Wacker Neuson G 2.5A, GS 5.6A, GS 8.5V, GS 9.7V, G 3.7A Repair Manual

...

www.wackergroup.com

Portable Generators

G 2.5A

G 3.7A

G 5.6A

GS 5.6A

GS 8.5V

GS 9.7V

REPAIR MANUAL

0112013 004

1002 en

0112013

Portable Generator Repair Foreword

wc_tx000224gb.fm i

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or make any repairs to it. Basic operating and

maintenance procedures are described in the operator’s / parts

manual supplied with the machine. The operator’s / parts manual

should be kept with the machine. Use it to order replacement parts

when needed. If this manual becomes lost, please contact Wacker

Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to

the attention of the operator, to prevent similar occurrences from

happening in the future.

This manual provides information and procedures to safely repair and

maintain this Wacker model. For your own safety and protection from

injury, carefully read, understand and observe the safety instructions

described in this manual. THE INFORMATION CONTAINED IN THIS

MANUAL WAS BASED ON MACHINES IN PRODUCTION A T THE

TIME OF PUBLICATION. WACKER CORPORATION RESERVES

THE RIGHT TO CHANGE ANY PORTION OF THIS INFORMATION

WITHOUT NOTICE.

This manual covers machines with Item Number:

0007188, 0007189, 0007190, 0007191, 0007661, 0007662

Foreword P o rtable Generator Repair

wc_tx000224gb.fm ii

Portable Generat or R e p a ir Table of C ontents

wc_bo0112013004gbTOC.fm 1

1. Foreword 5

2. Safety Information 6

2.1 Laws Pertaining to Spark Arresters ...................................................... 6

2.2 Operating Safety .................................................................................. 7

2.3 Operator Safety while using Internal Combustion Engines .................. 8

2.4 Service Safety ...................................................................................... 9

2.5 Label Locations ..................................................................................10

2.6 Safety and Operating Labels .............................................................. 13

3. Technical Data 18

3.1 Generator ........................................................................................... 18

3.2 Engine ................................................................................................ 22

4. Power Requirements 26

4.1 Determining Power Requirements ..................................................... 26

4.2 Outdoor Installation ............................................................................27

4.3 Indoor Installation .................................. ......... ......... .......... ......... ........27

4.4 Grounding the Generator ................................................................... 28

4.5 Use of Extension Cords ...................................................................... 29

5. G 2.5A 30

5.1 Theory of Operation – Capacitor Generators ..................................... 30

5.2 Rotor ................................................................................................... 31

5.3 Stator .................................................................................................. 31

5.4 Capacitor ............................................................................................ 32

5.5 Diodes ................................................................................................ 32

5.6 Circuit Breaker .................................................................................... 33

5.7 Ground Fault Interruptor ..................................................................... 34

5.8 Capacitors .......................................................................................... 35

5.9 Engine Speed .....................................................................................36

5.10 Loss of Residual Magnetism .............................................................. 37

Table of Contents Portable Generator Repair

wc_bo0112013004gbTOC.fm 2

5.11 Receptacle Panel Wiring .....................................................................38

5.12 Rotor Diode Testing ............................................................................38

5.13 Stator Winding Test .............................................................................39

5.14 Rotor Winding Test ..............................................................................40

5.15 Generator Disassembly .......................................................................41

5.16 Generator Assembly ............................................................................43

5.17 Troubleshooting ...................................................................................44

5.18 Periodic Maintenance Schedule ......................................... ......... ........45

5.19 Engine Service . .................................................................. .................45

5.20 Storing / Transporting ..........................................................................46

5.21 Wiring Schematic ................ ......... .......... ......... ......... .......... ......... ........47

6. G 3.7A;G/GS 5.6A;GS 8.5V;GS 9.7V 48

6.1 Theory of Operation – Brush Generators ............................................48

6.2 Rotor ....................................................................................................49

6.3 Stator ...................................................................................................49

6.4 Automatic Voltage Regulator ...............................................................49

6.5 Choke ..................................................................................................49

6.6 Bridge Rectifier ....................................................................................50

6.7 Engine Auto Idle Module (G 3.7A, G 5.6A and GS 5.6A Models) .......51

6.8 Engine Auto Idle Module (GS 8.5A and GS 9.7A Models) ..................52

6.9 Voltage Selector Switch (G 3.7A, G 5.6A and GS 5.6A Models) ........52

6.10 Checking the Voltage Selector Switch Functional Output

(G 3.7A, G 5.6A and GS 5.6A Models)................................................53

6.11 Main Circuit Breaker ............................................................................54

6.12 Ground Fault Interrupt .........................................................................54

6.13 Choke Test ..........................................................................................56

6.14 Engine Speed (G 3.7A, G 5.6A and GS 5.6A Models) ........................57

6.15 Auto Idle Switch ...................................................................................58

6.16 Checking Engine Electronic Governor Speed

(GS 8.5V and GS 9.7V models) .........................................................59

6.17 Removing and Installing Electronic Governor

(GS 8.5V and GS 9.7V Models) ..........................................................61

6.18 Receptacle Panel Wiring .....................................................................62

6.19 Loss of Residual Magnetism in Rotor ..................................................62

6.20 Diode Bridge ................................. .......... .............................................64

6.21 Stator Windings ...................................................................................65

6.22 Rotor Windings ....................................................................................67

6.23 Automatic Voltage Regulator ...............................................................68

Portable Generat or R e p a ir Table of C ontents

wc_bo0112013004gbTOC.fm 3

6.24 Slip Rings and Brushes ...................................................................... 69

6.25 Generator Disassembly ...................................................................... 70

6.26 Generator Assembly ........................................................................... 73

6.27 Troubleshooting ..................................................................................74

6.28

Period ic Main t enance S chedule (G 3.7A, G 5. 6A, and G S5. 6A Models)

75

6.29 Engine Service (G 3.7A, G 5.6A, and GS 5.6A Models) .................... 75

6.30 Periodic Maintenance Schedule (GS 8.5V and GS 9.7V Models) ...... 76

6.31 Engine Service (GS 8.5V and GS 9.7V Models) ................................ 76

6.32 Generator Wiring Schematic (G 3.7A, G 5.6A, and GS 5.6A Models) 77

6.33 Engine Wiring Schematic (G 3.7A, G 5.6A, and GS 5.6A Models) .... 79

6.34 Generator Wiring Schematic (GS 8.5V and GS 9.7V Models) ........... 80

6.35 Vanguard Engine Wiring Schematic (GS 8.5V and GS 9.7V Models) 83

6.36 Vanguard Key Switch ........................................................ ......... ........84

6.37 Storing ................................................................................................ 85

6.38 Transporting ....................................................................................... 85

Table of Contents Portable Generator Repair

wc_bo0112013004gbTOC.fm 4

Foreword

wc_si000081gb.fm 5

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components cont ain or em it chemical s known to the State of Califo rnia

to cause cancer and birth defects or other reproductive harm.

1. Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker model. For your own safety and protection

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publi cation. W acker Corpora tion reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2003 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

WARNING

Safety Information Portable Generator Repair

wc_si000081gb.fm 6

2. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the possibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

2.1 Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

DANGER

WARNING

CAUTION

Portable Generator Repair Safety Information

wc_si000081gb.fm 7

2.2 Operating Safety

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER

DISTRIBUTION SYSTEM CAN CAUSE SERIOUS INJURY OR

DEATH TO UTILITY WORKERS!

Improper connection of generator to a building's electrical system can

allow electrical current from the gene rato r to backfeed in to utility lines.

This may result in electrocution of utility workers, fire, or explosion.

Connections to a building's electrical system must be made by a

qualified electrician and comply with all applicable laws and electrical

codes.

If connected to a building's electrical system the generator must meet

the power, voltage, and frequency requirements of the equipment in

the building. Differences in power, voltage, and frequency

requirements may exist and improper connection may lead to

equipment damage, fire, and personal injury or death.

Familiarity and proper training are required for the safe operation of

equipment! Equipm ent ope rated imprope rly or by untra i ned per sonnel

can be dangerous! Read the operating instructions contained in both

this manual and the engine manual and familiarize yourself with the

location and proper use of all controls. Inexperienced ope rators should

receive instruction from someone familiar with the equipment before

being allowed to operate the machine.

2.2.1 NEVER operate generator when open containers of fuel, paint, or

other flammable liquids are near.

2.2.2 NEVER operate g enerator, or t ools atta ched to the g enerator , with wet

hands.

2.2.3 NEVER use worn electrical cords. Severe electrical shock and

equipment damage may result.

2.2.4 NEVER run electrical cords under the generator, or over vibrating or

hot parts.

2.2.5 NEVER enclose or cover generator when in use or when hot.

2.2.6 NEVER overload generator. The total amperage of the tools and

equipment attached to the generator must not exceed the load rating

of the generator.

2.2.7 NEVER operate machine in snow, rain, or standing water.

2.2.8 NEVER allow untraine d personnel to ope rate or servi ce the genera tor.

The generator set should be set up by a trained electrician.

2.2.9 ALWAYS store equipment properly when it is not being used.

Equipment shoul d be stored i n a clean , dry l ocation out o f the rea ch of

children.

2.2.10 ALWAYS be sure machine is on a firm, level surface and will not tip,

roll, slide, or fall while operating.

DANGER

WARNING

Safety Information Portable Generator Repair

wc_si000081gb.fm 8

2.2.11 ALWAYS transport generator in an upright position.

2.2.12 ALWAYS keep machine at least one meter (three feet) away from

structures, buildings and other equipment during use.

2.2.13 ALWAYS keep the ar ea i mmedi a tely sur roun ding the generator cl e an,

neat and free of debris. Make sure that the area overhead is clear of

debris that could fall onto or into the generator, or exhaust

compartment.

2.2.14 ALWAYS remove all tools, cor ds, and othe r loose ite ms from generat or

before starting it.

2.2.15 ALWAYS make certain machine is well-grounded and securely

fastened to a good earthen ground per national and local regulations.

2.3 Op erator Safety while using Internal Combustion Engines

Internal combustion e ngines p resen t special ha zards d uring o pera ti on

and fueling! Read and follow warning instructions in engine owner's

manual and safety guidelines below. Failure to follow warnings and

safety guidelines could result in severe injury or death.

2.3.1 DO NOT run machine indoors or in an enclosed area such as a deep

trench unless adequate ventilation, through such items as exhaust

fans or hoses, is provided. Exhaust gas from the engine contains

poisonous carbon monoxide gas; exposure to carbon monoxide can

cause loss of consciousness and may lead to death.

