Page 1

Operator’s Manual

5000188154

Hydronic Surface Heater

E3000

Type E3000

Document 5000188154

Date 1115

Versio n 05

Language EN

Page 2

Copyright notice

© Copyright 2015 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the

machine. Any other type of reproduction is prohibited without express

written permission from Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker

Neuson Production Americas LLC represents an infringement of valid

copyrights. Violators will be prosecuted.

Trademarks

Manufacturer

Original instructions

All trademarks referenced in this manual are the property of their

respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

This Operator’s Manual presents the original instructions. The original

language of this Operator’s Manual is American English.

Page 3

E 3000 Foreword

Foreword

This heater is designed and approved for use as a construction heater in

accordance with Standard ANSI Z83.7–CSGA 2.14. CHECK WITH YOUR LOCAL

FIRE SAFETY AUTHORITY IF YOU HA VE QUESTIONS ABOUT APPLICATIONS.

Other standards govern the use of fuel gases and heat producing products in

specific applications. Your local authority can advise you about these.

THE INSTALLATION OF THE UNIT SHALL BE IN ACCORDANCE WITH THE

REGULATIONS OF THE AUTHORITIES HAVING JURISDICTION.

WARNING

Risk of personal injury or machine damage from improper use.

f Before using the machine, read and understand all instructions and follow them

carefully.

f The manufacturer is not responsible for damages to goods or persons due to

improper use of this machine.

WARNING

Failure to comply with the precautions and instructions provided with this machine

can result in death, serious injury, and property loss or damage from fire, explosion,

burns, asphyxiation, carbon monoxide poisoning, and/or electric shock.

f Before using the machine, read and understand all precautions and instructions

that have been provided. Follow them carefully.

f Only persons who can understand and follow the precautions and instructions

should use or service this machine.

f Contact the manufacturer if you need assistance with operating the machine or

need replacement manuals or labels.

WARNING

Work site fire, burn, inhalation, and explosion hazards.

f Keep solid combustibles, such as building materials, paper, or cardboard at a

safe distance away from the machine as recommended by the instructions.

f Never use this machine in spaces which do or may contain volatile or airborne

combustibles, or products such as gasoline, solvents, paint thinner, dust particles, or unknown chemicals.

WARNING

Not for use in homes or recreational vehicles. Installing this machine in a home or

RV may result in fire, explosion, property damage, personal injury, or death.

f Operate the machine only for applications specified in Machine Description and

Intended Use.

wc_tx002028gb.fm

3

Page 4

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Ame ricas LLC and must be followed during installation,

operation, and maintenance of the machines.

Machine Item Number Revision

E 3000 0620158 225 and higher

E 3000G 0620219 225 and higher

E 3000 LB 0620678 225 and higher

E 3000 LB-G 0620679 225 and higher

E 3000 LB-G 52000004952 100 and higher

Machine

documentation

Expectations

for

information in

this manual

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

Refer to the separate Repair Manual for detailed instructions on servicing and

repairing the machine.

If you are missing any of these documents, please contact Wacker Neuson to

order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury , carefully read, underst and, and observe all instructions

described in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to change

any portion of this information without notice.

CALIFORNIA

Proposition

65 Warning

Laws

pertaining to

spark

arresters

Engine exhaust, some of its constituents, and certain vehicle components, contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United St ates Forest Service fo r this purpose. In order to

4

wc_tx002028gb.fm

Page 5

Foreword

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

wc_tx002028gb.fm

5

Page 6

Foreword

6

wc_tx002028gb.fm

Page 7

E 3000

Table of Contents

Foreword 3

1 Safety Information 11

1.1 Signal Words Used in this Manual ..................................................... 11

1.2 Machine Description and Intended Use ............................................. 12

1.3 Safety Guidelines for Operating the Machine ..................................... 13

1.4 Safety Guidelines for Lifting the Machine ........................................... 14

1.5 Safety Guidelines for Operating Combustion Burners ....................... 15

1.6 Safety Guidelines for Operating Gensets ........................................... 16

1.7 Service Safety .................................................................................... 18

1.8 Safety Guidelines for Towing the Machine ......................................... 20

1.9 Reporting Safety Defects ................................................................... 21

2 Labels 22

2.1 Label Locations .................................................................................. 22

2.2 Label Meanings .................................................................................. 24

3 Lifting and Transporting 30

3.1 Lifting the Machine ............................................................................. 30

3.2 Preparing the Machine for Transport on a Truck or Trailer ................ 31

3.3 Transporting the Machine on a Truck or Trailer ................................. 32

3.4 Before Towing Checklist ..................................................................... 34

3.5 Towing the Machine ........................................................................... 35

3.6 Testing the Breakaway System (Electric Brakes) .............................. 36

3.7 Hazardous Materials Placards ........................................................... 38

4 Operation 40

4.1 External Components ......................................................................... 40

4.2 Internal Components .......................................................................... 41

4.3 Rear Components .............................................................................. 42

4.4 Pumps, Gauges, and Valves .............................................................. 43

4.5 Control Panel ...................................................................................... 44

4.6 Control Panel Components ................................................................ 45

4.7 Genset Control Panel ......................................................................... 46

4.8 Preparing the Machine for First Use ................................................... 47

4.9 Breaking in the Genset ....................................................................... 47

4.10 General Sequence of Operation ......................................................... 48

4.11 Checking the HTF Level ..................................................................... 49

wc_bo5000188154_05TOC.fm

7

Page 8

Table of Contents

4.12 Recommended Fuel ............................................................................50

4.13 Refueling the Machine .........................................................................51

4.14 Positioning the Machine ......................................................................52

4.15 Pre-Starting Checks ............................................................................54

4.16 Connecting Power to the Machine ......................................................57

4.17 Starting and Stopping the Generator ...................................................58

4.18 Applying Power to the Machine ...........................................................59

4.19 Preheating the HTF .............................................................................60

4.20 Initiating HTF Flow ..............................................................................61

4.21 Setting the Operating Temperature .....................................................62

4.22 Unwinding and Positioning the Hoses .................................................63

4.23 Hose Spacing Guidelines ....................................................................64

4.24 Monitoring the Operating Parameters .................................................65

4.25 Rewinding the Hoses ..........................................................................66

4.26 Shutting Down and Packing Up the Machine ......................................68

4.27 Resetting a Low HTF Fault ..................................................................69

4.28 Quick-Connect Coupling Usage and Care ..........................................72

4.29 Operating States of the Beckett Burner Controller ..............................73

E 3000

5 Accessories 78

5.1 Available Accessories .........................................................................78

5.2 Expanding the Surface Heating Capacity ............................................79

5.3 Expanded Operation Using One HHS 3002 and One DPP .................80

5.4 Expanded Operation Using Two HHS 3002 and Two DPP .................82

5.5 Mounting and Connecting the Auxiliary Pump Panel ..........................85

5.6 Using Heat Exchangers to Heat Air .....................................................87

5.7 Connecting Six HX 50 Heat Exchangers .............................................88

5.8 Connecting Five HX 50 Heat Exchangers ...........................................90

5.9 Connecting Four HX 50 Heat Exchangers ..........................................92

5.10 Connecting Three HX 50 Heat Exchangers ........................................94

5.11 Connecting Two HX 50 Heat Exchangers ...........................................96

5.12 Connecting One HX 50 Heat Exchanger .............................................98

5.13 Connecting Three HX 100 Heat Exchangers ....................................100

5.14 Connecting Two HX 100 Heat Exchangers .......................................102

5.15 Connecting One HX 100 Heat Exchanger .........................................104

5.16 Connecting Two HX 200 Heat Exchangers .......................................106

5.17 Connecting One HX 200 Heat Exchanger .........................................108

6 Burner Setup—Oil 109

6.1 Factory Settings ................................................................................109

8

wc_bo5000188154_05TOC.fm

Page 9

E 3000

6.2 Setting up the Burner ....................................................................... 109

6.3 Setting/Checking the Electrodes ...................................................... 112

6.4 Replacing the Burner Nozzle ............................................................ 114

6.5 Setting the “Z” Distance .................................................................... 116

6.6 Adjusting the Air Settings ................................................................. 118

6.7 Adjusting the Fuel Pressure ............................................................. 119

Table of Contents

7 Burner Setup—Gas 120

7.1 Factory Settings ............................................................................... 120

7.2 Restrictions for Connecting the Gas Supply ..................................... 121

7.3 Setting up the Burner ....................................................................... 122

7.4 Removing and Installing the Combustion Head ............................... 124

7.5 Adjusting the Ionization Probe and the Electrode ............................ 126

7.6 Changing the Burner Diaphragm ...................................................... 127

7.7 Checking and Adjusting the Air Damper (Gate) Setting ................... 128

7.8 Adjusting the Combustion Head ....................................................... 129

7.9 Checking the Supply Gas Pressure ................................................. 130

7.10 Checking and Adjusting the Burner Gas Pressure ........................... 132

8 Maintenance 134

8.1 Periodic Maintenance Schedule ....................................................... 134

8.2 Inspecting the HTF System and the Fuel System ............................ 135

8.3 Repairing a Hose .............................................................................. 136

8.4 Inspecting the Electrical Components .............................................. 138

8.5 Filling the HTF Reservoir .................................................................. 140

8.6 Cleaning the HTF Strainer ................................................................ 142

8.7 Replacing the Fuel Filter .................................................................. 144

8.8 Lubricating the Hose Reel System ................................................... 145

8.9 Cleaning the Turbulators and the Exhaust Ducting .......................... 146

8.10 Inspecting/Replacing the Rope Gasket ............................................ 148

8.11 Removing the Oil Burner .................................................................. 149

8.12 Installing the Burner ......................................................................... 150

8.13 Storing the Machine ......................................................................... 151

8.14 Storing the Genset ........................................................................... 152

8.15 Preparing the Machine for Seasonal Operation ............................... 153

8.16 Connecting and Maintaining the Battery .......................................... 154

9 Genset Maintenance 155

9.1 Periodic Maintenance Schedule ....................................................... 155

wc_bo5000188154_05TOC.fm

9

Page 10

Table of Contents

9.2 Checking the Engine Oil ....................................................................156

9.3 Changing the Engine Oil and Oil Filter ..............................................157

9.4 Checking the Engine Coolant Level ..................................................159

9.5 Replacing the Air Filter Element ........................................................160

9.6 Replacing Engine Fuel Filter .............................................................161

9.7 Changing Engine Coolant .................................................................163

9.8 Genset Shut-Down Codes .................................................................165

E 3000

10 Troubleshooting 169

10.1 Troubleshooting the Machine ............................................................169

10.2 Troubleshooting the Oil Burner .........................................................171

10.3 Troubleshooting the Gas Burner .......................................................172

11 Technical Data 173

11.1 Machine .............................................................................................173

11.2 Trailer ................................................................................................174

11.3 Dimensions ........................................................................................174

MSDS: Dowfrost HD 50 175

Fuji Temperature Controller 183

Tire Safety Information 187

12 Schematics 200

12.1 Composite Schematic—Machine with Oil Burner ..............................200

12.2 Composite Schematic—Machine with Gas Burner ...........................201

12.3 Electrical Schematic Components .....................................................202

12.4 Circulation System Circuit .................................................................205

12.5 Rewind System Circuit ......................................................................206

12.6 Gas Train Schematic .........................................................................207

12.7 Generator ..........................................................................................208

12.8 Trailer Plug — Wiring Diagram ..........................................................209

12.9 Trailer Junction Box — Wiring Diagram ............................................210

12.10 Trailer Lights and Brakes — Wiring Diagram ....................................211

12.11 Trailer Lights and Brakes — Components ........................................212

10

wc_bo5000188154_05TOC.fm

Page 11

E 3000 Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f To avoid death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f To avoid possible death o r serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000579gb.fm

11

Page 12

Safety Information E 3000

1.2 Machine Description and Intended Use

This machine is a hydronic surface heater. The Wacker Neuson Hydronic Surface

Heaters consist of trailer-mounted enclosures that house an optional diesel

generator , a hydronic heater, electric motors, fixed pump(s) and plumbing , a diesel

(or gas) burner, a fuel tank, and a hose handling system.

