Page 1

Item Number / Artikel-Nummer / Número de referencia / Numéro de référence :

0007567, 0007566

This manual is divided into the sections listed below:

Diese Betriebsanleitung ist in folgende Kapitel eingeteilt:

Este manual está compuesto por las siguientes secciones:

Ce manuel contient les sections suivantes:

BS65Y

Operation

1A

Betrieb

1B

Operación

1C

Opération

1D

Machine Parts / Maschinenteile / Repuestos de la máquina / Pièces de la machine

2

This manual provides information and procedures to safely operate and maintain this WACKER model. For your

own safety and protection from injury, carefully read, understand and observe the safety instructions described

in this manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION

AT THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION

OF THIS INFORMATION WITHOUT NOTICE.

(English)

(Deutsch)

(Español)

(Français)

WARNING

!

Engine exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

1040SD71

Diese Betriebsanleitung enthält Informationen und Verfahren, um dieses WACKER Gerät sicher zu bedienen und zu

warten. Für Ihre Sicherheit und zur Verhinderung von Verletzungen, diese Betriebsanleitung bitte genau durchlesen

und die Angaben befolgen. DIE HIERIN ENTHALTENEN INFORMATIONEN SIND AKTUELL ZUM ZEITPUNKT DER

VERÖFFENTLICHUNG. ÄNDERUNGSRECHT VORBEHALTEN.

Este manual contiene información y procedimientos que son necesarios para operar y mantener esta máquina

WACKER. Para su propia seguridad y protección, lea por favor este manual cuidadosamente y observe todas las

instrucciones de seguridad descritas en este manual. TODA LA INFORMACION EN ESTE MANUAL SE BASA EN

MAQUINAS EN PRODUCCION VEGENTE A PARTIR DE LA FECHA DE PUBLICACION. TODOS DERECHOS

RESERVADOS POR WACKER CORPORACION.

Ce manuel fournit des informations et des procédures destinées à utiliser et à entretenir en toute sécurité cette machine

WACKER. Pour votre propre sécurité et afin d’éviter tout accident, lisez, comprenez et respectez soigneusement les

consignes de sécurité décrites dans ce manuel. LES INFORMATIONS CONTENUES DANS CE MANUEL SONT

BASEES SUR LES MACHINES EN COURS DE PRODUCTION AU MOMENT DE LA PUBLICATION. WACKER

CORPORATION SE RESERVE LE DROIT DE MODIFIER TOUTE PARTIE DE CES INFORMATIONS SANS

PREAVIS.

i

Page 2

BS65Y

Rev. Serial Number

MENOMONEE FALLS, WI USA 53051

hpkWlbs

dB(A) Manuf. Yr.

Model

kg

MADE

IN USA

Item Number

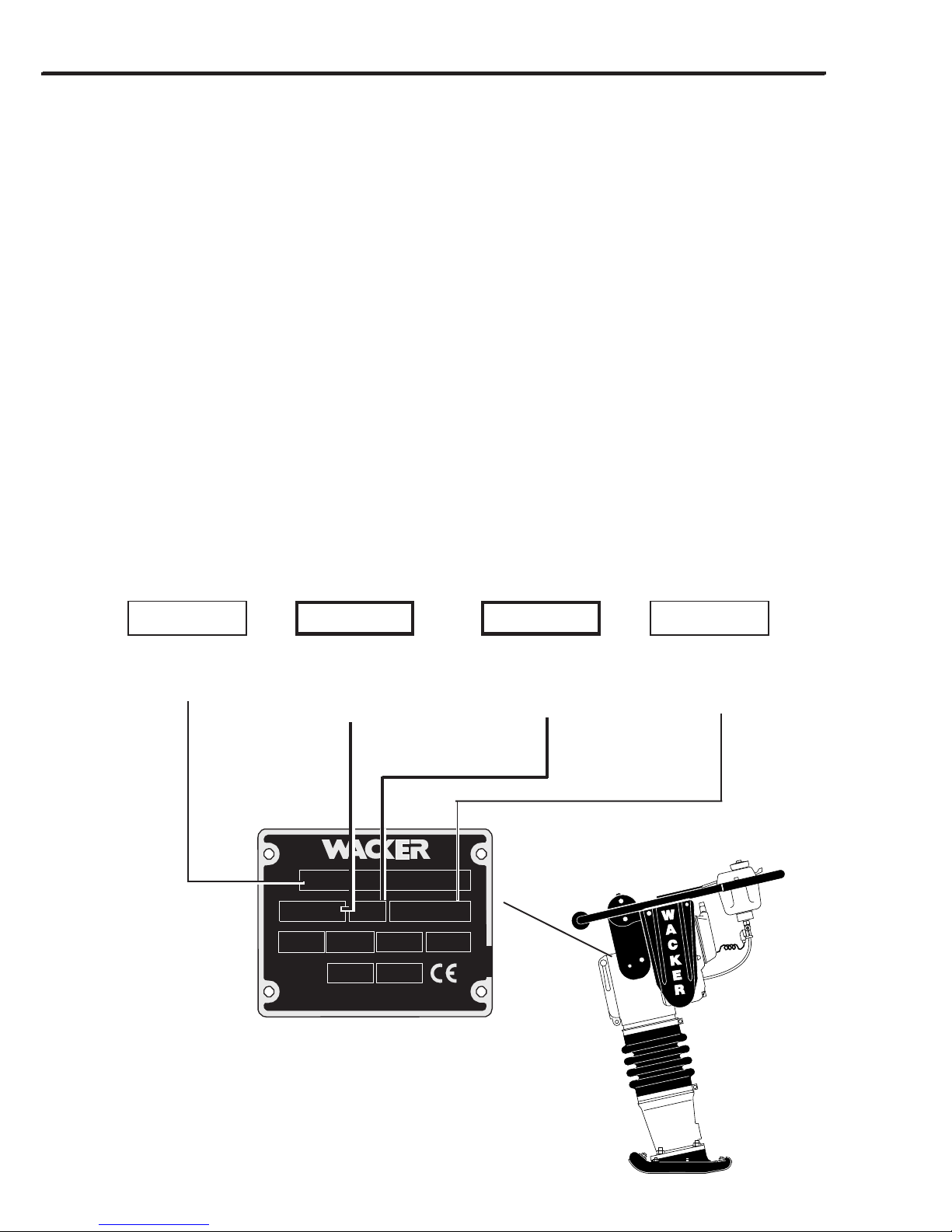

Nameplate / Typenschild / Placa de Identificación / Plaque signalétique

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is attached to each unit. Please

record the information found on this plate so it will be available should the nameplate become lost or damaged. When

ordering parts or requesting service information, you will always be asked to specify the model, item number,

revision number, and serial number of the unit.

