Page 1

Operator's manual

Vibratory plate

DPU

4545, 5545, 6555

Model DPU

Document 5100009744

Issue 07.2016

Version 04

Language en

Page 2

2 100_0000_0001.fm

Copyright © 2016 Wacker Neuson Produktion GmbH & Co. KG

Printed in Germany

All rights are reserved, in particular the world-wide applica ble co pyrig ht, right of duplication and r ight o f

distribution.

This document may only be used by the recipient for the intended purpose. The docu ment may not be

reproduced entirely or partially, or translated into any other language.

Reproduction or translation, even extracts thereof, only with written approval of Wacker Neuson

Produktion GmbH & Co. KG.

Any breach of the statutory provisions, in particular the protection of copyright, will lead to civil and

criminal prosecution.

Wacker Neuson Produktion GmbH & Co. KGis constantly working on the impr ovement of its products as

part of the technical further development. Therefore, we reserve the right to make changes to the

illustrations and descriptions in this documentation without incurring any obligation to make changes to

machines already delivered.

Errors excepted.

The machine on the cover may have special equipment (options).

Manufacturer

Wacker Neuson Produktion GmbH & Co. KG

Preussenstrasse 41

80809 Munich

www.wackerneuson.com

Tel.: +49-(0)89-354 02-0

Fax: +49-(0)89-354 02-390

Translation of the original operator's manual in German

Page 3

Table of contents

5100009744IVZ.fm 3

1 Preface ....................................................................................................................................5

2 Introduction ............................................................................................................................6

2.1 Using the manual..... ... ... .... ... ............................................................. ... .... ... ... ... .......................... 6

2.2 Storage location of the manual.................................................................................................... 6

2.3 Accident prevention regulations...................................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ................ 6

2.4 More information.......................................................................................................................... 6

2.5 Target group................................................................................................................................ 6

2.6 Explanation of symbols................................................................................................................ 6

2.7 Wacker Neuson Contact partner ................................................................................................. 7

2.8 Disclaimer.................................................................................................................................... 7

2.9 Product identification of the machine........................................................................................... 7

3 Security ..................................................................................................................................8

3.1 Policy........................................................................................................................................... 8

3.2 Areas of responsibility of the operator......................................................................................... 8

3.3 Operator responsibilities.............................................................................................................. 9

3.4 Personnel qualification................................................................................................................. 9

3.5 General sources of danger.......................................................................................................... 9

3.6 General safety instructions.......................................................................................................... 9

3.7 Specific safety instructions – Vibratory plates ........................................................................... 10

3.8 General safety instructions - Combustion engines.................................................................... 11

3.9 General safety instructions – fuel, lubricants and coolants........................................................ 11

3.10 General safety instructions – starter batteries........................................................................... 11

3.11 Maintenance.............................................................................................................................. 12

3.12 Personal Protective Equipment ................................................................................................. 12

3.13 Safety devices ........................................................................................................................... 13

3.14 Behavior in dangerous situations............................................................................................... 13

4 Safety and information labels ............................................................................................14

5 Setup and function ..............................................................................................................16

5.1 Standard package ..................................................................................................................... 16

5.2 Application areas.. ... ............................................................. .... ... ... ... ... ..................................... 16

5.3 Short description........................................................................................................................ 16

5.4 Versions..................................................................................................................................... 17

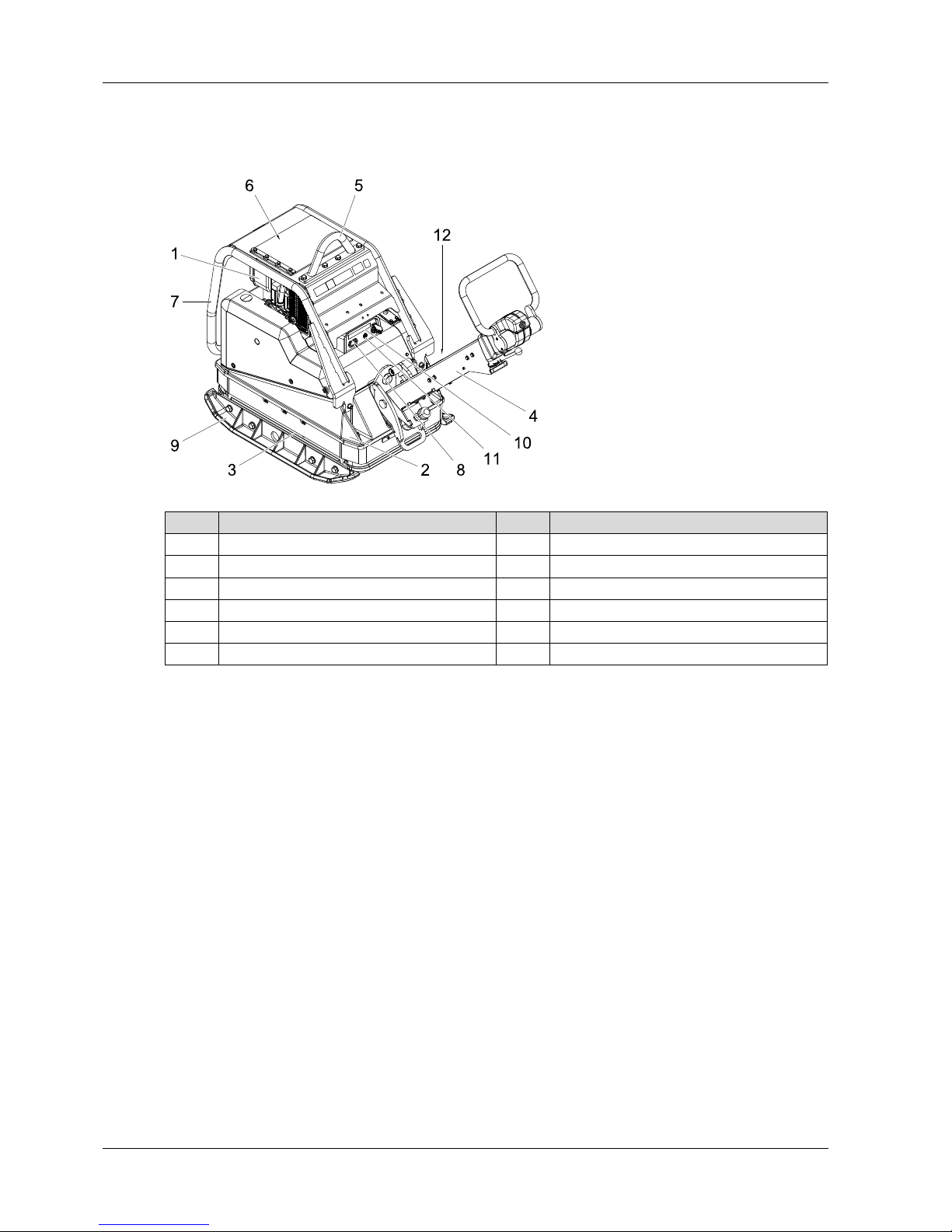

6 Components and operator's controls ................................................................................18

6.1 Components .............................................................................................................................. 18

6.2 Operator's controls .................................................................................................................... 19

7 Transport ..............................................................................................................................20

7.1 Loading and transport........ ........................................................................................................ 20

8 Operation and use ...............................................................................................................22

8.1 Before commissioning ............................. ... .... ... ... ... .... ... ... ........................................................ 22

8.2 Notes about operation ............................................................................................................... 22

8.3 Commissioning.......................................................................................................................... 23

8.4 Operation................................................................................................................................... 27

8.5 Decommissioning ...................................................................................................................... 28

9 Maintenance .........................................................................................................................30

9.1 Maintenance table ...................................... .... ... ... ... .... ... ... ... .... ................................................. 31

9.2 Maintenance jobs.................................. ... ... .... ... ... ... .... ... ... ........................................................ 31

10 Troubleshooting ..................................................................................................................38

10.1 Fault table.................................................................................................................................. 38

10.2 Perform jump start with donor starter battery ............................................................................ 38

Inhalt

Page 4

Table of contents

4 5100009744IVZ.fm

11 Disposal ...............................................................................................................................40

11.1 Disposal of batteries .................................................................................................................. 40

12 Accessories .........................................................................................................................41

13 Technical data .....................................................................................................................42

13.1 DPU4545 ................................................................................................................................... 42

13.2 Combustion engine.................................................................................................................... 44

14 Technical data .....................................................................................................................45

14.1 DPU5545 ................................................................................................................................... 45

14.2 Combustion engine.................................................................................................................... 48

15 Technical data .....................................................................................................................49

15.1 DPU6555 ................................................................................................................................... 49

15.2 Combustion engine.................................................................................................................... 53

16 Emission control systems information and warranty ......................................................54

EC declaration of conformity

.....................................................................................55

EC declaration of conformity .....................................................................................56

EC declaration of conformity .....................................................................................57

DIN EN ISO 9001 certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Page 5

1 Preface

100_0000_0002.fm 5

1 Preface

This operator's manual contains important information and procedures for the safe, proper and economic

operation of this Wacker Neuson machine. Carefully reading, understanding and ob serving is an aid to

avoiding hazards, repair costs and downtime, and therefore to increasing the availability and service life

of the machine.

