Page 1

5100015363

Operator's Manual

Dumpers

DW60

DW90

DW100

Machine type

Edition 1.1

Order no 5100015363

Language us

D18-01/D18-02/D18-03

Page 2

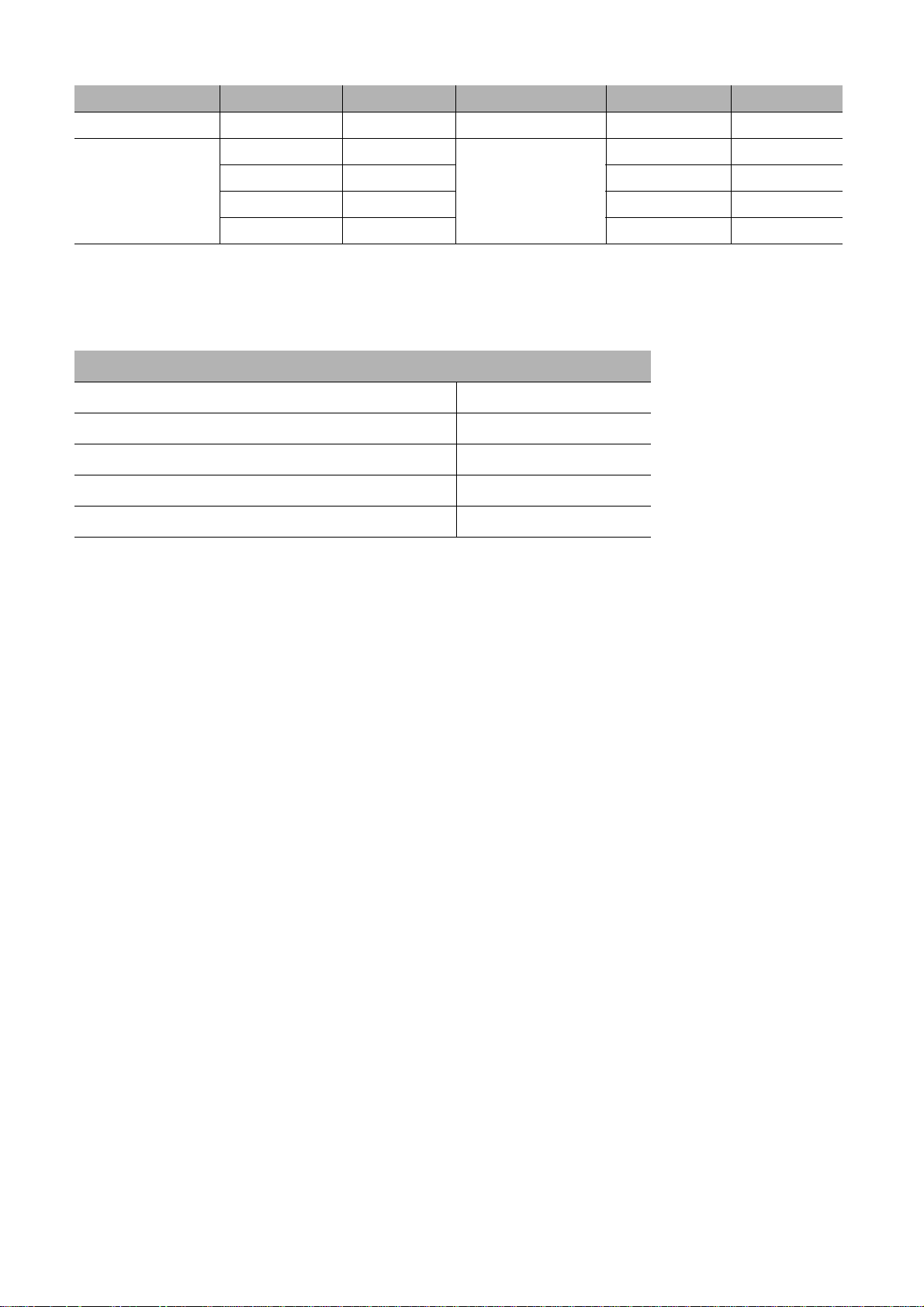

Documentation Language Order no. Documentation Language Order no.

Operator’s manual us 5100015363

DW 60 [de en fr] 1000333050

Spare parts list

Legend

Original Operator’s Manual x

Translation of original Operator’s Manual –

Edition 1.1

Date 02/2016

Document BA D18 us*

DW 60 [it es en] 1000333061 DW 100 [it es en] 1000333065

Spare parts list

DW 90 [de en fr] 1000333062

DW 90 [it es en] 1000333063

DW 100 [de en fr] 1000333064

Copyright © 2014 Wacker Neuson Linz GmbH, Hörsching

Printed in Austria

All rights reserved, in particular the copyright, the right of reproduction and the right of distribution applicable

worldwide.

No part of this publication may be reproduced, translated or used in any form or by any means – graphic,

electronic or mechanical including photocopying, recording, taping or information storage or retrieval systems –

without prior permission in writing from the manufacturer.

No reproduction or translation of this publication, in whole or part, without the written consent of Wacker Neuso n

Linz GmbH.

Violations of legal regulations, in particular of the copyright protection, will be subject to civil and criminal

prosecution.

Wacker Neuson Linz GmbH keep abreast of the latest technical developments and constantly improve their

products. For this reason, we may from time to time need to make changes to figures and descriptions in this

documentation which do not reflect products that have already been delivered and that will not be implemented

on these machines.

Technical data, dimensions and weights are only given as a n indicatio n. Non-me tric weig hts and mea sure ments

are approximate.Responsibility for errors or omissions not accepted.

The cover features the machine with possible optional equipment.

Photographs and graphics are symbolic representations and may differ from the actual products.

Wacker Neuson is authorized to reprint the copyright-protected material of Perkins Engines Company Ltd

contained in this document. Translation of original Operator´s Manual.

The Operator’s Manual and any amendments to it must always be available at the place of use of the machine.

Possible amendments are included at the end of the Operator’s Manual.

Wacker Neuson Linz G mbH

Flughafenstr. 7

A-4063 Hörsching

Phone: +43 (0) 7221 63000

Fax: +43 (0) 7221 63000-2200

E-mail: office.linz@wackerneuson.com

www.wackerneuson.com

Page 3

Table of contents

Table of contents

Table of contents

1Foreword

1.1 Operator’s Manual................................................................................................................................ 1-1

1.2 Warranty and liability ............................................................................................................................ 1-7

2 Safety

2.1 Safety symbols and signal words ....................................................... ... ... ... .... ... ... ... .... ........................ 2-1

2.2 Qualification of operating personnel..................................................................................................... 2-2

2.3 Conduct ................................................................................................................................................ 2-3

2.4 Operation.............................................................................................................................................. 2-4

2.5 Lifting gear applications............... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... .... ... .................................................. 2-8

2.6 Trailer operation ................................................................................................................................. 2-10

2.7 Attachment operation ......................................................................................................................... 2-10

2.8 Towing, loading and transporting ....................................................................................................... 2-11

2.9 Maintenance....................................................................................................................................... 2-13

2.10 Measures for avoiding risks................................................................................................................ 2-17

3 Introduction

3.1 Machine overview. ... ....................................... ... .... ... ... ... .... ... ... ............................................................ 3-1

3.2 Brief description of machine ................................................................................................................. 3-3

3.3 Information and regulations on use ...................................................................................................... 3-4

3.4 Labels................................................................................................................................................... 3-5

4 Putting into operation

4.1 Cabin/control stand...................................... ... ... .... ... ... ... .... ... ....................................... ........................ 4-1

4.2 Overview of control elements ............................................................................................................. 4-17

4.3 Indicator lights and warning lights (overview)..................................................................................... 4-24

4.4 Preparatory work ................................................................................................................................ 4-29

4.5 Starting and stopping the engine........................................................................................................ 4-34

5Operation

5.1 Steering system.... ... ....................................... ... .... ... ... ....................................... ... ... .... ........................ 5-2

5.2 Accelerator actuation...... ....................................... ... ... ... .... ... ... ... .... ..................................................... 5-3

5.3 Brakes .................................................................................................................................................. 5-4

5.4 Machine travel ... ... ... .... ... ... ... ....................................... ... .... ... ... ... .... ... .................................................. 5-9

5.5 Differential lock................................................................................................................................... 5-15

5.6 Lights/signaling system ...................................................................................................................... 5-16

5.7 Wiper/wash system (option) ............................................................................................................... 5-20

5.8 Heating, ventilation and air conditioning system................................................................................. 5-21

5.9 Operating hydraulics .... ....................................................................................................................... 5-22

5.10 Attachments........................................................................................................................................ 5-24

5.11 Work operation ................................................................................................................................... 5-24

5.12 Emergency lowering.................................... ... ... ....................................... ... .... ... ... ... .... ... ................... 5-29

5.13 Options ............................................................................................................................................... 5-29

5.14 Putting out of operation/back into operation....................................................................................... 5-32

5.15 Permanently putting out of operation........ .......................................................................................... 5-34

6Transportation

6.1 Towing the machine ............................................................................................................................. 6-1

6.2 Loading the machine ............................................................................................................................ 6-5

6.3 Transporting the machine..................................................................................................................... 6-9

BA D18 us* 1.1 * D18us1_1IVZ.fm I-1

Page 4

Table of contents

7 Maintenance

7.1 Information on maintenance................................................................................................................. 7-1

7.2 Maintenance overview................................................ ... ... ....................................... ... ... .... ...... ... ... .... ... 7-2

7.3 Fluids and lubricants........................................................................................................................... 7-10

7.4 Maintenance accesses .................................................. ... ... .... ... ... ... .... .............................................. 7-13

7.5 Cleaning and maintenance................................................................................................................. 7-16

7.6 Lubrication work................... ... ... .... ... ....................................... ... ... ... .... ... ... ... ... .................................. 7-19

7.7 Fuel system ........................................................................................................................................ 7-19

7.8 Engine lubrication system................. ... ... .... ... ... ....................................... ... ... ... .... ... ... ... .... ................. 7-25

7.9 Cooling system............. .... ... ... ... .... ...................................... .... ... ... ... .................................................. 7-28

7.10 Air filter................. ... ... ....................................... ... ... .... ... ..................................................................... 7-32

7.11 V-belt .................................................................................................................................................. 7-33

7.12 Hydraulic system ................................................................................................................................ 7-33

7.13 Electrical system............................................ ....................................... .............................................. 7-37

7.14 Heating, ventilation and air conditioning system................................................................................. 7-39

7.15 Washer system................................................................................................................................... 7-39

7.16 Axles................................................................................................................................................... 7-39

7.17 Braking system............. .... ... ... ... .... ... ... ....................................... ... ... .... ... ........................................... 7-39

7.18 Tires.................................................................................................................................................... 7-40

7.19 Maintenance of attachments............................................................................................................... 7-41

7.20 Maintenance of options........... ... .... ... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... ..................... 7-41

7.21 Exhaust gas treatment........................................................................................................................ 7-42

7.22 Machine preservation ......................................................................................................................... 7-48

8Malfunctions

8.1 Engine warning lights.............. ... .... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... ....... ................ 8-1

8.2 Engine and engine oil indicator lights ................................................................................................... 8-2

8.3 Malfunctions (display element/multifunctional display)......................................................................... 8-2

8.4 General malfunctions................. .... ... ... ... ....................................... ... .... ... ... ... ... .... ................................ 8-4

9 Technical data

9.1 Model designations and trade names................................................................................................... 9-1

9.2 Engine................................................................................................................................................... 9-1

9.3 Traveling drive/axles............................................................................................................................. 9-2

9.4 Brakes............................................................................................................................................ .... ... 9-3

9.5 Tires...................................................................................................................................................... 9-4

9.6 Steering system............................................................................................................................. ... . ... 9-4

9.7 Operating hydraulics............................................................................................................................. 9-4

9.8 Electrical system..... ... ... .... ... ... ... .... ...................................... .... ... ................................................ ... ....... 9-5

9.9 Tightening torques.................................................. .... ... ... ... ....................................... ... .......... ... ... .... ... 9-9

9.10 Coolant ............................................................................................................................................... 9-10

9.11 Noise emissions.................................................................................................................................. 9-10

9.12 Vibration.............................................................................................................................................. 9-11

9.13 Weight................................................................................................................................................. 9-14

9.14 Payload............................................................................................................................................... 9-15

9.15 Dimensions......................................................................................................................................... 9-16

Index

Index ..............................................................................................................................................................S-1

I-2 BA D18 us* 1.1 * D18us1_1IVZ.fm

Page 5

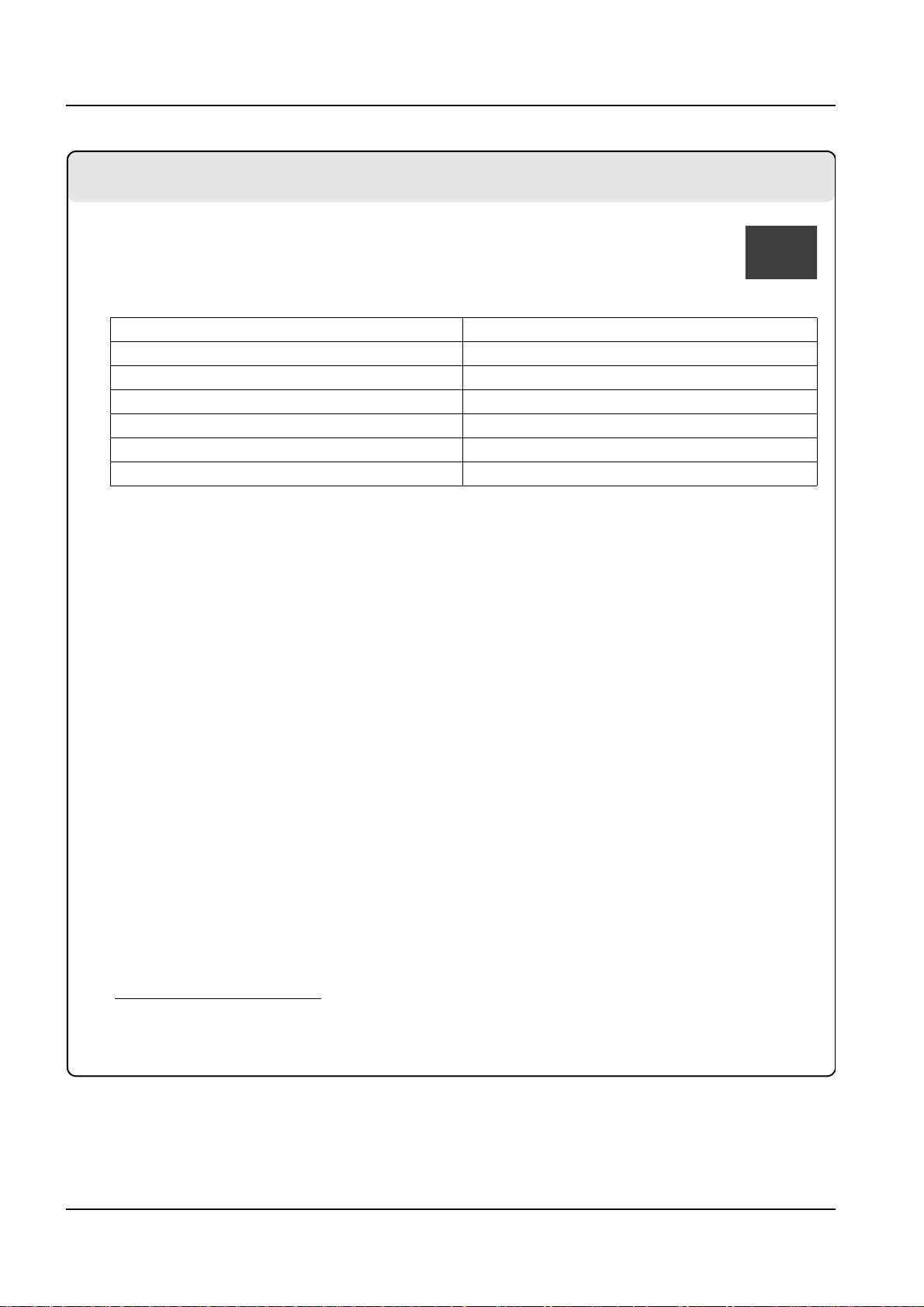

Manufacturer

Wacker Neuson Linz GmbH, Flughafenstr. 7, 4063 Hörsching, Austria

Product

Declaration of conformity

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test-, Prüf- und Zertifizierungsstelle

