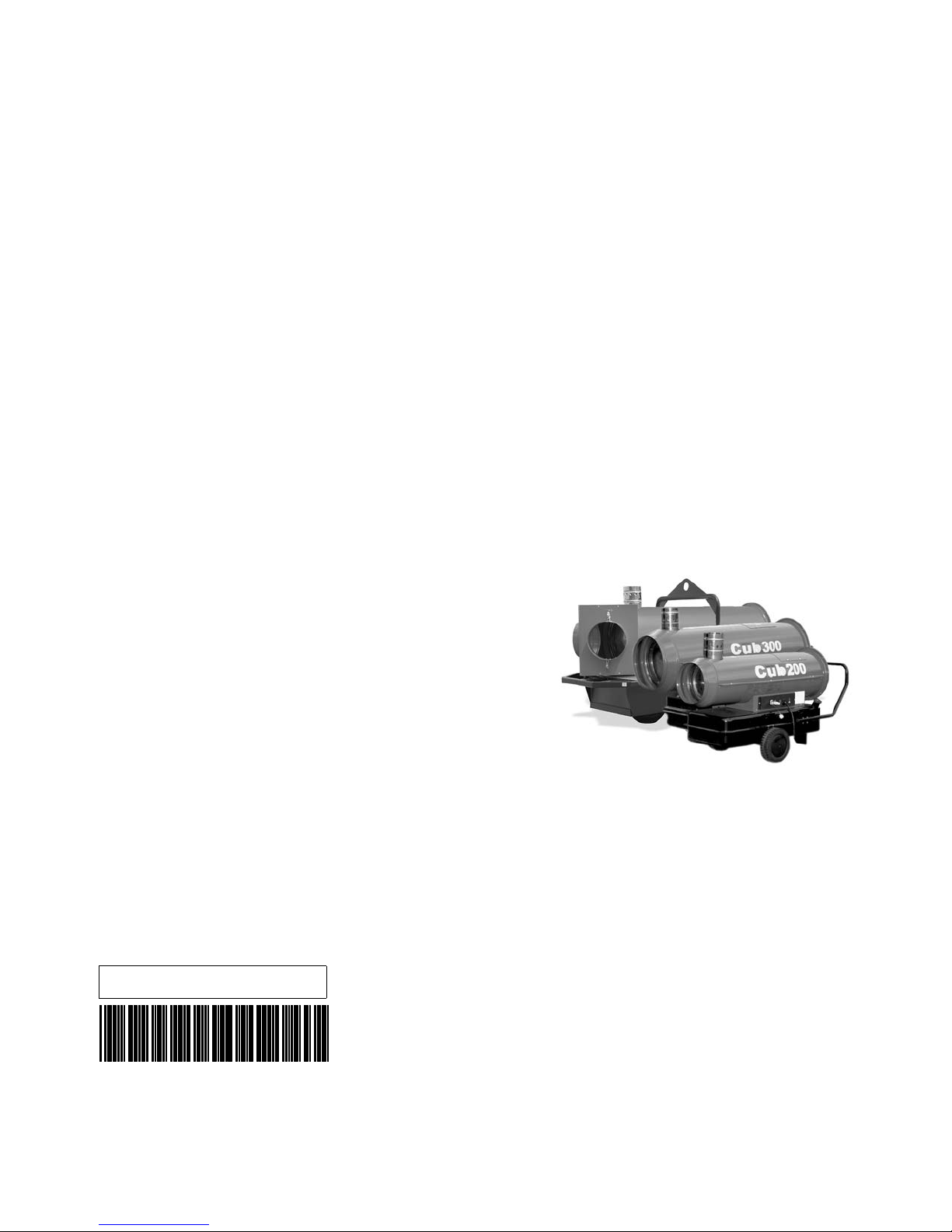

Wacker Neuson CUB 200, CUB 300 Repair Manual

Repair Manual

Indirect-Fired Air Heater

Cub 200

Cub 300

0179422en 001 1009

0179422EN

Copyright

notice

© Copyright 2009 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by W acker Neuson Corp oration

represents an infringement of valid copyrights. Violators will be prosecuted.

T ra d emarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Corporation

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Cub 200/300 Foreword

Foreword

Machines

covered by

this manual

Machine Item Number Machine Item Number

Cub 200 0620204 Cub 300 0620233

Cub 200 0620262 — —

Machine

documentation

Expectations

for

information in

this manual

Manufacturer’s

approval

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson

Corporation to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and obse rve a ll instructions

described in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Co rporation reserves the right to

change any portion of this information without notice.

