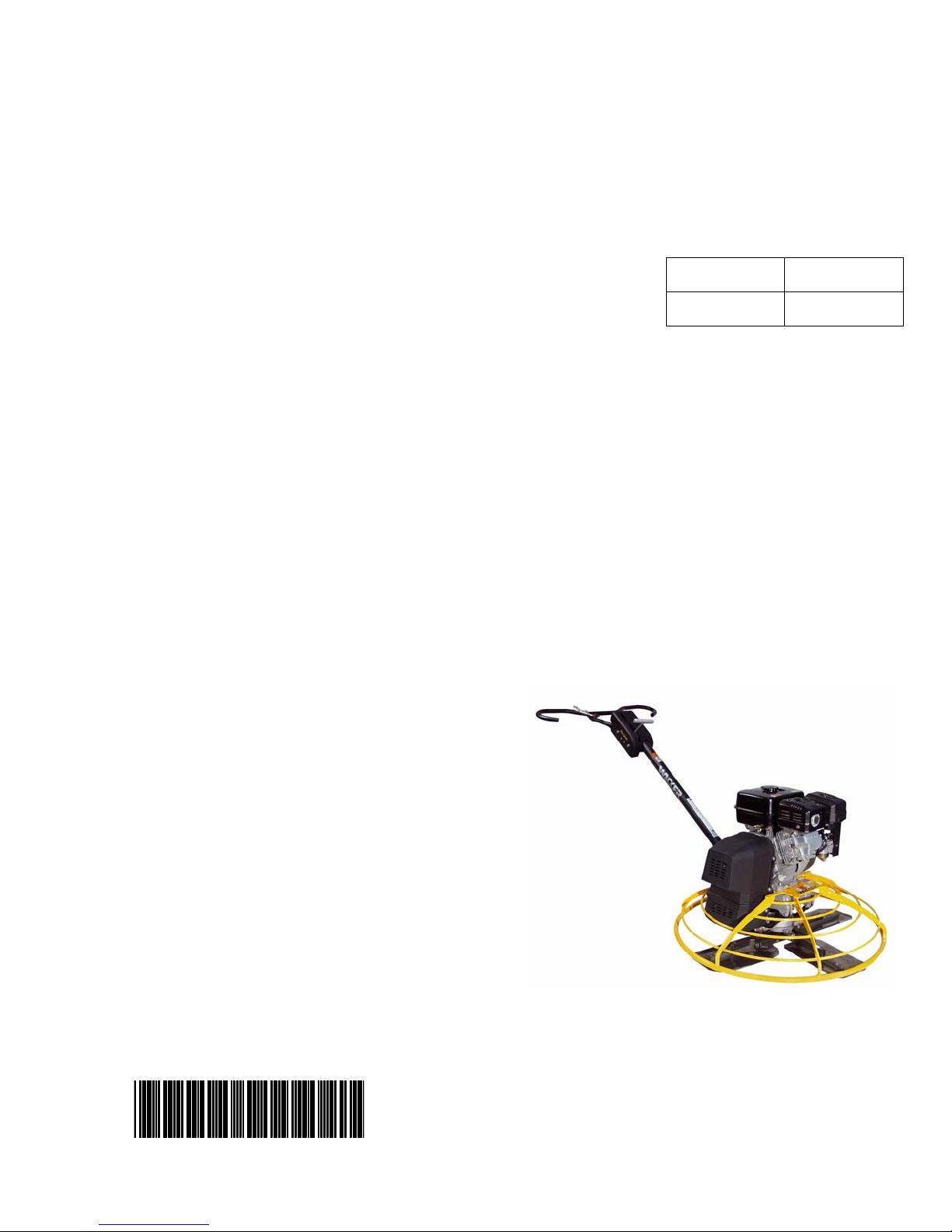

Wacker Neuson CT 36, CT 48 Repair Manual

www.wackergroup.com

0163091en 003

1007

Walk-Behind

Trowels

CT 36

CT 48

REPAIR MANUAL

0163091EN

CT Repair Foreword

This manual covers machines with Item Number:

0009438, 0009439, 0009442, 0009443, 0009444, 0009447, 0009449,

0009450, 0009452, 0009453, 0620106

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or make any repairs to it. Basic operating and

maintenance procedures are described in the operator’s / parts

manual supplied with the machine. The operator’s / parts manual

should be kept with the machine. Use it to order replacement parts

when needed. If this manual becomes lost, please contact Wacker

Corporation to order a replacement.

Damage caused by misuse or neglect of the unit should be brought to

the attention of the operator, to prevent similar occurrences from

happening in the future.

WARNING

This manual provides information and procedures to safely repair and

maintain the above Wacker model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. THE INFORMATION

CONTAINED IN THIS MANUAL IS BASED ON MACHINES

MANUFACTURED UP TO THE TIME OF PUBLICATION. WACKER

CORPORATION RESERVES THE RIGHT TO CHANGE ANY

PORTION OF THIS INFORMATION WITHOUT NOTICE.

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

wc_tx000550gb.fm 3

CT Repair Foreword

This manual provides information and procedures to safely operate

and maintain this Wacker model. For your own safety and protection

from injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this

manual or need an additional copy, please contact Wacker

Corporation. This machine is built with user safety in mind; however,

it can present hazards if improperly operated and serviced. Follow

operating instructions carefully! If you have questions about operating

or servicing this equipment, please contact Wacker Corporation.

The information contained in this manual was based on machines in

production at the time of publication. Wacker Corporation reserves the

right to change any portion of this information without notice.

All rights, especially copying and distribution rights, are reserved.

Copyright 2007 by Wacker Corporation.

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights and will be

prosecuted. We expressly reserve the right to make technical

modifications, even without due notice, which aim at improving our

machines or their safety standards.

wc_tx000550gb.fm 4

CT Repair Table of Contents

1. Safety Information 8

1.1 Laws Pertaining to Spark Arrestors ...................................................... 8

1.2 Operating Safety .................................................................................. 9

1.3 Operator Safety while using Internal Combustion Engines ................ 10

1.4 Service Safety .................................................................................... 11

1.5 Label Locations .................................................................................. 12

1.6 Safety and Information Labels ............................................................ 13

2. Technical Data 18

2.1 Dimensions and Weight ..................................................................... 18

2.2 Engine ................................................................................................ 20

2.3 Trowel ................................................................................................. 24

2.4 Sound and Vibration Data .................................................................. 25

3. Operation 26

3.1 Application .......................................................................................... 26

3.2 New Machine Set-up .......................................................................... 26

3.3 Recommended Fuel ........................................................................... 26

3.4 Installing Blades ................................................................................. 27

3.5 Installing and Adjusting Handles ........................................................ 28

3.6 Controls .............................................................................................. 30

3.7 Stop Button ......................................................................................... 31

3.8 Before Starting ................................................................................... 31

3.9 To Start - Honda ................................................................................. 32

3.10 To Stop - Honda ................................................................................. 33

3.11 To Start - Wacker ............................................................................... 34

3.12 To Stop - Wacker ............................................................................... 35

3.13 Engine Control Module ....................................................................... 36

3.14 Operation ............................................................................................ 36

3.15 Braking System .................................................................................. 38

3.16 Pitch Adjustment ................................................................................ 39

5

Table of Contents CT Repair

4. Maintenance 40

4.1 Periodic Maintenance Schedule - Honda ............................................40

4.2 Periodic Maintenance Schedule - Wacker ..........................................41

4.3 Engine Oil - Honda ..............................................................................42

4.4 Engine Oil - Wacker ............................................................................43

4.5 Air Cleaner - Honda .............................................................................44

4.6 Air Cleaner - Wacker ...........................................................................45

4.7 Spark Plug ...........................................................................................46

4.8 Cleaning Sediment Cup - Honda .........................................................47

4.9 Cleaning Fuel Strainer - Wacker .........................................................47

4.10 Adjusting Idle Speed - Honda ..............................................................48

4.11 Carburetor Adjustment - Honda ..........................................................49

4.12 Belt Replacement ................................................................................50

4.13 Trowel Lubrication ...............................................................................51

4.14 Optional Weights .................................................................................51

4.15 Lifting ...................................................................................................52

4.16 Storage ................................................................................................54

4.17 Troubleshooting ...................................................................................55

5. Guide Handle 56

5.1 Replacing the Throttle Cable ...............................................................56

5.2 Adjusting the Throttle Lever ................................................................58

5.3 Upper Handle/Twist Pitch Control—Exploded View ............................60

5.4 Upper Handle/Twist Pitch Control—Components ...............................61

5.5 Replacing the Upper Handle ...............................................................62

5.6 Replacing the Twist Pitch Control Cable .............................................64

5.7 Replacing the Lower Handle ...............................................................66

5.8 Replacing the Stop Switch ..................................................................67

6. Clutch 69

6.1 Replacing the Drive Belt ......................................................................69

6.2 Drive Belt—Standard Clutch ...............................................................70

6.3 Drive Belt—Variable Speed Clutch .....................................................71

6.4 Replacing the Standard Clutch ............................................................72

6.5 Standard Clutch—Exploded View .......................................................73

6.6 Standard Clutch Overhaul ...................................................................74

6.7 Replacing the Variable Speed Clutch ..................................................76

wc_br0163091en_003TOC.fm 6

CT Repair Table of Contents

7. Spider 78

7.1 Spider Assembly—Exploded View ..................................................... 78

7.2 Spider Assembly—Components ........................................................ 79

7.3 Replacing the Blades ......................................................................... 80

7.4 Replacing the Arms ............................................................................ 82

7.5 Balancing the Blade Pitch .................................................................. 84

7.6 Removing the Spider .......................................................................... 86

7.7 Installing the Spider ............................................................................ 88

7.8 Rebuilding the Lift Ring Assembly ...................................................... 90

8. Drivetrain 92

8.1 Drivetrain—Exploded View ................................................................. 92

8.2 Drivetrain—Components .................................................................... 93

8.3 Engine Removal ................................................................................. 94

8.4 Engine Installation .............................................................................. 96

8.5 Engine Wiring ..................................................................................... 98

8.6 Engine Wiring Components ................................................................ 99

8.7 Wiring Diagrams ............................................................................... 100

8.8 Engine Wiring Components .............................................................. 101

8.9 Replacing the Gearbox ..................................................................... 102

8.10 Gearbox—Exploded View ................................................................ 104

8.11 Gearbox—Components .................................................................... 105

8.12 Gearbox Disassembly ...................................................................... 106

8.13 Gearbox Assembly ........................................................................... 110

7

Safety Information CT 36 / CT 48

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, NOTICE and

NOTE callouts which must be followed to reduce the possibility of

personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

WARNING

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CAUTION

NOTICE: Used without the safety alert symbol, NOTICE indicates a

hazardous situation which, if not avoided, could result in property

damage.

Note: Contains additional information important to a procedure.

1.1 Laws Pertaining to Spark Arrestors

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

wc_si000139gb.fm 8

CT 36 / CT 48 Safety Information

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of

machine. Machines operated improperly or by untrained personnel

can be dangerous. Read the operating instructions contained in both

WARNING

1.2.1 NEVER allow anyone to operate this equipment without proper

1.2.2 NEVER touch the engine or muffler while the engine is on or

1.2.3 NEVER use accessories or attachments that are not recommended by

1.2.4 NEVER leave machine running unattended.

this manual and the engine manual and familiarize yourself with the

location and proper use of all controls. Inexperienced operators should

receive instruction from someone familiar with the machine before

being allowed to operate it.

training. People operating this equipment must be familiar with the

risks and hazards associated with it.

immediately after it has been turned off. These areas get hot and may

cause burns.