Fachausschuss Bauwesen, Landsberger Str. 309, 80687 Munich, Germany

Distinguishing EU number 0515

Notified body involved in procedure

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations of the following Directives

and standards:

2006/42/EC, 2004/108/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-6:2010, DIN EN ISO 3471:2010

Authorized representative for the compilation of technical documentation

Thomas Köck, team leader technical documentation

Flughafenstr. 7

4063 Hörsching

Austria

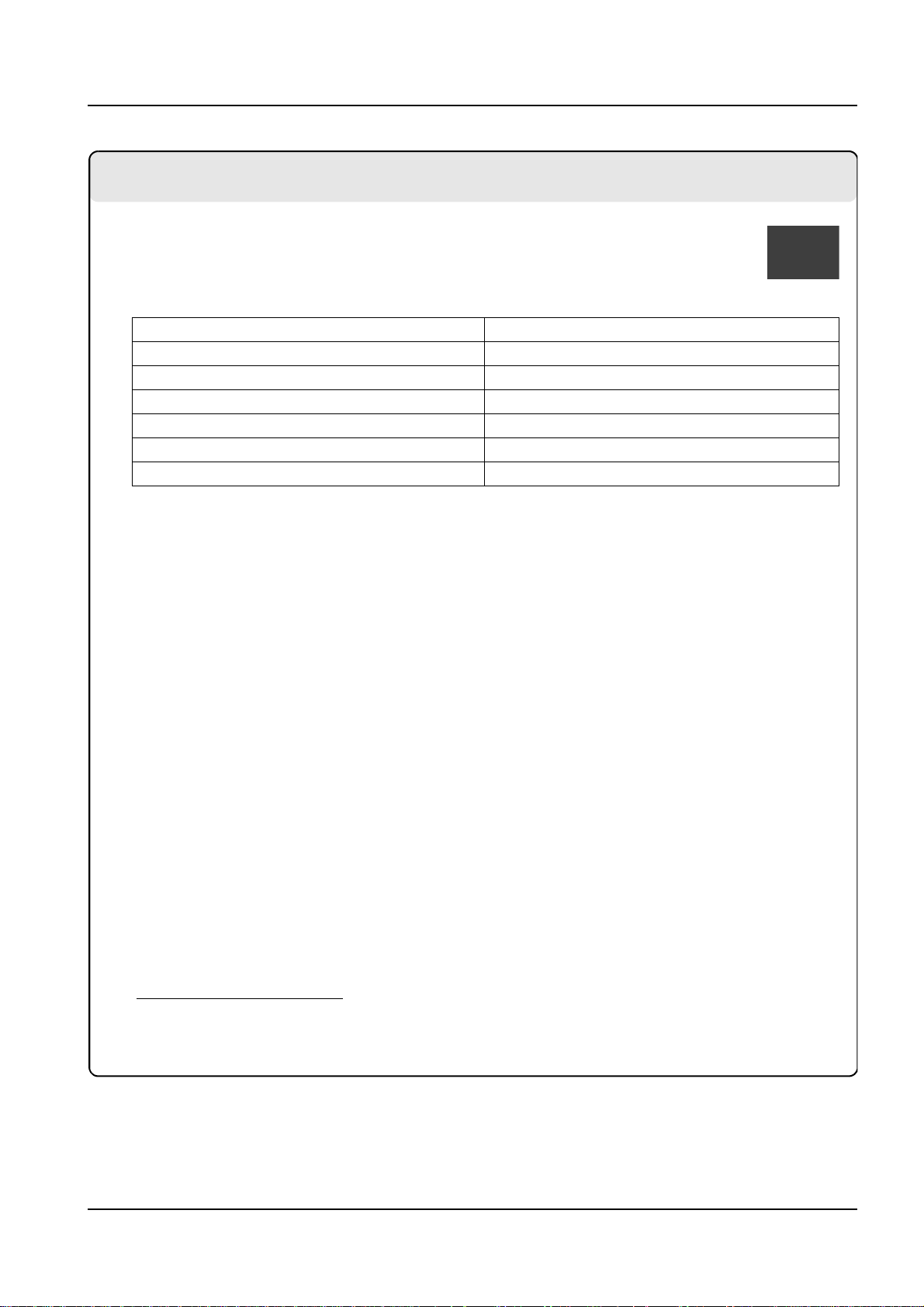

Machine designation Compact Dumper

Model/version D18-01

Trade name DW60

Serial number -Output in kW 55

Measured sound power level dB(A) 101

Guaranteed sound power level dB(A) 101

Johannes Mahringer,

Managing director

EC Declaration of Conformity

Declaration of conformity

Declaration of conformity

The indications specified above correspond to the existing information at time of going to press. They have possibly changed in the meantime (refer to the original declaration o f conformity suppli ed with the ma chine ). Applies

to EU countries, and countries with legislation similar to that of the EU. Applies to all machines with CE marks

that have not been modified without authorization since the product was placed on the market.

BA D18 us* 1.1 * D18konf.fm EG-1

Page 6

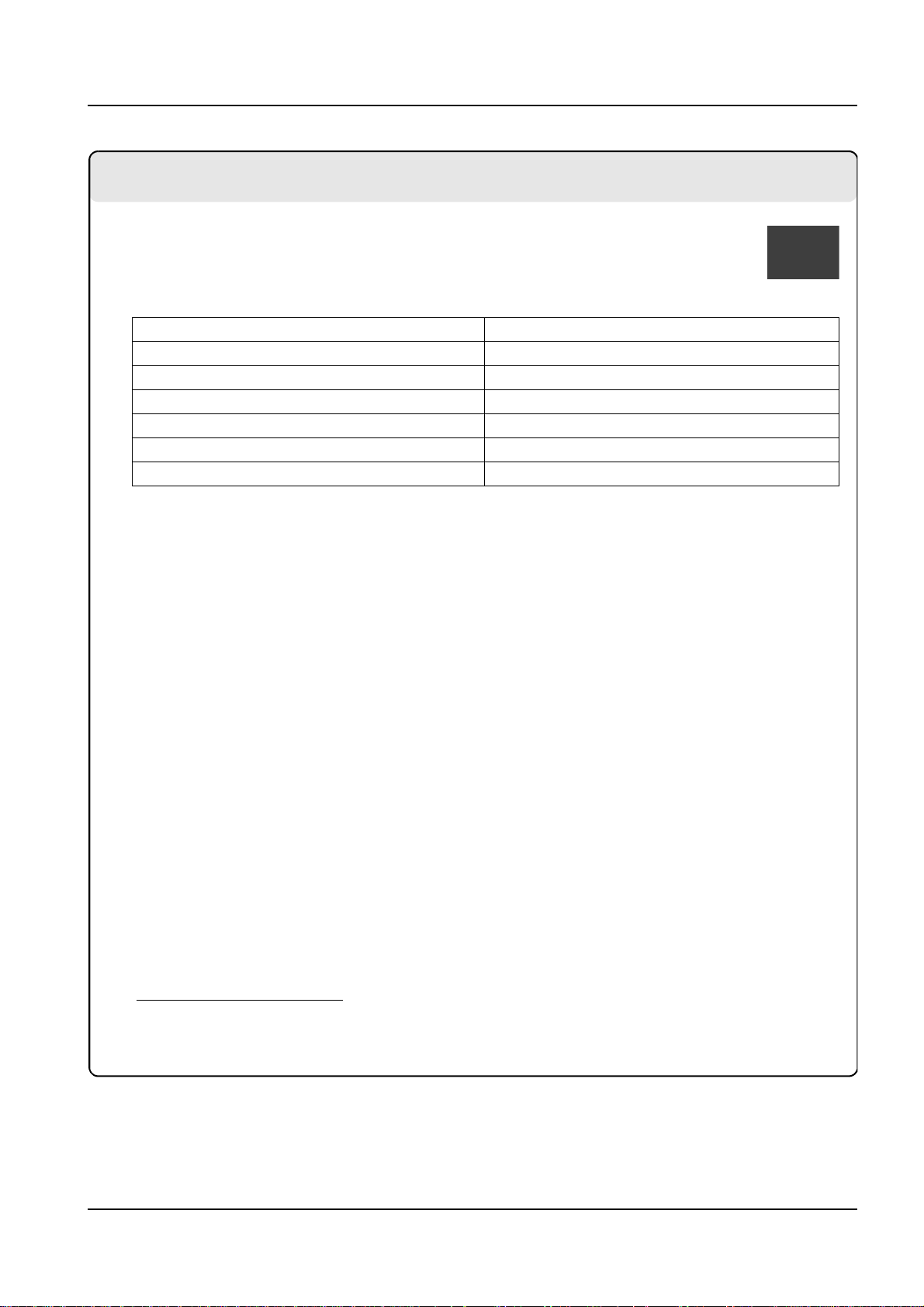

Declaration of conformity

Manufacturer

Wacker Neuson Linz GmbH, Flughafenstr. 7, 4063 Hörsching, Austria

Product

Declaration of conformity

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test-, Prüf- und Zertifizierungsstelle

Fachausschuss Bauwesen, Landsberger Str. 309, 80687 Munich, Germany

Distinguishing EU number 0515

Notified body involved in procedure

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations of the following Directives

and standards:

2006/42/EC, 2004/108/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-6:2010, DIN EN ISO 3471:2010

Authorized representative for the compilation of technical documentation

Thomas Köck, team leader technical documentation

Flughafenstr. 7

4063 Hörsching

Austria

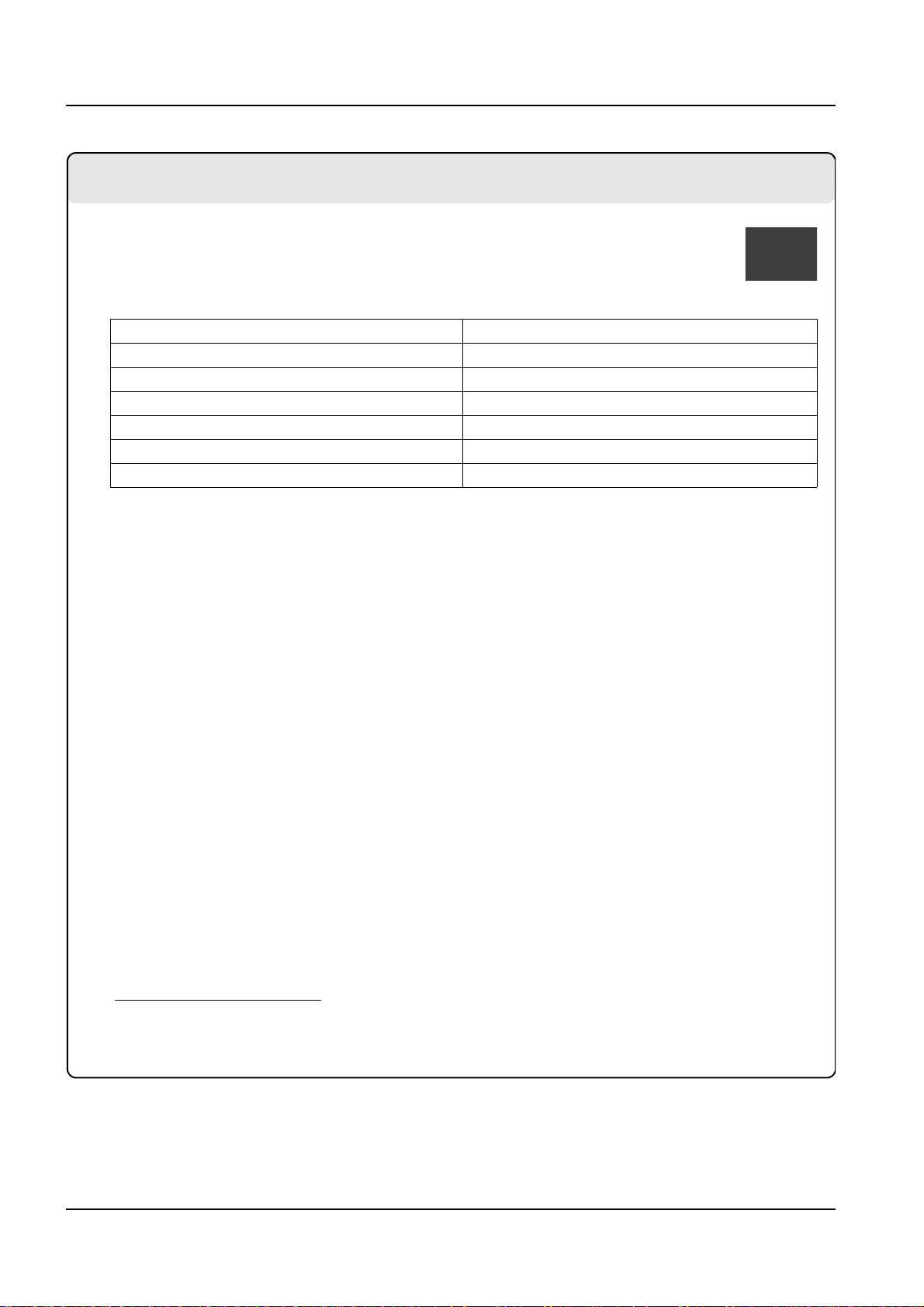

Machine designation Compact Dumper

Model/version D18-01

Trade name DW60

Serial number -Output in kW 86

Measured sound power level dB(A) 101

Guaranteed sound power level dB(A) 103

Johannes Mahringer,

Managing director

EC Declaration of Conformity

The indications specified above correspond to the existing information at time of going to press. They have possibly changed in the meantime (refer to the original declaration of conformity supplied with the machine). Applies

to EU countries, and countries with legislation similar to that of the EU. Applies to all machines with CE marks

that have not been modified without authorization since the product was placed on the market.

EG-2 BA D18 us* 1.1 * D18konf.fm

Page 7

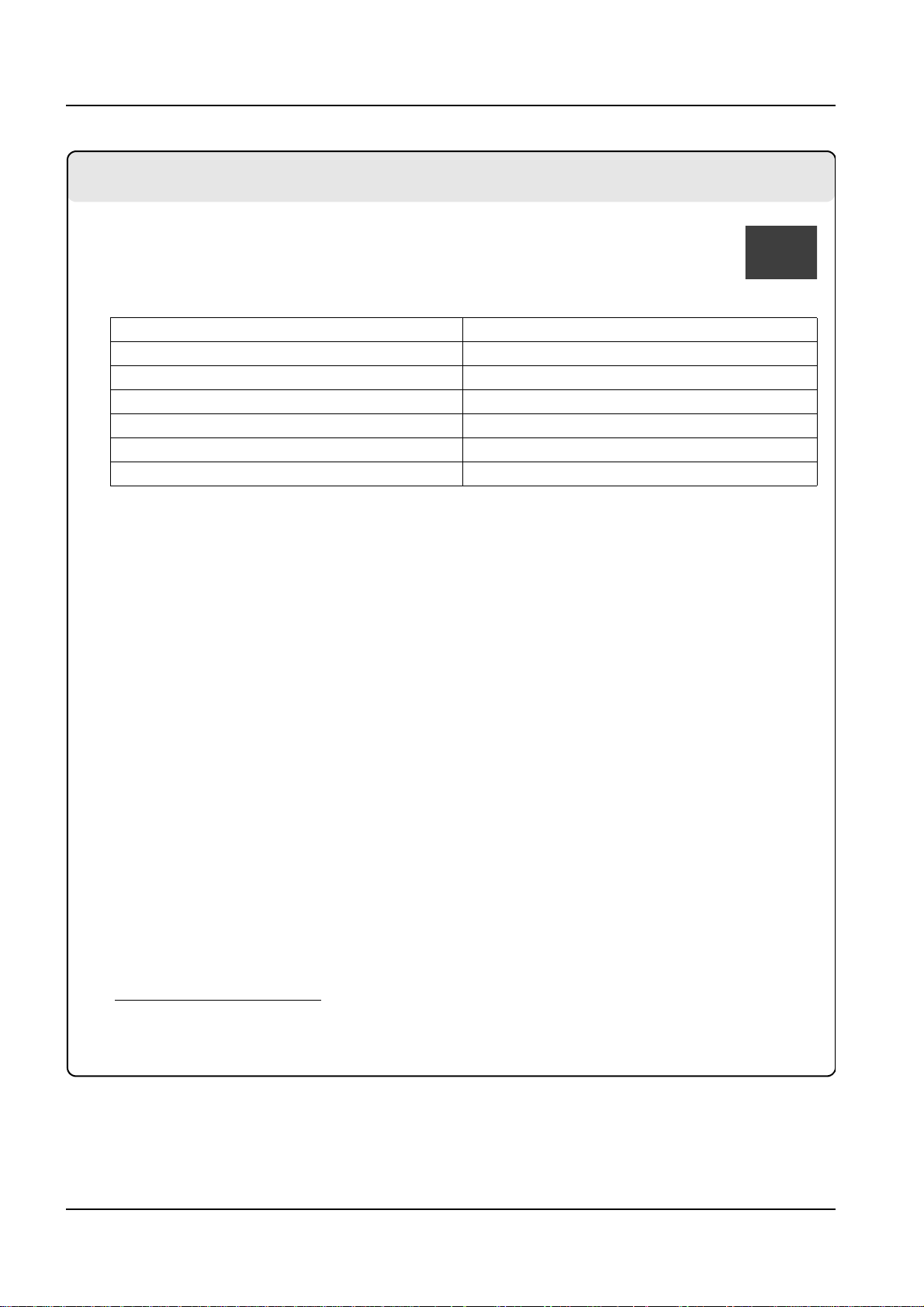

Manufacturer

Wacker Neuson Linz GmbH, Flughafenstr. 7, 4063 Hörsching, Austria

Product

Declaration of conformity

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test-, Prüf- und Zertifizierungsstelle

