Wacker Neuson EHB 10 series, EHB 10/230, EHB 10/240, EHB 10/230 THW, EHB 10/240 GB Operator's Manual

...Page 1

www.wackergroup.com

0200071en 001

11.2005

Electrik-hammer

EHB 10/...

Operator´s Manual

Page 2

Page 3

FOREWORD

Foreword

For your own safety and protection from bodily injuries, carefully read, understand and follow the safety instructions in this manual.

Please operate and maintain your Wacker machine in accordance with the instructions in this manual.

Defective machine parts are to be replaced as soon as possible.

All rights, especially the right for copying and distribution are reserved.

Copyright by Wacker Construction Equipment AG.

No part of this publication may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express permission in writing from Wacker Construction Equipment AG.

Any typeofreproduction,distributionorsavingondata carriers of any type or method not authorized by Wacker

represents an infringement of valid copyrights and will be prosecuted.

We expressly reserve the right to technical modifications- even without express due notice - which aim at improving our machines or their safety standards.

T00778GB

1

Page 4

TABLE OF CONTENTS

FOREWORD 1

SAFETY INSTRUCTIONS 3

General instructions 3

Operation 3

Safety checks 4

Maintenance 4

Transport 4

Maintenance checks 4

TECHNICAL DATA 5

DESCRIPTION 6

Application 6

Putting into operation 6

During operation 6

Disassembly 7

Assembly 7

MAINTENANCE 8

Maintenance schedule 8

Maintenance and lubrication 8

BREAKING TOOLS 9

DRILLING TOOLS 10

REFORGING OF TOOLS 12

DIAGRAM 13

WIRING DIAGRAM 14

EC - CONFORMITY-CERTIFICATE 15

2

Page 5

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS FOR THE USE OF DRILLING AND

BREAKING HAMMERS WITH ELECTRIC DRIVE

General instructions

1. Drilling and breaking hammers may only be operated by persons who

* are at least 18 years of age,

* are physically and mentally fit for this job

* have been instructed in operating drilling and breaking hammers and proven their ability for the job

to the employer

* may be expected to carry out the job they are charged with carefully.

The persons must be assigned the job of operating drilling and breaking hammers by the employer.

2. Drilling and breaking hammers are to be applied for their proper use. Both the manufacturer’s operator’s

manual and these safety instructions have to be observed.

3. The persons charged with the operation of these hammers have to be made familiar with the necessary

safety measures relating to the machine. In case of extraordinary uses, the employer shall give the

necessary additional instructions.

4. It is possible that these drilling and breaking hammers exceed the admissible sound level of 89 dB (A).

Operators must wear personal hearing protection if the admissible assessment sound level equals or

exceeds 89 dB (A).

Operation

1. The function of operation levers or elements is not to be influenced or rendered ineffective.

2. Make sure that the machine is connected only to voltage and frequency as indicated on its name plate.

Choose correct cross section for extension cord. See method of calculation instructions with diagram in

this manual.

3. The operator has to switch off drilling and breaking hammers, to disconnect them from the electric mains

and to store them in such a manner that they do not turn over be fore leaving the machines or going on

breaks.

4. Wear safety goggles in order to avoid injuries to the eyes.

5. We recommend wearing suitable working gloves.

6. Wear safety shoes while working with drilling and breaking hammers.

7. Drilling and breaking hammers are always to be operated with both hands on the handles provided for

this purpose.

8. When working with drilling and breaking hammers, especially when carrying out drilling jobs, the operator has to have a firm stand, particularly when working on scaffolding and ladders.

9. Drilling and breaking hammers are to be guided such that hand injuries caused by solid objects are

avoided. When carrying out demolition jobs at elevated places, special care is required to prevent the

machine or the operator from falling.

10. Avoid body contact with earthed components. When breaking connecting passages, make sure that

there are no electric wires or gas pipes. No one may stay in the room to which the passage is broken

through, as there is danger of injuries because of falling stones or tools.

11. During operation the tool holder must be closed. Tools and tool holder must be checked for wear in order

to guarantee proper functioning of holder.

12. The operation of this machine may cause broken - off pieces to be flung away. Therefore, during operation, no one except the operator is to come near this machine.