Wacker. Damage to equipment and injury to the user may result.

1.2.5 NEVER operate the machine with the beltguard missing. Exposed

drive belt and pulleys create potentially dangerous hazards that can

cause serious injuries.

1.2.6 NEVER operate this machine in applications for which it is not

intended.

1.2.7 NEVER use the trowel around pop-ups in the concrete that are lower

than the lowest ring on the ring guard.

1.2.8 NEVER lift the machine solely by the handle. The component may fail,

causing the machine to fall, possibly injuring bystanders.

1.2.9 ALWAYS wear protective clothing appropriate to the job site when

operating equipment.

1.2.10 ALWAYS wear hearing and eye protection when operating this

machine.

1.2.11 ALWAYS remain aware of moving parts and keep hands, feet, and

loose clothing away from the moving parts of the machine.

1.2.12 ALWAYS read, understand, and follow procedures in the Operator’s

Manual before attempting to operate the equipment.

1.2.13 ALWAYS store the equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the reach of

children.

1.2.14 ALWAYS close fuel valve on engines equipped with one when

machine is not being operated.

wc_si000139gb.fm 9

Safety Information CT 36 / CT 48

1.2.15 ALWAYS operate machine with all safety devices and guards in place

and in working order. DO NOT modify or defeat safety devices. DO

NOT operate machine if any safety devices or guards are missing or

inoperative.

1.2.16 ALWAYS be sure operator is familiar with proper safety precautions

and operation techniques before using machine.

1.2.17 ALWAYS test the function of the engine control module before

operating the trowel. DO NOT operate the trowel if the engine control

module is not functioning properly.

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation

and fueling. Read and follow the warning instructions in the engine

owner’s manual and the safety guidelines below. Failure to follow the

DANGER

1.3.1 DO NOT run the machine indoors or in an enclosed area such as a

warnings and safety guidelines could result in severe injury or death.

deep trench unless adequate ventilation, through such items as

exhaust fans or hoses, is provided. Exhaust gas from the engine

contains poisonous carbon monoxide gas; exposure to carbon

monoxide can cause loss of consciousness and may lead to death.

1.3.2 DO NOT smoke while operating the machine.

1.3.3 DO NOT smoke when refueling the engine.

1.3.4 DO NOT refuel a hot or running engine.

1.3.5 DO NOT refuel the engine near an open flame.

1.3.6 DO NOT spill fuel when refueling the engine.

1.3.7 DO NOT run the engine near open flames.

1.3.8 ALWAYS refill the fuel tank in a well-ventilated area.

1.3.9 ALWAYS replace the fuel tank cap after refueling.

wc_si000139gb.fm 10

CT 36 / CT 48 Safety Information

1.4 Service Safety

Poorly maintained machines can become a safety hazard! In order for

the machine to operate safely and properly over a long period of time,

periodic maintenance and occasional repairs are necessary.

WARNING

1.4.1 DO NOT attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.4.2 DO NOT crank a flooded engine with the spark plug removed on

gasoline-powered engines. Fuel trapped in the cylinder will squirt out

the spark plug opening.

1.4.3 DO NOT test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.4.4 DO NOT use gasoline or other types of fuels or flammable solvents to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.4.5 DO NOT remove blades while the machine is hanging overhead.

1.4.6 ALWAYS support the machine securely before changing blades.

1.4.7 ALWAYS keep the area around the muffler free of debris such as

leaves, paper, cartons, etc. A hot muffler could ignite the debris and

start a fire.

1.4.8 ALWAYS replace worn or damaged components with spare parts

designed and recommended by Wacker Corporation.

1.4.9 ALWAYS disconnect the spark plug on machines equipped with

gasoline engines, before servicing, to avoid accidental start-up.

1.4.10 ALWAYS keep the machine clean and labels legible. Replace all

missing and hard-to-read labels. Labels provide important operating

instructions and warn of dangers and hazards.

1.4.11 ALWAYS handle blades carefully. The blades can develop sharp

edges which can cause serious cuts.

wc_si000139gb.fm 11

Safety Information CT 36 / CT 48

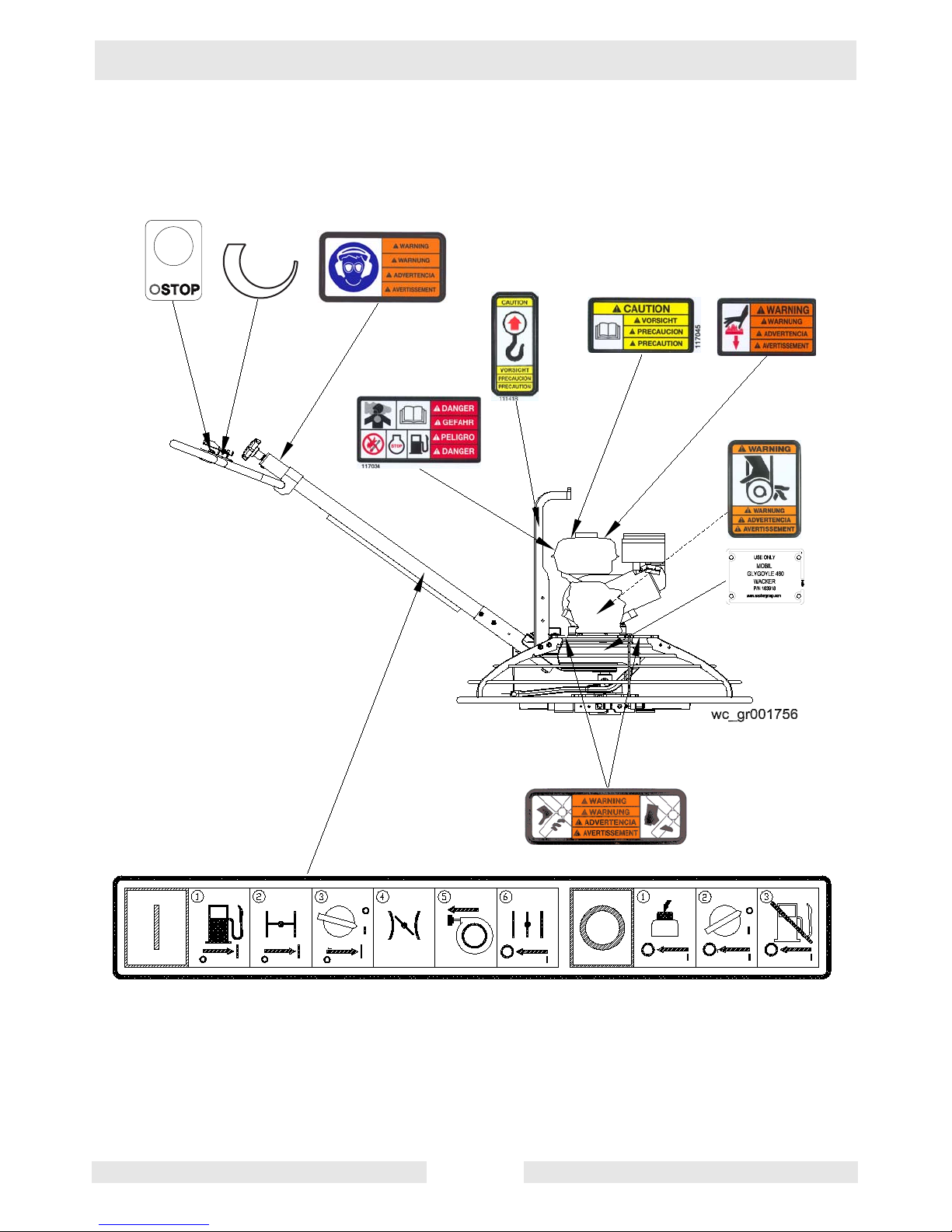

1.5 Label Locations

wc_si000139gb.fm 12

CT 36 / CT 48 Safety Information

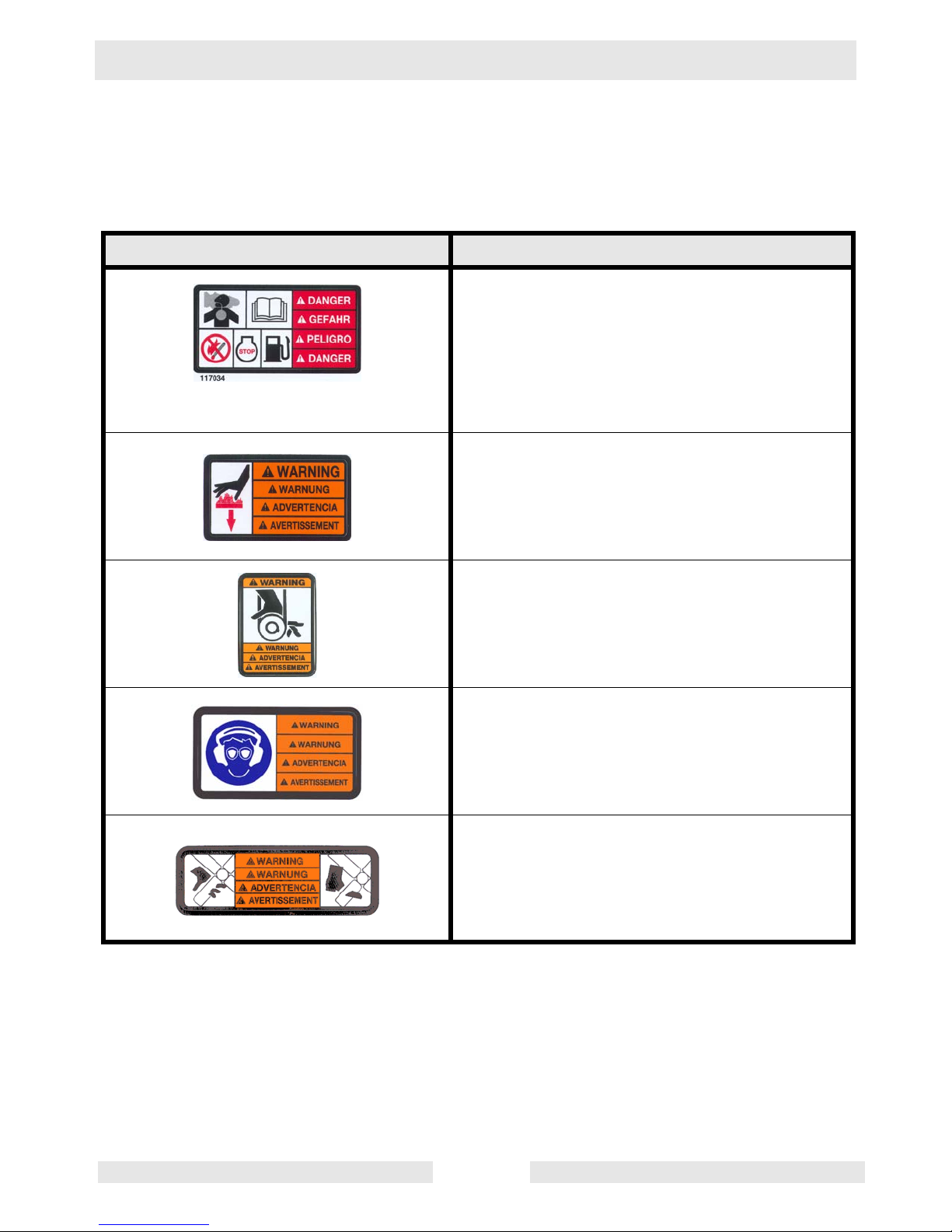

1.6 Safety and Information Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

DANGER!