Fachausschuss Bauwesen, Landsberger Str. 309, 80687 Munich, Germany

Distinguishing EU number 0515

Notified body involved in procedure

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations of the following Directives

and standards:

2006/42/EC, 2004/108/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-6:2010, DIN EN ISO 3471:2010

Authorized representative for the compilation of technical documentation

Thomas Köck, team leader technical documentation

Flughafenstr. 7

4063 Hörsching

Austria

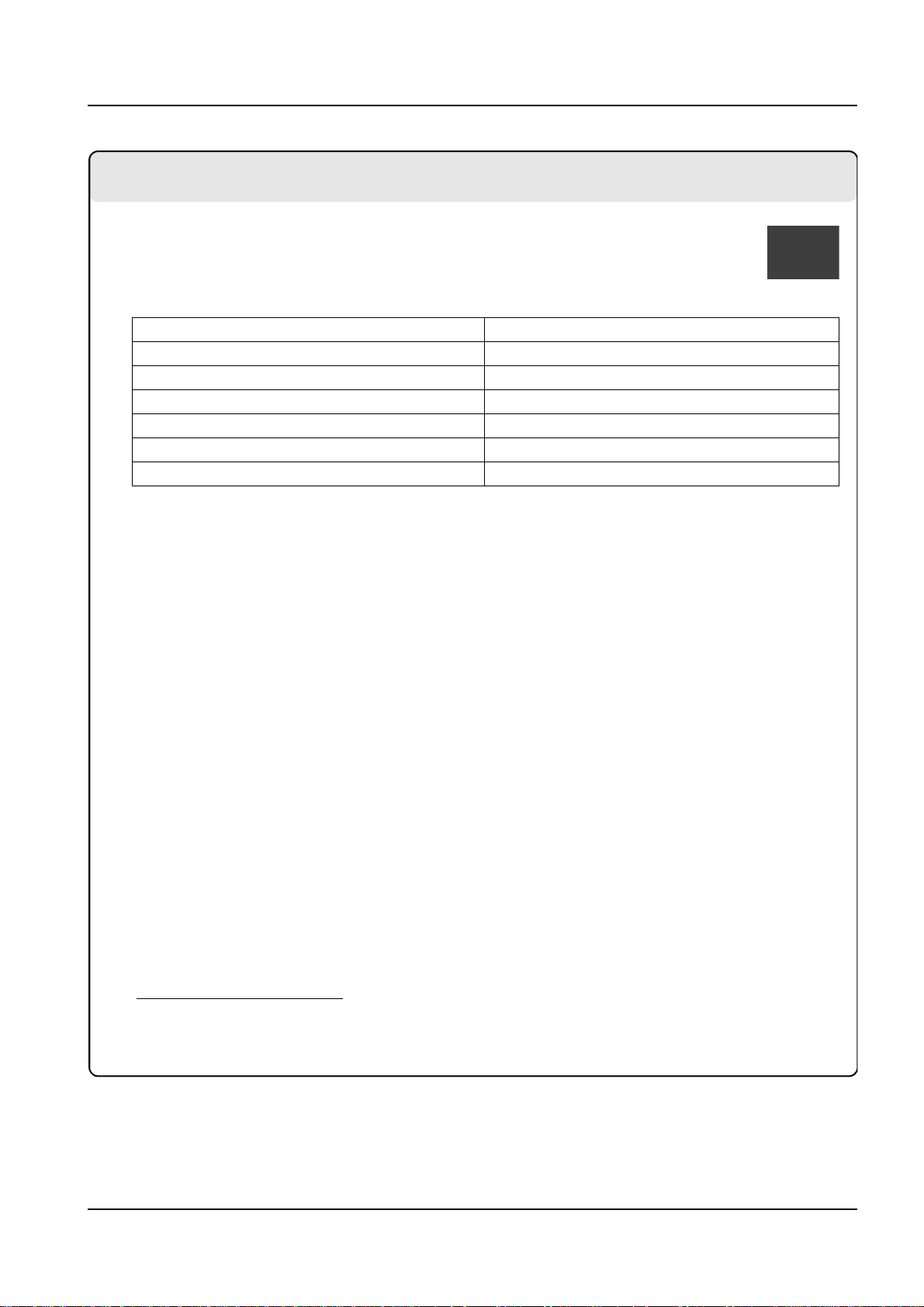

Machine designation Compact Dumper

Model/version D18-02

Trade name DW90

Serial number -Output in kW 55

Measured sound power level dB(A) 99

Guaranteed sound power level dB(A) 99

Johannes Mahringer,

Managing director

EC Declaration of Conformity

Declaration of conformity

The indications specified above correspond to the existing information at time of going to press. They have possibly changed in the meantime (refer to the original declaration o f conformity suppli ed with the ma chine ). Applies

to EU countries, and countries with legislation similar to that of the EU. Applies to all machines with CE marks

that have not been modified without authorization since the product was placed on the market.

BA D18 us* 1.1 * D18konf.fm EG-3

Page 8

Declaration of conformity

Manufacturer

Wacker Neuson Linz GmbH, Flughafenstr. 7, 4063 Hörsching, Austria

Product

Declaration of conformity

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test-, Prüf- und Zertifizierungsstelle

Fachausschuss Bauwesen, Landsberger Str. 309, 80687 Munich, Germany

Distinguishing EU number 0515

Notified body involved in procedure

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations of the following Directives

and standards:

2006/42/EC, 2004/108/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-6:2010, DIN EN ISO 3471:2010

Authorized representative for the compilation of technical documentation

Thomas Köck, team leader technical documentation

Flughafenstr. 7

4063 Hörsching

Austria

Machine designation Compact Dumper

Model/version D18-02

Trade name DW90

Serial number -Output in kW 86

Measured sound power level dB(A) 103

Guaranteed sound power level dB(A) 103

Johannes Mahringer,

Managing director

EC Declaration of Conformity

The indications specified above correspond to the existing information at time of going to press. They have possibly changed in the meantime (refer to the original declaration of conformity supplied with the machine). Applies

to EU countries, and countries with legislation similar to that of the EU. Applies to all machines with CE marks

that have not been modified without authorization since the product was placed on the market.

EG-4 BA D18 us* 1.1 * D18konf.fm

Page 9

Manufacturer

Wacker Neuson Linz GmbH, Flughafenstr. 7, 4063 Hörsching, Austria

Product

Declaration of conformity

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test-, Prüf- und Zertifizierungsstelle

Fachausschuss Bauwesen, Landsberger Str. 309, 80687 Munich, Germany

Distinguishing EU number 0515

Notified body involved in procedure

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations of the following Directives

and standards:

2006/42/EC, 2004/108/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-6:2010, DIN EN ISO 3471:2010

Authorized representative for the compilation of technical documentation

Thomas Köck, team leader technical documentation

Flughafenstr. 7

4063 Hörsching

Austria

Machine designation Compact Dumper

Model/version D18-03

Trade name DW100

Serial number -Output in kW 55

Measured sound power level dB(A) 99

Guaranteed sound power level dB(A) 99

Johannes Mahringer,

Managing director

EC Declaration of Conformity

Declaration of conformity

The indications specified above correspond to the existing information at time of going to press. They have possibly changed in the meantime (refer to the original declaration o f conformity suppli ed with the ma chine ). Applies

to EU countries, and countries with legislation similar to that of the EU. Applies to all machines with CE marks

that have not been modified without authorization since the product was placed on the market.

BA D18 us* 1.1 * D18konf.fm EG-5

Page 10

Declaration of conformity

Manufacturer

Wacker Neuson Linz GmbH, Flughafenstr. 7, 4063 Hörsching, Austria

Product

Declaration of conformity

Notified body according to Directive 2006/42/EC, appendix XI:

DGUV Test-, Prüf- und Zertifizierungsstelle

Fachausschuss Bauwesen, Landsberger Str. 309, 80687 Munich, Germany

Distinguishing EU number 0515

Notified body involved in procedure

TÜV SÜD Industrie Service GmbH

Westendstr. 199

D-80686 Munich

Directives and standards

We hereby declare that this product corresponds to the relevant regulations of the following Directives

and standards:

2006/42/EC, 2004/108/EC, 2005/88/EC, 2000/14/EC;

DIN EN ISO 12100:2010, DIN EN 474-1:2006+A1:2009, DIN EN 474-6:2010, DIN EN ISO 3471:2010

Authorized representative for the compilation of technical documentation

Thomas Köck, team leader technical documentation

Flughafenstr. 7

4063 Hörsching

Austria

Machine designation Compact Dumper

Model/version D18-03

Trade name DW100

Serial number -Output in kW 86

Measured sound power level dB(A) 103

Guaranteed sound power level dB(A) 103

Johannes Mahringer,

Managing director

EC Declaration of Conformity

The indications specified above correspond to the existing information at time of going to press. They have possibly changed in the meantime (refer to the original declaration of conformity supplied with the machine). Applies

to EU countries, and countries with legislation similar to that of the EU. Applies to all machines with CE marks

that have not been modified without authorization since the product was placed on the market.

EG-6 BA D18 us* 1.1 * D18konf.fm

Page 11

Table of contents

Index

Foreword

1 Foreword

1.1 Operator’s Manual

Information on this Operator’s Manual

The Operator’s Manual is stored in the document box under the seat.

This Operator’s Manual contains important information on how to work

safely, correctly and economically with the machine. Therefore, it aims not

only at new personnel, but it also serves as a reference for experienced

personnel.

This is why the Operator’s Manual must be kept at hand in the machine.

The operator must carefully read and understand the Operator’s Manual

before starting up, servicing or repairing the machine.

This Operator’s Manual will help to familiarize yourself more easily with

the machine, thereby enabling you to use it more safely and efficiently.

This Operator’s Manual does not include special superstructures.

Please contact your dealer if you require more information on the machine

or the Operator’s Manual.

Foreword 1

BA D18 us* 1.1 * D18v100.fm 1-1

Page 12

1 Foreword

Information

Environment

Explanation of symbols and abbreviations

Explanation of symbols

• Identifies a list

- Identifies a subdivision of a list

➥ Description of a result

1. Identifies an activity

Follow the order of the activity!

2. Continuation of an activity

Follow the order of the activity!

A Identifies an alphabetical list

B Continuation of an alphabetical list

Cross references: see page 1-1 (page)

Cross references: 7 (pos. no. or table no.)

Cross references: fig. 3 (fig. no. 1)

Cross references: – see chapter “5 Operation” on page 5-1

(see chapter)

Cross references: – see “Operation” on page 5-1 (– see text)

Identifies an information that, when followed, provides for a more efficient

and economical use of the machine.

Failure to observe the instructions identified by this symbol can cause

damage to the environment.

1-2 BA D18 us* 1.1 * D18v100.fm

Page 13

Abbreviations (in alphabetic order)

Fig. Figure

o/h Operating hours

approx. approximately

PCM particulate matter catalysts

FGPS Front Guard Protective Structure

FOPS Falling Objects Protective Structure

if nec. if necessary

max. maximum

min. minimum

Pos. Position

ROPS Roll Over Protective Structure (without losing contact with the ground)

TOPS Tip Over Protective Structure

Foreword 1

e.g. for example

BA D18 us* 1.1 * D18v100.fm 1-3

Page 14

1 Foreword

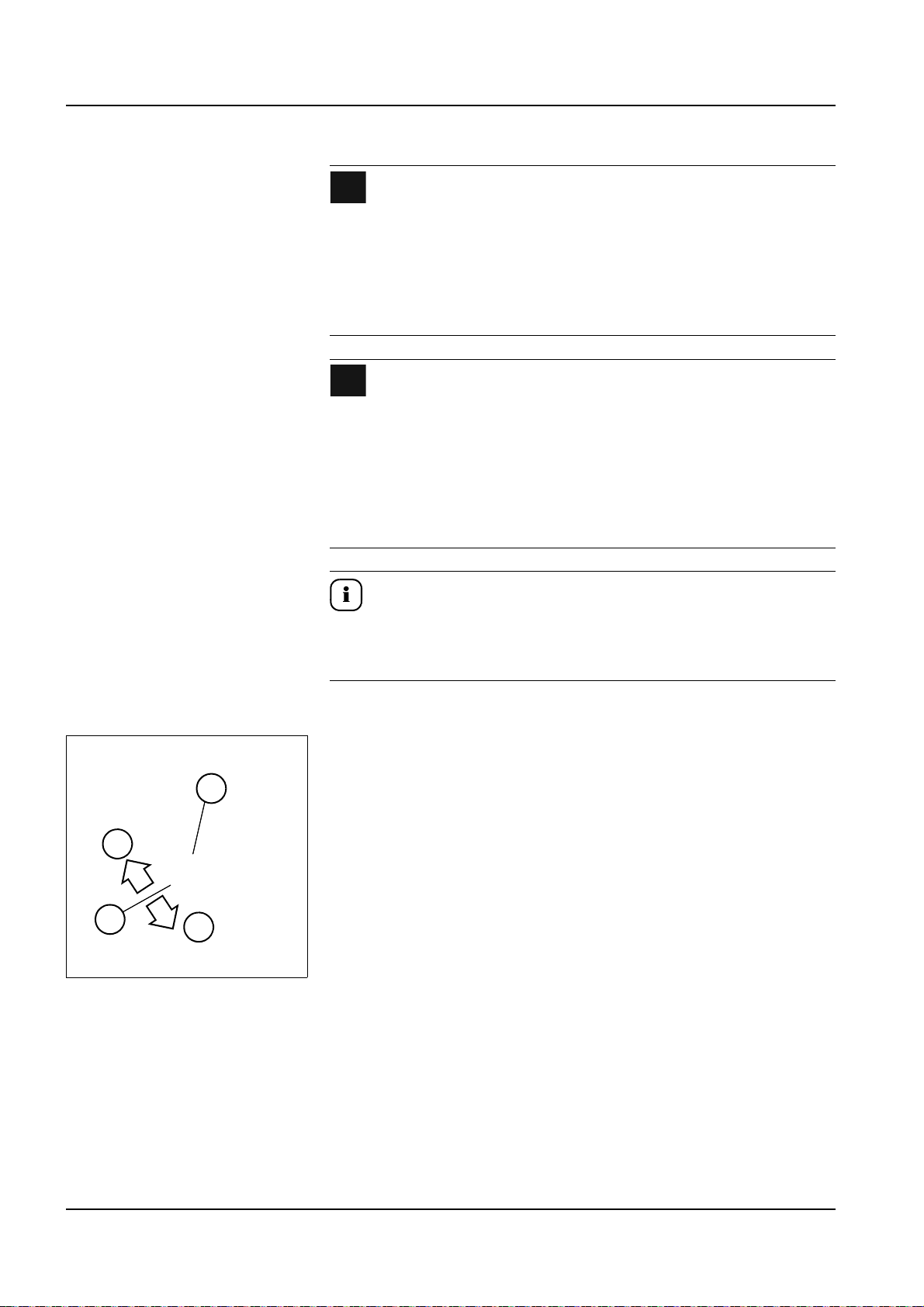

Fig. 1

4

21

3

Definitions

Towing The dumper tows another vehicle on public roads, or is towed itself.