2.3.2 DO NOT smoke while operating machine.

2.3.3 DO NOT smoke when refueling engine.

2.3.4 DO NOT refuel hot or running engine.

2.3.5 DO NOT refuel engine near open flame.

2.3.6 DO NOT spill fuel when refueling engine.

2.3.7 DO NOT run engine near open flames.

2.3.8 DO NOT start engine if fuel has spilled or an o dor of fuel is present.

Move generator away from the spill and wipe generator dry before

starting.

2.3.9 ALWAYS refill fue l tank in well-ventilated area.

2.3.10 ALWAYS replace fuel tank cap after refueling.

2.3.11 ALWAYS check fuel lines and fuel tank for leaks and cracks before

starting engine. Do not run machine if fuel leaks are present or fuel

lines are loose.

DANGER

Portable Generator Repair Safety Information

wc_si000081gb.fm 9

2.4 Service Safe ty

Poorly maintained equipment can become a safety hazard! In order

for the equipment to operate safely and properly over a long period of

time, periodic maintenance and occasional repairs are necessary. If

the generator is experiencing problems or is being serviced, attach a

"DO NOT ST ART" sign to the con trol panel to no tify other p eople of i ts

condition.

2.4.1 DO NOT use gas oli ne o r o ther types of fuels or flammable solvent s to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

2.4.2 DO NOT attempt to clean or service machine while it is running.

2.4.3 DO NOT modify the equ ipment with out express written approval of the

manufacturer.

2.4.4 DO NOT allow water to accumulate around the base of the machine.

If water is present, move the machine and allow it to dry before

servicing.

2.4.5 DO NOT service machine if clothing or skin is wet.

2.4.6 DO NOT allow untrained personnel to service this equipment. Only

trained electri cal technicians should be allo wed to service the e lectrical

components of this equipment.

2.4.7 ALWAYS keep machine clean and labels legible. Replace all missing

and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

2.4.8 ALWAYS replace safety devices and guards after repairs and

maintenance.

2.4.9 ALWAYS let engine cool before transporting or servicing.

2.4.10 ALWAYS keep hands, feet, and l oose clothing away fro m moving parts

on generator and engine.

2.4.11 ALWAYS turn engine off before servicing generator. If the engine has

electric start, disconnect negative terminal on battery

2.4.12 ALWAYS keep fuel lines in good condition and properly connected.

Leaking fuel and fumes are extremely explosive.

WARNING

Safety Information Portable Generator Repair

wc_si000081gb.fm 10

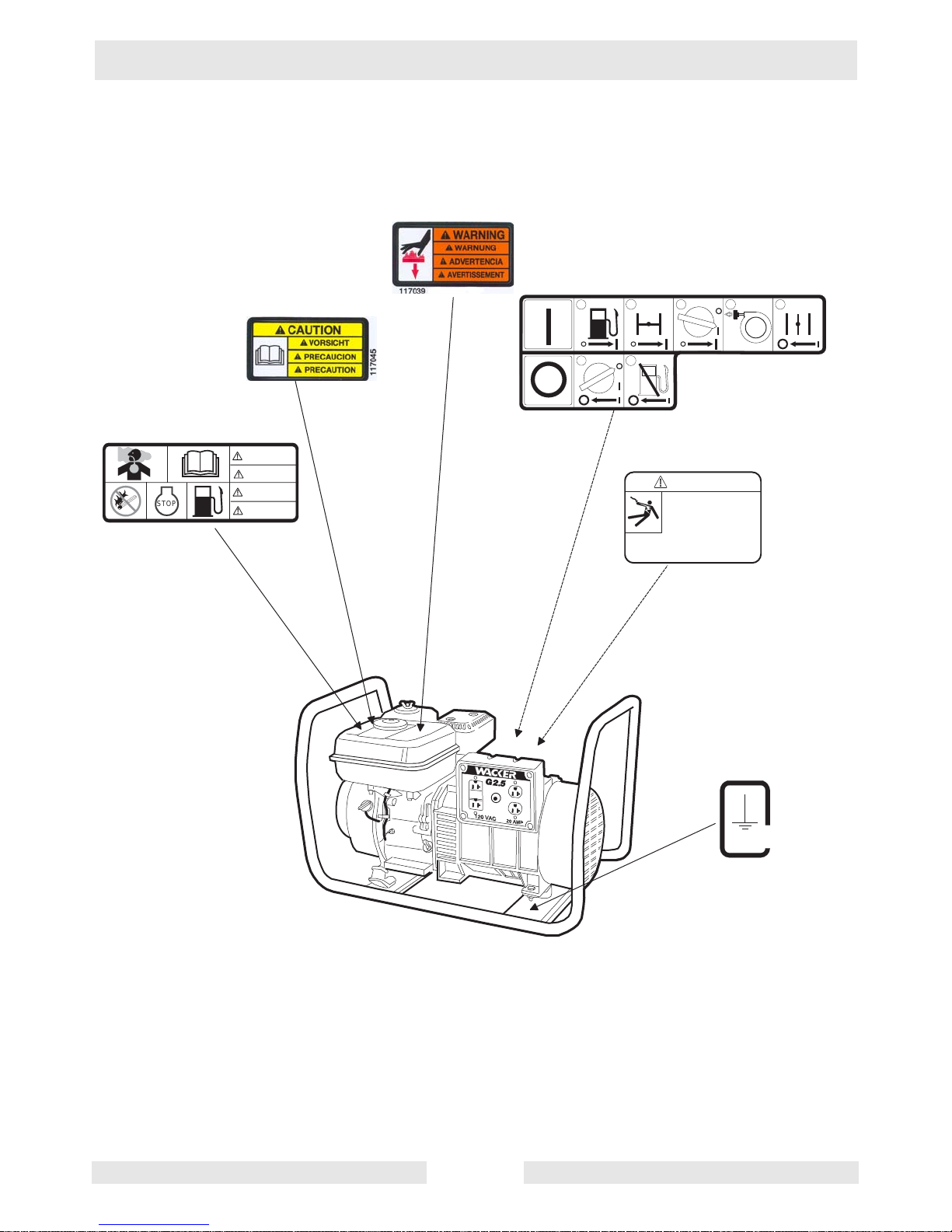

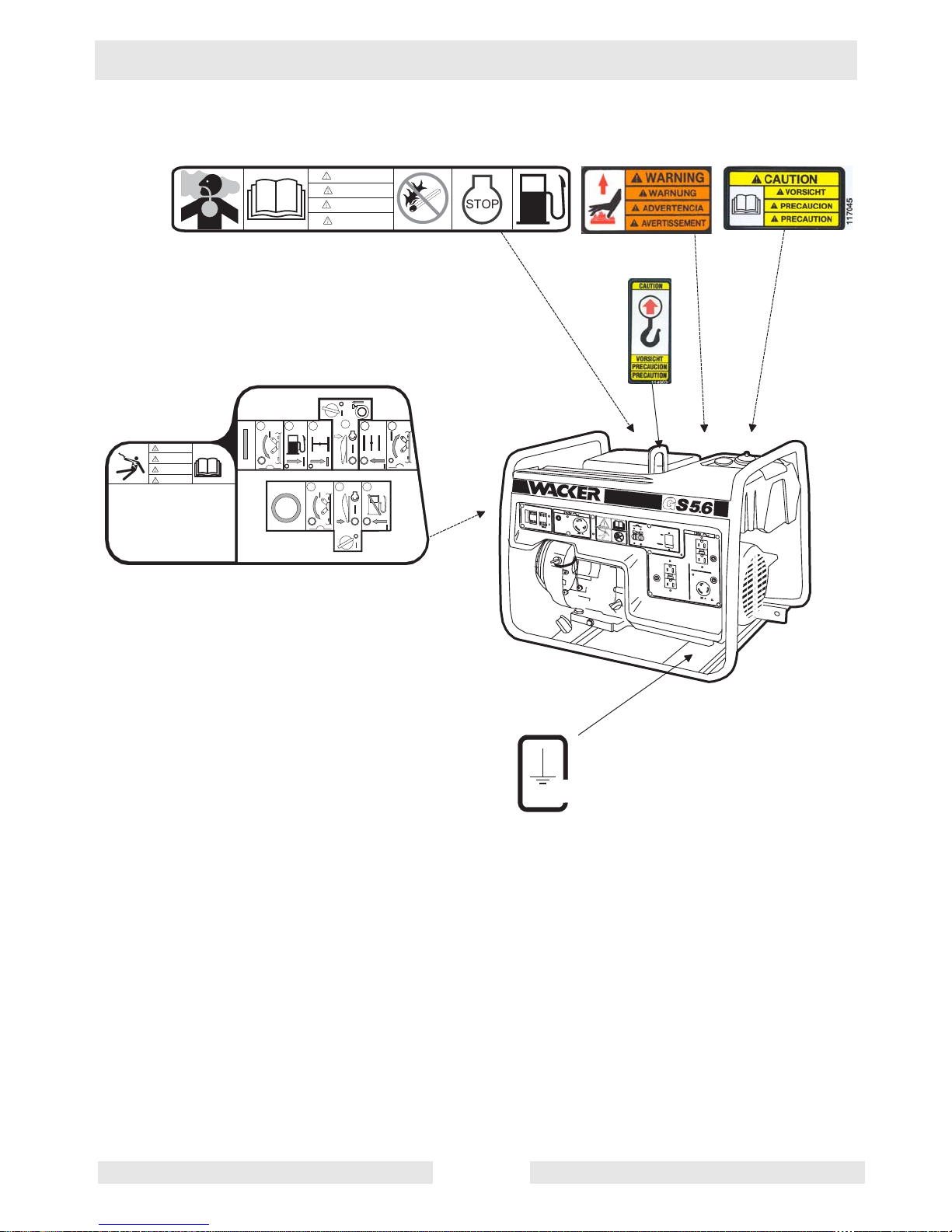

2.5 Label Locations

G 2.5A

w cgr 0 0 0 5 5 2

GND

88897

1

2

3

4

5

1

2

I M P R O P E R C O N N E C T IO N O F G E N E R A T O R

T O A B U I L D IN G ' S E L E C T R IC A L

S Y S T E M C A N A L L O W E L E C T R IC A L

C U R R E N T F R O M T H E G E N E R A T O R T O

B A C K F E E D I N T O U T I L I T Y L I N E S .

T H IS M A Y R E S U L T I N E L E C T R O C U T I O N

O F U T I L I T Y W O R K E R S , F I R E O R

E X P L O S I O N . C O N N E C T I O N S T O A

B U I L D I N G ' S E L E C T R I C A L S Y S T E M M U S T B E M A D E

B Y A Q U A L I F I E D E L E C T R I C I A N A N D C O M P L Y W I T H

A L L A P P L I C A B L E L A W S A N D E L E C T R I C A L C O D E S .

