Page 1

Operator’s Manual

Ride-On Trowel

CRT 36-25

CRT 36-26A

5200001020

5200001020

03 0515

Page 2

Copyright

notice

© Copyright 2015 by Wacker Neuson Production Americas LLC

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Production Americas LLC.

Any type of reproduction or distribution not authorized by Wacker Neuson Production

Americas LLC represents an infringement of valid copyrights. Violators will be

prosecuted.

T ra d emarks

Manufacturer

All trademarks referenced in this manual are the property of their respective owners.

Wacker Neuson Production Americas LLC

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Original

instructions

This Operator’s Manual presents the original instructions. The original language of this

Operator’s Manual is American English.

Page 3

CRT 36 Foreword

Foreword

SAVE THESE INSTRUCTIONS—This manual contains important instructions for

the machine models below. These instructions have been written expressly by

Wacker Neuson Production Americas LLC and must be followed during inst allation,

operation, and maintenance of the machines.

Machines

covered by

this manual

Machine Item Number Machine Item Number

CRT 36-26A 0620999 CRT 36-25 0620115

CRT 36-26A 0621000 CRT 36-25 0620295

CRT 36-26A 0621001 CRT 36-25 0620803

CRT 36-26A 0621002 CRT 36-25 0620804

Machine

documentation

Expectations

for

information in

this manual

From this point forward in this documentation, Wacker Neuson Production

Americas LLC will be referred to as Wacker Neuson.

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson to

order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

This manual provides information and procedures to safely operate and

maintain the above Wacker Neuson model(s). For your own safety and to

reduce the risk of injury, carefully read, understand, and observe all instructions

described in this manual.

Wacker Neuson expressly reserves the right to make technical modifications,

even without notice, which improve the performance or safety standards of its

machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson reserves the right to chan ge any

portion of this information without notice.

The illustrations, parts, and procedures in this manual refer to Wacker Neuson

factory-installed components. Your machine may vary depending on the

requirements of your specific region.

wc_tx001268gb.fm

3

Page 4

Foreword CRT 36

CALIFORNIA

Proposition

65 Warning

Laws

pertaining to

spark

arresters

Manufacturer’s

approval

Combustion exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm.

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental

discharge of sparks or flames from the engine exhaust. Spark arresters are

qualified and rated by the United States Forest Service for this purpose. In order to

comply with local laws regarding spark arresters, consult the engine distributor or

the local Health and Safety Administrator.

This manual contains references to approved parts, attachments, and

modifications. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker

Neuson service center according to written instructions published by Wacker

Neuson.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following

consequences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

4

wc_tx001268gb.fm

Page 5

EC Declaration of Conformity

Manufacturer

Wacker Neuson Production Americas LLC, N92W15000 Anthony Avenue,

Menomonee Falls, Wisconsin 53051 USA

Product

Product

Product category

Product function

Item number

CRT V36-26A, CRT 36-24A, CRT 36-25, CRT 48-35V,

CRT 48-35L, CRT 48-33K DF

Trowel

To smooth and finish semi-cured concrete

5200008546, 5000620803, 5000620804, 5000620806,

5000620807, 5000621001, 5000621002, 5200002354,

5200007687

Directives and Standards

We hereby declare that this product meets and complies with the relevant regulations and

requirements of the following directives and standards:

2006/42/EC, 2004/108/EC, EN12649

Authorized Person for Technical Documents

Leo Goeschka, Wacker Neuson Produktion GmbH & Co. KG, Preußenstraße 41,

80809 München

Menomonee Falls, WI, USA, 13.05.15

Keith Herr

Managing Director

For Wacker Neuson

2015-CE-CRT36-CRT48-en.fm

Dan Domanski

Technical Director

For Wacker Neuson

Original Declaration of Conformity

Scott V. Grahl

Manager, Product Engineering

For Wacker Neuson

Page 6

Page 7

CRT 36

Table of Contents

Foreword 3

EC Declaration of Conformity 5

1 Safety Information 9

1.1 Signal Words Used in this Manual ....................................................... 9

1.2 Machine Description and Intended Use ............................................. 10

1.3 Operating Safety ................................................................................ 11

1.4 Operator Safety while Using Internal Combustion Engines ............... 12

1.5 Service Safety .................................................................................... 13

2 Labels 15

2.1 Label Locations .................................................................................. 15

2.2 Label Meanings .................................................................................. 17

3 Operation 21

3.1 Features and Controls ........................................................................ 21

3.2 Position of the Operator ..................................................................... 23

3.3 Preparing the Machine for First Use ................................................... 23

3.4 Recommended Fuel ........................................................................... 23

3.5 Break-in Period ................................................................................... 24

3.6 Before Starting ................................................................................... 24

3.7 Starting ............................................................................................... 25

3.8 Stopping ............................................................................................. 25

3.9 Operation ............................................................................................ 25

3.10 Steering .............................................................................................. 26

3.11 Pitch Adjustment ................................................................................ 27

3.12 Emergency Shutdown Procedure ....................................................... 27

4 Maintenance 28

4.1 Maintaining the Emission Control System .......................................... 28

4.2 Periodic Maintenance Schedule ......................................................... 29

4.3 Trowel Gearboxes .............................................................................. 30

4.4 Control Linkage Lubrication ................................................................ 31

4.5 Control Arm Adjustment (Forward or Backward) ................................ 32

4.6 Right-hand Control Arm Adjustment (Right or Left) ............................ 33

4.7 Mounting Float Pans .......................................................................... 33

wc_bo5200001020_02TOC.fm

7

Page 8

Table of Contents

4.8 Transporting the Machine ....................................................................34

4.9 Drive Belt .............................................................................................35

4.10 Battery Jump Start Procedure .............................................................36

4.11 Spark Plug ...........................................................................................37

4.12 Air Cleaner—CRT 36 ..........................................................................38

4.13 Engine Oil and Filter (Honda engine) ..................................................39

4.14 Engine Oil and Filter (Wacker Neuson engine) ...................................40

4.15 Storage ................................................................................................41

4.16 Troubleshooting ...................................................................................42

CRT 36

5 Technical Data 44

5.1 Engine .................................................................................................44

5.2 Trowel ..................................................................................................45

5.3 Sound and Vibration Specifications .....................................................46

6 Emission Control Systems

Information and Warranty—Gasoline 47

6.1 Emission Control System Background Information .............................47

6.2 Limited Defect Warranty for Exhaust Emission Control System .........48

6.3 Limited Defect Warranty for Wacker Neuson Evaporative

Emission Control Systems ..................................................................48

7 Schematics 51

7.1 Schematic Components ......................................................................52

8 AEM Safety Manual 53

8

wc_bo5200001020_02TOC.fm

Page 9

CRT 36 Safety Information

1 Safety Information

1.1 Signal Words Used in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and NOTE

signal words which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

f Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

f To avoid death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

f To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

f To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation

which, if not avoided, could result in property damage.

Note: A Note contains additional information important to a procedure.

wc_si000377gb.fm

9

Page 10

Safety Information CRT 36

1.2 Machine Description and Intended Use

This machine is a ride-on concrete finishing trowel. The Wacker Neuson Ride-On

Trowel consists of a frame onto which are mounted a gasoline or diesel engine, a

fuel tank, a water tank, two gearboxes joined by a drive shaft, and an operator’s

platform with controls and a seat. A set of metal blades is connected to each

gearbox. A ring guard surrounds the blades. The engine rotates the blades via the

gearboxes and a clutch mechanism. The rotating blades ride on the surface of

curing concrete, creating a smooth finish. The operator, who sits on the operator’s

platform, uses the controls and the throttle pedal to control speed and direction of

the machine.

This machine is intended to be used for floating and burnishing curing concrete.

This machine has been designed and built strictly for the intended use described

above. Using the machine for any other purpose could permanently damage the

machine or seriously injure the operator or other persons in the area. Machine

damage caused by misuse is not covered under warranty.

The following are some examples of misuse:

Using the machine as a ladder, support, or work surface

Using the machine to carry or transport passengers or equipment

Using the machine to finish inappropriate materials such as slurries, sealers, or

epoxy finishes

Operating the machine outside of factory specifications

Operating the machine in a manner inconsistent with all warnings found on the

machine and in the Operator’s Manual

This machine has been designed and built in accordance with the latest global

safety standards. It has been carefully engineered to eliminate hazards as far as

practicable and to increase operator safety through protective guards and labeling.

However, some risks may rema in even after protective measures have been t aken.

They are called residual risks. On this machine, they may include exposure to:

Heat, noise, exhaust, and carbon monoxide from the engine

Chemical burns from the curing concrete

Fire hazards from improper refueling techniques

Fuel and its fumes, fuel spillage from improper lifting technique

Personal injury from improper lifting techniques

Cutting hazards from sharp or worn blades

To protect yourself and others, make sure you thoroughly read and understand the

safety information presented in this manual before operating the machine.

10

wc_si000377gb.fm

Page 11

CRT 36 Safety Information

1.3 Operating Safety

Familiarity and proper training are required for the safe operation of the machine.

Machines operated improperly or by untrained personnel can be hazardous. Read

the operating instructions contained in this manual and the engine manual, and

WARNING

Operator

qualifications

Personal

Protective

Equipment

(PPE)

familiarize yourself with the location and proper use of all controls. Inexperienced

operators should receive instruction from someone familiar with the machine

before being allowed to operate it.

Only trained personnel are permitted to start, operate, and shut down the machine.

