Wacker Neuson DPU80rLe670, DPU Series, DPU80Le770, DPU80rLe770, DPU90Le770 US Operator's Manual

...Page 1

Operator's manual

Vibratory plate

DPU

80, 90, 110

Model DPU

Document 5100008833

Issue 06.2016

Version 06

Language en

Page 2

Copyright © 2016 Wacker Neuson Produktion GmbH & Co. KG

Printed in Germany

All rights are reserved, in particular the world-wide app lica ble co pyright, rig ht of duplication an d r ight o f

distribution.

This document may only be used by the recipient for the intended purpose. The document may not be

reproduced entirely or partially, or translated into any other language.

Reproduction or translation, even extracts thereof, only with written approval of Wacker Neuson

Produktion GmbH & Co. KG.

Any breach of the statutory provisions, in particular the protection of copyright, will lead to civil and

criminal prosecution.

Wacker Neuson Produktion GmbH & Co. KGis constantly working on the im provement of its products as

part of the technical further development. Therefore, we reserve the right to make changes to the

illustrations and descriptions in this documentation without incurring any obligation to make changes to

machines already delivered.

Errors excepted.

The machine on the cover may have special equipment (options).

Manufacturer

Wacker Neuson Produktion GmbH & Co. KG

Preussenstrasse 41

80809 Munich

www.wackerneuson.com

Tel.: +49-(0)89-354 02-0

Fax: +49-(0)89-354 02-390

Translation of the original operator's manual in German

2 100_0000_0001.fm

Page 3

Inhalt

Table of Contents

1 Preface ....................................................................................................................................5

2 Introduction ............................................................................................................................6

2.1 Using the manual.. ... ... ... .... ... ... ... .............................................................. ... ... ... .... ... ................... 6

2.2 Storage location of the manual.................................................................................................... 6

2.3 Accident prevention regulations................................... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .......... 6

2.4 More information.......................................................................................................................... 6

2.5 Target group................................................................................................................................ 6

2.6 Explanation of symbols................................................................................................................ 6

2.7 Wacker Neuson Contact partner ................................................................................................. 7

2.8 Disclaimer.................................................................................................................................... 7

2.9 Product identification of the machine........................................................................................... 7

3 Security ..................................................................................................................................8

3.1 Policy........................................................................................................................................... 8

3.2 Areas of responsibility of the operator......................................................................................... 8

3.3 Operator responsibilities.............................................................................................................. 9

3.4 Personnel qualification................................................................................................................. 9

3.5 General sources of danger.......................................................................................................... 9

3.6 General safety instructions.......................................................................................................... 9

3.7 Specific safety instructions – Vibratory plates ........................................................................... 10

3.8 Specific safety instructions – remote controlled vibratory plates .................................... ... .... ... . 10

3.9 General safety instructions - Combustion engines.................................................................... 11

3.10 General safety instructions – fuel, lubricants and coolants........................................................ 11

3.11 General safety instructions – starter batteries........................................................................... 11

3.12 Maintenance.............................................................................................................................. 11

3.13 Personal Protective Equipment ................................................................................................. 12

3.14 Safety devices ........................................................................................................................... 12

3.15 Behavior in dangerous situations............................................................................................... 13

4 Safety and information labels ............................................................................................14

4.1 Safety and information labels on the remote control ................................................................. 15

5 Setup and function ..............................................................................................................16

5.1 Standard package ..................................................................................................................... 16

5.2 Application areas......................................................... ... ... ... .... ... ... ... ........................................ 16

5.3 Short description........................................................................................................................ 16

5.4 Versions..................................................................................................................................... 18

6 Components and operator's controls ................................................................................19

6.1 Components .............................................................................................................................. 19

6.2 Operator's controls .................................................................................................................... 20

6.3 Components and operator’s controls – remote control unit................................... ... ... ... ... .... ... . 23

7 Transport ..............................................................................................................................25

7.1 Loading and transport................................................................................................................ 25

8 Operation and use ...............................................................................................................27

8.1 Before commissioning .................... ... ... ... .............................................................. ... ... ... ... ........ 27

8.2 Notes about operation ............................................................................................................... 29

8.3 Commissioning.......................................................................................................................... 30

8.4 Operation................................................................................................................................... 33

8.5 Decommissioning ...................................................................................................................... 36

8.6 Setting the transmission channel (remote control) .................................................................... 41

8.7 Operating the diagnostic menu.................................................................................................. 41

8.8 Operation of the configuration menu ......................................................................................... 42

9 Maintenance .........................................................................................................................43

9.1 Maintenance schedule – One-time maintenance job................................ ... ... ... .... ... ... ... ... .... ... . 43

5100008833IVZ.fm 3

Page 4

Table of contents

9.2 Maintenance schedule – daily maintenance jobs ...................................................................... 44

9.3 Maintenance schedule – regular intervals ................................................................................. 44

9.4 Maintenance jobs....................................................................................................................... 45

10 Troubleshooting ..................................................................................................................52

10.1 Troubleshooting table – machine............................................................................................... 52

10.2 Troubleshooting table – receiving units ..................................................................................... 53

10.3 Fault table - Center pole head control lamp............................................................................... 53

10.4 Troubleshooting chart – remote control..................................................................................... 54

10.5 Troubleshooting table – display................................................................................................. 55

10.6 Perform jump start with donor starter battery ............................................................................ 59

11 Disposal ...............................................................................................................................61

11.1 Disposal of batteries .................................................................................................................. 61

12 Accessories .........................................................................................................................62

13 Technical data .....................................................................................................................63

13.1 DPU80 ....................................................................................................................................... 63

13.2 DPU80r...................................................................................................................................... 64

13.3 DPU90 ....................................................................................................................................... 65

13.4 DPU90r...................................................................................................................................... 66

13.5 DPU110 ..................................................................................................................................... 67

13.6 DPU110r.................................................................................................................................... 68

13.7 Combustion engine.................................................................................................................... 69

13.8 US combustion engine............................................................................................................... 70

14 Emission control systems information and warranty ......................................................71

EC declaration of conformity

.....................................................................................72

EC declaration of conformity .....................................................................................73

DIN EN ISO 9001 certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4 5100008833IVZ.fm

Page 5

1 Preface

This operator's manual contains important information and procedures for the safe, proper and economic

operation of this Wacker Neuson machine. Carefully reading, understanding and ob se rving is an aid to

avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life

of the machine.

This operator's manual is not a manual for extensive maintenance or repair work. Such work should be

carried out by Wacker Neuson service or by technically trained person nel. The Wacker Neuson machine

should be operated and maintained in accord ance with this operator's manual. An improper operation or

improper maintenance can pose dangers. Therefore, the operator's manual should be constantly

available at the location of the machine.

Defective machine parts must be exchanged immediately!

If you have any questions concerning the operation or maintenance, a Wacker Neuson contact person

is always available.

1 Preface

100_0000_0002.fm 5

Page 6

2 Introduction

2Introduction

2.1 Using the manual

This manual is to be considered part of the machine and should be carefully stored during the entire

service life of the machine. This manual shall be transferred to subsequent owners or users of the

machine.

2.2 Storage location of the manual

This manual is part of the machine and must be kept in the immediate vicinity of the machine and made

accessible to staff at all times.

If this manual is lost, or if a second copy is required, there are two options to obtain a replacement:

Download from the Internet www.wackerneuson.com

Contact your Wacker Neuson contact partner.

2.3 Accident prevention regulations

In addition to the notes and safety instructions in this manual, the local accident prevention regulations

as well as the national health and safety regulations apply.

2.4 More information

This manual applies to various machine types from one product series. For this reason, some figures

may vary slightly in appearance from the machine purchased. Depending on the model, there may be

descriptions of components that are not included in the standard package.

The information contained in this manual is based on machines manufactured up to the time of printing.

Wacker Neuson reserves the right to change this information.

The manufacturer shall immediately include any modifications or additions in this manual.

2.5 Target group

Individuals working with this machine must be regularly trained on the dangers of handlin g the machine.

This operator's manual is intended for the following persons:

Operating personnel:

These individuals have been trained on the machine and informed about the possible dangers in the

event of improper conduct.

Technically trained personnel:

These people have professional training as well as addi tional knowledge and experienc e. They are able

to assess the tasks assigned to them and recognize possible dangers.

2.6 Explanation of symbols

This manual contains specially emphasized safety instructions in the following categories: DANGER,

WARNING, CAUTION and NOTICE.

Before performing any work on or with this mach ine, the no tes and safety instructions must be read and

understood. All notes and safety instructions in this manual must be passed on to the maintenance,

repair, and transport personnel.

DANGER

This combination of symbol and signal word indicates a hazardous situation that will lead

to death or serious injury if it is not avoided.

WARNING

This combination of symbol and signal word indicates a hazardous situation that can lea d

to death or serious injury if it is not avoided.

CAUTION

This combination of symbol and signal word indicates a hazardous situation that can lea d

to minor injury or damage to the machine if it is not avoided.

6 100_0000_0013.fm

Page 7

NOTICE

Supplementary information.

2.7 Wacker Neuson Contact partner

Depending on the country, the Wacker Neuso n contact partner is a Wacker Neuson service department,

a Wacker Neuson affiliate, or a Wacker Neuson dealer.

On the Internet at www.wackerneuson.com.

The manufacturer's address can be found at the beginning of this manual.

2.8 Disclaimer

For the following violations, Wacker Neuson dismisses any liability for personal injury or material

damage:

Failure to follow this manual.

Unintended use.

Deployment of untrained personnel.

Using non-approved spare parts and accessories.

Improper handling.

Structural modifications of any kind.

Failure to observe the "General Terms and Conditions" (GT&Cs).

2.9 Product identification of the machine

Data of the nameplate

The nameplate contains information that uniquely identifies this machine. This information is required for

ordering spare parts and when inquiring about technical issues.

Enter information about the machine in the following table:

2 Introduction

Designation Your information

Group and model

Year of manufacture

Serial number

Version no.

Item number

100_0000_0013.fm 7

Page 8

3 Security

3 Security

3.1 Policy

In keeping with the latest technological developments

The machine has been built in keeping with the latest technological developments and the recognized

technical safety rules. Nevertheless, improper use can result in hazards to life and limb of the user or

third parties as well as damage to the equipment an d ot he r ma te r ial assets.

Proper use

The machine may only be used for the following purposes:

Soil compaction.

Asphalt compaction.

