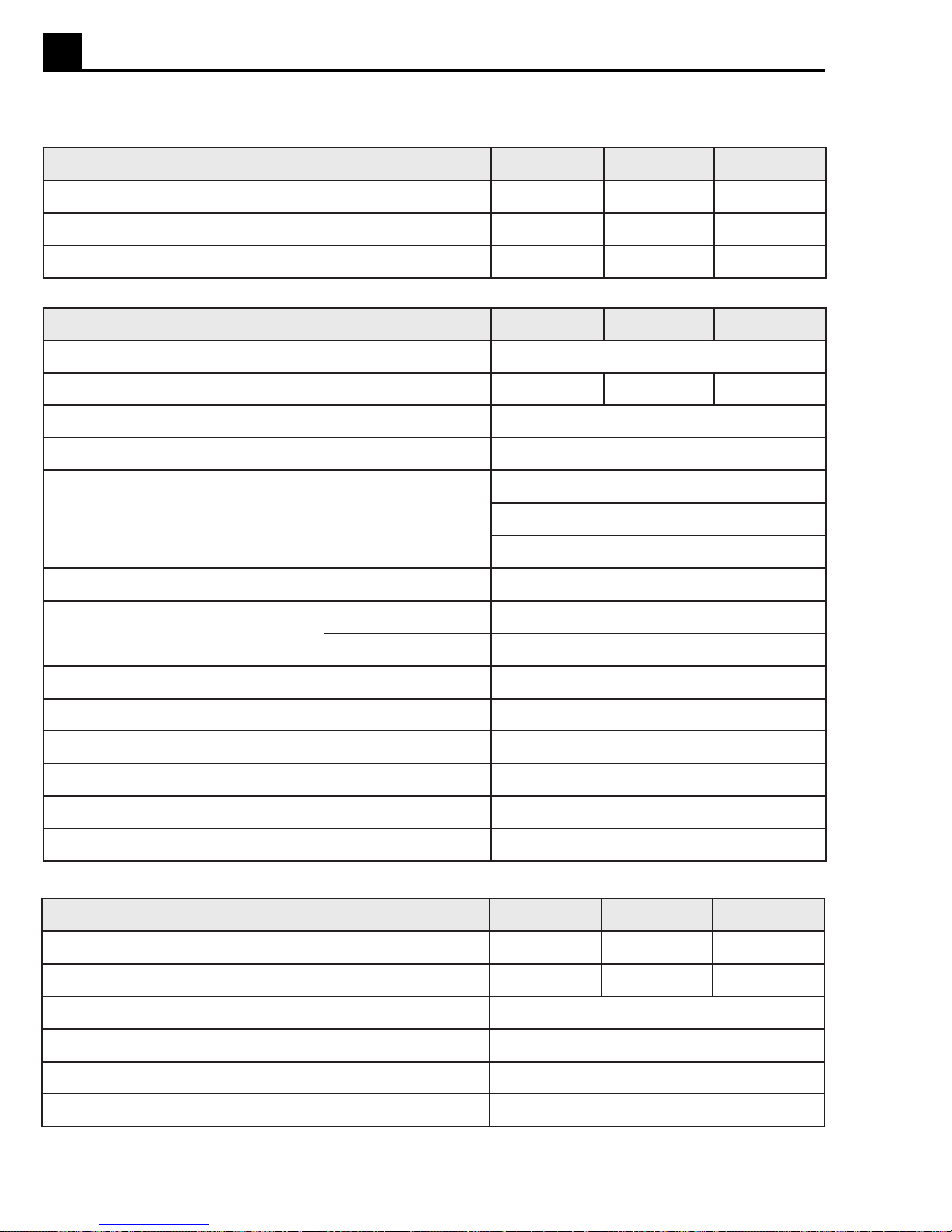

1.6 Technical Data

ecnamrofreP 05G 07G 58G

tuptuOybdnatSAVk/Wk65/5487/2609/27

tuptuOemirPAVk/Wk15/1427/7548/76

rekaerbniaMspmA571522052

rotareneG 05G 07G 58G

epyT/ekaM sselhsurB/nohtaraM

ledoM 1061LSP1632061LSP1634061LSP163

deepsrotareneGmpr0081

hctiwsrotcelesegatloV noitisop3

gaz-giz042/021

elbaliavasegatlovCA

ycneuqerF zH06

ø10.1

rotcafrewoP

ø38.0

noitalugeregatloV %00.1±

ssalcnoitalusnI H

teef32taleveldnuoS)A(Bd96

selcatpecerCA kcoltsiwt3,xelpud2

xelpudIFG021ø1spmA02

kcoltsiwtV042/021ø1spmA05

dikSdnareliarT 05G 07G 58G

diksfothgiewyrD)gk(.sbl)0551(8143)3851(0943)2261(6753

eyw-wol802/021

eyw-iH084/772

diksfothgiewgnitarepO)gk(.sbl)5471(8483)8771(0293)7181(6004

thgiewreliarT)gk(.sbl)092(046

RWVG)gk(.sbl)2312(0074

sekarbegruSepytdiulF3TOD

seriTezis51R57/522TS

1A-6

Page 13

G50/G70/G85 OPERATION 1A

enignE 05G 07G 58G

epyt/ekamenignE L5.4/ereeDnhoJ

ledoM

srednilycforebmuN 4

tnemecalpsiDni

deepsenignEmpr0081

-mpr0081@rewoP

ybdnats/suounitnoc

yticapactnalooC)l(.stq)32(42

yticapacliO)l(.stq)31(41

yrettaBACC/stloV027/21

epytleuF leseiD

yticapacknatleuF)l(.laG)923(78

daolsuounitnoc,noitpmusnocleuF)rh/l(rh/.laG)5.21(3.3)7.61(4.4)6.81(9.4

daolsuounitnoc,emitgninnuRsruoh3.628.917.71

3

mc(3))1054(6.472

pHB17/46001/09311/201

0

-51FD5404OT

051FT5404OT052FT5404OT

Dimensions

inches

38

84.5

60

96

61.5

157

1027SD70

1A-7

Page 14

1A OPERATION G50/G70/G85

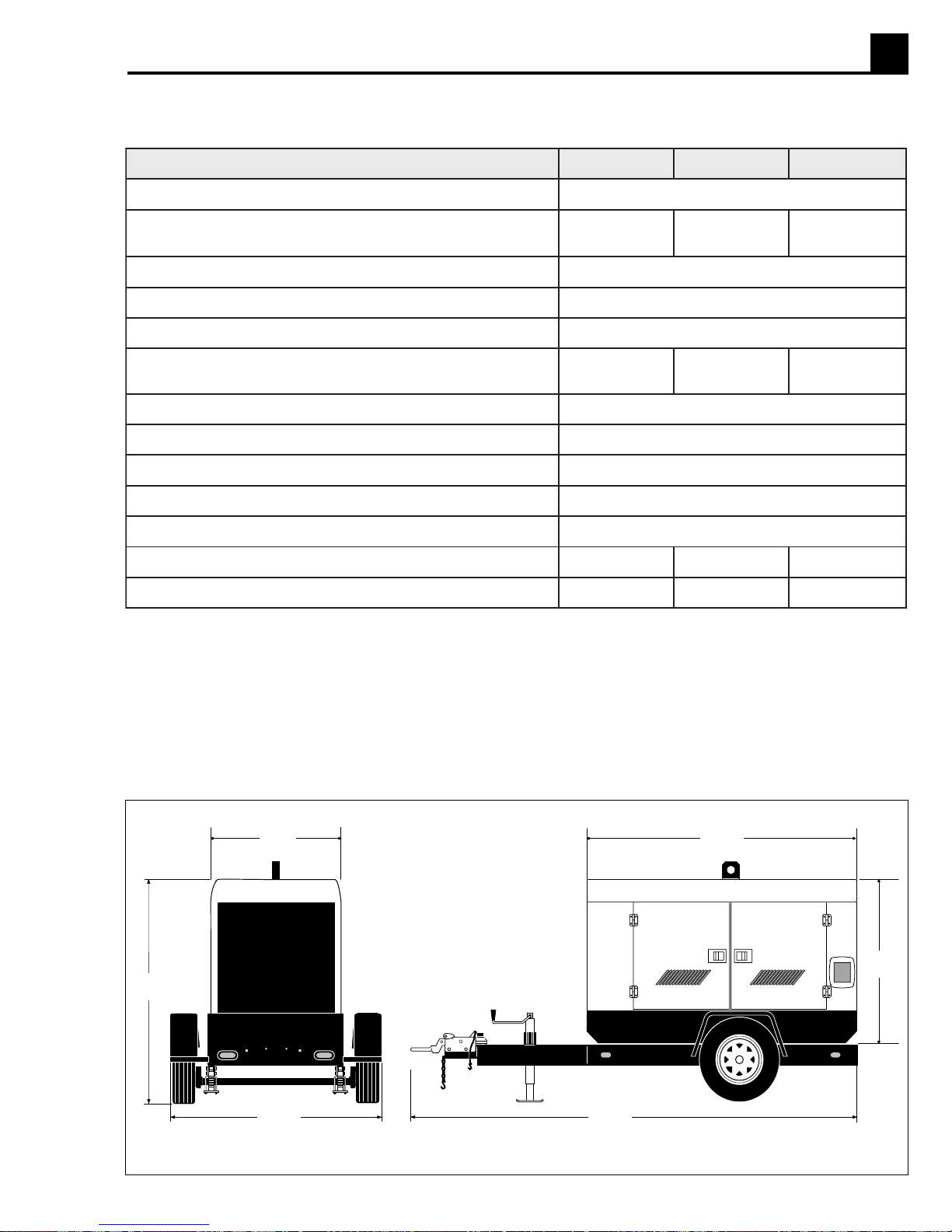

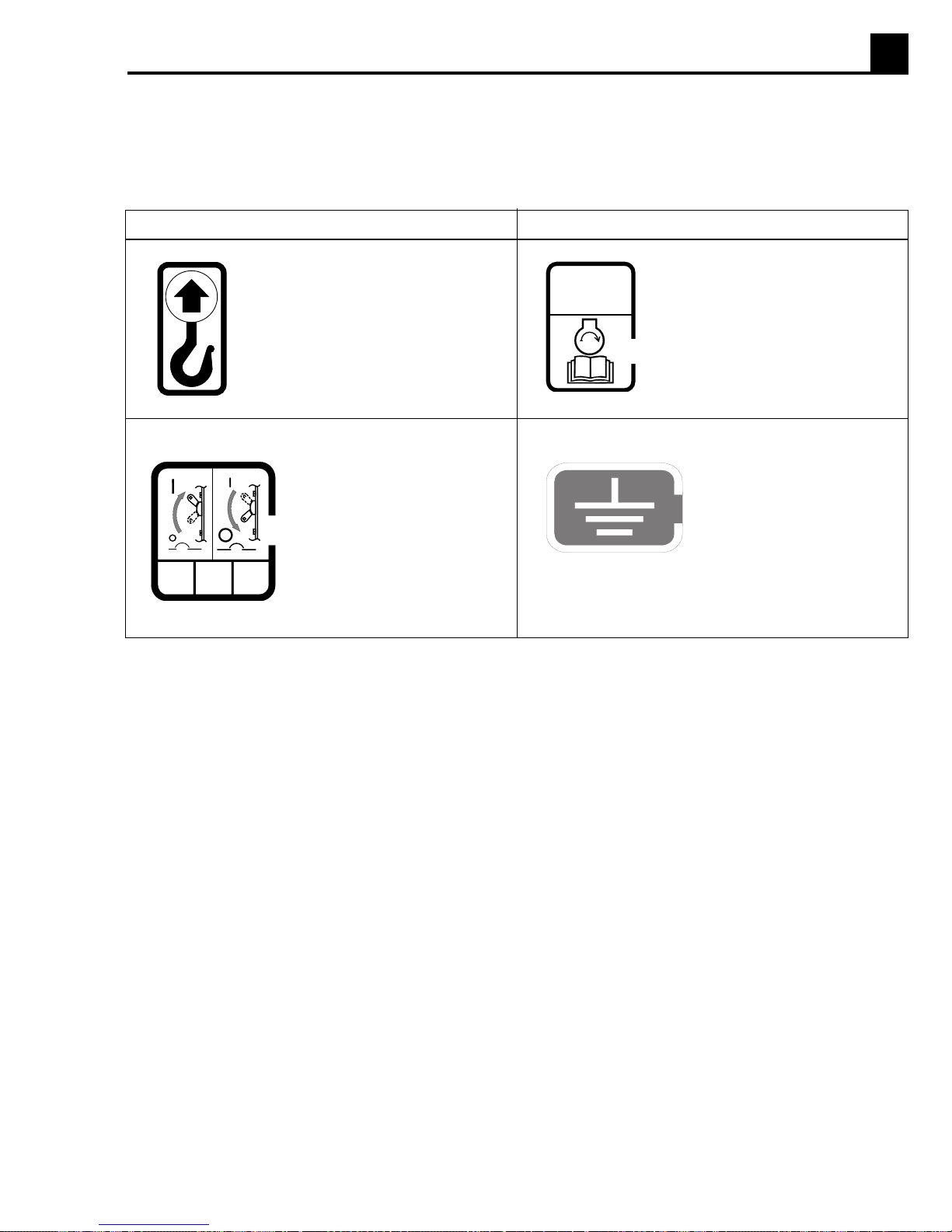

1.7 Labels

Warning & Informational Labels

This WACKER machine uses international pictorial labels where needed. These labels are described below:

Pictorial Meaning Pictorial Meaning

DANGER

GEFAHR

114899

PELIGRO

DANGER

Safety alert! Electrical shock hazard. Read

operator’s manual for instructions.

C A U T I O N

V O R S I C H T

P R E C A U C I O N

P R E C A U T I O N

Safety alert! Disconnect battery before performing maintenance. Read operator’s manual for

instructions.

Safety alert! Pinching hazard. Rotating

machinery. Read

operator’s manual for

instructions.

Safety alert! Asphyxiation hazard. Read operator’s

manual for instructions.

DANGER

GEFAHR

STOP

PELIGRO

DANGER

Safety alert! No sparks, flames, or burning objects

near machine. Stop the engine before adding fuel.

Use only diesel fuel.

Safety alert!

Pressurized contents. Do not open

114904

when hot!

Safety alert!

Hot surface.

114887

1A-8

114885

Wear hearing protection when machine is operating.

Page 15

G50/G70/G85 OPERATION 1A

114886

Operational Labels

This WACKER machine uses international pictorial labels where needed. These labels are described below:

Pictorial Meaning Pictorial Meaning

REMOTE START

FERNSTART

Lifting point. Remote start operation. Read

Operating the main circuit

breaker supplies or interrupts power to the customer connection lugs.

114893

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

operator’s manual for instructions.

114897

Electrical ground.

L1 L2 L3

1A-9

Page 16

1A OPERATION G50/G70/G85

114885

114886

114886

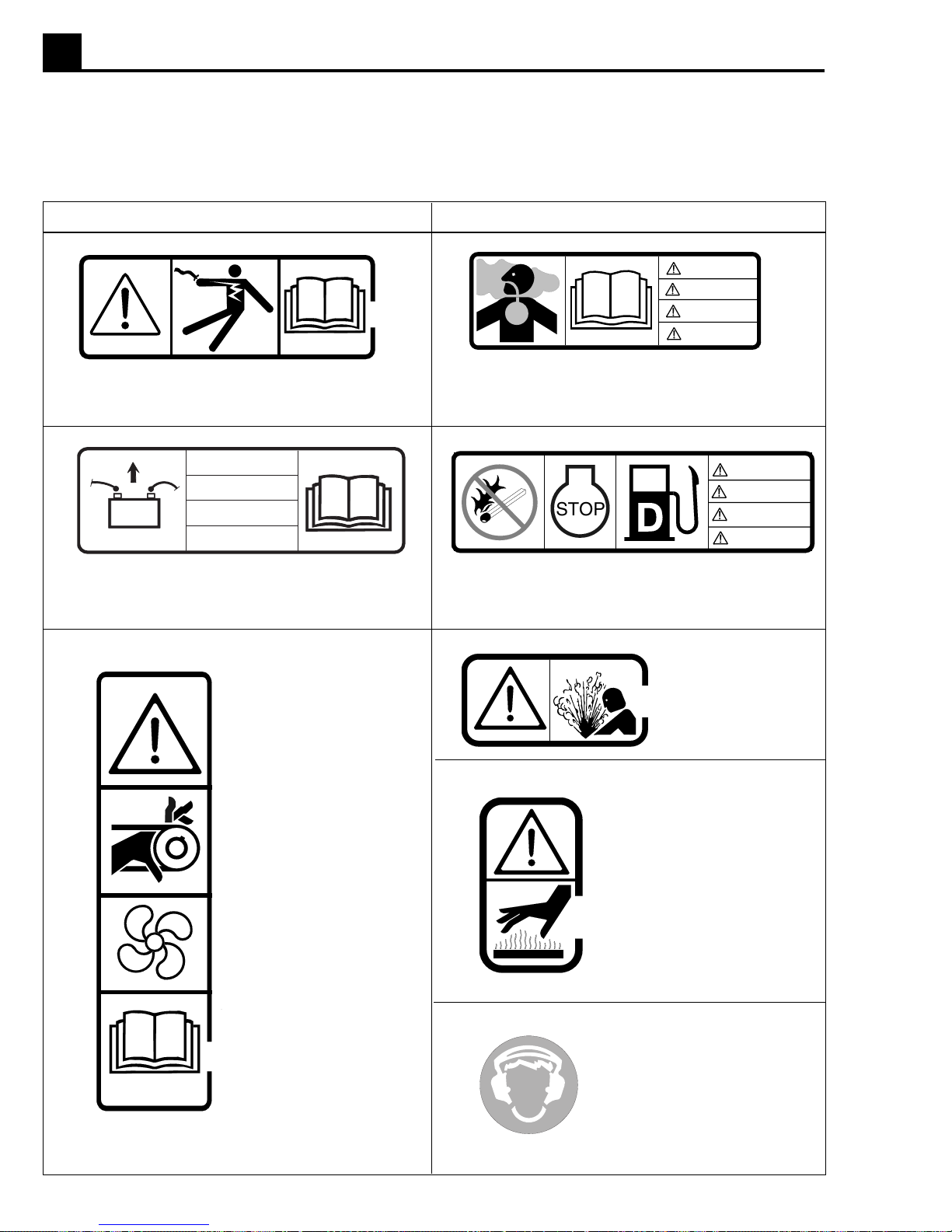

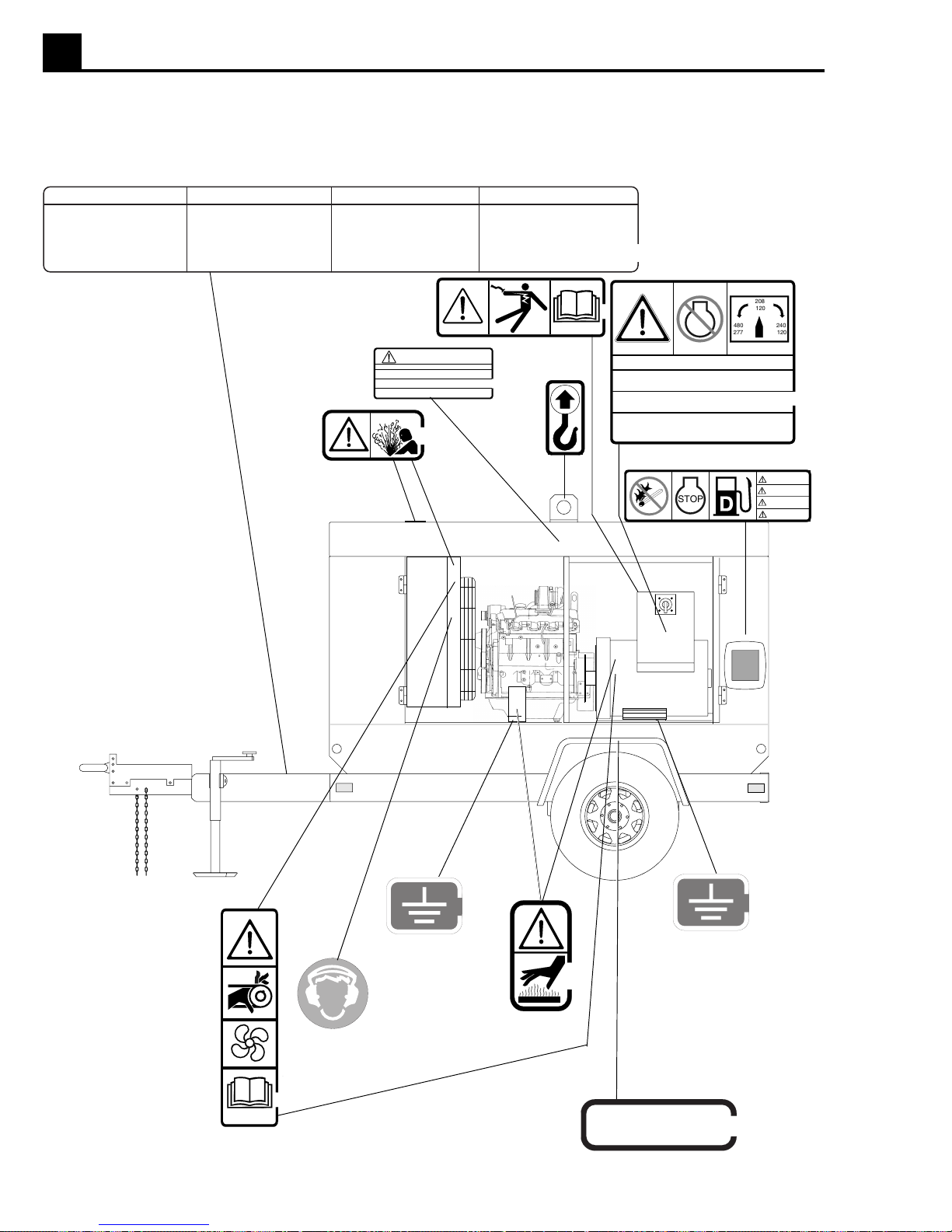

1.8 Label Locations

Labels on the generator provide operating and safety information. Make sure that all the labels are present and legible.