Engines emit carbon monoxide; operate only

in well-ventilated area. Read the Operator’s

Manual.

No sparks, flames, or burning objects near the

machine. Shut off the engine before refueling.

WARNING!

Hot surface!

WARNING!

Hand injury if caught in moving belt.

Always replace beltguard.

WARNING!

Always wear hearing and eye protection when

operating this machine.

WARNING!

Cutting hazard. Always replace blade guard!

wc_si000139gb.fm 13

Safety Information CT 36 / CT 48

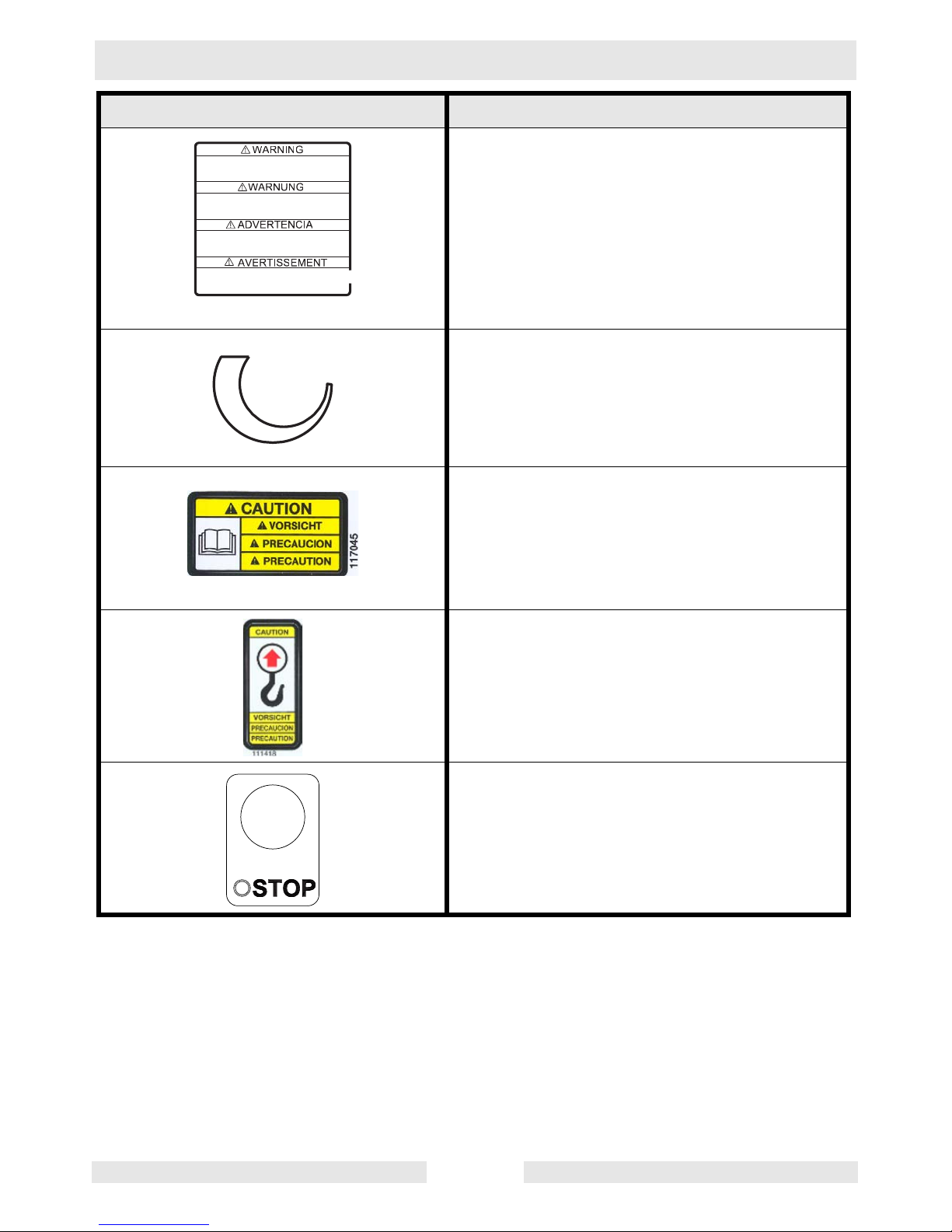

Label Meaning

R e m o v e p a n f r o m t r o w e l b e f o r e l i f t i n g m a c h i n e

o v e r h e a d .

P a n s c a n f a l l a n d c a u s e d e a t h o r s e r i o u s i n j u r y i f

a p e r s o n i s h i t .

G l e i t s c h e i b e v o m B e t o n g l ä t t e r e n t f e r n e n b e v o r

d a s G e r ä t u b e r K o p f h ö h e g e h o b e n w i r d .

G l e i t s c h e i b e k a n n f a l l e n u n d s c h w e r e V e r l e t z u n g

o d e r T o d v e r u r s a c h e n w e n n P e r s o n a l g e t r o f f e n w i r d .

Q u i t e e l d i s c o d e f l o t a c i ó n a n t e s d e l e v a n t a r l a

m á q u i n a a l i s a d o r a d e h o r m i g ó n .

L o s d i s c o s p o d r í a n c a e r y m a t a r o l a s t i m a r

s e r i a m e n t e a u n a p e r s o n a q u e s e e n c u e n t r e c e r c a .

A v a n t d e l e v e r l a p p a r e i l a u - d e s s u s d e v o t r e t ê t e ,

ô t e r l e d i s q u e d e t a l o c h a g e d e l a t r u e l l e .

L e d i s q u e d e t a l o c h a g e p e u t t o m b e r e t e n t r a î n e r

d e g r a v e s b l e s s u r e s o u m ê m e l a m o r t .

WARNING!

Remove pan from trowel before lifting machine

overhead. Pans can fall and cause death or

serious injury if a person is hit. (Located on top

side of float pan.)

1 1 8 6 8 8

Variable speed throttle

CAUTION!

Read and understand the supplied Operator’s

Manuals before operating this machine. Failure to do so increases the risk of injury to yourself or others.

CAUTION!

Lifting point.

Engine stop button:

Press to stop engine.

wc_si000139gb.fm 14

CT 36 / CT 48 Safety Information

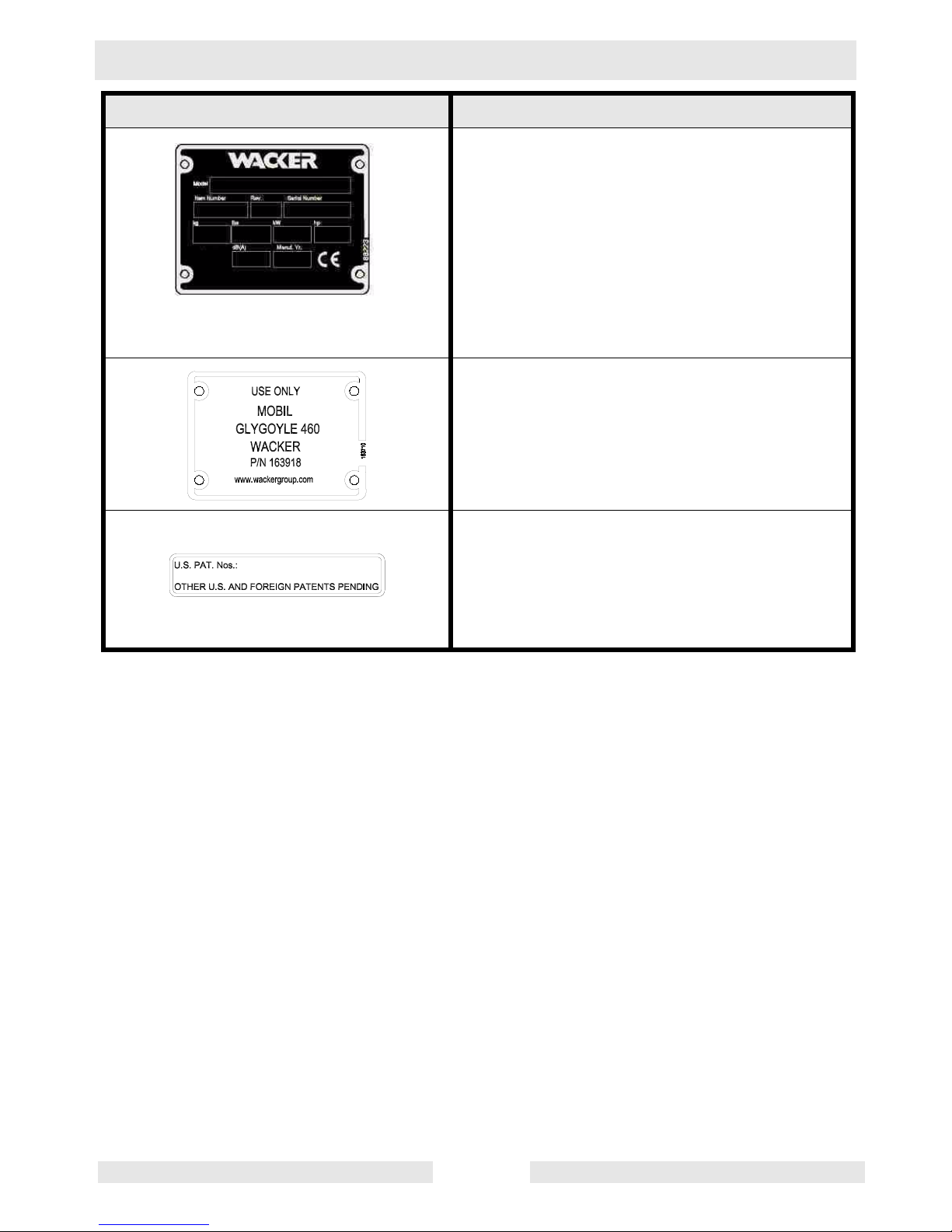

Label Meaning

A nameplate listing the model number, item

number, revision number, and serial number is

attached to each unit. Please record the information found on this plate so it will be available

should the nameplate become lost or damaged. When ordering parts or requesting service information, you will always be asked to

specify the model number, item number, revision number, and serial number of the unit.

Use only Glygoyle 460 gear oil in gearbox.