Ein Typenschild mit Typ, Artikelnummer, Version und Maschinen-Nummer ist an jedem Gerät angebracht. Die Daten

von diesem Schild bitte notieren, damit sie auch bei Verlust oder Beschädigung des Schildes noch vorhanden sind.

Der Typ, die Artikel-Nummer, die Versions-Nummer und die Maschinen-Nummer sind bei der Ersatzteilbestellung

oder Nachfragen bezüglich Service-Informationen stets erforderlich.

Una placa de identificación con el modelo, número de referencia, nivel de revisión y número de serie ha sido añadida

en cada máquina. Favor de anotar los datos en la placa en caso de que la placa de identificación sea destruida o

perdida. En todos los pedidos para repuestos necesita siempre el modelo, el número de referencia, el nivel de

revisión y el número de serie de la máquina en cuestión.

Une plaque signalétique mentionnant le modèle, le numéro de référence, le niveau de revision et le numéro de série

est fixée sur chaque machine. Veuillez noter les informations relevées sur cette plaque de façon à ce qu’elles soient

toujours disponibles si la plaque signalétique venait à être perdue ou endommagée. Lorsque vous commandez des

pièces détachées ou vous sollicitez des informations auprès-vente, on vous demandera toujours de préciser

le modèle, le numéro de référence, le niveau de revision et le numéro de série de la machine.

My machine’s numbers are / Die Nummern meines Gerätes sind /

Los números de mi máquina son / Les numéros de ma machine sont :

Model number

Typ

Modelo

Modèle

Item Number

Artikel-Nummer

Número de referencia

Numéro de référence

BS65YBS65Y

BS65Y

BS65YBS65Y

0001010100010101

00010101

0001010100010101

101101

00075660007566

0007566

00075660007566

101

101101

Revision

Version

Nivel de revisión

Niveau de revision

88223

Serial Number

Maschinen-Nummer

Número de Serie

Numéro de Série

WACKER

1014SD91

ii

Page 3

This machine may be covered by one or more of the following patents:

111891

OF THESE U.S. PATENTS:

4643611; 4555238; 5564375; 5586630; 4419048

WACKER MACHINES PROTECTED BY ONE OR MORE

Dieses Gerät ist unter einem oder mehreren der folgenden Patente geschützt:

Puede ser que las patentes a continuación sean válidas para esta máquina:

Cette machine peut être protégée sous les brevets d’invention ci-dessous :

BS65Y

PATENT PENDING

111545

Keep this manual or a copy of it with the machine. If you lose this manual or need an

additional copy, please contact WACKER Corporation. This machine is built with user

safety in mind, however, it can present hazards if improperly operated and serviced.

Follow operating instructions carefully! If you have questions about operating or

servicing this equipment, please contact WACKER Corporation.

Diese Betriebsvorschrift oder eine Kopie stets mit der Maschine aufbewahren. Weitere

Kopien sind von WACKER Corporation erhältlich. Diese Maschine ist unter Betracht der

Verbrauchersicherheit entwickelt, kann jedoch bei unfachgemäßem Gebrauch oder Wartung

Gefahren darstellen. Die Vorschriften genauestens befolgen! Sollten Sie Fragen bezüglich

Betrieb oder Service dieser Maschine haben, so steht WACKER Corporation Ihnen gerne zur

Verfügung.

Mantenga este manual o una copia de el con la máquina. Si se pierde o si Ud. desea un

ejemplar adicional, favor comunicarse con WACKER. Esta máquina fue fabricada con la

seguridad del usuario en mente; sin embargo, situaciones peligrosas pueden presentarse

si la máquina es utilizada o mantención es dada inapropiadamente. Siga las instrucciones

de operación cuidadosamente. Si Ud. tiene preguntas acerca de la operación o mantención

de este equipo, favor de comunicarse con WACKER CORPORATION.

Conserver ce manuel ou une copie de celui-ci avec la machine. Si vous perdez ce manuel

ou que vous avez besoin d’un exemplaire supplémentaire, veuillez contacter WACKER

Corporation. Cette machine est construite dans le soucis de la sécurité de l’utilisateur, elle

peut cependant présenter des dangers si elle est utilisée et entretenue de façon incorrecte.

Respectez attentivement les consignes d’utilisation ! Si vous avez des questions concernant

l’utilisation ou l’entretien de cet équipement, veuillez contacter WACKER Corporation.

iii

Page 4

BS65Y

EMISSION CONTROL SYSTEM

INFORMATION

Source of Emissions

The combustion process produces carbon monoxide,

oxides of nitrogen, and hydrocarbons. Control of hydrocarbons and oxides of nitrogen is very important because, under certain conditions, they react to form photochemical smog when subjected to sunlight. Carbon

monoxide does not react in the same way, but it is toxic.

WACKER utilizes lean carburetor settings and other

systems to reduce the emissions of carbon monoxide,

oxides of nitrogen, and hydrocarbons.

The U.S. and California Clean Air Acts

EPA and California regulations require all manufacturers

to furnish written instructions describing the operation

and maintenence of emission control systems.

The following instructions and procedures must be followed in order to keep the emissions from your WACKER

engine within the emissions standards.

Tampering and Altering

Tampering with or altering the emission control system

may increase emissions beyond the legal limit. Among

those acts that constitute tampering are:

• Removal or alteration of any part of the intake, fuel, or

exhaust systems.