Additional labels used on the operating panels are shown on the following pages.

TOWING INSTRUCTIONS ABSCHLEPPINSTRUKTIONEN INSTRUCCIONES DE REMOLQUE

1. READ OPERATOR'S MANUAL.

2. USE HITCH RATED FRO TRAILER'S

"GROSS VEHICLE WEIGHT RATING".

3. SECURELY ATTACH TRAILER TO TOW

VEHICLE.

4. ATTACH SAFETY CHAINS USING CROSS

PATTERN.

5. ATTACH BREAKDOWN CHAIN TO VEHICLE.

6. CHECK TRAILER LIGHTS.

1. BETRIEBSVORSCHRIFT LESEN.

2. ANHANGEVORRICHTUNG VERWENDEN,

DIE DER GESAMTBETRIEBSGEWICHTSKLASSE

ENTSPRICHT.

3. ANHANGER SICHER AM ZUGFAHRZEUG

BEFESTIGEN.

4. SICHERHEITSKETTEN KREUZWEISE ANBRINGEN.

5. ABREISSKETTE AM FAHRZEUG ANBRINGEN.

6. ANHANGERLEUCHTEN PRUFEN.

1. LEA EL MANUAL DEL OPERARIO.

2. UTILICE UN ACOPLE CORRECTAMENTE

CLASIFICADO PARA LA "CLASE DE PESO BUTO"

DEL VEHICULO DEL REMOLQUE.

3. ASEGURESE DE AMARRAR CORRECTAMENTE

EL REMOLQUE AL VEHICULO DE REMOLQUE.

4. FIJE EN CRUZ LAS CADENAS DE SEGURIDAD.

5. FIJE EN EL VEHICULO DE REMOLQUE LA CADENA

DE DESPRENDIMIENTO.

6. CONTROLE LAS LUCES DEL REMOLQUE.

WARNING ADVERTENCIA

WARNUNG AVERTISSEMENT

LOCK DOORS. ACCESS CAN CAUSE ELECTRIC SHOCK OR INJURY.

*

..

TUREN SCHLIESSEN! ZUGANG KANN ELEKTRISCHEN SCHLAG

ODER VERLETZUNG VERURSACHEN.

CIERRE LAS PUERTAS, YA QUE DE ORTO MODO EXISTE EL PELIGRO

DE UNA DESCARGA ELECTRICA O DE LESIONES PERSONALES.

FERMER LES PORTES D'ACCES OU IL POURRAIT EN RESULTER

RISQUE D'ELECTROCUTION OU ACCIDENTS DE PERSONNE.

114904

INSTRUCTIONS DE REMORQUAGE

1. LIRE LA NOTICE D'EMPLOI.

2. UTILISER UN GROCHET D'ATTELAGE CONFORME AU

DEBIT NOMINAL DU POIDS BRUT DE VEHICULE DU

TRACTEUR.

3. ATTACHER LA REMORQUE FERMEMENT AU VEHICULE

TRACTEUR.

4. ATTACHER LES CHAINES DE SURETTE EN UTILISANT

UNE METHODE CROISEE.

5. ATTACHER LA CHAINE DE REMORQUAGE AU VEHICULE.

6. VERIFIER LES LAMPES DE LA REMORQUE.

114899

114889

*

114894

208

120

240

480

120

277

NEVER CHANGE SWITCH POSITION WITH ENGINE RUNNING.

RESULTS IN ELECTRIC SHOCK AND DAMAGE TO MACHINE.

NIEMALS SCHALTER UMSTELLEN WENN MOTOR LAUFT.

VERURSACHT ELEKTRISCHEN SCHLAG UND BESCHADIGUNG

..

DES GERATES.

NUNCA CAMBIE LA POSICION DEL INTERRUPTOR AL ESTAR

MARCHANDO EL MOTOR. YA QUE ESTO PODRIA CONDUCIR A

UNA DESCARGA ELECTRICA Y DANOS EN EL EQUIPO.

NE JAMAIS CHANGER LA POSITION DE L'INTERRUPTEUR

PENDANT QUE LE MOTEUR EST EN MARCHE. IL POURRAIT

EN RESULTER RISQUE D'ELECTROCUTION ET DOMMAGES

A LA MACHINE.

STOP

..