They also must meet the following qualifications:

have received instruction on how to properly use the machine

are familiar with required safety devices

The machine must not be accessed or operated by:

children

people impaired by alcohol or drugs

Wear the following Personal Protective Equipment (PPE) while operating this

machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

Never operate this machine in applications for which it is not intended.

Do not allow anyone to operate this equipment without proper training. People

operating this equipment must be familiar with the risks and hazards associated

with it.

Do not touch the engine or muffler while the engine is on or immediately after it

has been turned off. These areas get hot and may cause burns.

Do not operate the machine with unapproved accessories or attachments.

Do not operate the machine with the beltguard missing. Exposed drive belt and

pulleys create potentially dangerous hazards that can cause serious injuries.

Do not leave the machine running unattended.

Do not run the machine indoors or in an enclosed area such as a deep trench

unless adequate ventilation, through such items as exhaust fans or hoses, is

provided. Engine exhaust contains carbon monoxide. This is a poison you

cannot see or smell. Exposure to carbon monoxide can cause loss of

consciousness and CAN KILL YOU IN MINUTES.

ALWAYS remain aware of moving parts and keep hands, feet, and loose

clothing away from the moving parts of the machine.

Always wear protective clothing appropriate to the job site when operating the

machine.

Read, understand, and follow procedures in the Operator’s Manual before

attempting to operate the machine.

Be sure operator is familiar with proper safety precautions and operation

techniques before using machine.

Close fuel valve on engines equipped with one when machine is not being

operated.

wc_si000377gb.fm

11

Page 12

Safety Information CRT 36

Store the machine properly when it is not being used. The machine should be

stored in a clean, dry location out of the reach of children.

Always operate the machine with all safety devices and guards in place and in

working order.

1.4 Operator Safety while Using Internal Combustion Engines

WARNING

Internal combustion engines present special hazards during operation and fueling.

Failure to follow the warnings and safety standards could result in severe injury or

death.

f Read and follow the warning instructions in the engine owner’s manual and the

safety guidelines below.

DANGER

Exhaust gas from the engine contains carbon monoxide, a deadly poison.

Exposure to carbon monoxide can kill you in minutes.

f NEVER operate the machine inside an enclosed area, such as a tunnel, unless

adequate ventilation is provided through such items as exhaust fans or hoses.

Operating

safety

Refueling

safety

When running the engine:

Keep the area around exhaust pipe free of flammable materials.

Check the fuel lines and the fuel tank for leaks and cracks before starting the

engine. Do not run the machine if fuel leaks are present or the fuel lines are

loose.

When running the engine:

Do not smoke while operating the machine.

Do not run the engine near sparks or open flames.

Do not touch the engine or muffler while the engine is running or immediately

after it has been turned off.

Do not operate a machine when its fuel cap is loose or missing.

Do not start the engine if fuel has spilled or a fuel odor is present. Move the

machine away from the spill and wipe the machine dry before starting.

When refueling the engine:

Clean up any spilled fuel immediately.

Refill the fuel tank in a well-ventilated area.

Reinstall the fuel tank cap after refueling.

Do not smoke.

Do not refuel a hot or running engine.

Do not refuel the engine near sparks or open flames.

Use suitable tools for refueling (for example, a fuel hose or funnel).

Do not refuel if the machine is positioned in a truck fitted with a plastic bed liner.

Static electricity can ignite the fuel or fuel vapors.

12

wc_si000377gb.fm

Page 13

CRT 36 Safety Information

1.5 Service Safety

A poorly maintained machine can become a safety hazard! In order for the

machine to operate safely and properly over a long period of time, periodic

maintenance and occasional repairs are necessary.

WARNING

Service

training

Personal

Protective

Equipment

(PPE)

Before servicing or maintaining the machine:

Read and understand the instructions contained in all manuals delivered with

the machine.

Familiarize yourself with the location and proper use of all controls and safety

devices.

Only trained personnel shall troubleshoot or repair problems occurring with the

machine.

Contact Wacker Neuson for additional training if necessary.

When servicing or maintaining this machine:

Do not allow improperly trained people to service or maintain the machine.

Personnel servicing or maintaining the machine must be familiar with the

associated potential risks and hazards.

Wear the following Personal Protective Equipment (PPE) while servicing or

maintaining this machine:

Close-fitting work clothes that do not hinder movement

Safety glasses with side shields

Hearing protection

Safety-toed footwear

In addition, before servicing or maintaining the machine:

Tie back long hair.

Remove all jewelry (including rings).

wc_si000377gb.fm

Do not attempt to clean or service the machine while it is running. Rot ating part s

can cause severe injury.

Do not crank a flooded engine with the spark plug removed on gasoline-

powered engines. Fuel trapped in the cylinder will squirt out the spark plug

opening.

Do not test for spark on gasoline-powered engines if the engine is flooded or the

smell of gasoline is present. A stray spark could ignite the fumes.

Do not use gasoline or other types of fuels or flammable solvents to clean parts,

especially in enclosed areas. Fumes from fuels and solvents can become

explosive.

ALWAYS turn engine off and remove key from machine before performing

maintenance or making repairs.

Handle blades carefully. The blades can develop sharp edges which can cause

serious cuts.

Keep the area around the muffler free of debris such as leaves, paper, cartons,

etc. A hot muffler could ignite the debris and start a fire.

13

Page 14

Safety Information CRT 36

When replacement parts are required for this machine, use only Wacker

Neuson replacement parts or those p arts equivalent to the original in all types of

specifications, such as physical dimensions, type, strength, and material.

Disconnect the spark plug on machines equipped with gasoline engines, before

servicing, to avoid accidental start-up.

ALWAYS switch off the power supply at the battery disconnect before adjusting

or maintaining the electrical equipment.

Keep the machine clean and labels legible. Replace all missing and hard-to-

read labels. Labels provide important operating instructions and warn of

dangers and hazards.

14

wc_si000377gb.fm

Page 15

CRT 36 Labels

2 Labels

2.1 Label Locations

D

J

B

C

wc_si000378gb.fm 15

Page 16

Labels CRT 36

16 wc_si000378gb.fm

Page 17

CRT 36 Labels

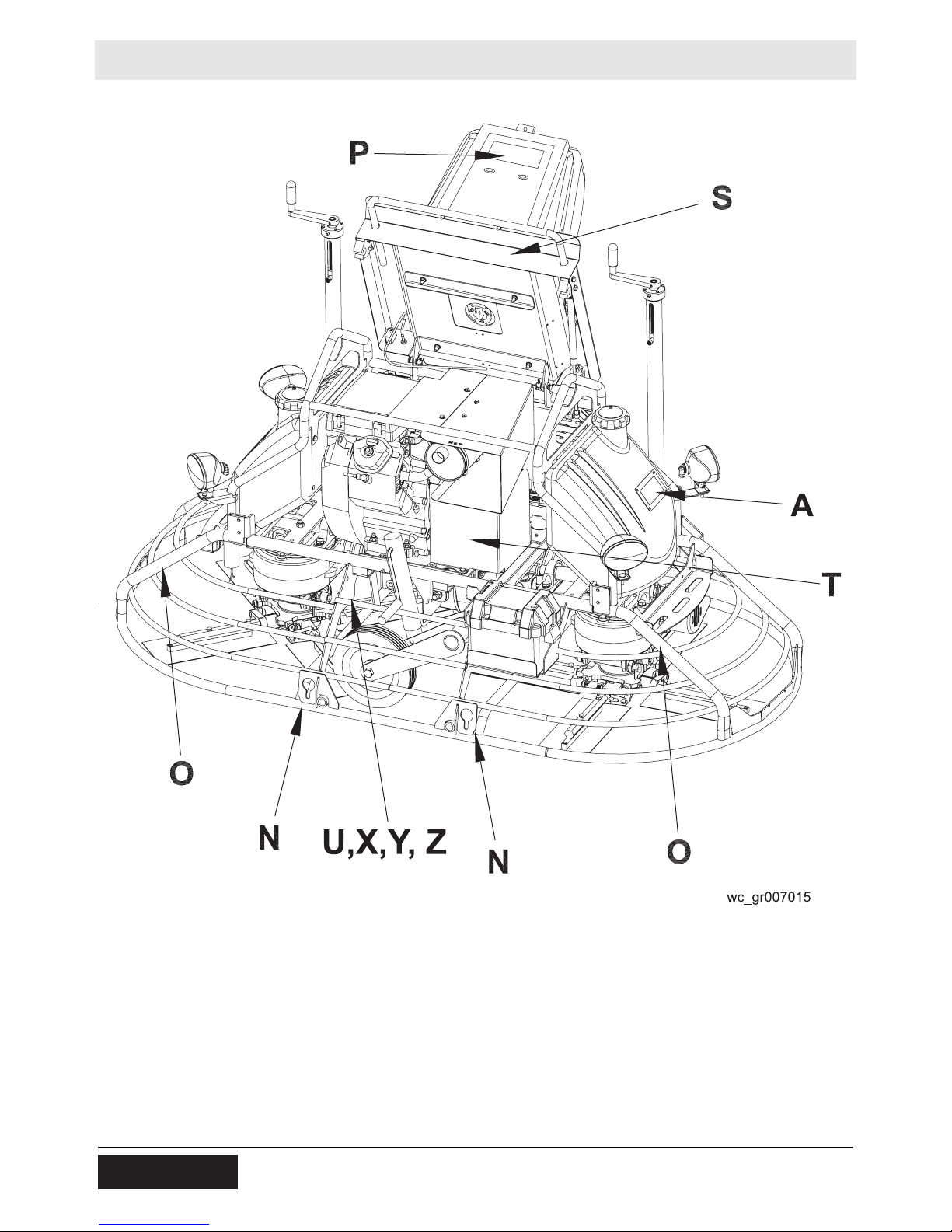

178745

2.2 Label Meanings

A

B

DANGER

Asphyxiation hazard.

