Page 1

0175257en 001

0608

Mobile Generator

G 43

OPERATOR’S MANUAL

0175257EN

Page 2

Page 3

G 43 Foreword

Foreword

Machines

covered by

this manual

Machine Item Number

G 43 0620545

Machine

Documentation

Expectations

for

information in

this manual

Copyright

notice

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson

Corporation to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Corporation reserves the right

to change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2008 by Wacker Neuson Corporation.

This publication may be reproduced through photocopying by the original

purchaser of the machine. Any other type of reproduction is prohibited without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker Neuson

Corporation represents an infringement of valid copyrights, and violators will be

prosecuted.

Trademarks

All trademarks referenced in this manual are the property of their respective

owners.

wc_tx000898gb.fm 3

Page 4

Foreword G 43

wc_tx000898gb.fm 4

Page 5

G 43 Table of Contents

Foreword 3

1 Safety Information 7

1.1 Signal Words Found in this Manual ...................................................... 7

1.2 Safety Instructions for Operating the Machine ..................................... 8

1.3 Safety Instructions for Towing ............................................................ 10

1.4 Safety Instructions for Servicing the Machine .................................... 11

1.5 Label Locations .................................................................................. 14

1.6 Label Meanings .................................................................................. 15

2 Transporting, Lifting, and Storing 16

2.1 Transporting ....................................................................................... 16

2.2 Storing ................................................................................................ 16

2.3 Lifting .................................................................................................. 17

3 Operating the Machine 19

3.1 Application .......................................................................................... 19

3.2 Control/Component Locations ............................................................ 20

3.3 Control/Component Descriptions ....................................................... 21

3.4 Control Panel/Microprocessor ............................................................ 22

3.5 Control Panel/Microprocessor Functions ........................................... 22

3.6 Main Control Switch Positions/Functions ........................................... 24

3.7 Preliminary Checklist .......................................................................... 26

3.8 Starting the Generator ........................................................................ 27

3.9 Stopping the Generator ...................................................................... 28

3.10 Connecting Loads to the Terminal Lugs ............................................. 29

3.11 Operating the Generator .................................................................... 30

3.12 Microprocessor Display Screens ........................................................ 31

4 Maintenance 34

4.1 Periodic Maintenance Schedule ......................................................... 34

4.2 Checking the Engine Oil ..................................................................... 35

wc_bo0175257_001TOC.fm 5

Page 6

Table of Contents G 43

4.3 Changing the Engine Oil .....................................................................36

4.4 Changing Oil Filter ...............................................................................37

4.5 Changing the Fuel Filter ......................................................................38

4.6 Air Cleaner Discharge Valve ...............................................................39

4.7 Cleaning/Changing Air Filter Cartridges ..............................................40

4.8 Checking the Alternator V-Belt ............................................................41

4.9 Lubricating the Trailer ..........................................................................42

4.10 Cleaning the Engine ............................................................................43

4.11 Changing/Tensioning Alternator V-Belt ...............................................44

4.12 Checking/Adjusting Valve Clearances ................................................45

4.13 Checking Battery Electrolyte ...............................................................47

5 Schematics 48

5.1 Power Wiring .......................................................................................48

5.2 Power Wiring Components ..................................................................49

5.3 Engine Wiring ......................................................................................50

5.4 Engine Wiring Components .................................................................51

5.5 Socket Wiring ......................................................................................52

5.6 Socket Wirng Components ..................................................................53

5.7 Control Wiring ......................................................................................54

5.8 Control Wiring Components ................................................................55

6 Basic Troubleshooting 56

7 Technical Data 58

7.1 Machine ...............................................................................................58

7.2 Engine .................................................................................................59

7.3 Dimensions ..........................................................................................60

7.4 Sound Specification .............................................................................61

wc_bo0175257_001TOC.fm 6

Page 7

50Hz Mobile Generators Safety Information

1 Safety Information

1.1 Signal Words Found in this Manual

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f Obey all safety messages that follow this symbol to avoid injury or death.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f Obey all safety messages that follow this symbol to avoid possible injury or

death.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f Obey all safety messages that follow this symbol to avoid possible minor or

moderate injury.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

wc_si000271gb.fm 7

Page 8

Safety Information 50Hz Mobile Generators

1.2 Safety Instructions for Operating the Machine

DANGER

Electric shock hazard. Backfeed from the generator into the public power distribution system can seriously injure or kill utility workers!

f Connections to a building’s electrical system must be made by a qualified elec-

trician and comply with all applicable laws and electrical codes.

Safety

devices,

controls, and

attachments

Operator

training

Only operate the machine when:

All safety devices and guards are in place and in working order.

All controls operate correctly.

The machine is set up correctly according to the instructions in the Operator’s

Manual.

The machine is clean.

The machine’s labels are legible.

To ensure safe operation of the machine:

Do not operate the machine if any safety devices or guards are missing or inop-

erative.

Do not modify or defeat the safety devices.

Do not use accessories or attachments that are not recommended by Wacker

Neuson Corporation.

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson Corporation for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Safe

operating

practices

When operating this machine:

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

Wear protective clothing appropriate to the job site when operating the

machine.

Wear safety glasses when operating this machine.

Wear hearing protection when operating this machine.

When operating this machine:

Do not operate a machine in need of repair.

wc_si000271gb.fm 8

Page 9

50Hz Mobile Generators Safety Information

Work area

Be aware of the work area.

Keep unauthorized personnel, children, and pets away from the machine.

Remain aware of changing positions and the movement of other equipment

and personnel in the application area/job site.

Keep the machine at least one meter (three feet) away from structures, build-

ings, and other equipment during use.

Keep the area immediately surrounding and underneath the machine clean,

neat, and free of debris and combustible materials. Make sure that the area

overhead is clear of debris that could fall onto or into the machine or exhaust

compartment.

Make sure the machine is on a firm, level surface and will not tip, roll, slide, or

fall while operating.

Be aware of the application area.

Never operate the machine indoors unless exhaust fumes can be adequately

ventilated.

Never operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

Never operate the machine if you or the machine are in water.

Electrical

safety

Storing the

machine

To increase electrical safety while operating this machine, follow the procedures

below.

Do not operate the generator, or tools attached to the generator, with wet

hands.

Do not use worn electrical cords.

Make certain the machine is well-grounded and securely fastened to a good

earthen ground per national and local regulations.

Do not overload the generator. The total amperage of the tools and equipment

attached to the generator must not exceed the load rating of the generator.

Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

wc_si000271gb.fm 9

Page 10

Safety Information 50Hz Mobile Generators

1.3 Safety Instructions for Towing

WARNING

Towing a trailer requires special care. To reduce the possibility of an accident:

f Both the trailer and the vehicle must be in good working condition.

f The trailer and the vehicle must be securely fastened to each other.

Hitch and

coupling

Tires and

wheels

Brakes and

lights

To reduce the possibility of an accident, perform the following before towing.

Check that the hitch and coupling on the vehicle are rated equal to, or greater

than, the trailer's “gross vehicle weight rating” (GVWR).