This manual contains several references to approved parts, att achment s, and mod-

ifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker Neu-

son service center according to written instructions published by Wacker Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

ghi_tx001204gb.fm 3

Foreword Cub 200/300

ghi_tx001204gb.fm 4

Cub 200/300 Table of Contents

1 Safety Information 7

1.1 Signal Words Found in this Manual ...................................................... 7

1.2 Safety Guidelines for Operating the Machine ....................................... 8

1.3 Safety Guidelines for Lifting the Machine ............................................. 9

1.4 Safety Guidelines While Using Combustion Burners ......................... 10

1.5 Safety Guidelines for Maintaining the Machine .................................. 11

2 Operation 12

2.1 Controls and Components .................................................................. 12

2.2 Control Panel ...................................................................................... 13

2.3 Starting/Stopping the Machine ........................................................... 14

3 Burner Setup 16

3.1 Control Board Sequence of Operation ............................................... 16

3.2 Setting Up the Burner ......................................................................... 18

3.3 Removing and Installing the Burner Assembly ................................... 21

3.4 Checking and Adjusting the Burner Electrodes .................................. 22

3.5 Checking and Replacing the Burner Nozzle ....................................... 23

3.6 Setting the Air Band ........................................................................... 24

3.7 Checking and Adjusting the Fuel Pressure ........................................ 25

4 Troubleshooting Basics 27

5 Troubleshooting the Blower 28

5.1 Checking the Fuse ............................................................................. 29

5.2 Checking Power to/from the Control Board ........................................ 31

5.3 Checking the ON-OFF Switch ............................................................ 33

5.4 Checking the Capacitor ...................................................................... 35

5

Table of Contents Cub 200/300

6 Troubleshooting the Burner 37

6.1 Checking the Ignition Transformer ......................................................39

6.2 Checking the Cad Cell .........................................................................42

6.3 Checking the Fuel Filter Heater ...........................................................44

6.4 Checking Output Voltage from the Control Board ...............................46

6.5 Checking the Air Pressure Switch .......................................................48

6.6 Checking the Fuel Solenoid ................................................................51

6.7 Checking the Flame Head ...................................................................54

6.8 Checking the Fuel Flow from the Nozzle .............................................55

6.9 Checking the Fuel Lines ......................................................................57

6.10 Checking the Fuel Pump Adapter .......................................................58

7 Schematic 59

7.1 Cub 200/Cub 300 Schematic ..............................................................59

ghi_br0179422en_001TOC.fm 6

Cub 200/300 Safety Information

1 Safety Information

1.1 Signal Words Found in this Manual

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f To avoid death or serious injury from this type of hazard, obey all safety mes-

sages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

ghi_si000343gb.fm 7

Safety Information Cub 200/300

1.2 Safety Guidelines for Operating the Machine

Operator

training

Machine

condition

Before operating the machine:

Read and understand the operating instructions contained in all manuals

delivered with the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Contact Wacker Neuson Corporation for additional training if necessary.

When operating this machine:

Do not allow improperly trained people to operate the machine. People

operating the machine must be familiar with the potential risks and hazards

associated with it.

Only operate the machine when:

All safety devices and guards are in place and in working order.

All controls operate correctly.

The machine is set up correctly according to the instructions in the Operator’s

Manual.

The machine is clean.

The machine’s labels are legible.

When operating the machine:

Do not modify or defeat the safety devices.

Do not use worn electrical cords.

Do not use faulty fuel supplies.

Guidelines for

operator

Work space

When operating the machine:

Remain aware of the machine’s moving parts. Keep hands, feet, and loose

clothing away from the machine’s moving parts.

Wear protective clothing appropriate to the job site when operating the machine.

Wear safety glasses.

When operating the machine:

Do not operate a machine in need of repair.

Do not smoke near the machine.

When operating the machine:

Position the machine on a firm, noncombustible, level surface.

Keep the area immediately surrounding and underneath the machine clean,

neat, and free of debris and combustible materials.

Keep the area above the machine clear of debris that could fall on the machine.

Store the machine properly when it is not being used.

Keep unauthorized personnel, children, and pets away from the machine.

8 ghi_si000343gb.fm

Cub 200/300 Safety Information

When operating the machine:

Do not connect ductwork between the exhaust outlet port and the supply air inlet

port.

Never operate the machine in areas that contain flammable objects, fuels, or

products that produce flammable vapors.

Do not position the electrical cords under the machine or over the top of the

machine.

1.3 Safety Guidelines for Lifting the Machine

Lifting/

transporting

the machine

When lifting/transporting the machine:

Make sure all lifting devices are attached securely and have enough weight-

bearing capacity to lift or hold the machine safely.

Remain aware of the location of other people when lifting the machine.

Only use the lifting points and tie-downs described in the Operator’s Manual.

Only use suitable transport vehicles with sufficient load-carrying capacity.

When lifting the machine:

Never walk or stand under a suspended machine.

Never climb, sit, or stand on the machine while lifting it or transporting it.

ghi_si000343gb.fm 9

Safety Information Cub 200/300

1.4 Safety Guidelines While Using Combustion Burners

When using the machine:

Clean up any spilled fuel immediately.

Replace the fuel tank cap after refueling the machine.

Refill the fuel tank in a well-ventilated area.

Shut down the generator, if equipped, when refueling.

When using the machine:

DANGER

Exhaust gas from the burner contains carbon monoxide, a deadly poison. Exposure

to carbon monoxide can kill you in minutes.

f Never run the machine indoors or in an enclosed area unless the machine is

vented properly.

Do not fill or drain the fuel tank near an open flame or while the machine is

running.

Do not smoke when refueling the machine.

10 ghi_si000343gb.fm

Cub 200/300 Safety Information

1.5 Safety Guidelines for Maintaining the Machine

Training

Cleaning

Maintenance

guidelines

Only trained personnel should troubleshoot or repair electrical problems occur-

ring with the machine.

When cleaning and servicing the machine:

Keep the area around the burner free of debris such as leaves, paper, cartons,

etc.

Keep the machine clean and labels legible.