..

~~~

DANGER

GEFAHR

PELIGRO

DANGER

114896

114887

1A-10

*One on each side

ST225/75R15(D) TIRES

*

AT 65 PSI COLD

15 X 6 RIMS

114888

1026SD79

Page 17

G50/G70/G85 OPERATION 1A

V

A

Hz

Ø

18300

REMOTE

START

REMOTE

START

INCHES

20

15

12

8

L1L2 L3

18262

Off/0

On/I

OPERATING INSTRUCTIONS

FOR MOBILE GENERATORS

BEFORE STARTING

1. READ OPERATOR'S MANUAL.

2. LEVEL UNIT.

3. BLOCK WHEELS.

4. GROUND UNIT.

5. CHECK ALL FLUID LEVELS.

MANUAL STARTING

1. DISCONNECT ALL EXTERNAL LOADS.

2. SET VOLTAGE SELECTOR SWITCH.

3. LOCK VOLTAGE SELECTOR SWITCH.

4. TURN EMERGENCY STOP BUTTON TO "ON" POSITION.

5. PUSH ENGINE START SWITCH TO

"START/RUN" POSITION.

6. ENGINE WILL MAKE 3 ATTEMPTS TO START.

REMOTE START

1. SEE OPERATOR'S MANUAL.

STOPPING

1. DISCONNECT ALL EXTERNAL LOADS.

2. PUSH ENGINE START SWITCH TO "OFF" POSITION.

3. FILL FUEL TANK.

INSTRUCCIONES PARA LA PUESTA EN MARCHA

DE GENERADORES MOVILES

ANTES DEL ARRANQUE

1. LEA EL MANUAL DEL OPERARIO.

2. NIVELE LA UNIDAD.

3. COLOQUE CUNAS DEBAJO DE LAS RUEDAS.

4. CONECTE LA UNIDAD A TIERRA.

5. CONTROLE TODOS LOS LIQUIDOS.

ARRANQUE MANUAL

1. DESCONECTE TODAS LAS CARGAS EXTERNAS.

2. AJUSTE LA LLAVE SELECTORA DE VOLTAJE.

3. BLOQUEE LA LLAVE SELECTORA DE VOLTAJE.

4. GIRE A LA POSICION "ON" EL BOTON DE

PARADA DE EMERGENCIA.

5. OPRIMA A LA POSICION "ARRANQUE/MARCHA" EL

INTERRUPTOR DE ARRANQUE DEL MOTOR.

6. EL MOTOR INTENTARA ARRANCAR 3 VECES.

ARRANQUE REMOTO

1. VEA EL MANUAL DEL OPERARIO.

DETENCION DEL MOTOR

1. DESCONECTE TODAS LAS CARGAS EXTERNAS.

2. OPRIMA A LA POSICION "OFF" EL INTERRUPTOR

DE ARRANQUE DEL MOTOR.

3. LLENE EL TANQUE DE COMBUSTIBLE.

BETRIEBSANLEITUNG

..

FUR MOBILEAGGREGATE

VOR DEM STARTEN

1. BETRIEBSVORSCHRIFT LESEN.

..

2. GERAT WAAGRECHT STELLEN.

..

3. RADER BLOCKIEREN.

..

4. GERAT ERDEN.

..

5. STAND ALLER FLUSSIGKEITEN PRUFEN.

HANDSTARTEN

1. ALLE AUSSEREN BELASTUNGEN ABSCHALTEN.

2. SPANNUNGSWAHLSCHALTER SETZEN.

3. SPANNUNGSWAHLSCHALTER VERRIEGELN.

4. NOTSTOPKNOPF IN "ON" POSITION SETZEN.

5. MOTORSTARTSCHALTER AUF POSITION "START/LAUF"

..

DRUCKEN.

6. MOTOR VOLLZIEHT 3 STARTVERSUCHE.

FERNSTART

1. SIEHE BETRIEBSVORSCHRIFT.

ABSCHALTEN

..

1. ALLE AUSSEREN BELASTUNGEN ABSCHALTEN.

2. MOTORSTARTSCHALTER AUF POSITION "OFF"

..

DRUCKEN.

3. KRAFTSTOFFTANK FULLEN.

INSTRUCTIONS D'OPERATION

DU GENERATEUR MOBILE

AVANT LE DEMARRAGE

1. LIRE LA NOTICE D'EMPLOI.

2. NIVELER LA MACHINE.

3. BLOQUER LES ROUES AVEC CALES DE ROUES.

4. METTRE A TERRE LA MACHINE.

5. VERIFIER LE NIVEAU DE TOUS LES FLUIDES.

DEMARRAGE A LA MAIN

1. DECONNECTER TOUS LES REGIMES EXTERNES.

2. REGLER LE COMMUTATEUR DES TENSIONS

D'ALIMENTATION.

3. SERRER LE COMMUTATEUR DES TENSIONS

D'ALIMENTATION.

4. TOURNER LE BOUTON D'ARRET D'URGENCE

A LA POSITION "ON".

5. PRESSER L'INTERRUPTEUR DE DEMARRAGE

DU MOTEUR A LA POSITION "DEMARRAGE/MARCHE".

6. LE MOTEUR S'ESSAYERA DE DEMARRER 3 FOIS.

DEMARRAGE A DISTANCE

1. LIRE LA NOTICE D'EMPLOI.

ARRET

1. DECONNECTER TOUS LES REGIMES EXTERNES.

2. PRESSER L'INTERRUPTEUR DE DEMARRAGE DU

MOTEUR A LA POSTION "OFF".

3. REMPLIR LE RESERVOIR A CARBURANT.

..

..

114904

114899

114902

DANGER

GEFAHR

PELIGRO

DANGER

114887

OPERATOR'S MANUAL MUST BE

STORED ON MACHINE.

REPLACEMENT OPERATOR'S

MANUAL CAN BE ORDERED

THROUGH YOUR LOCAL WACKER

DISTRIBUTOR.

DIE BETRIEBSVORSCHRIFT MUSS

AN DER MASCHINE AUFBEWAHRT

WERDEN. ZUR BESTELLUNG VON

ERSATZBÜCHERN WENDEN SIE

SICH BITTE AN IHREN

ÖRTLICHEN WACKER HÄNDLER.

EL MANUAL DE OPERACION DEBE

SER RETENIDO EN LA MAQUINA.

CONTACTE A SU DISTRIBUIDOR

WACKER MAS CERCANO PARA

PEDIR UN EJEMPLAR

ADICIONAL.

LA NOTICE D'EMPLOI DOIT

ETRE MUNIE SUR LA MACHINE.

CONTACTER LE DISTRIBUTEUR

WACKER LE PLUS PROCHE

POUR COMMANDER UN

EXEMPLAIRE SUPPLEMENTAIRE.

115096

T3

L3

L3

T3

T9

L3

DANGER PELIGRO

GEFAHR DANGER

TERMINAL CONNECTIONS

VERBINDUNGSKLEMMEN

L1

T1

T4

T7

T10

N

T11

T12

T9

T8

T5

T6

L-N

L1

T7

T1

T4

T10

T5

N

T12

T2

T9

T6

T11

T3

T8

L2

L-N

T6

T8

T2

T11

T12

T10

N

T5

T4

120V

240V

L-L

T2

L2

L-L

T7

T1

120V

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

READ OPERATORS MANUAL.

IMPROPER CONNECTION OF GENERATOR TO A

BUILDING'S ELECTRICAL SYSTEM CAN ALLOW

ELECTICAL CURRENT FROM THE GENERATOR

TO BACKFEED INTO UTILITY LINES.

THIS MAY RESULT IN ELECTROCUTION

OF UTILITY WORKERS, FIRE OR EXPLOSION.

CONNECTIONS TO A BUILDING'S ELECTRICAL

SYSTEM MUST BE MADE BY A QUALIFIED

ELECTRICIAN AND COMPLY WITH ALL

APPLICABLE LAWS AND ELECTRICAL CODES.

BORNES DE CONEXION

RACCORDS TERMINALS

480

277

L1-L2 = 480V L1-N = 277V

L2-L3 = 480V L2-N = 277V

L3-L1 = 480V L3-N = 277V

N-

480

277

L1-L2 = 208V L1-N = 120V

L2-L3 = 208V L2-N = 120V

