Page 1

www.wackergroup.com

Cut-Off Saws

BTS 930-8340

BTS 935-8341

BTS 1030-8339

BTS 1035-7975

REPAIR MANUAL

0118754en 005

0903

0118754EN

Page 2

Page 3

BTS Repair Table of Contents

wc_br0118754enTOC.fm 1

1. Technical Data 5

1.1 BTS 930 / BTS 935 / BTS 1030 / BTS 1035 ........................................ 5

2. Special Tools 6

3. Clutch 7

3.1 Dismantling the clutch/drum ................................................................. 7

3.2 Mounting muffler and heat plate ........................................................... 8

3.3 Repairing the clutch ........................................... ..... ..... .... ..................... 8

3.4 Mounting the clutch/drum ..................................................................... 9

4. Ignition System 10

4.1 Checking the spark plug ..................................................................... 10

4.2 Replacing the plug connector ............................................................. 11

4.3 Removing/assembling the ignition / short circuit cable ....................... 12

4.4 Removing/checking/mounting the ignition armature .......................... 14

4.5 Removing/mounting the flywheel ....................................................... 15

5. Starting System 16

5.1 Removing/mounting the starter / return spring ................................... 16

5.2 Pretensioning/checking the return spring ........................................... 17

5.3 Replacing the starter ratchet .............................................................. 17

6. Carburetor 18

6.1 Setting the carburetor ......................................................................... 18

6.2 Removing the carburetor and intake hose ......................................... 19

6.3 Carburetor - dismantling/testing the control side ................................20

6.4 Carburetor - dismantling/testing the pump side ..................................21

6.5 Carburetor - Cleaning the fuel filter ..... ..... ..... ..................................... 21

Page 4

Table of Contents BTS Repair

wc_br0118754enTOC.fm 2

7. Hood System / Air Filter / Winter Operation 22

7.1 Air Filter ...............................................................................................22

7.2 Winter Operation .................................................................................23

8. Front Handle / Vibration Absorbers 24

8.1 Removing and replacing the bracket handle .......................................24

8.2 Replacing the vibration absorbers .......................................................24

9. Fuel Tank / Fuel Filter 25

9.1 Removing/inserting the ventilation valve .............................................25

9.2 Replacing the throttle lever mechanism ..............................................25

9.3 Replacing the fuel pipe ........................................................................26

9.4 Testing the fuel filter ............................................................................26

10. Cylinder / Piston / Decompression Valve 27

10.1 Dismantling/mounting the cylinder / piston ..........................................27

10.2 Testing the decompression valve ........................................................28

11. Crankcase / Crankshaft 29

11.1 Crankcase / crankshaft ........................................................................29

12. Cutting Attachment 30

12.1 Replacing the pressure disc ................................................................30

12.2 Removing / mounting the V-belt pulley ................................................30

12.3 Replacing the drive axle ......................................................................31

12.4 Removing the complete pressure ring .................................................31

12.5 Cutter guard holding attachments .......................................................31

12.6 Replacing the guard stop ....................................................................32

12.7 Replacing the fixing screw ...................................................................32

Page 5

BTS Repair Table of Contents

wc_br0118754enTOC.fm 3

12.8 Removing / mounting the cutting device bearings .............................. 33

12.9 Adjusting the cutter guard holding attachment ................................... 34

12.10 Tensioning the V-belt ......................................................................... 34

13. Torques 35

13.1 BTS 930 / BTS 935 / BTS 1030 / BTS 1035 ...................................... 35

Page 6

Table of Contents BTS Repair

wc_br0118754enTOC.fm 4

Page 7

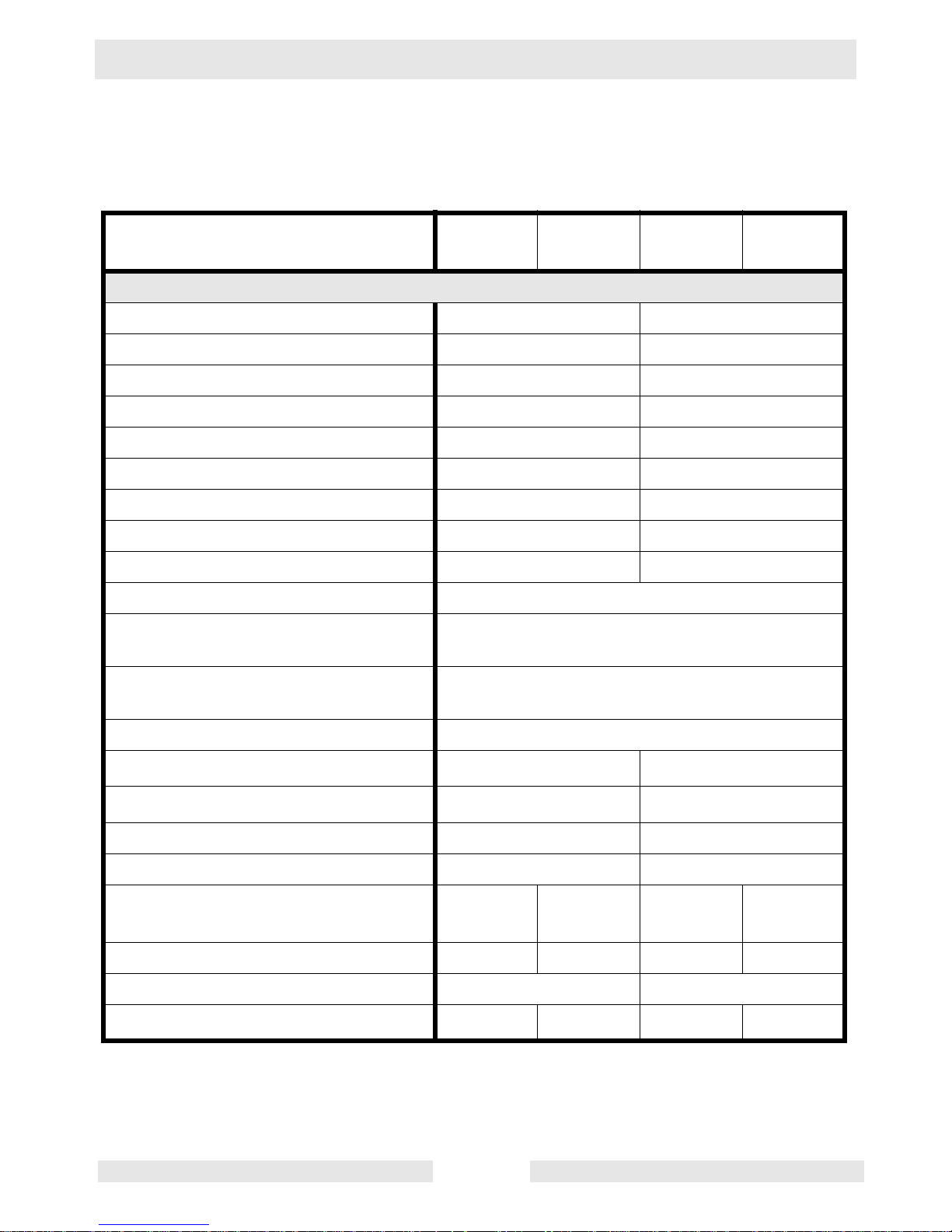

BTS Repair Technical Data

wc_td000126gb.fm 5

1. Technical Data

1.1 BTS 930 / BTS 935 / BTS 1030 / BTS 1035

Item No.

