Page 1

www.wackergroup.com

Portable Generators

G 2.1A

G 3.3A

G 4.6A

GS 4.6A

GS 5.7A

REPAIR MANUAL

0116567 002

1000 en

0116567

Page 2

Page 3

50 HZ PORTABLE GENERATORS FOREWORD

This manual covers machines with Serial Number or Item Number:

0008243, 0008244, 0008245, 0008246, 0008247, 0008248, 0008249,

0008250, 0008251, 0008252, 0008253, 0008254, 0008255, 0008256, 0008257, 0008258, 0008259,

0008260, 0008261, 0008262, 0008263, 0008264, 0008265, 0008266, 0008267, 0008268, 0008269,

0008270, 0008271, 0008272, 0008273, 0008274, 0008275, 0008276, 0008277, 0008278, 0008279,

0008280, 0008281, 0008282, 0008283, 0008284, 0008285, 0008309, 0008310, 0008311, 0008312,

0008313, 0008314, 0008315, 0008316

Operating/Parts Information

You must be familiar with the operation of this machine before you attempt to troubleshoot or make any repairs to it.

Basic operating and maintenance procedures are described in the operator's/parts manual supplied with the machine.

The operator's/parts manual should be kept with the machine. Use it to order replacement parts when needed. If this

manual becomes lost, please contact WACKER Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to the attention of the operator, to prevent similar

occurrences from happening in the future.

This manual provides information and procedures to safely repair and maintain this WACKER model. For your

own safety and protection from injury, carefully read, understand and observe the safety instructions described

in this manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION

AT THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION

OF THIS INFORMATION WITHOUT NOTICE.

Page 4

FOREWORD 50 HZ PORTABLE GENERATORS

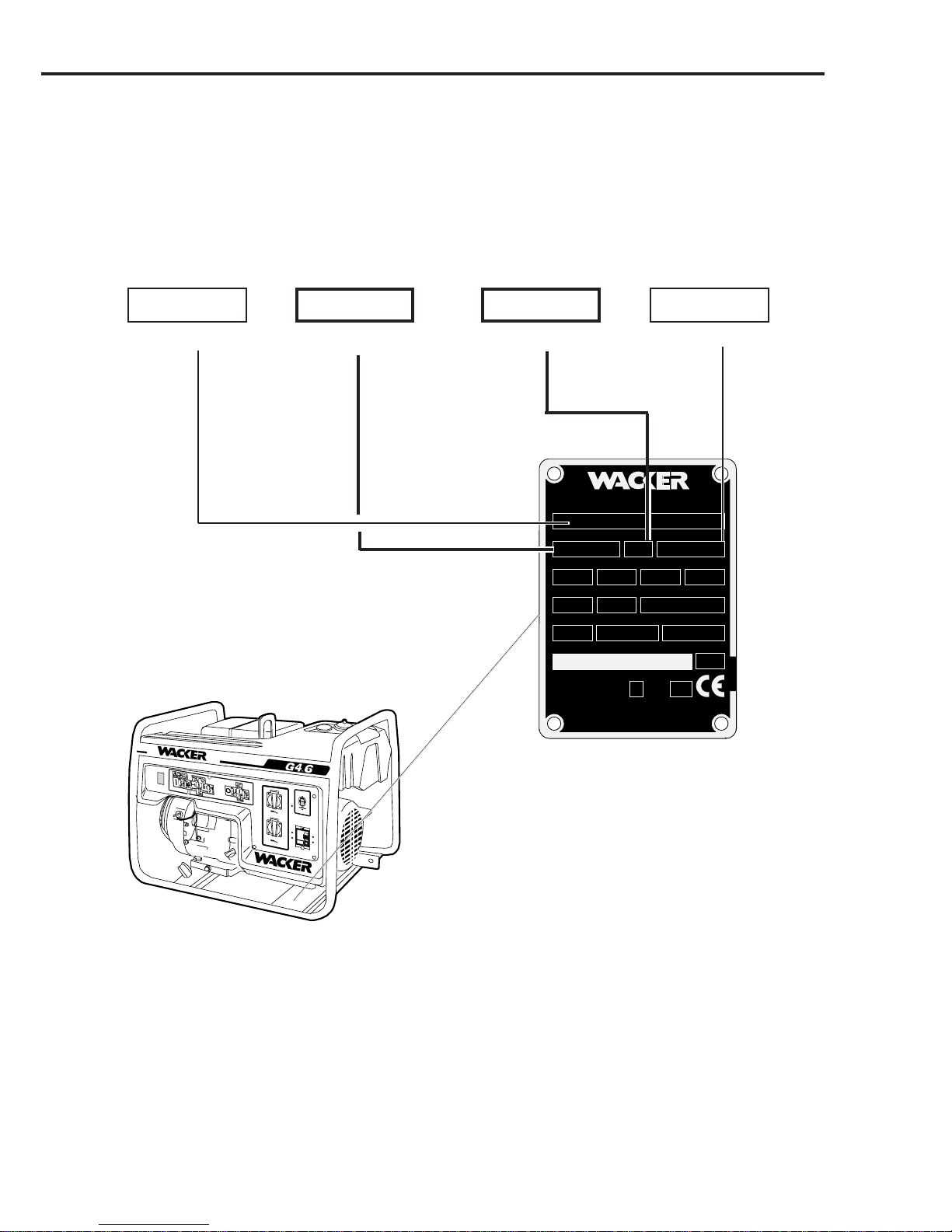

Nameplate

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is attached to each unit. Please

record the information found on this plate so it will be available should the nameplate become lost or damaged. When

ordering parts or requesting service information, you will always be asked to specify the model, item number,

revision number, and serial number of the unit.

My machine’s numbers are:

Model number

RevisionItem Number

Model

GS4.6AGS4.6A

GS4.6A

GS4.6AGS4.6A

Item No.

00082690008269

0008269 101101

00082690008269

kg

lbs

GENERATING SET ISO 8528

MADE

IN USA

Serial Number

MENOMONEE FALLS, WI USA 53051

Rev. Serial No.

Vclass

Insul.

Class

101101

101

hz

kW

Man.

Yr.

50101015010101

5010101

50101015010101

A

N/M

110635

1031SD44

Page 5

50 Hz Portable Generators

Repair Manual

Table of Contents

1 Safety

1.1 Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-1

1.2 Laws Pertaining to Spark Arresters . . . . . . . . . . . . . . . . . . . . . . 1A-1

1.3 Operating Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-2

1.4 Engine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-3

1.5 Service Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-3

2 Technical Data

2.1 Generator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-1

2.2 Engine Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-2

3 Power Requirements

3.1 Determining Power Requirements . . . . . . . . . . . . . . . . . . . . . . . 3A-1

3.2 Outdoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-1

3.3 Indoor Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-1

3.4 Grounding the Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-2

3.5 Use of Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3A-2

4 Model G2.1A

4.1 Theory of Operation – Capacitor Generators . . . . . . . . . . . . . . . 4A-1

4.2 Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

4.3 Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

4.4 Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

4.5 Diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

4.6 Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-3

4.7 Earth Leakage Circuit Breaker (ELCB) . . . . . . . . . . . . . . . . . . . 4A-3

4.8 Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-4

4.9 Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-4

4.10 Loss of Residual Magnetism in Rotor. . . . . . . . . . . . . . . . . . . . . 4A-5

4.11 Receptacle Panel Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-6

4.12 Rotor Diode Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-6

4.13 Stator Winding Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-7

4.14 Rotor Winding Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-8

4.15 Generator Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-9

4.16 Generator Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-9

4.17 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-10

4.18 Periodic Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . 4A-11

4.19 Storing/Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-11

4.20 Wiring Schematic (G2.1A Model) . . . . . . . . . . . . . . . . . . . . . . . 4A-12

Page 6

50 Hz Portable Generators

Repair Manual

Table of Contents, continued

5 Models G3.3A, G4.6A, GS4.6A, & GS5.7A

5.1 Theory of Operation – Brush Generators . . . . . . . . . . . . . . . . . . 5A-1

5.2 Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-2

5.3 Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-2

5.4 Automatic Voltage Regulator (AVR). . . . . . . . . . . . . . . . . . . . . . 5A-2

5.5 Choke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

5.6 Bridge Rectifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

5.7 Engine Auto Idle Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

5.8 Choke Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-3

5.9 Main Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-4

5.10 Earth Leakage Circuit Breaker (ELCB) . . . . . . . . . . . . . . . . . . . 5A-4

5.11 Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-6

5.12 Auto Idle Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-7

5.13 Loss of Residual Magnetism in Rotor . . . . . . . . . . . . . . . . . . . . 5A-9

5.14 Diode Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-9

5.15 Stator Windings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-10

5.16 Rotor Windings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-11

5.17 Slip Rings and Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-11

5.18 Automatic Voltage Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . 5A-11

5.19 Generator Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-13

5.20 Generator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-14

5.21 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-15

5.22 Periodic Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . 5A-16

5.23 Wiring Schematics – Generator/Engine . . . . . . . . . . . . . . . . . 5A-17

5.24 Storing/Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5A-22

Page 7

50 HZ PORTABLE GENERATORS SAFETY 1A

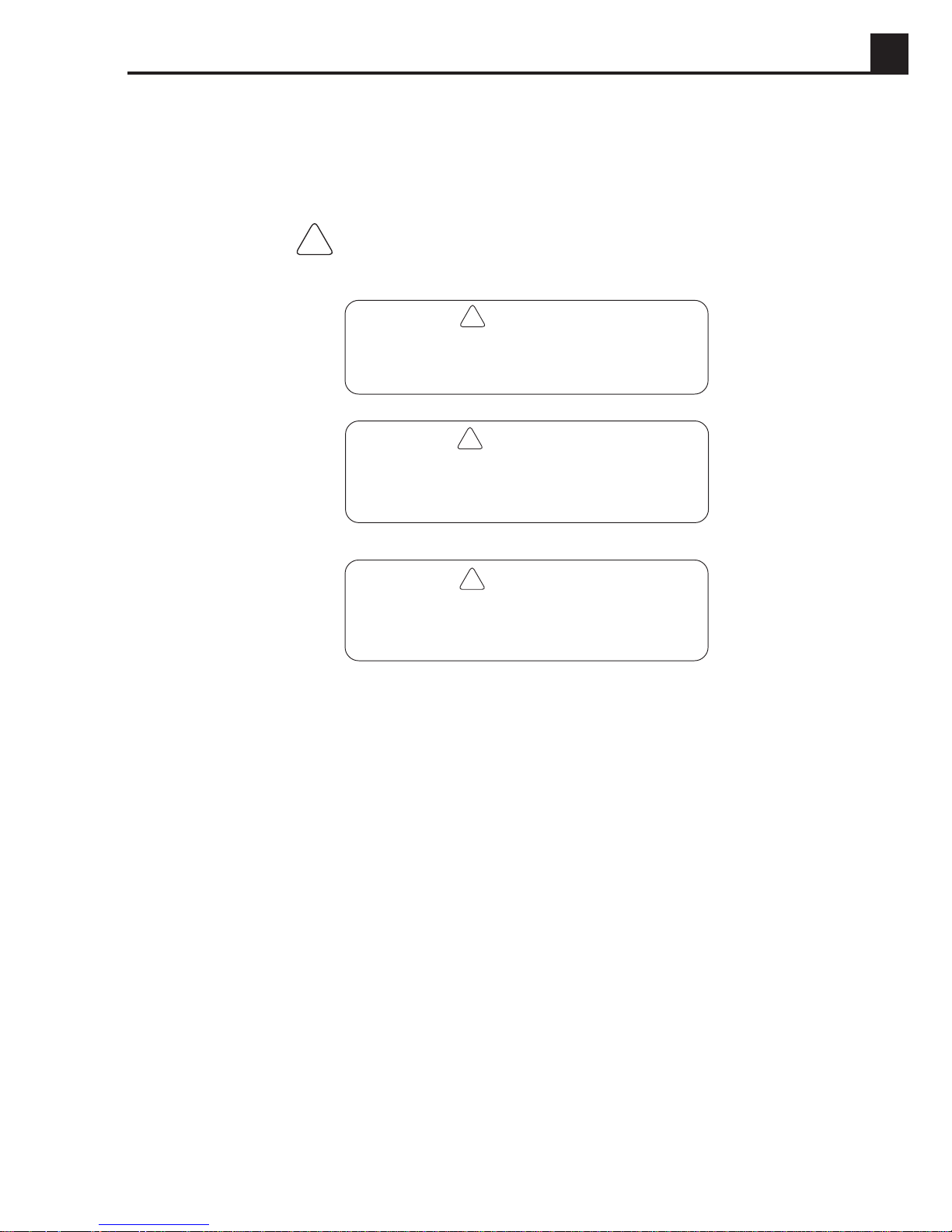

1.1 Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

!

this symbol to avoid possible injury or death.

