Page 1

www.wackergroup.com

0163091en 003

1007

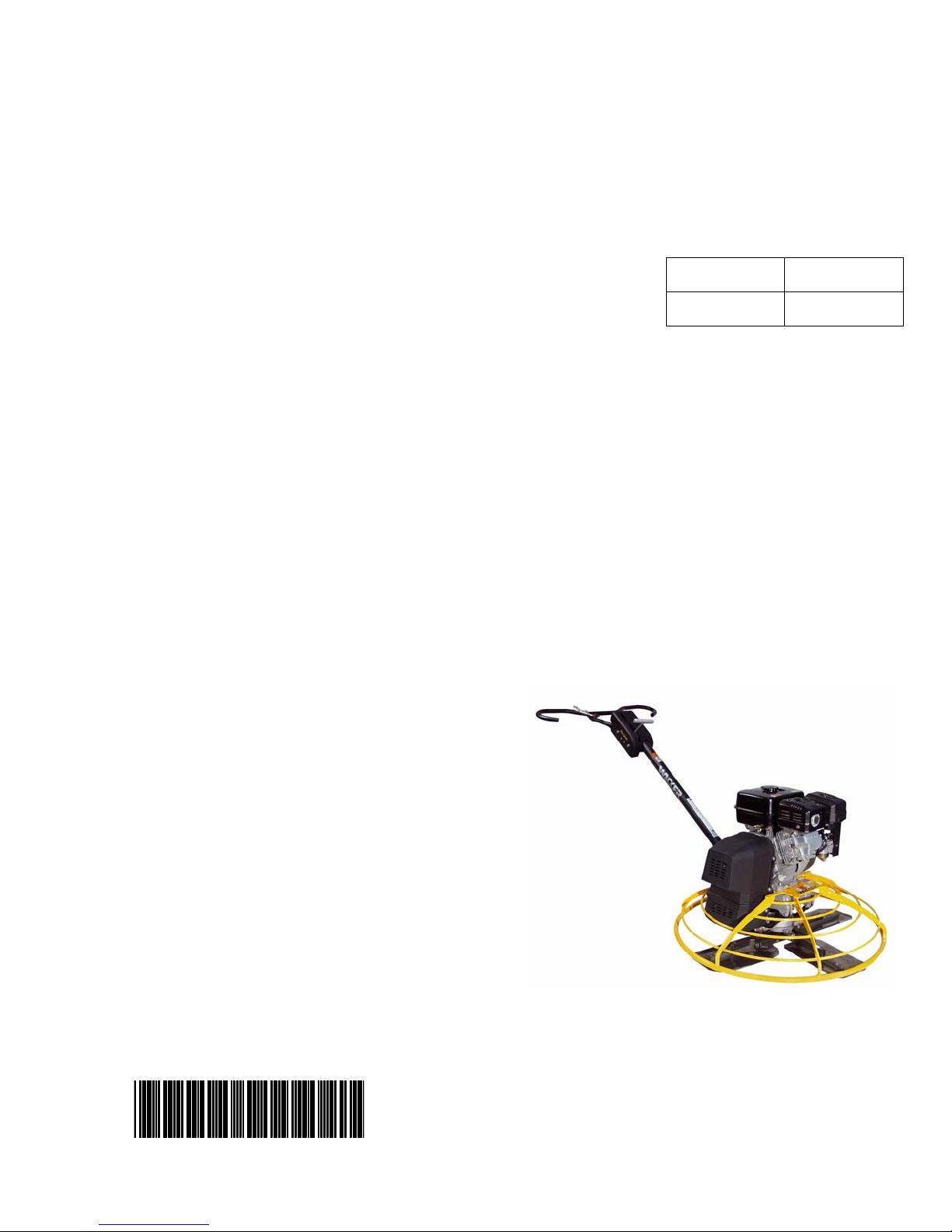

Walk-Behind

Trowels

CT 36

CT 48

REPAIR MANUAL

0163091EN

Page 2

Page 3

CT Repair Foreword

This manual covers machines with Item Number:

0009438, 0009439, 0009442, 0009443, 0009444, 0009447, 0009449,

0009450, 0009452, 0009453, 0620106

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or make any repairs to it. Basic operating and

maintenance procedures are described in the operator’s / parts

manual supplied with the machine. The operator’s / parts manual

should be kept with the machine. Use it to order replacement parts

when needed. If this manual becomes lost, please contact Wacker

Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to

the attention of the operator, to prevent similar occurrences from

happening in the future.

WARNING

This manual provides information and procedures to safely repair and

maintain the above Wacker model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. THE INFORMATION

CONTAINED IN THIS MANUAL IS BASED ON MACHINES

MANUFACTURED UP TO THE TIME OF PUBLICATION. WACKER

CORPORATION RESERVES THE RIGHT TO CHANGE ANY

PORTION OF THIS INFORMATION WITHOUT NOTICE.

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

wc_tx000550gb.fm 3

Page 4

CT Repair Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker model. For your own safety and protection

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2007 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

wc_tx000550gb.fm 4

Page 5

CT Repair Table of Contents

1. Safety Information 8

1.1 Laws Pertaining to Spark Arrestors ...................................................... 8

1.2 Operating Safety .................................................................................. 9

1.3 Operator Safety while using Internal Combustion Engines ................ 10

1.4 Service Safety .................................................................................... 11

1.5 Label Locations .................................................................................. 12

1.6 Safety and Information Labels ............................................................ 13

2. Technical Data 18

2.1 Dimensions and Weight ..................................................................... 18

2.2 Engine ................................................................................................ 20

2.3 Trowel ................................................................................................. 24

2.4 Sound and Vibration Data .................................................................. 25

3. Operation 26

3.1 Application .......................................................................................... 26

3.2 New Machine Set-up .......................................................................... 26

3.3 Recommended Fuel ........................................................................... 26

3.4 Installing Blades ................................................................................. 27

3.5 Installing and Adjusting Handles ........................................................ 28

3.6 Controls .............................................................................................. 30

3.7 Stop Button ......................................................................................... 31

3.8 Before Starting ................................................................................... 31

3.9 To Start - Honda ................................................................................. 32

3.10 To Stop - Honda ................................................................................. 33

3.11 To Start - Wacker ............................................................................... 34

3.12 To Stop - Wacker ............................................................................... 35

3.13 Engine Control Module ....................................................................... 36

3.14 Operation ............................................................................................ 36

3.15 Braking System .................................................................................. 38

3.16 Pitch Adjustment ................................................................................ 39

5

Page 6

Table of Contents CT Repair

4. Maintenance 40

4.1 Periodic Maintenance Schedule - Honda ............................................40

4.2 Periodic Maintenance Schedule - Wacker ..........................................41

4.3 Engine Oil - Honda ..............................................................................42

4.4 Engine Oil - Wacker ............................................................................43

4.5 Air Cleaner - Honda .............................................................................44

4.6 Air Cleaner - Wacker ...........................................................................45

4.7 Spark Plug ...........................................................................................46

4.8 Cleaning Sediment Cup - Honda .........................................................47

4.9 Cleaning Fuel Strainer - Wacker .........................................................47

4.10 Adjusting Idle Speed - Honda ..............................................................48

4.11 Carburetor Adjustment - Honda ..........................................................49

4.12 Belt Replacement ................................................................................50

4.13 Trowel Lubrication ...............................................................................51

4.14 Optional Weights .................................................................................51

4.15 Lifting ...................................................................................................52

4.16 Storage ................................................................................................54

4.17 Troubleshooting ...................................................................................55

5. Guide Handle 56

5.1 Replacing the Throttle Cable ...............................................................56

5.2 Adjusting the Throttle Lever ................................................................58

5.3 Upper Handle/Twist Pitch Control—Exploded View ............................60

5.4 Upper Handle/Twist Pitch Control—Components ...............................61

5.5 Replacing the Upper Handle ...............................................................62

5.6 Replacing the Twist Pitch Control Cable .............................................64

5.7 Replacing the Lower Handle ...............................................................66

5.8 Replacing the Stop Switch ..................................................................67

6. Clutch 69

6.1 Replacing the Drive Belt ......................................................................69

6.2 Drive Belt—Standard Clutch ...............................................................70

6.3 Drive Belt—Variable Speed Clutch .....................................................71

6.4 Replacing the Standard Clutch ............................................................72

6.5 Standard Clutch—Exploded View .......................................................73

6.6 Standard Clutch Overhaul ...................................................................74

6.7 Replacing the Variable Speed Clutch ..................................................76

wc_br0163091en_003TOC.fm 6

Page 7

CT Repair Table of Contents

7. Spider 78

7.1 Spider Assembly—Exploded View ..................................................... 78

7.2 Spider Assembly—Components ........................................................ 79

7.3 Replacing the Blades ......................................................................... 80

7.4 Replacing the Arms ............................................................................ 82

7.5 Balancing the Blade Pitch .................................................................. 84

7.6 Removing the Spider .......................................................................... 86

7.7 Installing the Spider ............................................................................ 88

7.8 Rebuilding the Lift Ring Assembly ...................................................... 90

8. Drivetrain 92

8.1 Drivetrain—Exploded View ................................................................. 92

8.2 Drivetrain—Components .................................................................... 93

8.3 Engine Removal ................................................................................. 94

8.4 Engine Installation .............................................................................. 96

8.5 Engine Wiring ..................................................................................... 98

8.6 Engine Wiring Components ................................................................ 99

8.7 Wiring Diagrams ............................................................................... 100

8.8 Engine Wiring Components .............................................................. 101

8.9 Replacing the Gearbox ..................................................................... 102

8.10 Gearbox—Exploded View ................................................................ 104

8.11 Gearbox—Components .................................................................... 105

8.12 Gearbox Disassembly ...................................................................... 106

8.13 Gearbox Assembly ........................................................................... 110

7

Page 8

Safety Information CT 36 / CT 48

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION

NOTICE: Used without the safety alert symbol, NOTICE indicates a

hazardous situation which, if not avoided, could result in property

damage.

Note: Contains additional information important to a procedure.

1.1 Laws Pertaining to Spark Arrestors

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

wc_si000139gb.fm 8

Page 9

CT 36 / CT 48 Safety Information

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of

machine. Machines operated improperly or by untrained personnel

can be dangerous. Read the operating instructions contained in both

WARNING

1.2.1 NEVER allow anyone to operate this equipment without proper

1.2.2 NEVER touch the engine or muffler while the engine is on or

1.2.3 NEVER use accessories or attachments that are not recommended by

1.2.4 NEVER leave machine running unattended.

this manual and the engine manual and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the machine before

being allowed to operate it.

training. People operating this equipment must be familiar with the

risks and hazards associated with it.

immediately after it has been turned off. These areas get hot and may

cause burns.

Wacker. Damage to equipment and injury to the user may result.

1.2.5 NEVER operate the machine with the beltguard missing. Exposed

drive belt and pulleys create potentially dangerous hazards that can

cause serious injuries.

1.2.6 NEVER operate this machine in applications for which it is not

intended.

1.2.7 NEVER use the trowel around pop-ups in the concrete that are lower

than the lowest ring on the ring guard.

1.2.8 NEVER lift the machine solely by the handle. The component may fail,

causing the machine to fall, possibly injuring bystanders.

1.2.9 ALWAYS wear protective clothing appropriate to the job site when

operating equipment.

1.2.10 ALWAYS wear hearing and eye protection when operating this

machine.

1.2.11 ALWAYS remain aware of moving parts and keep hands, feet, and

loose clothing away from the moving parts of the machine.

1.2.12 ALWAYS read, understand, and follow procedures in the Operator’s

Manual before attempting to operate the equipment.

1.2.13 ALWAYS store the equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the reach of

children.

1.2.14 ALWAYS close fuel valve on engines equipped with one when

machine is not being operated.

wc_si000139gb.fm 9

Page 10

Safety Information CT 36 / CT 48

1.2.15 ALWAYS operate machine with all safety devices and guards in place

and in working order. DO NOT modify or defeat safety devices. DO

NOT operate machine if any safety devices or guards are missing or

inoperative.

1.2.16 ALWAYS be sure operator is familiar with proper safety precautions

and operation techniques before using machine.

1.2.17 ALWAYS test the function of the engine control module before

operating the trowel. DO NOT operate the trowel if the engine control

module is not functioning properly.

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

DANGER

1.3.1 DO NOT run the machine indoors or in an enclosed area such as a

warnings and safety guidelines could result in severe injury or death.

deep trench unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

1.3.2 DO NOT smoke while operating the machine.

1.3.3 DO NOT smoke when refueling the engine.

1.3.4 DO NOT refuel a hot or running engine.

1.3.5 DO NOT refuel the engine near an open flame.

1.3.6 DO NOT spill fuel when refueling the engine.

1.3.7 DO NOT run the engine near open flames.

1.3.8 ALWAYS refill the fuel tank in a well-ventilated area.

1.3.9 ALWAYS replace the fuel tank cap after refueling.

wc_si000139gb.fm 10

Page 11

CT 36 / CT 48 Safety Information

1.4 Service Safety

Poorly maintained machines can become a safety hazard! In order for

the machine to operate safely and properly over a long period of time,

periodic maintenance and occasional repairs are necessary.

WARNING

1.4.1 DO NOT attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.4.2 DO NOT crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

1.4.3 DO NOT test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.4.4 DO NOT use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.4.5 DO NOT remove blades while the machine is hanging overhead.

1.4.6 ALWAYS support the machine securely before changing blades.

1.4.7 ALWAYS keep the area around the muffler free of debris such as

leaves, paper, cartons, etc. A hot muffler could ignite the debris and

start a fire.

1.4.8 ALWAYS replace worn or damaged components with spare parts

designed and recommended by Wacker Corporation.

1.4.9 ALWAYS disconnect the spark plug on machines equipped with

gasoline engines, before servicing, to avoid accidental start-up.