L3-L1 = 208V L3-N = 120V

N-

480

277

L1

L1-L3 = 240V

L1-N = 120V

L2-N = ----

L3-N = 120V

114885

C A U T I O N

V O R S I C H T

P R E C A U C I O N

P R E C A U T I O N

REMOTE START

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

114897

TRAILER WIRING

G - RIGHT BRAKE LIGHT AND DIRECTIONAL

Y - LEFT BRAKE LIGHT AND DIRECTIONAL

Br -TAIL, SIDE AND LICENSE PLATE LIGHTS

208

120

240

120

208

120

240

120

208

120

240

120

114898

W - GROUND

L - ELECTRIC BRAKES

B - BATTERY CHARGE

ANHÄNGER-VERDRAHTUNG

G - RECHTES BREMSLICHT UND BLINKER

Y - LINKES BREMSLICHT UND BLINKER

Br -SCHLUSS-, SEITEN- UND

KENNZEICHENLEUCHTE

W - ERDUNG

L - ELEKTRISCHE BREMSE

B - BATTERIE-LADUNG

DE REMOLQUE

G - LUZ FRENO Y GIRO DERECHA

Y - LUZ FRENO Y GIRO IZQUIERDA

Br -LUZ TRASERA, LATERAL Y PLACA

DE MATRICULA

W - TIERRA

L - FRENOS ELECTRICOS

B - CARGA BATERIA

DISPOSITION DES CABLES CANALISATION ELECTRICA

POUR REMORQUE

G - FEUX DE STOP ET DE DIRECTION D

Y - FEUX DE STOP ET DE DIRECTION G

Br -FEUX D'ARRIERE, DE POSITION ET

DE PLAQUE D'IMMATRICULATION

W - MISE A TERRE

L - FREINS ELECTRIQUES

B - CHARGE DE LA BATTERIE

1026SD80

115681

1A-11

Page 18

1A OPERATION G50/G70/G85

114886

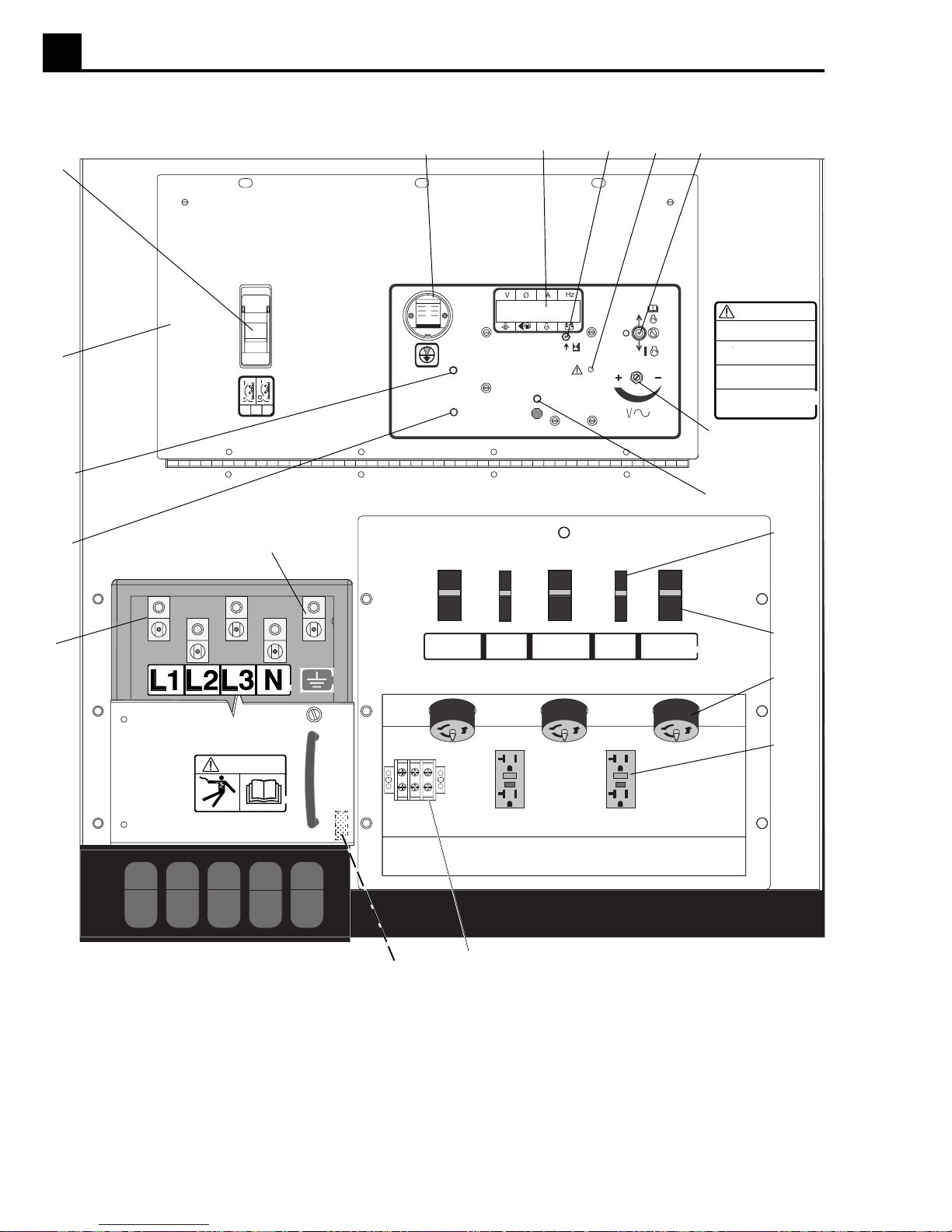

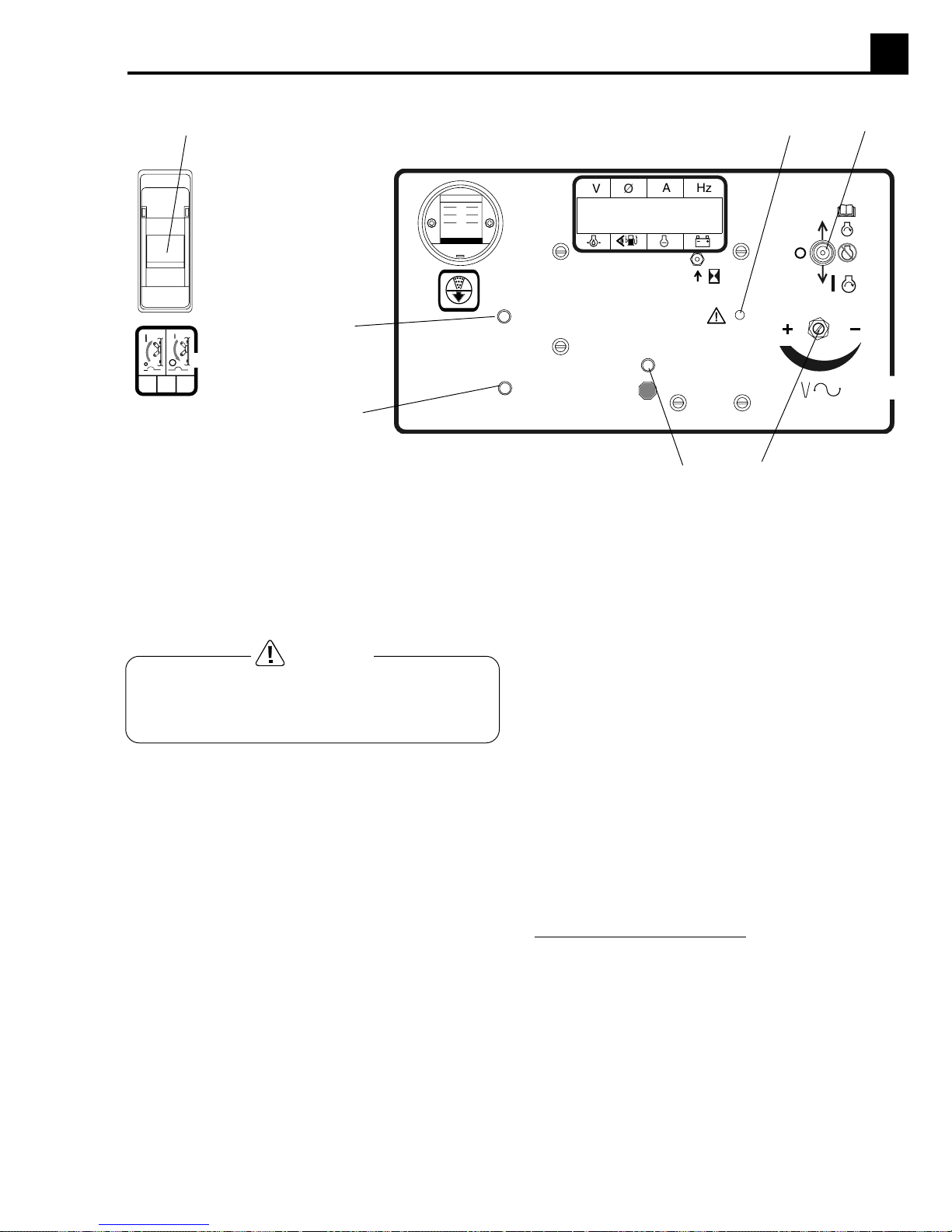

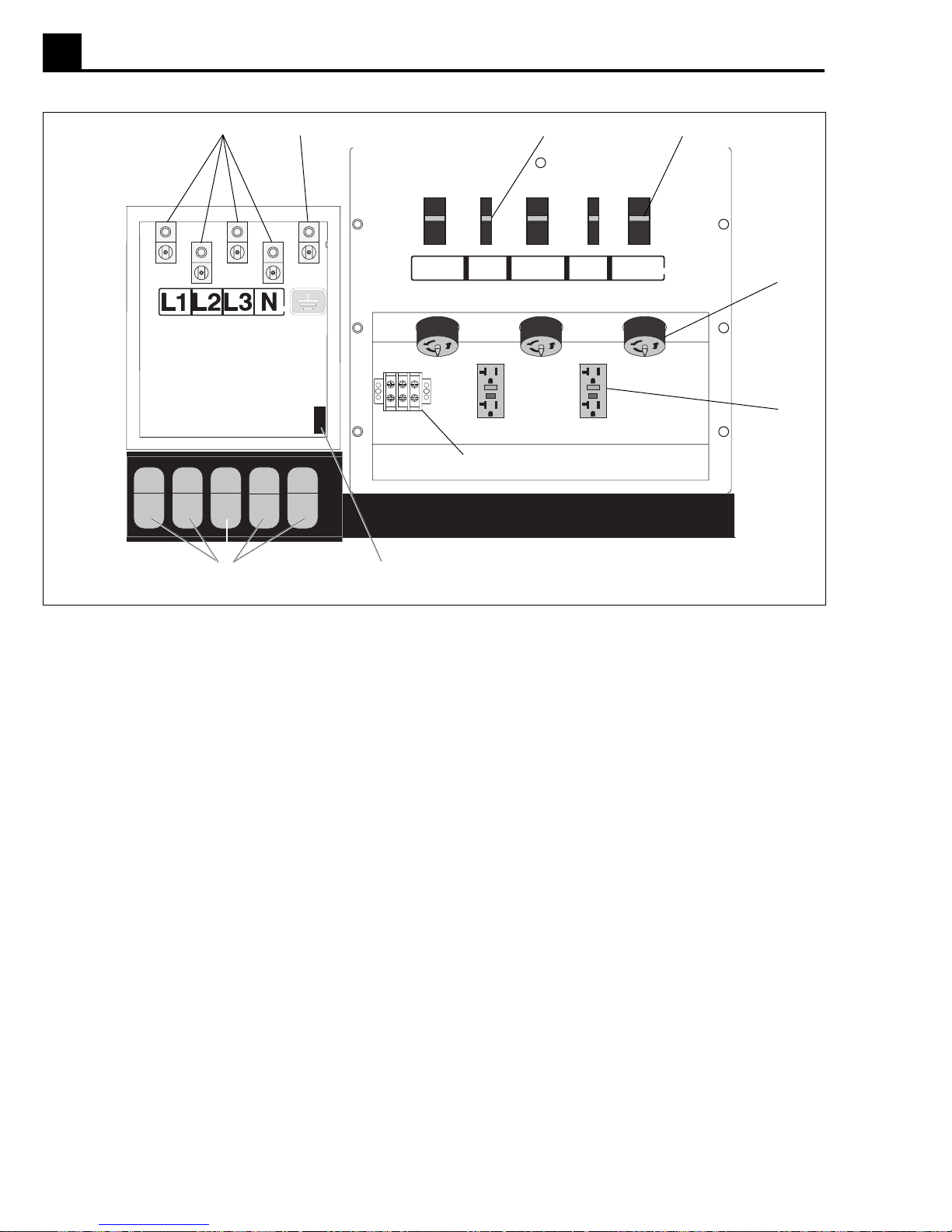

1.9 Control Panels

a

w

v

t

On/I

Off/0

L1 L2 L3

FERNSTART

DISTANCE

START/RUN

START/LAUF

e

f

START

WARNING ADVERTENCIA

WARNUNG AVERTISSEMENT

GENERATOR CAN AUTOMATICALLY START

RESULTING IN BODILY HARM.

DISCONNECT BATTERY BEFORE SERVICING.

AGGREGAT KANN AUTOMATISCH STARTEN

UND KORPERLICHE VERLETZUNG

VERURSACHEN.

VOR SERVICEARBEIT BATTERIE ABKLEMMEN.

GENERADOR PUEDE ARRANCAR

AUTOMATICAMENTE Y CAUSAR LESIONES

PERSONALES. DESCONECTE LA BATERIA

ANTES DE PRESTAR SERVICIO.

GENERATEUR PEUT DEMARRER

AUTOMATIQUEMENT RESULTANT EN DES

ACCIDENTS DEPERSONNE.

DECONNECTER BATTERIE AVANT TOUT

ENTRETIEN.

114901

g

bc

A

Ø

20

15

12

8

INCHES

EMERGENCY STOP SWITCH

NOTAUSSCHALTER

INTERRUPTOR DE URGENCIA

INTERRUPTEUR D'URGENCE

TERMINAL DOOR OPEN

KLEMMENABDECKUNG OFFEN

PUERTA DE BORNES ABIERTA

CACHE-BORNES OUVERT

V

STOP

d

Hz

REMOTE

ARRANQUE REMOTO

DEMARRAGE A

ARRANQUE/MARCHA

DEMARRAGE/MARCHE

h

s

j

r

114895

DANGER PELIGRO

GEFAHR DANGER

114890

a Main Circuit Breaker

b Engine Air Filter Gauge

c LCD Panel

d Engine Hours Switch

e Pre-alarm LED

f Engine Start Switch

g Voltage Adjustment Rheostat

h Shutdown LED

j Circuit Breaker (120V, 20 Amp) - two

k Circuit Breaker (120/240V, 50 Amp) - three

50A 20A 50A 20A 50A

p

o

m Twist Lock Receptacle (120/240 VAC,50 Amp) - three

n GFI Receptacle (120 VAC, 20 Amp) - two

o Remote Run Terminal Block

p Interlock Switch

r Customer Connection Terminal Lugs

s Ground Connection

t Terminal Door Open LED

v Emergency Stop Activated LED

w Control Panel Access Door

k

m

n

1026SD81

1A-12

Page 19

G50/G70/G85 OPERATION 1A

1.9 Control Panels (continued)

208

120

G

E

R

E

M

E

N

C

Y

S

P

T

O

Emergency Stop Button

LCD Read-out

The large LCD read-out on the metering panel simultaneously displays both engine and generator information

while the unit is running.

During operation the top line displays vital generator

information: voltage, frequency in Hertz and amperage.

Information is displayed for all three phases on a rotating

basis, with the values for phase 1 being displayed first,

followed by phase 2 and then phase 3. In single phase

120/240 position, phase 1 reads L1-N, phase 2 reads

L1-L3, and phase 3 reads L3-N.

The bottom line of the panel monitors vital engine information and continuously displays: oil pressure, engine

coolant temperature, battery voltage and fuel level.

The engine running time can be displayed by using the

Engine Hours switch. Holding the switch up will allow the

panel to scroll through the engine fault set points, the

engine sender condition, and the time until the next

engine service is due (“Time to Service”). The Engine

Hours switch can also be used to lock in the voltage,

amperage and frequency readings for any one phase. To

lock in readings for one phase, push the Engine Hours

switch down.

480

277

NEVER CHANGE SWITCH POSITION WITH ENGINE RUNNING.

RESULTS IN ELECTRIC SHOCK AND DAMAGE TO MACHINE.

NIEMALS SCHALTER UMSTELLEN WENN MOTOR LAUFT.

VERURSACHT ELEKTRISCHEN SCHLAG UND BESCHADIGUNG

..

DES GERATES.

NUNCA CAMBIE LA POSICION DEL INTERRUPTOR AL ESTA R

MARCHANDO EL MOTOR. YA QUE ESTO PODRIA CONDUCIR A

UNA DESCARGA ELECTRICA Y DANOS EN EL EQUIPO.

NE JAMAIS CHANGER LA POSITION DE L'INTERRUP TEUR

PENDANT QUE LE MOTEUR EST EN MARCHE. IL POURRAIT

EN RESULTER RISQUE D'ELECTROCUTION ET DOMMAGES

A LA MACHINE.