Vibration of sett paving (paving stones).

The machine may not be used for the following purposes:

Compaction of very cohesive soils.

Compaction of frozen soils.

Compaction of hard, non-com pr es sible soils .

Compaction of non-load-bearing soils.

Use in accordance with the intended purpose also includes the observation of all safety instructions in

this manual as well as complying with the prescribed care and maintenance instructions.

Any use that exceeds or is not in accordance with the intended purpose is considered improper. The

manufacturer's liability and warranty are canceled for any damage resulting from improper use. The risk

lies entirely with the operator.

NOTICE

Read and comply with all notes and safety instructions in this manual. Failure to comply

with these instructions can cause electric shock, fire and/or serious injuries as well as

damage to the machine and/or damage to other objects. Keep safety instructions and

notes for the future.

Structural changes

Structural modifications may not be undertaken without the written permission of the manufacturer.

Unapproved structural changes may result in risks to the operator and/or third parties as well as damage

to the machine.

In the case of unauthorized structural changes, the liability and warranty of the manufacturer are no

longer applicable.

The following cases are considered structural changes:

Opening the machine and the permanent removal of components.

Installing spare parts that do not originate from Wacker Neuson or are not comparable in the design

system and quality of the original parts.

Attaching any accessories that do not originate from Wacker Neuson .

Spare parts or accessories that originate from Wacker Neuson can be safely mounted. They can be

found on the Internet under www.wackerneuson.com.

3.2 Areas of responsibility of the operator

The operator is the individual who personally operates this machine for industrial or commercial

purposes or who entrusts a third party with the use. The operator bears legal responsibility for his/her

protection as well as that of third parties.

The user must make the operator's manual available to the operator and ensure that this has been read

and understood.

The manual must be kept next to the machine or place of use.

The operator must hand over the manual to subsequent operators or owners of the machine.

8 100_0202_si_0008.fm

Page 9

The country-specific regulations, standards, and guidelines on accident prevention and environmental

protection must be observed. The operator’s manual must supplem ented with additional instructions that

take regulatory, national, or generally applicable safety standards into consideration.

3.3 Operator responsibilities

Know and implement the applicable industrial safety regulations.

Use a risk assessment to identify the dangers that result from the working conditions at the site of

application.

Create operating instructions for the operation of this machine.

Periodically check whether the user instructions correspond to the current state of regulations.

Clearly regulate and specify responsibilities for operation, troubleshooting, maintenance, and

cleaning.

Regularly train employees and inform them about potential hazards.

Provide employees with the necessary equipment.

3.4 Personnel qualification

This machine may only be installed and operated by trained personnel.

Faulty operation, misuse or operation by untrained personnel can endanger health of the operator or

third parties and lead to damage to or total loss of the machine.

In addition, the operator should be:

physically and mentally fit.

not under the influence of drugs, alcohol or medication that can impair responsiveness.

familiar with the safety instructions in this manual.

familiar with the intended use of this machine.

the minimum age (18 years) to operate this machine.

Be instructed in the independent operation of the machine.

Be authorized to operate machines and systems independently according to the standards of safety

engineering.

3.5 General sources of danger

Residual dangers in particular are hazards when dealing with machines that, despite a safe design,

cannot be eliminated.

These residual dangers are not obvious and may be the source of a possible injury or health hazard.

If unforeseeable residual dangers occur, the oper ation of the machine is to be stopped immediately and

the competent supervisor is to be informed. This supervisor shall make the following decisions and

initiate everything required to eliminate the occurring danger.

If necessary, the machine manufacturer is to be informed.

3.6 General safety instructions

The safety instructions in this chapter include the "General Safety Instructions", which should be

reported in the manual in accordance with the applicable standards. There may be information that is

not relevant to this machine.

3.6.1 Working area

Before starting work, familiarize yourself with the working environment e.g. load-bearing capacity of

the floor or obstacles in the environment.

Make working area safe for the public transport sector.

Necessary fuse protection of walls and ceilings e.g. in trenches.

Keep the working area tidy. Cluttered or dark working areas can lead to accidents.

Using this machine in an explosive atmosphere is prohibited.

When using this machine, children and unauthorized individuals must be ke pt away. Distraction can

lead to loss of control of the machine.

Always protect the machine against tilting, rolling, sliding, and crashing. Risk of injury!

3.6.2 Service

The machine should only be maintained/repaired by technically trained personnel.

Use only original spare parts and accessories. This ensures the operational safety of the machine.

3.6.3 Personal safety

Working under the influence of drugs, alcohol, or drugs can lead to serious injuries.

3 Security

100_0202_si_0008.fm 9

Page 10

3 Security

Protective equipment should be worn for all work. Appropriate personal protective equipment

considerably reduces the risk of injury.

Remove any tools before the machine is put into operation. Tools that are located on a rotating

machine part can be ejected and cause serious injury.

Always ensure good footing.

In the case of extensive work with this machine, long-term vibration-in duced damage cannot be ruled

out. For exact values of vibration measurement, refer to the Technical Data section.

Wear suitable clothing. Keep loose clothing, gloves, jewelry, and lo ng hair away from moving/rotating

machine parts. Danger of being pulled!

Ensure that no other individuals are in the danger zone!

3.6.4 Handling and use

Handle machines with care. Do not operate machines with defective components or operator’s

controls. Immediately replace defective components or operator's controls. Machines with defective

components or operator's controls carry a high risk of injury!

The operator's controls of the machine shall not be improperly locked, manipulated, or changed.

The machine, accessories, and tools should be used in accordance with these instructions.

Store unused machines out of reac h of childr en . The machine may only be operated by authorized

personnel.

After operation, store the cooled-down machine in a locked, clean, frost-protected, and dry location

that is inaccessible to children and other unauthorized individuals.

3.7 Specific safety instructions – Vibratory plates

3.7.1 External influences

In the case of the following external influences, the vibratory plate may not be operated:

In heavy rain on sloped surfaces. Risk of slipping!

Oil field environments – methane leaks from bottom. Explosion hazard!

In dry, flammable vegetation. Fire hazard!

In potentially explosive areas. Explosion hazard!

3.7.2 Operational safety

When operating the machine, make sure that no ga s, water, or electric lines are damaged.

The machine must not be operated in tunnels or enclosed spaces.

Pay maximum attention near drops or slopes. Risk of crashing!

The operator must not leave the machine while it is in operation.

Do not leave the machine unattend ed . Risk of injur y!

Protect the machine from unauthorized operation. When not in use, lock the rear protective ho od with

a padlock.

Delimit spacious workspace and restri ct acce ss to un a utho riz ed indiv idu als . R isk of inju ry !

The operator of the machine must ensure that all individuals keep a minimum distance of 2 m from

the machine while it is in operation.

Do not use any starting aid sprays. These can caus e misfires as well as engine damage. Fire hazard!

When operating the machine on sloped surfaces, always approach slopes from below and always

stay above the machine on a slope. The machine could slip or tip over.

Do not exceed max. allowable slanting position of the machine – possible failure of the engine

lubrication, see chapter Technical Data.

Only Wacker Neusonuse starter batteries. These are vibration proof and therefore suitable for the

high vibration exposure.

3.7.3 Minimum safety distances

Compaction work near buildings can cause damage to buildings. Therefore, all potential effects and

vibrations on surrounding buildings must be checked in advance.

The relevant rules and regulations for measuring, evaluating and reducing vibration emissions,

especially the DIN 4150-3, must be considered.

Wacker Neuson assumes no liability for any damage to buildings.

3.8 Specific safety instructions – remote controlled vibratory plates

Always keep remote control and receivin g un its of the machine clean and free from dry, oil, and

grease.

10 100_0202_si_0008.fm

Page 11

Remote control and receiving units must not be taped over or covered.

During operation, the remote control should always be aimed directly a t the machin e. A clea r line of

sight must be maintained – infrared signals can be reflected.

The operator should remain 5 meters behind the machine in accordance with the intended purpose.

3.9 General safety instructions - Combustion engines

The following notes must be observed:

Before starting work, check the engine to ensure there are no leaks and/or cracks in the fuel lines,

tank, and fuel cap.

Do not operate a defective engine. Replace damaged parts immediately.

The pre-set engine speed may not be adjusted. This could lead to engine da mage.

Make sure that the exhaust system of the engine is free of debris. Fire hazard!

Switch off before refueling the engine.

Use the correct fuel type. The fuel may not be mixed with other liquids.

Use clean filling aids for refueling. Do not spill fuel. Immediately wipe up any spilled fuel.

The engine may not be started near spilled fuel. Explosion hazard!

When operating in partially enclosed spaces, adequate ventilation must be ensured. Do not inhale

exhaust fumes. Risk of poisoning!

The engine surface and exhaust system can quickly become extremely hot. Risk of burns!

Do not open the radiator cap when the engine is hot – Use caution: hot coolant!

3 Security

NOTICE

This machine is outfitted with an EPA-certified engine .

Adjusting the revolutions per minute (RPM) impacts the EPA-certification and the

emissions. Settings for this engine may only be changed by a professional.

For more information, contact the manufacturer or your Wacker Neuson contact partner.

3.10 General safety instructions – fuel, lubricants and coolants

The following notes must be observed:

Always wear safety glasses and protective gl ov es when handling fuel, lubricants, and coolants. If

hydraulic oil, fuel, oil, or coolant gets into your eyes, consult a physician immediately.

Avoid direct skin contact with fuel, lubricants and coolants. Immediately rinse skin with soap and

water.

Do not eat or drink while working with fuel, lubricants and coolants

Hydraulic oil or fuel contaminated by dirt or water can cause premature wear or failure of the machine.

Dispose of spilled fuel, lubricants and coolants according to the applicable provisions for

environmental protection.

If fuel, lubricants and coolants escape from the machine, do not operate the mach ine any longer and

have it repaired immediately by the Wacker Neuson contact partner.

3.11 General safety instructions – starter batteries

The following notes must be observed:

When disconnecting the starter battery, always disconnect the negative terminal first!

When connecting the starter battery, always connect the positive terminal first! Fasten battery

terminal cover!

Flames, sparks, and smoking are prohibited when handling starter batteries.

Starter batteries contain corrosive acid. Wear acid-proof protective gloves and safety glasses when

handling starter batteries.

Prevent incorrect connection of the starter battery or bridging of the terminals with tools. Risk of short

circuit!