This machine may be covered by one or more

patents.

wc_si000139gb.fm 15

Safety Information CT 36 / CT 48

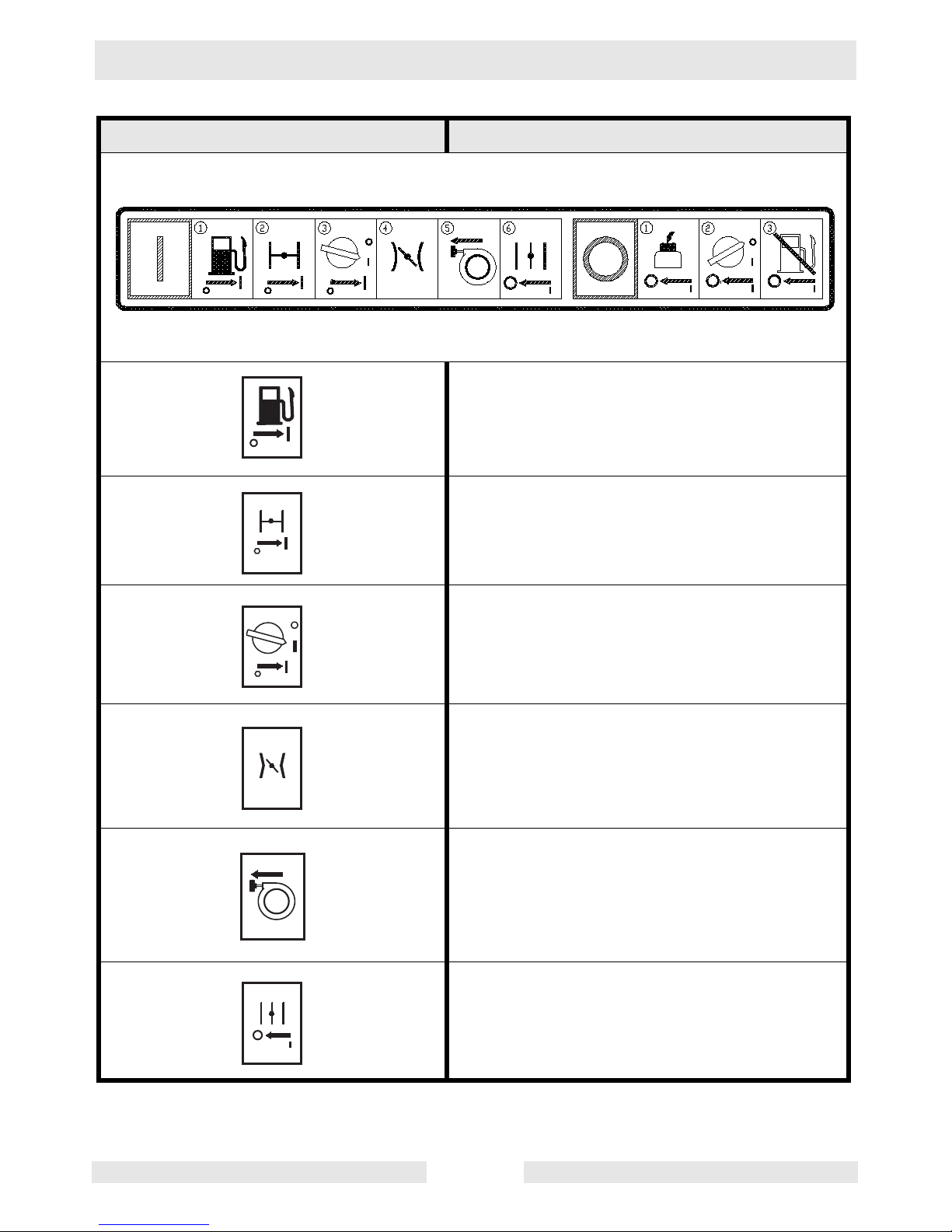

Label Meaning

Open the fuel flow valve.

Close the choke.

Turn engine key switch to “ON” position.

Place throttle in the IDLE position.

Pull the rewind starter.

Open the choke.

wc_si000139gb.fm 16

CT 36 / CT 48 Safety Information

Label Meaning

Press the stop button.

Turn engine key switch to “OFF” position.

Close the fuel flow valve.

wc_si000139gb.fm 17

Technical Data CT 36 / CT 48

2. Technical Data

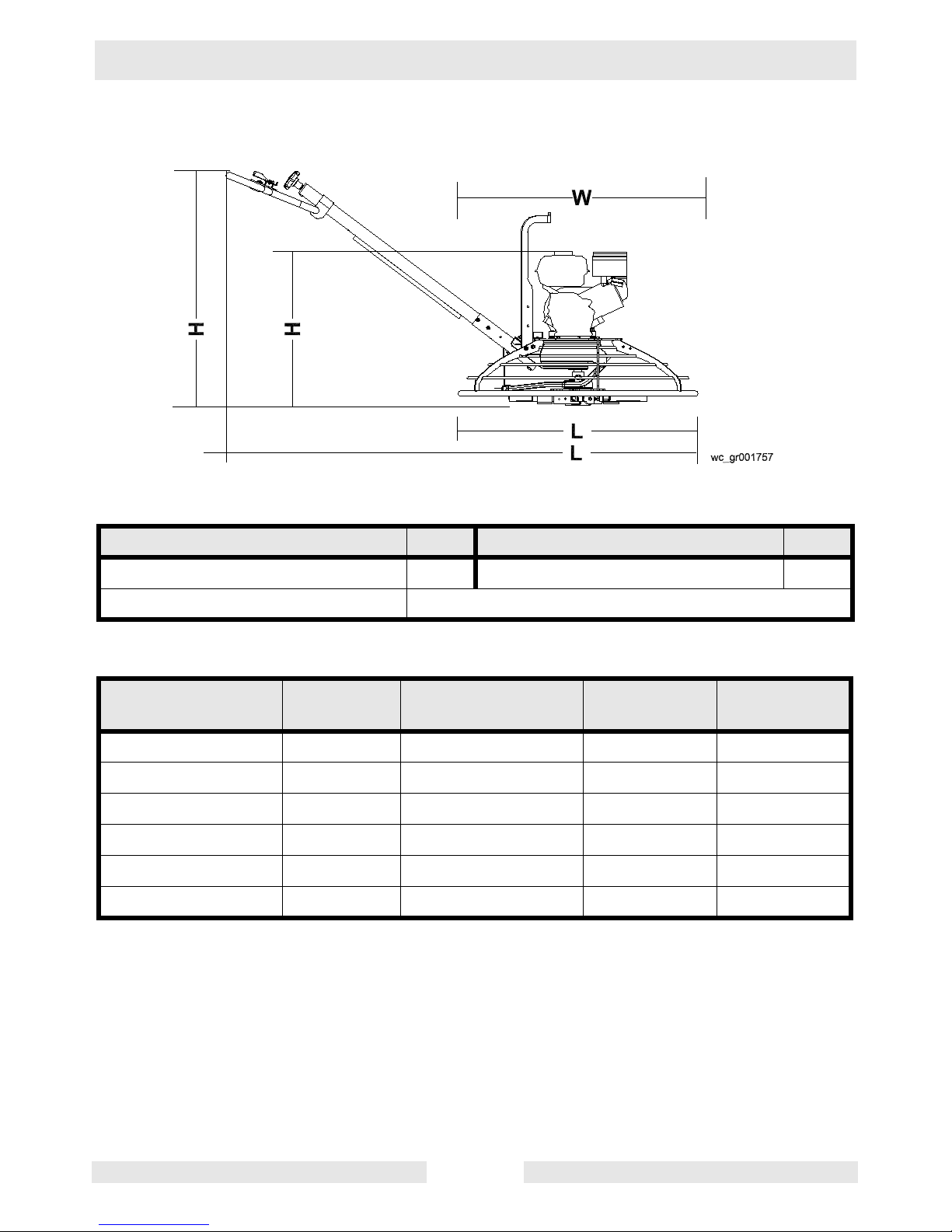

2.1 Dimensions and Weight

Guide

Description Ref. Description Ref.

Honda engine* A Variable Speed V

Engine Horse Power 4, 5, 6, 8, 9, 11, 13

*Standard models feature Wacker engine.

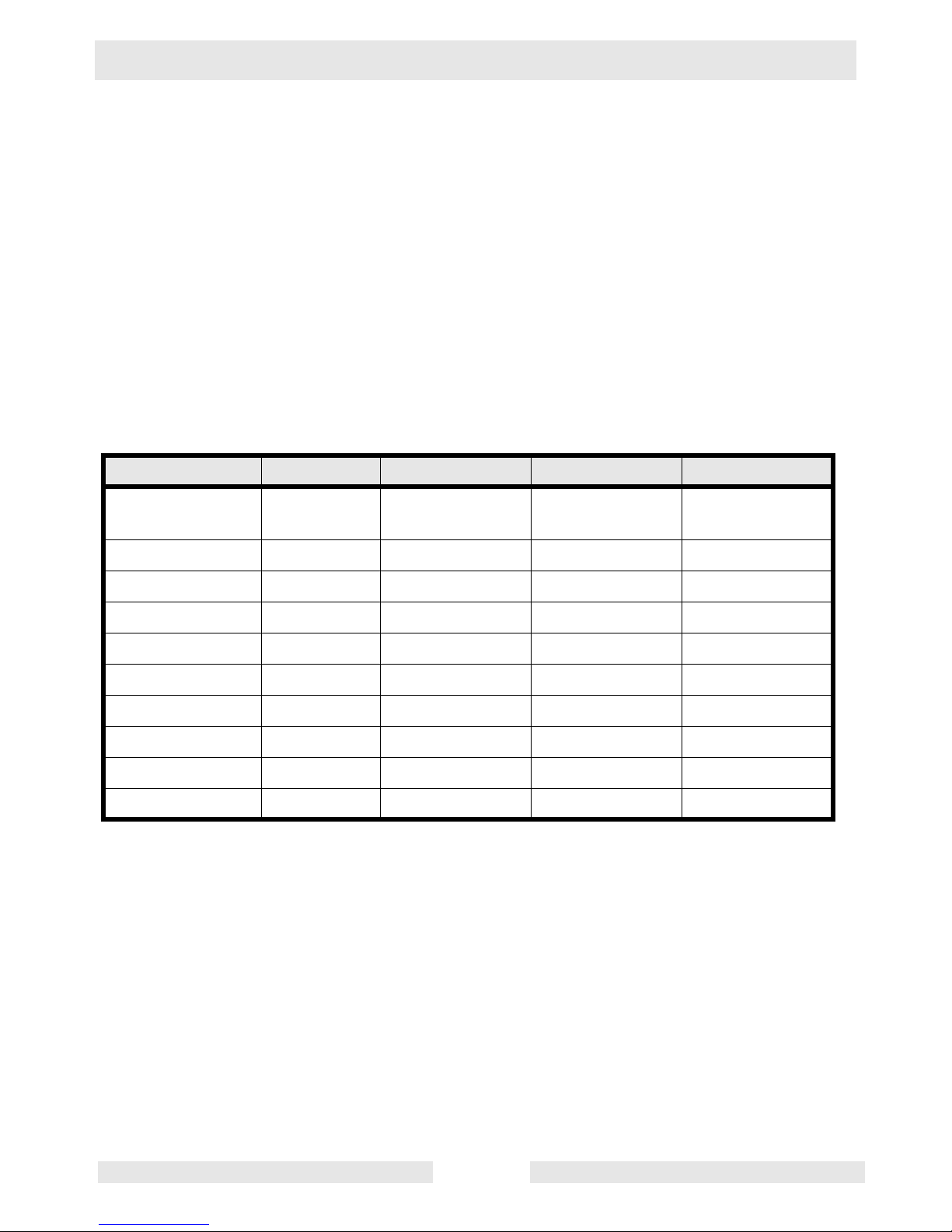

Handle Type Item No.