This operator's manual is not a manual for extensive maintenance or repa ir work. Such work should be

carried out by Wacker Neuson service or by technically trained personnel. The Wacker Neuson machine

should be operated and maintained in accordance with this operator's manual. An improper operation or

improper maintenance can pose dangers. Therefore, the operator's manual should be constantly

available at the location of the machine.

Defective machine parts must be exchanged immediately!

If you have any questions concerning the operation or maintenance, a Wacker Neuson contact person

is always available.

Page 6

2 Introduction

6 100_0000_0013.fm

2Introduction

2.1 Using the manual

This manual is to be considered part of the machine and should be carefully stored during the entire

service life of the machine. This manual shall be transferred to subsequent owners or users of the

machine.

2.2 Storage location of the manual

This manual is part of the machine and must be kept in the immediate vicinity of the machine and made

accessible to staff at all times.

If this manual is lost, or if a second copy is required, there are two options to obtain a replacement:

Download from the Internet www.wackerneuson.com

Contact your Wacker Neuson contact partner.

2.3 Accident prevention regulations

In addition to the notes and safety instructions in this manual, the local accident prevention regulations

as well as the national health and safety regulations apply.

2.4 More information

This manual applies to various machine types from one product series. For this reason, some figures

may vary slightly in appearance from the machine purchased. Depending on the model, there may be

descriptions of components that are not included in the standard package.

The information contained in this manual is based on machines manufactured up to the time of printing.

Wacker Neuson reserves the right to change this information.

The manufacturer shall immediately include any modifications or additions in this manual.

2.5 Target group

Individuals working with this machine must be regularly trained on the da ngers of handlin g the machine.

This operator's manual is intended for the following persons:

Operating personnel:

These individuals have been trained on the machine and informed about the possible dangers in the

event of improper conduct.

Technically trained personnel:

These people have professional training as well as additio nal knowledge and experience. Th ey are able

to assess the tasks assigned to them and recognize possible dangers.

2.6 Explanation of symbols

This manual contains specially emphasized safety instructions in the following categories: DANGER,

WARNING, CAUTION and NOTICE.

Before performing any work on or with this machine , the notes a nd safety instructions must be r ead and

understood. All notes and safety instructions in this manual must be passed on to the maintenance,

repair, and transport personnel.

DANGER

This combination of symbol and signal word indicates a hazardous situation that will lead

to death or serious injury if it is not avoided.

WARNING

This combination of symbol and signal word indicates a hazardous situation that can lead

to death or serious injury if it is not avoided.

CAUTION

This combination of symbol and signal word indicates a hazardous situation that can lead

to minor injury or damage to the machine if it is not avoided.

Page 7

2 Introduction

100_0000_0013.fm 7

2.7 Wacker Neuson Contact partner

Depending on the country, the Wacker Neuson contact partner is a Wacker Neuson service department,

a Wacker Neuson affiliate, or a Wacker Neuson dealer.

On the Internet at www.wackerneuson.com.

The manufacturer's address can be found at the beginning of this manual.

2.8 Disclaimer

For the following violations, Wacker Neuson dismisses any liability for personal injury or material

damage:

Failure to follow this manual.

Unintended use.

Deployment of untrained personnel.

Using non-approved spare parts and accessories.

Improper handling.

Structural modifications of any kind.

Failure to observe the "General Terms and Conditions" (GT&Cs).

2.9 Product identification of the machine

Data of the nameplate

The nameplate contains information that uniquely identifies this machine. This information is required for

ordering spare parts and when inquiring about technical issues.

Enter information about the machine in the following table:

NOTICE

Supplementary information.

Designation Your information

Group and model

Year of manufacture

Serial number

Version no.

Item number

Page 8

3 Security

8 100_0202_si_0006.fm

3 Security

3.1 Policy

In keeping with the latest technological developments

The machine has been built in keeping with the latest technological developments and the recognized

technical safety rules. Nevertheless, improper use can result in hazards to life and limb of the user, third

parties or to damage to the machine and other material assets.

Proper use

The machine may only be used for the following purposes:

Soil compaction.

Asphalt compaction.

Vibration of sett paving (paving stones).

The machine may not be used for the following purposes:

Compaction of very cohesive soils.

Compaction of frozen soils.

Compaction of hard, non-compr es sible soils .

Compaction of non-load-bearing soils.

Use in accordance with the intended purpose also includes the observation of all safety instructions in

this manual as well as complying with the prescribed care and maintenance instructions.

Any use that exceeds or is not in accordance with the intended purpose is considered improper. The

manufacturer's liability and warranty are canceled for any damage resulting from improper use. The risk

lies entirely with the operator.

Structural changes

Structural modifications may not be undertaken without the written permission of the manufacturer.

Unapproved structural changes may result in risks to the operator and/or third parties as well as damage

to the machine.

In the case of unauthorized structural changes, the liability and warranty of the manufacturer are no

longer applicable.

The following cases are considered structural changes:

Opening the machine and the permanent removal of components.

Installing spare parts that do not originate from Wacker Neuson or are not comparable in the design

system and quality of the original parts.

Attaching any accessories that do not originate from Wacker Neuson.

Spare parts or accessories from Wacker Neuson can be safely assembled or mounted. On the Inter net

at www.wackerneuson.com

3.2 Areas of responsibility of the operator

The operator is the individual who personally operates this machine for industrial or commercial

purposes or who entrusts a third party with the use. The operator bears legal responsibility for his/her

protection as well as that of third parties.

The user must make the operator's manual available to the operator and ensure that this has been read

and understood.

The manual must be kept next to the machine or place of use.

The operator must hand over the manual to subsequent operators or owners of the machine.

NOTICE

Read and comply with all notes and safety instructions in this manual. Failure to comply

with these instructions can cause electric shock, fire and/or serious injuries as well as

damage to the machine and/or damage to other objects. Keep safety instructions and

notes for the future.

Page 9

3 Security

100_0202_si_0006.fm 9

The country-specific regulations, standards, and guidelines on accident preven tion and environmental

protection must be observed. The operator's manual must be su pplemented with additio nal instructions

that take regulatory, national or generally applicable safety standards into consideration.

3.3 Operator responsibilities

Know and implement the applicable industrial safety regulations.

Use a risk assessment to identify the dangers that result from the working conditions at the site of

application.

Create operating instructions for the operation of this machine.

Periodically check whether the user instructions correspond to the current state of regulations.

Clearly regulate and specify responsibilities for operation, troubleshooting, maintenance, and

cleaning.

Regularly train employees and inform them about potential hazards.

Provide employees with the necessary equipment.

3.4 Personnel qualification

This machine may only be installed and operated by trained personnel.

In the event of misuse, misapplication or operatio n by untrained personnel, danger s threaten the health

of the operator or third parties and damage to or the complete failure of the machine a lso threatens.

In addition, the operator should be:

Be physically and mentally eligible.

No influence on the ability to respond on account of drugs, alcohol or medication.

Familiar with the safety instructions in this manual.

familiar with the intended use of this machine.

Have reached the minimum age of 18 to operate this machine.

Be instructed in the independent operation of the machine.

Be authorized to operate machines and systems independently according to the standards of safety

engineering.

3.5 General sources of danger

Residual dangers in particular are hazards when dealing with machines that, despite a safe design,

cannot be eliminated.

These residual dangers are not obvious and may be the source of a possible injury or health hazard.

If unforeseeable residual dangers occur, the operation of the machine is to be stopped immediately and

the competent supervisor is to be informed. This supervisor shall make the following decisions and

initiate everything required to eliminate the occurring danger.

If necessary, the machine manufacturer is to be informed.

3.6 General safety instructions

The safety instructions in this chapter include the "General Safety Instructions", which should be

reported in the manual in accordance with the applicable standards. There may be information that is

not relevant to this machine.

3.6.1 Working area

Before beginning work, familiarize yourself with the working environment, e.g. the load-bearing

capacity of the floor or obstacles in the vicinity.

Make working area safe for the public transport sector.

Necessary fuse protection of walls and ceilings, e.g. in trench applications.

Keep the working area tidy. Cluttered or dark working areas can lead to accidents.

Using this machine in an explosive atmosphere is prohibited.

When using this machine, children and unauthorized individuals must be kept away. Distra ction can

lead to loss of control of the machine.

Always protect the machine against tilting, rolling, sliding, and crashing. Risk of injury!

3.6.2 Service

The machine should only be maintained/repaired by technically trained personnel.

Use only original spare parts and accessories. This ensures the operational safety of the machine.

Page 10

3 Security

10 100_0202_si_0006.fm

3.6.3 Personal safety

Working under the influence of dru gs, alco ho l, or dru gs ca n lea d to serio u s injur ies .

Protective equipment should be worn for all work. Appropriate personal protective equipment

considerably reduces the risk of injury.

Remove any tools before the machine is put into operation. Tools that are located on a rotating

machine part can be ejected and cause serious injury.

Always ensure good footing.

In the case of extensive work with this machine, long-term vibration-indu ced damage cannot be ruled

out. For exact values of vibration measurement, refer to the Technical Data section.

Wear suitable clothing. Keep loose clothing, gloves, jewelry, and long hair away from moving/rotating

machine parts. Danger of being pulled!

Ensure that no other individuals are in the danger zone!

3.6.4 Handling and use

Handle machines with care. Do not operate machines with defective components or operator's

controls. Immediately replace defective components or operator's controls. Machines with defective

components or operator's controls carry a high risk of injury!

The operator's controls of the machine shall not be improperly locked, manipulated, or changed.