BTS 930

0008340

BTS 935

0008341

BTS 1030

0008339

BTS 1035

0007975

Saw

Displacement

cm³ (in³)

62 73

Bore

mm (in.)

47 (1.8) 50 (2.0)

Stroke

mm (in.)

37 (1.5) 37 (1.5)

Max. Power

kW (Hp)

3.3 (4.4) 4.2 (5.5)

Max. Torque

Nm

4.0 5.0

Idling Speed

rpm

2500 2500

Clutch engagement speed

rpm

3800 3800

Engine speed limitation

rpm

9350 9350

Max. spindle speed

rpm

4300 4300

Carburetor (diaphragm)

type

Tillotson HS-273 A

Ignition system

(with speed limitatio n)

type

electronic

Spark plug

type

NGK BPMR 7A / BOSCH WSR 6F /

CHAMPION RCJ 6Y

Electrode gap

mm (in.)

0.5 (0.020)

Fuel consumption

1)

l/h (qts./h)

1.85 (2) 2.36 (2.5)

Specific consumpti o n

1)

g/kWh

500 500

Fuel tank capacity

l (qts.)

1.1 (1.2) 1.1 (1.2)

Mixture ratio (fuel/two-stroke oil) 50:1 50:1

Cutting disc for 80 m/sec. 2)

(DSA approved)

mm

3)

300/20.0/5 350/24.5/5 300/20.0/5 350/24.5/5

Arbor diameter

mm

20.0 25.4 20.0 25.4

V-belt AVX 838 LA AVX 838 LA

Overall weight

4)

kg (lbs.)

9.7 (21) 9.9 (22) 9.8 (21) 10 (22)

1) At max. load per ISO 8893

2) Circumferance speed at max. engine speed

3) Outside diameter / arbor hole / thickness

4) tanks empty, without cutting disc.

Page 8

Special Tools BTS Repair

wc_tx000326gb.fm 6

2. Special Tools

Ref. Part Number Description

1. 0068900 Puller for flywheel

2. 0117570 Puller for oil seals

3. 0117573 Puller for ball bearing count er support

4. 0117569 Puller for ball bearing inside puller

5. 0117575 Set of piston ring tenson belt

6. 0117571 Piston stop wedge

7. 0117574 Mounting tool for clutch hub

3

5

6

1

2

7

wc_gr001381

Page 9

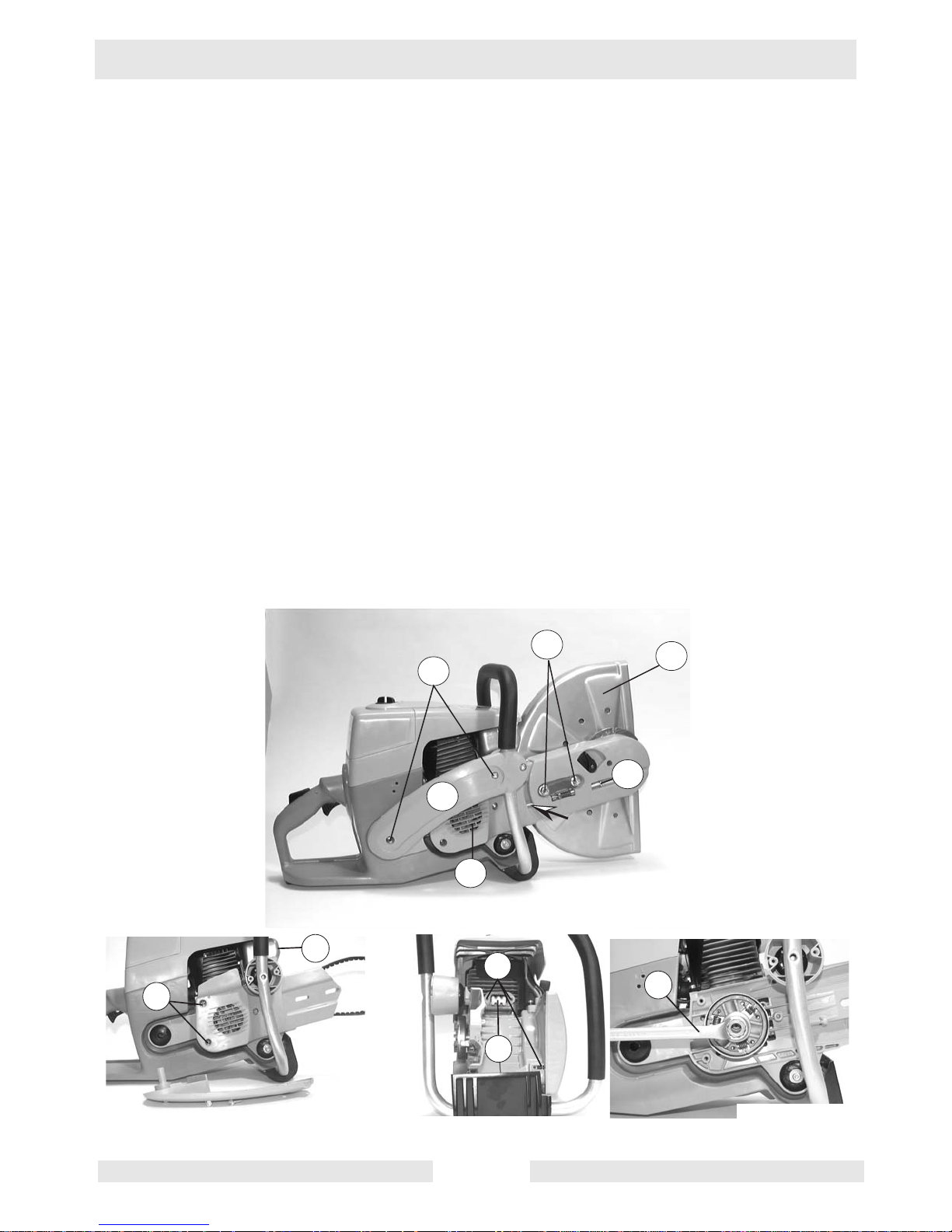

BTS Repair Clutch

wc_tx000298gb.fm 7

3. Clutch

3.1 Dismantling the clutch/drum

See Graphic: wc_gr001384 and wc_gr001385

3.1.1 To dismantle the clutch and drum, remove the cutting device (1), strut

(2) and V-belt cover (3).