Towing

Operating company/person

The dumper is towed out of an immediate danger zone (for e xample a ra ilroad

crossing or job site).

A company (or person) operating the machine. This can be a construction

company, for example.

Operators Person performing machine travel or operation.

Machine

Unless otherwise specified, the term “machine” refers to the dumpers

described in this Operator’s Manual.

All work (for example machine travel, moving material, daily maintenance) an

Machine operation

operator is allowed to or has to perform in connection with the machine. The

term “machine operation” does not include maintenance only a Wacker

Neuson service center is allowed to perform.

Visual aids

Tier III/Tier IV (exhaust-gas

standards)

Visual aids are, for example, rearview mirrors, cameras, but also persons

assisting the operator during machine operation.

The machine can be equipped with an Tier III or Tier IV engine, depending on

the destination country. Both engine variants are described separately if there

are engine-specific differences (for example regarding operation).

Right/left/front/rear

These terms are used as seen by the operator on the seat.

• 1: left

• 2: right

• 3: front

• 4: rear

1-4 BA D18 us* 1.1 * D18v100.fm

Page 15

Target-group definition

This Operator’s Manual is intended both for professional personnel on

construction sites accustomed to handling construction machin es, and

also for private persons, for example, renting and operati ng a construction

machine.

The Operator’s Manual has been written in a way that allows machine

operation by trained private persons without any special knowledge. As

far as possible, no technical terms specific to construction machines are

used.

This Operator’s Manual must be fully read and understood both by private

persons and the professional personnel on construction sites.

A dealer or person renting the machine must instruct the operator and

have this confirmed in writing.

Operator qualification and requirements for safe operation

Among other things, safe machine operation depends on the following

points:

• Machine model and equ ipment.

• Machine maintenance.

• Work and travel speed.

• Nature of ground and work environment.

The most important points are the operator’s qualification and power of

judgement. A well-trained operator following the Operator’s Manual and

maintenance plan ensures a long service life and durability of the

machine.

Specific training enables the operator to acquire, among other things, the

following skills:

• Correct assessment of work situations.

• Feeling for the machine.

• Recognition of possible risk situations.

• Safe working by making the correct decisions for man, machine and

the environment.

The operator is at risk if the machine is not operated correctly.

Follow the operating procedures and instructions described for the

machine.

Access to the machine or machine operation is prohibite d for childr en and

persons under the influence of alcohol, drugs or medicine.

Foreword 1

BA D18 us* 1.1 * D18v100.fm 1-5

Page 16

1 Foreword

Conversion table

The rounded imperial values are indicated in brackets, for example 1060

cm³ (64.7 in³).

Volume unit

1 cm³ (0.061 in³)

1 m³ (35.31 ft³)

1 ml (0.034 US fl.oz.)

1 l (0.26 gal)

1 l/min (0.26 gal/min)

Unit of length

1 mm (0.039 in)

1 m (3.28 ft)

Weight

1 kg (2.2 lbs)

1 g (0.035 oz)

Pressure

1 bar (14.5 psi)

1 kg/cm² (14.22 lbs/in²)

Force/output

1 kN (224.81 lbf)

1 kW (1.34 hp)

1 PS (0.986 hp)

Torque

1 Nm (0.74 ft.lbs.)

Speed

1 kph (0.62 mph)

Acceleration

1 m/s² (3.28 ft/s²)

1-6 BA D18 us* 1.1 * D18v100.fm

Page 17

1.2 Warranty and liability

Exemption from warranty and liability

Warranty

Warranty claims can be made only if the conditions of warranty have been

observed. They are included in the General Conditions of Sales and

Delivery for new machines and spare parts sold by the dealers of Wacker

Neuson Linz GmbH. Furthermore, all instructions in this Operator’s

Manual must be observed.

Have the maintenance, delivery inspection and the entries in the service

booklet performed by a Wacker Neuson service center, otherwise

warranty claims will not be acknowledged.

Exemption from liability

• Modifying Wacker Neuson products and fitting them with additional

equipment not included in our delivery program requires Wacker

Neuson’s written authorization, otherwise warranty and product liability

for possible damage caused by these modifications shall not be applicable.

• The safety of the machine can be negatively affe cted by performing

machine modifications without proper authority and by using spare

parts, equipment, attachments and option al eq uip m en t th at ha ve not

been checked and released by Wacker Neuson GmbH. Warranty and

product liability for possible damage caused by these modifications

shall not be applicable.

• Wacker Neuson Linz GmbH shall not be liable for injury or damage to

property that can caused by failure to observe the safety instructions

and the Operator’s Manual, and by the negligence of the duty to

exercise due care when:

- handling

- operating

- servicing and performing maintenance and

- repairing the machine. This is also applicable in those cases in which

special attention has not been drawn to the duty to exercise due

care, in the safety instructions as well as in the Operator’s an d

maintenance manuals.

- Read and understand the Operator’s Manual before starting up,

servicing or repairing the machine. Observe all safety instructions.

Foreword 1

BA D18 us* 1.1 * D18v100.fm 1-7

Page 18

1 Foreword

Notes:

1-8 BA D18 us* 1.1 * D18v100.fm

Page 19

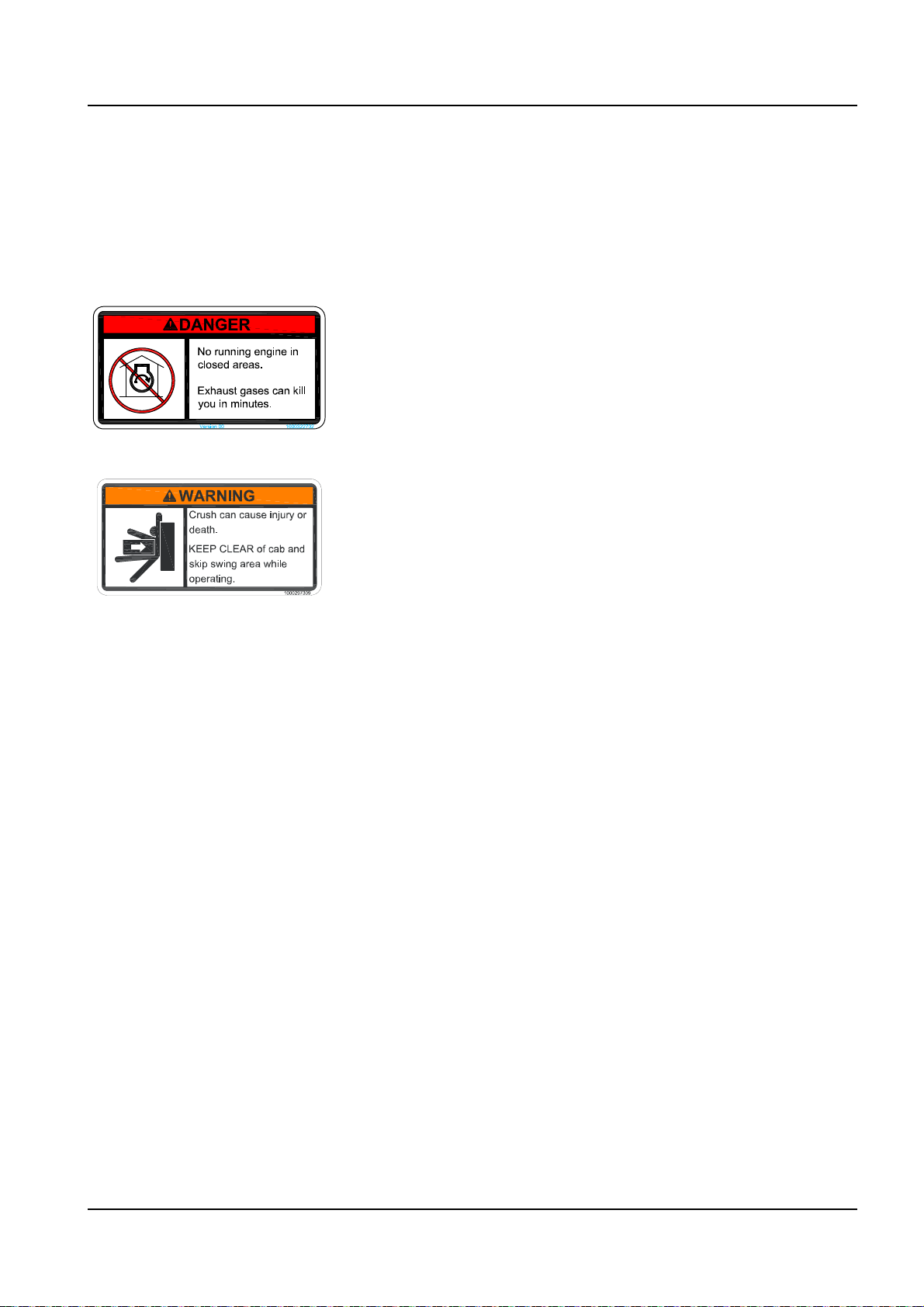

DANGER

WARNING

CAUTION

NOTICE

Safety

2 Safety

2.1 Safety symbols and signal words

Explanation

The following symbol identifies safety instructions. It is used for warning

against potential personal risk or danger.

DANGER identifies a situation causing death or serious injury if it is

not avoided.

Consequences in case of non-observance.

► Avoidance of injury or death.

Safety 2

WARNING identifies a situation that can cause death or serious

injury if it is not avoided.

Consequences in case of non-observance.

► Avoidance of injury or death.

CAUTION identifies a situation that can cause injury if it is not

avoided.

Consequences in case of non-observance.

► Avoidance of injury.

NOTICE identifies a situation that causes da mag e to the m achin e if it is

not observed.

► Avoidance of damage to property.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-1

Page 20

2 Safety

2.2 Qualification of operating personnel

Owner’s duties

• Only allow specifically authorized, trained and experienced persons to

operate, drive and perform maintenance on the machine.

• Do not allow persons to be trained or instructed by anyone other than

an authorized and experienced person.

• Have persons to be trained or instructed practice under supervision

until they are familiar with the machine and its behavior (for example

with the steering and braking behavior).

• Access to the machine or machine operation is prohibited for children

and persons under the influence of alcohol, drugs or medicine.

• Clearly and unequivocally define the responsibilities of the operating

and maintenance personnel.

• Clearly and unequivocally define the responsibilities on the job site,

also in view of traffic regulations.

• Give the operator the authority to refuse instructions by other persons

that are contrary to safety.

• Have the machine serviced and repaired only by a Wacker Neuson

service center.

Required knowledge of operator

• The operator is responsible for other persons.

• Avoid any operational mode that might be preju dicial to safety.

• The specific national driving license is required.

• The machine may only be operated by authorized and safetyconscious persons who are fully aware of the risks involved in

operating the machine.

• The operator an d owner are obligated to operate the machine on ly in a

safe and working condition.

• All persons working on or with the machine must have read and understood

the safety instructions in this Operator’s Manual before starting work.

• Follow, and instruct the operator in, legal and other mandatory regulations relevant to accident prevention.

• Observe and instruct the operator in regulations regarding road traffic

and environmental protection.

• Use only the defined accesses for getting on and off the machine.

• Be familiar with the emergency exit of the machine.

Preparatory measures for the operator

• Before starting, check the machine whether it can be driven and

operated safely.

• Tie back long hair and remove all jewelry.

• Wear close-fitting work clothes that do not hinder movement.

2-2 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 21

2.3 Conduct

Prerequisites for operation

Safety 2

• The machine has been designed and built in accordance with state-of-

the-art standards and the recognized safety regulations.

Nevertheless its use can cause danger to the operator or other

persons, or damage to the machine.

• Store this Operator’s Manual in the place provided for this in or on the

machine. Immediately replace a damaged or illegible Operator’s

Manual and any supplements to it.

• The machine m ust only be operated in accordance with its designated

use and the instructions set forth in this Operator’s Manual.

• The operator and owner are obligated not to put into operation or

operate a damaged or malfunctioning machine.

- If a damage or malfunction occurs during operation, put the machine

out of operation immediately and secure it against restart.

- Have all malfunctions jeopardizing the safety of the operator or other

persons immediately repaired by a Wacker Neuson service center.

• Do not put the machine into operation or operate it after an accident;

have it inspected for damage by a Wacker Neuson service center.

- Have the seat belt replaced by a Wacker Neuson service center after

an accident, even if there is no visible damage.

- Cabin and protective structures

• Remove all dirt, snow an d ice from climbing aids (for example from the

handholds, footholds, handrails).

• The owner is responsible for requiring the operating and maintenance

personnel to wear protective clothing and equipmen t as required by the

circumstances.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-3

Page 22

2 Safety

2.4 Operation

Preparatory measures

• Operation is only allowed with correctly installed and intact protective

structures.

• Keep the machine clean. This reduces injury, accident and fire

hazards.

• Safely store objects you carry with you in the places provided for this

(for example in the storage compartment, drinks holder).

• Do not carry objects with you that protrude into the operator’s work

space. They can create another danger in case of an accident.

• Observe all safety, warning and information labels.

• Start and operate the machine only with the se at belt fastened and only

from the place provided for this.

• Check the condition and the fastening of the seat belt. Have malfunctioning seat belts and mounting hardware r eplaced by a Wacker

Neuson service center.

• Before starting work, adjust the seating position so that all control

elements can be reached and fully operated.

• Perform the personal adjustment at machine standstill only (for

example of the operator seat, steering column).

• Ensure that all safety devices are properly installed and functional

before starting work.

• Before starting work or after interrupting work, ensure that the brake,

steering, signaling and light systems are functional.

• Before putting the mach ine into operation , ensu re that nobody is i n the

danger zone.

2-4 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 23

Job site

Safety 2

• The operator is responsible for other persons.

• Before starting work, familiarize yourself with the job site. This applies

to, for example:

- Obstacles in the job site and machine travel area

- Any barriers separating the job site from public roads

- Soil weight-bearing capacity

- Existing overhead and underground lines

- Special operating conditions (for example dust, steam, smoke,

asbestos)

• The operator must know the maximum di mensions of the m achine and

the attachment – see “Technical data”.

• Maintain a safe distance (for example from buildings, edges of building

pits).

• During work in buildings or in enclose d areas, look out for:

- Height of the ceiling/clearances

- Width of entries/passages

- Maximum load of ceilings and floors

- Sufficient room ventilation (for example risk of carbon monoxide

poisoning)

• Use existing visual aids to stay aware of the danger zone.

• In conditions of darkness and poor visibility, switch on existing work

lights and ensure that motorists are not blinded by these lights.

• If the existing lights of the machine are not sufficient for performing

work safely, ensure additional lighting of the job site.

• Due to hot machine parts, mainta in a safe distance from easily

flammable material (for example from hay, dry leaves).

Danger zone

Carrying passengers

• The danger zone is the area in which person s are in d anger due to the

movements of the machine, attachment and/or load.

• The danger zone also includes the area that can be affected by falling

material, equipment or by debris that is thrown out.

• Extend the danger zo ne sufficiently in the immediate vicinity of

buildings, scaffolds or other elements of constr uction.

• Seal off the danger zone should it not be possible to keep a sufficient

safety distance.

• Stop machine operation immediately if perso ns do not stay clear o f the

danger zone.

• Carrying passengers with the machine is PROHIBITED.

• Carrying passengers on/in attachments/tools is PROHIBITED.

• Carrying passengers on/in trailers is PROHIBITED.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-5

Page 24

2 Safety

Mechanical integrity

• The operator an d owner are obligated to operate the machine on ly in a

safe and working condition.

• Operate the machine only if all protective and safety-oriented

equipment (for example protective structures such as a cabin or

rollbar, removable safety devices) is installed and functional.

• Check the machine for visible damage and defects.

• In case of damage and/or unusual behavior, put the machine out of

operation immediately and secure it against restart.

• Have all malfunctions jeopardizing the safety of the operator or other

persons immediately repaired by a Wacker Neuson service center.

Starting the engine of the machine

• Start the engine only according to the Operator’s Manual.

• Observe all warning and indicator lights.

• Do not use any liquid or gaseous starting aids (for example ether or

starting fuel).

Machine operation

• Start and operate the machine only with the se at belt fastened and only

from the place provided for this.

• Put the machine into operation only if visibility is sufficient (have

another person guide you if necessary).

• Operation on slopes:

- Travel/work only uphill or downhill.