The hydronic heating system utilizes a burner that indirectly warms the Heat

Transfer Fluid (HTF). The warmed HTF is continuously circulated through a

vented, closed loop hose system. A positive displacement pump pushes the

warmed HTF through the hose system, thereby radiating and transferring the heat

to the required application area.

An insulated blanket may be laid over the hoses to increase efficiency. The low

HTF level protection device shuts down the machine if the HTF level drops below

minimum operational capacity.

This machine is intended to be used as a surface heater in order to thaw frozen

ground, to cure concrete, or to prevent frost and freezing. In addition, when used

with other Wacker Neuson accessories, this machine can be used to heat air.

This machine has been designed and built strictly for the intended use(s) described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

Using the machine to heat anything other than what is stated above

Using the machine to pump anything other than the factory recommended Heat

Transfer Fluid

Using the generator (if equipped) to power anything other than the machine

itself or Wacker Neuson accessory machines, as instructed in the Operator's

Manual

Using the machine as a ladder, support, or work surface

Using the machine to carry or transport passengers or equipment

Using the machine to tow other machines

Operating the generator (if equipped) in a manner that is inconsistent with all

federal, state, and local codes and regulations

Operating the machine outside of factory specifications

Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may rema in even after protective measures have been t aken.

They are called residual risks. On this machine, they may include exposure to:

Heat, noise, and exhaust from the engine or hydronic heater

Burns from the HTF or radiant heat from the hoses

12

wc_si000579gb.fm

Page 13

E 3000 Safety Information

Fire hazards from improper refueling techniques

Fuel and its fumes

Personal injury from improper lifting of the trailer tongue

Tripping hazards from the hoses

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

1.3 Safety Guidelines for Operating the Machine

Operator

training

Operator

qualifications

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

have received instruction on how to properly use the machine

are familiar with required safety devices

The machine must not be accessed or operated by:

children

people impaired by alcohol or drugs

Machine

condition

Only operate the machine when:

All safety devices and guards are in place and in working order.

All controls operate correctly.

The machine is set up correctly according to the instructions in the Operator’s

Manual.

The machine is clean.

The machine’s labels are legible.

When operating the machine:

Do not modify or defeat the safety devices.

Do not use worn electrical cords.

Do not use faulty fuel supplies.

Safe

operating

practices

wc_si000579gb.fm

When operating this machine:

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

13

Page 14

Safety Information E 3000

When operating this machine:

Do not operate a machine in need of repair.

Personal

Protective

Equipment

(PPE)

Work space

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

When operating the machine:

Position the machine on a firm, noncombustible, level surface, and chock the

wheels.

Position the machine on the job site so that neither it nor the operator are

standing in water.

Keep the area immediately surrounding and underneath the machine clean,

neat, and free of debris and combustible materials.

Keep the area above the machine clear of debris that could fall on the machine.

Store the machine properly when it is not being used.

Keep unauthorized personnel, children, and pets away from the machine.

When operating the machine:

Never operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

1.4 Safety Guidelines for Lifting the Machine

When lifting the machine:

Make sure slings, chains, hooks, ramps, jacks, forklifts, cranes, hoists, and any

other type of lifting device used is attached securely and has enough weightbearing capacity to lift or hold the machine safely. See section Technical Data

for machine weight.

Remain aware of the location of other people when lifting the machine.

Only use the lifting points and tie-downs described in the Operator’s Manual.

Make sure the transporting vehicle has sufficient load capacity a nd platform size

to safely transport the machine.

To reduce the possibility of injury:

Do not stand under the machine while it is being lifted or moved.

Do not get onto the machine while it is being lifted or moved.

14

wc_si000579gb.fm

Page 15

E 3000 Safety Information

1.5 Safety Guidelines for Operating Combustion Burners

When using the machine:

Clean up any spilled fuel immediately.

Replace the fuel tank cap after refueling the machine.

Refill the fuel tank in a well-ventilated area.

Shut down the generator, if equipped, when refueling.

When using the machine:

DANGER

Exhaust gas from the burner contains carbon monoxide, a deadly poison. Exposure

to carbon monoxide can kill you in minutes.

f Never run the machine indoors or in an enclosed area unless the machine is

vented properly.

When refueling the machine:

Do not fill or drain the fuel tank near an open flame or while the machine is

running.

Do not smoke when refueling the machine.

Do not use gasoline, crankcase oil, or any oil containing gasoline.

wc_si000579gb.fm

15

Page 16

Safety Information E 3000

1.6 Safety Guidelines for Operating Gensets

DANGER

f Carbon monoxide. Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot

see or smell. If you can smell the generator exhaust, you are breathing CO. But

even if you cannot smell the exhaust, you could be breathing CO.

WARNING

Electrocution hazard. Generators present special hazards during operation and

servicing. These include the risk of electrocution or severe electrical shock. Failure

to follow the safety information below can result in severe injury or death.

f Read and follow the safety instructions in this Operator’s Manual.

f Contact the genset manufacturer for additional information regarding the

genset.

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety instructions could result in severe injury or

death.

f Read and follow the safety instructions in this Operator’s Manual.

f Contact the genset manufacturer for additional information regarding the

genset.

General

precautions

WARNING

Most used oil contains small amou nts of materials tha t can cause cancer and oth er

health problems if inhaled, ingested, or left in contact with skin for prolonged

periods of time.

f Take steps to avoid inhaling or ingesting used engine oil.

f Wash skin thoroughly after exposure to used engine oil.

This machine is built with user safety in mind; however, like any electrical device it

can present serious hazards if improperly operated and serviced. Follow

instructions carefully. Should questions arise during operation or service of this

equipment, contact your Wacker Neuson dealer.

Keep a multi-class, type ABC or equivalent fire extinguisher at hand when using

the genset. Refer to NFPA No. 10 for further information regarding fire

extinguishers.

Do not use evaporative starting fluids. They are highly explosive.

Do not store items such as excess oil, oil rags, tools within the genset

compartment. Items stored within the genset compartment are a fire hazard and

can restrict cooling air.

Wash thoroughly after handling used engine oil.

16

wc_si000579gb.fm

Page 17

E 3000 Safety Information

Before

operating the

genset

Running the

genset

Refueling

safety

Know how to start, operate, and stop the genset before starting it.

Obtain the proper training for operating the genset. Do not allow untrained

personnel to operate or service the genset.

Check the fuel lines and the fuel tank for leaks and cracks before starting the

engine.

Clean the genset of any spilled fuel.

Do not start the engine if fuel has spilled or a fuel odor is present.

Keep the area around the exhaust pipe free of flammable materials.

Do not smoke while operating the genset.

Keep sparks, flames, electrical arcs, and other sources of ignition far away from

the genset.

Do not touch the engine or muffler while the engine is running or immediately

after it has been turned off.

Do not operate the genset with the maintenance covers off.

Do not overload the genset. The total amperage of the tools and equipment

attached to the genset must not exceed the load rating of the genset.

Do not operate the genset with wet hands.

Do not remove the radiator cap when the genset is running or is hot.

When adding fuel to the fuel tank:

Do not smoke.

Do not refuel a hot or running engine.

Maintenance

safety

When adding fuel to the fuel tank:

Keep sparks, flames, electrical arcs, and other sources of ignition far away from

the genset.

Refill the fuel tank only in a well-ventilated area.

Reinstall the fuel tank cap after refueling.

Only a trained technician should attempt to repair the genset.

Test procedures which require that the generator be running must be performed

using extreme caution.

Make sure clothing and shoes are dry , st and on a dry wooden plat form or rubber

insulating mat, and use tools with insulated handles when servicing the genset.

Engine antifreeze is toxic to humans and animals. Clean up spills and dispose

of used engine antifreeze in accordance with local environmental regulations.

Make sure all fasteners are secure and torqued properly.

wc_si000579gb.fm

17

Page 18

Safety Information E 3000

1.7 Service Safety

Service

training

Precautions

Before servicing or maintaining the machine:

Read and understand the instructions contained in all manuals delivered with

the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

Do not allow improperly trained people to service or maintain the machine.

Personnel servicing or maintaining the machine must be familiar with the

associated potential risks and hazards.

Follow the precautions below when servicing or maintaining the machine.

Read and understand the service procedures before performing any service to

the machine.

All adjustments and repairs must be completed before operating the machine.

Do not operate the machine with a known problem or deficiency.

All repairs and adjustments shall be completed by a qualified technician.

Turn off the machine before performing maintenance or making repairs.

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

Reinstall the safety devices and guards after repair and maintenance

procedures are complete.

Machine

modifications

Replacing

parts and

labels

Cleaning

When servicing or maintaining the machine:

Use only accessories/attachments that are approved by Wacker Neuson.

When servicing or maintaining the machine:

Do not defeat safety devices.

Do not modify the machine without the express written approval of Wacker

Neuson.

Replace worn or damaged components.

Replace all missing and hard-to-read labels.

When replacing electrical components, use components that are identical in

rating and performance to the original components.

When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those p arts equivalent to the original in all types of

specifications, such as physical dimensions, type, strength, and material.

When cleaning and servicing the machine:

Keep the machine clean and free of debris such as leaves, paper, cartons, etc.

Keep the labels legible.

wc_si000579gb.fm

18

Page 19

E 3000 Safety Information

When cleaning the machine:

Do not clean the machine while it is running.

Never use gasoline or other types of fuels or flammable solvents to clean the

machine. Fumes from fuels and solvents can become explosive.

Personal

Protective

Equipment

(PPE)

Maintenance

guidelines

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

When maintaining the machine:

Keep the fuel lines in good condition and properly connected.

Allow the burner to cool before maintaining the machine.

Allow the Heat Transfer Fluid (HTF) to cool before maintaining the machine.

Keep all electrical cords away from heat, oil, vibrating surfaces, and sharp

edges.

wc_si000579gb.fm

19

Page 20

Safety Information E 3000

1.8 Safety Guidelines for Towing the Machine

WARNING

Risk of severe injury or death. Improper trailer condition and towing technique can

lead to an accident.

f Obey the trailer manufacturer’s instructions and the instructions below to reduce

the risk of an accident.

When towing the machine:

Do not tow the machine if the towing vehicle’s hitch or the trailer’s coupler are

damaged.

Do not tow the machine if any of the trailer’s lug nuts are missing.

Do not tow the machine if the trailer’s tires have less than 1.5 mm (1/16 inch) of

tread.

Do not tow the machine unless the trailer’s brakes are functioning properly.

Do not exceed the trailer manufacturer’s speed limitations.

When towing the machine:

Only tow the machine when the trailer’s lug nuts are properly torqued.

Only tow the machine when the trailer’s tires are properly inflated.

Only tow the machine when all trailer lights are functioning correctly.

Only tow the machine when the trailer’s safety chains are connected to the

towing vehicle in a crisscross pattern.

Maintain extra distance between the towing vehicle and other vehicles.

Avoid soft shoulders, curbs, and sudden lane changes

Abide by all licensing requirements for your area.

If you have not driven a towing vehicle with trailer before, practice turning,

stopping, and backing up the towing vehicle with trailer in an area away from traffic.

Only drive the towing vehicle with trailer when you are confident in your ability to do

so.

20

wc_si000579gb.fm

Page 21

E 3000 Safety Information

1.9 Reporting Safety Defects

If you believe your trailer has a defect which could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Wacker Neuson.

If NHTSA receives similar complaints, it may open an investigation; and if it finds

that a safety defect exists in a group of trailers, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in individual problems

between you, your dealer, or Wacker Neuson.