Inspect the hitch and coupling for wear or damage. DO NOT tow the trailer

using defective parts.

Make sure the coupling is securely fastened to the vehicle.

Connect the safety chains.

Connect the breakaway cable safety hook to the bumper or rear of the vehicle.

Do not attach it to the hitch.

To reduce the possibility of an accident, perform the following before towing.

Check the condition, tread wear, and air pressure of the trailer tires. Replace

worn tires.

Check that the wheel lug nuts are tight and that none are missing.

To reduce the possibility of an accident, perform the following before towing.

Test the brake linkage on the trailer and the brakes on the towing vehicle.

Make sure directional and trailer lights are connected and working properly.

wc_si000271gb.fm 10

Page 11

50Hz Mobile Generators Safety Information

1.4 Safety Instructions for Servicing the Machine

WARNING

A poorly maintained machine can be a personal injury hazard.

f Follow the Periodic Maintenance schedule in this Operator’s Manual.

f Repair or replace any damaged or defective components immediately.

Service

training

Precautions

Safe servicing

practices

Before servicing or maintaining the machine:

Read and understand the instructions contained in all manuals delivered with

the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

Contact Wacker Neuson Corporation for additional training if necessary.

When servicing or maintaining this machine:

Do not allow improperly trained people to service or maintain the machine. Per-

sonnel servicing or maintaining the machine must be familiar with the associated potential risks and hazards.

Follow the precautions below when servicing or maintaining the machine.

Read and understand the service procedures before performing any service to

the machine.

All adjustments and repairs must be completed before operation. Do not oper-

ate the machine with a known problem or deficiency.

When servicing and maintaining this machine:

Be aware of the machine’s moving parts. Keep hands, feet, and loose clothing

away from the machine’s moving parts.

Wear protective clothing appropriate to the job.

Wear safety glasses.

Wear hearing protection if required.

Re-install the safety devices and guards after repairs and maintenance.

Machine

modifications

When servicing or maintaining the machine:

Use only accessories/attachments recommended by Wacker Neuson Corpora-

tion.

When servicing or maintaining the machine:

Do not defeat the safety devices.

Do not modify the machine without the express written approval of Wacker

Neuson Corporation.

wc_si000271gb.fm 11

Page 12

Safety Information 50Hz Mobile Generators

Replacing

parts and

labels

Before

servicing

Lifting and

transporting

Replace worn or damaged components.

Use only spare parts recommended by Wacker Neuson Corporation.

Replace all missing and hard-to-read labels.

When replacing electrical components, use components that are identical in

rating and performance as the original components.

Complete the following procedures before servicing the machine.

Turn off the machine.

Open the circuit breakers (“OFF”).

Disconnect the battery.

Attach a “DO NOT START” sign to the control panel.

Make sure that the remote start or transfer switch (if used) is also off and

tagged.

Let the engine cool.

When lifting the machine:

Make sure slings, chains, hooks, ramps, jacks and other types of lifting devices

are attached securely and have enough weight-bearing capacity to lift or hold

the machine safely.

Be aware of the location of other people when lifting the machine.

To reduce the possibility of injury:

Do not stand under the machine while it is being hoisted or moved.

Do not get onto the machine while it is being hoisted or moved.

wc_si000271gb.fm 12

Page 13

50Hz Mobile Generators Safety Information

Notes

wc_si000271gb.fm 13

Page 14

Safety Information 50Hz Mobile Generators

1.5 Label Locations

a

b

c

wc_gr005209

wc_si000271gb.fm 14

Page 15

50Hz Mobile Generators Safety Information

1.6 Label Meanings

Ref. Label Definition

a

b

Attention! Work with hood closed

WARNING!

Electric shock will cause serious

injury or death.

c

GND

d

88897

Electrical ground

Internal fuel tank connection

External fuel tank connection

wc_si000271gb.fm 15

Page 16

Transporting, Lifting, and Storing 50Hz Mobile Generators

2 Transporting, Lifting, and Storing

2.1 Transporting

When transporting the machine, only use transport vehicles with enough weightbearing capacity for both the generator and the trailer. See section Technical Data.

Secure the generator and the trailer to the transport vehicle.

2.2 Storing

When storing the machine for more than 30 days:

Drain the fuel tank.

Change the engine oil.

Disconnect the battery.

Clean the machine.

Cover the machine.

wc_tx000895gb.fm 16

Page 17

50Hz Mobile Generators Transporting, Lifting, and Storing

2.3 Lifting

Prerequisites

Procedure

Engine shut down

Appropriate lifting equipment (see section Technical Data for weights)

Follow the procedure below to lift the machine.

WARNING

Crush hazard. The weight of the machine may crush you if the lifting equipment

fails. Crushing may cause severe injury or death.

f Only use lifting equipment with enough lifting capacity to support the weight of

the machine and the trailer.

1. Turn off the engine.

2. Disconnect all loads.

3. Secure all doors in the closed position.

4. Connect an appropriate crane to the lifting eye (a) and lift the machine as

needed. A fork truck may also be used. Use the fork lift pockets (b) in the frame

of the machine.

WARNING

Crush hazard. The weight of the machine may crush you if the lifting equipment

fails. Crushing may cause severe injury or death.

f Do not stand underneath the machine when it is being lifted.

wc_tx000895gb.fm 17

Page 18

Transporting, Lifting, and Storing 50Hz Mobile Generators

Notes

wc_tx000895gb.fm 18

Page 19

50Hz Mobile Generators Operating the Machine

3 Operating the Machine

3.1 Application

Generator

application

Safety notices

This machine is a heavy-duty, compact, sound-attenuated generator designed to

provide single and three-phase power for construction, commercial, and industrial

applications where reliable power is needed.

.

Do not exceed the power output of the generator. Damage to tools or generator

will occur. Refer to Technical Data.

When using the generator as a standby or substitute power supply, make sure

the voltage and phase rotation of the line connections match those of the mains

lines. Failure to match phase rotation and voltage may cause equipment connected to the generator to operate incorrectly! This could create unsafe operating conditions.

Do not exceed the rated current limit of any receptacle.

wc_tx000884gb.fm 19

Page 20

Operating the Machine 50Hz Mobile Generators

3.2 Control/Component Locations

a

b c d e f

p

m

j

l

k

h

i

g

wc_gr005210

wc_tx000884gb.fm 20

Page 21

50Hz Mobile Generators Operating the Machine

3.3 Control/Component Descriptions

Ref. Description Ref. Description

a Emergency stop switch

Pressing this push button stops

the generator immediately.

When pressed, the LCD display

reads: “ALARM EMERGENCY”.