3.1.2 To remove the cutting device, loosen the fixing screws (4). Remove

screw (5) to the point whe re the end of the screw projects from the

cover (arrow).

3.1.3 The side strut is fixed with 3 screws (7) to the tank and the collector for

the right upper damper device.

3.1.4 The cover for the V-belt is fixed to the crankcase with 3 screws (8).

3.1.5 To remove the clutch and drum, the piston must be blocked. To do this,

unscrew the 3 screws (9) fixing the muffler (10) and insert the piston

stop wedge (0117571) into the exhaust port of the cylinder (11).

3.1.6 Unscrew the clutch with the special tool (0117574) and a 19mm

wrench (a).

Note: left-handed thread.

7

4

2

1

3

5

wc_gr001384

9

11

a

8

10

wc_gr001385

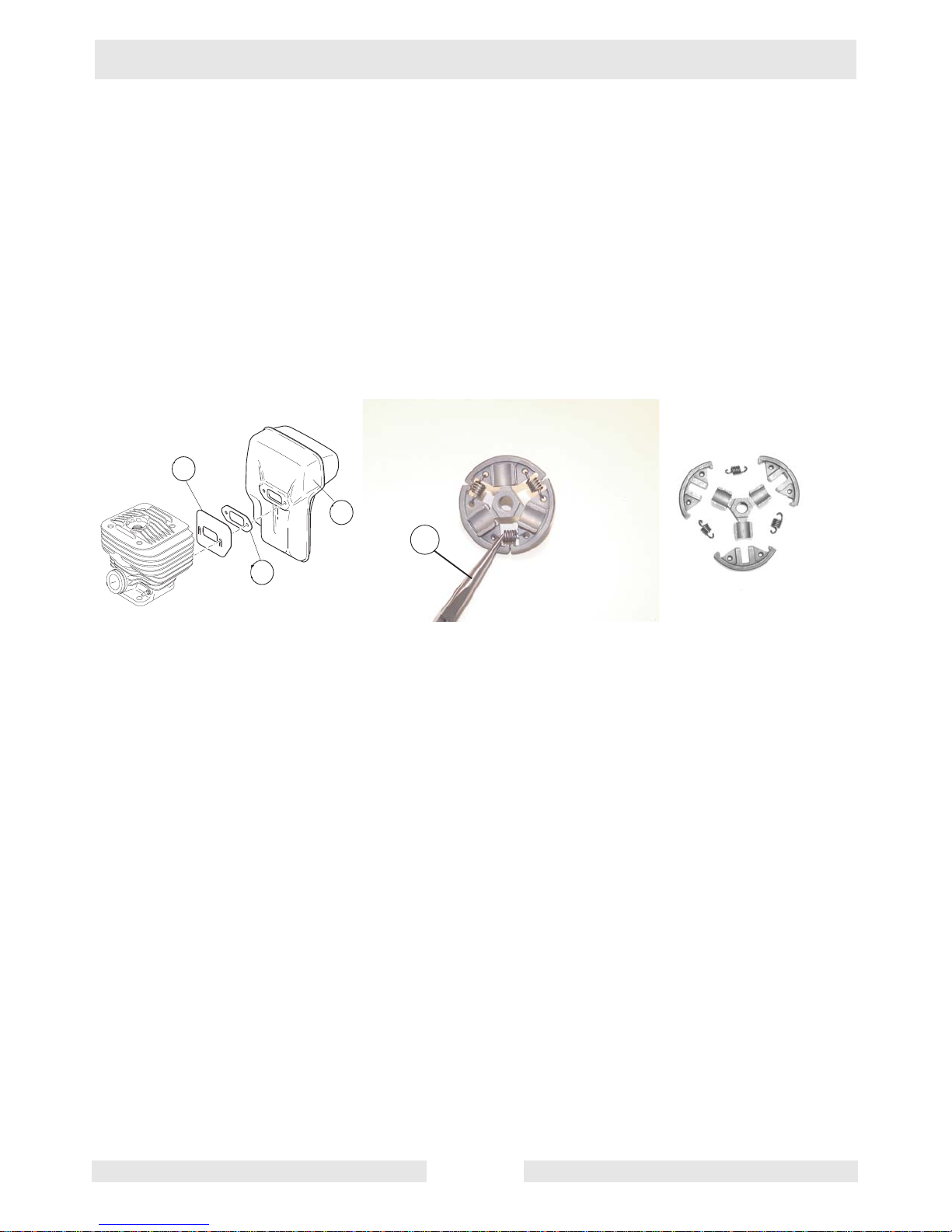

Page 10

Clutch BTS Repair

wc_tx000298gb.fm 8

3.2 Mounting muffler and heat plate

See Graphic: wc_gr001 38 6

When mounting the muffler (10) ensure that the heat plate (12) is

installed correctly.

Note: The heat plate goes directly onto the cylinder, then the gasket

(13) and muffler.

3.3 Repairing the clutch

See Graphic: wc_gr001 38 6

3.3.1 The tension springs of the clutch can be removed/ replaced with

pointed pliers (b). If spar es are requir ed, the 3 tension springs are onl y

available as individual parts.

3.3.2 The tension spring s shou ld on ly be re plac ed as a set if repl aceme nt is

required.

3.3.3 If the hub / flyweight is defective, the complete clutch must be

replaced.

wc_gr001386

b

Page 11

BTS Repair Clutch

wc_tx000298gb.fm 9

3.4 Mounting the clutch/drum

See Graphic : wc_gr001387

3.4.1 Before installing the clutch dr um, the ne edle bear ing that is pressed i n

must be greased. (Alvania #2)

3.4.2 When mounting the drum and the clutch, be careful to mount the

washers in the right order.

• (1) Ring (sits in the groove of the crankshaft)

• (2) End collar (with recess towards ring)

• (3) Guide washer

• (4) Clutch guide washer, before assembly.