Engines emit carbon monoxide.

Do not run the machine indoors or in an enclosed

area unless adequate ventilation, through such items

as exhaust fans or hoses, is provided.

Read the Operator’s Manual.

No sparks, flames, or burning objects near the

machine.

Stop the engine before refueling.

WARNING

To reduce the risk of hearing loss and eye injury , always

wear hearing protection and eye protection when

operating this machine.

178745

C

D

E

Positions of the key switch:

ON

OFF

Engine crank

Steering control:

Push both levers forward to move forward

Pull both levers backward to move rearward

Push the left lever forward and pull the right lever

backward to rotate clockwise

Pull the left lever backward and push the right lever

forward to rotate counterclockwise

Move both levers to the left to move left

Move both levers to the right to move right

Check engine oil level.

wc_si000378gb.fm 17

Page 18

Labels CRT 36

K

L

J

Read and understand the supplied Operator’s Manual

before operating the machine. Failure to do so

increases the risk of injury to yourself and others.

Pitch control:

To increase pitch: Rotate the left pitch control clockwise,

rotate the right pitch control counterclockwise.

To decrease pitch: Rotate the left pitch control

counterclockwise, rotate the right pitch control clockwise

NOTICE

Lifting point

N

O

Tie-down point

WARNING

Cutting hazard. Keep hands and feet away from moving

blade.

18 wc_si000378gb.fm

Page 19

CRT 36 Labels

P

S

Operator’s Manual must be stored on machine.

Replacement Operator’s Manual can be ordered

through your local Wacker Neuson distributor.

WARNING

Hot surface

T

U

W

WARNING!

Entanglement hazard. Keep hands away from spinning

belt and pulley.

Emission Control Information

This equipment meets U.S. EPA EVAP standards.

Evaporative Family: CW1XNHEQCL2

Exempt from tank permeation standards under 40 CFR

1054.145.

Water tank fill. Use only clean water or water-based

retardants.

wc_si000378gb.fm 19

Page 20

Labels CRT 36

--

R e m o v e p a n f r o m t r o w e l b e f o r e l i f t i n g m a c h i n e

o v e r h e a d .

P a n s c a n f a l l a n d c a u s e d e a t h o r s e r i o u s i n j u r y i f

a p e r s o n i s h i t .

G l e i t s c h e i b e v o m B e t o n g l ä t t e r e n t f e r n e n b e v o r

d a s G e r ä t u b e r K o p f h ö h e g e h o b e n w i r d .

G l e i t s c h e i b e k a n n f a l l e n u n d s c h w e r e V e r l e t z u n g

o d e r T o d v e r u r s a c h e n w e n n P e r s o n a l g e t r o f f e n w i r d .

Q u i t e e l d i s c o d e f l o t a c i ó n a n t e s d e l e v a n t a r l a

m á q u i n a a l i s a d o r a d e h o r m i g ó n .

L o s d i s c o s p o d r í a n c a e r y m a t a r o l a s t i m a r

s e r i a m e n t e a u n a p e r s o n a q u e s e e n c u e n t r e c e r c a .

A v a n t d e l e v e r l a p p a r e i l a u - d e s s u s d e v o t r e t ê t e ,

ô t e r l e d i s q u e d e t a l o c h a g e d e l a t r u e l l e .

L e d i s q u e d e t a l o c h a g e p e u t t o m b e r e t e n t r a î n e r

d e g r a v e s b l e s s u r e s o u m ê m e l a m o r t .

1 1 8 6 8 8

--

WARNING

Remove pan from trowel before lifting machine overhead. Pans can fall and cause death or serious injury if

a person is hit. (Label is located on top side of float pan.)

Use only Glygoyle 460 gear oil in gearbox.

WACKER NEUSON

--

A nameplate listing the model number, item number,

revision number, and serial number is attached to each

unit. Please record the information found on this nameplate so it will be available should the nameplate

become lost or damaged. When ordering parts or

requesting service information, you will always be asked

to specify the model number, item num ber, revision

number, and serial number of the unit.

--

This machine may be covered by one or more patents.

