Page 1

0170893en 006

0809

Indirect-fired Air

Heaters

Cub 200/300/300 HD

OPERATOR’S MANUAL

0170893EN

Page 2

Page 3

1 Foreword

WARNING

Foreword

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

This manual provides information and procedures to safely operate

and maintain this Wacker Neuson model. For your own safety and

protection from injury, carefully read, understand and observe the

safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker Neuson

Corporation. This machine is built with user safety in mind; however, it

can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Neuson

Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Neuson Corporation

reserves the right to change any portion of this information without

notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2009 by Wacker Neuson Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker

Neuson Corporation represents an infringement of valid copyrights

and will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

wcghi_tx000001gb diesel.fm 3

Page 4

Foreword

Notes:

wcghi_tx000001gb diesel.fm 4

Page 5

Table of Contents

1. Foreword 3

2. Safety Information 7

2.1 Operating Safety .................................................................................. 7

2.2 Operator Safety while using Combustion Burners ............................... 8

2.3 Service Safety ...................................................................................... 8

2.4 Label Locations .................................................................................. 10

2.5 Label Descriptions .............................................................................. 11

3. Operation 15

3.1 System Description ............................................................................ 15

3.2 Installing the Lift Brackets .................................................................. 15

3.3 System Component Locations ........................................................... 16

3.4 Mounting the Handle and Base Assembly ......................................... 17

3.5 Machine Location ............................................................................... 18

3.6 Suggested Venting ............................................................................. 18

3.7 Connecting Power to the Machine ..................................................... 20

3.8 Preliminary Checks ............................................................................ 20

3.9 Control Panel ...................................................................................... 21

3.10 Starting the Machine .......................................................................... 22

3.11 Starting the Machine in (Extreme) Cold Weather ............................... 23

3.12 Shutting Down the Machine ............................................................... 24

3.13 Using the Remote Thermostat ........................................................... 25

4. Maintenance 27

4.1 Periodic Maintenance Schedule ......................................................... 27

4.2 Removing and Installing the Burner Assembly ................................... 28

4.3 Replacing the Burner Nozzle .............................................................. 30

4.4 Replacing the Fuel Filter .................................................................... 31

4.5 Inspecting and Aligning the Burner Electrodes .................................. 32

4.6 Inspecting and Cleaning the Cadmium (CAD) Cell ............................ 33

4.7 Checking and Adjusting the Fuel Pressure ........................................ 34

4.8 Cleaning the Fan Blades and Motor ................................................... 36

4.9 Cleaning the Interior Shell .................................................................. 37

4.10 Inspecting the Flame Head ................................................................ 38

ghi_bo0170893en_006TOC.fm 5

Page 6

Table of Contents

4.11 Inspecting the Electrical Connections .................................................39

4.12 Fuel Blend Guide .................................................................................39

4.13 Transporting ........................................................................................40

4.14 List of Abbreviations ............................................................................41

4.15 Troubleshooting ...................................................................................42

4.16 Cub 200/300 Wiring Schematic ...........................................................44

4.17 Cub 300 HD Wiring Schematic ............................................................44

4.18 Schematic Legend ...............................................................................45

5. Technical Data 47

5.1 Machine Technical Data ......................................................................47

ghi_bo0170893en_006TOC.fm 6

Page 7

Cub 200/300/300 HD Safety Information

2 Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION

NOTICE: Used without the safety alert symbol, NOTICE indicates a

situation which, if not avoided, could result in property damage.

Note: Contains additional information important to a procedure.

2.1 Operating Safety

Familiarity and proper training are required for the safe operation of

equipment! Equipment operated improperly or by untrained personnel

can be dangerous! Read the operating instructions contained in this

WARNING

manual and familiarize yourself with the location and proper use of all

controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate

the machine.

2.1.1 Be sure the machine is on a firm, level surface and will not tip, roll,

slide, or fall while operating.

2.1.2 NEVER start a machine in need of repair.

wcghi_si000212gb.fm 7

Page 8

Safety Information Cub 200/300/300 HD

2.1.3 Keep unauthorized personnel, children, and pets away from the

machine.

2.1.4 Always operate machine with all safety devices and guards in place

and in working order. Do not modify or defeat safety devices. Do not

operate machine if any safety devices or guards are missing or

inoperative.

2.1.5 NEVER run the machine indoors or in an enclosed area unless

adequate ventilation, through such items as exhaust fans or hoses, is

provided and if local and national codes permit. Exhaust from the

burner contains poisonous carbon monoxide gas. Exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

2.1.6 Do not smoke while operating the machine.

2.1.7 NEVER run the machine in areas that contain flammable objects,

fuels, or products that produce flammable vapors.

2.1.8 NEVER connect ductwork between the exhaust outlet port and the

supply air inlet port.

2.1.9 NEVER block the air inlet or outlet.

2.1.10 The installation of this machine must be in accordance with the

regulations put forth by all governing bodies having jurisdiction

including the Canadian Standard B139.

2.2 Operator Safety while using Combustion Burners

2.2.1 Refill the fuel tank in a well-ventilated area.

2.2.2 Replace the fuel tank cap after refueling.

2.2.3 DO NOT spill fuel when refueling the machine. Clean up spilled fuel

immediately.

2.2.4 DO NOT smoke when refueling machine.

2.2.5 DO NOT refuel a hot or running machine.

2.2.6 The machine must be installed by qualified personnel who have read

and understand all supplied manuals and instructions.

2.2.7 When operating the machine indoors, install a carbon monoxide

detector in the work area according to the detector manufacturer’s

instructions.

2.2.8

2.3 Service Safety

HIGH VOLTAGE! This unit uses high voltage circuits capable of

causing serious injury or death. Only a qualified electrician should

troubleshoot or repair electrical problems occurring with this

WARNING

wcghi_si000212gb.fm 8

equipment.

Page 9

Cub 200/300/300 HD Safety Information

2.3.1 ALWAYS replace the safety devices and guards after repairs and

maintenance.

2.3.2 Keep the machine clean and labels legible. Replace all missing and

hard-to-read labels. Labels provide important operating instructions

and warn of dangers and hazards.

2.3.3 ALWAYS make sure slings, chains, hooks, ramps, jacks, and other

types of lifting devices are attached securely and have enough weightbearing capacity to lift or hold the machine safely. Always remain

aware of the location of other people in the area when lifting the

machine.

2.3.4 ALWAYS replace or repair electrical components with components

that are identical in rating and performance as the original component.

2.3.5 Do not use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

2.3.6 Always wear protective epuipment when servicing the machine. Some

machine components may be hot and contain hot fluids.

2.3.7 Notes:

wcghi_si000212gb.fm 9

Page 10

Safety Information Cub 200/300/300 HD

2.4 Label Locations

wcghi_si000212gb.fm 10

Page 11

Cub 200/300/300 HD Safety Information

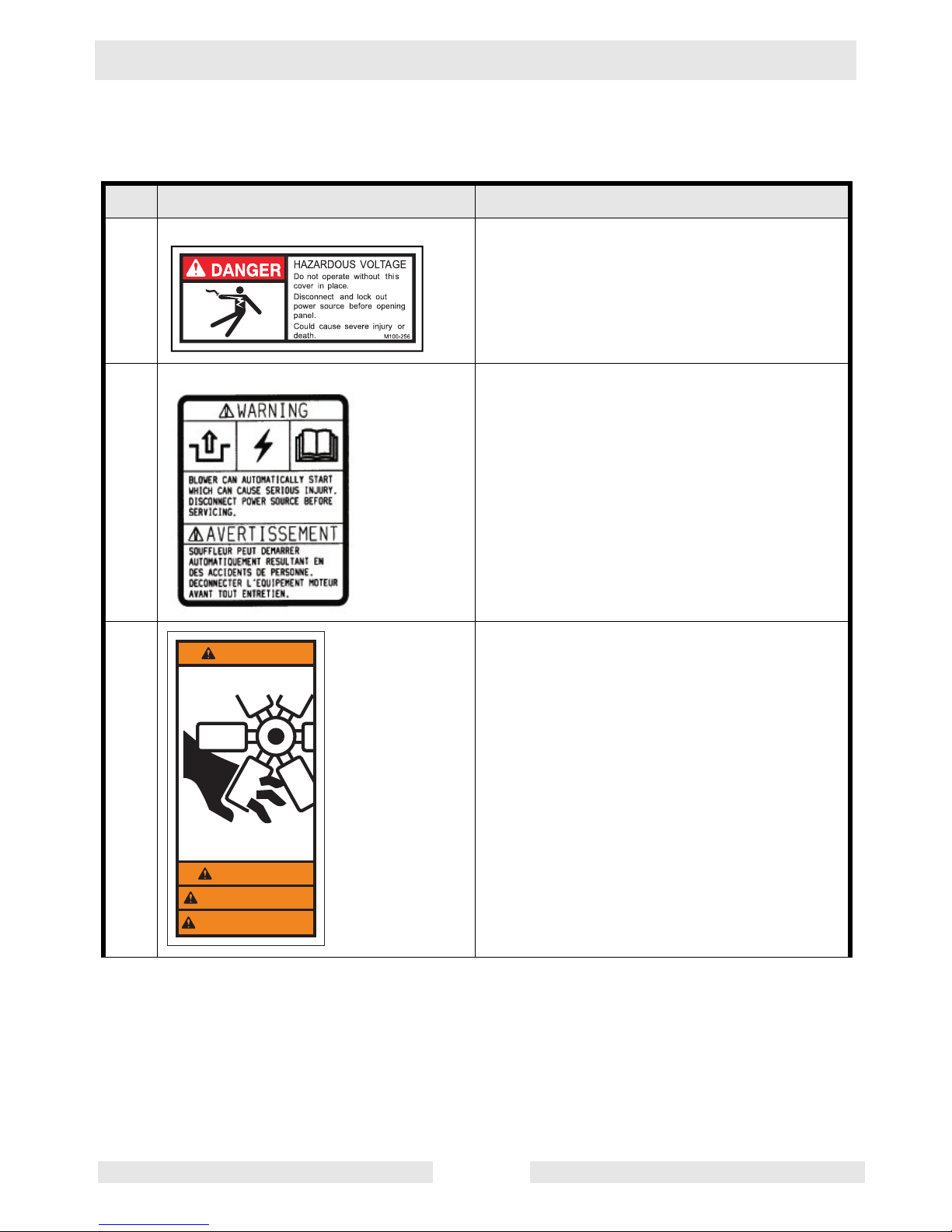

2.5 Label Descriptions

Ref. Label Label Text

1 Danger! Hazardous voltage. Do not oper-

ate without this cover in place. Disconnect

and lock out power source before opening

panel. Could cause severe injury or death.

2 Warning: Blower can automatically start

which can cause serious injury. Disconnect

power source before servicing.

3 Warning: Blower can automatically start

WARNING

which can cause serious injury. Disconnect

power source before servicing.