Press into the support on the back of the clutch hub.

wc_gr001387

a

Page 12

Ignition System BTS Repair

wc_tx000299gb.fm 10

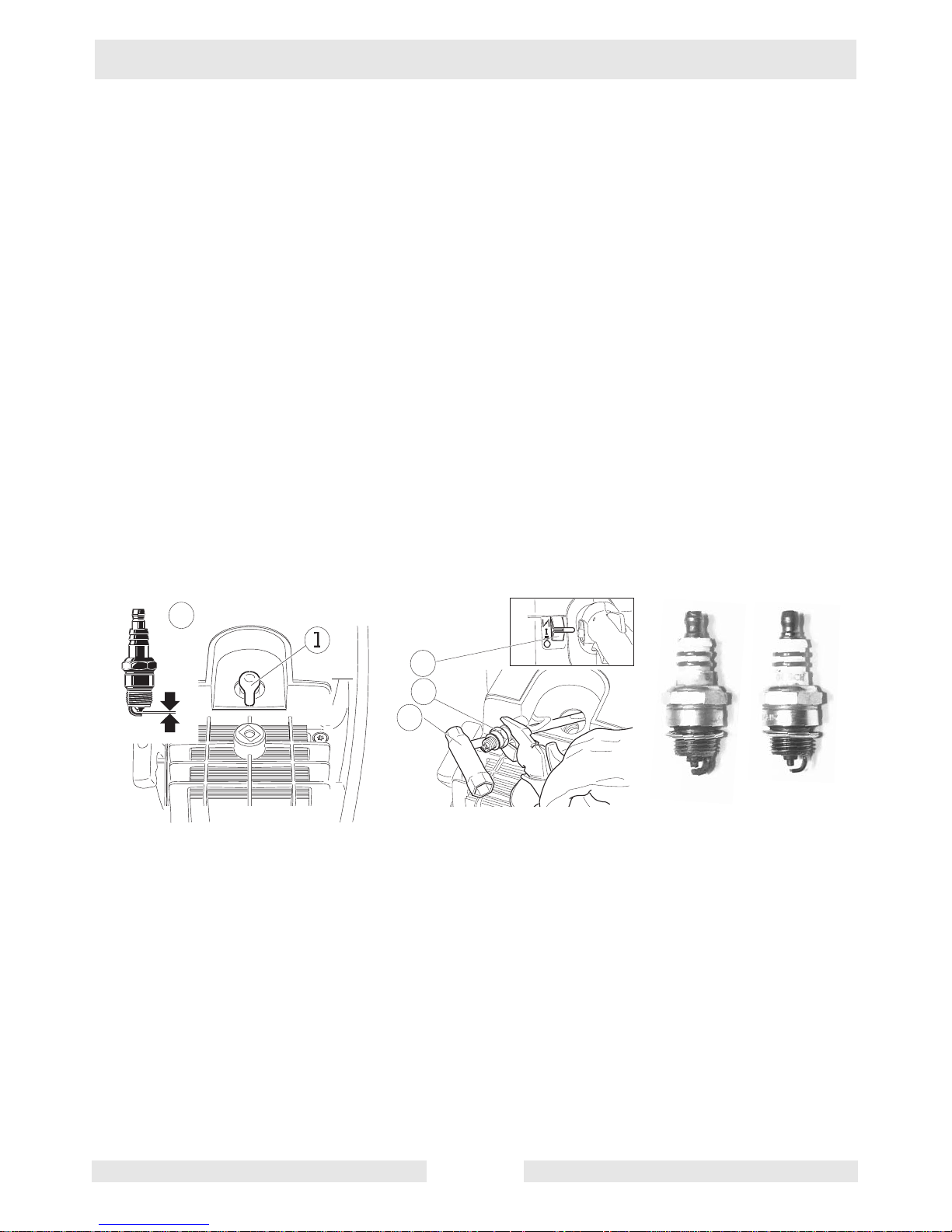

4. Ignition System

4.1 Checking the spark plug

See Graphic: wc_gr001 38 8

4.1.1 Remove filter hood.

4.1.2 Pull spark plug socket (1) off the spark plug and remove spark plug (2).

4.1.3 Connect spark plug (2) with plug socket and h old to ground (3). Pull out

starter cable. If no spark is produced, repeat procedure with new spark

plug.

Note: Switch (4) must be in position “I”.

4.1.4 Combustion and mo tor performance w ill be improved if the spark plugs

function properly. Dirty or faulty spark plugs should therefore be

cleaned or replaced.

• The spark plug pictured (a) has serious oil carbon deposits.

Clean or replace spark plug.

• This spark plug (b) is showing signs of wear (burning off) on the

middle electrode. Spark plug must be replaced.

S

T

O

P

0,5 mm

wc_gr001388

b

a

Page 13

BTS Repair Ignition System

wc_tx000299gb.fm 11

4.2 Replacing the plug connector

See Graphic : wc_gr001389

Hold the plug connector spring using pointed pliers and push the

rubber cap backwards over the ignition cable.

Note: Grease the ignition cable slightly beforehand.

a

wc_gr001389

Page 14

Ignition System BTS Repair

wc_tx000299gb.fm 12

4.3 Removing/assembling the ignition / short circuit cable

See Graphic: wc_gr001 39 0, wc_ g0 01 391, wc_gr001392 and wc_gr 001 393

Removing

4.3.1 Unscrew the starter device that is fixed with 4 screws (a).

4.3.2 Unscrew filter hood.

4.3.3 Remove ignition and short cir cuit cab le from the guide (1) of the hood .

4.3.4 Remove hood - to do this, unscrew the 3 screws (2).

4.3.5 The screw (2a) also holds the gr ounding wire.

4.3.6 Unscrew ignition from the ignition armature.

4.3.7 Loosen short circuit cable from the socket connection (b).

4.3.8 Loosen the hose clamp (3) of the intake hose.

4.3.9 Pull the suction hose (4) off the cylinder.

4.3.10 Loosen the locking device of the intake elbow from the tank housing.

To do this, push both levers inwards (arrows) and lift the intake elbow

slightly.

4.3.11 Push throttle control rod towards the cylinder using pointed pliers,

pulling upwards out of the guide of the gas grip (c).

4.3.12 Remove intake elbow with carburetor and choke shaft from the tank

housing (d).

4.3.13 Pull short circuit cable (5) from its place in the choke shaft (6).

4.3.14 Loosen grounding wire (7) from the socket connection of the contact

spring.

wc_gr001390

a

1

2

2a

3

4

b

wc_gr001391

Page 15

BTS Repair Ignition System

wc_tx000299gb.fm 13

Assembling

4.3.1 When mounting the short circuit cable, make sure that the connection

between the connector lug of th e short circuit cable and the contact

spring is in order (a).

4.3.2 Twist ignition cable into the ignition armature.

Note: To prevent moisture leaking in, fi ll protective cap (4) with silicone

before replacing.

4.3.3 As a safety measure, lay the short circuit cable in the brackets

underneath the ignition cable du ring assembly (b).

