Page 1

Operator's manual

Gasoline cut-off saw

BTS

630, 635, 635s

12.2011

0217780en / 006

Page 2

Manufacturer

Wacker Neuson Produktion GmbH & Co. KG

Preußenstraße 41

80809 München

www.wackerneuson.com

Tel.: +49-(0)89-354 02-0

Fax: +49-(0)89-354 02-390

Translation of the original operator's manual in German

Page 3

BTS 630, 635

Operator's manual 3

1 Foreword ....................................................................................................................5

2 Introduction ............................................................................................................... 6

2.1 Means of representation for this operator's manual ........................................... 6

2.2 Wacker Neuson representative .......................................................................... 7

2.3 Described machine types ................................................................................... 7

2.4 Identification of the machine............................................................................... 8

3 Safety .........................................................................................................................9

3.1 Principle.............................................................................................................. 9

3.2 Qualification of the operating personnel........................................................... 12

3.3 Protective gear ................................................................................................. 13

3.4 Transport .......................................................................................................... 14

3.5 Operating safety ............................................................................................... 15

3.6 Safety during the operation of hand machines................................................. 17

3.7 Safety during the operation of combustion engines ......................................... 17

3.8 Safety during cut-off saw operation.................................................................. 20

3.9 Maintenance..................................................................................................... 24

3.10 Safety and information labels ........................................................................... 25

3.11 Safety and information icons ............................................................................ 28

3.12 Safety devices .................................................................................................. 29

4 Scope of delivery ....................................................................................................30

5 Structure and function ...........................................................................................31

5.1 Application........................................................................................................ 31

5.2 Functionality ..................................................................................................... 31

6 Components and operator's controls ................................................................... 32

7 Transport .................................................................................................................35

8 Initial start up .......................................................................................................... 36

8.1 Mounting the cutting attachment on the outside............................................... 36

9 Use and operation .................................................................................................. 41

9.1 Prior to starting the machine............................................................................. 41

9.1.1 Checks before startup .......................................................................... 41

9.1.2 Changing the cutting blade................................................................... 41

9.2 Starting up ........................................................................................................ 43

9.2.1 Starting the engine ............................................................................... 43

9.3 Operating the machine ..................................................................................... 47

9.4 Decommissioning ............................................................................................. 48

Contents

Page 4

BTS 630, 635

4 Operator's manual

10 Maintenance ............................................................................................................ 49

10.1 Maintaining the emission control system.......................................................... 49

10.2 Maintenance schedule ..................................................................................... 50

10.3 Maintenance work ............................................................................................ 51

10.3.1 Cleaning the machine........................................................................... 51

10.3.2 Topping up with fuel ............................................................................. 51

10.3.3 Tightening the V-belt ............................................................................ 53

10.3.4 Checking the thrust washers ................................................................ 54

10.3.5 Cleaning/Changing the air cleaner ....................................................... 55

10.3.6 Checking/cleaning/replacing the spark plug......................................... 57

10.3.7 Replacing the V-belt ............................................................................. 59

10.3.8 Replacing the fuel filter......................................................................... 62

10.3.9 Setting the idle speed........................................................................... 63

10.3.10Cleaning the spark arrestor.................................................................. 64

10.3.11Cleaning the exhaust port .................................................................... 65

11 Troubleshooting ...................................................................................................... 67

12 Accessories ............................................................................................................. 68

13 Storage ..................................................................................................................... 69

14 Technical data ......................................................................................................... 70

14.1 BTS 630, 635, 635s.......................................................................................... 70

14.2 Fuel mixture table............................................................................................. 72

15 Emission control warranty ..................................................................................... 73

EC Declaration of Conformity ................................................................................77

Page 5

1 Foreword

5

1Foreword

This operator's manual contains information and procedures for the safe operation and maintenance of your Wacker Neuson machine. In the interest of your

own safety and to prevent accidents, you should carefully read through the safety

information, familiarize yourself with it and observe it at all times.

This operator's manual is not a manual for extensive maintenance and repair

work. Such work should be carried out by Wacker Neuson service or authorized

specialists.

The safety of the operator was one of the most important aspects taken into consideration when this machine was designed. Nevertheless, improper use or incorrect maintenance can pose a risk. Please operate and maintain your Wacker

Neuson machine in accordance with the instructions in this operator's manual.

Your reward will be troublefree operation and a high degree of availability.

Defective machine parts must be replaced immediately!

Please contact your Wacker Neuson representative if you have any questions

concerning operation or maintenance.

All rights reserved, especially reproduction and distribution rights.

Copyright 2011 Wacker Neuson Produktion GmbH & Co. KG

No part of this publication may be reproduced in any form or by any means, electronic or mechanical, including photocopying, without the expressed written permission of Wacker Neuson.

Any type of reproduction, distribution or storage on data media of any type and

form not authorized by Wacker Neuson represents an infringement of copyright

and will be prosecuted.

We expressly reserve the right to make technical modifications – even without

special notice – which aim at further improving our machines or their safety standards.

Page 6

2 Introduction

6

2 Introduction

2.1 Means of representation for this operator's manual

Warning symbols

This operator's manual contains safety information of the categories:

DANGER, WARNING, CAUTION, NOTICE.

They should be followed to prevent danger to life and limb of the operator or damage to equipment and exclude improper service.

Notes

Note: Complementary information will be displayed here.

DANGER

This warning notice indicates immediate hazards that result in serious injury or

even death.

f Danger can be avoided by the following the actions mentioned.

WARNING

This warning notice indicates possible hazards that can result in serious injury

or even death.

f Danger can be avoided by the following the actions mentioned.

CAUTION

This warning notice indicates possible hazards that can result in minor injury.

f Danger can be avoided by the following the actions mentioned.

NOTICE

This warning notice indicates possible hazards that can result in material damage.

f Danger can be avoided by the following the actions mentioned.

Page 7

2Introduction

7

Instructions

f This symbol indicates there is something for you to do.

1. Numbered instructions indicate that you have to carry out something in a defined

sequence.

This symbol is used for lists.

2.2 Wacker Neuson representative

Depending on your country, your Wacker Neuson representative is your Wacker

Neuson service, your Wacker Neuson affiliate or your Wacker Neuson dealer.

You can find the addresses in the Internet at www.wackerneuson.com.

The address of the manufacturer is located at the beginning of this operator's

manual.

2.3 Described machine types

This operator's manual is valid for different machine types from a product range.

Therefore some figures can differ from the actual appearance of your machine.

It is also possible that the descriptions include components which are not a part

of your machine.

Details for the described machine types can be found in the chapter Technical

data.