D A N G E R

STOP

DANGER

GEFAHR

PELIGRO

DANGER

Portable Generator Repair Safety Information

wc_si000081gb.fm 11

G 3.7A, G 5.6A, and GS 5.6A

w c _ g r 0 0 0 5 4

3

GND

88897

IMPROPER CONNECTION OF GENERATOR TO A

BUILDING'S ELECTRICAL SYSTEM CAN ALLOW

ELECTRICAL CURRENT FROM THE GENERATOR

TO BACKFEED INTO UTILITY LINES. THIS

MAY RESULT IN ELECTROCUTION OF UTILITY

WORKERS, FIRE OR EXPLOSION. CONNECTIONS

TO A BUILDING'S ELECTRICAL SYSTEM MUST

BE MADE BY A QUALIFIED ELECTRICIAN AND

COMPLY WITH ALL APPLICABLE LAWS AND

ELECTRICAL CODES.

4

321

321

656

5

DANGER

GEFAHR

DANGER

PELIGRO

D A N G E R

G E F A H R

D A N G E R

P E L I G R O

S T O P

Safety Information Portable Generator Repair

wc_si000081gb.fm 12

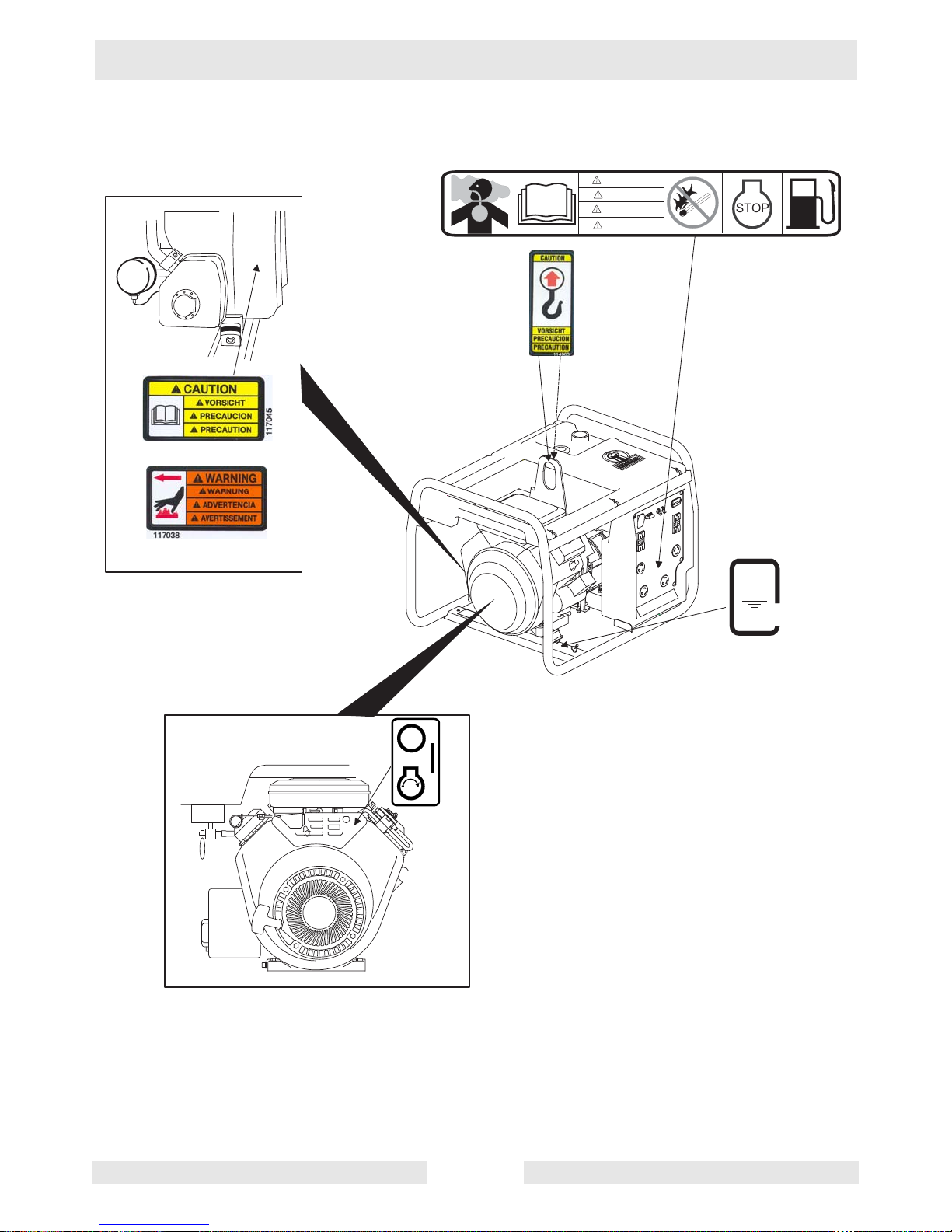

GS 8.5V and GS 9.7V

w c _ g r 0 0 0 5 5 8

GND

88897

D A N G E R

G E F A H R

D A N G E R

P E L I G R O

S T O P

Portable Generator Repair Safety Information

wc_si000081gb.fm 13

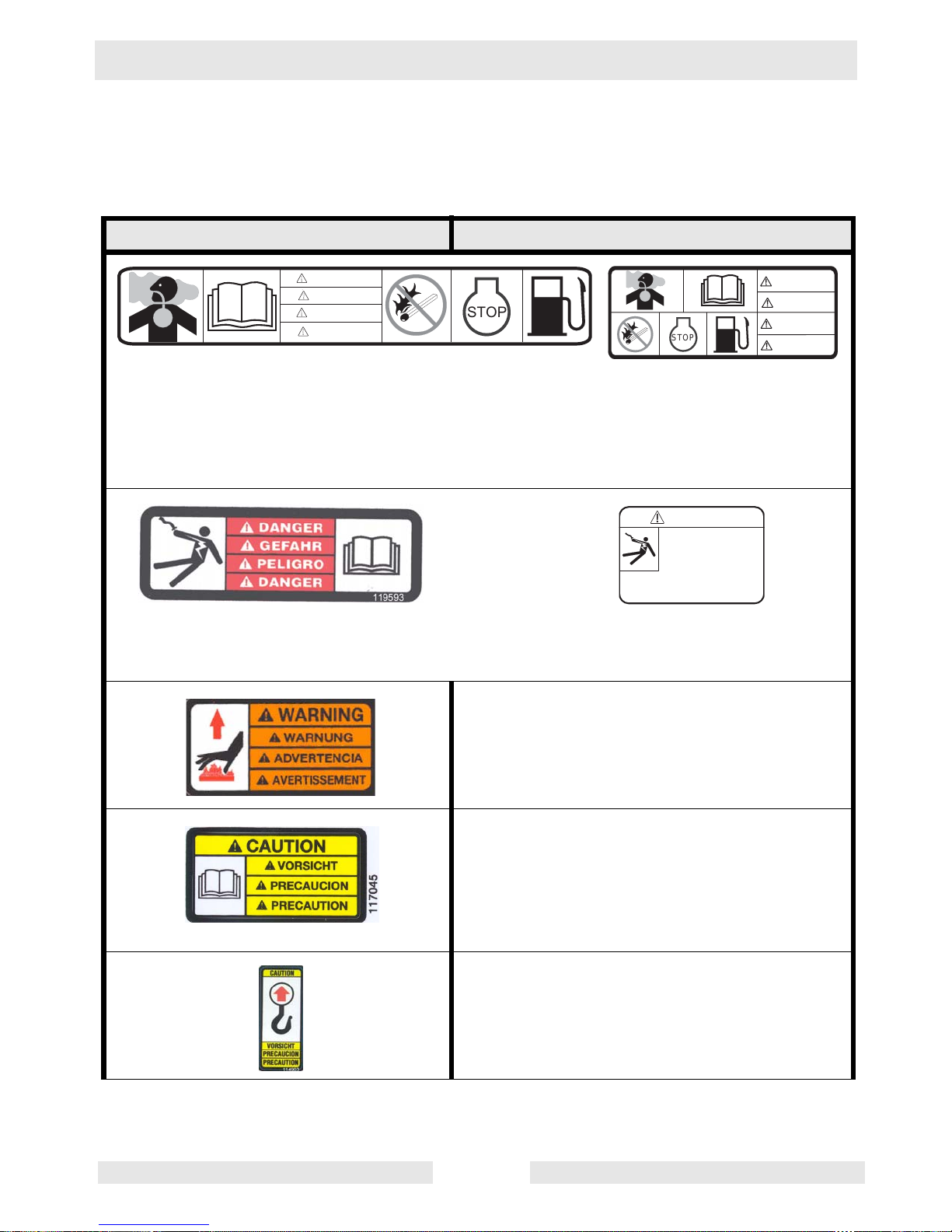

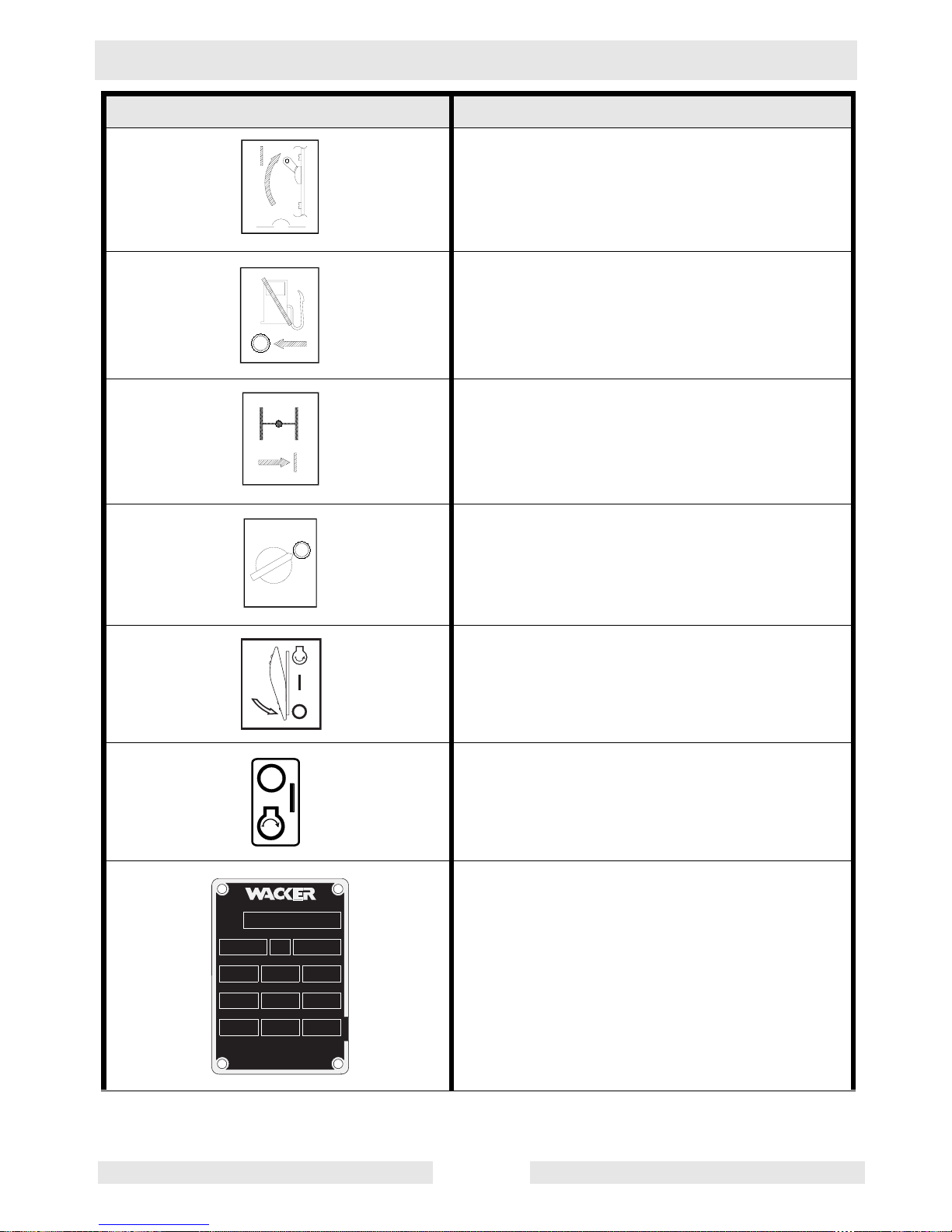

2.6 Safety and Operating Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

DANGER!

Engines emit carbon monoxide; operate only in well ventilated area. Read the operator's

manual.

No sparks, flames or burning objects near machine. Shut off engine before refueling.

DANGER!

Electric shock hazard. Read operator’s manual for instructions.

WARNING!

Hot surface.

CAUTION!

Read and understand the supplied operator's

manual before operating this machine. Failure

to do so increases the risk of injury to yourself

or others.

CAUTION!

Lifting point

D A N G E R

G E F A H R

D A N G E R

P E L I G R O

S T O P

STOP

DANGER

GEFAHR

PELIGRO

DANGER

I M P R O P E R C O N N E C T I O N O F G E N E R A T O R

T O A B U I L D I N G ' S E L E C T R I C A L

