Page 1

Operator’s Manual

Mobile Generator

G 50

EN

5000189846 05 0911

5000189846

Page 2

Copyright

notice

© Copyright 2011 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker Neuson Production

Americas LLC represents an infringement of valid copyrights. Violators will be

prosecuted.

Trademarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Original

instructions

This Operator’s Manual presents the original instructions. The original language of this

Operator’s Manual is American English.

Page 3

G 50 Foreword

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during

installation, operation, and maintenance of the machines.

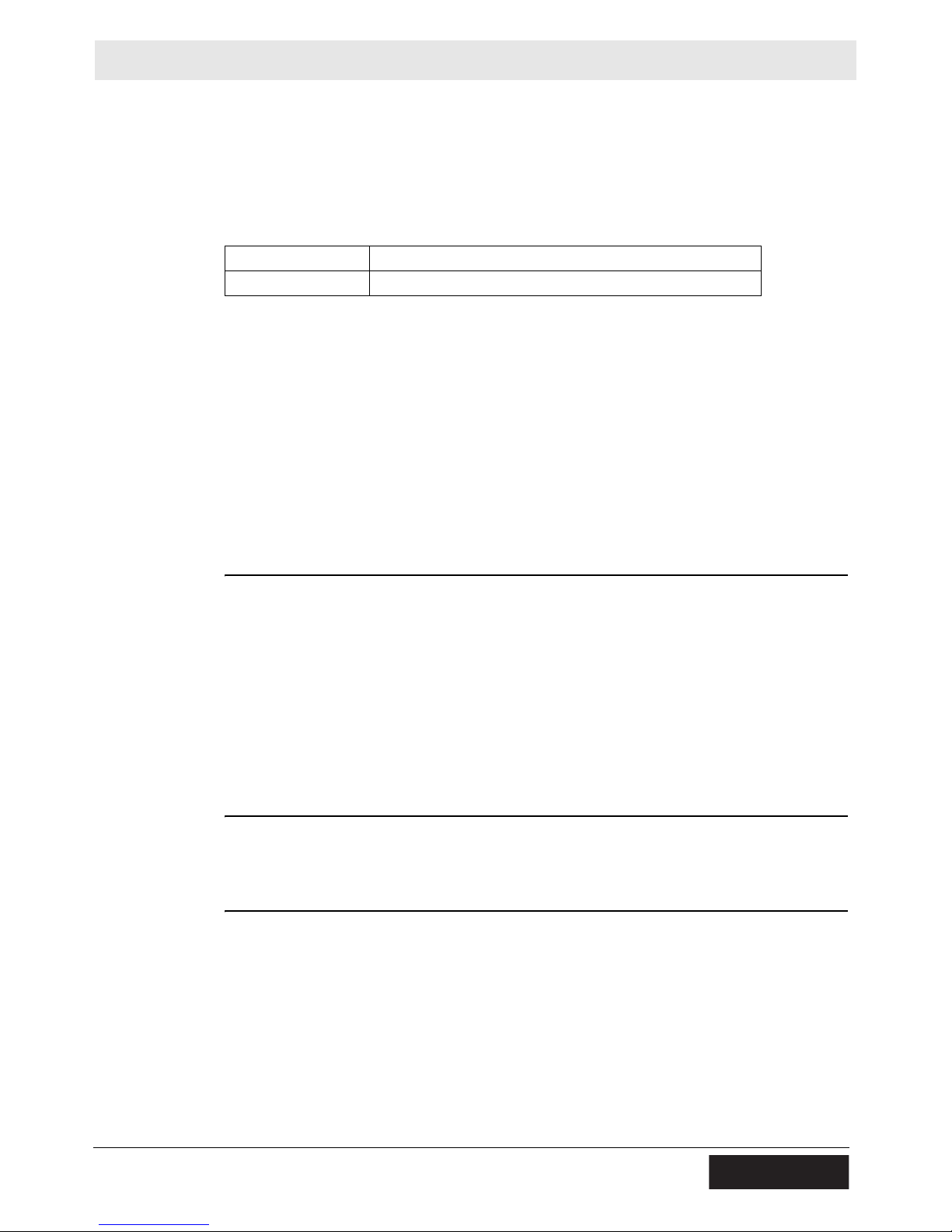

Machines covered in this manual

Machine Item Number

G 50 0620710, 0620964, 0620965, 0620966, 5200001317

Machine

documentation

Expectations

for

information in

this manual

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

Refer to the separate Repair Manual for detailed instructions on servicing and

repairing the machine.

If you are missing any of these documents, please contact Wacker Neuson to

order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change

any portion of this information without notice.

CALIFORNIA

Proposition

65 Warning

Laws

pertaining to

spark

arresters

Engine exhaust, some of its constituents, and certain vehicle components, contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose. In order to

