Wacker Neuson EH 9 BL/230 Loxam, 0008429 series, EH 9 BL/115 WC, 0008735 series, 0008753 series Operator's Manual

...Page 1

www.wackergroup.com

Operator´s Manual

Electrik-hammer

EH 9 BL/...

0203039en 002

06.2006

Page 2

Page 3

Foreword

1

1. Foreword

For your own safety and protection from bodily injuries, carefully read,

understand and follow the safety instructions in this manual.

Please operate and maintain your Wacker machine in accordance with

the instructions in this manual. Your Wacker machine will reward your

attention by giving trouble-free operation and a high degree of

availability.

Replace faulty or defective components Immediately.

All rights, especially the right for copying and distribution are reserved

Copyright 2006 by Wacker Construction Equipment AG

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express permission in writing from Wacker Construction Equipment AG.

Any type or manner of reproduction, distribution or storage on data

carriers or storage mediums not authorized by Wacker represents an

infringement of valid copyrights and will be prosecuted. We expressly

reserve the right to make technical modifications - even without due

notice - which aim at improving our machines or increasing their safety

standards.

Page 4

Table of contents

2

1. Foreword 1

2. Safety instructions 3

2.1 General Instructions ..............................................................................3

2.2 Operation ...............................................................................................3

2.3 Safety checks ........................................................................................5

2.4 Maintenance ..........................................................................................6

2.5 Transport ...............................................................................................6

2.6 Maintenance checks ..............................................................................6

3. Technical data 7

4. Description 9

4.1 Application .............................................................................................9

4.2 Putting into operation ............................................................................9

4.3 During operation ....................................................................................9

4.4 Disassembly ........................................................................................10

4.5 Assembly .............................................................................................11

5. Maintenance 12

5.1 Maintenance schedule ........................................................................12

5.2 Maintenance and lubrication ...............................................................12

6. Malfunction 13

6.1 Equipment failure ................................................................................13

7. Electric wiring diagram 14

8. Labels 15

9. Disposal 16

9.1 Environmentally friendly reuse ............................................................16

EC - Conformity Certificate 17

DIN EN ISO 9001 CERTIFICATE 19

Page 5

Drilling and breaking hammers Safety instructions

SV00046GB.fm 3

2. Safety instructions

for the use of drilling and breaking hammers with electric drive

2.1 General Instructions

2.1.1 Drilling and breaking hammers may only be operated by persons who

∗ are at least 18 years of age,

∗ are physically and mentally fit for this job,

∗ have been instructed in operating drilling and breaking hammers and

proven their ability for the job to the employer

∗ may be expected to carry out the job they are charged with carefully.

The persons must be assigned the job of operating drilling and

breaking hammers by the employer.

2.1.2 Drilling and breaking hammers are to be applied for their proper use.

Both the manufacturer’s operating instructions and these safety

instructions have to be observed.

2.1.3 The persons charged with the operation of these hammers have to be

made familiar with the necessary safety measures relating to the

machine. In case of extraordinary uses, the employer shall give the

necessary additional instructions.

2.1.4 It is possible that these drilling and breaking hammers exceed the

admissible sound level of 89 dB(A). Operators must wear personal

hearing protection if the admissible assessment sound level equals or

exceeds 89 dB (A).

2.2 Operation

2.2.1 The function of operation levers or elements is not to be influenced or

rendered ineffective.

2.2.2 Make sure that the machine is connected only to voltage and

frequency as indicated on its name plate. Choose correct cross section

for extension cord.

Page 6

Safety instructions Drilling and breaking hammers

SV00046GB.fm 4

2.2.3 The operator has to switch off drilling and breaking hammers, to

disconnect them from the electric mains and to store them in such a

manner that they do not turn over be fore leaving the machines or

going on breaks.

2.2.4 Wear safety goggles in order to avoid injuries to the eyes.

2.2.5 We recommend wearing suitable working gloves.

2.2.6 Wear safety shoes while working with drilling and breaking hammers.

2.2.7 Drilling and breaking hammers are always to be operated with both

hands on the handles provided for this purpose.

2.2.8 When working with drilling and breaking hammers, especially when

carrying out drilling jobs, the operator has to have a firm stand,

particularly when working on scaffolding and ladders.

