Page 1

www.wackergroup.com

0152792en 002

0902

Generator

G 2.5A

OPERATOR'S MANUAL

0152792EN

Page 2

DANGER

CARBON MONOXIDE

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot see or

smell. If you can smell the generator exhaust, you are breathing CO. But even if you cannot

smell the exhaust, you could be breathing CO.

• NEVER use a generator inside homes, garages, crawlspaces, or other partly enclosed

areas. Deadly levels of carbon monoxide can build up in these areas. Using a fan or

opening windows and doors does NOT supply enough fresh air.

• ONLY use a generator outside and far away from windows, doors, and vents. These

openings can pull in generator exhaust.

Even when you use a generator correctly, CO may leak into the home. ALWAYS use a

battery-powered or battery-backup CO alarm in the home.

If you start to feel sick, dizzy, or weak after the generator has been running, move to fresh

air RIGHT AWAY. See a doctor. You could have carbon monoxide poison.

Page 3

Foreword

wc_tx000001gb.fm

Engine exhaust, some of its constituents, and certain vehicle

components contain o r emit chemicals known to the State of Califor nia

to cause cancer and birth defects or other reproductive harm.

1. Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker m odel. For you r own safet y and prote ction

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights are reserved.

Copyright 2002 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission fr om Wacker Co rp or at io n.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

WARNING

Page 4

G2.5A

Nameplate / Plaque signalétique

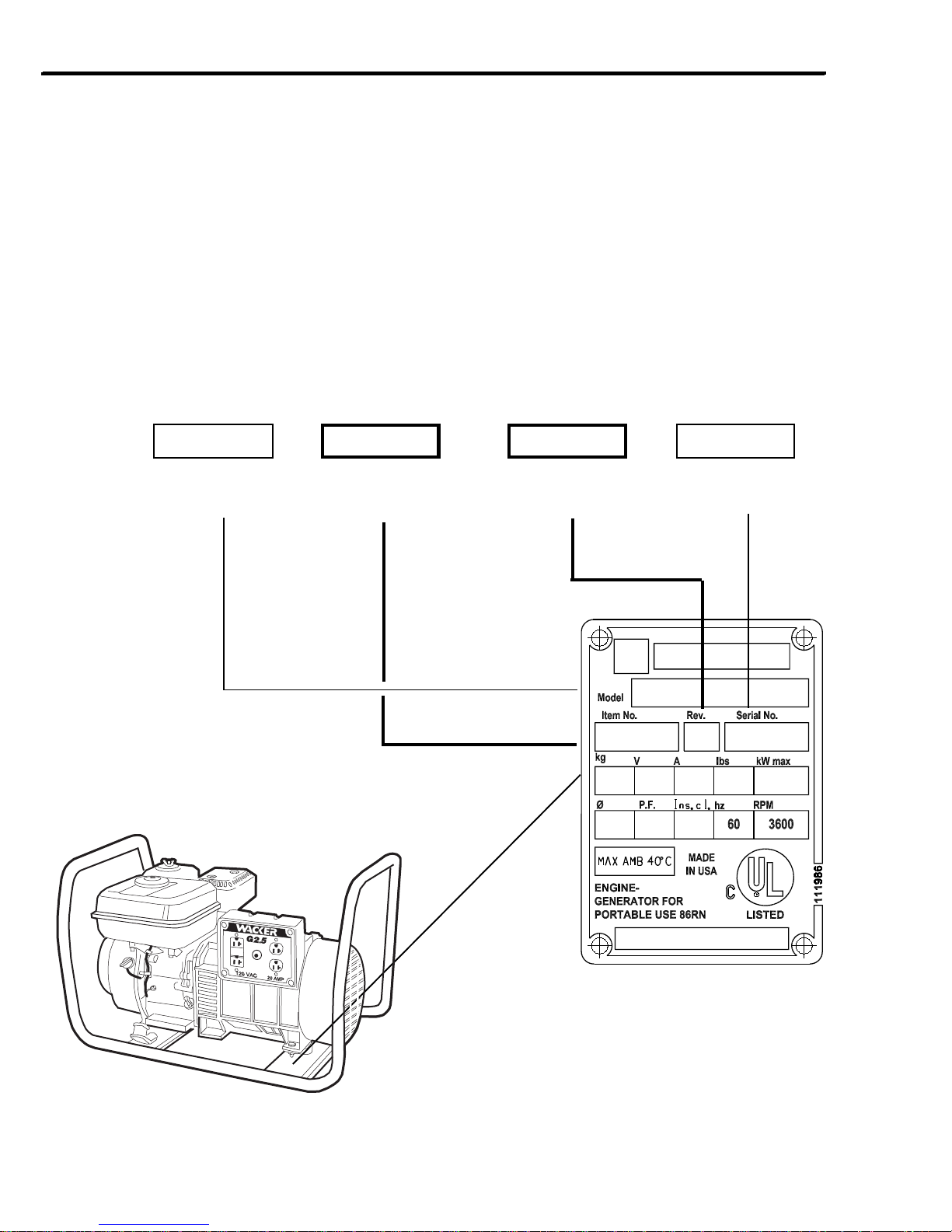

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is attached to each unit. Please

record the information found on this plate so it will be available should the nameplate become lost or damaged. When

ordering parts or requesting service information, you will always be asked to specify the model, item number,

revision number, and serial number of the unit.

Une plaque signalétique mentionnant le modèle, le numéro de référence, le niveau de revision et le numéro de série

est fixée sur chaque machine. Veuillez noter les informations relevées sur cette plaque de façon à ce qu’elles soient

toujours disponibles si la plaque signalétique venait à être perdue ou endommagée. Lorsque vous commandez des

pièces détachées ou vous sollicitez des informations auprès-vente, on vous demandera toujours de préciser

le modèle, le numéro de référence, le niveau de revision et le numéro de série de la machine.