20 wc_si000378gb.fm

Page 21

CRT 36 Operation

3 Operation

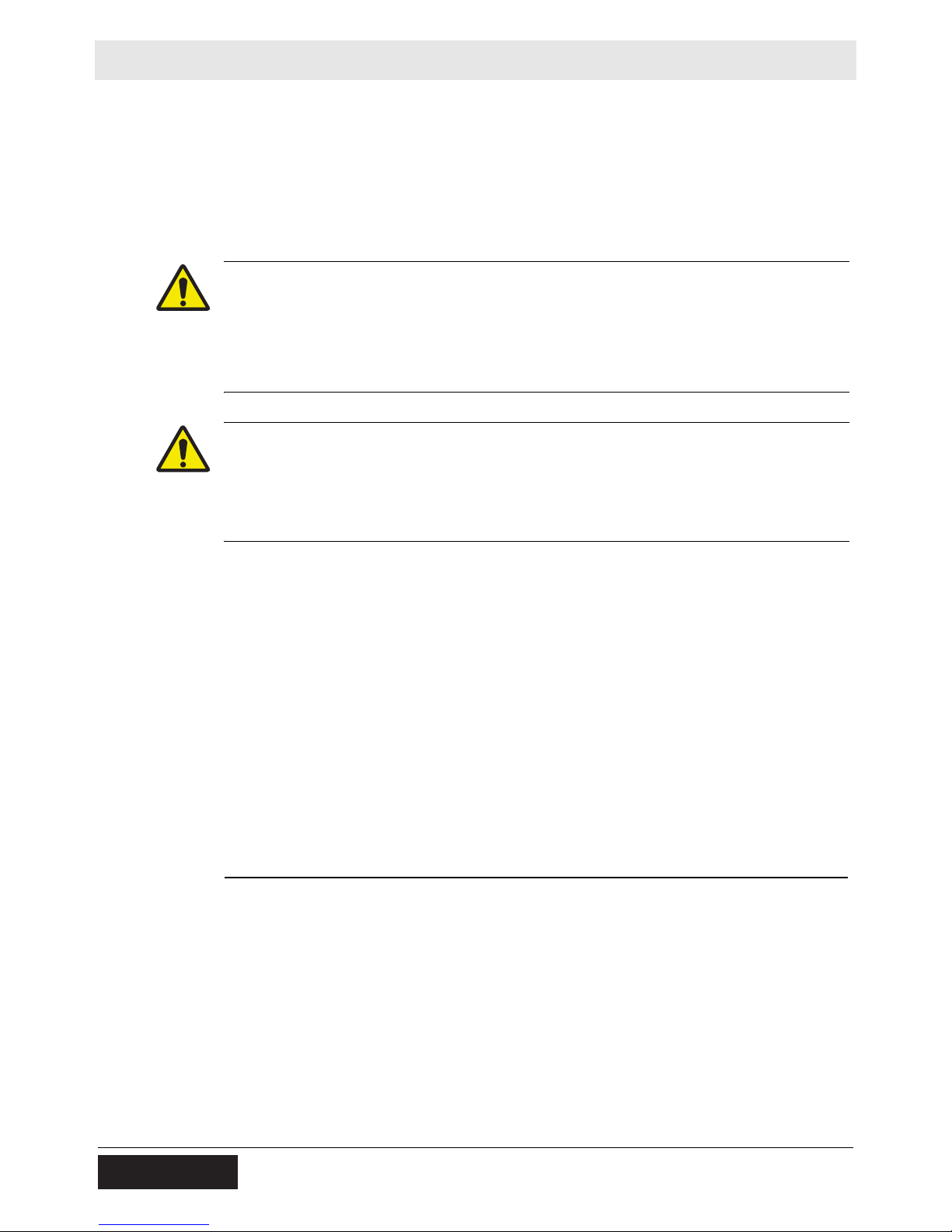

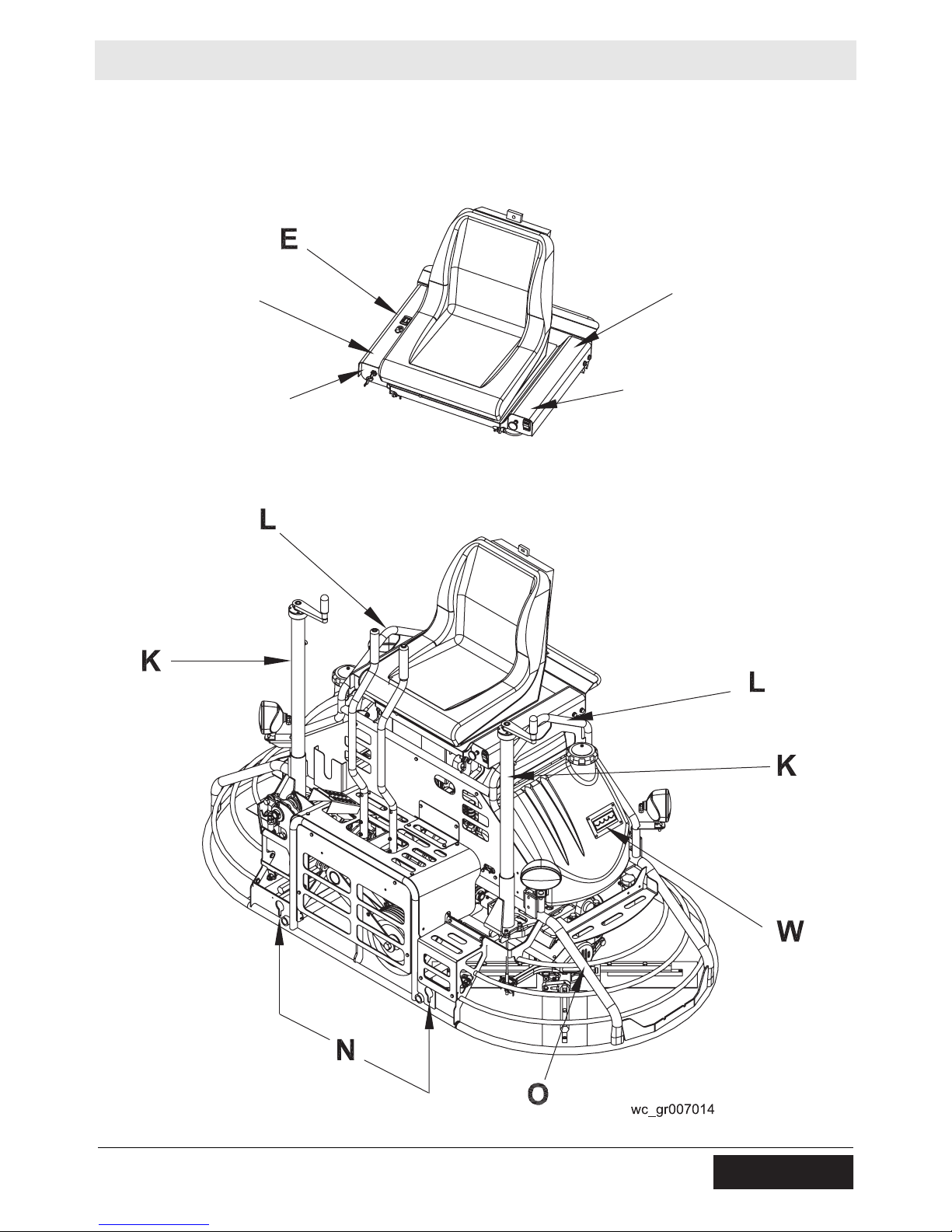

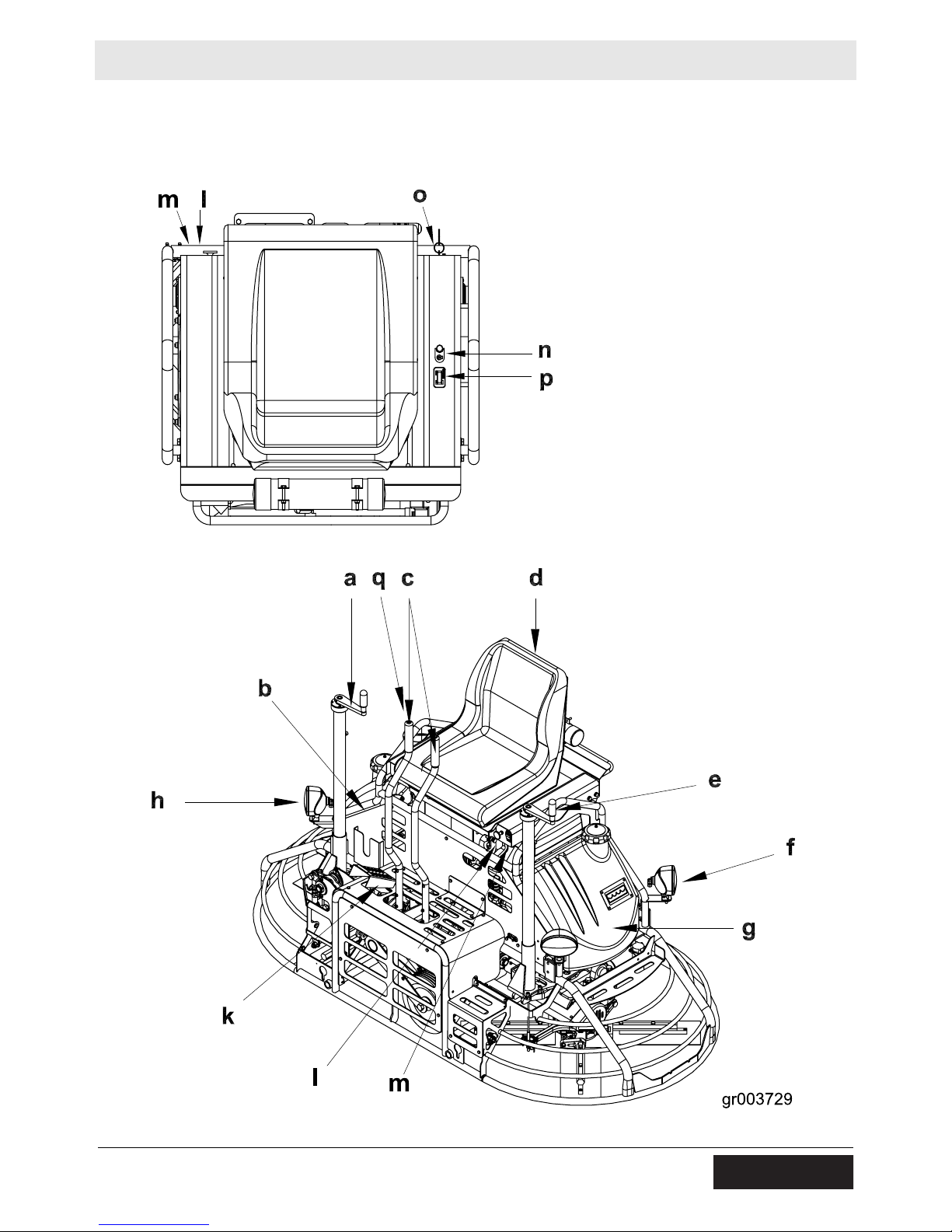

3.1 Features and Controls

wc_tx000639gb.fm

21

Page 22

Operation CRT 36

Control locations and functions:

Ref. Description Ref. Description

a Right pitch control k Foot pedal (throttle control)

b Fuel tank l Engine choke control

c Control arms m Work light switch

d Operator’s seat with “operator pres-

n Oil pressure indicator light

ence” switch

e Left pitch control o Engine keyswitch

f Rear work light (one each side) p Hour meter

g Water tank q Water spray control

h Work light (one each side) — —

The Ride-On Trowel features a seat with an integrated “operator presence”

system, which works in conjunction with a throttle mounted switch. This system

allows the engine to remain running (idling) with no operator seated in the seat, as

long as the throttle is not depressed. This system meets all safety requirements

and eliminates the need for a foot-operated “kill switch”.

To familiarize a new operator with the Ride-On Trowel the following steps should

be taken:

1. With the operator in the seat, show him or her the functions of the control arms

(c) and how to start the machine.

2. Have the operator practice steering the trowel. A hard concrete slab slightly

wetted with water is an ideal place for an operator to practice with the machine.

For this practice, pitch the blades up approximately ¼" on the leading edge.

Start by making the machine hover in one spot, and then practice driving the

machine in a straight line and making 180° turns. The best control is achieved

at full rpm.

22

wc_tx000639gb.fm

Page 23

CRT 36 Operation

3.2 Position of the Operator

Safe and efficient use of this machine is the op erator’s responsibility. Full control of

the machine is not possible unless the operator maintains the proper working

position at all times.

While operating this machine the operator must:

be seated in the operator’s seat facing forward

have both feet on the control deck

have both hands on the controls

3.3 Preparing the Machine for First Use

1. Make sure all loose packaging materials have been removed from the machine.

2. Check the machine and its components for damage. If there is visible damage,

do not operate the machine! Contact your Wacker Neuson dealer immediately

for assistance.

3. Take inventory of all items included with the machine and verify that all loose

components and fasteners are accounted for.

4. Attach component parts not already attached.

5. Add fluids as needed and applicable, including fuel, engine oil, and battery acid.

6. Move the machine to its operating location.

3.4 Recommended Fuel

The engine requires regular grade unleaded gasoline. Use only fresh, clean

gasoline. Gasoline containing water or dirt will damage the fuel system. Consult the

engine owner’s manual for complete fuel specifications.

Use of

oxygenated

fuels

Some conventional gasolines are blended with alcohol. These gasolines are

collectively referred to as oxygenated fuels. If you use an oxygenated fuel, be sure

it is unleaded and meets the minimum octane rating requirement.

Before using an oxygenated fuel, confirm the fuel’s contents. Some states and

provinces require this information to be posted on the fuel pump.

The following is the Wacker Neuson approved percentage of oxygenates:

ETHANOL - (ethyl or grain alcohol) 10% by volume. You may use gasoline

containing up to 10% ethanol by volume (commonly referred to as E10). Gasoline

containing more than 10% ethanol (such as E15, E20, or E85) may not be used

because it could damage the engine.

If you notice any undesirable operating symptoms, try another service station, or

switch to another brand of gasoline.

Fuel system damage or performance problems resulting from the use of an

oxygenated fuel containing more than the percentages of oxygenates mentioned

above are not covered under warranty.

wc_tx000639gb.fm

23

Page 24

Operation CRT 36

3.5 Break-in Period

1. To break in the gearboxes, run the engine at 50% of full throttle for the first 2–4

hours. This will prevent premature wear and extend gear life.