When cleaning the machine:

Do not clean the machine while it is running.

Never use gasoline or other types of fuels or flammable solvents to clean parts.

Fumes from fuels and solvents can become explosive.

When maintaining the machine:

Keep the fuel lines in good condition and properly connected.

Allow the burner to cool before maintaining the machine.

Reinstall the safety devices and guards after repairs and maintenance.

Keep all electrical cords away from heat, oil, vibrating surfaces, and sharp

edges.

Inspect all electrical cords before each use and replace damaged cords.

Replacing

parts and

labels

Accessories,

safety devices

and

modifications

When maintaining the machine:

Replace worn or damaged components.

Use only spare parts recommended by Wacker Neuson Corporation.

Replace all missing and hard-to-read labels.

Replace or repair electrical components with components that are identical in

rating and performance as the original component.

When using the machine:

Use only accessories/attachments that are recommended by Wacker Neuson

Corporation.

When using the machine:

Never operate the machine if any safety devices or guards are missing or inop-

erative.

Do not defeat safety devices.

Do not modify the machine without the express written approval of the manufac-

turer.

ghi_si000343gb.fm 11

Operation Cub 200/300

2 Operation

2.1 Controls and Components

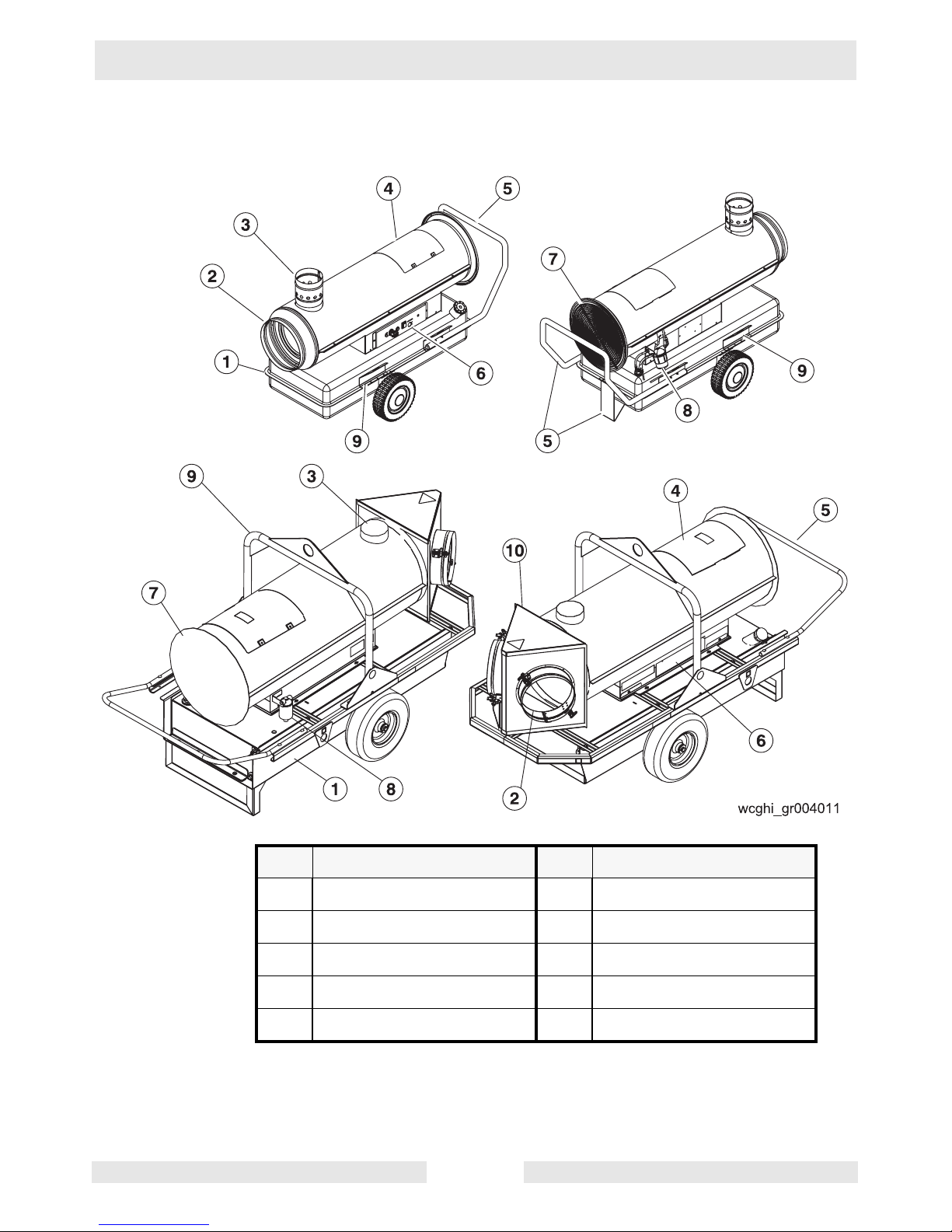

Ref Component Ref Component

1 Fuel tank 2 Air outlet

3 Flue collar (vent) 4 Burner access panel

5 Handle (and base) 6 Control panel

7 Blower 8 Fuel oil filter

9 Lifting device 10 Duct adapter

ghi_tx001205gb.fm 12

Cub 200/300 Operation

2.2 Control Panel

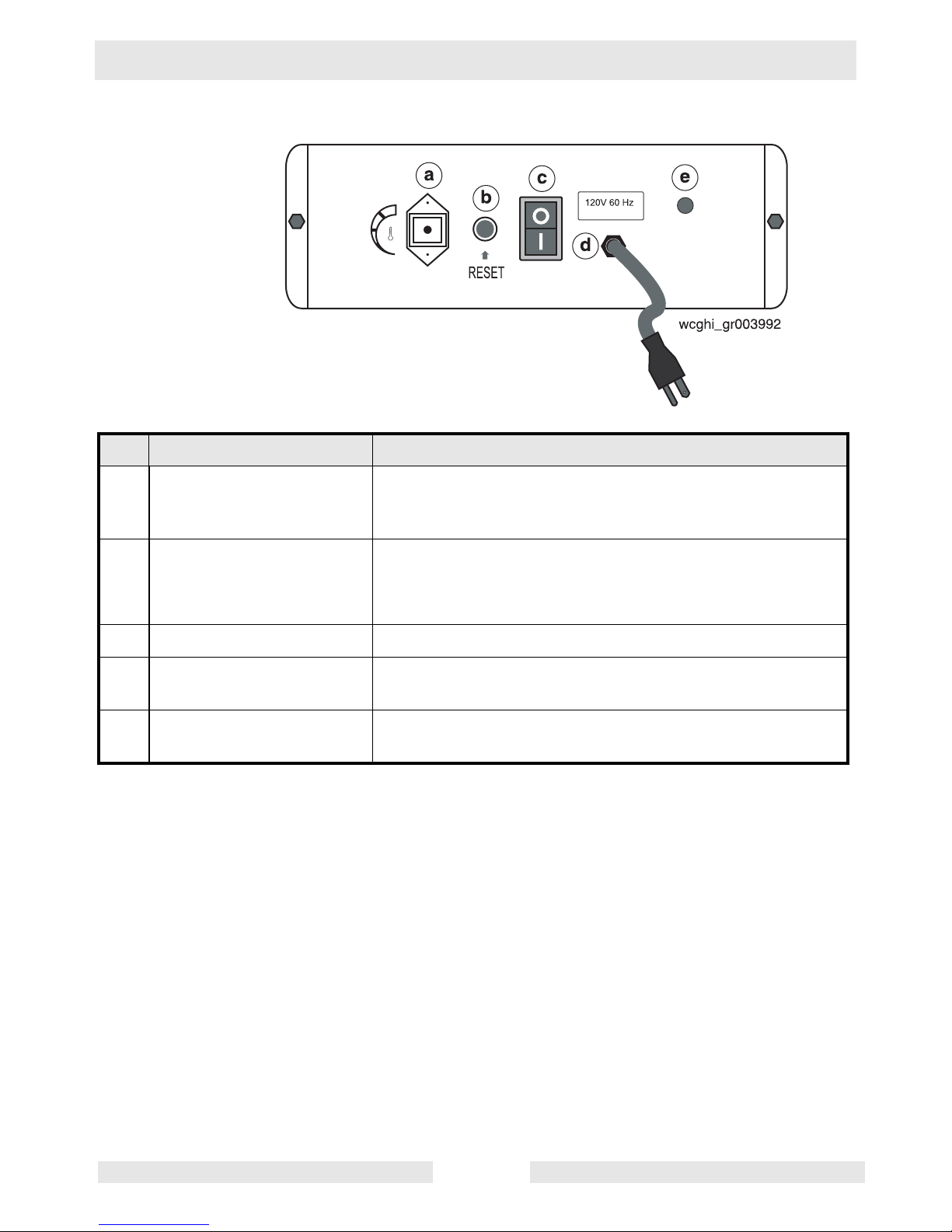

Ref Component Function

a Remote thermostat

receptacle

The remote thermostat receptacle (shown with protective

cap installed) is used for connecting an optional remote

thermostat.

b Burner fault lamp and reset

button (dual function)

The dual function burner fault lamp and reset button:

• illuminates red when the burner has faulted.

• resets the machine when pressed.

c Power switch The power switch provides power to the machine.

d Power cord The power cord provides a means of connecting the

machine to a 115V 60 Hz receptacle.

e Power indicator lamp The power indicator lamp illuminates green when the power

cord is connected to a 115V 60 Hz receptacle.