My machine’s numbers are / Les numéros de ma machine sont :

Model number

Modèle

Item Number

Numéro de référence

Revision

Niveau de revision

G2.5A

0009256 101 5010101

Serial Number

Numéro de Série

1038SD43

ii

Page 5

G2.5A

Operating Information

Table of Contents

1.1 Safety Information ..............................................................................1A-2

1.2 Operating Safety ................................................................................1A-3

1.3 Operator Safety while using Internal Combustion Engines.................1A-4

1.4 Service Safety....................................................................................1A-4

1.5 Technical Data ...................................................................................1A-5

1.6 Safety and Operating Labels ..............................................................1A-6

1.7 Label Locations ..................................................................................1A-7

1.8 Application and Power Requirements.................................................1A-8

1.9 Grounding the Generator ...................................................................1A-8

1.10 Outdoor Operation..............................................................................1A-8

1.11 Indoor Operation ................................................................................1A-9

1.12 Use of Extension Cords......................................................................1A-9

1.13 Ground Fault Circuit Interrupt (GFI)..................................................1A-10

1.14 Circuit Breaker Protection ................................................................1A-10

1.15 Before Starting .................................................................................1A-10

1.16 To Start ............................................................................................1A-11

1.17 To Stop ............................................................................................1A-11

1.18 Operating Heavy Loads....................................................................1A-11

1.19 Engine Maintenance.........................................................................1A-12

1.20 New Machines..................................................................................1A-12

1.21 Periodic Maintenance Schedule .......................................................1A-12

1.22 Changing Oil ....................................................................................1A-12

1.23 Servicing Air Cleaner........................................................................1A-13

1.24 Cleaning Sediment Cup....................................................................1A-13

1.25 Carburetor Adjustment .....................................................................1A-14

1.26 Setting Engine Speed.......................................................................1A-14

1.27 Transporting .....................................................................................1A-14

1.28 Storage ............................................................................................1A-15

1.29 Troubleshooting ...............................................................................1A-15

1.30 Wiring Schematic .............................................................................1A-16

1A

1A-1

Page 6

1A OPERATION G2.5A

!

1.1 Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

!

this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

!

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION: Used without the safety alert symbol,

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note:

Contains additional information

important to a procedure.

Laws Pertaining to Spark Arresters

Notice: Some local authorities require that in certain locations, spark arresters be used on internal combustion engines.

A spark arrester is a device designed to prevent the discharge of sparks or flames from the engine exhaust. It is often

required when operating equipment on forested land to reduce the risk of fires. Consult the engine distributor or local

authorities and make sure you comply with regulations regarding spark arresters.

1A-2

Page 7

G2.5A OPERATION 1A

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of electrical equipment! Equipment operated

improperly or by untrained personnel can be dangerous! Read the operating instructions and familiarize yourself with

the location and proper use of all instruments and controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the generator.

!

WARNING

NEVER operate generator when open containers of

fuel, paint, or other flammable liquids are near.

NEVER operate generator, or tools attached to the

generator, with wet hands.

NEVER use worn electrical cords. Severe electrical

shock and equipment damage may result.

NEVER run generator indoors or in an enclosed area

unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from

the engine contains poisonous carbon monoxide gas;

exposure to carbon monoxide can cause loss of

consciousness and may lead to death.

NEVER run electrical cords under the generator, or

over vibrating or hot parts.

NEVER enclose or cover generator when in use or

when hot.

NEVER overload generator. The total amperage of

the tools and equipment attached to the generator

must not exceed the load rating of the generator.

NEVER allow untrained personnel to operate or service the generator. Know how to operate and stop

generator before starting it.

NEVER operate generator in snow, rain, or standing

water.

ALWAYS keep generator at least one meter away

from structures, buildings, and other equipment during use.

ALWAYS keep generator out of reach of children and

pets.

ALWAYS keep the area immediately surrounding the

generator clean, neat and free of debris.

ALWAYS position and operate generator on a firm,

level surface.

ALWAYS remove all tools, cords, and other loose

items from generator before starting it.

ALWAYS make certain generator is well-grounded

and securely fastened to a good earthen ground.

NEVER stand on the machine.

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER DISTRIBUTION SYSTEM CAN

CAUSE SERIOUS INJURY OR DEATH TO UTILITY WORKERS!

Improper connection of generator to a building's electrical system can allow electrical current from the generator

to backfeed into utility lines. This may result in electrocution of utility workers, fire, or explosion. Connections to

a building's electrical system must be made by a qualified electrician and comply with all applicable laws and

electrical codes.

If connected to a building's electrical system the generator must meet the power, voltage, and frequency

requirements of the equipment in the building. Differences in power, voltage, and frequency requirements may

exist and improper connection may lead to equipment damage, fire, and personal injury or death.

!

DANGER

ALWAYS transport generator in an upright position.

1A-3

Page 8

1A OPERATION G2.5A

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation and fueling! Read and follow warning

instructions in engine owner's manual and safety guidelines below. Failure to follow the safety guidelines described

below could result in severe injury or death.

!

DANGER

DO NOT run engine indoors or in an enclosed area

unless adequate ventilation, through such items as

exhaust fans or hoses, is provided.

DO NOT fill or drain fuel tank near an open flame,

while smoking, or while engine is running.

DO NOT touch or lean against hot exhaust pipes.

DO NOT operate with the fuel tank cap loose or

missing.

DO NOT add fuel to a hot or running engine.

DO NOT fill fuel tank indoors or in an enclosed area

unless adequate ventilation, through such items as

exhaust fans, is provided.

DO NOT start engine if fuel has spilled or an odor of fuel

is present. Move generator away from the spill and wipe

generator dry before starting.

1.4 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly

over a long period of time, periodic maintenance and occasional repairs are necessary. If the generator is experiencing

problems or is being serviced, attach a “DO NOT START” sign to the control panel to notify other people of its condition.

!

WARNING

NEVER allow water to accumulate around the base

of the generator set. If water is present, move the

generator and allow it to dry before servicing.

NEVER service generator if clothing or skin is wet.

NEVER use gasoline or other low flash point solvents

to clean air filter elements.

ALWAYS turn engine off before servicing generator. If

engine has electric start, disconnect negative terminal

on battery.

ALWAYS keep generator clean and labels legible.

Replace all missing and hard-to-read labels. Labels

provide important operating instructions and warn of

dangers and hazards.

NEVER allow untrained personnel to service this

equipment. Only trained electrical tech-nicians should

be allowed to service the electrical components of this

equipment.

NEVER modify the equipment without express written approval from WACKER Corporation.

ALWAYS replace all guards and safety devices immediately after servicing.

1A-4

ALWAYS let engine cool before transporting or servicing.

ALWAYS remain aware of moving parts and keep

hands, feet, and loose clothing away from moving parts

on generator and engine.

ALWAYS keep fuel lines in good condition and properly connected. Leaking fuel and fumes are extremely

explosive.