177370

WARNUNG

ADVERTENCIA

AVERTISSEMENT

wcghi_si000212gb.fm 11

Page 12

Safety Information Cub 200/300/300 HD

D

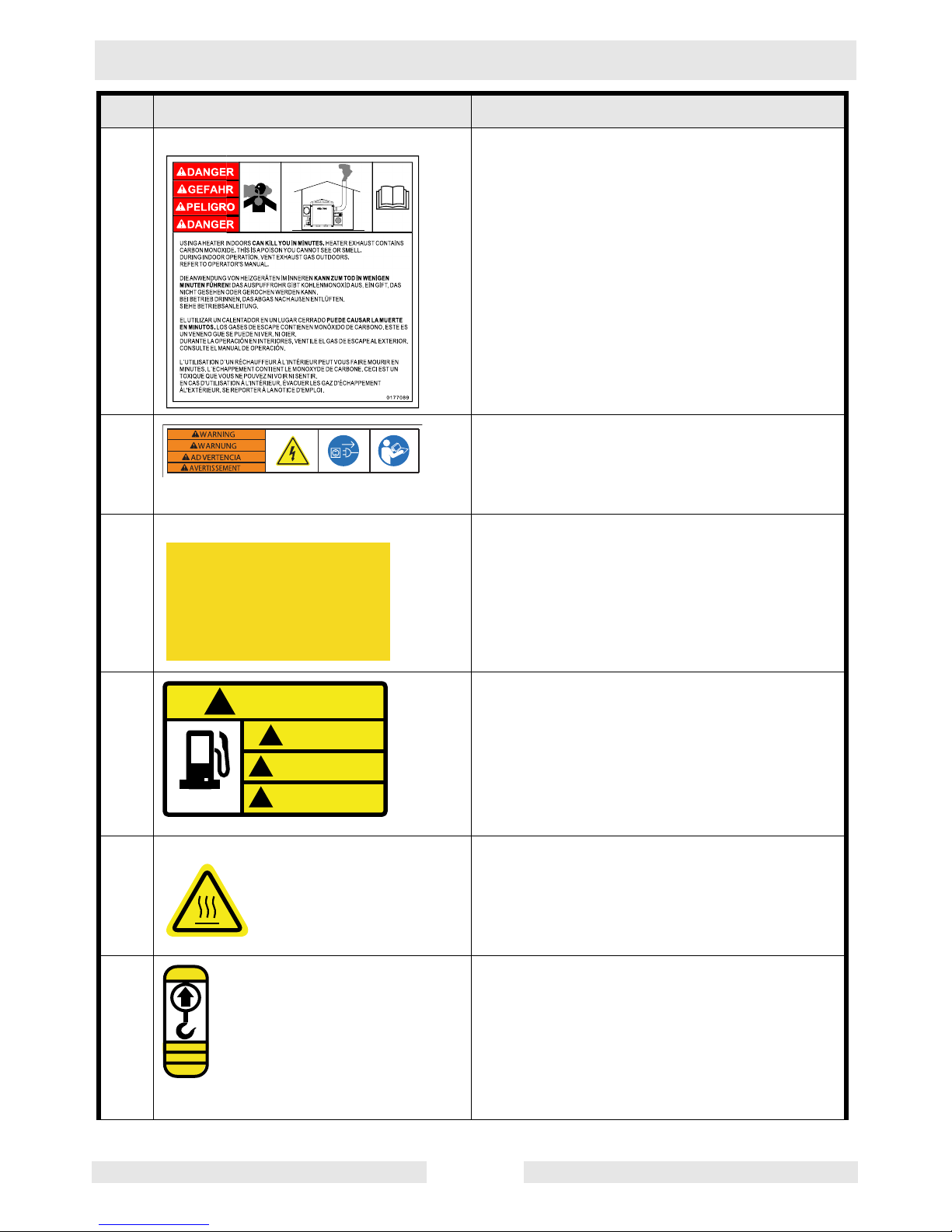

Ref. Label Label Text

4 Using a heater indoors can kill you in min-

utes. Heater exhaust contains carbon monoxide. This is a poison you cannot see or

smell. During indoor operation, vent

exhaust gas outdoors. Refer to Operator's

Manual.

5 Warning: Electric shock hazard.

Disconnect power before servicing.

Read Operator’s Manual.

6 Danger: To avoid injury from moving parts,

DANGER

TO AVOID INJURY FROM

MOVING PARTS, SHUT OFF

THE EQUIPMENT BEFORE

REMOVING THIS COVER.

shut off the equipment before removing this

cover.

7 Caution: This machine uses diesel fuel.

CAUTION

VORSICHT

PRECAUCION

DIESEL

8 Hot surface hazard!

9 Caution: Lift point.

CAUTION

PRECAUCION

Attach lifting device in this location.

VORSICHT

PRECAUCION

PRECAUTION

wcghi_si000212gb.fm 12

Page 13

Cub 200/300/300 HD Safety Information

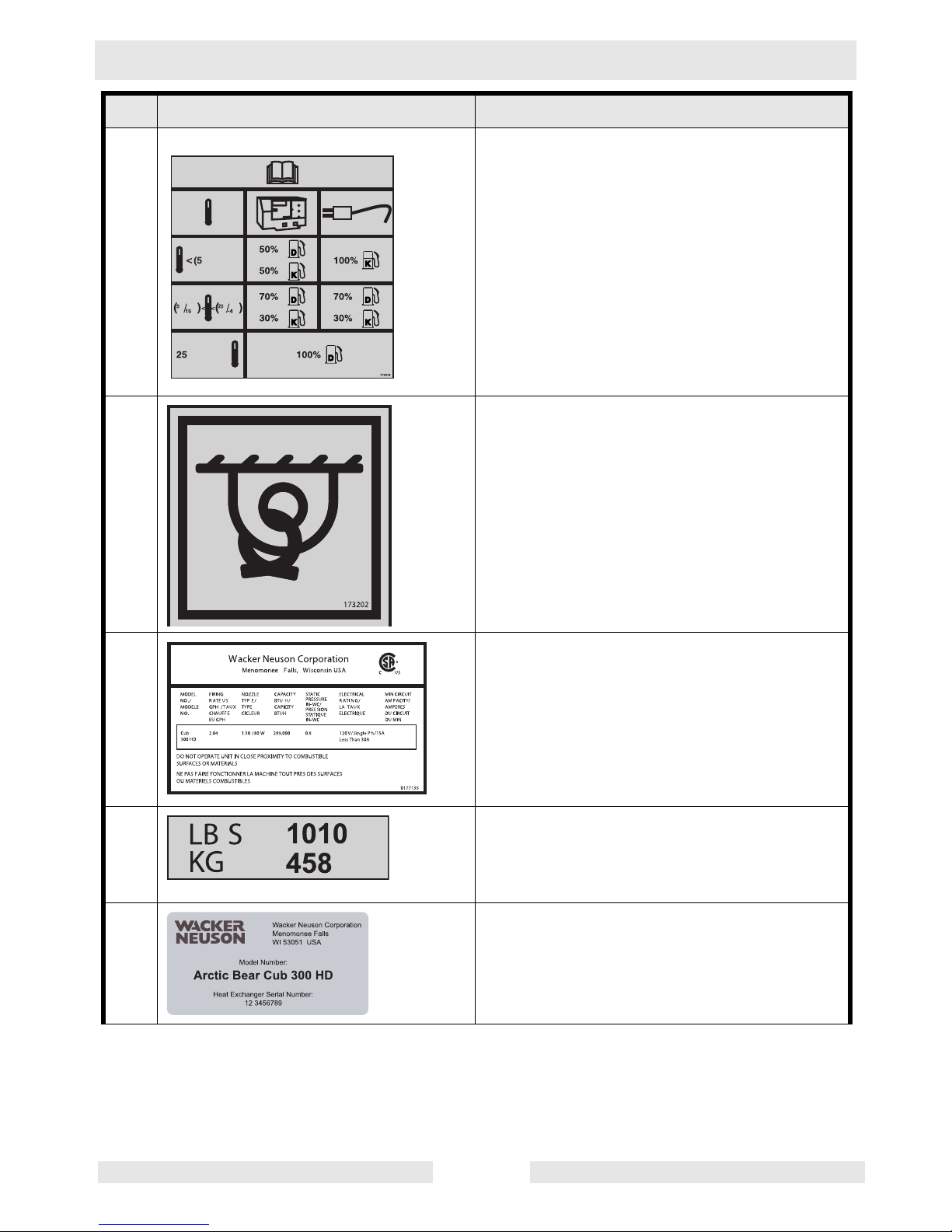

Ref. Label Label Text

10 Diesel fuel blend guide. This label indicates

the recommended fuel blending values for

diesel fuel usage.

11 Tie-down point.

12 Machine rating label: This label indicates

rating information for the machine.

13 Weight/mass label: This label indicates the

total weight of the machine, including the

trailer and a full fuel tank.

14 Model and serial number label: This label

shows the model name and the serial number for the heat exchanger on your

machine.

wcghi_si000212gb.fm 13

Page 14

Safety Information Cub 200/300/300 HD

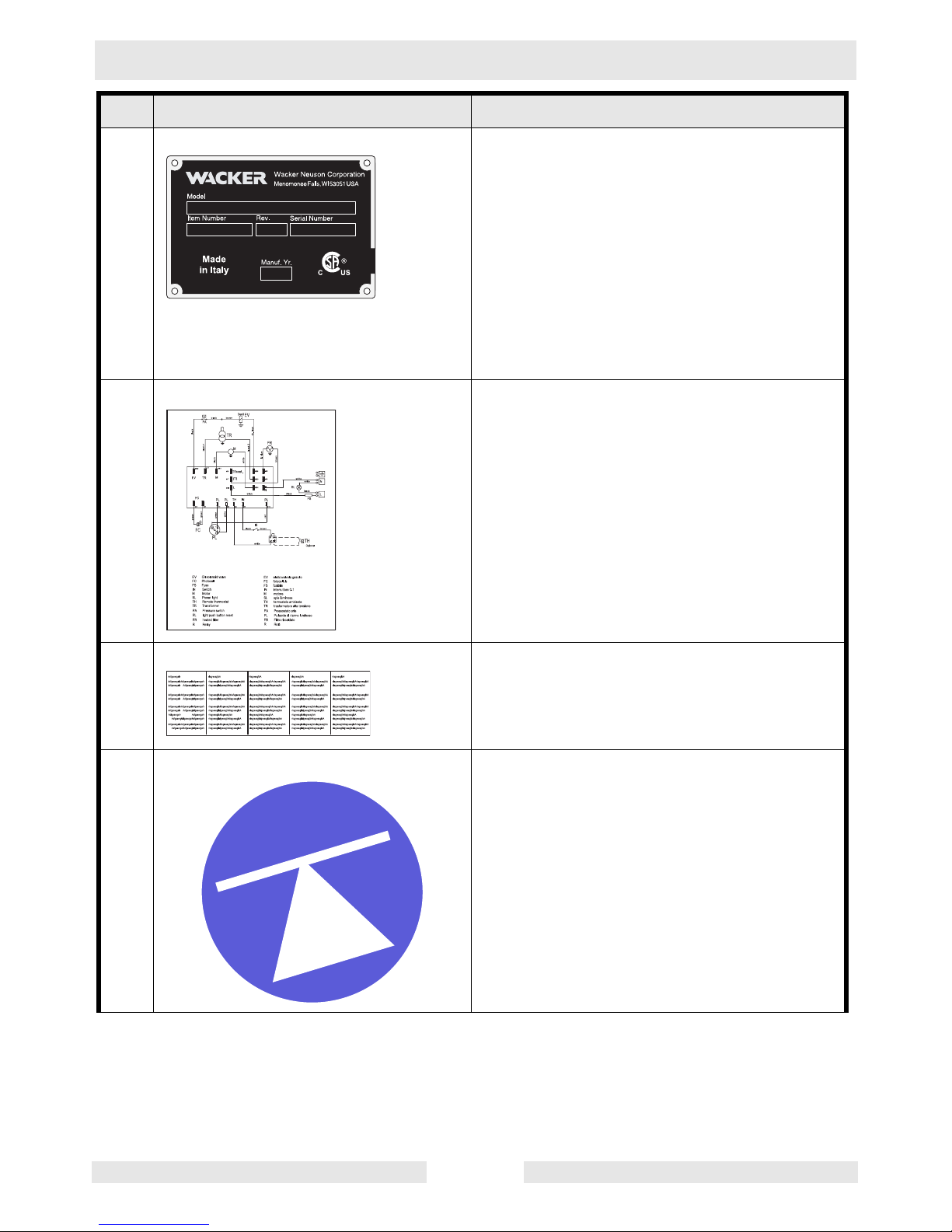

Ref. Label Label Text

15 A nameplate listing the model number, item

number, revision number, and serial number is attached to each unit. Please record

the information found on this plate so it will

be available should the nameplate become

16 Schematic label. This label, located behind

lost or damaged. When ordering parts or

requesting service information, you will

always be asked to specify the model number, item number, revision number, and

serial number of the unit.

the control panel, shows the electrical

schematic for the machine.

17 Installation and instruction label. This label

shows installation and operation instructions for the unit.