L

mm(in.)

Pitch

Type

Weight

kg (lbs.)

Solid 0159659 1740 (68.5) Twist 10 (21)

Folding 0159660 1740 (68.5) Twist 12 (26.5)

Adjustable/Folding 0164617 1740 (68.5) Twist 13 (28)

Adjustable 0164535 1740 (68.5) Twist 11 (24.5)

Adjustable/Folding 0159661 1740 (68.5) Pro-Shift® 15 (32.5)

Adjustable 0159662 1740 (68.5) Pro-Shift® 13 (29)

wc_td000141gb.fm 18

CT 36 / CT 48 Technical Data

without handle with handle

Model Item No.

CT 36-5A

0009438

0620106

CT 36-6 0009443

CT 36-8A 0009439

CT 36-8A-V 0009442

CT 36-9 0009444

CT 36-9-V 0009447

CT 48-8A 0009449

CT 48-9 0009453

LxWxH

mm

(in.)

915x915x607

(36x36x24)

915x915x607

(36x36x24)

915x915x686

(36x36x27)

915x915x686

(36x36x27)

915x915x686

(36x36x27)

915x915x686

(36x36x27)

1220x1220x686

(48x48x27)

1220x1220x686

(48x48x27)

LxWxH

mm

(in.)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2005x915x1040

(79x36x41)

2160x1220x1040

(85x48x41)

2160x1220x1040

(85x48x41)

without

weight kit

kg (lbs.)

with

weight kit

kg (lbs.)

85 (183) 91 (201)

85 (183) 91 (201)

94 (208) 103 (226)

94 (208) 103 (226)

90 (199) 98 (217)

90 (199) 98 (217)

105 (234) 114 (252)

105 (234) 114 (252)

CT 48-11A 0009450

CT 48-13A-V 0009452

1220x1220x712

(48x48x28)

1220x1220x712

(48x48x28)

2160x1220x1040

(85x48x41)

2160x1220x1040

(85x48x41)

113 (250) 122 (268)

121 (268) 130 (286)

wc_td000141gb.fm 19

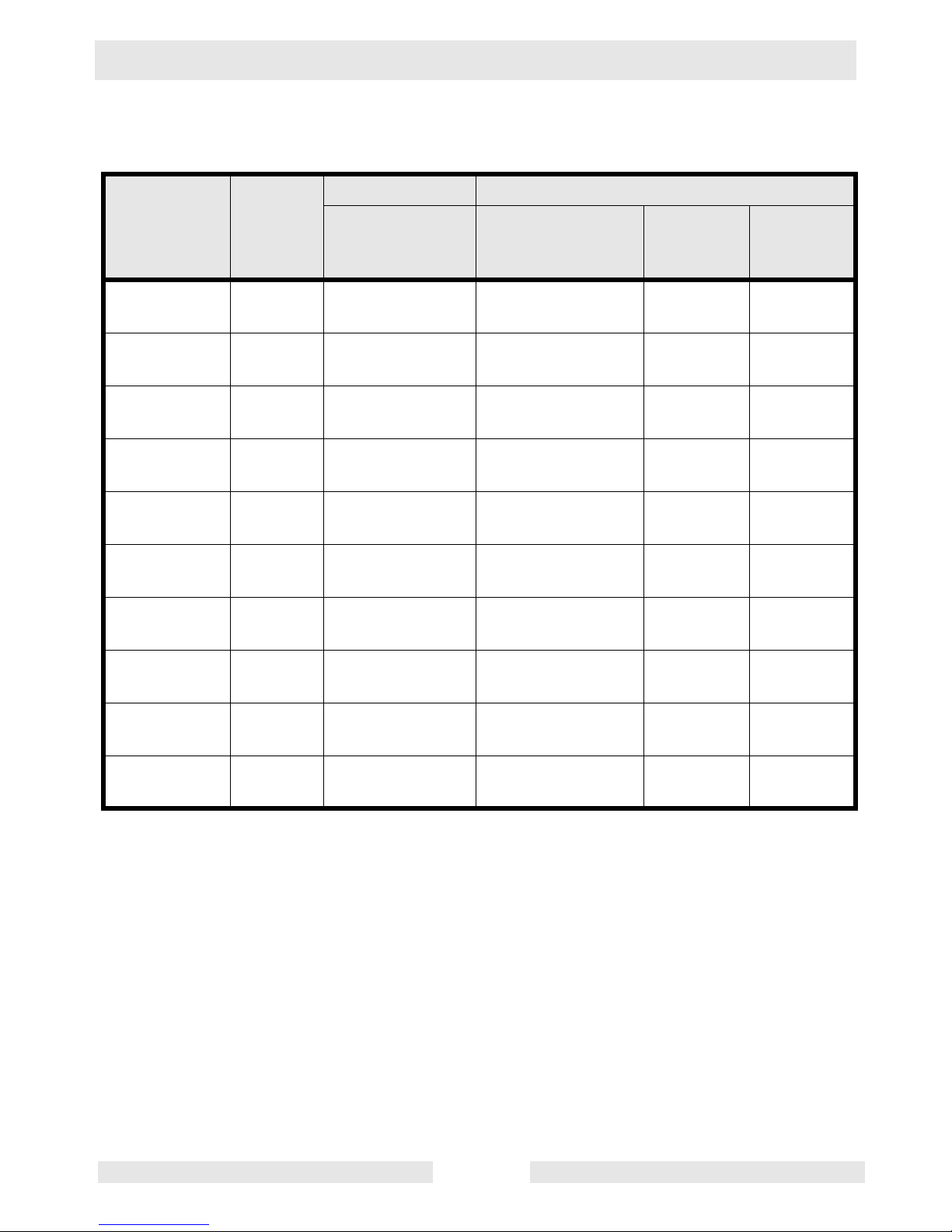

Technical Data CT 36 / CT 48

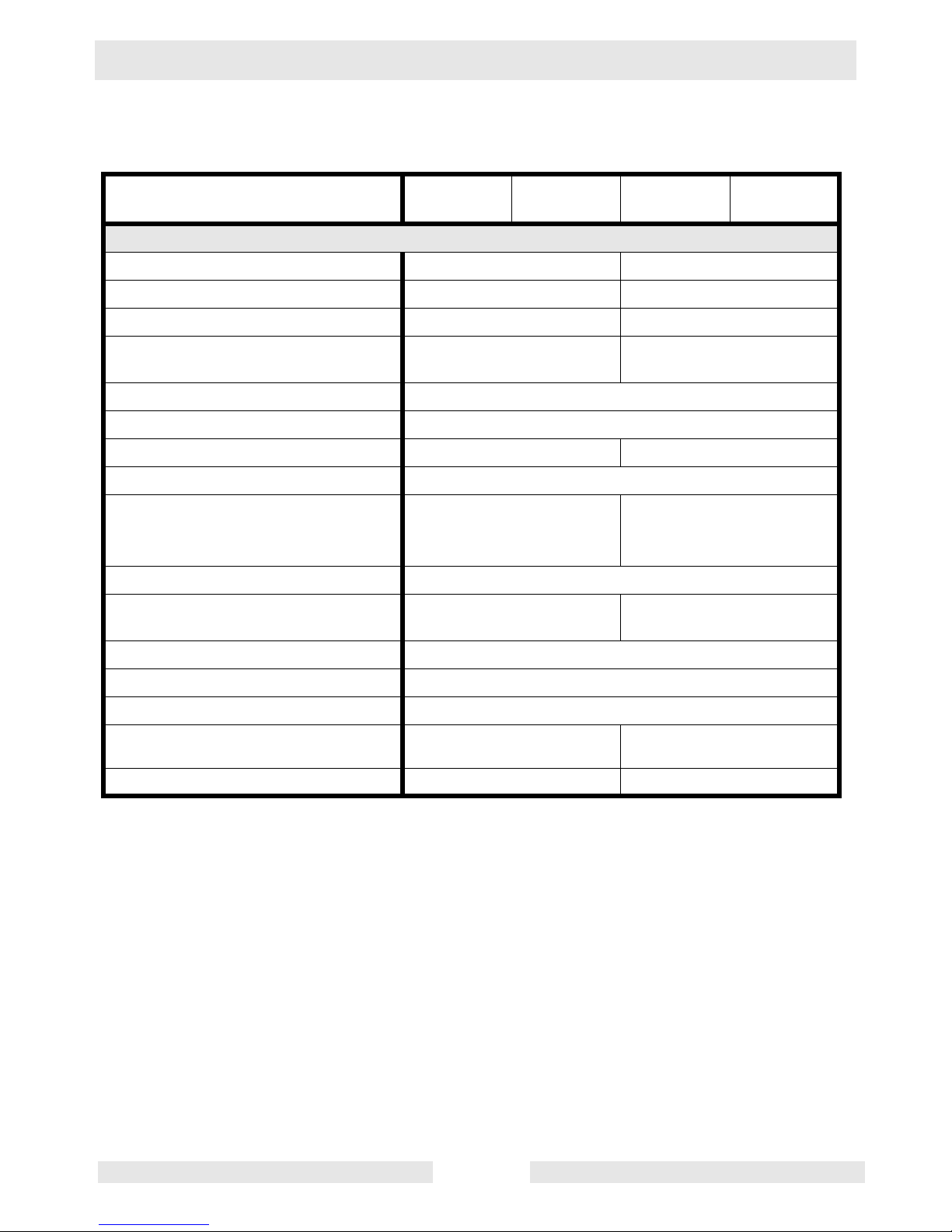

2.2 Engine

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 36-5A

0009438, 0620106

CT 36-6

0009443

Engine

Honda

GX 160 K1 QX2

4.3 (5.7) @ 3800rpm

NGK BPR 6ES NGK BR6HS

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30 SG or SF SAE 10W30

0.6 (20)

Regular unleaded gasoline

3.6 (3.8)

1.8 (1.9) 1.52 (1.6)

22.4

4.2 (5.6) @ 3800 rpm

0.6–0.7 (0.024–0.028)

0.07–0.13 (0.0028–0.0051)