To contact NHTSA, you may either contact the Vehicle Safety Hotline toll-free at

1-888-327-4236 (TTY: 1-800-424-9153), go to http://www.safercar.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about your motor vehicle safety from

http://www.safercar.gov

wc_si000579gb.fm

21

Page 22

Labels E 3000

2 Labels

2.1 Label Locations

603

601

999

618

626

602

608

998

wc_gr008850

wc_si000643gb.fm

22

Page 23

E 3000 Labels

616

609

625

608

995

604

613

600

612

617

607

602 611

616

609

612

618

613

619

626

602

wc_si000643gb.fm

625

613

wc_gr008849

23

Page 24

Labels E 3000

2.2 Label Meanings

Ref. Label Definition

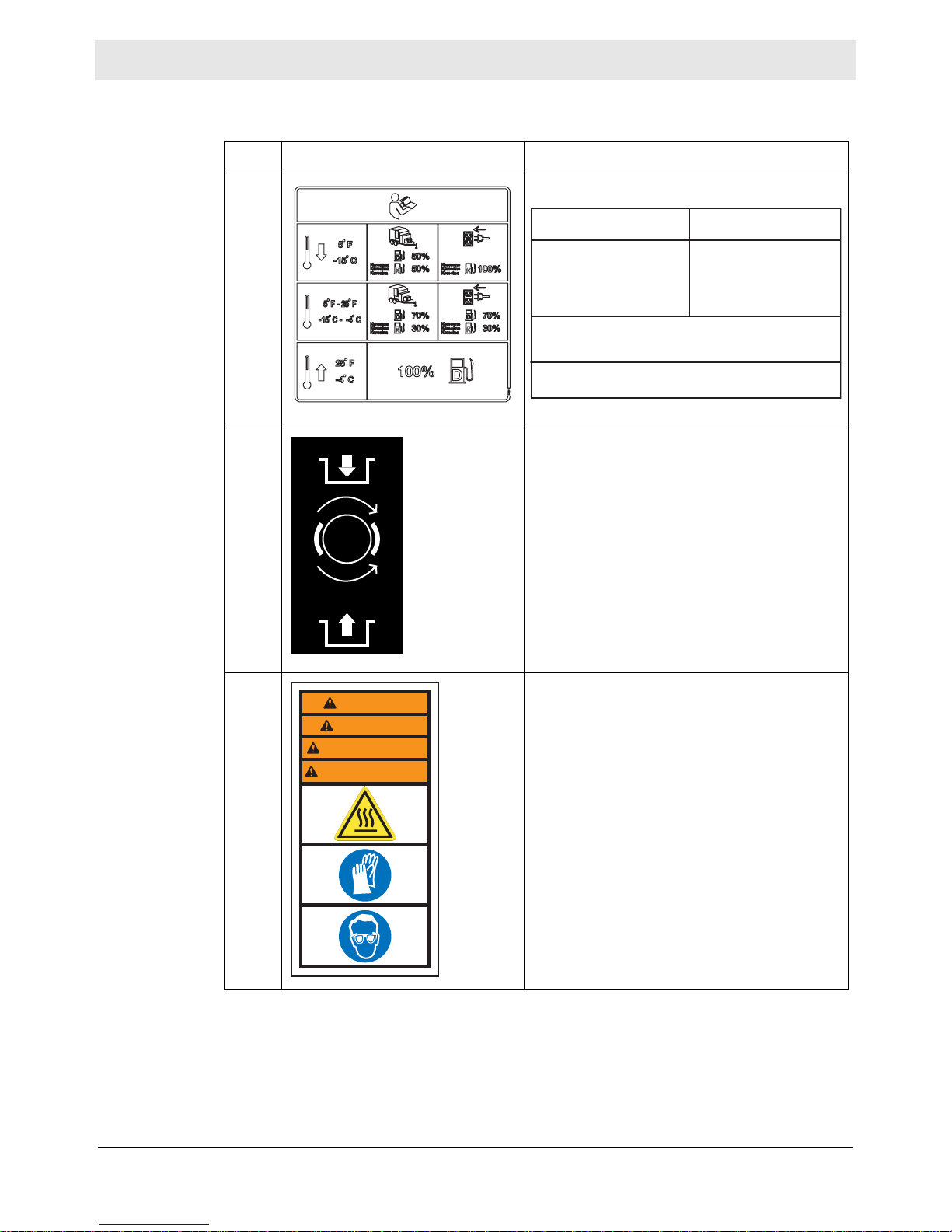

600

For machines powered by

the generator:

Use a 50-50 blend of #2 diesel

and #1 diesel plus additives,

or a 50-50 blend of #2 diesel

and K1 kerosene plus additives when temperatures

are below 5°F (-15°C).

Use a 70-30 blend of #2 diesel and #1 diesel plus additives or

a 70-30 blend of #2 diesel and K1 kerosene plus additives

when temperatures are in the range 5 to 25°F (-15 to -4°C).

Use a winter-blend diesel when temperatures are above

25°F (-4°C).

For machines powered by

the power utility:

Use 100% #1 diesel plus

additives or 100% K1 kerosene plus additives when

temperatures are below

are below 5°F (-15°C).

wc_gr008377

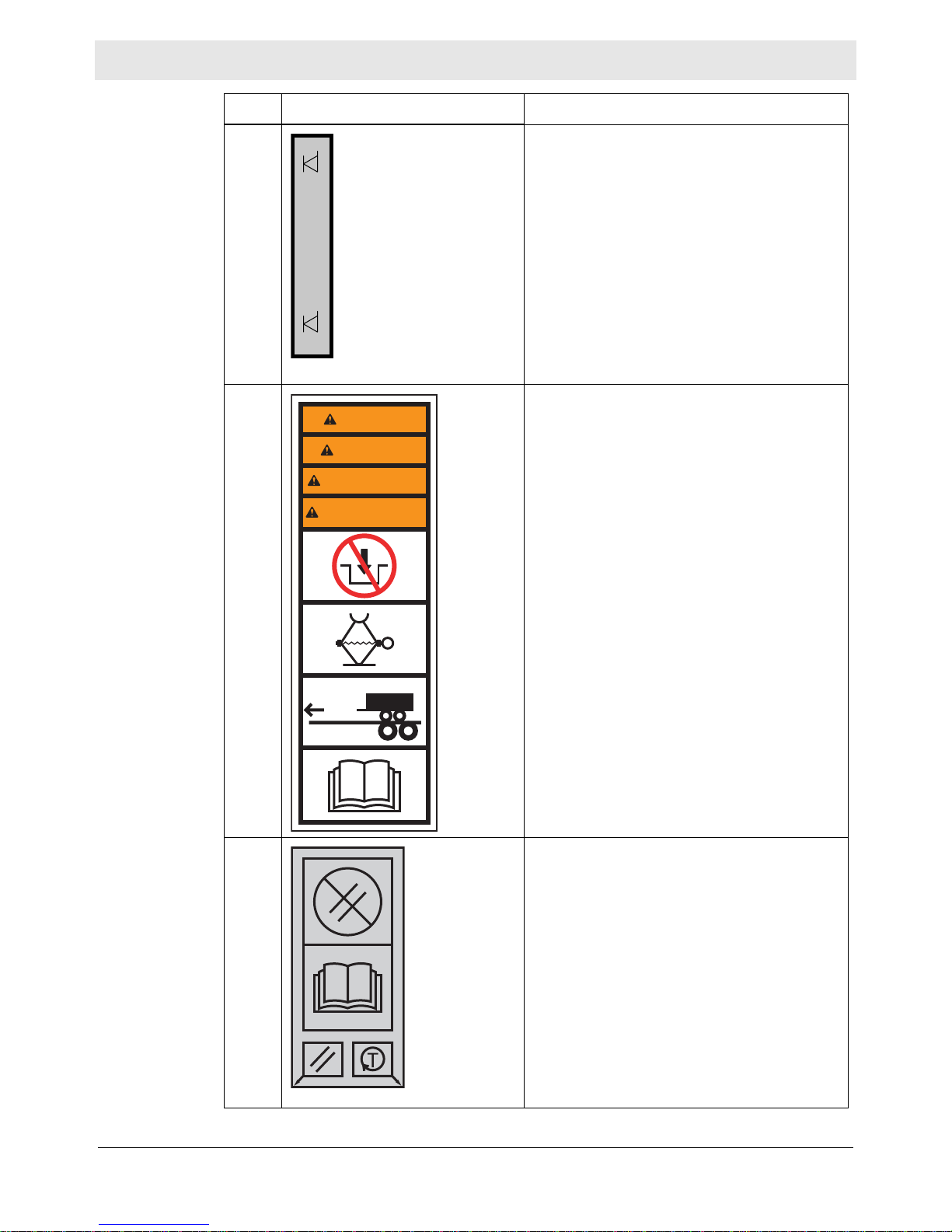

601 Turn the handle clockwise to engage the

hose reel brake.

Turn the handle counterclockwise to release

the hose reel brake.

602 WARNING!

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

173199

Hot surface hazard.

Wear safety gloves.

Wear eye protection.

24

wc_si000643gb.fm

Page 25

E 3000 Labels

Ref. Label Definition

603 Heat Transfer Fluid level. This label indicates

the minimum and maximum level for the

Heat Transfer Fluid. This label is located

adjacent to a sight gauge on the Heat Transfer Fluid reservoir.

604 WARNING!

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

Do not engage trailer jack while transporting

the machine.

Refer to the Operator’s Manual for further

instructions.

607 Do not reset.

wc_si000643gb.fm

173200

173201

Refer to Operator’s Manual.

25

Page 26

Labels E 3000

Ref. Label Definition

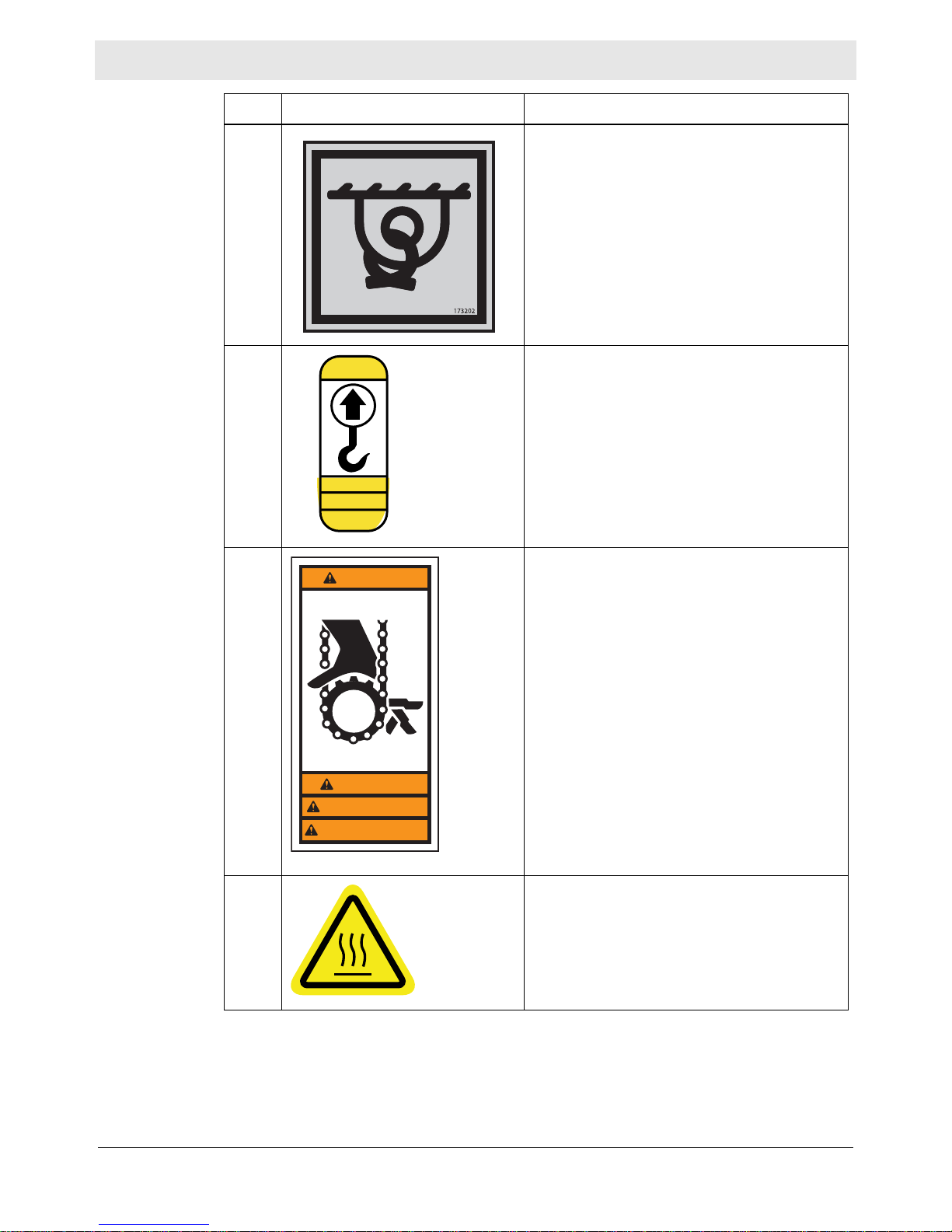

608 Tie-down location marker.

609 NOTICE!

CAUTION

Lift point.