18 Center of gravity.

wcghi_si000212gb.fm 14

Page 15

Cub 200/300/300 HD Operation

3 Operation

3.1 System Description

The Cub series Air Heater machines are indirect-fired air heaters. The

Cub series Air Heater machines incorporate aluminized steel shells

and heat exchangers. The machines run on three fuel options: diesel,

Kerosene, or winter blend diesel (winter blend diesel is treated with

anti-gelling conditioners for use in cold weather). The fuel is consumed

in a closed combustion chamber. The exhaust gasses must be vented

outdoors through a vent pipe. The clean, dry hot air is recirculated by

means of an enclosed blower.

The Cub series Air Heater machines are intended to heat air on

construction sites and in other rugged environments. Do not use the

machines for any other purpose.

3.2 Installing the Lift Brackets

See graphic ghi_gr005931

Before attempting to lift the Cub 200 and 300 models, the lift brackets

must be installed.

3.2.1 Remove the machine from the crate.

3.2.2 Intstall the four lift brackets (a) as shown using the supplied bolts and

washers.

wcghi_tx000720gb.fm 15

Page 16

Operation Cub 200/300/300 HD

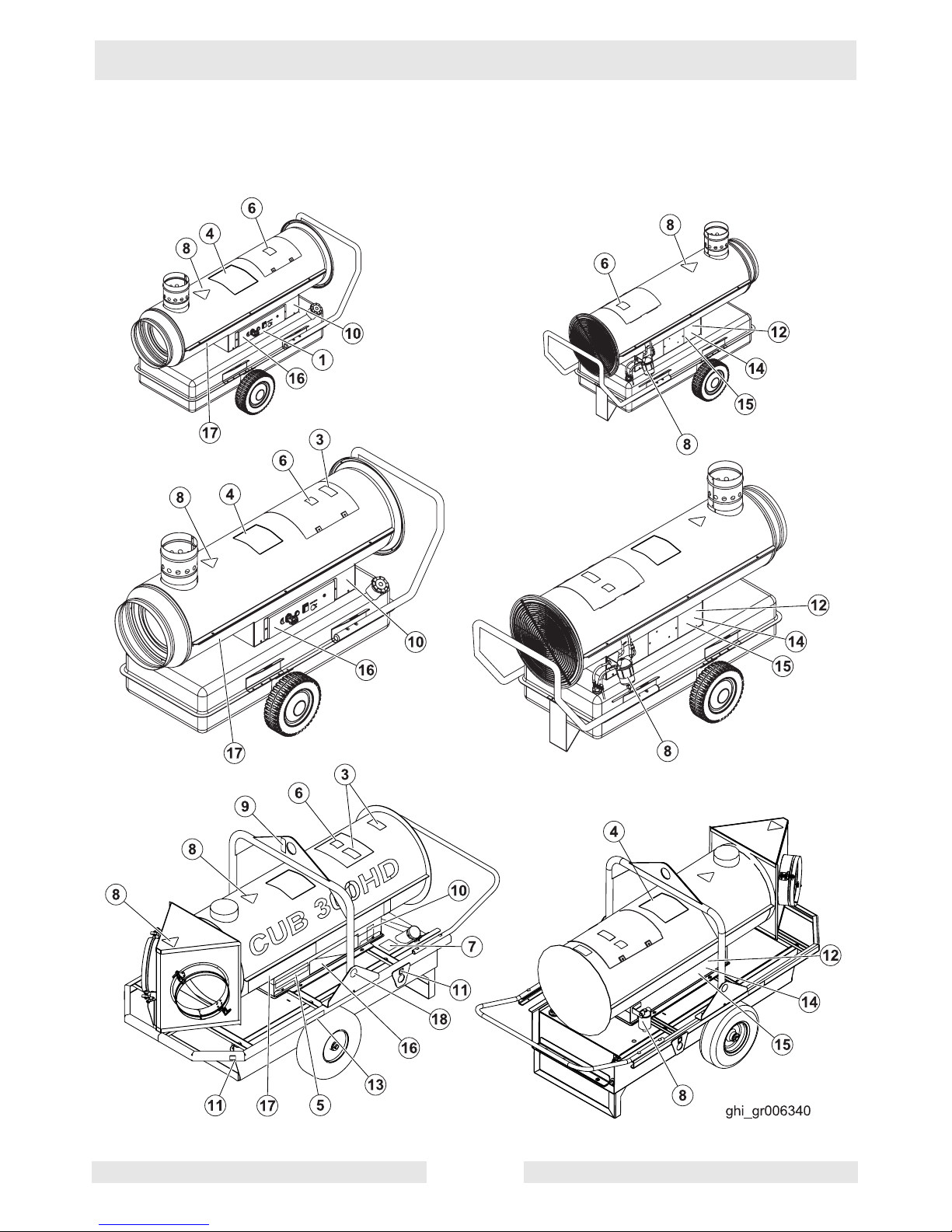

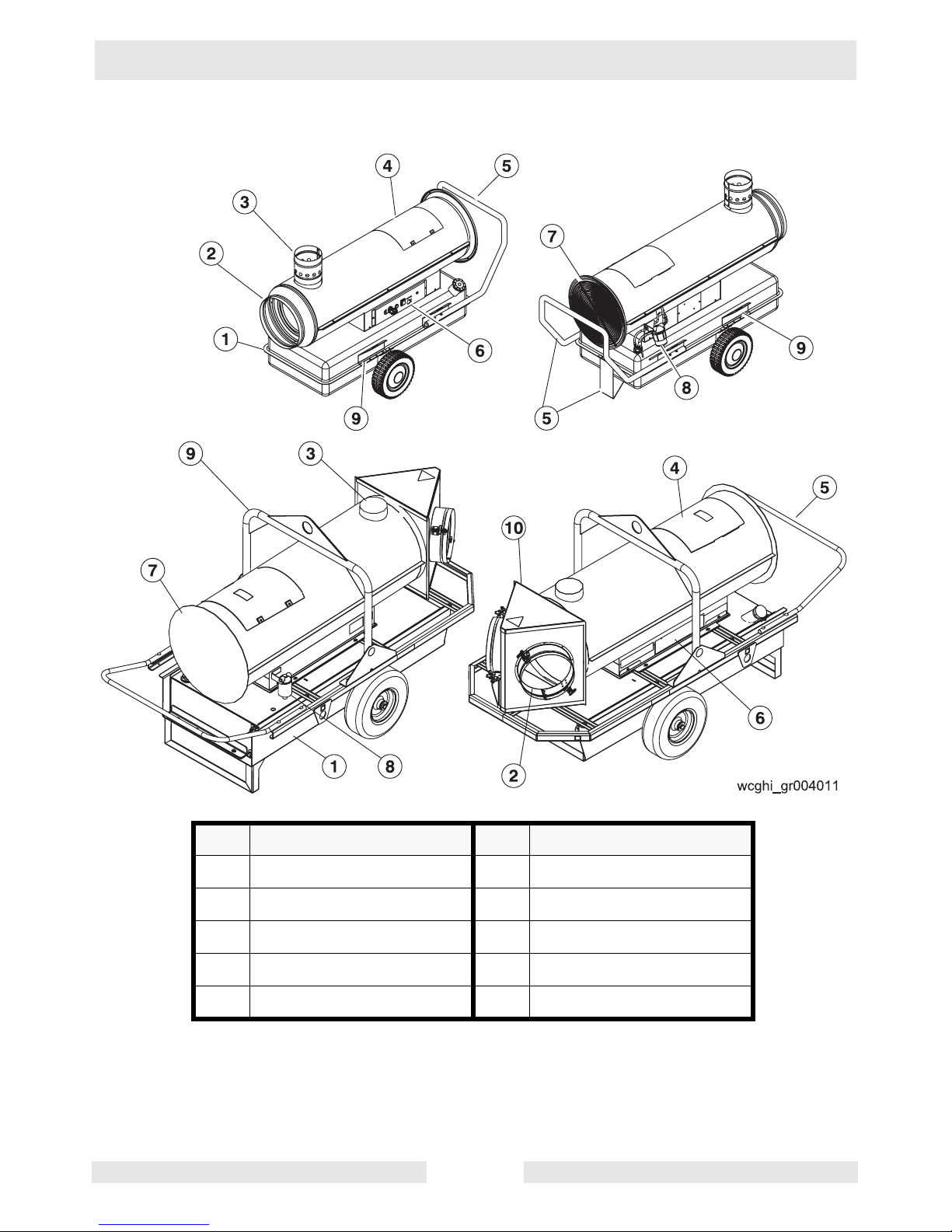

3.3 System Component Locations

Ref Component Ref Component

1 Fuel tank 2 Air outlet

3 Flue collar (vent) 4 Burner access panel

5 Handle (and base) 6 Control panel

7 Blower 8 Fuel oil filter

9 Lifting device 10 Duct adapter

wcghi_tx000720gb.fm 16

Page 17

Cub 200/300/300 HD Operation

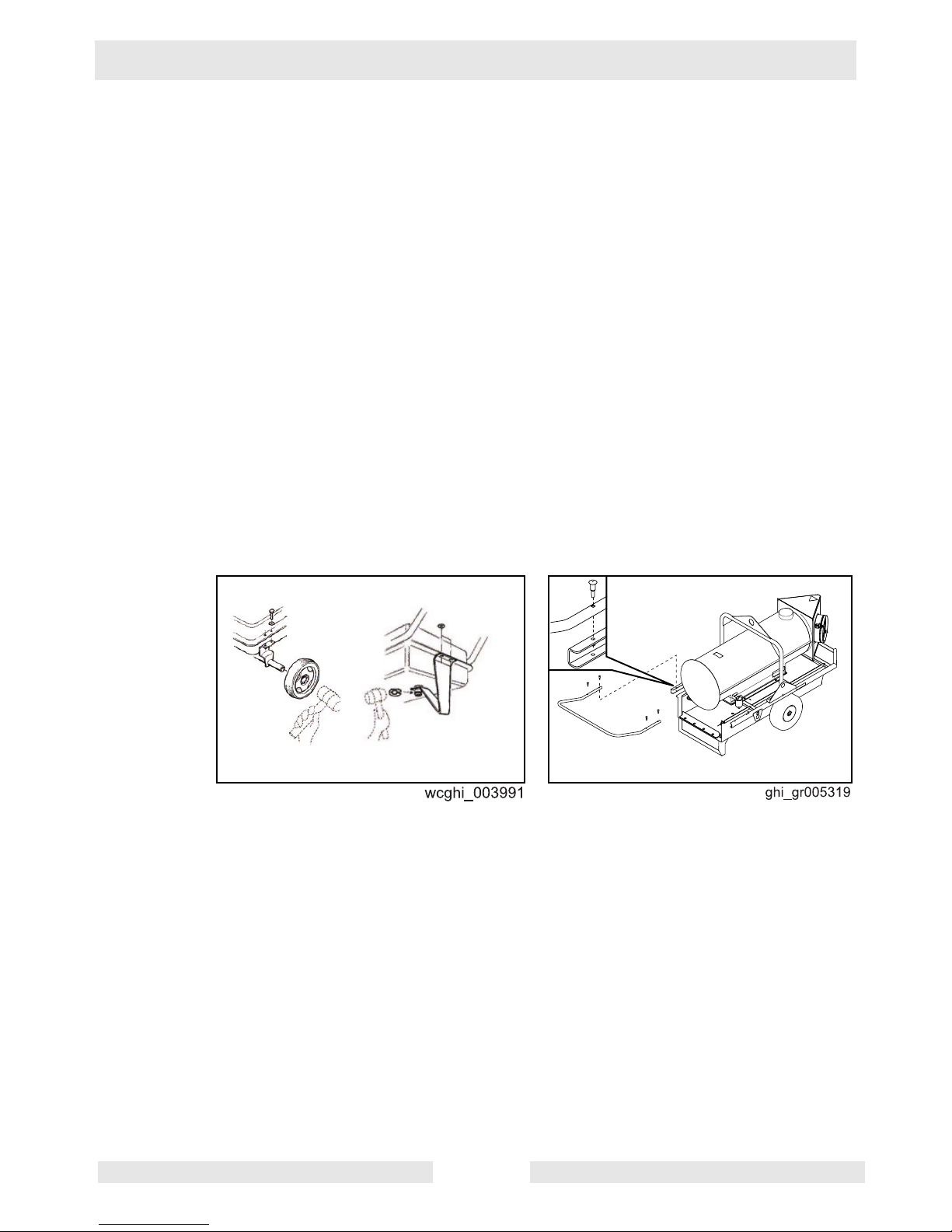

3.4 Mounting the Handle and Base Assembly

See graphics: wcghi_003991 and ghi_gr005319

The Cub series Air Heater machines are shipped partially assembled.