13. Drilling and breaking hammers have to be disconnected from the electric mains before changing tools.

14. The tools always have to be in perfect conditions.

15. Do not operate these machine in areas where explosions may occur.

SV00011GB

3

Page 6

SAFETY INSTRUCTIONS

16. Do not misuse the electric cable to pull or lift up the unit or to pull the plug out of the socket. Protect cable

from heat, oil and sharp edges.

17. Electric equipment and material may only be used if they comply with the operational and local safety

requirements. They must be in proper condition and this condition is to be maintained.

18. Do not expose electric tools to rain. Do not use electric tools in damp or wet surroundings.

Safety checks

1. Drilling and breaking hammers may only be operated with all safety devices installed.

2. Before starting operation, the operator has to check that all control and safety devices function properly.

3. Before starting operation, the overload clutch of drilling hammers has to be checked for proper functioning.

4. Regularly check cable for damage.

5. In case of defects of the safety devices or other defects reducing the operational safety of the drilling and

breaking hammers, the supervisor has to be informed immediately.

6. In case of defects jeopardizing the operational safety of the hammers, the machine has to be

switched immediately.

Maintenance

1. Only use original spare parts. Modifications to this machine, including the adjustment of the maximum

engine speed set by the manufacturer, are subject to the express approval of Wacker. In case of nonobservance all liabilities shall be refused.

2. Disconnect the drilling and breaking hammer from the electric mains before carrying out maintenance

and repair jobs.

3. Work on the electric parts of the machines may only be carried out by skilled technicians.

4. The green and yellow ground wire of the connecting cable of machines without protective insulation has

to be longer than the other wires so that it is no ripped out first in case the strain relief fails. A break in

this wire would entail grave danger. Check ground wire for passage after repairs.

5. As soon as maintenance and repair jobs have been completed, all safety devices have to be reinstalled

properly.

Transport

When being transported on vehicles, precautions have to be taken that these hammers do not slip or turn over.

Maintenance checks

According to the conditions and frequency of use, drilling and breaking hammers have to be checked for safe

operation at least once every 6 months by skilled technicians, such as those found at Wacker-service depots

and have to be repaired if necessary.

Please also observe the corresponding rules and regulations valid in your country.

SV00011GB

4

Page 7

TECHNICAL DATA

EHB 10/230 EHB 10/240

EHB 10/230 THW EHB 10/240 GB

EHB 10/230 DBP

EHB 10/230 SEV

EHB 10/230 BW

Item no. 0006943 ... 0007084 ...

0007082 ... 0007085 ...

0007081 ...

0007083 ...

0007087 ...

Length x width x height (without tool) mm: 545 x 105 x 245

Operating weight (mass) without tool kg: 10

Voltage V: 230 ~ 240 ~

Power input kW: 1,15 1,1

Current consumption A: 5 4,5

Frequency Hz: 50/60 50

Percussion rate electronic control min-1: 1300 - 2100

Drill speed electronic control min-1: 170 - 265

Special lubricating grase Grease Unirex N2

Shaft for drilling tools hexagonal SW 19 x 80

Shaft for breaking tools SW 19 x 82,5

Power transmission percussion system From motor via crank mechanism to air-cushioned

percussion system

Power transmission drilling drive From motor via crank mechanism to bevel

gear, safety clutch, drive shaft, tool holder

bushing

Drive motor Built-in insulatet universal motor for single

phase operation

Sound pressure level at operators station LPA: 96 dB(A)

The weighted effective acceleration value,

determined according to ISO 8662, Part 1

TD00032GB

m/s2: is7,7

5

Page 8

DESCRIPTION

Application

This versatile breaking and drilling hammer is used in civil engineering and building industry, in concrete works,

cast stone plants, foundries, by plumbing installation firms and communities. It is particularly suited for use on

natural andcast stone, as well as for all kinds of brickwork and concrete. A wide selection of easily interchangeable tools is available for drilling holes from 12 to 125 mm, for breaking, chiselling, digging, puddling, hammering ramming and deburring.

Putting into operation

1. Attachment of the tool

* Snap out holder spring.