• Altering or defeating the speed-adjusting mechanism

to cause the engine to operate outside its design

parameters.

Problems That May Affect Emissions

If you are aware of any of the following symptoms, have

your engine inspected and repaired by your servicing

dealer.

• Hard starting or stalling after starting.

• Rough idle.

• Misfiring or backfiring under load.

• Afterburning (backfiring).

• Black exhaust smoke or high fuel consumption.

Replacement Parts

The emission control systems on your WACKER engine

were designed, built, and certified to conform with EPA

and California emissions regulations. We recommend

the use of genuine WACKER parts whenever you have

maintenence done. These original-design replacement

parts are manufactured to the same standards as the

original parts, so you can be confident of their performance. The use of replacement parts that are not of the

original design and quality may impair the effectiveness

of your emission control system.

A manufacturer of an aftermarket part assumes the

responsibility that the part will not adversely affect emission performance. The manufacturer or rebuilder of the

part must certify that use of the part will not result in a

failure of the engine to comply with emission regulations.

Maintenance

Follow the maintenance schedule. Remember that this

schedule is based on the assumption that your machine

will be used for its designed purpose. Sustained highload or high-temperature operation, or use in unusually

wet or dusty conditions, will require more frequent service.

OXYGENATED FUELS

Some conventional gasolines are being blended with

alcohol or an ether compound. These gasolines are

collectivly referred to as oxygenated fuels. To meet clean

air standards, some areas of the United States and

Canada use oxygenated fuels to help reduce emissions.

If you use an oxygenated fuel, be sure it is unleaded and

meets the minimum octane rating requirement.

Before using an oxygenated fuel, try to confirm the fuel’s

contents. Some states / Provinces require this information to be posted on the pump.

The following are EPA approved percentages of oxygenates:

ETHANOL - (ethyl or grain alcohol) 10% by volume. You

may use gasoline containing up to 10% ethanol by

volume. Gasoline containing ethanol may be marketed

under the name “Gasohol”.

MTBE - (methyl tertiary butyl ether) 15% by volume. You

may use gasoline containing up to 15% MTBE by volume.

METHANOL - (methyl or wood alcohol) 5% by volume.

You may use gasoline containing up to 5% methanol by

volume, as long as it contains cosolvents and corrosion

inhibitors to protect the fuel system. Gasoline containing

more than 5% methanol by volume may cause starting

and/or performance problems. It may also damage metal,

rubber, and plastic parts of your fuel system.

If you notice any undesirable operating symptoms, try

another service station, or switch to another brand of

gasoline.

Fuel system damage or performance problems resulting from the use of an oxygenated fuel containing more than the percentages of oxygenates mentioned above are not covered under warranty.

iv

Page 5

BS65Y

Emission Control System Warranty

Your new WACKER engine complies with the U.S. EPA emissions regulations. WACKER provides the same emission

warranty coverage for engines sold in all 50 states.

YOUR WARRANTY RIGHTS AND OBLIGATIONS

All States

WACKER must warrant the emission control system on your engine for the period of time listed below provided there

has been no abuse, neglect or improper maintenance of your engine. Where a warrantable condition exists, WACKER

will repair your engine at no cost to you including diagnosis, parts and labor.

Your emission control system may include such parts as the carburetor, the ignition system and the catalytic converter.

Also included may be hoses, connectors and other emission-related assemblies.

MANUFACTURER’S WARRANTY COVERAGE:

The 1998 and later engines are warranted for two years. If any emission-related part on your engine is defective, the

part will be repaired or replaced by WACKER.

OWNER’S WARRANTY RESPONSIBILITY:

As the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s

manual. WACKER recommends that you retain all receipts covering maintenance on your engine, but WACKER

cannot deny warranty coverage solely for the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the engine owner, you should be aware that WACKER may deny you warranty coverage if your engine or a part

has failed due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your engine to a WACKER dealer as soon as a problem exists. The warranty repairs

should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact your local WACKER

dealer.

WARRANTY COVERAGE:

WACKER engines sold after January 1, 1998, are covered by this Emission Control System Warranty for a period of

two years from the date of delivery to the original retail purchaser. This warranty is transferable to each subsequent

purchaser for the duration of the warranty period.

Warranty repairs will be made without charge for diagnosis, parts or labor. All defective parts replaced under this

warranty become property of WACKER. A list of warranted parts is located on the next page. Normal maintenance

items, such as spark plugs and filters, that are on the warranted parts list are warranted up to the required replacement

interval only.

WACKER is also liable for damages to other engine components caused by a failure of any warranted parts during

the warranty period.

Only WACKER approved replacement parts may be used in the performance of any warranty repairs and must be

provided without charge to the owner. The use of replacement parts not equivalent to the original parts may impair the

effectiveness of your engine emission control system. If such a replacement part is used in the repair or maintenance

of your engine, and an authorized WACKER dealer determines it is defective or causes a failure of a warranted part,

your claim for repair of your engine may be denied. If the part in question is not related to the reason your engine requires

repair, your claim will not be denied.

v

Page 6

BS65Y

TO OBTAIN WARRANTY SERVICE:

You must take your WACKER product along with proof of original purchase date, at your expense, to any WACKER

authorized dealer during their normal business hours. Claims for repair or adjustment found to be caused solely by

defects in material or workmanship will not be denied because the engine was not properly maintained and used.

EXCLUSIONS:

FAILURES OTHER THAN THOSE RESULTING FROM DEFECTS IN MATERIAL OR WORKMANSHIP ARE NOT

COVERED BY THIS WARRANTY. THIS WARRANTY DOES NOT EXTEND TO EMISSION CONTROL SYSTEMS

OR PARTS WHICH ARE AFFECTED OR DAMAGED BY OWNER ABUSE, NEGLECT, IMPROPER MAINTENANCE,

MISUSE, MISFUELING, IMPROPER STORAGE, ACCIDENT AND/OR COLLISION, THE INCORPORATION OF, OR

ANY USE OF, ANY ADD-ON OR MODIFIED PARTS, UNSUITABLE ATTACHMENTS, OR THE UNAUTHORIZED

ALTERATION OF ANY PART.