1.4.10 ALWAYS keep the machine clean and labels legible. Replace all

missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

1.4.11 ALWAYS handle blades carefully. The blades can develop sharp

edges which can cause serious cuts.

wc_si000139gb.fm 11

Page 12

Safety Information CT 36 / CT 48

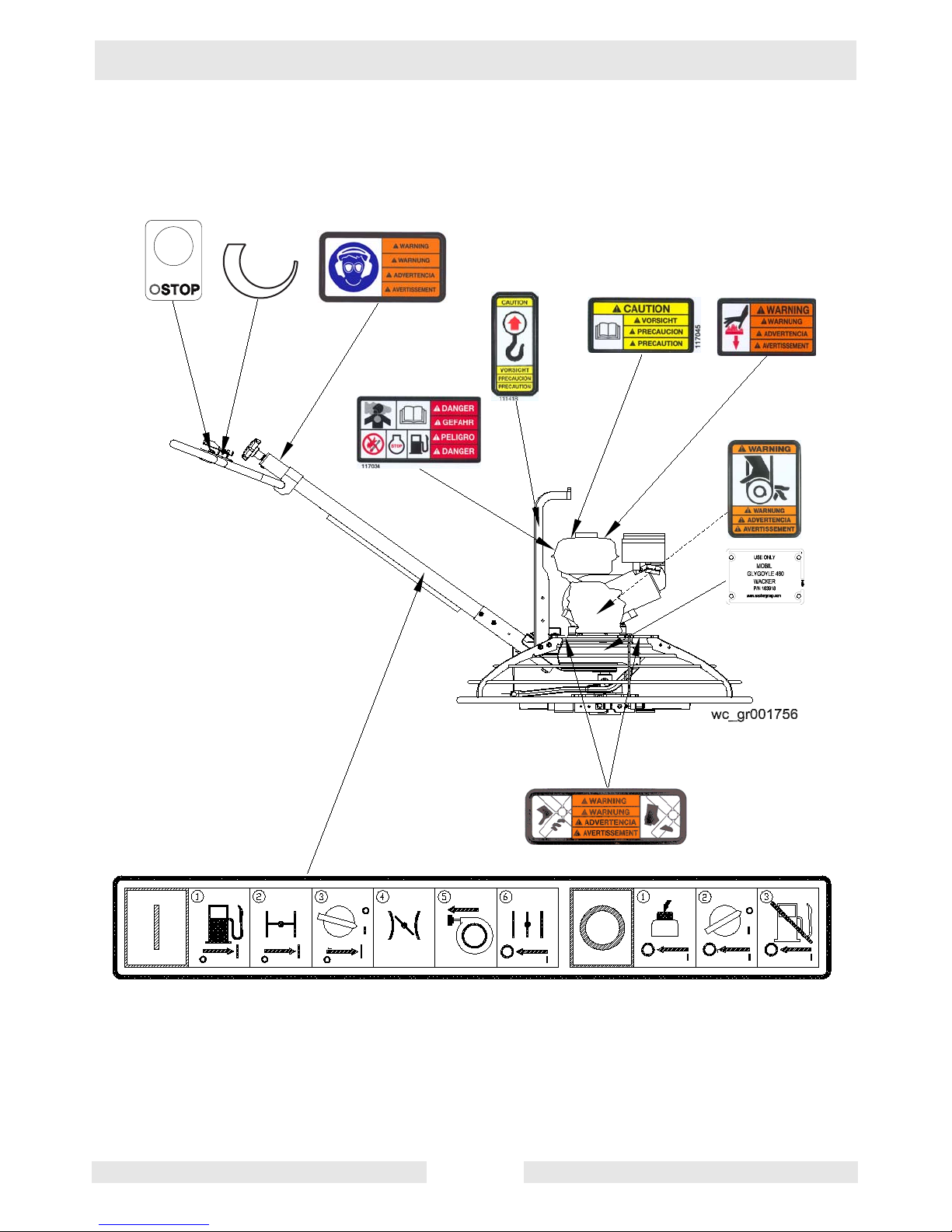

1.5 Label Locations

wc_si000139gb.fm 12

Page 13

CT 36 / CT 48 Safety Information

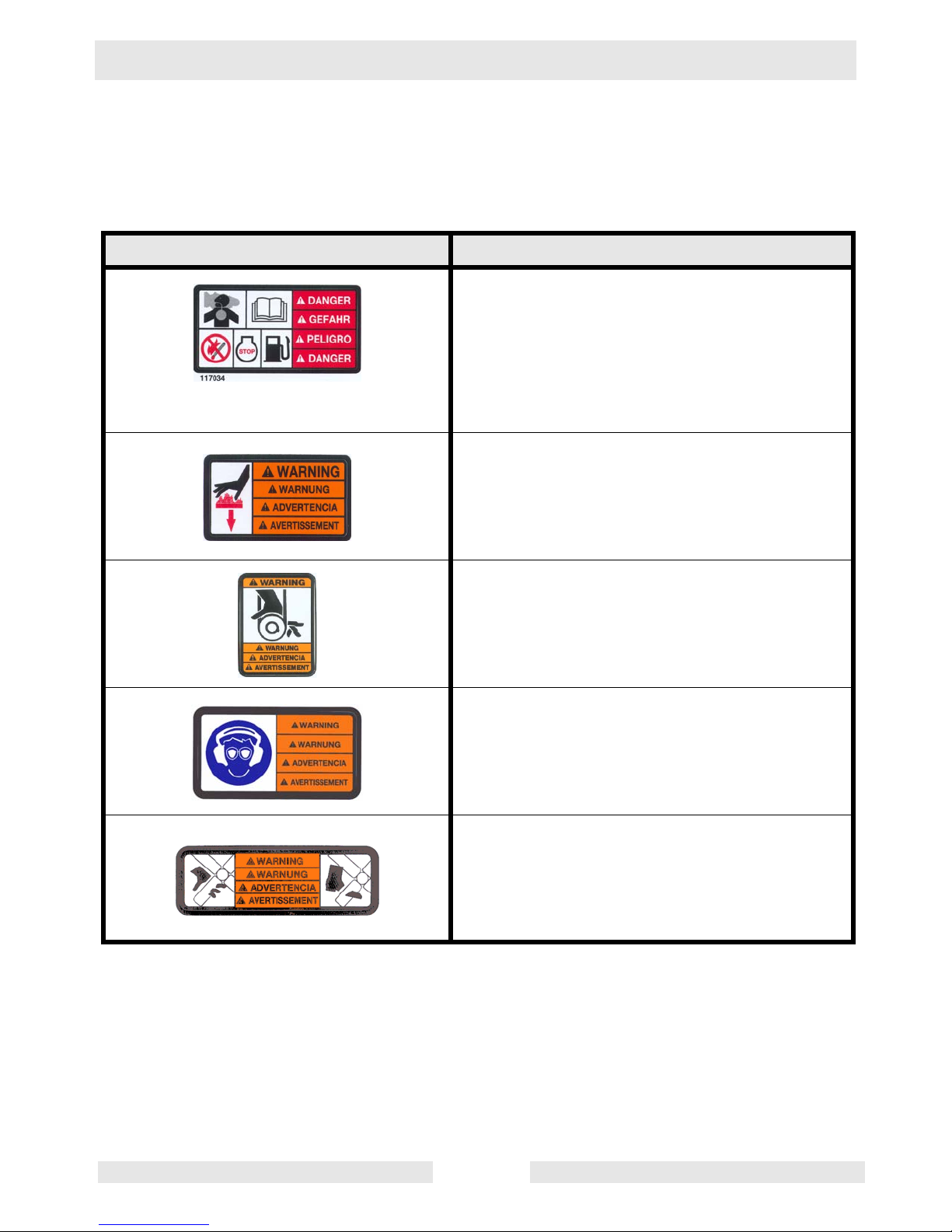

1.6 Safety and Information Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

DANGER!

Engines emit carbon monoxide; operate only

in well-ventilated area. Read the Operator’s

Manual.

No sparks, flames, or burning objects near the

machine. Shut off the engine before refueling.

WARNING!

Hot surface!

WARNING!

Hand injury if caught in moving belt.

Always replace beltguard.

WARNING!

Always wear hearing and eye protection when

operating this machine.

WARNING!

Cutting hazard. Always replace blade guard!

wc_si000139gb.fm 13

Page 14

Safety Information CT 36 / CT 48

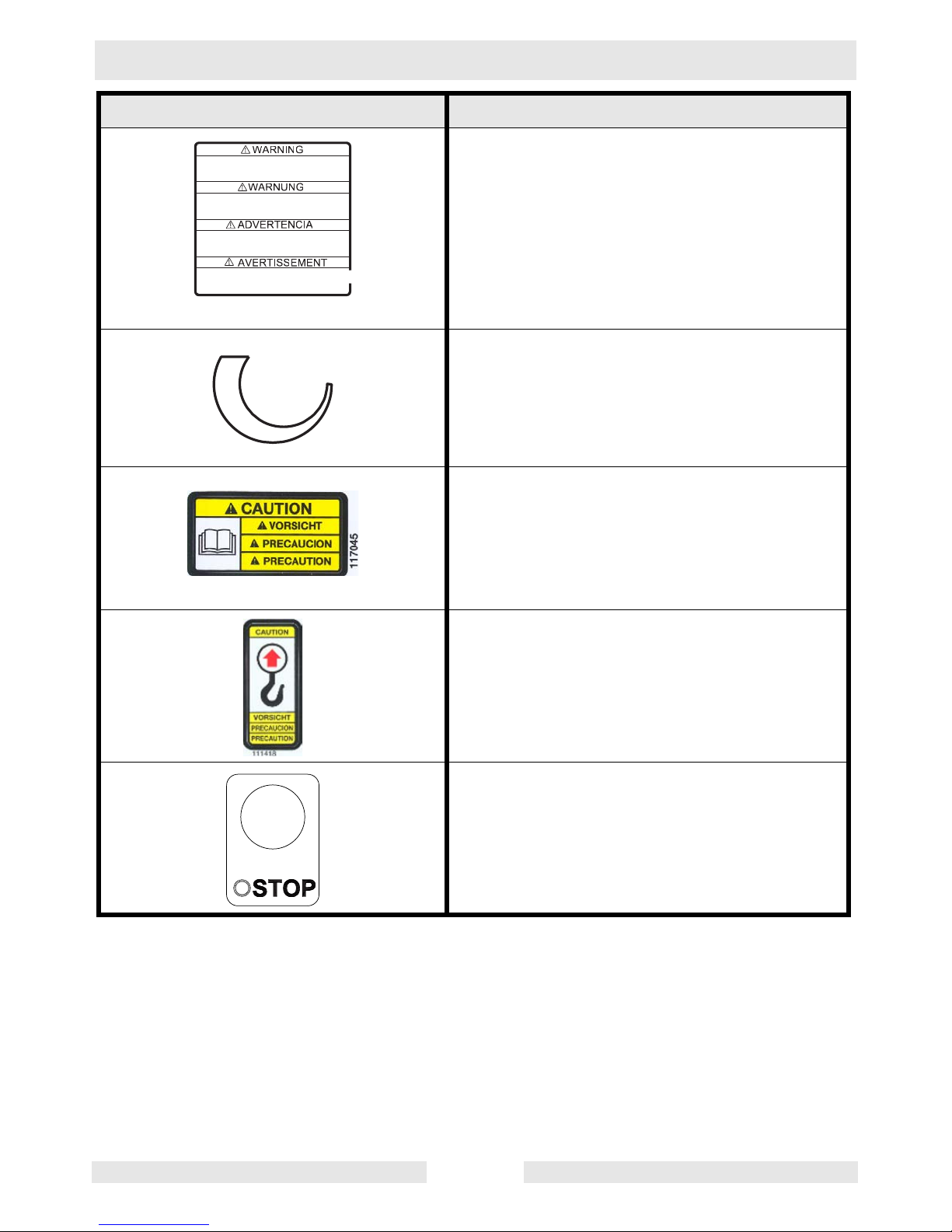

Label Meaning

R e m o v e p a n f r o m t r o w e l b e f o r e l i f t i n g m a c h i n e

o v e r h e a d .

P a n s c a n f a l l a n d c a u s e d e a t h o r s e r i o u s i n j u r y i f

a p e r s o n i s h i t .

G l e i t s c h e i b e v o m B e t o n g l ä t t e r e n t f e r n e n b e v o r

d a s G e r ä t u b e r K o p f h ö h e g e h o b e n w i r d .

G l e i t s c h e i b e k a n n f a l l e n u n d s c h w e r e V e r l e t z u n g

o d e r T o d v e r u r s a c h e n w e n n P e r s o n a l g e t r o f f e n w i r d .

Q u i t e e l d i s c o d e f l o t a c i ó n a n t e s d e l e v a n t a r l a

m á q u i n a a l i s a d o r a d e h o r m i g ó n .

L o s d i s c o s p o d r í a n c a e r y m a t a r o l a s t i m a r

s e r i a m e n t e a u n a p e r s o n a q u e s e e n c u e n t r e c e r c a .

A v a n t d e l e v e r l a p p a r e i l a u - d e s s u s d e v o t r e t ê t e ,

ô t e r l e d i s q u e d e t a l o c h a g e d e l a t r u e l l e .

L e d i s q u e d e t a l o c h a g e p e u t t o m b e r e t e n t r a î n e r

d e g r a v e s b l e s s u r e s o u m ê m e l a m o r t .

WARNING!

Remove pan from trowel before lifting machine

overhead. Pans can fall and cause death or

serious injury if a person is hit. (Located on top

side of float pan.)

1 1 8 6 8 8

Variable speed throttle

CAUTION!

Read and understand the supplied Operator’s

Manuals before operating this machine. Failure to do so increases the risk of injury to yourself or others.

CAUTION!

Lifting point.

Engine stop button:

Press to stop engine.

wc_si000139gb.fm 14

Page 15

CT 36 / CT 48 Safety Information

Label Meaning

A nameplate listing the model number, item

number, revision number, and serial number is

attached to each unit. Please record the information found on this plate so it will be available

should the nameplate become lost or damaged. When ordering parts or requesting service information, you will always be asked to

specify the model number, item number, revision number, and serial number of the unit.

Use only Glygoyle 460 gear oil in gearbox.