* Insert tool as far as it will go.

* Only use sharp tools.

* Snap back holder spring.

Use tools with shanks in proper condition to eliminate rebound blows. It is recommended to slightly grease

or oil the tool shanks and tool holder bushing to avoid dry operation resulting in seizure.

2. Connectionn

This electric hammer is powered by 230/240 V, A. C. (single phase). A suitable plug is provided for connection.

During operation

1. Changing the application

The position for breaking or drilling is indicated by the arrow on the cylinder housing and the respectivesymbol situated opposite on the control lever. To change application turn lever 1/2 turn to the next notch.

2. Speed control

To reduce the power of the hammer turn knurling wheel in handle in anti-clockwise direction (-). Turn wheel

as far as it will go. (Operation at reduced power is necessary for spot drilling and for work on brittle material).

To set hammer to full power turn knurling wheel in clockwise driection (+).

3. Lock button

Lock control lever by means of lock button when using the hammer for long breaking operations. When

pression on control tongue, lock button i released.

☛ATTENTION! Do not use lock button for drilling jobs!

4. Handle at tool holder

Can be turned 360o according to need; tighten strongly with supplied tommy ban before starting work.

T00122GB

6

Page 9

DESCRIPTION

Disassembly

1. Tool holder/Cylinder housing

Remove pin. Remove supplementary handle with holder spring from tool holder. Remove cheese head

screw. Remove tool holder, tool holder bushing, intermediate gear and intermediate plate. Remove cylinder

housing with drive shaft from crankcase. Remove percussion piston.

2. Crankcase

Access to rotor circlip : Remove hexagon screws, take bearing cover and crank mechanism out of crankcase.

3. Disassembly of handle

Remove cheese head screws and slotted screws. Remove handle half.

4. Motor

Access to carbon brushes: Remove self-tapping screws remove cover. Take both carbon brushes out of

brush holder. Access to stator pack and rotor: Remove cheese head screws, remove bearing bracket from

crankcase. Remove self-tapping screws, then remove stator pack . After that pull out protection sleeve. Remove circlip and force out rotor.

Assembly

For assembly proceed in the reverse order to dismantling. The following has to be observed in particular:

* All parts must be carefully cleaned and checked. Grease bearings, crank mechanism and percussion sy-

stem with special grease (see technicla data).

* Clean front surfaces of cylinder housing and crankcase and seal with Omni Visc, model 1002.

* Use Omnifit 230L to glue outer race of deep groove ball bearing.

* After completion of any kind of repairs, test-run with increasing load.