Store unused machines out of reach of childr en . The machine may only be operated by authorized

personnel.

The machine, accessories, and tools should be used in accordance with these instructions.

After operation, store the cooled-down machine in a locked, clean, frost-protected, and dry location

that is inaccessible for children and other unauthorized individuals.

3.7 Specific safety instructions – Vibratory plates

3.7.1 External influences

In the case of the following external influences, the vibratory plate may not be operated:

In heavy rain on sloped surfaces. Risk of slipping!

Oil field environments – methane leaks from bottom. Explosion hazard!

In dry, flammable vegetation. Fire hazard!

In potentially explosive areas. Explosion hazard!

3.7.2 Operational safety

When operating the machine, make sure that no gas, water, or electric lines are damaged.

The machine must not be operated in tunnels or enclosed spaces.

Pay maximum attention near drops or slopes. Risk of crashing!

The operator must not leave the operator location behind th e center pole while it is in operation.

Do not leave the machine unattended . Risk of injur y!

Delimit spacious workspace and restrict acce ss to un a ut horiz ed indiv idu als. Risk of injury!

Machine operators must ensure that people in the working area keep a minimum distance of 2 meters

from the running machine.

Do not use any starting aid sprays. These can cause misfire s as well as engine damage. Fire hazard!

When operating the machine on sloped surfaces, always approach slopes from below and always

stay above the machine on a slope. The machine could slip or tip over.

Do not exceed max. allowable slanting position of the machine – possible failure of the engine

lubrication, see chapter Technical Data.

Only Wacker Neuson use starter batteries. These are vibration proof and therefore suitable for the

high vibration exposure.

3.7.3 Minimum safety distances

Compaction work near buildings can cause damage to buildings. Therefore, all potential effects and

vibrations on surrounding buildings must be checked in advance.

The relevant rules and regulations for measuring, evaluating and reducing vibration emissions especially the DIN 4150-3 - must be considered.

Wacker Neuson assumes no liability for any damage to buildings.

Page 11

3 Security

100_0202_si_0006.fm 11

3.8 General safety instructions - Combustion engines

The following notes must be observed:

Before starting work, check the engine to ensure there are no leaks and/or cracks in the fuel lines,

tank, and fuel cap.

Do not operate a defective engine. Replace damaged parts immediately.

The pre-set engine speed may not be adjusted. This could lead to engine damage.

Make sure that the exhaust system of the engine is free of debris. Fire hazard!

Switch off before refueling the engine.

Use the correct fuel type. The fuel may not be mixed with other liquids.

Use clean filling aids for refueling. Do not spill fuel. Immediately wipe up any spilled fuel.

The engine may not be started near spilled fuel. Explosion hazard!

For operation in partially closed spaces, sufficient ventilation and aeration must be ensured. Do not

inhale exhaust fumes. Risk of poisoning!

The engine surface and exhaust system can quickly become extremely hot. Risk of burns!

3.9 General safety instructions – fuel, lubricants and coolants

The following notes must be observed:

Always wear safety glasses and protective glov es when handling fuel, lubricants, and coolants. If

hydraulic oil, fuel, oil, or coolant gets into your eyes, see a doctor immediately.

Avoid direct skin contact with fuel, lubricants and coolants. Immediately rinse skin with soap and

water.

Do not eat or drink while working with fuel, lubricants and coolants

Contaminated hydraulic oil or fuel from dirt or water can lead to premature wear or failure of the

machine.

Dispose of spilled fuel, lubricants and coolants according to the applicable provisions for

environmental protection.

If fuel, lubricants and coolants escape from the machine, do not operate the machine any longer and

have it repaired immediately by the Wacker Neuson contact partner.

3.10 General safety instructions – starter batteries

The following notes must be observed:

When disconnecting the starter battery, always disconnect the negative terminal first!

When connecting the starter battery, always connect the positive terminal first! Fasten battery

terminal cover!

Flames, sparks, and smoking are prohibited when handling starter batteries.

Starter batteries contain corrosive acid. Wear acid-proof protective gloves and safety glasses when

handling starter batteries.

Prevent incorrect connection of the starter battery or bridging of the terminals with tools. Risk of short

circuit!

NOTICE

This machine is outfitted with an EPA-certified engine.

Adjusting the revolutions per minute (RPM) impacts the EPA-certification and the

emissions. Settings for this engine may only be changed by a professional.

For more information, contact the manufacturer or your Wacker Neuson contact partner.

NOTICE

Never add acid or distilled water.

Observe the battery manufacturer's instructions for charging.

Never open the battery to remove the aeration.

Page 12

3 Security

12 100_0202_si_0006.fm

3.11 Maintenance

The following notes must be observed:

This machine may not be maintained, repaired, adjusted or cleaned while switched on.

Adhere to maintenance intervals.

After each maintenance or repair, the safety devices on this machine must be reattached.

Observe the maintenance schedule. Non-listed work must be taken over by the service department

of the Wacker Neuson contact partner.

Immediately replace worn or damaged machine parts. Only use spare parts from Wacker Neuson.

Keep the machine clean.

Missing, damaged, or illegible safety warning labels should be replaced immediately. Safety stickers

contain important information for the protection of the operator.

Maintenance jobs must be performed in a clean and dry vicinity (e.g. workshop).

3.12 Personal Protective Equipment

NOTICE

To prevent personal injury when handling this machine, personal protective equipment

must be worn when working on or around this machine.

Pictogram Significance Description

Wear safety shoes! Safety shoes provide protection from bruises, falling

objects, and slipping.

Wear protective gloves! Protective gloves provide protection from abrasion,

cuts, punctures, and hot surfaces.

Wear ear protection! Ear protection provides protection from permanent

hearing impairment.

NOTICE

With this machine, the permissible, country-specific noise limit (personal rating level) may

be exceeded. Therefore, ear protection must be worn. For exact values regarding noise

emissions, refer to Technical Data section.

Work particularly cautiously and pay attention when wearing ear protection, as your ability

to hear noises, such as screams or signal tones, is restricted.

Wacker Neuson recommends always wearing ear protection.

Page 13

3 Security

100_0202_si_0006.fm 13

3.13 Safety devices

Safety devices protect the user of this machine from being exposed to existing hazards. These are

barriers (separating protective devices) or other technical measures. This preven ts the user from being

exposed to a danger. The source of danger will be eliminated in certain situations or the danger will be

reduced.

This machine has the following safety equipment:

3.14 Behavior in dangerous situations

Preventive measures:

Always be prepared for accidents.

Keep first aid equipment on hand.

Make sure that all employees are familiar with accident reporting, first aid, and rescue facilities.

Keep access routes clear for emergency vehicles.

Make sure that employees receive firs t aid tr ain ing .

Measures in the case of an emergency:

Immediately take the machine out of opera tio n.

Remove injured and other people from the danger zone.

Initiate first aid measures.

Alert rescuers.

Keep access routes clear for emergency vehicles.

Inform the person responsible at the site of application.

Item Designation Item Designation

1 Contact protection of exhaust system 3 Automatic central position of control handle

2 Belt guard

NOTICE

Always tighten loosened screwed connections with the prescribed torque setting.