Before operating either machine, use the following procedure to mount

the handles and base assembly. This assembly includes the handle,

base support, and wheels with axles.

Note: There are pre-drilled bolt holes for all the components installed

within this procedure.

Note: The Cub 300 HD requires that only the handle be attached.

Refer to the procedure below to install the handle.

3.4.1 Attach the axles to the sides of the fuel tank using the supplied bolts

and washers.

3.4.2 Install the wheels using a rubber mallet to secure them to the axle

ends.

3.4.3 Attach the base support to the rear of the fuel tank using the supplied

bolts and washers.

3.4.4 Attach the handle to the machine using the supplied bolts (and

washers, if applicable).

wcghi_tx000720gb.fm 17

Page 18

Operation Cub 200/300/300 HD

3.5 Machine Location

The Air Heater machines may be located outdoors or in any

environment that requires heating. When locating a machine within the

area to be heated, the exhaust gases must be vented to the outdoors.

The machines must be installed:

• By qualified personnel who have read and understood all

supplied instructions.

• On a flat, firm surface.

• With the following minimum clearances:

• 3.05 m (10 ft.) to front.

• 0.61 m (2 ft.) to rear.

• 0.61 m (2 ft.) to sides.

• 1.52 m (5 ft.) to top.

• 0.915 m (3 ft.) to flue pipe.

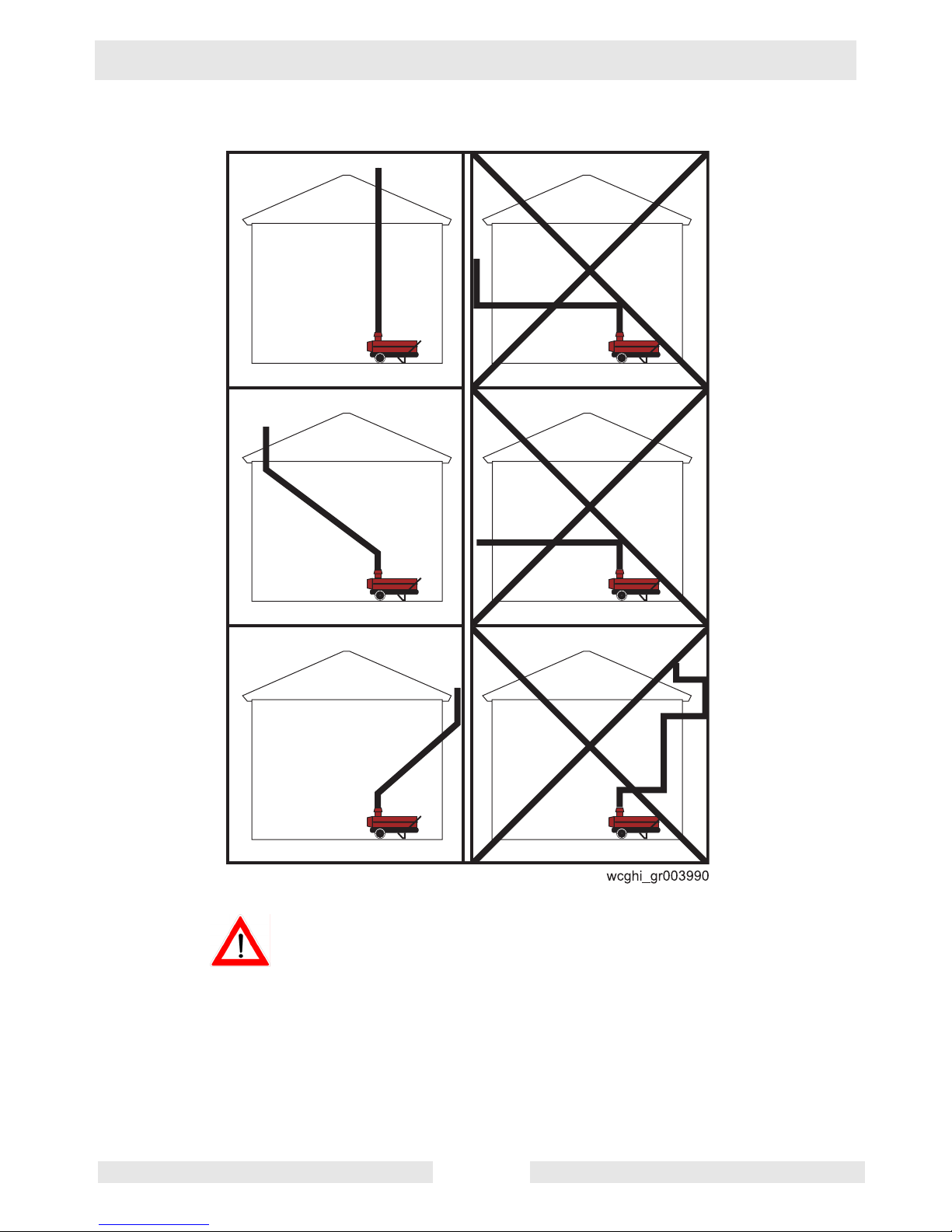

3.6 Suggested Venting

See Graphic: wcghi_gr003990

Exhaust gas from this machine CAN KILL YOU IN MINUTES. The

exhaust contains carbon monoxide, a deadly poison you can not see

or smell. This machine must be properly vented to reduce the risk of

WARNING

carbon monoxide poisoning.

When installing vents:

• Adhere to all local and national codes.

• Consult all appropriate governing bodies or local contractor for

venting and fresh air requirements.

• Place the machine in a manner that avoids excessive vent bends

(elbows), and long horizontal runs.

• Keep air inlets and outlets free from obstruction.

• Route the venting pipes in a manner that avoids any flammable

material.

• Route the venting pipes in a manner that avoids contact with

humans.

wcghi_tx000720gb.fm 18

Page 19

Cub 200/300/300 HD Operation

Exhaust gas from this machine CAN KILL YOU IN MINUTES. The

exhaust contains carbon monoxide, a deadly poison you can not see

or smell. This machine must be properly vented to reduce the risk of

WARNING

carbon monoxide poisoning.

• The above venting diagram shows suggested venting layouts

only. Consult all appropriate governing bodies or local contractor

for venting and fresh air requirements.

wcghi_tx000720gb.fm 19

Page 20

Operation Cub 200/300/300 HD

3.7 Connecting Power to the Machine

Fire and electric shock hazard. High voltage can cause severe injury

or death. This unit must be electrically grounded. Do NOT use

adapters.

WARNING

The Air Heater machines come equipped with power cords. Connect

the power cord to a grounded outlet rated for 115V, 60 Hz, 15A.

3.8 Preliminary Checks

Before starting the machine, check the following:

• Fuel supply on diesel burning machines. See Fuel Blend Guide.

• Position of power switch. It must be in the Off (“O”) position.

• Power supply. The machine must be connected to a 115V 60Hz

power supply.

• Machine location. Ensure that the machine is properly located

according to the Machine Location guidelines in this manual.

• Remote thermostat connection. If the remote thermostat will not

be used, the remote thermostat receptacle cover must be

installed.

wcghi_tx000720gb.fm 20

Page 21

Cub 200/300/300 HD Operation

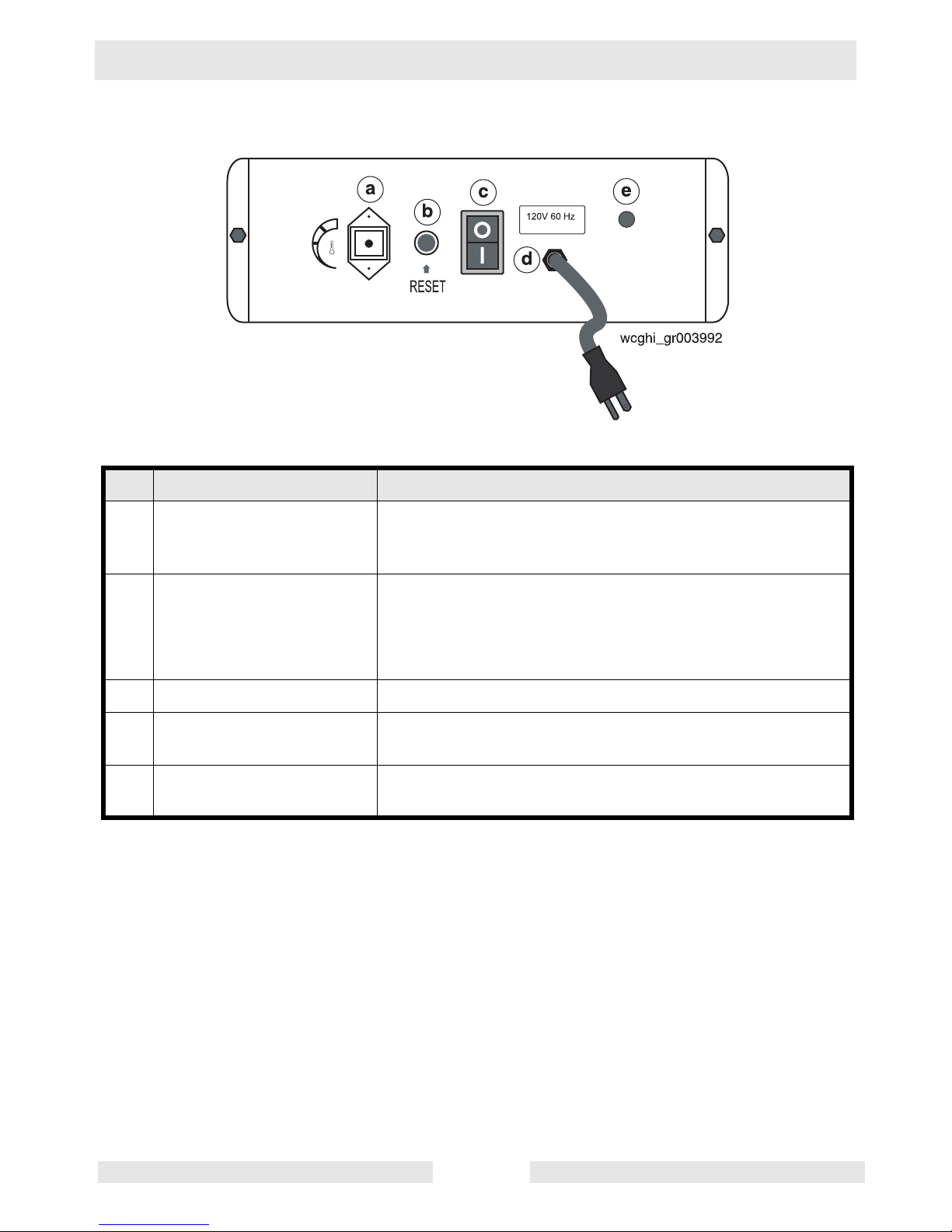

3.9 Control Panel

Ref Component Function

a Remote thermostat

receptacle

The remote thermostat receptacle (shown with protective

cap installed) is used for connecting an optional remote

thermostat

b Burner fault lamp and reset

button (dual function).

The dual function burner fault lamp and reset button:

• illuminates red when the burner has

faulted.

• resets the machine when pressed.

c Power switch The power switch provides power to the machine.

d Power cord The power cord provides a means of connecting the

machine to a 115V 60 Hz receptacle.

e Power indicator lamp The power indicator lamp illuminates green when the power

cord is connected to a 115V 60 Hz receptacle.

wcghi_tx000720gb.fm 21

Page 22

Operation Cub 200/300/300 HD

3.10 Starting the Machine

3.10.1 Perform the necessary preliminary checks. See section Preliminary

Checks.

3.10.2 If using the remote thermostat, connect it to the control panel at the

remote thermostat receptacle. Place the remote thermostat in the area

to be heated. Set it to the desired temperature.

