Page 1

5200016123 1.3

1113

Track Excavator

ET18/20/24

This Operator's Manual includes

the AEM Safety Manual

OPERATOR’S MANUAL

5200016123

Page 2

OM/Service booklet

Operator's Manual us 5200016123 ET18 (E12-02) de/en/fr 1000279963

Service Booklet

Language Order no.

de 1000146850 ET18 (E12-02) de/it/es 1000279982

en 1000148392 ET20 (E12-03) de/en/fr 1000281454

fr 1000148394 ET20 (E12-03) de/it/es 1000281455

it 1000148395 ET24 (E12-04) de/en/fr 1000281027

Spare parts list

Language Order no.

--

Legend

Original Operator‘s Manual

Translation of original Operator‘s Manual x

Edition 1.3

Date 11/2013

Document OM ET18/20/24 us

Copyright 2013 Wacker Neuson Baumaschinen GmbH, Hörsching

Printed in Michigan, USA

All rights reserved, in particular the globally applicable copyright, right of reproduction and right of distribution.

No part of this publication may be reproduced, translated or used in any form or by any means – graphic, electronic

or mechanical including photocopying, recording, taping or information storage or retrieval systems – without prior

permission in writing from the manufacturer.

No reproduction or translation of this publication, in whole or part, without the written consent of Wacker Neuson

Linz GmbH.

Violations of legal regulations, in particular of the copyright protection, will be subject to civil and criminal prosecution.

Wacker Neuson Linz GmbH keep abreast of the latest technical developments and constantly improve their products. For this reason, we may from time to time need to make changes to diagrams and descriptions in this documentation which do not reflect products which have already been delivered and which will not be implemented on

these machines.

Technical data, dimensions and weights are given as an indication only. Responsibility for errors or omissions not

accepted. Non-metric weights and measurements are approximate.

The cover features the machine with possible optional equipment.

ET24 (E12-04) de/it/es 1000281028

-

Wacker Neuson Linz GmbH

Flughafenstraße 7

A-4063 Hörsching

Document: OM ET18/20/24 us

Order no.: 5200016123

Edition: 1.3

Page 3

Table of Contents

Table of Contents

EC declaration of conformity (Yanmar 3TNV76-SNSE12)..................................................................EG-1

Declaration of conformity without CE mark on the type lab el – except USA and Canada ( Yanmar 3TNV76-

SNSE12)EG-2

1Foreword

1.1 Operator’s Manual................................................................................................................................ 1-1

1.2 Warranty and liability ............................................................................................................................ 1-5

2 Safety Information

2.1 Safety Symbols Found in this Manual ................... ... ... ... .... ... ... ... .... ... ... ... ... ....... ... ... .... ... ... ... ... ... ......... 2-1

2.2 Warranty............................................................................................................................................... 2-2

2.3 Designated Use.................................................................................................................................... 2-2

2.4 Preparing to use the machine............................................................................................................... 2-3

2.5 Operator and Technician Qualifications and Basic Responsibilities......................... .... ... ..................... 2-6

2.6 Safety instructions Regarding Operation.............................................................................................. 2-6

2.7 Applications with Lifting Gear ................................................... ... .... ..................................................... 2-9

2.8 Attachments........................................................................................................................................ 2-10

2.9 Transport and Towing......................................................................................................................... 2-11

2.10 Safety Guidelines for Maintenance..................................................................................................... 2-11

2.11 Safety Guidelines while using Internal Combustion Engines.............................................................. 2-16

3 Introduction

3.1 Machine overview.................................................................................. ............................................... 3-1

3.2 Brief description of the machine ........................................................................................................... 3-2

3.3 Notices and regulations on use ............................................................................................................ 3-4

3.4 Labels................................................................................................................................................... 3-8

4 Putting into operation

4.1 Cab/control stand ................................................................................................................................. 4-1

4.2 Control element overview................................................................................................................... 4-29

4.3 Indicator lights and warning lights (overview)..................................................................................... 4-34

4.4 Preparatory work ................................................................................................................................ 4-37

4.5 Starting and stopping the engine........................................................................................................ 4-41

5Operation

5.1 Steering system..................................................................................... ............................................... 5-1

5.2 Accelerator actuation....................................................................................... ..................................... 5-1

5.3 Brakes .................................................................................................................................................. 5-2

5.4 Travel operation.................................................................................................................................... 5-3

5.5 Differential lock..................................................................................................................................... 5-8

5.6 Lights/signalling system........................................................................................................................ 5-8

5.7 Wiper/wash system (option) ............................................................................................................... 5-10

5.8 Heating, ventilation and air conditioning system................................................................................. 5-11

5.9 Work hydraulics.................................................................................................................................. 5-12

5.10 Attachments........................................................................................................................................ 5-40

5.11 Work operation ................................................................................................................................... 5-44

5.12 Emergency lowering........................................................................................................................... 5-49

5.13 Additional equipment/options ............................................................................................................. 5-50

5.14 Decommissioning and putting the machine back into operation......................................................... 5-57

5.15 Final decommissioning of machine..................................................................................................... 5-59

6Transport

6.1 Towing the machine ............................................................................................................................. 6-1

6.2 Loading the machine ............................................................................................................................ 6-3

6.3 Transporting the machine..................................................................................................................... 6-6

OM ET18/20/24 us 1.3 * et18_20_24us1_3IVZ.fm I-1

Page 4

7 Maintenance

7.1 Important information on maintenance ................................................................................................. 7-1

7.2 Maintenance overview.......................................................................................................................... 7-2

7.3 Fluids and lubricants........................................................................................................................... 7-10

7.4 Maintenance accesses .............. .......................................... ............................................................... 7-14

7.5 Cleaning and maintenance on or with the machine............................................................................ 7-20

7.6 Lubrication work................... ................................................................................. .............................. 7-23

7.7 Fuel system ........................................................................................................................................ 7-26

7.8 Engine lubrication system.................................................................................................. ................. 7-32

7.9 Cooling system ............. .... ... ... ... .... ..................................................................................................... 7-34

7.10 Air filter................. ................................................................................. .............................................. 7-37

7.11 V-belt .................................................................................................................................................. 7-40

7.12 Hydraulic system ................................................................................................................................ 7-41

7.13 Electrical system........ ... .... ... ... ... ......................................................................................................... 7-45

7.14 Heating, ventilation and air conditioning system................................................................................. 7-47

7.15 Washer system................................................................................................................................... 7-48

7.16 Brake system...................................................................................................................................... 7-48

7.17 Tires/tracks......................................................................................................................................... 7-49

7.18 Maintenance of attachments............................................................................................................... 7-52

7.19 Maintenance of options........... ... .... ... ... .......................................... ..................................................... 7-52

8 Troubleshooting

8.1 Diesel engine malfunctions................................................................................................................ ... 8-1

8.2 Malfunctions of the traveling drive ........................................................................................................ 8-1

8.3 Malfunctions of the hydraulic system.................................................................................................... 8-1

8.4 Malfunctions of the electrical system.................................................................................................... 8-1

8.5 Troubleshooting the air conditioning..................................................................................................... 8-1

8.6 Malfunctions of attachments................................................................................................................. 8-2

9 Specifications

9.1 Models and trade names...................................................................................................................... 9-1

9.2 Engine................................................................................................................................................... 9-1

9.3 Traveling drive/axles............................................................................................................................. 9-3

9.4 Brakes................................................................................................................................................... 9-3

9.5 Tracks................................................................................................................................................... 9-3

9.6 Steering system................................................................................................................................ . ... 9-3

9.7 Work hydraulics ................ ... ... ................................................................................. ............................. 9-3

9.8 Electrical system........ ... .... ... ... ... ........................................................................................................... 9-5

9.9 Tightening torques.................................................. .......................................... .................................... 9-7

9.10 Coolant .............................................................................................................................. .. . ... ... ... ....... 9-8

9.11 Noise emissions.................................................................................................................................... 9-8

9.12 Vibration................................................................................................................................................ 9-9

9.13 Weight................................................................................................................................................. 9-12

9.14 Payload/stability.................................................................................................................................. 9-14

Index

Index ..............................................................................................................................................................S-1