Attach lifting device in this location.

VORSICHT

PRECAUCION

PRECAUTION

611 WARNING!

WARNING

Hand entanglement hazard. Moving parts

can crush and cut. Do not operate with guard

removed.

173224

WARNUNG

ADVERTENCIA

AVERTISSEMENT

612 CAUTION!

Hot surface hazard!

wc_si000643gb.fm

26

Page 27

E 3000 Labels

Ref. Label Definition

613 Not a step.

616 Weight/mass label: This label indicates the

total weight of the machine, including the

8582

trailer and a full fuel tank.

3900

617 CAUTION

This machine uses diesel fuel.

618

DANGER

Asphyxiation hazard.

Using a Hydronic Surface Heater indoors

CAN KILL YOU IN MINUTES. Generator and

burner exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

Never use inside an enclosed area even if

doors and windows are open.

Only use outside away from windows, doors,

and vents.

Read manual before use.

wc_si000643gb.fm

27

Page 28

Labels E 3000

Ref. Label Definition

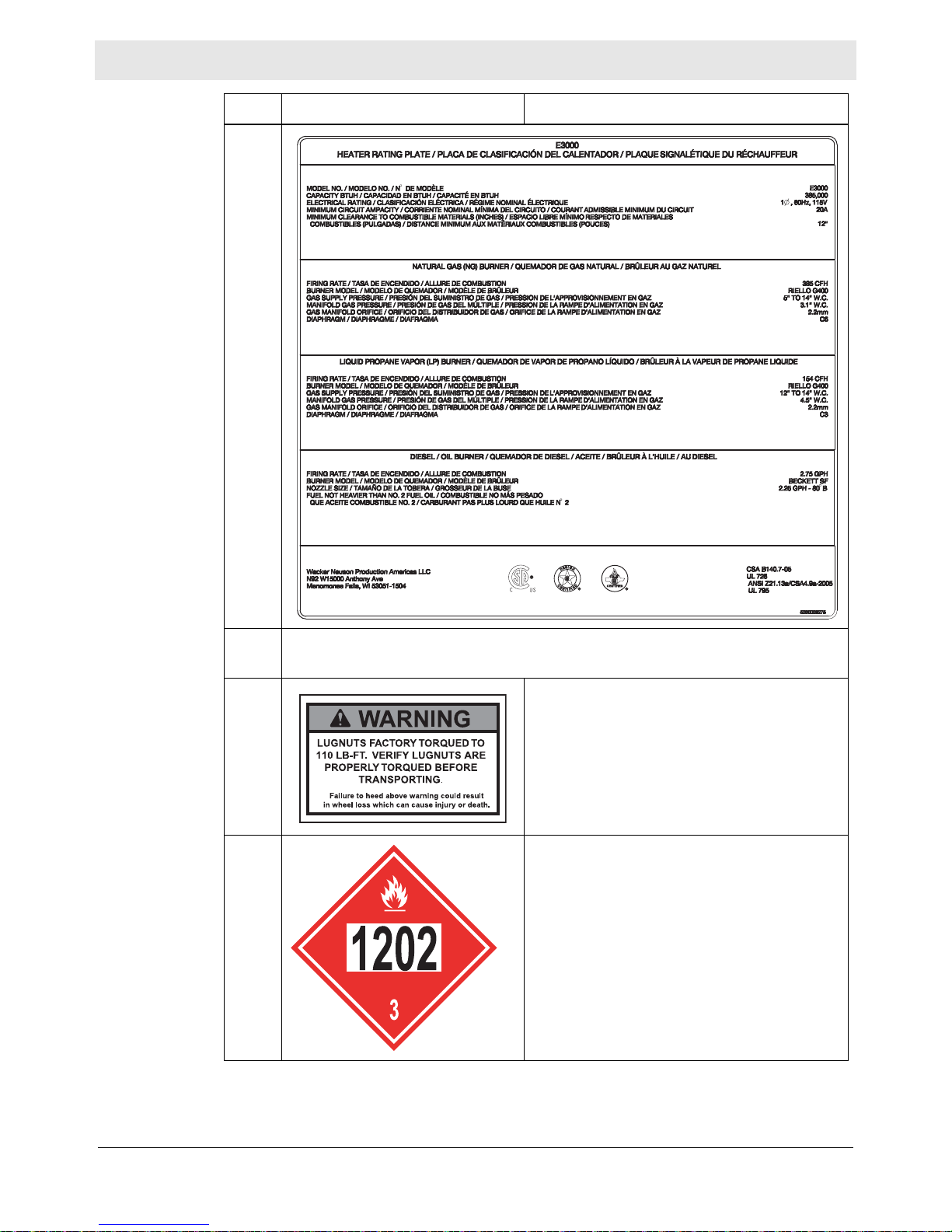

619

Machine rating label: This label indicates rating information for the machine.

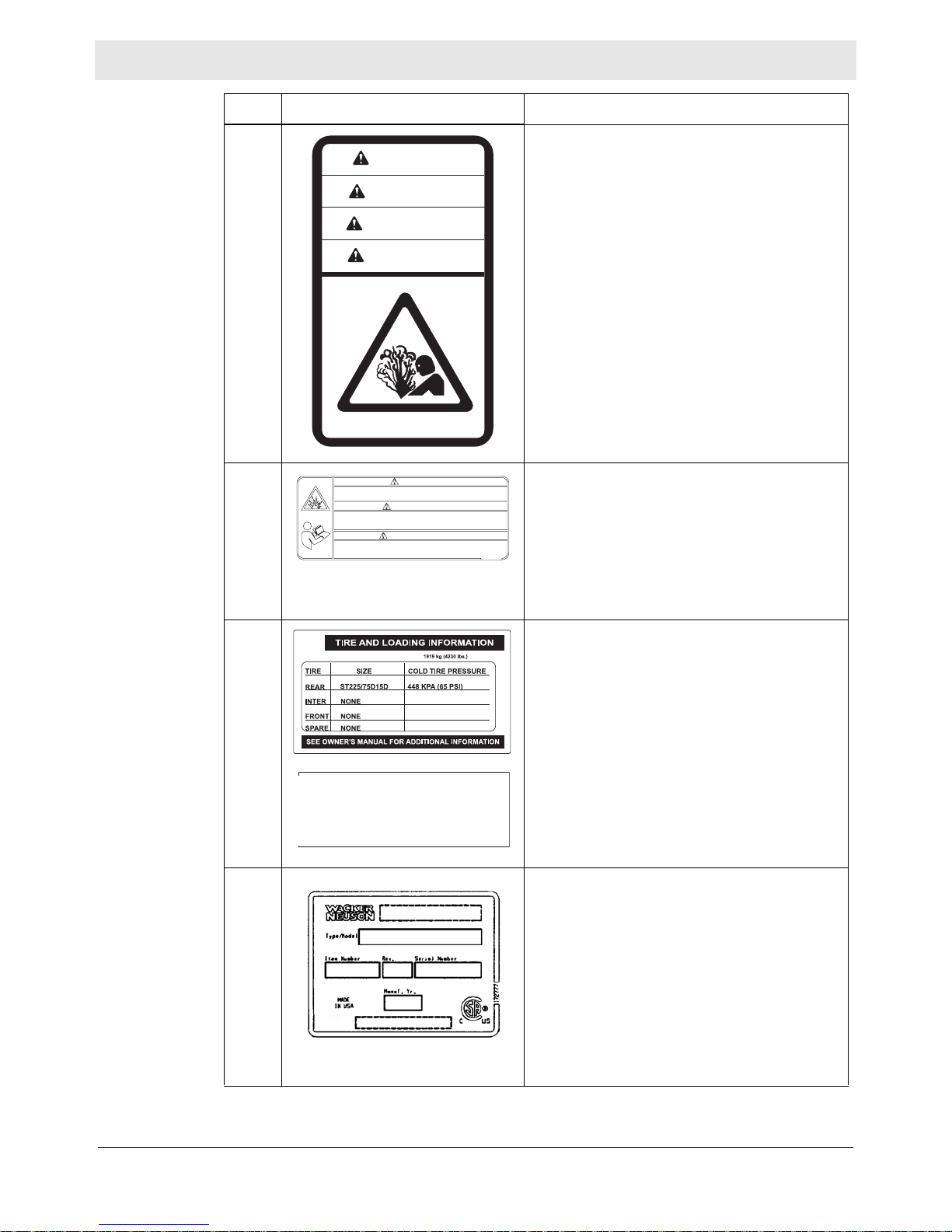

625 WARNING!

Lugnuts factory torqued to 110 ft.lbs. Verify

lugnuts are properly torqued before transporting. Failure to heed above warning could

result in wheel loss which can cause injury or

death.

— Magnetic placards that display the numeric

hazardous material code for diesel fuel are

included with each machine. These placards

must be placed on three sides of the

machine during transport if the fuel tank contains any amount of fuel or fuel residue.

28

wc_si000643gb.fm

Page 29

E 3000 Labels

Ref. Label Definition

626 CAUTION!

CAUTION

VORSICHT

ATENCION

ATTENTION

183255

Pressurized contents. Do not open when hot!

995 WARNING!

Never operate in an explosive environment or near flammable vapors, fuels

or combustibles. Explosion or fire may occur. Risk of severe injury or death.

Nunca opere en un ambiente explosivo o cerca de los vapores inflamables,

gasolina o combustibles. Explosión o un incendio puede ocurrir.

Riesgo de lesiones graves o la muerte.

Ne faire jamais fonctionner dans un environnement explosif ou à proximité

des vapeurs inflammables, des carburants ou combustibles. Explosion ou un

incendie peut se produire. Risque de blessures graves ou la mort.

WARNING

ADVERTENCIA

AVERTISSEMENT

5200002911

Never operate in an explosive environment

or near flammable vapors, fuels or combustibles. Explosion or fire may occur. Risk of

severe injury or death.

998 (on trailer)

The weight of cargo should never exceed

Tire and loading information label:

This label indicates tire and loading information for the trailer.

(on trailer)

VIN label. This label displays vehicle identifi-

cation numbers and other related information.