To release the emergency status, place the main control switch

in the LOCK position, then turn

and pull out the emergency stop

switch.

b Main circuit breaker

The main circuit breaker controls

voltage to both the lugs and to

the individual circuit breakers.

c Microprocessor

The microprocessor controls the

operation of the generator.

d 3-phase voltage lugs

Connection point for 400V, 3Ø

loads.

e Alternator

MeccAlte alternator (generator)

f Engine

Deutz

g Grounding stake

The grounding stake is used to

connect the machine to earthen

ground.

h Socket

250V, 16A, 1P + N Shuko

i Socket

220V, 16A, 1P +N CEE/IEC309

j Socket

380V, 16A, 3P +N CEE/IEC309

k Socket

380V, 32A, 3P +N CEE/IEC309

l Socket

380V, 63A, 3P +N CEE/IEC309

m Individual circuit breaker panel

Each socket has its own individual circuit breaker.

n Battery cut-off switch

This switch disconnects the battery from the engine and the

microprocessor.

o External fuel tank connection

point and control valves

p Engine protection switch

This switch controls battery

power to the engine and the

microprocessor.

wc_tx000884gb.fm 21

Page 22

Operating the Machine 50Hz Mobile Generators

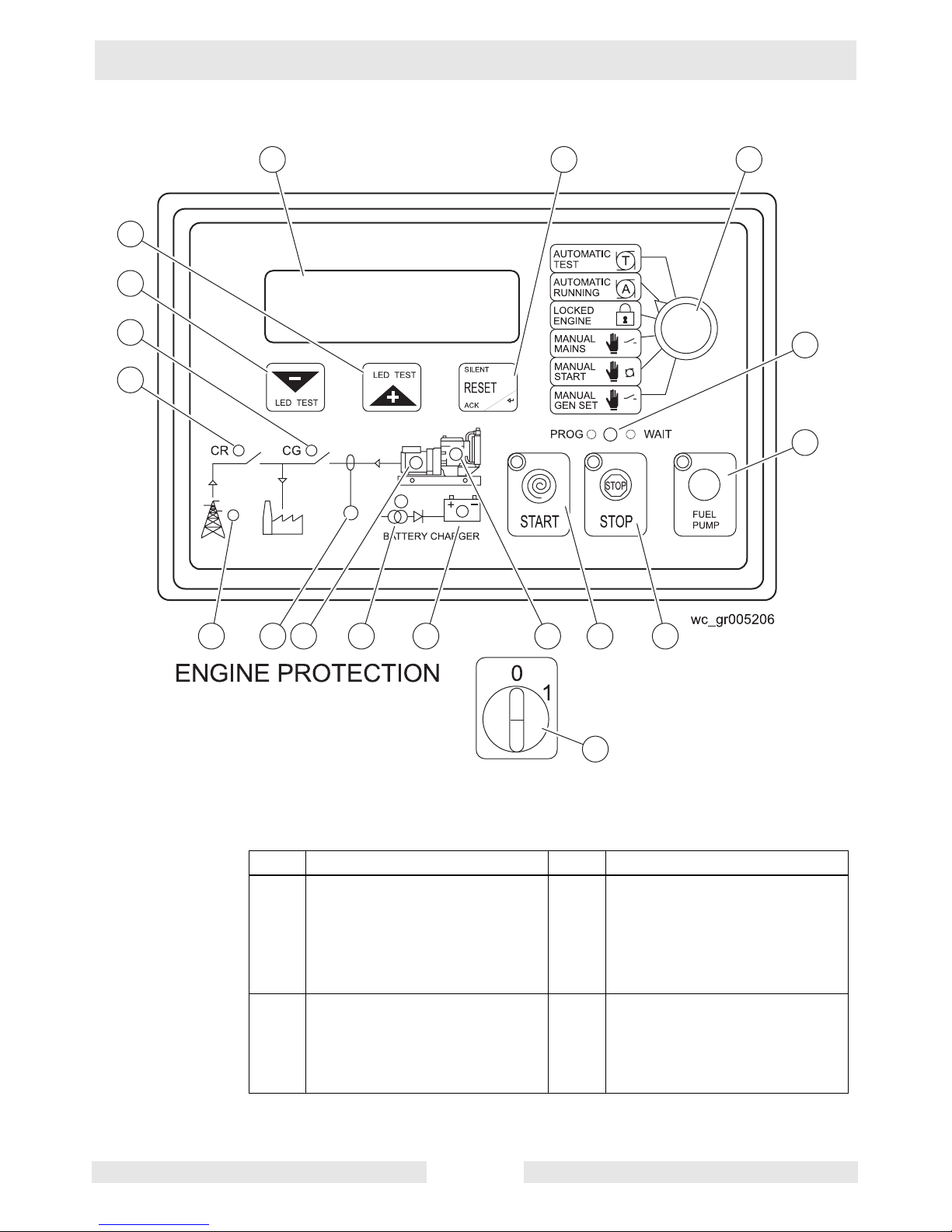

3.4 Control Panel/Microprocessor

a

b

c

q

p

o

CR

d

n

ENTER

CG

e

m

ijkl

h

3.5 Control Panel/Microprocessor Functions

Ref. Description Ref. Description

a LCD display

The microprocessor displays the

various functions and alarms of

the generator in this window.

b Reset button

Pressing this button once

silences the audible alarm.

Pressing it again resets the

microprocessor.

j Charging system LED

k Alternator LED

g

f

r

This LED illuminates when the

charging system is active. This

LED will flash when there is a

problem with the charging system.

This LED illuminates when the

alternator is active. This LED will

flash when there is a problem

with the alternator.

wc_tx000884gb.fm 22

Page 23

50Hz Mobile Generators Operating the Machine

Ref. Description Ref. Description

c Main control switch l Trip LED

This LED illuminates when the

main breaker has tripped.

d Microprocessor status LED

This LED flashes when the

microprocessor is computing a

function.

e Fuel pump button

Pressing this button activates the

auxiliary fuel pump. This switch

is only used with an optional auxiliary fuel tank which is not

offered on this machine.

f Stop button

Pressing this button stops the

engine.

gStart button

Pressing this button starts the

engine when the main control

switch is in the MANUAL START

position.

h Engine protection LED

This LED illuminates when the

engine protection system is

active. This LED will flash when

there is a problem with the

engine.

i Battery LED

This LED illuminates when the

battery is charged. This LED will

flash when there is a problem

with the battery.

m Mains LED

This LED illuminates when the

mains is connected and supplying voltage.

n CR Contact LED

This LED illuminates when contacts CR are closed signifying

that the Mains is the source supply of voltage to the end consumer.

o CG Contact LED

This LED illuminates when contacts CG are closed signifying

that the generator is the source

supply of voltage to the end consumer.

p Down arrow button (–)

Pressing this button scrolls backward through the screens of the

LCD display.

q Up arrow button (+)

Pressing this button scrolls forward through the screens of the

LCD display.

r Engine Protection Switch

This switch connects battery

power to the microprocessor.

The microprocessor then monitors: high water temperature, low

oil pressure, overspeed, battery

charger failure, low fuel level,

and a general programmable

alarm. Once the unit detects the

alarm, it will stop the engine after

a certain time, programmed

internally and not changeable.

wc_tx000884gb.fm 23

Page 24

Operating the Machine 50Hz Mobile Generators

3.6 Main Control Switch Positions/Functions

Position Description

AUTOMATIC TEST With the control switch in this position:

The engine will start automatically.