- Avoid machine travel across a slope, observe the machine’s permis-

sible inclination (and of the trailer if necessary).

- Keep loads on the uphill side of the machine and as close as

possible to it.

- Keep attachments/work equipment close to the ground.

• Adapt the travel speed to the circumstances (for example the ground

conditions, weather conditions).

• There is increased dange r during backward machine travel. Persons in

the blind spot of the machine cannot be seen by the operator.

- Ensure that nobody is in the danger zone when you change the

travel direction.

• Never get on a moving machine and never jump off the machine.

2-6 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 25

Machine travel on public roads/sites

• The specific national driving license is required.

• Observe the national regulations (for example the road traffic regula-

tions) during machine travel on public roads/sites.

• Ensure that the machine is in compliance with the national regulations.

• In order not to blind other motorists, using the existing work lights

during machine travel on public roads/site is prohibited.

• When crossing underpasses, bridges, tunnels, for example, ensure

that the clearance height and width is sufficient.

• The attachment fitted onto the machine must be certified for travel on

public roads/sites (see for example the registration documents).

• The attachment fitte d onto the machine must be em pty and in transport

position.

• The attachment fitted onto the ma chine must be equipped with the

mandatory lights and protective equipment.

• Take measures against unintentional op eration of the operating

hydraulics.

• If the machine ha s different steering mo des, ensure that the mandatory

steering mode is selected.

Safety 2

Stopping the engine of the machine

• Stop the engine only according to the Operator’s Manual.

• Before stopping the engine, lower the work equipment/attachment to

the ground.

Stopping and securing the machine

• Unbuckle the seat belt only after stopping the engine.

• Before leaving the machine, secure it to prevent it from rolling away

(for example with the parking brake, suitable wheel chocks).

• Remove the starting key an d secure the machine against unauthorized

operation.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-7

Page 26

2 Safety

2.5 Lifting gear applications

Requirements

• Have loads fastened and the operator guided by a qualified person

having specific knowledge of lifting gear applicat ion s an d th e us ua l

hand signals.

• The person giving instructions to the operator must stay in visual

contact with the operator when fastening, guiding or removing the load

(maintain visual contact).

• If this not be possible, ask one more person with the same qualifications to guide.

• The operator may not leave his seat as long as the load is raised.

Fastening, guiding and removing loads

• Follow the applicable specific regulations for fastening, guiding and

removing a load.

• Wear protective clothing and equipment when fastening, guiding and

removing loads (for example a hard hat, safety glasses, protective

gloves, safety boots).

• Do not place lifting and fastening gear over sharp edges or rotating parts.

Loads must be fastened so as to prevent them from slipping or falling.

• Move loads only on horizontal, level and firm ground.

• Move loads close to the ground.

• In order to avoid oscillating movements of loads:

- Perform smooth, slow movements with the machine.

- Use cables to guide the load (do not use hands to guide).

- Bear in mind the weather conditions (for example the wind force).

- Keep a minimum safety distance from objects.

• The operator may allow the load to be fastened and removed only if

the machine and its work equipment are not being moved.

• Danger zones must not over lap with the work zones of other machines.

2-8 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 27

Lifting gear applications

Safety 2

• The machine must be certified for lifting gear applications.

• Observe the national regulations for lifting gear applications.

• Lifting gear applications are procedures involving raising, transporting

and lowering loads with the help of lifting and fastening gear.

• The help of an accompanying person is necessary for fastening,

guiding and removing the load.

• There must be nobody under the load.

• Stop the mach ine immediately and stop th e engine if persons enter the

danger zone.

• Use the machine for lifting gear applications ONLY if the mandatory

lifting gear (for example a joint rod and load hook) and safety

equipment (for example optical and acoustic warning devices, hose

burst valve, stability table) is installed and functional.

• Use only lifting and fastening gear certified by a test/certification body,

observe the inspection intervals (Use only chains and shackles. No

belts, slings or cables).

• Do not use any lifting and fastening gear that is dirty, damaged or not

of sufficient size.

• Do not interrupt the work process with a load attached.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-9

Page 28

2 Safety

2.6 Trailer operation

Trailer operation

• The machine must be certified for trailer operation.

• Observe the natio nal regulations for trailer operation.

• The specific national driving license is required.

• Carrying passengers on/in trailers is PROHIBITED.

• Observe the maximum permissible vertical and trailer load.

• Do not exceed the permissible trailer speed.

• Trailer operation with the towing gear of the machine is prohibited.

• Trailer operation changes the machine’s operating behavior, the

operator must be familiar with this and act accordingly.

• Bear in mind the machine’s steering mode and the trailer’s turning

circle.

• Before hitching/unhitching the tra iler, secure it to prevent it from rolling

away (for example with the parking brake, suitable wheel chocks).

• There must be nobody between the machine and the trailer when

hitching a trailer.

• Hitch the trailer onto the machine correctly.

• Ensure that all equipment works correctly (for example the brakes,

lights).

• Before starting machine travel, ensure that nobody is between the

machine and the trailer.

2.7 Attachment operation

Attachments

• Use only attachments that are certif ied for the machine or its protective

equipment (for example a shatter protection).

• All other attachments require the machine manufacturer’s release.

• The danger zon e and the work zon e depend on the attachment used –

see the Operator’s Manual of the attachment.

• Secure the load.

• Do not overload attachments.

• Check the correct position of the lock.

Operation

• Carrying persons on/in an attachment is prohibited.

• Installing a work platform is prohibited.

- Exception: The machine is certified and equipped with th e necessary

• Attachments and counterweights modify handling, as well as the

steering and brake capability of the machine.

• The operator must be familiar with these modifications and act accordingly.

• Before starting work, operate the attachment to check that it works

correctly.

• Before putting the attachment into operation, ensure that nobody is in

danger.

• Lower the attachment to the ground before leaving the operator seat.

safety equipment.

2-10 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 29

Removing and fitting attachments

• Before uncoupling or coupling hydraulic connections:

- Stop the engine

- Releasing the pressure in the operating hydraulics

• Picking up and lowering attachments to the ground require s special

care:

- Pick up and safely lock the attachment in accordance with the

Operator’s Manual.

- Lower the attachment only to firm, level ground and secure it to

prevent it from tipping over or rolling away.

• Put the machine and the attachment into operation only if:

- The protective equipment has been installed and is functional.

- The connections for the lights and the hy dr au lic syst em ha ve be e n

established and are functional.

• Perform a visual check of the lock after locking the attachment.

• There must be n obody b etwe en th e m achine and the eq uipm ent whe n

picking up or lowering an attachment to the ground.

2.8 Towing, loading and transporting

Towing

• Seal off the danger zone.

• Ensure that no one is near the towing bar or cable. The safety distance

is equal to 1.5 times the length of the towing equipment.

Use a towing cable for machines with a total weight of up to 4.0 tons.

Use a towing bar for machines with a total weight of over 4.0 tons.

• Observe the mandatory transport position, permissible speed and

itinerary.

• A tractor vehicle of the same weight category must be used as a

minimum. Furthermore, the tractor vehicle must be equipped with a

safe braking system and sufficient tractive power.

• Use only towing bars or cables certified by a test/certification body,

observe the inspection intervals.

• Do not use any towin g bars or cables that are dirty, damaged or not of

sufficient size.

• Fasten towing bars or cables only at the defined points.

• Tow away only in accordance with this Operator’s Manual to avoid

damage to the machine.

• Observe the national regulations (for example the light regulations)

when towing on public roads/sites.

Safety 2

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-11

Page 30

2 Safety

Crane-lifting

• Seal off the danger zone.

• The crane and the lifting gear must have suitable dimensions.

• Observe the machine’s overall weight – see “Technical data”.

• Wear protective clothing and equipment when fastening, guiding and

removing the machine (for example a hard hat, safety glasses, safety

boots).

• Use only lifting and fastening gear certified by a test/certification body

(for example cables, belts, hooks, shackles), observe the inspection

intervals.

• Do not use any lifting and fastening gear that is dirty, damaged or not

of sufficient size.

• Perform a visual check to ensure that all slinging points are neither

damaged nor worn (no widening, no sharp edges, no cracks).

• Have loads fastene d and crane operators only guided by experienced

persons.

• The person guid ing the crane oper ator must be within sight or sound of

him.

• Observe all movements of the machine and lifting gea r.

• Secure the machine against unintentional movement.

• Raise the machine only after it is safely attached and the person

attaching the machine has given his approval.

• Use only the slinging points provided for fastening the lifting gear (for

example cables, belts).

• Do not attach the machine by twining the lifting gear (for example

cables, belts) around it.

• Ensure an even load distribution (center of gravity!) when fastening the

lifting gear.

• Ensure that no one is in, on or under the machine when loading the

machine.

• Observe the national regulations (for example “Merkheft Erdbaumaschinen”, leaflet on earth moving machines of the German

employers’ liability insurance association for construction engineering).

• Load the machine only in accordance with this Operator’s Manual to

avoid damage to the machine.

• Do not raise a machine that is stuck or frozen onto the ground, for

example.

• Bear in mind the weather conditions (for example the wind force,

visibility conditions).

2-12 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 31

Transportation

Safety 2

• For the safe transportation of the machine:

- The transport vehicle must have a sufficient load capacity and

platform – see “Technical data”

- The maximum weight rating of the transport vehicle must not be

exceeded.

• Use only lifting and fastening gear certified by a test/certification body,

observe the inspection intervals.

• Do not use any lifting and fastening gear that is dirty, damaged or not

of sufficient size.

• In order to secure the machine on the platform, use only the fastening

points provided for this purpose.

• Ensure that nobody is in or on the machine during transportation.

• Observe the national regulations (for example “Merkheft Erdbaumaschinen”, leaflet on earth moving machines of the German

employers’ liability insurance association for construction engineering).

• Bear in mind the weather conditions (for example ice, snow).

• Ensure the minimum load on the steering axle(s) of the transport

vehicle, and ensure an even load distribution.

2.9 Maintenance

Maintenance

• Observe the intervals prescribed by law and those specified in this

Operator’s Manual for routine checks/inspections and maintenance.

• For inspection and maintenance, ensure that all tools and service

center equipment are adapted to the performance of the task

described in this Operator’s Manual.

• Do not use any damaged or malfunctioning tools.

• Have hydraulic hoses replaced within stipulated intervals even if no

visual defects can be detected.

• The machine and the engine must be stopped during maintenance.

• Once maintenance is over, cor rectly install safety equipment ag ain that

has been removed.

• Wait for the machine to cool down before touching components.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-13

Page 32

2 Safety

Personal safety measures

• Avoid any operational mode that might be preju dicial to safety.

• Wear protective clothing and equipment (for example a hard ha t,

protective gloves, safety boots).

• Tie back long hair and remove all jewelry.

• If maintenance on a running engine cannot be avoided:

- Only work in groups of two.

- Both persons must be authorized and trained for the oper ation of the

machine.

- One person must be seated on the operator seat and stay in contact

with the second person.

- Keep a safe distance from rotating parts (for example from fan

blades, belts).

- Keep a safe distance from hot parts (for example from the exhaust

system).

- Perform maintenance only in well-ventilated rooms or rooms with an

exhaust-gas suction system.

• Safely lock/support machine components before starting work.

• Apply special care when work ing on the fuel system due to the

increased fire hazard.

2-14 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 33

Preparatory measures

Safety 2

• Attach a warning label to the control elements (for example “Machine

being serviced, do not start”).

• Before performing assembly work on the machine, support the areas to

be serviced and use suitable lifting and supporting equipment for the

replacement of parts over 9 kg (20 lbs.).

• Perform maintenance only if:

- the machine is positioned on firm and level ground

- the machine is secured to prevent it from rolling away (for example

with the parking brake, wheel chocks), and if all attachments/the

work equipment is lowered to the ground

- the engine is stopped

- the starting key has been removed

- the pressure in the operating hydraulics has been released

• If maintenance has to be performed under a raised machine/

attachment, support the machine/attachment (for example with a lift

platform, trestles) ensuring safety and stability.

• Hydraulic cylinders or jacks alone do not sufficiently secure a raised

machine/attachment.

Measures for performing maintenance

• Perform only the maintenance described in this Operator’s Manual.

• All work that is not described in this Operator’s Manual must be

performed by qualified and authorized technical personnel.

• Follow the maintenance plan – see “Maintenance plan”.

• Always use specially designed or otherwise safety-oriented ladders

and working platforms to perform overhead maintenance. Do not use

machine parts or attachments as a climbing aid.

• Do not use attachments/work equipment as a lift platform for persons.

• Remove all dirt, snow an d ice from climbing aids (for example from the

handholds, footholds, handrails).

• Disconnect the negative terminal of the battery before working on the

electrical system.

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-15

Page 34

2 Safety

Modifications and spare parts

• Do not modify the machine and the work equipment/attachment (for

• Modifications must be app roved by the manufacturer and perfor med by

• Use only original spare parts.

Protective structures

• The cabin, rollbar and protective screen are tested protective structures and

• Perform a visual check according to the maintenance plan (for

• If damage or defects are detected, have them immediately checked

• Have retrofitting work only performed by a Wacker Neuson service center.

• Replace self-locking fasteners (for example self-locking nuts) by new

example the safety equipment, lights, tires, straightening and welding work).

a Wacker Neuson service center.

may not be modified (for example no drilling, bending, welding).

example check fastenings for damage).

and repaired by a Wacker Neuson service center.

ones after removing them.

2-16 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 35

2.10 Measures for avoiding risks

Tire s

• Have repair work on the tir es only performed by trained technical

personnel.

• Check the tires for correct pressure and visible damage (for example

cracks, cuts).

• Tighten the wheel nuts to the specified tightening torque. (see chapter

7.18 Tires/tracks).

• Use only approved tires.

• The machine mu st have i den tical tir es (for examp le p rofile, revo lutions

per mile).

Tracks

• Repair work on tracks may only be performed by trained technicians.

• Check the tracks for correct tension and visible damage (for example

cracks, cuts).

• Proceed with extreme care on slippery ground (for example on steel

plates, ice), increased slipping hazard.

• Use only approved tracks.

Safety 2

Hydraulic and compressed-air system

• Check all lines, ho ses and threaded fittings regularly for leaks and

visible damage.

• Splashed oil can cause injury and fire.

• Leaking hydraulic and compressed-air lines can cause the full loss of

the brake effect.

• Have damage and leaks immediately repaired by a Wacker Neuson

service center.

• Have hydraulic hoses replaced by a Wacker Neuson service center

within stipulated intervals even if no visual defects can be detected.

Electrical system

• Use only fuses with the specified current rating.

• In case of damage or malfunction in the electrical system:

- Put the machine out of operation immediately and secure it against restart

- Disconnect the battery or operate the battery master switch

- Have the malfunction repaired

• Ensure that work on the electrical system is only performed by trained

technical personnel.

• Have the electrical system checked regularly and malfunctions repaired

immediately (for example loose connections, scorched cables).

• The operating voltage of machine, the attachment and the trailer must

be the same (for example 12 V).

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-17

Page 36

2 Safety

Battery

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals and related accessories contain lead and lead

compounds, chemical known to the State of California to cause cancer

and reproductive harm. Wash hands after handling.

• Batteries contain caustic substances (for example sulfuric acid ). When

handling the battery observe the specific safety instructions and

regulations relevant to accident prevention.

• A volatile oxyhydrogen mixture forms in batteries during normal

operation and especially during charging. Always wear gloves and eye

protection when working with batteries.

• Do not perform battery maintenance near open flames.

• Perform battery maintenance only in we ll-ventilated areas (for example

due to vapors harmful to health, explosion hazard).

• Starting the machine with battery jumper cables is dangerous if

performed improperly. Observe the safety instructions regarding the

battery.

Safety instructions regarding internal combustion engines

CALIFORNIA

Proposition 65 Warning

Engine exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm.

• Internal combustion engines present special hazards during operation

and fueling.

• Failure to follow the warnings and safety instructions can cause

serious injury or death.

• Keep the area aroun d the exhaust system fre e of flammable materials.

• Check the engine and fuel system for leaks (for example loose fuel

lines). Do start or let the engine run in case of leaks.

• Breathing the exhaust fumes causes death very quickly.

• Engine exhaust contains gases you cannot see or smell (for example

carbon monoxide and dioxide).

- Never operate the machine in enclosed premises or areas (for

example in pits), if there is no suitable ventilation (for example

exhaust-gas filters, suction systems).

• Do not operate the machine in potentially explosive areas.