THIS WARRANTY DOES NOT COVER REPLACEMENT OF EXPENDABLE MAINTENANCE ITEMS MADE IN

CONNECTION WITH REQUIRED MAINTENANCE SERVICES AFTER THE ITEM’S FIRST SCHEDULED REPLACEMENT AS LISTED IN THE MAINTENANCE SECTION OF THE PRODUCT OWNER’S MANUAL, SUCH AS

SPARK PLUGS AND FILTERS.

DISCLAIMER OF CONSEQUENTIAL DAMAGE AND LIMITATIONS OF IMPLIED WARRANTIES:

WACKER DISCLAIMS ANY RESPONSIBILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES SUCH AS

LOSS OF TIME OR THE USE OF THE POWER EQUIPMENT, OR ANY COMMERCIAL LOSS DUE TO THE FAILURE

OF THE EQUIPMENT; AND ANY IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THIS WRITTEN

WARRANTY. THIS WARRANTY IS APPLICABLE ONLY WHERE THE U.S. EPA EMISSION CONTROL SYSTEM

WARRANTY REGULATION IS IN EFFECT.

Emission Control System Warranty Parts

SYSTEMS COVERED PARTS

BY THIS WARRANTY DESCRIPTIONS

FUEL METERING CARBURETOR ASSEMBLY

EXHAUST SYSTEM MUFFLER

AIR INDUCTION AIR FILTER HOUSING

AIR FILTER ELEMENT*

IGNITION FLYWHEEL MAGNETO

IGNITION MODULE

SPARK PLUG CAP

SPARK PLUG*

MISCELLANEOUS PARTS TUBING, FITTINGS, SEALS, GASKETS

AND CLAMPS ASSOCIATED

WITH THESE LISTED ITEMS

* Indicates expendable maintenance items.

vi

Page 7

1A OPERATION BS65Y

1.1 Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

!

this symbol to avoid possible injury or death.

!

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

!

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION: Used without the safety alert symbol,

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note:

Contains additional information

important to a procedure.

Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes dictate when an engine

must use a spark arrester. State codes will also specify that a spark arrester be rated by

the United States Forest Service.

The correct spark arresting muffler for use on this machine is WACKER P/N 58406.

1A-2

Page 8

BS65Y OPERATION 1A

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of equipment! Equipment operated improperly or

by untrained personnel can be dangerous! Read the operating instructions and familiarize yourself with the

location and proper use of all instruments and controls. Inexperienced operators should receive instruction from

someone familiar with the equipment before being allowed to operate the rammer.

!

WARNING

NEVER operate rammer in applications for which it

is not intended.

NEVER allow improperly trained personnel to operate rammer.

NEVER use choke to stop engine.

NEVER touch hot muffler, engine cylinders, or

cooling fins. Burns will result.

NEVER use accessories or attachments which are

not recommended by WACKER for rammer. Damage to rammer and/or injury to user may result.

NEVER leave a running machine unattended.

ALWAYS read, understand, and follow procedures

in Operator’s Manual before attempting to operate

equipment.

ALWAYS be sure operator is familiar with proper

safety precautions and operation techniques before using rammer.

ALWAYS wear protective clothing when operating

rammer. For instance, goggles or safety glasses will

protect against eye damage caused by flying debris,

and wearing safety shoes will reduce the chance of

foot injuries.

ALWAYS keep hands, feet, and loose clothing away

from moving parts of rammer.

ALWAYS use common sense and caution when

operating rammer.

ALWAYS be sure rammer will not tip over, roll, slide,

or fall when not being operated.

ALWAYS turn engine OFF when rammer is not being

operated.

ALWAYS close fuel valve when rammer is not being

operated.

ALWAYS remove or disconnect engine spark plug

before servicing rammer, to avoid accidental start-up.

1A-3

Page 9

1A OPERATION BS65Y

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation and fueling! Failure to follow the safety

guidelines described below could result in severe injury or death.

!

DANGER

NEVER smoke while operating rammer.

NEVER smoke when refueling engine.

NEVER refuel hot or running engine.

NEVER refuel engine near open flame.

NEVER spill fuel when refueling engine.

NEVER operate rammer near open flames.

ALWAYS refill fuel tank in well-ventilated area.

ALWAYS replace fuel tank cap after refueling.

1.4 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly

over a long period of time, periodic maintenance and occasional repairs are necessary.

!

WARNING

NEVER attempt to clean or service rammer while it

is running.

ALWAYS replace safety devices and guards after

repairs and maintenance.

NEVER operate equipment with safety devices or

guards removed or not in working order.

NEVER operate equipment without air cleaner.

NEVER remove air cleaner or air cleaner cover while

operating rammer.

NEVER alter engine to run at speeds other than

those specified in Technical Data Section.

1A-4

ALWAYS keep area around muffler free of debris in

order to reduce the chance of an accidental fire.

ALWAYS do Periodic Maintenance as recommended

in Operator’s Manual.

ALWAYS clean debris from engine cooling fins.

ALWAYS replace worn or damaged components

with spare parts designed and recommended by

WACKER for servicing this rammer.

Page 10

BS65Y OPERATION 1A

1.5 Technical Data

Engine speed - full rpm 4500 ± 200

Engine speed - idle rpm 1500 ± 100

Clutch engagement rpm 2800 ± 100

Cylinder head compression-cold

psi (kg/cm2) 120–140 (8.0–9.7)

Spark plug - Gap in. (mm) Champion RL86C: 0.035 (0.8–0.9)

Bosch WR 8 AC: 0.02 (0.5)

P/N 48333

Engine Lubrication oil grade Two-cycle or outboard motor oil conforming to BIA-TC-W

specifications - ratio 50:1

Note: Use 25:1 for first tank of fuel.