The microprocessor will test the function of

the generator systems. The results of the

tests are displayed on LCD screens. Scroll

through the LCD screens by using the arrow

keys.

The tests do not require the mains supply to

be disconnected from the end consumer.

AUTOMATIC RUNNING With the control switch in this position:

The engine will start automatically if the

machine is not connected to a mains supply.

The microprocessor is programmed to route

power (CR closed) from the mains supply to

the end consumer (utility) unless a problem

with the mains supply is detected. At such a

time, the microprocessor starts the generator

and routes power (CG closed, CR open)

from the generator to the end consumer. At

the point where the mains supply is again

stable, the microprocessor closes contacts

CR and opens contacts CG. The engine will

run for approximately 1 minute to allow it to

cool.

LOCKED ENGINE With the control switch in this position:

The engine will not start.

Power to all generator systems is discon-

nected.

The mains supply is the sole source of power

to the end consumer if connected.

wc_tx000884gb.fm 24

Page 25

50Hz Mobile Generators Operating the Machine

Position Description

MANUAL MAINS With the control switch in this position:

The engine will not start even if the START

push button is pressed.

The microprocessor is programmed to

always use the mains as the supply for the

end consumer.

The mains contacts (CR) are closed.

The generator contacts (CG) are open.

MANUAL START With the control switch in this position:

The engine will start when the START push

button is pressed.

The microprocessor is programmed to moni-

tor engine functions and generator output.

MANUAL GEN SET With the control switch in this position:

The engine will not start even if the START

push button is pressed.

The microprocessor is programmed to

always use the generator as the supply for

the end consumer (utility).

The mains supply contacts (CR) are open.

The generator contacts (CG) are closed.

wc_tx000884gb.fm 25

Page 26

Operating the Machine 50Hz Mobile Generators

3.7 Preliminary Checklist

Prerequisites

Procedure

Machine on a flat, horizontal surface

Wheels of trailer chocked

Have a certified electrician set up the generator. Complete the following preliminary

checks before putting the generator into service.

1. Make a walk-around inspection of the generator. Open side doors and visually

inspect engine compartment for obvious damage or the presence of foreign

objects which might affect operation.

2. Fill the engine cooling system with coolant. See the engine manual.

3. Check and fill the engine sump with oil. See the engine manual.

4. Check the engine air filter.

5. Check the fuel level. Fill the fuel tank if necessary.

6. Remove the grounding stake (a) from the machine and drive it into the ground.

7. Connect the cable form the grounding stake to the machine at the grounding

location (b).

8. Connect the battery.

wc_tx000884gb.fm 26

Page 27

50Hz Mobile Generators Operating the Machine

3.8 Starting the Generator

Prerequisites

Procedure

Machine on a flat, horizontal surface

Wheels of trailer chocked

Follow the procedure below to start the generator.

1. Disconnect all loads from the generator.

2. Place the battery cut-off switch (n) in the ON position.

3. Place the fuel valves (o) in the appropriate OPEN position.

4. Place the control switch in the MANUAL START position.

CR

ENTER

CG

5. Turn the ENGINE PROTECTION switch to the ON position (1).

6. Press the START push button. Release the START push button when the

engine starts.

NOTICE: Do not hold the START push button depressed for more than 20 seconds. Damage to the starter may occur. Allow 30 second of cooling time between

starting attempts.

wc_tx000884gb.fm 27

Page 28

Operating the Machine 50Hz Mobile Generators

3.9 Stopping the Generator

Prerequisites

Procedure

All tools disconnected from generator

Wheels of trailer chocked

Follow the procedure below to stop the generator.

1. Disconnect all tools from the generator.

2. Place the main circuit breaker and the individual circuit breakers in the OFF

position.

3. Allow the engine to run 2–3 minutes to cool down.

4. Press the STOP push button.

CR

ENTER

CG

5. Turn the ENGINE PROTECTION switch to the OFF position (0).

6. Place the control switch in the LOCKED ENGINE position.

7. Place the battery cut-off switch (l) in the OFF position.

If storing the machine, see section Transporting, Lifting, and Storing.

wc_tx000884gb.fm 28

Page 29

50Hz Mobile Generators Operating the Machine

3.10 Connecting Loads to the Terminal Lugs

Prerequisites

Procedure

Engine shut down

Wheels of trailer chocked

The appropriate qualifications and training mandated by the country where the

generator will be installed. If you do not have the appropriate qualifications, do

not continue with this procedure.

Follow the procedure below when connecting to the terminal lugs.

WARNING

Electric shock hazard. High voltage exists at the terminal lugs when the engine is

running. Electric shock can cause severe injury or death.

f Do not attempt to connect cables to the terminal lugs while the engine is run-

ning.

1. Shut down the engine.

2. Place the main circuit breaker in the OFF position.

3. Remove the screw that secures the terminal lug door (a).

4. Open the terminal lug door.

5. Connect the cables to the terminal lugs.

6. Close the terminal lug door.

7. Secure the cables with the latching device (b).

wc_tx000884gb.fm 29

Page 30

Operating the Machine 50Hz Mobile Generators

3.11 Operating the Generator

Prerequisites

Procedure

All preliminary checks made

Wheels of trailer chocked

Follow the procedure below when operating the generator.

WARNING

Electric shock hazard. High voltage exists at the terminal lugs when the engine is

running. Electric shock can cause severe injury or death.

f Do not attempt to connect cables to the terminal lugs while the engine is run-

ning.

1. Place the main circuit breaker (a) and the individual circuit breakers (b) in the

OFF position.

2. Connect the cables to terminal lugs if the load requires this type of connection.

3. Start the engine.

4. Place the main circuit breaker in the ON position.

5. Connect loads as required using the appropriate socket(s).

6. Place the individual circuit breakers in the ON positions as needed.

wc_tx000884gb.fm 30

Page 31

50Hz Mobile Generators Operating the Machine

3.12 Microprocessor Display Screens

The following screens appear when the control switch is placed in the TEST position. Scroll through the screens using the control panel arrow keys.

GEN. I1 32

I2 0 I3 0

GEN. V1N V2N V3N

222 221 221

GEN. V12 V23 V13

389 388 392

GEN. V12 389

HZ 50.1 I1 32

DIF

RET

MON 18:02:05

STARTING 135

FAILED STARTING 1

0.00 (0.30)A

0.3)S

This screen shows the amp draw (load) on each individual phase.

This screen shows the voltage between each phase

and neutral.

This screen shows the voltage between one phase and

another.

This screen shows frequency, voltage, and current on

phase 1.

This screen shows the programmed values of the differential protection system.

This screen shows the day, date, and year. It resets

each time the battery is disconnected.

This screen shows the number of starting occurrences

and the number of failed starting attempts.