3.12 Maintenance

The following notes must be observed:

This machine may not be maintained, repaired, adjusted or cleaned while switched on. Disconnect

the starter battery when working on the electrical system!

Adhere to maintenance intervals.

100_0202_si_0008.fm 11

Page 12

3 Security

After each maintenance or repair, the safety devices on this machine must be reattached.

Observe the maintenance schedule. Identified work must be taken over by the service department of

the Wacker Neuson contact partner.

Immediately replace worn or damaged machine parts. Only use spare parts from Wacker Neuson.

Keep the machine clean.

Missing, damaged, or illegible safety warning labels should be replaced immediately. Safety stickers

contain important information for the protection of the operator.

Maintenance jobs must be carried out in clean and dry environment (e.g. in a workshop).

3.13 Personal Protective Equipment

NOTICE

To prevent personal injury when handling this machine, personal protective equipment

must be worn when working on or around this machine.

Pictogram Significance Description

Wear safety shoes! Safety shoes provide protection from bruises, falling

objects, and slipping.

Wear protective gloves! Protective gloves provide protection from abrasion,

cuts, punctures, and hot surfaces.

Wear ear protection! Ear protection provides protection from permanent

hearing impairment.

NOTICE

With this machine, the permissible, country-specific noise limit (personal rating level) may

be exceeded. Therefore, ear protection must be worn. For exact values regarding noise

emissions, refer to Technical Data section.

When wearing ear protection, remain alert because your ability to hear noises such as

screams or signal tones is restricted.

Wacker Neuson recommends always wearing ear protection.

3.14 Safety devices

Safety devices protect the user of this machine from being exposed to existing hazards. These are

barriers (separating protective devices) or other technical measures. This prevents the user from being

exposed to a danger. The source of danger will be eliminated in certain situations or the danger will be

reduced.

12 100_0202_si_0008.fm

Page 13

This machine has the following safety equipment:

1

3

2

1

3

Item Description Item Description

1 Protective frame / protective hoods 3 Emergency stop switch

2 Automatic central position of control handle

NOTICE

Always tighten loosened screwed connections with the prescribed torque setting.

3 Security

Protective frame / protective hoods

The protective frame with the protective hoods protects the operator in particular from hot engine parts

and noise.

Emergency stop switch

The emergency stop switch is used solely to switch off the machine in the case of danger. Activating the

emergency stop switch results in the machine immediately switching off. Operation can only be resumed

after unlocking the emergency stop switch.

Automatic central position of control handle

If the control handle is released in full load, it automatically returns to the central position and the

machine enters stand vibration.

3.14.1 Safety shutdown – Remote-controlled machinery

The machine is operated via an infra-red remote control. For safety reasons, it switches off

vibration and movement in the following situations:

When the operator enters the proximity area (approx. 1–2 meters from a receiving unit).

When the operator leaves the receiving area (a maximum of 20 meters from the machine).

Interruption of the clear line of sight betwee n th e re mo te con tr ol and re ce ivin g un its of the machine.

Power failure of remote control and/or machine.

3.15 Behavior in dangerous situations

Preventive measures:

Always be prepared for accidents.

Keep first aid equipment on hand.

Make sure that all employees are familiar with accident reporting, first aid, and rescue facilities.

Keep access routes clear for emergency vehicles.

Make sure that employees receive first aid training.

Measures in the case of an emergency:

Immediately take the machine out of ope ra tio n.

Remove injured and other people from the danger zone.

100_0202_si_0008.fm 13

Initiate first aid measures.

Alert rescuers.

Keep access routes clear for emergency vehicles.

Inform the person responsible at the site of application.

Page 14

4 Safety and information labels

1

2

3

4

56

7

7

8

9

10

0219175

0216633

0

2

2

0

0

0

0

0216635

4 Safety and information labels

WARNING

Illegible symbols

Over time, labels and signs on the machines can become dirty or otherwise

unrecognizable.

Keep all safety, warning, and operating instructions on the machine in a legible

condition.

Replace damaged labels and signs immediately.

The following labels are found on and in the machines:

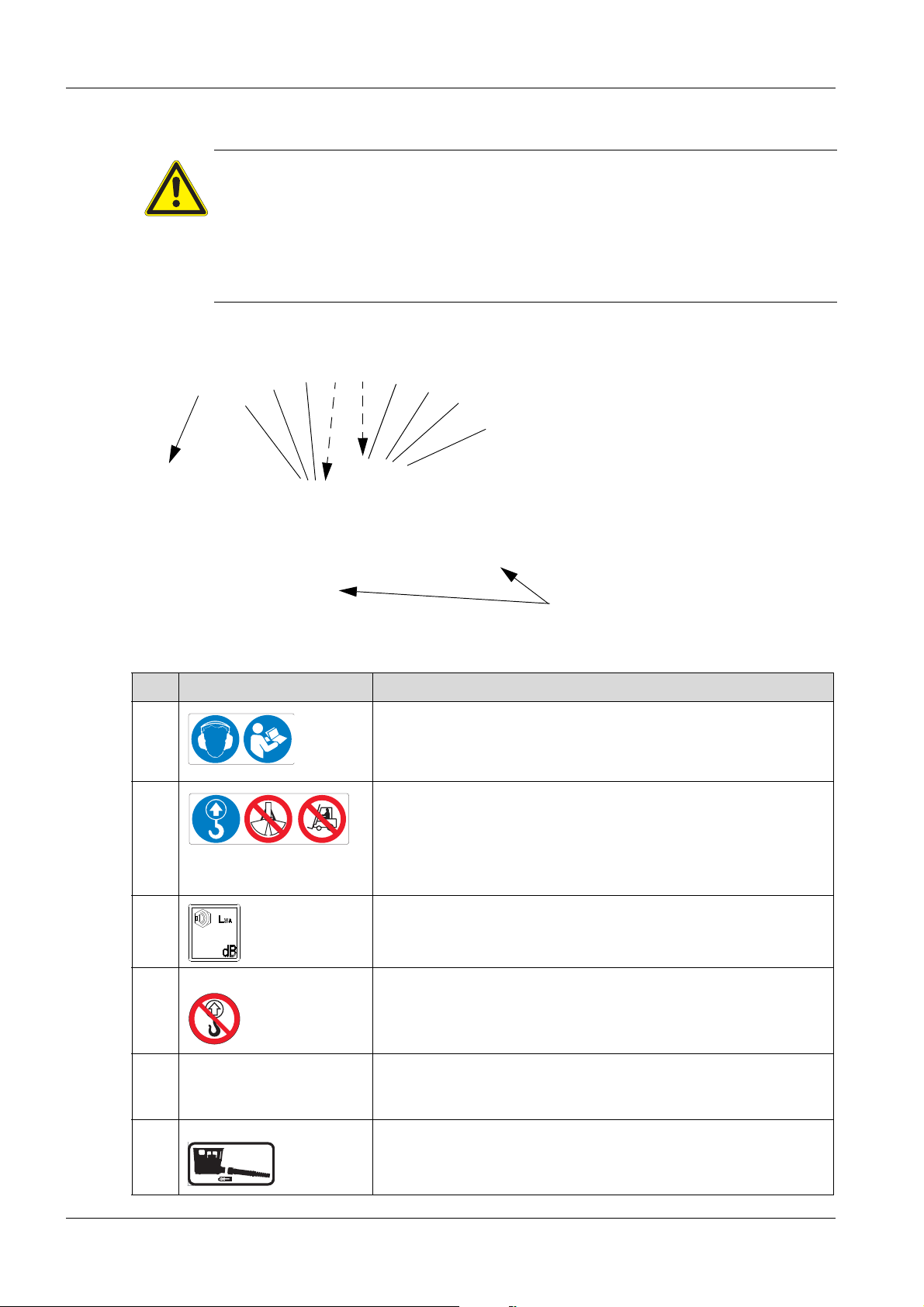

Item Label Description

1 Use personal protection equipment in order to prevent injuries and

health hazards.

Ear protecti on.

Read operator's manual.

2 Falling machines can cause serious injury.

Only lift machine at the central lifting point with certified lifting gear

and tackle (safety load hook).

Do not lift the machine on the central lifting point with an excavator

bucket.

Do not lift the machine on the central lifting point with a forklift.

3 Guaranteed sound power level.

4 Center pole machines Falling machines can cause serious injury.

Do not lift the machine with the control handle or center pole.

5 The coolant is under pressure.

6 Remote controlled machines

Hot coolant can spurt out and cause injury from scalding.

Only open the cover of the radiator after the engine has cooled down.

Label identifies the remote control in the bracket.

Label identifies the connection of the charging cable for charging.

14 100_0202_ls_0009.fm

Page 15

Item Label Description

0219261

WARNING

WARNUNG

ADVERTENCIA

ADVERTISSEMENT

0219176

0207747

2

1

7 US Machines Warning.

8 Closing the protective hood can lead to crushing wou nds.

Wh en closing the protective hood, do not grab between the machine

and the protective hood.

9 Warning against hot surface.

10 Tie-down lugs.

4.1 Safety and information labels on the remote control

The following labels are found on the remote control:

4 Safety and information labels

Item Label Description

1 US Machines To prevent interfere nce of the infrared transmission and

possible machine malfunction, do not attach to housing.

Clean before transmitter and receiver eye before

commissioning!

Clean remote control and receiving unit before

commissioning!

2 US Machines To prevent damage and possible malfunction of the

transmitter unit, do not open housing! See operator's manual!

100_0202_ls_0009.fm 15

Page 16

5 Setup and function

5 Setup and function

5.1 Standard package

The machine is delivered fully assembled and is ready for operation out of the box.

The standard package includes:

Vibratory plate

Remote control (optional)

Operator's manual

Manual for machine configuration (includes PIN data of the machine)

5.2 Application areas

The vibratory plate is used for compacting soil. It is used in gardening and landscaping as well as civil

engineering, road construction, and paving.

5.3 Short description

The water-cooled drive motor in the upper mass hydraulically powers the eccentric weight of the base

plate.

The exciter is designed as a centrally mounted exciter This principle enables the modification of the

direction of oscillation (by adjusting the eccentric weights) and thus the movement of the machine

(forwards, in reverse or on-the-spot vibration).

For the exciter of the remote controlled machine, eccentric weights can be individually adjusted in order

to allow steering movements. In addition, spot vibratio n ca n be adjusted.

The radiator reduces the temperature of the engine coolant as well as that of the hydraulic oil.