NOTICE: Running the engine at full throttle during the break-in period could result

in premature gear failure.

2. Verify that the horizontal blade pitch links are properly assembled. When

seated on the machine, the right rotor should have an “R” designation located

towards the upper portion of the pitch link and the left rotor should have an “L”.

3.6 Before Starting

Before starting the trowel, check the following:

fuel level

oil level in the engine

condition of the air filter

condition of trowel arms and blades

Grease the trowel arms daily.

wc_gr001252

24

wc_tx000639gb.fm

Page 25

CRT 36 Operation

3.7 Starting

Before starting the operator must know the location and function of all controls.

1. Push down on the throttle foot pedal, turn the engine keyswitch (o), and hold it

until the engine starts.

Note: If the engine is cold, pull out the choke control knob fully. The choke may

need to be opened even when starting a warm engine.

NOTICE: Cranking the engine for more than 5 seconds can cause st arter damage.

If the engine fails to start, release the keyswitch and wait 10 seconds before

operating the starter again.

Note: The engine has an oil alert light to notify operator if the oil pressure is low. If

engine will not start, or stops during operation, check engine oil level.

2. Allow the engine to warm up before operating the trowel.

3.8 Stopping

To stop trowel movement, return control levers to their neutral position and release

pressure on the throttle foot pedal.

To stop the engine, turn the keyswitch to “O” (off).

3.9 Operation

To utilize your Wacker Neuson Ride-On Trowel to its fullest capacity, the machine

should be driven in the direction that the operator is facing. This will finish the

widest possible area, while giving the operator an excellent view of the slab surface

about to be troweled. When the machine reaches the end of the slab, make a 180°

U-turn, and repeat the straight line of direction to the other end of the slab.

Note: During the break-in period, run the engine at 50% of full throttle. Refer to

Section New Machines.

NOTICE: DO NOT use excessive pressure on the control levers. Excessive

pressure does not improve the reaction time of the machine and can damage the

steering controls.

NOTICE: Attempting to use the trowel too early in the curing stage of the concrete

may result in an undesirable finish. Only experienced concrete finishers should

operate the trowel.

wc_tx000639gb.fm

25

Page 26

Operation CRT 36

3.10 Steering

Refer to the illustration for the necessary hand motions to move the trowel in the

desired direction, described below.

1 - forward

2 - reverse

3 - rotate clockwise

4 - rotate counter-clockwise

5 - left sideways

6 - right sideways

1

2

43

56

wc_gr000146

26

wc_tx000639gb.fm

Page 27

CRT 36 Operation

3.11 Pitch Adjustment

When changing or setting the pitch (angle) of the trowel blades, slow the machine,

set the desired pitch on the left side of the machine, then adjust the right side to

match.

To increase pitch: Rotate the left pitch control (L) clockwise, rotate the right pitch

control (R) counterclockwise.

To decrease pitch: Rotate the left pitch control (L) counterclockwise, rotate the right

pitch control (R) clockwise.

Working Conditions

of Concrete

1. Wet surface working stage

2. Wet to plastic working stage

3. Semi-hard working stage

4. Hard finishing stage

(burnishing)

3.12 Emergency Shutdown Procedure

Procedure

If a breakdown or accident occurs while the machine is operating, follow the

procedure below:

1. Stop the engine.

2. Close the fuel valve.

3. Remove the machine from the job site using the wheel kit.

4. Clean concrete from the blades and the machine.

Suggested Working

Pitch

Flat (No Pitch)

Slight Pitch

Additional Pitch

Maximum Pitch

5. Contact the rental yard or machine owner for further instructions.

wc_tx000639gb.fm

27

Page 28

Maintenance CRT 36

4 Maintenance

4.1 Maintaining the Emission Control System

For machines sold in North America:

Normal maintenance, replacement, or repair of emission control devices and

systems may be performed by any repair establishment or individual; however,

warranty repairs must be performed by a dealer/service center authorized by

Wacker Neuson. The use of service parts that are not equivalent in performance

and durability to authorized parts may impair the effectiveness of the emission

control system and may have a bearing on the outcome of a warranty claim.

28

wc_tx000640gb.fm

Page 29

CRT 36 Maintenance

4.2 Periodic Maintenance Schedule

The table below lists basic machine maintenance. Tasks designated with check

marks may be performed by the operator. Tasks designated with square bullet

points require special training and equipment.

Refer to the engine operator’s manual for information on engine maintenance.

Grease trowel arms.

Check fuel level.

Check engine oil level.

Inspect air filter. Replace as needed.

Check external hardware.

Pressure wash all surfaces until free of

concrete.

Check oil level in gearboxes.

Grease gearbox, drive system and pitch posts

fittings.

Grease control linkage.

Check drive belt for wear.

2

1

Daily Every

20

hrs.

3

3

3

3

3

Every

50

hrs.

3

Every

100

hrs.

Every

200

hrs.

Every

300

hrs.

Change engine oil.

Check fuel filter.

Clean and check spark plug.

Replace oil filter.

Replace spark plug.

Replace fuel filter.

Replace oil in gearboxes.

1

Check engine oil twice daily (every 4 hours).

2

Pressure wash immediately after use.

wc_tx000640gb.fm

3

3

3

Change engine oil after first 20 hours of operation.

29

Page 30

Maintenance CRT 36

4.3 Trowel Gearboxes

Check the gearboxes for the correct oil level after every 20 hours of operation.

Change the gearbox oil every 300 hours.

To check the oil level:

Each CRT gearbox is equipped with two oil fill plugs. Remove one gearbox oil fill

plug (b). If the level is below the threads of the oil fill plug hole, add synthetic gear

oil through the opening. DO NOT overfill. Wipe the threads dry on both the gearbox

and the oil fill plug, apply Loctite 545 or equivalent to the oil fill plug threads,

replace the oil fill plug and torque to 16–20 Nm (12–15 ft.lbs.).

NOTICE: DO NOT mix types of gear oil. DO NOT overfill the gearbox with oil.

Damage to the gearbox may occur if oils are mixed, or if the gearbox is overfilled.

See Technical Data for oil quantity and type.

To change gearbox oil:

1. Place a container of sufficient capacity (approximately 3.8 l [1 gallon]) under

each gearbox.

2. Remove the gearbox oil drain plug (c) and allow the oil to drain out. It may be

necessary to remove the gearbox oil fill plug(s) to facilitate draining. After most

of the oil has drained out, tip the back of the trowel upwards to allow the

remaining oil to drain out.

3. After all the oil has drained out, wipe the threads dry on both the gearbox and

the oil drain plug, apply Loctite 545 or equivalent to the oil drain plug threads,

and replace the gearbox oil drain plug.

Note: Dispose of used gear oil in accordance with environmental protection

legislation.

4. With the trowel level, fill the gearbox with approximately 1.83 l (62 oz.) synthetic

gear oil through the oil fill plug as described above.

5. Wipe the threads dry on both the gearbox and the oil fill plug, apply Loctite 545

or equivalent to the oil fill plug threads, replace the oil fill plug(s), and torque all

plugs to 16-20 Nm (12–15 ft.lbs.).

Each gearbox has a pressure relief valve (a) which can become clogged over

time. Check or replace as needed. Failure to replace the valve can result in oil

leakage from the gearbox shaft seals.

30

wc_tx000640gb.fm

Page 31

CRT 36 Maintenance

4.4 Control Linkage Lubrication

The drive system, gearbox and pitch posts are equipped with several grease

fittings. Grease these fittings once a week, or every 20 hours, to prevent wear.

Use a general purpose grease and add one to two shots of grease at each fitting.

wc_tx000640gb.fm

31

Page 32

Maintenance CRT 36

4.5 Control Arm Adjustment (Forward or Backward)

The control arms should line up evenly . If ar ms appear out of adjustment, they can

be re-adjusted forward or backward as follows:

1. Loosen jam nuts (b).

2. Turn the vertical linkage (a) as follows:

Extend the linkage to adjust control levers forward. See section 4.5 before

extending linkage.

Shorten the linkage to adjust control levers backward.

3. After the arms have been adjusted to the desired position, tighten jam nuts (b).

NOTICE: Control arms are adjusted as part of the steering assist system.

Changing orientation of the control arms may affect steering effort.

32

wc_tx000640gb.fm

Page 33

CRT 36 Maintenance

4.6 Right-hand Control Arm Adjustment (Right or Left)

The arms should be set to be perfectly vertical. Should the arms come out of

adjustment, adjust as follows:

1. Loosen the jam nuts (d).

2. Drop the horizontal linkage (e) down to clear the bracket.

3. Shorten the linkage to move the control arms to the left.

4. Extend the linkage to move the control arms to the right.

5. After the control lever has been adjusted to the desired position, re assemble the

nut and the bolt (c) and tighten the jam nuts (d).

4.7 Mounting Float Pans

Certain applications may require the use of float pans. Optional float pans (a) are

available, and are used with the machines in the non-overlapping configuration

only.

To mount float pans:

Lift trowel off the ground with the engine off and position the pan against the

blades. Turn pan either to the right or left to engage clip angles (b) as shown.

Remember, the right-hand trowel blades turn counterclockwise; the left-hand

blades turn clockwise.

wc_gr000151

wc_tx000640gb.fm

33

Page 34

Maintenance CRT 36

4.8 Transporting the Machine

ALWAYS turn the engine off and remove the key from the machine before moving

or transporting machine.