!

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

!

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION: Used without the safety alert symbol,

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note:

Contains additional information

important to a procedure.

1.2 Laws Pertaining to Spark Arresters

Notice: Some local authorities require that in certain locations, spark arresters be used on internal combustion engines.

A spark arrester is a device designed to prevent the discharge of sparks or flames from the engine exhaust. It is often

required when operating equipment on forested land to reduce the risk of fires. Consult the engine distributor or local

authorities and make sure you comply with regulations regarding spark arresters.

1A-1

Page 8

1A SAFETY 50 HZ PORTABLE GENERATORS

WARNING

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER DISTRIBUTION SYSTEM CAN

CAUSE SERIOUS INJURY OR DEATH TO UTILITY WORKERS!

Improper connection of generator to a building’s electrical system can allow electrical current from the generator

to backfeed into utility lines. This could result in electrocution of utility workers, fire, or explosion. Connections to

a building’s electrical system must be made by a qualified electrician and comply with all applicable laws and

electrical codes.

1.3 Operating Safety

Familiarity and proper training are required for the safe operation of electrical equipment! Equipment operated

improperly or by untrained personnel can be dangerous! Read the operating instructions and familiarize yourself with

the location and proper use of all instruments and controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the generator.

NEVER operate generator when open containers of

fuel, paint, or other flammable liquids are nearby.

NEVER operate generator, or tools attached to the

generator, with wet hands.

NEVER use worn electrical cords. Severe electrical

shock and equipment damage may result.

NEVER run generator indoors or in an enclosed area

unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from

the engine contains poisonous carbon monoxide

gas; exposure to carbon monoxide can cause loss of

consciousness and may lead to death.

NEVER run electrical cords under the generator, or

over vibrating or hot parts.

NEVER enclose or cover generator when in use or

when hot.

NEVER overload generator. The total amperage of

the tools and equipment attached to the generator

must not exceed the load rating of the generator.

WARNING

NEVER allow untrained personnel to operate or

service the generator. Know how to operate and stop

generator before starting it.

NEVER operate generator in snow, rain, or standing

water.

ALWAYS keep generator at least three feet (one

meter) away from structures, buildings, and other

equipment during use.

ALWAYS keep generator out of reach of children

and pets.

ALWAYS keep the area immediately surrounding

the generator clean, neat and free of debris.

ALWAYS position and operate generator on a firm,

level surface.

ALWAYS remove all tools, cords, and other loose

items from generator before starting it.

ALWAYS make certain generator is well-grounded

and securely fastened to a good earthen ground.

1A-2

ALWAYS transport generator in an upright position.

Page 9

50 HZ PORTABLE GENERATORS SAFETY 1A

1.4 Engine Safety

Internal combustion engines present special hazards during operation and fueling! Read and follow warning

instructions in engine owner’s manual and safety guidelines below. Failure to follow the safety guidelines described

below could result in severe injury or death.

WARNING

DO NOT run engine indoors or in an enclosed area

unless adequate ventilation, through such items as

exhaust fans or hoses, is provided.

DO NOT fill or drain fuel tank near an open flame,

while smoking, or while engine is running.

DO NOT fill fuel tank indoors or in an enclosed area

unless adequate ventilation, through such items as

exhaust fans, is provided.

DO NOT touch or lean against hot exhaust pipes.

DO NOT operate with the fuel tank cap loose or

missing.

DO NOT add fuel to a hot or running engine.

DO NOT start engine if fuel has spilled or an odor of

fuel is present. Move generator away from the spill

and wipe generator dry before starting.

1.5 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly

over a long period of time, periodic maintenance and occasional repairs are necessary. If the generator is experiencing

problems or is being serviced, attach a “DO NOT START” sign to the control panel to notify other people of its condition.

WARNING

NEVER allow water to accumulate around the

base of the generator set. If water is present,

move the generator and allow it to dry before

servicing.

NEVER service generator if clothing or skin is

wet.

NEVER use gasoline or other low flash point

solvents to clean air filter elements.

NEVER allow untrained personnel to service

this equipment. Only trained electrical technicians

should be allowed to service the electrical

components of this equipment.

NEVER modify the equipment without express

written approval from WACKER Corporation.

ALWAYS replace all guards and safety devices

immediately after servicing.

ALWAYS turn engine off before servicing generator.

If engine has electric start, disconnect negative

terminal on battery.

ALWAYS keep generator clean and labels legible.

Replace all missing and hard-to-read labels. Labels

provide important operating instructions and warn of

dangers and hazards.

ALWAYS let engine cool before transporting or

servicing.

ALWAYS remain aware of moving parts and keep

hands, feet, and loose clothing away from moving

parts on generator and engine.

ALWAYS keep fuel lines in good condition and

properly connected. Leaking fuel and fumes are

extremely explosive.

1A-3

Page 10

1A SAFETY 50 HZ PORTABLE GENERATORS

Notes:

1A-4

Page 11

50 HZ PORTABLE GENERATORS TECHNICAL DATA 2A

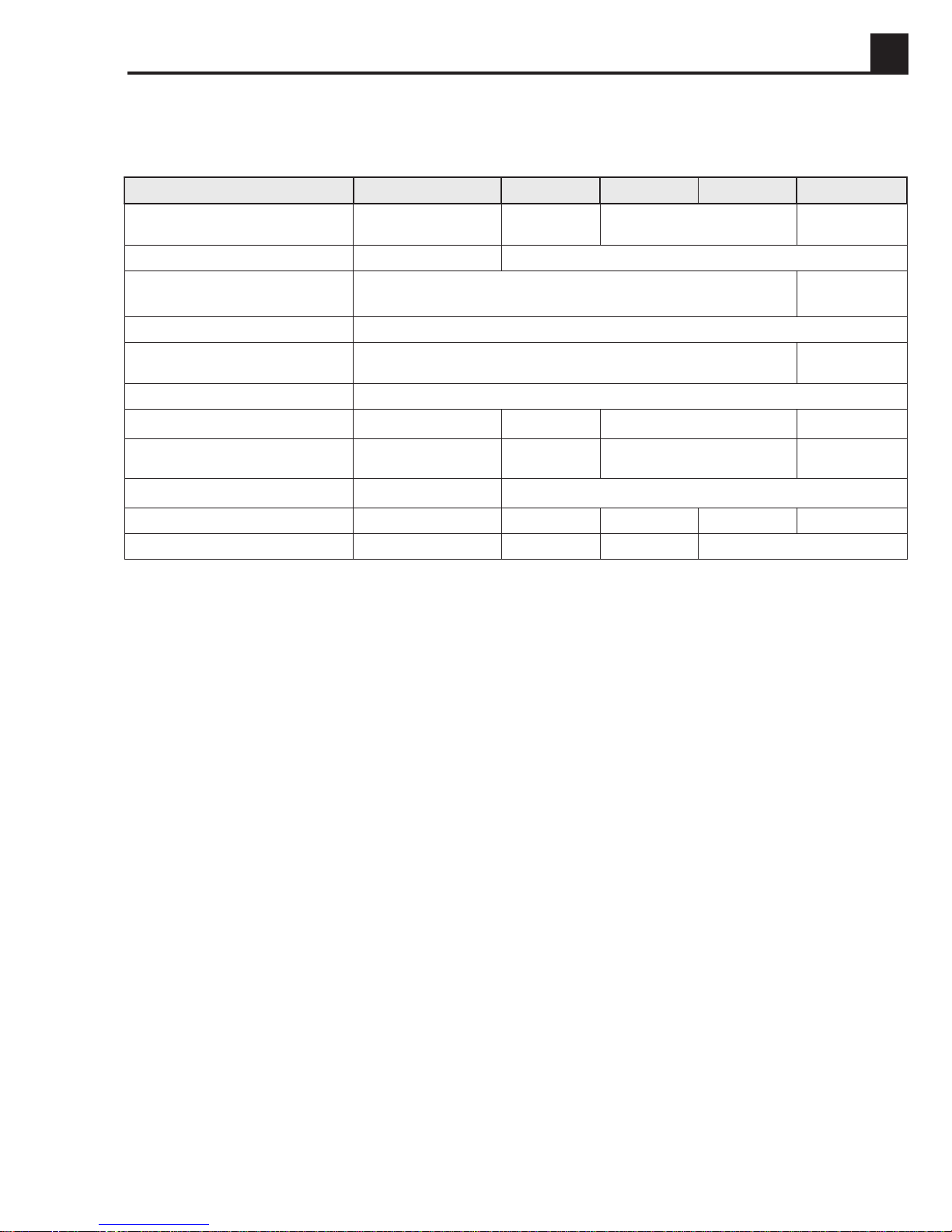

2.1 Generator Specifications

Table 2-1.