The intake air is aspirated in the cold area between the radiator and the re ar protective hood and purified

via an air cleaner equipped with a pre-cleaner.

The muffler discharges exhaust fumes from the front.

To start the drive motor automatically, the glow plugs are preheated. The spee d of the drive motor is

controlled via a lifting magnet. The machine is switched off via an electrically controlled solenoid valve

on the fuel filter.

The electrical control unit is located in the electrical box.

The operator’s controls are located at the electrical box and at the center pole head.

The maintenance-free starter battery is located below the bracket for the remote control.

The machine is controlled with the center pole. For the remote controlled machine, it is controlled

exclusively via the remote control.

5.3.1 Remote-control vibratory plate

The machine is controlled exclusively by the remote control.

Within the receiving area, the commands of the remote control are transmitted to the machine via

infrared signal.

For trouble-free transmission of the infrared signal, t he remote co ntrol must always be aimed d irectly at

one of the receiving units of the machine.

The following commands are possible with the remote control:

Start engine.

Move machine with simultaneous vibration.

Switch spot vibration on and off.

Move machine slow or fast.

Switch off engine.

Infrared system

If the remote control has been activated by pressing the ON/OFF switch, it permanently sends infrared

signals to the respective receiving unit of the machine.

The receiving unit of the machine converts the infrared signal into an electrical signal. The control

electronics the process the electrical signal and control the machine in accordance with the control

command.

16 100_0202_sf_0010.fm

Page 17

5 Setup and function

1

2

2

3

3

In order for the machine to be able to execute the control commands, the remote control and machine

must be set to the same transmission channel.

Each machine has its own address for the transmission channel. Upon delivery, the transmitter unit is

set to the address of the machine and will only work with this machine. If the transmitter unit operates

another machine, this can be adjusted, see Setting the transmission channel (remote control) chapter.