I-2 OM ET18/20/24 us 1.3 * et18_20_24us1_3IVZ.fm

Page 5

EC Declaration of Conformity

According to Machine Directive 2006/42/EC, appendix II A

Manufacturer

Wacker Neuson Linz GmbH

Flughafenstr. 7

A-4063 Hörsching

Product

Machine designation: Hydraulic excavator

Machine model: ET 18, ET 20, ET 24

Serial no.: ______________

Output (kW): 13.4 kW

Measured sound power level: 92.8 dB (A)

Guaranteed sound power level: 93 dB (A)

Conformity assessment procedure

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test

Prüf- und Zertifizierungsstelle

Fachbereich Bauwesen

Landsberger Str. 309

D-80687 Munich

Distinguishing EU number 0515

Notified body according to Directive 2000/14/EC, appendix VI:

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations and requirements of the

following Directives and standards:

2006/42/EC, 2004/108/EC, 2002/44/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-5:2012,

DIN EN 13510:2010, DIN EN ISO 3744:2010 , DIN EN ISO 3449:2008

Technical director

Responsible for documentation

Hörsching,

Place, date

Declaration of conformity

Declaration of conformity

EC declaration of conformity (Yanmar 3TNV76-SNSE12)

OM ET18/20/24 us 1.3 * et18_20_24konf.fm EG-1

Page 6

Declaration of conformity without CE mark on the type label – except

Declaration of conformity

Manufacturer

Wacker Neuson Linz GmbH

Flughafenstr. 7

A-4063 Hörsching

Product

Machine designation: Hydraulic excavator

Machine model: ET 18, ET 20, ET 24

Serial no.: ______________

Output (kW): 13.4 kW

Measured sound power level: 92.8 dB (A)

Guaranteed sound power level: 93 dB (A)

Directives and standards

We hereby declare that this product corresponds to the relevant regulations and requirements of the

following Directives and standards:

2006/42/EC, 2004/108/EC, 2002/44/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009 (except 7.3), DIN EN 474-5:2012,

DIN EN 13510:2010, DIN EN ISO 3744:2010, DIN EN ISO 3449:2008

Technical directorResponsible for documentation

Hörsching,

Place, date

USA and Canada (Yanmar 3TNV76-SNSE12)

EG-2 OM ET18/20/24 us 1.3 * et18_20_24konf.fm

Page 7

Table of Contents

Index

Foreword

1 Foreword

1.1 Operator’s Manual

Notices on this Operator’s Manual

This Operator’s Manual is stored in the compartment under the seat if the

machine is equipped with a canopy. If the machine is equipped with a cab,

this Operator’s Manual is stored behind the seat. A document box on the

headliner is available as an option for the cab version.

This Operator’s Manual contains important information on how to work

safely, correctly and economically with the machine. Therefore, it aims not

only at new personnel, but it also serves as a reference for experienced

personnel.

Furthermore, the reliability and the service life of the machine will be

increased by following the instructions in the Operator’s Manual. This is

why the Operator’s Manual must always be kept at hand in the machine.

The operator must carefully read and understand the Operator’s Manual

before starting up, servicing or repairing the machine.

This Operator’s Manual will help to familiarize yourself more easily with

the machine, thereby enabling you to use it more safely and efficiently.

This Operator’s Manual does not include special superstructures.

This Operator’s Manual will help to familiarize yourself more easily with

the machine, thereby enabling you to use it more safely and efficiently.

Please contact your dealer if you require more information on the machine

or the Operator’s Manual.

1

OM ET18/20/24 us 1.3 * et18_20_24v100.fm 1-1

Page 8

1

Information

Environment

Explanation of symbols and abbreviations

Explanation of symbols

• Identifies a list

- Identifies a subdivision of a list

➥ Description of a result

1. Identifies an activity

Follow the order of the activity!

2. Continuation of an activity

Follow the order of the activity!

A Identifies an alphabetical list

B Continuation of an alphabetical list

Cross reference formats: see page 1-1 (page)

Cross reference formats: 7 (pos. no. or table no.)

Cross reference formats: Fig. 5 (fig. no. 1)

Cross references: – see chapter “5 Operation” on page 5-1

(see chapter)

Cross references: – see “Operation” on page 5-1 (-see text)

Identifies an instruction that, when followed, provides for a more

efficient and economical use of the machine.

Failure to observe the instructions identified by this symbol can

result in damage to the environment.

1-2 OM ET18/20/24 us 1.3 * et18_20_24v100.fm

Page 9

Abbreviations

AUX = Auxiliary hydraulic circuit

B=Width

NE = Nominal width

ROPS = Roll Over Protective Structure

FOPS = Falling Objects Protective Structure

TOPS = Tip Over Protective Structure

FGPS = Front Guard Protective Structure

PS = Stabilizer blade

LS = Stick

VDS = Vertical Digging System

HSWS = Hydraulic quickhitch, Easy Lock

s/h = Se rv ice hours

1

Pos. = Position

Fig. = Figure

e.g. = for example

approx. = approximately

=

max. = maximum

min. = minimum

OM ET18/20/24 us 1.3 * et18_20_24v100.fm 1-3

Page 10

1

Conversion table

The rounded imperial values are indicated in brackets, for example 1060

cm³ (64.7 in³).

Volume unit

1 cm³ (0.061 in³)

1 m³ (35.31 ft³)

1 ml (0.034 US fl.oz.)

1 l (0.26 gal)

1 l/min (0.26 gal/min)

Unit of length

1 mm (0.039 in)

1 m (3.28 ft)

Weight

1 kg (2.2 lbs)

1 g (0.035 oz)

Pressure

1 bar (14.5 psi)

1 kg/cm² (14.22 lbs/in²)

Force/output

1 kN (224.81 lbf)

1 kW (1.34 hp)

1 PS (0.986 hp)

Torque

1 Nm (0.74 ft.lbs)

Speed

1 kph (0.62 mph)

Acceleration

1 m/s² (3.28 ft/s²)

1-4 OM ET18/20/24 us 1.3 * et18_20_24v100.fm

Page 11

1.2 Warranty and liability

Exemption from warranty and liability

Warranty

Warranty claims can be made only if the conditions of warranty have been

observed. They are included in the General Conditions of Sales and

Delivery for new machines and spare parts sold by the dealers of Wacker

Neuson Linz GmbH. Furthermore, all instructions in this Operator’s

Manual must be observed.

Have the maintenance on or with the machine, deliver y inspection and the

entries in the service booklet performed by a Wacker Neuson service

center, otherwise warranty claims will not be acknowledged.

Liability

• Modifying Wacker Neuson products and fitting them with additional

equipment and attachments that are not inc l ud ed in our deliv er y

program requires Wacker Neuson’s written authorization, otherwise

warranty and product liability for possible damage caused by these

modifications shall not be applicable.

• The safety of the machine can be negatively affected by performing

machine modifications without proper authority and by using spare

parts, equipment, attachments and optio n al eq uip men t th at ha ve not

been checked and released by Wacker Neuson GmbH. Warranty and

product liability for possible damage caused by these modifications

shall not be applicable.

• Wacker Neuson Linz GmbH shall not be liable for personal injury and/

or damage to property caused by failure to observe the safety instructions and the Operator’s Manual, and by the negligence of the duty to

exercise due care when:

- handling

- operating

- servicing and performing maintenance on or with the machine and

- repairing the machine. This is also applicable in those cases in which

special attention has not been drawn to the duty to exercise due

care, in the safety instructions as well as in the Operator’s an d

maintenance manuals.

- Read and understand the Operator’s Manual before starting up,

servicing or repairing the machine. Observe all safety instructions.

1

OM ET18/20/24 us 1.3 * et18_20_24v100.fm 1-5

Page 12

1

Notes:

1-6 OM ET18/20/24 us 1.3 * et18_20_24v100.fm

Page 13

2 Safety Information

DANGER

WARNING

CAUTION

Notice

2.1 Safety Symbols Found in this Manual

This is the safety alert symbol. It is used to alert you to potential personal

hazards.

• Obey all safety messages that follow this symbol.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Consequences in case of non-observance.

► Obey all safety messages that follow this symbol to avoid

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Consequences in case of non-observance.