ledoM A1.2G A3.3G A6.4G A6.4SG A7.5SG

tuptuOAVk1,23,36,4

epyTsselhsurBrotalugeRegatloVcitamotuA

Ø11,4

Ø37,5

elbaliavasegatloVCA

esahp&egatlov

ycneuqerFzH05

rotcaFrewoP0,1

selcatpeceRCAlanoitpO

rekaerBtiucriCniaMpma)elop1(01)elop1(51)elop1(02)elop3(9

tnerruCsuounitnoC

V004/V032tapma.A.N/1,9.A.N/3,41.A.N/0,022,8/0,81

LxWxH

)yrd(thgieWgK4417083838

yrettaBA/NA/NA/N02/21/A-L81N-05

mm

586x544x534586x585x035

V032

esahp1

Ø1V032

Ø3V004

Ø10,1

Ø38,0

2A-1

Page 12

TECHNICAL DATA 50 HZ PORTABLE GENERATORS

2A

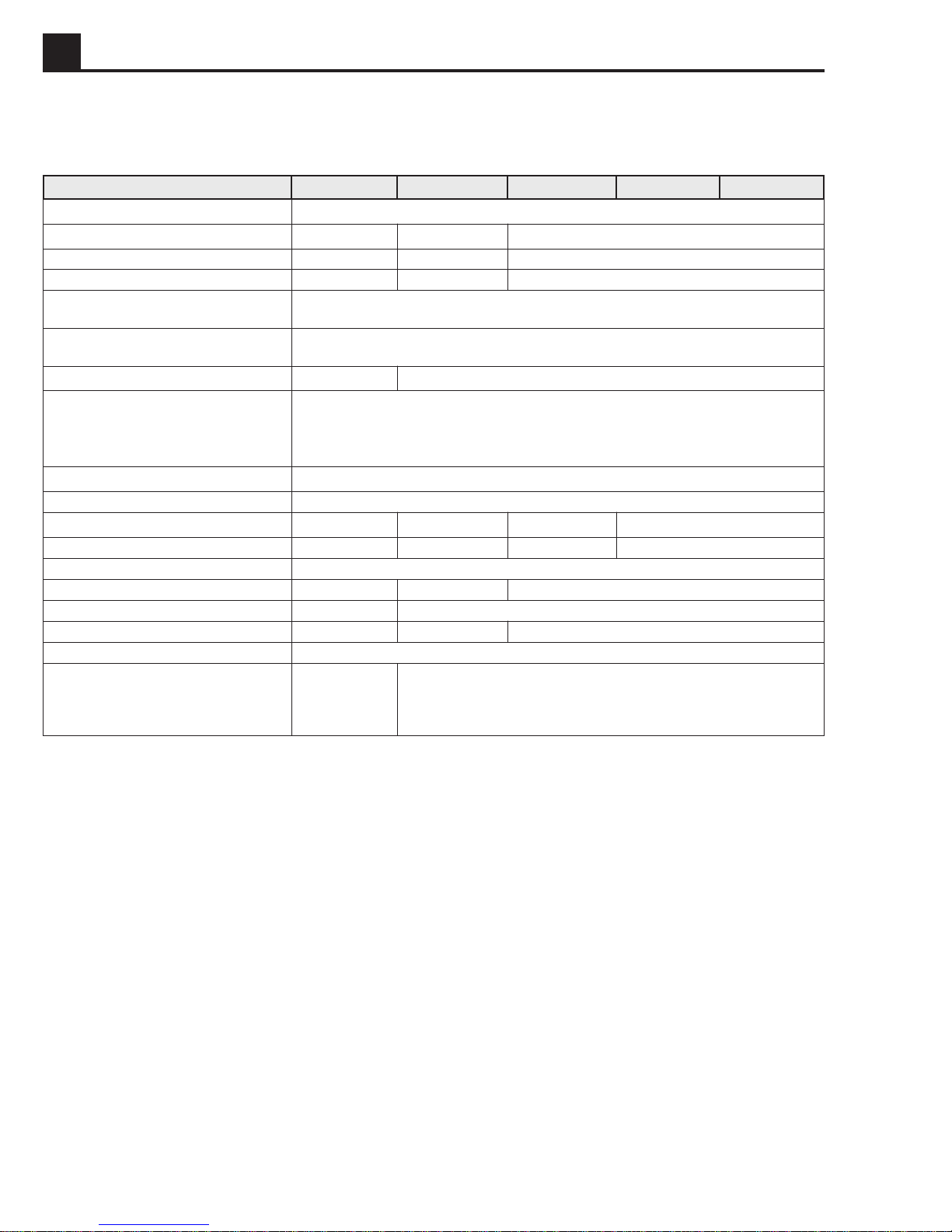

2.2 Engine Specifications

ledoM A1.2G A3.3G A6.4G A6.4SG A7.5SG

ekaMenignE adnoH

ledoMenignEXV1K061XG1K042XG1K043XG

mpr0003@rewoPWk1,40,62,8

cibuctnemecalpsiDmc361242733

–deepSgnitarepO

daolon

–deepSgnitarepO

daollluf

deepSeldIotuAmprA/N0022±05

ecnaraelCevlaV

)dloc(

tsuahxe

ekatni

gulPkrapSepytU-RPE02W/SE6RPB

paGgulPkrapSmm8,0–7,0

retratS)V/epyt(A/NA/NA/NV21/cirtcelE

rotanretlApmaA/NA/NA/N1

leuFepyT)enatcO77.niM(dedaelnuralugeR

noitpmusnoCleuFrh/retil7,14,22,3

yticapaCknaTleuFretil7,35,91

emiTgninnuR.rh2,22,80,6

renaelCriAepytrenaelc-erpmaofdettew-liohtiwepytyrD

noitacirbuLenignE

yticapaC

mpr

mpr

mm02,0

edarglio

ecivres

ssalc

lm

006

Table 2-2.

03W01EAS

ESro,FS,GS

05±0013

0003±50

51,0

03W01EAS

FSroGS

0011

2A-2

Page 13

50 HZ PORTABLE GENERATORS POWER REQUIREMENTS 3A

3.1 Determining Power

Requirements

These generators are designed to operate single-phase,

50 hertz appliances or tools running at 230 VAC for the

G2.1A, G3.3A, G4.6A, and GS4.6A models, and a single

phase voltage of 230 VAC and a three phase voltage of

400 VAC for the GS5.7A model. Check the nameplate or

label provided on tools and appliances to make sure their

power requirements match the power output of the

generator.

Some appliances and tools require a surge of current

when starting. This means that the amount of power

needed to initially start the equipment is larger than the

power required to keep it running. The generator must be

capable of supplying this “surge” current. Other types of

appliances require more power than is actually stated on

their nameplates.

The chart below is offered only as a general guideline to

help you in determining power requirements for different

types of equipment. Check with your nearest WACKER

Dealer, or contact the manufacturer or dealer of the tool

or appliance, with questions regarding power

requirements.

3.2 Outdoor Installation

Place the generator in an area where it will not be

exposed to rain or snow. Make sure it is positioned on

firm, level ground so it will not slide or shift. Position

engine exhaust away from areas where people may be

present.

If operating the generator inside a tunnel or deep trench,

make sure there is adequate ventilation. Precautions

similar to those required when operating indoors may be

necessary.

The surrounding area must be free of water and moisture.

All components must be protected from excessive

moisture.

3.3 Indoor Installation

If the generator must be operated indoors, adequate

ventilation or exhaust hoses must be provided. When

venting exhaust fumes, make sure the exhaust piping is

large enough to prevent excessive back pressure to the

engine. Back pressure reduces engine efficiency and

may cause the engine to overheat.

• Incandescent lights and appliances such as irons

and hot plates use a resistive-type heating element

and require the same wattage to start and run as is

stated on their nameplates.

• Fluorescent and mercury lamps require 1.2 – 2 times

their stated wattage to start.

• Electrical motors and many types of electrical tools

often require a large starting current. The amount of

starting current depends on the type of motor and its

use.

• Most electrical tools require 1.2 – 3 times their stated

wattage for running.

• Loads such as submersible pumps and air compressors require a very large force to start. They need as

much as 3 – 5 times the wattage stated on their

nameplates in order to start.

If the wattage is not given for a particular tool or appliance, it can be calculated by multiplying its voltage and

amperage requirements:

VOLTS x AMPS = WATTS

CAUTION: If a tool or appliance does not reach full

speed within a few seconds when switched on, turn it off

immediately to avoid damage.

WARNING

Exhaust gas from the engine contains poisonous

carbon monoxide gas; exposure to carbon monoxide

can cause loss of consciousness and may lead to

death. Never run generator indoors or in an enclosed

area unless adequate ventilation, through such items

as exhaust fans or hoses, is provided.

When operated indoors, steps to prevent fire and explosion

such as, providing a good earthen ground, removing all

flammable materials near generator, and using only

electric cords in good condition, must be observed. See

Section 1.3

Operating Safety.

CAUTION: When starting loads, DO NOT exceed two

(2) times the given Continuous Current rating for model

G2.1A, or one-and-one-half (1 1/2) times for all other

models, as damage to the generator may occur. See

Section 2.1

Generator Specifications

.

3A-1

Page 14

3A POWER REQUIREMENTS 50 HZ PORTABLE GENERATORS

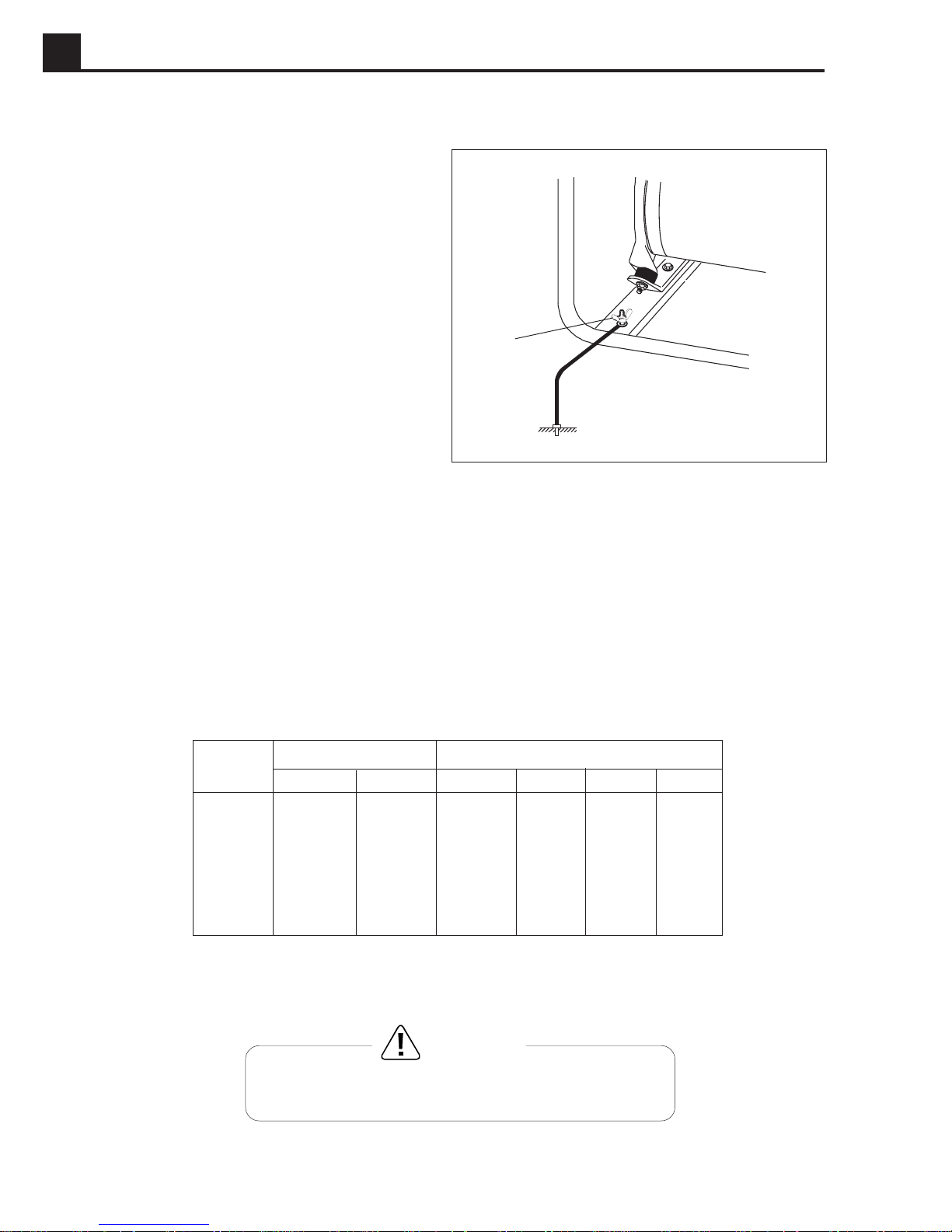

3.4 Grounding the Generator

The generator should be grounded to a good ground

source in compliance with National Electric Code standards and local regulations.