OUT 123456789ABC

01010000

IN 123456789ABCD

00111111111101

HOUR-METER

4 h 7m 40S

1500RPM LC 92%

PO 4.4bar TM 83°C

BATTERY CHARGER

27.2V 1.4A

GEN.

KWh 13953

This screen shows the status of any outputs setup by

the installation engineers.

This screen shows the status of any inputs setup by the

installation engineers.

This is the hour meter display.

This screen shows: engine rpm, fuel percentage (LC);

oil pressure (PO); engine temperature (TM).

This screen shows battery voltage and amp draw.

This screen shows the supplied voltage from the genset

in kiloWatt hours.

wc_tx000884gb.fm 31

Page 32

Operating the Machine 50Hz Mobile Generators

GEN. COS. L 1.00

FREQ 50.0HZ

GEN. 0KVAr

7KVA 7KW

This screen shows the power factor phase displacement angle between voltage and current (COS.). For

inductive loads: L 0.xx; for capacitive loads: C 0.xx.

This screen shows generator power: apparent kVA,

actual kW, and reactive kVAr.

The following screens appear when the control switch is placed in the TEST position while the generator is connected to the mains supply. Scroll through the

screens using the control panel arrow keys.

MAIN 0KVAr

7KVA 7KW

MAIN V1N V2N V3N

224 221 224

MAIN V12 V23 V13

389 388 394

MAIN V12 389

HZ 50.0 I1 22

This screen shows the amp draw (load) on each individual phase.

This screen shows the voltage between each phase

and neutral.

This screen shows the voltage between one phase and

another.

This screen shows frequency, voltage, and current on

phase 1.

DIF

RET

MON 18:02:05

STARTING 135

FAILED STARTING 1

OUT 123456789ABC

01010000

IN 123456789ABCD

00111111111101

HOUR-METER

4 h 7m 40S

1500RPM LC 92%

PO 4.4bar TM 83°C

0.00 (0.30)A

0.3)S

This screen shows the programmed values of the differential protection system.

This screen shows the day, date, and year. It resets

each time the battery is disconnected.

This screen shows the number of starting occurrences

and the number of failed starting attempts.

This screen shows the status of any outputs setup by

the installation engineers.

This screen shows the status of any inputs setup by the

installation engineers.

This is the hour meter display.

This screen shows: engine rpm, fuel percentage (LC);

oil pressure (PO); engine temperature (TM).

wc_tx000884gb.fm 32

Page 33

50Hz Mobile Generators Operating the Machine

BATTERY CHARGER

27.2V 1.4A

MAIN COS. L 1.00

FREQ 50.0HZ

MAIN 0KVAr

7KVA 7KW

This screen shows battery voltage and amp draw.

This screen shows the power factor phase displacement angle between voltage and current (COS.). For

inductive loads: L 0.xx; for capacitive loads: C 0.xx.

This screen shows generator power: apparent power

kVA; actual power kW; reactive power kVAr.

wc_tx000884gb.fm 33

Page 34

Maintenance 50Hz Mobile Generators

4 Maintenance

4.1 Periodic Maintenance Schedule

Refer to the Deutz engine manual for detailed information on maintaining the

engine.

Interval* (hours of service)

(10) (250) (500) (1000) (2000) (6000)

Item Task

Air cleaner Check

Battery connections Check

Engine lube oil level** Check

Fuel level Check

Air cleaner discharge valve Clean

Air cleaner filter cartridge Clean

Daily 3

months6 months

Yea rl y 2

years

6

years

Alternator V-belt Check

Battery electrolyte level Check

Air cleaner valve Clean

Air cleaner filter cartridge Clean

Battery electrolyte density Check

Engine Clean

Engine oil and filter Change

Fuel filter Replace

Trailer Lubricate

Valve clearances Check/

adjust

Air cleaner safety cartridge Change

Alternator V-belt Change

Engine Partial

* Use whichever comes first, calendar time or service hours.

** Change engine oil and filter after first 50 hours of operation.

wc_tx000885gb.fm 34

overhaul

Page 35

50Hz Mobile Generators Maintenance

4.2 Checking the Engine Oil

Prerequisites

When

Procedure

Machine on a level surface

Engine off

Every 10 hours of service or daily

Follow the procedure below to check the engine oil.

1. Clean around the dipstick (a).

2. Remove the dipstick and wipe it clean.

3. Re-insert the dipstick and check the oil level. Maintain the oil level between the

“MAX” and “MIN” marks on the dipstick.

4. Remove the oil filler cap and add oil as needed. See Technical Data for oil type

and amount.

NOTICE: Do not overfill the machine with oil. Engine damage may result.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 35

Page 36

Maintenance 50Hz Mobile Generators

4.3 Changing the Engine Oil

Prerequisites

When

Procedure

Machine on a level surface

Engine off

Engine oil warm—approximately 80°C (176°F)

Oil tray

Drain plug seal ring

Every 1000 hours of service or yearly

Follow the procedure below to change the engine oil.

1. Place the oil tray underneath the engine.

CAUTION

Burn hazard. Hot engine oil can cause burns.

f Avoid touching the hot oil.

2. Remove the drain plug and drain the oil into the oil tray.

Note: Collect, store and dispose of all used oil and filters in accordance with current environmental protection regulations.

3. Attach a new seal ring to the drain plug.

4. Install the drain plug into the engine.

5. Remove the oil filler cap and add oil as needed. See section Technical Data for

type and quantity.

NOTICE: Do not overfill the machine with oil. Engine damage may occur.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 36

wc_gr005230

Page 37

50Hz Mobile Generators Maintenance

4.4 Changing Oil Filter

Prerequisites

When

Procedure

Machine on a level surface

Engine off

Engine oil warm—approximately 80°C (176°F)

New oil filter

Every 1000 hours of service or yearly

Follow the procedure below to change the oil filter.

1. Place the oil tray underneath the engine.

CAUTION

Burn hazard. Hot engine oil can cause burns.

f Avoid touching the hot oil.

2. Remove the oil filter. Catch any dripping oil.

Note: Collect, store and dispose of all used oil and filters in accordance with current environmental protection regulations.

3. Clean the filter housing base.

4. Apply a thin coat of engine oil to the seal of the new oil filter.

5. Install the new filter cartridge and tighten by hand. When the seal contacts the

base, tighten the filter cartridge an additional 1/2 turn.

6. Start and run the engine for a few minutes, then switch off the engine.

7. Check the oil level. Add oil as needed.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 37

Page 38

Maintenance 50Hz Mobile Generators

4.5 Changing the Fuel Filter

Prerequisites

When

Procedure

Engine off

New fuel filter

Every 1000 hours of service or yearly

Follow the procedure below to change the oil filter.

1. Close the fuel shut-off valve(s).

WARNING

Fire hazard. Diesel fuel is flammable. Fire can cause severe burns.

f Keep flames and smoking materials away from the fuel system.

2. Remove the fuel filter. Clean up any spilled fuel.

Note: Collect, store and dispose of all used fuel and filters in accordance with current environmental protection regulations.