Page 8

2 Introduction

8

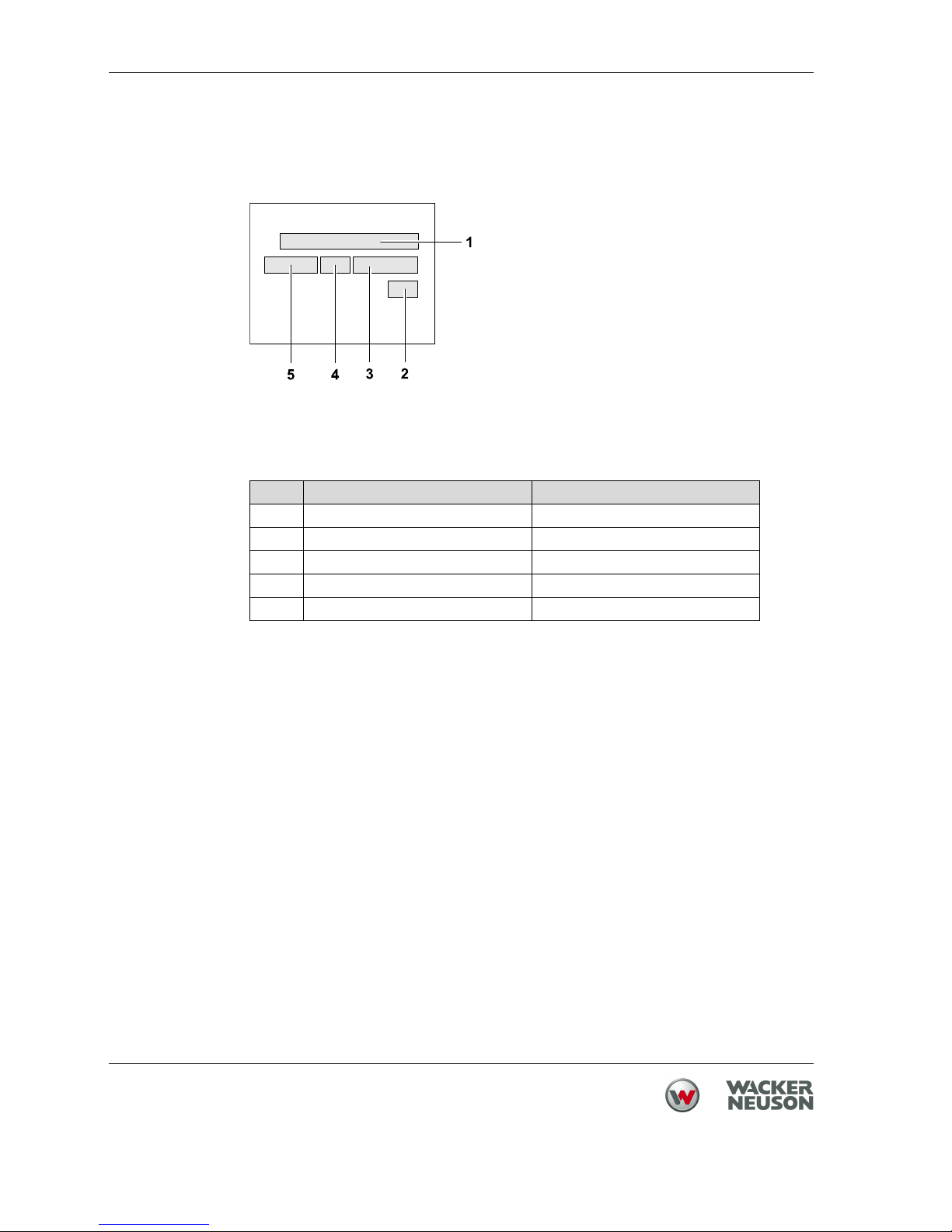

2.4 Identification of the machine

Nameplate data

The nameplate lists information that uniquely identifies your machine. This information is needed to order spare parts and when requesting additional technical

information.

f Enter the information of your machine into the following table:

Item Designation Your information

1 Group and type

2 Construction year

3 Machine no.

4 Version no.

5 Item no.

Page 9

BTS 630, 635 3 Safety

Operator's manual 9

3Safety

3.1 Principle

State of the art

This machine has been constructed with state-of-the-art technology according to

the recognized rules of safety. Nevertheless, when used improperly, dangers to

the life and limb of the operator or to third persons or damage to the machine or

other materials cannot be excluded.

Proper use

The machine must only be used for the following purposes:

Cutting concrete, stone and ceramic.

Cutting metal.

Cutting asphalt.

The machine may only be used with cutting blades that are intended for use with

the machine and the material to be cut.

The machine may not be used for the following purposes:

Cutting wood.

Cutting plastics.

Cutting materials that contain asbestos or other hazardous materials.

Cutting fibrous or soft materials.

Grinding (with the side surface of the cutting blade).

The machine may not be operated with blades, knives, brushes, etc.

Do not use the machine as a hand-held circular saw.

Its proper use also includes the observance of all instructions contained in this

operator's manual as well as complying with the required service and

maintenance instructions.

Any other use is regarded as improper. Any damage resulting from improper use

will void the warranty and the liability on behalf of the manufacturer. The operator

assumes full responsibility.

Page 10

3 Safety BTS 630, 635

10 Operator's manual

Structural modifications

Never attempt to modify the machine without the written permission of the

manufacturer. To do so will endanger your safety and the safety of other people!

In addition, this will void the warranty and the liability on behalf of the

manufacturer.

Especially the following are cases of structural modifications:

Opening the machine and the permanent removal of components from

Wacker Neuson.

Installing new components which are not from Wacker Neuson and not

equivalent to the original parts in design and quality.

Installation of accessories which are not from Wacker Neuson.

It is no problem to install spare parts from Wacker Neuson.

It is no problem to install accessories that are available in the Wacker Neuson

product range of your machine. Please refer to the installation regulations in this

operator's manual.

Do not drill into the housing, e. g. to install signs. Water could penetrate the

housing and damage the machine.

Requirements for operation

The ability to operate the machine safely requires:

Proper transport, storage and setup.

Careful operation.

Careful service and maintenance.

Operation

Operate the machine only as intended and only when in proper working

condition.

Operate the machine in a safety-conscious manner with all safety devices

attached and enabled. Do not modify or disable any safety devices.

Before starting operation, check that all control and safety devices are

functioning properly.

Never operate the machine in a potentially explosive environment.

Maintenance

Regular maintenance work is required in order for the machine to operate

properly and reliably over time. Failure to perform adequate maintenance

reduces the safety of the machine.

Strictly observe the prescribed maintenance intervals.

Do not use the machine if it requires maintenance or repairs.

Page 11

BTS 630, 635 3 Safety

Operator's manual 11

Malfunctions

If you detect a malfunction, you must shut down and secure the machine

immediately.

Eliminate the malfunctions that impair safety immediately!

Have damaged or defective components replaced immediately!

For further information, refer to chapter Troubleshooting.

Spare parts, accessories

Use only spare parts from Wacker Neuson or such that are equivalent to the

original parts in design and quality.

Only use accessories from Wacker Neuson.

Non-compliance will exempt the manufacturer from all liability.

Exclusion of liability

Wacker Neuson will refuse to accept liability for injuries to persons or for damage

to materials in the following cases:

Structural modifications.

Improper use.

Failure to comply with this operator's manual.

Improper handling.

Using of spare parts which are not from Wacker Neuson and not equivalent

to the original parts in design and quality.

Using of accessories which are not from Wacker Neuson.

Operator's manual

Always keep the operator's manual near the machine or near the worksite for

quick reference.

If you have misplaced the operator's manual or require an additional copy,

contact your Wacker Neuson representative or download the operator's manual

from the Internet (www.wackerneuson.com).

Always hand over this operator's manual to other operators or to the future owner

of the machine.

Country-specific regulations

Observe the country-specific regulations, standards and guidelines in reference

to accident prevention and environmental safety, for example those pertaining to

hazardous materials and wearing protective gear.

Complement the operator's manual with additional instructions taking into

account the operational, regulatory, national or generally applicable safety

guidelines.

Page 12

3 Safety BTS 630, 635

12 Operator's manual

Operator's controls

Always keep the operator's controls of the machine dry, clean and free of oil or

grease.

Operating elements such as ON/OFF switch, throttle levers etc. may not be

locked, manipulated or changed without authorization.

Checking for signs of damage

Inspect the machine when it is switched off for any signs of damage at least once

per work shift.

Do not operate the machine if there is visible damage or defects.

Have any damage or defects eliminated immediately.

Supervision

Never leave the machine running unattended!

3.2 Qualification of the operating personnel

Operator qualifications

Only trained personnel are permitted to start and operate the machine. The

following rules also apply:

You are at least 18 years of age.

You are physically and mentally fit.

You have received instruction on how to independently operate the machine.

You have received instruction in the proper use of the machine.

You are familiar with required safety devices.

You are authorized to start machines and systems in accordance with the

standards governing safety.

Your company or the operator has assigned you to work independently with

this machine.

Do not operate the machine if you have a pacemaker.

Incorrect operation

Incorrect operation or misuse by untrained personnel can endanger the health

and safety of the operator or third persons and also cause machine and material

damage.

Operating company responsibilities

The operating company must make the operator's manual available to the

operator and ensure that the operator has read and understood it.

Page 13

BTS 630, 635 3 Safety

Operator's manual 13

Work recommendations

Please observe the recommendations below:

Work only if you are in a good physical condition.

Work attentively, particularly as you finish.

Do not operate the machine when you are tired.

Carry out all work calmly, circumspectly and carefully.

Never operate the machine under the influence of alcohol, drugs or

medication. This can impair your vision, reactions and your judgment.

Work in a manner that does not endanger others.

Ensure that no persons or animals are within the danger zone.

3.3 Protective gear

Work clothing

Clothing should be appropriate, i.e. should be close-fitting but not restrict your

movement.

When on construction sites, do not wear long hair loosely, loose clothing or

jewelry including rings. These objects can easily get caught or be drawn in by

moving machine parts.

Only wear clothing made of material that is not easily flammable.

Personal protective gear

Wear personal protective gear to avoid injuries or health hazards:

Non-skid, hard-toed shoes.

Work gloves made of durable material.

Overalls made of durable material.

Hard hat.

Ear protection.

Face protection.

Eye protection.

Breathing protection in the case of dusty ambient air.

When cutting metal wear work clothing made of material that is not easily

flammable. Danger of fire due to sparks.

Page 14

3 Safety BTS 630, 635

14 Operator's manual

Ear protection

This machine generates noise that exceeds the country-specific permissible

noise levels (individual rating level). It may therefore be necessary to wear ear

protection. You can find the exact value in the chapter Technical Data.

When wearing ear protection while working, you must pay attention and exercise

caution because your hearing is limited, e.g. in case someone screams or a

signal tone sounds.

Wacker Neuson recommends that you always wear ear protection.

Wear special ear protection which allows you to hear audio signals.

Breathing protection

If a lot of dust is produced when cutting, always wear suitable breathing

protection.

Use the water supply or an extractor if possible.

Provision of fire extinguishers

Ensure that a fire extinguisher is always to hand on the worksite.

Do not exceed the service life

The machine produces vibrations and generates noise.

Observe the regulations which apply in your country and guidelines concerning

the maximum service life of the machine.

Always wear the prescribed safety clothing.

Details on noise and vibration levels produced by the machine can be found in

chapter Technical Data.