Page 9

G2.5A OPERATION 1A

1.5 Technical Data

Generator

Maximum Output W 2500

Continuous Output W 2250

Type Single voltage, single phase, brushless system

AC Voltages available volts phase 120 1ø

Frequency Hz 60

Power Factor 1.0

AC Receptacles

120V GFI duplex amp 15

120V duplex

Main Circuit Breaker

L x W x H in. (mm) 27 x 17.5 x 17 (685 x 445 x 435)

Weight (dry) lbs. (kg) 94 (43)

amp 15

amp 20

Engine

Engine Make Honda

Engine Model GX 160 K1VX

Power @ 3600 rpm Hp (kW) 5.5 (4.1)

Operating Speed - no load rpm 3700 ± 100

Operating Speed - full load rpm 3600 ± 100

Spark Plug NGK / ND BPR6ES / W20EPR-U

Electrode Gap in. (mm) 0.028 – 0.031 (0.7 – 0.8)

Fuel type Regular unleaded

Fuel Consumption qt. (l)/hr 1.8 (1.7)

Fuel Tank Capacity qt. (l) 3.9 (3.7)

Running Time hrs. 2.1

Air Cleaner type Dry type with oil-wetted foam pre-cleaner

Engine Lubrication

Oil Capacity oz. (l) 1.2 (1.1)

Lubrication oil grade SAE 10W30 - service class SF, SE, SD or SC

1A-5

Page 10

1A OPERATION G2.5A

1.6 Safety and Operating Labels

This WACKER machine uses international pictorial labels where needed. These labels are described below:

1

1

2

2

3

4

5

110426

DANGER

IMPROPER CONNECTION OF GENERATOR

TO A BUILDING'S ELECTRICAL

SYSTEM CAN ALLOW ELECTRICAL

CURRENT FROM THE GENERATOR TO

BACKFEED INTO UTILITY LINES.

THIS MAY RESULT IN ELECTROCUTION

OF UTILITY WORKERS, FIRE OR

BUILDING'S ELECTRICAL SYSTEM MUST BE MADE

BY A QUALIFIED ELECTRICIAN AND COMPLY WITH

ALL APPLICABLE LAWS AND ELECTRICAL CODES.

EXPLOSION. CONNECTIONS TO A

Pictorial Meaning Pictorial Meaning

Open fuel flow valve.

Open choke.

Turn engine switch to "ON"

position.

Close fuel flow valve.

Close choke.

Turn engine switch to "OFF"

position.

88456

Pull rewind starter.

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

CAUTION

VORSICHT

PRECAUCION

PRECAUTION

STOP

Warning!

Hot surface.

DANGER

GEFAHR

PELIGRO

DANGER

117039

117045

111023

DANGER! Electric shock hazard!

Electrical ground location.

88897

GND

Caution! Read and understand the supplied

operator's manual before operating this machine.

Failure to do so increases the risk of injury to

yourself or others.

Danger! Engines emit carbon monoxide; operate only

in well ventilated area. Read the operator's manual.

No sparks, flames or burning objects near machine.

Shut off engine before refueling.

1A-6

Page 11

G2.5A OPERATION 1A

1

2

3

4

5

1

2

IMPROPER CONNECTION OF GENERATOR

TO A BUILDING'S ELECTRICAL

SYSTEM CAN ALLOW ELECTRICAL

CURRENT FROM THE GENERATOR TO

BACKFEED INTO UTILITY LINES.

THIS MAY RESULT IN ELECTROCUTION

OF UTILITY WORKERS, FIRE OR

EXPLOSION. CONNECTIONS TO A

BUILDING'S ELECTRICAL SYSTEM MUST BE MADE

BY A QUALIFIED ELECTRICIAN AND COMPLY WITH

ALL APPLICABLE LAWS AND ELECTRICAL CODES.

DANGER

Danger!

Electric shock will cause serious injury or death.

119593

Neutral bonded to frame.

155503

1.7 Label Locations

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

DANGER

GEFAHR

STOP

CAUTION

PELIGRO

DANGER

VORSICHT

PRECAUCION

PRECAUTION

GND

1038SD43

88897

1A-7

Page 12

1A OPERATION G2.5A

1.8 Application and Power Requirements

This generator is designed to operate single-phase,

60 Hz appliances running at 120 VAC.

Some appliances and tools require a surge of current

when starting. This means that the amount of power

needed to initially start the equipment is larger than the

power required to keep it running. The generator must be

capable of supplying this “surge” current. Other types of

appliances require more power than is actually stated on

their nameplate.

Chart 1 is offered only as a general guideline to help you

determine power requirements for different types of

equipment. Check with your nearest WACKER Dealer,

or contact the manufacturer or dealer of the tool or

appliance, if you have questions regarding power requirements.

CAUTION: If a tool or appliance does not reach full

speed within a few seconds after it is switched on, turn it

off immediately to avoid damage.

Chart 1 : Approximate Starting Power Requirements

Incandescent lights and appliances such as

irons and hot plates, which use a resistive-type

heating element, require the same wattage to

start and run as is stated on their nameplates.

Fluorescent and mercury lamps require 1.2–2

times their stated wattage to start.

Electrical motors and many types of electrical

tools often require a large starting current. The

amount of starting current depends on the type

of motor and its use.

Most electrical tools require 1.2–3 times their

stated wattage for running.

Loads such as submersible pumps and air

compressors require a very large force to start.

They need as much as 3–5 times the wattage

stated on the nameplate in order to start.

1.9 Grounding the Generator

The generator should be grounded to a good ground

source in compliance with National Electric Code standards and local regulations.

Use #8 wire and secure one end to the ground terminal

(a) provided on the generator frame and the other end to

a suitable ground source.

1.10 Outdoor Operation

Place the generator in an area where it will not be

exposed to rain, snow, or other forms of moisture. Make

sure it is positioned on firm, level ground so it will not slide

or shift. Position engine exhaust away from areas where

people may be present.

a

1001SD02

If operating the generator inside a tunnel or deep trench,

make sure there is adequate ventilation. Precautions

similar to those required when operating indoors may be

necessary.

1A-8

Page 13

G2.5A OPERATION 1A

1.1 1 Indoor Operation

If the generator must be operated indoors, adequate

ventilation or exhaust hoses must be provided. When

venting exhaust fumes, make sure the exhaust piping is

large enough to prevent excessive back pressure to the

engine. Back pressure reduces engine efficiency and

may cause the engine to overheat.

!

DANGER

Exhaust gas from the engine contains poisonous

carbon monoxide gas; exposure to carbon monoxide can cause loss of consciousness and may lead

to death. Never run generator indoors or in an

enclosed area unless adequate ventilation, through

such items as exhaust fans or hoses, is provided.

When operated indoors, steps to prevent fire and explosion such as providing a good earthen ground, removing

all flammable materials near generator, and using only

electric cables in good condition, must be observed. See

Section

Operating Safety.

1.12 Use of Extension Cords

When a long extension cord is used to connect an

appliance or tool to the generator, a voltage loss occurs—

the longer the cord, the greater the voltage loss. This

results in less voltage being supplied to the appliance or

tool and increases the amount of current draw or reduces

performance. A heavier cord with a larger wire size will

reduce the voltage loss.