7

8

5

6

c

d

wc_gr001392

wc_gr001393

b

4

a

Page 16

Ignition System BTS Repair

wc_tx000299gb.fm 14

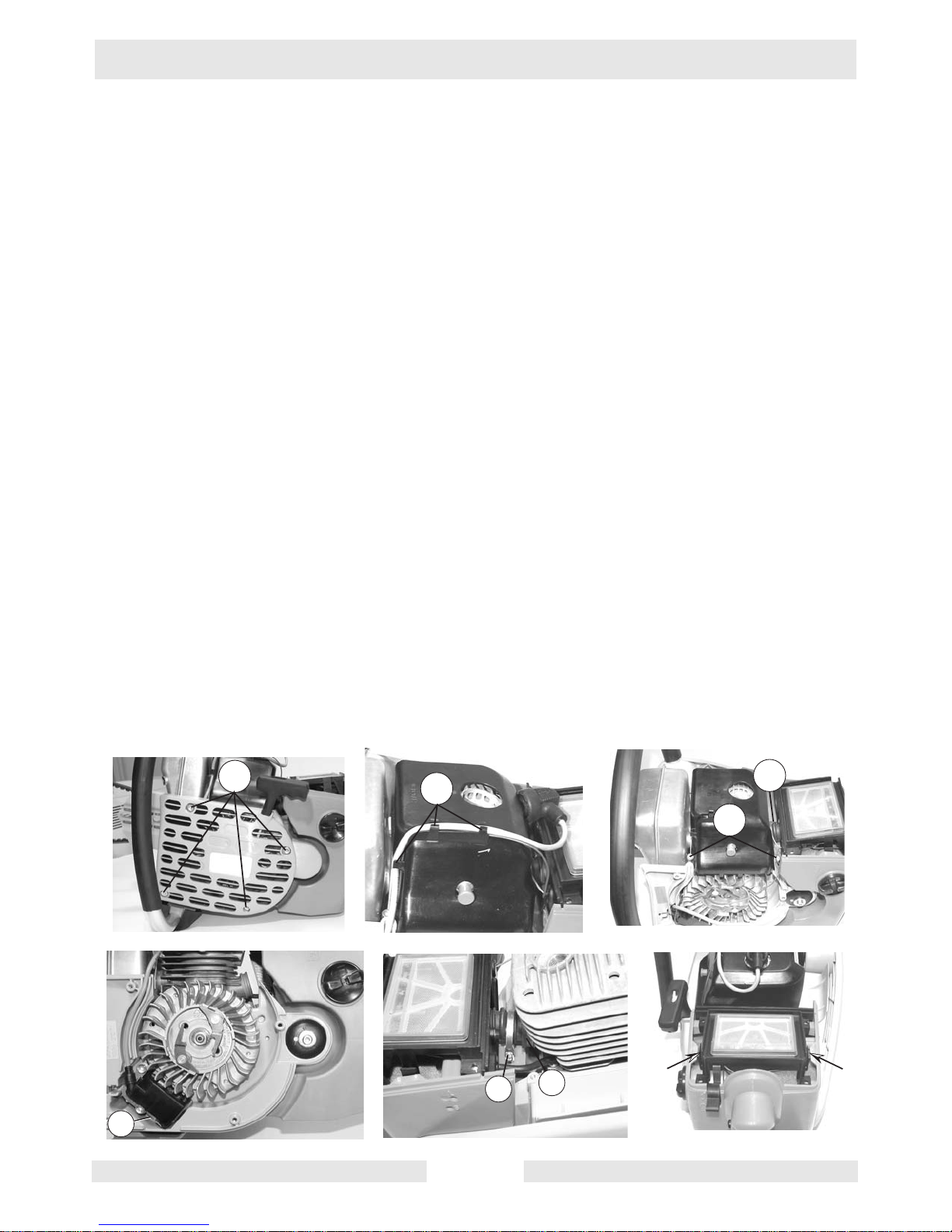

4.4 Removing/checking/mounting the ignition armature

See Graphic: wc_gr001 39 4

Removing

4.4.1 Unscrew starting device.

4.4.2 Remove the two screws (1) of the ignition armature. Clip off ignition

and short circuit cable.

Checking

4.4.1 In the event of a fault, first check the ignition ground connection.

To do this, loosen and then tighten the screws (1) a few times, then

check ignition once again.

Mounting

4.4.1 Connect ignition and short circuit cable.

4.4.2 Position with 0.012" – 0.016" (0.3 mm – 0.4 mm) (a) between ignition

device and magnet on the flywheel.

4.4.3 Press ignition device firmly whilst at the same time tightening the

screws evenly.

1

a

b

wc_gr001394

Page 17

BTS Repair Ignition System

wc_tx000299gb.fm 15

4.5 Removing/mounting the flywheel

See Graphic : wc_gr001395

Removing

4.5.1 Block the piston using the piston stop wedge.

4.5.2 Unscrew bolt (2) and remove washer (3).

4.5.3 Rem ove flywheel with pulling device 0037576 (a).

CAUTION: To avoid damage to the crankshaft, always use the

protective cap included with the pu lling device.

Mounting

4.5.1 Before mounting the flywheel, the cone seat and the crankshaft (4)

must be cleaned.

4.5.2 The flywheel is tightened with a torque of 23 ft.lbs. (30 Nm).

wc_gr001395

2

3

a

4

Page 18

Starting System BTS Repair

wc_tx000300gb.fm 16

5. Starting System

5.1 Removing/mounting the starter / return spring

See Graphic: wc_gr001 39 6

Removing the starter

5.1.1 Remove air duct (1).

5.1.2 Relieve the tension on the return spring by pulling out the starter cable

(2) slightly.

5.1.3 Hold cable drum and remove cable from rope drum. Let drum spool

back slowly.

Removing the return spring

5.1.1 To remove the return spring, remove the circlip ring (3); the return

spring (4) is in a cartridge which is fixed to the fan housing with three

screws (5).

Note: Lightly grea se new spring.

Mounting the return spring /starter cable

5.1.1 Thread cable through, kno tting (6) into the cab le dr um and kno tting (7)

into the starter grip (8).

5.1.2 The washer (9) is mounted between the starter grip and the knot.

Note: Melt cable ends.

2

1

wc_gr00139

6

Page 19

BTS Repair Starting System

wc_tx000300gb.fm 17

5.2 Pretensioning/checking the return spring

See Graphic : wc_gr001367

Pretensioning the return spring

Wrap the starter cable as far as p ossibl e aroun d th e dr um . Hol d cable

tight and turn the drum with the cable 2-3 times to pretension (a).

Checking the return spring

When the starter cable is fully extend ed, the rope drum m ust still turn

at least half a turn (b).

5.3 Replacing the starter ratchet

See Graphic : wc_gr001367

5.3.1 Knock out the bolts with a punch (c).

5.3.2 To assemble, push the punch in so far that there is only 0.06"–0.07"

(0.15 mm–0.2 mm) between the ratchet and the bolt (10).

22

10

c

b

a

wc_gr001397

Page 20

Carburetor BTS Repair

wc_tx000301gb.fm 18

6. Carburetor

6.1 Setting the carburetor

See Graphic: wc_gr001 39 8

Set Idling Nozzle “L” at 1 3/8 (-1/16) turn

For the basic setting, turn in the idling nozzle “L” carefully as far as it

will go. Then back off “L” nozzle 1 3/8 turn.

For fine tuning, the “L” nozzle only needs to be changed by max.

- 1/16 of a turn.