2.2.9 Drilling and breaking hammers are to be guided such that hand injuries

caused by solid objects are avoided. When carrying out demolition

jobs at elevated places, special care is required to prevent the machine

or the operator from falling.

2.2.10 Avoid body contact with earthed components. When breaking

connecting passages, make sure that there are no electric wires or gas

pipes. No one may stay in the room to which the passage is broken

through, as there is danger of injuries because of falling stones or

tools.

2.2.11 During operation the tool holder must be closed. Tools and tool holder

must be checked for wear in order to guarantee proper functioning of

holder.

2.2.12 The operation of this machine may cause broken - off pieces to be

flung away. Therefore, during operation, no one except the operator is

to come near this machine.

2.2.13 Drilling and breaking hammers have to be disconnected from the

electric mains before changing tools.

Page 7

Drilling and breaking hammers Safety instructions

SV00046GB.fm 5

2.2.14 The tools always have to be in perfect conditions.

2.2.15 Do not operate this machine in areas where explosions may occur.

2.2.16 Do not misuse the electric cable to pull or lift up the unit or to pull the

plug out of the socket. Protect cable from heat, oil and sharp edges.

2.2.17 Electric equipment and material may only be used if they comply with

the operational and local safety requirements. They must be in proper

conditions and they must be maintained in this condition.

2.2.18 Do not expose electric tools to rain. Do not use electric tools in damp

or wet surroundings.

2.3 Safety checks

2.3.1 Drilling and breaking hammers may only be operated with all safety

devices installed.

2.3.2 Before starting operation, the operator has to check that all control and

safety devices function properly.

2.3.3 Before starting operation, the overload clutch of drilling hammers has

to be checked for proper functioning.

2.3.4 Regularly check cable for damage.

2.3.5 In case of defects of the safety devices or other defects reducing the

operational safety of the drilling and breaking hammers, the supervisor

has to be informed immediately.

2.3.6 The machine must to be switched off immediately in case of defects

jeopardizing the operational safety of the equipment.

Page 8

Safety instructions Drilling and breaking hammers

SV00046GB.fm 6

2.4 Maintenance

2.4.1 Only use original spare parts. Modifications to this machine are subject

to the express approval of the Wacker Company. All liabilities shall be

refused in case of nonobservance.

2.4.2 Disconnect the drilling and breaking hammer from the electric mains

before carrying out maintenance and repair jobs.

2.4.3 Work on the electric parts of the machines may only be carried out by

skilled technicians.

2.4.4 All safety devices must be reinstalled properly immediately after

maintenance and repair jobs have been completed.

2.5 Transport

2.5.1 When being transported on vehicles, precautions have to be taken that

these hammers do not slip or turn over.

2.6 Maintenance checks

2.6.1 According to the conditions and frequency of use, drilling and breaking

hammers have to be checked for safe operation at least once every 6

months by skilled technicians, such as those found at Wacker-service

depots and have to be repaired if necessary.

Please also observe the corresponding rules and regulations valid in your

country.