This machine may be covered by one or more

patents.

wc_si000139gb.fm 15

Page 16

Safety Information CT 36 / CT 48

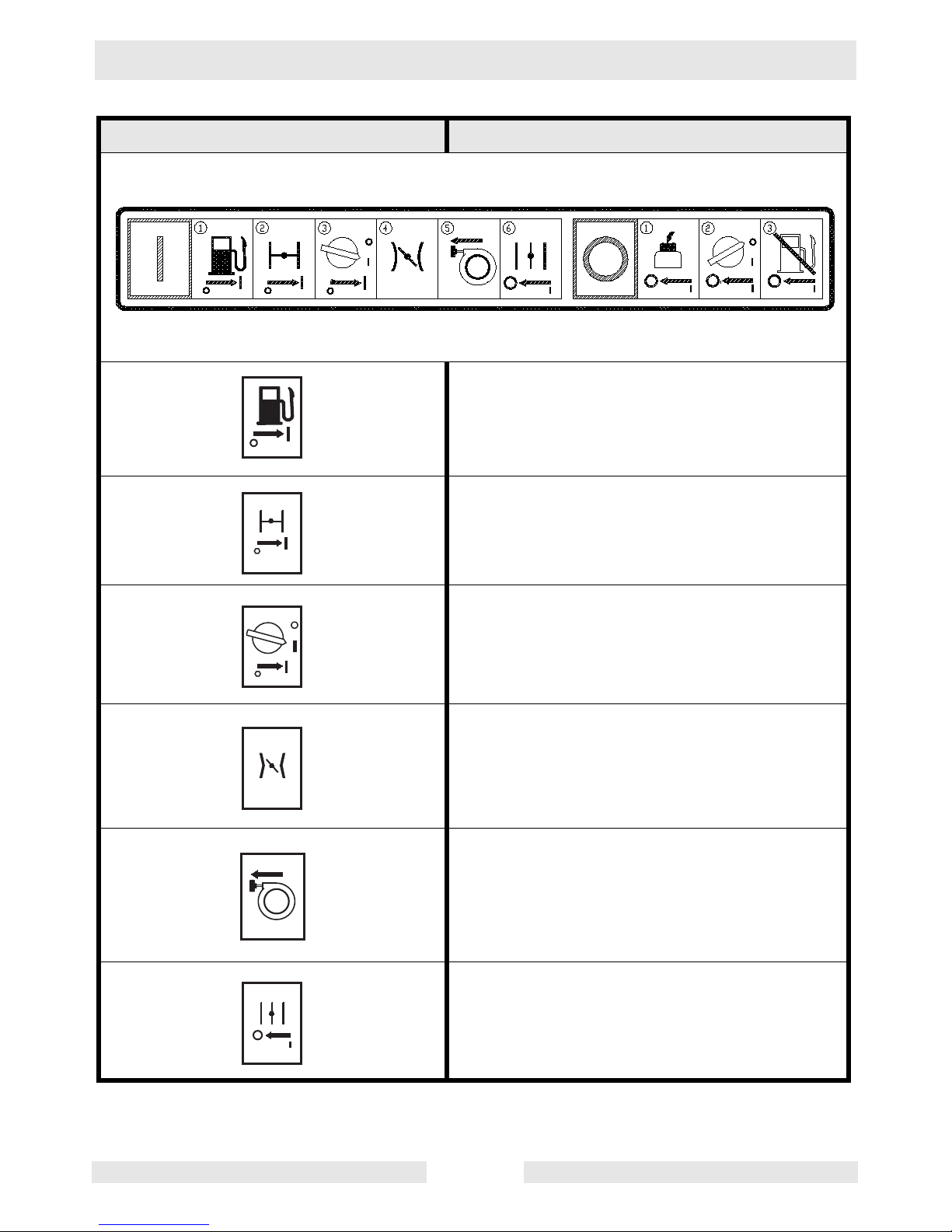

Label Meaning

Open the fuel flow valve.

Close the choke.

Turn engine key switch to “ON” position.

Place throttle in the IDLE position.

Pull the rewind starter.

Open the choke.

wc_si000139gb.fm 16

Page 17

CT 36 / CT 48 Safety Information

Label Meaning

Press the stop button.

Turn engine key switch to “OFF” position.

Close the fuel flow valve.

wc_si000139gb.fm 17

Page 18

Technical Data CT 36 / CT 48

2. Technical Data

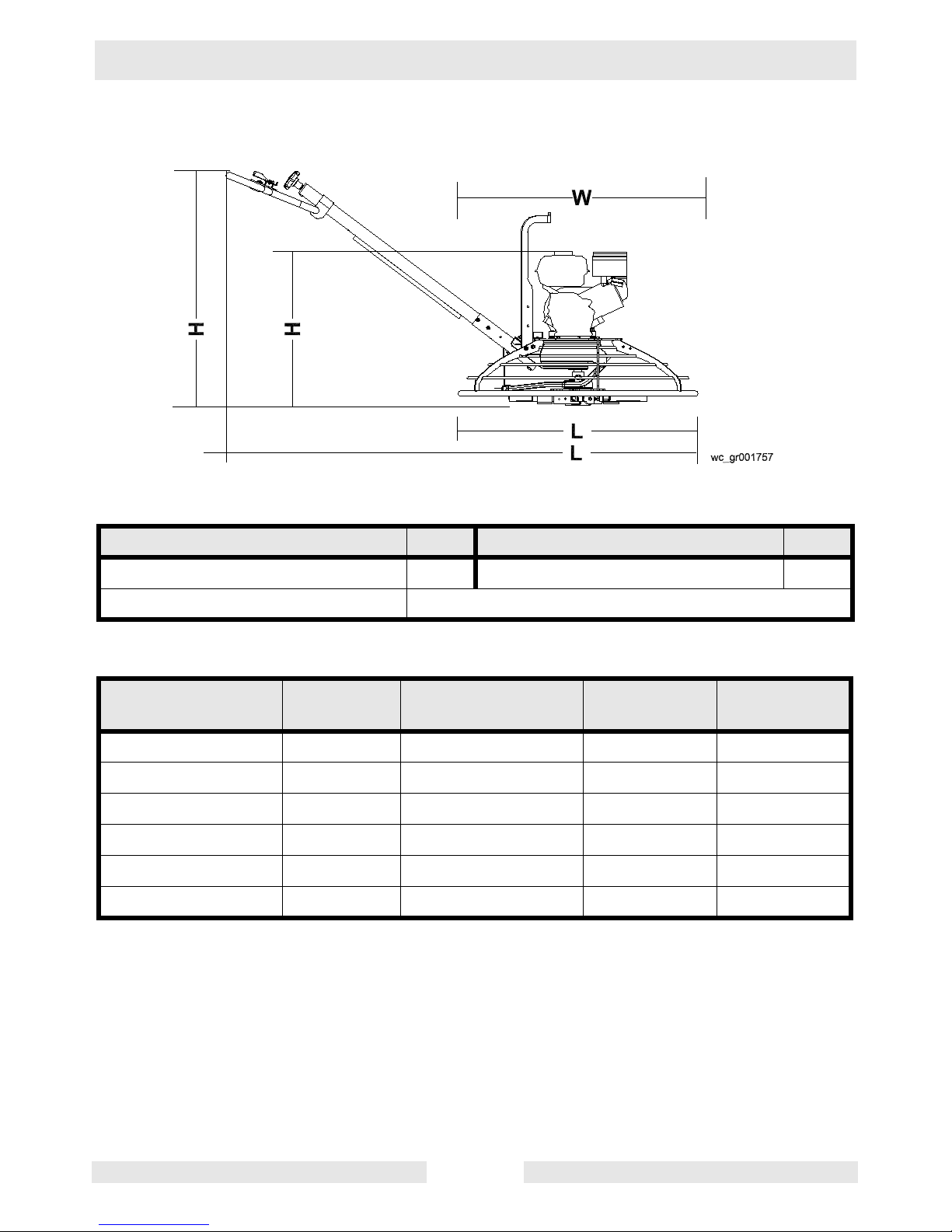

2.1 Dimensions and Weight

Guide

Description Ref. Description Ref.

Honda engine* A Variable Speed V

Engine Horse Power 4, 5, 6, 8, 9, 11, 13

*Standard models feature Wacker engine.

Handle Type Item No.

L

mm(in.)

Pitch

Type

Weight

kg (lbs.)

Solid 0159659 1740 (68.5) Twist 10 (21)

Folding 0159660 1740 (68.5) Twist 12 (26.5)

Adjustable/Folding 0164617 1740 (68.5) Twist 13 (28)

Adjustable 0164535 1740 (68.5) Twist 11 (24.5)

Adjustable/Folding 0159661 1740 (68.5) Pro-Shift® 15 (32.5)

Adjustable 0159662 1740 (68.5) Pro-Shift® 13 (29)

wc_td000141gb.fm 18

Page 19

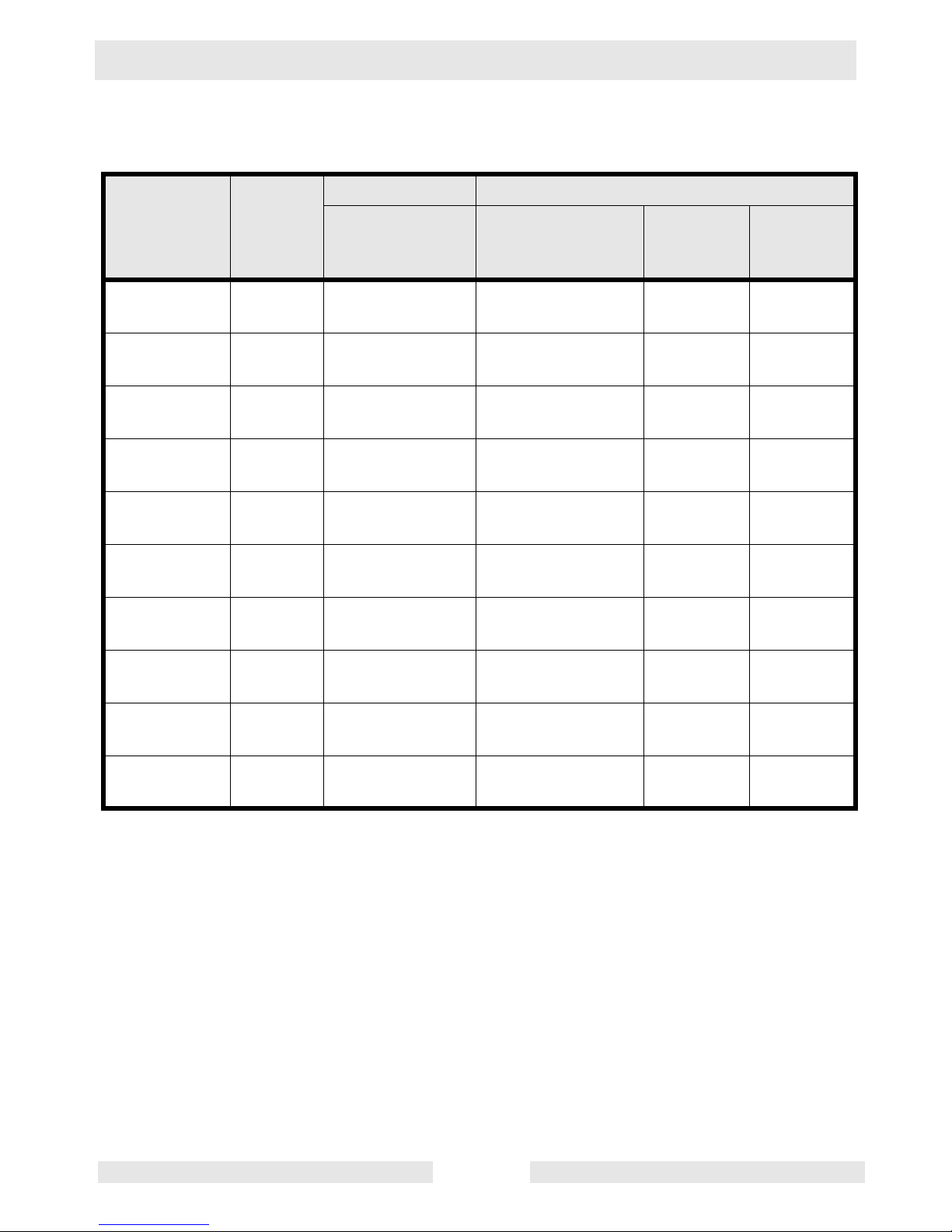

CT 36 / CT 48 Technical Data

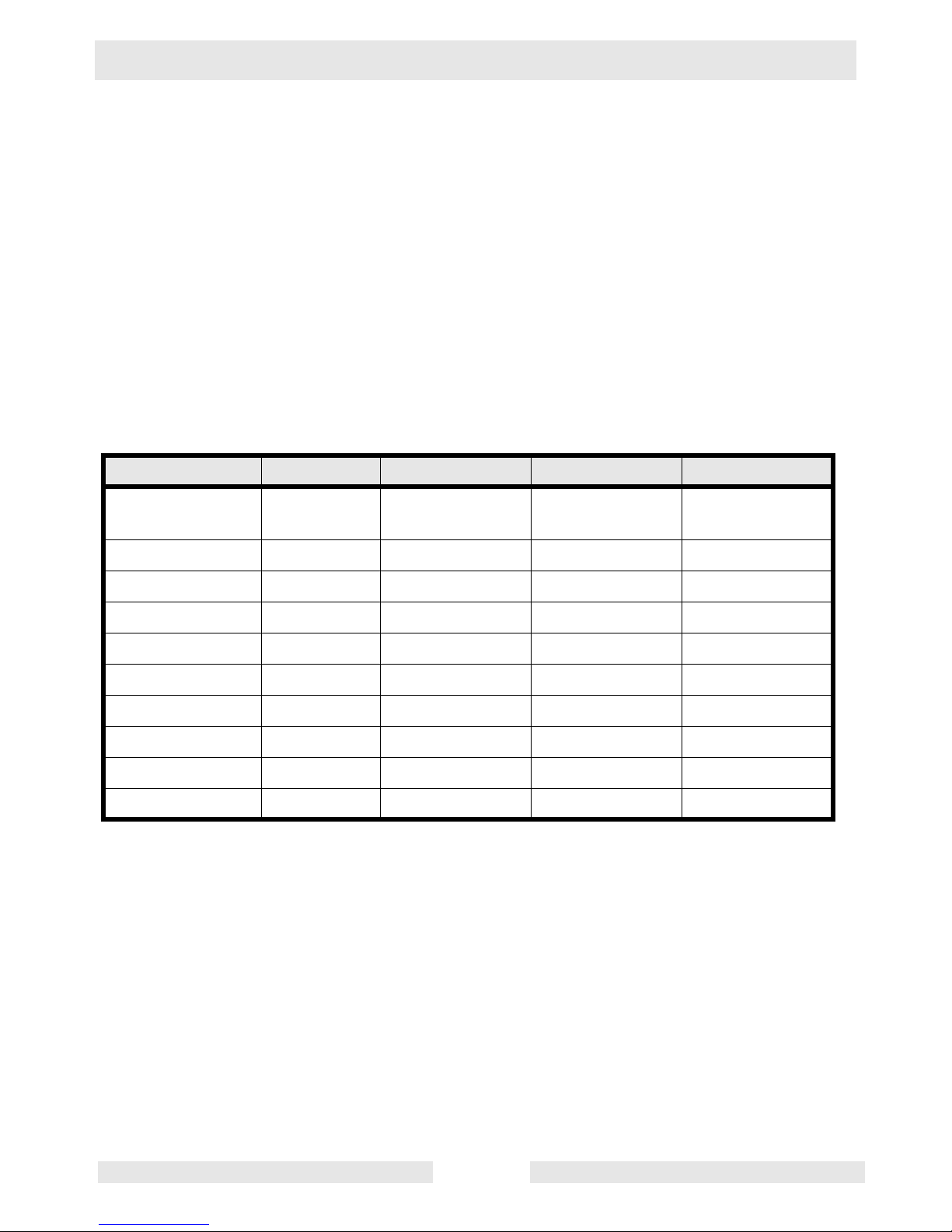

without handle with handle

Model Item No.

CT 36-5A

0009438

0620106

CT 36-6 0009443

CT 36-8A 0009439

CT 36-8A-V 0009442

CT 36-9 0009444

CT 36-9-V 0009447

CT 48-8A 0009449

CT 48-9 0009453

LxWxH

mm

(in.)

915x915x607

(36x36x24)

915x915x607

(36x36x24)

915x915x686

(36x36x27)

915x915x686

(36x36x27)

915x915x686

(36x36x27)

915x915x686

(36x36x27)

1220x1220x686

(48x48x27)

1220x1220x686

(48x48x27)

LxWxH

mm

(in.)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2160x1220x1040

(85x48x41)

2160x1220x1040

(85x48x41)

without

weight kit

kg (lbs.)

with

weight kit

kg (lbs.)