“S” Idling Screw

When during idling the engine speed is too high (moving of cutting

disc) or too low (engine stalls), correct the the settin g of idling screw

“S” (speed) accordingly.

“H” Main Nozzle

BTS 930/935: The main nozzle “H ” is set at the factor y to 6/8 of a turn.

BTS 1030/1035: The main nozzle “H” is set at the factory to 7/8 of a

turn except for machines built in 2002 (S/Ns 5289575 to 5355979)

which were set at the factory to 6/8 of a turn.

S

H

L

wc_gr001398

Page 21

BTS Repair Carburetor

wc_tx000301gb.fm 19

6.2 Removing the carburetor and intake hose

See Graphic : wc_gr001399

Removing the carburetor

6.2.1 Remove intake elbow with carburetor.

6.2.2 Remove choke shaft (1), choke rod (2) and throttle control rod (3).

Unscrew the two fixing screws (4).

6.2.3 Remove the carbure tor from the intake elbow.

6.2.4 The seal (5) must not block the bore (6) for ventilating th e con tr ol si de

of the carburetor (compensation system).

Intake hose

6.2.1 Pull the intake ho se (7) out of the intake elbow and check for damage.

6.2.2 Replace the insert (8) in the intake hose again before assembling the

carburetor.

wc_gr

001399

6

5

3

2

4

1

Page 22

Carburetor BTS Repair

wc_tx000301gb.fm 20

6.3 Carburetor - dismantling/testing the control side

See Graphic: wc_gr001 40 0

Dismantling the control side

6.3.1 Unscrew cover (1). Carefully remove the seal (2) and diaphragm (3)

from the control lever (4).

6.3.2 Remove control lever, spring (5) and inlet needle (6) from the

carburetor.

Testing the control membrane

6.3.1 After removing the control diaphragm, it must remain flat. The rim

around the stiffe ning plate (7) must be even. Faulty diaphragm must be

replaced immediately.

Testing the control unit

6.3.1 After removing the contr ol diaphragm, remove the int ake pin with valve

rocker and spring.

Note: If there is visible wear (arrows), the control unit must be

replaced.

wc_gr001400

Page 23

BTS Repair Carburetor

wc_tx000301gb.fm 21

6.4 Carburetor - dismantling/testing the pump side

See Graphic : wc_gr001401

Dismantling the pump side

Unscrew cover (8). Remove seal (9) and diaphragm (10) from the

carburetor.

Testing the pump membrane

The two valve flaps (arrow) must re st flat on the body of the carburetor.

Damaged diaphragms must be replaced immediately, as starting and

running problems may otherwise occur.

6.5 Carburetor - Cleaning the fuel filter

See Graphic : wc_gr001401

The fuel filter (11) may be carefully remove d fr om th e carbu r eto r b ody

for cleaning with a pointed object. After cleaning replace the fuel filter

with a pin.

wc_gr001401

a

a

Page 24

Hood System / Air Filter / Winter Operation BTS Repair

wc_tx000302gb.fm 22

7. Hood System / Air Filter / Winter Operation

7.1 Air Filter

See Graphic: wc_gr001 40 2

Only well-maintained filters will guarantee efficient engine

performance and a long working life. Damaged or worn filters must

therefore be replaced.

Removing the air filter

7.1.1 Remover filter hood (5), unscrew cover hood (4).

7.1.2 Filter system consists of the pre-filter (1), the paper cartridge (2) and

the inside filter (3).

Cleaning the pre-filter

7.1.1 Clean the pre-filter (a) in lukewarm soapy water using normal liquid

detergent. Dry before replacing.

Note: If the inserts are extremely dusty, the pre-filter may need to be

oiled slightly.

Cleaning the paper cartridge

7.1.1 Unscrew the 4 screws on the cover hood (4). To clean, fan the paper

cartridge (b) out slightly and tap gently.

Note: Never wash the paper cartridge to clean it.

Clean inside filter

7.1.1 The inside filter (c) should also be washed out in lukewarm soapy

water.

b

a

wc_gr001402

Page 25

BTS Repair Hood System / Air Filter / Winter

wc_tx000302gb.fm 23

7.2 Winter Operation

See Graphic : wc_gr001403

Temperatures below zero may cause the filter/ carburetor to freeze.

Remove summer-winter insert from summer mode (6) and insert in

winter mode (7) as shown.

Return to summer mode when temperature is above 32°F (0°C).

wc_gr00140

3

c

d

Page 26

Front Handle / Vibration Absorbers BTS Repair

wc_tx000303gb.fm 24

8. Front Handle / Vibration Absorbers

8.1 Removing and replacing the bracket handle

See Graphic: wc_gr001 40 4

To dismantle the front handle, the strut (1) with 3 screws and the foot

(2) with 2 screws must be unscrewed.

8.2 Replacing the vibration absorbers

See Graphic: wc_gr001 40 5

The system consists of 4 vibration absorbers, 3 of which are on the

clutch side.

8.2.1 To dismantle them, the front handle, filter system and tank must be

removed.

8.2.2 The fourth vibration absorber is on the flywheel side. To dismantle it,

the starter device must be removed.

8.2.3 The vibration absorbers are slotted into the housing. Mount the

sleeves (3+4) with the collars inwards.

8.2.4 Lightly grease vibration absorbers.

1

2

wc_gr001404

b

3

4

a

wc_gr001405

Page 27

BTS Repair Fuel Tank / Fuel Filter

wc_tx000304gb.fm 25

9. Fuel Tank / Fuel Filter

9.1 Removing/inserting the ventilation valve

See Graphic : wc_gr001406

Removing

Push the ventilation valve with a pin into the tank (arrow) and remove

with pointed pliers throug h the filler opening (a).

Inserting

Press the new ventilation valve with a pin into the housing until the

white sinter plastic projects about 2–3 mm beyond the tank (b).

9.2 Replacing the throttle lever mechanism

See Graphic : wc_gr001406

Push the two cylindrical pins (1) out of the handle dish (2).

The throttle lever (3), spring (4) and throttle lock (5) may now be

removed.

The throttle lock pin (6) for half throttle can also now be replaced.

2-3mm

(.080”-0.12”)

2

b

a

wc_gr001406

Page 28

Fuel Tank / Fuel Filter BTS Repair

wc_tx000304gb.fm 26

9.3 Replacing the fuel pipe

See Graphic: wc_gr001 40 7

Unscrew tank cap, remove suction head (7) from tank and pull off the

suction pipe (8). Pull suction pipe upwards out of the tank.

9.4 Testing the fuel filter

See Graphic: wc_gr001 40 7

Dirty felt filters or filters which have become hardened/blocked with

fuel will lead to leanin g of the fu el/air mix and w ill damag e the e ngine

(c).

Note: The fuel filter mus t therefore be checked/replaced regularly.

A fingernail test ca n b e u sed to ch eck wh ether the filter is blocke d (d) .