3. Clean the filter housing base.

4. Apply a thin coat of engine oil or diesel fuel to the seal of the new fuel filter.

5. Install the new filter cartridge and tighten by hand. When the seal contacts the

base, tighten the filter cartridge an additional 1/2 turn.

6. Open the fuel shut-off valve(s).

7. Start the engine and check for leaks.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 38

Page 39

50Hz Mobile Generators Maintenance

4.6 Air Cleaner Discharge Valve

Prerequisites

When

Procedure

Engine off

Machine cool

Every 250 hours of service or every 3 months

Follow the procedure below to empty the air cleaner discharge valve.

1. Empty the air cleaner discharge valve (1) by pressing apart the lips of the discharge slot as indicated by the arrows.

2. Remove any caked dirt by pressing together section of valve.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 39

Page 40

Maintenance 50Hz Mobile Generators

4.7 Cleaning/Changing Air Filter Cartridges

Prerequisites

When

Procedure

Engine off

Source of compressed air

Every 500 hours of service or every 6 months (safety cartridge: 2 years)

Follow the procedure below to clean/change the air filter cartridges.

1. Unclip the fasteners (1).

2. Remove hood (2).

3. Remove cartridge (3).

4. Clean cartridge (3) with compressed air, blowing from inside to outside.

5. Do not clean safety cartridge (4). Instead, replace it every 2 years. Remove nut

(5) to remove safety cartridge.

6. Re-install cartridge (3).

7. Re-install hood (2).

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 40

Page 41

50Hz Mobile Generators Maintenance

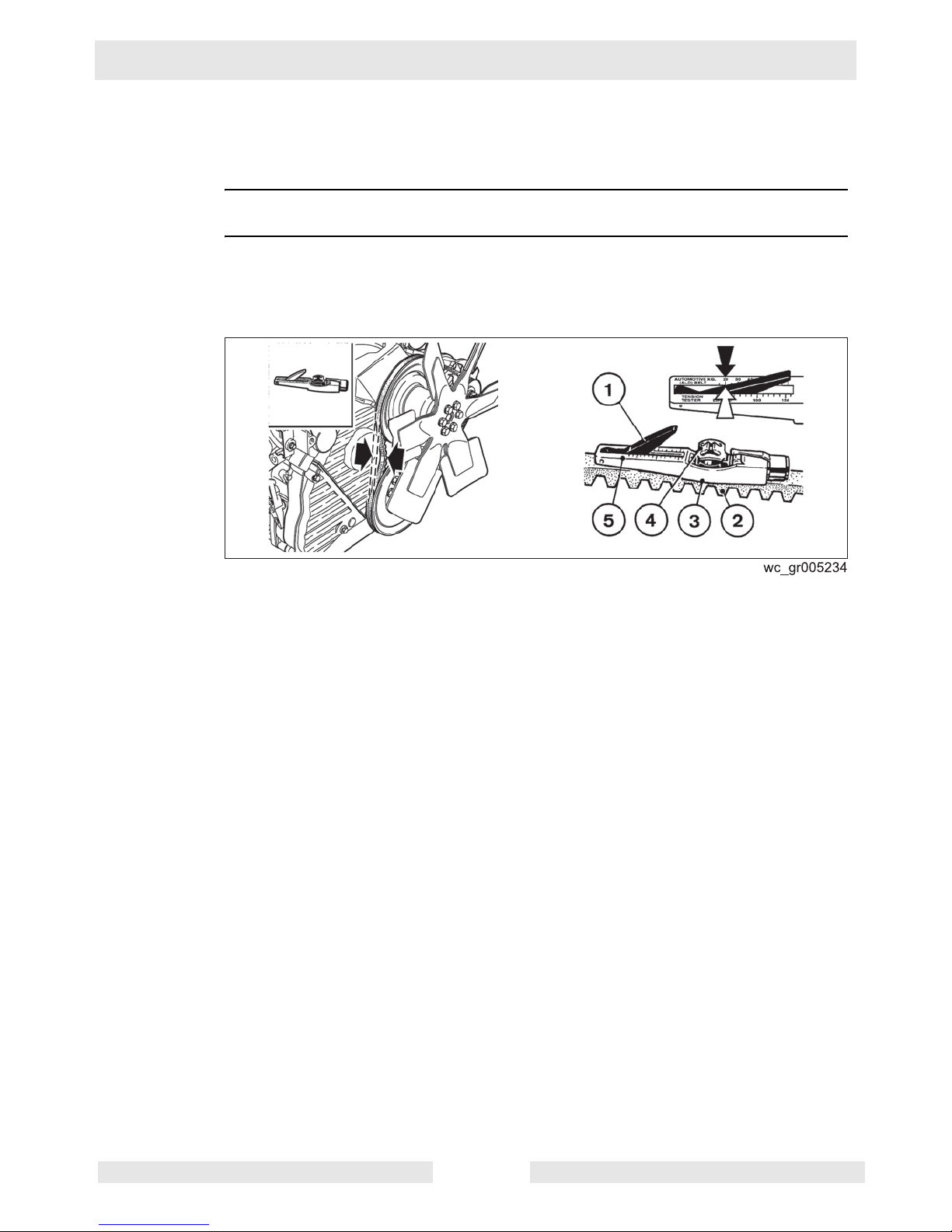

4.8 Checking the Alternator V-Belt

Prerequisites

When

Procedure

Engine off

Tension gauge

Every 250 hours of service or every 3 months

Follow the procedure below to check the alternator V-belt.

1. Run the engine under load for 15 minutes. Then, turn engine off.

2. Visually inspect the alternator V-belt for damage.

3. Place indicator arm (1) into the gauge.

4. Position the gauge (3) on the alternator V-belt midway between the pulleys.

5. Push slowly on the black pad (4) at right angles to the alternator V-belt (2) until

the spring is heard or felt to trigger.

6. Carefully remove the gauge without altering the position of indicator arm (1).

7. Read the value where black indicator arm (1) intersects scale (5). See section

Technical Data for setting.

8. Retension the alternator V-belt and measure again if necessary.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 41

Page 42

Maintenance 50Hz Mobile Generators

4.9 Lubricating the Trailer

Prerequisites

When

Procedure

Engine off

Trailer chocked

Multi-purpose grease to DIN 51825 KTA 3K4

Every 10,000–15,000 km of service or yearly

Follow the procedure below to lubricate the trailer.

1. Grease the drawbar (1) in the area of the bellows.

wc_gr005250

2. Grease the bearing bushing through the grease nipple (2) on the housing and

the cartridge.

3. Grease the pivot bolt (3) of the overrun lever and the handbrake levers through

the grease nipple.

4. Grease the end of the brake rod end fitting (4).

5. Oil the joints of the spring cylinder in the handbrake lever (5).

wc_tx000885gb.fm 42

Page 43

50Hz Mobile Generators Maintenance

4.10 Cleaning the Engine

Prerequisites

When

Procedure

Engine off

Engine cool

Every 1000 hours of service or yearly

Follow the procedure below to clean the engine.