Ramming System Lubrication

oil grade SAE 30

oz. (ml) 25 (750)

Sound and Vibration Measurements

The required sound specifications, per Appendix 1, Paragraph 1.7.4.f of the EC-Machine Regulations, are:

- the sound pressure level at operator’s location (LpA) = 93 dB(A)

-

the sound power level (LWA) = 104 dB(A)

These sound values were determined according to ISO 3744 for the sound power level (LWA) and ISO 6081 for the sound

pressure level (LpA) at the operator’s location.

The weighted effective acceleration value, determined according to ISO 8662 Part 1, is 10 m/s2.

The sound and vibration measurements were obtained with the machine operating on crushed gravel at nominal engine

speed.

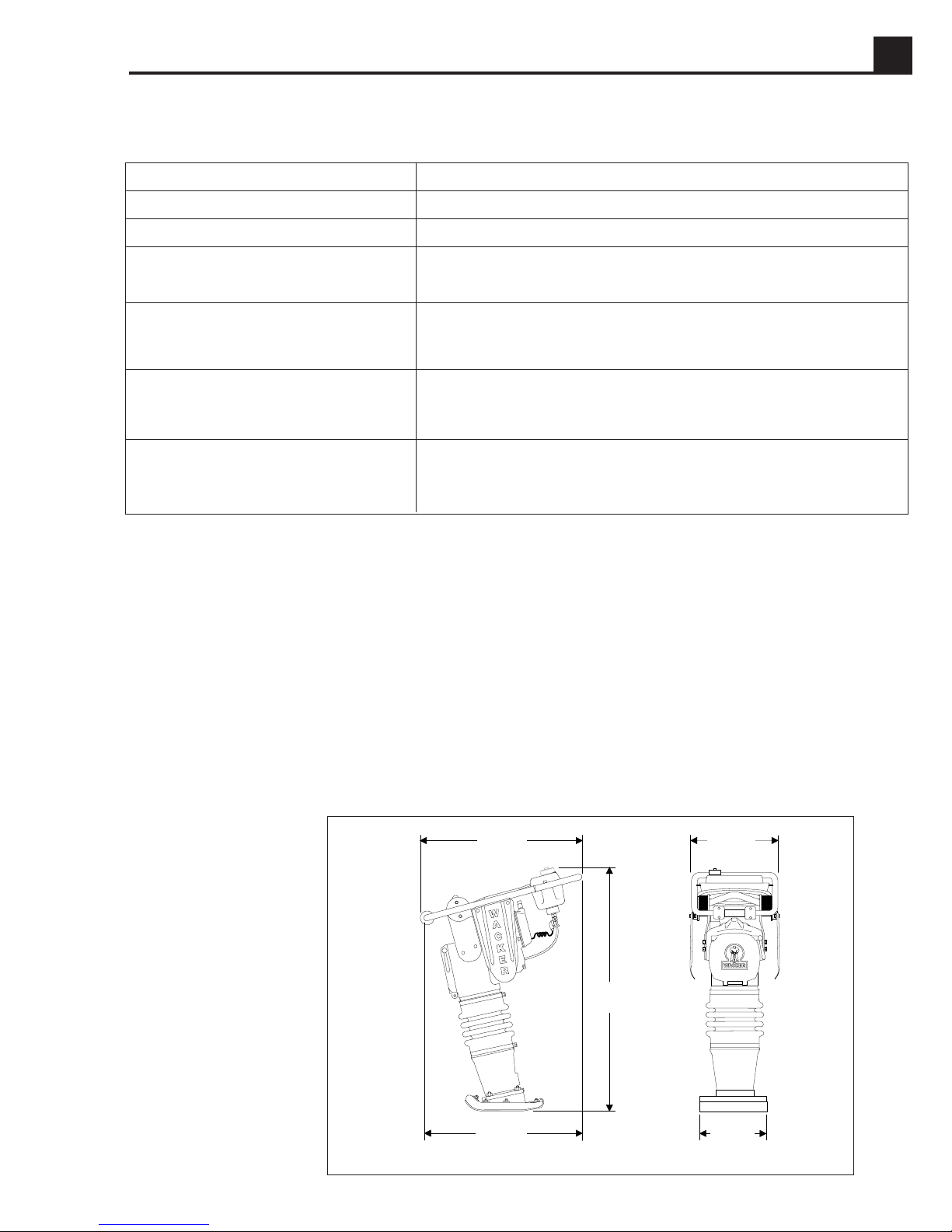

1.6 Dimensions

in. (mm)

WACKER

28 (710)

37

(940)

14 (360)

1014SD89

27 (685)

11 (280)

13 (330)

1A-5

Page 11

1A OPERATION BS65Y

c

c

1

2

c

3

b

1

b

2

f

1002SD08

1.7 Recommended Fuel

This rammer engine requires a two-cycle gasoline/oil

mixture.

Note:

Mix regular unleaded gasoline and two-cycle / outboard

motor oil in separate container before filling tank.

Use 25:1 mixture for first tank of fuel only. Use

50:1 mixture thereafter.

WACKER

d

1002SD27

a

2

1014SD91

1.9 Before Starting

1. Read safety instructions at the beginning of this

manual.

2. Fill tank with proper fuel mixture.

3. Set ramming stroke. Read Sections 1.13 and 1.14.

4. Place rammer on loose soil or gravel. DO NOT start

rammer on hard surfaces such as asphalt or concrete.

a

1

1005SD68

Fuel Ratio 50:1

Gasoline Oil Gasoline Oil

1 gallon 2.5 ounces 5 liters 100 ml

3 gallons 8.0 ounces 10 liters 200 ml

5 gallons 13.0 ounces 15 liters 300 ml

1.8 Application

Rammers are designed to compact loose soils and

gravel to prevent settling and to provide a firm, solid base

for the placement of footings, concrete slabs, foundations, and other structures.

1A-6

1.10 To Start

1. Open fuel valve (a

2. If engine is cold, close choke (b

3. Open throttle no more than 1/4 (c

4. Press button (f) on carburetor twice.

5. Pull starter rope (d) until engine starts.

6. Open choke (b

Note:

Cold engine should run approximately one

(1) minute at idle

).