ghi_tx001205gb.fm 13

Operation Cub 200/300

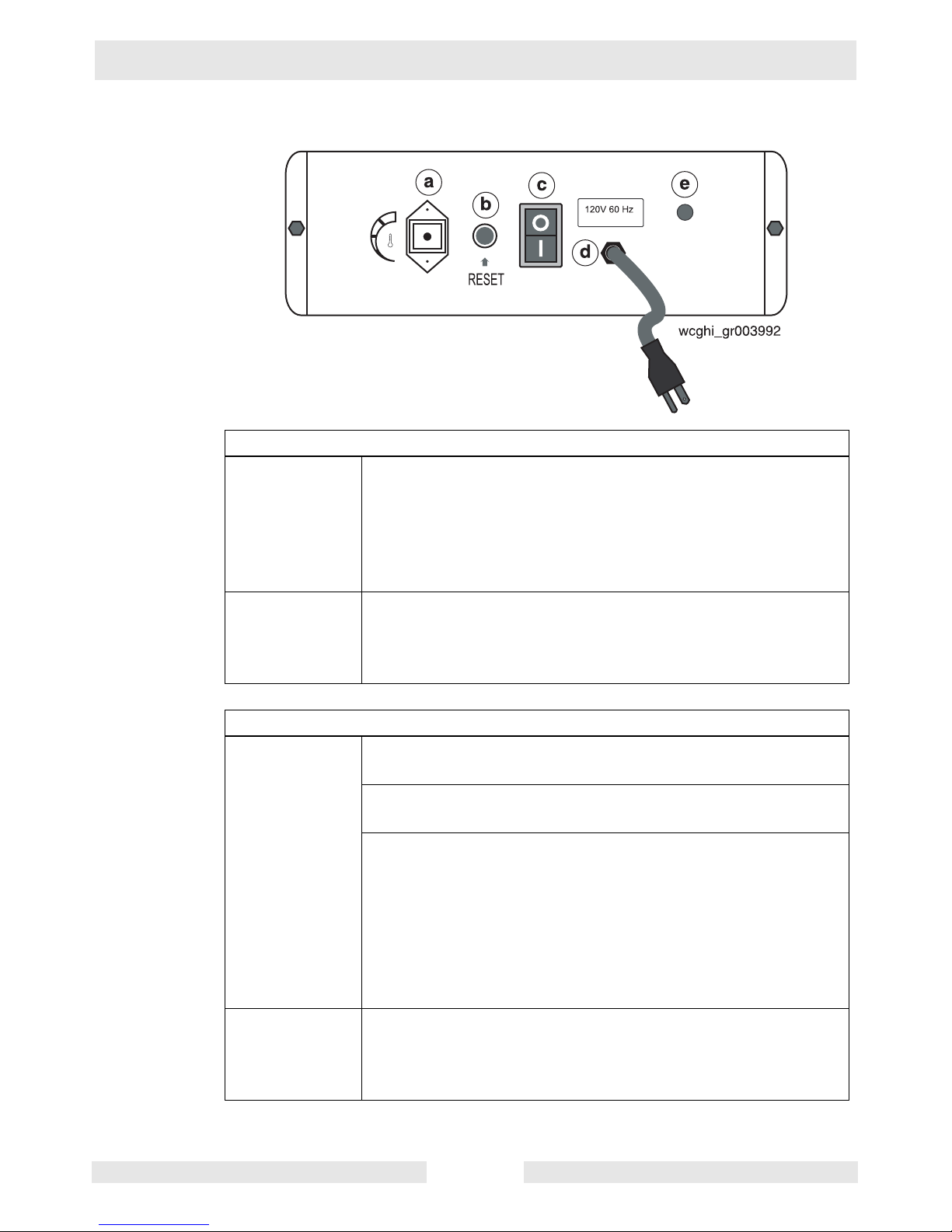

2.3 Starting/Stopping the Machine

If not using the remote thermostat

Turning ON

Turning OFF

1. Move the power switch (c) to the ON “I” position.

The blower will turn on immediately.

The burner will go through a prepurge cycle and then

ignite.

The burner will continue to fire and the blower will con-

tinue to operate until the machine is turned off.

2. Move the power switch to the OFF position.

The burner will shut down.

The blower will continue to operate for approximately

two minutes to allow the combustion chamber to cool.

If using the remote thermostat

Turning ON

1. Connect the remote thermostat to the control panel at the

remote thermostat receptacle (a).

2. Place the remote thermostat in the area to be heated. Set it

to the desired temperature.

3. Move the power switch (c) to the ON “I” position.

The blower will turn on immediately.

The burner will go through a prepurge cycle and then

light.

The burner will continue to fire until the temperature of

the space being heated reaches the temperature set by

the thermostat. At that time, the burner shuts down but

the blower will remain on.

Turning OFF

4. Move the power switch to the OFF position.

The burner will shut down.

The blower will continue to operate for approximately

two minutes to allow the combustion chamber to cool.