WARNING

To hoist the trowel:

Attach a sling or chains through the lifting bars (a) on each side of the seat

pedestal.

NOTICE: Make sure the lifting device has enough weight-bearing capacity to lift

machine safely. Refer to section Technical Data.

DO NOT lift the trowel by the guard rings or any part of the trowel other than the

lifting fixture, as the component may fail, causing the trowel to fall, possibly injuring

WARNING

bystanders.

If equipped with the optional integrated wheel kit (b):

From the rear of machine, use the jack handle to raise the blades off the ground

76-102 mm (3-4 in.). Push the machine using the upper frame.

34

wc_tx000640gb.fm

Page 35

CRT 36 Maintenance

4.9 Drive Belt

To replace the drive belt:

1. Place the trowel on a flat, level surface with the blades pitched flat.

2. Turn engine off and disconnect battery.

3. Remove the beltguard.

4. Remove 2 bolts (a), washers (b) and nuts (c) from each bearing flange.

5. Remove the 4 bolts (d) holding each inside universal joint to the shaft fitting.

Remove universal joints and shims (if included) from ends of drive shaft.

6. Lift the drive pulley up far enough to slide belt past.

7. Remove the old belt and install a new one.

8. Reverse the procedure for assembly . Align the bearings and shaf t as straight as

possible. Adjust pulley offset and center distance to values as shown.

9. Torque the bearing bolts (a) to 99±10 ft.lbs. Torque the universal joint bolt s (d) to

10±1 ft.lbs.

wc_tx000640gb.fm

35

Page 36

Maintenance CRT 36

4.10 Battery Jump Start Procedure

Occasionally, it may be necessary to jump start a weak battery. If jump starting is

necessary, the following procedure is recommended to prevent starter damage,

battery damage, and personal injuries.

Jump starting a battery incorrectly can cause battery to explode, resulting in severe

personal injury or death. Do not smoke or allow ignition sources near the battery,

DANGER

WARNING

and do not jump start a frozen battery.

Electrical arcing can cause severe personal injury. Do not allow positive and

negative cable ends to touch.

1. Disconnect engine load.

2. Use a battery of the same voltage (12V) as is used with your engine.

3. Attach one end of the positive booster cable (red) to the positive (+) terminal of

the booster battery. Attach the other end to the positive terminal of your engine

battery.

4. Attach one end of the negative booster cable (black) to the negative (–)

terminal of the booster battery. Attach other end of negative cable to a solid

chassis ground on your engine.

NOTICE: Jump star ting in any other manner may result in damage to the battery or

the electrical system.

5. Push down on the throttle foot pedal, turn the engine keyswitch and hold it until

the engine starts.

NOTICE: Cranking the engine for more than 5 seco nds can cause st arter damage.

If the engine fails to start, release the keyswitch and wait 10 seconds before

operating the starter again.

NOTICE: When using lights or high amperage draw accessories, idle the engine

for a period of 20 minutes to bring the battery to charge state.

36

wc_tx000640gb.fm

Page 37

CRT 36 Maintenance

4.11 Spark Plug

Clean or replace spark plug as needed to ensure proper operation. Refer to the

engine Owner’s Manual.

Note: Refer to the Technical Data for the recommended spark plug type and the

electrode gap setting.

The muffler and engine cylinder become very hot during operation and remain hot

for a while after stopping the engine. Allow engine to cool before removing spark

WARNING

plug.

1. Remove spark plug and inspect it.

2. Replace plug if the insulator is cracked or chipped. Clean spark plug electrodes

with a wire brush.

3. Set the electrode gap (a)

4. Tighten spark plug securely.

NOTICE: A loose spark plug can become very hot and may cause engine damage.

wc_tx000640gb.fm

a

wc_gr012563

37

Page 38

Maintenance CRT 36

4.12 Air Cleaner—CRT 36

The engine is equipped with a dual element air cleaner. Service air cleaner

frequently to prevent carburetor malfunction.

NOTICE: NEVER run engine without air cleaner. Severe engine damage will occur .

NEVER use gasoline or other types of low flash point solvents for cleaning the air

cleaner. A fire or explosion could result.

WARNING

To service:

1. Remove air cleaner cover (a). Remove both elements (b, c) and inspect them

for holes or tears. Replace damaged elements.

2. Wash foam element (b) in solution of mild detergent and warm water. Rinse

thoroughly in clean water. Allow element to dry thoroughly.

Do not put oil on the foam element.

3. Tap paper element (c) lightly to remove excess dirt. Replace paper element if it

appears heavily soiled.

b

a

c

wc_gr008243

38

wc_tx000640gb.fm

Page 39

CRT 36 Maintenance

4.13 Engine Oil and Filter (Honda engine)

Drain oil while engine is still warm.

1. Remove oil fill cap (a) and drain plug (b) to drain oil.

Note: In the interests of environmental protection, place a plastic sheet and a

container under the machine to collect any liquid which drains off. Dispose of this

liquid in accordance with environmental protection legislation.

2. Install drain plug and tighten.

3. Fill engine crankcase with recommended oil to the upper limit mark on the

dipstick (c).

4. Install oil fill cap and dipstick securely.

5. Remove front pedestal panel to access oil filter. To replace the oil filter, remove

the installed oil filter after oil has been drained. Apply a thin coat of oil to the

rubber gasket of the replacement oil filter . Screw the filter on until it just contact s

the filter adapter, then turn it an additional 22.24 mm (7/8 in.) turn. Refill with oil

as described above.

a

c

b

wc_gr000155

WARNING

Most used oil contains small amounts of materials that can cause cancer and other

health problems if inhaled, ingested, or left in contact with skin for prolonged

periods of time.

f Take steps to avoid inhaling or ingesting used engine oil.

f Wash skin thoroughly after exposure to used engine oil.

wc_tx000640gb.fm

39

Page 40

Maintenance CRT 36

4.14 Engine Oil and Filter (Wacker Neuson engine)

Drain the oil while the engine is still warm. To drain oil:

1. Remove the filler cap (a) and drain cap (d). Drain oil into a suitable container.

Note: In the interests of environmental protection, place plastic sheeting and a

container under the machine to collect the liquid which drains off. Dispose of this

liquid properly.

2. Re-insert the drain cap and tighten.

3. Fill the engine with the recommended oil to the upper limit mark on the dipstick

(b). See section Technical Data for the oil quantity and type.

Burn hazard. Care must be taken when draining hot engine oil. Hot oil can burn!

WARNING

To change the filter:

1. Drain the engine oil. Remove used filter.

2. Before installing the new filter, lightly oil the filter gasket (c) with fresh, clean

engine oil. Screw the filter on by hand until the gasket makes contact, then

tighten an additional 7/8 turn.

3. Fill the engine with the recommended oil. See section Technical Data for oil

quantity and type.

4. Start and run the engine to check for leaks. Stop the engine. Recheck the oil

level and add oil if required. Refer to the engine owner’s manual.

a

c

b

d

WM 720

WARNING

Most used oil contains small amount s of materials that ca n cause can cer and other

health problems if inhaled, ingested, or left in contact with skin for prolonged

periods of time.

f Take steps to avoid inhaling or ingesting used engine oil.

f Wash skin thoroughly after exposure to used engine oil.

WM 650

d

wc_gr004396

40

wc_tx000640gb.fm

Page 41

CRT 36 Maintenance

4.15 Storage

When

Maintaining

the machine

Maintaining

the engine

Follow the procedures below if the machine is to be stored for more than 30 days.

To prepare the machine for long-term storage:

1. Drain the fuel tank and the water tank.

2. Change the engine oil.

3. Maintain the engine (see below).

4. Clean the entire trowel and engine compartment.

5. Remove dirt from the cooling fins on the engine cylinders and on the blower

housing.

6. Remove the battery from the machine and charge it periodically.

7. Cover the entire machine and place it in a dry protected area.

If your machine has a diesel engine, consult your engine owner’s manual for

maintenance instructions.

If your machine has a gasoline engine:

1. Disconnect the ignition wires from the spark plugs. Remove the spark plugs.

2. Pour approximately 30 ml (1 ounce) of SAE 30W oil into each engine cylinder

through the spark plug opening.

3. Reinstall the spark plugs, but leave the ignition wires disconnected to prevent

the engine from starting.

4. Crank the engine for one or two seconds to distribute the oil inside the engine

cylinders.

5. Reconnect the ignition wires.

wc_tx000640gb.fm

41

Page 42

Maintenance CRT 36

4.16 Troubleshooting

Problem Reason Remedy

Engine does not start. Engine problem. Consult engine manufacturer’s

service manual.

Machine out of balance; wobbling

excessively.

Poor handling; excessive range in

control lever movement.

Operator is over-steering. The movement of each gearbox is

controlled by “stops” to provide

the correct relationship of the

control arm movement to machine

movement. Excessive pressure

on control arms in any direction

will not improve reaction time and

can damage steering controls

causing machine to wobble.

Trowel arm(s) bent. Replace trowel arm(s).

Trowel blade(s) bent. Replace trowel blade(s).

Main shaft(s) bent due to machine

being dropped.

Worn bushings due to lack of

lubrication.

Control arm lever adjustment has

moved or control arm has been

bent.

Replace main shafts(s).

Replace bushings and lubricate at

least every 20 hours.

Reset control arm lever.

Lower control arm(s) bent. This

can be caused by dropping

machine.

42

Replace lower control arm(s). Use

lifting brackets and/or forklift

pockets provided on machine for

lifting.

wc_tx000640gb.fm

Page 43

CRT 36 Maintenance

Problem Reason Remedy

Machine does not move. Drive belt broken. Replace drive belt.