Page 9

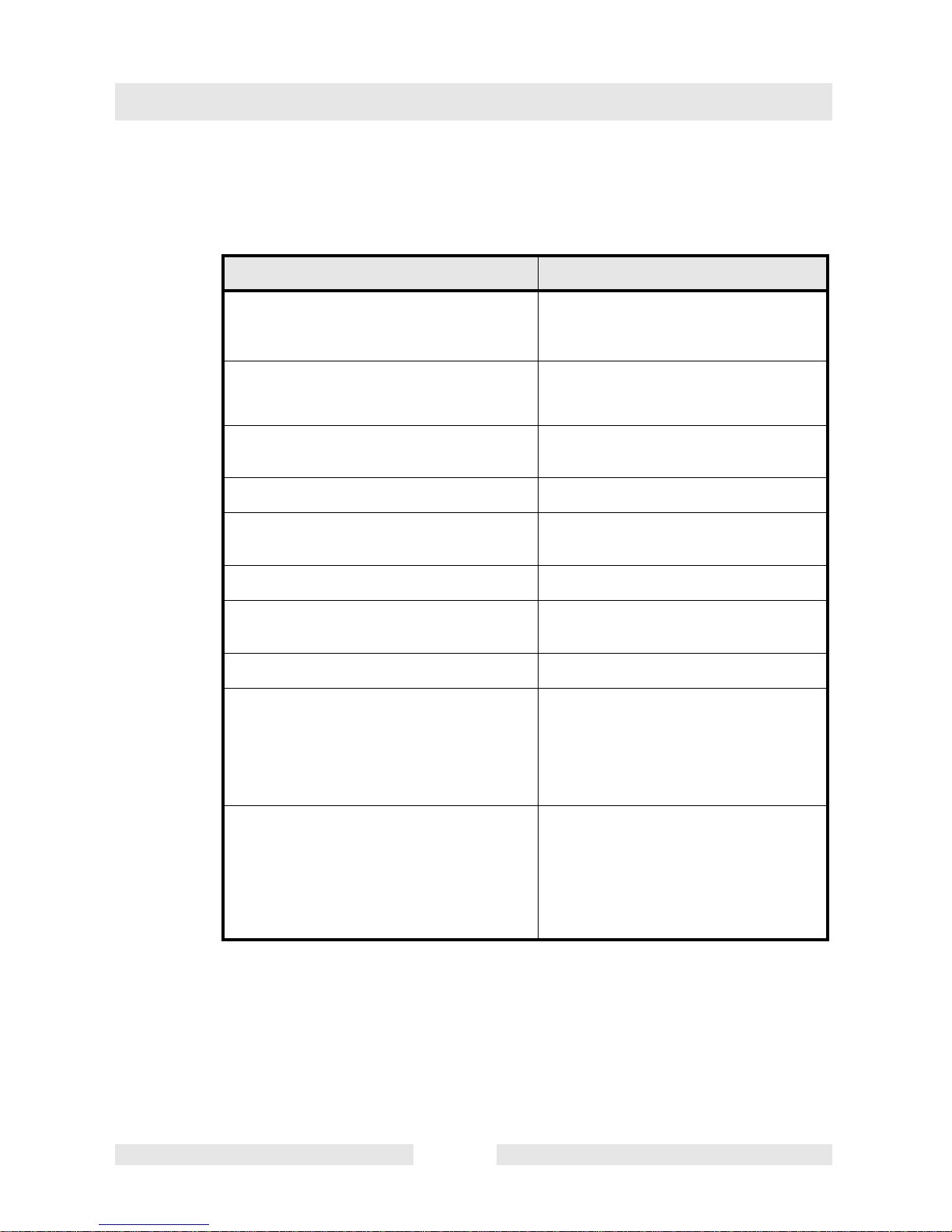

Technical data

TD00705GB.fm 7

3. Technical data

EH 9 BL/230

EH 9 BL/

230

Loxam

Item no 0008429 ... 0008917 ... 0008735 ... 0008753 ...

Length x width x height

(without tool) mm:

560 x 105 x 245

Operating weight (mass) without

tool kg:

10

Voltage V: 220 - 240 1~

Power input kW: 1,38

Minimum generator output

requirements for single

connection kW:

3,3

Current consumption A: 7,5

Frequency Hz: 50 / 60

Percussion rate electronic

control

min

-1

:

1300 - 2150

Drill speed electronic control grease Retinax LX2

Special lubricating grease Lagre spline drive SW 19 x 82,5

Kraftübertragung Schlagsystem

From motor via crank mechanism to air-percussion

system

Drive motor

Frequency converter driven three-phase AC motor,

with protective insulation

Single drill work J: 19

Breaking output (Concrete B25) kg/h: 630

Sound pressure level at

operators station

L

PA

:

93 dB(A)

The weighted effective

acceleration value, determined

according to EN ISO 5349

m/s

2

:

is 9,8

Required cable cross-section in case of cable extensions

Max. cable length m: 26 44 70 104

Cable cross-section

mm

2

:

1,5 2,5 4 6

Page 10

Technical data

TD00705GB.fm 8

EH 9 BL/115 EH 9 BL/115 WC

Item no 0008436 ... 0008734 ...