85 (183) 91 (201)

85 (183) 91 (201)

94 (208) 103 (226)

94 (208) 103 (226)

90 (199) 98 (217)

90 (199) 98 (217)

105 (234) 114 (252)

105 (234) 114 (252)

CT 48-11A 0009450

CT 48-13A-V 0009452

1220x1220x712

(48x48x28)

1220x1220x712

(48x48x28)

2160x1220x1040

(85x48x41)

2160x1220x1040

(85x48x41)

113 (250) 122 (268)

121 (268) 130 (286)

wc_td000141gb.fm 19

Page 20

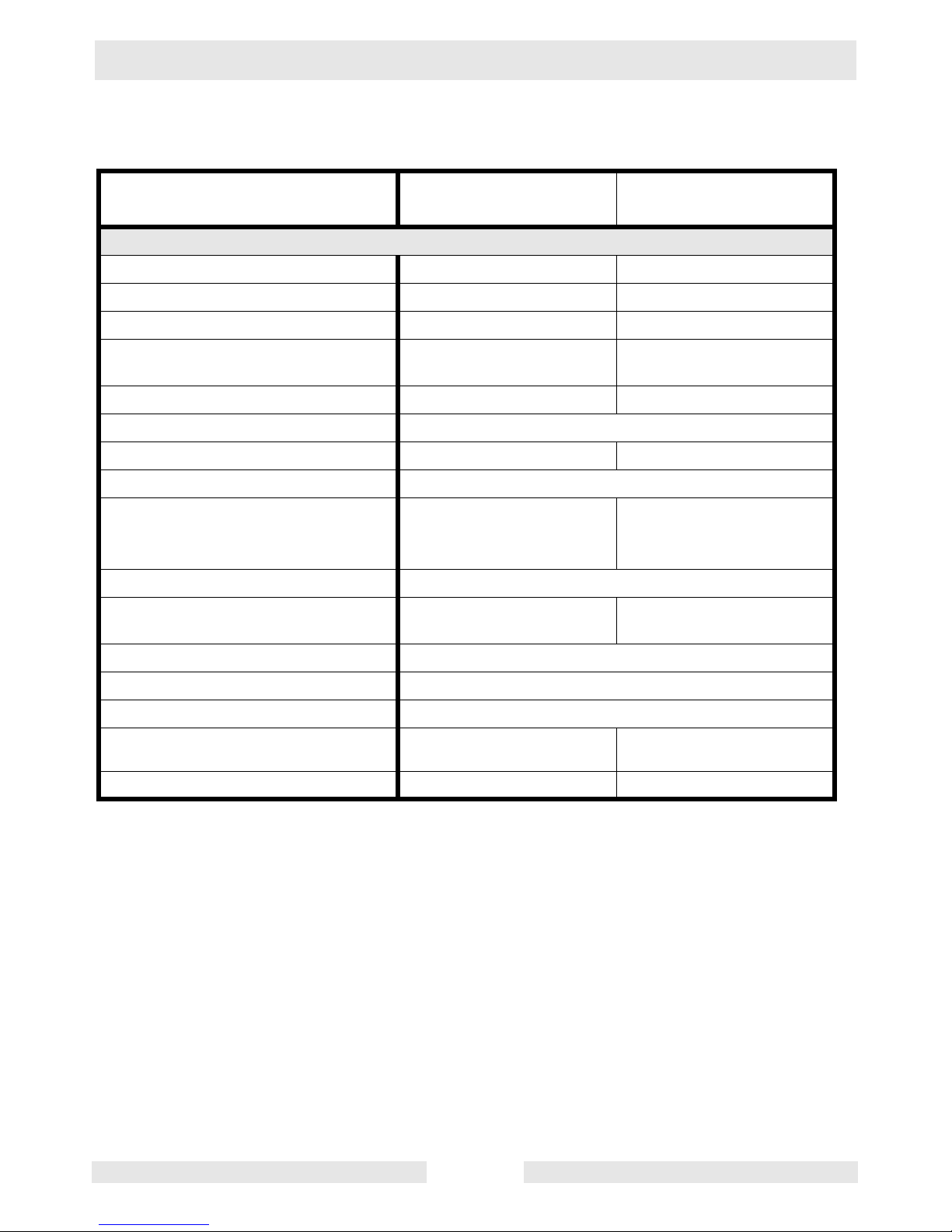

Technical Data CT 36 / CT 48

2.2 Engine

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 36-5A

0009438, 0620106

CT 36-6

0009443

Engine

Honda

GX 160 K1 QX2

4.3 (5.7) @ 3800rpm

NGK BPR 6ES NGK BR6HS

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30 SG or SF SAE 10W30

0.6 (20)

Regular unleaded gasoline

3.6 (3.8)

1.8 (1.9) 1.52 (1.6)

22.4

4.2 (5.6) @ 3800 rpm

0.6–0.7 (0.024–0.028)

0.07–0.13 (0.0028–0.0051)

0.17–0.23 (0.0067–0.0091

Wacker

WM170

Champion RL86C

1400 ± 100

SE or higher

wc_td000141gb.fm 20

Page 21

CT 36 / CT 48 Technical Data

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 36-8A

0009439

CT 36-8A-V

0009442

CT36-9

0009444

CT 36-9-V

0009447

Engine

Honda Wacker

GX 240 K1 QA WM270

6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm

NGK BPR 6ES

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100 1400 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30 SG or SF

1.1 (37)

Regular unleaded gasoline

6.0 (6.4)

2.7 (2.8) 2.5 (2.6)

2.25 2.4

NGK BR6HS

Champion RL86C

0.07–0.13 (0.0028–0.0051)

0.17–0.23 (0.0067–0.0091

SAE 10W30

SF, SE, SD, or SC

wc_td000141gb.fm 21

Page 22

Technical Data CT 36 / CT 48

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 48A-8A

0009449

CT 48-9

0009453

Engine

Honda Wacker

GX 240 K1 QA WM270

6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm

NGK BPR 6ES

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100 1400 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30 SG or SF

1.1 (37)

Regular unleaded gasoline

6.0 (6.4)

2.7 (2.8) 2.5 (2.6)

2.25 2.4

NGK BR6HS

Champion RL86C

0.07–0.13 (0.0028–0.0051)

0.17–0.23 (0.0067–0.0091

SAE 10W30

SF, SE, SD, or SC

wc_td000141gb.fm 22

Page 23

CT 36 / CT 48 Technical Data

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 48-11A

0009450

CT 48-13A-V

0009452

Engine

Honda

GX 340 K1 QA GX 390 U1 QA

8.7 (11.6) @ 3800 rpm 10 (13.4) @ 3800 rpm

NGK BPR 6ES

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30

SG or SF

1.1 (37)

Regular unleaded gasoline

6.0 (6.4)

2.7 (2.8)

2.25

wc_td000141gb.fm 23

Page 24

Technical Data CT 36 / CT 48

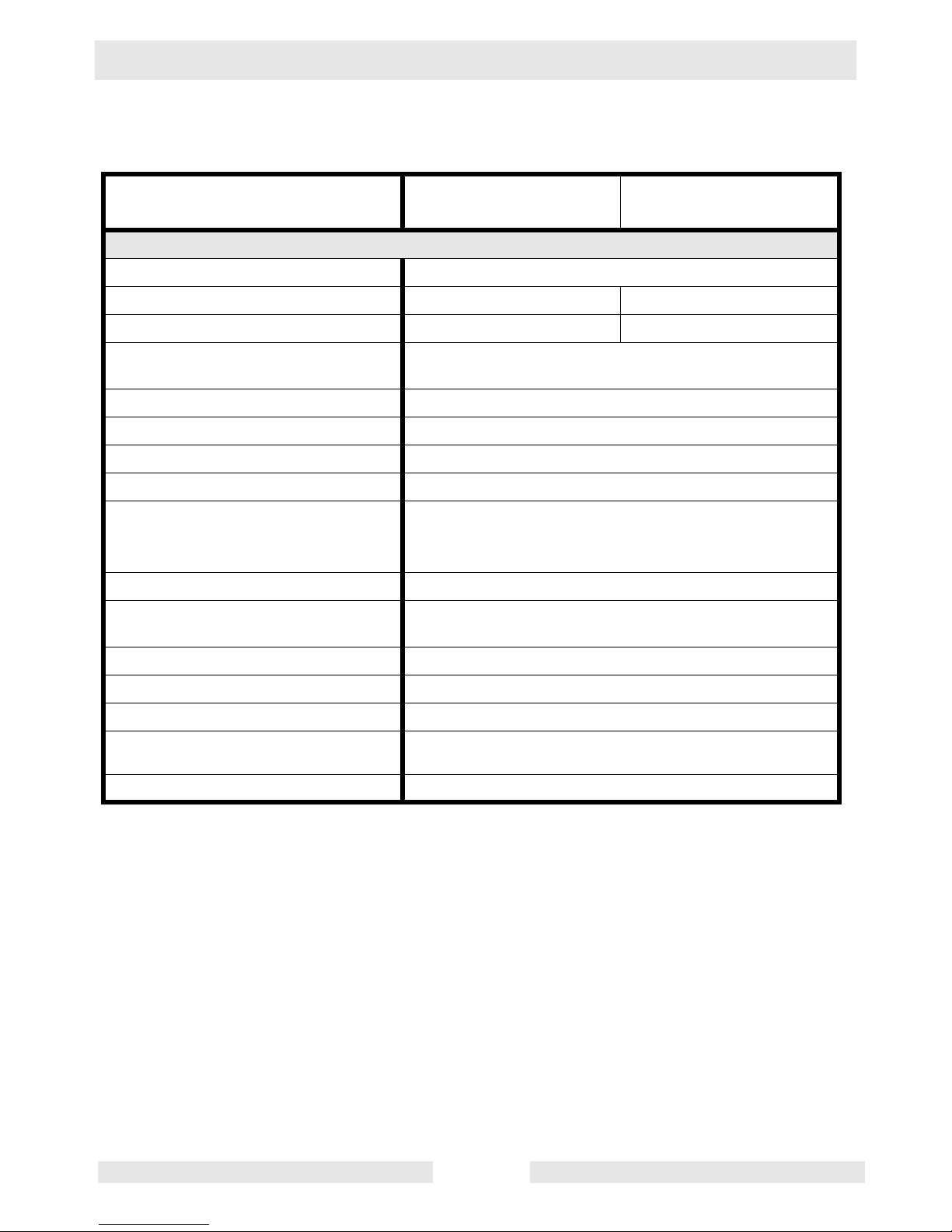

2.3 Trowel

Model Item No.

Trowel

Diameter*

mm (in.)

Number

of

Blades

Gear Box

Lubrication

type/ml (oz.)

Speed

Range

rpm

Trowel

CT 36-5A

0009438

0620106

60–125

CT 36-6 0009443

CT 36-8A 0009439 60–125

CT 36-8A-V 0009442 25–200

CT 36-9 0009444 60–125

CT 36-9-V 0009447 25–200

CT 48-8A 0009449

915 (36)

Mobil

Glygoyle

4

460

Approx.

620 (21)

60–125CT 48-9 0009453

1220 (48)

CT 48-11A 0009450

CT 48-13A-V 0009452 25–200

*Trowel blades must NOT be interchanged, i.e., do NOT put larger diameter blades on a smaller

diameter trowel.

Pitch

Range

degrees

0–30

wc_td000141gb.fm 24

Page 25

CT 36 / CT 48 Technical Data

2.4 Sound and Vibration Data

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• the sound pressure level at operator’s location (L

• the guaranteed sound power level (L

) = “B” dB(A)

WA

) : “A” dB(A)

pA

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 6081 for the sound pressure level

(LpA) at the operator’s location.

• The weighted effective acceleration value, determined according to

ISO 8662 Part 1, is: “C” m/s2.

The sound and vibration specifications were obtained with the unit

operating on wetted and cured concrete at full engine speed.

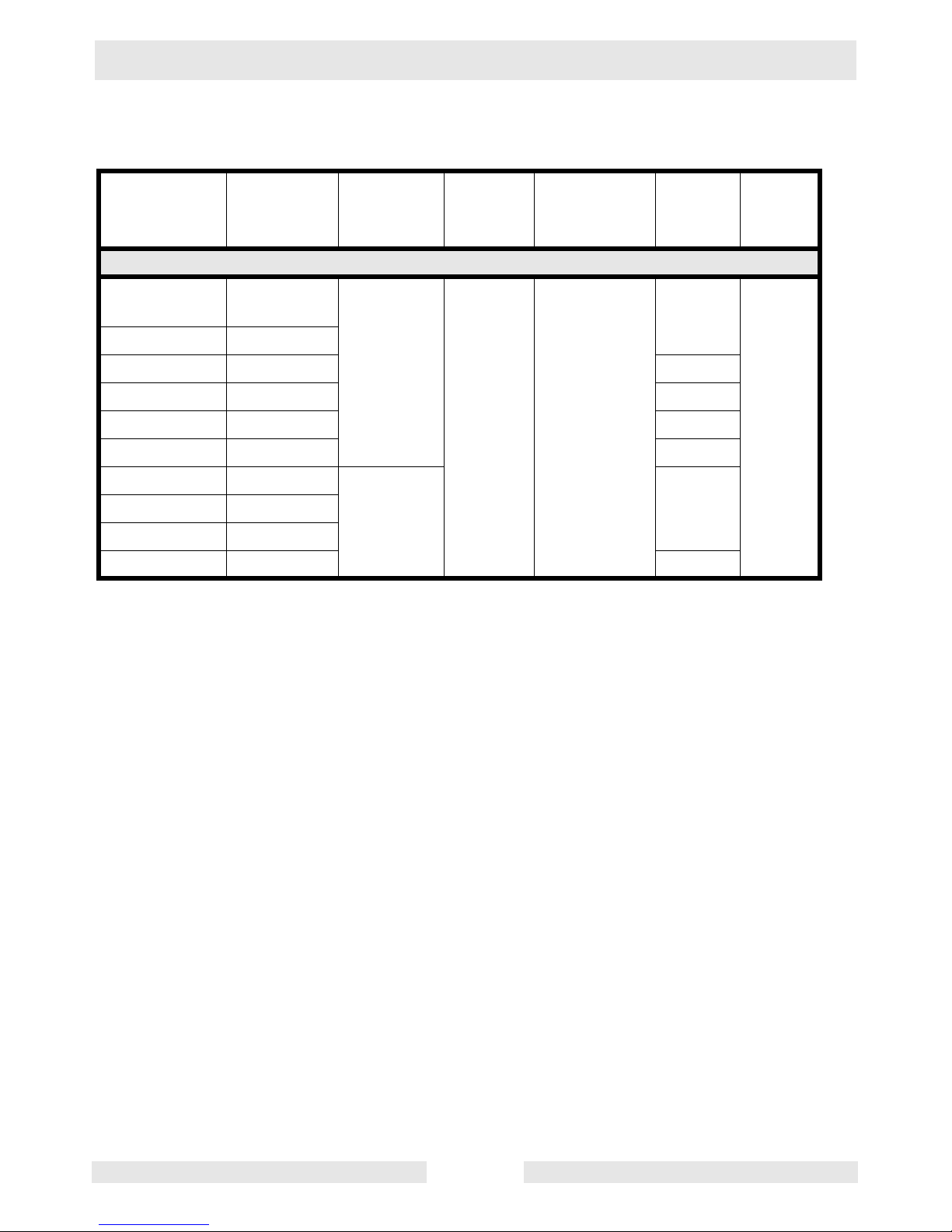

Model Item No. A B C

CT 36-5A

0009438

0620106

103 89 5.3

CT 36-6 0009443 103 89 5.3

CT 36-8A 0009439 109 95 4.3

CT 36-8A-V 0009442 109 95 4.0

CT 36-9 0009444 109 95 7.1

CT 36-9-V 0009447 109 95 6.6

CT 48-8A 0009449 109 95 5.3

CT 48-9 0009453 109 95 5.3

CT 48-11A 0009450 113 96 7.1

CT 48-13A-V 0009452 115 98 4.1

wc_td000141gb.fm 25

Page 26

Operation CT 36 / CT 48

3. Operation

3.1 Application

This trowel is a modern, high production machine intended for floating

and finishing freshly poured concrete slabs. The machine's good

balance, adjustable handle, and easily reached controls add to

operator comfort and productivity. An automatic stop sensor provides

added operator safety. Finishing rates will depend on operator skill and

job conditions.