► Obey all safety messages that follow this symbol to avoid

possible injury or death

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

Consequences in case of non-observance

► Obey all safety messages that follow this symbol to avoid

possible minor or moderate injury.

NOTICE indicates a situation which, if not avoided, could result

in property damage.

Note: Contains additional informatio n impo rt an t to a pro ced u re .

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-1

Page 14

Information

Environment

2.2 Warranty

2.3 Designated Use

Information identifies an instruction that, when followed,

provides for a more efficient and economical use of the machine.

Failure to observe the instructions identified by this symbol can

result in damage to the environment. The environment is in

danger if environmentally hazardous material, such as waste oil,

is not subject to proper use or disposal.

Warranty claims must be submitted to your Wacker Neuson dealer only.

1. In accordance with its designated use, the ma ch in e ma y be use d

ONLY for moving earth, gravel, coarse gravel or ballast and rubble. It

may also be used for working with the attachments approved in the

“Fields of Application” chapter.

2. No other applications are designated for the use of the machine.

Wacker Neuson will not be liable for damage resulting from use other

than mentioned above. The operator alone will bear the risk.

3. “Designated use” also includes observing the instructions set forth in

this Operator’s Manual and observing the maintenance schedule.

4. Machine safety can be negatively affected by performing machine

modifications without proper authority and by using spare parts,

equipment,

attachments and optional equipment which have not been checked

and released by Wacker Neuson. Wacker Neuson will not be liable for

damage resulting from unapproved parts or unauthorized

modifications.

5. Wacker Neuson shall not be liable for personal injury and/or damage to

property caused by failure to observe the safety instructions on labels

and in this Operator’s Manual, and by the negligence of the duty to

exercise due care when:

• transporting the machine

• operating the machine

• servicing the machine and performing ma inte n an ce on or with th e

machine

• repairing the machine

This is also applicable when special attention has not been drawn to the

duty to exercise due care.

1. Read and understand this Operator’s Manual before starting, moving,

operating, servicing or repairing the machine. Observe all safety

instructions.

2. The machine shall NOT be used for transport jobs on public roads!

2-2 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 15

2.4 Preparing to use the machine

Conditions for use

• The machine has been designed and built in accordance with state-of-

the-art standards and recognized safety regulations. Nevertheless, its

use can constitute a risk to the operator or to third parties, or cause

damage to the machine and to other material property.

• Read and follow this Operator’s Manual and other manuals that

accompany the machine.

• The machine must only be used in accordance with its designated use

and the instructions set forth in this Operator’s Manual.

• The machine must only be used by qualified operators who are fully

aware of the risks involved in operating the machin e.

• Do not start, move or operate a damaged or malfunctioning machine.

Any mechanical dysfunctions, especially th os e aff ec tin g the s afet y of

the machine, must be repaired immediately. Only qualified technicians

shall determine how to move a damaged or malfunctioning mach ine to

a safe place for diagnoses and repair.

• The operator/machine owner commits himself to op erate and keep the

machine in serviceable condition and, if necessary or required by law,

to require the operating or servicing persons to wear protective clothing

and safety equipment

Operator training and knowledge

• Always keep this Operator’s Manual and other manuals that

accompany the machine in their storage compartment provided in the

operator station on the machine. Immediately replace an incomplete or

illegible Operator’s Manual.

• All persons working on or with the machine must read and understand

the safety information in this Manual before beginning work. This

applies especially to persons working only occasionally on the

machine, such as performing set-up or maintenance tasks.

• Follow, and instruct the operator in, legal and other mandatory regula-

tions relevant to accident prevention and envir on m en ta l

protection.These may include handling hazardous sub stances, issuing

and/or wearing personal protective equipment, or obeying traffic

regulations.

• The operator/machine owner must regularly ensure that all persons

entrusted with operation or maintenance of the machine are working in

compliance with this Operator's Manual and are aware of the risks and

safety factors of the machine.

Preparing for use

• Before starting up the machine, ALWAYS inspect the machin e to make

sure that it is ready for safe work and travel operation.

• Wear close-fitting work clothes that do not hinder movement. Tie back

long hair and remove all jewelry (including rings).

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-3

Page 16

Modifications and spare parts

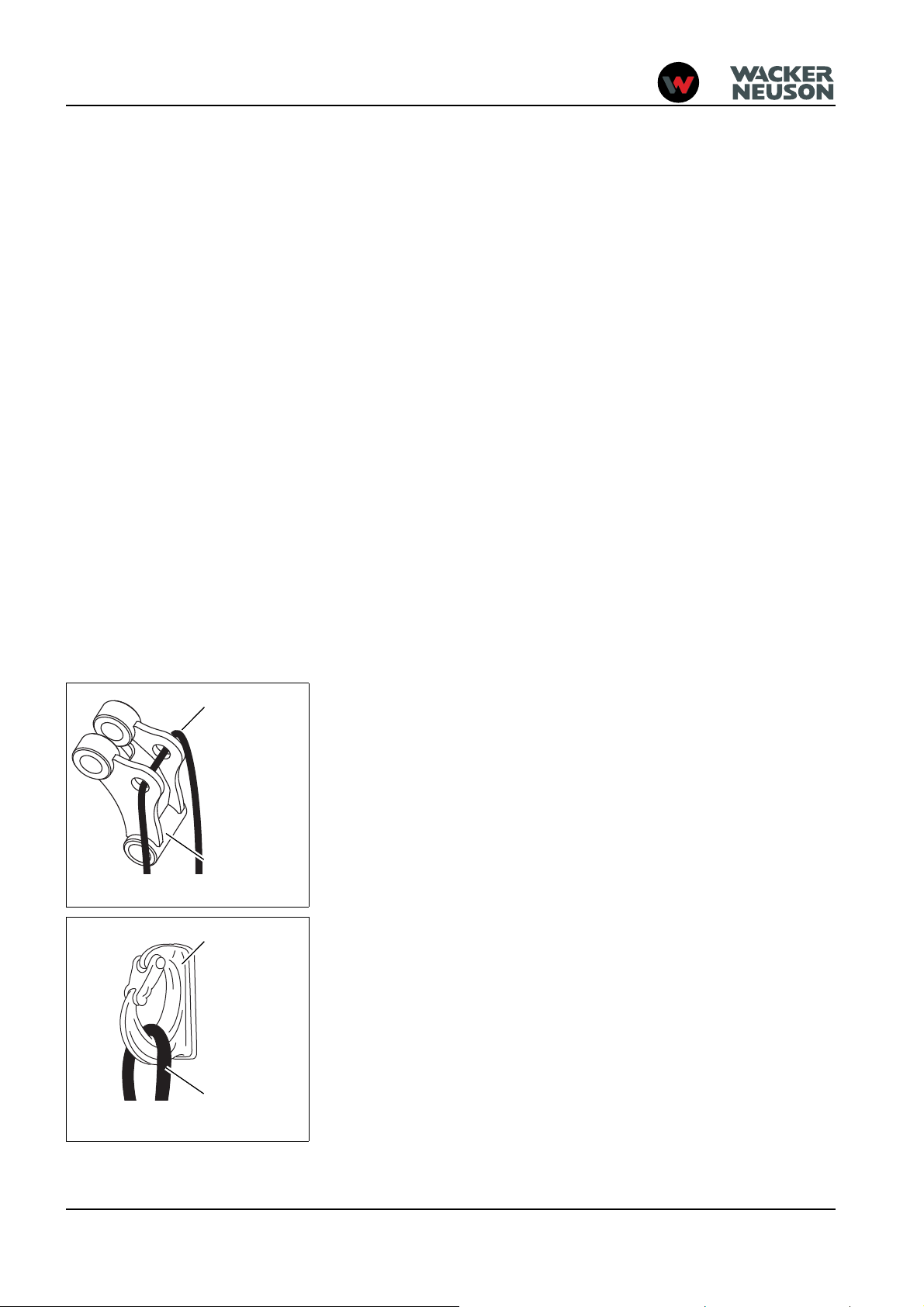

Abb. 1: Lifting gear – joint rod

Lifting gear

(joint rod)

Sling

Abb. 2: Load hook

Lifting gear

Load hook

• NEVER make any modifications, additions or conversions to the

• Spare parts must comply with the technical requirements specified by

• The operator/machine owner commits hi mself to operate and keep the

• In the event of safety-relevant modifications or changes on the

• Safety-relevant damage or malfunctions of the machine must be

Applications with lifting gear

Lifting gear applications are procedures involving raising, transpor ting and

lowering loads with the help of slings and load-securing devices (e.g.

ropes, chains).