3.4 Transport

Carrying the machine

Do not carry or transport the machine when the cutting blade is rotating.

Only carry the machine if the engine is idling and the cutting blade is not rotating.

Switching off the machine

Before you transport the machine, it must be switched off, and the engine must

be given sufficient time to cool down.

Emptying the tank

Wacker Neuson recommends that the fuel tank be emptied and the carburetor

run dry prior to transporting it. Fuel could run out, e.g. if the machine is tilted.

Observe the national safety guidelines and the hazardous materials regulations

that apply to the respective means of transportation.

Page 15

BTS 630, 635 3 Safety

Operator's manual 15

Transporting the machine

Secure the machine on the transport device against tilting, falling or slipping.

Restarting

Machines, machine parts, accessories or tools that were detached for transport

purposes must be re-mounted and fastened before restarting.

Only operate in accordance with the operating instructions.

3.5 Operating safety

Explosible environment

Never operate the machine in a potentially explosive environment.

Work environment

Familiarize yourself with your work environment before you start work. This

includes e.g. the following items:

Obstacles in the work and traffic area.

Load-bearing capacity of the ground.

The measures needed to cordon off the construction site from public traffic in

particular.

The measures needed to secure walls and ceilings.

Options available in the event of an accident.

Safety in the work area

When working with the machine especially pay attention to the following points:

Electric lines or pipes in work area.

Gas lines or water lines in the work area.

Material becoming separated, dropping down or ejected. Make sure that you

do not put other persons in danger.

Pay maximum attention in the vicinity of drops or slopes. Risk of falling.

Maintain a sufficient distance from flammable materials.

Checks before starting work

Check the following points before beginning work:

Condition of cutting blade.

Safety devices.

Page 16

3 Safety BTS 630, 635

16 Operator's manual

Starting the machine

Observe the safety information and warning notices located on the machine and

in the operator's manual.

Never attempt to start a machine that requires maintenance or repairs.

Start the machine as described in the operator's manual.

Vertical stability

Always make sure that you stand firmly when working with the machine.

Do not work with the machine on ladders or scaffolding.

Do not use the machine at heights above shoulder height.

Danger of falling over

Operate the machine so that it cannot tip over or fall down from bordered areas,

edges and steps.

Caution with movable parts

Keep your hands, feet and loose clothing away from moving or rotating machine

parts. Parts of your body being pulled in or crushed can cause serious injuries.

Caution with toxic materials

Some materials may contain toxic chemicals which are released during

demolition. Therefore personal protective equipment must be worn to prevent

inhalation of and skin contact with work dust.

No persons endangered

Be sure that no persons are endangered by flying or falling materials. Always

work very attentively, and anticipate potential hazards.

Switching off the machine

Switch off the engine in the following situations:

Before breaks.

If you are not using the machine.

Before storing the machine, wait until it has completely stopped running.

Store the machine or put it down in such a way that it cannot tilt, fall down or slip.

Storage

Set the machine down or store it securely so that it cannot tilt, fall down or slip.

Page 17

BTS 630, 635 3 Safety

Operator's manual 17

Storage location

After operation, allow the machine to cool and then store it in a sealed-off, clean

and dry location protected against frost and inaccessible to children.

Vibrations

When manually operated machines are intensively used, long-term damage

caused by vibrations cannot be precluded.

Observe the relevant legal instructions and guidelines to minimize vibration

stress.

Details on vibration stress associated with the machine can be found in the

chapter Technical Data.

Health hazards due to dust particles or vapor

Working with the machine may cause the release of dust particles or vapor

containing hazardous materials, e.g. silicon dust.

Only cut materials which you are familiar with and always wear suitable breathing

protection.

3.6 Safety during the operation of hand machines

Safe working with hand machines

Secure loose workpieces with suitable methods.

While working, as a rule hold the machine on the provided handles with both

hands.

While working, hold the machine in such a way that hand injuries are avoided

when hitting hard objects.

Setting the hand machine down properly

Set the machine down carefully. Do not drop the machine to the floor or from

greater heights. Dropping the machine can cause injuries to other persons or the

machine itself can be damaged.

3.7 Safety during the operation of combustion engines

Checking for signs of damage

Check the engine while switched off for leaks and cracks in the fuel line, tank and

fuel cap at least once per work shift.

Do not operate the machine if there is visible damage or defects.

Have any damage or defects eliminated immediately.

Page 18

3 Safety BTS 630, 635

18 Operator's manual

Dangers during operation

Combustion engines can be dangerous, particularly during operation and when

refueling.

Read and follow all safety instructions. Otherwise there is a risk of personal injury

and/or damage to property!

Do not start the engine near spilt fuel or if you smell fuel – this may cause an

explosion!

Remove the machine from such areas.

Remove the spilt fuel immediately!

Do not change the engine speed

Do not change the preset engine speed, as this may cause engine damage.

You may only change the idle speed. The idle speed must be set such that the

cutting blade does not rotate while the engine is idling.

Preventing fires

Open flames and smoking are strictly prohibited in the immediate vicinity of the

machine.

Make sure that waste, such as paper, dry leaves or grass do not accumulate

around the exhaust muffler. The waste materials may ignite.

Safety precautions when refueling

Please observe the following safety-relevant instructions when refueling:

Do not refuel near open flames.

Do not smoke.

Turn off the engine before refueling and allow it to cool down.

Refuel in a well-ventilated environment.

Wear fuel-proof protective gloves and, if there is the possibility of spraying,

protective goggles and clothing.

Do not inhale fuel vapors.

Avoid skin and eye contact with fuel.

For refueling, use clean tools such as a hopper.

Do not spill fuel, especially onto hot parts.

Remove any spilt fuel immediately.

Use the correct fuel grade.

Do not mix fuel with other liquids.

Fill the tank only up to the maximum marking. If there is no Maximum

marking, do not fill up the tank completely.

Lock the fuel cap securely after refueling.

Page 19

BTS 630, 635 3 Safety

Operator's manual 19

Operation in closed rooms

In closed or partially closed rooms such as tunnels, drifts or deep trenches,

ensure sufficient ventilation by, for example, providing a powerful exhaust air fan.

Danger of poisoning! Do not inhale exhaust fumes. They contain toxic carbon

monoxide that can lead to unconsciousness or death.

Caution with hot parts

Do not touch any hot parts such as the engine block or exhaust muffler during

operation or directly afterwards. These parts can become very hot and cause

severe burns.

Cleaning the engine

Clean the engine when it is cool to remove any dirt.

Do not use gasoline or solvents. Danger of explosion!

Health hazard due to exhaust fumes

Warning

The engine's exhaust fumes contain chemicals which are known to the State of

California to cause cancer, congenital defects or other reproductive anomalies.

Notes on the EPA engine (for USA and Canada)

Caution

This machine is equipped with an EPA certified engine. Operating the machine

at an atmospheric pressure below 96 kPa may increase emissions and decrease

fuel efficiency and performance.

Do not use any starter sprays

Highly flammable starter sprays pose a fire hazard.

Do not use any starter sprays.

Starter sprays are highly flammable and can cause backfiring and engine

damage.