Page 14

4 Safety and information labels

14 100_0202_ls_0006.fm

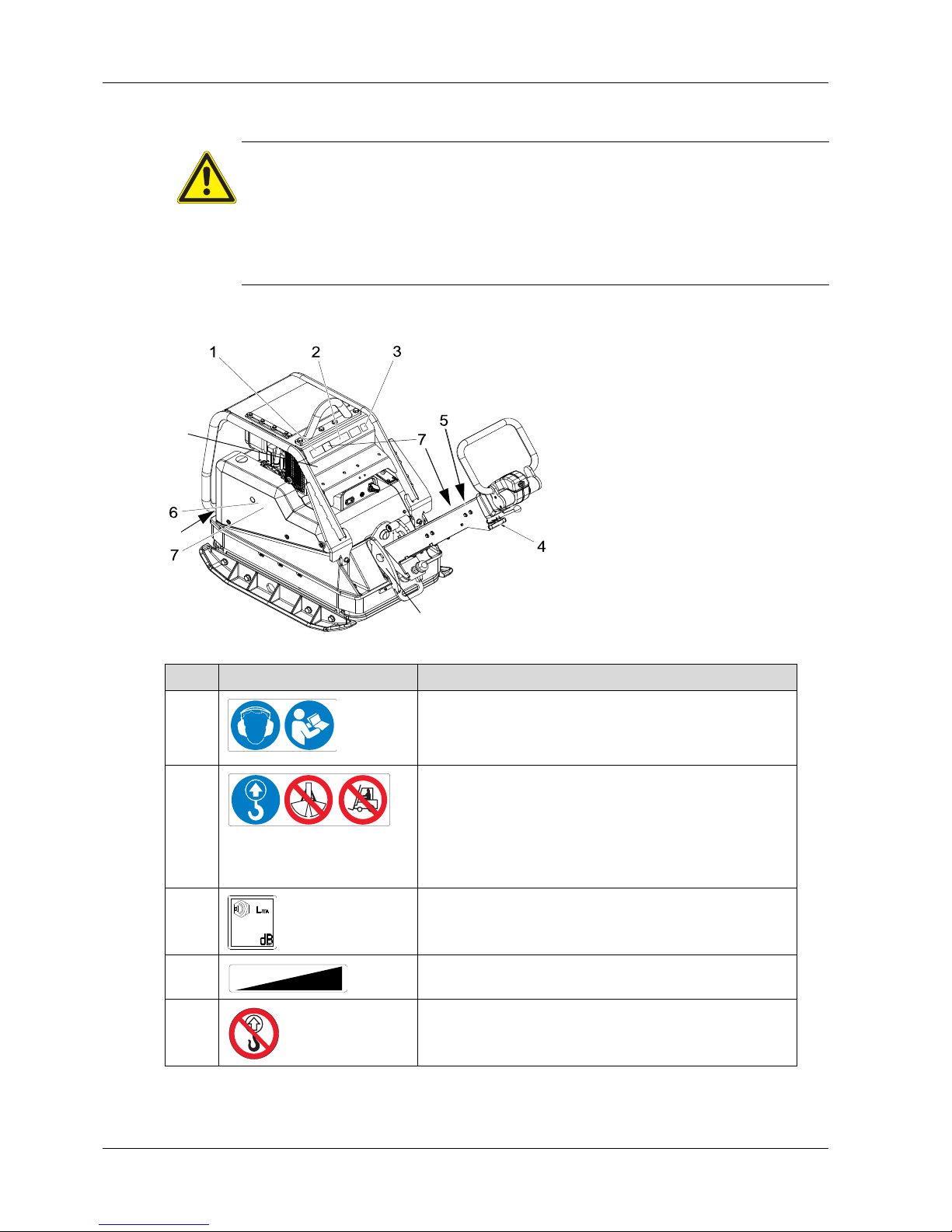

4 Safety and information labels

The following labels are located on the machine:

WARNING

Illegible symbols

Over time, labels and signs on the machines can become dirty or otherwise

unrecognizable.

Keep all safety, warning, and operating instructions on the machine in a legible

condition.

Replace damaged labels and signs immediately.

Item Label Description

1 Use personal protection equipment in order to avoid injuries

and health hazards:

Ear protection.

Read operator's manual.

2 Falling machines can cause serious injury.

Only lift machine at the central lifting point with certified

lifting gear and tackle (safety load hook).

Do not lift the machine on the central lifting point with an

excavator bucket.

Do not lift the machine on the central lifting point with a

forklift.

3 Guaranteed sound power level.

4 Start/Stop.

5 Falling machines can cause serious injury.

Do not lift the machine with the control hand le or center

pole.

8

9

9

0219175

0216633

0219259

0

2

2

0

0

0

0

Page 15

4 Safety and information labels

100_0202_ls_0006.fm 15

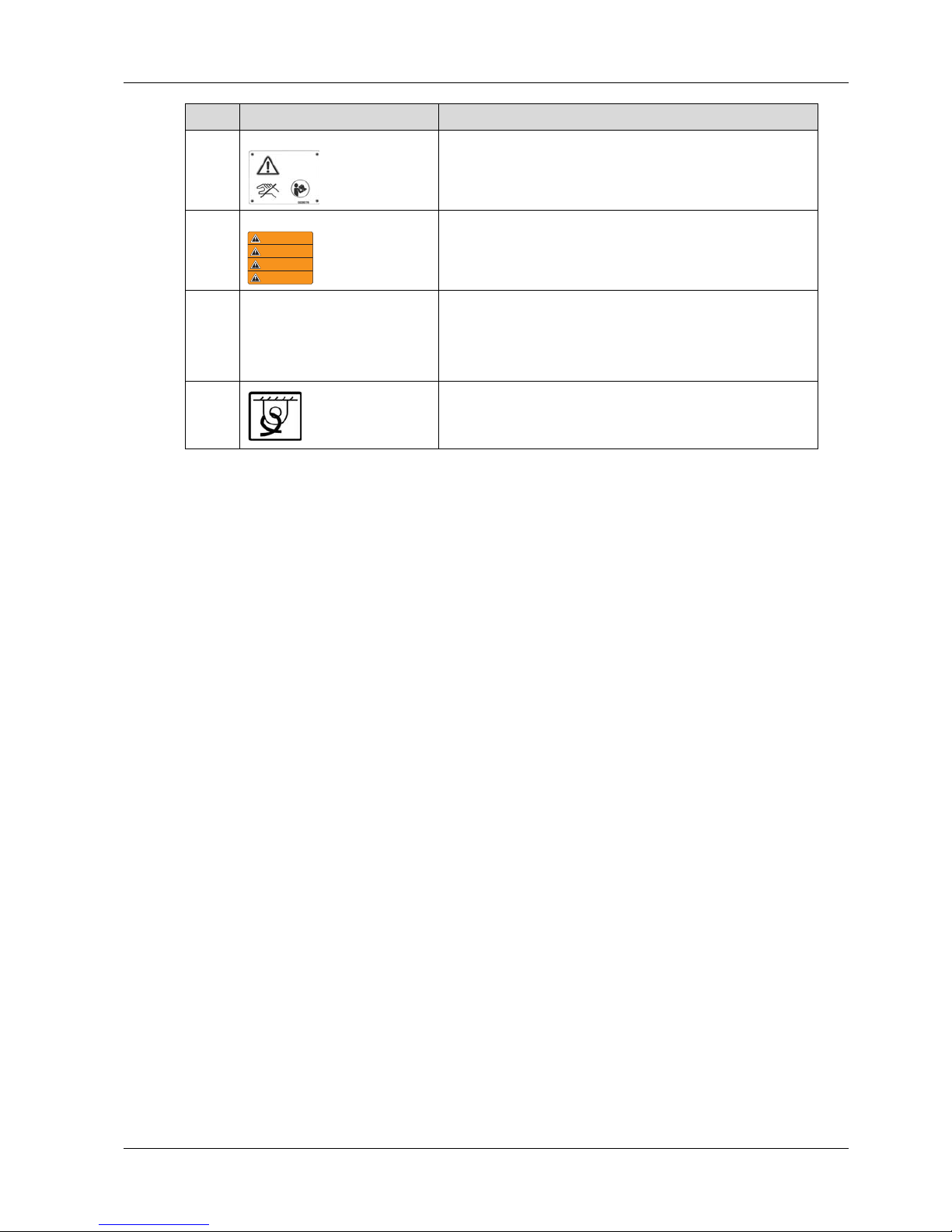

6 DPU45.., DPU55.. Warning.

Body parts can be crushed or cut off from rotating engine parts.

Do not touch the supp ort of the starting crank.

7 US Machines Warning.

8 Machines with electric starter Start/Stop.

9 Tie-down.

Item Label Description

0219261

WARNING

WARNUNG

ADVERTENCIA

ADVERTISSEMENT

0219176

Page 16

5 Setup and function

16 100_0202_sf_0006.fm

5 Setup and function

5.1 Standard package

The machine is delivered fully assembled and is ready for operation out of the box.

The standard package includes:

Vibratory plate

Starting crank (optional)

Operator's manual

5.2 Application areas

The vibratory plate is used for compacting soil. It is used in gardening and landscaping as well as civil

engineering, road construction, and paving.

5.3 Short description

The vibratory plate is a machine used to compact soils.

The vibration required for the compression is generated by the exciter firmly connected to the base plate.

This exciter is designed as a centrally mounted exciter with single-plane vibrations. Such a principle

allows for a modification in the vibration direction by turning the eccentric weights.

A variable transition between compression in travel speed, on the spot compaction and in reverse travel

is therefore possible. This process is controlled hydraulically with the control handle on the center pole

head.

The drive motor attached to the upper mass drives the exciter. The torque is firmly transferred through

the centrifugal clutch and the exciter V-belt.

At low engine speeds, the centrifugal clutch interrupts the force flow to the exciter and the reby allows a

flawless idling of the drive motor.

The automatic v-belt pulley combined with the centrifugal clutch ensures an optimal tensio n of the exciter

V-belt during operation and for relief of the exciter V-belt during offsetting or during transport of the

machine.

In addition, the automatic v-belt pulley automatically adjusts to the wear of the V-belt edges and thus

makes the entire drive system from the engine to the exciter maintenance-free.

The drill speed of the drive motor can be variably adjusted by remote control on the throttle lever and

locked into the idle position. The upper mass and base pla te are connected to ea ch other by 4 vibration

absorbing rubber metal buffers. This attenuation prevents a transmission of the very high frequen cies to

the upper mass. The functionality of the drive motor therefore remains preserve d, despite the high

compaction performance. The drive motor works according to the diesel pr inciple, is e lectrically started

via a gear and pinion starter, draws the combustion air through a dry-type air cleaner and is air-cooled.

To facilitate the starting process (when very cold, during manual start), the drive motor has a

decompression automation system. This causes the compression to be very low when starting to turn,

but to steadily increase after a few revolutions to then switch to full compression.

Operating hour meter (optional)

On the operating hour meter, the operating hours of the machine can be accurately read, thereby

allowing for better observance of the maintenance intervals.

Extension plates

For larger working areas, additional mounting plates are recommended.

Compatec – compaction display (optional):

The Compatec compaction display is attached to the battery cover and is within the operator’s line-ofsight. The display, which consists of eight light-adjusting LEDs, displays the relative compaction

progress by successively lighting up. When the number of illuminated LEDs no longer increases, this

means that no further compaction can be achieved with the machine. The operator can finish the work

and avoid unnecessary passes or over-compaction of the soil.

The overload display indicates if the machine is being operated on too hard of a surface. The operator

is notified of this through rapid flashing of all eight LED's.