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

wc_tx001048gb.fm 3

Page 4

Foreword G 50

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

4 wc_tx001048gb.fm

Page 5

Table of ContentsG 50

Foreword 3

1 Safety Information 9

1.1 Signal Words Used in this Manual ....................................................... 9

1.2 Machine Description and Intended Use ............................................. 10

1.3 Operating Safety ................................................................................ 12

1.4 Service Safety .................................................................................... 14

1.5 Operator Safety while using Internal Combustion Engines ................ 16

1.6 Towing Safety ..................................................................................... 17

1.7 Reporting Trailer Safety Defects ........................................................ 17

2 Labels 18

2.1 Label Locations .................................................................................. 18

2.2 Label Meanings .................................................................................. 20

3 Lifting and Transporting 29

3.1 Lifting the Machine ............................................................................. 29

3.2 Towing the Machine ........................................................................... 29

4 Operation 32

4.1 Safety Notices .................................................................................... 32

4.2 CO Alarms .......................................................................................... 32

4.3 Refueling the Machine ........................................................................ 33

4.4 Control Panel ...................................................................................... 34

4.5 Voltage Selector Switch ..................................................................... 36

4.6 Emergency Stop Switch ..................................................................... 37

4.7 Generator Monitoring ......................................................................... 38

4.8 Engine Monitoring .............................................................................. 39

4.9 Engine shutdown faults ...................................................................... 40

4.10 Current Overload Fault ....................................................................... 41

4.11 Event Log ........................................................................................... 41

4.12 Main Line Circuit Breaker ................................................................... 42

wc_bo5000189846_05TOC.fm 5

Page 6

Table of Contents G 50

4.13 Engine Start Switch .............................................................................43

4.14 Voltage Adjustment Rheostat ..............................................................43

4.15 Warning Light ......................................................................................43

4.16 Connection Lugs .................................................................................44

4.17 Grounding the Generator ....................................................................45

4.18 Convenience Receptacles ...................................................................46

4.19 Remote Run Terminal Block ...............................................................46

4.20 Panel Door Interlock Switch ................................................................46

4.21 Terminal Connections .........................................................................47

4.22 Before Starting ....................................................................................48

4.23 Manual Start-Up ..................................................................................48

4.24 Running the Generator ........................................................................51

4.25 Engine Power Correction Factors .......................................................52

4.26 Shutting down the generator ...............................................................52

4.27 Cold Weather Start-Up ........................................................................52

4.28 Automatic/Remote Start-Up ................................................................53

4.29 Remote/Transfer Switch ......................................................................54

5 Using the LCD Panel and Keypad 55

5.1 Navigating the Menus ..........................................................................56

5.2 Entering Passwords ............................................................................58

5.3 Adjusting Screen Contrast ...................................................................59

5.4 Setting the Time or Date .....................................................................60

5.5 Changing User Preferences ................................................................61

5.6 Changing / Disabling Low Fuel Fault ...................................................62

5.7 Changing Cooldown Time ...................................................................63

6 Factory-Installed Options 64

6.1 Engine Block Heater Option ................................................................64

6.2 Electronic Governor .............................................................................65

6.3 Automatic LCD Heat ............................................................................66

6.4 Low Coolant Shutdown .......................................................................67

6.5 Lube Level Maintainer .........................................................................68

6.6 Temperature-Activated Shutters .........................................................69

6.7 Lockable Battery Disconnect ...............................................................69

6.8 Extended Run Tank .............................................................................70

6.9 Battery Charger ...................................................................................70

6 wc_bo5000189846_05TOC.fm

Page 7

Table of ContentsG 50

6.10 Camlocks ............................................................................................ 71

6.11 Containment System .......................................................................... 72

6.12 Wiring Diagram (Factory-Installed Options) ....................................... 73

6.13 Wiring Diagram Components (Factory-Installed Options) .................. 74

7 Maintenance 75

7.1 Periodic Maintenance Schedule ......................................................... 75

7.2 New Machines .................................................................................... 76

7.3 Resetting the Periodic Maintenance Timer ........................................ 76

7.4 Electronic Control Unit (ECU) ............................................................. 77

7.5 Servicing the Air Cleaner .................................................................... 78

7.6 Engine Oil ........................................................................................... 79

7.7 Checking Engine Coolant ................................................................... 80

7.8 Troubleshooting Automatic Shutdown ................................................ 81

7.9 Maintaining the Trailer ........................................................................ 83

8 Technical Data 84

8.1 Engine ................................................................................................ 84

8.2 Generator ........................................................................................... 85

8.3 Machine ............................................................................................. 85

8.4 Trailer and Skid .................................................................................. 86

8.5 Dimensions ......................................................................................... 88

9 Schematics 89

9.1 Generator and Receptacle Wiring ...................................................... 90

9.2 Generator and Receptacle Wiring Components ................................. 91

9.3 Engine Wiring ..................................................................................... 92

9.4 Engine Wiring Components ................................................................ 93

9.5 Trailer Wiring ...................................................................................... 94

9.6 Trailer Wiring Components ................................................................. 95

wc_bo5000189846_05TOC.fm 7

Page 8

Table of Contents G 50

8 wc_bo5000189846_05TOC.fm

Page 9

G 50 Safety Information

1 Safety Information

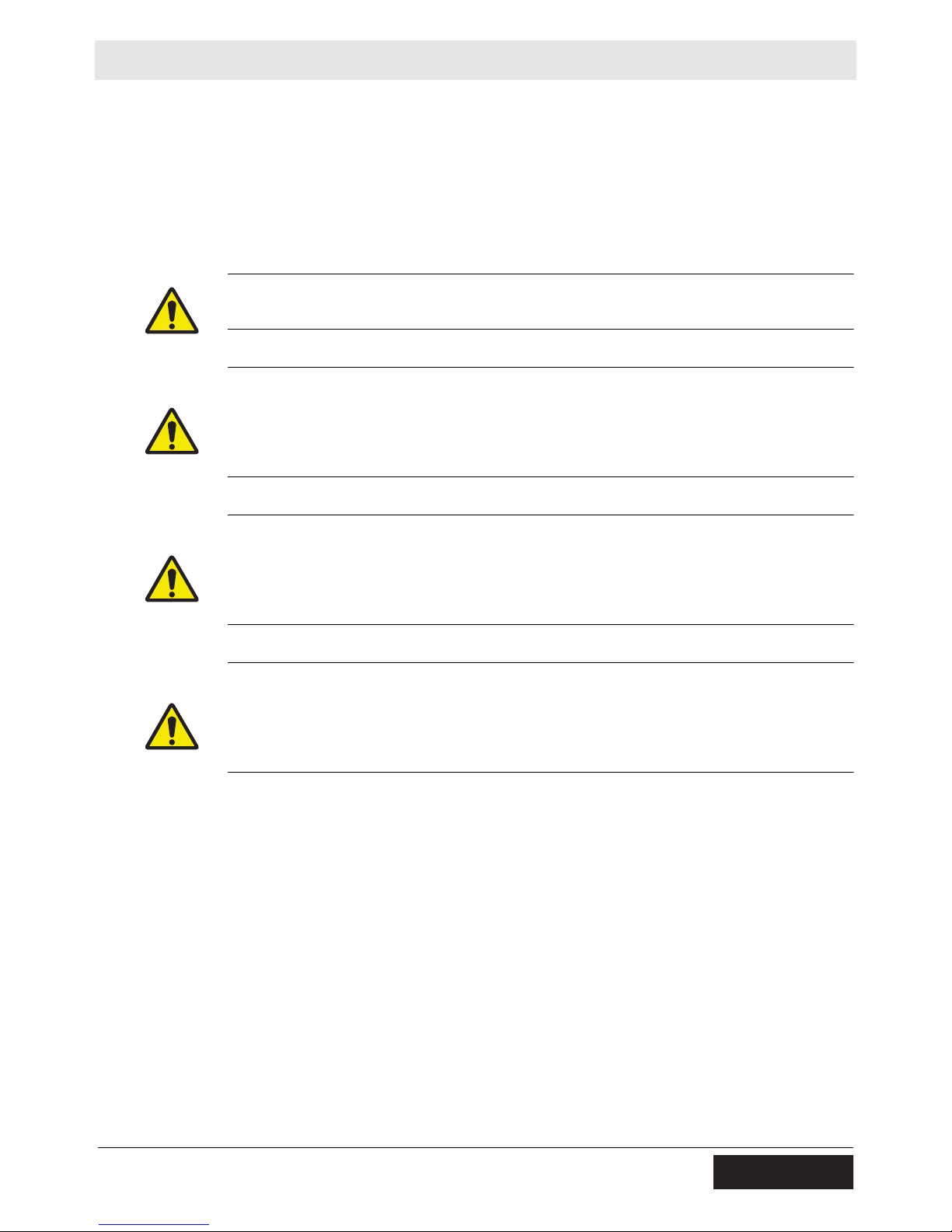

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE,

and NOTE signal words which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper

service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

To avoid death or serious injury from this type of hazard, obey all safety messages that

f

follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f

To avoid possible death or serious injury from this type of hazard, obey all safety messages that follow this signal word.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

To avoid possible minor or moderate injury from this type of hazard, obey all safety

f

messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000533gb.fm 9

Page 10

Safety Information G 50

1.2 Machine Description and Intended Use

This machine is a mobile electric power source. The Wacker Neuson

Mobile Generator consists of a trailer-mounted cabinet containing an

electric alternator, a fuel tank, and a diesel engine. A control panel,

receptacles, and connection lugs are provided on the side of the

cabinet. As the engine runs, the generator converts mechanical

energy into electric power. The operator connects loads to the electric

power receptacles and connection lugs.

This machine is intended for the purpose of supplying electrical power

to connected loads. Refer to the product specifications for the output

voltage and frequency of this generator, and for the maximum output

power limit of this generator.

This machine has been designed and built strictly for the intended use

described above. Using the machine for any other purpose could

permanently damage the machine or seriously injure the operator or

other persons in the area. Machine damage caused by misuse is not

covered under warranty.

The following are some examples of misuse:

• Connecting a load that has voltage and frequency requirements

that are incompatible with the generator output

• Overloading the generator with a load that draws excessive

power during either continuous running or start-up

• Operating the generator in a manner that is inconsistent with all

federal, state and local codes and regulations

• Using the machine as a ladder, support, or work surface

• Using the machine to carry or transport passengers or equipment

• Using the machine to tow other machines

• Operating the machine outside of factory specifications

• Operating machine in a manner inconsistent with all warnings

found on the machine and in the Operator’s Manual

This machine has been designed and built in accordance with the

latest global safety standards. It has been carefully engineered to

eliminate hazards as far as practicable and to increase operator

safety through protective guards and labeling. However, some risks

may remain even after protective measures have been taken. They

are called residual risks. On this machine, they may include exposure

to:

• Heat, noise, exhaust, and carbon monoxide from the engine

• Fire hazards from improper refueling techniques

• Fuel and its fumes

10 wc_si000533gb.fm

Page 11

G 50 Safety Information

G

• Electric shock and arc flash

• Personal injury from improper lifting the trailer tongue

• Typical hazards related to towing a trailer on roads and highways

To protect yourself and others, make sure you thoroughly read and

understand the safety information presented in this manual before

operating the machine.

Electrocution hazard!

Electrocution or severe electrical shock hazards are present

WARNIN

throughout the generator any time the engine is running! Read all

safety notes contained in this section before operating or servicing this

equipment.

No one except a trained electrician, familiar with this equipment,

should attempt repairs to the generator! Test procedures which require

that the generator be running must be performed using extreme

caution.

This machine is built with user safety in mind; however, like any

electrical device it can present serious hazards if improperly operated

and serviced. Follow instructions carefully! Should questions arise

during operation or service of this equipment, contact Wacker Neuson

Corporation.

wc_si000533gb.fm 11

Page 12

Safety Information G 50

1.3 Operating Safety

Familiarity and proper training are required for the safe operation of

the machine. Machines operated improperly or by untrained

personnel can be dangerous. Read the operating instructions

WARNING

Operator qualifications

contained in both this manual and the engine manual and familiarize

yourself with the location and proper use of all controls. Inexperienced

operators should receive instruction from someone familiar with the

machine before being allowed to operate it.

Only trained personnel are permitted to start, operate, and shut down

the machine. They also must meet the following qualifications:

• have received instruction on how to properly use the machine

• are familiar with required safety devices

The machine must not be accessed or operated by:

• children

• people impaired by alcohol or drugs

Personal Protective Equipment (PPE)

Wear the following Personal Protective Equipment (PPE) while

operating this machine:

• Close-fitting work clothes that do not hinder movement

• Safety glasses with side shields

• Hearing protection

• Safety-toed footwear

1.3.1 Do not operate the generator when open containers of fuel, paint, or

other flammable liquids are near.

1.3.2 Do not place flammable material or liquids near the generator.

1.3.3 Do not operate the generator, or tools attached to the generator, with

wet hands.

1.3.4 Do not use worn electrical cords. Severe electrical shock and

equipment damage may result.

1.3.5 Do not operate the machine indoors unless exhaust fumes can be

adequately ventilated.

1.3.6 Do not overload the generator. The total amperage of the tools and

equipment attached to the generator must not exceed the load rating

of the generator.

1.3.7 Do not allow untrained personnel to operate or service the generator.

The generator set should be set up by a certified electrician.

1.3.8 Do not operate generator in standing water.

1.3.9 Do not touch the hot engine, exhaust, or generator components.

Burns will result.

12 wc_si000533gb.fm

Page 13

G 50 Safety Information

1.3.10 Do not start a machine in need of repair.

1.3.11 Use the emergency stop button only in an actual emergency. Do not

restart the engine until the cause of the trouble has been determined

and fixed.

1.3.12 Wear hearing protection when operating equipment.

1.3.13 Follow starting and stopping instructions described in this manual.

Know how to operate and stop generator before starting it.

1.3.14 Make a walk-around inspection of the generator set before starting it.

Open side doors and visually inspect engine compartment for obvious

damage or the presence of foreign objects which might affect

operation.

1.3.15 Keep the machine at least one meter (three feet) away from

structures, buildings, and other equipment during use.

1.3.16 Store the machine properly when it is not being used. The machine

should be stored in a clean, dry location out of the reach of children.

1.3.17 Keep the area immediately surrounding and underneath the machine

clean, neat, and free of debris and combustible materials. Make sure

that the area overhead is clear of debris that could fall onto or into the

machine or exhaust compartment.

1.3.18 Make sure the machine is on a firm, level surface and will not tip, roll,

slide, or fall while operating.

1.3.19 Remove all tools, cords, and other loose items from the generator

before starting it.

1.3.20 Make sure the machine is well-grounded and securely fastened to a

good earthen ground per national and local regulations.

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER

DISTRIBUTION SYSTEM CAN CAUSE SERIOUS INJURY OR

DEATH TO UTILITY WORKERS!

WARNING

Improper connection of generator to a building’s electrical system can

allow electrical current from the generator to backfeed into utility lines.

This may result in electrocution of utility workers, fire, or explosion.

Connections to a building’s electrical system must be made by a

qualified electrician and comply with all applicable laws and electrical

codes.

If connected to a building’s electrical system, the generator must meet

the power, voltage, and frequency requirements of the equipment in

the building. Differences in power, voltage, and frequency

requirements may exist and improper connection may lead to

equipment damage, fire, and personal injury or death.

wc_si000533gb.fm 13

Page 14

Safety Information G 50

1.4 Service Safety

A poorly maintained machine can become a safety hazard! In order

for the machine to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary.

WARNING

Personal Protective Equipment (PPE)

Wear the following Personal Protective Equipment (PPE) while

servicing or maintaining this machine:

• Close-fitting work clothes that do not hinder movement

• Safety glasses with side shields

• Hearing protection

• Safety-toed footwear

In addition, before servicing or maintaining the machine:

• Tie back long hair.

• Remove all jewelry (including rings).

1.4.1 Do not perform even routine service (oil/filter changes, cleaning,

etc.) unless all electrical components are shut down. Before

servicing this machine, make sure the engine start switch is turned to

off “O”, the circuit breakers are open (off), the emergency stop switch

is closed (pushed in), and the negative terminal on battery is

disconnected. Attach a “DO NOT START” sign to the control panel.

This will notify everyone that the unit is being serviced and will reduce

the chance of someone inadvertently trying to start the unit. If the unit

is connected to a remote start or transfer switch, make sure the

remote switch is also off and tagged.

1.4.2 Ground Connection

The generator must be connected to a good earthen ground for

proper operating safety!

A central “equipment ground” is provided at the customer connection

lugs. This point is connected directly to the generator set base. All

other system grounds are connected to this central point. Ground the

generator in accordance with the standards defined in national, state,

and local regulations.

1.4.3 Do not attempt to open the radiator cap while the unit is running or

before the engine has cooled down. Severe burns may result!

1.4.4 Do not allow water to accumulate around the base of the machine. If

water is present, move the machine and allow the machine to dry

before servicing.

1.4.5 Do not service the machine if your clothing or skin is wet.

14 wc_si000533gb.fm

Page 15

G 50 Safety Information

1.4.6 Do not allow untrained personnel to service this equipment. Only

trained electrical technicians should be allowed to service the

electrical components of this equipment.

1.4.7 Do not modify the machine without the express written approval of the

manufacturer.

1.4.8 Do not pressure wash the control panel, generator end, or any other

electrical components when cleaning the unit. Never allow water to

accumulate around the base of the generator set. If water is present,

DO NOT service!

1.4.9 Allow the engine to cool before performing any service work on the

machine.

1.4.10 Remain aware of moving parts and keep hands, feet, and loose

clothing away from the moving parts of the generator and engine.

1.4.11 Replace all guards, fasten doors, and make sure all safety devices

operate properly after making repairs or servicing the equipment.