Note: If the ambient temperature is below 32°F (0°C), it may be

necessary to preheat the fuel. See section Preheating the Fuel Filter

and Nozzle Heater.

3.10.3 Move the power switch to the On “I” position.

• The blower will turn on immediately.

• The burner will go through a prepurge cycle and then light.

• The burner will continue to fire until the temperature of the space

being heated reaches the temperature set by the thermostat. At

that time, the burner shuts down but the blower will remain on.

• If not using the remote thermostat, the blower will continue to

operate until shutdown.

wcghi_tx000720gb.fm 22

Page 23

Cub 200/300/300 HD Operation

3.11 Starting the Machine in (Extreme) Cold Weather

In temperatures below 32°F (0°C), it may be necessary to preheat the

fuel inside the fuel filter canister. The fuel filter and nozzle contain lowwattage heating elements that are controlled by a thermostat and are

specifically designed for this purpose.

Hot surface hazard.

The external surface of the fuel filter may be hot.

CAUTION

• Wear safety gloves when handling the fuel filter.

Note: Excess heating may increase the need for maintenance. See

sections “Replacing the Fuel Filter” and “Replacing the Burner Nozzle”.

To preheat the fuel, carry out the following procedure.

3.11.1 Connect power to the machine. See section Connecting Power to the

Machine.

3.11.2 Wait 20-30 minutes—longer for colder temperatures.

3.11.3 Start the machine. See section Starting the Machine.

Note: In extreme wind, the machine may need to be temporarily

blocked from the wind in order to start.

3.11.4 If the burner does not start on the first attempt, allow the power-on

sequence to cycle again (see 3.10.3).

3.11.5 If, after the second power-on sequence completes, the machine will

not fire, move the power switch to the off position.

3.11.6 Wait another 20-30 minutes and attempt to start the machine again.

wcghi_tx000720gb.fm 23

Page 24

Operation Cub 200/300/300 HD

3.12 Shutting Down the Machine

Electric shock and cutting injury hazard! At temperatures above 104°F

(40°C), electric power is available at the supply blower even with the

WARNING

3.12.1 Move the power switch to the Off (“O”) position.

3.12.2 When the blower has shut off automatically, disconnect the power

3.12.3 Disconnect the remote thermostat and re-install the receptacle cover.

operation mode switch in the OFF position. Always remove all power

to the machine before servicing it.

Note: The burner will shut down; however, the fan will continue to

operate for approximately two minutes to allow the combustion

chamber to cool.

supply cord.

wcghi_tx000720gb.fm 24

Page 25

Cub 200/300/300 HD Operation

3.13 Using the Remote Thermostat

See Graphic: wcghi_gr004009

In order for the machine to function, the remote thermostat (b) or the

receptacle cover (a) must be installed into the control panel. To use the

remote thermostat:

3.13.1 Plug (c) the remote thermostat into the control panel.

3.13.2 Set the sensor end within the space to be heated.

3.13.3 Adjust the temperature setting with dial (d).

wcghi_tx000720gb.fm 25

Page 26

Operation Cub 200/300/300 HD

Notes:

wcghi_tx000720gb.fm 26

Page 27

Cub 200/300/300 HD Maintenance

4 Maintenance

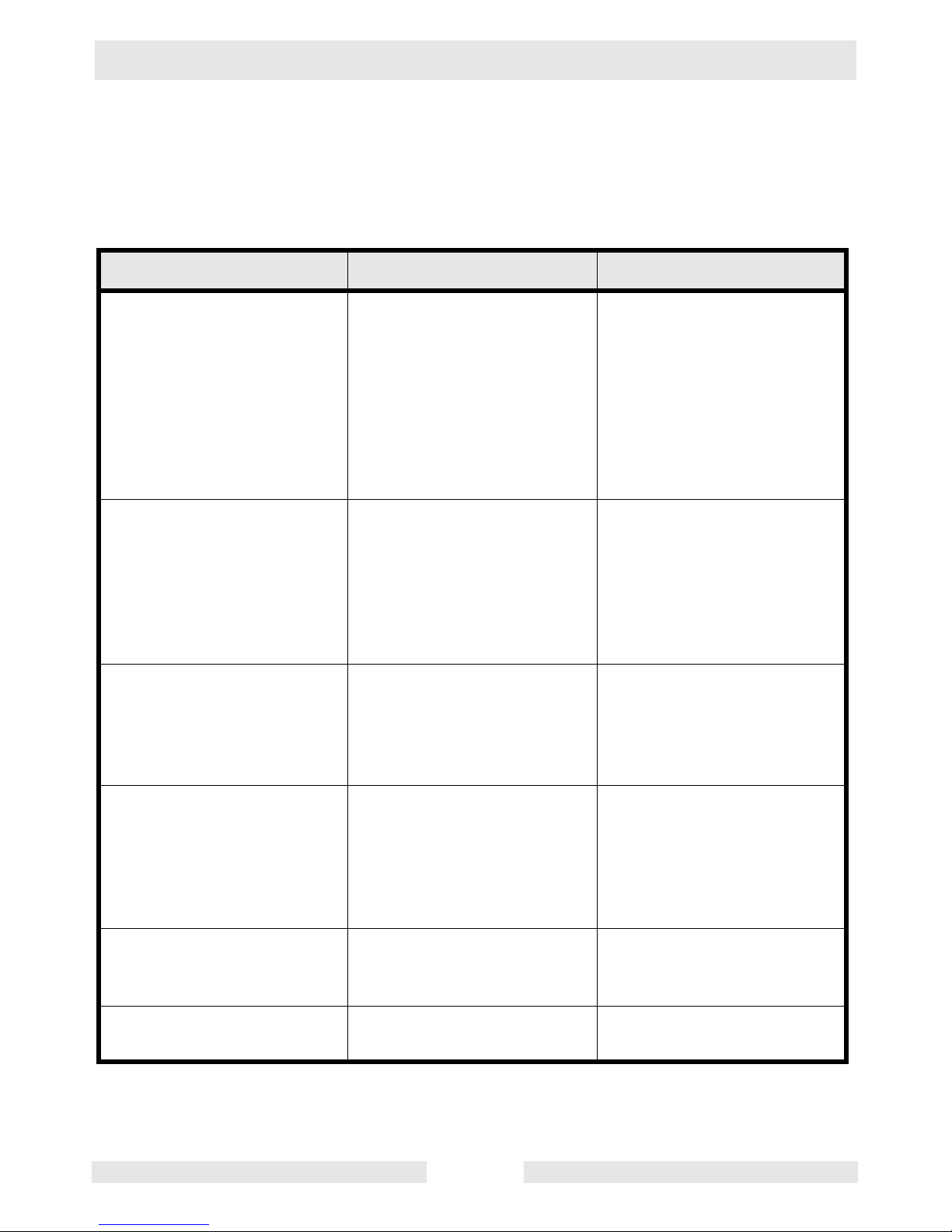

4.1 Periodic Maintenance Schedule

Replace the burner nozzle

Replace the fuel filter

Inspect the burner electrodes

Inspect and clean the Cadmium (CAD)

cell.

Check the fuel pressure

Clean the fan blades and motor

Clean the interior shell

Inspect the flame head

Inspect all electrical connections

Prior to first

seasonal use

As needed or

during regular

maintenance

Every 1200

hours

or yearly

wcghi_tx000721gb.fm 27

Page 28

Maintenance Cub 200/300/300 HD

4.2 Removing and Installing the Burner Assembly

See graphic: wcghi_gr004015

Before performing any maintenance on the burner assembly, it must

be removed from the machine. To remove or install the burner

assembly perform the following procedure:

Removal:

4.2.1 Shut down the machine and allow it to cool.

4.2.2 Disconnect the power cord from the power source.

4.2.3 Remove the two bolts (a) and open the access panel.

4.2.4 Remove the screw (d) to disconnect the ground wire (c) from the

burner assembly.

4.2.5 Rotate the burner assembly (b) counter-clockwise and remove it from

the flame head and air tube assembly (e).

4.2.6 Perform the required maintenance.

Note: Refer the maintenance procedures in this manual.

4.2.7 Re-install the burner assembly. Refer to the steps below to install the

burner assembly.

Installation:

4.2.8 Place the burner assembly into the flame head and air tube assembly

(e).

4.2.9 Rotate the burner assembly clockwise to lock it into place.

4.2.10 Install the ground wire (c) using the screw (d).

4.2.11 Close the access panel and re-install the two bolts (a) that secure the

panel.

wcghi_tx000721gb.fm 28

Page 29

Cub 200/300/300 HD Maintenance

wcghi_tx000721gb.fm 29

Page 30

Maintenance Cub 200/300/300 HD

4.3 Replacing the Burner Nozzle

See Graphic: wcghi_gr004016

To replace the burner nozzle, carry out the following procedure:

Removal:

4.3.1 Remove the burner. See section Removing and Installing the Burner

Assembly.

4.3.2 Place an adjustable wrench on the large fitting (1) on the nozzle base

(3).

4.3.3 Place another adjustable wrench on the nozzle (2).

4.3.4 Rotate the nozzle counter-clockwise and remove it from the assembly.

Installation:

4.3.5 Install the new nozzle (2) onto the nozzle base (3).

4.3.6 Tighten the nozzle (2) using an adjustable wrench. Rotate the wrench

clockwise.

4.3.7 Re-install the burner assembly. See section Removing and Installing

the Burner Assembly.

wcghi_tx000721gb.fm 30

Page 31

Cub 200/300/300 HD Maintenance

4.4 Replacing the Fuel Filter

See Graphic: wcghi_gr004019

Hot surface hazard.

The external surface of the fuel filter may be hot.

CAUTION

WARNING

• Allow the machine to cool before servicing.

• Wear safety gloves.

Hot fluids.

The fuel inside the filter canister may be hot.

• Allow the machine to cool before servicing.

• Wear safety glasses.

To replace the fuel filter (b), carry out the following procedure.

Removal:

4.4.1 Shut down the machine and allow it to cool.

4.4.2 Remove all power from the machine (unplug).

4.4.3 Remove the screw (a) that secures the cover to the housing.

4.4.4 Remove the filter (b).

Installation:

4.4.1 Install the new filter (b).

4.4.2 Inspect the rubber gasket (c) for damage.

4.4.3 Install the cover and the screw (a).

wcghi_tx000721gb.fm 31

Page 32

Maintenance Cub 200/300/300 HD

4.5 Inspecting and Aligning the Burner Electrodes

See graphic: wcghi_gr004020

To inspect and align the burner electrodes, carry out the following

procedure.

Inspection:

4.5.1 Remove the burner assembly. See section Removing and Installing

the Burner Assembly.

4.5.2 Inspect the electrodes for the following:

• Wear. Be sure to inspect the ends of the electrodes for

pitting. Replace any worn electrodes. See section

“Replacement or Alignment”.

• Straightness. Replace any bent or broken electrodes.

See section “Replacement or Alignment”.

• Corrosion and/or cleanliness. Clean the electrodes with a soft dry

cloth or replace if necessary. See section “Replacement or

Alignment”.

• Correct alignment. Align the electrodes as shown.

Replacement or Alignment:

4.5.3 Loosen the screw (1).

4.5.4 Align the electrode as shown or remove if necessary.

4.5.5 Install a new electrode if necessary.

4.5.6 Tighten the screw (1).

4.5.7 Verify the electrodes are correctly aligned.

4.5.8 Reinstall the burner. See section Removing and Installing the Burner

Assembly.

wcghi_tx000721gb.fm 32

Page 33

Cub 200/300/300 HD Maintenance

4.6 Inspecting and Cleaning the Cadmium (CAD) Cell

See Graphic: wcghi_gr004021

To inspect and clean the CAD cell, carry out the following procedure.

4.6.1 Remove the burner assembly. See section Removing and Installing

the Burner Assembly.

4.6.2 Twist and pull out the plastic protective holder (1) off the base of the

burner assembly. The CAD cell is inside this plastic holder.

4.6.3 Inspect the CAD cell for the following:

• Cleanliness. Be sure the cell is free of debris or soot.