0.17–0.23 (0.0067–0.0091

Wacker

WM170

Champion RL86C

1400 ± 100

SE or higher

wc_td000141gb.fm 20

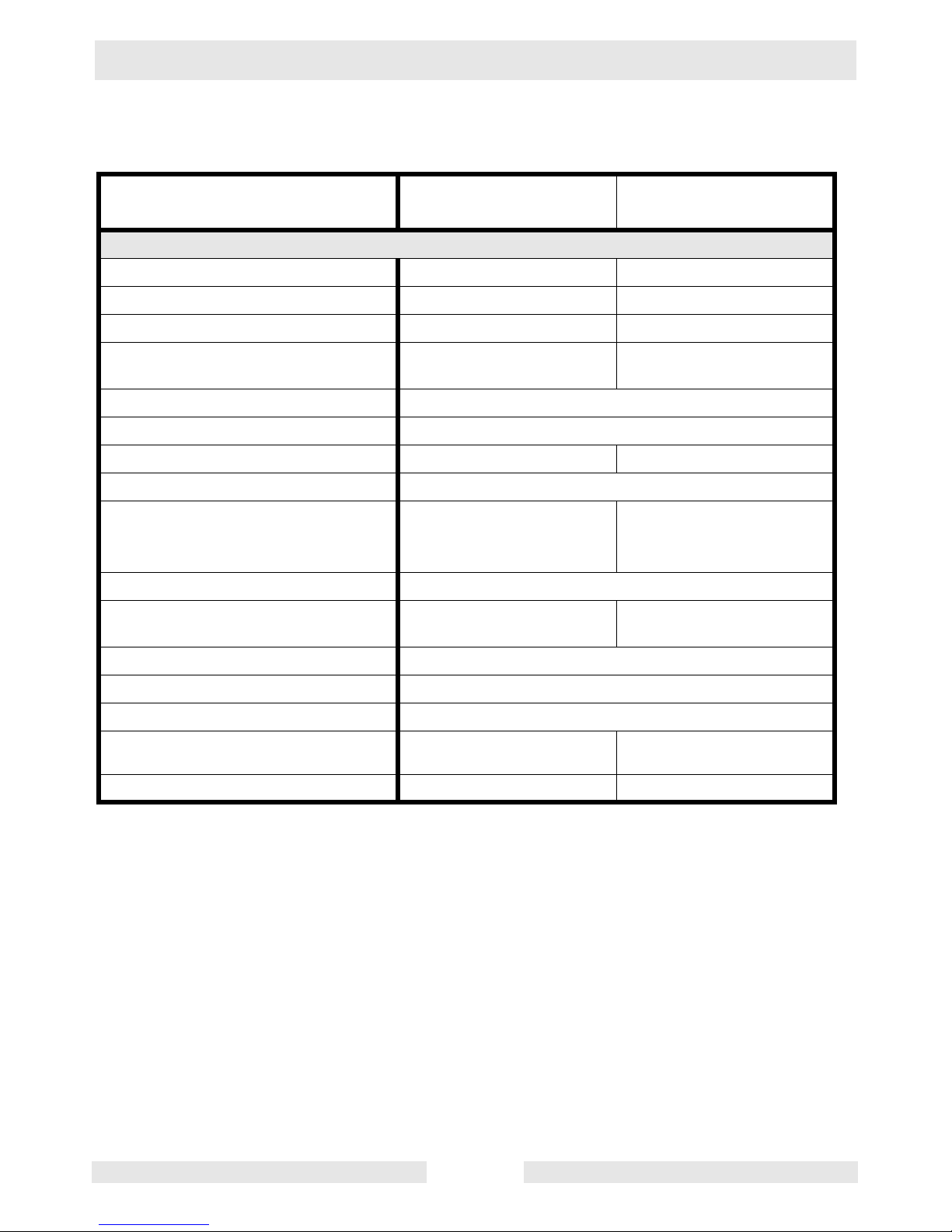

CT 36 / CT 48 Technical Data

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 36-8A

0009439

CT 36-8A-V

0009442

CT36-9

0009444

CT 36-9-V

0009447

Engine

Honda Wacker

GX 240 K1 QA WM270

6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm

NGK BPR 6ES

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100 1400 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30 SG or SF

1.1 (37)

Regular unleaded gasoline

6.0 (6.4)

2.7 (2.8) 2.5 (2.6)

2.25 2.4

NGK BR6HS

Champion RL86C

0.07–0.13 (0.0028–0.0051)

0.17–0.23 (0.0067–0.0091

SAE 10W30

SF, SE, SD, or SC

wc_td000141gb.fm 21

Technical Data CT 36 / CT 48

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 48A-8A

0009449

CT 48-9

0009453

Engine

Honda Wacker

GX 240 K1 QA WM270

6.2 (8.3) @ 3800 rpm 6.5 (8.7) @ 3800 rpm

NGK BPR 6ES

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100 1400 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30 SG or SF

1.1 (37)

Regular unleaded gasoline

6.0 (6.4)

2.7 (2.8) 2.5 (2.6)

2.25 2.4

NGK BR6HS

Champion RL86C

0.07–0.13 (0.0028–0.0051)

0.17–0.23 (0.0067–0.0091

SAE 10W30

SF, SE, SD, or SC

wc_td000141gb.fm 22

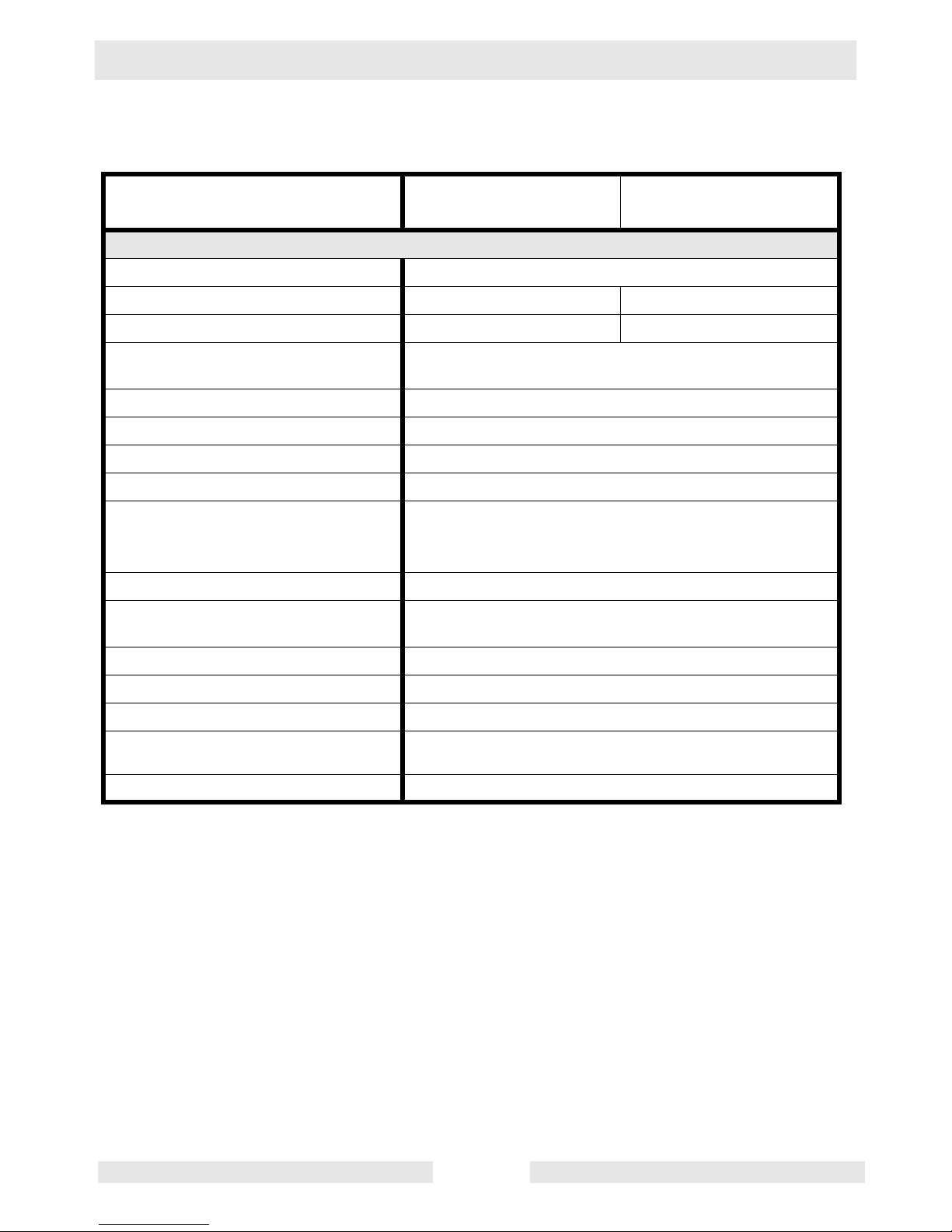

CT 36 / CT 48 Technical Data

Item No.

Engine Make

Engine Model

Rated Power

Spark Plug

Electrode Gap

Engine Speed - full load

Engine Speed - idle

Clutch engagement

Valve Clearance (cold)

intake:

exhaust:

Air Cleaner

Engine Lubrication

Engine Oil Capacity

Fuel

Fuel Tank Capacity

Fuel Consumption

Running time

kW (Hp)

mm (in.)

rpm

rpm

rpm

mm (in.)

type

oil grade

l (oz.)

type

l (qts.)

l (qts.)

/hr

hr.

CT 48-11A

0009450

CT 48-13A-V

0009452

Engine

Honda

GX 340 K1 QA GX 390 U1 QA

8.7 (11.6) @ 3800 rpm 10 (13.4) @ 3800 rpm

NGK BPR 6ES

0.7 – 0.8 (0.028 – 0.031)

3800 ± 100

1450 ± 100

1800

0.15 (0.006)

0.20 (0.008)

Dual element

SAE 10W30

SG or SF

1.1 (37)

Regular unleaded gasoline

6.0 (6.4)

2.7 (2.8)