999 A nameplate listing the model number, item

number, revision number, and serial number

is attached to each unit. Please record the

information found on this plate so it will be

available should the nameplate become lost

or damaged. When ordering parts or

requesting service information, you will

always be asked to specify the model number, item nu mber , revision number, and serial

number of the unit.

wc_si000643gb.fm

29

Page 30

Lifting and Transporting E 3000

3 Lifting and Transporting

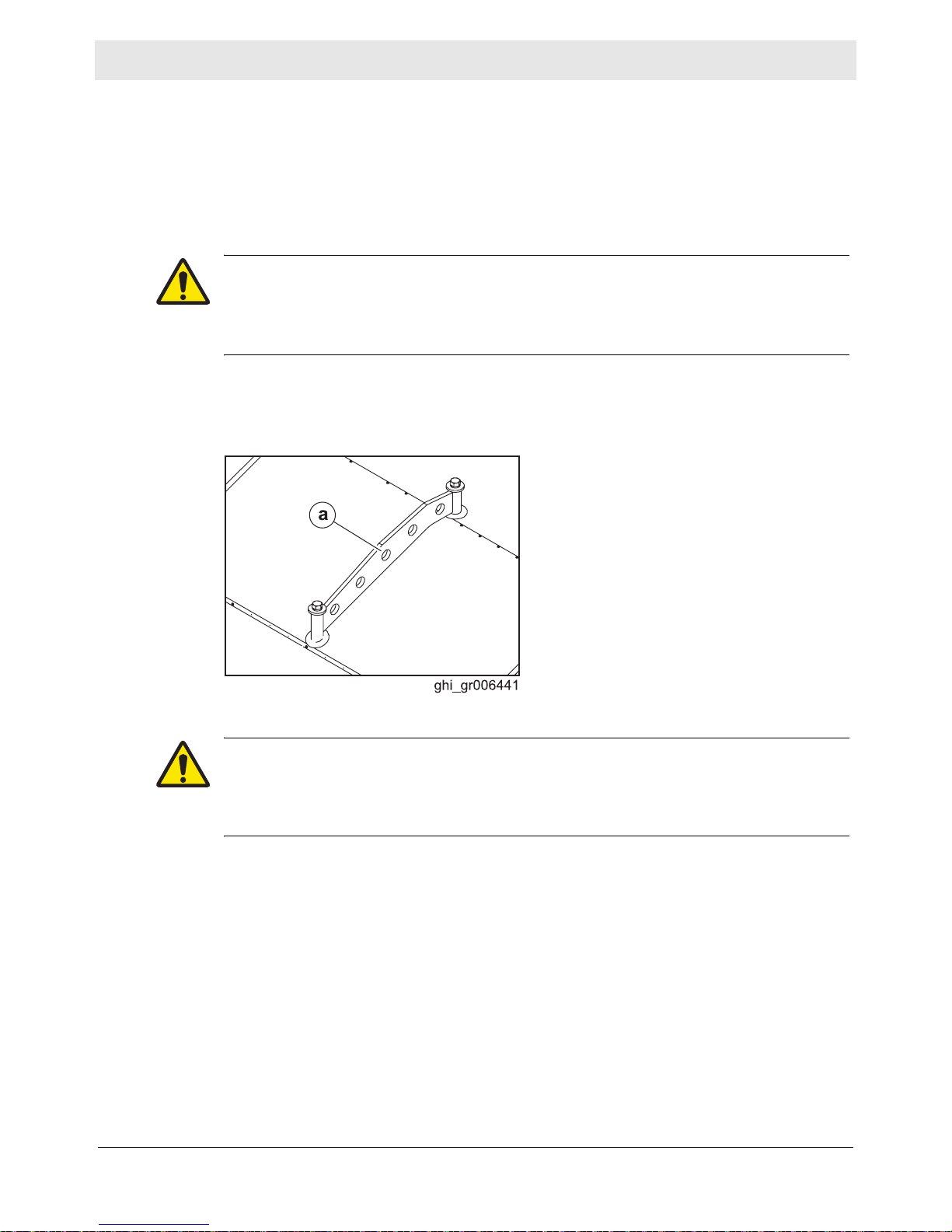

3.1 Lifting the Machine

Requirements

Procedure

Properly rated lifting equipment (crane or hoist). See Chapter Technical Data.

Machine stopped. See topic Stopping the Machine.

All doors and access covers closed and secured.

WARNING

Crushing hazard. You may be crushed if the lifting devices fail.

f Never stand under, or get onto, the machine while it is being lifted or moved.

f Use only the designated lifting points to lift the machine.

Follow the procedure below to lift the machine.

1. Attach the lifting equipment to one of the lifting eyes (a) on the machine using

hooks, shackles, and chains.

2. Lift the machine a small distance.

WARNING

Crushing hazard. An unstable machine may cause the lifting devices to fail. You

may be crushed if the lifting devices fail.

f Check for stability before continuing.

3. Check for stability. If necessary, lower the machine, reposition the lifting device,

and lift the machine a small distance again.

4. Continue lifting the machine as necessary.

30

ghi_tx001160gb.fm

Page 31

E 3000 Lifting and Transporting

3.2 Preparing the Machine for Transport on a Truck or Trailer

Requirements

Checklist

Machine stopped.

Flatbed truck or trailer capable of supporting the machine’s weight.

Chains, hooks, or straps capable of supporting the machine’s weight.

WARNING

Crushing hazard. Improperly securing the machine can lead to a crushing hazard.

f Use only the designated tie-down points to secure the machine to a truck or

trailer.

Before transporting the machine, check the following items:

Machine

Check that all accessories are securely stored within the machine.

Check that all doors and access panels of the machine are closed.

Check that all electrical supplies are disconnected from the machine.

For machines with external fuel supplies, check that all fuel supplies are

disconnected from the machine.

For machines with generators, check that the generator is shut down.

Loading and transporting equipment

Check t hat the transport vehicle or trailer can sup port the weight of the machine.

Check that the transport vehicle or trailer is wide enough to support the

machine.

Check that the wheels of the transport vehicle or trailer are chocked during the

loading process.

Check that the transport vehicle or trailer is clean and free of grease, oil, ice,

and other loose material.

If the machine is mounted to a trailer , check that the jackstand or other transport

block (piece of wood or other similar material) is available to support the trailer

tongue during transporting. Do not use the machine’s trailer jack to support the

trailer tongue during transporting.

Check that any ramps used in the loading process:

Can support the weight of the machine

Are clean and free of grease, oil, ice, and other loose material.

Are securely connected to the transport vehicle or trailer.

Are of sufficient length to keep the loading angle 15° or less.

In addition:

Check that the loading area is flat and the ground is stable.

Check the overall height of the machine once loaded. Plan your travel route so

there will be adequate clearance for overpasses, road signs, buildings, etc.

Check local regulations regarding transporting and obey these regulations.

ghi_tx001160gb.fm

31

Page 32

Lifting and Transporting E 3000

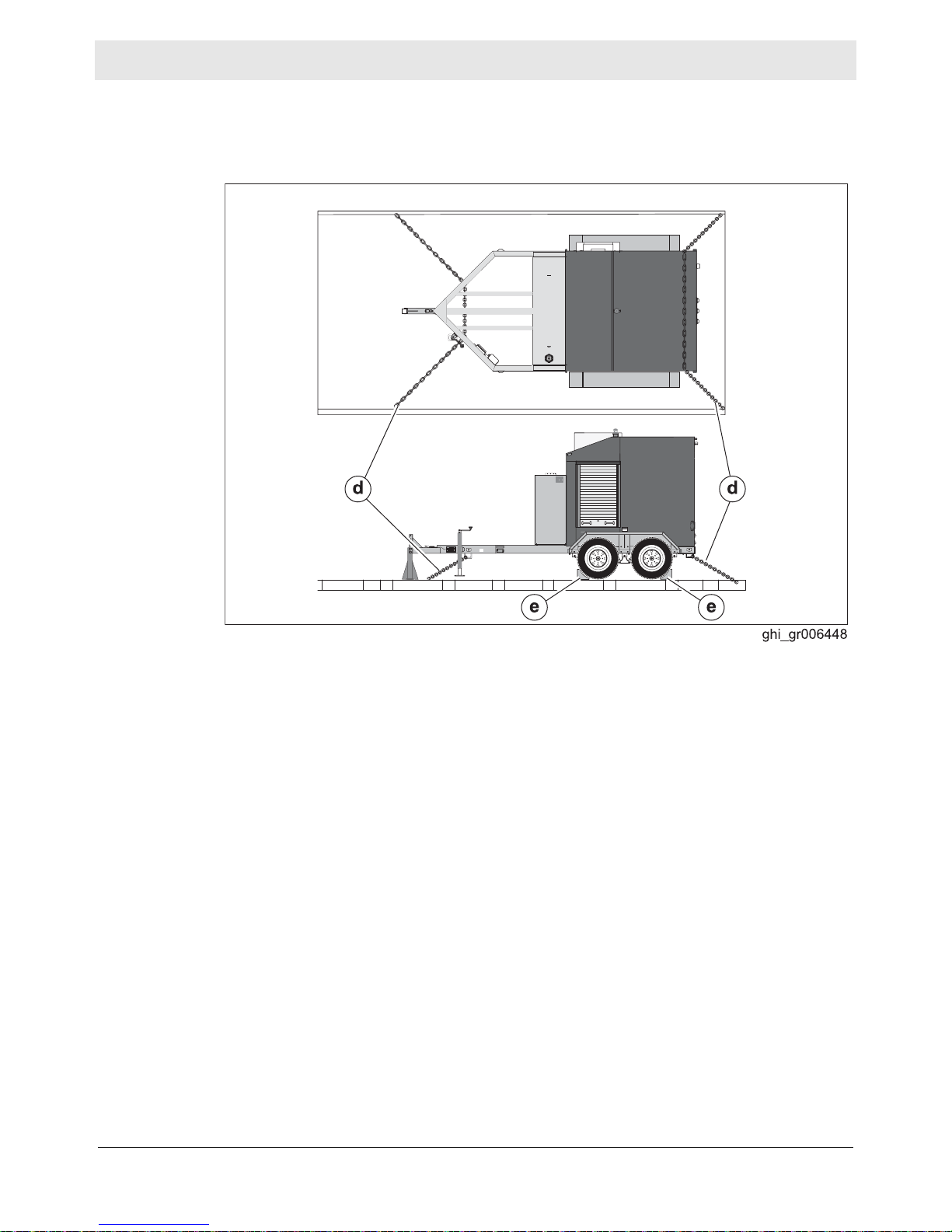

3.3 Transporting the Machine on a Truck or Trailer

Requirements

Move the

machine

Machine stopped. See topic Stopping the Machine.

All doors and access covers closed and secured.

WARNING

Crushing hazard. Improperly securing the machine can lead to a crushing hazard.

f Use only the designated tie-down points to secure the machine.

NOTICE: Do not run chains or straps across painted surfaces. Chains or straps

may damage your machine.

1. Move the machine onto the flat bed using properly rated ramps or docks.

NOTICE: The flat bed must be at least 98 inches wide.

Support the

tongue

2. Raise the tongue using the trailer jack (a).

3. Install the tongue support (b) using two 5/8 inch bolts.

NOTICE: If the supplied tongue support is missing, use any mechanism capable of

supporting the tongue weight.

4. Lower the tongue and retract the trailer jack (a) at least two inches from the

surface of the truck bed.

This procedure continues on the next page.

32

ghi_tx001160gb.fm

Page 33

E 3000 Lifting and Transporting

Continued from the previous page.

Secure the

machine

5. Install properly rated securing mechanisms (d) such as chains or straps.

6. Install chocks (e) under all four wheels.

Result

The machine is ready to be transported.

ghi_tx001160gb.fm

33

Page 34

Lifting and Transporting E 3000

3.4 Before Towing Checklist

Before towing the machine, check the licensing requirements for trailers in your

area. Also check the following items:

Hitch and coupler

Check that the towing vehicle and hitch have a rating equal to or greater than

the GVWR of the machine. See Technical Data.

Check that the hitch of the towing vehicle and coupler of the trailer are

compatible.

Check the condition of both the coupler and the hitch.

Check that all fasteners on the coupler are secure.

Check that the coupler has fresh grease applied to it.