• Easy to push in = filter OK

• Cannot be pushed in = replace

wc_gr001407

c

d

Page 29

BTS Repair Cylinder / Piston / Decompression Valve

wc_tx000305gb.fm 27

10. Cylinder / Piston / Decompression Valve

10.1 Dismantling/mounting the cylinder / piston

See Graphic: wc_gr001408 and wc_gr001409

Dismantling the cylinder

10.1.1 To disman tle t he cylin der, u nscre w the 4 scr ews (1) from the cylinder

foot.

10.1.2 Pull cylinder off crankcase and piston.

Dismantling the cylinder - piston

10.1.1 Remove piston pin securing ring (2) from the an nul a r slo t i n the pi st on

using pointed pliers. Push piston pin out.

Note: During assembly, make sure the securing ring clicks completely

into the groove.

Mounting the cylinder - piston

10.1.1 Wh en mounting pist on, the arrow on top of the piston has to point in

direction of muff ler.

Note: Before assembling the piston ensure that the cylinder base

gasket (3) is fitted correctly.

Mounting the cylinder

10.1.1 Position the fork (4) of the piston ring tight ening device (0117575) onto

the crankcase. Press the piston ring together using the ring clamp.

When positioning the cylinder, push the ring clamp away downwards.

10.1.2 After positioning the cylinder, tighten fixing screw with a torque of 10

ft.lbs. (14 Nm) (b).

1

1

2

wc_gr001408

3

Page 30

Cylinder / Piston / Decompression Valve BTS Repair

wc_tx000305gb.fm 28

10.2 Testing the decompression valve

See Graphic: wc_gr001 40 9

Unscrew valve and check valve seating (a) and the hole in the cyli nder

for dirt.

Replace valve if dirty. Clean hole carefully.

4

b

a

wc_gr001409

Page 31

BTS Repair Crankcase / Crankshaft

wc_tx000306gb.fm 29

11. Crankcase / Crankshaft

11.1 Crankcase / crankshaft

See Graphic: wc_gr001410 and wc_gr001411

Complete crankcase

The complete crankcase is divided into the crankcase magnet side (2)

“MS”, and the crankcase clutch side (1) “KS”.

Removing the crankcase “MS”

To dismantle the magnet side (MS), unscrew the 4 fixing screws (3)

and the left lower screw (4).

Dismantling the crankcase

After removing the 5 fixing screws, separate the crankca se carefully by

tapping with a plastic hammer (a).

Replacing the crankshaft / bearing

First push bearing onto the crankshaft, then insert crankshaft with

bearing (5) into the case, “KS”. Place gasket on centering pins.

Note: To dismantle or assemble the bearings, heat the crankcase to

212–248°F (100–120°C ) .

Mounting the bearing / crankcase

Heat the crankcase “MS” and fit bearing into the case (b).

Note: The bearing faces with its open side to the crankshaft. Before

installation moisten the outside of the bearing with “Loctite 601”.

Mounting the crankcase

Tighten the 5 fixing screws with a torque of 7 ft.lbs. (10 Nm) (c).

1

2

4

3

a

wc_gr001410

5

b

c

wc_gr001411

Page 32

Cutting Attachment BTS Repair

wc_tx000307gb.fm 30

12. Cutting Attachment

12.1 Replacing the pressure disc

See Graphic: wc_gr001 41 2

12.1.1 Undo screw (1) and remove pressure disc.

Note: W ith the 25.4 mm (1") axle, the inner flange is located behi nd the

recess of the axle (2).

12.1.2 Remove axle and flange together.

12.2 Removing / mounting the V-belt pulley

See Graphic: wc_gr001 41 2

Removing

Block the V-belt pulley (3). To do this, push a pin throu gh the ho le (4)

in the V-belt pulley into the housing. Remove screw (5).

Mounting

When mounting the pulley, make sure that the shim 0108152 (6) is

mounted betwee n the V-belt pulley and the ball bearing .

Note: Th e V-belt pulley is on ly fixed in place when the cutting disk is

mounted.

wc_gr001412

1

2

3

4

5

6

Page 33

BTS Repair Cutting Attachment

wc_tx000307gb.fm 31

12.3 Replacing the drive axle

See Graphic : wc_gr001413

To remove the axle (7), the pressure disk (8) and the V-belt pulley must

be dismantled.

Note: When mo unting th e inner flang e disk, make su re that th e spacer

sleeve (9) 0108151 is mounted.

12.4 Removing the complete pressure ring

See Graphic : wc_gr001413

Unscrew the 3 screws with springs (10), the housing (14) and the

pressure ring (11).

Note: The screws (10) have to be fitted at angles of 120° and are

tightened to 7.3 ft.lbs. (10 Nm).

12.5 Cutter guard holding attachments

See Graphic : wc_gr001413

When mounting, place as follows:

Inside Outside

11 Pressure ring 14 Housing

12 Teflon ring 12 Teflon ring

13 Rubber part 16 Locking plate

- 15 Rubber part

10

14

wc_gr001413

Page 34

Cutting Attachment BTS Repair

wc_tx000307gb.fm 32

12.6 Replacing the guard stop

See Graphic: wc_gr001 41 4

Knock the shaft (1) with a pin out of the handle (2).

To assemble, push the ne w handle onto the shaf t until the shaft is flu sh

with the outside edge of the handle.

12.7 Replacing the fixing screw

See Graphic: wc_gr001 41 4

Push the screws (3) out of the housing.

Before inserting, wet the stop area (arrow) on the screws with “Loctite

609”.

wc_gr001414

Page 35

BTS Repair Cutting Attachment

wc_tx000307gb.fm 33

12.8 Remo ving / mounting the cutting device bearings

See Graphic : wc_gr001415

Removing

12.8.1 Warm housing, remove ball bearings, spacer sleeve and snap rings

from the housing.

Mounting

12.8.1 Hea t housing up to approx. 212°F (100°C).

12.8.2 Mount external snap ring (4).

12.8.3 Push ball bearing (5) up against the ring.

12.8.4 Insert middle ring (6) and spacer sleeve (7), then push second ball

bearing up to ring.

wc_gr001415

a

4

5

7

8

Page 36

Cutting Attachment BTS Repair

wc_tx000307gb.fm 34

12.9 Adjusting the cutter guard holding attachment

See Graphic: wc_gr001 41 6

If the guard is subjected to high stresses, the holding attachment and

the guard may no longer be aligned (arrows).

For correction, loosen screws (8) and adjust holding attachment.

12.10 Tensioning the V-belt

See Graphic: wc_gr001 41 6

12.10.1 After mounting the cutting device, tighten the nuts (9) by hand.

12.10.2 Turn the screw (10) until the squar e nut (11) is aligned with the marking

(12) on the hood.