DO NOT use this machine for any application other than troweling

concrete.

3.2 New Machine Set-up

Trowels are shipped from the factory with the handle removed. Follow

instructions on Installing Blades and Installing and Adjusting Handles

when setting up new machines or when installing new handles and

blades.

3.3 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh,

clean gasoline. Gasoline containing water or dirt will damage fuel

system. Consult engine Owner’s Manual for complete fuel

specifications.

wc_tx000373gb.fm 26

Page 27

CT 36 / CT 48 Operation

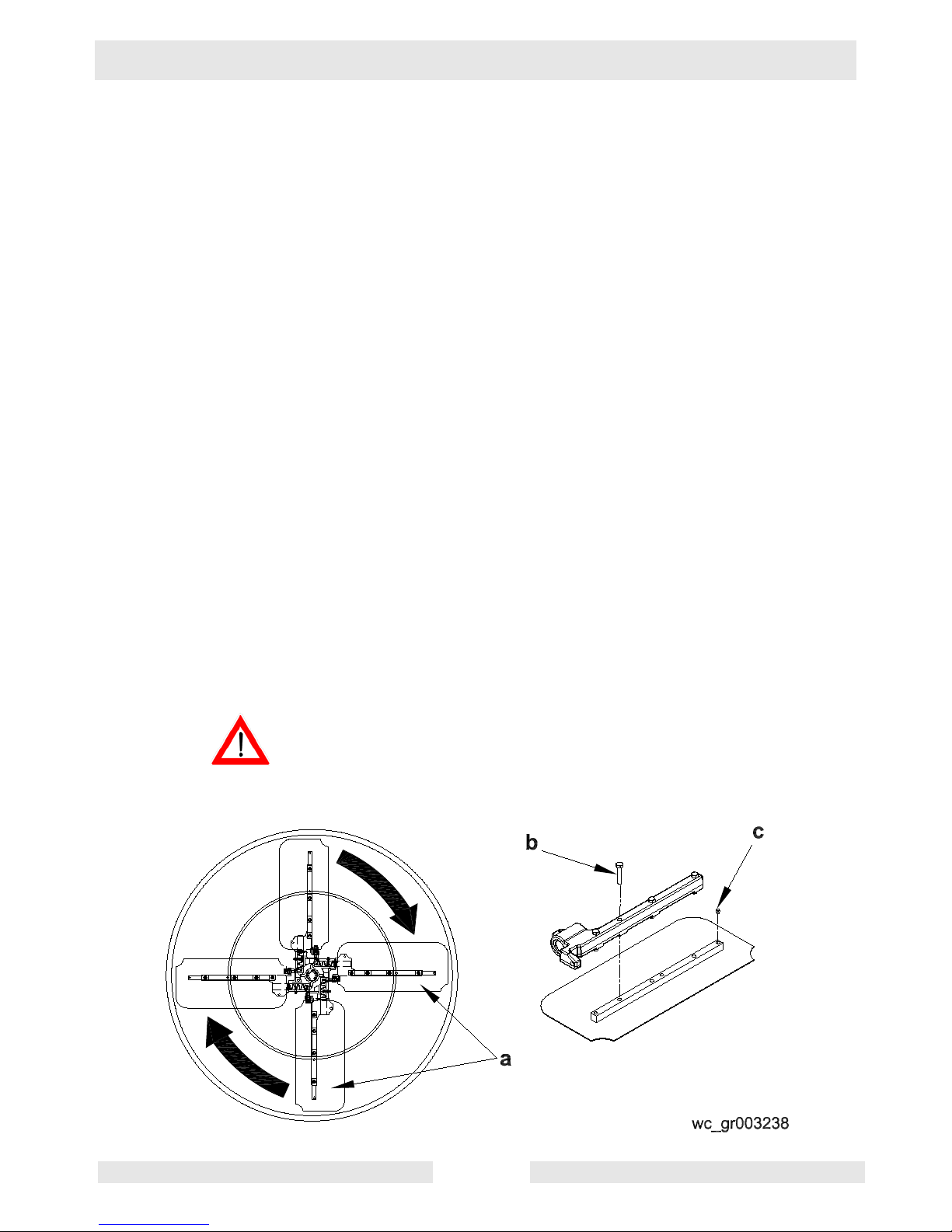

3.4 Installing Blades

See Graphic: wc_gr003238

There are four types of blades available for the trowels. Float pans are

large "pizza pan" style blades, which hook on over finish or

combination blades and are available for the 36" machines only. Float

blades are available for all machines and clip on over finish or

combination blades. Both are used in the earliest stages of work, and

are not pitched.

Finish blades are used in the final stages of working, and are

progressively pitched to burnish the concrete.

Combination blades can be used throughout the concrete working

process. They are used in place of float blades or pans and finish

blades.

Note: Trowel blades must NOT be interchanged, i.e., do NOT put

larger diameter blades on a smaller diameter trowel.

3.4.1 Finish blades are flat on both edges and can be installed in either

direction.

When installing combination blades, orient blades as shown (a). This

positions the raised edges of the blade correctly for the clockwise

rotation of the machine.

3.4.2 Secure blades to trowel arms with screws (b). Dip threads of screws in

grease prior to installation. This will prevent concrete from cementing

the screws in place and will make removal of the blades easier later on.

3.4.3 Plug the remaining threaded holes in the blade brace with plastic plugs

(c) to prevent them from filling with concrete.

Do not lift the trowel overhead with a float pan attached, as the pan

could fall off and strike personnel working in the vicinity.

WARNING

wc_tx000373gb.fm 27

Page 28

Operation CT 36 / CT 48

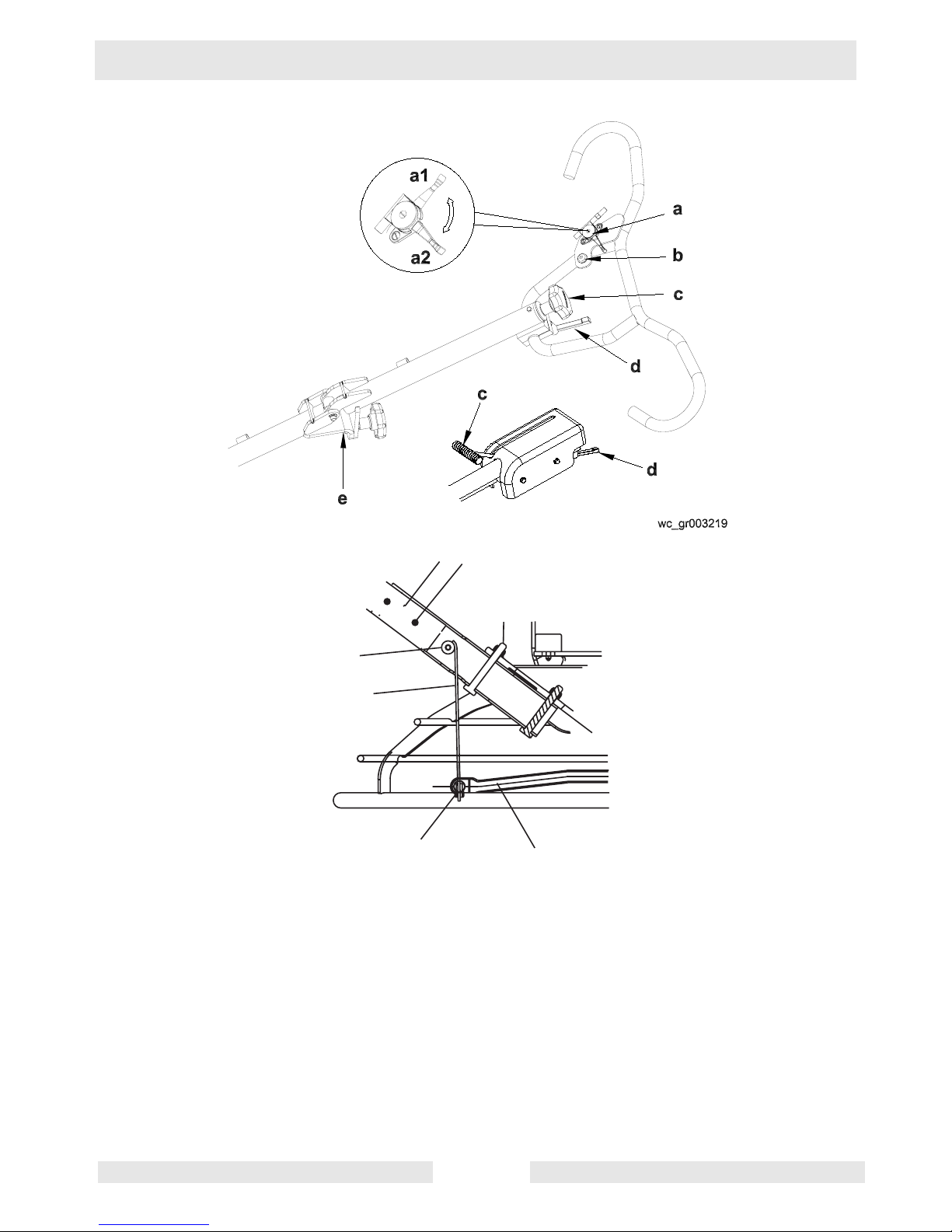

3.5 Installing and Adjusting Handles

See Graphic: wc_gr001758, wc_gr003219

On new machines the pipe handle comes assembled with the pitch

control (Twist or Pro-Shift®) (c), stop button (b), throttle (a), screws

(g), and nut (m).

To install the pipe handle assembly:

3.5.1 On machines with the foldable handle, straighten the handle and

tighten the knob (e) to secure the handle in position.

3.5.2 Pull the pitch control cable (j) from bottom end of the tube and remove

the nut from the cable.

3.5.3 Thread the cable through the handle base (f) and over the pulley (h)

as shown.

3.5.4 Attach the pipe handle to the handle base with two M8x65 screws (g).

Torque the screws to 25 Nm (18 ft.lbs.).

3.5.5 Push the Pro-Shift® handle all the way forward (away from the

operator) OR turn the twist pitch control handle counterclockwise as far

as possible. Connect the cable to the fork (k) as shown and adjust the

cable nut (m) so the cable is snug and the trowel blades lay flat (0°

pitch).

3.5.6 Move throttle (a1) to idle position. Remove air cleaner cover. Feed

cable through clamp on recoil cover. Connect throttle cable to engine

throttle bracket by placing z-bend through hole in throttle plate. Clamp

cable into throttle casing bracket. Replace air cleaner cover.

3.5.7 Connect electrical wire on handle to both ends of the engine wire. See

handle instruction sheet for additional detail on installation.

Note: On machines with Wacker engines, do not connect wires in bag

to wires in handle.

3.5.8 On machines with an adjustable handle, position the handle by

loosening the knob (d) and adjusting the handle up or down to suit the

operator. Tighten the knob to secure the handle in position.

wc_tx000373gb.fm 28

Page 29

CT 36 / CT 48 Operation

e

f

g

h

wc_gr001758

k

j

wc_tx000373gb.fm 29

Page 30

Operation CT 36 / CT 48

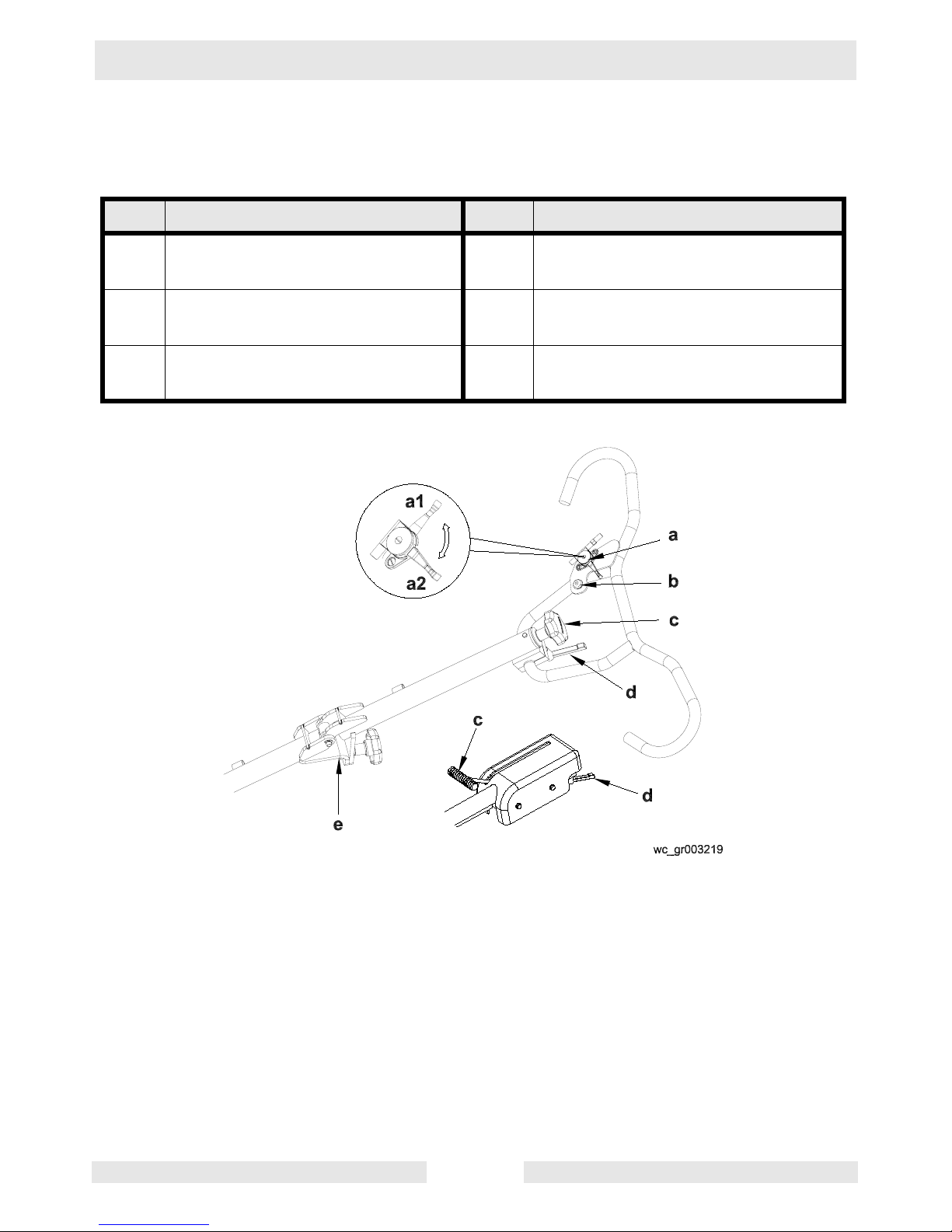

3.6 Controls

See Graphic: wc_gr003219

Ref. Description Ref. Description

a Throttle lever d Handle height adjustment (if

equipped)

b Stop button e Foldable handle adjustment (if

equipped)

c Twist pitch control or Pro-Shift®

pitch control

wc_tx000373gb.fm 30

Page 31

CT 36 / CT 48 Operation

3.7 Stop Button

See Graphic: wc_gr003219

When the stop button (b) is pressed, the engine will shut off.