1.4.12 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

1.4.13 Check all external fasteners at regular intervals.

1.4.14 Make sure slings, chains, hooks, ramps, jacks, and other types of

lifting devices are attached securely and have enough weight-bearing

capacity to lift or hold the machine safely. Always remain aware of the

location of other people in the area when lifting the machine.

wc_si000533gb.fm 15

Page 16

Safety Information G 50

1.5 Operator Safety while using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling. Failure to

follow the warnings and safety standards could result in severe injury or death.

f Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison. Exposure to carbon monoxide can kill you in minutes.

f NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating safety

When running the engine:

• Keep the area around exhaust pipe free of flammable materials.

• Check the fuel lines and the fuel tank for leaks and cracks before

starting the engine. Do not run the machine if fuel leaks are present

or the fuel lines are loose.

When running the engine:

• Do not smoke while operating the machine.

• Do not run the engine near sparks or open flames.

• Do not touch the engine or muffler while the engine is running or

immediately after it has been turned off.

• Do not operate a machine when its fuel cap is loose or missing.

• Do not start the engine if fuel has spilled or a fuel odor is present.

Move the machine away from the spill and wipe the machine dry

before starting.

Refueling safety

When refueling the engine:

• Clean up any spilled fuel immediately.

• Refill the fuel tank in a well-ventilated area.

• Replace the fuel tank cap after refueling.

• Do not smoke.

• Do not refuel a hot or running engine.

• Do not refuel the engine near sparks or open flames.

16 wc_si000533gb.fm

Page 17

G 50 Safety Information

1.6 Towing Safety

Towing a large trailer requires special care. Both the trailer and vehicle

must be in good condition and securely fastened to each other to

reduce the possibility of an accident.

WARNING

1.6.1 Verify that the hitch and coupling on the vehicle are rated equal to, or

greater than, the trailer's “gross vehicle weight rating” (GVWR).

1.6.2 Inspect the hitch and coupling for wear or damage. DO NOT tow the

trailer using defective parts.

1.6.3 Make sure the coupling is securely fastened to the vehicle.

1.6.4 Check the tires on the trailer for tread wear, inflation, and condition.

Replace worn tires.

1.6.5 Connect the safety chains.

1.6.6 Connect the breakaway cable safety hook to the bumper or rear of the

vehicle. DO NOT attach it to the hitch.

1.6.7 Test the surge brakes on the trailer and the brakes on the vehicle that

will be used for towing.

1.6.8 Make sure directional and trailer lights are connected and working

properly.

1.6.9 Check that the lug nuts holding the wheels are tight and that none are

missing.

1.7 Reporting Trailer Safety Defects

If you believe your trailer has a defect which could cause a crash or

could cause injury or death, you should immediately inform the

National Highway Traffic Safety Administration (NHTSA) in addition to

notifying Wacker Neuson Corporation.

If NHTSA receives similar complaints, it may open an investigation;

and if it finds that a safety defect exists in a group of vehicles, it may

order a recall and remedy campaign. However, NHTSA cannot

become involved in individual problems between you, your dealer, or

Wacker Neuson Corporation.

To contact NHTSA, you may either contact the Auto Safety Hotline tollfree at 1-800-424-9393 (or 366-0129 in Washington DC area),

www.nhtsa.com, or write to NHTSA, U.S. Department of

Transportation, 400 7th Street SW, (NSA-11), Washington, DC 20590.

You can also obtain other information about motor vehicle safety from

the Auto Safety Hotline.