Use #8 wire and secure one end to the ground terminal

(a) provided on the generator frame and the other end to

a suitable ground source. See Figure 3-1.

a

1001SD02

Figure 3-1. Grounding

3.5 Use of Extension Cords

When a long extension cord is used to connect an appliance or tool to the generator, a voltage loss occurs – the longer

the cord, the greater the voltage loss. This results in less voltage being supplied to the appliance or tool and increases

the amount of current draw or reduces performance. A heavier cord with a larger wire size will reduce the voltage loss.

Use Table 3-1 below as a guide for selecting proper cable size.

Use only extension cords rated for outdoor use and equipped with a third-wire ground.

Table 3-1.

Current Load in Watts Maximum Cable Length in Ft.

Amps 120V 240V #10 #12 #14 #16

2.5 300 600 1000 ft. 600 ft. 375 ft. 250 ft.

5 600 1200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1800 350 ft. 200 ft. 125 ft. 100 ft.

10 1200 2400 250 ft. 150 ft. 100 ft.

15 1800 3600 150 ft. 100 ft. 65 ft.

20 2400 4800 125 ft. 75 ft. 50 ft.

CAUTION: Operating equipment at low voltage can cause overheating.

Keep electrical cords in good condition. DO NOT use worn,

bare, or frayed cords which can cause electrical shock.

3A-2

WARNING

Page 15

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

4.1 Theory of Operation – Capacitor Generators

Basic Generator Theory

Wacker air-cooled generators work on the principle of

electromagnetic induction i.e., the cutting of magnetic

lines of force by a coil of wire to produce an electric

voltage in the coil of wire.

The two main components of the generator, the rotor and

stator, are the key. The rotor acts as the magnet and the

stator acts as the coil of wire. As the rotor rotates, its

magnetic lines of force are cut by the coils of wire in the

stationary stator. The voltage induced in the windings of

the stator is tapped off and available at the receptacles.

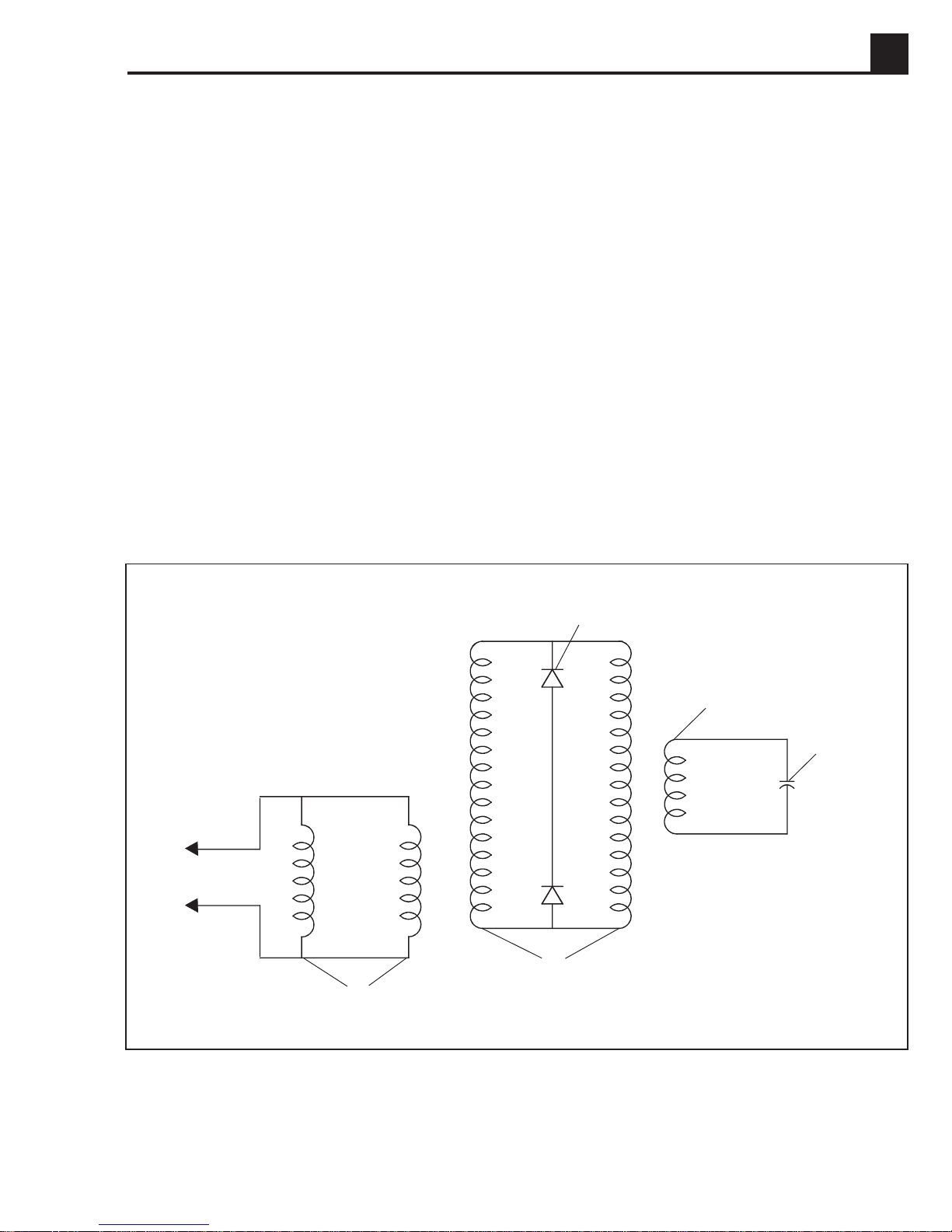

Brushless Generator

This model generator uses a brushless design to generate

and regulate power. It consists of a rotor, stator, diodes,

and an auxiliary winding. The brushless generator also

contains a capacitor that is connected to the auxiliary

winding. Its purpose is to regulate the voltage in the main

windings and prevent a voltage drop when a load is

applied.

This generator is designed to operate with single phase

loads at or near a power factor of 1.0. The principle of

operation is schematically represented in Figure 4-1, and

a cross-sectional view in Figure 4-2. The auxiliary

winding (a), in conjunction with the capacitor, provide

excitation by inducing current in the rotor windings (b)

which is rectified by the diodes (c) to produce direct

current. The main stator winding (d) is designed for

parallel connection to give a voltage output with no

voltage adjustment possible.

Diodes

(Rectifier)

c

b

d

Main Windings

Figure 4-1. Principle of Operation Schematic

Rotor Field

Windings

a

Auxiliary Winding

Capacitor

1023SD44

4A-1

Page 16

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

a

b

d

c

Figure 4-2. Brushless Type Generator

4.2 Rotor (a)

The inside of the rotor shaft is tapered and connected

directly to the taper on the engine crankshaft. This end is

supported by the engine crankshaft bearing. The opposite end of the rotor is supported by a bearing installed in

the generator housing. This end also contains the two

diodes mounted on the diode bracket assembly. There

are two individual coils wound on the rotor. When the

engine is running, these two windings create the magnetic field for the main stator windings.

4.3 Stator (b)

The stator houses both the main windings and auxiliary

winding. The main windings are connected directly to the

main circuit breaker to supply power to the output receptacles. The auxiliary winding induces the initial voltage in

the field windings of the rotor and regulates the voltage.

It is connected directly to the main capacitor.

1022SD88

4.4 Capacitor (c)

A capacitor is connected in series with the auxiliary

winding. Its purpose is to regulate the voltage when a

load is applied.

4.5 Diodes (d)

Two diodes are located on the rotor. These diodes form

a half wave rectifier to convert the induced AC voltage in

the rotor windings to DC voltage.

4A-2

Page 17

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

4.6 Control Panel

The generator is protected by a 10 amp circuit breaker

(a) located on the control panel.

The circuit breaker protects the generator from severe

overloads or short circuits. If the circuit breaker opens,

turn the engine off immediately and determine the cause

before restarting. Check the appliances and tools attached to the generator for defects and make sure their

power requirements do not exceed the power rating of

the generator.

When the circuit breaker opens, the breaker button will

pop out. To reset circuit breaker, push button in.

Depending on model, the generator will have one of the

four styles of receptacles, the Danish IP44 type

Swiss IP X4 type (c), the France/Belgium IP44 type (d),

or the Schuko IP44 (CEE 7) type (e).

Note:

Enlargements of receptacles show protective

covers removed for identification purposes only. Never

remove protective covers.

(b), the

bc

a

de

230V 230V

Control Panel

a Main circuit breaker - 10 Amp.

b Danish IP44 style receptacle.

c Swiss IP X4 style receptacle.

d France/Belgium IP44 style receptacle.

e Schuko IP44 (CEE 7) style receptacle.

1031SD43

4.7 Earth-leakage Circuit Breaker

Generator model G2.1AE is equipped with an earthleakage circuit breaker. The circuit breaker is current

operated and shuts off the power to the receptacles when

a ground fault of 30 milli-Amps or greater occurs in the

generator or to a piece of equipment attached to the

generator. The circuit breaker is located on the opposite

side of the generator as the control panel.

The circuit breaker should be tested for proper operation

every time the generator is used.

To test the earth-leakage circuit breaker:

Start the generator. Place main circuit breaker in closed

position. Push in TEST button (g). The circuit breaker

lever will lower to the open position (f

at both receptacles. If the lever does not lower, the circuit

breaker is not working. Do not use the generator until the

problem can be corrected. To restore power to the

receptacles, raise the circuit breaker lever to the closed

position (f

If the circuit breaker lever lowers to the open position

during operation, stop the generator and check it and

equipment for defects. Repair all defects before operating generator.

).

1

). Power is now off

2

f

1

f

2

T

E

S

T

g

1020SD80

4A-3

Page 18

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

4.8 Capacitors

WARNING

ALWAYS handle or test capacitors with the engine

stopped. Extremely high voltage is present at the

capacitor terminals while the generator is in use.

Although the capacitors used in this generator are

designed to discharge when the engine is stopped,

it is still a good idea to discharge them manually

before handling. To discharge a capacitor, place a

conductor, such as a screwdriver with an insulated

handle, across the capacitor terminals. Be sure to

touch only the insulated handle. This will short out

across the terminals and discharge the capacitor.

Testing Capacitor

1. Discharge capacitor as described above, then

disconnect all wire leads from the terminals.

2. Check the capacitor charge and discharge readings

using an ohmmeter as described below or use a

capacitor checker. See Figure 4-4.

4.9 Engine Speed

All generators require a fixed engine speed to maintain

the correct voltage output. Engine speed is controlled by

a governor which automatically adjusts to varying loads

on the engine to maintain a constant speed of 3000 –

3100 rpm.

Testing Engine Speed

Measure the engine speed using a tachometer with no

load applied to the generator. The engine must be

running at 3100 ± 50 rpm. Voltage output is directly

related to engine speed. A slow engine will reduce

voltage. Refer to the Operator’s Manual for engine speed

adjustment.