No applications with lifting gear under any circum st an ce s!

Machines with a maximum authorized lifting capacity of over 1000 kg

(2,205 lbs.) or an overturning moment of over 40,000 Nm (29,500 ft.lbs.)

may be used for lifting gear applications if the following conditions are

fulfilled:

• Acoustic and optical warning device

• Load holding control valve – see chapter 3.17 “Load holding control

• Proper equipment for slinging and securing the load must be available

• The lift capacity table must be observed – see chapter 6 Specifications

machine and its superstructures (for example, cab, etc.), or the

machine’s attachments, without the approval of Wacker Neuson! Such

modifications may affect safety and/or machine performance. This also

applies to the installation and adjustment of safety device s and valves,

as well as to welding work on load-bearing elements.

Wacker Neuson. Contact your Wacker Neuson dealer for assistance.

machine in perfect condition, and, if necessary or required by law, to

require the operating or servicing persons to wear protective clothing

etc.

machine or of its behavior, stop the machine immediately and report

the malfunction to the competent authority/person.

rectified immediately.

– see chapter 3.20 Safe load indicator (option) on page 3-72

valve” safety feature (option) on page 3-65

(joint rod enabling loads to be picked up, Powertilt unit with load hook).

on page 6-1.

- Get informed on and follow the legal regulations of your country.

2-4 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Instructions on fastening loads

• The help of an accompanying person is necessary for securing and

detaching the load.

• The load must be secured so as to prevent it from falling or slipping.

• Fasten the lifting gear so that it is not possible to unhook the sling

unintentionally.

• Position the lifting gear ensuring the sling is not deflected by other

parts.

• Do not use any lifting gear and slings that are damaged or not sufficiently dimensioned.

• The lifting gear must be designed to withstand the load s tha t can arise

in the different positions of the work equipment or parts of the boom.

Lateral loads and diagonal tensile forces must also be taken into

account.

Page 17

• The lifting gear must be checked regularly by a technician, at least

once a year.

• Replace damaged lifting gear immediately.

• Fasten lifting gear and slings avoiding danger (rotating parts, crushing

or shearing) for the person securing the load. Furthermore, neither

must the work equipment be affected by the lifting gear, nor must the

functions of the lifting gear be affected by external influences (e.g. dirt

that cannot be removed by simple means).

• Do not place slings over sharp edges.

• Always wear protective gloves and a hard hat when working with lifting

gear and slings.

• The persons attaching or securing loads may approach the boom from

the side only, and only after the machine operator has given his

permission. The machine operator may give his permission only after

the machine is at a standstill and the work attachment no longer

moves!

General instructions

• Staying under suspended loads, in the danger zone or under the

machine's attachment is prohibited.

• The machine operator and the person attaching or securing the load

must have visual contact.

• Persons guiding the load or securing it must stay in visual contact with

the machine operator! Should this not be possible, ask anoth er person

to guide.

• The machine operator must guide the load the nearest possible to the

ground and avoid any oscillating or swinging movements!

• Perform machine travel with a raised load only if the path of the

machine is level!

• The machine operator must not raise loads over persons.

• The machine operator may not leave his seat as long as the load is

raised.

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-5

Page 18

2.5 Operator and Technician Qualifications and Basic Responsibilities

Operator/machine owner responsibility

• Only allow trained and experienced individuals to travel, maintain, or

repair the machine. NEVER let unauthorized or underaged persons

operate with the machine.

• Clearly and unequivocally define the individual responsibilities of the

operator and technician for operation, maintenance, and repair.

• Define the machine operator’s responsibilities on the job site and for

observing traffic rules. Give the operator the authority to refuse instructions by third parties that are contrary to safety.

• Do not allow persons to be trained or instructed by anyone other than

an experienced person. Also, NEVER allow persons taking part in a

general training course to work on or with the machine without being

supervised by an experienced person.

• Before working on or with the machine, remove jewelery, such as

rings, wristwatches, bracelets etc., and tie back long hair and do not

wear loose-fitting garments, such as unbuttoned or unzipped jackets,

ties or scarves.

• Injury can result from being caught up in the machinery or from rings

catching on moving parts!

Repair person qualifications

• Work on the electric system and equipment, on the undercarriage and

the steering and brake systems can be performed only by skilled

individuals who have been specially trained for such work.

• Work on the hydraulic system of the machine must be performed only

by a technician with special knowledge and experience in hydraulic

equipment.

2.6 Safety instructions Regarding Operation

Preparing for use

• The machine must only be used in technically perfect condition in

accordance with its designated use and the instructions set forth in the

Operator's Manual, and only by safety-conscious persons who ar e fully

aware of the risks involved in operating the machine. Any functional

disorders, especially those affecting the safety of the machine, must

therefore be rectified immediately!

• Before starting up the machine, inspect the machine for safety in work

and road operation!

• In addition to the Operator's Manual, observe and instruct the ope rator

in all other generally applicable legal and other mandatory regulations

relevant to accident prevention and environmental protection.

• These compulsory regulations may also deal with handling hazardous

substances, issuing and/or wearing personal protective equipment, or

traffic regulations.

• With regard to specific operational features, e.g. those relevant to job

organization, work sequences or the persons entrusted with the work,

supplement the Operator's Manual by corresponding instructions,

including those relevant to supervising and reporting duties.

2-6 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 19

Starting and stopping

• Careful and prudent working is the best way to avoid accidents!Keep

the machine clean. This reduces fire hazard (such as from combustible

materials like rags), and reduces the injury hazard or operational

accidents that can be caused by dirt build-up on the travel pedals or

foot rests and steps.

• Observe all safety, warning, and informational signs and labels on the

machine.

• Start and operate the machine from the seat only.

• The operator must sit in the seat, fasten and adjust the seat belt before

putting the machine into operation.

• Always adjust the seat position before starting work. Do not change the

seat position during machine travel or machine operation.

• Make sure that all safety devices are properly installed and functional

before starting work.

• Before putting the machine/attachment into oper ation (startup/moving),

make sure that no one in the immediate vicinity will be at risk.

• Perform starting and stopping procedures according to this Operator’s

Manual.

• Observe all indicator lights.

• Do not use starting fluid (for example, ether) especially in those cases

in which a heater plug (intake air pre-heating) is used at the same time.

• Make sure the control levers, the signaling and the light systems are

functional before operating the machine, and also before restarting

after an interruption of work.

• Fold up the control lever base before releasing the seat belt in order to

avoid unintentional operation.

Work area awareness

• Familiarize yourself with the surroundings and circumstances of the

work site before beginning work. Be aware of:

- obstacles in the working and traveling area

- the soil bearing capacity

- any necessary barriers separating the work site from public roads

• Always keep at a safe distance from the edges of building pits and

slopes.

• Look out for the following when working in buildings or in enclosed

areas:

- height of the ceiling/clearances

- width of entrances

- maximum load of ceilings and floors

- sufficient room ventilation — carbon monoxide poisoning hazard.

• Observe the danger zone. See “Danger zone awareness”.

• Use the rearview mirror to stay aware of work area obstacles and

personnel.

• Always switch on the work lights in conditions of poor visibility and after

dark. However, make sure that users of public roads will not be temporarily blinded by the work lights.

• Provide additional lighting of the work area if the lights of the machine

are not sufficient for performing work safely.

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-7

Page 20

Danger zone awareness

Operating the machine

• The danger zone is the area in which persons are in danger du e to the

movements of the machine, work equipment, additional equipment, or

material.

• The danger zone also includes the area affected by falling material,

equipment or construction debris. The danger zone must be extended

by 0.5 m (20 inches) in the immediate vicinity of buildings, scaffolds, or

other elements of construction.

• Seal off the danger zone if it is not possible to keep a safe distance.

Stop work immediately if persons do not leave the danger zone in spite

of warnings!

• Never operate the machine if you are standing on the ground.