S Y S T E M C A N A L L O W E L E C T R I C A L

C U R R E N T F R O M T H E G E N E R A T O R T O

B A C K F E E D I N T O U T I L I T Y L I N E S .

T H I S M A Y R E S U L T I N E L E C T R O C U T I O N

O F U T I L I T Y W O R K E R S , F I R E O R

E X P L O S I O N . C O N N E C T I O N S T O A

B U I L D I N G ' S E L E C T R I C A L S Y S T E M M U S T B E M A D E

B Y A Q U A L I F I E D E L E C T R I C I A N A N D C O M P L Y W I T H

A L L A P P L I C A B L E L A W S A N D E L E C T R I C A L C O D E S .

D A N G E R

Safety Information Portable Generator Repair

wc_si000081gb.fm 14

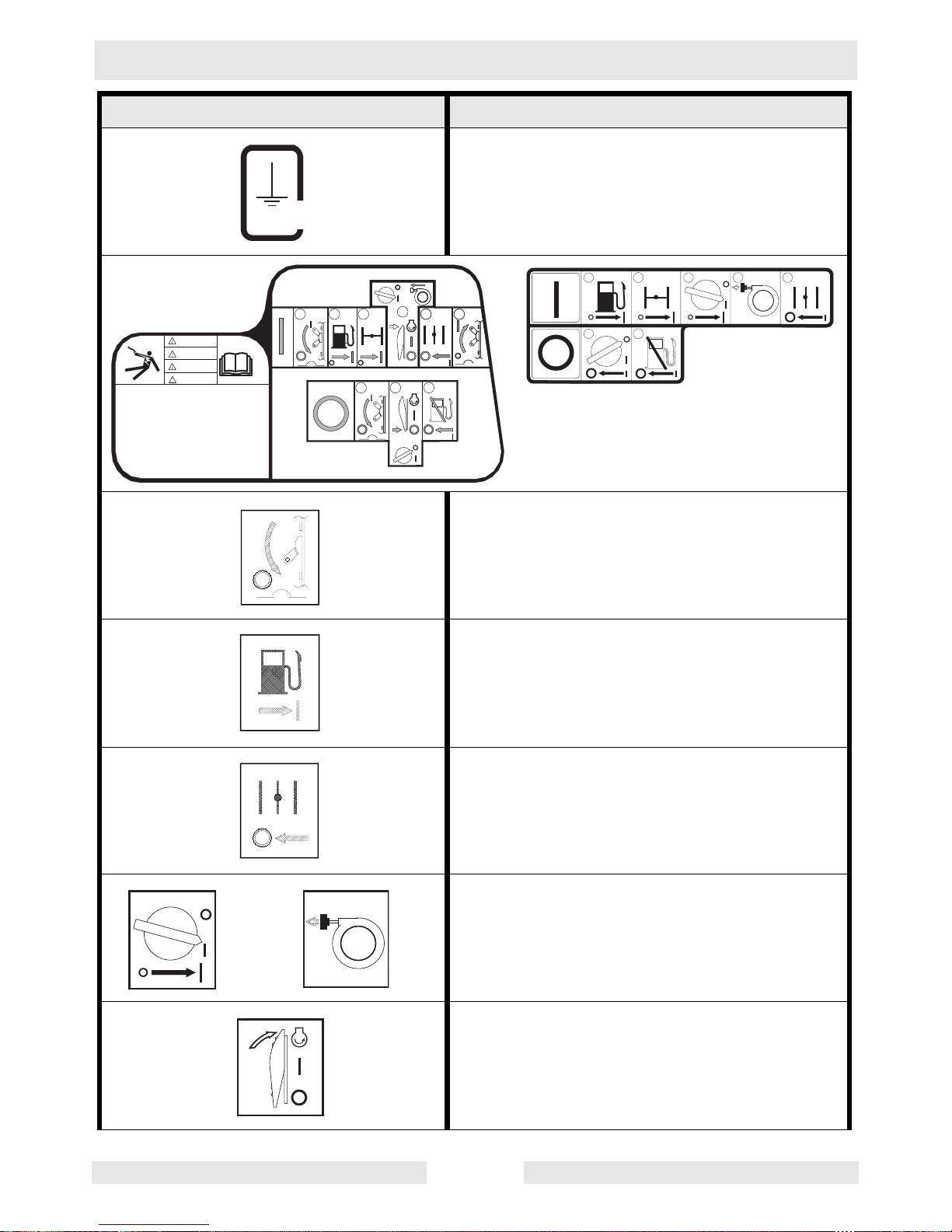

Electrical ground.

Open main circuit breaker.

Open fuel flow valve.

Open choke.

Push or turn engine switch to ON position.

Pull rewind starter.

Press engine crank switch to "CRANK" position.

Label Meaning

GND

88897

IMPROPER CONNECTION OF GENERATOR TO A

BUILDING'S ELECTRICAL SYSTEM CAN ALLOW

ELECTRICAL CURRENT FROM THE GENERATOR

TO BACKFEED INTO UTILITY LINES. THIS

MAY RESULT IN ELECTROCUTION OF UTILITY

WORKERS, FIRE OR EXPLOSION. CONNECTIONS

TO A BUILDING'S ELECTRICAL SYSTEM MUST

BE MADE BY A QUALIFIED ELECTRICIAN AND

COMPLY WITH ALL APPLICABLE LAWS AND

ELECTRICAL CODES.

4

321

321

656

5

DANGER

GEFAHR

DANGER

PELIGRO

1

2

3

4

5

1

2

Portable Generator Repair Safety Information

wc_si000081gb.fm 15

Close main circuit breaker.

Close fuel flow valve.

Close choke.

Push or turn engine switch to OFF position.

Press engine crank switch to "OFF" position.

Key switch:

off

on

start

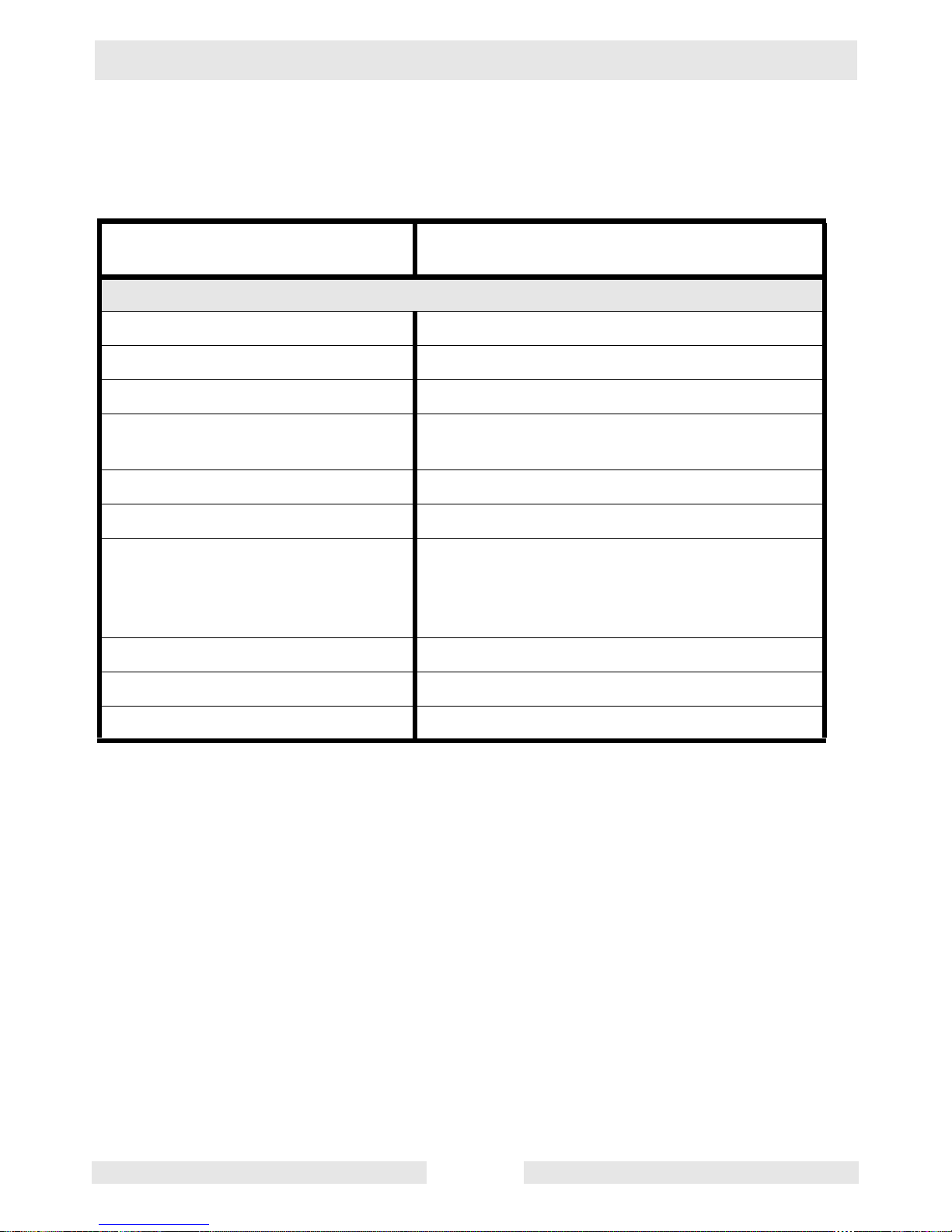

A nameplate listing the Model Number, Item

Number, Revision, and Serial Number is

attached to each unit. Please record the information found on this plate so it will be available should the nameplate become lost or