The generator is designed to produce no output if

engine rpm falls 10% or more below the required

speed (approximately 2700 rpm).

Setting Engine Speed

Setting the engine speed requires the adjustment to the

governor. See Figure 4-5.

To set the engine to the proper speed:

Set Ohmmeter on R x 10k scale.

Set meter leads on capacitor terminals. The meter

should deflect momentarily towards zero (fully

discharged) and then slowly climb up to infinity

(charging).

Reverse meter leads and repeat procedure. Results

should be the same.

3. If meter does not deflect torward zero, or deflects to

zero and remains there, the capacitor is open or

shorted and must be replaced.

Turn the engine speed adjusting screw (a) in or out

to obtain a no-load speed of 3100 rpm.

CAUTION: Setting the engine speed too high or too low

may damage tools and other appliances attached to the

generator.

a

1001SD15

Figure 4-5. Engine Speed Adjusting Screw

Figure 4-4. Testing Capacitor

4A-4

1007SD87

Page 19

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

4.10 Loss of Residual Magnetism in Rotor

If the rotor has been removed, or the generator has been

stored over six months, the rotor’s magnetism may be

lost. Loss of magnetism will prevent the generator from

building voltage.

WARNING

Contact with exposed connections inside the control

box or while handling battery leads can cause severe electrical shocks. Be extremely careful to avoid

touching any exposed connections. Never wear

jewelry or use tools or metal items that may make

contact across exposed connections. Review safety

rules at beginning of this manual.

To restore magnetism to the rotor, “flash” it as follows:

1. Remove the two screws and the end cover. Locate the

capacitor that is attached to the stator housing.

2. Run generator at normal no-load speed – 3100 rpm,

auto-idle off.

3. Briefly touch a 12 VDC battery across the two capacitor

connections to pulse the auxiliary winding. The leads

should remain attached to capacitor. The polarity of

the battery leads is not important.

CAUTION: DO NOT hold battery leads on connection

longer than two seconds.

The output voltage should quickly come up to normal

levels. Repeat if necessary. See Figure 4-6.

4. Stop engine and replace end cover.

Stator Hous-

ing

Capacitor

12 VDC

Battery

1023SD45

Figure 4-6. “Flashing” the Rotor

4A-5

Page 20

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

POS

NEGPOS

NEG

4.11 Receptacle Panel Wiring

Remove receptacle panel from control box and inspect

the wiring for worn or loose wires. Make sure all wire

connections are secure and tight at the screws. DO NOT

allow wires to be pinched, kinked or damaged in any

way. Inspect for tight connections at circuit breakers,

capacitors, switches and receptacles. Replace any

broken or damaged parts.

4.12 Rotor Diode Testing

To check diode:

1. Disassemble generator and remove rotor. See Section

4.15

Generator Disassembly

2. Set ohmmeter in lowest scale. Test diode in forward

position. Meter should read low or close to zero.

3. Reverse meter leads and test diode in reverse position.

Meter should read high or close to infinity.

A zero reading in both directions indicates a shorted

diode. A reading of Infinity in both directions indicates an

open diode. The diode must be replaced in either case.

If one diode is defective it is recommended that both

diodes be replaced since the remaining diode may have

been weakened.

To remove diode, use a soldering iron to soften solder

and remove wires.

When soldering on wires do not allow soldering iron to

remain on diodes longer than 10 seconds or diode may

be damaged.

.

HIGH VALUE

LOW VALUE

Figure 4-7. Rotor Diode Testing

4A-6

1024SD03

Page 21

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

4.13 Stator Winding Testing

The stator includes the main winding and the auxiliary

winding.

To check stator windings:

1. Unplug stator connector at control box.

2. Disconnect ground wire.

3. Set ohmmeter to lowest scale. Place meter leads on

connector terminals as shown and record resistance

values, see Figure 4-8.

Check resistance values with those listed on Table 4-1.

A high or low reading indicates an open or shorted

winding and the stator must be replaced.

4. Test for grounded windings by checking for continuity

between winding and metal frame.

If continuity exists, winding is grounded and stator

assembly must be replaced.

Auxiliary Windings

Capacitor

Note:

Make sure stator is completely disconnected

from generator. The main winding is intentionally

grounded to the generator to form a neutral and will

give a false reading.

5. Check for continuity between auxiliary winding and

main winding. If continuity exists, the auxiliary winding

has a short to the main winding and stator must be

replaced.

6. Test the auxilliary windings by disconnecting themfrom

the capacitor and taking a resistance reading. Reading

should compare with the value in Table 4-1.

Table 4-1.

Resistance Values (Ohms)

niaM

gnidniW

yrailixuA

gnidniW

rotoR

gnidniW

819,040,121,8

Resistance values are very small and require a good

quality meter with the ability to be zeroed out. A poor

quality meter may not provide accurate readings.

All resistance values are approximate.

1023SD46

Figure 4-8. Stator Winding Testing

4A-7

Page 22

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

POS

NEG

4.14 Rotor Winding Testing

Before testing rotor, visually inspect windings for dark

streaks which indicate a burned or shorted winding.

Rotate ball bearing by hand. Replace it if it is rough or

noisy.

To check rotor:

1. Remove end cover, locknut, stator and rotor from

generator. See Section 4.15

2. Unsolder wires from diodes, being careful not to break

wires.

3. Measure rotor resistance as shown in Figure 4-9.

4. Record resistance values of both windings and compare them with values listed in Table 4-1.

Generator Disassembly

.

5. Check for grounded windings by holding one meter

lead to winding and other lead to metal frame on rotor.

Replace rotor if windings are open, shorted internally or

shorted to metal frame.

2

1024SD04

Figure 4-9. Rotor Winding Testing

3

4

5

8

7

13 ft. lbs.

(17.5 Nm)

5

1

15

14

4A-8

13

Figure 4-10. Brushless Generator

12

9

10

11

1023SD47

Page 23

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

4.15 Generator Disassembly

Capacitor

1. Remove the two end cover screws (10) and the end

cover (9). See Figure 4-10.

2. Disconnect the leads from the capacitor

nylon tie wrap, and remove the capacitor mounting

screw.

(11), cut the

Stator

1. Remove the control panel, unscrew the ground wire

(14) and unplug the stator wire (15) from the back of

the panel. See Figure 4-10.

2. Remove the shaft securing nut (7).

3. Remove the four nuts (13) securing the generator

frame (12) to the engine adapter flange.

4. Remove the two bolts and nuts that secure the stator

(12) to the shock mount bracket.

5. With a block of wood and a mallet, tap stator frame

away from the engine. Withdraw stator frame

assembly (12) over the rotor (3) carefully to avoid

damage to windings in the stator or rotor.

Note:

skip step 6.

6. Support the rotor weight with a sling or place a block

If the rotor comes out with the stator,

between the rotor and base.

Diode and/or Varistor

1. Unsolder leads from the diodes (5) and (8) and

unscrew diode stud. See Figure 4-10.

2. Unsolder varistor lead from the solder tag on the

diode stud.

3. Remove the silicon sealant supporting the varistor

from the diode bracket (4).

4.16 Generator Assembly

When assembling the generator be sure to observe the

following:

1. Install diodes (5) to the diode bracket (4) assembly

on the rotor, by placing the solder tags on the diode

stud and tighten to the diode base. See Figure 4-10.

2. Insert varistor leads first, and push varistor well

down into the diode bracket assembly recess. Solder

leads to the diode pin and the solder tag on the diode

stud. Reseal varistor with silicon sealant.

3. Make sure inner taper on rotor and outer taper on the

engine crankshaft are clean and free of rust and oil.

Rotor

Rotor (3) removed with stator:

1. Place stator on flat surface with bearing (8) end up.

Elevate the stator (12) by placing two blocks of wood

on the edge of the stator frame to allow the rotor to

drop. See Figure 4-10.

2. Partially screw one of the frame mounting bolts into

the bearing and tap screw with a mallet. The rotor

should drop out of the stator.

Rotor (3) still attached to the engine:

1. Remove stator per instructions above.

2. Release the rotor (3) from the engine shaft by

supporting rotor in one hand and with a mallet,

striking firmly on a pole face.

4. Install the rotor (3) on crankshaft.

5. Slide stator (12) over the rotor carefully to avoid

hitting and damaging windings. Tap the frame onto

the rotor bearing.

6. Attach the four nuts (13) to secure frame to the

engine adapter flange.

7. Install the shaft securing nut (7). Tighten to 13 ft. lbs.

(17.5 Nm).

8. Install the capacitor (11) using the mounting screw

and a new nylon tie wrap. Re-attach the two leads.

9. Install the end cover (9) and two mounting screws

(10).

10. Reconnect the ground wire (14) and the stator wire

(15) to the control panel, and reinstall panel.

4A-9

Page 24

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

4.17 Troubleshooting

Table 4-2.

Generator Chart

motpmySesuaCelbissoPnoituloS

toNseoDenignE

tratS

.1.noitisop”FFO“nisihctiwsenignE.1.noitisop”TRATS“othctiwsenigneevoM

.2nodnaknatleufrednusevlavleuF

.desolceraenigne

.3.ytpmesiknatleuF.3.knatleuflliF

.2.sevlavleufnepO

.4.noitisopgnorwnisirevelekohC.4.noitisoptcerrocotrevelekohcevoM

.5.noitidnocroopnisigulpkrapS.5.gulpkrapsecalpeR

.6.esoolsipacgulpkrapS.6.pacgulpkrapsnethgiT

.7.wolsilevellioenignE.7.liollifeR

egatloVtuptuOoN.1.wolsootdeepsenignE.1,mpr0013otdeepsenigneesaercnI

.2.neporekaerbtiucriC.2.rekaerbteseR

.3.nepoIFG.3.evitcefedfiecalpeR.BCLEteserdnatseT

.4.msitengamlaudiserfossoL.4)01.4noitceseeS(.sdleifrotorhsalF

.5.hctiwsroelcatpecerevitcefeD.5.riaperdnastnenopmocdnagniriwtcepsnI

.6.detrohsroneposedoidrotoR.6)21.4noitceseeS(.ecalperdnasedoidtseT

.7.sgnidniwrotatsdetrohsronepO.7)31.4noitceseeS(.ecalperdnarotatstseT

.8.sgnidniwrotordetrohsronepO.8)41.4noitceseeS(.ecalperdnarotortseT

.9lortnocotrotarenegmorfrotcennoC

.detcennocsidroesoolsilenap

.9.ylthgitllatsnI

.)enignedloca

gnitratsnehwrevelekohcesolC(

)9.4noitceseeS(.daol-on

.tnerrucgnikael,evitcefedecnailpparolooT

)7.4noitceseeS(

)11.4noitceseeS(

egatloVwoL.1002–041neewtebegatlovdaol-oN

.2,deepsgnitarepowolebylthgilsenignE

.3.evitcefedsiroticapaC.3.yrassecenfiecalperdnaroticapactseT

.4.edoidtaffonekorberiwgnidniwrotoR.4.edoidoteriwredloseR

.5.detrohsyllaitrapgnidniwrotoR.5ecalpeR.ecnatsisergnidniwrotortseT

.6.tfahsknarcenignenognippilsrotoR.6.detrohsyllaitrapgnidniwrotoR

egatloVhgiH.1.hgihootdeepsenignE.1,mpr0013otdeepsenigneecudeR

egatloVdaol-oN

sidaoLnehw

deilppA

.1.daolrednunwodgniggulenignE.1erotserotlaunamriaperenigneotrefeR

sllaFtublamroN

.deeps

4A-10

tcerroctagnitarepoenigne,stlov

.1.detrohsroneporotornoedoidenO

.2,mpr0013otdeepsenigneesaercnI

.tuptuollaespallocothguonetontub

)8.4noitceseeS(

.rotor

)41.4noitceseeS(

.rewopenigne

)9.4noitceseeS(.daol-on

)9.4noitceseeS(.daol-on

)21.4noitceseeS(.sedoidllaecalpeR

Page 25

50 HZ PORTABLE GENERATORS G2.1A/G2.1AE 4A

4.18 Periodic Maintenance Schedule

.leveltcerrocotlliF.lioenignekcehC

.renaelcriakcehC

*.renaelcrianaelC

.lioenigneegnahC

.roterubractapuctnemideskcehC

.gulpkrapstsujdadnanaelC

.)yrosseccalanoitpo(retserrakrapsnaelC

*.ecnaraelcevlavtsujdadnakcehC

*.knatleufnaelC

.enilleuffonoitidnockcehC

.yrassecennehwecalpeR

* Service more frequently in dusty conditions.

yliaD

erofeB

gnitratS

3yrevE

roshtnom

sruoh05

6yrevE

roshtnom

sruoh001

yrevE

roraey

sruoh003

yrevE

roraey

sruoh005

•

•

•

•

•

•

•

.yrassecennehwecalpeR.stnuomkcohskcehC

•

•

•

••

Table 4-3.