Length x width x height

(without tool) mm:

560 x 105 x 245

Operating weight (mass) without

tool kg:

10

Voltage V: 110 - 127 1~

Power input kW: 1,2

Minimum generator output

requirements for single

connection kW:

3,3

Current consumption A: 13

Frequency Hz: 50 / 60

Percussion rate electronic

control

min

-1

:

1300 - 2150

Drill speed electronic control grease Retinax LX2

Special lubricating grease Lagre spline drive SW 19 x 82,5

Kraftübertragung Schlagsystem

From motor via crank mechanism to air-percussion

system

Drive motor

Frequency converter driven three-phase AC motor,

with protective insulation

Single drill work J: 19

Breaking output (Concrete B25) kg/h: 630

Sound pressure level at

operators station

L

PA

:

93 dB(A)

The weighted effective

acceleration value, determined

according to EN ISO 5349

m/s

2

:

is 9,8

Required cable cross-section in case of cable extensions

Max. cable length m: 7 12 20 30

Cable cross-section

mm

2

:

1,5 2,5 4 6

Page 11

Description

T00755GB.fm 9

4. Description

4.1 Application

4.1.1 Wacker’s breaking hammer is commonly used in building construction,

civil engineering, facilities construction, municipal projects, concrete

plants, artificial stone plants, foundries, installation projects, and many

other applications. The breaking hammer is very well suited for

handling natural and artificial stone and every type of masonry and

concrete. Various quick-change tools facilitate chasing, chiseling,

breaking, digging, puddling, knocking, ramming, and deburring.

4.2 Putting into operation

4.2.1 Placing and removing of tool.

∗

Pull plug from electric socket.

∗

Snap out holder spring.

∗ Insert tool as far as it will go.

∗ Snap back holder spring.

Only use perfectly sharp tools with tool shank in perfect conditions. It

is advisable to lightly grease or oil tool shank and tool holder to avoid

dry running and premature excessive wear.

4.2.2 Connection

This electric hammer is powered by A. C. (single phase) (see technicla

data). A suitable plug is provided for connection.

4.3 During operation

4.3.1 Percussion rate and impact control

To reduce the power of the hammer turn knurling wheel in handle in

anti-clockwise direction (-). Turn wheel as far as it will go. To set

hammer to full power turn knurling wheel in clockwise direction (+).

Page 12

Description

T00755GB.fm 10

4.3.2 Lock button

Lock control lever by means of lock button when using the hammer for

long breaking operations. When pression on control tongue, lock

button is released.

4.3.3 Handle system at tool holder (consisting of two handle pieces)

∗ Offset handle

Than handle can be turned perpendicularly to the tool shaft direction

and according to the application requirements by approx. 270o.

Loosen the adjusting ring for turning of handle. The handle can be

adjusted in 22,5o steps by tightening the adjusting ring.

∗ Radial handle

This handle can be screwed into either the additional handle or at the

side of the housing.

4.3.4 The complete handle system can additionally be turned by 360o,

perpendicularly to the tool shaft direction. It must be tightened with the

SW13 hex of the radial handle before starting any application (approx.

14 Nm).

4.4 Disassembly

4.4.1 Tool holder/Cylinder housing

emove pin. Remove supplementary handle with holder spring from tool

holder. Remove cheese head screws. Remove tool holder, tool holder

bush and damping sleeve. Remove cylinder housing from crankcase.

Remove percussion piston.

Page 13

Description

T00755GB.fm 11

4.4.2 Crankcase

Access to rotor circlip: Remove screws, take bearing cover and crank

mechanism out of crankcase.

4.4.3 Disassembly of handle

Remove screws. Remove handle half and back handle.

4.4.4 Motor

Access to stator pack and rotor: Remove screws, remove bearing

bracket from crankcase. Remove stator pack. Then pull out O-ring and

air guiding bushing. Remove circlip and force out rotor.

4.5 Assembly

For assembly proceed in the reverse order to dismantling. The

following has to be observed in particular:

∗ All parts must be carefully cleaned and checked. Grease bearings,

crank mechanism and percussion system with special grease (see

technicla data).

∗ Clean front surfaces of cylinder housing and crankcase and seal with

Omni Visc, model 1002.

∗ Use Omnifit 230L to glue outer race of deep groove ball bearing.

∗ After completion of any kind of repairs, test-run with increasing load.