wc_si000533gb.fm 17

Page 18

Labels G 50

AVERTISSEMENT

ADVERTENCIA

WARNING

WARNUNG

114885

AVERTISSEMENT

WARNING

WARNUNG

ADVERTENCIA

2Labels

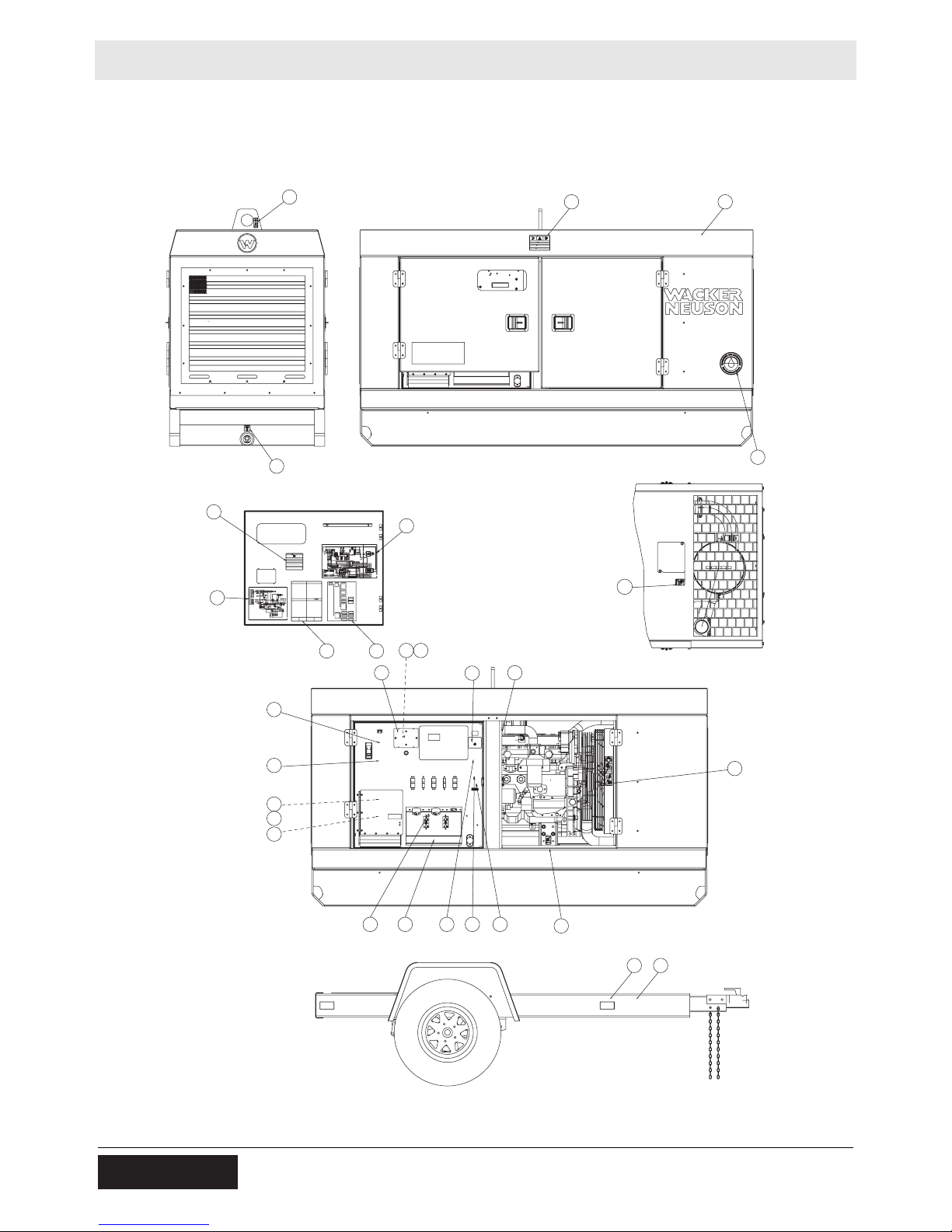

2.1 Label Locations

L

HH

CC

U

BG

JJ

GG

A

K

DD

M1

M2

QQ

H

EE

KK

Q

J

Z

NN

OO

LL

MM

FF

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

114885

P

G

AA

T

X

wc_gr007670

18 wc_si000520gb.fm

Page 19

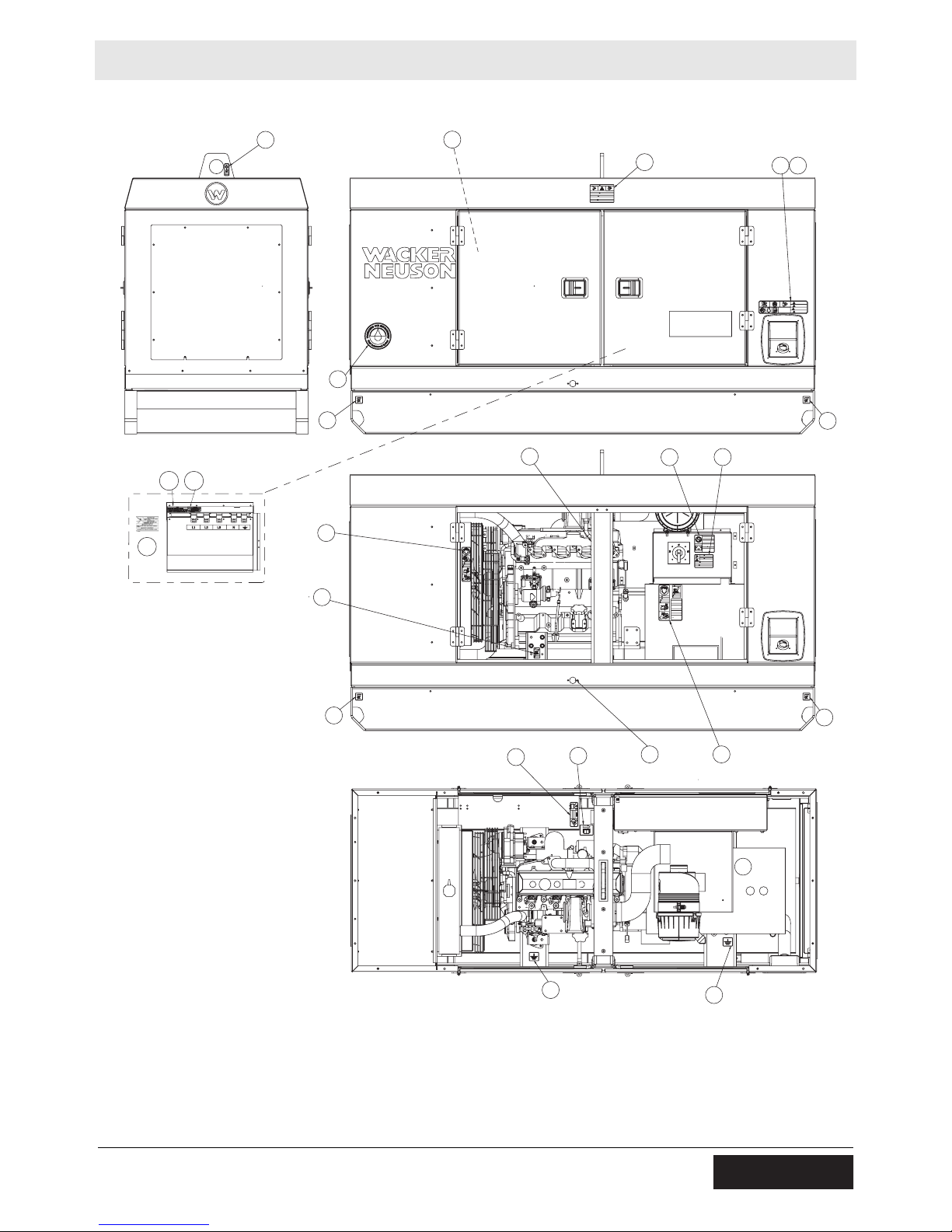

G 50 Labels

RR

SS

TT

U

JJ

V

P

PP

B

R

C

D

E

UU

V

G

V

O

Y

W

FS

W

wc_gr007671

V

wc_si000520gb.fm 19

Page 20

Labels G 50

2.2 Label Meanings

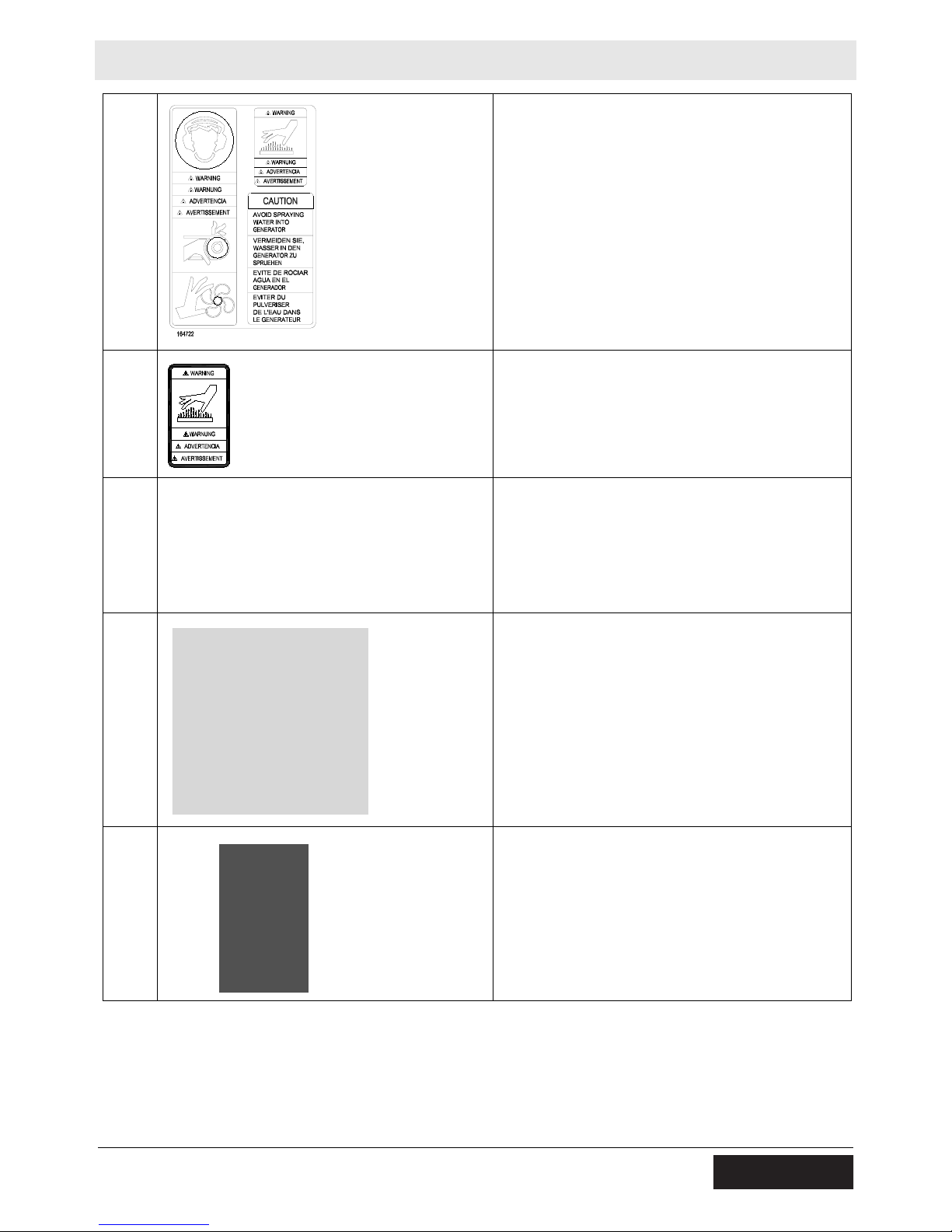

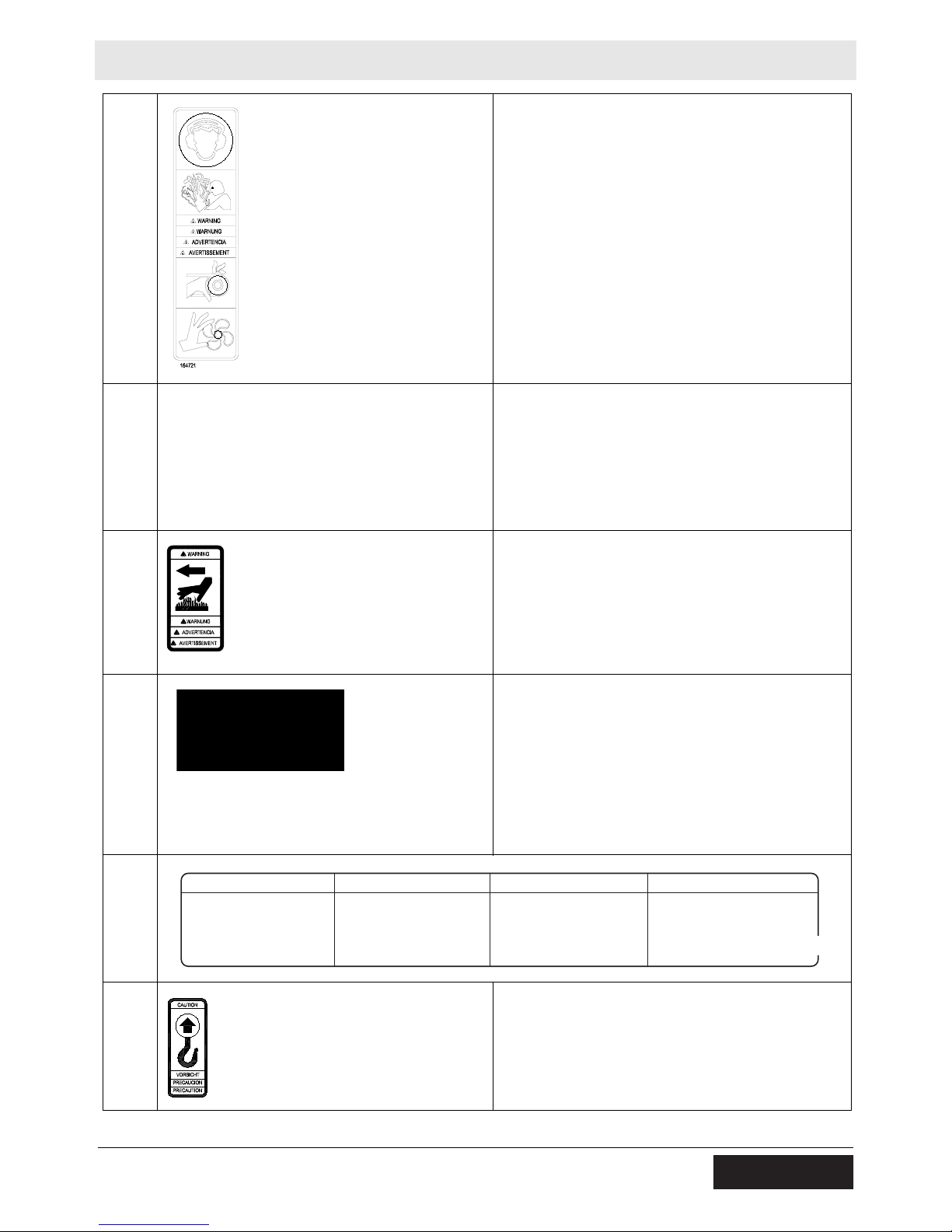

A

B

C

WARNING!

Pressurized contents. Do not open when hot!

WARNING!

Lock doors. Access can cause electric shock or

injury.

NOTICE

Never change switch position with engine running. Results in damage to machine.

D

E

WARNING!

Electric shock can cause serious injury or death.

DANGER!

Asphyxiation hazard.

Engines emit carbon monoxide.

Do not run the machine indoors or in an

enclosed area.

Only use OUTSIDE and far away from win-

dows, doors, and vents.

Read the Operator’s Manual.

No sparks, flames, or burning objects near the

machine.

Stop the engine before refueling.

Use only clean, filtered diesel fuel.

20 wc_si000520gb.fm

Page 21

G 50 Labels

F

G

H

WARNING!

To prevent hearing loss, wear hearing protection.

Hand injury if entangled in moving belt.

Rotating machinery! Do not reach inside with

engine running.

WARNING!

Hot surface

CAUTION!

Avoid spraying water into generator.

WARNING!

Hot surface

WARNING

Electric shock at cooling fins.

J

K

DANGER!

Asphyxiation hazard.

Engines emit carbon monoxide.

Do not run the machine indoors or in an

enclosed area.

Electric shock and arc flash can cause serious

injury or death.

WARNING!

Generator can automatically start which can

cause serious injury. Disconnect battery before

servicing.

wc_si000520gb.fm 21

Page 22

Labels G 50

L

M1

M2

WARNING!

Read and understand the supplied Operator’s

Manual before operating the machine. Failure to

do so increases the risk of injury to yourself and

others.

WARNING!

To reduce the risk of electrical shock and arc

flash, read the Operator’s Manual. Improper connection of the generator to a building’s electrical

system can allow electrical current from the generator to backfeed into utility lines. This may

result in electrocution of utility workers, fire, or

explosion. Connections to a building’s electrical

system must be made by a qualified electrician

and comply with all applicable laws and electrical

codes.

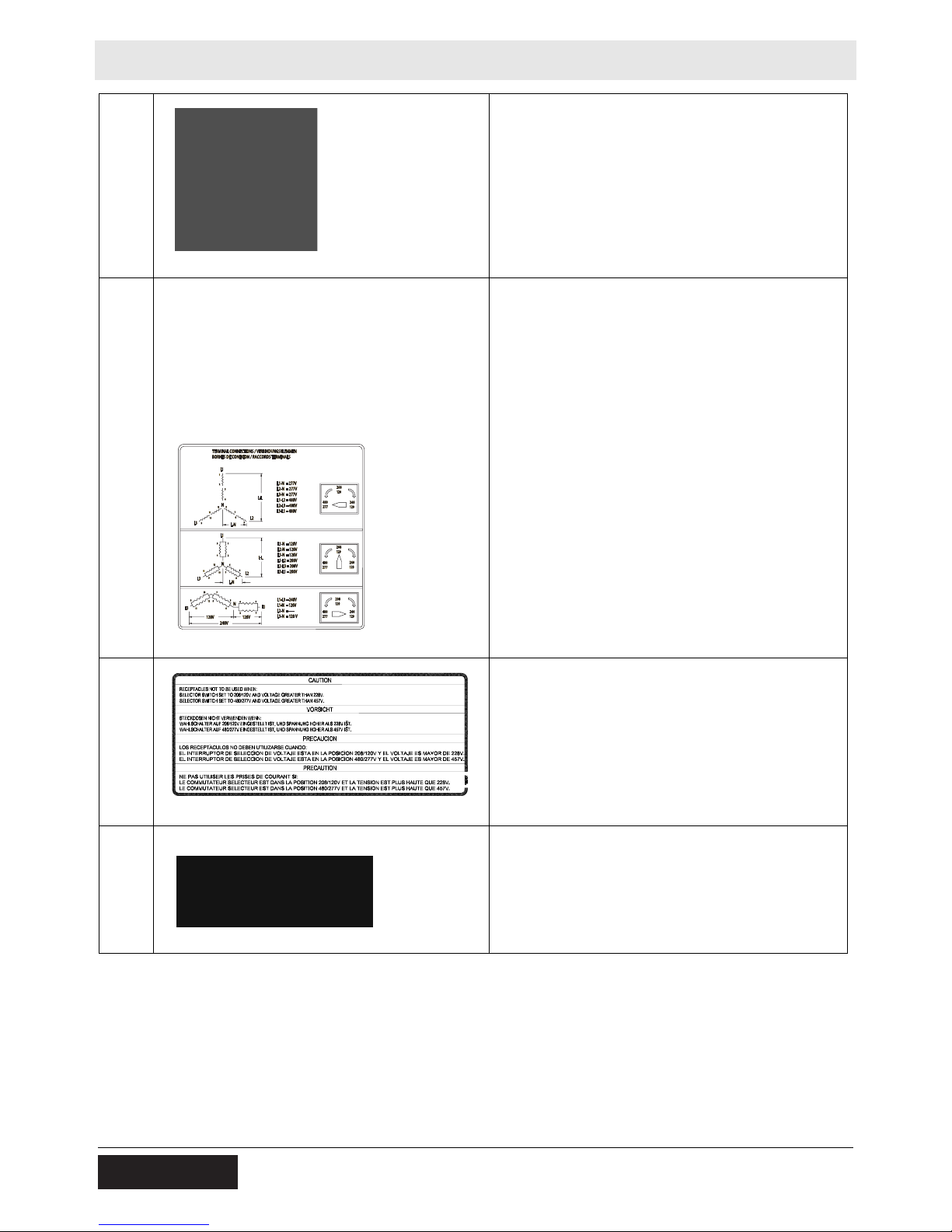

N

O

CAUTION!