Engine Service

Normal servicing of the engine such as cleaning the air cleaner, sediment cup, carburetor adjustments, auto idle speed

and engine speed can be located in the Operator’s manual. In depth engine service should be performed by qualified

personnel or by the nearest Honda dealer.

4.19 Storing/Transporting

Before storing generator for a long period of time:

1. Close the fuel valve and remove and empty sediment

cup under carburetor.

2. Disconnect the fuel line from the carburetor. Place

open end of fuel line into a suitable container and open

fuel valve to drain fuel from tank.

WARNING

Gasoline is extremely flammable. Drain fuel tank in

a well-ventilated area. DO NOT drain tank in an area

with flames or sparks.

3. Loosen the drain screw on the carburetor and drain

any remaining fuel from carburetor.

4. Change the engine oil.

5. Remove the spark plug and pour approximately one

tablespoon (1 ounce) of clean engine oil into the

cylinder. Crank the engine a few turns to distribute the

oil to the inside of the cylinder walls.

6. Pull the starter rope slowly until resistance is felt and

leave handle in this position. This ensures that the

intake and exhaust valves are closed.

7. Store generator in a clean, dry area.

WARNING

To avoid burns or fire hazards, let engine cool before

transporting generator or storing indoors.

Turn the fuel valves under the tank and on engine to

the off position and keep the engine level to prevent

fuel from spilling.

4A-11

Page 26

4A G2.1A/G2.1AE 50 HZ PORTABLE GENERATORS

4.20 Wiring Schematic (G2.5A Model)

G

5

6

W- White

Y - Yellow

Br - Brown

Gr - Gray

Or - Orange

Pr - Purple

T - Tan

4

7

B

Y

B

Wire Colors

B - Black

G - Green

L - Blue

P - Pink

R - Red

LL-Light blue

7

G/Y

R/Gr

G/Y

R/B

G/Y

B/R

LL/Gr

LL/B

3

B(3)

B(1)

2

1

B(2)

B(4)

2

1

R/W

2

LL

R

4

R

Br

3

2

W

Br

1

1

G/Y

LL

1

L

ABC

4A-12

G/Y

B

10

1 = Main stator winding

2 = Main circuit breaker

3 = Earth-leakage circuit breaker (G2.1AE only)

4 = Ignition switch

5 = Oil level switch

6 = Coil

7 = 16 Amp receptacle

8 = Rotor winding

9 = Capacitor (25µF)

10 = Auxiliary winding

9

B

8

C = Engine

B = Control box

A = Generator

1020SD79

Page 27

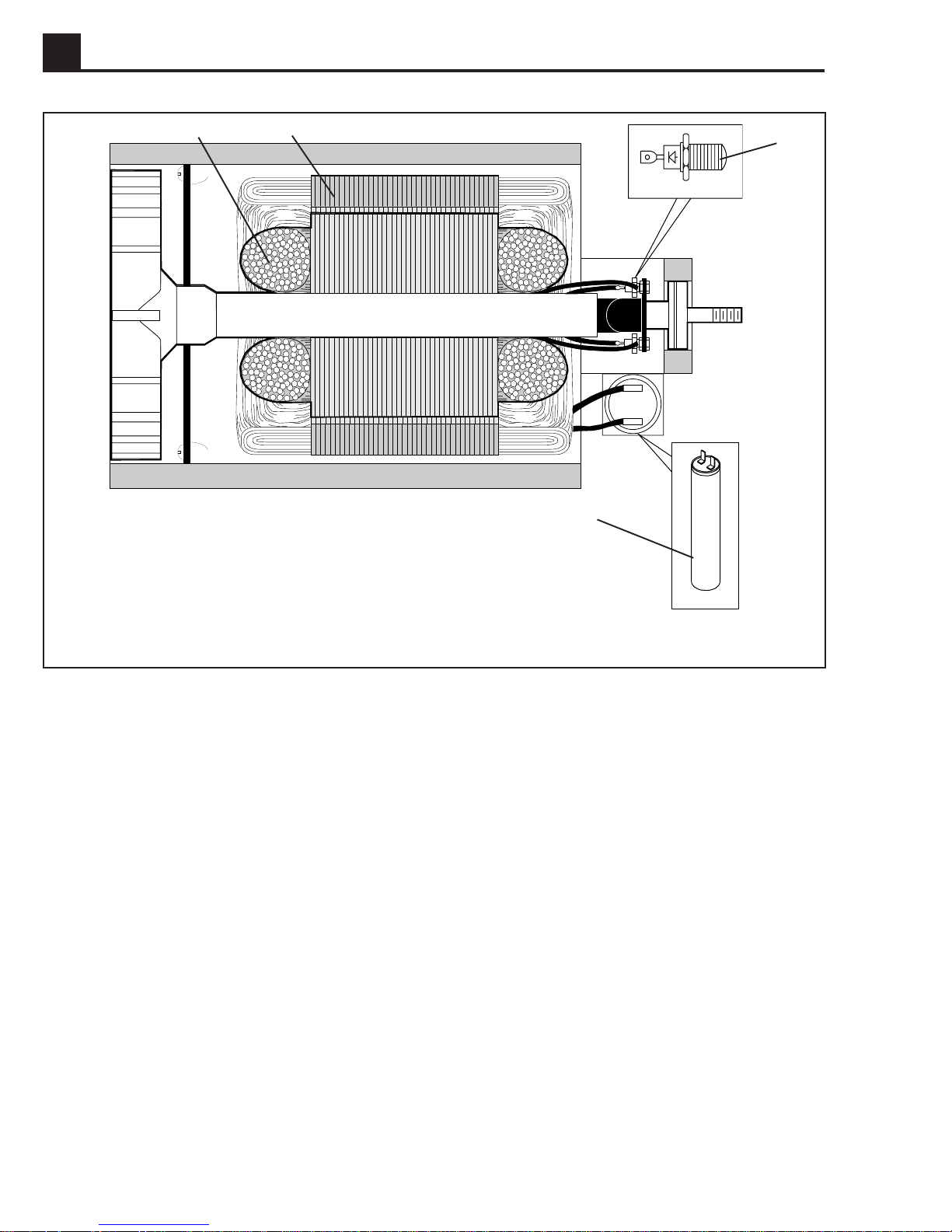

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

5.1 Theory of Operation – Brush Generators

Basic Generator Theory

These generator models use a brush/slip ring design to

generate and regulate power and consist of a rotor,

stator, diode bridge, and an auxiliary winding. They also

incorporate a choke that is connected in series with the

auxiliary winding. The choke’s purpose is to bring the

current in the auxiliary winding “in phase” with the main

windings. The current from the auxiliary winding is carried

to the rotor via the brushes and slip rings.

The generators also contain an Automatic Voltage

Regulator (AVR) that maintains a specific voltage output

regardless of load. The voltage regulator accomplishes

this by regulating DC current from the auxiliary winding.

When the load on the generator increases, the voltage

regulator allows additional DC current into the main rotor.

The additional DC current allows the generator to increase

output and maintain the desired output voltage.

Brush and Slip

Bridge Rectifier

c

Ring Assembly

Auxiliary

Winding

a

These models are designed to operate with close

regulation when supplying single phase loads. The

principle of operation is schematically represented in

Figure 5-1, and a cross-sectional view in Figure 5-2. The

auxiliary winding (a) provides excitation power through

a choke (b) and bridge rectifier (c) into the rotor winding

(d) via slip rings and brushes. The AVR (e) diverts

excess excitation to maintain the stator winding (f)

output voltage within close limits. The main stator winding

is designed for series/parallel connection to give a dual

voltage output.

Automatic

Voltage

Regulator

e

b

Choke

d

Rotor

Winding

f

Main

Stator

Winding

Figure 5-1. Principle of Operation Schematic

f

Main

Stator

Winding

1022SD73

5A-1

Page 28

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

F1

a b

Z3

e

Voltage Adjust Pot

F2

F2

F1

L2

L1

Z2

d

F1

F2

c

Figure 5-2. Brush-Type Generator

5.2 Rotor

The inside of the rotor shaft is tapered and connected

directly to the taper on the engine crankshaft. This end is

supported by the engine crankshaft bearing. The opposite end of the rotor is supported by a bearing housed in

the generator housing. This end also contains the two slip

rings. There are two individual coils wound on the rotor

(a). When the engine is running, these two windings

create the magnetic field for the main stator windings.

1023SD48

5.3 Stator

The stator (b) houses both the main windings and

auxiliary winding. The main windings are connected

directly to the main circuit breaker and voltage selector

switch to supply power to the output receptacles. The

auxiliary winding induces the initial current in the field

windings of the rotor. It is connected directly to the choke

and the AC input to the bridge rectifier.

5A-2

Page 29

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

5.4 Automatic Voltage Regulator (AVR)

The Automatic Voltage Regulator (AVR) (c) provides the

generator with a means of maintaining a specific voltage

regardless of load. The AVR accomplishes this by

regulating DC current from the auxiliary winding. When

the load on the generator increases, the AVR allows

additional DC current into the rotor. The additional DC

voltage allows the generator to increase output and

maintain voltage.

5.5 Choke

The purpose of the choke (d) is to bring the auxiliary

winding “in phase” with the main windings.

5.6 Bridge Rectifier

The bridge rectifier (e) is located on the stator housing

and is placed in a cooling air flow of the rotor. This bridge

rectifier forms a full wave rectifier to convert induced AC

current in the auxilliary winding to DC current.

5A-3

Page 30

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

5.7 Main Circuit Breaker

The circuit breaker protects the generator from severe

overloads or short circuits. If the circuit breaker opens,

turn the engine off immediately and determine the cause

before restarting. Check the appliances and tools attached

to the generator for defects and make sure their power

requirements do not exceed the power rating of the

generator or the current limit of the receptacles.