4.6.4 Clean the cell if necessary.

NOTICE: Do NOT use solvents or liquids to clean the CAD cell. Use a

soft dry cloth to clean the CAD cell.

4.6.5 Reinstall the plastic protective holder (1) onto the base of the burner

assembly.

4.6.6 Reinstall the burner assembly. See section Removing and Installing

the Burner Assembly.

wcghi_tx000721gb.fm 33

Page 34

Maintenance Cub 200/300/300 HD

4.7 Checking and Adjusting the Fuel Pressure

See Graphic: wcghi_gr004025

To check the fuel pressure a pressure gauge is needed. To check and/

or adjust the fuel pressure, carry out the following procedure:

4.7.1 Shut down the machine and allow it to cool.

4.7.2 Disconnect the power cord from the power source.

4.7.3 Remove the two bolts (a) and open the access panel.

4.7.4 Remove the threaded plug (b) from the pressure test port using an

allen wrench. Set the plug in a safe location to be re-installed later.

4.7.5 Install a pressure gauge with adapter in the pressure test port (c).

4.7.6 Start the machine. See section Starting the Machine.

4.7.7 With the machine running, verify the fuel pressure setting. For the

correct settings, refer to the Technical Data charts in this manual.

4.7.8 Shut down the machine. See section Shutting Down the Machine.

4.7.9 Adjust the fuel pressure if necessary using the adjusting screw (e) and

re-check the settings. Repeat steps 6-8 to re-check the settings.

Do not adjust the fuel pressure to a setting outside the safe operational

parameters.

4.7.10 Remove the pressure gauge (d) from the pressure test port (c).

4.7.11 Re-install the threaded plug (b) into the pressure test port (c).

4.7.12 Close the access panel and re-install the two bolts (a) that secure the

panel.

wcghi_tx000721gb.fm 34

Page 35

Cub 200/300/300 HD Maintenance

wcghi_tx000721gb.fm 35

Page 36

Maintenance Cub 200/300/300 HD

4.8 Cleaning the Fan Blades and Motor

See graphic: wcghi_gr004030

To clean the fan blades and motor, carry out the following procedure:

4.8.1 Shut down the machine and allow it to cool.

4.8.2 Disconnect the power cord from the power source.

4.8.3 Remove the fan guard. There are four screws that secure the guard.

4.8.4 Remove the six bolts that secure the top portion of the shell.

4.8.5 Remove the top shell to access the interior of the machine.

4.8.6 Inspect and, if necessary, clean the motor using compressed air.

4.8.7 Clean the fan blades using a brush.

4.8.8 Re-install the top shell using the six bolts.

4.8.9 Re-install the fan guard.

wcghi_tx000721gb.fm 36

Page 37

Cub 200/300/300 HD Maintenance

4.9 Cleaning the Interior Shell

See graphic: wcghi_gr004029

To clean the interior shell, carry out the following procedure:

4.9.1 Shut down the machine and allow it to cool.

4.9.2 Disconnect the power cord from the power source.

4.9.3 Remove the fan guard. There are four screws that secure the guard.

4.9.4 Remove the six bolts that secure the top portion of the shell.

4.9.5 Remove the top shell to access the interior of the machine.

4.9.6 Inspect and, if necessary, clean the interior shell using compressed air.

4.9.7 Re-install the top shell using the six bolts.

4.9.8 Re-install the fan guard.

wcghi_tx000721gb.fm 37

Page 38

Maintenance Cub 200/300/300 HD

4.10 Inspecting the Flame Head

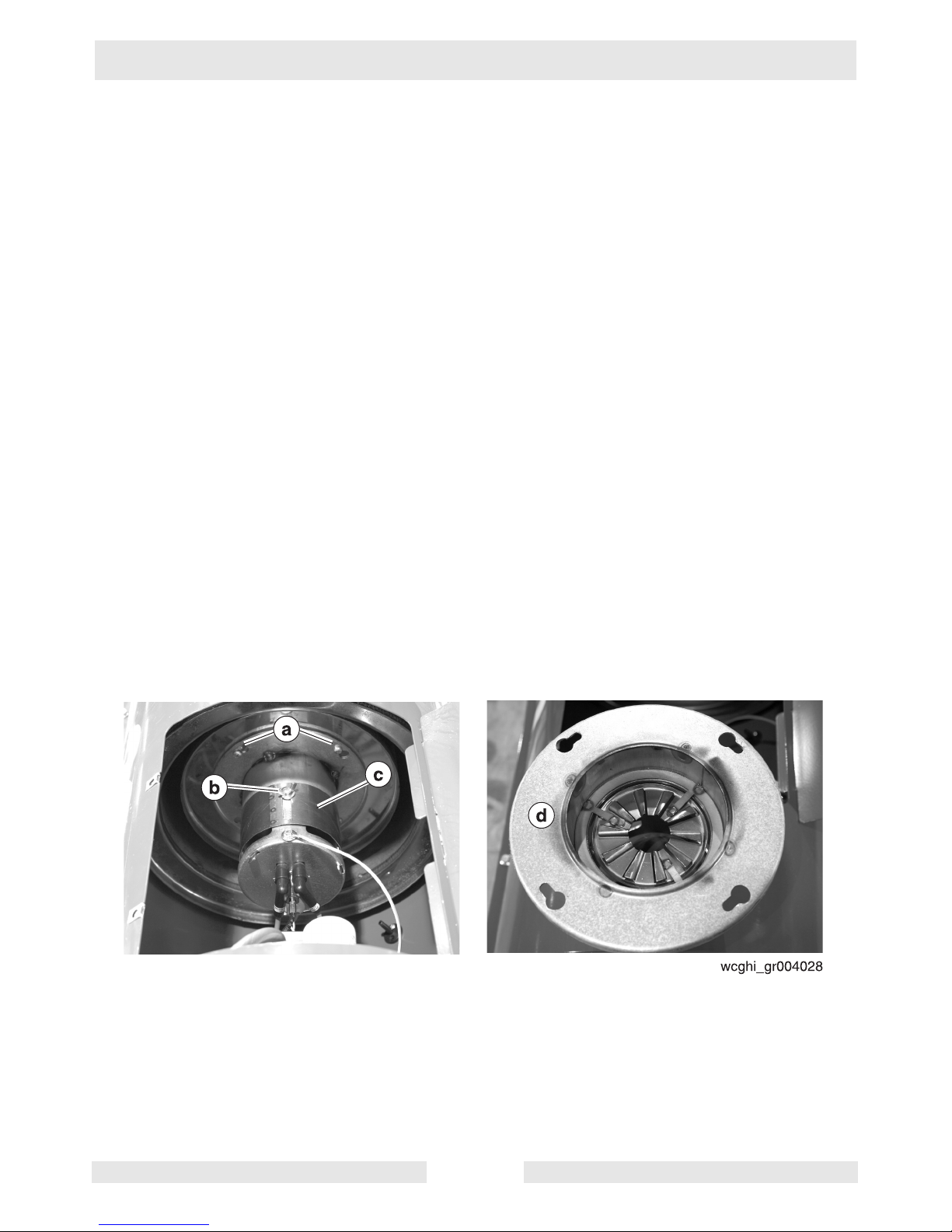

See Graphic: wcghi_gr004028

To inspect the flame head, carry out the following procedure:

4.10.1 Remove the burner assembly. See section Removing and Installing

the Burner Assembly.

4.10.2 Mark the location of the air lock sleeve (c) with a pencil.

4.10.3 Loosen the wing nut (b).

4.10.4 Loosen the four screws (a) that secure the flame head (d).

4.10.5 Turn the flame head (d) counter-clockwise and remove.

4.10.6 Inspect the flame head (d) for the following:

• Wear. Replace if necessary.

• Cleanliness. Clean the flame head if necessary.

• Thermal stress. Replace if necessary.

4.10.7 Re-install the flame head (d).

4.10.8 Position the air lock sleeve (c) at the marked location.

4.10.9 Tighten the wing nut (b).

4.10.10 Tighten the four screws (a).

4.10.11 Re-install the burner assembly. See section Removing and Installing

the Burner Assembly.

wcghi_tx000721gb.fm 38

Page 39

Cub 200/300/300 HD Maintenance

4.11 Inspecting the Electrical Connections

After disconnecting the power cord, check all electrical connections for

the following:

• Proper connections. Be sure that all connections are complete and

tight.

• Corrosion. Clean or replace if necessary.

• Damaged wires/connectors. Replace if necessary.

• Proper ground.

4.12 Fuel Blend Guide

Fuel Blend Guide

Temperature Range

Fuel Blend

15° to 30°F 80% #2 : 20% #1

0° to 15°F 70% #2 : 30% #1

–15° to 0°F 50% #2 : 50% #1

below –15°F 30% #2 : 70% #1

wcghi_tx000721gb.fm 39

Page 40

Maintenance Cub 200/300/300 HD

4.13 Transporting

Cub series Air Heater machines must be supported by use of blocks

during transport. NOTICE: DO NOT strap or chain down the unit with

the foot or wheels in contact with the transporter.

• Openings or the entire unit should be covered during transport to

avoid road debris and clutter.

• Take care when placing straps on areas which are painted red.

Use corner protectors and never use chains.

• Excessive loading on the foot, wheels, and axle will cause

permanent damage

• The foot and wheels are for moving by hand and for parking only.

• This unit is not designed to be towed with any vehicle.

• All venting external to the machine must be removed prior to

transporting.

• Only qualified riggers should attempt aerial lifting.

wcghi_tx000721gb.fm 40

Page 41

Cub 200/300/300 HD Maintenance

4.14 List of Abbreviations

Amp ampere (unit of electrical current)

asl above sea level

BTU British Thermal Unit

°C Celsius (metric unit of temperature)

°F Fahrenheit (unit of temperature)

2

ft

square foot/square feet (measurement of area)

ft.lbs. foot pounds (unit of torque)

gph gallons per hour (unit of liquid flow)

GFI Ground Fault Interrupt(er) (protection device)

Hz Hertz (unit of frequency)

ID inner diameter

in. inch

kg kilogram

kilo-cal kilo-calorie (1000 calories) (metric unit of heat energy)

kPal kilo-Pascals (metric unit of pressure)

kW kilo-Watt (unit of electrical power)

lb. pound

m meter

mm millimeter (1/1000 of a meter)

psig pounds per square inch gauge (unit of pressure)

VAC Volts, Alternating Current

VDC Volts, Direct Current

VFD Variable Frequency Drive

HTF Heat Transfer Fluid

wcghi_tx000721gb.fm 41

Page 42

Maintenance Cub 200/300/300 HD

4.15 Troubleshooting

Note: The following symptoms and remedies are some of the more

common issues that have arisen during the history of these machines.

These do not represent all the possibilities. If you need advanced

troubleshooting assistance, please contact Wacker Neuson Product

Support.

Symptom Possible Causes Remedy

The burner does not start • The remote thermostat

or thermostat plug is not

inserted correctly.

• Faulty cable or power

supply

• The over temperature

limit has tripped

• The burner is in lock-out

mode.

The burner starts, the flame

does not ignite, the unit

locks out

• No fuel

• Worn burner nozzle

• Faulty electrodes

• Cad cell detecting

external light.

• Cad cell defective

• Burner control defective

The burner starts, flame

ignites, but the unit locks

out

• Incorrect fuel pressure

• Worn burner nozzle

• Incorrect air lock setting

• Cad cell defective

• Burner control defective

• Insert the remote

thermostat or thermostat

plug.

• Check cable and power

supply

• Press the reset button.

• Fill fuel tank

• Replace burner nozzle

• Replace electrodes

• Check the Cad cell

enclosure

• Increase fuel pressure

• Replace burner nozzle

• Re-adjust air lock setting

The burner ignites but the

performance is poor

Black smoke from vent pipe • Insufficient combustion

The machine stops due to

pressure switch fault

wcghi_tx000721gb.fm 42

• Worn burner nozzle

• Clogged fuel filter

• Air leaks in the fuel lines

• Insufficient oil pressure

air

• Insufficient ventilation air

• Overheat condition

• Faulty pressure switch

• Replace burner nozzle

• Replace the fuel filter

• Inspect the lines for

leaks; replace if

necessary

• Remove any

obstructions from the air

inlet and outlet areas.