~~~

240

120

208

120

240

480

120

277

..

..

114896

1026SD771026SD84

Voltage Selector Switch

Should a fault condition occur such as:

• low oil pressure

• high engine temperature

• low fuel level

• engine overspeed

• overcrank

• current overload

• engine underspeed

the LCD panel will display the condition causing the fault.

At the same time, the engine will shut down and lock out.

To restart the engine the engine start switch must be

manually returned to its off “O” position.

The panel will also display the engine sender failure and

Time to Service information. These conditions will not

shut down the machine, but will alert the operator.

1A-13

Page 20

1A OPERATION G50/G70/G85

1.10 Generator Monitoring

Generator information is displayed on the top line of the

LCD panel and is scrolled continuously while the generator is operating, to show the voltage, amperage and

frequency of each phase.

Note:

To prevent the display from scrolling, press the

ENG HRS switch down.

Volts “V”- Displays the AC output voltage being produced by the generator.

Phase “Ø” - Indicates which phase is currently being

displayed.

Amps “A” - Displays the AC output amperage produced

by the generator. If the generator is operating at no-load,

output amperage will display a 0.

Hertz “Hz” - Displays output frequency. This gauge

should read approximately 61.5 Hz under a no-load

condition. If the frequency is too high, check the engine

rpm.

(SAMPLE DISPLAY WITH ENGINE RUNNING)

Ø

V

A

Hz

208 1 24 61.5

78 85% 175 14.3

(SAMPLE DISPLAY IN “AUTO” MODE)

Ø

V

A

Hz

UNIT IN AUTO

O 100% 85 13.2

1A-14

1026SD65

Page 21

G50/G70/G85 OPERATION 1A

1.11 Engine Monitoring

With the engine start switch set to “RUN/START” or

“REMOTE START”, engine information will be continuously displayed on the bottom line of the LCD panel.