2.25

wc_td000141gb.fm 23

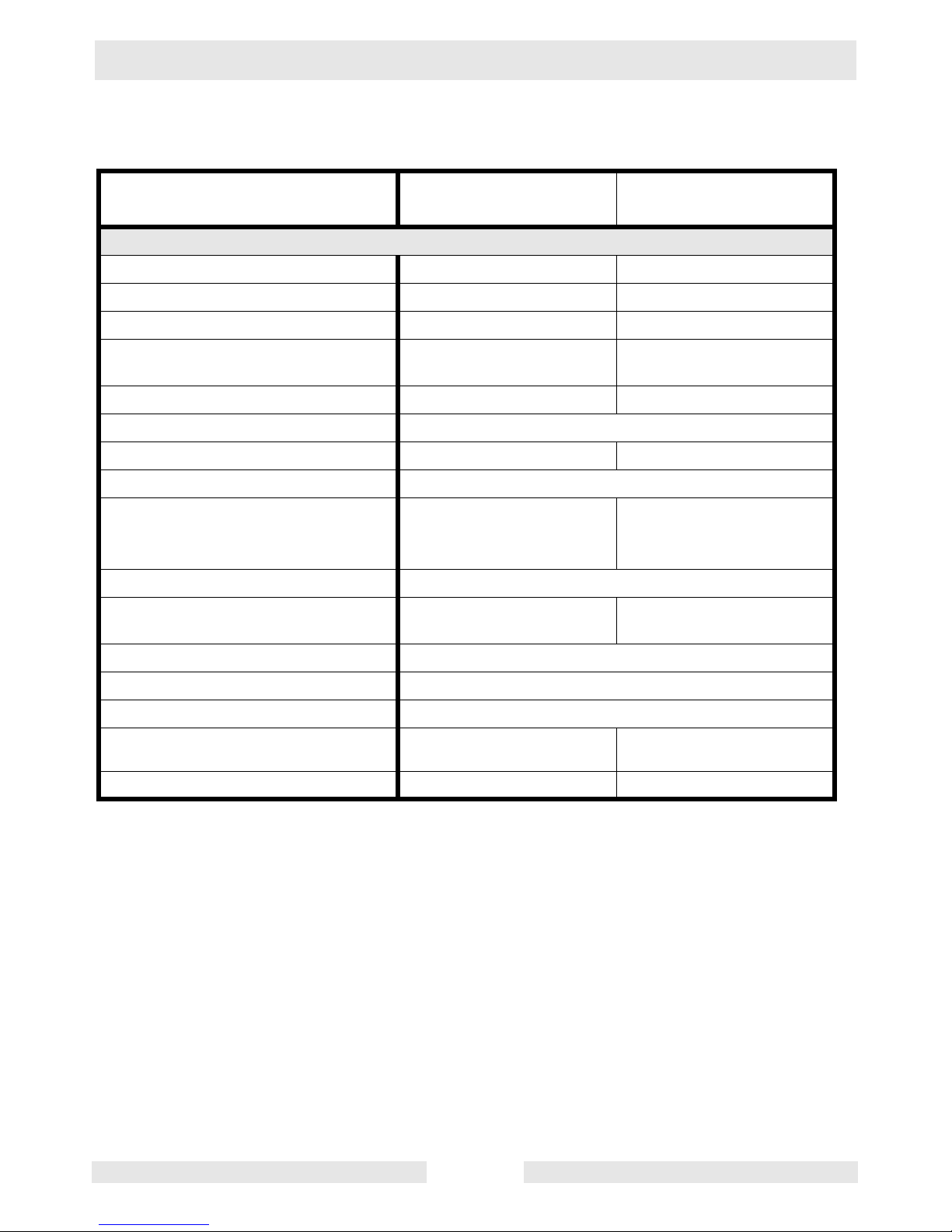

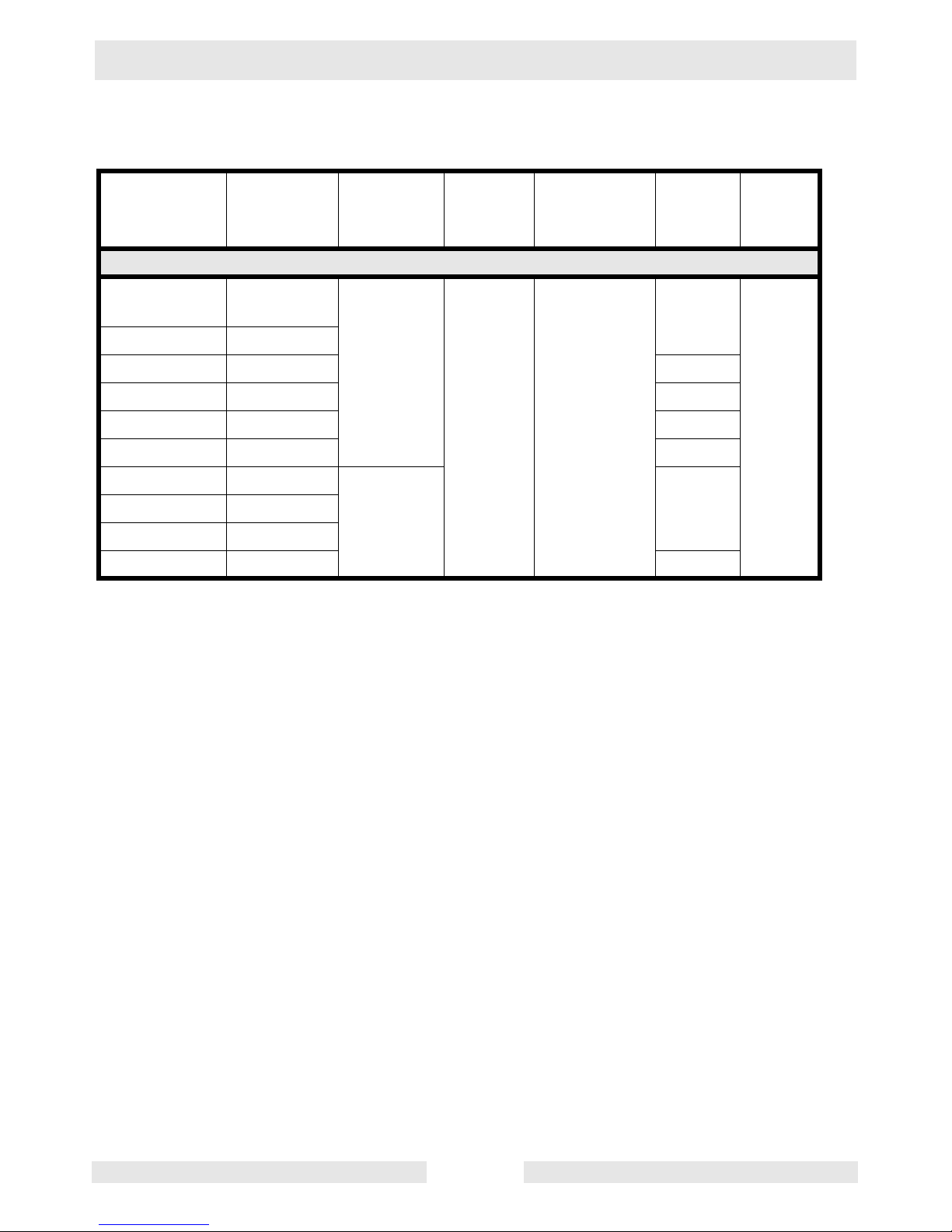

Technical Data CT 36 / CT 48

2.3 Trowel

Model Item No.

Trowel

Diameter*

mm (in.)

Number

of

Blades

Gear Box

Lubrication

type/ml (oz.)

Speed

Range

rpm

Trowel

CT 36-5A

0009438

0620106

60–125

CT 36-6 0009443

CT 36-8A 0009439 60–125

CT 36-8A-V 0009442 25–200

CT 36-9 0009444 60–125

CT 36-9-V 0009447 25–200

CT 48-8A 0009449

915 (36)

Mobil

Glygoyle

4

460

Approx.

620 (21)

60–125CT 48-9 0009453

1220 (48)

CT 48-11A 0009450

CT 48-13A-V 0009452 25–200

*Trowel blades must NOT be interchanged, i.e., do NOT put larger diameter blades on a smaller

diameter trowel.

Pitch

Range

degrees

0–30

wc_td000141gb.fm 24

CT 36 / CT 48 Technical Data

2.4 Sound and Vibration Data

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• the sound pressure level at operator’s location (L

• the guaranteed sound power level (L

) = “B” dB(A)

WA

) : “A” dB(A)

pA

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 6081 for the sound pressure level

(LpA) at the operator’s location.

• The weighted effective acceleration value, determined according to

ISO 8662 Part 1, is: “C” m/s2.

The sound and vibration specifications were obtained with the unit

operating on wetted and cured concrete at full engine speed.

Model Item No. A B C

CT 36-5A

0009438

0620106

103 89 5.3

CT 36-6 0009443 103 89 5.3

CT 36-8A 0009439 109 95 4.3

CT 36-8A-V 0009442 109 95 4.0

CT 36-9 0009444 109 95 7.1

CT 36-9-V 0009447 109 95 6.6

CT 48-8A 0009449 109 95 5.3

CT 48-9 0009453 109 95 5.3

CT 48-11A 0009450 113 96 7.1

CT 48-13A-V 0009452 115 98 4.1

wc_td000141gb.fm 25

Operation CT 36 / CT 48

3. Operation

3.1 Application

This trowel is a modern, high production machine intended for floating

and finishing freshly poured concrete slabs. The machine's good

balance, adjustable handle, and easily reached controls add to

operator comfort and productivity. An automatic stop sensor provides

added operator safety. Finishing rates will depend on operator skill and

job conditions.

DO NOT use this machine for any application other than troweling

concrete.

3.2 New Machine Set-up

Trowels are shipped from the factory with the handle removed. Follow

instructions on Installing Blades and Installing and Adjusting Handles

when setting up new machines or when installing new handles and

blades.

3.3 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh,

clean gasoline. Gasoline containing water or dirt will damage fuel

system. Consult engine Owner’s Manual for complete fuel

specifications.

wc_tx000373gb.fm 26

CT 36 / CT 48 Operation

3.4 Installing Blades

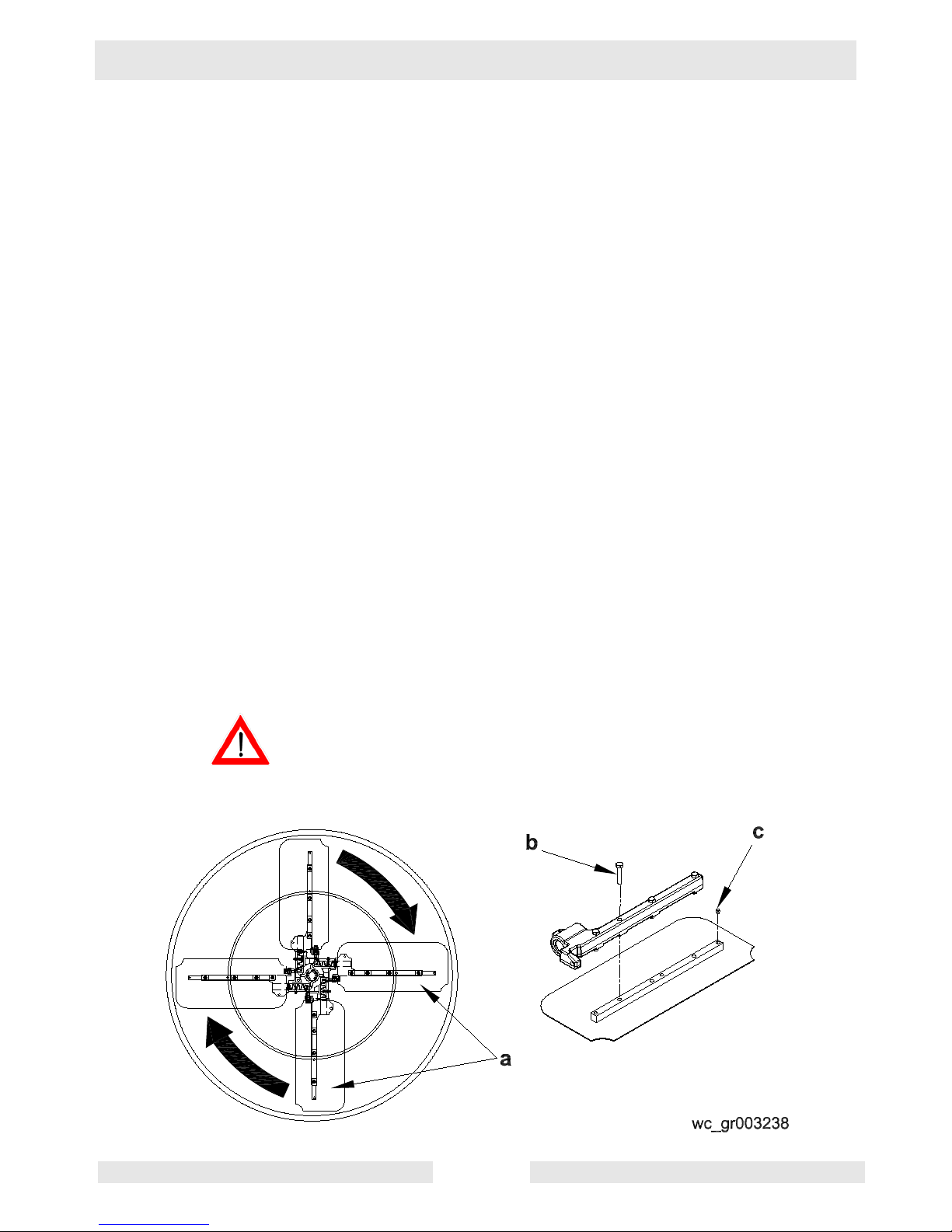

See Graphic: wc_gr003238

There are four types of blades available for the trowels. Float pans are

large "pizza pan" style blades, which hook on over finish or

combination blades and are available for the 36" machines only. Float

blades are available for all machines and clip on over finish or

combination blades. Both are used in the earliest stages of work, and

are not pitched.