Page 14

Maintenance

T00757GB.fm 12

5. Maintenance

5.1 Maintenance schedule

5.2 Maintenance and lubrication

5.2.1 General instructions

Keep hammer and tools clean.

5.2.2 Mechanical part

∗ Every 20 hours of operation moderately grease crank mechanism and

percussion system via lubricating nipple situated on crankcase. Use

special grease (see technicla data).

∗ Check tool holder brushing for wear. The tool may have a play of max.

6 mm at a distance of approx. 200 mm from the entrance. If the

bushing is worn to a greater degree, replace it to avoid damages and

operational failures.

Component Maintenance work

Maintenance

interval

Feed line

Check for perfect condition - if cable defective,

replace.

daily

Miscellaneous Fan slits dirt - free - clean if necessary.

Tools

Check the shafts and cutting edges ifnecessary, sharpen, reforge or replace.

Miscellaneous Regrease via grease nipples. 20 hours

Tool holder Check for wear - change if necessary. monthly

Miscellaneous Regrease crankshaft drive. 600 hours

Page 15

Malfunction

T01040GB.fm 13

6. Malfunction

6.1 Equipment failure

Cause Remedy

for 115V machines:

Input voltage to high (>150V) or to low (<45V)

Make sure to have the correct voltage.

Check extension cable for sufficient

conductor cross section

for 230V machines:

Input voltage to high (>300V) or to low

(<170V)

Let equipment cool off

Converter temperature to high

Check supply cable incl. clamp contacts

and replace if necessary.

Supply cable interruption Replace

Switch defect

Replace cable (incl. plug) with converterswitch repair set

Broken cable between converter and switch Replace converter

Defect the converter electronics

Replace cable (incl. plug) with converterstator repair set

Broken cable between converter and stator Replace stator

Stator defect

* Let equipment run warm in warmer

environment (e.g. warm room)

* remove excessive grease from

percussion system

* replace defective components

Blocked percussion system:

* due to high grease resistance because of

low external termperatures

* due to over-greasing

* due to seizing of moving parts (e.g. due to

prolonged dry running)

Make sure to have the correct voltage.