ghi_tx001205gb.fm 14

Cub 200/300 Operation

Notes

ghi_tx001205gb.fm 15

Burner Setup Cub 200/300

3 Burner Setup

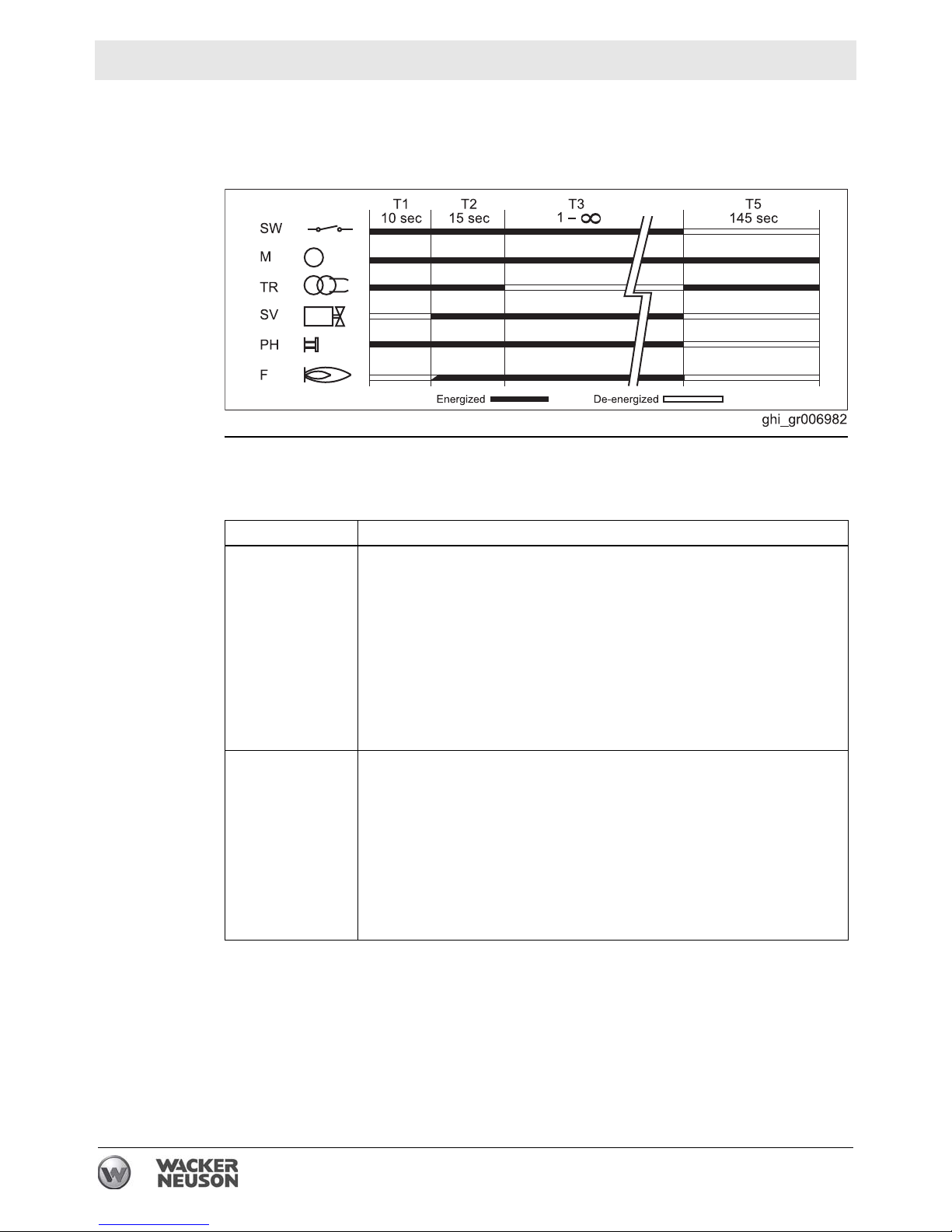

3.1 Control Board Sequence of Operation

Periods

The burner controller has several periods it sequences through during normal

operation. These periods are described below.

.

Period Action or Function

Prepurge (T1) As soon as the control switch (SW) is turned ON, the prepurge period

begins. It lasts approximately 10 seconds.

During this period:

The fan blows air into the combustion chamber to expel any resid-

ual exhaust gases.

The ignition transformer (TR) turns ON and remains ON. It pro-

duces a continuous spark across the electrodes so that any residual fuel is ignited and burned off.

The flame control unit (cad cell) (PH) checks for presence of a

flame. If a consistent flame is detected, the ignition sequence is

interrupted and the heater locks out.

Ignition (T2) After the prepurge period, the ignition period begins. It lasts

approximately 15 seconds.

During this period:

The fan runs .

The ignition transformer (TR) is ON, producing a continuous spark

across the electrodes.

The fuel solenoid (SV) opens and the fuel is ignited. The fuel sole-

noid will remain open if the cad cell (PH) detects a flame within 1

second from the start of this period. If no flame is detected, the fuel

solenoid closes and the heater locks out.

16 ghi_tx001317gb.fm

Cub 200/300 Burner Setup

Period Action or Function

Operation (T3) After the ignition period, the operation period begins. It will last as

long as there is flame or until the heater is turned off.

During this period:

The fan runs.

The ignition transformer (TR) is OFF. There is no spark across the

electrodes.

The fuel solenoid (SV) is open and flame is self-sustaining. The

cad cell (PH) monitors the flame. If the flame is interrupted through

lack of fuel or lack of air, the machine will go through the prepurge

and ignition period in an attempt to re-establish the flame. If the

flame is not re-established, the aftercooling period begins.

Aftercooling (T5) After the heater is turned OFF (or af ter flame re-establishment has

failed), the aftercooling period begins. It last s appro ximately 1 minute

and 45 seconds.

During this period:

The power switch is OFF .

The fan runs. After approximately 1 minute and 45 seconds, the

fan stops.

The ignition transformer (TR) turns ON and remains ON. It pro-

duces a continuous spark across the electrodes so that any residual fuel is ignited and burned off.