Receptacles not to be used when:

Selector switch set to 208/120V and voltage

greater than 228V.

Selector switch set to 480/277V and voltage

greater than 457V.

WARNING!

Disconnect battery before servicing.

Read the Operator’s Manual.

22 wc_si000520gb.fm

Page 23

G 50 Labels

P

Q

R

WARNING!

To prevent hearing loss, wear hearing protection

when operating the machine.

WARNING!

Pressurized contents. Do not open when hot!

WARNING!

Hand injury if entangled in moving belt.

WARNING!

Rotating machinery! Do not reach inside

machine with engine running.

WARNING!

Electric shock at cooling fins.

WARNING!

Hot surface

S

T

U

(if equipped)

Battery disconnect must be in “ON” position to

start engine.

NOTICE: Do not use the battery disconnect

switch while engine is running. Damage to the

electrical components may occur.

TOWING INSTRUCTIONS ABSCHLEPPINSTRUKTIONEN INSTRUCCIONES DE REMOLQUE

1. READ OPERATOR'S MANUAL.

2. USE HITCH RATED FRO TRAILER'S

"GROSS VEHICLE WEIGHT RATING".

3. SECURELY ATTACH TRAILER TO TOW

VEHICLE.

4. ATTACH SAFETY CHAINS USING CROSS

PATTERN.

5. ATTACH BREAKDOWN CHAIN TO VEHICLE.

6. CHECK TRAILER LIGHTS.

1. BETRIEBSVORSCHRIFT LESEN.

2. ANHANGEVORRICHTUNG VERWENDEN,

DIE DER GESAMTBETRIEBSGEWICHTSKLASSE

ENTSPRICHT.

3. ANHANGER SICHER AM ZUGFAHRZEUG

BEFESTIGEN.

4. SICHERHEITSKETTEN KREUZWEISE ANBRINGEN.

5. ABREISSKETTE AM FAHRZEUG ANBRINGEN.

6. ANHANGERLEUCHTEN PRUFEN.

1. LEA EL MANUAL DEL OPERARIO.

2. UTILICE UN ACOPLE CORRECTAMENTE

CLASIFICADO PARA LA "CLASE DE PESO BUTO"

DEL VEHICULO DEL REMOLQUE.

3. ASEGURESE DE AMARRAR CORRECTAMENTE

EL REMOLQUE AL VEHICULO DE REMOLQUE.

4. FIJE EN CRUZ LAS CADENAS DE SEGURIDA D.

5. FIJE EN EL VEHICULO DE REMOLQUE LA CADENA

DE DESPRENDIMIENTO.

6. CONTROLE LAS LUCES DEL REMOLQUE.

NOTICE

Lifting point.

INSTRUCTIONS DE REMORQUAGE

1. LIRE LA NOTICE D'EMPLOI.

2. UTILISER UN GROCHET D'ATTELAGE CONFORME AU

DEBIT NOMINAL DU POIDS BRUT DE VEHICULE DU

TRACTEUR.

3. ATTACHER LA REMORQUE FERMEMENT AU VEHICULE

TRACTEUR.

4. ATTACHER LES CHAINES DE SURETTE EN UTILISANT

UNE METHODE CROISEE.

5. ATTACHER LA CHAINE DE REMORQUAGE AU VEHICULE.

6. VERIFIER LES LAMPES DE LA REMORQUE.

114894

wc_si000520gb.fm 23

Page 24

Labels G 50

V

W

X

Tie-down point

Electrical ground

24 wc_si000520gb.fm

Page 25

G 50 Labels

Y

Z

AA

CC

Operator’s Manual must be stored on machine.

Replacement Operator’s Manual can be ordered

through your local Wacker Neuson distributor.

Remote start operation. Read Operator’s Manual

for instructions.

Drain containment system.

DD

EE

FF

Operating the main circuit breaker supplies or

interrupts power to the customer connection lugs.

Neutral bonded to frame

Fuses

Read the Operator’s Manual for machine information.

1 - Start / Run Circuit

2 - Not used

3 - Not used

4 - Controller

wc_si000520gb.fm 25

Page 26

Labels G 50

GG

HH

Generator and receptacle wiring

Engine wiring

JJ

KK

Protecting Our Environment

Fluid containment system

Diagnostic menu navigation

26 wc_si000520gb.fm

Page 27

G 50 Labels

LL

MM

NN

A nameplate listing the model number, item number, revision number, and serial number is

attached to each unit. Please record the information found on this nameplate so it will be available

should the nameplate become lost or damaged.

When ordering parts or requesting service information, you will always be asked to specify the

model number, item number, revision number,

and serial number of the unit.

This machine may be covered by one or more

patents.

Certification Label (VIN Number)

Also attached to each unit is a Certification Label.

This label specifies that the trailer conforms with

all Federal Motor Vehicle Standards in effect at

the time of manufacture. The label includes the

Vehicle Identification Number (VIN) for the trailer.

OO

QQ

RR

SS

Remote start switch

Lug door must be closed for lugs and receptacles

to energize.

(Camlock models only)

WARNING!

Electric shock can cause serious injury or death.

(Camlock models only)

wc_si000520gb.fm 27

NOTICE

Separate overcurrent protection must be

provided. Do not exceed 400 amps per

receptacle.

Page 28

Labels G 50

TT

(Camlock models only)

WARNING!

Electric shock and arc flash can cause serious

injury or death.

28 wc_si000520gb.fm

Page 29

G 50 Lifting and Transporting

3 Lifting and Transporting

3.1 Lifting the Machine

A central lifting eye is located at the top of the generator and is

attached to a lifting frame inside the housing.

Crushing / machine damage hazard. Make sure the lifting devices

have sufficient capacity to lift the unit safely. Refer to Technical Data

WARNING

3.2 Towing the Machine

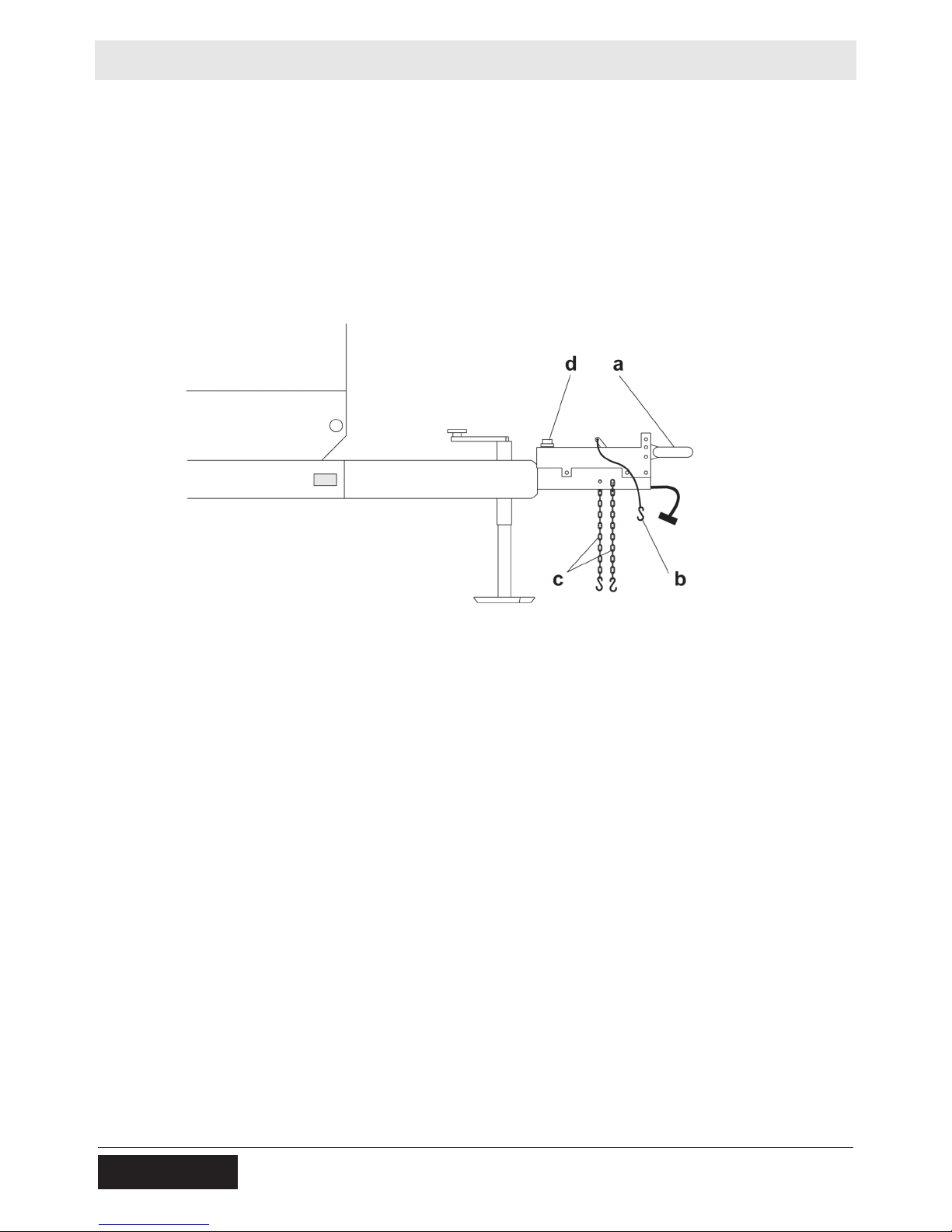

See Graphic: wc_gr000510

3.2.1 Check that the towing vehicle and hitch have a rating equal to or

for the proper operating weight of the generator.

When lifting the generator, attach a hook or sling securely to the lifting

eye.

The generator trailer is equipped with brakes, lights, and coupler

connection. Before towing the generator, perform the following:

greater than the GVWR. Refer to the Technical Data.