Page 20

3 Safety BTS 630, 635

20 Operator's manual

3.8 Safety during cut-off saw operation

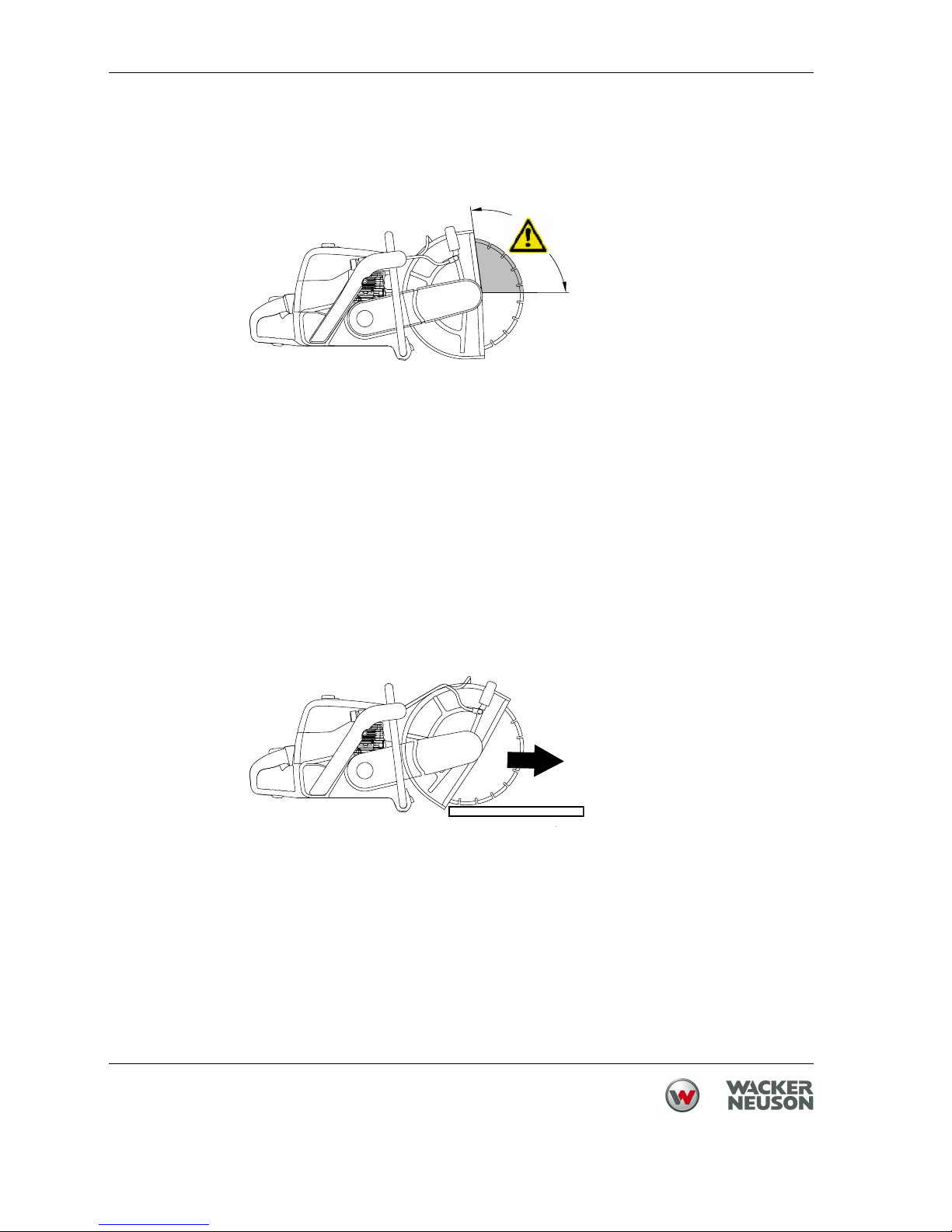

Kickback

If the upper quarter of the cutting blade is applied to a material, the machine can

be flung back toward the operator with great force.

The machine and the rotating cutting blade can cause severe injury.

To prevent kickback, follow these rules:

While working, as a rule hold the machine on the provided handles with both

hands.

Do not use the upper quarter of the cutting blade to cut.

Make sure that the material does not shift out of place.

Ensure that the cut does not become constricted during the cutting process.

Ensure that the cutting blade does not become pinched during the cutting

process.

Pulling away

When the cutting blade is set onto the material from above, the machine pulls

away toward the front.

While working, as a rule hold the machine on the provided handles with both

hands.

Page 21

BTS 630, 635 3 Safety

Operator's manual 21

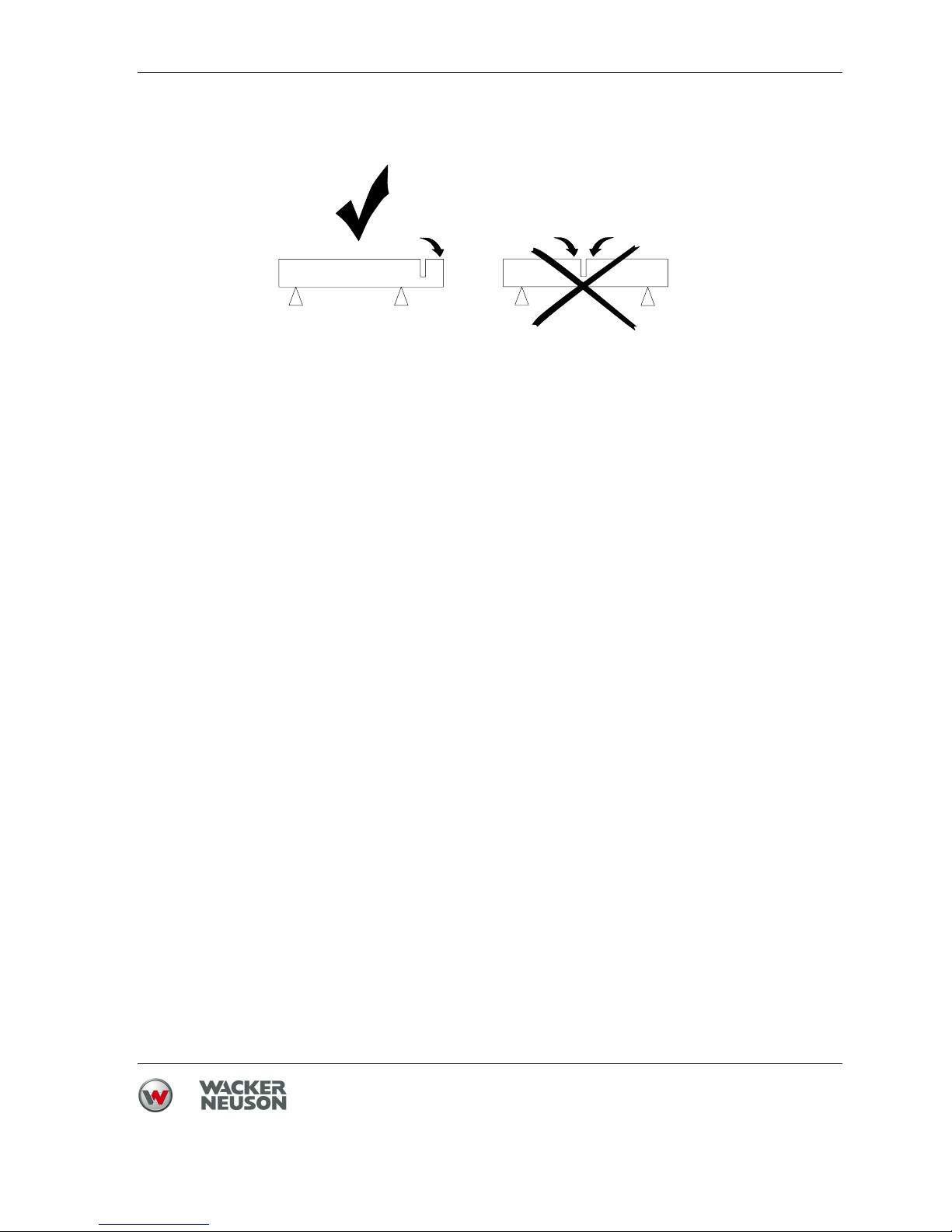

Preventing pinching

Prevent the cut from becoming constricted and pinching the cutting blade during

the cutting process.

Support the material such that the cut remains open and does not become

constricted during the entire cutting process.

Notes regarding cutting blades

The cutting blade must be suitable for use with the cut-off saw.

The cutting blade must be suitable for the material to be cut.

The speed allowed for the cutting blade must be the same as or higher than

the maximum machine spindle speed.

Mount the cutting blade such that its rotation direction is the same as that of

the machine.

Only use cutting blades with permissible cutting blade diameters.

When using cutting blades with a hole diameter greater than the machine

shaft, use the suitable adapter ring.

Only use undamaged cutting blades.

Ensure that you also follow the instructions of the cutting blade manufacturer.

Do not use cutting blades that have fallen.

Change the cutting blade only when the engine has been turned off.

Always tighten the cutting blade with the specified torque.

Test the new cutting blade for approx. 1 min at maximum speed (without

cutting).

Do not use the side surface of the cutting blade for grinding.

Only use cutting blades with use-by dates that have not expired.

When storing cutting blades, always lay them flat in an area that is protected

from frost.

Only operate the machine with a mounted cutting blade

If you operate the machine without a cutting blade, conical spring washer and

screw could become loose, causing severe injury.

Only operate the machine with mounted cutting blade.

Page 22

3 Safety BTS 630, 635

22 Operator's manual

Belt guard

Never operate the machine without a belt guard!

Exposed V-belts and belt pulleys are dangerous and can cause serious injuries

if they pull in any part of your body or if parts are ejected.

Protective hood

Never operate the machine without a protective hood.

The protective hood performs the following functions:

Protects the operator from the rotating cutting blade.

Diverts workpiece particles and sparks or chips from a damaged cutting

blade away from the operator.

Set the protective hood such that its lower section is almost in contact with the

workpiece.

Wet cutting

Use a water sprayer when dust formation is excessive, e.g. when cutting

concrete or stone.

Only use cutting blades that are suitable for wet cutting.

Before ending the wet cutting process, allow the cutting blade to run without the

water sprayer until it is dry.

Notes regarding work methods

Set the protective hood such that its lower section is almost in contact with

the workpiece. The protective hood can catch material flung away from the

work area and divert it away from the operator.

Always operate the machine at full throttle even when first placing it into the

cut.

When first placing the the cutting blade into the cut, set it slowly onto the

material. Excessive pressure can damage the cutting blade.

Do not press down on the machine while cutting.

Move the machine in a straight line together with the cutting blade. Pressure

from the side can damage the cutting blade.

Do not use the upper quarter of the cutting blade to cut. Machine kickback

can cause severe injury.

Hold the machine with both hands

While working, as a rule hold the machine on the provided handles with both

hands.