Reset To reset the heater:

1. Wait 30 seconds after the lockout condition has occurred.

2. Push th e reset button.

ghi_tx001317gb.fm 17

Burner Setup Cub 200/300

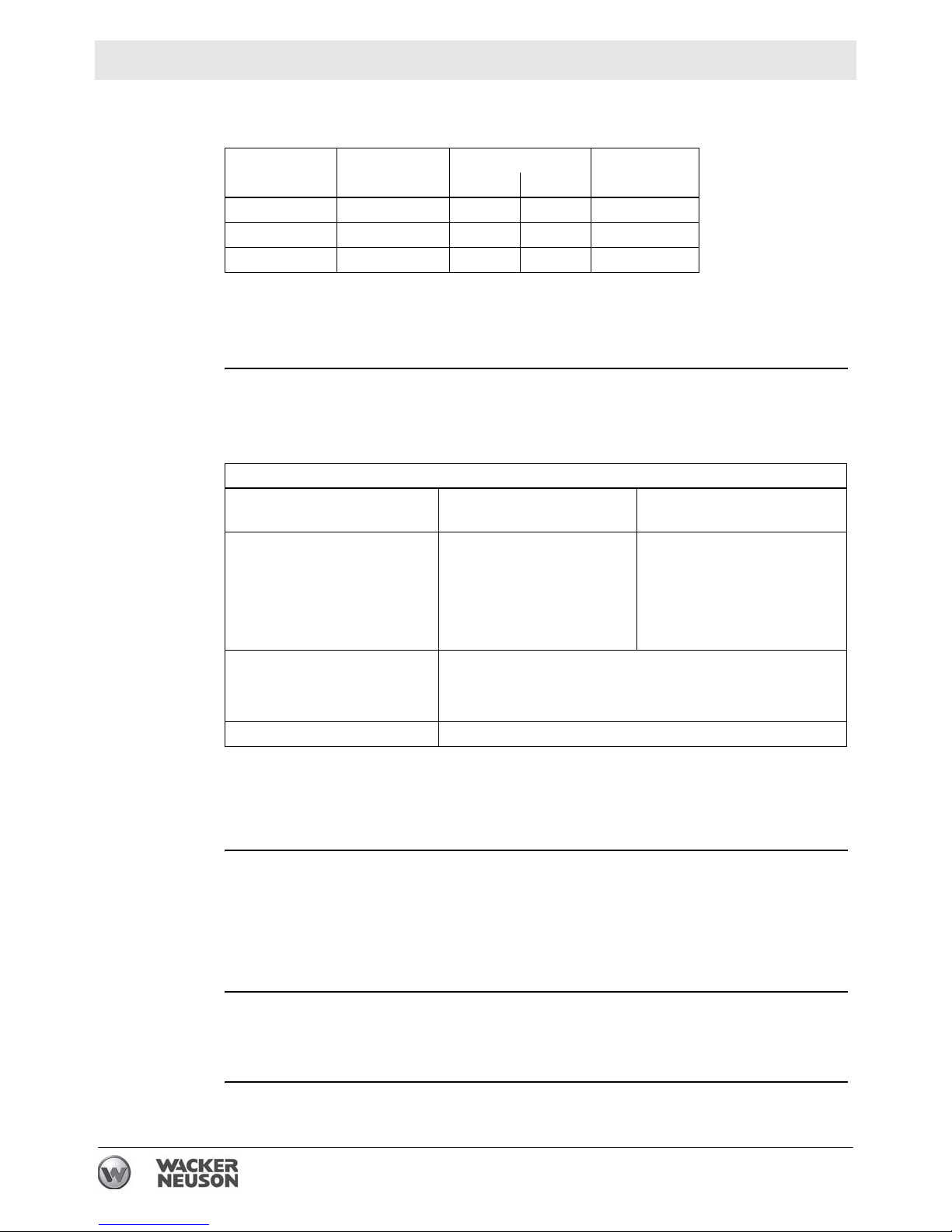

3.2 Setting Up the Burner

Factory

settings

Machine Nozzle size Fuel pressure

gph psi bar

Cub 200 1.0 x 60°A 175 12 2

Cub 300 1.5 x 80°W 175 12 3

Cub 300HD 1.35 x 80°H 218 15 5

Air band

setting

Background

Fuel

The burner consists of several different components and subsystems. Each of

these components or subsystems must be operating correctly for the burner to

function properly.

Low ambient temperatures cause diesel fuels to gel. Gelled fuels will cause burner

ignition failure and/or burner fuel pump damage. Always use the proper fuel for the

conditions.

Fuel Blend Guide

Lowest expected ambient

temperature °F (°C)

Below 5 (-15)

5 to 25 (-15 to -4)

Above 25 (-4) Winter-blend diesel

Generator powered Shore powered

50-50 blend of #2 diesel

and #1 diesel, plus

additives

OR

50-50 blend #2 diesel and

K1 kerosene, plus

additives

70-30 blend of #2 diesel and #1 diesel, plus additives

70-30 blend of #2 diesel and K1 kerosene,

plus additives

100% #1 diesel plus

additives

OR

100% K1 kerosene,

plus additives

OR

Note: The burner on this machine was calibrated by test-firing for correct op eration

at Wacker Neuson Corporation located 180 m (600 ft.) above sea level using #2

diesel fuel combined with an anti-gelling additive.

Tools required

Mandates

The following tools are required to adjust the burner:

High-quality combustion analyzer

Smoke spot tester

Fuel pressure test gauge

General hand tools

Adjustments made shall be done so that the machine conforms to the require-

ments of local, state, and federal codes and authorities.

Adjustments shall be made at the job site.

This procedure continues on the next page.

18 ghi_tx001317gb.fm

Cub 200/300 Burner Setup

Continued from the previous page.