To prevent uncontrolled spinning of the trowel, the engine control

module is designed to shutoff the engine under certain conditions. For

example, if the operator loses his/her grip on the trowel, the engine

control module will sense that the machine is spinning and shut off the

engine. The momentum of the spinning trowel will engage the brake

and stop the handle from spinning past 270°.

3.8 Before Starting

Before starting trowel, check the following:

• oil level in engine

• oil level in gearbox

• fuel level

• condition of air filter

• condition of fuel lines

• condition of trowel arms and blades

• condition of ring guard

• label descriptions

• handle height to suit operator

wc_tx000373gb.fm 31

Page 32

Operation CT 36 / CT 48

3.9 To Start - Honda

See Graphic: wc_gr003219, wc_gr001098

3.9.1 Open fuel valve by moving lever to the right (g1).

Note: If engine is cold, move choke lever to closed position (i1). If

engine is hot, set choke to open position (i2).

3.9.2 Turn engine switch to “ON” (h1).

3.9.3 Move the throttle lever to the idle position (a1).

Note: Start engine with throttle in the idle position. If the engine is

started when the throttle is not in the idle position, the engine should

not start. This is a feature of the engine control module that prevents

wide open throttle startup.

3.9.4 Pull starter rope (j).

Do not place foot on the ring guard when starting the engine, as severe

injury can occur if foot slips through the ring guard as the blades start

WARNING

to spin.

Note: If the engine oil is low, the engine will not start. If engine does

not start, check the oil level and add oil as needed.

3.9.5 Open choke as engine warms (i2).

3.9.6 Open throttle (a2) to operate trowel. Adjust blade RPM with throttle

speed to suit conditions.

wc_tx000373gb.fm 32

Page 33

CT 36 / CT 48 Operation

g1

g2

3.10 To Stop - Honda

See Graphic: wc_gr003219, wc_gr001098

3.10.1 Reduce engine RPM to idle by moving the throttle lever to idle position

(a1).

3.10.2 Push the stop button (b).

3.10.3 Turn engine switch to “OFF” (h2).

3.10.4 Close fuel valve by moving lever to the left (g2).

h2

h1

i1

i2

j

wc_gr001098

wc_tx000373gb.fm 33

Page 34

Operation CT 36 / CT 48

3.11 To Start - Wacker

See Graphic: wc_gr003219, wc_gr002747

3.11.1 Open fuel valve by moving lever down (g1).

Note: If engine is cold, move choke lever to close position (i2). If

engine is hot, set choke to open position (i1).

3.11.2 Turn engine switch to “ON” (h2).

3.11.3 Move the throttle lever to the idle position (a1).

Note: Start engine with throttle in the idle position. If the engine is

started when the throttle is not in the idle position, the engine should

not start. This is a feature of the engine control module that prevents

wide open throttle startup.

3.11.4 Pull starter rope (j).

Do not place foot on the ring guard when starting the engine, as severe

injury can occur if foot slips through the ring guard as the blades start

WARNING

to spin.

Note: If the engine oil is low, the engine will not start. If engine does

not start, check the oil level and add oil as needed.

3.11.5 Open choke as engine warms (i1).

3.11.6 Open throttle (a2) to operate trowel. Adjust blade RPM with throttle

speed to suit conditions.

wc_tx000373gb.fm 34

Page 35

CT 36 / CT 48 Operation

g2

g1

h2

h1

3.12 To Stop - Wacker

See Graphic:wc_gr003219, wc_gr002747

3.12.1 Reduce engine RPM to idle by moving the throttle lever to idle position

(a1).

3.12.2 Push the stop button (b).

3.12.3 Turn engine switch to “OFF” (h1).

3.12.4 Close fuel valve (g2).

i1

i2

j

wc_gr002747

wc_tx000373gb.fm 35

Page 36

Operation CT 36 / CT 48

3.13 Engine Control Module

To prevent uncontrolled spinning of the trowel, the engine control

module is designed to shutoff the engine under certain conditions. For

example, if the operator loses his/her grip on the trowel, the engine

control module will sense that the machine is spinning and shut off the

engine. The momentum of the spinning trowel will engage the brake

and stop the handle from spinning past 270°.

To test the engine control module, start the machine and jerk the

handle to the right. The engine should stop. If the engine does not stop,

repeat the jerking motion until the engine stops. If the engine does not

shut off, push the stop button and turn the engine off. DO NOT operate

the machine until the engine control module is replaced.

DO NOT operate the trowel if the engine control module is

disconnected or not functioning properly.

WARNING

3.14 Operation

See Graphic: wc_gr003239

ALWAYS test the function of the engine control module before

operating the trowel. DO NOT operate the trowel if the engine control

WARNING

3.14.1 Adjust handle height to suit operator. See Installing and Adjusting

module is not functioning properly.

Choose correct blade type and attach blades to trowel arms. Do not

mix float or finish blades with combination blades.

Note: When operating on soft concrete, do not let trowel stand in one

spot too long. Always lift trowel from slab when operation is complete.

Note: “Left” and “Right” references are made from the operator's

position.

Handles.

NOTICE: Do not attempt to adjust handle height on the trowel while it

is running.

3.14.2 Start engine and engage blades by increasing engine speed. Set

speed with throttle control on handle bar to appropriate speed for job

conditions.

3.14.3 To move trowel forward twist handle clockwise (a).

3.14.4 To move backward twist handle counterclockwise (b).

3.14.5 To move to the left lift up slightly on the handle (c).

wc_tx000373gb.fm 36

Page 37

CT 36 / CT 48 Operation

3.14.6 To move to the right press down slightly on the handle (d).

3.14.7 Clean trowel after each use to remove concrete splatter.

Allow the muffler to cool before cleaning or servicing the machine. A

hot muffler could ignite the fuel and start a fire.

WARNING

It is recommended that each set of work passes be at 90° to the

previous set of work passes. This will help prevent the creation of

valleys in the slab surface.

For example, in the illustration, the second set of work passes (2) is

90° to the first set of work passes (1).

Personnel other than the trowel operator should not be allowed in the

work area, as severe injury can occur from contact with operating

WARNING

trowel blades.

Do not attempt to clean, service or perform adjustments on the trowel

while it is running.

a

1

c

d

2

b

wc_gr003239

wc_tx000373gb.fm 37

Page 38

Operation CT 36 / CT 48

3.15 Braking System

The braking system of the trowel is spring loaded. The brake is

engaged anytime the input shaft of the gearbox is not rotating and/or

there is no resistance placed against the blades of the trowel. The

brake is released when the input shaft is rotated and is shifted out from

its seated position. This is accomplished when the gear on this shaft

rotates, working against the output shaft gear, forcing the shaft out. If

there is no or low resistance against the blades, the brake may not

release as it is the resistance against the blades that allows the brake

to release. If the machine is suspended or on a highly polished,

slippery surface, the brake will not release and could cause belt

slippage.

wc_tx000373gb.fm 38

Page 39

CT 36 / CT 48 Operation

3.16 Pitch Adjustment

See Graphic: wc_gr003220

To adjust blade pitch (angle):

A = Twist pitch: turn the pitch adjusting knob (a) clockwise to increase

pitch and counterclockwise to decrease pitch.

B = Pro-Shift®: pull the handle (b) towards the operator to increase

pitch and away from the operator to decrease pitch.

AB

a

b

C

1

D

2

5˚

3

10˚

4

15-30˚

Ref. C = Working condition of concrete D = Suggested working pitch

wc_gr003220

1 Wet surface working stage Flat (no pitch)

2 Wet to plastic working stage Slight pitch (5°)

3 Plastic working stage Additional pitch (10°)

4 Semi-hard working stage to hard

finishing stage (burnishing)

For final finishing stages, it is sometimes desirable to add weights to the trowel guard rings to

increase the burnishing force. Wacker supplies weight kits for this purpose.

wc_tx000373gb.fm 39

Maximum pitch (15-30°)

Page 40

Maintenance CT 36 / CT 48

4. Maintenance

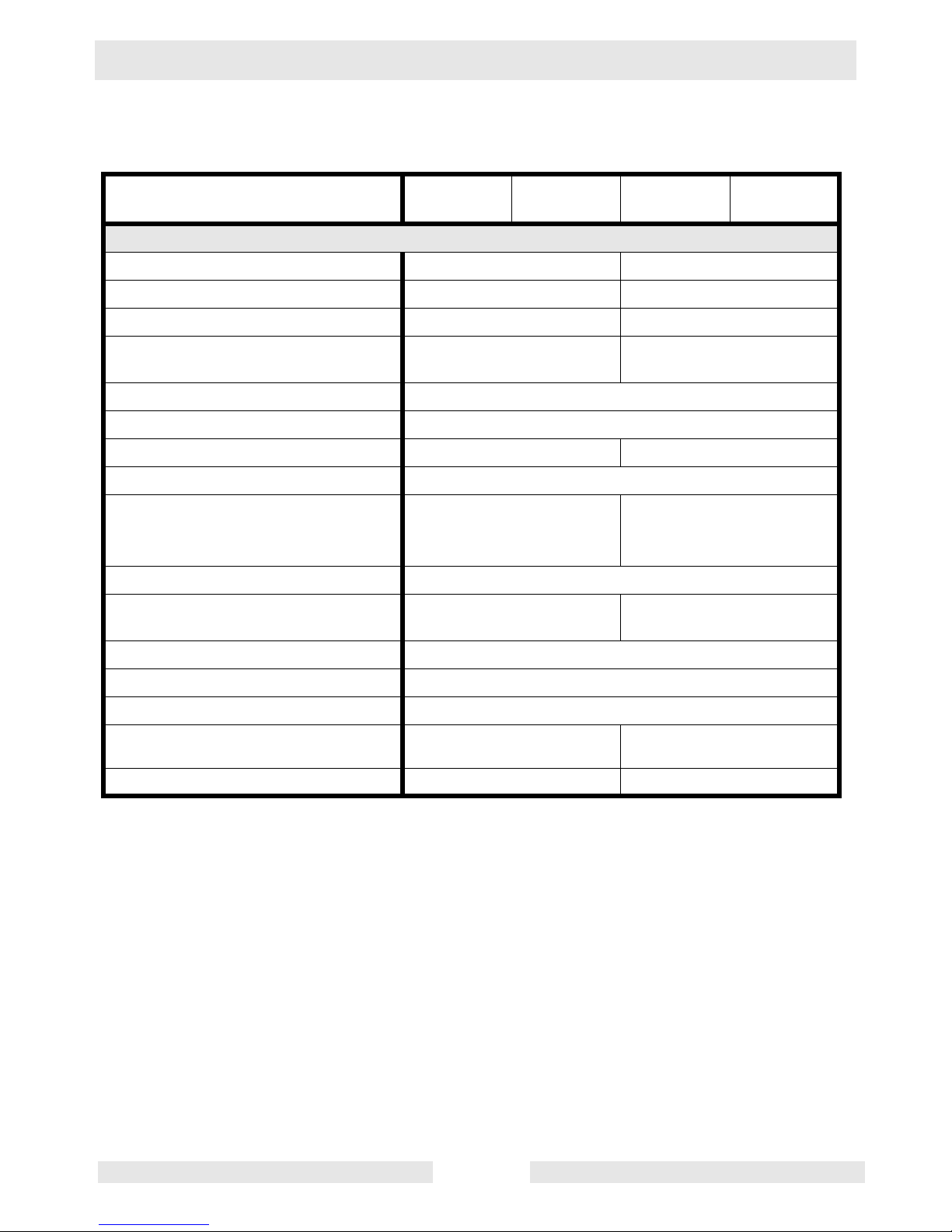

4.1 Periodic Maintenance Schedule - Honda

The chart below lists basic machine and engine maintenance. Refer to

the engine manufacturer’s Operator’s Manual for additional

information on engine maintenance.

Check fuel level.

Check engine oil level.

Inspect fuel lines.

Inspect air filter. Replace as needed.

Check external hardware.

Clean trowel after each use to remove

concrete splatter.

Grease blade arms as needed.

Clean air cleaner elements.

Change engine oil.

Check drive belt.

Clean sediment cup.

Daily

After

first

20 hrs.

Every

50

hrs.

Every

100

hrs.

Every

300

hrs.

Check and clean spark plug.