Page 23

BTS 630, 635 3 Safety

Operator's manual 23

Do not stand in the machine's swing area

Hold and guide the machine such that no body parts are in the machine's swing

area.

Securing the material

Before cutting, secure the material so that it does not slide away or tip over. Do

not ever secure the material with your foot.

Remove foreign objects before cutting

Before cutting, remove foreign objects such as nails, etc. from the cutting area.

Supporting the machine's weight

At the end of the cutting procedure the cutting blade no longer supports the

machine's weight. The operator must support the machine's weight.

While working, as a rule hold the machine on the provided handles with both

hands.

Cutting several materials at once

Do not cut several materials in one cutting procedure.

Cutting very thin materials

Make sure that very thin materials do not get trapped between the cutting blade

and the lateral protection cover.

Do not touch a rotating cutting blade

Never touch a rotating cutting blade with your hand or any other body part.

Danger of severe injury.

Running cutting blade

The cutting blade continues to run for awhile after the throttle lever is released.

Danger of injury.

Danger of fire due to sparks

Danger of fire due to hot workpiece particles flung away from the work area.

Do not work near flammable materials.

Only wear clothing made of material that is not easily flammable.

Do not leave any tools inserted

Before operating the machine, make sure that tools have been removed.

Page 24

3 Safety BTS 630, 635

24 Operator's manual

3.9 Maintenance

Maintenance work

Service and maintenance work must only be carried out to the extent described

in these operating instructions. All other procedures must be performed by your

Wacker Neuson representative.

For further information, refer to chapter Maintenance.

Switching off the engine

Before carrying out care or maintenance work, switch off the engine and allow it

to cool down.

For gasoline powered engines, you must pull off the spark plug cap.

Cleaning

Always keep the machine clean and be sure to clean it each time you have

finished using it.

Do not use gasoline or solvents. Danger of explosion!

Do not use high pressure washers. Permeating water can damage the machine.

When electrical equipment is present, this can pose a serious injury risk from

electric shocks.

Assembling safety devices

If it was necessary to dismantle safety devices, they must be reassembled and

checked immediately after completing maintenance work.

Always tighten loosened screw connections, complying with prescribed starting

torque.

Handling operating fluids safely

Observe the following points when handling operating fluids, e.g. fuels, oils,

greases, coolants etc.:

Always wear personal safety clothing.

Avoid skin and eye contact with operating fluids.

Do not inhale or swallow operating fluids.

In particular, avoid contact with hot operating fluids. Burn and scalding

hazard.

Dispose of replaced or spilled operating fluids according to the applicable

regulations for environmental protection.

If operating fluids escape from the machine, cease operation of the machine

and have it repaired immediately by your Wacker Neuson representative.

Page 25

BTS 630, 635 3 Safety

Operator's manual 25

3.10 Safety and information labels

Your machine has adhesive labels containing the most important instructions

and safety information.

Make sure that all the labels are kept legible.

Replace any missing or illegible labels.

The item numbers for the labels are in the parts book.

Item Label Description

1

Do not exceed the maximum cutting

blade diameter.

Only use cutting blades with the

specified hole diameter.

Do not exceed the maximum cutting

blade width.

2 The machine may not be operated with

blades, knives, brushes, etc.

Page 26

3 Safety BTS 630, 635

26 Operator's manual

2 Wear personal protective gear to avoid

injuries or health hazards:

Hard hat.

Ear protection.

Eye protection.

Breathing protection.

Face protection.

Work gloves made of durable material.

Overalls made of durable material.

Non-skid, hard-toed shoes.

2 Danger of fire due to sparks.

Do not work near flammable materials.

Only wear clothing made of material

that is not easily flammable.

2 Before operation, read and follow the

information in the operator's manual.

2 Smoking and open flames are prohibited.

Danger of fire.

2

Maximum spindle speed.

Maximum peripheral speed.

The speed allowed for the cutting blade

must be the same as or higher than the

maximum machine spindle speed.

2 Guaranteed sound power level.

2 The machine may only be operated with

a fuel mixture consisting of unleaded

gasoline and two-cycle engine oil.

The mixture ratio is 50:1.

Item Label Description

Page 27

BTS 630, 635 3 Safety

Operator's manual 27

2 Danger of kickback.

Machine kickback can cause severe

injury.

Do not use the upper quarter of the

cutting blade to cut.

2 Cutting blades can break, causing severe

injuries.

Only use undamaged cutting blades.

Do not use cracked, broken or twisted

cutting blades.

2 Danger of poisoning.

Do not inhale exhaust fumes. They

contain toxic carbon monoxide that can

lead to unconsciousness or death.

In closed or partially closed rooms such

as tunnels, drifts or deep trenches,

ensure sufficient ventilation by, for

example, providing a powerful exhaust

air fan.

3 EU emission information label

3

This label is an example only

and may vary from machine to

machine.

EPA emission information label (for EPA

machines).

Emission Control (Exhaust &

Evaporative) EPA 2010 and later.

The emission control system for the

engine is EM (Engine Modification) and

for the fuel tank the control system is

EVAP (Evaporative Emissions) or N (for

Nylon tank).

Product emission durability (Emission

compliance period).

The 300 hours emission durability

compliance period is the time span

selected by the manufacturer certifying

the engine emissions output meets

applicable emissions regulations,

provided that approved maintenance

procedures are followed as listed in the

maintenance section of this manual.

Item Label Description

Page 28

3 Safety BTS 630, 635

28 Operator's manual

3.11 Safety and information icons

Item Symbol Description

1Choke.

2Start.

3 Stop.

4 The machine may only be operated with

a fuel mixture consisting of unleaded

gasoline and two-cycle engine oil.

The mixture ratio is 50:1.

5 Mark for setting the V-belt tension.

6 Machine's direction of rotation.

Mount the cutting blade such that its

rotation direction is the same as that of

the machine.

Page 29

BTS 630, 635 3 Safety

Operator's manual 29

3.12 Safety devices

Protective hood

Never operate the machine without a protective hood.

The protective hood performs the following functions:

Protects the operator from the rotating cutting blade.

Diverts workpiece particles and sparks or chips from a damaged cutting

blade away from the operator.

Set the protective hood such that its lower section is almost in contact with the

workpiece.

WARNING

Danger of injury due to open moving parts.

f Only operate the machine with properly installed and functioning safety

devices.

f Do not modify or remove safety devices.

Item Designation

1 Protective hood

Page 30

4 Scope of delivery BTS 630, 635

30 Operator's manual

4 Scope of delivery

Item Designation Item Designation

1 Machine 4 5 mm Allen wrench

2 Operator's manual 5 6 mm Allen wrench

3 Parts book 6 Combination wrench 13/19 mm

Page 31

BTS 630, 635 5 Structure and function

Operator's manual 31

5 Structure and function

5.1 Application

Use the machine only as intended, see chapter Safety, Proper use.

5.2 Functionality

Principle

The machine is a gasoline cut-off saw.

It is driven by a two-cycle combustion engine.

The powertrain from the engine to the cutting blade is driven by a centrifugal

clutch and V-belt.

The machine has an electronic ignition system that is maintenance-free.

The multi-stage air cleaner system consists of a cyclone, foam material prefilter

and paper air cleaner cartridge.

Page 32

6 Components and operator's controls BTS 630, 635

32 Operator's manual

6 Components and operator's controls

Item Designation Item Designation

1 Front handle 8 Fuel tank

2 Water supply 9 Recoil starter

3 Multifunction switch 10 Cutting blade

4 Throttle lever lock 11 Protective hood

5 Rear handle 12 Decompression valve

6 Throttle lever 13 Fuel pump

7 Lock button

Page 33

BTS 630, 635 6 Components and operator's controls

Operator's manual 33

Water supply

You can connect a water supply unit to the water supply connection.

The water supply performs the following functions:

Cools the cutting blade evenly.

Causes dust particles to stick together.

Multifunction switch

You can switch the machine on and off with the multifunction switch.

The multifunction switch has a choke setting for cold starts.

Throttle lever lock

Unintentional pressing of the throttle lever is prevented by the throttle lever lock.

You can only press the throttle lever if you are pressing the throttle lever lock at

the same time.

If you release the throttle lever, the throttle lever lock also returns to its original

position.

Throttle lever

The machine speed can be continuously varied using the throttle lever.

Lock button

The lock button can lock the throttle lever in the half-gas position.

Recoil starter

The recoil starter starts the engine.

Protective hood

The protective hood performs the following functions:

Protects the operator from the rotating cutting blade.

Diverts workpiece particles and sparks or chips from a damaged cutting

blade away from the operator.

Set the protective hood for operation such that workpiece particles are diverted

away from the operator.

Decompression valve

When starting the engine, the decompression valve allows some of the

compressed air to escape from the cylinder. The lower compression in the

cylinder reduces the drag on the starter rope.

When the engine is running, the decompression valve returns to its original

position.

Page 34

6 Components and operator's controls BTS 630, 635

34 Operator's manual

Fuel pump

The fuel pump is used to fill the fuel lines and the carburetor after the machine

has not been used for a while. The integrated return pipe prevents too much fuel

from entering the carburetor as a result of excessive pumping.