When

Procedure

Adjust the burner:

Before operating the machine at elevations 305 m (1,000 ft) above or below the

location of where the last adjustments were made

Before starting at a new job site

After any burner maintenance or repair has been performed

If burner performance is in question

Follow the procedure below to set up the burner.

1. Shut down the machine.

2. Set the burner electrodes.

(See Section 3.4 Checking and Adjusting the Burner Electrodes on page 22.)

3. Check the burner nozzle.

(See Section 3.5 Checking and Replacing the Burner Nozzle on page 23.)

4. Set the air band.

(See Section 3.6 Setting the Air Band on page 24.)

5. Start the machine and the burner.

6. Check/set the fuel pressure.

(See Section 3.7 Checking and Adjusting the Fuel Pressure on page 25.)

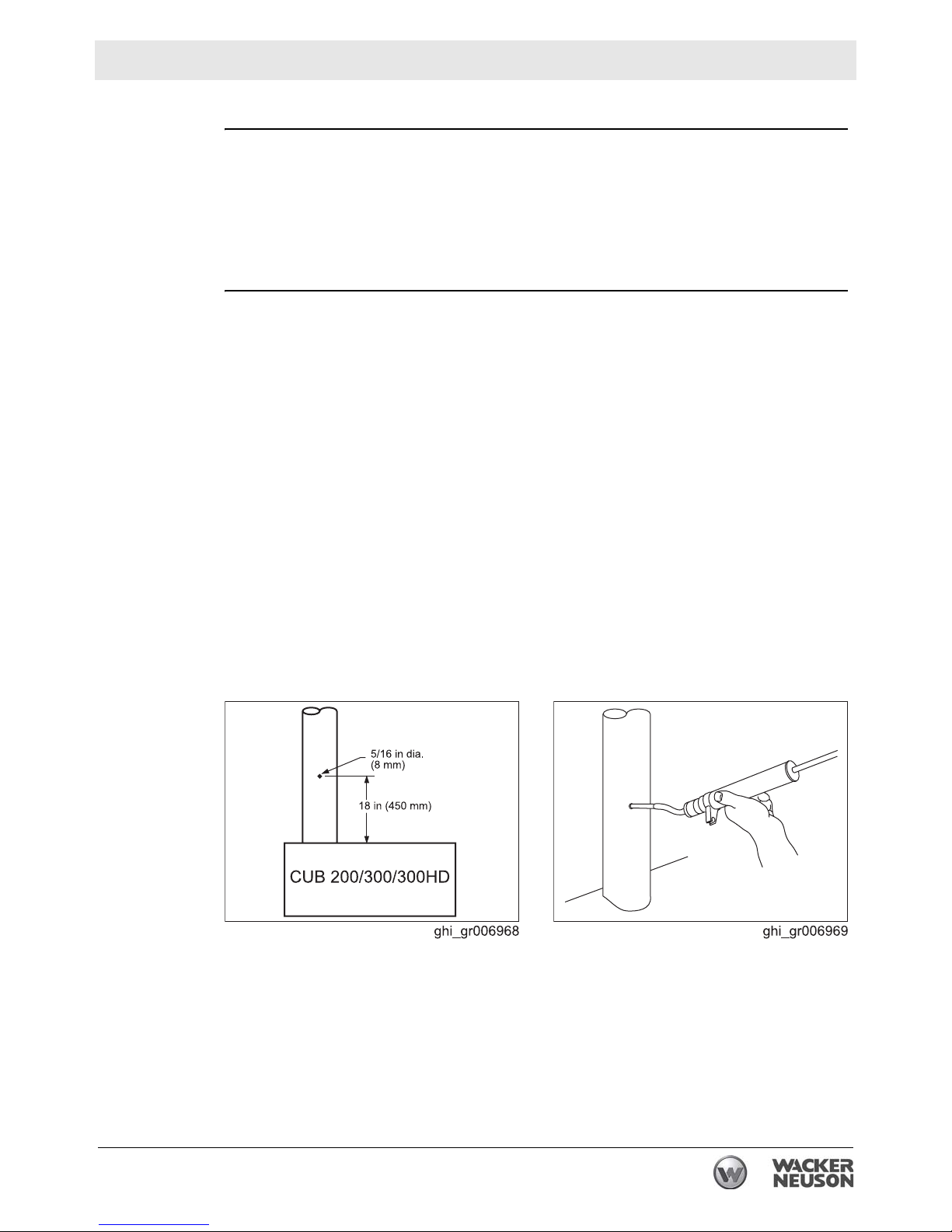

7. Conduct a smoke spot test. Follow the smoke spot tester manufacturer’s

instructions and the general guidelines below.

Use the access hole in the exhaust stack.

Several samples should be taken as the heater warms.

The final sample should be taken just before the heater reaches 71°C (160°F).

This procedure continues on the next page.

ghi_tx001317gb.fm 19

Burner Setup Cub 200/300

Continued from the previous page.

8. Analyze the combustion. Follow the combustion analyzer manufacturer’s

instructions and the general guidelines below.

Use the access hole in the exhaust stack.

Take several samples as the heater warms.

Take the final sample just before the heater reaches 71°C (160°F).

9. Re-adjust the air band, if necessary, until the smoke spot test and combustion

analysis are within the following parameters:

Result

O

content: 3–5%

2

Smoke spot: less than 1

The burner has now been set.

20 ghi_tx001317gb.fm

Loading...

Loading...