3.2.2 Check the condition of both the coupler and hitch. DO NOT tow the

trailer if the coupler or hitch is damaged.

3.2.3 Make sure that the hitch and coupler are compatible. The generator

trailer is equipped with either a pintle type coupler (a) or 50 mm (2 in.)

ball coupler.

3.2.4 Check that the directional and running lights on the trailer are working.

3.2.5 Connect the safety chains (c) using a crossed pattern under the trailer

tongue.

3.2.6 On trailers with surge or electric brakes, connect the breakaway cable

(b) on the trailer coupler to the rear bumper or frame of the vehicle.

This cable will actuate the brake system on the trailer if both the

coupling and safety chains have failed. The breakaway cable is not a

parking brake and should not be used as one.

3.2.7 Check that all fasteners on the coupling are secure.

3.2.8 Check the tread wear and inflation of tires. Make sure that all lug nuts

are in place and are tight.

3.2.9 Check the operation of the optional surge brakes by braking the

vehicle at a slow speed before entering traffic. Both the vehicle and the

trailer should brake smoothly. If the trailer seems to be pushing, check

the fluid level (d) in the surge brakes or the operation of the electric

brakes.

A film of grease on the coupler will extend coupler and ball life and

eliminate squeaking. Wipe the coupler and ball clean and apply fresh

grease each time the trailer is towed.

wc_tx001580gb.fm 29

Page 30

Lifting and Transporting G 50

NOTICE: When towing, maintain extra space between vehicles and

avoid soft shoulders, curbs and sudden lane changes. If you have not

pulled a trailer before, practice turning, stopping, and backing up in an

area away from heavy traffic.

DO NOT exceed 55 mph when towing a trailer.

In most states, large trailers must be registered and licensed by the

State Department of Transportation. Before towing, be sure to check

licensing requirements.

30 wc_tx001580gb.fm

Page 31

G 50 Lifting and Transporting

Notes:

wc_tx001580gb.fm 31

Page 32

Operation G 50

4 Operation

Preparing for first use

To prepare your machine for first use:

4.0.1 Make sure all loose packaging materials have been removed from the

machine.

4.0.2 Check the machine and its components for damage. If there is visible

damage, do not operate the machine! Contact your Wacker Neuson

dealer immediately for assistance.

4.0.3 Take inventory of all items included with the machine and verify that

all loose components and fasteners are accounted for.

4.0.4 Attach component parts not already attached.

4.0.5 Add fluids as needed and applicable, including fuel, engine oil, and

battery acid.

4.0.6 Move the machine to its operating location.

4.1 Safety notices

4.2 CO Alarms

• Do not exceed the power output of the generator. Damage to

tools or generator will occur. Refer to Technical Data.

• When using the generator as a standby or substitute power

supply, make sure the voltage and phase rotation of the line

connections match those of the utility lines. Failure to match

phase rotation and voltage may cause equipment connected to

the generator to operate incorrectly! This could create unsafe

operating conditions.

• Do not exceed the rated current limit of any receptacle.

• The bonding bar between the ground connections must remain in

place at all times unless a qualified electrician determines

otherwise.

Because this machine produces carbon monoxide (CO), Wacker

Neuson recommends that CO alarms be installed in all structures in

close proximity to the machine. CO alarms provide an extra measure

of protection against this poison that you cannot see or smell.

Install battery-operated CO alarms or plug-in CO alarms with battery

backup, according to the manufacturer’s instructions. CO alarms

should be certified to the requirements of the latest safety standards

(UL 2034, IAS 6-96, or CSA 6.19.01). Test the CO alarm batteries

monthly.

32 wc_tx001049gb.fm

Page 33

G 50 Operation

4.3 Refueling the Machine

Requirements

• Machine shut down

• Engine cool

• Machine/fuel tank level with the ground

• Fresh, clean fuel supply

Procedure

Perform the procedure below to refuel the machine.

WARNING

Fire hazard. Fuel and its vapors are extremely flammable. Burning fuel can cause

severe burns.

f Keep all sources of ignition away from the machine while refueling.

f Refuel only when the machine is outdoors.

f Clean up spilled fuel immediately.

4.3.1 Remove the fuel cap.

4.3.2 Fill the fuel tank until the fuel level gauge indicates that the tank is full.

CAUTION

Fire and health hazard. Fuel expands when heated. Expanding fuel in an over-filled

tank can lead to spills and leaks.

f Do not overfill the fuel tank.

4.3.3 Reinstall the fuel cap.

Result

The procedure to refuel the machine is now complete.

wc_tx001049gb.fm 33

Page 34

Operation G 50

E

M

E

R

G

E

N

C

Y

S

T

O

P

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

AUS

APAGADO

ARRET

OFF

REMOTE START

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

START / LAUFEN

ARRANQUE / MARCHA

DEMARRER / MARCHE

START / RUN

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

4.4 Control Panel

DIAGNOSTICS

2

g

4

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

1

5

3

a b f

6

de

OFF

AUS

APAGADO

ARRET

START / RUN

REMOTE START

START / LAUFEN

FERNSTART

ARRANQUE / MARCHA

ARRANQUE REMOTO

DEMARRER / MARCHE

DEMARRAGE A

DISTANCE

h

k

t

j

o

k

p

nl mqsr

wc_gr006314

34 wc_tx001049gb.fm

Page 35

G 50 Operation

Ref. Description Ref. Description

a Main circuit breaker o Remote run terminal block

b Voltage adjustment rheostat p Emergency stop switch

d Pre-alarm/shutdown LED q Interlock switch

e LCD panel r Customer connection terminal lugs

f Engine start switch s Ground connection

g Keypad t Bond bar

h Circuit breaker

(240V, 50 Amp)

j Circuit breaker

(240V, 30 Amp)

k Circuit breaker

(120V, 20 Amp)–two

l Twist-lock receptacle

(120/240 VAC, 50 Amp)

m Twist-lock receptacle

(120/240 VAC, 30 Amp)

n GFI receptacle

(120 VAC, 20 Amp)–two

1 Right arrow button

(right / forward)

2 Up arrow button

3 Down arrow button

4 Left arrow key

(left / backward)

5 Check mark button

(enter / accept)

6 Reset button

(cancel / reset)

wc_tx001049gb.fm 35

Page 36

Operation G 50

4.5 Voltage Selector Switch

See Graphic: wc_gr001682

The voltage selector switch is located in a separate enclosure on the

generator on the opposite side of the machine.

The selector switch is a three-position switch which mechanically

changes the connections between the generator output leads and the

terminal lugs on the generator. This allows three different volt ranges

to be selected.

120/240 VAC 1Ø

120/208 VAC 3Ø

139/240 VAC 3Ø (Refer to Section Voltage Adjustment Rheostat.)

277/480 VAC 3Ø

Voltage ranges are selected by rotating the handle on the switch to the

desired voltage. The switch is equipped with a locking mechanism.

This allows the voltage setting to be locked in place to prevent

unauthorized personnel from changing the voltage selection. To lock

switch in position, push lock up and attach a padlock through the

openings in the locking strip.

WARNING

NOTICE: NEVER CHANGE THE VOLTAGE SELECTOR SWITCH

WITH THE ENGINE RUNNING. This can cause arcing and can

severely damage the switch and the generator windings.

ELECTROCUTION HAZARD! High voltage is present inside this

panel when the generator is operating!

36 wc_tx001049gb.fm

Page 37

G 50 Operation

E

M

E

R

G

E

N

C

Y

S

T

O

P

E

M

E

R

G

E

N

C

Y

S

T

O

P

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

AUS

APAGADO

ARRET

OFF

REMOTE START

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

START / LAUFEN

ARRANQUE / MARCHA

DEMARRER / MARCHE

START / RUN

4.6 Emergency Stop Switch

See Graphic: wc_gr006062

The emergency stop switch (p) is the red button located below the

receptacle panel and can be accessed with the panel doors closed.

Activate the emergency stop switch by pushing the red button in.

Pushing the emergency stop switch opens the main circuit breaker and

the fuel solenoid, and results in the engine shutting down. The switch

will remain activated until the button is pulled out.

NOTICE: PRESS THE EMERGENCY STOP BUTTON ONLY IN THE

CASE OF AN ACTUAL EMERGENCY WHERE THE GENERATOR

MUST BE STOPPED IMMEDIATELY! In all other instances, open the

main line circuit breaker and then turn the engine start switch to off “O”.

OFF

AUS

APAGADO

ARRET

START / RUN

REMOTE START

START / LAUFEN

FERNSTART

ARRANQUE / MARCHA

ARRANQUE REMOTO

DEMARRER / MARCHE

DEMARRAGE A

DISTANCE

p

wc_gr006315

wc_tx001049gb.fm 37

Page 38

Operation G 50

A

Ø

HZ

V

A

Ø

HZ

V

4.7 Generator Monitoring

Generator information is displayed on the top line of the LCD panel and

is scrolled continuously while the generator is operating, to show the

voltage, amperage and frequency of each phase.

Volts “V”- Displays the AC output voltage being produced by the

generator.

Phase “Ø” - Indicates which leg/phase is currently being displayed. In

three-phase mode, the display will read P1, P2, or P3. In single-phase

mode, the display will read L1, L3, or LL.

Amps “A” - Displays the AC output amperage produced by the

generator. If the generator is operating at no-load, output amperage

will display a 0.

Hertz “Hz” - Displays output frequency. If the frequency is too high or

too low, check the engine rpm.

Sample display with engine running.

208 P1 24 61.5

85% 175 78 14.3

READY

100% 175 0 13.2

Sample display in “Auto” mode.

38 wc_tx001049gb.fm

Page 39

G 50 Operation

4.8 Engine Monitoring

With the engine start switch set to “RUN/START” or “REMOTE

START”, engine information will be continuously displayed on the

bottom line of the LCD panel.

OIL —Displays engine oil pressure. The gauge registers oil

pressure between 0–100 psi. Normal operating pressure is between

60–80 psi. If oil pressure drops below 15 psi, the engine will

automatically shut down.

FUEL —Indicates the relative fuel level in the fuel tank. If fuel

level drops to 5% the engine will automatically shut down.

TEMPERATURE —Displays the temperature of the engine's

coolant. If the coolant temperature gets too high, the engine will

automatically shut down.

BATTERY —This gauge measures the engine starting battery

voltage. A normal reading is 13.5–14.5V. If the gauge falls much

below or above these values, the engine charging system should be

checked. With the engine switch set to “REMOTE START” and the

generator in stand-by mode, actual battery voltage is displayed.

ENGINE HOURS—The engine running hours are displayed on the

hour meter. Engine hours are accumulated only while the engine is

actually running.

SENDER FAILURE - Indicates that the coolant temperature sensor,

fuel lever sender, speed signal source, or the oil pressure sensor has

failed. This fault will not be displayed unless the fault has occurred;

also, this fault will not shut down the machine. If all speed signal

sources fail, the machine will shut down.

Engine Fault Set Points

Fuel Level = 5%

Low Oil Pressure = 1 bar (15 psi)

High Temperature = 115°C (239°F)

Underspeed = 55Hz (1650 rpm)

Overspeed = 66Hz (1980 rpm)

Overcrank = Three 12-second crank/rest cycles

wc_tx001049gb.fm 39

Page 40

Operation G 50

4.9 Engine shutdown faults

The Engine Control Module (ECM) continuously monitors vital engine

functions for seven fault conditions. When a fault condition occurs, the

engine will shut down and the LCD panel will display the fault causing

the shutdown. To reset the ECM and resume operation, return the

engine start switch manually to off “O”. Also refer to Section Warning

Light.