Va cu um between bottom of

blades and surface of concrete.

Key sheared in the main shaft. Replace damaged key.

Trowel noisy. Trowel blades have become

misaligned and are contacting

each other during rotation.

Sheared key. Check all keys in drive system.

Loose clutch. Tighten clutch.

Change pitch on blades to break

suction.

Replace damaged blades. Align

blades so that one set represents

a (+) and the other an (x) when

viewed from above.

wc_tx000640gb.fm

43

Page 44

Technical Data CRT 36

5 Technical Data

5.1 Engine

Engine Power Rating

Net power rating per SAE J1349. Actual power output may vary due to conditions

of specific use.

Part No.

CRT 36-26A CRT 36-25

Engine

Engine make Honda Wacker Neuson

Engine model GX690 WM720

Max. rated power @ rated speed

Displacement

Spark plug NGK ZFR5F

kW (Hp)

cm³ (in³)

16.6 (22.2)

@ 3600 rpm

18.6 (25)

@ 3600 rpm

690 (42) 720 (44)

NGK BPR4EY

DENSO KJ16CR

Electrode gap

Engine speed - operating

Engine speed - idle

Battery

Fuel

mm (in.)

rpm

rpm

V / size

type

0.70 (0.028)

3850

1400

12 / 340CCA

Regular unleaded gasoline

Fuel tank capacity

Fuel consumption

Running time

Clutch

Engine oil capacity

Engine lubrication

l (gal.)

l (qt.)/hr.

hrs.

type

l (qt.)

oil grade

44

24.6 (6.5)

9 (9.5)

3.3

Variable speed

2 (2.1) 1.9 (1.8)

SAE 10W30 API CF-4, CF, SJ

wc_td000187gb.fm

Page 45

CRT 36 Technical Data

5.2 Trowel

Part No.

Operating Weight

without wheel kit

with wheel kit

Dimensions (L x W x H)

Rotor Speed (range)

Blade Pitch (range)

Gearbox

Gearbox Lubrication

Driveshaft

Trowel

kg (lbs.)

mm

(in.)

rpm

degrees

type

type

l (oz.)

type

Operation

CRT 36-26A CRT 36-25

373 (830)

392 (865)

376 (835)

395 (870)

2042 x 1041 x 1372

(80 x 41 x 54)

25–165

0-25

heavy duty

Mobil Glygoyle 460

1.83 (62) each

splined universal joint

Troweling Width

with pans (non-overlapping)

without pans (non-overlapping)

Troweling Area

with pans (non-overlapping)

without pans (non-overlapping)

mm (in.)

m2 (ft2)

1975 (78)

1905 (75)

1.8 (19)

1.6 (18)

wc_td000187gb.fm

45

Page 46

Technical Data CRT 36

5.3 Sound and Vibration Specifications

The required sound specifications, per Annex I, Directive 2006/42/EC of the ECMachine Regulations, are:

Vibration

Uncertainties

the sound pressure level at operator’s location (L

and 91.7 dB(A) (CRT 36-25).

the guaranteed sound power level (L

): 104.7 dB(A) (CRT 36-26A) and 108.6

WA

dB(A) (CRT 36-25)

These sound values were determined according to ISO 3744 for the sound power

level (L

) and ISO 11204 for the sound pressure level (LpA) at the operator’s

WA

location.

The weighted effective acceleration value, determined accordin g to ISO 5349-1and

ISO 2631, is:

for whole body: 0.215 m/s2 (CRT 36-26A) and 0.316 m/s2 (CRT 36-25).

or hand/arm: 1.81 m/s2 (CRT 36-26A) and 1.72 m/s2 (CRT 36-25).

The sound and vibration specifications were obtained with the unit operating on

fully cured, water wetted concrete at nominal engine speed.

Hand-transmitted vibration was measured per ISO 5349-1. This measurement

2

includes an uncertainty of 1.5 m/sec

.

): 91.2 dB(A) (CRT 36-26A),

pA

Whole body vibration was measured per ISO 2631-1. This measurement includes

an uncertainty of 0.3 m/sec

2

.

46

wc_td000187gb.fm

Page 47

Emission Control Systems Information and Warranty—Gasoline

6 Emission Control Systems

Information and Warranty

—Gasoline

The Emission Control Warranty and associated information is valid only for the

U.S.A., its territories, and Canada.

6.1 Emission Control System Background Information

Introduction

Wacker Neuson spark-ignited engines/equipment must conform with applicable

Environmental Protection Agency (EPA) and the State of California emissions

regulations. There are two types of emissions that fall under these regulations: 1)

exhaust, and 2) evaporative. These regulations require that manufacturers warrant

the emission control systems for defects in materials and workmanship.

Furthermore, EPA and California regulations require all manufacturers to furnish

written instructions describing how to operate and maintain the e ngines/equipment

including the emission control systems. This information is provided with all

Wacker Neuson engines/equipment at the time of purchase.

Exhaust Emissions

The combustion process produces carbon monoxide, oxides of nitrogen, and

hydrocarbons. Control of hydrocarbons and oxides of nitrogen is very important

because, under certain conditions, they react to form photochemical smog when

subjected to sunlight. Carbon monoxide does not react in the same way, but it is

toxic.

Wacker Neuson utilizes lean carburetor settings and other systems to reduce the

emissions of carbon monoxide, oxides of nitrogen, and hydrocarbons.

Evaporative Emissions

Evaporative emissions are fuel emissions and generally include emissions that

result from permeation of fuel through the fuel-system materials or from ventilation

of the fuel system.

Wacker Neuson utilizes low-permeation fuel lines and fuel tanks where applicable

to reduce evaporative emissions.

Problems that may affect Emissions

If any of the following symptoms arise, have the engine/equipment inspected and

repaired by a Wacker Neuson dealer/service center.

Hard starting or stalling after starting

Rough idling

Misfiring or backfiring under load

Afterburning (backfiring)

Presence of black exhaust smoke during operation

High fuel consumption

wc_tx001754gb.fm 47

Page 48

Emission Control Systems Information and Warranty—Gasoline

Tampering and Altering

Tampering with or altering the emission control system may increase emissions

beyond the legal limit. If evidence of tamp ering is found, Wacker Neuson may deny

a warranty claim. Among those acts that constitute tampering are:

Removing or altering of any part of the air intake, fuel, or exhaust systems.

Altering or defeating the speed-adjusting mechanism causing the engine to

operate outside its design parameters.

6.2 Limited Defect Warranty for Exhaust Emission Control System

See the supplied engine owner’s manual for the applicable emission warranty

statement.

6.3 Limited Defect Warranty for Wacker Neuson Evaporative

Emission Control Systems

The Emission Control Warranty is valid only for the U.S.A., its territories, and

Canada.

Wacker Neuson Sales Americas, LLC, N92 W15000 Anthony Avenue,

Menomonee Falls, WI 53051, (hereinafter “Wacker Neuson”) warrants to the initial

retail purchaser and each subsequent owner, that this engine/equipment, including

all parts of its evaporative emission cont rol system, have bee n designed, built, and

equipped to conform at the time of initial sale to all applicable evaporative emission

regulations of the U.S. Environmental Protection Agency (EPA), and that the

engine/equipment is free of defects in materials and workmanship which would

cause this engine/equipment to fail to conform to EPA regulations during its

warranty period.

Wacker Neuson is also liable for damages to other engine/equipment components

caused by a failure of any warranted parts during the warranty period.

Limited Defect Warranty Period for Wacker Neuson Evaporative

Emission Control Systems

The warranty period for this engine/equipment begins on the date of sale to the

initial purchaser and continues for a minimum of two (2) years. For the warranty

terms for your specific engine/equipment, visit wackerneuson.com.

Any implied warranties are limited to the duration of this written warranty.

What is covered

Wacker Neuson recommends the use of genuine Wacker Neuson parts, or the

equivalent, whenever maintenance is performed. The use of replacement parts not

equivalent to the original parts may impair the effectiveness of the engine/

equipment emission controls systems. If such a replacement part is used in the

repair or maintenance of the engine/equipment, assure yourself that such part is

warranted by its manufacturer to be equivalent to the parts offered by Wacker

Neuson in performance and durability. Furthermore, if such a replacement part is

48 wc_tx001754gb.fm

Page 49

Emission Control Systems Information and Warranty—Gasoline

used in the repair or maintenance of the engine/equipment, and an authorized

Wacker Neuson dealer/service center determines it is defective or causes a failure

of a warranted part, the claim for repair of the engine/equipment may be denied. If

the part in question is not related to the reason the engine/equipment requires

repair, the claim will not be denied.

For the components listed in the following table, an authorized Wacker Neuson

dealer/service center will, at no cost to you, make the necessary diagnosis, repair,

or replacement necessary to ensure that the engine/equipment complies with the

applicable EPA regulations. All defective parts replaced under this warranty

become property of Wacker Neuson.

System Covered Components

Evaporative emissions Fuel tank (if applicable)

Fuel tank cap (if applicable)

Fuel line (if applicable)

Fuel line fittings (if applicable)

Clamps (if applicable)

Carbon canister (if applicable)

Purge port connector (if applicable)

Miscellaneous parts associated with the

evaporative emission control system

Clamps

Gaskets

Mounting brackets

What is not covered

Failures other than those resulting from defects in material or workmanship.