OIL - Displays engine oil pressure. The gauge

registers oil pressure between 0 –100 psi. Normal oper-

ating pressure is between 60–80 psi. If oil pressure drops

below 15 psi, the engine will automatically shut down.

(SAMPLE DISPLAY OF ENG. HRS.)

Ø

V

A

Hz

RUNNING HOURS

135.2

FUEL - Indicates the relative fuel level in the fuel

tank. If fuel level drops to 15% the engine will automatically shut down.

TEMPERATURE - Displays the temperature of the

engine's coolant. If the coolant temperature exceeds

239°, the engine will automatically shut down.

BATTERY - This gauge measures the engine

starting battery voltage. A normal reading is 13.5–14.5V.

If the gauge falls much below or above these values, the

engine charging system should be checked. With the

engine switch set to “REMOTE START” and the generator in stand-by mode, actual battery voltage is displayed.

ENGINE HOURS - Pressing the switch UP causes

the engine’s running hours, the periodic maintenance

timer, and the Engine Fault set points to be displayed.

Engine hours are accumulated only while the engine is

actually running.

Note:

When held down, this switch can be used to lock

in a specific display for a single phase.

SENDER FAILURE - Indicates that the coolant temperature sensor or the oil pressure sensor has failed. This

fault will not be displayed unless the fault has occurred;

also, this fault will not shut down the machine.

(SAMPLE DISPLAY OF PERIODIC MAINTENANCE TIMER.)

Ø

V

A

Hz

TIME TO SERVICE

180.2 hrs.

(SAMPLE DISPLAY SHOWING ENGINE FAULT SET POINTS.)

Ø

V

A

Hz

LOP<15 HWT>239

OS > 67

Engine Fault Set Points

Low Oil Pressure = 15 psi

High Temperature = 239° F

Underspeed = 55 Hz (1650 rpm)

Overspeed = 67 Hz (2000 rpm)

Overcrank = Three 10-second crank/rest cycles

Fuel Level = 15%

1A-15

Page 22

1A OPERATION G50/G70/G85

V

A

Hz

Ø

V

A

Hz

Ø

V

A

Hz

Ø

V

A

Hz

Ø

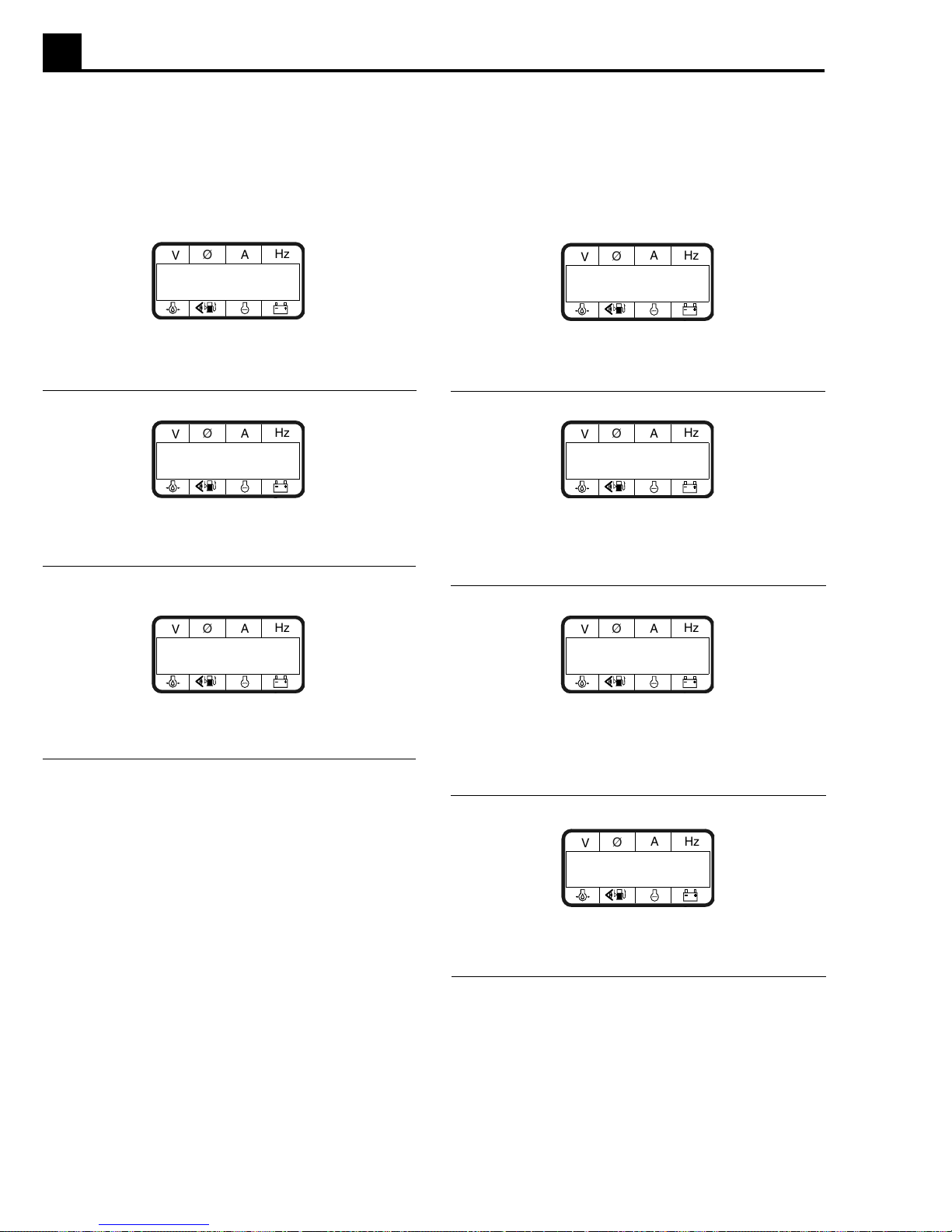

1.12 Engine Shutdown Faults

The engine control module (ECM) continuously monitors vital engine functions for six fault conditions. When a fault

condition occurs, the engine will shut down and the LCD panel will display the fault causing the shutdown. To reset the

Engine Control Module and resume operation, return the Engine Start Switch manually to off “O”. Also refer to Section

1.19

Warning Light.

Hz

A

Ø

V

EMERGENCY

STOP

FAULT

OVERSPEED 2200

Indicates that the emergency stop button has been

depressed. This display will remain on until the emergency stop button is pulled back out.

Hz

A

Ø

V

FAULT LOW OIL

PRESSURE 14

Indicates that the engine oil pressure dropped below

15 psi for more than 5 seconds and the Engine Control

Module (ECM) has shut the engine down.

Hz

A

Ø

V

FAULT HIGH ENGINE

TEMPERATURE 255

Indicates that the engine coolant temperature has exceeded 239°F for more than 5 seconds, and the ECM has

automatically shut down the engine.

Indicates that the engine speed exceeded approximately

2000 rpm (110% of its rated speed of 1800 rpm) and the

ECM has automatically shut the engine down.

FAULT

OVERCRANK

An overcrank fault is displayed when the engine fails to

start during the normal cranking cycle, and the Engine

Control Module has automatically shut down the generator due to an overcrank condition.

LOW FUEL

A low fuel fault condition will be displayed when the fuel

tank drops to 15% and the Engine Control Module has

shut the engine down. This fault condition prevents the

fuel lines from running completely dry and avoids the

need to bleed the lines when the tank is refilled.

1A-16

FAULT

UNDERSPEED 53

Indicates that the engine speed dropped below 55 Hz for

more than 15 seconds and the ECM has automatically

shut the engine down.

1026SD65

Page 23

G50/G70/G85 OPERATION 1A

1.13 Current Overload Fault

Along with engine functions the ECM continuously monitors the current load in each phase. The values for current

overload are programmed into the ECM at the factory and are different for each generator size.

Hz

A

Ø

V

FAULT

OVERLOAD

When an overload condition is sensed in any leg, the engine will shut down and the LCD panel will display the fault

condition shown above.

Before restarting the generator the cause of the overload should be determined and eliminated. Review all loads

attached to the generator and make sure they do not exceed the power rating of the unit.

1A-17

Page 24

1A OPERATION G50/G70/G85

208

120

G

E

R

N

E

C

Y

P

T

O

480

277

240

120

M

E

S

1026SD77 1026SD84

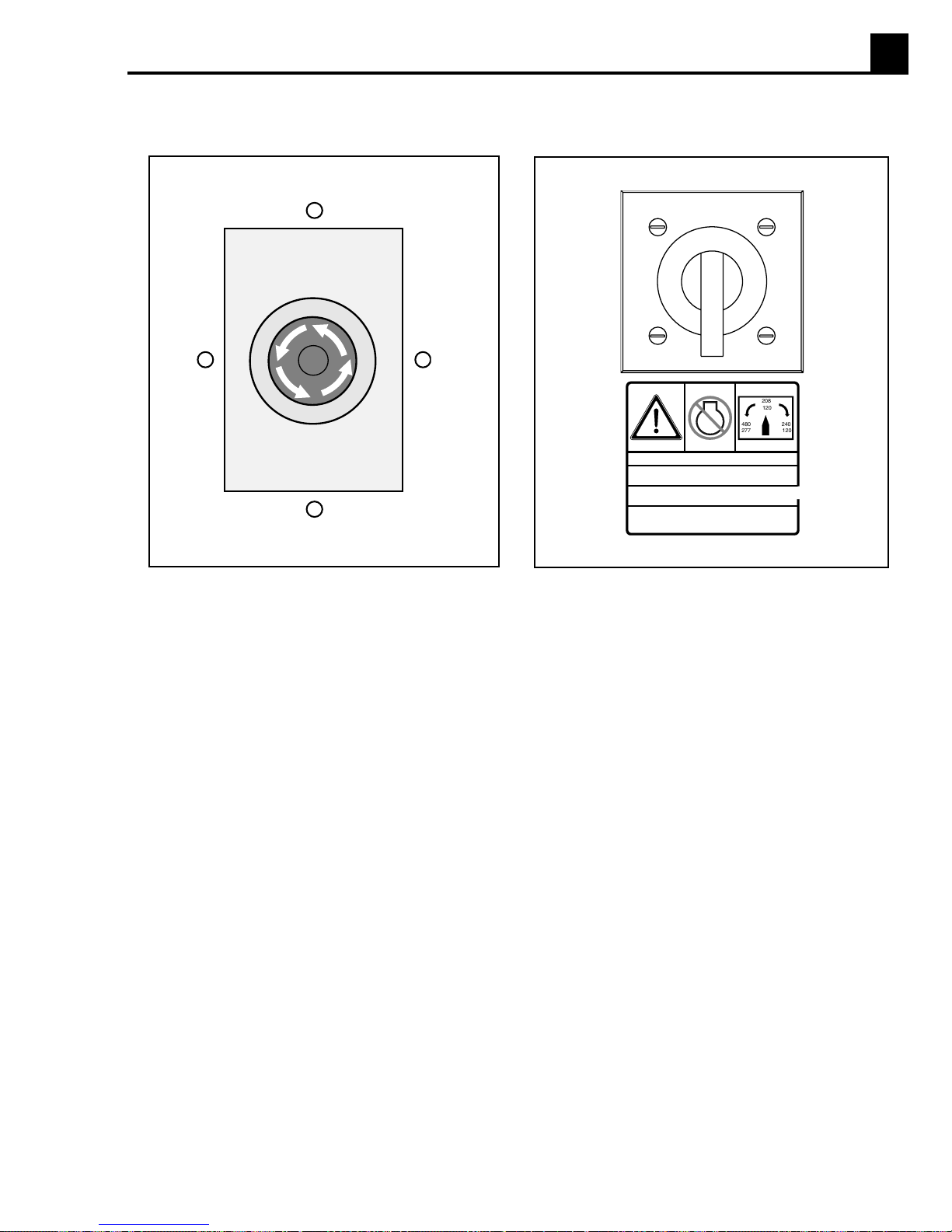

1.14 Voltage Selector Switch

The voltage selector switch is located in a separate

enclosure on the generator on the opposite side of the

machine.