Compatec – compaction display is suitable for all highly compactable and mixed-grained soils.

Page 17

5 Setup and function

100_0202_sf_0006.fm 17

Narrow protective frame (optional)

For narrow cable trenches, the narrow protective frame is recommended.

5.4 Versions

This operator's manual covers the following models:

NOTICE

Compatec – compaction display only supports soil compaction and does not replace the

professional measuring of soil density by an expert.

Versions Description

e Electric starter

h Operating hour meter

ap Extension plates

c Compatec – compaction display

s Narrow protective cage

Page 18

6 Components and operator's controls

18 100_0202_cp_0004.fm

6 Components and operator's controls

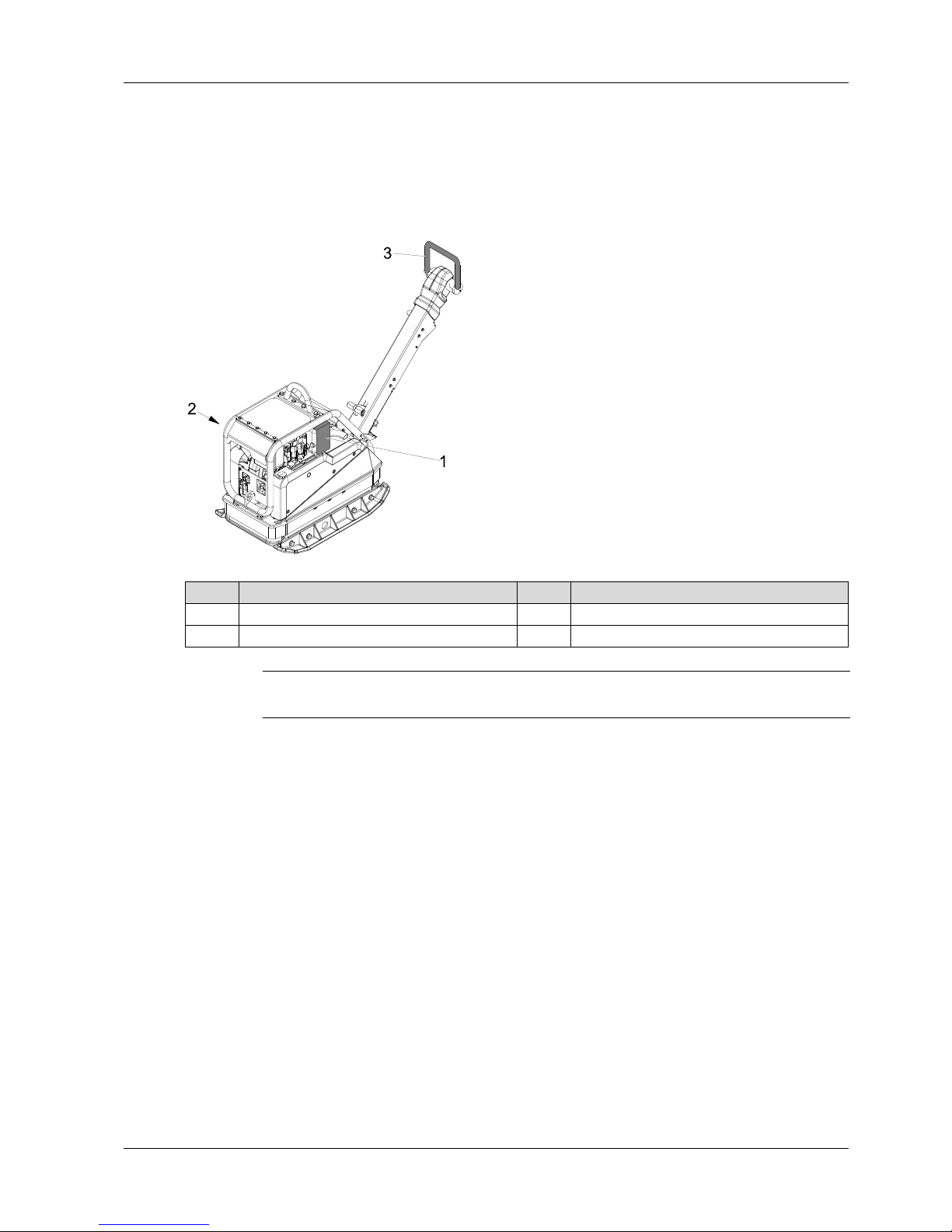

6.1 Components

Center pole

The optimal working height of the center pole can be adjusted by adjusting the threaded spindle.

Central lifting point

The central lifting point is used to lift the machine. It is located exactly in the center of gravity of the

machine, but can be offset to the rear for applications where the overall height is crucial.

Item Designation Item Designation

1 Drive motor 7 Protective frame

2 Upper mass 8 Operating hour meter (optional)

3 Base plate 9 Extension plates

4 Center pole 10 Compatec – compaction display (optional):

5 Central lifting point 11 Control lamp operation

6 Fuel tank 12 Nameplate

Page 19

6 Components and operator's controls

100_0202_cp_0004.fm 19

6.2 Operator's controls

Always keep the display and operator's controls on the machine clean, dry, and free of oil and grease.

Operator's controls, such as the ON/OFF switch, throttle control handles, etc. may not be locked,

manipulated or changed without permission.

Control handle

The control handle is used to continuously regulate the speed and travel direction.

Throttle lever

The drill speed of the drive motor can be continuously adjusted by remote control on the throttle lever

and locked into the idle position.

Decompression lever

The decompression lever may only be actuated to sta rt the m ach ine.

Jump start pin

The jump start pin facilitates connecting the jumper cable when jump starting.

Handle center pole lock

The handle center pole lock is used to release the center pole so that it can be returned to working

position.

Threaded spindle

The threaded spindle is used to set the optimal working height of the center pole.

Item Designation Item Designation

1 Control handle 5 Ignition lock

2 Throttle lever 6 Handle center pole lock

3 Decompression lever 7 Threaded spindle

4 Jump start pin

Page 20

7 Transport

20 100_0202_tr_0006.fm

7 Transport

7.1 Loading and transport

Carry out preparations

When loading and transporting, the center pole must be locked into place by engaging the center pole

lock in the vertical position.

WARNING

Improper handling may result in injury or serious material damage.

Please read and follow all safety instructions in this operator's manual.

DANGER

Danger from falling.

Falling machines can cause serious injury e.g. through crushing.

Only use suitable and tested lifting gear and tackle (safety load hooks) of sufficient

lifting capacity.

Only lift the machine from the central lifting point.

Reliably secure the machine to the lifting gear.

Do not lift the machine on the central lifting point with a forklift or excavator bucket.

Do not lift the machine at the control handle.

Evacuate danger zone while lifting, do not stop under suspended loads.

WARNING

Risk of fire and explosion from fuel.

Escaping fuel may catch fire and cause serious burns.

Lift and transport the machine upright.

CAUTION

If the central lifting point of the machine is fixed offset, the machine is no longer in the

center of gravity and may tilt to the rear.

NOTICE

Wacker Neuson recommends emptying the fuel tank prior to transport.

Item Designation Item Designation

1 Center pole 2 Handle center pole lock

2

1

Page 21

7 Transport

100_0202_tr_0006.fm 21

Lifting and lashing down the machine

1. To lift the motor, hang suitable tackle at the central lifting point.

2. Carefully load machine into or onto a stable means of transport.

3. After loading the machine, lash down the machine to prevent it from rolling off, slipping, or tipping

over. Attach tie-down lugs to the designated lashing points.

NOTICE

Appoint a specialist flagman for a safe lifting operation.

Item Designation Item Designation

1 Central lifting point 2 Tie-down lugs

Item Designation

1Belt

2

2

1

Page 22

8 Operation and use

22 100_0202_op_0009.fm

8 Operation and use

8.1 Before commissioning

8.1.1 Inspection before commissioning

Check the machine and components for damage. In the event of visible damag e, do not operate the

machine and immediately contact a Wacker Neuson dealer.

Ensure that loose packaging material has been removed from the machine.

Check fuel level.

Check the engine oil level.

Check hydraulic oil level.

Check the fuel lines for leak tightness.

Check to ensure the screwed connections are firmly seated.

8.1.2 Set center pole

The optimal working height of the center pole can be adjusted by adjusting the threaded spindle.

8.2 Notes about operation

WARNING

Improper handling may result in injury or serious material damage.

Please read and follow all safety instructions in this operator's manual.

NOTICE

Perform control procedures according to the Maintenance chapter. If necessary, top off

missing fuel, lubricants and coolants, see chapterTechnical Data.

Item Designation Item Designation

1 Center pole 2 Threaded spindle

WARNING

Danger of tipping

There is a serious risk of injury from slipping or tipping over of the machine.

Near edges, at least 2/3 of the machine must be on a load-bearing surface.

Turn off the machine and lift it back onto a load-bearing surface.

WARNING

Health hazard from exhaust fumes

The exhaust fumes of this engine contain chemicals, which the state of California

knows can cause cancer, birth defects or other reproductive damage.

2

1

Page 23

8 Operation and use

100_0202_op_0009.fm 23

Operation on sloped surfaces

Always stand above the machine within the area of a slope.

Only approach gradients from below (a gradient that can be easily driven up can also be driven down

without any risk).

Do not stand in the direction of descent of the machine.

Do not exceed the maximum allowable slanting position (see Technical Data) chapter.

Only operate the machine for a short time in maximum allowable slanting position.