12.10.3 Tighten the nuts (9) to 14 ft.lbs. (20 Nm).

8

wc_gr00141

6

Page 37

BTS Repair Torques

wc_tx000327gb.fm 35

13. Torques

13.1 BTS 930 / BTS 935 / BTS 1030 / BTS 1035

Assembly set Nm (ft.lbs.)

Muffler 10 + 1 (7) **

Crankcase 10 + 1 (7) **

Cylinder 14 + 1 (10) **

Ignition coil 6 + 1 (53 in.lbs.) **

Fro nt ha ndl e 7 ± 0.5 (60 in.lbs.)

Rubber mounts 7 ± 0.5 (60 in.lbs.)

Carburetor 1.5 ± 0.5 (13 in.lbs.)

Clutch 55 ± 0.2 (40)

Flywheel 30 ± 2.5 (22)

Spark plug 25 ± 2.5 (19)

V-belt pulley 25 + 5 (19)

** Screws with locking serration

Page 38

Torques BTS Repair

wc_tx000327gb.fm 36

Page 39

Threadlockers and Sealants

Threadlockers and Sealants

Threadlocking adhesives and sealants are specified throughout this

manual by a notation of “S” plus a number (S#) and should be used

where indicated. Threadlocking compounds normally break down at

temperatures above 175°C (350°F). If a screw or bolt is hard to

remove, heat it using a small propane torch to break down the sealant.

When applying sealant s, follow instru ctions on conta iner. The sealant s

listed below are recommended for use on Wacker equipment.

TYPE

( ) = Europe

COLOR USAGE

PART NO. SIZE

Loctite 222

Hernon 420

Omnifit 1150 (50M)

Purple Low strength, for locking threads smaller than 6 mm

(1/4").

Hand tool removable.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

73287 - 10 ml

Hernon 423

Omnifit 1350 (100M)

Blue Medium strength, for locking threads larger than

6 mm (1/4").

Hand tool removable.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

29311 - .5 ml

17380 - 50 ml

Loctite 271/277

Hernon 427

Omnifit 1550 (220M)

Red High strength, for all threads up to 25 mm (1”).

Heat parts before disassembly.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

29312 - .5 ml

26685 - 10 ml

73285 - 50 ml

Loctite 290

Hernon 431

Omnifit 1710 (230LL)

Green Medium to high strength, for locking preassembled

threads and for sealing weld porosity (wicking).

Gaps up to 0.13 mm (0.005")

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

28824 - .5 ml

25316 - 10 ml

Loctite 609

Hernon 822

Omnifit 1730 (230L)

Green Medium strength retaining compound for slip or press

fit of shafts, bearings, gears, pulleys, etc.

Gaps up to 0.13 mm (0.005")

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

29314 - .5 ml

Loctite 545

Hernon 947

Omnifit 1150 (50M)

Brown Hydraulic sealant

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

79356 - 50 ml

Loctite 592

Hernon 920

Omnifit 790

White Pipe sealant with Teflon for moderate pressures.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

26695 - 6 ml

73289 - 50 ml

Loctite 515

Hernon 910

Omnifit 10

Purple Form-in-place gasket for flexible joints.

Fills gaps up to 1.3 mm (0.05")

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

70735 - 50 ml

Loctite 496

Hernon 110

Omnifit Sicomet 7000

Clear Instant adhesive for bonding rubber, metal and plas-

tics; general purpose.

For gaps up to 0.15 mm (0.006")

Read caution instruct io ns befo re using.

Temp. range, -54 to 82 ° C (-65 to 180 ° F)

52676 - 1 oz.

Page 40

Threadlockers and Sealants

Loctite Primer T

Hernon Primer 10

Omnifit VC Activator

Aerosol

Spray

Fast curing primer for threadlocking, retaining and

sealing compounds. Must be used with stainless

steel hardware. Recommended for use with gasket

sealants.

2006124 6 oz.

TYPE

( ) = Europe

COLOR USAGE

PART NO. SIZE

Page 41

Torque Values

Torque Values

Metric Fasteners (DIN)

TORQUE VALUES (Based on Bolt Size and Hardness) WRENCH SIZE

Size ft.lb. Nm ft.lb. Nm ft.lb. Nm Inch Metric Inch Metric

M3 *11 1.2 *14 1.6 *19 2.1 7/32 5.5 - 2.5

M4 *26 2.9 *36 4.1 *43 4.9 9/32 7 - 3

M5 *53 6.0 6 8.5 7 10 5/16 8 - 4

M6 7 10 10 14 13 17 - 10 - 5

M8 18 25 26 35 30 41 1/2 13 - 6

M10 36 49 51 69 61 83 11/16 17 - 8

M12 63 86 88 120 107 145 3/4 19 - 10

M14 99 135 140 190 169 230 7/8 22 - 12

M16 155 210 217 295 262 355 15/16 24 - 14

M18 214 290 298 405 357 485 1-1/16 27 - 14

M20 302 410 427 580 508 690 1-1/4 30 - 17

1 ft.lb. = 1.357 Nm. * = in.lb. 1 Inch = 25.4 mm

8.8

10.9 12.9

Page 42

Torque Values

Inch Fasteners (SAE)

Size ft.lb. Nm ft.lb. Nm ft.lb. Nm Inch Metric Inch Metric

No.4 *6 0.7 *14 1.0 *12 1.4 1/4 5.5 3/32 -

No.6 *12 1.4 *17 1.9 *21 2.4 5/16 8 7/64 -

No.8 *22 2.5 *31 3.5 *42 4.7 11/32 9 9/64 -

No.10 *323.6*455.1*606.83/8 - 5/32 -

1/4 6 8.1 9 12 12 16 7/16 - 3/32 -

5/16 13 18 19 26 24 33 1/2 13 1/4 -

3/8 23 31 33 45 43 58 9/16 - 5/16 -

7/16 37 50 52 71 69 94 5/8 16 3/8 -

1/2 57 77 80 109 105 142 3/4 19 3/8 -

9/16 82 111 115 156 158 214 13/16 - - -

5/8 112 152 159 216 195 265 15/16 24 1/2 -

3/4 200 271 282 383 353 479 1-1/8 - 5/8 -

1 ft.lb. = 1.357 Nm. * = in.lb. 1 Inch = 25.4 mm

Page 43

Page 44

Wacker Construction Equipment AG · Preußenstraße 41 · D-80809 München · Tel.: +49-(0)89-354 02 - 0 · Fax: +49 - (0)89-354 02-390

Wacker Corporation · P.O. Box 9007 · Menomonee Falls, WI 53052-9007 · T el. : +1-(1)(262) 255-0500 · Fax: +1-(1)(262) 255-0550 · Tel. : (800) 770-0957

Wacker Asia Pacific Operations · Sunley Center, Unit 912, 9/F · 9 Wing Qin Street, Kwai Chung, N.T. · Hong Kong · Tel. + 852 2406 60 32 · Fax: + 852 2406 60 21

Loading...

Loading...