Check extension cable for sufficient

conductor cross section

Page 16

Electric wiring diagram

SK00686GB.fm 14

7. Electric wiring diagram

white

grey

black

brown blue

Plug

Conducting

Switch

Frequency converter

Engine

Page 17

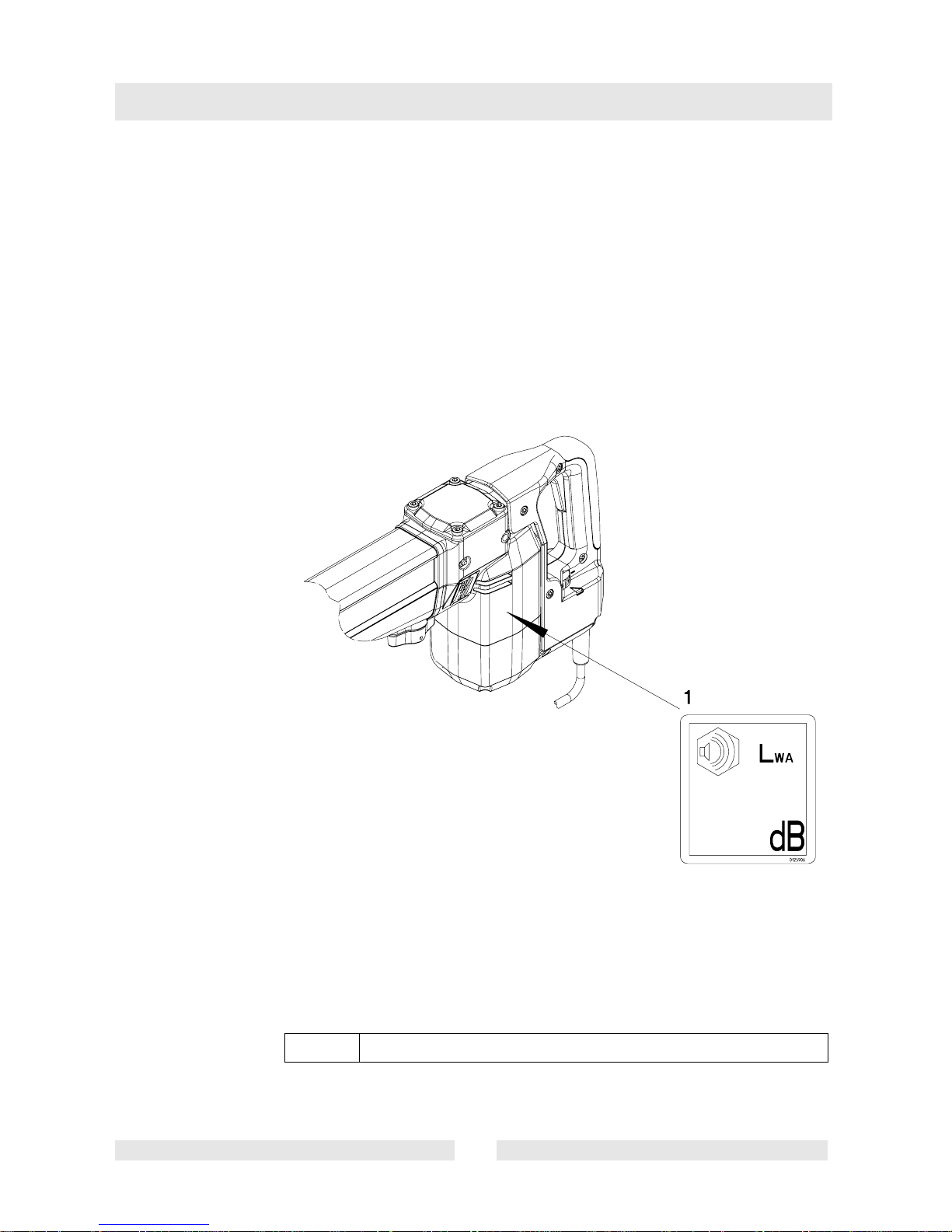

15

8. Labels

for the following machines:

0008429 ..., 0008732 ..., 0008735 ..., 0008736 ..., 0008737 ...,

0008738 ..., 0008753 ..., 0008917 ..., 0008918 ...

1 Decal - Sound power level

Page 18

Disposal

T01088GB.fm 16

9. Disposal

9.1 Environmentally friendly reuse

Provide for environmentally friendly reuse of the machine. Comply with

all regional regulations and directives such as the European directive

regarding old electric and electronic devices.

Do not add the device to normal waste disposal. Instead,

it should be collected separately.

Page 19

C0027004GB.fm

File certificate carefully

EC - Conformity Certificate

Wacker Construction Equipment AG, Preußenstraße 41, 80809 München

hereby certify that the construction equipment specified hereunder:

1. Category:

Breaking / Drilling hammer

2. Type:

EHB 9 BL/230

3. Equipment item number:

0008429 ..., 0008734 ..., 0008735 ...,

0008736 ..., 0008753 ..., 0008917 ...

4. Operating weight:

10 kg

has been evaluated in conformity with Directive 2000/14/EC:

and has been manufactured in accordance with the following directives:

* 2000/14/EG

* 89/336/EG

* 98/37/EG

* 73/23/EG

Conformity

assessment procedure

At the following notified

body

Measured sound

power level

Guaranteed sound

power level

Annex VIII VDE Prüf- und

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

101 dB(A) 105 dB(A)

Dr. Stenzel

Research and Development Management

Page 20

Page 21

DIN EN ISO 9001 CERTIFICATE

Page 22

Wacker Construction Equipment AG - Preußenstraße 41 - 80809 München - Tel.: +49-(0)89-3 54 02-0 - Fax: +49-(0)89-3 54 02-390

Wacker Corporation - P.O. Box 9007 - Menomonee Falls, WI 53052-9007 - Tel.: +1-(1)(262)-255-0500 - Fax: +1-(1)(262)-255-0550 - Tel.: (800)770-0957

Wacker Asia Pacific Operations-Skyline Tower, Suite 2303, 23/F, 39 Wang Kwong Road, Kowloon Bay, Hong Kong-Tel.: +852 2406 6032-Fax: +852 2406 6021

Page 23

Page 24

Loading...

Loading...