Vibrating sett paving (paving stones)

When compacting interlocking paving stones, Wacker Neuson r ecommends the application of the sliding

mechanism in order to avoid damage to the machine and compaction material. See chapter

Accessories.

8.3 Commissioning

8.3.1 Commissioning the machine (manual start)

1. Put the throttle lever in the full throttle position.

2. Pull the decompression lever up.

NOTICE

If the maximum permissible slanting position is exceeded, this results in a failure of the

engine lubrication and therefore inevitably causes a defect of important engine parts.

DANGER

Fire hazard

Jumper cable sprays are highly flammable; they can ignite and cause severe burns.

Do not use jumper cable sprays.

WARNING

The starting crank can cause serious injuries.

Do not use any defective starting cranks.

Only use a clean starting crank.

Item Designation Item Designation

1 Throttle lever 3 Starting crank support

2 Decompression lever

1

2

3

Page 24

8 Operation and use

24 100_0202_op_0009.fm

3. Stand next to the machine.

4. Insert the starting crank into the support.

5. Grab the crank handle with one hand. Support yourself on the protective cage with the other hand.

6. First slowly turn the starting crank counter-clockwise until the ratchet snaps into place. Then turn

powerfully with increasing speed.

7. Pull the starting crank out of the support.

8. Put the throttle lever in the idle position and lock into place.

9. Suspend the starting crank in the provided bracket.

10.Allow the machine to warm up by idling for a few minutes.

NOTICE

In this position, the decompression automation system audibly locks into place and the

engine is ready to start.

NOTICE

After the decompression automation system locks into place, give starting crank

revolutions are required until the engine can be re-compressed and strike.

NOTICE

Once the engine starts, the decompression lever disengages (the maximum possible

speed must be reached), the engine starts and the vibration starts.

The friction connection between the engine and starting crank must be ensured through

the anti-twist holding of the crank handle and rapid cranking and may not be interrupted

during the starting process under any circumstances.

If a recoil occurs during the starting process from not turning the crank hard enough, the

connection between the crank web and starting dog is disengaged via the crank handle

due to the short backturn.

When making another attempt at starting, wait until the engine comes to a standstill. Do

not actuate the decompression lever when the engine is running.

Page 25

8 Operation and use

100_0202_op_0009.fm 25

8.3.2 Commissioning the machine in the cold (manual start)

1. Move the decompression lever to the center position.

2. Crank the engine with the starting crank counter-clockwise until it noticeably rotates more easily (10

- 20 crank revolutions).

3. Press the lever of the mechanical oil pressure monitoring for 15 seconds.

4. Fill motor oil in the metering device up to the upper rim.

5. Seat the cover and forcibly press it in.

6. Pull the decompression lever up until the detent.

7. Then start the engine immediately. See the chapter "Commissioning the machine (manual start).”

NOTICE

For temperatures below -5 °C, generally freely turn the engine.

Item Designation Item Designation

1 Decompression lever 3 Metering device

2 Lever for the oil pressure monitoring

NOTICE

Remove dirt in the area of the metering device cover and remove the cover.

NOTICE

Two fillings in succession are necessary.

1

3

2

Page 26

8 Operation and use

26 100_0202_op_0009.fm

8.3.3 Commissioning the machine (electric start)

1. Put the throttle lever in the full throttle position.

2. Insert the ignition switch key into the ignition lock and turn to the right. The charge control lamp will

illuminate and the acoustic signal will sound.

3. Turn ignition switch key to position ll. As soon as the engine starts, release the ignition switch key.

4. Put the throttle lever in the idling position.

5. Allow the machine to warm up by idling for a few minutes.

Item Designation Item Designation

1 Throttle lever 3 Ignition lock

2 Decompression lever 4 Charge control lamp

NOTICE

In extreme cold, actuate the decompression lever as well and push it up. In this position,

the decompression automation system audibly locks into place and the engine is ready to

start.

NOTICE

As soon as the engine starts, the vibration will begin.

Page 27

8 Operation and use

100_0202_op_0009.fm 27

Machine with Compatec – compaction display (optional)

1. During the first few seconds after starting the machine, a light progress bar appears on the display

unit.

2. LEDs light up starting from left to right.

3. All LEDs will briefly light up again at reduced brightness.

4. The sensor is thus successfully tested and the display is ready for operation.

8.4 Operation

In accordance with the intended purpose, the operator should stand behind the machine.

Guide and steer machine using the control handle.

8.4.1 Select the travel direction

1. Put the throttle lever in the full throttle position.

2. Select travel direction and speed with the control handle.

Item Designation Item Designation

1 Display unit 2 LEDs/light progress bar

NOTICE

If all LEDs light up, the system is fault-free. The LEDs will then switch off one after the

other.

NOTICE

If all LEDs permanently light after initialization, the sensor has not been successfully

tested; see troubleshooting chapter.

Item Designation Item Designation

1 Forward 2 Reverse

1

2

1

2

Page 28

8 Operation and use

28 100_0202_op_0009.fm

8.4.2 Reading Compatec – compaction display

This display roughly indicates the progress of the compaction.

The number of LEDs lit is proportional to the soil density, more illuminated LEDs corresponds to a

higher soil density.

8.5 Decommissioning

8.5.1 Decommissioning the machine (manual start)

1. Put the throttle lever back to the detent.

2. The engine comes to a standstill.

NOTICE

To protect the machine, the display unit warns the operator of over -compaction by quickly

flashing all LEDs. The brightness of the LED automatically adjusts to the light conditions

of the working area.

NOTICE

It is possible to detect missing spots (non-compactable material) if the spot is longer th an

one meter.

In the case of abrupt change from high to low-compacted soil (or vice versa), there is a

slow increase or decrease of the LEDs.

NOTICE

Do not decommission the machine with the decompression lever, since this inevitably

leads to damage to the machine or engine.

Item Designation

1 Throttle lever

1

Page 29

8 Operation and use

100_0202_op_0009.fm 29

8.5.2 Decommissioning the machine (electric start)

1. Put the throttle lever back to the detent.

2. After the engine has come to a standstill, turn the ignition switch key in the ignition lock to the left and

pull out. The charge control lamp will go out and the acoustic signal will be silent.

Item Designation Item Designation

1 Throttle lever 3 Charge control lamp

2 Ignition lock

NOTICE

The Compatec compaction display automatically switches itself off once the ignition switch

key is pulled out. The display unit has no "sleep function." Continuous operation without

engine operation leads to battery drainage.

1

3

2

Page 30

9 Maintenance

30 100_0202_mt_0008.fm

9 Maintenance

WARNING

Improper handling may result in injury or serious material damage.

Please read and follow all safety instructions in this operator's manual.

WARNING

Danger of poisoning from exhaust fumes.

Exhaust fumes contain poisonous carbon monoxide, which ca n lead to un consciousness

or to death.

Only perform maintenance jobs with the engine switched off and the machine

decommissioned.

WARNING

Risk of injury from uncontrolled starting of the machine and moving parts.

Only perform maintenance jobs with the engine switched off and the machine

decommissioned.

WARNING

Risk of fire and explosion from fuel and fuel vapors.

Fuel and fuel vapors may ignite or catch fire and cause serious burns.

Do not smoke.

Do not refuel near open flames.

Switch off the engine and allow to cool before refueling.

WARNING

Warning of hot surfaces

The muffler and engine can become extremely hot, which can lead to severe skin burns if

touched.

Always allow the engine to cool down completely after use.

If the cool-down phase cannot be adhered to (e.g. due to an emergency), use heat-

resistant protective gloves.

WARNING

Risk of injury due to non-existent or non-functioning safety devices.

Only oper at e th e ma ch ine if the safe ty de vice s ar e pr op e rly fixe d an d functioning.

Do not modify or remove safety devices.

Page 31

9 Maintenance

100_0202_mt_0008.fm 31

9.1 Maintenance table

9.2 Maintenance jobs

Maintenance jobs Daily h/year Weekly Monthly

Clean the machine

Visual inspection for completeness

Visual inspection for damage

Check the engine oil level*

Replace the engine oil* 25 h/250 h

Replace the engine oil filter* 25 h/250 h

Clean, set, repair, replace the injection nozzles* 1500 hours

Clean, set, repair the injection valve* 3000 hours

Replace the fuel filter* 500 hours

Check water trap*

Check the intake area of the combustion air*

Check air cleaner service indicator*

Clean the air cleaner cartridge* 500 hours

Check the tapped clearance** 25 h/250 h

Check the exciter oil level

Replace the exciter oil 250 h/1/2

year

Check hydraulic oil level**

Check hydraulic hose lines** 125 hours

Check / replace the V-belt

Check the rubber buffer** 125 hours

Check the to ensure the screwed connections are firmly

seated

Re-lubricate the threaded spindle and ratchet pin

*

Note the engine operator's manual.

**

Have this work performed by the service department of your Wacker Neuson contact partner.

CAUTION

Health risk from fuel, lubricants and coolants.

Do not inhale fuel, lubricants, coolants or vapors.

Avoid contact of skin or eyes with fuel, lubricants and coolants.

Page 32

9 Maintenance

32 100_0202_mt_0008.fm

Carry out preparations:

1. Place the machine on a level surface.

2. Decommissioning the machine.

3. Allow engine to cool down.

Check the fuel level and top off

1. Fold the cover to the side.

2. Remove dirt accumulation within the range of the fuel filler neck.

3. Open the fuel filler neck

4. Check the fuel level by visual check

5. If necessary, top off the fuel with a clean filling container.

Fuel type See chapter Technical Data.