The selector switch is a three-position switch which

mechanically changes the connections between the generator output leads and the terminal lugs on the generator. This allows three different volt ranges to be selected.

120/240 VAC 1Ø

120/208 VAC 3Ø

277/480 VAC 3Ø

Voltage ranges are selected by rotating the handle on the

switch to the desired voltage. The switch is equipped with

a locking mechanism. This allows the voltage setting to

be locked in place to prevent unauthorized personnel

from changing the voltage selection. To lock switch in

position, push lock up and attach a padlock through the

openings in the locking strip.

CAUTION: NEVER CHANGE THE VOLTAGE SELEC-

TOR SWITCH WITH THE ENGINE RUNNING. This can

cause arcing and can severely damage the switch and

the generator windings.

1.15 Emergency Stop Switch

The emergency stop switch is the red button located to

the left of the control panel and can be accessed with the

panel doors closed.

Close the emergency stop switch by pushing the red

button in. Closing the emergency stop switch opens the

main circuit breaker and the fuel solenoid and results in

the engine shutting down and the red LEDs (g) and (j)

lighting up. The switch will remain closed until the button

is rotated and it pops out.

CAUTION: PRESS THE EMERGENCY STOP BUT-

TON ONLY IN THE CASE OF AN ACTUAL EMERGENCY WHERE THE GENERATOR MUST BE

STOPPED IMMEDIATELY! In all other instances, open

the main line circuit breaker and then turn the engine start

switch to off “O”.

DANGER

DANGER OF ELECTROCUTION! High voltage is

present inside this panel when the generator is

operating!

1A-18

1.16 Main Line Circuit Breaker

The main line circuit breaker (c) is located on the control

panel.

In the off “O” position, this breaker interrupts power from

the selector switch to the terminal lugs at the bottom of the

generator panel.

CAUTION: Before shutting down the generator or per-

forming any service to the generator unit, make sure the

main circuit breaker is in the off “O” position.

Page 25

G50/G70/G85 OPERATION 1A

c

20

On/I

Off/0

j

18262

L1 L2 L3

h

CAUTION: The convenience receptacles are not con-

nected through the main line circuit breaker but are

connected directly to the generator windings. As a result,

the receptacles are powered even with the main breaker

in the off “O” position. To turn off power to receptacles,

open the individual circuit breakers provided for each.

15

12

8

INCHES

EMERGENCY STOP SWITCH

NOTAUSSCHALTER

INTERRUPTOR DE URGENCIA

INTERRUPTEUR D'URGENCE

TERMINAL DOOR OPEN

KLEMMENABDECKUNG OFFEN

PUERTA DE BORNES ABIERTA

CACHE-BORNES OUVERT

d

Hz

A

Ø

V

START

REMOTE

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

START/RUN

START/LAUF

ARRANQUE/MARCHA

DEMARRAGE/MARCHE

STOP

e

115871

1026SD72

fg

1.18 Voltage Adjustment Rheostat

Directly below the engine start switch is the voltage

adjustment rheostat (f). Use the rheostat to adjust the AC

voltage output. Turn adjusting screw clockwise to increase voltage, counter-clockwise to decrease voltage.

The voltage can be monitored at the LCD panel.

DANGER

DANGER OF ELECTROCUTION! High voltage is

present inside this panel when the generator is

operating!

1.17 Engine Start Switch

The engine start switch (e) is a three-position switch:

“REMOTE START”, off “O”, and “RUN/START”. The

“REMOTE START” position is the normal setting used

when using the generator as a back-up power supply

connected to a remote switch. In the REMOTE START

position the generator is in stand-by mode and will not

start until the remote switch closes. In the “RUN/START”

position the switch immediately initiates the engine start

cycle, pre-heats the engine, then activates the starter

motor to crank the engine.

When set in the “REMOTE START” or “RUN/START”

position this switch applies battery power to the engine

control module to turn on the LCD panel, and also

energizes the engine’s electrical system. In the off “O”

position power to the engine’s electrical system, including the fuel solenoid, is disconnected.

1.19 Warning Light

The amber warning light (d) on the metering panel will

turn on prior to an engine fault condition occurring. This

acts as a pre-alarm to call attention to a potential fault

condition. At the same time the warning light goes on, the

LCD panel will begin blinking to indicate which engine

function is approaching its fault value.

Engine Pre-alarm Set Points:

• Fuel Level = 25%

• High Temperature = 234° F

• Low Temperature = 70° F

• Low Oil Pressure = 20 psi

• Time to Service = 0 hours

• Sender Failure = engine coolant and oil pressure

senders.

Note:

Time to Service and Sender Failure faults will not

shut down the generator.

1A-19

Page 26

1A OPERATION G50/G70/G85

a

b

18244

g

jh

c

d

50A20A50A50A 20A

e

f

1026SD87

1.20 Connection Lugs

The customer connection lugs (a) are located on left at

the bottom of the panel behind a hinged door. The lugs

provide connection points for attachment of outside

loads.

A large label like the one shown in section 1.25

Connections

It shows the correct terminal connections for selected

voltages.

Connections to the lugs should be made by running the

power cables up through the slots (j) in the bottom of the

panel and into the lug. Use a 3/8" Allen wrench to tighten

cable connections in place.

is attached to the inside of the terminal door.

Terminal

1.21 Ground Connection

A ground connection (b) is located next to the terminal

lugs. The unit must have this ground lug connected to a

good earthen ground for proper operating safety in compliance with NEC and local standards.

1A-20

Page 27

G50/G70/G85 OPERATION 1A

1.22 Convenience Receptacles

The generator is equipped with three 120V/240V twist

lock receptacles

receptacles

(GFI). Receptacles do not connect through the main line

circuit breaker. Each receptacle is protected by its own

circuit breaker (c, d) which is located directly above it.

Power to the receptacles is available any time the generator engine is running, even with the main line circuit

breaker open.

When the voltage selector switch is in the 480/277 V

Note:

3Ø position, voltage at the duplex receptacles is 139 V,

and voltage at the 50 A receptacles is 139/240 V. When

the voltage selector switch is in the 208/120 V 3Ø

position, voltage at the 50 A receptacles 120/208 V.

(e) rated at 50A. The two 120V duplex

(f) are equipped with ground fault interrupts

1.23 Remote Run Terminal Block

The remote run terminal block (g) is located just to the left

of the 120V duplex receptacles. It provides connection

points for installation of a remote start switch. When it is

connected to a transfer switch, it allows the generator to

be used as a standby power supply.

1.24 Panel Door Interlock Switch

The customer connection lugs panel access door is

equipped with an interlock switch (h). When the door is

opened this switch automatically trips the main circuit

breaker and disconnects power to the generator voltage

regulator. Voltage to the receptacles will not be cut.

1A-21

Page 28

1A OPERATION G50/G70/G85

1.25 Terminal Connections

DANGER PELIGRO

GEFAHR DANGER

TERMINAL CONNECTIONS

VERBINDUNGSKLEMMEN

L1

T1

T4

T7

T10

N

T11

T12

T9

T6

T3

L3

T10

T12

T9

T3

L3

T8

T5

L-N

L1

T7

T1

T4

T5

N

T6

T2

T11

T8

L2

L-N

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

READ OPERATORS MANUAL.

IMPROPER CONNECTION OF GENERATOR TO A

BUILDING'S ELECTRICAL SYSTEM CAN ALLOW

ELECTICAL CURRENT FROM THE GENERATOR

TO BACKFEED INTO UTILITY LINES.

THIS MAY RESULT IN ELECTROCUTION

OF UTILITY WORKERS, FIRE OR EXPLOSION.

CONNECTIONS TO A BUILDING'S ELECTRICAL

SYSTEM MUST BE MADE BY A QUALIFIED

ELECTRICIAN AND COMPLY WITH ALL

APPLICABLE LAWS AND ELECTRICAL CODES.

BORNES DE CONEXION

RACCORDS TERMINALS

208

120

480

277

L-L

240

120

L1-L2 = 480V L1-N = 277V

L2-L3 = 480V L2-N = 277V

T2

L2

L-L

L3-L1 = 480V L3-N = 277V

N-

208

120

277

480

240

120

L1-L2 = 208V L1-N = 120V

L2-L3 = 208V L2-N = 120V

L3-L1 = 208V L3-N = 120V

N-

208

T6

T8

T2

240V

T11

N

T5

T7

T10

T4

120V

L1

T1

T12

T3

T9

L3

120V

120

277

480

240

120

L1-L3 = 240V

L1-N = 120V

L2-N = ----

L3-N = 120V

114898

ALL CONNECTIONS TO THE TERMINALS MUST BE MADE BY A TRAINED ELECTRICIAN.

DANGER

BACKFEED FROM THE GENERATOR INTO THE UTILITY’S DISTRIBUTION SYSTEM CAN

CAUSE A SERIOUS INJURY OR DEATH TO UTILITY WORKERS!

Improper connection of generator to a building’s electrical system can allow electrical current from

the generator to backfeed into utility lines. This may result in electrocution of utility workers, fire or

explosion. Connections to a building’s electrical system must be made by a qualified electrician

and comply with all applicable laws and electrical codes.

DANGER

ALWAYS OPEN MAIN CIRCUIT BREAKER AND SET ENGINE STOP SWITCH TO OFF “O”

BEFORE INSPECTING OR ATTEMPTING ANY CONNECTIONS TO THE TERMINAL BLOCK!