When the circuit breaker opens, the breaker lever will

snap down. To reset the circuit breaker, lift lever up. See

Figures 5-5 and 5-6.

5.8 Earth-leakage Circuit Breaker

Generator models G3.3AE, G4.6AE, GS4.6AE, and

GS5.7AE are equipped with an earth-leakage circuit

breaker. The circuit breaker is current-operated and

shuts off the power to the receptacles when a ground fault

of 30 milli-Amps or greater occurs in the generator or to

a piece of equipment attached to the generator. The

circuit breaker is located on the control panel and should

be tested for proper operation every time the generator

is used.

To test the earth-leakage circuit breaker:

Start the generator. Place main circuit breaker in closed

position. Push the TEST button (g) on the circuit breaker.

The circuit breaker lever will lower to the open position

(a2). Power is now off at both receptacles. If the lever

does not lower, the circuit breaker is not working. Do not

use the generator until the problem can be corrected. To

restore power to the receptacles, raise the circuit breaker

lever to the closed position (a

If the circuit breaker lever lowers to the open position

during operation, stop the generator and check it and

equipment for defects. Repair all defects before operating generator.

).

1

T

E

S

T

Figure 5-4a. ELCB for G3.3AE, G4.6AE, and

GS4.6AE Models

5A-4

a

1

a

2

g

1020SD80

g

1020SD89

Figure 5-4b. ELCB for GS5.7AE Models

a

1

a

2

Page 31

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

cbdef

a

a

a

g

1

2

1

2

3

1

4

365

2

Control Panel

a Main circuit breaker - 15 Amp.

b Australian style receptacle.

c Danish IP44 style receptacle.

d Swiss IP X4 style receptacle.

e France/Belgium IP44 style receptacle.

f Schuko IP44 (CEE 7) style receptacle.

g Earth-leakage circuit breaker (G3.3AE, G4.6AE, GS4.6AE).

Figure 5-5. Control Panel (G3.3A, G4.6A, and GS4.6A Models)

230V

230V

T

E

S

T

1031SD41

b

j

1

j

2

j

3

j

2

3

1

c

65

4

def

1

3

2

Control Panel

a Main circuit breaker - 9 Amp.

b Australian style receptacle.

c Danish IP44 style receptacle.

d Swiss IP X4 style receptacle.

e France/Belgium IP44 style, 230 Volt receptacle.

f Schuko IP44 (CEE 7) style, 230 Volt receptacle.

g Earth-leakage circuit breaker (GS5.7AE).

h 3 Phase/400 volt (CEE 17, 3P+N+E, IP44)receptacle.

j Engine crank switch.

h

a

a

1

230V

a

2

400V

g

1031SD42

Figure 5-6. Control Panel (GS5.7A Models)

5A-5

Page 32

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

5.9 Engine Speed (G3.3A, G5.7A,and GS5.7A Models)

Generators require a fixed engine speed to maintain the

correct voltage. Engine speed is controlled by a governor

which automatically adjusts to varying loads on the

engine to maintain a constant speed of 3600 rpm. There

is no throttle control.

To set the engine to the proper speed:

k

Turn the speed adjusting screw

no-load speed of 3100 rpm. See Figure 5-7.

CAUTION: Setting the engine speed too high or too low

may damage tools and other appliances attached to the

generator.

(k) in or out to obtain a

1001SD15

Figure 5-7. Engine Speed Adjusting Screw

5A-6

Page 33

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

5.10 Periodic Maintenance Schedule (G3.7A, G5.6A, and GS5.6A Models)

yliaD

erofeB

gnitratS

.leveltcerrocotlliF.lioenignekcehC

•

3yrevE

roshtnom

sruoh05

6yrevE

roshtnom

sruoh001

.renaelcriakcehC •

*.renaelcrianaelC •

.lioenigneegnahC •

.roterubractapuctnemideskcehC •

.gulpkrapstsujdadnanaelC •

.)yrosseccalanoitpo(retserrakrapsnaelC •

.yrassecennehwecalpeR.stnuomkcohskcehC •

*.ecnaraelcevlavtsujdadnakcehC •

*.knatleufnaelC •

.enilleuffonoitidnockcehC

.yrassecennehwecalpeR

sgnirpilsdna**sehsurbfonoitidnockcehC

sledoMA6.5SGdnaA6.5G,A7.3Grof

yrevE

roraey

sruoh003

yrevE

roraey

sruoh005

•

•

* Service more frequently in dusty conditions.

** Brushes should not be less than 8mm long.

Table 5-3

Engine Service (G3.7A, G5.6A, and GS5.6A Models)

Normal servicing of the engine such as cleaning the air cleaner, sediment cup, carburetor adjustments, auto idle speed

and engine speed can be located in the Operator’s manual. In depth engine service should be performed by qualified

personnel or by the nearest Honda dealer.

5A-7

Page 34

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

Z1

Z3

F2

F1

a

Figure 5-11. Brush Type Generator

c

b

1031SD62

5.11 Loss of Residual Magnetism in Rotor

General

If the rotor has been removed, the generator stored for a considerable time, or the rotor (field) connections reversed

during service, the residual magnetism may have been destroyed. Loss of magnetism will prevent the generator from

building voltage.

To check residual voltage, run the generator at normal no-load speed and measure the voltage at 120 VAC

receptacles. This voltage should be at least 1.5 volts. If the voltage is less than 1.5 volts, the residual magnetism must

be restored by “flashing” with a 12 volt battery.

5A-8

Page 35

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

Restoring Residual Magnetism to the Brush Type Generators

Disconnect leads F1 and F2 from the brush holder (a). Run the generator at its normal speed and apply 12 volts from

a battery to the brush holder for approximately 3 seconds. Ensure the positive lead is applied to the brush holder nearest

the bearing housing. The output voltage of the generator, with the 12 volt supply connected, should be approximately

normal voltage. See Figure 5-12.

Stop the generator and reconnect leads F1 – F2.

CAUTION: Ensure the battery leads are connected to the brush holder with the correct polarity, and leads F1 – F2

are isolated from each other and earth. Loss of residual magnetism will result if leads touch ground, each other, or wrong

polarity.

5.12 Testing the Bridge Rectifier

Accessing the Bridge Rectifier

F1

1. Remove the generator cover.

2. Remove leads Z2 and Z3 from the bridge rectifier (b),

and leads F1 and F2 that go to the brush assembly.

Z3

Z3

F1

Z2

Checking Bridge Rectifier

To check the rectifier, follow these steps:

1. Set multi-meter on R x 1000 range.

2. Remove all wires connected to the rectifier.

3. Place the meter probes on two adjacent rectifier

terminals and check resistance value. See Figure

5-13.

4. Reverse the probes and recheck.

5. The meter should indicate low resistance in one

direction and a high resistance in the other direction.

6. Repeat this procedure for each adjacent set of terminals on the rectifier until all four diodes have been

checked.

F2

F2

Figure 5-12. Diode Bridge

Figure 5-13. Checking Diode Bridge

Z2

1023SD52

1023SD98

5.13 Testing the Choke

To test the choke remove wires Z1 and Z3 from the

choke (c) and the choke assembly. The resistance

value of the choke should be 7.5 ohms.

5A-9

Page 36

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

5.14 Stator Windings

The stator includes the two main power windings and the

auxiliary winding. See Figure 5-14.

To check stator windings:

1. Unplug stator connector at control box.

2. Set ohmmeter to lowest scale. Place meter leads on

connector terminals as shown and record resistance

values.

Check resistance values with those listed on Table 5-

1.

A high or low reading indicates an open or shorted

winding and the stator must be replaced.

3. Test for grounded windings by checking for continuity

between winding and metal frame.

If continuity exists, winding is grounded and stator

assembly must be replaced.

Note:

Make sure stator is completely disconnected

from generator. The main windings are intentionally

grounded to the generator to form a neutral and will

give a false reading.

4. Check for continuity between auxiliary winding and

main windings. If continuity exists, the auxiliary winding

has made contact with the main winding and stator

must be replaced.

Figure 5-14. Checking Stator

1024SD05

Table 5-1.

Resistance Values

rotareneG

ledoM

A3.3G54.090.28.01

A6.4G93.079.13.11

A6.4SG93.079.13.11

V7.5SG27.1

Resistance values are very small and require a good quality meter with the ability

to be zeroed out. Using a poor quality meter may not provide accurate readings.

All figures are approximate values in ohms.

niaM

gnidniW

)noitcesrep(

yrailixuA

gnidniW

—

rotoR

gnidniW

3.11

5A-10

Page 37

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

5.15 Rotor Windings

Before testing rotor, visually inspect windings for dark

streaks which indicate a burned or shorted winding.

Rotate ball bearing by hand. Replace it if it is rough, noisy

or dry.

Checking Rotor

1. Remove end cover and brush assembly.

2. Measure resistance as shown in the illustration, by

measuring the winding at the slip rings. See Figure

5-15.

3. Record resistance values of both windings and

compare them with values listed in Table 5-1.

4. Check for grounded windings by holding one meter

lead to winding and other lead to metal frame on rotor.

Replace rotor if windings are open, shorted internally or

shorted to metal frame.

5.16 Slip Rings and Brushes

Slip Rings

Inspect the slip rings for dirt or damage. If the slip rings

are dirty, use an eraser or non-metallic abrasive pad to

clean the rings and then retry the generator.

Brushes

Inspect the brushes for damage, dirt, freedom of

movement, or brush length. Brushes less than 8 mm in

length should be replaced. Also replace damaged

brushes.

5.17 Automatic Voltage Regulator

To check the regulator:

• If the generator has low voltage, approximately 2 – 5

VAC as measured at the 120 VAC receptacles,

remove F1 and F2 from the regulator. Start and run

the generator. If voltage output is approximately 150

VAC measured at the receptacles and engine speed

is 3750 rpm, replace regulator.

• If the generator has low voltage, approximately 65

VAC measured at the 120 VAC receptacles, remove

F1 and F2 from the regulator. Start and run the

generator. If voltage output is approximately 150

VAC measured at the receptacles, and engine speed

is 3750 rpm, replace regulator.

• If the generator has high voltage, approximately 150

VAC as measured at the 120 VAC receptacles, and

the engine speed is 3750 rpm, replace regulator.

1024SD02

Figure 5-15. Checking Rotor

5A-11

Page 38

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

2

1

4

8

10

7

11

16

15

14

17

30

31

25

Figure 5-16. Brush Type Generator

5A-12

22

24

18

21

19

23

20

1020SD78

Page 39

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

5.18 Generator Disassembly

Bridge Rectifier

1. Remove the two end cover screws (19) and the end

cover (20). See Figure 5-16.

2. Remove the four leads from the bridge rectifier

confirming lead markings per Figure 5-17.

(16)

F1

Z3

F1

Z3

Z2

Z2F2

F2

Figure 5-17. Diode Bridge Rectifier

3. Remove the choke/rectifier mounting screw (15).

Choke

1. Remove the bottom mounting screw (17) and carefully pull choke assembly (18) away from stator (14).

See Figure 5-16.

2. Disconnect the two leads (Z1 & Z3).

Fuel Tank and Control Box

1. Remove the fuel tank mounting bolts and tilt the tank

to gain access to the gas line and shut off valve.

1023SD53

2. Remove 3 mounting screws

3. If brushes

terminal plate and withdraw springs and brushes.

New brushes must be seated using a medium grade

abrasive cloth.