CAUTION: Operating equipment at low voltage can

cause it to overheat.

Use the chart as a guide for selecting proper cable size.

Use only extension cords rated for outdoor use and

equipped with a third-wire ground.

!

WARNING

Damaged cords can cause electrical shock. Electric

shock can cause serious injury or death. DO NOT

use worn, bare, or frayed cords. Replace damaged

cords immediately.

TABLE 3 Maximum Extension Cord Length

Current Load in Watts Maximum Cord Length in Ft.

Amps 120V 240V #10 #12 #14 #16

2.5 300 600 1000 ft. 600 ft. 375 ft. 250 ft.

5 600 1200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1800 350 ft. 200 ft. 125ft. 100 ft.

10 1200 2400 250 ft. 150 ft. 100 ft.

15 1800 3600 150 ft. 100 ft. 65 ft.

20 2400 4800 125 ft. 75 ft. 50 ft.

1A-9

Page 14

1A OPERATION G2.5A

1.13 Ground Fault Circuit Interrupt (GFI)

The 120V, 20 Amp duplex receptacle (a) is equipped with

a ground fault circuit interrupt (GFI). The GFI shuts off the

power to the receptacle when a ground fault occurs in the

generator or to a piece of equipment attached to the

generator. This GFI also protects the second 120V,

20Amp duplex receptacle

The GFI should be tested for proper operation every time

the generator is used.

(c).

a

d

e

To test GFI:

Start generator. Push TEST button

The RESET button

the receptacle. If the RESET button does not pop out, the

GFI is not working. Do not run generator until the problem

can be corrected. To restore power to receptacle, push

the RESET button in.

If the RESET button pops out during operation, stop the

generator and check it and equipment for defects.

(e) will pop out. Power is now off at

(d) on receptacle in.

1.14 Circuit Breaker Protection

The generator is also protected by a 20 Amp circuit

breaker (b) located on the control panel.

The circuit breaker protects the generator from severe

overloads or short circuits. If the circuit breaker opens,

turn the engine off immediately and determine the cause

before restarting. Check the appliances and tools attached to the generator for defects and make sure their

power requirements do not exceed the power rating of

the generator or the current limit of the receptacles.

When the circuit breaker opens, the breaker button will

pop out. To reset circuit breaker, push button in.

120 VAC 20 AMP

b

c

wc_gr000268

1.15 Before Starting

1. Read and understand safety and operating instructions at beginning of this manual.

2. Read and understand the meanings of all warning and

operating labels.

3. Inspect generator for any signs of damage which may

affect operation or pose a safety hazard. Tighten any

loose nuts or bolts.

4. Check engine oil and fill to recommended level.

Note:

The engine is equipped with an oil alert system.

If the oil level in the engine drops too low the engine

will not start.

5. Fill fuel tank with fresh, regular, unleaded grade

gasoline. DO NOT use an oil/gas mixture. The use of

gasohol or any fuel containing more than 10% ethanol

is not recommended. Consult engine owner’s manual

for complete fuel specifications.

1A-10

Page 15

G2.5A OPERATION 1A

CHOKE

1.16 To Start

c

1

c

2

1015SD03 1015SD04

e

2

e

1

d

1

d

2

f

1005SD47

1.17 To Stop

1005SD49

Before starting, be sure you read and understand all the

safety and operating instructions in this manual.

1. Disconnect all loads from the generator.

2. Open fuel valve by moving lever to the right (c

Note:

position

position

3. Turn engine switch to “ON” (e

4. Pull starter rope (f).

Note:

If engine is cold, move choke lever to closed

(d1).

If engine is hot, set choke to open

(d2).

).

1

If the oil level in the engine is low, the engine

).

1

will not start. If this happens, check oil level and add

oil as needed.

5. As engine warms up move choke lever to OPEN

position (d

6. Allow engine to warm up a few minutes before attaching loads.

).

2

1. Turn off and disconnect all tools and appliances

attached to the generator.

2. Turn engine switch to “OFF” (e

3. Close fuel valve by moving lever to the left (c

Note:

engine switch to "OFF"

To stop engine quickly in an emergency, turn

(e2).

).

2

).

2

1.18 Operating Heavy Loads

Limit operations requiring the maximum rated output

of 2500 W to 20 – 30 minutes. For continuous operation

do not exceed the continuous rated output of 2250 W.

CAUTION: DO NOT exceed the current limit specified

on the control panel for any one receptacle.

1A-11

Page 16

1A OPERATION G2.5A

1.19 Engine Maintenance

The Periodic Maintenance Schedule below lists basic maintenance intervals for the engine and generator. Please

read the detailed maintenance procedures for the engine described in engine Owner’s Manual. This manual was

supplied with the generator. Replacement copies of these manuals can be ordered from WACKER Corporation or

directly from the engine manufacturer.

1.20 New Machines

Change engine oil and replace oil filter after the first 20 hours of operation.