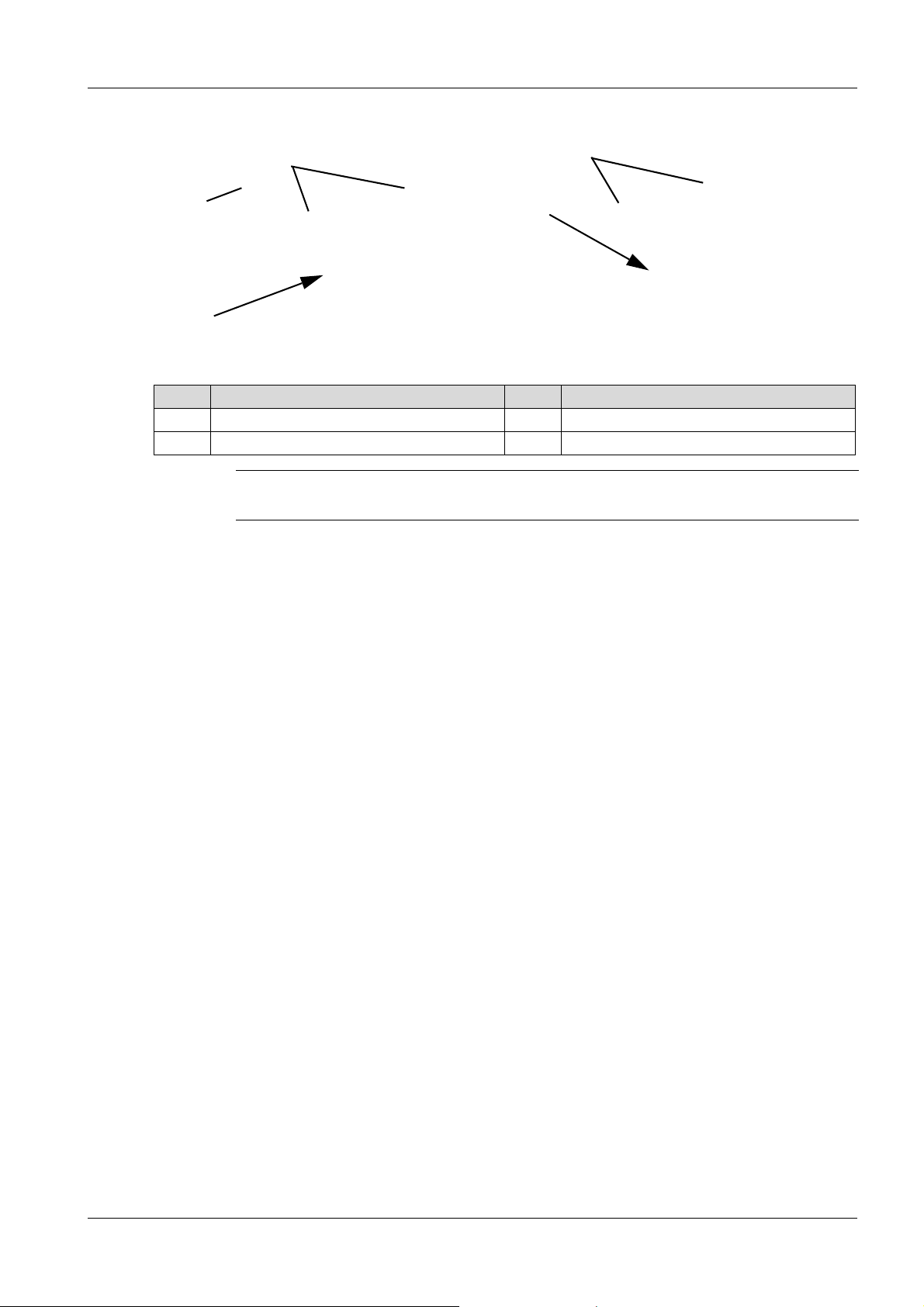

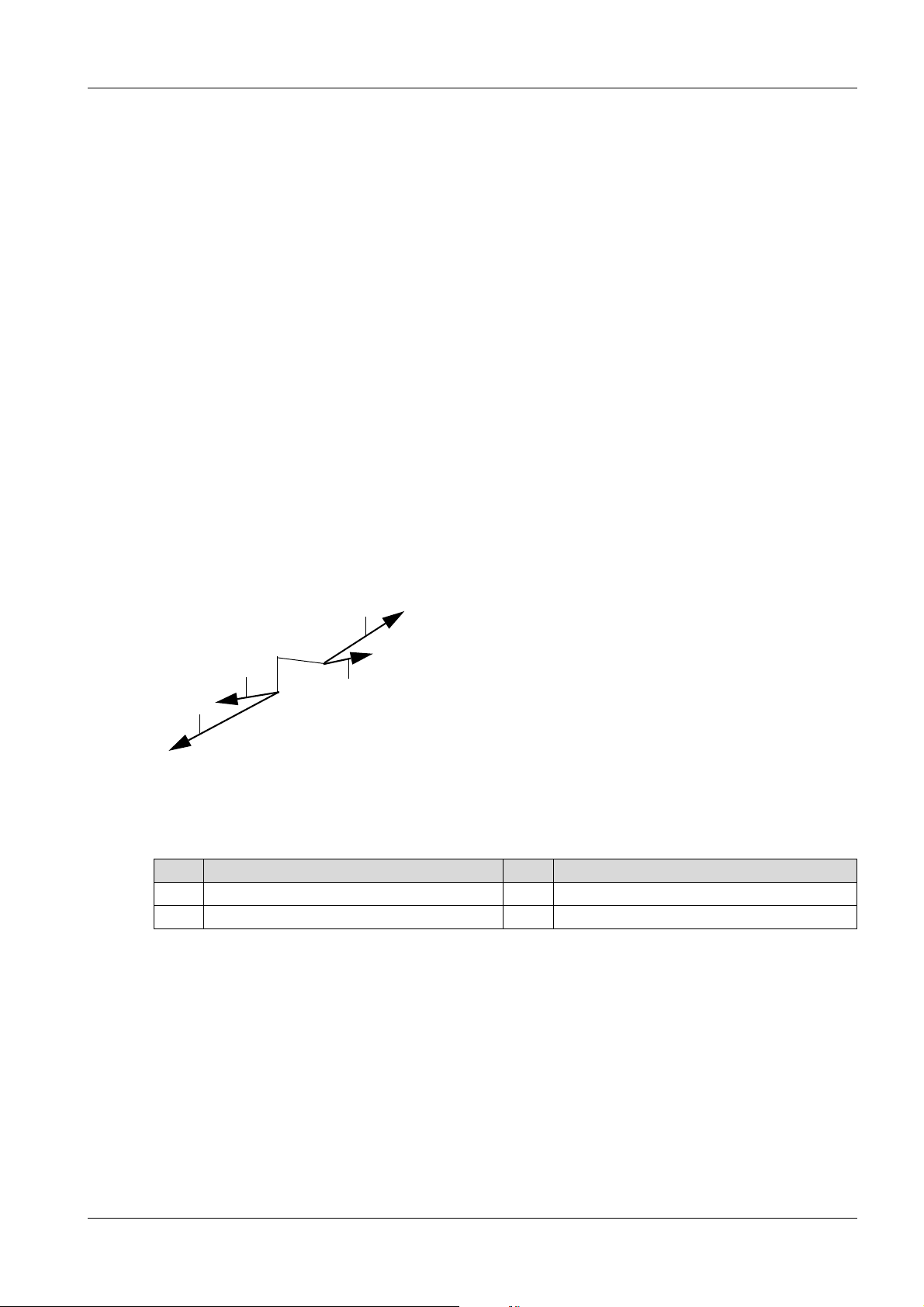

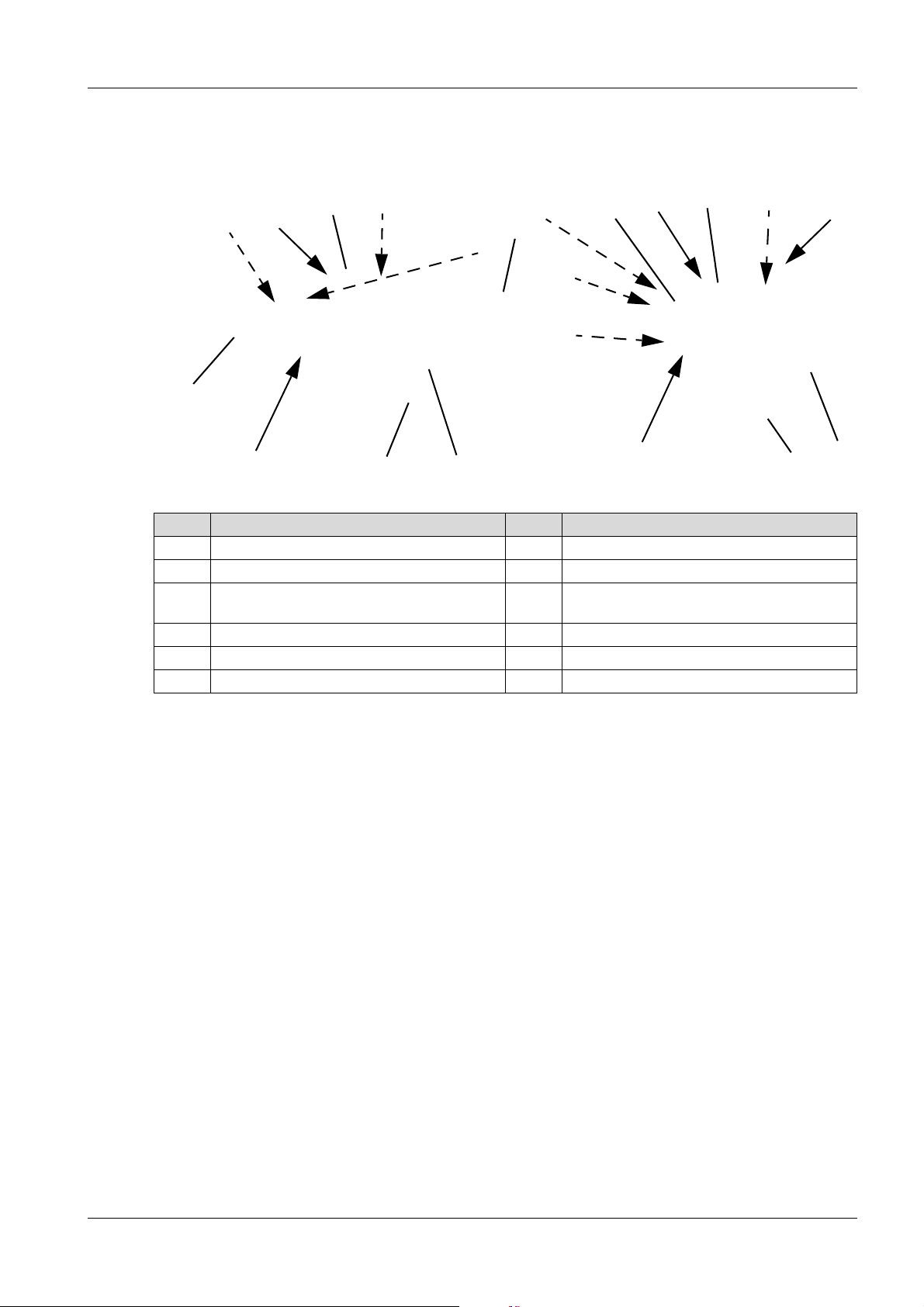

Receiving area

Operation is only possible when the machine is within the receiving area. The receiving area is

approximately 20 meters from a receiving unit of the machine.

Within the receiving area, there must always be a cle ar line of sight b etween the remote control and th e

machine. If there is no clear line of sight, the machine will cease all vibration and movement.

Outside of the receiving area, the machine will not receive the commands. The machine will stop

vibrating and moving.

Proximity area

If the machine comes within 1–2 meters (proximity area) of the operator, it will cease all vibration and

movement. Once the operator leaves the proximity area, the machine is once again able to receive

commands.

If the operator is laterally closer than 1–2 m from the machine or if the infrared signals of the remote

control are transmitted via reflection, a stopping of the vibration and movement is not guaranteed.

If another person comes within 1–2 meters (proximity area) of the machine, the machine will not cease

vibration and movement. The shutdown in the proximity area only works in conjunction with the remote

control unit.

Item Designation Item Designation

1 Receiver unit (front, rea r) 3 Receiving area

2 Proxi mity area

5.3.2 Diagnostic system

The diagnostic system of the machine consists of control electronics and sensors that monitor various

components of the machine.

If the diagnostic system detects a fault or an error, this is signaled to the receiving unit by solid or flashing

red lights. A fault indication with error code appears on the display.

Each error code stands for a specific fault. The diagnostic system can distinguish between approx. 30

error codes.

In case of serious faults, the error code is entered into the error memory, and the machine will

automatically switch off the motor or deactivate itself.

100_0202_sf_0010.fm 17

Page 18

5 Setup and function

5.3.3 Machine configuration system

In the machine configuration system, machine parameters can be changed by the user (e.g. switching

an activation PIN on or off).

5.3.4 Machine protection – installation (optional)

The acceleration load of the upper mass is monitored via a sensor. When a threshold value

corresponding to an operation of the vibratory plate on an extremely ha rd surface ( concrete, asphalt) is

exceeded, a warning is given to the operator that the vibrator plate is overloaded. This warning is that

the control lamp on the center pole head or the receiving unit will flash red.

In addition, the machine will respond in one of the following ways (adjustable in the machine

configuration):

Only an entry in the error memory.

Lowering the excitation speed.

Shutdown of the machine with entry in the error memory.

Switch-over to slow mode.

5.3.5 Compatec system (optional)

The Compatec system is integrated into the rear protective hood and is located within the ope rator’s lineof-sight. The display, which consists of eight light-adjusting LEDs, displays the relative compaction

progress while driving by successively lighting up. When the number of illuminated LEDs no longer

increases, this means that no further compaction can be achieved with the machine. The operator can

finish the work and avoid unnecessary passes.

The overload display indicates if the machine is being operated on too hard of a surface. The operator

is notified of this through an alternating flashing of the LED's.

The Compatec system is suitable for all highly compactable and mixed (well graded) soils.

5.4 Versions

This operator's manual covers the following models:

Versions Description

r Remote start

m Machine protection – installation

c Compatec system

NOTICE

The Compatec system only supports soil compaction and does not replace the

professional measuring of soil density by an expert.

18 100_0202_sf_0010.fm

Page 19

6 Components and operator's controls

2

3

1

5

6

7

11

4

1

2

3

5

6

7

8

8

9

11

10

6.1 Components

6 Components and operator's controls

Item Designation Item Designation

1 Drive motor 7 Eyelet for padlock

2 Upper mass 8 Receiving units

3 Base plate 9 Bracket for remote control and charging

cable

4 Center pole 10 Bracket for operator's manual

5 Fuel tank 11 Nameplate

6 Central lifting point

Center pole

The center pole can be adjusted to the optimum working height.

Central lifting point

The central lifting point is used to lift the machine. When the overall height is a deciding factor, the central

lifting points can be folded.

Receiving units

On the remote controlled machine, there are two receiving units (front and rear) with integrated status

display. Depending on the position of the operator, the front or rear receiving unit receives the

commands of the remote controller via infrared signal.

The integrated status display uses lights and flashing signals to indicate the current opera ting status of

the machine.

To better distinguish between the front and rear of the machine, the rece iving units have different colors.

Eyelet for padlock

The rear protective hood features a lug for attaching a padlock. The machine is thus protected against

unauthorized opening of the rear protective hood as well as unauthorized operation.

Bracket for remote control and charging cable

The bracket is used to store and charge the remote control unit as well as to protect it against damage

and theft.

Bracket for operator's manual

The bracket is used to store the operator's manual.

100_0202_cp_0006.fm 19

Page 20

6 Components and operator's controls

2

3

4

5

6

7

11

8

9

10

1

11

6.2 Operator's controls

Always keep the display and operator's controls on the machine clean, dry, and free of oil and grease.

Operator's controls such as the ON/OFF switch, and throttle control handles may not be locked,

manipulated, or changed without permission.

Item Designation Item Designation

1 Hood opener 7 Vibratory rammer

2 ON/OFF switch (red) 8 Control handle

3 Display and control lamps (diagnostic and

configuration menu)

4 Adjusting key (black) 10 Footrest of center pole lock

5 Start button 11 Emergency stop switch

6 Slow/fast rocker switch

Control handle

The control handle is used to continuously regulate the speed and travel direction.

Footrest of center pole lock

The footrest of the center pole lock is used to release the center pole from the transport position so that

it can be returned to working position. The individually adjusted working hei ght is maintained.

Emergency stop switch

The emergency stop switch is used solely to switch off the machine in the case of danger. Activating the

emergency stop switch results in the machine immediately switching off. Operation can only be resumed

after unlocking the emergency stop switch.

Height adjustment mechanism of center pole

The center pole height-adjustment mechanism allows for con tinuous height adjustment in order to adjust

the center pole individually to the optimum working height. This is done by turning the star knob.

In addition, by pushing down on the star knob, the center po le can be brought into the lower position e.g.

to be able to travel through low passages. If the center pole is raised, the respective optimally adjusted

working height is once again active.

ON/OFF switch (red)

With the red ON/OFF switch, the machine is activated for starting with the start button on the center pole

head or remote control.

The machine is completely deactivated with the ON/OFF button.