1

) on carburetor as engine warms up.

2

(c

) on carburetor.

1

).

2

)

to warm up.

1

Page 12

BS65Y OPERATION 1A

1.11 To Stop

1. Place throttle in “IDLE” (c

2. Shut off engine by closing fuel valve

).

1

(a2) on tank.

1.12 Proper Operation

1. Open throttle completely (c

smoothest operation. Do not overthrottle. Best compaction is achieved when rammer is running smoothly.

Normally, a low stroke setting requires a lower engine

speed.

CAUTION: Running the engine too fast will result in

poor operation and unnecessary wear to components.

2. Guide rammer with handle. Allow machine to pull

itself forward. DO NOT try to overpower the machine.

3. For best compaction, shoe must hit the ground flat

(g), not on its toe or heel. This will save on excessive

shoe wear.

), then adjust for the

3

g

1002SD24

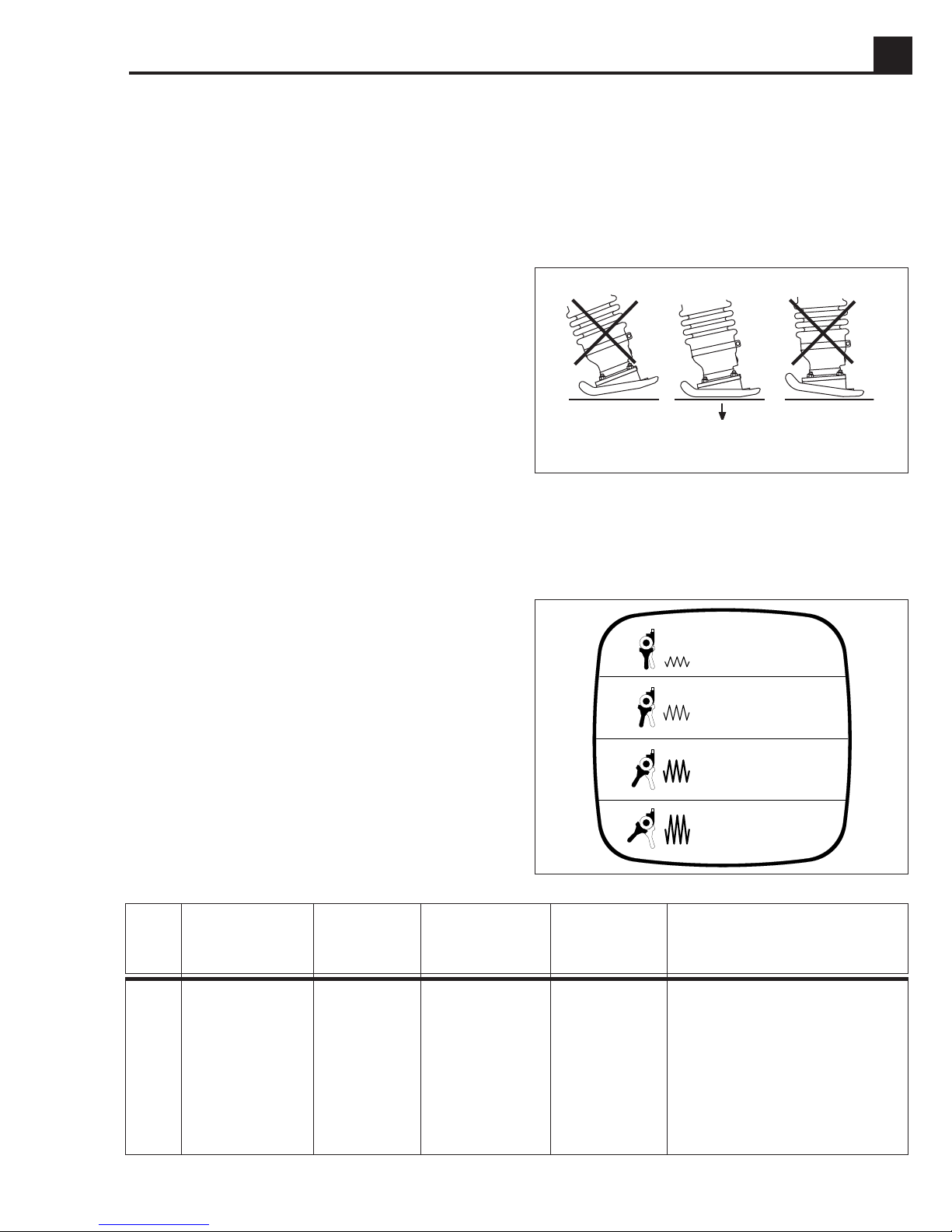

1.13 Selecting Ramming Stroke

GLÄTTUNGSARBEIT

The length of the ramming stroke directly affects the

impact force delivered by the rammer. Selecting the best

1

level depends on job requirements and soil conditions.

The label located inside the front cover indicates the

2

general compaction application, together with approximate throttle settings and impact levels for each stroke

level. It should be used as a general guide when

3

selecting ramming stroke.

4

Summary of Stroke and Throttle Settings

Stroke Throttle Percussion Stroke at Single-Stroke Applications

Setting Position Blows/Min. Ramming Shoe Impact in

in. (mm) lbs. (kN)