(22) are to be changed, remove the brush

(25).

Stator

1. Remove the shaft securing nut (7).

2. Remove the four nuts (11) from the four studs (2)

securing the generator frame (14) to the engine

adapter flange (1).

3. For units with electric start:

A. Disconnect the negative lead from the battery

terminal first, and then the positive lead.

B. Loosen battery mounting bracket nuts and slide

mounting bracket off the battery.

C. Remove battery and store in cool dry place.

4. Remove the two bolts (30) and nuts (31) that mount

the stator (14) to the lifting bracket (10). Remove the

two bolts (30) and nuts (31) that mount the other end

of the stator (14) to the shock mounted support.

5. With a block of wood and a mallet, tap stator frame

away from the engine. Withdraw stator frame assembly

(14) over the rotor (4) carefully to avoid damage to

windings in the stator or rotor.

Note:

On some occasions, the rotor may come out with

the stator. If it does, skip step 6.

6. Support the rotor weight with a sling or place a block

between the rotor and base.

2. Close the fuel valve and disconnect the fuel line.

Remove the fuel tank.

3. Remove the screws that mount the control panel to

the control box, and disconnect the harnesses and

ground wire from the control panel. Set the control

panel aside.

4. Remove the screws that mount the control box to the

generator and set control box aside.

Automatic Voltage Regulator (AVR) and

Brush Assembly

Disconnect the leads from the AVR (24) and brush

holder (23).

1. Remove the mounting screw (21), AVR (24) and

brush holder (23).

Rotor

Rotor (3) removed with stator:

1. Place stator (14) on flat surface with bearing (8) end

up. Elevate the stator by placing two blocks of wood

on the edge of the stator frame to allow the rotor to

drop.

2. Partially screw one of the frame mounting bolts into

the bearing and tap screw with a mallet. The rotor

should drop out of the stator.

Rotor (3) still attached to the engine:

1. Remove stator per instructions above.

2. Release the rotor (3) from the engine shaft by supporting rotor in one hand and with a mallet, striking

firmly on a pole face.

5A-13

Page 40

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

5.19 Generator Assembly

When assembling the generator be sure to observe the

following:

1. Make sure inner taper on rotor and outer taper on the

engine crankshaft are clean and free of rust and oil.

See Figure 5-16.

2. Install the rotor (4) on crankshaft.

3. Slide stator (14) over the rotor carefully to avoid

hitting and damaging windings. Tap the frame onto

the rotor bearing.

4. Attach the four nuts (11) to secure frame to the

adapter studs (2).

5. Install the washer and shaft securing nut (7). Tighten

to 13 ft. lbs. (17.5 Nm).

6. If brushes were changed, reinstall the brushes,

springs and terminal plate.

Note:

New brushes must be seated using a medium

grade abrasive cloth.

7. Attach AVR (24) to brush holder (23) using three

mounting screws (25).

8. Reattach the two leads (Z1 and Z3) to the choke.

Using the two mounting screws (15) and (17), install

the diode bridge rectifier (16) and choke (18).

9. Reattach lead to bridge rectifier (16).

10. Install the end cover (20) and two mounting screws

(19).

11. Reconnect the stator wires (26) and (27) to the

control panel and reinstall panel.

5A-14

Page 41

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

2

1

4

8

10

7

11

16

15

14

17

30

31

25

22

24

18

21

19

23

20

1020SD78

5A-15

Page 42

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

5.20 Troubleshooting

Table 5-2. Generator Chart

motpmySesuaCelbissoPnoituloS

toNseoDenignE

tratS

.1.noitisop”FFO“nisihctiwsenignE.1.noitisop”TRATS“othctiwsenigneevoM

.2nodnaknatleufrednusevlavleuF

.desolceraenigne

.3.ytpmesiknatleuF.3.knatleuflliF

.2.sevlavleufnepO

.4.noitisopgnorwnisirevelekohC.4.noitisoptcerrocotrevelekohcevoM

.5.noitidnocroopnisigulpkrapS.5.gulpkrapsecalpeR

.6.esoolsipacgulpkrapS.6.pacgulpkrapsnethgiT

.7.wolsilevellioenignE.7.liollifeR

egatloVtuptuOoN.1.neporekaerbtiucriC.1.rekaerbteseR

.2.nepoIFG.2.evitcefedfiecalpeR.IFGteserdnatseT

.3.msitengamlaudiserfossoL.3)71.5noitceseeS(.sdleifrotorhsalF

.4.hctiwsroelcatpecerevitcefeD.4.riaperdnastnenopmocdnagniriwtcepsnI

.5lortnocotrotarenegmorfrotcennoC

.detcennocsidroesoolsilenap

.6sgnidniwrotatsdetrohsronepO.6)91.5noitceseeS(.ecalperdnarotatstseT

.7.sgnidniwrotordetrohsronepO.7)02.5noitceseeS(.ecalperdnarotortseT

egatloVwoL.1.evitcefedrotalugeregatlovcitamotuA.1.ecalperdnaRVAtseT

.2.ekohcevitcefeD.2)31.5noitceseeS(.ecalperdnaekohctseT

.3.reifitceregdirbedoidevitcefeD.3noitceseeS(.ecalperdnareifitcertseT

.5.ylthgitllatsnI

.)enigne

dlocagnitratsnehwrevelekohcesolC(

.tnerrucgnikael,evitcefedecnailpparolooT

)21.5noitceseeS(

)61.5noitceseeS(

)81.5

.4.nekorbrodegamadsehsurB.4.egamadroftcepsnI

.5.tfahsknarcenignenognippilsrotoR.5.tlobretnecrotornethgiT

.6.denetrohsyllaitrapgnidniwrotoR.6.rotorecalpeR.ecnatsisergnidniwrotortseT

.7.nekorbrodegamadsgnirpilS.7.tridroegamadroftcepsnI

egatloVhgiH.1.evitcefedrotalugeregatlovcitamotuA.1.ecalperdnaRVAtseT

toNeldIotuA

deepSenignE(

)gnitautculF

.1.gnitnuhronrevog,wolootdeepseldI.1.mpr0562otdeepselditsujdA

yltcerroCgnikroW

.2.nwolbesufpmAenO.2.esufecalpeR

.3.evitcefedhctiwseldiotuA.3)51.5noitceseeS(.hctiwsecalperdnatseT

-4

.

.5.evitcefedeludomeldiotuA.5.eludomeldiotuaecalperdnatseT

.6.dioneloseldiotuaevitcefeD.6.ecalperdnatseT

.7deepsotpuemoctonlliwtinU

5A-16

)02.5noitceseeS(

.detcennocsidssenraheriW.4.tcennoceR

)8.5dna7.5snoitceseeS(

.7.egatlovreporprofyrettabkcehC

.)ylno5.8SG/7.9SG(

Page 43

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

5.21 Wiring Schematics – Generator/Engine

Wiring Schematic (G3.3A Model)

C

BA

5

OFF

ON

6

B

LL/Gr

LL/B

G

Y

LL/B

B/R

4

R/B

B

4

R/Gr

G/Y

7

G/Y

W- White

Y - Yellow

Wire Colors

B - Black

G - Green

Br - Brown

Gr - Gray

Or - Orange

Pr - Purple

L - Blue

P - Pink

R - Red

LL-Light blue

T - Tan

6 = Oil level switch

7 = Coil

8 = Choke

9 = Auxiliary winding

10 = Rotor winding

11 = Radio interference suppressor

12 = Automatic voltage regulator

1

2

LL/W

2

R

4

R

R/W

1

L1

3

1

W

L2

3

T

2

3

LL/W

Br

11

12

4

F2

F1

LL/B

R/B

F2

B

R

2

1

Br

2

F1

R/B

L/L

L

G/Y

1

1

10

G/Y

G/Y

Z1

9

Z2

Z1

8

Z3

Z3

Z2

(G3.3AE only)

1 = Main stator winding

2 = Main circuit breaker

3 = Earth-leakage circuit breaker

4 = 16 Amp receptacle

5 = Ignition switch

A = Generator

B = Control box

C = Engine

1020SD83

5A-17

Page 44

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

Generator Wiring Schematic (G4.6A, GS4.6A Models)

W- White

Y - Yellow

Br - Brown

Gr - Gray

Or - Orange

Pr - Purple

T - Tan

4

Wire Colors

B - Black

G - Green

L - Blue

P - Pink

R - Red

LL-Light blue

LL/Gr

G/Y

LL/B

R/Gr

4

2

R

4

3

LL/W

1

R/W

LL/B

G/Y

R/B

R/B

4

LL/B

2

G/Y

1

R/B

3

1 = Main stator winding

2 = Main circuit breaker

3 = Earth-leakage circuit breaker (G4.6AE, GS4.6AE only)

4 = 16 Amp receptacle

5 = Choke

6 = Auxiliary winding

7 = Rotor winding

8 = Radio interference suppressor

9 = Automatic voltage regulator

LL/W

Br

3

2

G/Y

G/Y

1

R

W

Br

8

1

F2

F2

L2

L1

9

5A-18

B

R

F1

F1

L

Z1

1

6

Z1

Z2

5

Z3

Z3

Z2

7

1020SD85

Page 45

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

Engine Wiring Schematic (G4.6A , GS4.6AModels)

13

G

14

W- White

Y - Yellow

Br - Brown

Gr - Gray

Or - Orange

Pr - Purple

T - Tan

11

Wire Colors

B - Black

G - Green

L - Blue

P - Pink

R - Red

12

Y

LL-Light blue

1

10

B

L/W

2

3

16

R

4

15

W

5

Y

10 = Engine crank switch

11 = Oil level switch

12 = Coil

13 = Battery

14 = Charging coil

15 = Starter

16 = Starter solenoid

17 = 15 Amp fuse

B

18 = Ignition switch

L/W

1

3

4

6

G

R

18

OFF

ON

B

11

B

Y

12

2

T

5

W

17

GS4.6 Models

B/R

G4.6 Models

1021SD67

5A-19

Page 46

5A G3.3A/G4.6A/GS4.6A/GS5.7A 50 HZ PORTABLE GENERATORS

Generator Wiring Schematic (GS5.7A Models)

G/YG/YG/Y

55

2

R/W

143

2

R/W

V/W

R/Gr

R/B

Br/W

V/W

Br/R

LL/W

Br/W

35

1

N

3

LL/Gr LL/R

4

V/B

LL/W

Br/B

6T

Br/B

4

2

N

R/B

143

2

V/B

LL/B

LL/B

G/Y

W- White

Y - Yellow

Br - Brown

Wire Colors

B - Black

G - Green

L - Blue

Gr - Gray

Or - Orange

Pr - Purple

P - Pink

R - Red

LL-Light blue

T - Tan

V

Br

RU

1

3

4

V

N

1

7

5A-20

W

L2

L1

F1

LL

F2

G/Y

6

1 = Main stator winding

2 = Main circuit breaker

3 = Earth-leakage circuit breaker (GS5.7AE)

4 = 400 volt/16 Amp receptacle

5 = 230 volt/16 Amp receptacle

6 = Radio interference suppressor

7 = Automatic voltage regulator

8 = Rotor winding

6

8

F2

B

R

F1

1021SD04

Page 47

50 HZ PORTABLE GENERATORS G3.3A/G4.6A/GS4.6A/GS5.7A 5A

Engine Wiring Schematic (GS5.7A Models)

12

G

13

10

11

Y

B