1A-22

Page 29

G50/G70/G85 OPERATION 1A

1.26 Before Starting

Before putting the generator into service, review each item on the following checklist. Because generators are often

run for long periods of time unattended, it is important to make sure that the unit is set up properly to reduce possible

problems.

WARNING

Failure to follow the procedures listed may cause injury to personnel or damage to the generator. Be certain that

all persons setting up the generator are certified or fully trained on the installation of the generator.

✓ Check for any damage that might have been caused during shipping or towing.

✓ Check to make sure no debris has lodged in or near radiator (both sides) or fan.

✓ Check that generator is level.

✓ Chock trailer wheels.

✓ Check that generator is grounded to a good earthen ground per NEC and local regulations.

✓ Check engine oil, coolant and fuel levels, and fill as required.

✓ Determine voltage needs. Set voltage selector switch and make correct terminal connections.

✓ Check that all electrical connections were made in compliance with local regulations and NEC standards.

✓ Check fan belt and hoses on engine for loose connections or fraying. Tighten or replace as required.

✓ Close and secure side panel access doors.

✓ Review and follow safety instructions found in the front of this manual.

1A-23

Page 30

1A OPERATION G50/G70/G85

1.27 Manual Start-up

Before starting the generator set for the first time, thoroughly review the pre-start-up checklist in the previous

section. Proceed with generator start-up only after checking each item in that section.

Thoroughly read and make sure you understand the

engine Operator’s Manual supplied with the generator.

Follow the steps below and the illustration on the opposite page in the order listed.

WARNING

Before placing the Engine Start Switch (e) in the

“REMOTE START” position, verify that the con-

tacts on any remote switch linked to the generator

set are OPEN. If the contacts on a remote switch are

closed, the generator will crank and start when the

Engine Start Switch is moved to the “REMOTE

START” position.

WARNING

When using the generator as a standby or substitute

power supply, make sure the voltage and phase

rotation of the line connections match those of the

utility lines or of any other power source normally

used. Failure to match phase rotation and volt-

age may cause equipment connected to the generator to operate incorrectly! This could create

unsafe operating conditions.

1. Check position of Voltage Selector Switch (a) and

make sure it is set for the desired voltage output.

Lock the switch be in place.

2. Make sure the Engine Start Switch (e) is in the off “O”

position.

3. Turn main line circuit breaker (c) and convenience

receptacle circuit breakers to off “O”. This will disconnect all loads from the generator.

ab

208

120

480

277

NEVER CHANGE SWITCH POSITION WITH ENGINE RUNNING.

RESULTS IN ELECTRIC SHOCK AND DAMAGE TO MACHINE.

NIEMALS SCHALTER UMSTELLEN WENN MOTOR LAUFT.

VERURSACHT ELEKTRISCHEN SCHLAG UND BESCHADIGUNG

..

DES GERATES.

NUNCA CAMBIE LA POSICION DEL INTERRUPTOR AL ESTAR

MARCHANDO EL MOTOR. YA QUE ESTO PODRIA CONDUCIR A

UNA DESCARGA ELECTRICA Y DANOS EN EL EQUIPO.

NE JAMAIS CHANGER LA POSITION DE L'INTERRUPTEUR

PENDANT QUE LE MOTEUR EST EN MARCHE. IL POURRAIT

EN RESULTER RISQUE D'ELECTROCUTION ET DOMMAGES

A LA MACHINE.

5. Press in the Emergency Stop Button (b). The LCD

panel should read “EMERGENCY STOP”, and the

red LEDs (g) should light up. Release the stop button

after verifying the display and the LED, and return the

Engine Start Switch to off “O”.

6. Start engine by moving the Engine Start Switch to

the “RUN/START” position.

The LCD display will read “STARTING ENGINE” as

the engine begins its crank cycle. The normal cycle

is for the engine to crank for 15 seconds, then rest for

10 seconds. This cycle will repeat three (3) times. If

the engine does not start within this time, the Engine

Control Module will shut down the engine and “FAULT

OVERCRANK” will be displayed on the LCD panel.

To repeat crank cycle, return start switch to off “O” to

reset Engine Control Module. Allow starter motor to

cool between start-up attempts.

240

120

208

120

240

480

120

277

..

..

~~~

114896

1026SD77 1026SD84

G

E

R

N

E

C

Y

M

E

S

P

T

O

4. Move Engine Start Switch (e) to “REMOTE START”

to check operation of engine control module. The

LCD panel should momentarily display “SYSTEM

OK” followed by “UNIT IN AUTO” and engine

information. Check fuel level and battery values.

Note:

The amber Warning Light

(d)

the fuel level is below 25%, or engine temperature is

below 70° F. This will not prevent the engine from

starting.

1A-24

will come on if

Page 31

G50/G70/G85 OPERATION 1A

c

20

On/I

Off/0

18262

L1 L2 L3

7. After engine starts, allow it to warm up for a few

minutes and check readouts on LCD panel. The

“TIME TO SERVICE” interval will be displayed.

Make sure battery charging system, oil pressure and

engine temperature readings are within normal

ranges.

8. Check that AC voltage is correct. Voltage can be

fine-adjusted by turning the voltage adjustment rheostat (f) on the metering panel.

9. Check frequency. Under no-load conditions, frequency should read around 61.5 Hz, dropping to

near 60 Hz as the generator load is switched on.

15

12

8

INCHES

EMERGENCY STOP SWITCH

NOTAUSSCHALTER

INTERRUPTOR DE URGENCIA

INTERRUPTEUR D'URGENCE

TERMINAL DOOR OPEN

KLEMMENABDECKUNG OFFEN

PUERTA DE BORNES ABIERTA

CACHE-BORNES OUVERT

e

START

115871

1026SD72

g

d

Hz

A

Ø

V

REMOTE

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

START/RUN

START/LAUF

ARRANQUE/MARCHA

DEMARRAGE/MARCHE

STOP

f

1.28 Running the Generator

Leave the Engine Start Switch (e) in the “RUN/START”

position while the generator is operating. If the generator

was started using a remote switch, leave Engine Start

Switch in the “REMOTE START” position. Let the generator run for a few minutes to warm engine before

closing main circuit breaker.

WARNING

Before closing breakers, make sure that any electrical devices attached downstream from the generator will not start up unexpectedly.

While the generator is running, check for excessive

vibration, oil leaks, or coolant leaks.

1A-25

Page 32

1A OPERATION G50/G70/G85

1.29 Engine Power Correction Factors

Performance data on John Deere engines are measured

at the following standard conditions:

• 29.31 inches of mercury dry air pressure

• 600 feet altitude

• 0 % relative humidity

• 77° F air intake temperature

• 104°F fuel inlet temperature

Refer to the table to estimate the engine power decrease

in percent, as environmental factors vary from the standard conditions.

36

34

32

30

28

LEUF

LEDOM

05G71.005.100.301.0

07G

58G

PMET

ESIR

F°8.1fo

91.005.0

PMETRIA

ESIR

F°01fo

EDUTITLA

ESIR

tf0001fo

trahcees

woleb

EVITALER

YTIDIMUH

ESIR

%01fo

70.0

26

24

22

20

18

16

14

Engine Power Deration (%)

12

10

8

6

4

2

0

7 8 9 101112 1314 15 161718

1A-26

Altitude X 1000 Feet

Page 33

G50/G70/G85 OPERATION 1A

1.30 Shutting Down Generator

Check with other personnel on the jobsite and let them

know that power is being turned off. Make sure that the

power shutdown will not create any hazards by turning off

devices such as pumps, heaters, or lights that may need

to be kept on.

1. Remove (turn off) all loads from generator.

2. Open (turn off “O”) main line circuit breaker.

3. Let engine run for approximately 5 minutes to allow it

to cool down.

4. Move Engine Start Switch to the off “O” position.

1.31 Cold Weather Start-up

1.33 Overnight Storage

When storing unit overnight, make sure all access doors

are closed and padlocked.

DO NOT store generator overnight in a low lying area that

might fill with water during a heavy storm.

1.34 Long-term Storage

If the generator is being stored for several months, follow

the engine manufacturer’s recommendations for longterm storage. These procedures are designed to help

minimize engine corrosion.

Good cold-weather starting requires that the battery be at

peak power, the correct weight motor oil is used, and the

starter motor is in good condition. The ECM will automatically activate the cold starting aid when the temperature

is low enough and will display “ACTIVATING INTAKE

HEATER” during the time the cold starting aid is activated.

1.32 Lifting

A central lifting eye (a) is located at the top of the

generator and is attached to a lifting frame inside the

trailer housing.

Refer to the Technical Data for the proper operating

weight of the generator. Make sure the lifting devices

have sufficient capacity to lift the unit safely.

When lifting the generator, attach a hook or sling securely

to the lifting eye.

a

1026SD70

1A-27

Page 34

1A OPERATION G50/G70/G85

1.35 Automatic/Remote Start-up

In the “REMOTE START” position the generator can be

started remotely, either through a transfer switch or some

other type of remote start switch. “REMOTE START” is

the normal setting when using the generator as a standby

power supply. Before placing the generator in the automatic start-up mode, review the pre-start and manual

Start-up sections in this manual and follow procedure

below.

WARNING

Before placing the Engine Start Switch in the

“REMOTE START” position, verify that the con-

tacts on any remote switch linked to the generator

set are OPEN. If the contacts on a remote switch are

closed, the generator will crank and start when the

Engine Start Switch is moved to the “REMOTE

START” position.

1. Perform a manual start at least once to verify that the

metering panel is operating correctly. Refer to Section

1.26

Before Starting

tions in this manual.

2. If a check of auto start-up circuit is desired, attach a

short jumper wire (minimum 16 gauge insulated)

equipped with alligator clips between the two terminals on the remote run terminal block. This applies a

ground to the Engine Control Module to complete the

start circuit. The engine should crank, start and run.

Move the Engine Start Switch to off “O” to stop engine.

Remove jumper from remote run terminals after testing is complete.

3. Secure generator by closing and locking all doors.

4. Set Engine Start Switch to “REMOTE START” and

close main line circuit breaker.

The generator is now ready for automatic start-up.

If the generator is to be used as a stand-by power supply

for more than a month, provisions must be made to

maintain battery charge. This can be done either by

attaching a battery charger to the battery or by starting

generator manually and running engine periodically to

maintain charge. See Section 1.27

and 1.27

Manual Start-up

Manual Start-up.

sec-

1A-28

Page 35

G50/G70/G85 OPERATION 1A

1.36 Remote/Transfer Switch

Installation of a transfer switch or other type of remote

DANGER

When the generator is used as a standby power

supply, it must be equipped with a device which

isolates it from the utility’s distribution system.

Failure to isolate the generator from the utility’s

electrical distribution system could cause output from the generator to backfeed into the

utility lines and cause injury or death to utility

workers!

The same is true if using the generator as a backup to some other type of power supply system.