T00122GB

7

Page 10

MAINTENANCE

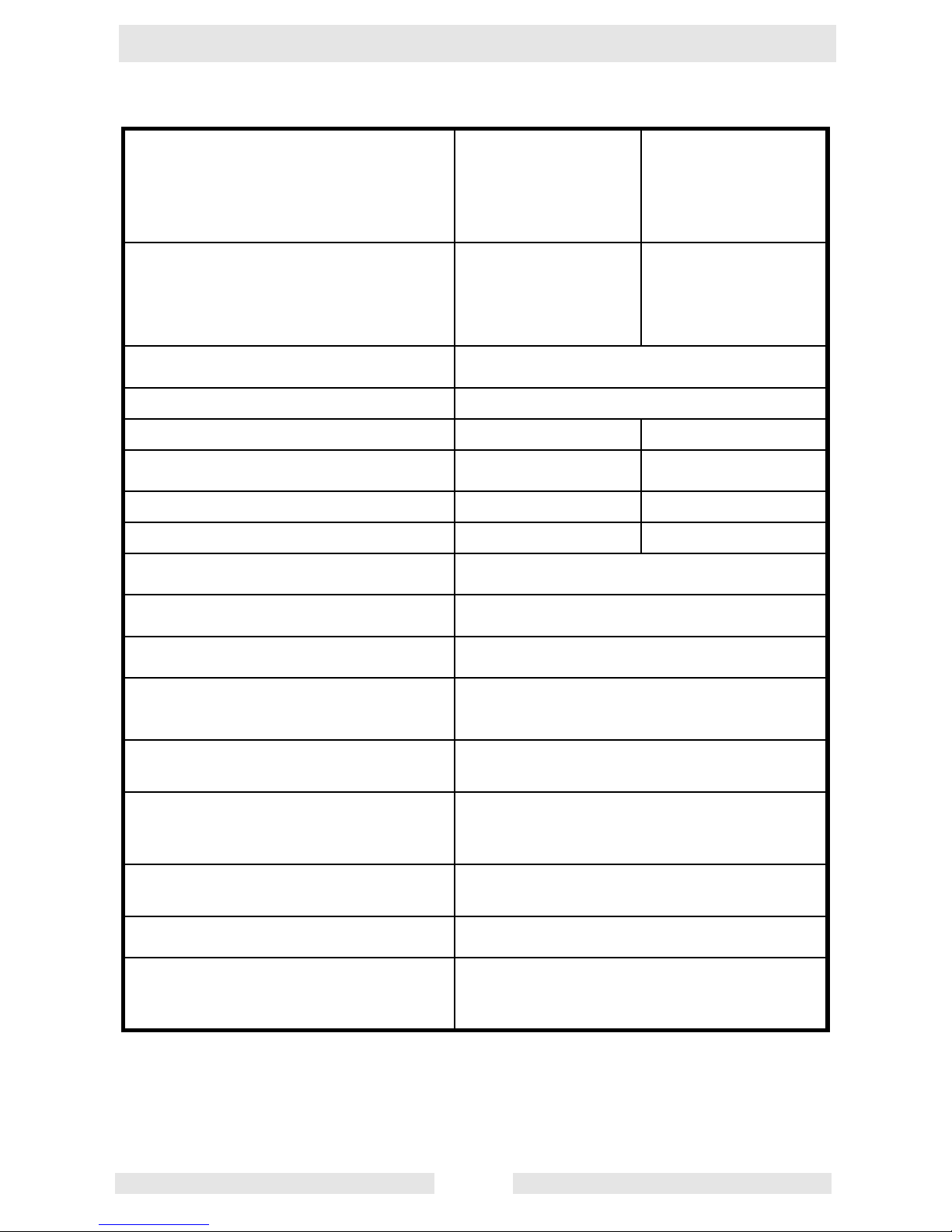

Maintenance schedule

Check all external screw connections for tight fit approx. 8 hours after first operation.

Component Maintenance work Maintenance interval

Feed line Check for perfect condition - if cable daily

defective, replace.

Miscellaneous Fan slits dirt - free - clean if necessary.

Tools Check the shafts and cutting edges - if necessary,

sharpen, reforge or replace.

Miscellaneous Regrease via grease nipples. 20 hours

Tool bush Check for wear - change if necessary. monthly

Carbon brush Check for wear, remaining length about 9 mm 80 hours

- change if necessary.

Miscellaneous Check cheese head screws of housing for tight

fit retighten if necessary - 25 Nm.

Miscellaneous Regrease crankshaft drive. 600 hours

Maintenance and lubrication

1. General instructions

Keep hammer and tools clean.

2. Motor

Carbon brushes: This hammer is equipped with automatic switch-off carbon brushes. Thes brushes switchoff the hammer as soon as their length is worn down to approx. 9 mm. Therefore, before starting a long

operation check brushes for wear. Replace if necessary.

3. Mechanical part

Every 20 hours of operation moderately grease crank mechanism and percussion system via lubricating

nipple situated on crankcase (see technicla data). Use special grease. Check tool holder brushing for wear.

The tool may have a play of max. 6 mm at a distance of approx. 200 mm from the entrance. If the bushing

is worn to a greater degree, replace it to avoid damages and operational failures.

T00066GB

8

Page 11

BREAKING TOOLS

Shank for breaking: Hexagonal, spanner

opening SW 19x82,5

For breaking:

Moil point

Flat chisel, wide 24 mm Effective length

Wedge flat chisel, wide 25 mm Effective length

Star profile chisel Effective length

Blank Effective length

Flat spade, wide 90 mm Effective length

Effective length

230 mm

430 mm

230 mm

190 mm

250 mm 0109321

660 mm 0034103

280 mm 0022769

Type

Ref. - No.