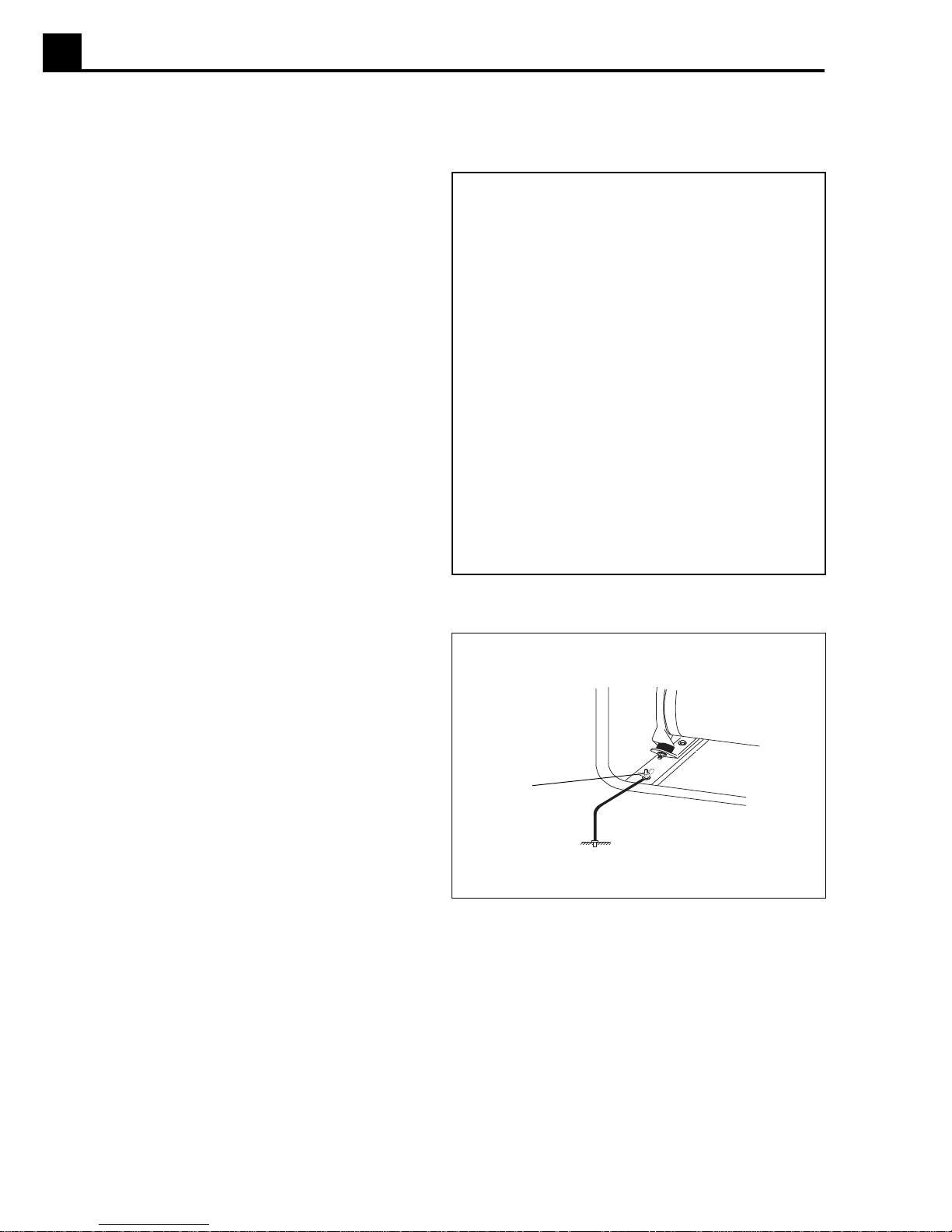

1.21 Periodic Maintenance Schedule

Check engine oil. Fill to correct level.

Check air cleaner.

Clean air cleaner.*

Change engine oil.

Check sediment cup at carburetor.

Clean and adjust spark plug.

Clean spark arrester (optional accessory).

Check shockmounts. Replace when necessary.

Check and adjust valve clearance.*

Clean fuel tank.*

Check condition of fuel line. Replace when necessary.

* Service more frequently in dusty conditions.

Daily

Before

Starting

Every 3

months or

50 hours

Every 6

months or

100 hours

Every year

or 300

hours

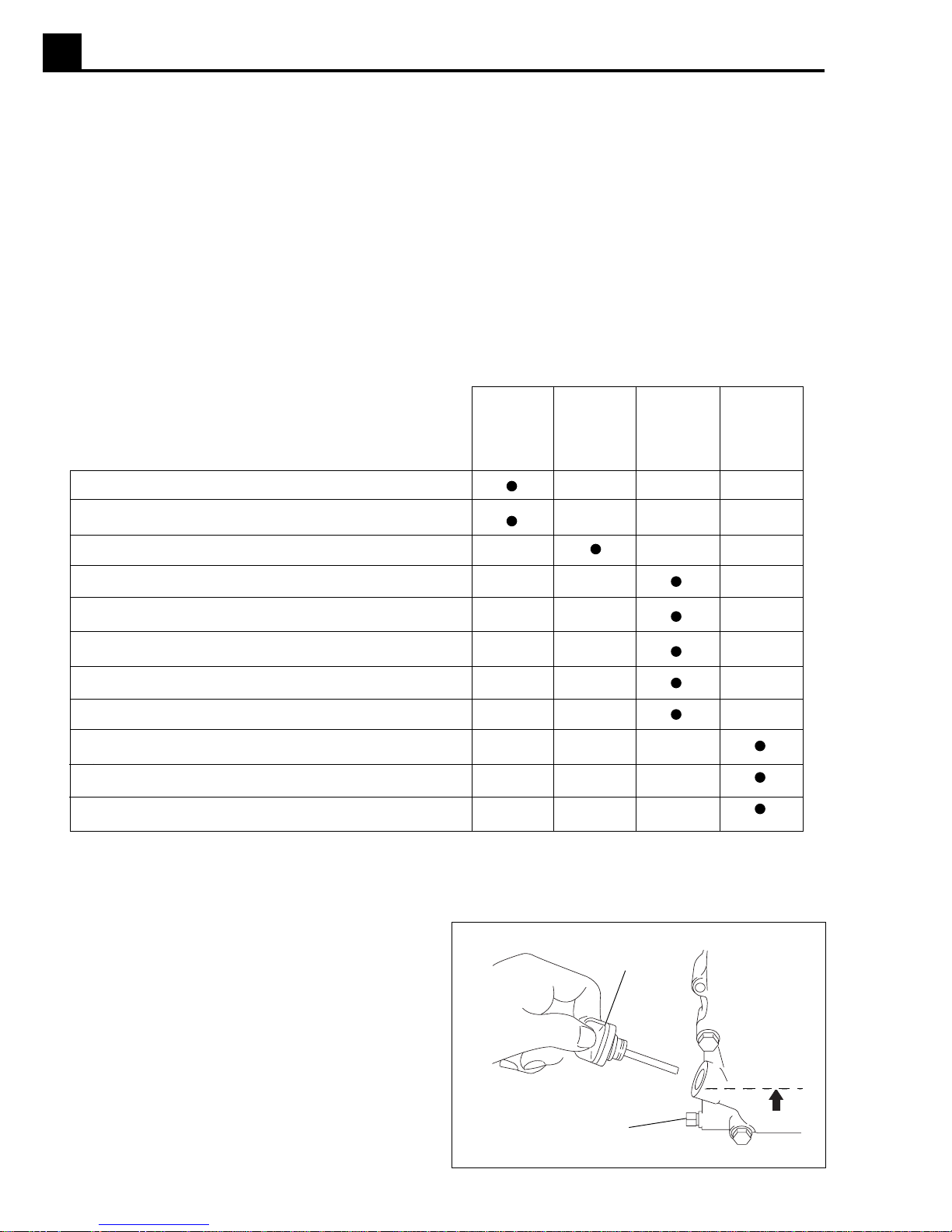

1.22 Changing Oil

Drain oil while engine is still warm.

1. Remove oil fill plug (g) and drain plug (h) to drain oil.

2. Install drain plug.

3. Fill engine crankcase with recommended oil up to

level of plug opening (i).