1. Cover electric/electrical components and connection: alternator, starter, governor, solenoid.

2. Blow compressed air through the engine stating with the exhaust side. Take

care not to damage cooling fins of cooling system.

3. Cold water jet or steam cleaning is allowed. Limit pressure to 60 bar and temperature to 90°C.

4. Remove the covering from electric/electrical components installed in step 1.

5. Start engine and allow remaining water to evaporate.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 43

Page 44

Maintenance 50Hz Mobile Generators

4.11 Changing/Tensioning Alternator V-Belt

Prerequisites

When

Procedure

Engine off

New alternator V-belt

Every 2000 hours of service or every 2 years

Follow the procedure below to change/tension the alternator V-belt.

1. Loosen the screws (1), (2), and (3).

2. Rotate the alternator (4) downward until the alternator V-belt can be removed.

Remove the alternator V-belt.

3. Install the new alternator V-belt.

4. Rotate the alternator upward by turning screw (3).

5. Check alternator V-belt tension.

6. Tighten the screws (1), (2), and (3).

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 44

Page 45

50Hz Mobile Generators Maintenance

4.12 Checking/Adjusting Valve Clearances

Prerequisites

When

Procedure

Engine off and cool

Cylinder head gasket

Feeler gauges

Every 1000 hours of service or yearly

Follow the procedure below to check/adjust the valve clearances.

1. Turn the crankshaft until both valves in cylinder 1 overlap (exhaust valve about

to close, inlet valve about to open). Position 1 of diagram below.

2. Adjust the valves marked in black in position 1 of diagram.

3. Remove the cylinder head cover.

This procedure continues on the next page.

wc_tx000885gb.fm 45

Page 46

Maintenance 50Hz Mobile Generators

Continued from the previous page.

4. Check valve clearance (1) between rocker arm/tappet contact face (2) and valve

stem (3) with the feeler gauge (6).

5. To adjust clearance, loosen locknut (4).

6. Adjust set screw (5) so that correct clearance is established. See section Tech-

nical Data.

7. Tighten locknut (4).

8. Rotate crankshaft 360°.

9. Check/adjust clearances of valves marked in black in position 2 of diagram.

10.Re-install cylinder head cover with new gasket.

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 46

Page 47

50Hz Mobile Generators Maintenance

4.13 Checking Battery Electrolyte

Prerequisites

When

Procedure

Engine off & cool

Distilled water

Every 250 hours of service or every 3 months

Follow the procedure below to check the battery electrolyte.

1. Disconnect the battery.

WARNING

Burn hazard. Battery acid is caustic. It can cause severe burns.

f Do not touch battery acid with your bare hands.

2. Remove the sealing caps (1).

If testers (2) are present, the electrolyte should reach the base of the testers.

If testers are not present, the electrolyte should be 10–15mm above the plates of

the battery.

3. Add distilled water as needed to obtain the correct electrolyte level.

4. Measure the electrolyte density with a commercial hydrometer.

Electrolyte density

kg/l Charge status

Normal - ---

1.28 Well charged

1.20 Semi-charged, re-charge

1.12 Discharged, immediately charge

5. Re-install the sealing caps (1).

Note: Refer to the Deutz engine manual for detailed information on maintaining the

engine.

wc_tx000885gb.fm 47

Page 48

Schematics 50Hz Mobile Generators

5 Schematics

5.1 Power Wiring

wc_tx000886gb.fm 48

Page 49

50Hz Mobile Generators Schematics

5.2 Power Wiring Components

Components

(+) Connection for 230V III AC

(++) Connection for 230V III AC

Circuit breaker

Load

Genset

To control board

wc_tx000886gb.fm 49

Page 50

Schematics 50Hz Mobile Generators

5.3 Engine Wiring

wc_tx000886gb.fm 50

Page 51

50Hz Mobile Generators Schematics

5.4 Engine Wiring Components

Components

+ Battery

– Battery

Alarm

EXT. (External) alarm

Start

Fuel solenoid

EXT. (External) alarm relay

Low oil pressure

Charge alternator D+

High coolant temperature

High oil temperature

Low fuel level

Low water level (standard Deutz 1012)

Fuel level

Engine temperature (only Deutz 1012)

Engine rpm

Start pre-heat RES. (resistor)

Start preheat relay

wc_tx000886gb.fm 51

Page 52

Schematics 50Hz Mobile Generators

5.5 Socket Wiring

wc_tx000886gb.fm 52

Page 53

50Hz Mobile Generators Schematics

5.6 Socket Wirng Components

Components

Main circuit breaker

DIFF. (differential) breaker

wc_tx000886gb.fm 53

Page 54

Schematics 50Hz Mobile Generators

5.7 Control Wiring

wc_tx000886gb.fm 54

Page 55

50Hz Mobile Generators Schematics

5.8 Control Wiring Components

Components

Current transformer

X1-Connector engine

X2-Connector gen set

X4- Connector LTS (microprocessor)

(**) 230V connection

(***) Option: glow plug

Alarm

Level

Circuit board

Mains voltage

Contact

Emergency stop

Negative 2

Pin 18

Pin 20

Board

Cable to LTS (microprocessor)

Alarm

Level

wc_tx000886gb.fm 55

Page 56

Basic Troubleshooting 50Hz Mobile Generators

6 Basic Troubleshooting

Problem Cause Remedy

Engine doesn’t start Battery discharged

Battery connections corroded

Defective starter

Engine tries to start but

stops

Engine doesn’t reach operating speed

No generator output Voltage regulator malfunc-

Low oil pressure Low oil level

No fuel

Clogged fuel filter

Fuel circuit failure

Speed regulator failure

Fuel circuit failure

Speed regulator failure

Voltage regulator malfunction

tion

Overload switch ON

Triggered switch. Short circuit or earth fault.

Clogged oil filter

Oil pump failure

Alarm failure

Charge battery.

Clean battery connections.

Replace starter.

Fill tank with fuel.

Replace fuel filter.

Check fuel lines.

Call for service.

Check fuel lines.

Call for service.

Call for service.

Call for service.

Reduce load.

Check circuits downstream

by checking faults in equipment and/or connection

cables.

Fill engine sump with oil.

Replace oil filter.

Call for service.

Check connections

between sensor and panel.

If necessary, replace sensor.

High coolant temperature Overload

Low coolant level

Clogged oil filter

Oil pump failure

Engine overspeed Speed regulator failure

Overload switch ON

Alarm failure

Black smoke Fuel circuit failure

Clogged air filter

Overload

High oil level

Reduce load.

Fill with coolant.

Replace oil filter.

Call for service.

Call for service.

Reduce load.

Check connections

between sensor and panel.

If necessary, replace sensor.

Call for service.

Clean/replace air filter cartridges.

Reduce load.