damaged. When ordering parts or requesting

service information, you will always be asked

to specify the model, item number, revision

number, and serial number of the unit.

Label Meaning

M E N O M O N E E F A L L S , W I U S A 5 3 0 5 1

M o d e l

S e r i a l N o .

k W m a x

V

I t e m N o .

k g

A

l b s

R e v .

P . F .

h z

M A D E I N U S A

1 1 0 9 9 2

Safety Information Portable Generator Repair

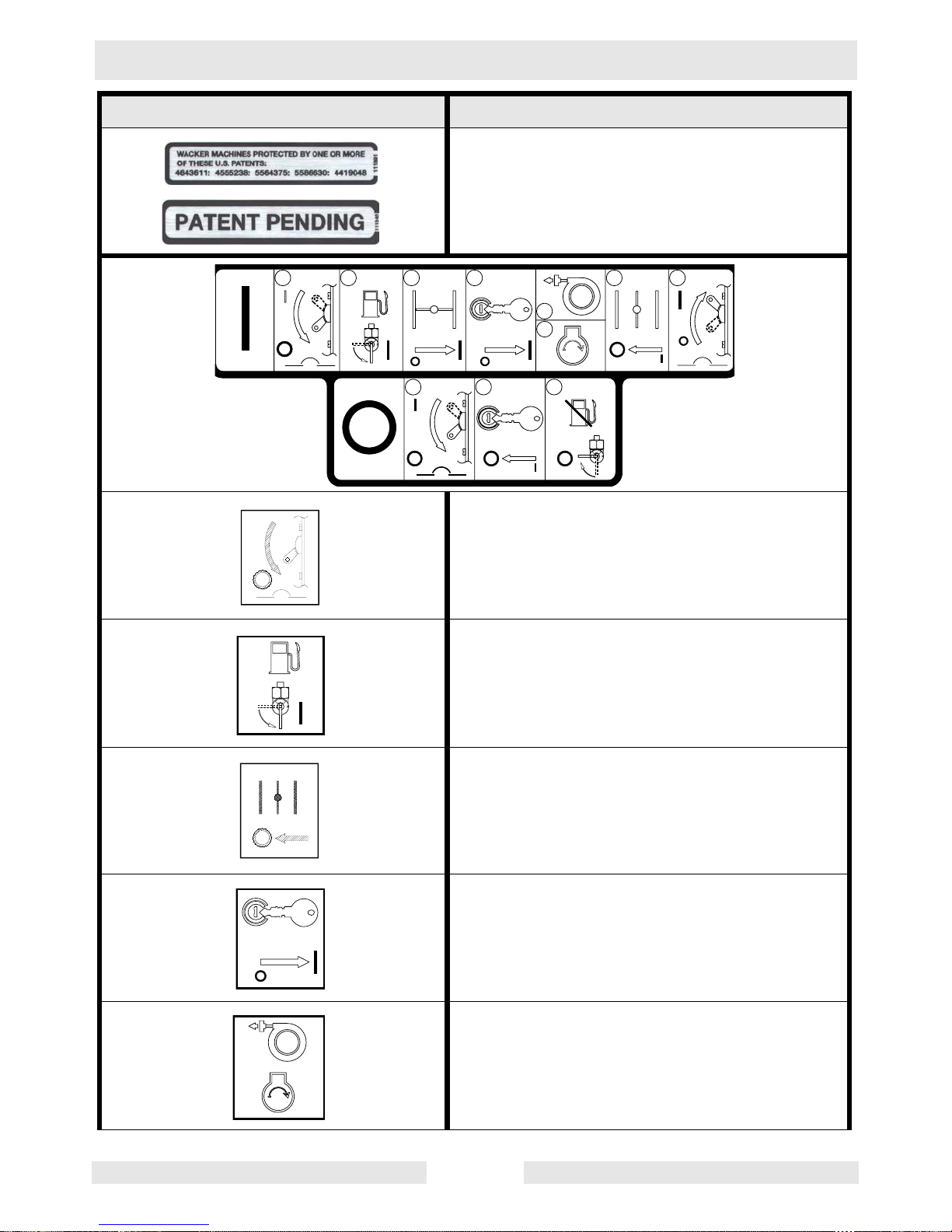

wc_si000081gb.fm 16

This machine may be covered by one or more

patents.

Open main circuit breaker.

Open fuel flow valve.

Open choke.

Turn engine key switch to “ON” position.

Pull rewind starter or turn engine k e y s wi tch to

crank starter.

Label Meaning

1 2

3

4

5B

5A

6

7

1

2

3

Portable Generator Repair Safety Information

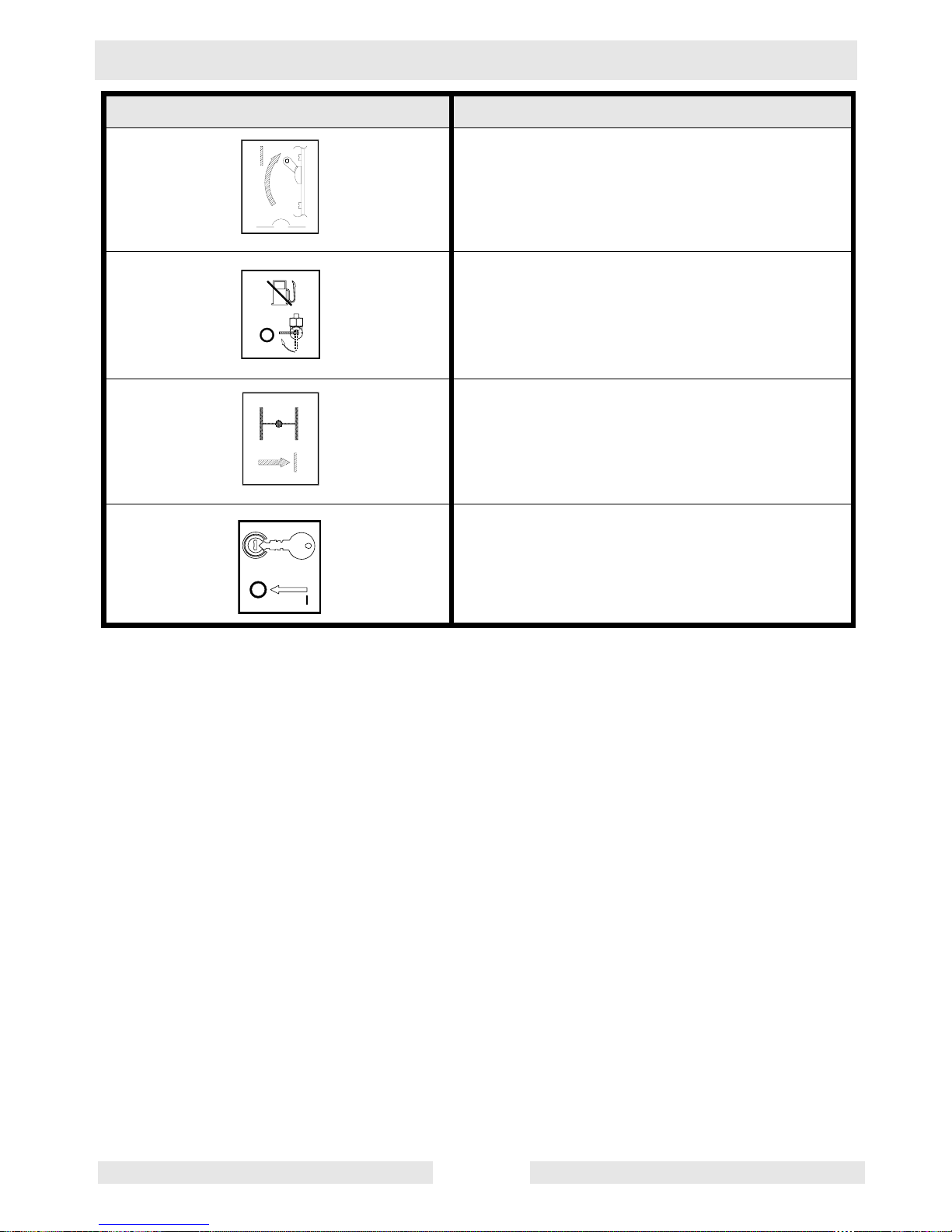

wc_si000081gb.fm 17

Close main circuit breaker.

Close fuel flow valve.

Close choke.

Turn engine key switch to “OFF” position.