Wheels

Check that all lug nuts are in place and are properly torqued.

Check the tread wear of the tires.

Check that the tires are inflated to the proper pressure.

Trailer operation

Check that the directional and running lights on the trailer function correctly.

Check that the safety chains of the trailer are connected to the towing vehicle

using a crisscross pattern.

Check that the trailer’s breakaway cable is attached to the towing vehicle.

Check the opera tion of the trailer brakes by braking the towing ve hicle at a slow

speed. Both the vehicle and the trailer must brake smoothly. If the trailer

pushes, check the fluid level in the surge brakes or the operation of the electric

brakes.

Test the function of the breakaway system.

ghi_tx001160gb.fm

34

Page 35

E 3000 Lifting and Transporting

3.5 Towing the Machine

WARNING

Risk of severe injury or death. Improperly torqued lug nuts can lead to loss of

wheels. Loss of wheels can cause an accident, severe injury or death.

f Tighten the lug nuts to the proper torque before towing the machine.

NOTICE: The towing vehicle must be equipped with a Class III or above hitch.

Procedure

Perform the procedure below when towing the machine.

1. Read and follow the towing safety guidelines. See topic Safety Guidelines for

Towing the Machine.

2. Complete the shut-down procedures. See topic Stopping and Packing Up the

Machine.

3. Adjust the amount of fuel in the machine to approximately 70% cap acity to avoid

fuel spillage.

4. Complete the Before Towing Checklist. See topic Before Towing Checklist.

5. Connect the machine to the towing vehicle.

6. Rotate the trailer jack to a horizontal position.

7. Tow the machine as needed.

ghi_tx001160gb.fm

35

Page 36

Lifting and Transporting E 3000

3.6 Testing the Breakaway System (Electric Brakes)

Requirements

When

Procedure

Voltmeter

Battery charger or backup battery (charged)

Test the breakaway system:

Before towing

Monthly if the machine is not in service

Perform the following procedure to test the breakaway system.

NOTICE: Disconnect the trailer wiring plug from the tow vehicle before testing.

Failure to do so will result in severe damage to the electronic brake control.

1. Connect the machine/trailer to the tow vehicle.

2. Disconnect the trailer wiring plug (a) from the tow vehicle.

a

c

b

wc_gr008470

3. Pull the breakaway pin (b) out of the brake switch (c) (to activate the brakes)

and attempt to tow the machine/trailer at a very slow speed (less than 5 mph (8

km/hr)). When activated, a properly working breakaway system will cause

substantial drag on the trailer wheels and may even cause the trailer wheels to

lock.

4. Stop the tow vehicle.

WARNING

Personal injury hazard. A faulty breakaway system may lead to an accident and

personal injury if the machine/trailer breaks away.

f Do not tow the machine/trailer if the breakaway system is faulty.

This procedure continues on the next page.

wc_gr008471

36

ghi_tx001160gb.fm

Page 37

E 3000 Lifting and Transporting

Continued from the previous page.

5. If the brakes did not function, check the voltage of the breakaway battery. To do

so:

a.Remove the cover of the battery box.

b.Remove the wires connected to the breakaway battery (d).

c.Measure the voltage. If 12–14 VDC is not measured, replace or recharge the

breakaway battery.

d

1000

F

200

V

20

2

200m

A

V- COM

VDC

wc_gr008472

6. If 12–14 VDC was measured but the brakes did not function, there is a wiring or

mechanical fault with the brakes. Repair any faults before towing.

Result

7. If the brakes function properly:

a.Reconnect the wires to the breakaway battery.

b.Reinstall the cover to the battery box.

a.Reinstall the breakaway pin (b) into the brake switch.

b.Connect the trailer wiring plug to the tow vehicle.

The procedure to test the breakaway system is now complete.

ghi_tx001160gb.fm

37

Page 38

Lifting and Transporting E 3000

3.7 Hazardous Materials Placards

Hazardous

materials

placards

The Pipeline and Hazardous Materials Safety Administration (PHMSA) requires

that hazardous materials placards be placed on this machine when transporting it

unless the fuel tank has been drained and purged of all fuel and residue.

Before transporting the machine:

1. Drain and purge the fuel tank of all fuel and fuel residue OR place placards that

display the numeric hazardous material code for diesel fuel on three sides of the

machine.

Note: The placards are included with the machine.

2. Consult the Department of Transportation (DOT), or equivalent agency, in the

states or countries in which this machine is to be transported, regarding:

Driver’s licensing requirements for transporting machines that bear hazard-

ous materials placards

Other restrictions for use of this machine

38

ghi_tx001160gb.fm

Page 39

E 3000 Lifting and Transporting

Notes

ghi_tx001160gb.fm

39

Page 40

Operation E 3000

4 Operation

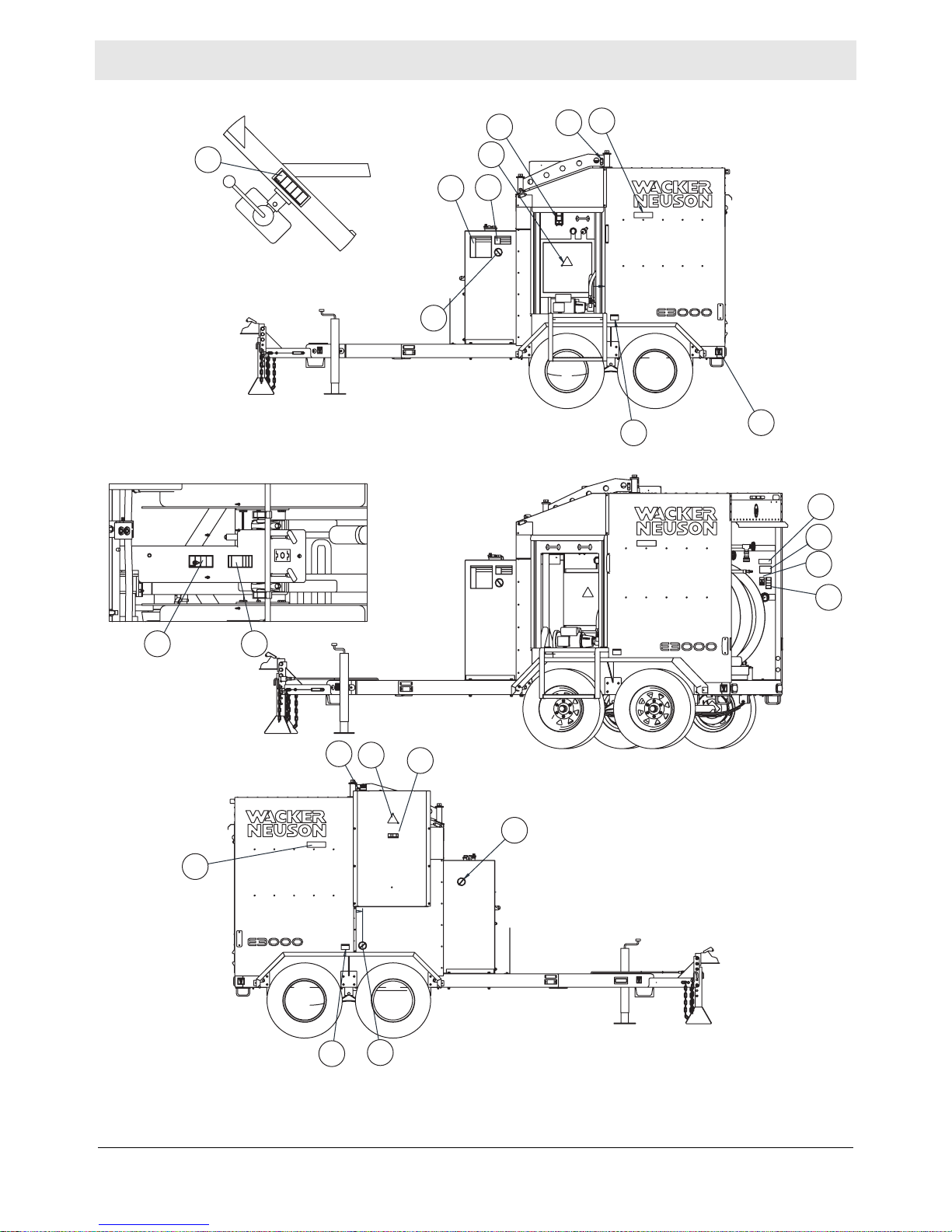

4.1 External Components

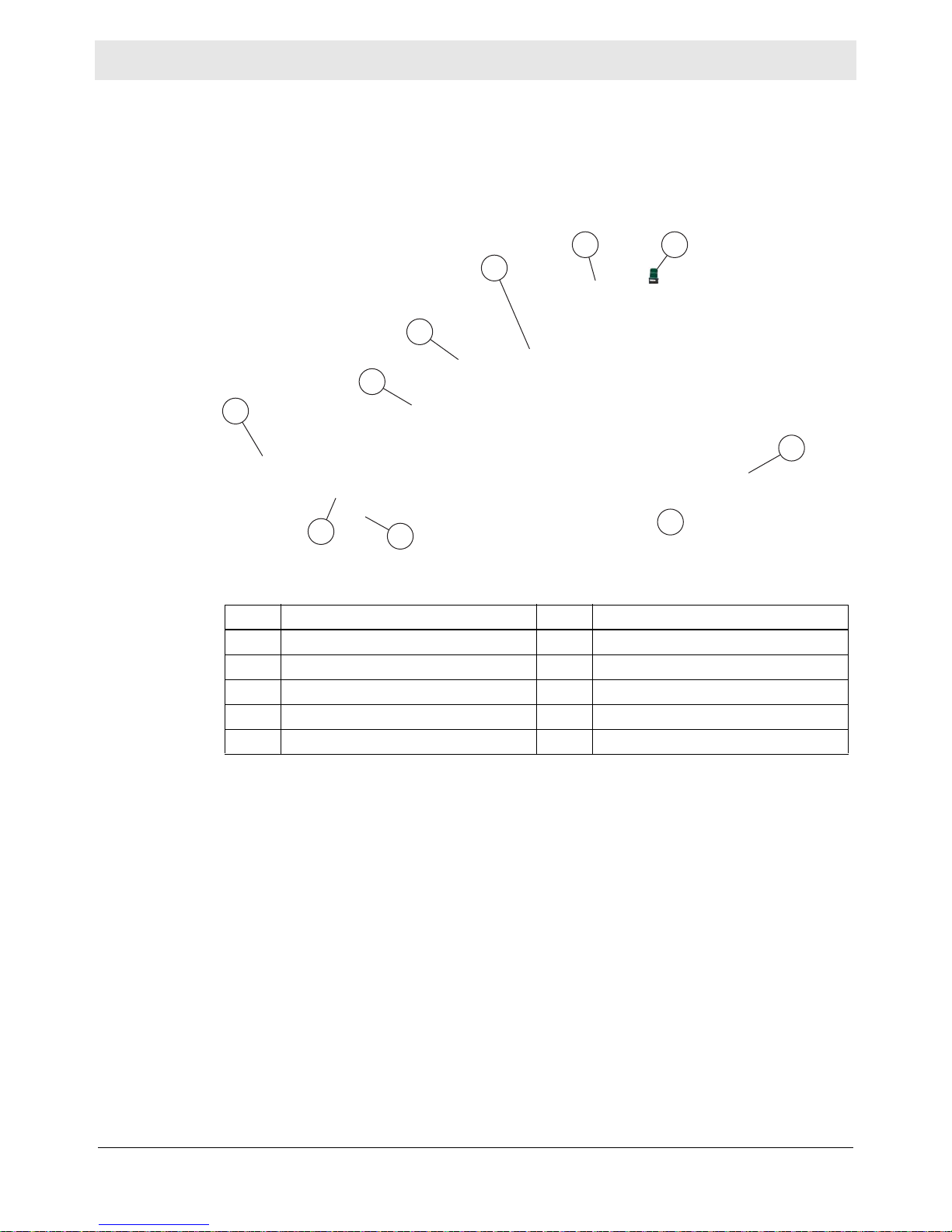

10

5

4

3

7

1

2

Ref. Description Ref. Description

1 Hitch (ball or pintle) 6 Fender

2 Tie-down 7 Onan genset (option)

3 Fuel tank 8 Jack stand

4 Fuel tank cap 9 Tandem axles

5 Performance monitoring light 10 Lifting bail

8

9

6

wc_gr008851

40

wc_tx001951gb.fm

Page 41

E 3000 Operation

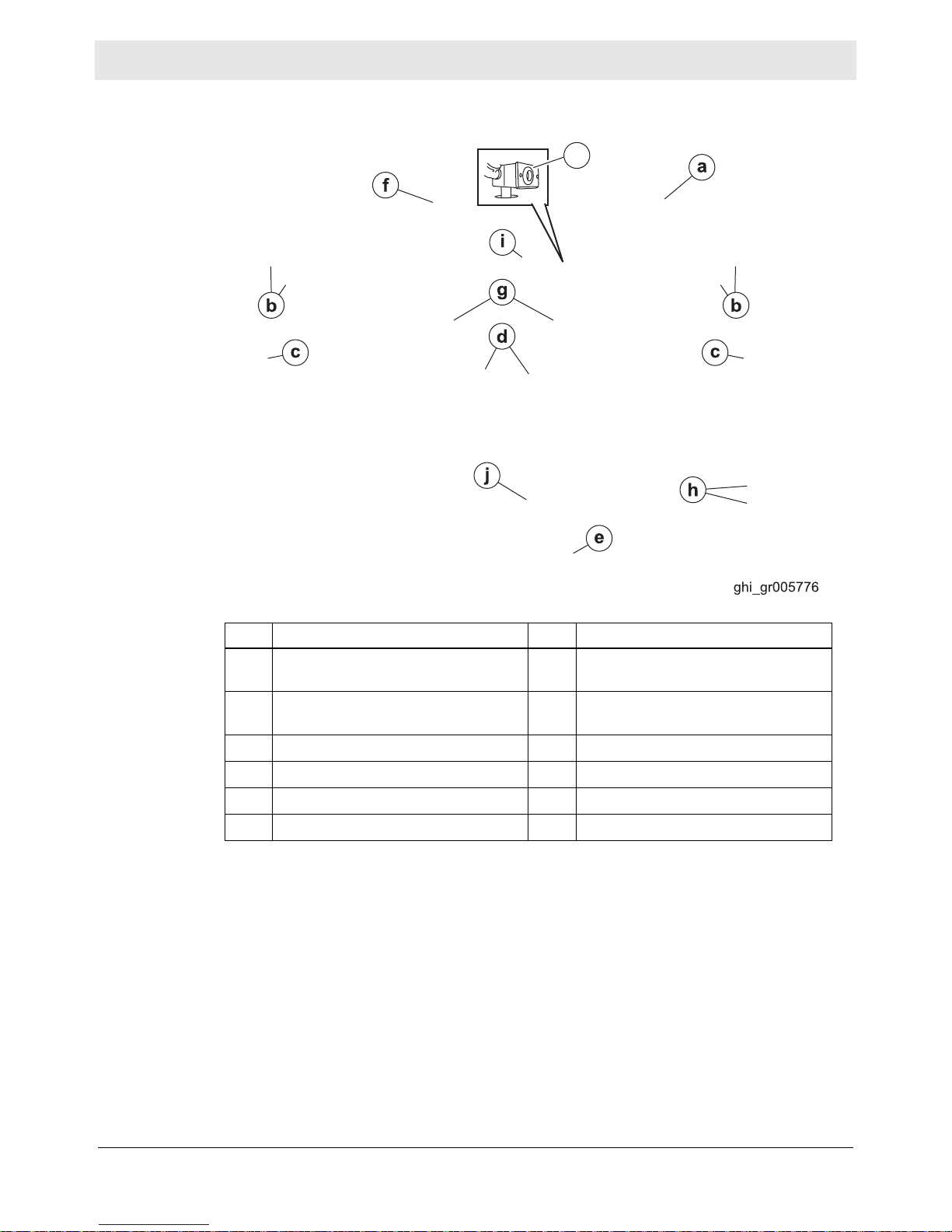

4.2 Internal Components

g

wc_gr008296

Ref. Description Ref. Description

a Hydronic heater

1

h Fill valve #3

b Burner (oil burning shown) i HTF pumps

c Suction valve #2 j Low-level shut-down device

d Fuel filter k Thermocouple

e Battery l Temper ature/pressure gauges

f Fuel sight gauge m HTF filter

g Fuel sight gauge valve n Motor (HTF pump)

1

This hydronic heater operates at zero (atmospheric) pressure and is not subject to regulations

applicable to pressurized “boilers”.

wc_tx001951gb.fm

41

Page 42

Operation E 3000

4.3 Rear Components

k

Ref. Description Ref. Description

Control panel

a

Heat Transfer Fluid (HTF) return

b

plumbing

HTF supply plumbing

c

Hose reel brake T-handle

d

Rewind system foot control pedal

e

HTF expansion tank sightglass

f

Hose reels and hose

g

Pump Pack supply connections

h

Duplex receptacle

i

Operator’s Manual holder

j

Thermal switch (snap switch)

k

—

—

42

wc_tx001951gb.fm

Page 43

E 3000 Operation

4.4 Pumps, Gauges, and Valves

Pumps and

Gauges

Valves

Ref. Description

aLeft pump

b Return flow indicator

c Accessory HTF return thermometer

d Main HTF return thermometer

e Check valves

f Pump pressure gauge

g Right pump

Valve # Description

1 Pump Pack supply and drain valve

2 Pump suction valve (behind hose

reel)

3 HTF fill valve (behind hose reel)

4 Left hose reel supply valve

5 Cross connect valve

6 Right hose reel supply valve

7 Pump Pack supply valve

wc_tx001951gb.fm

43

Page 44

Operation E 3000

1

2

4.5 Control Panel

m

a

b

n

c

d

e

l

k

j

hi

o

g

f

p

wc_gr008606

44

wc_tx001951gb.fm

Page 45

E 3000 Operation

4.6 Control Panel Components

Ref Description Function

a Main breaker 1 Controls power to electrical circuit 1.

b Hour meter Meters usage of the machine.

c Main breaker 2 Controls power to the pump circuit (20A)

d Circuit 2 GFCI Provides protection for the operator.

e Temperature control

f Cab light ON-OFF switch Switches electric power ON and OFF to the

g Hose rewind ON-OFF (right and

left) switch

h Burner ON-OFF switch Switches electric power ON and OFF to the

i Pump 2 ON-OFF switch Switches electric power ON and OFF to

j Pump 1 ON-OFF switch Switches electric power ON and OFF to

k HTF fill switch This momentary switch bypasses the low-

l Low level fault indicator Illuminates to indicate a low HTF level condi-

Allows the user to control the HTF target

application temperature.

Shows the actual temperature of the HTF.

cab light.

Controls power to the hose rewind motor.

This switch has two ON modes—one each in

the up and down positions. OFF mode is in

the middle position.

burner.

Pump 2.

Pump 1.

level shut-down device and provides power

to the pumps. It is used when filling the HTF

reservoir after a low level fault.

tion.

m Burner fault indicator Illuminates to indicate a burner fault condi-

n Circuit 1 GFCI Provides protection for the operator.

o Thermal switch (snap switch)

p HTF low-level reset switch (mod-

ule is located inside the auxiliary

control panel)

wc_tx001951gb.fm

45

tion.

Disconnects power to the burner circuit in the

event of an over-temperature condition. This

switch opens at 88°C (190°F). This switch

must be manually

Pressing this switch resets the low-level

shut-down device.

reset.

Page 46

Operation E 3000

4.7 Genset Control Panel

a

b

f

e

Ref Description

Oil fill cap and dipstick

a

Coolant recovery access panel

b

Coolant level sightglass

c

Control switch and status light

d

Line circuit breakers

e

Coolant fill access panel

f

c

d

wc_gr008140

46

wc_tx001951gb.fm

Page 47

E 3000 Operation

4.8 Preparing the Machine for First Use

Preparing for

first use

To prepare your machine for first use:

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

4.9 Breaking in the Genset

Background

Procedure

New gensets require a break-in period for the engine. If you are the first owner of

this machine, or the genset’s engine has just been rebuilt, break in the engine as

stated below.

1. Check that the engine oil level is correct. Check that the engine oil viscosity is

appropriate for the temperature conditions. Change the oil if it is not appropriate

for the temperature conditions.

2. Operate the genset at approximately 1/2 rated power for the first two hours.

3. Operate the genset at approximately 3/4 rated power for two more hours.

4. Check the engine oil level every four hours (or twice daily) during the first 24

hours of operation.

5. Change the engine oil and filter after the first 50 hours of operation.

wc_tx001951gb.fm

47

Page 48

Operation E 3000

4.10 General Sequence of Operation

Follow the sequence of operation below. Refer to the specific topic for details.

Task When/Where See Topic

1. Check HTF level. Before leaving for the job site.

2. Check fuel level. 4.13 / 4.15

3. Position the machine. At the job site. 4.14

4. Perform pre-starting checks. 4.15

5. Connect power. 4.16

6. Start the generator (if equipped) 4.17

7. Power up the machine. 4.18

8. Run the machine. —

a. Preheat the HTF (if necessary). 4.19

b. Initiate HTF flow. 4.20

c. Unwind and position the hoses. 4.22 / 4.23

d. Monitor the operating parameters. 4.24

Or, when at the job site before

daily operation.

4.11 / 4.15

e. Rewind the hoses. 4.25

9. Shut down and pack up the machine. 4.26

48

wc_tx001951gb.fm

Page 49

E 3000 Operation

4.11 Checking the HTF Level

When

Prerequisites

Procedure

If low

Before leaving for the job site, or

Before beginning operation at the job site

The machine is level.

The machine is cool.

The Heat Transfer Fluid (HTF) level must be between the marks on the

sightglass (c).

If the HTF level is low, HTF must be added. Filling the HTF reservoir requires

electric power to the machine and knowledge of the machine’s operation.

Familiarize yourself with the function of the machine’s controls, then see topic

Filling the HTF Reservoir for detailed instructions.

wc_tx001951gb.fm

49

Page 50

Operation E 3000

4.12 Recommended Fuel

Low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner

ignition failure and/or burner fuel pump damage. Always use the proper fuel for the

conditions.