6. Tightly seal the tank cap.

WARNING

Risk of fire and explosion from fuel and fuel vapors.

Do not smoke.

Do not refuel near open flames.

Switch off engine and allo w to cool be fo re refueling. Only refuel in a well-ventilated

vicinity.

Item Designation

1 Fuel filler neck

NOTICE

Only fill the fuel tank to the bottom edge of the filler neck.

1

Page 33

9 Maintenance

100_0202_mt_0008.fm 33

Check water trap

1. Dismantle the plate cover.

2. Loosen the hexagonal bolt 2-3 by revolutions.

3. Collect the escaping drops in a transparent container.

4. Once only fuel is escaping, tighten the hexagonal bolt.

5. Attach the plate cover.

Cleaning the machine

1. After cleaning, check the cable, hoses, utility lines and hardware for leaks, loose connections, chafe

marks and other damage.

2. Immediately eliminat e de te cte d dama ge .

Screwed connections

For the vibratory plates, the screwed connections must be regularly checked for a firm seat.

Check and replace V-belt and belt stabilizer

Item Designation Item Designation

1 Plate cover 2 Hexagonal bolt

NOTICE

Since water is specifically heavier than diesel fuel, the water will exit first and then the fuel.

This can be seen by a clear separating line.

WARNING

Risk of fire and explosion when using flammable cleaning agents.

Do not clean the machine and elements with gasoline or other solvents.

NOTICE

Penetrating water can damage the engine, electrical operator's controls or components of

the machine. Do not aim high pressure washer directly at air intake area and electrical

elements.

Page 34

9 Maintenance

34 100_0202_mt_0008.fm

1. Disassemble the belt guard.

2. Check the condition of the V-belt and the belt stabilizer. If the V-belt width should be less than 15.5

mm or if there is visible damage, this must be replaced.

3. Loosen the screw.

4. Remove the mushroom-shaped plate, bellville lock washers and gasket.

5. Pull the v-belt pulley (engine) away from the machine and the V-belt will loosen.

6. Push the V-belt down until it slips away from the v-belt pulley (exciter).

7. Push the V-belt up and out.

8. Place the new V-belt around the v-belt pulley (exciter) and press over the v-belt pulley (engine).

9. Push the v-belt pulley (engine) inwards towards the machine.

10.Screw the gasket, bellville lock washers and mushroom-shaped plate back on with the screw. The

torque setting is 49 Nm.

11.Seat the belt guard and screw tight. The torque setting is 25 Nm.

Replace the exciter oil and check the oil level

Item Designation Item Designation

1 Belt guard 2 Screw

NOTICE

Do not oil or grease coupling parts, as this could damage the graphite bushings and the

friction linings and V-belt could slip.

NOTICE

Move the V-belt back and forth to check whether this is seated properly in both v-belt

pulleys.

NOTICE

Due to the application of the automatic centrifugal clutch, it is not necessary to re-tension

the V-belt.

DANGER

Risk of scalding

Use caution when draining hot oil.

2

Page 35

9 Maintenance

100_0202_mt_0008.fm 35

1. Tip the machine to the side of the filler boring and support it.

2. Place an appropriate collecting container below the filler boring.

3. Remove dirt accumulation within the range of the filler boring.

4. Unscrew the screw plug from the filler boring and allow the waste oil to drain completely.

5. Tip the machine to the other side and support it.

6. Fill new oil (see chapterTechnical Data for the exciter oil type and volume) in the filler boring. Use an

appropriate and clean filling container.

7. Place the machine level on the ground.

8. Screw the screw plug with seal ring into the filler boring. The torque setting is 100 Nm.

NOTICE

Perform oil change and oil level check with warm exciter oil. Machine must not be in use

and must be level.

Item Designation Item Designation

1 Screw plug 2 Filler boring

NOTICE

Lay an impermeable film on the working surface to protect against escaping oil.

NOTICE

Collect escaping or overflowing oil and dispose of with the waste oil in an environmentally

friendly manner in accordance with the existing rules and regulations of the legislative

body.

NOTICE

Only fill with the prescribed volume of oil.

1, 2

Page 36

9 Maintenance

36 100_0202_mt_0008.fm

Changing the starter battery

DANGER

Risk of electric shock

Risk of injury from simultaneous touching of positive terminal and ground.

Always disconnect the negative terminal first.

Always connect the positive terminal first.

Always cover one terminal to prevent accidental short circuits.

Hazard from fuel, lubricants and coolants - acid splashes.

NOTICE

Only Wacker Neuson use starter batteries.

Only replace defective starter batteries with Wacker Neuson starter batteries. See

Technical Data section.

Only the Wacker Neuson starter battery is vibration proof and therefore suitable for the

high vibration exposure.

Item Designation Item Designation

1 Protective frame 3 Starter battery

2 Battery cover

3

1

2

Page 37

9 Maintenance

100_0202_mt_0008.fm 37

1. Remove the protective cage.

2. Remove the battery cover and disconnect the positive terminal cover.

3. Disconnect starter battery.

4. Lift out defective starter battery and remove battery protection support.

5. Attach battery protection support to the new starter battery.

6. Insert the new starter battery.

7. Attach the positive terminal cover.

8. Connect starter battery.

9. Attach the battery cover.

10.Attach the protective cage.

NOTICE

First disconnect negative terminal, then positive terminal.

NOTICE

First connect positive terminal, then the negative terminal.

Item Designation Item Designation

1 Positive terminal cover 2 Coiled helix cable

NOTICE

Before installing the battery cover, ensure that the positive terminal cover is attached.

When assembling the starter battery, pay attention to the coiled helix cable.

2

1

Page 38

10 Troubleshooting

38 100_0202_ts_0008.fm

10 Troubleshooting

10.1 Fault table

10.2 Perform jump start with donor starter battery

If the starter battery of the machine is discharged and the engine does not star t, a jump-start with a donor

battery is possible.

DANGER

Danger to life from unauthorized troubleshooting.

If faults occur with this machine that are not described in this manual, contact the

manufacturer. Do not eliminate the faults independently.

Fault Possible causes Remedial measure

The reverse travel speed is too low. Not enough hydraulic oil in the

center pole head.

Top off the hydraulic oil.

The forward travel speed is too low. Too much hydraulic oil in the center

pole head.

Correct the oil level accordingly.*

Air in the hydraulic control system. Bleed.*

No travel speed. Mechanical fault. Have the machine repaired.*

Loss of hydraulic oil. Leaks Have the machine repaired.*

Motor will not start. Defective ignition lock. Have the machine repaired.*

Defective starter motor.

Discharge starter battery. Charge starter battery.

Low oil level Top up oil and actuate valve hood

on the oil filter housing.

The charge control lamp will not go

out.

Defective alternator. Have the machine repaired.*

The acoustic signal will not stop

sounding.

Defective voltage regulator.

Compaction display (optional):

If all LEDs permanently flash after

initialization, the sensor has not

been successfully tested.

Switch-on with the engine running. Have the machine repaired.*

Sensor is defective.

*

Have this work performed by the service department of your Wacker Neuson contact partner.

WARNING

Risk of explosion from explosive gas.

Risk of injury from splashing acid.

Wear safety glasses and protective gloves.

The donor battery and starter battery of the machine must have the same voltage (12

V).

Avoid short circuit from reverse polarity (plus to plus, minus to minus).

Use correct sequence when connecting the jumper cables.

NOTICE

Use only insulated jumper cables with a conductor cross-section of at least 16 mm².

Page 39

10 Troubleshooting

100_0202_ts_0008.fm 39

1. Pull out jump start pin and conne ct cl am p ing ton gs of the red jumper cable to the jump start pin.

2. Connect the second clamping tongs of the red jumper cable to the positive terminal of the donor

battery.

3. Connect clamping tongs of the black jumper cable to the negative terminal of the donor battery.

4. Connect the second clamping tongs of the black jumper cable to a grounding point of the machine,

e.g. at the engine block.

Perform jump start

5. Start engine.

If the engine does not start after a maximum of 15 seconds, stop the starting process and contact

your Wacker Neuson contact person.

6. Run engine for a few minutes.

Disconnect the jumper cable

7. Disconnect clamping tongs of the black jumper cable from the grounding point of the machine.

8. Disconnect the second clamping tongs of the black jumper cable from the donor battery.

9. Disconnect the clamping tongs of the red jumper cable from the jump start pin and ensure that the

jump start pin is completely retracted.

10.Disconnect the second clamping tongs of the red jumper cable from the positive termina l of the donor

battery.

Item Designation Item Designation

1 Jump start pin 4 Negative terminal of the donor battery

2 Negative terminal at the grounding point 5 Positive terminal of the donor battery

3 Black jumper cables 6 Red jumper cables

Page 40

11 Disposal

40 100_0000_0007.fm

11 Disposal

11.1 Disposal of batteries

The machine contains one or more batteries or rechargeable batteries (hereinafter referred to as "the

battery"). Proper disposal of the battery prevents negative effects on individuals and the environment,

follows the specific treatment of pollutants, and ensures the recycling of useful raw materials.

For customers in EU countries

This battery is subject to the European Directive on (old) batteries and (old) rechargeable batteries, and

the respective national laws. The battery directive outlines the framework for an EU-wide treatmen t of

batteries.