• Operate the machine ONLY when you are seated and you have

fastened your seat belt. Stop the engine before releasing the seat belt.

• During operation on slopes, travel or work uphill or downhill. If traveling

across a slope cannot be avoided, bear in mind the tilting limit of the

machine. Always keep the attachments/work equipment close to the

ground. This also applies to traveling downhill. When traveling or

working across a slope, the load must be on the uphill side of the

machine.

• On sloping terrain, adapt your travel speed to the prevailing ground

conditions.

• Never get on or off during machine operation or tra vel, and do not jump

off the machine.

• The travel control levers require practice before an operator becomes

familiar with the control response. Therefore, adjust the travel speed to

your abilities and the surroundings.

• When traveling across a slope with the telescopic undercarriage

extended, position the boom facing down the slope, and the bucket

about 10–20 cm (4–8’’) above the ground. This will help to minimize

the possibility of personal injuries and equipment damage caused by a

hydraulic hose/connector failure in the telescopic undercarriage

actuation system. The weight of the machine will cause the undercarriage to retract to the narrow configuration if h ydraulic system pressure

decreases due to lost fluid.

• Install a front guard when working in areas with a risk of objects falling

from the front (e.g. demolition work).

• On sloping terrain always adapt your travel speed to the prevailing

ground conditions! Never change to lower gear on a slope but always

before reaching it!

Carrying passengers

• Do not transport people on the machine or in the attachment.

• Never install a man basket or a working platform to the machine.

Mechanical integrity

• Take the necessary precautions to make sure the machine is used

only when in a safe and serviceable state.

• Operate the machine ONLY if all protective and safety-oriented

devices (ROPS, removable safety devices, soundproofing elements,

mufflers, etc.) are in place and fully functional.

2-8 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 21

• Check the machine before entering the cab to operate the machine for

visible damage and defects. Report any changes, including chang es in

the machine’s function and response, to your supervisor immediately!

• If the machine is functioning unpredictably, stop the machine immedi-

ately, lock it, and report the malfunction to a qualified tecnician or

supervisor. Safety-relevant damage or malfunctions of the machine

must be rectified immediately.

Traveling

• When traveling on or in public areas, observe all applicable regula-

tions. Make sure beforehand that the machine is in compliance with

these regulations.

• Installed work lights must NOT be used for travel.

• When crossing underpasses, gates, bridges and tunnels, or when

passing under overhead lines, make sure the clearance height and

width are sufficient to avoid contact.

• Empty the bucket before traveling on public roads.

2.7 Applications with Lifting Gear

General information

• Craning applications are procedures involving ra ising, transporting and

lowering loads with the help of slings and load-securing devices (for

example, ropes and tracks). In doing so, the help of persons is

necessary for securing and detaching the load. This ap p lies, for

example, to lifting and lowering pipes, shaft rings or containers.

• The excavator may be used for applications with lifting gear ONLY if

the prescribed safety devices are in place and functional.

Safety criteria

• When used for craning applications, the machine must meet the

• In addition, a safe load indicator is required for machines bearing loa ds

Conditions for safe operation

• Secure the load to prevent it from falling or slipping. Install an OSHA-

• Have loads fastened, and crane operators instructed, by a qualified

• The load shall be kept as close to the surface as practical to accom-

following criteria:

- Proper equipment for slinging and securing the load

- Proper lift capacity per tables in this Operator’s Manual

of over 1000 kg (2,205 lbs.) or an overturning moment of over 40000

Nm (29,477 ft.lbs.).

approved load hook after removing the bucket or other approved

attachment to provide a secure attachment point for the lifting sling,

track, or cable.

person competent in raning operation and standard hand signals. The

person giving instructions to the operator must be within sight of the

operator during load attachment and load disconnection.

plish the craning operation. The operator shall gently move the controls

and machine to avoid swing or oscillating motion of the load. A tether

line is recommended to dampen the tendency of the load to swing or

oscillate during the craning operation.

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-9

Page 22

• Machine travel with a raised load must be done very carefully on a

level surface moving very slowly to avoid sudden motion that can

cause swinging or oscillating motion of the load.

• The person(s) attaching the load to the excavator shall a pproach only if

the operator is in visual contact with them. No one shall approach the

machine or attempt to attach the load until the excavator has stopped

and the operator has signaled for the attachment.

2.8 Attachments

General information regarding attachments

• Prior to traveling remove all attachments which cannot be secured in

compliance with the legal regulations of your country.

• The machine operating characteristics including steering vary with

different option attachments and counter weights. The operator shall

be familiar with the variations and act accordingly.

• Use only approved attachments and connecting hardware.

• Attach and remove attachments carefully to avoid damage and

potential injury.

• Attach and remove attachments carefully to avoid damage and

potential injury.

• Confirm that the attachment has been properly and securely attached

to the machine according to the instructions. Before using the

attachment, the operator shall confirm that the attachment performs

correctly in response to control actuation.

• Do not attach the attachment with the engine running and the machine

moving.

• Before putting the machine/attachment into operation (startup/moving),

make sure that no one in the immediate vicinity will be at risk.

• Before leaving the seat, always secure the machine against unintentional movement and unauthorized use. Lower the attachments to the

ground.

• Mount the attachments only if the engine and the drive have been

stopped.

• Especially when traveling or operating machines equipped with a

quickhitch for the attachments, make sure the attachment is securely

locked in the quickhitch. The lock pin must be visible on either side of

the bores on the attachment. Check before starting work.

Installation notes

• Couple and uncouple hydraulic hoses/lines (hydraulic quick couplers) only if the engine

is stopped and the controls actuated to release the hydraulic pressure remaining in the

circuit. Follow the operating instructions for releasing the pressure.

• Operate the machine only if all protective devices for the attachments have been

installed and are functional, and if all brake, light and hydraulic connections have been

connected.

• If an optional attachment is installed, make sure that all lights and associated indicator

lights are installed and functional.

• The lock pin of the quick hitch attachment shall be visible at each end of the pin to

confirm that the attachment is securely locked in place. The operator shall perform a

check operation to confirm the latching integrity before operating at a production pace.

2-10 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 23

• Prior to fitting attachments to the stick (the mobile extension of the boom), secure the

control lever of the hydraulic control unit against unintentional movement. Raise the left

arm rest to avoid unintentional activation for the ISO/SAE operating mode. Avoid

actuating the right hand control if the alternative control mode is selected.

2.9 Transport and Towing

Towing

The machine must be towed, loaded and transported according to the

procedures described within this Operator’s Manual.

Transporting

• The transporting vehicle must have sufficient load capacity and

platform size to safely transport the machine. Refer to section 6 of this

manual to determine the physical characteristics of the machine before

loading and transporting.

• Use OSHA-approved straps, chains or cables to securely fastened the

machine to the surface of the transport.

• Use the tie down points provided on the load surface of the transport.

• Attach the tie down devices to the excavator at the designated tie down

points.

• Confirm that the excavator tie down procedures will prevent sideways,

forward, rearward and upward motion of the excavator in the event the

transport vehicle is involved in an incident or sudden avoidance

maneuver.

2.10 Safety Guidelines for Maintenance

General maintenance notes

• Adhere to prescribed intervals or those specified in this Operator’s

Manual for routine checks/inspections and maintenance on or with the

machine.

• For inspection and maintenance on or with the machine, ensure that all

tools and service center equipment are capable of performin g the tasks

prescribed. Do not use malfunctioning or broken tools. Use certified

measuring devices that are routinely calib r at ed for ac cu ra cy (to rqu e

wrench, pressure gauge, ammeter, etc.).

• Replace hydraulic hoses within stipulated and appropriate intervals

even if no safety-relevant defects have been detected.

• Recycle scrapped parts and drained fluids according to environmental

and hazardous material requirements. To avoid fire and health

hazards, dispose of soiled shop towels by approved methods.

• Always tighten any screws, electrical connections, or hose connections

that may have been loosened during maintenance.

• Upon completion of the maintenance and repair work, immediately r efit

and check any safety devices removed for set-up or maintenance

purposes.

Personal safety measures

• Brief the technician and the operator before beginning maintenance or

repair work. Appoint someone to supervise the activities.