4.9.1 EMERGENCY STOP

Indicates that the emergency stop button has been depressed. This

display will remain on until the emergency stop button is pulled back

out.

4.9.2 LOW OIL PRESSURE

Indicates that the engine oil pressure dropped below 1 bar (15 psi) and

the ECM has shut the engine down.

4.9.3 HIGH ENGINE TEMPERATURE

Indicates that the engine coolant temperature has exceeded 115°C

(239°F) and the ECM has automatically shut down the engine. Normal

engine running temperature is 85°C±8°C (185°F±15°F ).

4.9.4 OVERSPEED

Indicates that the engine speed exceeded approximately 1980 rpm

(110% of its rated speed of 1800 rpm) and the ECM has automatically

shut the engine down.

4.9.5 OVERCRANK

An overcrank fault is displayed when the engine fails to start after three

cycles of the normal cranking cycle, and the ECM has automatically

shut down the generator due to the overcrank condition.

4.9.6 LOW FUEL

A low fuel fault condition will be displayed when the fuel tank drops to

5% and the ECM has shut down the engine. This fault condition

prevents the fuel lines from running completely dry and avoids the

need to bleed the lines when the tank is refilled.

The low fuel fault can be disabled if desired. See Changing/Disabling

Low Fuel Fault.

4.9.7 UNDERSPEED

Indicates that the engine speed dropped below 55Hz (1650 rpm) for

more than 15 seconds and the ECM has automatically shut down the

engine.

40 wc_tx001049gb.fm

Page 41

G 50 Operation

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

4.10 Current Overload Fault

Along with engine functions, the ECM continuously monitors the

current load in each phase. The values for current overload are

programmed into the ECM at the factory and are different for each

generator size.

a

d

wc_gr006061

4.10.1 When an overcurrent condition is sensed in any leg, the warning/fault

4.10.2 If the overcurrent condition persists, the main circuit breaker (a) will

4.10.3 To clear the overload fault, reset the main circuit breaker. Failing to

4.11 Event Log

LED (d) will flash and the display will indicate OVERCURRENT.

open and the display will change to OVRLOAD - SET BRKR. This

indicates an overload fault.

reset the main circuit breaker will cause the machine to shut down

after 5 minutes. The display will then change to OVERLOAD.

The control module contains an event log that records the first and

last occurrences of pre-alarms and alarms. See Using the LCD and

Keypad for instructions on how to access the event log.

wc_tx001049gb.fm 41

Page 42

Operation G 50

G

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

AUS

APAGADO

ARRET

OFF

REMOTE START

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

START / LAUFEN

ARRANQUE / MARCHA

DEMARRER / MARCHE

START / RUN

wc_gr005866

g

4.12 Main Line Circuit Breaker

See Graphic: wc_gr005866

The main line circuit breaker (a) is located on the control panel.

In the off “O” position, this breaker interrupts power from the selector

switch to the terminal lugs at the bottom of the generator panel.

NOTICE: Before shutting down the generator or performing any

service to the generator unit, make sure the main circuit breaker is in

the off “O” position.

The convenience receptacles are not connected through the main line

circuit breaker but are connected directly to the generator windings. As

a result, the receptacles are powered even with the main breaker in the

off “O” position. To turn off power to receptacles, open the individual

circuit breakers provided for each.

NOTE: The warning light (d) will flash and the message MAIN

BREAKER OPEN will display on the LCD panel when the main line

circuit breaker is in the off “O” position and the controller has power.

WARNIN

ELECTROCUTION HAZARD! High voltage is present inside this

panel when the generator is operating!

OFF

AUS

APAGADO

ARRET

FERNSTART

DEMARRAGE A

DISTANCE

START / RUN

START / LAUFEN

ARRANQUE / MARCHA

DEMARRER / MARCHE

REMOTE START

ARRANQUE REMOTO

wc_gr005866

42 wc_tx001049gb.fm

Page 43

G 50 Operation

4.13 Engine Start Switch

See Graphic: wc_gr005866

The engine start switch (f) is a three-position switch: “REMOTE

START”, off “O”, and “START/RUN”. The “REMOTE START” position

is the normal setting used when using the generator as a back-up

power supply connected to a remote switch. In the REMOTE START

position, the generator is in stand-by mode and will not start until the

remote switch closes. In the “START/RUN” position, the switch

immediately starts the engine start cycle and activates the starter

motor to crank the engine. When set in the “REMOTE START” or

“START/RUN” position, the switch applies battery power to the control

module to turn on the LCD panel, and also energizes the engine’s

electrical system. In the off “O” position, power to the engine’s

electrical system, including the fuel solenoid, is disconnected.

4.14 Voltage Adjustment Rheostat

See Graphic: wc_gr005866

The voltage adjustment rheostat (b) is located above the customer

connection lugs. Use the rheostat to adjust the AC voltage output. Turn

clockwise to increase voltage, counter-clockwise to decrease voltage.

The voltage can be monitored at the LCD panel.

4.15 Warning Light

See Graphic: wc_gr005866

The warning light (d) on the metering panel will flash before a machine

fault condition occurs. This acts as a pre-alarm to call attention to a

potential fault condition. At the same time the warning light begins

flashing, the LCD panel will indicate which engine function is

approaching its fault value. Pressing the right arrow on the keypad (g)

will show a list of all active pre-alarms.

Engine Pre-alarm Set Points:

• Fuel Level = 15%

• High Temperature = 112°C (234°F)

• Low Oil Pressure = 1.4 bar (20 psi)

• Time to Maintenance = 0 hours

• Sender Failure = engine coolant and oil pressure senders

Note: “Time to Maintenance” and “Sender Failure” faults will not shut

down the generator.

wc_tx001049gb.fm 43

Page 44

Operation G 50

G

E

M

E

R

G

E

N

C

Y

S

T

O

P

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

4.16 Connection Lugs

See Graphic: wc_gr005864

The customer connection lugs (r) are located on left at the bottom of

the panel behind a hinged door. The lugs provide connection points for

attachment of outside loads.

A large label like the one shown in section Terminal Connections is

attached to the inside of the terminal door. It shows the correct terminal

connections for selected voltages.

Connections to the lugs should be made by running the power cables

up under the lug door in the bottom of the panel and into the lug. Use

a 3/8 in. Allen wrench to tighten cable connections in place.

ELECTROCUTION HAZARD! High voltage is present inside this

panel when the generator is operating!

WARNIN

h

k

j

k

nl mqsr

wc_gr006316

44 wc_tx001049gb.fm

Page 45

G 50 Operation

4.17 Grounding the Generator

Location

A ground connection is located at the customer connection terminal

lugs.

wc_gr008288

Function

This ground connection is used for electrically grounding the

generator when necessary to comply with the National Electrical

Code and other federal, state, and local regulations. For grounding

requirements in your area, consult with a qualified electrician,

electrical inspector, or local agency having jurisdiction over electrical

compliance.

• If the generator is used at a construction site, there may be

additional regulations which must be observed.

• In some areas, generators are required to be registered with local

utility companies.

wc_tx001049gb.fm 45

Page 46

Operation G 50

4.18 Convenience Receptacles

See Graphic: wc_gr005864

The generator is equipped with two 120V/240V twist lock receptacles

(l) rated at 50A, and one 120V/240V twist lock receptacle (m) rated at

30A. The two 120V duplex receptacles (n) are equipped with ground

fault interrupts (GFI). Receptacles do not connect through the main

line circuit breaker. Each receptacle is protected by its own circuit

breaker (h, j, k) which is located directly above it. Power to the

receptacles is available any time the generator engine is running, even

with the main line circuit breaker open.

Note: When the voltage selector switch is in the 480 V / 3Ø position,

voltage at the duplex receptacles is 139 V, and voltage at the 30/50 A

receptacles is 139/240 V. When the voltage selector switch is in the

208 V / 3Ø position, voltage at the 30/50 A receptacles is 120/208 V.

When the voltage selector switch is in the 208 V / 3Ø position, the

voltage can be adjusted with the voltage adjustment rheostat (f) to 240

V / 3Ø. The voltage at the duplex receptacles is 139 V, and voltage at

the 30/50 A receptacles is 139/240 V.

4.19 Remote Run Terminal Block

See Graphic: wc_gr005864

The remote run terminal block (o) is located just to the right of the twist

lock receptacles. This block provides connection points for installation

of a remote start switch. When connected to a transfer switch, it allows

the generator to be used as a standby power supply.

4.20 Panel Door Interlock Switch

See Graphic: wc_gr005864

The customer connection lugs panel access door is equipped with an

interlock switch (q). When the door is opened this switch

automatically trips the main circuit breaker. Voltage to the receptacles

will not be cut.

46 wc_tx001049gb.fm

Page 47

G 50 Operation

4.21 Terminal Connections

WARNING

WARNING

ALL CONNECTIONS TO THE TERMINALS MUST BE MADE BY A

TRAINED ELECTRICIAN.

BACKFEED FROM THE GENERATOR INTO THE UTILITY’S

DISTRIBUTION SYSTEM CAN CAUSE A SERIOUS INJURY OR

DEATH TO UTILITY WORKERS!

Improper connection of generator to a building’s electrical system can

allow electrical current from the generator to backfeed into utility lines.

This may result in electrocution of utility workers, fire or explosion.

Connections to a building’s electrical system must be made by a

qualified electrician and comply with all applicable laws and electrical

codes.

ELECTROCUTION HAZARD! ALWAYS OPEN MAIN CIRCUIT

BREAKER AND SET ENGINE STOP SWITCH TO OFF “O”

BEFORE INSPECTING OR ATTEMPTING ANY CONNECTIONS TO

THE TERMINAL BLOCK! LETHAL VOLTAGE COULD BE

PRESENT ON THE TERMINAL LUGS!