Label Meaning

Technical Data Portable Generator Repair

wc_td000082gb.fm 18

3. Technical Data

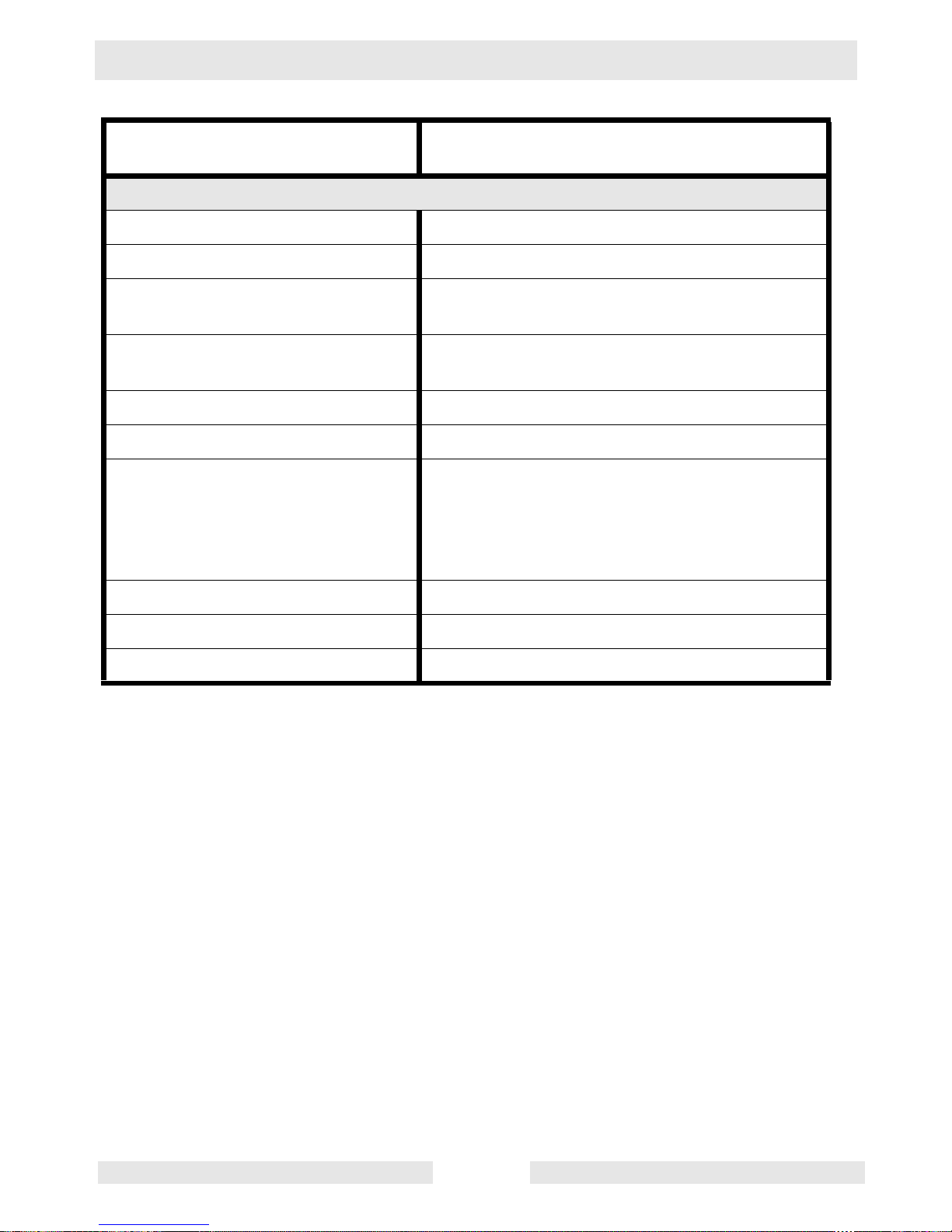

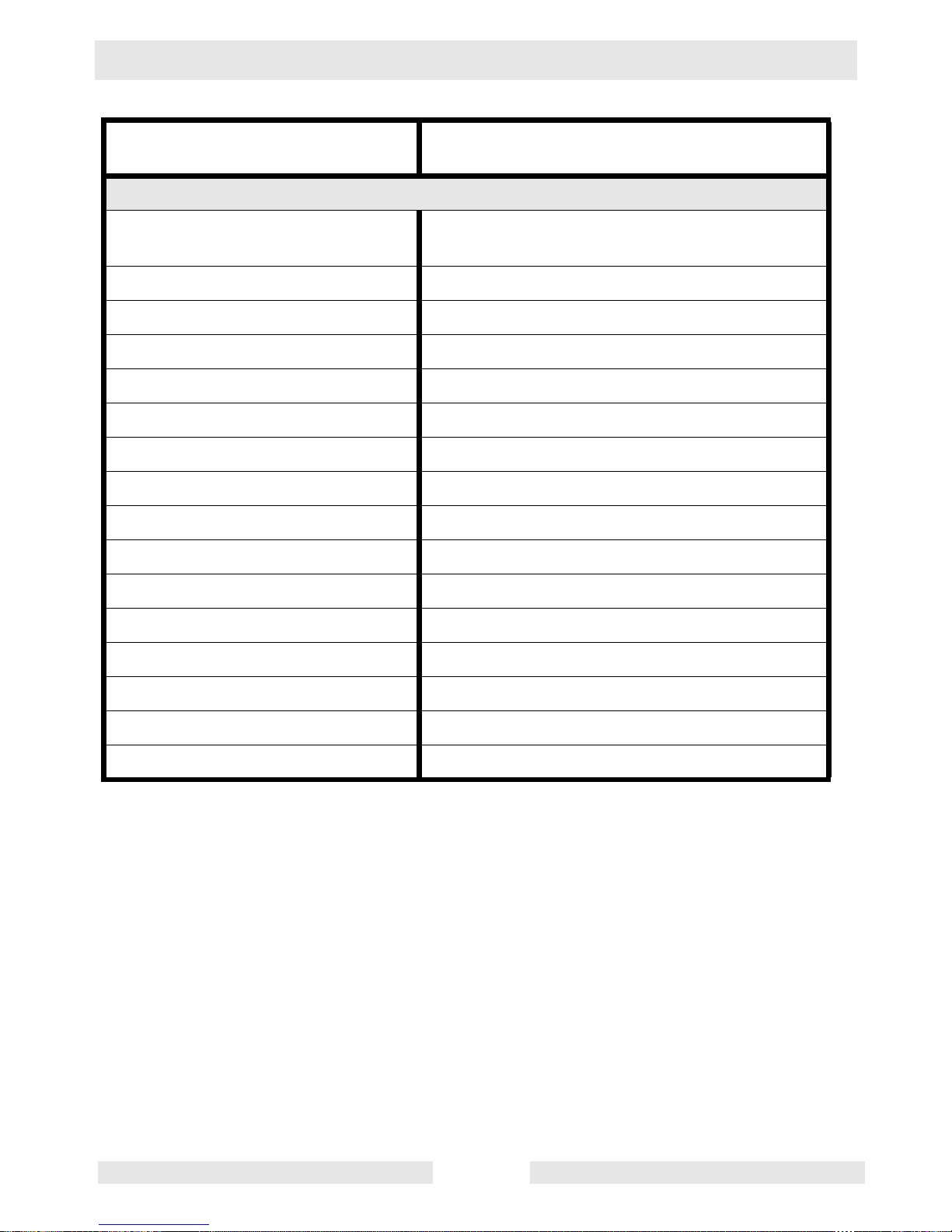

3.1 Generator

Item No. G 2.5A

0007188

Generator

Maximum Output

W

2500

Continuous Output

W

2250

Type Single voltage, single phase, brushless system

AC Voltages Available

volts

phase

120

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

120V GFI duplex

120V duplex (also protected by GFI)

amp

amp

20

20

Main Circuit Breaker

amp

20

L x W x H

mm (in.)

685 x 445 x 435 (27 x 17.5 x 17)

Weight (dry)

Kg (lbs.)

43 (94)