Page 35

BTS 630, 635 7 Transport

Operator's manual 35

7 Transport

Transporting the machine

1. Switch off the engine.

2. Detach the cutting blade.

3. Lift the machine using the front handle.

4. Place the machine on or into a suitable means of transport.

5. Secure the machine against falling over and down or sliding.

WARNING

Improper handling can result in injury or serious material damage.

f Read and follow all safety information of this operator's manual, see chapter

Safety.

WARNING

Hazard of fire and explosions by fuel.

Any fuel that escapes can ignite and cause severe burns.

f Lift and move the machine in the upright position.

Page 36

8 Initial start up BTS 630, 635

36 Operator's manual

8 Initial start up

8.1 Mounting the cutting attachment on the outside

By default the cutting attachment is mounted in the center of the machine.

The cutting attachment can be mounted on the outside to maneuver around

obstacles that are very close to the cutting line (e.g. curbs or brick walls).

When the cutting attachment is in the external position, using the guide cart

makes it even easier to see the cutting line.

Performing preparations

1. Switch off the engine.

2. Let machine cool off.

3. Detach the cutting blade.

Note: You must detach the cutting blade because otherwise, after the

conversion, the rotation direction of the cutting blade will no longer be the

same as that of the machine.

WARNING

Improper handling can result in injury or serious material damage.

f Read and follow all safety information of this operator's manual, see chapter

Safety.

Page 37

BTS 630, 635 8 Initial start up

Operator's manual 37

Converting the protective hood

1. Unscrew both hose connections and remove them.

2. Rotate the protective hood clockwise as far as it will go.

3. Unscrew and remove the vibration dampers.

4. Rotate the protective hood counter-clockwise until the mounting hole in the

vibration damper is visible.

5. Position the vibration damper and tighten it.

6. Unscrew the adjustment handle on top and remove it.

7. Position the adjustment handle below and tighten it.

Item Designation

1 Hose connection (2 pieces)

2 Vibration dampers

Item Designation

1 Adjustment handle

2 Vibration dampers

Page 38

8 Initial start up BTS 630, 635

38 Operator's manual

Slackening the V-belt

1. Loosen both belt guard screws by approximately one turn.

2. Rotate the adjusting screw counter-clockwise until the V-belt is slackened

completely.

3. Unscrew the belt guard screws and remove them.

4. Remove the belt guard.

Item Designation Item Designation

1 Screw (2 pieces) 3 Belt guard

2 Adjusting screw 4

Page 39

BTS 630, 635 8 Initial start up

Operator's manual 39

Mounting the cutting attachment on the outside

1. Remove the cutting attachment.

2. Clean the cutting attachment, V-belt pulley, belt guard and screws.

3. Rotate the cutting attachment 180° and place it in position.

4. Place the V-belt in position.

5. Place the belt guard in position and affix it with screws.

6. Rotate the adjusting screw clockwise until the square nut is located between

the two marks.

7. Tighten the belt guard screws.

Torque 25 Nm.

8. Position the hose connections and tighten them.

Item Designation Item Designation

1 Hose connection (2 pieces) 3 Adjusting screw

2 Belt guard 4 Screw (2 pieces)

Page 40

8 Initial start up BTS 630, 635

40 Operator's manual

9. Turn the thrust washer 2-3 times to make sure the tension is equal across the

V-belt.

10. Check the V-belt tension again and re-tighten the V-belt if necessary.

Page 41

BTS 630, 635 9 Use and operation

Operator's manual 41

9 Use and operation

9.1 Prior to starting the machine

9.1.1 Checks before startup

Checking the machine

Always check the following points before beginning work:

Damage to the machine and to all components.

If the machine is damaged, do not start the machine. Have any damage or

defects eliminated immediately.

Damage to the cutting blade (cracks, sections broken off, deformation, off

balance, etc.)

Fuel level, see chapter Maintenance.

V-belt tension, see chapter Maintenance.

Tightness of the protective hood.

9.1.2 Changing the cutting blade

Performing preparations

1. Place the machine upright on a flat surface.

2. Set the multifunction switch to Stop.

WARNING

Improper handling can result in injury or serious material damage.

f Read and follow all safety information of this operator's manual, see chapter

Safety.

Page 42

9 Use and operation BTS 630, 635

42 Operator's manual

Changing the cutting blade

1. To block the shaft, put an Allen wrench into the bore.

Note: If necessary, rotate the spindle until the Allen wrench engages in the

bore.

2. Unscrew and remove the screw together with the thrust washer.

3. Clean thrust washer and spindle of the machine.

4. Place the cutting blade onto the spindle in the correct rotation direction.

5. Place the screw together with the thrust washer in position and tighten.

Torque 23 Nm.

6. Remove the Allen wrench from the bore.

7. Test the new cutting blade for approx. 1 min at maximum speed (without

cutting).

Item Designation Item Designation

1Bore 4Thrust washer

2Spindle 5Screw

3 Cutting blade

Page 43

BTS 630, 635 9 Use and operation

Operator's manual 43

9.2 Starting up

9.2.1 Starting the engine

Performing preparations

1. Set down the machine such that the cutting blade can rotate freely.

2. Set the multifunction lever to the appropriate position.

Cold engine: Position "choke".

Warm engine: Position "I".

3. Press the fuel pump bellows repeatedly until the bellows is completely filled

with fuel.

4. Actuate the decompression valve.

If you detect resistance when pressing, move the decompression valve back

and forth a bit.

When the engine is running, the decompression valve returns to its original

position.

Item Designation

1Fuel pump

2 Decompression valve

Page 44

9 Use and operation BTS 630, 635

44 Operator's manual

Bringing the throttle lever into the start position

1. Press and hold the throttle lever lock and the throttle lever.

2. Press the lock button.

3. Release the throttle lever.

The throttle lever is locked in the half-gas position.

4. Release the lock button.

Item Designation Item Designation

1 Throttle lever lock 3 Lock button

2 Throttle lever 4

Page 45

BTS 630, 635 9 Use and operation

Operator's manual 45

Starting the engine

Note: When starting the engine, move to a position at least 3 m from the fueling

area.

1. Grasp the front handle with one hand.

2. Place your foot in the rear handle to stabilize the machine.

3. Pull out the starter rope slowly until compression resistance can be felt and

then let it slowly roll back in again.

NOTICE

Improper handling can damage the machine.

f Do not pull the starter rope as far as it can go.

f Let starter rope slowly roll back in.

CAUTION

Incorrect handling during starting can result in minor injuries.

f Do not pull the starter rope until sufficient space is available and nobody is in

the immediate vicinity.

Item Designation Item Designation

1 Starter rope 3 Rear handle

2 Front handle

Page 46

9 Use and operation BTS 630, 635

46 Operator's manual

4. Pull the starter rope with force, but not suddenly.

When you first hear the engine ignite, move the multifunction switch from the

"Choke" position to the "I" position.

If necessary, actuate the decompression valve once again.

5. Pull the starter rope with force, but not suddenly (several times, if necessary)

until the engine starts.

6. Let starter rope slowly roll back in.

7. Press the throttle lever to release the lock in the half-gas position.

8. Allow the engine to warm up.

Page 47

BTS 630, 635 9 Use and operation

Operator's manual 47

9.3 Operating the machine

Note: When cutting, lightly pressing the cutting blade against the cutting

material produces a very pleasant vibration response as well as a

particularly narrow cut.

Holding and guiding the machine

1. Stand in a fixed position.

2. Always hold the machine with both hands, using both handles.

Setting the protective cover

f Use the adjustment handle to set the protective hood such that its lower

section is almost in contact with the workpiece.

WARNING

Injuries from insufficiently guided or uncontrolled machine.

f Always hold machine with both hands and stand firmly.

Item Designation

1 Adjustment handle

Page 48

9 Use and operation BTS 630, 635

48 Operator's manual

9.4 Decommissioning

Switching off the machine

1. Release the throttle lever.

2. Set down the machine in such a way that it cannot tilt, fall or slip.

3. Set the multifunction switch to "Stop".

4. Detach the cutting blade and store in a dry place.

Item Designation

1 Multifunction switch

2 Throttle lever

Page 49

BTS 630, 635 10 Maintenance

Operator's manual 49

10 Maintenance

10.1 Maintaining the emission control system

Normal maintenance, replacement or repair of emission control devices and

systems may be performed by any repair establishment or individual; however,

warranty repairs must be performed by a dealer/service center authorized by

Wacker Neuson.

The use of service parts that are not equivalent in performance and durability to

authorized parts may impair the effectiveness of the emission control system and

may have a bearing on the outcome of a warranty claim.

WARNING

Improper handling can result in injury or serious material damage.

f Read and follow all safety information of this operator's manual, see chapter

Safety.

WARNING

Hazard of poisoning by exhaust fumes.

Exhaust fumes contain toxic carbon monoxide that can lead to

unconsciousness or death.

f Carry out maintenance work only when the engine is off.