• Always work in groups of two when diagnosing a machine problem

requiring the engine to be running. Both persons must be trained on

the machine—one person must be seated on the seat and maintain

visual contact with the other person.

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-11

Page 24

• Observe the specific safety instructions in the Maintenance section of

this Operator’s Manual.

• Always keep a safe distance from all rotating and moving parts, for

example, fan blades, V-belt drives, PTO shaft drives, fans, etc.

• Before starting work on the machine, always ensure safe blocking/

support.

• Apply special care when working on the fuel system due to the

increased fire hazard.

• Engine and muffler system become very hot during operation and

require cool-down time after machine is shut off. Avoid contact with hot

parts. Wait for the machine to cool before touching components.

• Retainer pins can fly out or splinter when struck with force. Avoid

striking the pins during operation, repair, or maintenance.

• Do not use starting fluid (for example, ether), especially in those cases

in which a heater plug (intake air pre-heating) is used at the same time.

•

Preparing for maintenance and repair work

• Prior to performing repair and maintenance on or with the machine,

always attach a warning label such as “Repair work—do not start

machine!” to the control elements as a precautionary measure.

• Observe the startup and shutdown procedures set forth in this

Operator’s Manual. This applies to any work concerning the o peration,

conversion or adjustment of the machin e an d its sa fet y- or ien te d

devices, or any work related to inspection and maintenance.

• Prior to performing assembly work on the machine, stabilize the area

under repair and use proper lifting and sup port devices to change parts

weighing more than

9 kg (20 lbs.).

• Perform maintenance on or with the machine ONLY if:

- the machine is positioned on firm and level ground

- secured against unintentional movement

- all hydraulically movable attachments and wor kin g eq uip m en t ha ve

been lowered to the ground

- if the engine is stopped

- if the starting key has been removed

- the pressure accumulator is discharged

• Perform maintenance on or with the machine beneath a raised

machine, attachments or additional equipment ONLY if a safe and

secure support has been provided. The use of hydraulic cylinders or

jacks as the sole method of support does NOT sufficient ly secure

raised machines or equipment/attachments!

Performing maintenance and repairs

• Observe the adjustment, maintenance and inspection activities and

intervals set forth in this Operator’s Manual, including information on

the replacement of parts and partial equipment. These activities must

be performed only by qualified personnel.

• Disconnect the negative battery terminal when working on the

electrical system.

• Do not allow the machine to be serviced, repaired, or test-driven by

unauthorized personnel.

• If maintenance with the engine running cannot be avoided, lower the

stabilizer blade and raise the control lever base.

2-12 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 25

• Wear a safety harness when performing elevated maintenance on or

with the machine. Keep all handles, steps, handrails, platforms,

landings, and ladders free from dirt, snow and ice.

• Always use specially designed or otherwise safety-oriented ladders

and working platforms to perform overhead assembly work. NEVER

use machine parts or attachments/superstructures as a climbing aid!

• Do not use the work equipment as lifting platforms for persons.

• In accordance with this Operator’s Manual and instructions for the

respective assembly, release the pressur e in all system sec tio ns and

pressure lines (hydraulic system) before performing any maintenance

on or with the machine.

• Prior to performing assembly work on the machine, make sure no

movable parts will roll away or start moving.

• To avoid accident hazard, parts and large assemblies being moved for

replacement purposes must be carefully attached and secured to lifting

gear.

• Use only suitable lifting gear and suspension systems in a technically

perfect state with adequate load-bearing capacity! Stay clear of

suspended loads!

• Clean the machine, especially connections and threaded unions, of

any traces of oil, fuel or preservatives before performed maintenance/

repair work!

• Do not use aggressive detergents!

• Use lint-free cleaning rags!

• Before cleaning the machine with water, steam jet (high-pressure

cleaner) or detergents, cover or tape up all openings which – for safety

and functional reasons – must be protected against water, steam or

detergent penetration. Special care must be taken with the electrical

system.

• After cleaning, remove all covers and tapes applied for that purpose!

• After cleaning, examine all fuel, lubricant and hydraulic oil lines for

leaks, chafe marks and damage!

• Rectify all defects without delay!

• Always tighten any screw connections that have been loosened during

maintenance and repair!

• Any safety devices removed for set-up, maintenance or repair

purposes must be refitted and checked immediately upon completion

of the maintenance and repair work

• Make sure all consumables and replaced parts are disposed of safely

and with minimum environmental impact!

Special Hazards

Battery

• In case of a frozen battery or of an insufficient electrolyte level, do not

try starting the machine with battery jumper cables. The battery can

burst or explode.

• Batteries contain caustic sulphuric acid. When handling the battery,

observe the specific safety instructions and regulatio ns relative to

accident prevention.

• A volatile oxyhydrogen mixture forms in batteries during normal

operation and especially when charging. Always wear gloves and eye

protection when working with batteries.

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-13

Page 26

Tracks

• Starting the machine with a battery jumper cable can be hazardous if

performed improperly. Observe the safety instructions regarding the

battery.

• Before taking up work on machine parts hazardous for life and limb

(bruising, cutting), always ensure safe blocking/support of these areas

• Perform maintenance and repair work beneath a raised machine,

attachments or additional equipment only if a safe and secure suppor t

has been provided for (the sole use of hydraulic cylinders, jacks etc.

does not sufficiently secure raised machines or equipment/attachments)

• Avoid contact with hot parts, such as the engine block or the exhaust

system during the operation of the machine and for some time afterwards – burn hazard!

• Retainer pins can fly out or splinter when struck with force – personal

injury hazard.

• Do not use starting fuel! This especially applies to those cases in which

a heater plug (intake-air preheating) is used at the same time –

explosion hazard.

• Apply special care when working on the fuel system – increased fire

hazard.

• Repair work on the tracks must be performed only by trained technical

staff or by a Wacker Neuson service center.

• Malfunctioning tracks reduce the machine's operational safety.

Therefore, check the tracks regularly for cracks, cuts or other damage.

• Check track tension at regular intervals.

Electric energy

• Use only original fuses with the specified current rating.

• In case of electrical system malfunctions, stop the machine immediately, disconnect the battery (by using the battery master switch), and

perform troubleshooting procedures.

• When operating the machine, maintain a safe distance from overhead

electric lines! If work must be performed close to overhead lines, the

equipment and attachments must be kept well away from them.

• If the machine comes into contact with a live wire:

• Immediately travel the machine out of the danger zone.

• Warn others against approaching and touching the machine.

• Do not leave the machine until the line that has been touched or

damaged has been safely de-energized!

• Make sure that work on the electric system is performed only by a

technician with appropriate training, in accordance with applicable

electrical engineering codes.

• Inspect and check the electrical equipment of the machine at regular

intervals. Defects such as loose connections or scorched cables must

be repaired immediately.

• Observe the operating voltage of the machine/attachments. The

voltages must be compatible (12 volts) and confirm that an appropriate

fuse or circuit breaker is incorporated in the system to prevent dama ge

from malfunction or short circuit.

• Always remove the grounding strap from the battery when working on

the electric system.

2-14 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 27

Hydraulics

Noise

MSDS

Gas, dust, steam, smoke

• Check all lines, hoses, and threaded couplers and fittings regularly for

leaks and obvious damage. Repair any damage and leaks immediately. Splashed oil can cause injury and fire!

• In accordance with the Operator's Manual/instructions for the

respective assembly, release the pressur e in all system sec tio ns and

pressure lines (hydraulic system) to be opened before perform any

implementing/repair work!

• Hydraulic and compressed-air lines must be laid and fitted properly.

Make sure no connections are interchanged. The fittings, lengths and

quality of the hoses must comply with the technical requirements

• Close all doors and windows if practical.

• Wear ear protection. This is especially important when performing

hammer operations or working in enclosed areas.

• When handling oil, grease, and other chemical substances such as

battery electrolyte or hydraulic fluid, observe the product-related safety

regulations (Material Safety Data Sheet (MSDS).

• Operate the machine only on adequately ventilated premises! Before

starting internal combustion engines or operating fuel-operated heating

systems on enclosed premises, make sure there is sufficient ventilation!

• Observe the regulations in force at the respective site!

• Perform welding, flame-cutting and grinding work on the machine only

if this has been expressly authorized. There can be a explosion and

fire hazard, for example!