1 1/4–1/2 750 up to 1 (25) 2040 (9.2) smoothing

2 1/2–3/4 650 up to 2.6 (65) 2640 (11.7) normal compaction

3 3/4–full load 650 up to 3 (75) 3400 (15.1) heavy compaction

LISSAGE

SMOOTHING

APLANAMIENTO

NORMALE VERDICHTUNGSARBEIT

COMPACTAGE NORMAL

NORMAL COMPACTION WORK

COMPACTACION NORMAL

STARKE VERDICHTUNGSARBEIT

COMPACTAGE FORT

HEAVY COMPACTION WORK

COMPACTACION FUERTE

NASSE UND BINDIGE BÖDEN

SOLS HUMIDES ET COHERENTS

WET AND COHESIVE SOILS

SUELOS COHERENTES

39761

4 full load 600 up to 3.2 (80) 3640 (16.2) wet and cohesive soils;

not for hard soils which

are difficult to compact

1A-7

Page 13

1A OPERATION BS65Y

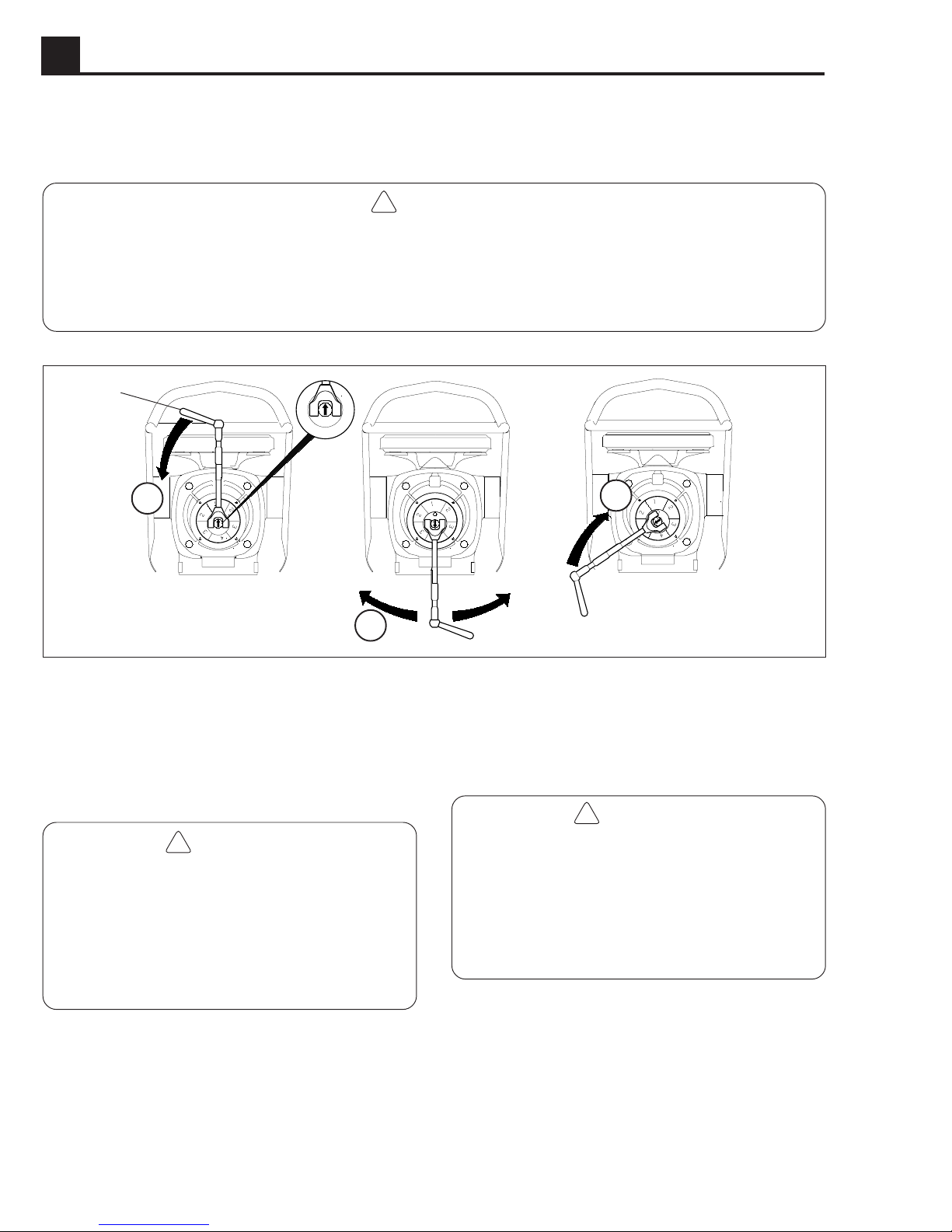

1.14 Adjusting Ramming Stroke

When adjusting the ramming stroke, observe the following precautions to avoid injury to yourself and others.

!

WARNING

- Adjust stroke with machine standing upright and resting on a firm, level surface. Do not adjust stroke if the

machine is in an unstable position where it can easily tip or slide.

- Always stop engine before adjusting stroke. The clutch could engage, causing rammer to jump unexpectedly.

- Adjustment should be performed by one person and with no one else near the machine. The tool used to make

the adjustment could slip out of your hands and hit someone standing nearby.

b

a

1

2

To adjust ramming stroke:

1. Remove adjusting tool from cover. Open cover.

2. Check that arrow (a) on center of locking lever is

pointing up.

!

WARNING

If arrow is pointing down, the spring system is not

balanced and could cause the top half of the rammer

to drop unexpectedly while making the stroke adjustment. To balance spring system, stand behind the

rammer and use guide handle to rock machine back

and forth until you feel the spring system relax. The

arrow should now be facing up.

3. Insert adjusting tool (b) into bore on locking lever.

Make sure it is fully seated so it will not slip out. Steady

rammer by holding guide handle and use adjusting

tool to push locking lever straight down until it is

completely disengaged (refer to Operation 1 in illustration above).

3

1006SD66

4. Using adjusting tool, move locking lever until center

arrow is pointing at the desired stroke setting (Operation 2).

!

WARNING

During this adjustment, tension is applied to the

spring system. This tension will release as the

locking lever is returned back to its locked position.

When this happens, the rammer will settle, causing

the handle and crankcase to drop down. The

movement is slight but happens quickly. Be aware

of this when moving locking lever.

5. Push or pull the adjusting tool to move the locking

lever back to its locked position (Operation 3). When

the locking lever is halfway between the locked and

unlocked position the spring system will settle and

move as described in warning above.

6. Remove adjusting tool. Close cover and lock it in

place with tool.