Check and adjust valve clearances.

wc_tx000374gb.fm 40

Page 41

CT 36 / CT 48 Maintenance

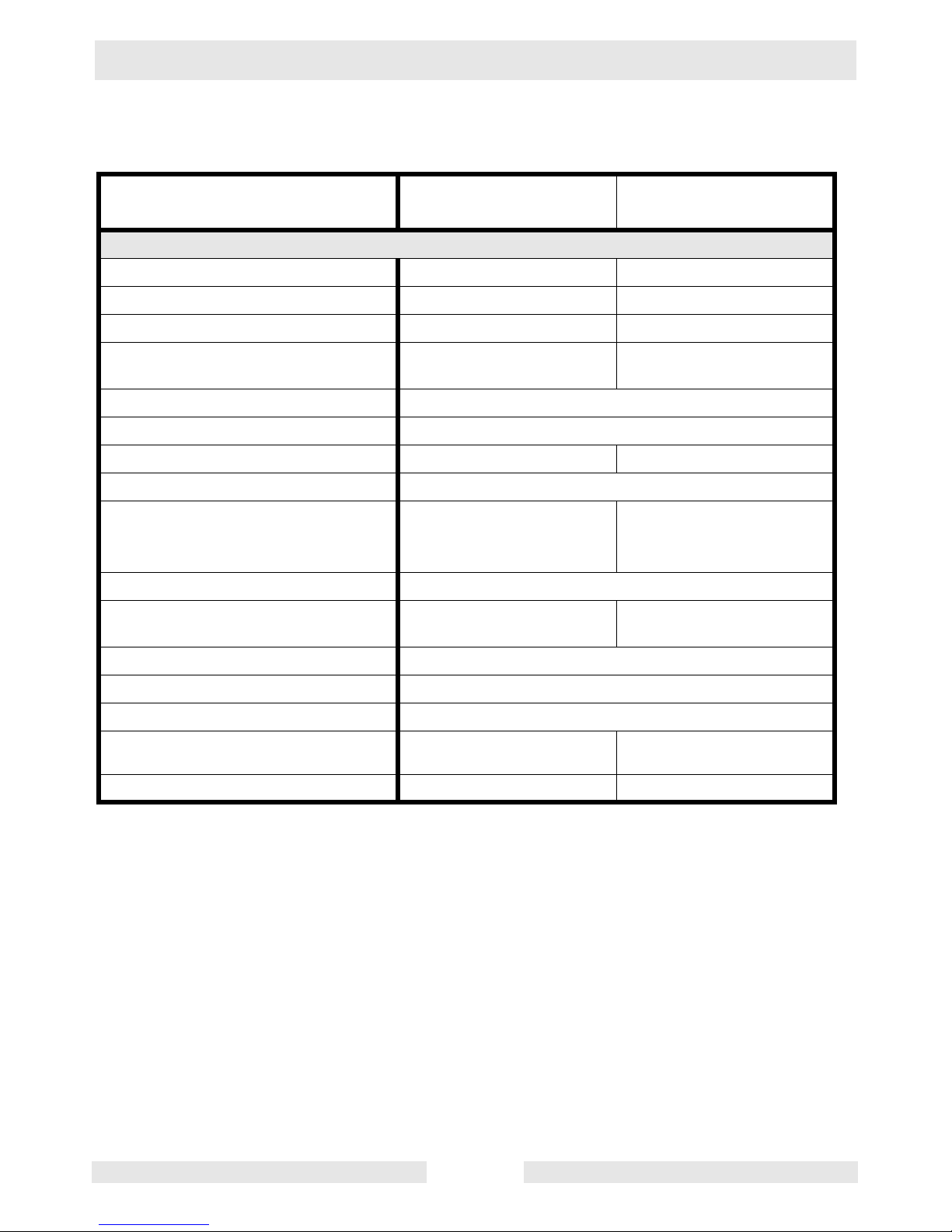

4.2 Periodic Maintenance Schedule - Wacker

The chart below lists basic machine and engine maintenance. Refer to

the engine manufacturer’s Operator’s Manual for additional

information on engine maintenance.

Daily After

first 20

hours

Check fuel level.

Check engine oil level.

Inspect fuel lines.

Inspect air filter. Replace as

needed.

Check external hardware.

Clean trowel after each use to

remove concrete splatter.

Change engine oil. *

Grease blade arms as needed

Clean air cleaner elements.

Clean sediment cup / fuel filter.

Every

2 weeks

or

50 hrs.

Every

month

or

100 hrs.

Every

year

or

300 hrs.

Every

500 hrs.

Check and clean spark plug.

Check and adjust valve clearance.

Replace spark plug.

* Perform initially after first 20 hours of operation.

Maintenance, replacement or repair of emission control devices and systems may be performed by

any repair establishment or individual.

wc_tx000374gb.fm 41

Page 42

Maintenance CT 36 / CT 48

4.3 Engine Oil - Honda

See Graphic: wc_gr002381

4.3.1 Drain oil while the engine is still warm.

4.3.2 Remove the oil fill plug (a) and drain cap (b) to drain oil.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

4.3.3 Install drain cap.

4.3.4 Fill the engine crankcase with recommended oil up to the level of the

plug opening (c). See Technical Data for oil quantity and type.

4.3.5 Install the oil filler plug.

wc_tx000374gb.fm 42

Page 43

CT 36 / CT 48 Maintenance

4.4 Engine Oil - Wacker

See Graphic: wc_gr003201

4.4.1 Drain oil while engine is still warm.

Note: In the interests of environmental protection, place a plastic sheet

and a container under the machine to collect any liquid which drains

off. Dispose of this liquid in accordance with environmental protection

legislation.

4.4.2 Remove the oil drain cap (a).

4.4.3 Allow the oil to drain.

4.4.4 Install the drain cap.

4.4.5 Fill the engine crankcase through the oil filler opening (b), to the upper

mark on the dipstick (c). Do not thread in the dipstick to check the level.

See Technical Data for oil quantity and type.

4.4.6 When the crankcase is full, reinstall the dipstick.

c

a

b

wc_gr003201

wc_tx000374gb.fm 43

Page 44

Maintenance CT 36 / CT 48

4.5 Air Cleaner - Honda

See Graphic: wc_gr000025

The engine is equipped with a dual element air cleaner. Service air

cleaner frequently to prevent carburetor malfunction.

NOTICE: NEVER run engine without air cleaner. Severe engine

damage will occur.

NEVER use gasoline or other types of low flash point solvents for

cleaning the air cleaner. A fire or explosion could result.

WARNING

To service:

4.5.1 Remove air cleaner cover (a). Remove both elements and inspect

them for holes or tears. Replace damaged elements.

4.5.2 Wash foam element (b) in solution of mild detergent and warm water.

Rinse thoroughly in clean water. Allow element to dry thoroughly. Soak

element in clean engine oil and squeeze out excess oil.

4.5.3 Tap paper element (c) lightly to remove excess dirt. Replace paper

element if it appears heavily soiled.

wc_tx000374gb.fm 44

Page 45

CT 36 / CT 48 Maintenance

4.6 Air Cleaner - Wacker

See Graphic: wc_gr000656

NEVER use gasoline or other types of low flash point solvents for

cleaning the air cleaner. A fire or explosion could result.

WARNING

NOTICE: NEVER run engine without air cleaner. Severe engine

damage will occur.

The engine is equipped with a dual element air cleaner. Under normal

operating conditions, elements should be cleaned once every week.

Under severe, dry and dusty conditions, the elements should be

maintained daily. Replace an element when saturated with dirt that

cannot be removed.

4.6.1 Remove the air cleaner cover (a). Remove the filter assembly by

pulling it straight up. Inspect both elements for holes or tears. Replace

damaged elements.

4.6.2 Wash the foam element (b) in a solution of mild detergent and warm

water. Rinse it thoroughly in clean water. Allow the element to dry

thoroughly.

4.6.3 Tap the paper element (c) lightly to remove excess dirt or blow

compressed air through the filter from the inside out. Replace the

paper element if it appears heavily soiled.

a

b

c

wc_gr000656

wc_tx000374gb.fm 45

Page 46

Maintenance CT 36 / CT 48

4.7 Spark Plug

See Graphic: wc_gr000028

Clean or replace the spark plug as needed to ensure proper operation.

Refer to the engine owner’s manual.

The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Do not touch the muffler while it is hot.

WARNING

Note: Refer to the Technical Data for the recommended spark plug

type and the electrode gap setting.

4.7.1 Remove the spark plug and inspect it.

4.7.2 Replace the spark plug if the insulator is cracked or chipped.

4.7.3 Clean the spark plug electrodes with a wire brush.

4.7.4 Set the electrode gap (a).

4.7.5 Tighten the spark plug securely.

NOTICE: A loose spark plug can become very hot and may cause

engine damage.

wc_tx000374gb.fm 46

Page 47

CT 36 / CT 48 Maintenance

4.8 Cleaning Sediment Cup - Honda

See Graphic: wc_gr000029

4.8.1 Turn the fuel valve off.

4.8.2 Remove the sediment cup (a) and the O-ring (b).

4.8.3 Wash both thoroughly in a nonflammable solvent. Dry and reinstall

them.

4.8.4 Turn the fuel valve on and check for leaks.

b

a

wc_gr000029

4.9 Cleaning Fuel Strainer - Wacker

See Graphic: wc_gr001093

4.9.1 To remove water and dirt, close the fuel lever and remove the fuel

strainer.

4.9.2 Inspect the fuel strainer (a) for water and dirt.

4.9.3 After removing any dirt and water, wash the fuel cup with a

nonflammable solvent.

4.9.4 Reinstall securely to prevent leakage.

wc_tx000374gb.fm 47

Page 48

Maintenance CT 36 / CT 48

4.10 Adjusting Idle Speed - Honda

See Graphic: wc_gr001122

Remove the drive belt before making any adjustment to the carburetor.

See Belt Replacement. The blades will engage unless the belt is

WARNING

4.10.1 Start the engine and allow it to warm up to normal operating

4.10.2 Turn the throttle stop screw (a) in to increase speed, out to decrease

removed from the machine.

Adjust engine to the no load or idle speed per the Technical Data.

temperature.

speed. Make sure the throttle lever is touching the stop screw before

measuring rpm.

a

wc_gr001122

wc_tx000374gb.fm 48

Page 49

CT 36 / CT 48 Maintenance

4.11 Carburetor Adjustment - Honda

See Graphic: wc_gr0001061

Remove the drive belt before making any adjustment to the carburetor.

See Belt Replacement. The blades will engage unless the belt is

WARNING

removed from the machine.

The pilot screw (a) is fitted with a limiter cap to prevent excessive

enrichment of the air-fuel mixture in order to comply with emission

regulations. The mixture is set at the factory and no adjustment should

be necessary. Do not attempt to remove the limiter cap. The limiter cap

cannot be removed without breaking the pilot screw.

a

wc_gr001061

wc_tx000374gb.fm 49

Page 50

Maintenance CT 36 / CT 48

4.12 Belt Replacement

See Graphic: wc_gr002380, wc_gr003221

The trowel is equipped with a self-adjusting clutch. This clutch

automatically tightens the belt and compensates for belt wear. Replace

the belt if the clutch can no longer tighten belt enough to engage

gearbox without slipping.

To replace the drive belt:

4.12.1 Disconnect the spark plug lead.

To avoid accidental starting of the engine, always disconnect the spark

plug lead before working on machine.

WARNING

4.12.2 Loosen the screws (d) and remove the belt guard (c).

4.12.3 Slowly turn the pulley (b) and roll the belt (a) off.

Note: The clutch and the pulley are aligned at the factory and neither

should be removed during belt replacement.

4.12.4 Install the new belt.

4.12.5 Reattach the belt guard with washers and screws. Torque the screws

to 5 Nm (3.7 ft.lbs.).

wc_tx000374gb.fm 50

Page 51

CT 36 / CT 48 Maintenance

4.13 Trowel Lubrication

See Graphic: wc_gr001755

Grease trowel arms (b) with Shell Alvania RL2 grease or equivalent.

Oil the pitch control cable and other parts of trowel on an as needed

basis.

Oil in the gearbox should not require replacement unless it was

drained to service gearbox. Check quantity through plug (a) located on

side of gearbox. Oil level should be to bottom of the plug threads. See

Technical Data for oil quantity and type.

4.14 Optional Weights

To install optional weights, place equal number of weights in both front

and rear of guard ring in designated area. Tighten screw to keep

weights in place.

Under no circumstances should any object be used as additional

weight other than the weights recommended by Wacker. The use of

WARNING

wc_tx000374gb.fm 51

unauthorized weights could lead to personal injury or machine

damage.

Page 52

Maintenance CT 36 / CT 48

4.15 Lifting

See Graphic: wc_gr001762

NEVER lift the machine solely by the handle. The component may fail,

causing the machine to fall, possibly injuring bystanders.

WARNING

See Technical Data for the weight of the machine.

To lift the machine manually:

4.15.1 Stop engine.

4.15.2 Obtain a partner and plan the lift.

4.15.3 Balance the weight between the partners and lift the machine by the

guard ring (a), or proceed as follows:

a. Attach optional lifting bracket (c) to trowel with screws and locknuts.

Torque screws to 25 Nm (18 ft.lbs.).

b. Insert a 2x4 or other suitable lumber into the bracket. The lumber

must be long enough to extend past the ring guard.

c. Balance the weight between the partners and lift the machine by the

handle and the lumber.

To reduce risk of back injury while lifting, keep your feet flat on ground

and shoulder width apart. Keep your head up and back straight.

WARNING

To lift the machine mechanically:

4.15.4 Stop engine.

4.15.5 See Dimensions and Weight for weight of machine and be sure that

lifting device(s) can safely lift the weight.

4.15.6 Attach optional lifting bracket (b) to trowel with screws and locknuts.

Torque to 25 Nm (18 ft.lbs.).

4.15.7 Attach hook, harness, or cable to the lifting bracket on machine as

shown and lift as desired.

Do not lift the trowel overhead with a float pan attached, as the pan

could fall off and strike personnel working in the vicinity.

WARNING

wc_tx000374gb.fm 52

Page 53

CT 36 / CT 48 Maintenance

wc_tx000374gb.fm 53

Page 54

Maintenance CT 36 / CT 48

4.16 Storage

If trowel is being stored for more than 30 days:

• Change engine oil.

• Drain fuel from engine.

• Remove spark plug and pour 15 ml (½ ounce) of SAE 30 engine

oil into the cylinder. Replace spark plug and crank engine to

distribute oil. Refer to engine manual.

• Clean dirt from cylinder, cylinder head fins, blower housing,

rotating screen, and muffler areas.

• To save space, place handle in its storage position.

• Cover trowel and engine and store in a clean, dry area.

wc_tx000374gb.fm 54

Page 55

CT 36 / CT 48 Maintenance

4.17 Troubleshooting

Problem / Symptom Reason / Remedy

Trowel does not develop full

speed.

Engine runs;

poor trowel operation.

Engine does not start or runs

erratically.

• Remove deposits built up in engine cylinder and

engine head.

• Engine speed too low. Adjust speed.

• Clean or replace air filter.

• Clean debris from moving parts and trowel blades.

• In cold weather, warm engine in idle 3 or 4 minutes.

• Check throttle lever and cable for proper operation.

• Check drive belt for wear or damage.

• Check clutch for wear or damage.

• Clean debris from moving parts and trowel arms.

• Check fuel level. Open fuel valve.

• Clean air filter.

• Check/replace spark plug.

• Check in-line fuel filter.

• Check engine oil level.

• Check engine stop button.

Trowel handle tends to rotate

when idling.

• Check that throttle is in idle position when starting

machine.

• Check engine idle speed. (It may be too high).

• Belt alignment may be off.

wc_tx000374gb.fm 55

Page 56

Guide Handle CT Repair

5. Guide Handle

5.1 Replacing the Throttle Cable

See Graphic: wc_gr003362

Disassembly:

5.1.1 Remove the engine air cleaner (d) if necessary to gain access to the

throttle cable at the engine. Unclamp the throttle cable from the throttle

casing clamp (g).