• Do not touch the engine, exhaust system and cooling system as long

as the engine is still running or has not cooled down yet.

• Do not remove the radiator cap when the engine is running or hot.

• The coolant is hot, under pressure and can cause serious burns.

2-18 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 37

Bleeding the fuel system and refueling

• Do not bleed the fuel system or refuel near open flames.

• Bleed the fuel system and refuel only in well-ventilated areas (for

example due to vapors harmful to health, explosion hazard).

• Wipe away fuel spills immediately (for example due to fire hazard,

slipping hazard).

• Firmly close the fuel tank cap, replace a malfunctioning fuel tank cap.

Handling oil, grease and other substances

• When handling oil, grease and other chemical substances (f or example the

battery electrolyte, coolant), observe the safety data sheets.

• Wear appro priate protective equipm ent (for examp le protective gloves,

safety glasses).

• Be careful when handling hot consumables – burn hazard.

• In polluted environment (dust, vapors, smoke, asbestos), work only

with appropriate personal protective equipment (for example with a

breathing mask).

• Do not use machine in radioactive, biological or ch emical contami-

nated areas.

Fire hazard

• Fuel, lubricants and coolants are flammable.

• Do not put the machine into operation if there is a fire hazard.

• Do not use flammable detergents.

• Keep the area aro und the exhaust system free of flammable materials.

• Due to hot machine parts, mainta in a safe distance from easily

flammable material (for example from hay, dry leaves).

- Stop and park the machine only in fire-protected areas.

• If the machine is equipped with a fire extinguisher, have it installed in

its specific location.

• Keep the machine clean to reduce the fire hazard.

Safety 2

Working near electric supply lines

• Before performing any work, the operator must check whether there

are any electric supply lines in the job site.

• If there are electric supply lines, only a machine with cabin may be

used (Faraday cage).

• Keep a safe distance from existing electric supp ly lines.

• If this is not possible, the operator must take other safety measures (for

example switching off the current) in agreement with the operating

company or owner of the supply lines.

• If supply lines are exposed, they must be fastened, supported and

secured accordingly.

• If live supply lines are touched nevertheless:

- Do not leave/touch the cabin (Faraday cage)

- If possible, drive the machine out of the danger zone

- Warn others against approaching and touching the machine

- Have the live wire de-energized

- Do not leave the machine until the supply lines that have been

touched or damaged have been safely de-energized

OM D18 us* 1.1 * Sicherheit_25022014.fm 2-19

Page 38

2 Safety

Working near non-electric supply lines

• Before performing any work, the operator must check whether there

are any non-electric supply lines in the job site.

• If there are non-electric supply lines, the operator must take safety

measures (for example switching off the supply line) in agreement with

the operating company or owner of the supply lines.

• If supply lines are exposed, they must be fastened, supported and

secured accordingly.

Behavior during thunderstorm

• Stop machine operation if a thund erstorm is gathering, stop the

machine, secure and leave it, and avoid being near it.

Noise

• Observe the noise regulations (for example during applications in

enclosed premises).

• Bear in mind external sources of noise (compressed-air hammer,

concrete saw).

• Do not remove the sound baffles of the machine/attachment.

• Have damaged sound baffles immediately replaced (for example an

insulating mat, muffler).

• Before starting work, get informed on the noise level of the machine/

attachment (for example on the adhesive label) – wear ear protectors.

• Do not wear ear protectors dur ing machine tr avel on public r oads/sites.

Cleaning

• Injury hazard from compressed air and high-pressure cleaners.

- Wear appropriate protective clothes.

• Do not use any dangerous and aggressive detergents.

- Wear appropriate protective clothes.

• Operate the machine only in a clean condition.

- Remove all dirt, snow and ice from climbing aids (for example from

the handholds, footholds, handrails).

- Keep the cabin glazing and visual aids clean.

- Keep the light system and reflectors clean.

- Keep the control elements and indicators clean.

- Keep the safety, warning and information labels clean, and replace

damaged and missing labels by new ones.

• Perform cleaning work only if the engine is stopped and cooled down.

• Bear in mind sensitive components and protect them accordingly (for

example electronic control units, relays).