Remove excess oil.

wc_tx000896gb.fm 56

Page 57

50Hz Mobile Generators Basic Troubleshooting

wc_tx000896gb.fm 57

Page 58

Technical Data G 43

7 Technical Data

7.1 Machine

Item number G 43 0620545

Prime power kVA 41,3

Standby power kVA 43,4

AC Voltage 1 phase V 230

AC Voltage 3 phase V 400

Frequency Hz 50

Power factor Cos Ø 0,8

Fuel capacity l 78

Run time (continuous load) h 8,3

Working weight (w/o trailer) kg 1021

Alternator Make/

model

Insulation Class H

Voltage regulation Model/

type (%)

MeccAlte / ECO 32 3S

SR7/2 / electronic (± 1%)

wc_td000277gb.fm 58

Page 59

G 43 Technical Data

7.2 Engine

Engine

Type Diesel

Make Deutz

Model BF4M 2011

Prime rating power at rated

speed

Operating Speed rpm 1500

Cooling system type Oil with radiator

Speed rpm 1500

Displacement cc 3110

Cylinders no. 4

Aspiration type Turbo

Governor type Mechanical

Battery V/cca 12/680

Electrical system (DC) Volt 12

Oil type

Oil quantity*** l 13,5

V-belt pretension / tension* N 450 / 350 ± 20

Valve clearance (cold)** mm Inlet: 0.3+.01; outlet: 0.5+.01

kW 36,4 @ 1500 rpm

20 W 20

(SAE)

* After engine has been running under load for 15 minutes.

** Engine oil should be less than 80°C.

*** Including oil cooler, without oil filter.

wc_td000277gb.fm 59

Page 60

Technical Data G 43

7.3 Dimensions

wc_td000277gb.fm 60

Page 61

G 43 Technical Data

7.4 Sound Specification

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC Machinery

Directive, is:

guaranteed sound power level (LWA) = 89 dB(A).

This sound value was determined according to ISO 3744 for the sound power level

(LWA).

wc_td000277gb.fm 61

Page 62

Page 63

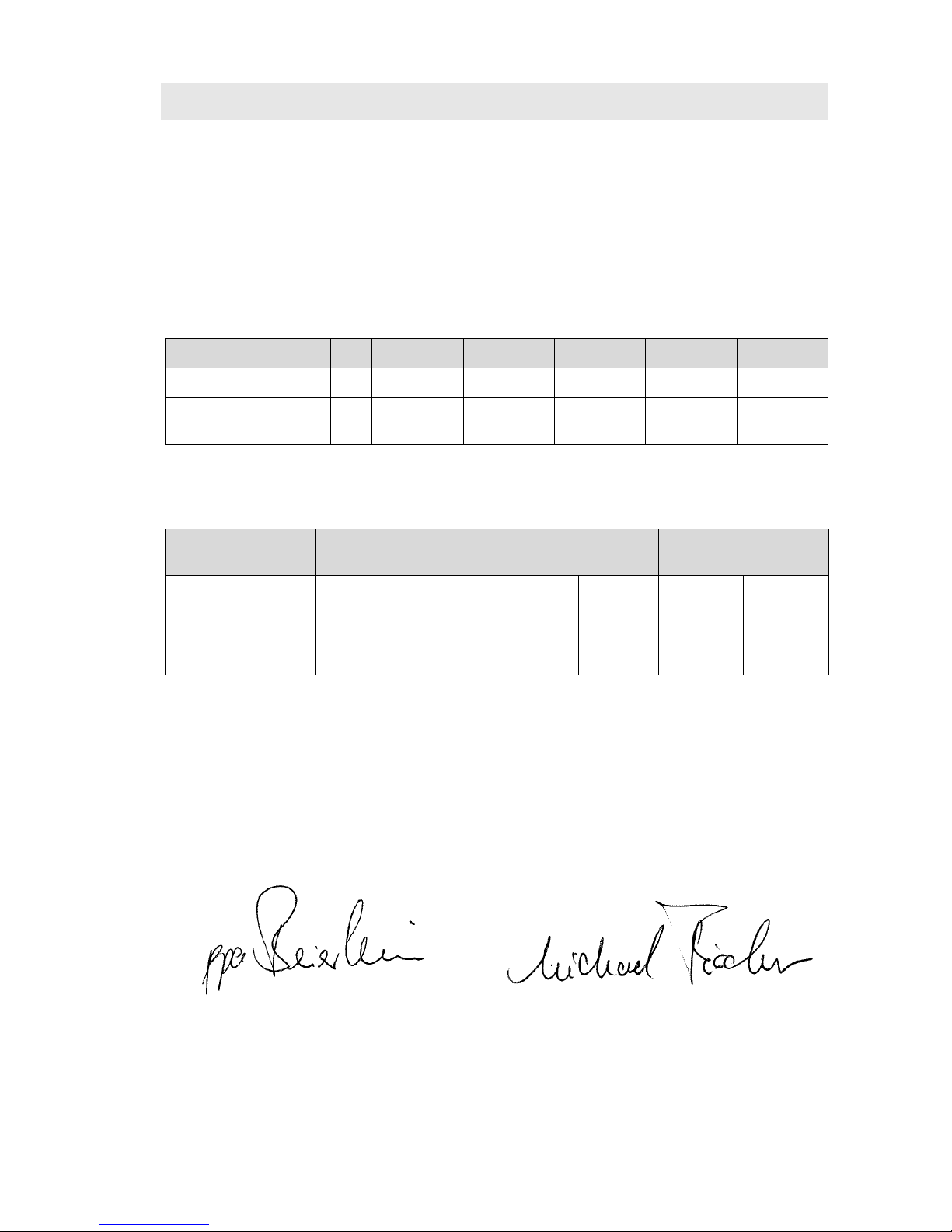

EC Declaration of Conformity

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München certifies that the

construction machines:

Category

Mobile Generator

fulfill the requirements of the following directives:

98/37/EC

2004/108/EC

2000/14/EC

2006/95/EC

Typ e G 22 G 32 G 43 G 66 G 78

Machine type number 0620543 0620544 0620545 0620546 0620547

Absolute installed

power

kVA20,830,441,358,774,3

Conformity assessment procedure

At the following test

center

Measured sound

power level

Guaranteed sound

power level

Appendix VIII SNCH Société

Nationale de Certification

et ’Homologation

11, route de Luxembourg

L-5230 Sandweiler

G 22,

G 32, G 43

G 66,

G 78

G 22,

G 32, G 43

G 66,

G 78

88 dB(A) 95 dB(A) 89 dB(A) 96 dB(A)

Beierlein

Head of product management

Dr. Fischer

Head of Research and Development

Page 64

Page 65

Wacker Construction Equipment AG · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-3 54 02 - 0 · Fax: +49 - (0)89-3 54 02-3 90

Neuson Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : (262) 255-0500 · Fax: (262) 255-0550 · Tel. : (800) 770-0957

Wacker

Wacker Asia Pacific Operations · Skyline Tower, Suite 2303, 23/F · 39 Wang Kwong Road, Kowloon Bay, Hong Kong · Tel. +852 2406 60 32 · Fax: +852 2406 60 21

Loading...

Loading...