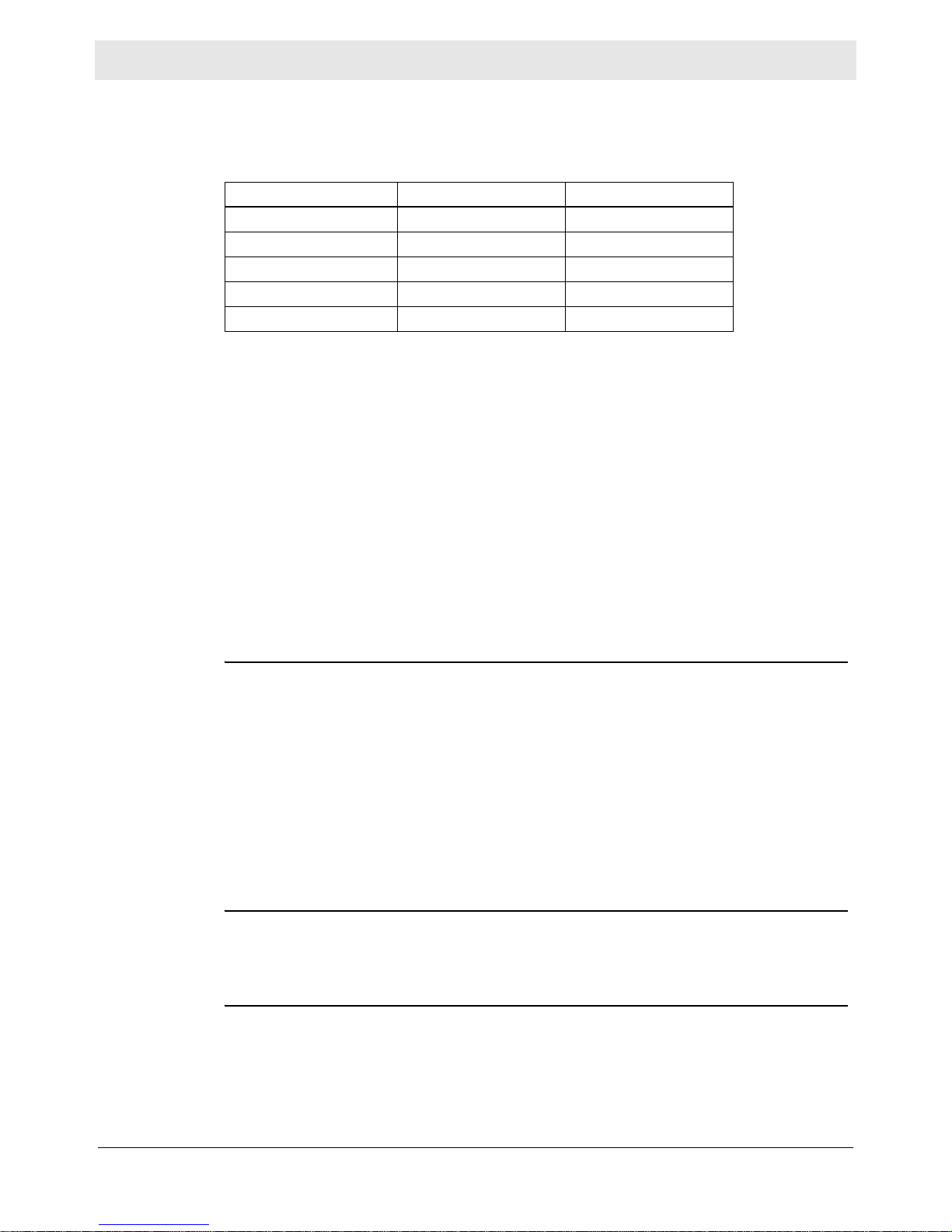

Fuel Blend Guide

Lowest expected ambient

temperature °F (°C)

Below 5 (-15)

Generator-powered Shore-powered

50-50 blend of #2 diesel

and #1 diesel, plus

additives

OR

50-50 blend #2 diesel and

K1 kerosene, plus

additives

100% #1 diesel plus

additives

OR

100% K1 kerosene,

plus additives

70-30 blend of #2 diesel and #1 diesel, plus additives

5 to 25 (-15 to -4)

Above 25 (-4) Winter-blend diesel

70-30 blend of #2 diesel and K1 kerosene,

OR

plus additives

NOTICE: Do not use B20 or any other type of biodiesel fuel in this machine.

CAUTION

Fire hazard.

f Do not use gasoline, crankcase oil, or any oil containing gasoline.

50

wc_tx001951gb.fm

Page 51

E 3000 Operation

4.13 Refueling the Machine

Requirements

Procedure

Machine shut down

Machine level with the ground

Diesel fuel supply

Perform the procedure below to refuel the machine.

Note: On models with generators, it is not necessary to fill the generator’s fuel

tank. Both the burner and the generator use the machine’s fuel tank.

1. Lift the lever (a) on the fuel cap.

a

wc_gr008446

2. Rotate the lever counterclockwise until it stops.

wc_gr008447

3. Remove the fuel cap from the tank.

b

wc_gr008448 wc_gr008599

4. Fill the tank with the appropriate grade of fuel for the weather conditions until the

gauge (b) reads full. Leave room within the tank for possible fuel expansion.

CAUTION

Fire and health hazard. Fuel expands when heated. Expanding fuel in a overly-full

tank can lead to spills and leaks.

f Do not overfill the fuel tank.

5. Reinstall the fuel cap.

Result

wc_tx001951gb.fm

The procedure to refuel the machine is now complete.

51

Page 52

Operation E 3000

4.14 Positioning the Machine

DANGER

Asphyxiation hazard.

Exhaust gas from the burner contains carbon monoxide, a deadly poison you

cannot see or smell. Exposure to carbon monoxide can kill you in minutes.

f Position the machine so that burner exhaust will not enter any nearby

structures.

WARNING

Fire hazard. Do not move the machine while it is running.

f Shut down the machine before moving or repositioning it.

WARNING

Fire hazard. Machines positioned on a hill or an incline may slide, break away or

roll over.

f Do not position the machine on a hill or an incline.

CO Alarms

Requirements

WARNING

Explosion and fire hazard. Risk of severe injury or death.

f Do not operate the machine near flammable vapors, fuels, or combustibles.

Because this machine produces carbon monoxide (CO), Wacker Neuson

recommends that CO alarms be installed in all structures in close proximity to the

machine. CO alarms provide an extra measure of protection against this poison

that you cannot see or smell.

Install battery-operated CO alarms or plug-in CO alarms with battery backup,

according to the manufacturer’s instructions. CO alarms should be certified to the

requirements of the latest safety standards (UL 2034, IAS 6-96, or CSA 6.19.01).

Test the CO alarm batteries monthly.

Position the machine:

so that burner exhaust will not enter nearby structures.

so that the machine does not block traffic.

so that the machine is not close to any combustible material or flammable vapor .

so that all of the machine’s access doors/panels may be accessed.

so that HTF hoses do not pose tripping hazards, and so the HTF hoses cannot

be damaged by machines or other equipment on the job site.

This procedure continues on the next page.

52

wc_tx001951gb.fm

Page 53

E 3000 Operation

Continued from the previous page.

Procedure

Result

Perform the following procedure to position the machine.

1. Place the machine near the application area (a) on solid, stable, and level

ground.

E

TI

N

TIE

DOW

N

TIE

DOWN

DOW

b

wc_gr008529

2. For machines with trailers, install chocks (b) under the wheels.

The machine is now properly positioned.

E

TI

WN

DO

wc_tx001951gb.fm

53

Page 54

Operation E 3000

4.15 Pre-Starting Checks

Requirements

Checks

Machine properly positioned

Power connected to the machine

Before starting the machine, check the following items:

Fuel System

Fuel sight gauge valve

(a)

f Check that the fuel sight

gauge valve is open.

Fuel sight gauge

(b)

f Check that the fuel tank is

full.

Quick connects

(d)

f Check that the quick-con-

nect couplings are secure.

b

a

wc_gr008602

Heat Transfer Fluid (HTF) System

d

wc_gr008605

54

wc_tx001951gb.fm

Page 55

E 3000 Operation

Suction valve (#2)

f Check that suction valve (#2)

is open.

HTF fill valve

(#3)

f Check that HTF fill valve (#3)

is closed and locked with the

locking pin.

NOTICE:

remain closed and locked during

normal operation. An open HTF fill

valve will cause HTF leakage.

The HTF fill valve must

HTF sight gauge (c)

f Check that the HTF level is

within the operating range.

NOTICE:

with low HTF will damage the

pumps.

Starting the machine

wc_tx001951gb.fm

HTF Hose connections (e)

f Check that all HTF hose

quick-connects are secure.

55

Page 56

Operation E 3000

Hydronic heater

(f)

f Inspect for signs of exhaust

leaks. See topic

Replacing the Rope Gasket.

Inspecting/

Genset (g) (if equipped)

f Check oil level. See topic

Checking the Engine Oil.

f Inspect for signs of fuel and

exhaust leaks

.

f

wc_gr008603

g

Result

wc_gr008141

The machine is ready to have power applied.

56

wc_tx001951gb.fm

Page 57

E 3000 Operation

1

2

4.16 Connecting Power to the Machine

Prerequisites

Extension

cords

Procedure

Power source

Machine properly positioned

WARNING

Fire hazard and electric shock hazard. The use of undersized extension cords can

lead to fire and electric shock. Fire and electric shock can cause severe injury.

f Do not use undersized extension cords.

Restrictions for extension cords:

Use only 3-wire type extension cords with heavy-duty plugs.

The maximum length of extension cord usage per circuit is 30 m (100 ft).

Use 12-gauge extension cords for lengths up to 15 m (50 ft).

Use 10-gauge extension cords for lengths up to 30 m (100 ft).

Follow the procedure below to connect power to the machine.

1. Move both circuit breaker switches (a and b) to the OFF position.

a

b

c

d

POWER 2

POWER 1

wc_gr008601

2. Connect the main power cords (c) to a properly-rated power source or to the

generator (d) if included.

Result

Power has now been connected.

wc_tx001951gb.fm

57

Page 58

Operation E 3000

4.17 Starting and Stopping the Generator

Background

Starting

Only general starting and stopping procedures for the gene rator are included in this

manual. See the generator manufacturer’s operation manual for detailed

procedures.

Perform the procedure below to start the generator.

1. Move the circuit breaker switches on the genset to the OFF position.

2. Prime the fuel system if needed. The fuel system will need to be primed if:

Fuel system has run dry

Fuel system has been drained

The fuel filter has been changed

The genset has not been run for several weeks

f To prime the fuel system: Press and hold the control switch in the “S top / Prime”

position. The fuel pump will start two seconds after the control switch is initially

placed in the “Stop / Prime” position. Continue holding the control switch for at

least one minute.

Start /

Preheat

Stopping

Stop /

Prime

O

wc_gr007811

3. Press and hold the control switch in the “Start / Preheat” position. The genset

will first preheat (for up to 15 seconds depending on how cold it is). Then, the

starter will engage and the engine will start.

NOTICE: Do not crank the engine for more than 30 seconds at a time. Wait at

least two minutes before cranking the engine again.

Perform the procedure below to stop the genset.

1. Move the generator circuit breakers to the OFF position.

2. Allow the genset to run two minutes to cool down.

3. Press the control switch to the “Stop / Prime” position.

58

wc_tx001951gb.fm

Page 59

E 3000 Operation

1

2

4.18 Applying Power to the Machine

Requirements

Procedure

Pre-starting checks have been completed

Power connected to the machine

Follow the procedure below to apply power to the machine.

1. Move both circuit breaker switches (a) to the ON position.

wc_gr008607

2. Check that the indicator lights of both GFCIs (b) are off. Press the “RESET”

button of the GFCI if its indicator light is ON.

3. Check that the low-level-fault indicator light (c) is OFF. If this light is ON, add

Heat Transfer Fluid (HTF) to the reservoir. See topic Filling the HTF Reservoir.

Result

4. Check that the displays of the temperature controller (d) illuminate. If the

displays of the temperature controller do not illuminate, there is a problem with

the GFCI 1 or with the wiring to the temperature controller. Disconnect the main

power supply and rectify the problem before continuing.

The machine is ready for operation.

wc_tx001951gb.fm

59

Page 60

Operation E 3000

4.19 Preheating the HTF

NOTICE: Starting the machine with frozen or partially frozen Heat Transfer Fluid

(HTF) will permanently damage the pumps. Preheat the HTF when ambient air

temperature is below -26°C (-15° F).

Requirements

Procedure

HTF reservoir full

Machine powered up

Follow the procedure below to preheat the HTF.

1. Use the up and down arrows (a) on the temperature controller to set the HTF

temperature to 100°F (40°C). This is the set point temperature.

b

ghi_gr006377

2. Move the burner ON-OFF switch (b) to the ON position. The following sequence

occurs:

a.The burner motor starts after a 5-second delay.

b.The burner fires after a 15-second delay.

c.The burner will operate, with little or no visible exhaust smoke, until the HTF

reaches the set point temperature, at which time, the burner will stop firing.