2-20 OM D18 us* 1.1 * Sicherheit_25022014.fm

Page 39

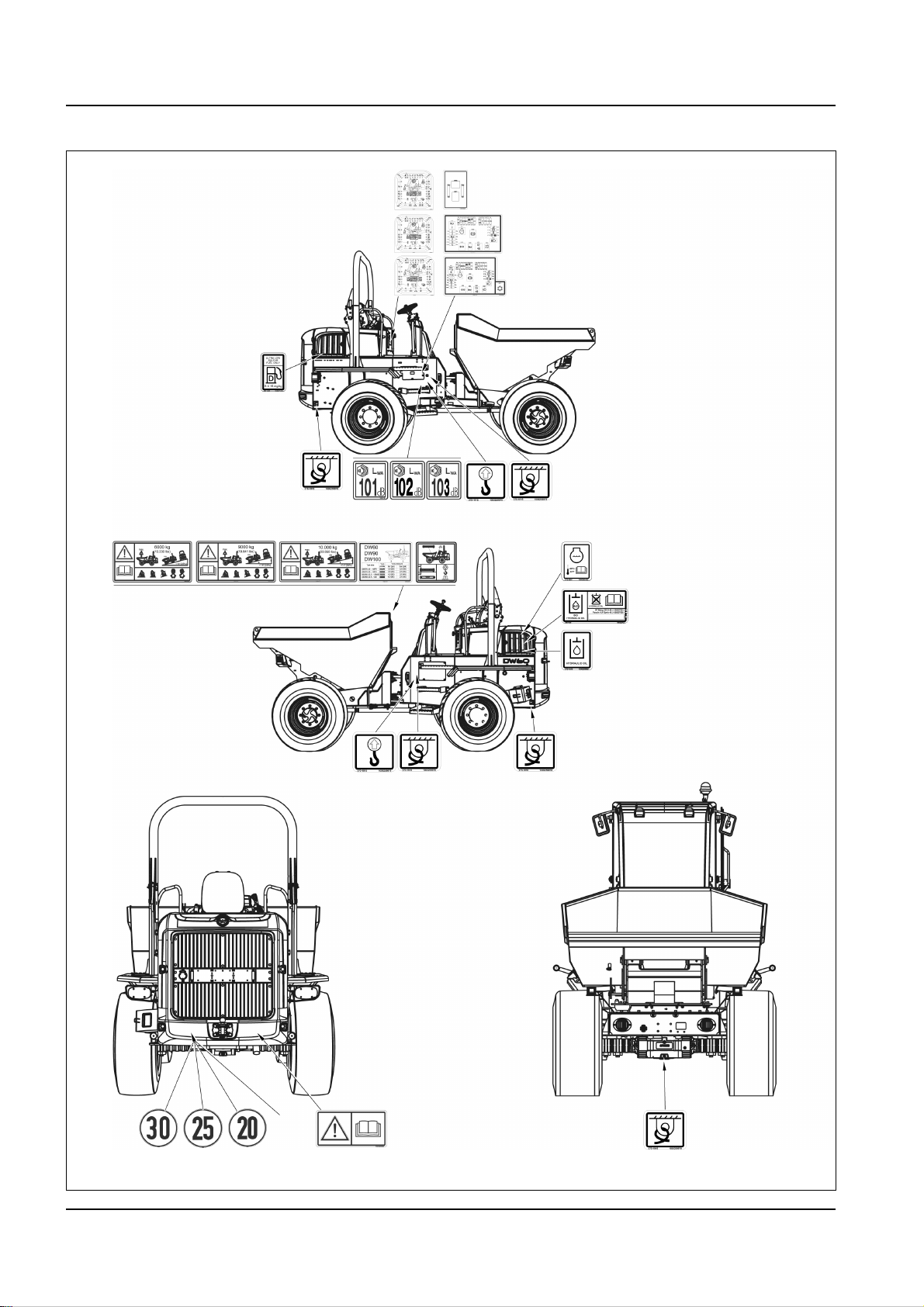

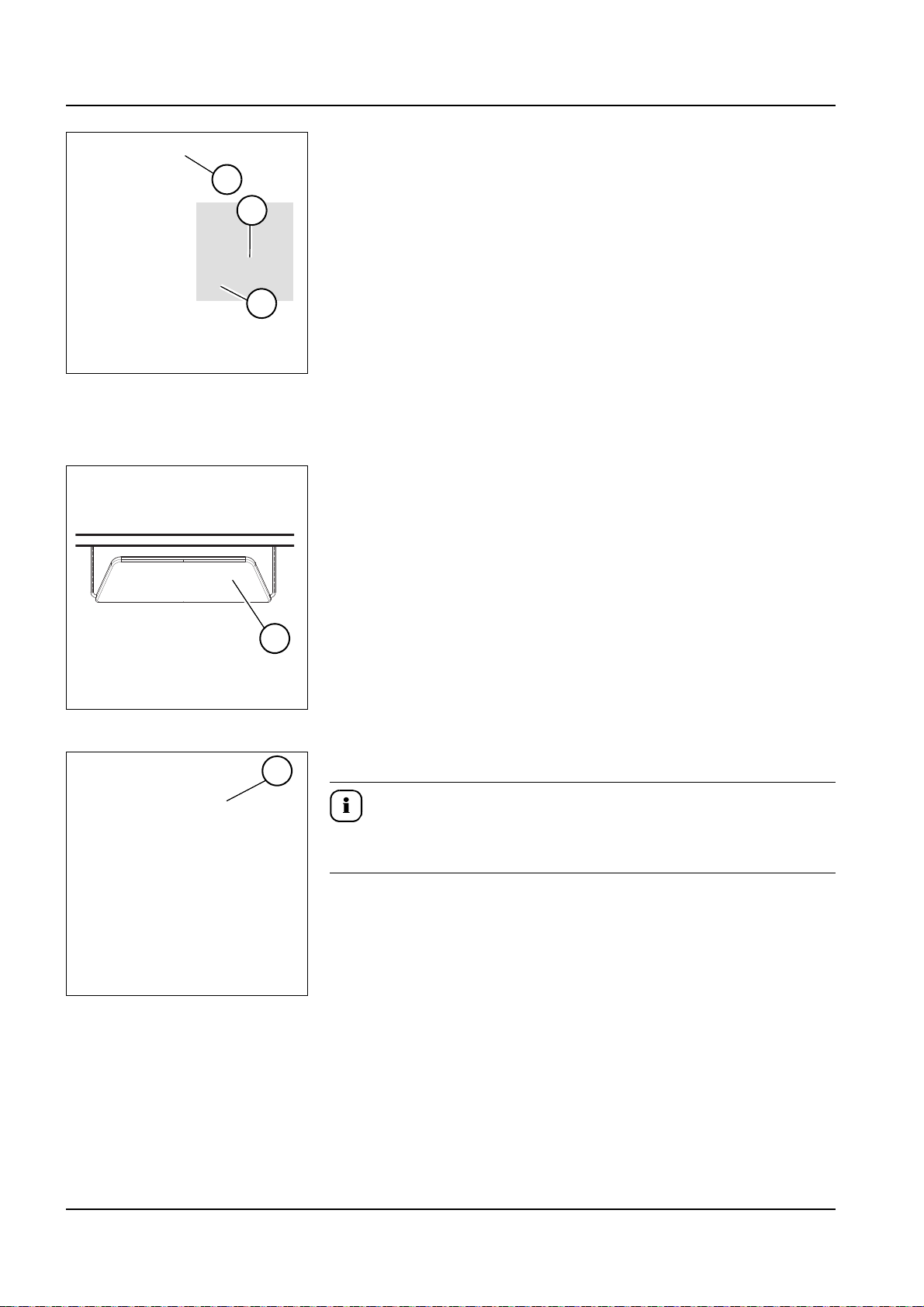

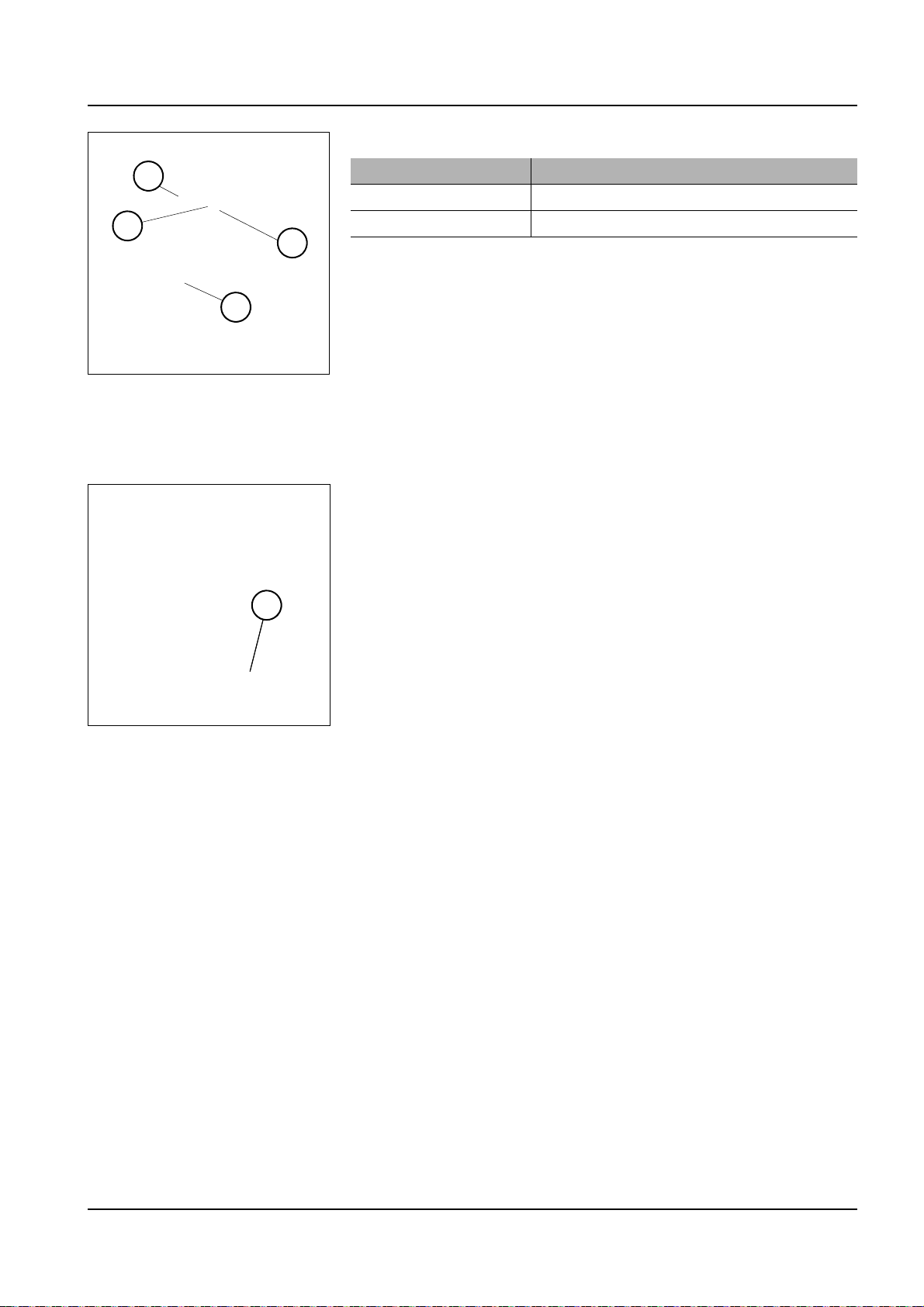

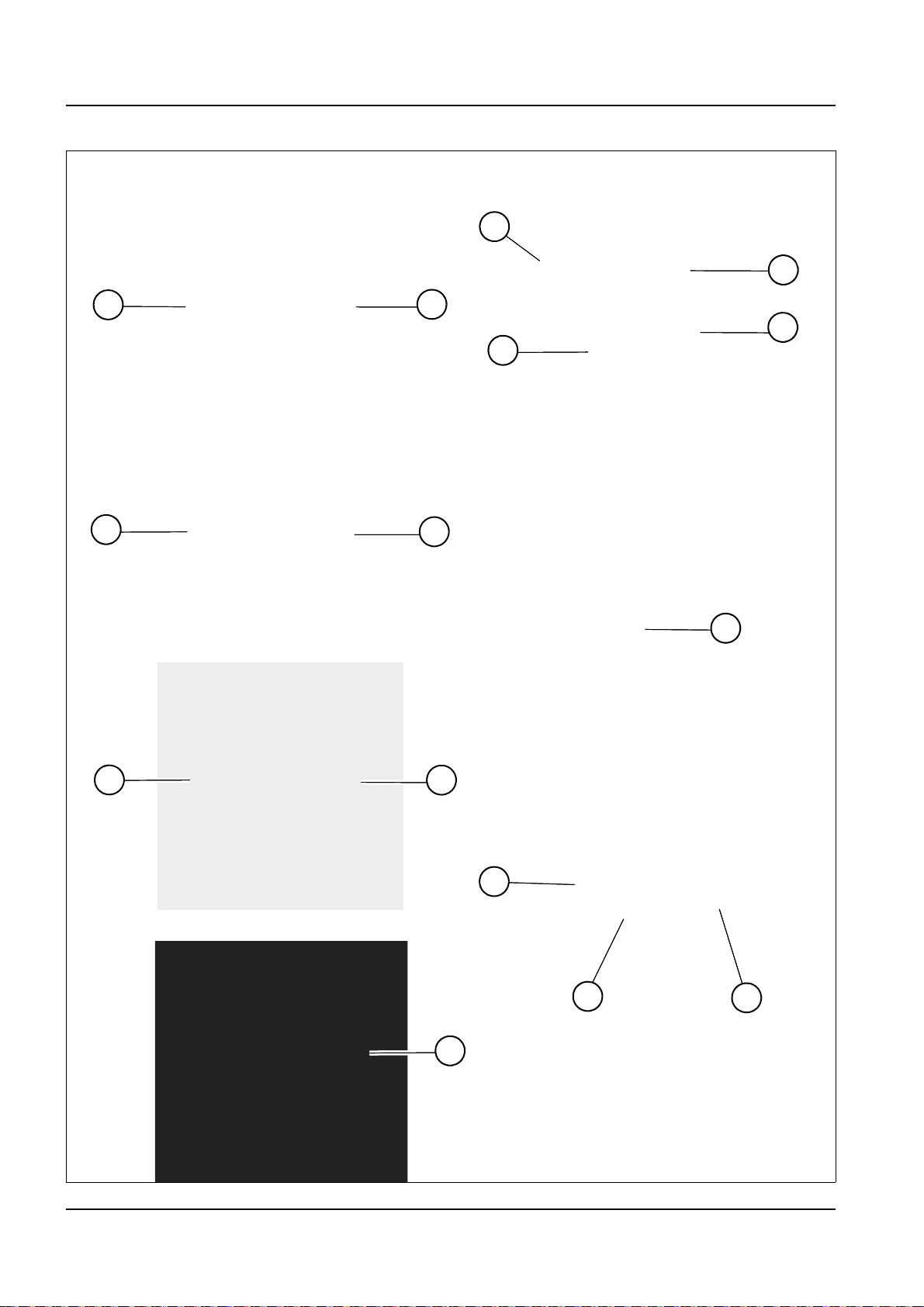

Fig. 2 (symbolic representations)