1A-8

Page 14

BS65Y OPERATION 1A

1.15 Periodic Maintenance Schedule

Daily After Every Every Every

before first week month 3 months

starting 5 or or or

hours 25 hrs. 100 hrs. 300 hrs.

Check fuel level.

Check oil level in sightglass.

Check cannister type air filter.

Replace filter element as required.

Tighten ramming shoe hardware.

Check and tighten engine cylinder screws.

Check and tighten external hardware.

Clean engine cooling fins.

Clean and check spark plug gap.

Replace spark plug.

Clean recoil starter.

Change ramming system oil.*

Clean engine muffler and exhaust port.

* Change ramming system oil after first 50 hours of operation.

1.16 Canister-Type Air Cleaner

1. To remove air cleaner, unsnap spring clips (j), and

remove cover (k) and filter element (l).

2. Gently tap element on flat surface to knock off loose

dirt. Be careful not to damage rubber seals or dent

element. If element is heavily soiled or wet, replace it.

Note:

3. Place element on bracket. Replace cover. By pressing centers of clips in toward cover, the clips will snap

into place. Be sure cover is properly seated and clips

securely in grooves on cover before starting machine.

DO NOT wash or use compressed air to clean

filter element.

k

l

j

1002SD06

1A-9

Page 15

1A OPERATION BS65Y

1.17 Low Maintenance Air Cleaner

This air cleaner is self-cleaning and uses the movement of the machine to shake dust and dirt loose from the air cleaner

element while the rammer is operating. Under normal operating conditions this element will not require cleaning and

should not be removed from the machine. If the element does become plugged with dirt, the engine will begin to lose

power. In this case the air cleaner element can be removed and cleaned as described below. Replace element if it

becomes so plugged with dirt it can no longer be cleaned.

1. Remove the two locknuts from the top of the air

cleaner and lift air cleaner off.

2. Use compressed air directed from the inside of the air

cleaner, through the grommet hole (a), to blow dirt

and dust from element.

CAUTION: Air pressure must not exceed 100 psi.

a

3. Run fresh water through grommet hole

runs clear.

(a) until water

CAUTION: DO NOT use solvents, fuel oil, or gasoline

to wash filter.

4. Plug or cover hole in air cleaner (b) using a cork or

tape to prevent dirty water from entering inside of

element. Soak air cleaner (c) in a solution of warm

water and a low suds detergent for at least 15 minutes. Longer periods of time (up to several hours) of

soaking may be required, depending on how dirty the

element is.

5. Remove air cleaner from wash and repeat rinse

described in Step 3. Allow element to air dry in a dustfree area. DO NOT use heat to speed drying.

6. Inspect grommet before assembly and replace it if it

is worn or damaged. Install grommet on element

carefully to avoid cutting it.

7. Install air cleaner on mount and secure it with washers

and locknuts. DO NOT overtighten. Overtightening

can deform washers and indent top of air cleaner.

b

c

1002SD10

1002SD12

Note:

so it slides easily on mount.

Apply grease or liquid soap to inside of grommet

1A-10

Page 16

BS65Y OPERATION 1A

WACKER

1.18 Lubrication

1. Change ramming system oil after first 50 hours of

operation and every 300 hours thereafter. To drain oil,

remove plug

on handle.

(d) and tilt machine back until it is resting

e

2. With rammer on level surface, add oil through plug

Proper ramming system lubrication is indicated when

approximately 1/2–3/4 of the sightglass (f) is full.

(e).

1.19 Shoe Hardware

On new machines, or after replacing shoe, check and

tighten shoe hardware (g, h) after the first 5 hours of

operation. Inspect hardware every week thereafter.

Torque hardware as specified.

58 ft.lbs.

(79 Nm)

g

f

d

1014SD95

18 ft.lbs.

(25 Nm)

h

1.20 Carburetor Adjustments

Bing Carburetor

Idle Speed

Adjust engine idle speed with the throttle closed and the

engine running at idle. Attach tachometer and set idle

speed screw (i) on carburetor to achieve the specified

idle speed. Refer to “Technical Data”.

No other carburetor adjustments are required.

1004SD06

i

1002SD11

1A-11

Page 17

1A OPERATION BS65Y

WACKER

WACKER

1.21 Long-term Storage

1. Drain fuel from tank.

2. Start engine and run until remaining fuel is used.

3. Remove spark plug. Pour approximately 1 oz. (30 ml) of clean SAE 30W engine oil into cylinder through spark plug

opening.

4. Pull starter rope slowly to distribute oil in engine.

5. Re-install spark plug.

1.22 Transportation

1. Always shut off engine and close fuel valve

when transporting machine.

2. Make sure lifting device has enough capacity

to hold machine (see identification plate on

machine for weight).

3. Use central lifting point (a) when lifting machine.

4. Tie down machine on vehicle to prevent it

from tipping, falling, or rolling. Lay machine

down flat and tie to vehicle at points (b) and

a

(c).

CAUTION: Drain fuel tank as required to

prevent fuel leaking from cap (d).

1.23 Troubleshooting

Problem / Symptom Reason / Remedy

Engine does not start, or stalls. 1. No fuel in tank.

2. Spark plug fouled.

3. Fuel valve closed.

b

d

1014SD90

c

Engine does not accelerate, 1. Improper fuel mix. Too much oil.

is hard to start, or runs erratically. 2. Spark plug fouled.

Engine overheats. 1. Improper fuel mix. Not enough oil.

Engine runs; rammer does not tamp. 1. Inspect clutch for damage. Replace if necessary.

Engine runs, rammer operation is erratic. 1. Oil/grease on clutch.

1A-12

3. Clean muffler and exhaust port.

4. Crankshaft seals are leaking.

5. Air cleaner may be clogged.

2. Carburetor set too lean.

3. Clean cooling fins and fan blades.

2. Broken connecting rod or crankgear.

3. Low engine performance. Compression loss.

Plugged exhaust port.

2. Broken/worn springs.

3. Soil buildup on ramming shoe.

4. Broken parts in ramming system or crankcase.

5. Engine operating speed is too high.

Loading...

Loading...