Page 50

10 Maintenance BTS 630, 635

50 Operator's manual

10.2 Maintenance schedule

Task Daily

before

operation

Daily after

operation

Every

50 hours

or every

six

months

Every

90 hours

or once a

year

Check fuel system for:

Fuel tank fill level.

Leaks in fuel tank and fuel

cap.

Check V-belt tension. Tighten

V-belt as necessary.

Visual inspection of all parts

for damage.

Check function of throttle

lever, throttle lever lock and

lock button.

Check protective hood:

Damage.

Tightness.

Check cutting blade:

Damage.

Tightness.

Check thrust washers:

Damage.

Wear.

Clean the machine.

Replace the fuel filter.

Clean or replace spark plug.

Air cleaner: *

Clean air cleaner housing.

Change prefilter and air

cleaner cartridge.

Clean the muffler.

Replace fuel cap gasket.

Clean the spark arrestor (only

for EPA machines in the USA

and Canada).*

Page 51

BTS 630, 635 10 Maintenance

Operator's manual 51

Note: For EPA machines (in the USA and Canada), have the exhaust port of the

machine cleaned by the service team of your Wacker Neuson contact

every 90 h.

10.3 Maintenance work

Working in the workshop

Perform maintenance work in a workshop on a workbench. This has the following

benefits:

Protection of the machine of contamination on the construction site.

A level and clean work surface makes work easier.

There is a better overview over small parts and they are not lost as easily.

10.3.1 Cleaning the machine

f Wipe the housing with a damp and clean cloth.

10.3.2 Topping up with fuel

Performing preparations

1. Switch off the engine.

2. Let the machine cool off.

3. Position the machine on its side such that the fuel cap points up.

4. Remove any dirt around the fuel cap.

* In case of loss in engine performance, shorten maintenance intervals.

WARNING

Hazard of fire and explosions by fuel and fuel vapors.

f Do not smoke.

f Do not refuel near open flames.

f Turn off the engine before refueling and allow it to cool down.

CAUTION

Health hazard due to fuel.

f Refuel in a well-ventilated environment.

f Do not inhale fuel vapors.

f Avoid skin and eye contact with fuel.

Page 52

10 Maintenance BTS 630, 635

52 Operator's manual

Topping up with fuel

1. Slowly unscrew and remove the fuel cap.

Note: Slowly unscrew the fuel cap so that any overpressure can slowly escape.

2. Top up with fuel.

See chapter Technical data for the fuel specification.

See chapter Technical data for the fuel mixing table.

3. Position the fuel cap and tighten it.

Item Designation

1 Fuel cap

Page 53

BTS 630, 635 10 Maintenance

Operator's manual 53

10.3.3 Tightening the V-belt

Performing preparations

1. Switch off the engine.

Tightening the V-belt

1. Loosen both belt guard screws by approximately one turn.

2. Rotate the adjusting screw clockwise until the square nut is flush with the

mark.

3. Tighten both belt guard screws.

Torque 25 Nm.

Item Designation Item Designation

1 Screw (2 pieces) 3 Square nut

2 Adjusting screw

Page 54

10 Maintenance BTS 630, 635

54 Operator's manual

10.3.4 Checking the thrust washers

1. Check the thrust washers for wear and sharp edges.

In case of wear or damage, change the thrust washers.

2. Clean the thrust washers.

Item Designation

1 Thrust washer (2 pieces)

2 Cutting blade

Page 55

BTS 630, 635 10 Maintenance

Operator's manual 55

10.3.5 Cleaning/Changing the air cleaner

Performing preparations

1. Switch off the engine.

2. Remove any dirt around the air cleaner cap.

3. Unscrew and remove the air cleaner cap.

NOTICE

Operating the engine without air cleaner can cause rapid engine wear.

f Do not run the engine without an air cleaner or air cleaner cap.

Item Designation Item Designation

1 Air cleaner cap 4 Air cleaner cover

2 Prefilter 5 Air cleaner cartridge

3 Screw (4 pieces) 6 Seal (2 pieces)

Page 56

10 Maintenance BTS 630, 635

56 Operator's manual

Changing the prefilter

1. Remove the prefilter.

2. Clean the air cleaner cover and the entire air cleaner housing with a brush

and a clean cloth.

Note: Use a vacuum cleaner to remove the dirt from the air cleaner housing.

3. Insert a new prefilter.

Changing the air cleaner cartridge

1. Unscrew and remove the air cleaner cover.

2. Remove the air cleaner cartridge.

3. Insert new air cleaner cartridge.

4. Position the air cleaner cover and tighten it.

5. Position the air cleaner cap and tighten it.

Torque 5 Nm.

6. Check if the seals in the air cleaner housing are free of dirt and are correctly

positioned. If necessary, clean the seals with a brush.

NOTICE

Dirt can fall into the engine combustion chamber and damage the engine.

f Before changing the air cleaner, clean the machine thoroughly.

Page 57

BTS 630, 635 10 Maintenance

Operator's manual 57

10.3.6 Checking/cleaning/replacing the spark plug

Performing preparations

1. Switch off the engine.

2. Let the machine cool off.

Removing the spark plug

1. Unscrew and remove the air cleaner cap.

2. Clean the air cleaner housing and the area around the spark plug thoroughly.

3. Pull off the spark plug cap from the spark plug.

Note: Do not pull the spark plug cap off the spark plug by the ignition cable.

4. Loosen the spark plug with a combination wrench.

5. Unscrew the spark plug manually.

CAUTION

Touching a hot spark plug can cause burns.

f Only remove the spark plug when the engine has cooled down.

Item Designation

1 Air cleaner cap

2 Spark plug cap

Page 58

10 Maintenance BTS 630, 635

58 Operator's manual

Checking/cleaning the spark plug

1. Check the isolator – if damaged, replace the spark plug.

2. Clean the electrodes with a wire brush.

3. Measure the spark plug gap with a feeler gauge – if necessary, correct it by

bending the lateral electrode.

See chapter Technical data for the spark plug gap.

4. Check the spark plug gasket – if damaged, replace the spark plug.

Installing the spark plug

1. First screw in the spark plug manually then tighten it with a combination

wrench.

2. Place the spark plug cap onto the spark plug.

3. Position the air cleaner cap and tighten it.

Torque 5 Nm.

Item Designation

1 Spark plug air gap

2Isolator

NOTICE

A spark plug that is too loose or too tight can damage the engine.

f Tighten the spark plugs with the specified torque.

Page 59

BTS 630, 635 10 Maintenance

Operator's manual 59

10.3.7 Replacing the V-belt

Performing preparations

1. Switch off the engine.

2. Let the machine cool off.

Removing the covers

1. Loosen the belt guard screws.

2. Rotate the adjusting screw counter-clockwise until the V-belt is slackened

completely.

3. Unscrew the belt guard screws and remove them.

4. Remove the belt guard.

5. Unscrew the clutch cover screws and remove them.

6. Remove the clutch cover.

Item Designation Item Designation

1 Screw (2 pieces) 4 Screw (3 pieces)

2 Adjusting screw 5 Clutch cover

3 Belt guard

Page 60

10 Maintenance BTS 630, 635

60 Operator's manual

Replacing the V-belt

1. Remove the cutting attachment.

2. Remove the V-belt.

3. Place the new V-belt in position.

4. Place the cutting attachment in position and thread the V-belt in.

Item Designation

1 Cutting attachment

2 V-belt

Page 61

BTS 630, 635 10 Maintenance

Operator's manual 61

Attaching the covers

1. Place the clutch cover in position and tighten it with screws.

2. Place the belt guard in position and affix it with screws.

3. Rotate the adjusting screw clockwise until the square nut is flush with the

mark.

4. Tighten the belt guard screws.

Torque 25 Nm.

Item Designation Item Designation

1 Screw (2 pieces) 4 Screw (3 pieces)

2 Adjusting screw 5 Clutch cover

3 Belt guard

Page 62

10 Maintenance BTS 630, 635

62 Operator's manual

10.3.8 Replacing the fuel filter

Note: The fuel filter is located in the tank. The fuel filter cannot be cleaned.

Performing preparations

1. Switch off the engine.

2. Let the machine cool off.

3. Empty the tank.

Replacing the fuel filter

1. Unscrew the fuel cap.

2. Pull the fuel cap together with the retainer out of the fuel tank.

3. Pull the fuel filter out of the fuel tank with a wire hook.

4. Use a small screwdriver to loosen and remove the fuel filter.

5. Place a new fuel filter in position and press it in tightly.

6. Insert the fuel cap retainer into the fuel tank.

7. Position the fuel cap and tighten it.

Item Designation Item Designation

1 Fuel filter 3 Retainer

2 Fuel cap

Page 63

BTS 630, 635 10 Maintenance

Operator's manual 63

10.3.9 Setting the idle speed

1. Start the engine.

2. Allow the engine to warm up.

3. Set the idle speed with a screwdriver:

If the cutting blade rotates in idle, turn the adjusting screw for idle speed

counter-clockwise until the cutting blade stops.