• Before performing welding, flame-cutting and grinding work, clean the

machine and its surroundings from dust and other flammable

substances, and make sure the premises are adequately ventilated –

explosion hazard.

OM ET18/20/24 us 1.3 * Sicherheit(us).fm 2-15

Page 28

2.11 Safety Guidelines while using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards

during operation and fueling.

Failure to follow the warnings and safety guidelines could result

in severe injury or death.

► Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines be low.

Running the engine

When running the engine:

• Keep the area around muffler pipe free of flammable materials.

• Check the fuel lines and the fuel tank for leaks and cracks before

starting the engine. Do not run the machine if fuel leaks are present or

the fuel lines are loose.

When running the engine:

• Engine exhaust CAN KILL YOU IN MINUTES. Engine exhaust

contains carbon monoxide. This is a poison you cannot see or smell.

Never run the machine indoors or in an enclosed area such as a deep

trench unless adequate ventilation, through such items as muffler fans

or hoses, is provided.

• Do not smoke while operating the machine.

• Do not run the engine near open flames.

• Do not touch the engine or muffler while the engine is running or

immediately after it has been turned off.

• Do not operate a machine when its fuel cap is loose or missing.

• Do not remove the radiator cap when the engine is run ning or ho t. The

radiator fluid is hot and under pressure, and may cause severe burns!

Fueling the engine

When fueling the engine:

• Clean up any spilled fuel immediately.

• Refill the fuel tank in a well-ventilated area.

• Replace the fuel tank cap after refueling.

When fueling the engine:

• Do not smoke.

• Do not refuel a hot or running engine.

• Do not refuel the engine near an open flame.

2-16 OM ET18/20/24 us 1.3 * Sicherheit(us).fm

Page 29

Fig. 3: Machine overview

Position Designation

1. Working light on boom

2.

Roof lights (option)

3.

Lifting eye

4.

Rotating beacon (option)

5.

Door arrester

6.

Engine cover

7.

Fuel tank filler inlet

8.

Side cover

9.

Exhaust pipe

10.

Eye hook for tying down the machine

11.

Stabilizer blade

12.

Travel gear

13.

Handle

14.

Auxiliary hydraulics

15.

Door handle and lock

2

12

1

6

13

11

10

15

2

8

4

5

9

14

10

2

3

3

13

8

10

10

7

Introduction

3Introduction

3.1 Machine overview

3

OM ET18/20/24 us 1.3 * et18_20_24e300.fm 3-1

Page 30

3

Information

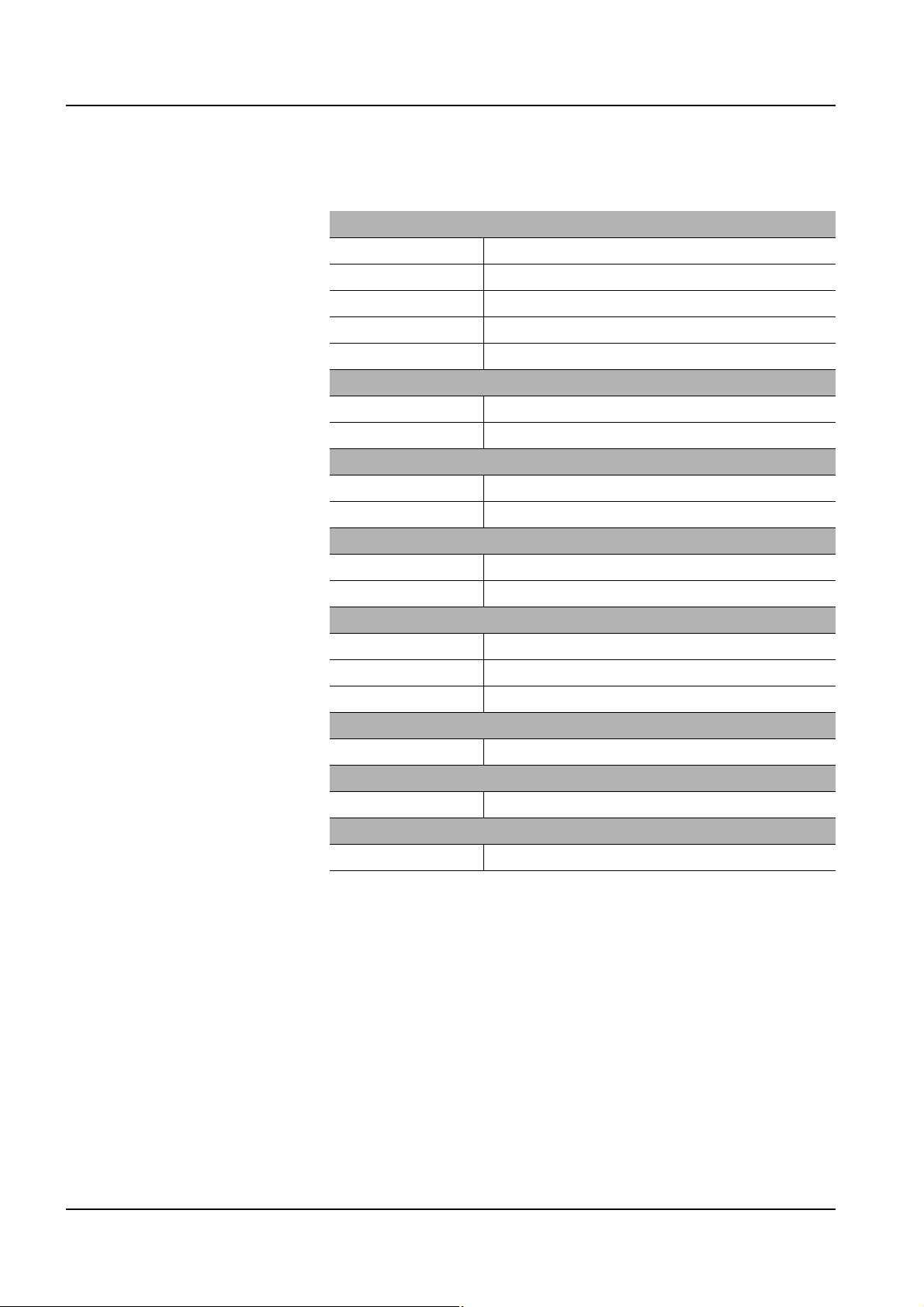

Overview of model designations and trade names

Machine model/machine designation Trade name

E12-02 ET18

E12-03 ET20

E12-04 ET24

3.2 Brief description of the machine

The machine model ET18/ET 20/ET24 is a self-propelled work machine.

Get informed on and follow the legal regulations of your country.

This machine is a versatile and powerful helper for moving earth, gravel

and debris on construction sites and elsewhere. A wide range of

attachments accounts for the numerous applications of the machine,

among others hammer and grab applications. When using these

attachments, observe the legal regulations of your country and equip the

machine with all the safety equipment required. See chapter 1.4 Fields of

application and use of attachments on page 3-5 for further applications.

The main components of the machine are:

• Travel gear

- Travel gear

- Stabilizer blade

- Live ring

• Upper carriage

-Cab

- Water-cooled diesel engine

- Hydraulic and electrical components

•Boom

The machine can be equipped with the “Telematic” feature (for

transmitting operating data, location, etc. via satellite)!

Traveling drive

The diesel engine permanently drives a twin axial variable displacement

pump whose oil flow is sent to the control valve. Depending on actuation,

each pump supplies a hydraulic motor or the work hydraulics with oil.

Work hydraulics

The twin axial variable displacement pump supplies the work hydraulics

for the main components with oil. This pump is output-controlled and

supplies the oil quantity depending on the outpu t required. This machine is

also equipped with a gear pump flanged onto the variable displacement

pump. Depending on engine speed, this pump supplies oil for the swivel

unit, the stabilizer blade and travel gear extension/retraction (option).

Shock cartridges (option)

The auxiliary hydraulics are equipped with Schock cartridges to

compensate pressure peaks in the hydraulic system.

Cooling system

Coolant temperature is monitored with the indicator light on th e machine’ s

instrument panel.

3-2 OM ET18/20/24 us 1 .3 * et18_20_24e3 00.fm

Page 31

Cab/canopy

The cab/canopy have been specially designed for protection in case of an

accident.