Any systems or parts which are affected or damaged by owner abuse,

tampering, neglect, improper maintenance, misuse, improper fueling,

improper storage, accident and/or collision; the incorporation of, or any use

of, add-on or modified parts, or unsuitable attachments, or the alteration of

any part.

Replacement of expendable maintenance items made in connection with

required maintenance services after the item’s first scheduled replacement

as listed in the maintenance section of the engine/equipment operator’s

manual, such as spark plugs and filters.

Incidental or consequential damages such as loss of time or the use of the

engine/equipment, or any commercial loss due to the failure of the engine/

equipment.

Diagnosis and inspection charges that do not result in warranty-eligible

service being performed.

Any non-authorized replacement part, or malfunction of authorized p arts due

to use of-non authorized parts.

Owner’s Warranty Responsibility

The engine/equipment owner, is responsible for the performance of the required

maintenance listed in the Wacker Neuson engine/equipment operator’s manual.

wc_tx001754gb.fm 49

Page 50

Emission Control Systems Information and Warranty—Gasoline

Wacker Neuson recommends that all receipts covering maintenance on the

engine/equipment be retained, but Wacker Neuson cannot deny warranty

coverage solely for the lack of receipts or for the failure to ensure the performance

of all scheduled maintenance.

Normal maintenance, replacement, or repair of emission control devices and

systems may be performed by any repair establishment or individual; however,

warranty repairs must be performed by an authorized Wacker Neuson dealer/

service center.

The engine/equipment must be presented to an authorized W acker Neuson dealer/

service center as soon as a problem exists. Contact Wacker Neuson Product

Support Department (1-800-770-0957) or visit wackerneuson.com to find a dealer/

service center in your area, or to answer questions regarding warranty rights and

responsibilities.

How to Make a Claim

In the event that any emission-related part is found to be defective during the

warranty period, you shall notify Wacker Neuson Product Support Department

(1-800-770-0957, or technical.support@wackerneuson.com, or

wackerneuson.com), and you will be advised of the appropriate dealer/service

center where warranty repair can be performed. All repairs qualifying under this

limited warranty must be performed by an authorized Wacker Neuson dealer/

service center.

You must take your Wacker Neuson engine/equipment along with proof of original

purchase date, at your expense, to the authorized Wacker Neuson dealer/service

center during their normal business hours.

For owners located more than 100 miles from an authorized dealer/service center

(excluding the states with high-altitude areas as identified in 40 CFR Part 1068,

Appendix III), Wacker Neuson will p ay for pre-a pproved shipping cost s to and fro m

an authorized Wacker Neuson dealer/service center.

Claims for repair or adjustment found to be caused solely by defects in material or

workmanship will not be denied because the engine/equipment was not properly

maintained and used.

The warranty repairs should be completed in a reasonable amount of time, not to

exceed 30 days.

50 wc_tx001754gb.fm

Page 51

CRT 36 Schematics

7 Schematics

wc_tx001324gb.fm

51

Page 52

Schematics CRT 36

7.1 Schematic Components

Ref. Description Ref. Description

A Battery U Spray pump motor

B Oil pressure switch (dual circuit) V Engine connector

C Fuel pump W Fuel cut-off solenoid

D Fuel pump relay X Starter motor

E Key switch Y Engine crank solenoid

F Hour meter Z Glow plug fuse

G Oil pressure indicator light AA Relay—safety system

H Operator presence switch

(normally open)

J Throttle sense switch

(normally closed)

K Neutral relay DD Glow plug temperature sensors

L Right front light EE Glow plugs

M Right rear light FF Keyed power fuse

N Left rear light GG Temperature sensor

O Left front light HH Coils—ignition

P Fuse—spray system JJ Ignition module

Q Fuse—main KK Engine speed sensor

R Fuse—light circuit LL External voltage regulator

S Light switch MM Glow plug relay

T Spray pump switch — —

BB Voltage regulator

CC Alternator

(Honda engines only)

52

wc_tx001324gb.fm

Page 53

Page 54

SAFETY ALERT SYMBOL

This Safety Alert Symbol means

ATTENTION is required!

The Safety Alert Symbol identifies important safety

messages on machines, safety signs, in manuals

or elsewhere. When you see this symbol, be alert

to the possibility of personal injury or death. Follow

the instructions in the safety message.

Why is SAFETY important to YOU?

3 BIG REASONS

• Accidents KILL or DISABLE

• Accidents COST

• Accidents CAN BE AVOIDED

1

NOTICE OF COPYRIGHT PROTECTION

AEM Safety Manuals are protected as a copyrighted work with

ownership duly registered with the Copyright Office,

Washington, D.C. Any reproduction, translation, decompiling or

other use of an AEM Safety Manual, or portion thereof, or the

creation of derivative works based on an AEM Safety Manual,

without the prior written approval of AEM is expressly prohibited.

Copyright infringement can result in civil and criminal sanctions,

damages and other penalties being imposed.

Copyright © 2003 – Association of Equipment Manufacturers

!

Trowel.qxd 11/24/04 10:18 AM Page 1

U.S. Department of Labor publishes Safety and

Health Regulations and Standards under the

authority of the Occupational Safety and Health Act

for the General Construction and Mining Industries.

Its address is: U.S. Department of Labor,

Washington, DC 20210 (www.OSHA.gov and

www.MSHA.gov).

ANSI – American National Standards Institute, c/o

The American Society of Mechanical Engineers,

United Engineering Center, 345 East 47th Street,

New York, NY 10017 (www.ANSI.org).

ISO – International Standards Organization,

1, rue de Varembe Case postale 56, CH-1211

Geneva 20, Switzerland (www.ISO.ch).

SAE – Society of Automotive Engineers, Inc.,

400 Commonwealth Drive, Warrendale, PA 15096,

publishes a list, “Operator Precautions” SAE J153

MAY 87 (www.SAE.org).

AEM – Association of Equipment Manufacturers,

111 East Wisconsin Avenue, Milwaukee, WI 53202

(www.AEM.org).

WORD OF EXPLANATION

2

The following is a partial list of reference material on safe operating practices:

Trowel.qxd 11/24/04 10:18 AM Page 2

Page 55

3

TABLE OF CONTENTS

Page

WORD OF EXPLANATION ................................................................2

FOREWORD........................................................................................4

A WORD TO THE USER ....................................................................5

FOLLOW A SAFETY PROGRAM ......................................................6

PREPARE FOR SAFE OPERATION ..................................................7

START SAFELY ................................................................................11

WORK SAFELY ................................................................................13

SHUT DOWN SAFELY......................................................................15

LOAD AND UNLOAD SAFELY ........................................................16

PERFORM MAINTENANCE SAFELY ..............................................17

TEST YOUR KNOWLEDGE..............................................................22

A FINAL WORD TO THE USER........................................................23

Trowel.qxd 11/24/04 10:18 AM Page 3

This safety manual is intended to point out some of

the basic situations which may be encountered

during the normal operation and maintenance of

your walk-behind or ride-on concrete power trowel

and to suggest possible ways of dealing with these

conditions.

Additional precautions may be necessary,

depending on application and attachments used

and conditions at the work site or in the

maintenance area.

The trowel manufacturer has no direct control over

machine application, operation, inspection,

lubrication, or maintenance. Therefore, it is your

responsibility to use good safety practices in these

areas.

Do not use the trowel for any purpose other than its

intended purposes or applications.

The information provided in this manual

supplements the specific information about your

machine and its application that is contained in the

manufacturer’s manual(s).

Other information which may affect the safe

operation of your machine may be displayed on

safety signs, or in insurance requirements,

employer’s safety programs, safety codes, local,

state/provincial, and federal laws, rules, and

regulations.

If you do not understand any of this information, or

if errors or contradictions seem to exist, consult

with your supervisor before operating your trowel!

IMPORTANT: If you do not have the

manufacturer’s manual(s) for your particular

machine, get a replacement manual from your

employer, equipment dealer, or manufacturer of

your machine. Keep this safety manual and the

manufacturer’s manual(s) accessible to the

operator and maintenance personnel.

FOREWORD

4

Trowel.qxd 11/24/04 10:18 AM Page 4

Page 56

Remember that YOU are the key to safety. Good

safety practices not only protect you but also

protect the people around you. It is your

responsibility to study this manual and the

manufacturer’s manual(s) for your specific machine

before operating your machine. Make them a

working part of your safety program. Keep in mind

that this safety manual is written for concrete power

trowels only. Practice all other usual and customary

safe working precautions, and above all –

REMEMBER – SAFETY IS UP TO YOU

YOU CAN PREVENT SERIOUS

INJURY OR DEATH

A WORD TO THE USER

5

Trowel.qxd 11/24/04 10:18 AM Page 5

EQUIPMENT/CLOTHING

Consult your supervisor for specific instructions on

a job, and the personal safety equipment required.

For instance, you may need:

• Hard Hat

• Heavy Gloves

• Eye Protection

• Ear Protectors

• Safety Shoes

• Dust Mask or Respirator

Do not wear loose clothing or any accessory –

flopping cuffs, dangling neckties and scarves, or

jewelry – that can catch in moving parts.

DUST PRECAUTION

Some dust created by construction activities may

cause silicosis or respiratory harm.

Your risk of exposure varies depending on how

often you do this type of work. To reduce your risk,

work in a well ventilated area, use a dust control

system, and wear approved personal safety

equipment such as a dust/particle respirator

designed to filter out microscopic particles.

FOLLOW A SAFETY PROGRAM

6

Trowel.qxd 11/24/04 10:18 AM Page 6

Page 57

LEARN TO BE SAFE

• Read the operator’s