0022763

0032860

0022764

0109320

Asphalt spade, wide 80 mm Effective length

320 mm 0032601

Plaster chisel, wide 65 mm Effective length

180 mm 0022772

For roughing:

Bush hammer holder and bush

hammer inserts

Effective length

110 mm

5 x 5 tooths

7 x 7 tooths

9 x 9 tooths

0022775

2006935

2006937

2006939

SK00010GB

9

Page 12

DRILLING TOOLS

Shank for drilling tools: Hexagonal, spanner

opening SW 19x80 (82,5)

For drilling purposes:

Carbide-tipped twist drill,

Carbide-tipped twist drill, 200 mm WI

Carbide-tipped twist drill,

(We recommend predrilling with

short drill)

160 mm WI

ø 26 mm

ø 42 mm

ø 22 mm

ø 25 mm

250 mm WI

ø 18 mm

ø 20 mm

ø 28 mm

ø 32 mm

ø 35 mm

ø 40 mm

400 mm WI

ø 22 mm

ø 25 mm

ø 28 mm

ø 32 mm

ø 40 mm

ø 45 mm

Type Ref. - No.

0065671

0047653

0096626

0096627

0096628

0096629

0096630

0096631

0096632

0096633

0096634

0096635

0096636

0096637

0096638

0096639

550 mm WI

ø 35 mm

ø 55 mm

ø 65 mm

ø 80 mm

Pilot drilll 50 mm WI

ø 16 mm 0124287

75 mm WI

ø 16 mm 0124288

Threaded bolt 65 mm WI 0124277

Adapter 200 mm WI

300 mm WI

460 mm WI

Adapter with WACKER-connection 330 mm WI 0124281

Conveyor spiral for concrete and

natural stone

80 mm Whole

length

ø 33 mm

ø 48 mm

ø 63 mm

ø 78 mm

0096640

0065672

0039859

0065673

0124278

0124279

0124280

0124282

0124283

0124284

0124285

SK00503GB

10

Page 13

DRILLING TOOLS

Shank for drilling tools: Hexagonal, spanner

opening SW 19x80 (82,5)

Cone adapter 1:10 55 mm WI 0037105

Machine adapter 0124275

Adapter for Hilti tools 0063747

Cross drill crown type G ø 65 mm

ø 70 mm

ø 80 mm

ø 90 mm

ø 100 mm

ø 110 mm

ø 125 mm

Cross drill crown type X ø 35 mm

ø 40 mm

ø 42 mm

ø 50 mm

ø 52 mm

ø 55 mm

ø 60 mm

ø 65 mm

ø 70 mm

ø 80 mm

ø 90 mm

ø 100 mm

ø 110 mm

ø 125 mm

Type Ref. - No.

0124289

0124290

0124291

0124292

0124293

0124294

0124295

0124296

0124297

0124298

0124299

0124300

0124301

0124302

0124303

0124304

0124305

0124306

0124307

0124308

0124309

Cross drill crown type S ø 35 mm

SK00503GB

ø 42 mm

ø 50 mm

ø 52 mm

ø 55 mm

ø 60 mm

ø 65 mm

ø 70 mm

ø 80 mm

ø 90 mm

ø 100 mm

ø 110 mm

ø 125 mm

11

0124310

0124311

0124312

0124313

0124314

0124315

0124316

0124317

0124318

0124319

0124320

0124321

0124322

Page 14

REFORGING OF TOOLS

☛ATTENTION! Use safety glasses when doing this job.

When reforging of the tools becomes necessary, care should be taken that only that part of the tool that needs

reforging is heated. Moreover, it is important that the heat is increased slowly and that it is constantly watched,

otherwise heat cracks are likely to occur on hardened tools.

Forging temperature: 800o to 1000o (1470o to 1830o F) bright cherry - red to yellow

The tool should be forged within these limits and, if necessary, shoud be heated repeatedly. A temperature

below 800oC (1470oF) may cause tension cracks, where as when the temperature exceeds 1000oC (1830

F) the steel is overheated and spoilt. After forging, the tools should be quenched in an ash or sand box. Do not

harden the tools before they have cooled from the forging.