Portable Generator Repair Technical Data

wc_td000082gb.fm 19

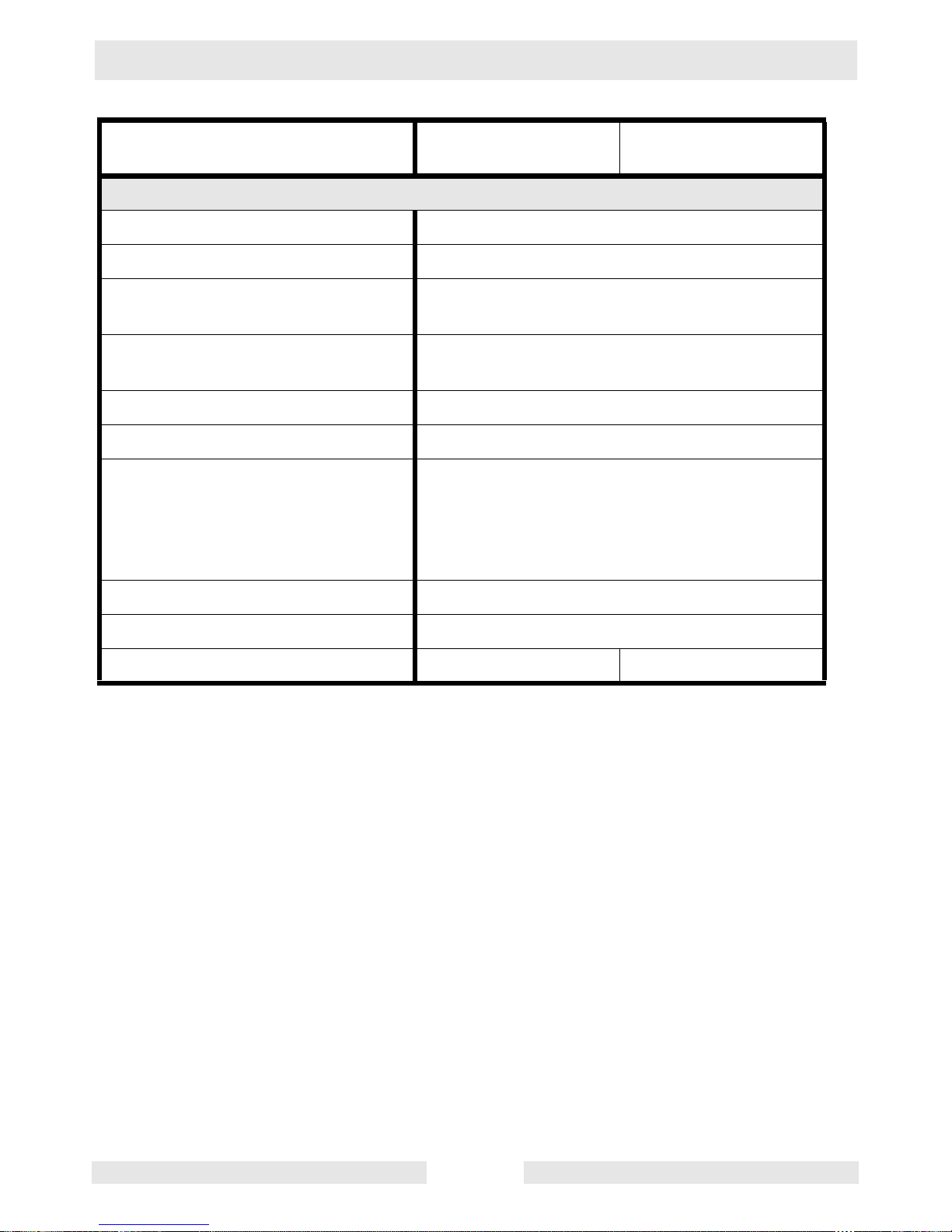

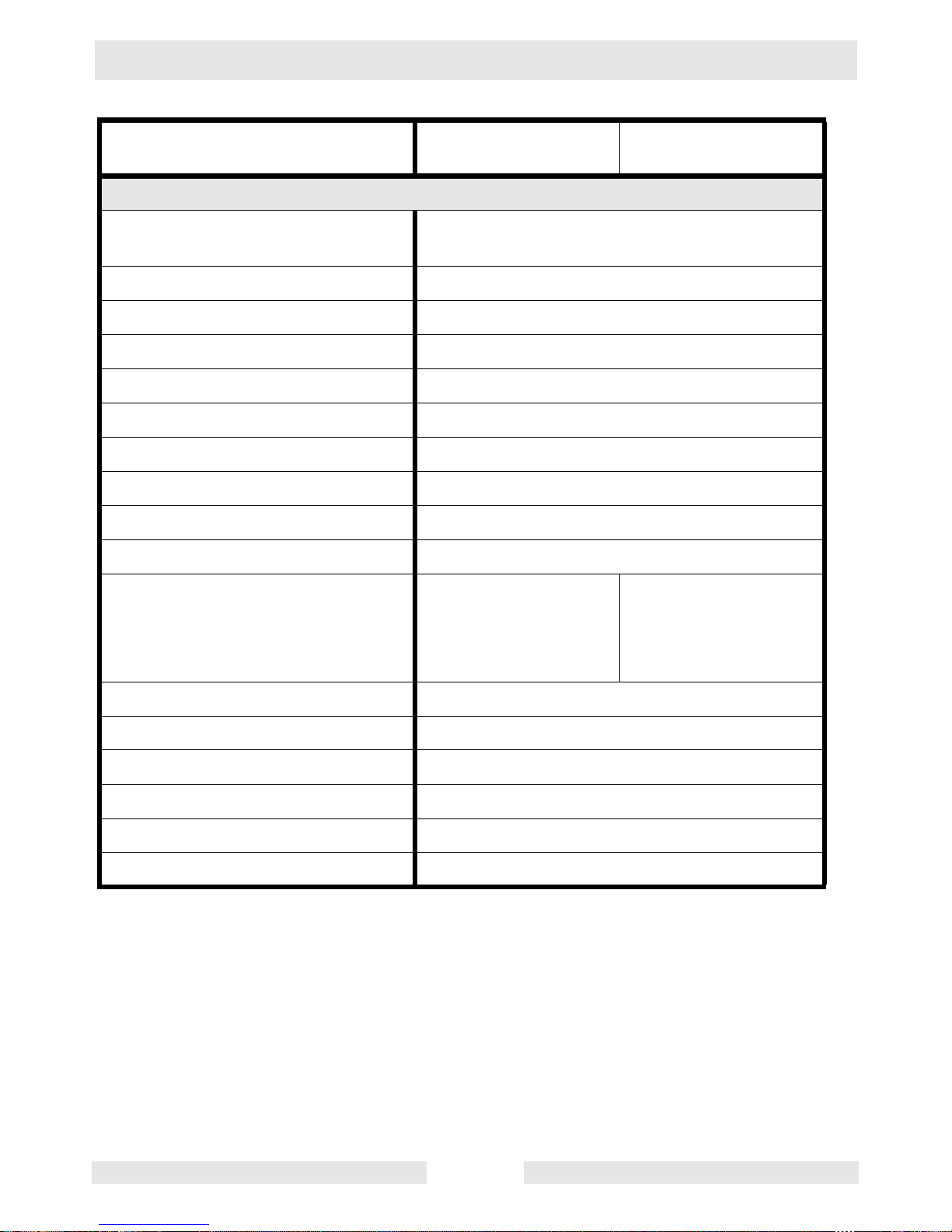

Item No. G 3.7A

0007189

Generator

Maximum Output

W

3700

Continuous Output

W

3320

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages Available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

120V GFI duplex

120V GFI duplex

120V twist lock

240V twist lock

amp

amp

amp

amp

20

20

30

20

Main Circuit Breaker

amp

32 (2-pole, 16 amp each pole)

L x W x H

mm (in.)

685 x 585 x 530 (27 x 23 x 21)

Weight (dry)

Kg (lbs.)

68 (150)

Technical Data Portable Generator Repair

wc_td000082gb.fm 20

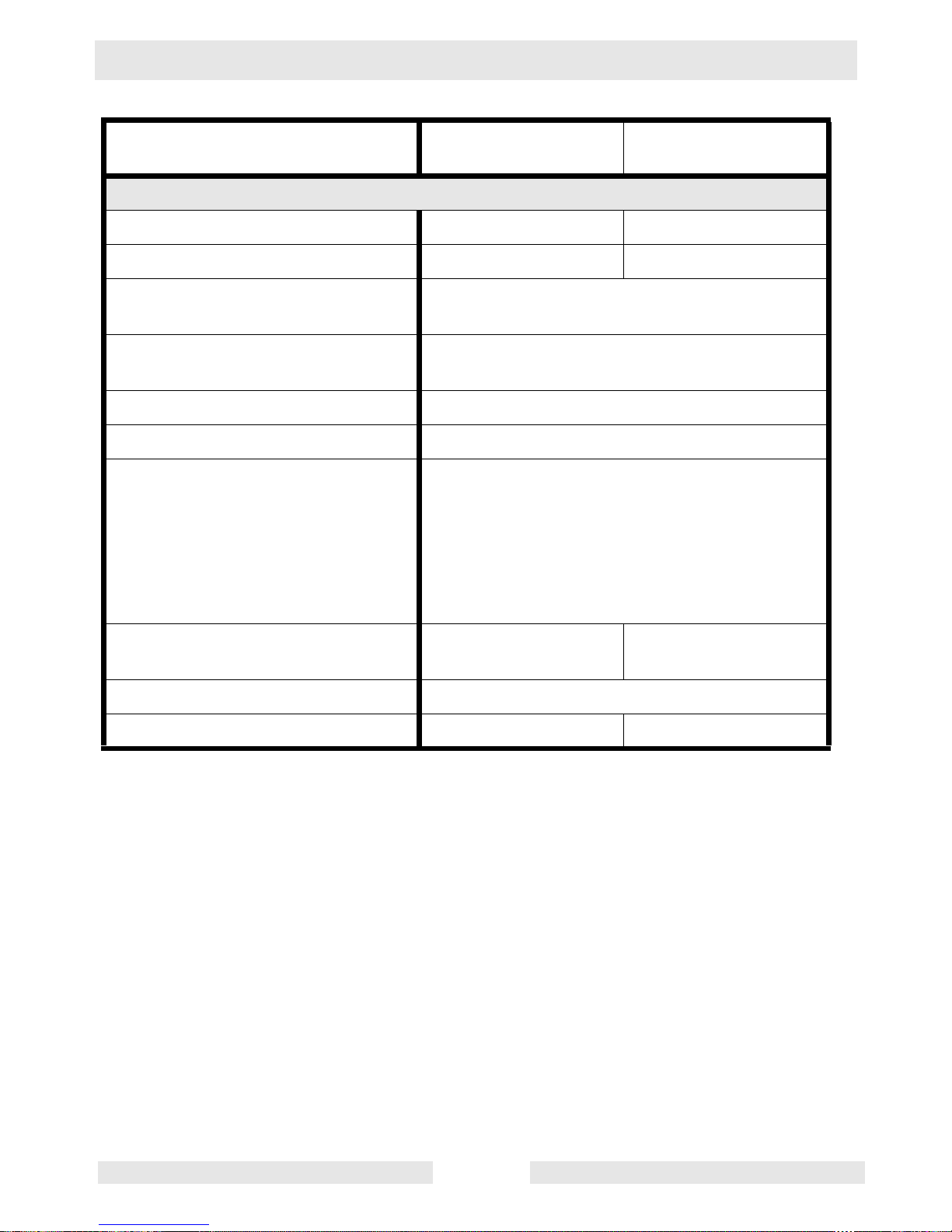

Item No. G 5.6A

0007190

GS 5.6A

0007191

Generator

Maximum Output

W

5600

Continuous Output

W

5350

Type Dual voltage, single phase,

Auto voltage regulator system

AC Voltages Available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

120V GFI duplex

120V GFI duplex

120V twist lock

240V twist lock

amp

amp

amp

amp

20

20

30

20

Main Circuit Breaker

amp

48 (2-pole, 24 amp each pole)

L x W x H

mm (in.)

685 x 585 x 530 (27 x 23 x 21)

Weight (dry)

Kg (lbs.)

76 (168) 79 (175)