Oil Capacity: 21 oz. (0.6 liters)

4. Install oil filler cap.

Note:

In the interests of environmental protection, place

a plastic sheet and a container under the machine to

collect any liquid which drains off. Dispose of this liquid

in accordance with environmental protection legislation.

1A-12

g

i

h

1005SD53

Page 17

G2.5A OPERATION 1A

1.23 Servicing Air Cleaner

The engine is equipped with a dual element air cleaner—

service frequently to prevent carburetor malfunction.

CAUTION: NEVER run engine without air cleaner.

Severe engine damage will occur.

a

!

WARNING

NEVER use gasoline or other types of low flash

point solvents for cleaning the air cleaner. A fire or

explosion could result.

b

1. Remove wing nut and air cleaner cover (a). Remove

both elements and inspect them for holes or tears.

Replace damaged elements.

2. Foam Element

Wash in solution of mild detergent and warm water.

Rinse thoroughly in clean water. Allow element to dry

thoroughly.

Soak element in clean engine oil and squeeze out

excess oil.

(c)

c

3. Paper element (b)

Tap element lightly to remove excess dirt or blow

compressed air through filter from the inside out.

Replace paper element if it appears heavily soiled.

1.24 Cleaning Sediment Cup

Turn fuel valve off. Remove sediment cup (e) and O-ring

(d). Wash them thoroughly in a nonflammable solvent.

Dry them and reinstall. Turn fuel valve on and check for

leaks.

1001SD12

d

e

1001SD13

1A-13

Page 18

1A OPERATION G2.5A

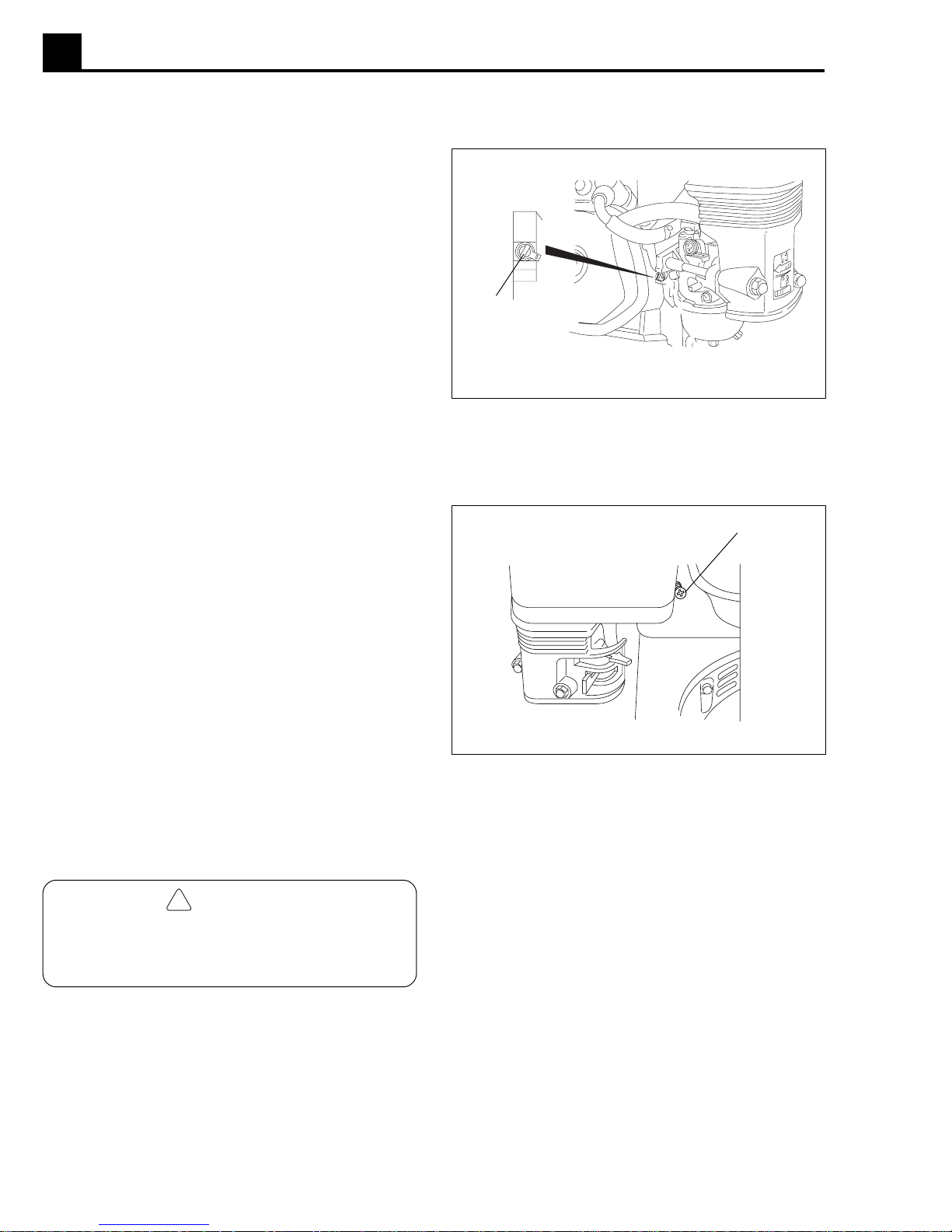

1.25 Carburetor Adjustment

The pilot screw (a) is fitted with a limiter cap to prevent

excessive enrichment of the air-fuel mixture in order to

comply with emission regulations. The mixture is set at

the factory and no adjustment should be necessary. Do

not attempt to remove the limiter cap. The limiter cap

cannot be removed without breaking the pilot screw.

a

1015SD05

1.26 Setting Engine Speed

Generators require a fixed engine speed to maintain the

correct voltage. Engine speed is controlled by a governor

which automatically adjusts to varying loads on the

engine to maintain a constant speed of 3600–3700 rpm.

To set governor speed:

Turn governor speed adjusting screw (j) in or out to

obtain a no-load speed of 3700 rpm.

CAUTION:

low may damage tools and other appliances attached to

the generator.

Setting the governor speed too high or too

1.27 Transporting

!

WARNING

Let engine cool before transporting generator or

storing indoors, to avoid burns or fire hazards.

j

1001SD15

When transporting the generator:

1. Turn the engine fuel valve to the off position.

2. Position the generator level to prevent fuel from

spilling.

3. Secure the generator by tying it down with suitable

rope.

1A-14

Page 19

G2.5A OPERATION 1A

1.28 Storage

Before storing generator for a long period of time:

1. Close the fuel valve and remove and empty sediment

cup under carburetor.

2. Disconnect the fuel line from the carburetor. Place

open end of fuel line into a suitable container and open

fuel valve to drain fuel from tank.