If the engine shuts off in idle, turn the adjusting screw a bit clockwise.

Note: If the cutting blade still rotates after setting the idle speed, have it repaired

by your Wacker Neuson representative.

Item Designation

1 Adjusting screw

Page 64

10 Maintenance BTS 630, 635

64 Operator's manual

10.3.10 Cleaning the spark arrestor

Note: Only EPA machines (in the USA and Canada) have a spark arrestor.

Cleaning the spark arrestor

1. Detach the cutting device, see chapter Initial start up, mounting the cutting

attachment on the outside.

2. Unscrew and remove the guide plate.

3. Remove the spark arrestor grid.

4. Clean the spark arrestor grid using a wire brush.

5. Mount and screw the guide plate and spark arrestor grid into position.

Torque 2 Nm.

6. Install the cutting device, see chapter Initial start up, mounting the cutting

attachment on the outside.

Item Description Item Description

1 Muffler 3 Guide plate

2 Spark arrestor grid 4 Screw (2 pieces)

Page 65

BTS 630, 635 10 Maintenance

Operator's manual 65

10.3.11 Cleaning the exhaust port

Note: For EPA machines (in the USA and Canada), have the exhaust port of the

machine cleaned by the service team of your Wacker Neuson

representative every 90 h.

1. Detach the cutting device, see chapter Initial start up, mounting the cutting

attachment on the outside.

2. Remove the spark plug cap.

3. Unscrew and remove the muffler.

4. To stop the cylinder area from getting dirty, bring the piston to the top

position.

5. Use a wooden tool (e.g. stick) to remove the combustion residue in the

exhaust port.

6. Clean the seal face of the cylinder and muffler.

CAUTION

Improper handling can severely damage the machine.

f Do not use hard or metallic tools for cleaning.

f Make sure that no combustion residue enters the cylinder.

Item Description Item Description

1 Seal 3 Screw (4 pieces)

2 Muffler

Page 66

10 Maintenance BTS 630, 635

66 Operator's manual

7. Screw the muffler (with new seal) to the cylinder.

Torque 18 Nm.

8. Install the cutting device, see chapter Initial start up, mounting the cutting

attachment on the outside.

Page 67

BTS 630, 635 11 Troubleshooting

Operator's manual 67

11 Troubleshooting

Potential faults, their causes and remedies can be found in the following table.

Notify your Wacker Neuson representative in case of malfunctions you cannot or

may not remedy yourself.

Malfunction Cause Remedy

Engine does not start. Multifunction switch is in the

stop position.

Set multifunction switch to the

"I" or the "Choke" position.

Spark plug cap is defective. Have the machine repaired. *

* Have these tasks carried out by the service department of your Wacker Neuson representative.

Spark plug is defective. Replace spark plug.

Spark plug is loose. Tighten spark plug.

Spark plug gap is set

incorrectly.

Set spark plug gap.

Fuel filter is clogged. Replace fuel filter.

Engine shuts off right after

starting.

Idle speed is adjusted

incorrectly.

Set idle speed.

Fuel filter is clogged. Replace fuel filter.

Fuel tank is empty. Top up with fuel.

Engine has low performance. Air cleaner is dirty. Replace air cleaner.

Cutting blade does not rotate. V-belt is defective. Replace V-belt.

Clutch is defective. Have the machine repaired. *

Cutting blade rotates in idle. Idle speed is adjusted

incorrectly.

Set idle speed.

Engine cannot be turned off. Electrical connection of the

multifunction switch is

defective.

1. Set multifunction switch to

"Choke". The engine will

switch off after a few

seconds.

2. Have the machine repaired. *

Page 68

12 Accessories BTS 630, 635

68 Operator's manual

12 Accessories

There is a wide range of accessories available for the machine.

For more information on the individual accessories, visit the following website:

www.wackerneuson.com.

Page 69

BTS 630, 635 13 Storage

Operator's manual 69

13 Storage

If the machine will not be operated for a while, e.g. during the winter, do the

following:

Performing preparations

1. Switch off the engine.

2. Detach the cutting blade and store in a dry place.

3. Let the machine cool off.

Emptying the fuel system

The gasoline in the fuel partially evaporates during long-term storage. The twocycle oil in the fuel does not evaporate. After long-term storage the mixture ratio

of gasoline to two-cycle oil is no longer correct. For this reason, the fuel system

must be be empty for long-term storage.

1. Remove any dirt around the fuel cap.

2. Slowly unscrew and remove the fuel cap.

3. Pump the fuel out into a suitable container or tank, e.g. with a suction pump.

4. Position the fuel cap and tighten it.

5. Start the engine and let it idle until the fuel in the carburetor is used up and

the engine stops.

Storing the machine

1. Clean the machine.

2. Store the machine in a dry place.

Page 70

14 Technical data BTS 630, 635

70 Operator's manual

14 Technical data

14.1 BTS 630, 635, 635s

Machine

Designation Unit BTS 630 BTS 635 BTS 635s

Item no. 0610186,

0610187

0610190,

0610191

0610192,

0610193

Length x Width x Height mm (ft) 800 x 315 x 400

(2.6 x 1 x 1.3)

825 x 315 x 420

(2.7 x 1 x 1.4)

825 x 315 x 420

(2.7 x 1 x 1.4)

Weight (without cutting

blade or accessories, tank

empty)

kg (lb) 10.9 (24) 11.1 (24.5) 11.3 (24.9)

Soft Start — —

Max. cutting blade

diameter

mm (in) 300 (12) 350 (14) 350 (14)

Max. width mm (in) 4.5 (0.2) 4.5 (0.2) 4.5 (0.2)

Spindle diameter mm (in) 20 (0.8) 25.4 (1.0) 25.4 (1.0)

Max. cutting depth mm (in) 103 (4.1) 128 (5.0) 128 (5.0)

Tank capacity l (gal) 1.1 (0.3) 1.1 (0.3) 1.1 (0.3)

Fuel consumption l/h

(gal/h)

2.3 (0.6) 2.3 (0.6) 2.3 (0.6)

Max. spindle speed rpm 4,240 4,240 4,240

Max. peripheral speed m/s

(ft/s)

67 (219.8) 78 (255.9) 78 (255.9)

Measured sound power

level L

WA

at 50 feet

dB(A) 0610186: —

0610187: 80

0610190: —

0610191: 80

0610192: —

0610193: 80

Measured sound power

level L

WA

*

dB(A) 114 115 115

Guaranteed sound power

level L

WA

dB(A) 116 117 117

Sound pressure level L

pA

at operator's station *

dB(A) 103 104 104

Page 71

BTS 630, 635 14 Technical data

Operator's manual 71

Drive engine

Total vibration value of the

acceleration a

hv

* at the

front handle

m/s

2

(ft/s2)

4.4 (14.4) 4.2 (13.8) 4.2 (13.8)

Total vibration value of the

acceleration a

hv

* at the

rear handle

m/s

2

(ft/s2)

4.5 (14.8) 4.8 (15.7) 4.8 (15.7)

Uncertainty of

measurement of the

vibration total value of the

acceleration ahv

m/s

2

(ft/s2)

1.5 (4.9) 1.5 (4.9) 1.5 (4.9)

* According to DIN EN ISO 19432:2006

Designation Unit BTS 630 BTS 635 BTS 635s

Combustion method 2-cycle

Engine type Gasoline engine

Engine displacement cm³ (in³) 85.8 (5.2)

Rated output kW 4.3

Rated speed rpm 9,300

Max. torque Nm 5.0

Max. speed rpm 10,000

Idle speed rpm 2,800

Operating fluid Fuel-oil mixture

Fuel mixture ratio 50:1

Fuel specification Regular gasoline, lead-free 91 ROZ (87 R+M)

Oil specification, 2-cycle

oil

ISO L-EGD

Spark plug NGK BPMR7A

Spark plug air gap mm (in) 0.6 (0.02)

Designation Unit BTS 630 BTS 635 BTS 635s

Page 72

14 Technical data BTS 630, 635

72 Operator's manual

14.2 Fuel mixture table

Note: Only use fuel in a mixture ratio of 1:50.

Gasoline volume in

liters (qt)

Oil volume in liters

(qt)

1 (1.06) 0.02 (0.02)

5 (5.28) 0.1 (0.11)

10 (10.57) 0.2 (0.21)

15 (15.85) 0.3 (0.32)

20 (21.13) 0.4 (0.42)

25 (26.42) 0.5 (0.53)

Page 73

BTS 630, 635 15 Emission control warranty

Operator´s manual 73

15 Emission control warranty

This Emission control warranty is valid only for U.S.A., its Territories, and Canada.

Emission control warranty statement

The Environmental Protection Agency (EPA) and Wacker Neuson are pleased

to explain the emission control system warranty on your 2010 and later equipment/small off-road engine (SORE).

New equipment/SORE must be designed, built and equipped to meet stringent

EPA anti-smog standards. Wacker Neuson must warrant the emission control

system on your equipment/SORE for the periods of time listed below, provided

there has been no abuse, neglect or improper maintenance of your equipment/

SORE.