• Contact Wacker Neuson

Product Support

Page 43

Cub 200/300/300 HD Maintenance

Notes:

wcghi_tx000721gb.fm 43

Page 44

Maintenance Cub 200/300/300 HD

4.16 Cub 200/300 Wiring Schematic

4.17 Cub 300 HD Wiring Schematic

wcghi_tx000721gb.fm 44

Page 45

Cub 200/300/300 HD Maintenance

4.18 Schematic Legend

Ref. Description Ref. Description

Fuel solenoid valve

a

Photo cell

b

Fuse

c

ON-OFF switch

d

Motor

e

Power light

f

Remote thermostat

g

Transformer

h

Pressure switch

i

Push button reset light

j

Heated filter

k

Relay

l

Temperature limit control

m

Capacitor

n

Air temperature switch

o

Nozzle preheater

p

wcghi_tx000721gb.fm 45

Page 46

Maintenance Cub 200/300/300 HD

wcghi_tx000721gb.fm 46

Page 47

Cub 200/300/300 HD Technical Data

5 Technical Data

5.1 Machine Technical Data

Item Number

Model

0620204

0620262

Cub 200

0620233

Cub 300

0620253

Cub 300 HD

Units

Heat input BTU/hr 180,000 289,000 289,000

Heat output BTU/hr 147,000 232,000 232,000

Air flow cfm 1300 2600 2600

Fuel consumption L (gal)/hr 4.85 (1.28) 7.72 (2.04) 7.72 (2.04)

Fuel nozzle size gal/hr-deg 1.00-60 1.5-80 1.35-80

Efficiency % 81.5 80 80

Noise level at 2 m dB (A) 73 71 73.9 (at 3 m)

Power requirement VAC/Hz 115/60 115/60 115/60

Electrical current Ampere 7 12 14

Weight (no fuel) kg (lb) 79.4 (175) 116.1 (256) 264(583)

Height cm (in.) 78.7 (31) 116.8 (46) 130.8(51.5)

Length cm (in.) 139.7 (55) 172.7 (68) 228.3(89.9)

Width cm (in.) 61 (24) 69.9 (27.5) 97.5(38.4)

Flue diameter cm (in.) 15.2 (6) 15.2 (6) 15.2 (6)

Fuel tank capacity L (gal) 100 (26.42) 138.9 (36.7) 232.8(61.5)

Fuel pressure psi 175 175 218

Air lock setting number 2 3 5

wcghi_td000213gb.fm 47

Page 48

Technical Data Cub 200/300/300 HD

wcghi_td000213gb.fm 48

Page 49

Page 50

Wacker Neuson SE · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-3 54 02-0 · Fax: +49 - (0)89-3 54 02-390

Wacker Neuson Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · Tel. : (262) 255-0500 · Fax: (262) 255-0550 · Tel. : (800) 770-0957

Wacker Neuson Limited - Room 1701–03 & 1717–20, 17/F. Tower 1, Grand Century Place, 193 Prince Edward Road West, Mongkok, Kowloon, Hongkong.

Tel: (852) 3605 5360, Fax: (852) 2758 0032

Page 51

www.wackerneuson.com

0620253 105

05.2010

Portable Indirect Air Heaters

Fahrbare Kaminheizgeräte

Calentadores de aire indirectos portátiles

Réchauffeurs indirects d'air (portatifs)

CUB 300HD

Parts Book

Ersatzteile

Lista de Repuestos

Liste de Pièces de Rechange

Page 52

Page 53

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is

attached to each unit. Please record the information found on this plate so it will be available

should the nameplate become lost or damaged. When ordering parts or requesting service

information, you will always be asked to specify the model, item number, revision number,

and serial number of the unit.

Ein Typenschild mit Typ, Artikelnummer, Version und Maschinen-Nummer ist an jedem

Gerät angebracht. Die Daten von diesem Schild bitte notieren, damit sie auch bei Verlust

oder Beschädigung des Schildes noch vorhanden sind. Der Typ, die Artikel-Nummer, die

Versions- Nummer und die Maschinen-Nummer sind bei der Ersatzteilbestellung oder

Nachfragen bezüglich Service-Informationen stets erforderlich.

Una placa de identificación con el modelo, número de referencia, nivel de revisión y número

de serie ha sido añadida en cada máquina. Favor de anotar los datos en la placa en caso

de que la placa de identificación sea destruida o perdida. En todos los pedidos para

repuestos necesita siempre el modelo, el número de referencia, el nivel de revisión y el

número de serie de la máquina en cuestión.

Une plaque signalétique mentionnant le modèle, le numéro de référence, le niveau de

revision et le numéro de série est fixée sur chaque machine. Veuillez noter les informations

relevées sur cette plaque de façon à ce qu’elles soient toujours disponibles si la plaque

signalétique venait à être perdue ou endommagée. Lorsq ue vous commandez des pièces

détachées ou vous sollicitez des informations après-vente, on vous demandera toujours de

préciser le modèle, le numéro de référence, le niveau de revision et le numéro de série de

la machine.

My machine’s numbers are / Die Nummern meines Gerätes sind /

Los números de mi máquina son / Les numéros de ma machine son :

CUB 300HD

Nameplate

Typenschild

Plaque signalétique

Placa de Identificación

0620253 - 105

3

Page 54

Part Numbers appearing in boldface type are recommended spare parts. This means that

these parts are subject to wear under normal operating conditions and may require periodic

service or replacement. It is recommended that these items be stocked to meet the

expected service requirements of this model. Actual stocking quantities of these and other

parts used in more extensive repairs will depend on the service practices of each customer.

Bei den in den Ersatzteillisten fettgedruckten Nummern handelt es sich um empfohlene

Ersatzteile. Dies bedeutet, daß diese Teile bei normalen Anwendungsbedingungen

natürlicher Abnutzung ausgesetzt sind und gelegentlich ersetzt oder überarbeitet werden

müssen. Es wird geraten, diese Teile auf Lager bereit zu haben, um für Service-Arbeiten an

diesem Gerät vorbereitet zu sein. Lagerbestände für diese und andere Teile, welche für

ausgiebigere Reparaturarbeiten benötigt werden, können je nach Service-Gewohnheiten

der einzelnen Kunden variieren.

Los números de partes en negritas en las Listas Ilustradas de Partes son los repuestos

recomendados, ésto quiere decir que estas partes se desgastarán bajo circunstancias de

funcionamiento normales y pueden requerir servicio periódico o su reemplazo. Se

recomienda que el cliente mantenga un abastecimiento adecuado de estas partes para

poder satisfacer la demanda requerida por el servicio a la máquina. La cantidad de

repuestos que el cliente necesitará para reparaciones dependerá de la póliza de servicio de

cada cliente.

Les numéros de pièces imprimés en caractères gras dans les Listes des Pièces Détachées

de ce manuel sont les pièces détachées recommandées par la Wacker. Cela veut dire que

ces pièces sont sujettes à usure dans des conditions de travail normales et peuvent

nécessiter de l’entretien ou leur remplacement. Nous recommandons que vous disposez

d’un stock de ces pièces pour pouvoir satisfaire la demande d’entretien de cette machine.

Le client doit decider lui-même de la quantité exacte de pièces de rechange qu’il disposera

dans ses stocks.

Part Numbers - Boldface

Fettgedruckte Artikelnummern

CUB 300HD

Números de partes en negritas

Numéros de pièce - en caractères gras

4

0620253 - 105

Page 55

Heater

Heizung

Calentador

Réchauffeur

6

Frame/Components

Rahmen/Bestandteile

Chasis/Componentes

Châssis/Composants

12

Labels

Aufkleber

Calcomanias

Autocollants

16

CUB 300HD

Table of Contents

Inhaltsverzeichnis

Indice

Table des matières

0620253 - 105

5

Page 56

Heater

Heizung

CUB 300HD

Calentador

Réchauffeur

6

0620253 - 105

Page 57

Ref.

Pos.

Part No.

Artikel Nr.

Qty.

St.

Description

Beschreibung

Descripción

Description

Measurem./Abm.

Torque/Drehm.

Norm

Sealant

Schmierstoff

1 0172597 1

Fan

Gebläserad

Ventilador

Ventilateur

2 0172598 1

Motor-fan

Motor, Lüfter

Motor-ventilador

Moteur - ventilateur

3 0172092 1

Adapter fan

Adapter, Lüfter

Ventilador adaptador

Adaptateur, ventilateur

4 0172599 1

Capacitor-fan

Kondensator, Lüfter

Condensador-ventilador

Condensateur - ventilateur

5 0172093 1

Solenoid coil

Solenoidwindung

Bobina del solenoide

Bobine du solénoïde

6 0172094 2

Cable-fuel pump

Kabel, Kraftstoffpumpe

Cable-bomba de combustible

Câble - pompe à carburant

7 0172095 1

Hose-fuel

Kraftstoffschlauch

Manguera-combustible

Flexible - carburant

8 0172096 1

Fitting-fuel D

Verschraubung, Kraftstoff D

Unión-combustible D

Raccord - carburant D

9 0172600 1

Pump-fuel

Kraftstoffpumpe

Bomba-combustible

Pompe - carburant

10 0172097 2

Washer

Scheibe

Arandela

Rondelle

11 0172098 3

Fitting-fuel B

Verschraubung, Kraftstoff B

Unión-combustible B

Raccord - carburant B

12 0172099 5

Fitting-fuel A

Verschraubung, Kraftstoff A

Unión-combustible A

Raccord - carburant A

13 0172100 2

Fitting-fuel C

Verschraubung, Kraftstoff C

Unión-combustible C

Raccord - carburant C

14 0172601 2

Hose-back flow

Schlauch, Rückfluss

Manguera-retroflujo

Flexible - retour

15 0172102 2

Hose-return fuel

Schlauch, Rückleitung, Kraftstoff

Manguera-combustible de retorno

Flexible - retour carburant

16 0170280 1

Sensor-flame

Flammensensor

Sensor-llama

Capteur - flamme

17 0172103 2

Cable-electrode

Kabelelektrode

Cable-electrodo

Câble - électrode

18 0180719 1

Head-flame

Vibrationsflasche, Flamme

Cabezal-llama

Tête - flamme

20 0170282 2

Electrode

Elektrode

Electrodo

Électrode

21 0172105 1

Cover-electric panel

Abdeckung, Schaltfeld

Tapa-panel eléctrico

Couvercle - tableau électrique

22 0170283 1

Transformer

Transformator

Transformador

Transformateur

23 0170284 1

Lamp

Lampe

Lámpara

Voyant

24 0170285 1

Switch, on/off

Schalter, ein/aus

Interruptor, enc./apag.

Interrupteur, marche/arrêt

25 0172107 1

Cable-power

Kabel, Strom

Cable-alimentación

Câble - alimentation

26 0172603 1

Fuse

Sicherung

Fusible

Fusible

CUB 300HD

Heater

Heizung

Calentador

Réchauffeur

0620253 - 105

7

Page 58

Heater

Heizung

CUB 300HD

Calentador

Réchauffeur

8

0620253 - 105

Page 59

Ref.

Pos.

Part No.

Artikel Nr.

Qty.

St.

Description

Beschreibung

Descripción

Description

Measurem./Abm.

Torque/Drehm.