The battery is marked with the following symbol of a crossed-out garbage bin . Below this

symbol, there is also the name of the pollutants contained therein, i.e. "Pb" for lead, "Cd"

for cadmium, and "Hg" for mercury.

Batteries may not be disposed of with nor mal household waste! As an end-user, yo u

may only dispose of used batteries via the manufacturer or specially equipp ed colle ction

facilities (statutory obligation to return); the delivery is free. Retailers and manufacturers are obliged to

take back these batteries and properly recycle them or dispose of them as hazardous waste (legal

obligation).

Batteries obtained through Wacker Neuson can be retur ned to Wacker Neuson free of charge after use.

If the batteries cannot be personally returned to a Wacker Neuson branch, there are instructions in the

sales contract or in the Terms and Conditions of the location where they were purchased.

For customers in other countries

Wacker Neuson recommends that you do not dispose of the battery in normal household waste but

rather in a separate, environmentally friendly collection fa cili ty. Nationa l laws m ay also ha ve provisions

for the separate disposal of batteries. Disposal of the battery in accordance with current national

guidelines must be assured.

Page 41

12 Accessories

100_0202_ac_0004.fm 41

12 Accessories

A wide range of accessories is offered for the machine.

More information about the individual accessories can be found online at www.wackerneuson.com.

Extension plates

For the machine, the extension plates are available in different widths with which the operating width of

the machine can be expanded or reduced.

Sliding mechanism

Sliding mechanisms offer optimal protection again st damage to the sett paving (paving stone) surface,

which is especially required for surface-coated types of paving.

Starting crank

DPU4545 and DPU5545 - short tool shank of the starting crank.

DPU6555 - long tool shank of the starting crank.

Starting crank holder

A starting crank holder can be attached to store the starting crank on the machine.

Undercarriage

An undercarriage is offered for easier transport on the construction site.

CAUTION

Accessories and spare parts that do not originate from Wacker Neuson ca n in cr ea se the

risk of injury and possible damage to the machine.

The use of other accessories and spare parts that do not originate from

Wacker Neuson shall cancel any liability.

Page 42

13 Technical data

42 100_0202_td_0015.fm

13 Technical data

13.1 DPU4545

Designation Unit DPU4545H DPU4545He DPU4545Heh

Item number 5100009661 5100016951 5100009659

Centrifugal force kN 45.00 45.00 45.00

Oscillations Hz 69 69 69

1/min 4,140 4,140 4,140

Compaction performance* m

2

/h 910 910 910

Travel speed m/min 25.0 25.0 25.0

Gradeability % 57.7 57.7 57.7

Length (center pole in working

position)

mm 1,661 1,661 1,661

Width mm 604 604 604

Height mm 1,308 1,308 1,308

Operating weight kg 402.0 423.0 423.0

Ground clearance mm 790 – 914 790 – 914 790 – 914

Electrical load rating ** kW 6.4 6.4 6.4

Nominal speed 1/min 2,850 2,850 2,850

Exciter oil volume l 0.75 0.75 0.75

Exciter oil type

SAE 75W-90 SAE 75W-90 SAE 75W-90

Hydraulic oil volume l 0.5 0.5 0.5

Type of hydraulic oil MR 520 MR 520 MR 520

Storage temperature range °C -15 – +40 -15 – +40 -15 – +40

Operating temperature range °C -15 – +40 -15 – +40 -15 – +40

Sound pressure level

At location of operation L

pA

dB(A) 94 94 94

Standards EN 500-4

Sound power level L

wa

measured

guaranteed

dB(A)

107

108

107

108

107

108

Standards EN 500-4

Vibration total value a

hv

m/s

2

< 2.5 < 2.5 < 2. 5

Standards EN 500-4

Uncertainty of measurement of

the vibration total value a

hv

m/s

2

0.5 0.5 0.5

*

Depending on the soil properties.

**

Corresponds to the net installed power according to directive 2000/14/EC.

Page 43

13 Technical data

100_0202_td_0015.fm 43

Designation Unit DPU4545

Hec

DPU4545

Hech

DPU4545

Heh US

DPU4545

Hech US

Item number 5100016953 5100015429 5100009660 5100016952

Centrifugal force kN 45.00 45.00 45.00 45.00

Oscillations Hz 69 69 69 69

1/min 4,140 4,140 4,140 4,140

Compaction performance* m

2

/h 910 910 910 910

Travel speed m/min 25.0 25.0 25.0 25.0

Gradeability % 57.7 57.7 57.7 57.7

Length (center pole in working

position)

mm 1,661 1,661 1,661 1,661

Width mm 604 604 604 604

Height mm 1,308 1,308 1,308 1,308

Operating weight kg 424.0 425.0 423.0 423.0

Ground clearance mm 790 – 914 790 – 914 790 – 914 790 – 914

Electrical load rating ** kW 6.4 6.4 6.4 6.4

Nominal speed 1/min 2,850 2,850 2,850 2,850

Exciter oil volume l 0.75 0.75 0.75 0.75

Exciter oil type

SAE 75W-90 SAE 75W-90 SAE 75W-90 SAE 75W-90

Hydraulic oil volume l 0.5 0.5 0.5 0.5

Type of hydraulic oil MR 520 MR 520 MR 520 MR 520

Storage temperature range °C -15 – +40 -15 – +40 -15 – +40 -15 – +40

Operating temperature range °C -15 – +40 -15 – +40 -15 – +40 -15 – +40

Sound pressure level

At location of operation L

pA

dB(A) 94 94 94 94

Standards EN 500-4

Sound power level L

wa

measured

guaranteed

dB(A)

107

108

107

108

107

108

107

108

Standards EN 500-4

Vibration total value a

hv

m/s

2

< 2.5 < 2.5 < 2.5 < 2.5

Standards EN 500-4

Uncertainty of measurement

of the vibration total value a

hv

m/s

2

0.5 0.5 0.5 0.5

*

Depending on the soil properties.

**

Corresponds to the net installed power according to directive 2000/14/EC.

Page 44

13 Technical data

44 100_0202_td_0015.fm

13.2 Combustion engine

Designation Unit

Manufacturer Hatz

Type of engine 1D42S-151 1D42S-152 1D42S-177

Combustion method Four-cycle Four-cycle Four-cycle

Cooling Air cooling Air cooling Air cooling

Cylinders 1 1 1

Displacement cm³ 445 445 445

Max. slanting position ° 30 30 30

Fuel type Diesel Diesel Diesel

Fuel consumption l/h 1.6 1.6 1.6

Tank capacity l 5.0 5.0 5.0

Oil specification SAE 10W40 SAE 10W40 SAE 10W40

Max. oil filling l 1.1 1.1 1.1

Max. performance kW 7.0 7.0 7.0

Standards ISO 3046 IFN

Drill speed (max. output) 1/min 3,600 3,600 3,600

Electrical load rating kW 6.4 6.4 5.8

Standards ISO 3046 IFN

Nominal speed 1/min 2,850 2,850 2,850

Rated power output kW 4.9 4.9 4.9

Standards ISO 3046 IFN

Operating speed 1/min 3,000 3,000 3,000

Standards ISO 3046 IFN

Upper engine speed without

load

1/min 3,060 3,060 3,060

Air cleaner Dry-type air cleaner Dry-type air cleaner Dry-type air cleaner

Starter type Manual crank start Electric starter Electric starter

Battery voltage V – Special Wacker Neuson starter battery for

vibratory plates, 12 V, 45 Ah

Battery capacity (nominal

value)

Ah –

Page 45

14 Technical data

100_0202_td_0016.fm 45

14 Technical data

14.1 DPU5545

Designation Unit DPU5545H DPU5545He DPU5545

Heh

DPU5545

Heap

Item number 5100009656 5100016947 5100009652 5100016949

Centrifugal force kN 55.00 55.00 55.00 55.00

Oscillations Hz 69 69 69 69

1/min 4,150 4,150 4,150 4,150

Compaction performance* m

2

/h 980 980 980 1,170

Travel speed m/min 27.0 27.0 27.0 26.0

Gradeability % 57.7 57.7 57.7 57.7

Length (center pole in working

position)

mm 1,661 1,661 1,661 1,661

Width mm 604 604 604 750

Height mm 1,308 1,308 1,308 1,308

Operating weight kg 399.0 424.0 424.0 447.0

Ground clearance mm 790 – 914 790 – 914 790 – 914 790 – 914

Electrical load rating ** kW 6.4 6.4 6.4 6.4

Nominal speed 1/min 2,850 2,850 2,850 2,850

Exciter oil volume l 0.75 0.75 0.75 0 .7 5

Exciter oil type SAE 75W-90 SAE 75W-90 SAE 75W-90 SAE 75W-90

Hydraulic oil volume l 0.5 0.5 0.5 0.5

Type of hydraulic oil MR 520 MR 520 MR 520 MR 520

Storage temperature range °C -15 – +40 -15 – +40 -15 – +40 -15 – +40

Operating temperature range °C -15 – +40 -15 – +40 -15 – +40 -15 – +40

Sound pressure level

At location of operation L

pA

dB(A)

94 94 94 94

Standards EN 500-4

Sound power level L

wa

measured

guaranteed

dB(A)

107

108

107

108

107

108

107

108

Standards EN 500-4

Vibration total value a

hv

m/s

2

< 2.5 < 2.5 < 2.5 < 2.5