1

2

3

6

5

7

8

9

11

10

4

Introduction

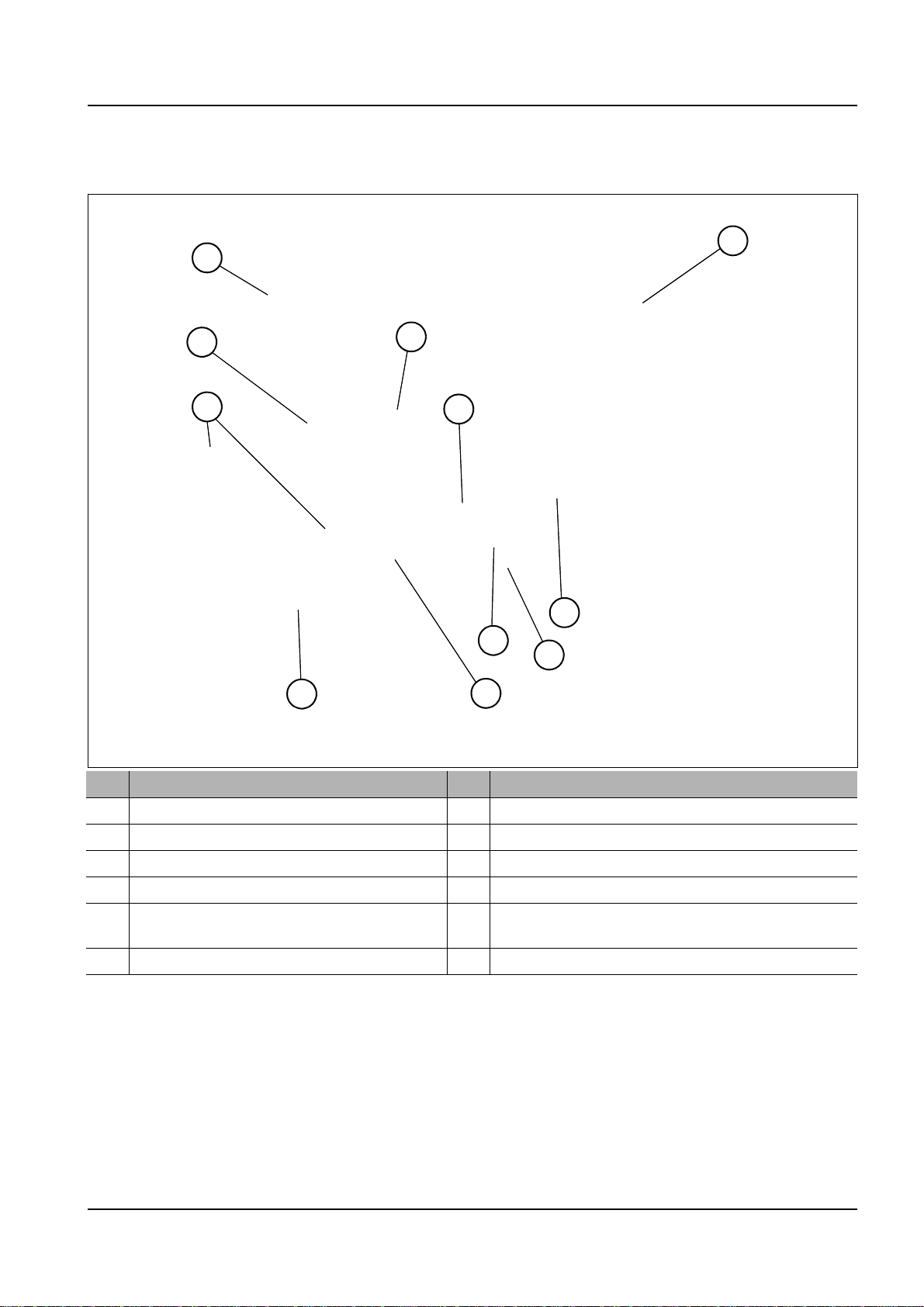

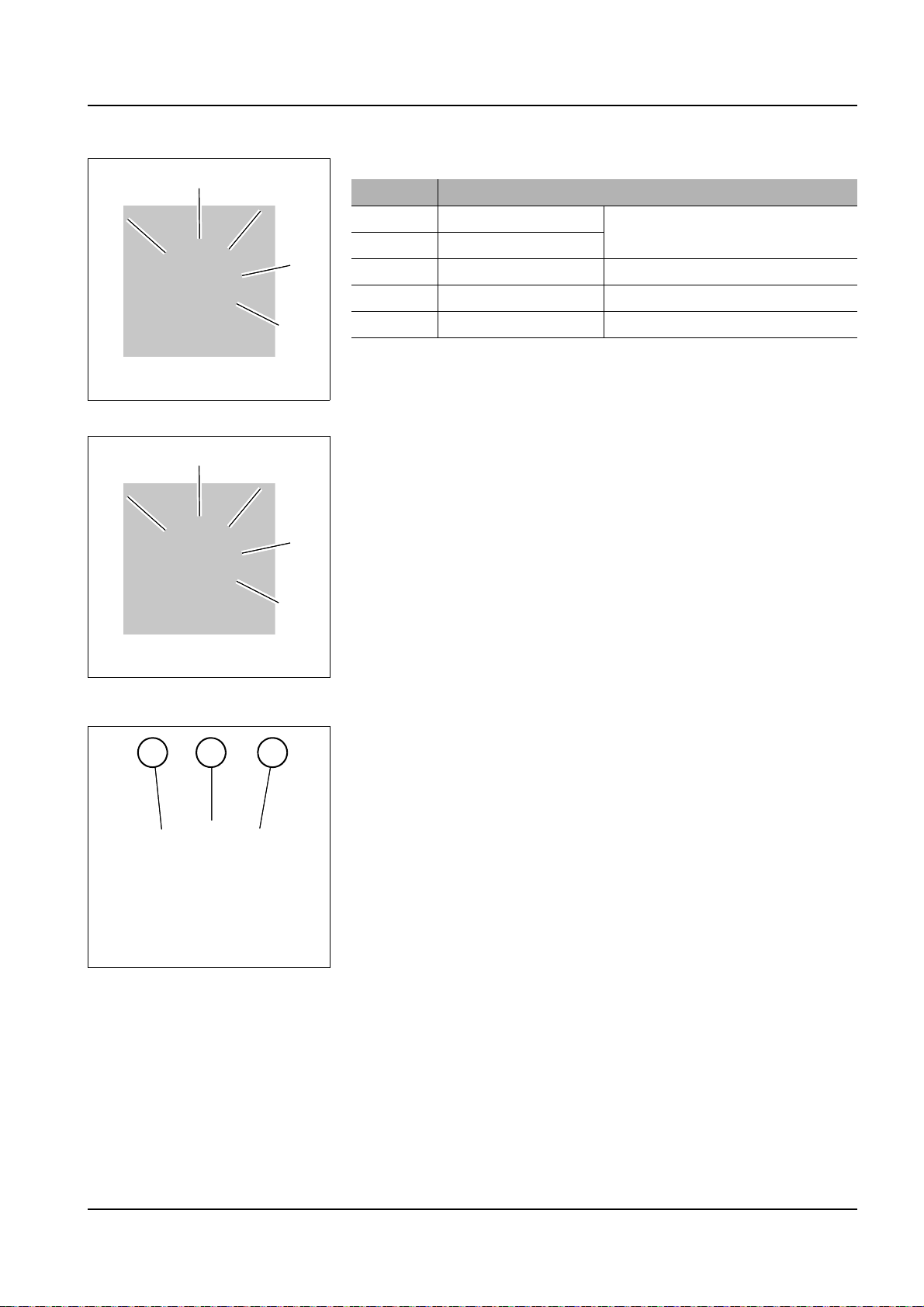

3Introduction

3.1 Machine overview

Introduction 3

No. Designation No. Designation

1 Rear chassis 7 Rollbar

2 Front chassis 8 Control stand

3 Tilt cylinder 9 Skip

4 Mudguard 10 Steering cylinder

Engine cover/

5

maintenance flap on left und right

6 Operator seat

11 Articulated joint

BA D18 us* 1.1 * D18e300.fm 3-1

Page 40

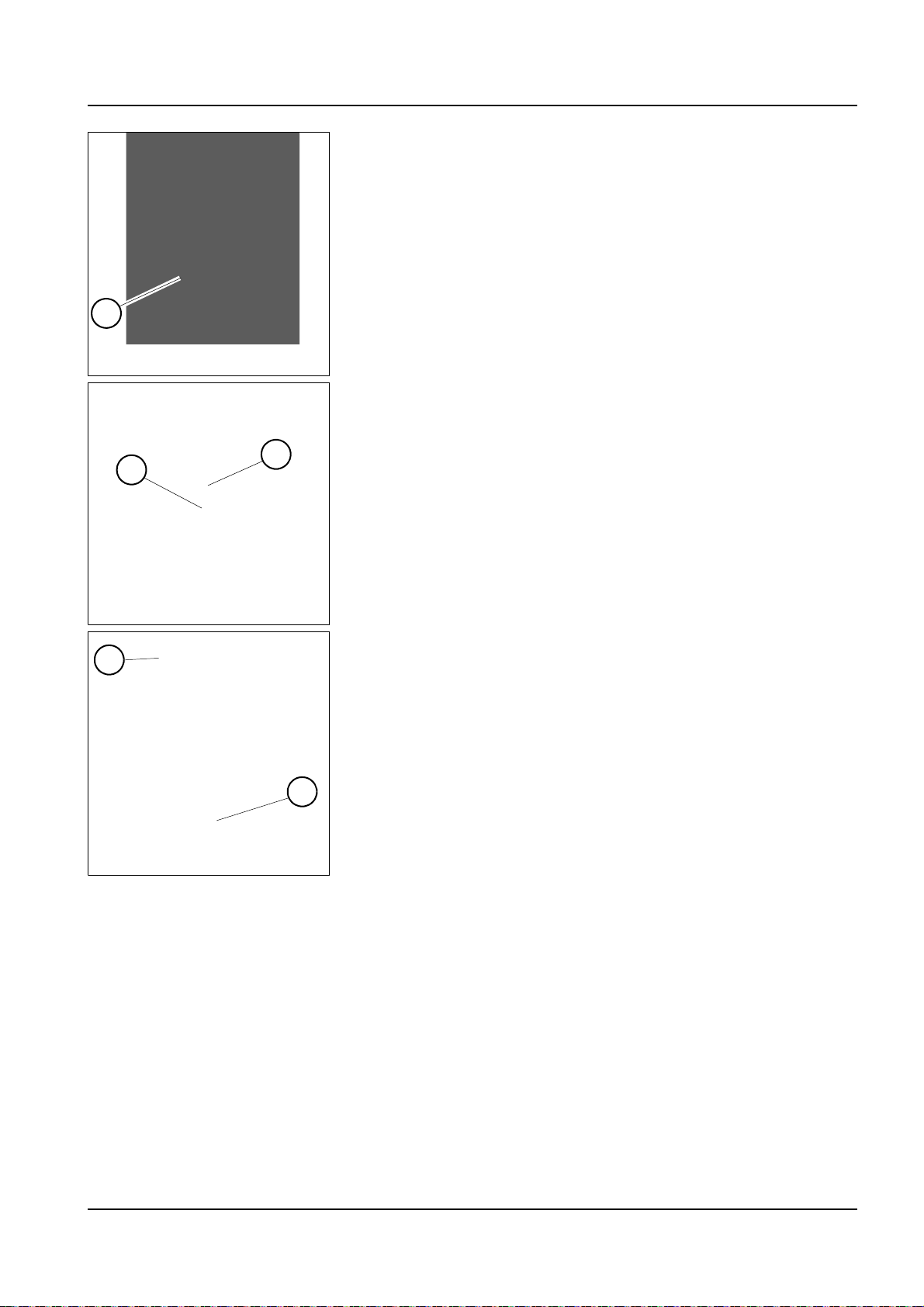

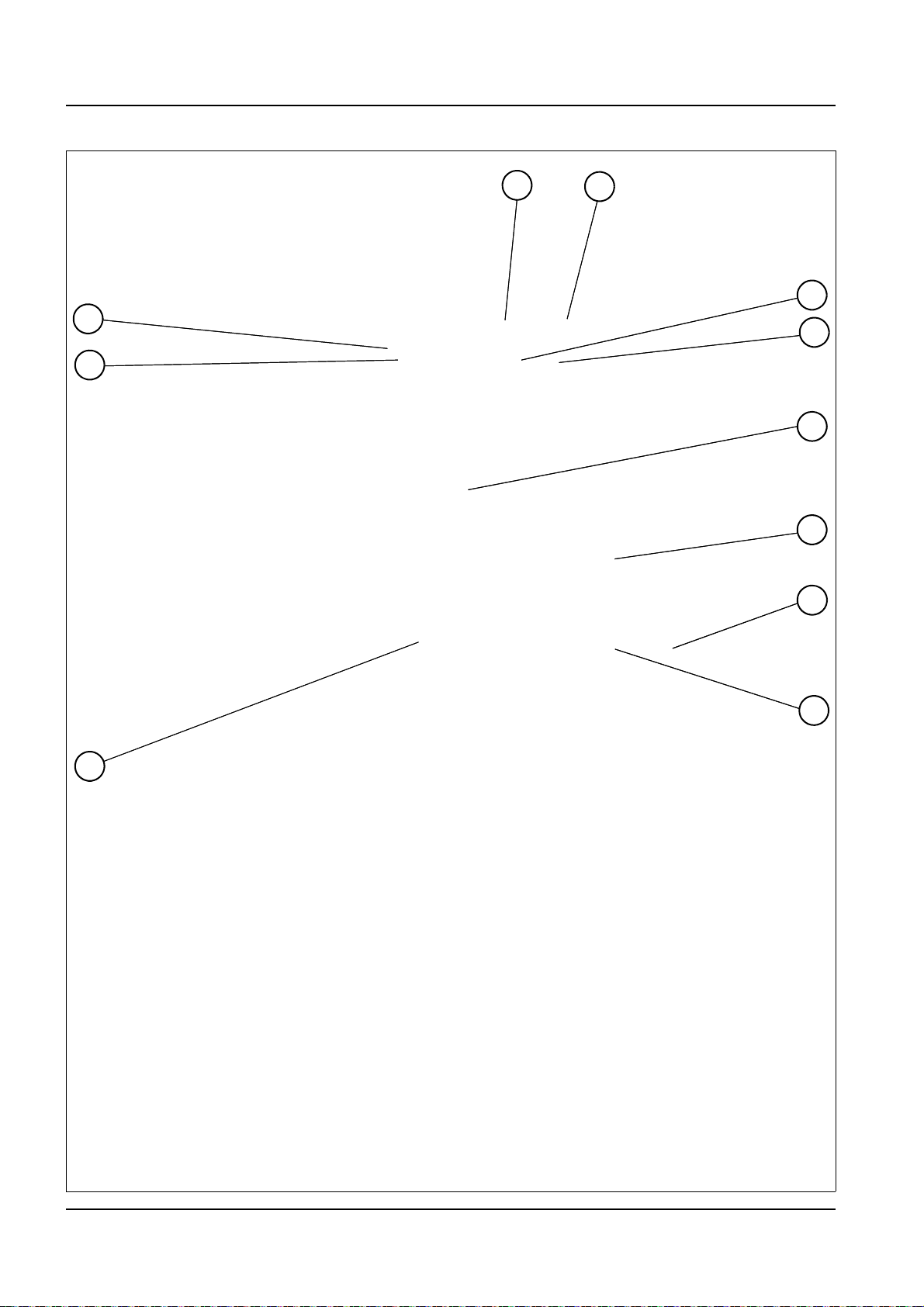

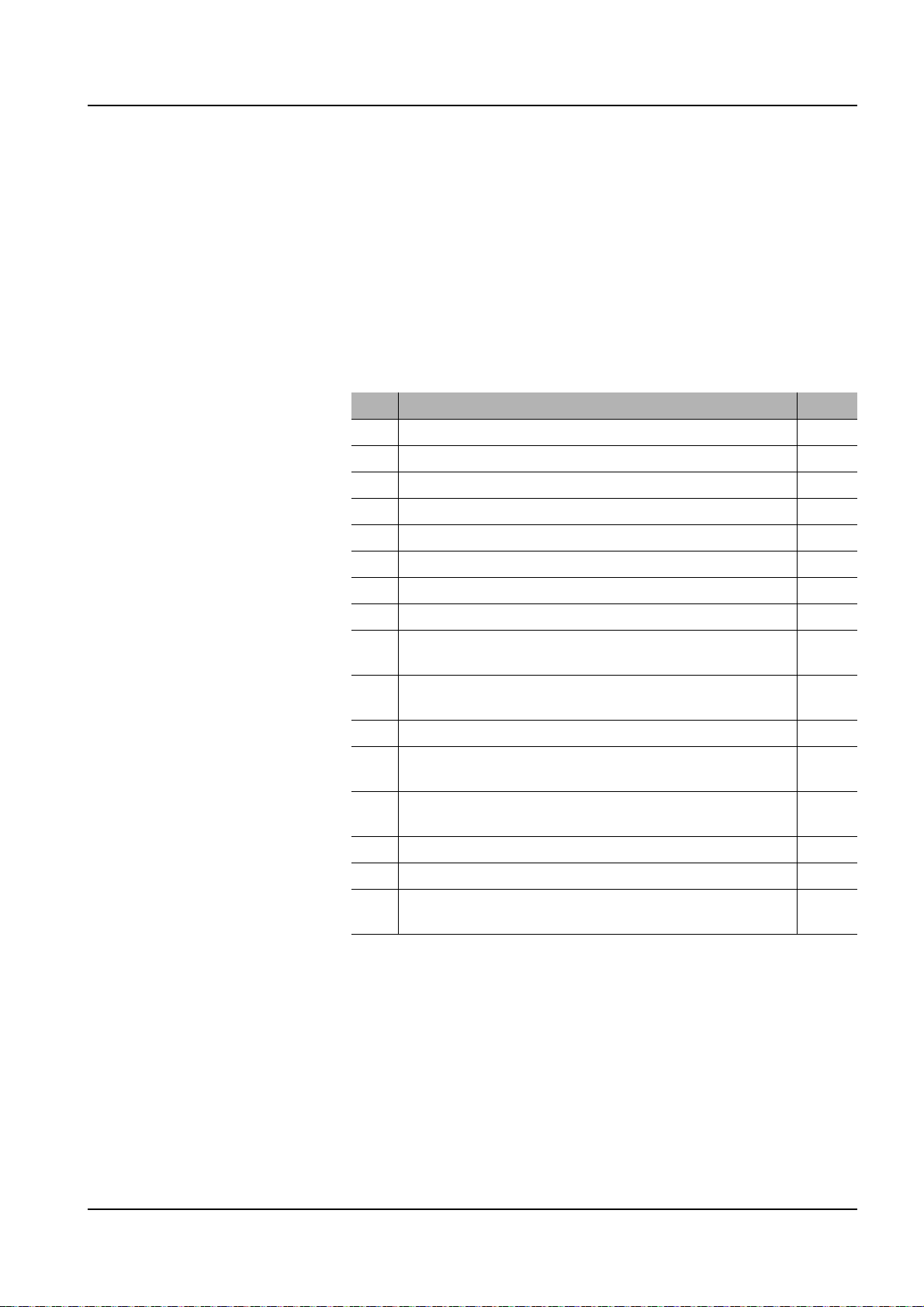

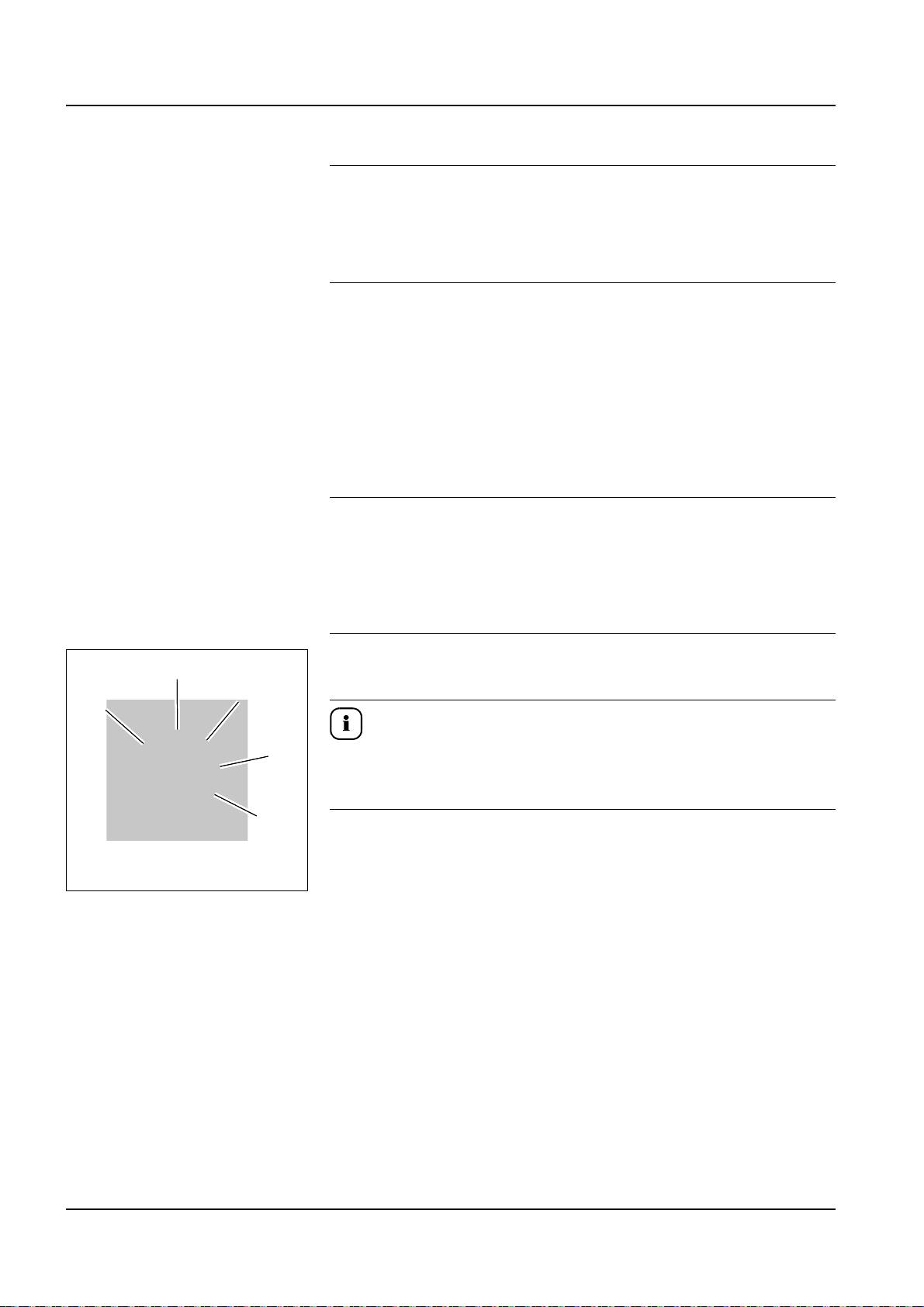

3 Introduction

Fig. 3 (symbolic representations)

1

2

3

4

5

6

7

8

10

11

9

12

13

14

No. Designation No. Designation

1 Rear chassis 8 Skip

2 Front chassis 9 Tilt cylinder

3 Articulated joint 10 Steering cylinder

4 Operator seat 11 Swivel centring

5 Control stand 12 Swiveling cylinder

6 Mudguard 13 Swiveling console

Engine cover/

7

maintenance flap on left und right

14 Cabin

3-2 BA D18 us* 1.1 * D18e300.fm

Page 41

3.2 Brief description of machine

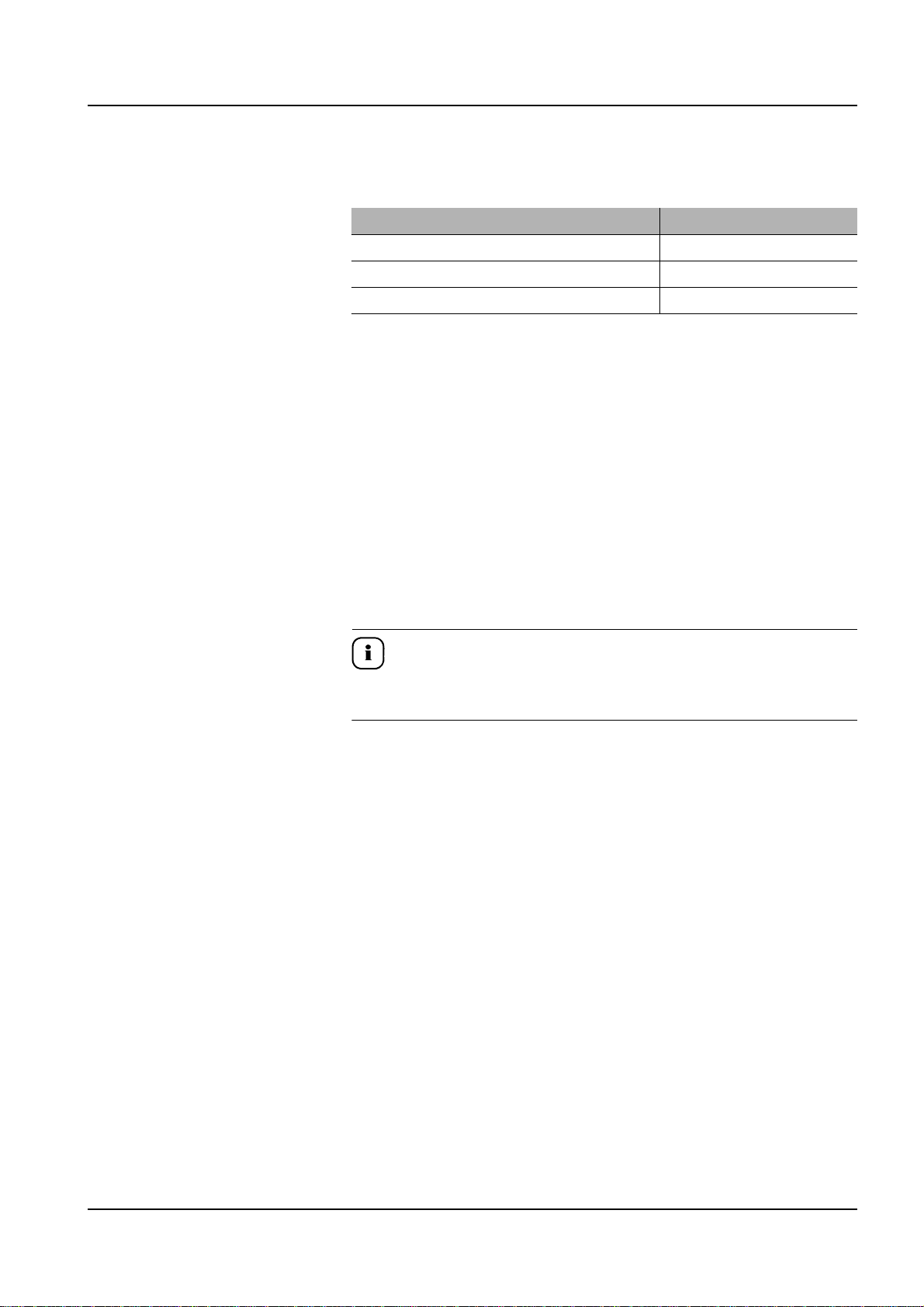

Information

Overview of models and trade names

Machine model/machine designation Trade name

The Wacker Neuson model D18 dumpers are self-propelled work

machines.

These powerful, highly flexible and efficient construction machines with

minimum environmental impact are ma in ly use d fo r mo vin g ea rt h, gr av el

and rubble on construction sites.

Follow the relevant national and regional regulations.

The main components of the machine are:

• Sturdy steel sheet chassis

• Front skip or swivel skip (option)

• Rollbar or cabin (option)

• Four-cylinder Perkins diesel engine 55 kW/62.5 kW/86 kW

• Articulated machine

• 2 rigid axles

• Permanent 4 wheel drive

Introduction 3

D18-01 DW60

D18-02 DW90

D18-03 DW100

The machine can be equipped with the Telematic option (for transmitting

operating data, location, etc. via satellite).

Rollbar

• The rollbar has been specially designed for protection in case of an

accident.

• TOPS/ROPS tested rollbar.

Cabin (option)

The cabin has been specially designed for protection in case of an

accident.

• ROPS/TOPS tested cabin.

• The cabin complies with the FOPS level II requirements according to

EN ISO 3449:2008.

BA D18 us* 1.1 * D18e300.fm 3-3

Page 42

3 Introduction

3.3 Information and regulations on use

Designated use

• The machine is intended for:

- Moving earth, gravel, coarse gravel or ballast and rubble.

Every other use is regarded as not designated for the use of the

machine. Wacker Neuson will not be liable for damage resulting from

use other than mentioned above. The operator/machine owner alo ne

will bear the risk.

- Designated use also includes observing the instructions set forth in

the Operator’s Manual and observing the maintenance and service

conditions.

• Follow the national regulations for machine travel on public roads.

Earth moving machinery on public roads

Earth moving machines may be used on public roads only if they are

equipped according to the road traffic regulations of your country.

Equipment

Austrian road traffic regulations, for example §53 StVO, require to have

the following equipment on board:

• 1 warning vest according to ÖNORM EN 471

• 1 warning triangle with design certification

• 1 warning light with design certification

• 1 first-aid kit in accordance with the legal regulations of your country

Driving license

Earth moving machinery may be driven on public roads only if the

operator has a driving license as stipulated by national road traffic

regulations for a specific machine.