Hardening: Heat point or blade in direction of tool shank up to a cherry red colour (780o- 810oC) over the

shortest distance possible (approx. 30 - 40 mm), then quench in water with approx. 20oC while constantly

swinging tool around.

Tempering: Heat tool at shaft approx. 10 cm behind tip until point or blade reaches brown-red tempering col-

our:

Let tool cool off in air.

Polish one side of the tool‘s point or blade to be able to recognize tempering colour.

Grinding: Sharpen the insert tools on grinding wheels-favourably sandstone-under sufficient cooling water.

The edges should not be allowed to turn blue as the hardness of the tools will be affected. Take care to achieve

the proper cutting edge and pointed angle. The harder the material to be cut, the greater the angle should be.

o

Tools made out of

tempering steel C70W2 - can be

forged, hardened and

ground

Tools with hardmetal bits may

only be sharpened on special

emerywheelmachines for hard

metal

Point chisel Flat chisel Blank Plaster chisel

Spade Pointed spade Asphalt cutter Gouge, cranked

Carbide-tipped twist drill

SK00011GB

12

Page 15

DIAGRAM

Selection of required cross section for extension of cables and power lines

This procedure takes into consideration:

1. The ohmic and inductive resistance of the line with an admissible loss of voltage of 5% and cos phi =

0,8 as per voltage-frequency-curves.

2. The admissible warming-up of the lines as per VDE standard (table of required minimum cross section).

☛ATTENTION! The larger one of both cross sections has to be chosen.

Example:

Nominal voltage 3 ~ 400 V, 50 Hz

Rated current 15 A Line length 100 m

15 A x 100 m = 1500 A x m

Cross section as per diagramm: 2,5 mm

Cross section as per table: 15 A : 1 mm

Chosen cross section: 2,5 mm

Voltage - Frequency - Curves

Cross-section area of cable in mm

2

2

2

2

Minimum cross-section

area according to VDE

Max. Max.

Cable load fuse

2

mm

115 10

1,5 18 10/3~16/1~

2,5 26 20

434 25

644 35

10 61 50

16 82 63

25 108 80

AA

Rated current x length of cable A x m

SK00001GB

13

Page 16

WIRING DIAGRAM

Handle

Screw union Capacitor

white/yellow

Plug

Conducting

Switch

Plug-blue

Plug-red

white/red

white/green

white

Electronic

white/yellow

Engine

white/green

white/red

black

SK00012GB

14

Page 17

EC - CONFORMITY-CERTIFICATE

Wacker Construction Equipment AG , Preußenstraße 41, 80809 München

hereby certify that the construction equipment specified hereunder:

1. Category: Breaking / Drilling hammer

2. Type:

EHB 10/230 EHB 10/240

3. Equipment item number:

0006943 ...

0007081 ...

0007084 ...

0007085 ...

0007082 ...

0007083 ...

0007087 ...

4. Operating weight:

10 kg

has been evaluated in conformity with Directive 2000/14/EC:

Conformity

assessment

At the following notified

body

Measured

sound power level

procedure

Annex VIII VDE Prüf- und

104 dB(A) 105 dB(A)

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

and has been manufactured in accordance with the following directives:

Guaranteed

sound power level

* 2000/14/EG

* 89/336/EG

* 98/37/EG

* 73/23/EG

File certificate carefully

C0023004.GB

Dr. Stenzel

Research and Development Management

Page 18

16

Page 19

DIN EN ISO 9001 CERTIFICATE

Page 20

Wacker Construction Equipment AG - Preußenstraße 41 - 80809 München - Tel.: +49-(0)89-3 54 02-0 - Fax: +49-(0)89-3 54 02-390

WackerCorporation - P.O. Box 9007 - Menomonee Falls,WI53052-9007 - Tel.: +1-(1)(262)-255-0500 - Fax: +1-(1)(262)-255-0550 - Tel.: (800)770-0957

Wacker Asia Pacific Operations-Skyline Tower, Suite 2303, 23/F, 39 Wang Kwong Road, Kowloon Bay, Hong Kong-Tel.: +852 2406 6032-Fax: +852 2406 6021

Page 21

Page 22

Loading...

Loading...