Finish blades are used in the final stages of working, and are

progressively pitched to burnish the concrete.

Combination blades can be used throughout the concrete working

process. They are used in place of float blades or pans and finish

blades.

Note: Trowel blades must NOT be interchanged, i.e., do NOT put

larger diameter blades on a smaller diameter trowel.

3.4.1 Finish blades are flat on both edges and can be installed in either

direction.

When installing combination blades, orient blades as shown (a). This

positions the raised edges of the blade correctly for the clockwise

rotation of the machine.

3.4.2 Secure blades to trowel arms with screws (b). Dip threads of screws in

grease prior to installation. This will prevent concrete from cementing

the screws in place and will make removal of the blades easier later on.

3.4.3 Plug the remaining threaded holes in the blade brace with plastic plugs

(c) to prevent them from filling with concrete.

Do not lift the trowel overhead with a float pan attached, as the pan

could fall off and strike personnel working in the vicinity.

WARNING

wc_tx000373gb.fm 27

Operation CT 36 / CT 48

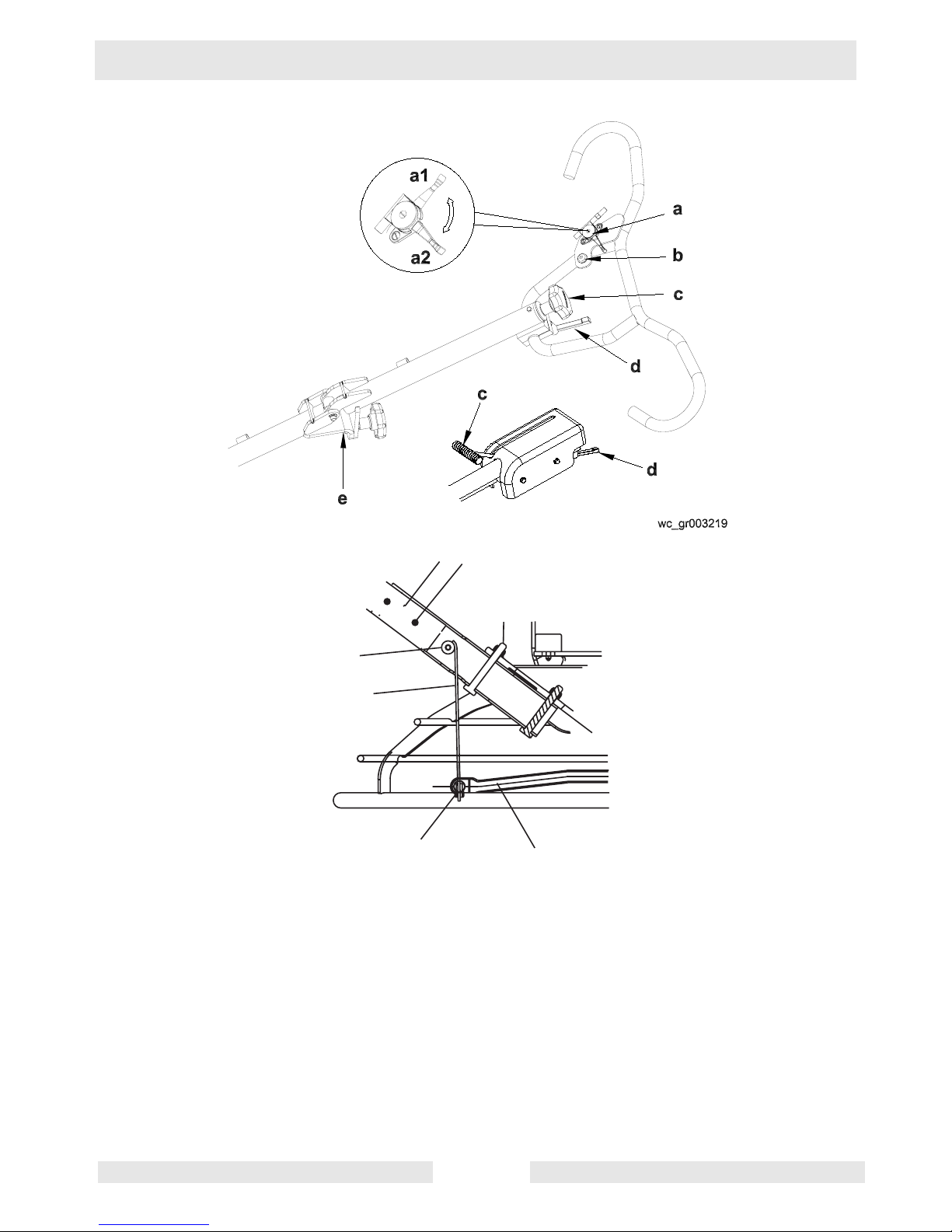

3.5 Installing and Adjusting Handles

See Graphic: wc_gr001758, wc_gr003219

On new machines the pipe handle comes assembled with the pitch

control (Twist or Pro-Shift®) (c), stop button (b), throttle (a), screws

(g), and nut (m).

To install the pipe handle assembly:

3.5.1 On machines with the foldable handle, straighten the handle and

tighten the knob (e) to secure the handle in position.

3.5.2 Pull the pitch control cable (j) from bottom end of the tube and remove

the nut from the cable.

3.5.3 Thread the cable through the handle base (f) and over the pulley (h)

as shown.

3.5.4 Attach the pipe handle to the handle base with two M8x65 screws (g).

Torque the screws to 25 Nm (18 ft.lbs.).

3.5.5 Push the Pro-Shift® handle all the way forward (away from the

operator) OR turn the twist pitch control handle counterclockwise as far

as possible. Connect the cable to the fork (k) as shown and adjust the

cable nut (m) so the cable is snug and the trowel blades lay flat (0°

pitch).

3.5.6 Move throttle (a1) to idle position. Remove air cleaner cover. Feed

cable through clamp on recoil cover. Connect throttle cable to engine

throttle bracket by placing z-bend through hole in throttle plate. Clamp

cable into throttle casing bracket. Replace air cleaner cover.

3.5.7 Connect electrical wire on handle to both ends of the engine wire. See

handle instruction sheet for additional detail on installation.

Note: On machines with Wacker engines, do not connect wires in bag

to wires in handle.

3.5.8 On machines with an adjustable handle, position the handle by

loosening the knob (d) and adjusting the handle up or down to suit the

operator. Tighten the knob to secure the handle in position.

wc_tx000373gb.fm 28

CT 36 / CT 48 Operation

e

f

g

h

wc_gr001758

k

j

wc_tx000373gb.fm 29

Operation CT 36 / CT 48

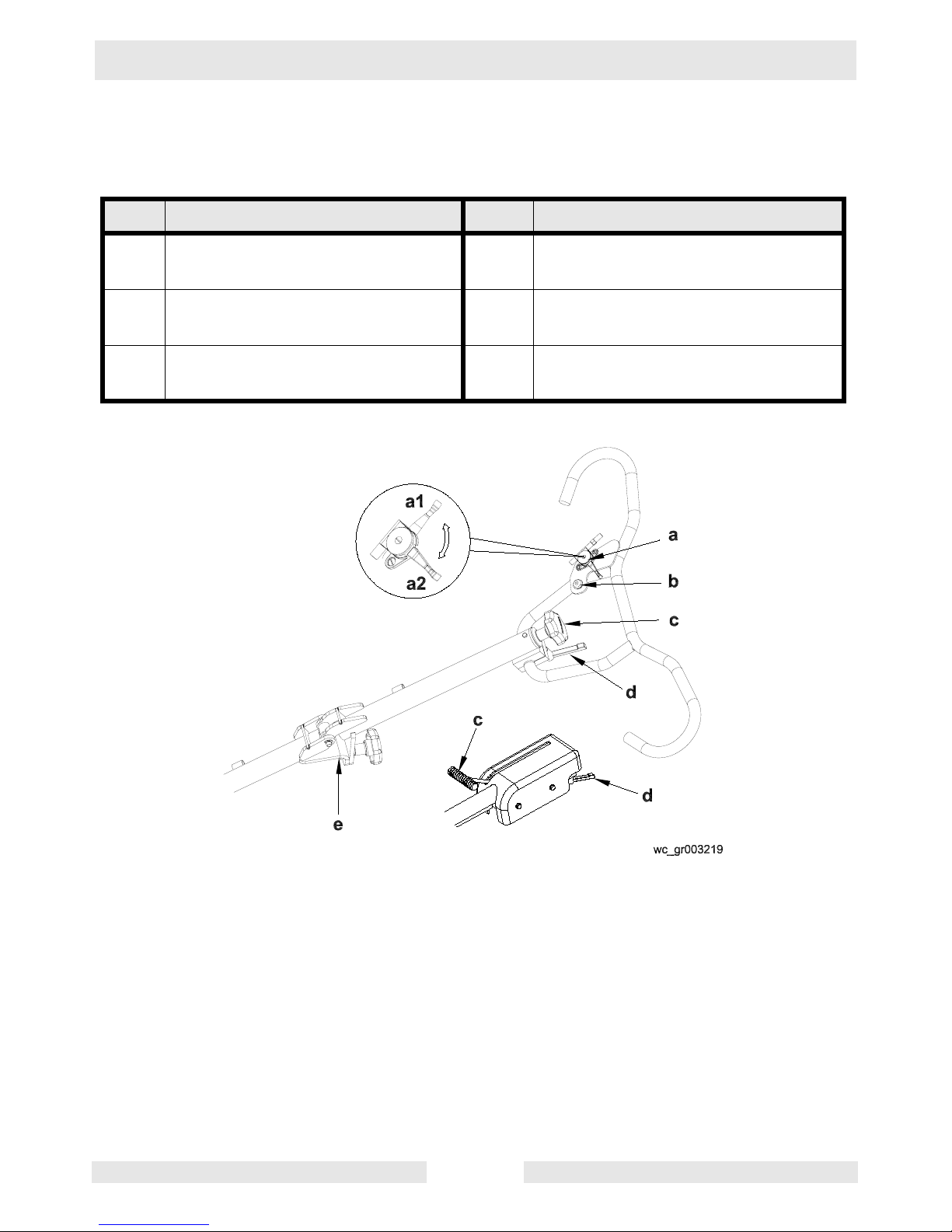

3.6 Controls

See Graphic: wc_gr003219

Ref. Description Ref. Description

a Throttle lever d Handle height adjustment (if

equipped)

b Stop button e Foldable handle adjustment (if

equipped)

c Twist pitch control or Pro-Shift®

pitch control

wc_tx000373gb.fm 30

Loading...

Loading...