!

WARNING

Gasoline is extremely flammable. Drain fuel tank in

a well-ventilated area. DO NOT drain tank in an area

with flames or sparks.

3. Loosen the drain screw on the carburetor and drain

any remaining fuel from carburetor.

4. Change the engine oil.

5. Remove the spark plug and pour approximately one

tablespoon (1 ounce) of clean engine oil into the

cylinder. Crank the engine a few turns to distribute the

oil to the inside of the cylinder walls.

1.29 Troubleshooting

If engine doesn't start, check that:

1. Engine switch is on "Start".

2. Fuel valves under fuel tank and on engine are open.

3. Fuel tank has fuel.

4. Choke lever is in correct position. Choke should be

closed when starting a cold engine.

5. All loads are disconnected from generator.

6. Spark plug is in good condition.

7. Spark plug cap is tight.

8. Engine oil level is adequate.

If engine starts but there is no power at receptacles,

check that:

1. Circuit breaker is closed.

2. Connector from generator to control panel is tight.

6. Pull the starter rope slowly until resistance is felt and

leave handle in this position. This ensures that the

intake and exhaust valves are closed.

7. Store generator in a clean, dry area.

1A-15

Page 20

1A OPERATION G2.5A

1.30 Wiring Schematic

G

1

5

6

0

7

B

W/Y

B

Y

B/R

20A

120VAC

Wire Colors

B/Y

B - Black W- White

G - Green Y - Yellow

L - Blue Br- Brown

R - Red T - Tan

O - Orange

G/Y

20A

120VAC

BC

G

G/W

B

20A

G/Y

R

1

R

W

2

W

A

1

3

4

1A-16

2

A= Generator

B= Control Box

C= Engine

1= Main Windings

2= Auxiliary Windings

3= Capacitor

4= Rotor Windings

5= Ingnition Switch

6= Oil Level Switch

7= Coil

3

25 uF

400 V

4

B

B

wc_gr000262

Page 21

UNITED KINGDOM

LONDON LEA ROAD Tel. (44)(01992) 707200

Washington Washington/Tyne N37 1LH Tel. (0191) 4 16 63 92

Warrington Winwick Quay, Warrington WA2 8RE Tel. (01925) 57 39 55

Worksop Worksop S81 7BE Tel. (01909) 48 45 06

Redditch Washford, Redditch B98 0DQ Tel. (01527) 2 45 56

Pontypool Pontypool, Gwent NP4 6PD Tel. (01495) 75 05 95

Ashford Ashford, Kent TN23 2NF Tel. (01233) 64 52 27

Exeter Clyst, Honiton, Exeter EX5 2LG Tel. (01392) 6 97 71

Hungerford Hungerford R617 OYX Tel. (01488) 68 14 28

Lanarks Bellshill, Lanarks ML4 3NN Tel. (01698) 84 58 15

WALTHAM CROSS, HERTS EN9 1AW

ÖSTERREICH

1110 WIEN SCHEMMERLSTR.82 Tel. (43) 01-7671515

4050 Traun Wiener Bundesstr. 147 Tel. 07229-73739

9020 Klagenfurt Wiegelegasse 18 Tel. 0463-262716

8054 Graz-Strassgang Kärntner Str. 512 Tel. 0316-281690

6122 Fritzens Innstr. 11 Tel. 05224-51351

5300 Hallwang b. Sbg. Wiener Bundesstr. 17 Tel. 0662-661741

3106 St. Pölten Hnilickastr. 9 Tel. 02742-73170

DEUTSCHLAND

80809 MÜNCHEN PREUSSENSTR. 41 Tel. 089/35 40 21

85757 Karlsfeld (WLZ) Tel. 018131-59780

21109 Hamburg Fax 040/75 73 90 Tel. 040/75 15 66

24145 Kiel Fax 0431/71 46 25 Tel. 0431/71 15 25

23566 Lübeck Fax 0451/62 56 15 Tel. 0451/62 56 19

28307 Bremen-Mahndorf Fax 0421/48 15 36 Tel. 0421/48 15 01

26789 Leer-Bingum Fax 0491/6 25 39 Tel. 0491/6 72 20

30165 Hannover Fax 0511/3 52 49 69 Tel. 0511/3 52 40 61

38112 Braunschweig Fax 0531/31 29 24 Tel. 0531/31 21 80

34233 Fuldatal Fax 0561/81 10 58 Tel. 0561/81 10 59

40721 Hilden Fax 02103/4 69 31 Tel. 02103/3 10 48

41065 Mönchengladbach Fax 02161/4 25 44 Tel. 02161/48 11 41

46485 Wesel Fax 0281/5 16 37 Tel. 0281/8 98 79

45326 Essen Fax 0201/32 13 02 Tel. 0201/31 17 93

48291 Telgte Fax 02504/71 47 Tel. 02504/26 68

49565 Bramsche Fax 05461/49 22 Tel. 05461/6 21 21

44319 Dortmund Fax 0231/21 82 27 Tel. 0231/21 82 26

33659 Bielefeld Fax 0521/40 31 14 Tel. 0521/4 07 77

52355 Düren Fax 02421/6 21 22 Tel. 02421/6 30 51

53842 Troisdorf Fax 02241/4 65 75 Tel. 02241/4 40 31

56218 Mülheim-Kärlich Fax 0261/2 65 55 Tel. 0261/2 65 10

57080 Siegen Fax 0271/31 10 49 Tel. 0271/31 50 55

60388 Frankfurt Fax 069/41 71 89 Tel. 069/42 40 80

35398 Gießen Fax 0641/2 98 19 Tel. 0641/2 22 69

55129 Mainz-Hechtsheim Fax 06131/50 79 80 Tel. 06131/59 20 70

66119 Saarbrücken Fax 0681/85 15 30 Tel. 0681/85 20 11

67133 Maxdorf Fax 06237/50 08 Tel. 06237/72 00

74172 Neckarsulm-Obereisesheim Fax 07132/4 36 19 Tel. 07132/4 36 18

71254 Ditzingen Fax 07156/1 82 04 Tel. 07156/60 54

72336 Balingen-Frommern Fax 07433/3 76 86 Tel. 07433/47 53

76327 Pfinztal Fax 0721/46 86 60 Tel. 0721/46 04 67