20 100_0202_cp_0006.fm

9 Height adjustment mechanism of center pole

Page 21

6 Components and operator's controls

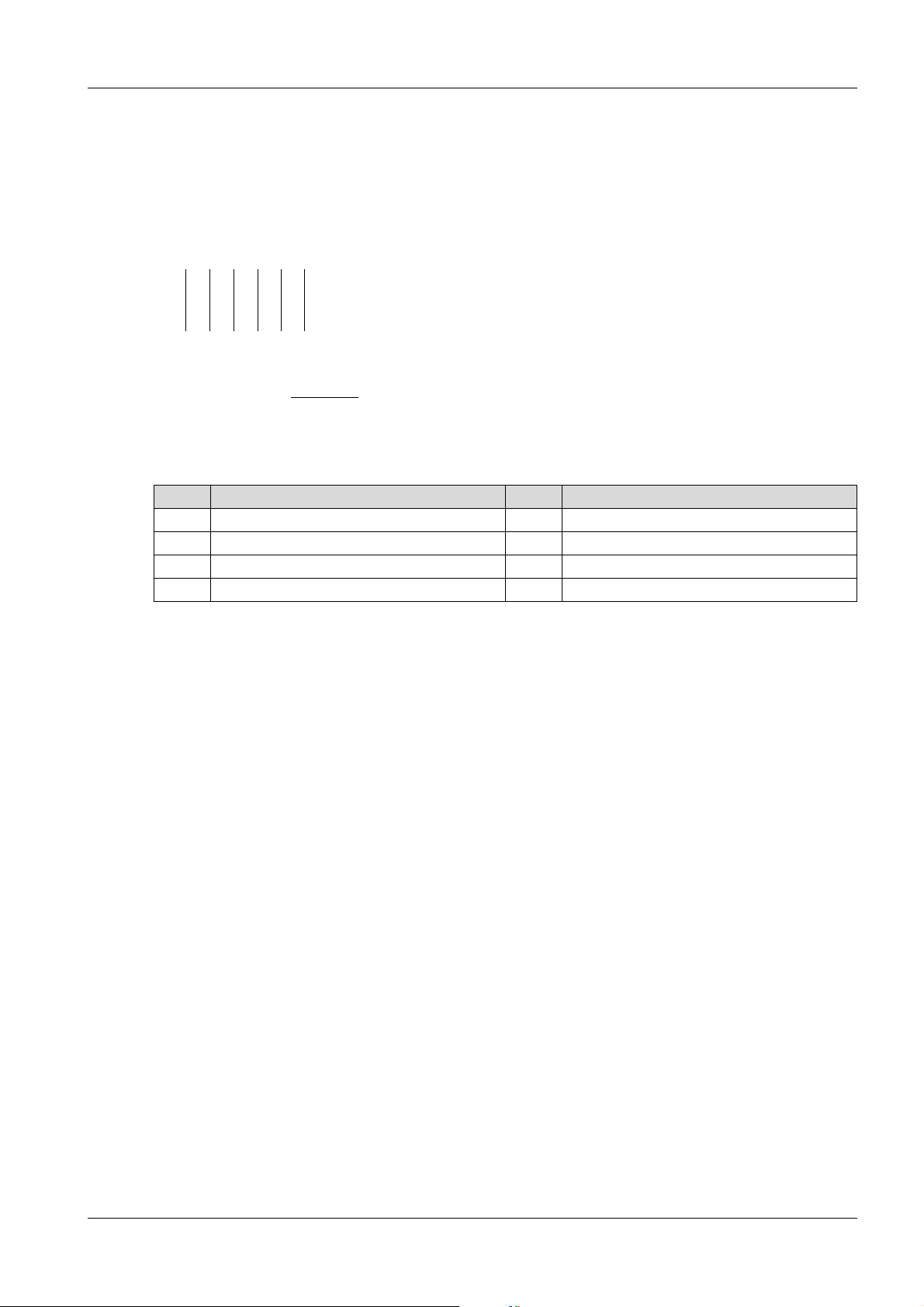

1 2 3 4 5 6

7

With the ON/OFF switch, the diagnostic and configuration menus can also be called up and menu items

can be changed.

Setting key

Digits of the activation PIN, setup PIN, or machine settings can be adjusted with the black setting key.

Display and control lamps

Item Designation Item Designation

1 Control lamp for operation 5 Control lamp for oil pressure

2 Control lamp for charging 6 Control lamp for coolant temperature

3 Control lamp for preheating 7 Display

4 Control lamp for air cleaner

Control lamp for operation

The control lamp for operation indicates whether the machine has been a ctivated via the ON/OFF switch.

The control lamp for operation lights up green when the machine h as been activated via the ON/OFF

switch.

The control lamp for operation goes out when the machine has been deactivated via the ON/OFF

switch.

Control lamp for charging

The control lamp for charging indicates whether the starter battery of the machine is being charged.

The control lamp for charging lights up red when the machine is activated.

The control lamp for charging goes out when the engine is running.

The control lamp for charging lights up red when the starter battery of the machine is no longer

charged.

Control lamp for preheating

When the engine is started, the control lamp for preheating indicates whether the glow plugs are being

preheated.

The control lamp for preheating lights up yellow as long as the glow plugs of the engine a re preheated

during starting.

The control lamp for preheating goes out when preheating is completed.

Control lamp for air cleaner

The control lamp for the air cleaner displays the mainten a nc e con d itio n of th e air cleane r.

The control lamp for the air cleaner lights up yellow when the air cleaner is dirty.

Control lamp for oil pressure

The oil-pressure control lamp indicates whether the oil pressure is sufficient.

The control lamp for oil pressure lights up red when the machine is activated.

The control lamp for oil pressure goes out when the engine is running.

The control lamp for oil pressure lights up red when the oil pressure is too low.

100_0202_cp_0006.fm 21

Page 22

6 Components and operator's controls

Diagnostics

Setup

Control lamp for coolant temperature

The control lamp for coolant temperature indicates whether the coolant temperature is within the

permissible range.

The control lamp for coolant temperature lights up red when the coolant temperature is too high.

Display

The following information is displayed in sequence:

Number of operating hours.

Transmission channel (optional)

Error statuses.

Diagnostic menu.

Configuration menu.

Diagnostic menu

In the diagnostic menu on the display, the following information about the machine can be accessed:

Overview of all detected errors (error memory).

Starter battery voltage.

Coolant temperature of the engine.

Hydraulic oil temperature (optional).

Engine speed.

Software version (SW version).

Switch test.

Transmission test.

Configuration menu

NOTICE

The operation of the configuration menu is described in the manual for machine

configuration.

In the configuration menu on the display, the following machine settings can be adjusted:

Change/activate/deactivate activation PIN of the machine.

Setting turn-off time of the machine.

Select the display language (English, German, French, or Spanish).

Adjust machine response in the case of ove rlo ad (ov erl oa d se ns or ).

Setting the hydraulic parameters/centrifugal force.

Change setup PIN.

22 100_0202_cp_0006.fm

Page 23

6 Components and operator's controls

1

1

2

33

4

8 7 6 5

11 10 9

6.3 Components and operator’s controls – remote control unit

The remote control of the DPU80r, DPU90r and DPU110r may only be used for these machines.

Item Designation Item Designation

1 Joystick (left, right) 7 Engine start button

2 Socket for charging cable 8 ON/OFF switch

3 Carrying strap 9 Control lamp for charging

4 Rechargeable battery 10 Control lamp for operation

5 Spot compaction button 11 Diagnostic control lamp

6 Button for slow/fast operation

Joystick (left, right)

By pressing the joystick, the vibration starts, and the machine moves.

ON/OFF switch

The remote control unit is switched on via the ON/OFF switch. When switching off, the remote control

and the engine are turned off.

Engine start button

The start button starts the engine.

Button for slow/fast operatio n

The slow/fast button is used to switch between slow and fast operation. Fast operation is selected by

default.

Quick mode – operating mode for compa ctin g .

Slow operation – mode with reduced engine speed to traverse highly compacted or hard surfaces.

Spot compaction button

The spot vibration button must remain pressed so that the machine compresses on the spot.

Carrying strap

The carrying strap is used to hang the remote control.

Rechargeable battery

The rechargeable battery powers the remote control unit. The rechargeable battery can be recharged

with the charging cable of the machine or with an external battery charger.

Control lamps

Charging

The control lamp for charging lights up green when the rechargeable battery is charging.

The control lamp for charging goes out once the rechargeable battery is charged.

100_0202_cp_0006.fm 23

Page 24

6 Components and operator's controls

Operation

Operation control lamp flashes green when the remote control is switched on.

The control lamp for operation flashes green when the remote control is switched on.

The control lamp for operation flashes red when the charge situation of the rechargeable battery is

low.

The control lamp for operation lights up red when the rechargeable battery is discharged.

Diagnostics

The control lamp for diagnosis briefly flashes green when a joystick is moved or a button on the

remote control unit is pressed.

24 100_0202_cp_0006.fm

Page 25

7 Transport

1

2

7 Transport

WARNING

Improper handling may result in injury or serious material damage.

Please read and follow all safety instructions in this operator's manual.

DANGER

Danger from falling.

Falling machines can cause serious injury e.g. through crushing.

O nly us e suitable an d te ste d lifting gear and tackle (safety load hooks) of sufficient

lifting capacity.

Only lift the machine from the central lifting point.

Reliably sec ure the machin e to th e lifting gear.

Do not lift the machine on the central lifting point with a for klift or excavato r bu cke t.

Do not lift the machine at the control handle.

Evacuate danger zone while lifting, do not stop under suspended loads.

WARNING

Risk of fire and explosion from fuel.

Escaping fuel may catch fire and cause serious burns.

Lift and transport the machine upright.

7.1 Loading and transport

Carry out preparations

Item Designation Item Designation

1 Center pole 2 Center pole lock

When loading and transporting, the center pole must be locked into place by engaging the locking the

center pole lock in the vertical position.

100_0202_tr_0009.fm 25

Page 26

7 Transport

1

2

Lift machine

Item Designation Item Designation

NOTICE

Appoint a specialist flagman for a safe lifting operation.

1 Central lifting point (attachment point) 2 Tie-down lugs

1. Place the central lifting point in the vertical position.

2. To lift the motor, hang suitable tackle at the central lifting point.

3. Carefully load machine into or onto a stable means of transport.

4. After loading the machine, lash down the machine to prevent it from rolling off, slipping, or tipping

over. Attach tie-down lugs to the designated lashing points.

26 100_0202_tr_0009.fm

Page 27

8 Operation and use

1

2

WARNING

Improper handling may result in injury or serious material damage.

Please read and follow all safety instructions in this operator's manual.

8.1 Before commissioning

8.1.1 Inspection before commissioning

Open protective hoods

8 Operation and use

Item Designation Item Designation

1 Hood opener of rear protective hood 2 Hood opener of front protective hood

1. Pull hood opener of rear protective hood until it is unlocked. Completely open protective hood.

2. Pull hood opener of front protective hood until it is unlocked. Completely open protective hood.

Complete the following ins p ec ti o ns :

Check the machine and components for damage. If there is any visible damage, do not use the

machine and immediately contact the Wacker Neuson service.

Ensure that loose packaging material has been removed from the machine.

Ensure that there are no loose items unde r th e protective hoods, e.g. gloves or tools.

Check fuel level.

Check the engine oil level.

Check hydraulic oil level.

Check the fuel lines for leak tightness.

Check to ensure the screwed connections are firmly seated.

Ensure that the receiving units are free of dirt accu mu la tio n.

NOTICE

Perform control procedures according to the Maintenance chapter. If necessary, top off

missing fuel, lubricants and coolants, see chapterTechnical Data.