5.1.2 Disconnect the throttle cable (e) from the engine throttle bracket (f).

5.1.3 Pull the throttle cable through the cable guide (c) of the handle.

5.1.4 Remove the cable ties (a) from the handle.

5.1.5 Remove the screw and the casing fastener from the throttle control

lever (b) and remove the throttle cable from the machine.

Assembly:

5.1.6 Place the engine’s throttle control lever in the idle position. Connect the

throttle cable (e) to the engine throttle bracket (f) by placing the Z-bend

at the end of the cable through the hole in the throttle plate.

5.1.7 Using the throttle casing clamp (g) secure the throttle cable to the

engine.

5.1.8 Push the opposite side of the throttle cable through the cable guide (c)

of the handle.

5.1.9 Secure the throttle cable to the throttle control lever (b) and adjust it as

needed. See section Adjusting the Throttle Lever.

5.1.10 Secure the throttle cable to the handle with new cable ties (a).

wc_tx000551gb.fm 56

Page 57

CT Repair Guide Handle

Honda

f

d

c

a

b

e

g

Honda Wacker

f

f

g

e

e

g

wc_gr003362

wc_tx000551gb.fm 57

Page 58

Guide Handle CT Repair

5.2 Adjusting the Throttle Lever

See Graphic: wc_gr003361

The throttle lever is used to vary the speed of the engine and to control

the rpm of the trowel blades to meet specific applications and job

conditions.

5.2.1 Be sure the engine’s throttle control can obtain the idle (slow) position.

If necessary, loosen the throttle casing clamp at the engine and

reposition the throttle cable so that the engine’s throttle control can

reach the idle (slow) position.

5.2.2 Remove the screw (a) on top of throttle lever (b) and lift off the throttle

lever.

5.2.3 Position the throttle lever in the idle (slow) position (1) (parallel with the

body of the control body) so that it engages the teeth of the throttle

cable (c).

5.2.4 Remove the nut (d) and test the position of the throttle cable. When the

throttle lever is at 90° (2) (perpendicular to the control body) two teeth

should show outside the control body (e). Adjust the position of the

throttle lever as necessary.

5.2.5 Secure the throttle lever to the control body with the screw (a).

wc_tx000551gb.fm 58

Page 59

CT Repair Guide Handle

a

c

b

12

e

d

wc_gr003361

wc_tx000551gb.fm 59

Page 60

Guide Handle CT Repair

5.3 Upper Handle/Twist Pitch Control—Exploded View

$

#

#

"

"

'

$

&

!

&

!

%

%

$

'

!

wc_tx000551gb.fm 60

!

Page 61

CT Repair Guide Handle

5.4 Upper Handle/Twist Pitch Control—Components

Ref. Description Ref. Description

1 Handle 13 Pin

3 Push button switch 14 Retaining ring

4 Nut 15 Spring

5 Bearing holder 16 Ball

6 Wiring harness 17 Tie cable

7 Cable 18 Hex head screw

8 Throttle cable 19 Hex head screw

9 Kit-CT throttle 20 Flat head screw

10 Pitch control knob 21 Socket head screw

11 Plate 23 Locknut

12 Flange-bearing 26 Flat washer

wc_tx000551gb.fm 61

Page 62

Guide Handle CT Repair

5.5 Replacing the Upper Handle

See Graphic: wc_gr003360

Disassembly:

5.5.1 Remove the throttle lever (a) and the throttle cable from the upper

handle. See section Replacing the Throttle Cable.

5.5.2 Disconnect and remove the stop switch (b). See section Replacing the

Stop Switch.

5.5.3 Disconnect the handle ground wire if equipped on your machine.

5.5.4 Remove the lock nut (c) from the end of the pitch control cable (d). Pull

the pitch control cable from the yoke (e) and slide it from the pulley (f)

of the lower handle (g).

5.5.5 Remove the two screws (h) holding the upper handle to the lower

handle. Carefully pull the upper handle and the pitch control cable

away from the lower handle.

5.5.6 Remove the pitch control device (i) (twist pitch or Pro-Shift®) and the

pitch control cable from the upper handle.

Assembly:

5.5.7 Thread the pitch control cable through the upper handle. Attach the

pitch control device (i) (twist pitch or Pro-Shift®) to the upper handle.

On models with twist-pitch control, turn the knob counterclockwise as

far as possible. On models with Pro-Shift® control, position the lever

towards the operator.

5.5.8 Position the upper handle near the lower handle (g) so that you can

thread the pitch control cable (d) through the lower handle and around

the pulley (f) of the lower handle. Then, slide the upper handle into the

lower handle.

5.5.9 Secure the upper handle to the lower handle with two screws (h) and

lock nuts.

5.5.10 Thread the pitch control cable into the yoke (e) and connect the lock

nut (c). Adjust the lock nut so that the cable is snug with the trowel

blades flat (0° pitch).

5.5.11 Attach (by threading) the stop switch (b) to the upper handle. See

sections Engine Wiring and Replacing the Stop Switch.

5.5.12 Connect the handle ground wire if equipped on your machine.

5.5.13 Attach the throttle lever (a) and throttle cable. See section Replacing

the Throttle Cable.

wc_tx000551gb.fm 62

Page 63

CT Repair Guide Handle

a

d

f

b

h

g

wc_tx000551gb.fm 63

d

e

c

wc_gr003360

Page 64

Guide Handle CT Repair

5.6 Replacing the Twist Pitch Control Cable

See Graphic: wc_gr003363

Disassembly:

5.6.1 Remove the upper handle. See section Replacing the Upper Handle.

5.6.2 Remove the hex head screw (a) from the handle and the socket head

screw (b) from the underside of the twist control assembly (c).

5.6.3 Pull the twist control assembly and the pitch control cable (d) from

handle.

5.6.4 Drive the roll pin (e) from the twist control assembly. Remove the pitch

control cable.

Assembly:

5.6.5 Attach the knob (f) to the twist control assembly (c).

5.6.6 Place the pitch control cable (d) into the twist control assembly and

secure it with the roll pin (e).

5.6.7 Lubricate the threads (g) on the twist control assembly.

5.6.8 Slide the pitch control cable down through the handle and position the

twist control assembly into the upper handle, lining up the holes in the

twist control assembly with those of the handle. Attach the socket head

screw (b) to the underside of the twist control assembly.

5.6.9 Apply Loctite 243 or equivalent to the threads of the hex head screw

(a) and secure it to the handle. Torque the hex head screw to 10 Nm

(7 ft.lbs.).

5.6.10 Replace the upper handle. See section Replacing the Upper Handle.

wc_tx000551gb.fm 64

Page 65

CT Repair Guide Handle

c

f

b

e

d

g

a

wc_gr003363

wc_tx000551gb.fm 65

Page 66

Guide Handle CT Repair

5.7 Replacing the Lower Handle

See Graphic: wc_gr003156

Disassembly:

5.7.1 Remove the upper handle. See section Replacing the Upper Handle.

5.7.2 Remove the two locknuts (80) and washers (73) from the screws (60).

5.7.3 Pull the lower handle (17) from the gearbox.

5.7.4 If replacing the pulley (25), pull the cotter pin (46) from the clevis pin

(42) and remove the pulley.

Assembly:

5.7.5 If removed, replace the pulley (25) and reattach it with the clevis pin

(42) and cotter pin (46).

5.7.6 Position the lower handle (17) into the gearbox and secure it with the

screws (60), washers (73), and locknuts (80).

5.7.7 Install the upper handle. See section Replacing the Upper Handle.

wc_tx000551gb.fm 66

Page 67

CT Repair Guide Handle

5.8 Replacing the Stop Switch

See Graphic: wc_gr003371

To replace the stop screw (a), carry out the following procedures:

Removal:

5.8.1 Remove the protective boot (b).

5.8.2 Disconnect the wire (c).

5.8.3 Unthread the stop switch from the handle.

Installation:

5.8.4 Thread the stop switch (a) into the handle.

5.8.5 Connect the wire (c).

5.8.6 Install the protective boot (b).

b

a

c

wc_tx000551gb.fm 67

wc_gr003371

Page 68

Guide Handle CT Repair

Notes

wc_tx000551gb.fm 68

Page 69

CT Repair Clutch

6. Clutch

6.1 Replacing the Drive Belt

See Graphic: wc_gr003153 and wc_gr003382

The trowel is equipped with the standard self-adjusting clutch or a

variable speed clutch. Replace the belt if the clutch can no longer

tighten the belt enough to engage the gearbox without slipping. The

procedure to change the belt is the same for both clutches.

To replace the drive belt:

6.1.1 Disconnect the spark plug lead.

To avoid accidental starting of the engine, disconnect the spark plug

lead before working on the machine.

WARNING

6.1.2 Remove the screws and the washers that secure the beltguard and

remove the beltguard.

6.1.3 Slowly turn the pulley and roll the belt off the pulley.

6.1.4 Slowly turn the pulley and roll the new belt on the pulley.

6.1.5 Reattach the beltguard with the washers and the screws. Torque the

screws to 5 Nm (3.7 ft.lbs.).

wc_tx000552gb.fm 69

Page 70

Clutch CT Repair

6.2 Drive Belt—Standard Clutch

wc_gr003153

Ref. Description Ref. Description

3 Beltguard 53 Hex head screw

4 Beltguard plate 54 Hex head screw

23 Clutch assembly 69 Fender washer

24 Pulley 70 Flat steel washer

26 V-belt 72 Washer

36 Spacer 82 Key

50 Screw 84 Key (square)

51 Hex head screw

wc_tx000552gb.fm 70

Page 71

CT Repair Clutch

6.3 Drive Belt—Variable Speed Clutch

81

4

50

36

23

84

71

74

58

3

51

24

132

26

70

127

69

53

Ref. Description Ref. Description

3 Upper belt guard 58 Hex head screw

4 Beltguard plate 69 Fender washer

23 Clutch 70 Washer

wc_gr003382

24 Clutch pulley 71 Washer

26 Belt 84 Key

36 Spacer 127 Lower beltguard

51 Screw 132 Key

53 Hex head Screw - ---

wc_tx000552gb.fm 71

Page 72

Clutch CT Repair

6.4 Replacing the Standard Clutch

See Graphic: wc_gr003153, wc_gr002068

Removal:

6.4.1 Remove the drive belt as described in section Replacing the Drive Belt.

6.4.2 Remove the screw (51) and the washer (72) that secure the clutch

assembly (23) to the crankshaft.

6.4.3 Loosen the setscrew(s) (2) on the clutch assembly. Pull the clutch

assembly from the crankshaft. If a three-jaw puller is used, thread in

the screw (51) removed in step two 4–6 turns to protect the threads in

the crankshaft. Push against the bolt head rather than directly against

the threads of the crankshaft.

6.4.4 Remove the spacer (36) and the key (84) from the crankshaft. Inspect

the key and the keyways for signs of shearing. Replace the key if it is

deformed or if its edges are rounded.

Installation:

6.4.5 Coat the engine crankshaft with an anti-seize compound and reinstall

the spacer (36).

6.4.6 Install the key (84) in the keyway and slide the clutch assembly over

the crankshaft. Tap the key with a rubber mallet if necessary. Tighten

the setscrew.

6.4.7 Replace the washer (72) and the screw (51). Torque the screw to 25

Nm (18 ft.lbs.).

6.4.8 Reinstall the drive belt as described in Replacing the Drive Belt.

wc_tx000552gb.fm 72

wc_gr003153

Page 73

CT Repair Clutch

6.5 Standard Clutch—Exploded View

8

1

7

5

4

3

2

Ref. Description Ref. Description

1 Clutch assembly (incl. 2–8) 5 Clutch shoe

2 Setscrew 6 Ball bearing

3 Clutch plate 7 Clutch drum

6

wc_gr002068

4 Spring 8 Clutch pulley

wc_tx000552gb.fm 73

Page 74

Clutch CT Repair

6.6 Standard Clutch Overhaul

See Graphic: wc_gr002068 and wc_gr003364

This procedure requires a propane torch or similar heating device.

Disassembly:

6.6.1 Remove the setscrew (2). Slide the clutch plate (3) off of the clutch

pulley shaft (8).

6.6.2 Remove and inspect the clutch shoes (5), the clutch spring (4) and the

clutch drum (7). Replace any worn or damaged component.

6.6.3 Inspect the bearing (6) for free rotation on the shaft. Replace the

bearing if necessary. To remove the bearing, heat it with a propane

torch. Then, while protecting your hands from any hot surface, pick up

the clutch pulley-bearing assembly (a) and strike it against a wooden

(or similar) surface (b). The force of the blow should free the bearing.

Use a puller to remove the bearing the rest of the way if necessary.

Assembly:

NOTICE: Do not grease or oil the clutch pulley shaft or the clutch drum.

6.6.4 Press the bearing (6) onto the clutch pulley shaft (8).

6.6.5 Slide the clutch drum over the clutch pulley shaft.

6.6.6 Band the clutch shoes (5) with the clutch spring. Then, slide the clutch

shoes over the clutch pulley shaft. The clutch shoes should move

freely over the clutch pulley shaft.

6.6.7 Slide the clutch plate (3) over the clutch pulley shaft and tighten the

setscrew (2).

wc_tx000552gb.fm 74

Page 75

CT Repair Clutch

8

1

2

6

7

5

4

3

wc_gr002068

a

wc_tx000552gb.fm 75

b

wc_gr003364

Page 76

Clutch CT Repair

6.7 Replacing the Variable Speed Clutch

See Graphic: wc_gr003383, wc_gr002068

Removal:

6.7.1 Remove the drive belt. See section Replacing the Drive Belt.

6.7.2 Remove the bolt (51) that secures the clutch (23) to the engine drive

shaft and slide the clutch from the engine drive shaft. Note: Use a gear

puller if necessary.

6.7.3 Remove the key (84).

6.7.4 Remove the bolt (58) that secures the clutch pulley (24) to the gearbox

input shaft and remove the clutch pulley.

6.7.5 Remove the key (132).

Installation:

6.7.6 Install the key (132) onto the gearbox input shaft.

6.7.7 Slide the clutch pulley (24) over the gearbox input shaft.

6.7.8 Apply Loctite 243 or equivalent to the bolt (58) and secure the clutch

pulley to the gearbox input shaft.

6.7.9 Install the key (84) onto the engine drive shaft.

6.7.10 Slide the clutch (23) over the engine drive shaft.

6.7.11 Apply Loctite 243 or equivalent to the bolt (51) and secure the clutch

to the engine drive shaft.

wc_tx000552gb.fm 76

Page 77

CT Repair Clutch

81

4

50

23

36

84

71

74

24

132

26

70

127

69

53

58

51

3

wc_tx000552gb.fm 77

wc_gr003383

Page 78

Spider CT Repair

7. Spider

7.1 Spider Assembly—Exploded View

wc_tx000553gb.fm 78

Page 79

CT Repair Spider

7.2 Spider Assembly—Components

Ref. Description Ref. Description