77746 Schutterwald Fax 0781/5 97 13 Tel. 0781/5 23 43

78315 Radolfzell Fax 07732/5 65 08 Tel. 07732/5 64 85

79112 Freiburg-Opfingen Fax 07664/5 97 76 Tel. 07664/10 14

89155 Erbach Fax 07305/86 10 Tel. 07305/61 22

88353 Kißlegg-Zaisenhofen Fax 07563/85 73 Tel. 07563/82 76

85716 Unterschleißheim Fax 089/3 17 13 07 Tel. 089/3 10 60 31

85077 Manching Fax 08459/76 02 Tel. 08459/69 97

82538 Geretsried Fax 08171/3 14 09 Tel. 08171/3 12 68

83064 Raubling Fax 08035/39 79 Tel. 08035/22 22

94491 Hengersberg Fax 09901/32 13 Tel. 09901/21 99

93128 Regenstauf Fax 09402/33 66 Tel. 09402/45 01

90765 Fürth-Stadeln Fax 0911/76 34 90 Tel. 0911/76 40 24

95326 Kulmbach Fax 09221/8 44 87 Tel. 09221/26 20

97080 Würzburg Fax 0931/9 81 58 Tel. 0931/9 17 08

63741 Aschaffenburg Fax 06021/8 36 17 Tel. 06021/8 36 16

86167 Augsburg Fax 0821/70 78 58 Tel. 0821/70 22 07

13627 Berlin Fax 030/349 919-12 Tel. 030/349 919-0

13627 Berlin-Nord (Land-Brandenburg) Fax 030/344 13 52 Tel. 030/344 30 47

14974 Genshagen (Berlin-Süd) Fax 03378/81 06 23 Tel. 03378/81 06 21

19061 Schwerin/Görrîes Fax 0385/660 513 Tel. 0385/650 55

01097 Dresden Fax 0351/803 60 91 Tel. 0351/8036090

04430 Blenltz/OT Dölzlg (Leipzig) Fax 034205/5 89 83 Tel. 034205/58982

99428 Nohra (Erfurt) Fax 03643/82 58 28 Tel. 03643/825826

09247 Röhrsdorf (Chemnitz) Fax 03722/50 24 85 Tel. 03722/502 484

39167 Irxleben (Magdeburg) Fax 039204/6 64 78 Tel. 039204/56 78

17033 Neubrandenburg Fax 0395/369 00 41 Tel. 0395/3690040

Fax 089/35 40 23 90

Page 22

UNITED STATES

CORPORATE OFFICE

MENOMONEE FALLS, WI 53052 N92 W15000 ANTHONY AVE. Tel. (262) 255-0500

CANADA

MISSISSAUGA, ONT. L5T 2N6 160 ADMIRAL BLVD. Tel. (905) 795-1661

Calgary, Alta. T2H 2H9 #11, 6115-4 St. S.E. Tel. (403) 255-3336

St. Laurent, Quebec H4R 2C1 3526 Rue Ashby Tel. (514) 337-1708

MEXICO

MEXICO CITY 2A. CERRADA NORTE 147 NO. 20 Tel. (55) 53-53-15-03

Monterrey, Nuevo León Calle Nardo #970, Col. Cementos, C. P. 64520 Tel. (81) 83-31-12-85

C. P. 45010, Zapopan, Jalisco Periférico Poniente No. 2100-Int. F, Tel. (33) 36271499

C. P. 37530 León, Guanajuato Privada Manzanares #103, Fracc.San Isidro de Jerez Tel. (477)7-11-34-35

C. P. 91700 Veracruz, Ver. Miguel Alemán N

COL. SAN MIGUEL AMANTLA 02700 Mexico D.F.

Col. Lomas del Colli

o

. 1001B, Col. Centro Tel. (229)9-35-10-44

ARGENTINA Colectora Oeste de Ruta Panamerica Tel. 5411-4-748-6800

BUENOS AIRES 1611 Km 28.5 Don Torcuato

BRASIL Avda. Arquimedes 1070 Tel. 5511-4582-4333

SÃO PAULO Unidade Autonoma No. 6

Jundiai, São Paulo

CHILE

SANTIAGO El Rosal 5000, Huechuraba, Casilla 130 - Correo 30 Tel. (56) 2-7400014

Antofagasta Orella 975 Tel. (56) 55-227250

Temuco Balmaceda 298 Tel. (56) 45-214425

AUSTRALIA

CLAYTON, VIC. 3169 PO Box 1315 RMDC Tel . (61) 03-95474033

Norwood, S.A. 5067 45 Beulah Road Tel. 08-3622331

Woodridge, QLD 4114 Unit 2, 6-8 Pendrey Court Tel. 07-32089577

Osborne Park, W.A. 6017 Unit P, 69-73 Hector Street Tel. 09-4452911

Auburn, N.S.W. 2144 14 Vore Street Tel. 02-7480366

JAPAN

OHTA-KU, TOYKO 144 2-CHOME 18-1, MINAMI-KAMATA Tel. (81) 03-37329281/5

Hirano-ku, Osaka-shi Miyake Nishi, 4-Chome Tel. 0723 30-0571

Sendai-shi Tachimachi 1-7-21 Tel. 022 284-8032

Fukuoka-shi Sannoh 1-7-1, Hakata-ku Tel. 092 451-1083

MALAYSIA

46150 PETALING JAYA 5. JALAN PJS 11/22 Tel. (03) 7364770

Selangor Darul Ehsan Bandar Sunway

NEW ZEALAND 4A Ponui Place

WIRI-AUCKLAND Mt. Wellington, Auckland Tel. (64) (9) 270 3784

SINGAPORE

JURONG TOWN SINGAPORE 2263 NO. 23, Tuas Ave. 18 Tel. (65) 861-0446

THAILAND 22/197 Pattanakarn Rd. Tel. (66) 2-319-9363/65

BANGKOK 10250 Soi Mooban Panya

www.wackergroup.com

SOUTH AFRICA 1031 KATROL AVE., ROBERTVILLE X10 Tel. H/O Jhb(011) 672-0847

JOHANNESBURG Roodepoort / P.O. Box 2163, Florida 1710, Gauteng.

Durban 10 Kinsman Rd. P.O. Box 420, New Germany 3620 Tel. Dbn(031) 702-3337

Capetown Cor. Beatrix & Carel, Marincowitz St.

P.O. Box 398, Brackenfell 7560 Tel. Cpt(021) 981-2197

CHINA Unit 611-612, 6/F Sunley Centre Tel. (852) 24068613

HONG KONG 9 Wing Yin Street

Wacker Corporation - P. O. Box 9007 - Menomonee Falls, WI 53052-9007 - Tel.: (262)-255-0500 - Fax: (262)-255-0550

Wacker-Werke GmbH & Co. KG - Preußenstraße 41 - 80809 München - Tel.: +49-(0)89-354 02-0 - Fax: +49-(0)89-35 402-390

Kwai Chung, New Territories

0902

Loading...

Loading...