100_0202_op_0011.fm 27

Page 28

8 Operation and use

1

2

1

2

3

4

8.1.2 Set center pole

Item Designation Item Designation

1 Center pole 2 Star knob

The optimum working height of the center pole can be adjusted by turning the star knob.

8.1.3 Remote controlled machine

Remove remote control from the bracket

Item Designation Item Designation

1 Remote control 3 Charge cable

2 Bracket for remote control 4 Bracket for charger cable

1. Pull hood opener of rear protective hood until it is unlocked.

2. Completely open the rear protective hood with the hood opener.

3. Unscrew the charging cable from the remote control.

4. Place charging cable in the bracket.

NOTICE

Improper handling can result in damage to the charging cable.

When placing charging cable in the bracket, make sure it will not get pinched when

closing the protective hood.

5. Screw screwed nose cap on the connection socket of the remote control.

6. Remove the remote control from the bracket.

Check remote control

Remote control and carrying strap are undamaged.

Remote control is free of dirt.

28 100_0202_op_0011.fm

Page 29

8.2 Notes about operation

1

3

2

4

WARNING

Danger of tipping

There is a serious risk of injury from slipping or tipping over of the machine.

Near edges, at least 2/3 of the machine must be on a load-bearing surface.

If not, decommission the machine and lift back on a load-bearing surface.

WARNING

Health hazard from exhaust fumes

The exhaust fumes of this engine contain chemicals, which the state of California

knows can cause cancer, birth defects or other reproductive damage.

Operation on sloped surfaces

Always stand above the machine within the area of a slope.

Only approach gradients from below (a gradient that can be easily driven up can also be driven down

without any risk).

Do not stand in the direction of descent of the machine.

Do not exceed the maximum allowable slanting position (see Technical Data) chapter.

Only operate the machine for a short time in maximum allowable slanting position.

8 Operation and use

NOTICE

If the maximum permissible slanting position is exceeded, this results in a failure of the

engine lubrication and therefore inevitably causes a defect of important engine parts.

Remote-controlled machinery – locational info rma tio n

Item Designation Item Designation

1 Front (transparent receiving unit) 3 Rear (rear receiving unit)

2 Right 4 Left

100_0202_op_0011.fm 29

Page 30

8 Operation and use

1

2

3

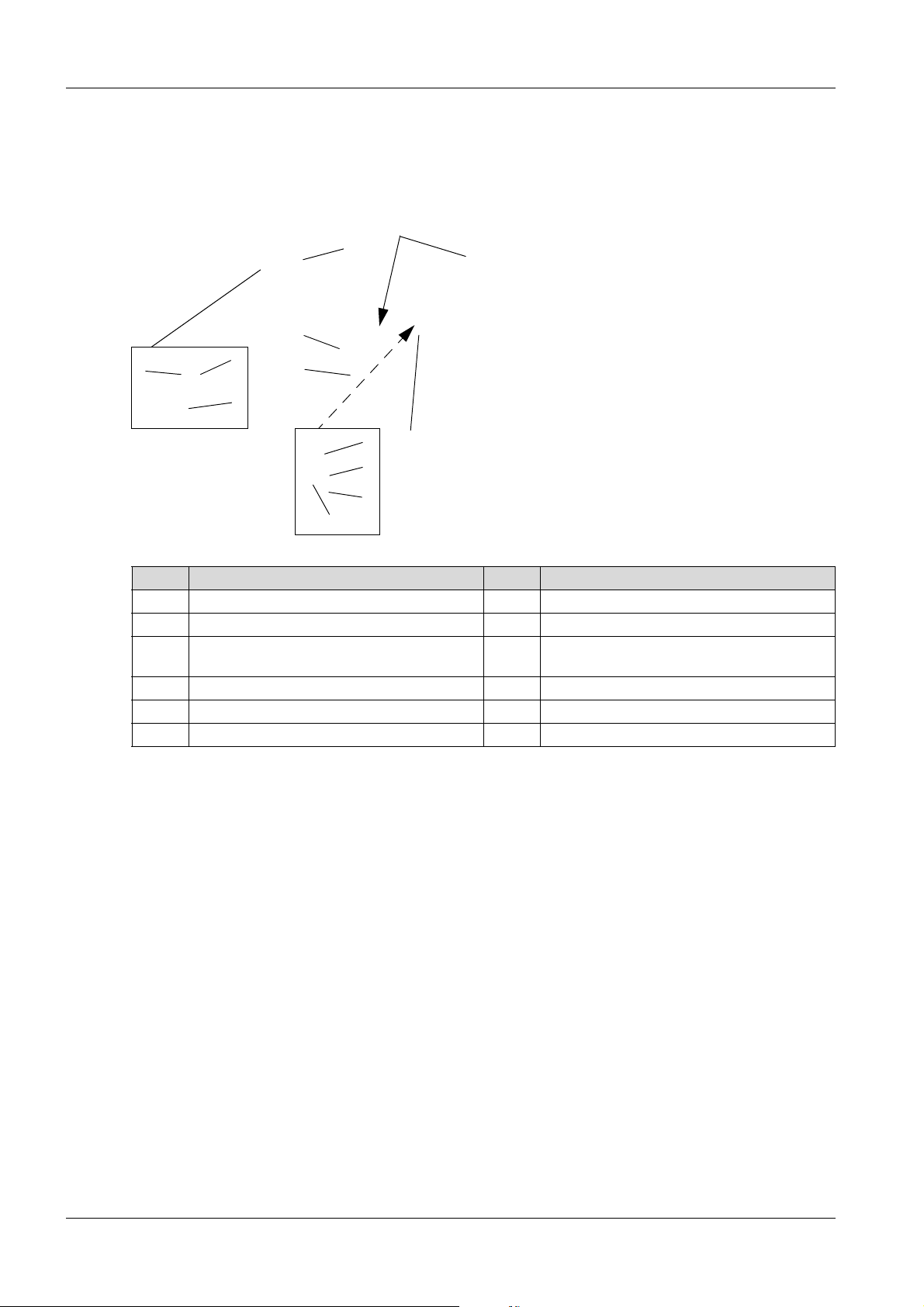

Remote-controlled machinery – direction of movement

The direction of movement of the machine is self-contained from the position of the operator. If the

joystick of the remote control is pressed forward, the machine moves always forward.

Operator behind the machine Operator in front of the machine

WARNING

Mixing up the direction of movement of the machine poses a danger of crushing for others

Operate the machine from behind and maintain a minimum safety distance of at least

2 meters.

Ensure that no other individuals are in the proximity area or working area of the

machine.

If the operator is located behind the machine and

presses both joysticks forward – the machine

moves forward away from the operator.

8.3 Commissioning

DANGER

Fire hazard

Jumper cable sprays are highly flammable; they can ignite and cause severe burns.

Do not use jumper cable sprays.

8.3.1 Activate machine

If the operator is located in front of the machine

and presses both joysticks forward – the machine

moves backward away from the operator.

Item Designation Item Designation

1 Control lamps 3 ON/OFF switch (red)

2 Display

1. Pull hood opener of rear protective hood until it is unlocked.

2. Completely open the rear protective hood with the hood opener.

3. Press the ON/OFF switch on the machine.

30 100_0202_op_0011.fm

Page 31

When the machine is activated, all control lamps light up for approx. 1 second.

1

2

3

4

0XXX

The following are displayed in sequence:

Auto-engaging status.

The transmission channel set on the machine (optional).

Number of operating hours.

4. Close and lock rear protective hood into place.

Enter activation PIN

NOTICE

PIN entry is deactivated by default. If the machine should be secured by an activation PIN,

this must be set in the configuration menu; see Manual for Machine Configuration.

The activation PIN should always be kept secret and never be listed on the machine or

remote control.

8 Operation and use

Item Designation Item Designation

1 Digit of the activation PIN 3 ON/OFF switch (red)

2 Position of the activation PIN 4 Adjusting key (black)

NOTICE

The engine can only be started if the correct activation PIN has been entered with the

remote control.

1. When the display prompts you to enter the activation PIN, press the ON/OFF switch.

2. Enter activation PIN:

NOTICE

If an incorrect PIN is entered four times in succession, you must wait five minutes before

re-entering the PIN. During the wait time, the request to wait is displayed.

To select the next position, press the ON/OFF switch on the machine.

To select the digit, press the selection button repeatedly until the correct value is achieved.

3. Once all of the digits of the activation PIN have been selected, press the ON/OFF switch of the

machine.

100_0202_op_0011.fm 31

Page 32

8 Operation and use

1

2

3

1

2

8.3.2 Commission machine (center pole)

Item Designation Item Designation

1 Start button 3 Vibratory rammer

2 Control lamp

1. The red control lamp on the center pole flashes briefly at intervals of 5 s to signal readiness to start.

2. The vibration switch must be pressed to start (vibration off).

3. Briefly press start button of the center pole – the motor will start automatically.

NOTICE

The starting process can take up to 2 minutes. As long as the control lamp is red, the

automatic start up runs. Depending on the operating temperature of the engine, the gl ow

plugs are optionally preheated and warmed up.

8.3.3 Commission machine (remote control)

Switch on remote control unit

Item Designation Item Designation

1 Control lamp for operation 2 ON/OFF switch

1. Press the ON/OFF switch of the remote control unit Operation control lamp flashes green when the

remote control is switched on.

NOTICE

If the operation-control lamp flashes or lights red, recharge the rechargeable battery.

2. Hang the remote control with the carrying strap.

32 100_0202_op_0011.fm

Page 33

8 Operation and use

1

1

2

Start engine

Item Designation

1 Engine start button

1. Directly aim remote control towards a receiver unit.

2. Briefly press start button of the remote control – the motor will start automatically. When the receiving

units flash yellow, the machine is ready for operation.

NOTICE

The starting process can take up to 2 minutes. As long as the receiving units light red, the

automatic startup will run. Depending on the operating temperature of the engine, the glow

plugs are optionally preheated and warmed up.

8.3.4 Machine with Compatec system (optional)

Item Designation Item Designation

1 Compatec - display unit 2 LEDs/light progress bar

1. During the first few seconds after starting the machine, a light progress bar appears on the Compatec

display unit.

2. LEDs light up starting from left to right.

NOTICE

If all LEDs light up, the Compatec display unit is fault-free. The LEDs will then switch off

one after the other.

3. All LEDs will briefly light up again at reduced brightness.

4. The sensor is thus successfully tested and the Compatec system is ready for operation.

NOTICE

If the brief lighting up of all LEDs does not occur, the sensor has not been successfully

tested. See Troubleshooting chapter.