Portable Generator Repair Technical Data

wc_td000082gb.fm 21

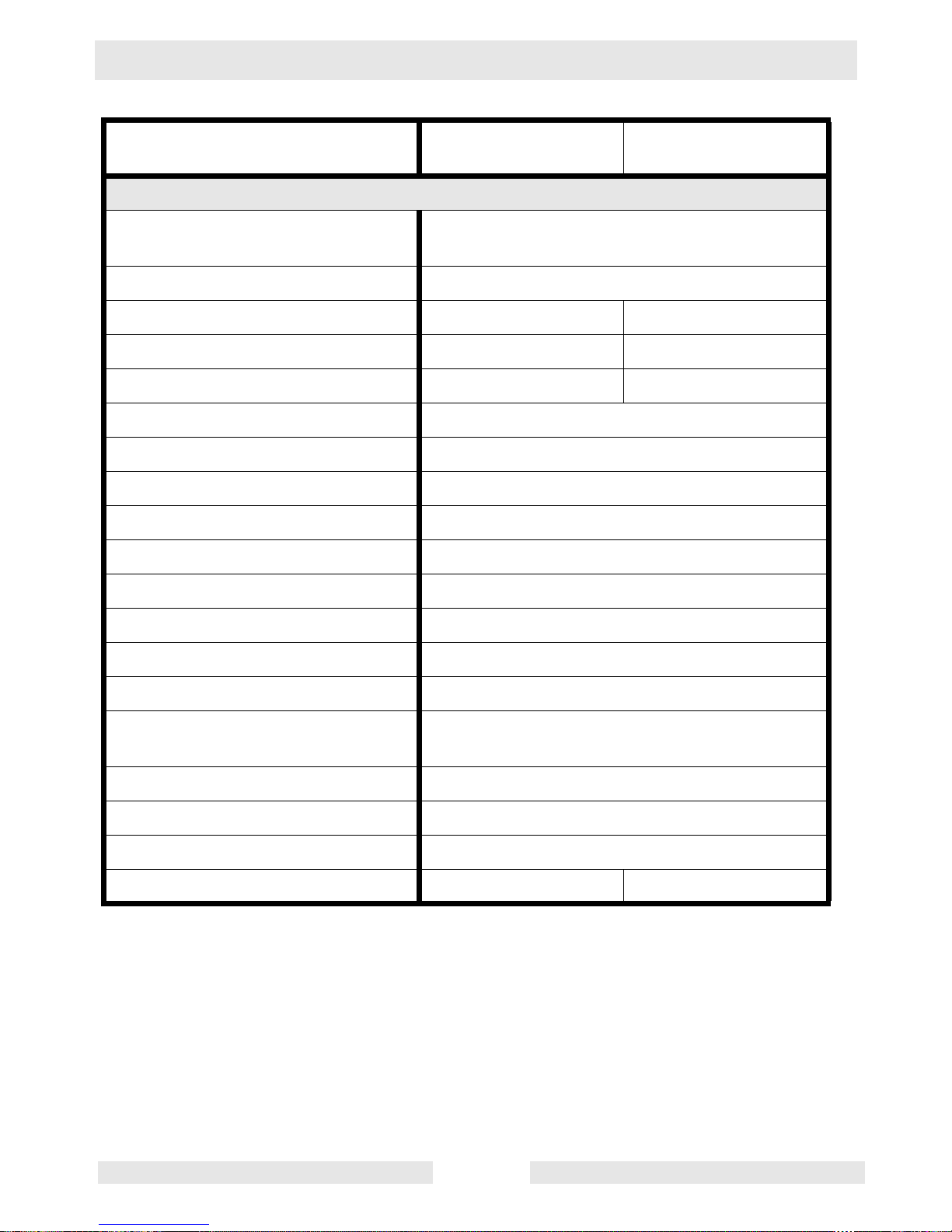

Item No. GS 8.5V

0007661

GS 9.7V

0007662

Generator

Maximum Output

kW / kVA

8.5 / 8.5 9.7 / 9.7

Continuous Output

W

8.2 9.3

Type Dual voltage, single phase,

brush-type system

AC Voltages Available

volts

phase

120 / 240

1ø

Frequency

Hz

60

Power Factor 1.0

AC receptacles:

120V GFI duplex

120V GFI duplex

120V twist lock

120V twist lock

240V twist lock

120/240V twist lock

amp

amp

amp

amp

amp

amp

20

20

20

30

20

30

Continuous Current

at 120V

amp

68.3 77.5

L x W x H

mm (in.)

800 x 635 x 603 (31.5 x 25 x 23.75)

Weight (dry)

Kg (lbs.)

97 (214) 99 (218)

Technical Data Portable Generator Repair

wc_td000082gb.fm 22

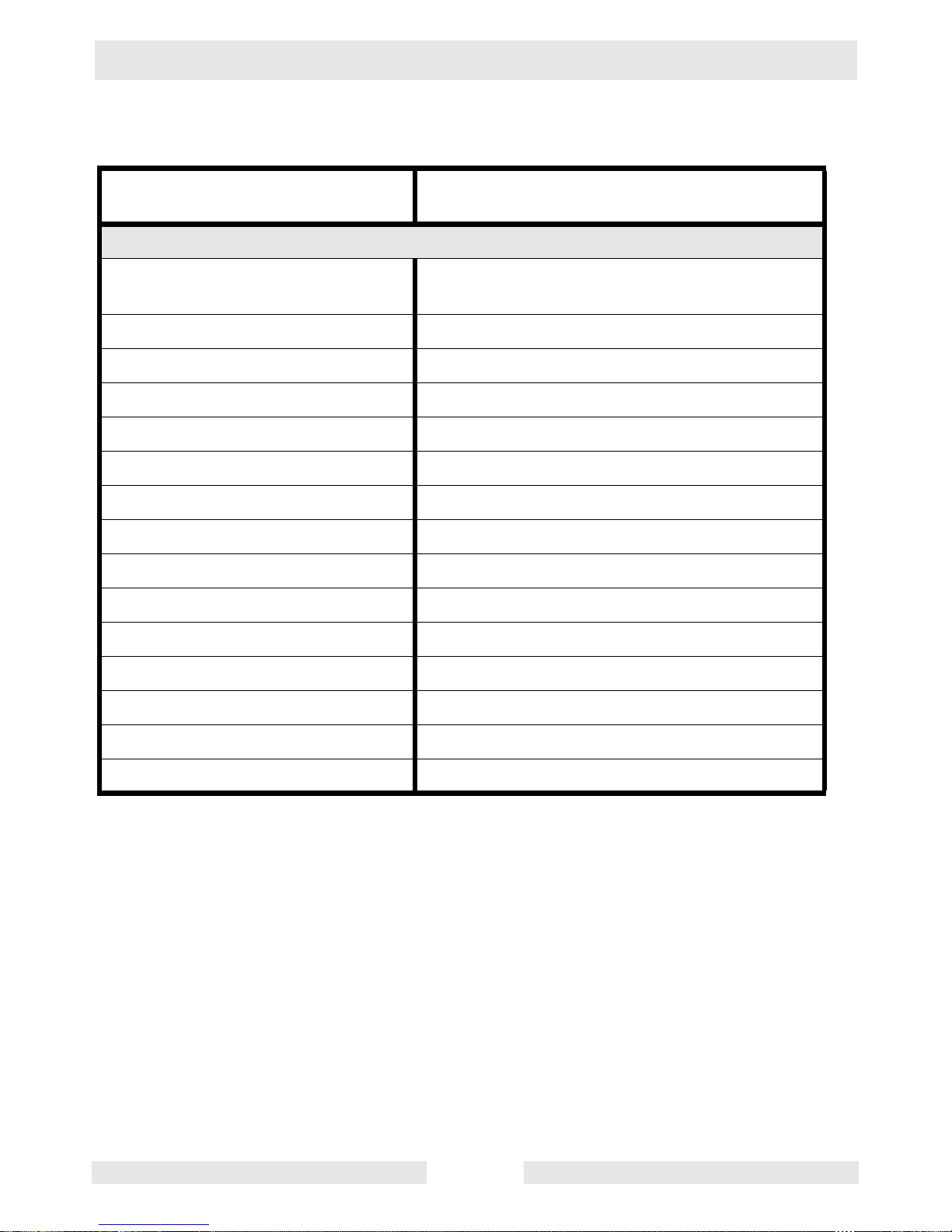

3.2 Engine

Item No. G 2.5A

0007188

Engine

Engine Type Single cylinder, 4-cycle,

air-cooled, gasoline engine

Engine Make Honda

Engine Model GX 160 K1VX

Rated Power

kW (Hp)

4.1 (5.5)

Spark Plug BPR6ES / W20EPR-U

Electrode Gap

mm (in.)

0.7 - 0.8 (0.028 - 0.031)

Engine Speed - full load

rpm

3600 ± 100

Engine Speed - no load

rpm

3700 ± 100

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD or SC

Engine Oil Capacity

l (oz.)

0.6 (21)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (qt.)

3.7 (3.9)

Fuel Consumption

l (qts.)/h r.

1.7 (1.8)

Running Time

hrs.

2.1

Portable Generator Repair Technical Data

wc_td000082gb.fm 23

Item No. G 3.7A

0007189

Engine

Engine Type Single cylinder, 4-cycle,

air-cooled, gasoline engine

Engine Make Honda

Engine Model GX 240 K1

Rated Power

kW (Hp)

5.9 (8)

Spark Plug BPR6ES / W20EPR-U

Electrode Gap

mm (in.)

0.7 - 0.8 (0.028 - 0.031)

Engine Speed - full load

rpm

3600 ± 100

Engine Speed - no load

rpm

3700 ± 100

Auto Idle Speed

rpm

2200 ± 50

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD or SC

Engine Oil Capacity

l (qts.)

1.1 (1.2)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

19.5 (5.2)

Fuel Consumption

l (qts.)/h r.

2.6 (2.8)

Running Time

hrs.

7.4

Technical Data Portable Generator Repair

wc_td000082gb.fm 24

Item No. G 5.6A

0007190

GS 5.6A

0007191

Engine

Engine Type Single cylinder, 4-cycle,

air-cooled, gasoline engine

Engine Make Honda

Engine Model GX 340 K1

Rated Power

kW (Hp)

8.2 (11)

Spark Plug BPR6ES / W20EPR-U

Electrode Gap

mm (in.)

0.7 - 0.8 (0.028 - 0.031)

Engine Speed - full load

rpm

3600 ± 100

Engine Speed - no load

rpm

3700 ± 100

Auto Idle Speed

rpm

2200 ± 50

Air Cleaner

type

Dry type with oil-wetted foam pre-cleaner

Battery

type

V/capacity

Size (in.)

N/A Y50-N18L-A or

C50-N18L-A

12V - 20 Amp-hour

8-1/8 x 3-9/16 x 6-7/

16

Engine Lubrication

oil grade

SAE 10W30 service class SF, SE, SD or SC

Engine Oil Capacity

l (qts.)

1.1 (1.2)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

19.5 (5.2)

Fuel Consumption

l (qts.)/h r.

3.6 (3.8)

Running Time

hrs.

5.4

Portable Generator Repair Technical Data

wc_td000082gb.fm 25

Item No. GS 8.5V

0007661

GS 9.7V

0007662

Engine

Engine Type 2 cylinder, 4-cycle,

air-cooled, gasoline engine

Engine Make Briggs and Stratton

Engine Model Vanguard 303447 Vanguard 350447

Rated Power

kW (Hp)

11.9 (16) 13.4 (18)

Displacement

cm3 (in3)

480 (29.3) 570 (34.75)

Spark Plug Champion RC12YC

Electrode Gap

mm (in.)

0.76 (0.030)

Starter

type / V

Electric / 12

Alternator

amp

16

Engine Speed - full load

rpm

3600

Auto Idle Speed

rpm

2200

Valve Clearance (cold)

mm (in.)

0.10–0.16 (0.004–0.006)

Air Cleaner

type

Dual element

Battery

V/size/CCA

12 / 22NF / 230

Engine Lubrication

oil grade

ser vice class

SAE 10W30

SG, SF, or SE

Engine Oil Capacity

l (qts.)

1.6 (1.7)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (gal.)

28 (7.4)

Fuel Consumption

l (gal.)/hr.

5.03 (1.33) 6.21 (1.64)

Loading...

Loading...