Norm

Sealant

Schmierstoff

27 0170287 1

Reset-pushbutton

Rückstellungsdrucktaste

Restablecimiento-botón

Réinitialisation - bouton - poussoir

28 0172109 1

Plug-thermostat

Stecker, Temperaturregler

Tapón-termostato

Fiche - thermostat

29 0170313 1

Thermostat socket

Temperaturregler, Buchse

Toma para el termostato

Thermostat, douille

30 0176675 1

Housing

Gehäuse

Caja

Carter

31 0172112 1

Control panel

Schalttafel

Tablero de mando

Tableau de commande

32 0176676 1

Spacer

Abstandsstück

Espaciador

Entretoise

33 0170288 1

Burner control

Brennerbetätigung

Control del quemador

Commande de brûleur

36 0176678 1

Suction hose

Saugschlauch

Manguera de succión

Tuyau de succion

37 0172114 1

Fitting-fuel E

Verschraubung, Kraftstoff E

Unión-combustible E

Raccord - carburant E

39 0172115 1

Nut-fuel line

Mutter, Kraftstoffleitung

Tuerca-línea de combustible

Écrou - conduite de carburant

40 0172116 1

Bracket-filter

Halterung, Filter

Ménsula-filtro

Support - filtre

41 0172117 1

Fitting-fuel F

Verschraubung, Kraftstoff F

Unión-combustible F

Raccord - carburant F

42 0176682 1

Filter-oil, heated

Ölfilter, erwärmt

Filtro-aceite, caliente

Filtre - huile, chauffée

48 0172123 1

Fitting-fuel suction

Verschraubung, Kraftstoffansaugung

Unión-succión de combustible

Raccord - aspiration carburant

50 0172605 1

Guard-fan

Schutz, Lüfter

Protector-ventilador

Protection - ventilateur

51 0172606 1

Rim-fan

Rand, Lüfter

Aro-ventilador

Couronne - ventilateur

52 0172607 1

Cover-inspection

Abdeckung, Inspektion

Tapa-inspección

Couvercle - inspection

53 0176679 1

Panel-top

Panel, oben

Panel-superior

Panneau - haut

55 0172129 2

Grommet

Tülle

Ojal

Passe-fil

56 0172130 2

Grommet

Tülle

Ojal

Passe-fil

65 0172137 1

Cover-air, burner

Abdeckung, Luft, Brenner

Tapa-aire, quemador

Couvercle - air, brûleur

66 0172612 1

Head-flame

Vibrationsflasche, Flamme

Cabezal-llama

Tête - flamme

67 0172613 1

Cylinder-combustion

Zylinder, Verbrennung

Cilindro-combustión

Cylindre - combustion

68 0172614 1

Cover-heat

Abdeckung, Heizung

Tapa-calor

Couvercle - chaleur

69 0176680 1

Duct adapter kit

Luftleitblechadaptersatz

Juego adaptador del conducto

Jeu d?adaptateur de conduit

CUB 300HD

Heater

Heizung

Calentador

Réchauffeur

0620253 - 105

9

Page 60

Heater

Heizung

CUB 300HD

Calentador

Réchauffeur

10

0620253 - 105

Page 61

Ref.

Pos.

Part No.

Artikel Nr.

Qty.

St.

Description

Beschreibung

Descripción

Description

Measurem./Abm.

Torque/Drehm.

Norm

Sealant

Schmierstoff

70 0172140 1

Stack-flue

Schacht, Luftklappe

Tubo-cañón

Cheminée - conduit

71 0172141 6

Clip-cover

Klemme, Abdeckung

Sujetador-tapa

Couvre - attache

72 0172616 1

Panel-bottom

Boden-Panel

Panel inferior

Tableau - fond

73 0176681 1

Thermostat

Temperaturregler

Termóstato

Thermostat

74 0180715 1

Pressure Switch

Druckschalter

Interruptor de Presión

Interrupteur à Pression

75 0172143 1

Bracket-air pressure gauge

Halterung, Luftdruckmesser

Ménsula-indicador de presión de aire

Support - manomètre d'air

77 0172145 1

Fitting-air hose

Verschraubung, Luftschlauch

Unión-manguera de aire

Raccord - flexible d'air

80 0172118 1

Cover-fuel filter

Abdeckung, Kraftstofffilter

Tapa-filtro de combustible

Couvercle - filtre à carburant

82 0170290 1

Filter cartridge

Filterpatrone

Cartucho del filtro

Cartouche de filtre

83 0180717 1

Heating element

Heizelement

Elemento de calefacción

Élément chauffant

200W

84 0172122 1

Casing-fuel filter

Umhüllung, Kraftstofffilter

Envoltura-filtro de combustible

Gaine - filtre à carburant

85 0172108 1

Cover-reset button

Abdeckung, Rückstelltaste

Tapa-botón de restablecimiento

Couvercle - bouton de réinitialisation

86 0176683 1

Gasket Kit

Dichtungssatz

Juego de juntas

Jeu de joints

91 0180716 1

Cover

Deckel

Tapa

Couvercle

92 0180718 1

Thermostat

Temperaturregler

Termóstato

Thermostat

93 0172649 1

Adapter-fuel

Adapter, Kraftstoff

Adaptador-combustible

Adaptateur - combustible

CUB 300HD

Heater

Heizung

Calentador

Réchauffeur

0620253 - 105

11

Page 62

Frame/Components

Rahmen/Bestandteile

CUB 300HD

Chasis/Componentes

Châssis/Composants

12

0620253 - 105

Page 63

Ref.

Pos.

Part No.

Artikel Nr.

Qty.

St.

Description

Beschreibung

Descripción

Description

Measurem./Abm.

Torque/Drehm.

Norm

Sealant

Schmierstoff

1 0173663 1

Upper frame

Oberer Rahmen

Chasis superior

Châssis supérieur

2 0173665 1

Fuel tank

Kraftstofftank

Depósito de combustible

Réservoir de carburant

3 0173671 1

Lifting bracket

Hebebügel

Ménsula alzadora

Support de relèvement

4 0173664 1

Lower frame

Unterer Rahmen

Chasis inferior

Châssis inférieur

5 0173879 1

Lifting bail handle

Tragegriff

Manija de Agarradero de izar

Poignée de relèvement

7 0173927 2

Mounting bracket

Konsole

Ménsula

Support

9 0177335 1

Fuel tank bracket

Kraftstofftankkonsole

Ménsula de tanque de combustible

Support de réservoir de carburant

200 0173670 1

Heater core

Heizung, Wellenseele

Núcleo del calentador

Réchauffeur, Âme

201 0177156 2

Wheel

Rad

Rueda

Roue

16,3 OD, 760lb

202 0170453 1

Gauge-fuel

Kraftstoffanzeiger

Indicador-combustible

Jauge - carburant

S9

203 0168154 1

Plug

Stopfen

Tapón

Bouchon

3/4in NPT

S9

204 0173890 1

Fuel tank cap

Tankverschluß

Tapa del tanque

Chapeau de réservoir

2,50in

205 0173998 2

Cap

Kappe

Tapa

Capuchon

207 0168611 2

Clip

Clip

Clip

Clip

1/16in

500 0010374 42

Flat washer

Scheibe

Arandela elástica

Rondelle de ressort

B8,4

501 0011457 22

Hex head screw

Sechskantschraube

Tornillo

Vis à tête hexagonale

M8 x 25

20Nm/14ft.lbs

502 0033198 54

Lock washer

Federring

Federring

Rondelle de ressort

B8

503 0010882 24

Hex nut

Sechskantmutter

Tuerca hexagonal

Écrou six-pans

M8

504 0010373 5

Fender washer

Unterlegscheibe

Arandela

Rondelle

B6,4

505 0173995 4

Bolt

Bolzen

Perno

Boulon

M8 x 45

506 0011470 2

Hexagonal head cap screw

Sechskantschraube

Tornillo hexagonal

Boulon à tête hexagonale

M6 x 20

10Nm/7ft.lbs

507 0173987 4

Lock washer

Federring

Federring

Rondelle de ressort

No.6

508 0173988 2

Hexagon nut

Sechskantmutter

Tuerca hexagonal

Écrou hexagonal

M6

510 0025661 4

Cotter pin

Sicherungssplint

Clavija hendida

Goupille fendue

1/8 x 1-3/4in

511 0025641 4

Flat steel washer

Scheibe

Arandela

Rondelle

1in

CUB 300HD

Frame/Components

Rahmen/Bestandteile

Chasis/Componentes

Châssis/Composants

0620253 - 105

13

Page 64

Frame/Components

Rahmen/Bestandteile

CUB 300HD

Chasis/Componentes

Châssis/Composants

14

0620253 - 105

Page 65

Ref.

Pos.

Part No.

Artikel Nr.

Qty.

St.

Description

Beschreibung

Descripción

Description

Measurem./Abm.

Torque/Drehm.

Norm

Sealant

Schmierstoff

512 0167806 2

Fender washer

Unterlegscheibe

Arandela

Rondelle

1/4 x 3/4in

513 0028404 2

Hexagonal flange head screw

Sechskantflanschschraube

Tornillo hexagonal de brida

Vis hexagonale de bride

M8 x 20

20Nm/14ft.lbs

514 0178277 1

Washer

Scheibe

Arandela

Rondelle

24mm ID

S9

515 0179112 1

Clamp

Schelle

Abrazadera

Agrafe

3/8in ID

600 0177336 1

Ground wire

Erdungsdraht

Alambre a tierra

Fil de masse

801 0181250 1

Nut

Mutter

Tuerca

Écrou

802 0183685 1

Gasket

Dichtung

Junta

Joint

CUB 300HD

Frame/Components

Rahmen/Bestandteile

Chasis/Componentes

Châssis/Composants

0620253 - 105

15

Page 66

Labels

Aufkleber

CUB 300HD

Calcomanias

Autocollants

16

0620253 - 105

Page 67

Ref.

Pos.

Part No.

Artikel Nr.

Qty.

St.

Description

Beschreibung

Descripción

Description

Measurem./Abm.

Torque/Drehm.

Norm

Sealant

Schmierstoff

1 0176654 1

Label -logo

Aufkleber, Logo

Calcomanía -logotipo

Autocollant - logo

2 0176655 1

Label-warning

Aufkleber-Warnung

Calcomania-Advertencia

Autocollant-Avertissement

3 0176656 1

Label-instruction plate

Anweisungsschild

Placa-instrucciones

Plaque d'instructions

4 0176657 1

Label-hazardous voltage

Aufkleber, gefährliche Spannung

Calcomanía-voltaje peligroso

Autocollant - tension dangereuse

5 0176658 1

Label-danger

Aufkleber, Gefahr

Calcomanía, peligro

Autocollant-danger

7 0176660 1

Label-diesel fuel selection

Aufkleber, Dieselkraftstoffauswahl

Calcomanía-selección de combustible

diesel

Autocollant - choix du carburant diesel

8 0176661 1

Label-danger

Aufkleber, Gefahr

Calcomanía, peligro

Autocollant-danger

401 0177155 1

Label-rating plate

Aufkleber, Typenschild

Calcomanía-placa de clasificación

Autocollant - plaque signalétique

402 0177368 2

Label-weight

Aufkleber, Gewicht

Calcomanía-Peso

Autocollant - Poids

403 0177369 4

Label-tie down marker

Aufkleber, Festzurrmarkierung

Calcomanía-marcador de ataduras

Autocollant - marqueur d'arrimage

404 0177370 3

Label-warning

Aufkleber-Warnung

Calcomania-Advertencia

Autocollant-Avertissement

405 0177371 1

Label-warning

Aufkleber-Warnung

Calcomania-Advertencia

Autocollant-Avertissement

406 0168897 2

Label-center of gravity

Aufkleber, Schwerpunkt

Calcomanía-centro de gravedad

Autocollant - centre de gravité

407 0168893 1

Label-hot surface

Aufkleber-heisse Oberfläche

Calcomania-superficie caliente

Autocollant-surface brûlante

408 0172640 2

Caution label

Aufkleber-Vorsicht

Calcomania-Precaución

Autocollant-Précaution

409 0172224 1

Diesel fuel label

Aufkleber, Dieselkraftstoff

Calcomanía, combustible Diesel

Autocollant de carburant diesel

3 x 6

CUB 300HD

Labels

Aufkleber

Calcomanias

Autocollants

0620253 - 105

17

Page 68

Wacker Neuson SE - Preußenstraße 41 - 80809 München - Tel.: +49-(0)89-35402-0 - Fax: +49-(0)89-35402-390

Wacker Neuson Corporation - P. O. Box 9007 - Menomonee Falls, WI 53052-9007 - Tel.: (262)-255-0500 - Fax: (262)-255-0550

Wacker Neuson Ltd. - Tower 1, Grand Century Place - 193 Prince Edward Road West - Mongkok, Kowloon - Hong Kong, VR China - Tel: +852-3605 5360, Fax: +852-2406 6021

Loading...

Loading...