wc_tx001049gb.fm 47

Page 48

Operation G 50

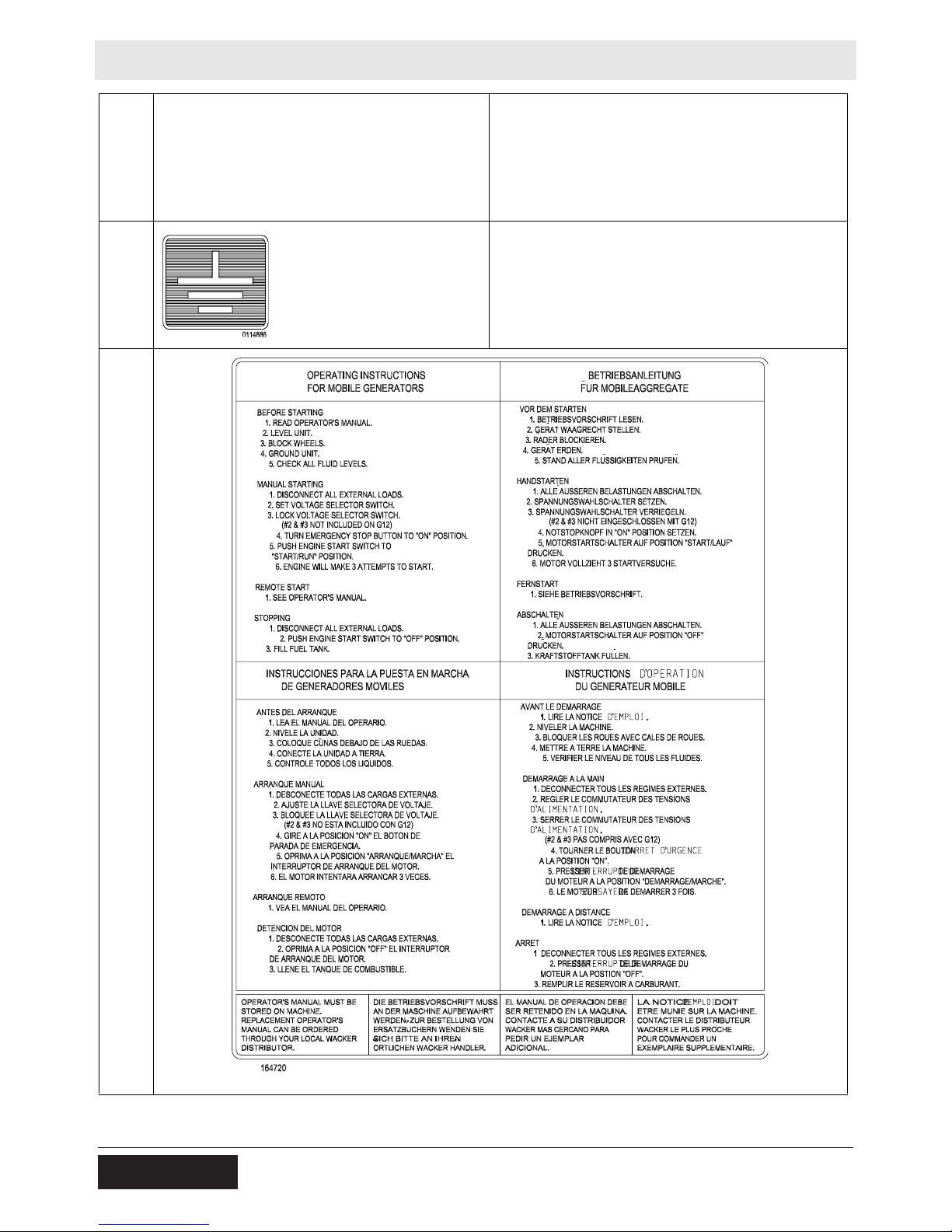

4.22 Before Starting

Before putting the generator into service, review each item on the

following checklist. Because generators are often run for long periods

of time unattended, it is important to make sure that the unit is set up

properly to reduce possible problems.

Failure to follow the procedures listed may cause injury to personnel or

damage to the generator. Be certain that all persons setting up the

WARNING

generator are certified or fully trained on the installation of the

generator.

• Check for any damage that might have been caused while towing to

the job site.

• Check to make sure no debris has lodged in vents, near radiator, or

around fan. Check to make sure that the exhaust compartment is

clean and nothing is touching the muffler or exhaust pipes.

• Check that generator is level.

• Chock trailer wheels.

• Check that generator is grounded to a good earthen ground per local

regulations and NEC standards.

• Check engine oil, coolant and fuel levels, and fill as required.

• Determine voltage needs. Set voltage selector switch and make

correct terminal connections.

• Check that all electrical connections were made in compliance with

local regulations and NEC standards.

• Check fan belt and hoses on engine for loose connections or fraying.

Tighten or replace as required.

• Close and secure side panel access doors.

• Review and follow safety instructions found in the front of this manual.

4.23 Manual Start-Up

See Graphic: wc_gr001682, wc_gr001677, wc_gr005866

Before starting the generator set, thoroughly review the pre-start-up

checklist in the previous section. Proceed with generator start-up only

after checking each item in that section.

Thoroughly read and make sure you understand the engine operator’s

manual supplied with the generator. Follow the steps below and the

illustration on the opposite page in the order listed.

48 wc_tx001049gb.fm

Page 49

G 50 Operation

When using the generator as a stand-by or substitute power supply,

make sure the voltage and phase rotation of the line connections

WARNING

4.23.1 Check position of voltage selector switch and make sure it is set for the

4.23.2 Make sure the engine start switch (f) is in the off “O” position.

4.23.3 Turn main line circuit breaker (a) and convenience receptacle circuit

4.23.4 Move engine start switch (f) to “REMOTE START” to check operation

match those of the utility lines or of any other power source normally

used. Failure to match phase rotation and voltage may cause

equipment connected to the generator to operate incorrectly!

This could create unsafe operating conditions.

desired voltage output. Lock the switch in place.

breakers to off “O”. This will disconnect all loads from the generator.

of engine control module. The LCD panel should momentarily display

INITIALIZING followed by READY and engine information. Check fuel

level and battery values.

Note: The warning light (d) will flash if the fuel level is below 15%. This

will not prevent the engine from starting.

4.23.5 Press the emergency stop button (p). The LCD panel should read

EMERGENCY STOP. Pull out the emergency stop button after

verifying the display and return the engine start switch to off “O”.

4.23.6 Start engine by moving the engine start switch to the “START/RUN”

position.

After displaying INITIALIZING and NOT IN AUTO sequence, the LCD

display will read START DELAY followed by CRANKING as the

engine begins its crank cycle. The normal cycle is for the engine to

crank for 12 seconds, then rest for 12 seconds. This cycle will repeat

three (3) times. If the engine does not start within this time, the engine

control module (ECM) will shut down the engine and OVERCRANK

will be displayed on the LCD panel. To repeat crank cycle, return start

switch to off “O” to reset the ECM. Allow starter motor to cool between

start-up attempts.

4.23.7 After engine starts, allow it to warm up for a few minutes and check

readouts on LCD panel. Make sure battery charging system, oil

pressure and engine temperature readings are within normal ranges.

4.23.8 Check that AC voltage is correct. Voltage can be fine-adjusted by

turning the voltage adjustment rheostat (b) on the metering panel.

4.23.9 Check frequency. The frequency should read 60 Hz.

wc_tx001049gb.fm 49

Page 50

Operation G 50

A

Ø

HZ

V

R

Basler

DIAGNOSTICS

DIAGNOSEN

DIAGNOSTICOS

DIAGNOSTICS

AUS

APAGADO

ARRET

OFF

REMOTE START

FERNSTART

ARRANQUE REMOTO

DEMARRAGE A

DISTANCE

START / LAUFEN

ARRANQUE / MARCHA

DEMARRER / MARCHE

START / RUN

G

E

R

N

a b fdeg

E

M

E

S

T

O

C

Y

P

wc_gr001677

OFF

AUS

APAGADO

ARRET

START / RUN

REMOTE START

START / LAUFEN

FERNSTART

ARRANQUE / MARCHA

ARRANQUE REMOTO

DEMARRER / MARCHE

DEMARRAGE A

DISTANCE

wc_gr006322

50 wc_tx001049gb.fm

Page 51

G 50 Operation

4.24 Running the Generator

See Graphic: wc_gr005866

Leave the engine start switch (f) in the “START/RUN” position while

the generator is operating. If the generator was started using a remote

switch, leave engine start switch in the “REMOTE START” position.

Let the generator run for a few minutes to warm engine before closing

main circuit breaker.

Before closing breakers, make sure that any electrical devices

attached downstream from the generator will not start up

WARNING

WARNING

unexpectedly.

While the generator is running, check for excessive vibration, oil leaks,

or coolant leaks.

Before placing the engine start switch (f) in the “REMOTE

START” position, verify that the contacts on any remote switch linked

to the generator set are OPEN. This will prevent the generator from

immediately starting when the engine start switch is moved to the

“REMOTE START” position.

wc_tx001049gb.fm 51

Page 52

Operation G 50

4.25 Engine Power Correction Factors

Performance data conditions

Performance data on John Deere engines are measured at the

following standard conditions:

• 744 mm (29.31 in.) of mercury dry air pressure

• 0% relative humidity

• 25°C (77°F) air intake temperature

• 40°C (104°F) fuel inlet temperature

Refer to the table below to estimate the engine power decrease in

percent as environmental factors vary from the standard conditions.

Engine power correction factors

Altitude

rise of 305 m

(1000 ft)

above 3050 m

(10,000 ft)

Model

G 50

Fuel temp

rise of 1°C

(1.8°F)

None

(ECU

compensated)

Air temp

rise of -12°C

(10°F)

0.50 4.00 0.07 0.5

4.26 Shutting down the generator

Check with other personnel on the jobsite and let them know that

power is being turned off. Make sure that the power shutdown will not

create any hazards by turning off devices such as pumps, heaters, or

lights that may need to be kept on.

4.26.1 Remove all loads from generator.

4.26.2 Open (turn to off “O”) main line circuit breaker.

4.26.3 Let engine run for approximately 5 minutes to allow it to cool down.

4.26.4 Move engine start switch to the off “O” position.

Relative

humidity rise

of 10%

Altitude

rise of 305 m

(1000 ft)

below 3050 m

(10,000 ft)

4.27 Cold Weather Start-Up

Successful cold weather starting requires that the battery be at peak

power, the correct weight motor oil is used, and the starter motor is in

good condition. The ECM will automatically activate the cold starting

aid and will display START DELAY as the heater heats.

52 wc_tx001049gb.fm

Page 53

G 50 Operation

4.28 Automatic/Remote Start-Up

See graphic: wc_gr005938

In the “REMOTE START” position the generator can be started

remotely, either through a transfer switch or some other type of remote

start switch. “REMOTE START” is the normal setting when using the

generator as a stand-by power supply. Before placing the generator in

the automatic starting mode, review the Before Starting and Manual

Starting sections in this Manual and follow procedure below.

Before placing the engine start switch (f) in the “REMOTE

START” position, verify that the contacts on any remote switch linked

WARNING

4.28.1 Perform a manual start at least once to verify that the metering panel

to the generator set are OPEN. This will prevent the generator from

immediately starting when the engine start switch is moved to the

“REMOTE START” position.

is operating correctly. Refer to the Before Starting and Manual Starting

sections in this Manual.

4.28.2 If a check of auto starting circuit is desired, attach a short jumper wire

(minimum 16 gauge insulated) between the two terminals on the

remote run terminal block. This applies a ground to the engine control

module to complete the start circuit. The engine should crank, start and

run.

Move the engine start switch to off “O” to stop engine. Remove jumper

from remote run terminals after testing is complete.

4.28.3 Secure generator by closing and locking all doors.

4.28.4 Set engine start switch to “REMOTE START” and close main line

circuit breaker.

The generator is now ready for automatic starting.

If the generator is to be used as a stand-by power supply for more than

a month, provisions must be made to maintain battery charge. This can

be done either by attaching a battery charger to the battery or by

starting generator manually and running engine periodically to

maintain charge. See Section Manual Starting.

Note: A cooldown timer is activated once the remote run signal is

removed. The cooldown time can be changed if desired. See

“Changing Cooldown Time.”

wc_tx001049gb.fm 53

Page 54

Operation G 50

4.29 Remote/Transfer Switch

When the generator is used as a stand-by power supply, it must be

equipped with a device which isolates it from the utility’s distribution

system.

WARNING

Failure to isolate the generator from the utility’s electrical

distribution system could cause output from the generator to

backfeed into the utility lines and cause injury or death to utility

workers!

The same is true if using the generator as a backup to some other type

of power supply system.

A transfer switch is designed to transfer electrical loads from the

normal power source (utility) to the emergency power source

(generator) when normal voltage falls below a prescribed level.

The transfer switch automatically returns the load back to the normal