8.4 Operation

In accordance with the intended purpose, the operator should stand behind the machine.

Guide and steer machine using the control handle.

Control machine with remote control.

100_0202_op_0011.fm 33

Page 34

8 Operation and use

1

2

3

4

1

8.4.1 Operating machines with center pole

Item Designation Item Designation

1 Vibratory rammer 3 Forward

2 Central position of control handle 4 Reverse

1. Pull vibration switch

2. Select travel direction and speed with the control handle.

Speed display by lighting of the slow/fast-rocker switch or flashing for intermediate positions.

Switch slow/fast mode on and off

Item Designation

1 Slow/fast rocker switch

Slowly press the slow/fast switch up to increase the speed.

Slowly press the slow/fast switch down to reduce the speed.

If the control lamp lights up, the maximum speed is set.

If the control lamp lights up, the speed is lower than the maximum.

If the control lamp lights up, the lowest stage is reached.

NOTICE

To switch from maximum to minimum (or vice versa) speed, the slow/fast operation button

must be presser for approx. 2–3 s.

34 100_0202_op_0011.fm

Page 35

8.4.2 Operating a remote-controlled machine

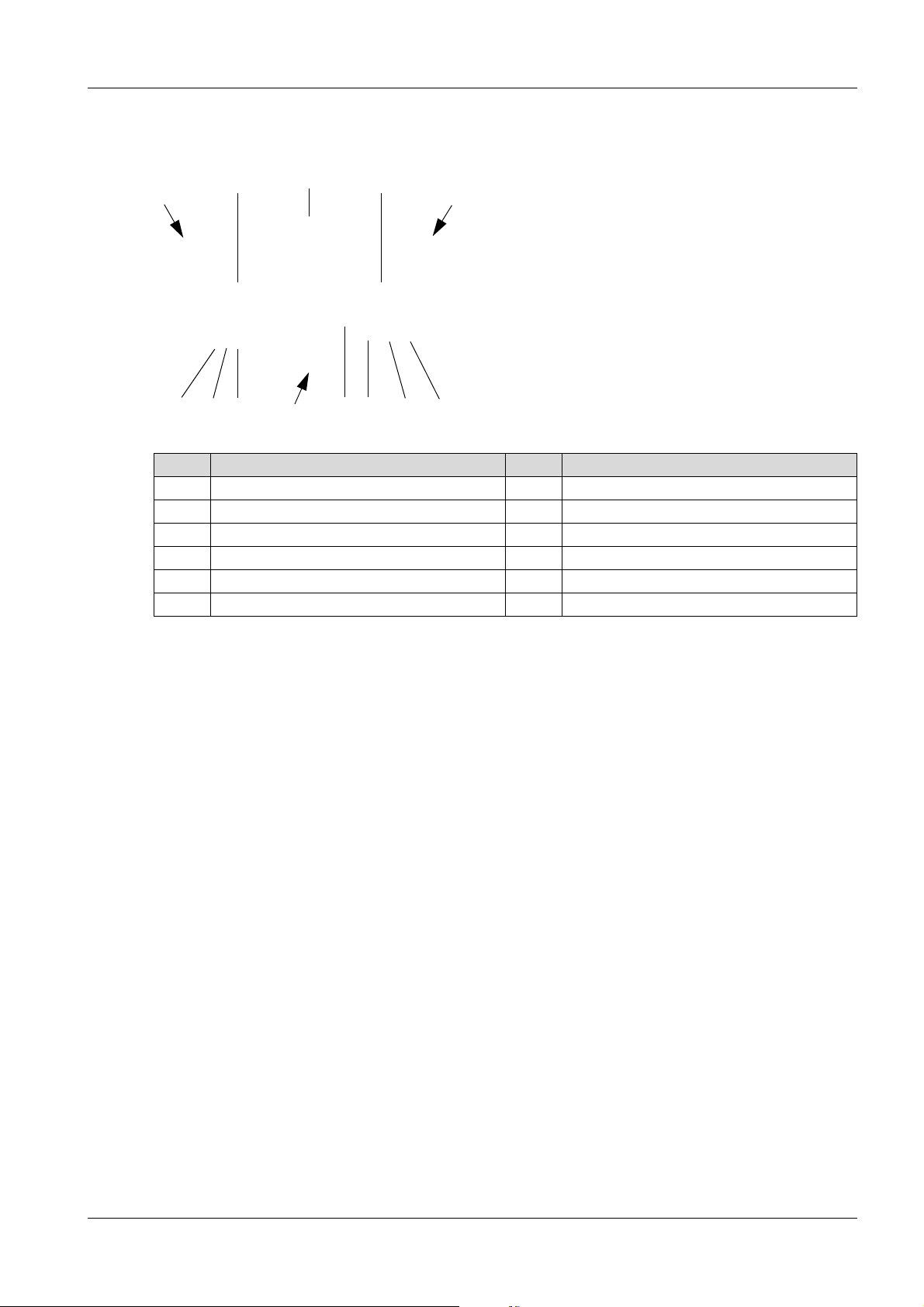

The following table shows how the machine moves when the respective joystick of the remote

control is operated:

Forward Reverse

Forward left turn Forward right turn

Reverse left turn Reverse right turn

Left stand rotation Right stand rotation

8 Operation and use

No movement

Moving and stopping the machine

1. Press the joystick of the remote control to the desired position and hold. The machine starts vibrating

and moves in the desired direction – the further the joysticks are pushed forward or backward, the

faster the machine moves.

2. Release both joysticks of the remote control. The machine stops moving and vibr ating – after approx.

6 s, the engine switches to idle.

Switch slow/fast mode on and off

NOTICE

Fast operation is selected by default.

The slow mode is only intended for traversing highly compressed or hard surfaces.

1. Press slow/fast mode button to switch between slow and fast operation.

When the receiving units flash yellow, the machine is in slow mode.

Switching stand vibration on and off

1. Pressing and holding stand vibration button – The machine compresses on the spot without moving

in one direction.

2. Releasing stand vibration button – The machine will return to normal operating condition.

8.4.3 Machine protection – installation (optional)

To protect the machine, a warning is activated in the event of an overload:

The red control lamps on the center pole flash.

The receiving units flash red.

Alternating flashing of the LEDs of the Compatec display unit (optional).

In addition, a machine response can be set in the configuration menu:

Switching off the machine.

Switch-over to slow mode.

Reduced power operation.

100_0202_op_0011.fm 35

Page 36

8 Operation and use

2

1

8.4.4 Read the Compatec display unit (optional)

This display roughly indicates the progress of the compaction.

NOTICE

The functionality of the machine protection installation is integrated. See the chapter

Machine protection installation.

NOTICE

The brightness of the LED automatically adjusts to the light conditions of the workin g area.

The number of LEDs lit is proportional to the soil density, more illuminated LEDs corresponds to a

higher soil density.

NOTICE

It is possible to detect non-compactable material if the spot is longer than one meter.

In the case of abrupt change from high to low-compacted soil (or vice versa), there is a

slow increase or decrease of the LEDs.

NOTICE

The LED bar utilization of the Compatec display unit is tailored to soils that can be

compacted easily. A soil density that is well beyond the achievable values of soils that can

be compacted easily is signaled by the flashing of all LEDs.

NOTICE

If the machine is operated in reduced power mode

Preselected using the slow/fast rocker switch or button.

Overload setting in the configuration menu.

No LEDs of the Compatec display unit are illuminated.

8.5 Decommissioning

8.5.1 Decommissioning the machine (center pole)

Item Designation Item Designation

1 Vibratory rammer 2 Start button

36 100_0202_op_0011.fm

Page 37

1. Press vibration switch – Vibratio n switches off and machine stops.

1

2

2. Press the start button – the engine switches off.

NOTICE

The Compatec display unit automatically switches itself off once the machine is turned off.

8.5.2 Decommissioning the machine (remote control)

Switch off remote control and engine

8 Operation and use

Item Designation Item Designation

1 Control lamp for operation 2 ON/OFF switch

1. Release both joysticks of the remote control.

2. Directly aim remote control towards a receiver unit.

NOTICE

If the remote control is not directly aimed at the receiving unit, only the remote control will

be switched off.

3. Press the ON/OFF switch of the remote control to turn off the engine and remote control – the

operation control lamp switches off when the remote control is switched off.

NOTICE

The remote control automatically switches off after about 10 minutes if no control of the

joystick or touch controls takes place.

8.5.3 Deactivate machine

WARNING

Operation of the machine by unauthorized persons can lead to serious injur y.

Ensure that no unauthorized persons have access to the machine and remote control.

Always keep the remote control in a safe place, e.g. within the locked machine.

100_0202_op_0011.fm 37

Page 38

8 Operation and use

1

2

3

1

Item Designation Item Designation

1 Control lamps 3 ON/OFF switch (red)

2 Display

1. Open rear protective hood.

2. Press the ON/OFF switch on the machine in order to deactivate it. If the o peration and re ceiving unit

control lamps turn off, the machine is deactivated.

3. Charge rechargeable battery of the remote control with the charger cable.

4. Close rear protective hood.

NOTICE

If the machine is not deactivated, it will automatically deactivate after about 15 minutes

(center pole machine) or after about 1 hour (remote controlled machine).

The deactivation time can be set in the configuration menu.

Decommissioning the machine in an emergency situation (emergency stop)

NOTICE

The emergency stop switch is a safety device and sh ould only be us ed for the immediate

switch off of the machine in the case of an emergency situation.

Item Designation

1 Emergency stop switch

1. Pressing the emergency stop switch – The machine will immediately stop moving and vibrating and

will automatically deactivate itself.

To unlock, turn the emergency stop switch to the left. The machine can then be re-activated.

38 100_0202_op_0011.fm

Page 39

8.5.4 Charge rechargeable battery (remote control)

1

2

3

4

5

NOTICE

Charging the battery at temperatures below 0°C may not be possible.

Charging rechargeable battery with charging cable

NOTICE

After connecting the charging cable to the remote control, the rechargeable battery is

loaded. Overcharging the battery is not po ssib le ; the cha rgi ng cab le mu st not be

disconnected from the remote control after charging. Note that after a longer downtime/

service life of the machine, the rechargeable batte ry charges more slowly. It ma y need to

be recharged.

A charging time of 15 min is sufficient to operate the machine for about 1 h.