• ROPS/TOPS tested canopy (open version).

• ROPS/TOPS tested cab (closed version/option).

• Protective FOPS structure (option) for cab/canopy; protective structure

against falling objects.

• Front Guard with integrated FOPS (option) for cab/canopy; protective

structure against objects from the front (for example pipes, tree trunks

etc.) and falling objects.

• Shatter protection (option) for canopy; protective structure against

fragments flying around from the front.

Definition of FOPS/Front Guard levels

Level I:

Protection against small falling objects (FOPS) or small objects

penetrating into the cab from the front (Front Guard) , such as bricks, small

pieces of concrete, tools, for machines that are used for repairing roads,

landscaping work and for working on other construction sites, for example.

Level II:

Protection against heavy falling objects (FOPS) or heavy objects

penetrating into the cab from the front (Front Guard), such as trees,

pieces of rock, for machines that are used for clearance work, demolition

work and forestry work.

3

OM ET18/20/24 us 1.3 * et18_20_24e300.fm 3-3

Page 32

3

3.3 Notices and regulations on use

Designated use

• The machine is intended for:

- moving earth, gravel or rubble, for hammer operation as well as for

- working only with the attachments mentioned in chapter Fields of

application and use of attachments on page 3-5.

- Every other use is regarded as not designated for the use of the

machine. Wacker Neuson will not be liable for damage resulting from

use other than mentioned above. The operator/machine owner alone

will bear the risk.

Designated use also includes observing the instructions set forth in

the Operator’s Manual and observing the maintenance and service

conditions.

• The machine may not be used for transport jobs on public roads.

• In applications with lifting gear, the machine is used according to its

designated use only if the mandatory devices are installed and

functional!

• The quickhitch is only used for locking an attachment.

• Hammer operation is only allowed in specified areas.

3-4 OM ET18/20/24 us 1 .3 * et18_20_24e3 00.fm

Page 33

Fields of application and use of attachments

Notice

Information

In order to avoid damage to the machine, only the attachments

listed below have been certified for installation on the machine.

► Contact a Wacker Neuson service center if you wish to use

other attachments.

Using attachments of other manufacturers, or attachments which have

been released for other machine types, can reduce the machine’s output

and stability considerably, and can also cause damage to the machine

and injuries to the operator or the personnel.

Always compare the weight of the attachment and its maximum payload

with the indications in the lift capacity/stability table. Never exceed the

maximum payload stated in the lift capacity/stability table.

3

Please refer to the Operator’s and maintenance manual of the

attachment manufacturer for using and performing mainte nance

on attachments such as hammers, grabs, hy dr au lic qu ickh itch,

etc.

Description of attachment Weight Capacity Machine Remarks

-- ET18

Easy Lock quickhitch

Powertilt with Easy Lock

19 kg

(42 lbs)

55 kg

(121 lbs)

-- ET 20

-- ET 24

-- ET 18

-- ET 20

Required for operation of the

Wacker Neuson quickhitch

system.

-- ET 24

3

ET 18

3

ET 18 Easy Lock quickhitch

3

ET 20 Easy Lock quickhitch

Backhoe bucket 250 mm (10 in)

Backhoe bucket 250 mm (10 in)

Backhoe bucket 250 mm (10 in)

30 kg

(66 lbs)

31 kg

(68 lbs)

34 kg

(75 lbs)

0.023 m

(0.81 ft3)

0.023 m

(0.81 ft3)

0.030 m

(1.06 ft3)

OM ET18/20/24 us 1.3 * et18_20_24e300.fm 3-5

Page 34

3

Description of attachment Weight Capacity Machine Remarks

3

ET 18

3

ET 18 Easy Lock quickhitch

3

ET 20

3

ET 20 Easy Lock quickhitch

3

ET 24

3

ET 24 Easy Lock quickhitch

3

ET 18

3

ET 18 Easy Lock quickhitch

3

ET 20

3

ET 20 Easy Lock quickhitch

3

ET 24

3

ET 24 Easy Lock quickhitch

3

ET 18

3

ET 18 Easy Lock quickhitch

3

ET 20

3

ET 20 Easy Lock quickhitch

3

ET 24

3

ET 24 Easy Lock quickhitch

Backhoe bucket 300 mm (12 in)

Backhoe bucket 400 mm (16 in)

Standard bucket

Backhoe bucket 500 mm (20 in)

32 kg

(71 lbs)

34 kg

(75 lbs)

42 kg

(93 lbs)

37 kg

(82 lbs)

40.3 kg

(89 lbs)

43 kg

(95 lbs)

37 kg

(82 lbs)

39 kg

(86 lbs)

46 kg

(101 lbs)

44 kg

(97 lbs)

48 kg

(106 lbs)

50 kg

(110 lbs)

43 kg

(95 lbs)

47 kg

(104 lbs)

56 kg

(123 lbs)

52 kg

(115 lbs)

54.3 kg

(120 lbs)

60 kg

(132 lbs)

0.027 m

(0.95 ft3)

0.028 m

(0.99 ft3)

0.037m

(1.31 ft3)

0.036 m

(1.27 ft3)

0.043 m

(1.52 ft3)

0.042 m

(1.48 ft3)

0.035 m

(1.24 ft3)

0.037 m

(1.31 ft3)

0.051 m

(1.80 ft3)

0.048 m

(1.70 ft3)

0.059 m

(2.08 ft3)

0.056 m

(1.98 ft3)

0.044 m

(1.55 ft3)

0.046 m

(1.62 ft3)

0.064 m

(2.26 ft3)

0.060 m

(2.12 ft3)

0.075 m

(2.65 ft3)

0.070 m

(2.47 ft3)

3-6 OM ET18/20/24 us 1 .3 * et18_20_24e3 00.fm

Page 35

Description of attachment Weight Capacity Machine Remarks

3

ET 18

3

ET 18 Easy Lock quickhitch

3

ET 20

3

ET 20 Easy Lock quickhitch

3

ET 24

3

ET 24 Easy Lock quickhitch

3

ET 24

ET 18

3

Easy Lock quickhitchET 20

Backhoe bucket 600 mm (24 in)

Backhoe bucket 700 mm (28 in)

Ditch cleaning bucket 850 mm (33

in)

63 kg

(139 lbs)

53 kg

(117 lbs)

61 kg

(134 lbs)

59 kg

(130 lbs)

63 kg

(139 lbs)

67 kg

(148 lbs)

71 kg

(157 lbs)

63 kg

(139 lbs)

0.053 m

(1.87 ft3)

0.055 m

(1.94 ft3)

0.077 m

(2.72 ft3)

0.072 m

(2.54 ft3)

0.091 m

(3.21 ft3)

0.084 m

(2.97 ft3)

0.107 m

(3.78 ft3)

0.065 m

(2.30 ft3)

ET 24

ET 18

3

ET 20

ET 24

ET 18

3

Easy Lock quickhitchET 20

Ditch cleaning bucket 1000 mm (39

in)

65.4 kg

(144 lbs)

72 kg

(159 lbs)

0.082 m

(2.90 ft3)

0.078 m

(2.75 ft3)

ET 24

3

ET 24

ET 18

3

Easy Lock quickhitchET 20

Ditch cleaning bucket 1200 mm (47

in)

75 kg

(165 lbs)

84 kg

(185 lbs)

0.098 m

(3.46 ft3)

0.094 m

(3.32 ft3)

ET 24

3

ET 18 Easy Lock quickhitch

3

ET 20

Easy Lock quickhitch

ET 24

3

ET 18 Easy Lock quickhitch

3

ET 20

Easy Lock quickhitch

ET 24

3

ET 20

ET 24

Easy Lock quickhitch

ET 20

ET 24

Easy Lock quickhitch

Offset bucket 850 mm (33 in)

Offset bucket 1000 mm (39 in)

Offset bucket 1200 mm (47 in)

Hydraulic hammer NE 8

Hydraulic hammer NE 12

Hydraulic hammer NE 16

86 kg

(190 lbs)

103 kg

(227 lbs)

93 kg

(205 lbs)

110 kg

(243 lbs)

121 kg

(267 lbs)

66 kg