WACKER Group PDT 2, PDI 3, PDI 2, PDT 3 Repair Manual

www.wackergroup.com

Pump

PDT 2

PDI 2

PDT 3

PDI 3

REPAIR MANUAL

0163153en 001

0606

0163153EN

PD Repair Foreword

wc_tx000591gb.fm i

Operating / Parts Information

You must be familiar with the operation of this machine before you

attempt to troubleshoot or repair it. Basic operating and maintenance

procedures are described in the Operator’s Manual supplied with the

machine. Keep a copy of the Operator’s Manual with the machine at all

times. Use the separ ate Parts Book supp lied with the mach ine to order

replacement parts. If you are missing either of the documents, please

contact Wacker Corporation to order a replacement.

Damage caused by misuse or neg lect of the unit should be brough t to

the attention of the operator to prevent similar occurrences from

happening in the future.

This manual provides information and procedures to safe ly repair and

maintain the above Wacker model(s). For your own safety and

protection from injury, carefully read, understand, and observe all

instructions described in this manual. THE INFORMATION

CONTAINED IN THIS MANUAL IS BASED ON MACHINES

MANUFACTURED UP TO THE TIME OF PUBLIC ATION. WACKER

CORPORATION RESERVES THE RIGHT TO CHANGE ANY

PORTION OF THIS INFORMATION WITHOUT NOTICE.

This manual covers machines with Item Number:

0007610, 0007614, 0007624, 0007625, 0007628, 0007629, 0009407,

0009489, 0009491, 0009492, 0009494, 0009495

Foreword PD Repair

wc_tx000591gb.fm ii

CALIFORNIA

Proposition 65 Warning:

Engine exhaust, some of its constituents, and certain vehicle

components, contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproductive

harm.

Laws Pertaining to Spark Arresters

Notice: State Health Safety Codes and Public Resources Codes

specify that in certain locations spark arresters be used on internal

combustion engines that use hydrocarbon fuels. A spark arrester is a

device designed to prevent accidental discharge of sparks or flames

from the engine exhaust. Spark arresters are qualified and rated by

the United States Forest Service for this purpose.

In order to comply with local laws regarding spark arresters, consult

the engine distributor or the local Health and Safety Administrator.

All rights, especially copying and distribution ri ghts, are reserved.

Copyright 2006 by Wacker Corporation

No part of this pu blication may be rep roduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission from Wacker Corporation.

Any type of reproduction or distribution not authorized by Wacker

Corporation represents an infringement of valid copyrights, and

violators will be prosecuted. We expressly reserve the right to make

technical modifications, even without due notice, which aim at

improving our machines or their safety standards.

WARNING

PD 2/3 Table of Contents

wc_br0163153001enTOC.fm 1

1. Safety Information 3

1.1 Operating Safety .................................................................................. 4

1.2 Operator Safety while using Internal Combustion Engines .................. 5

1.3 Service Safety ...................................................................................... 5

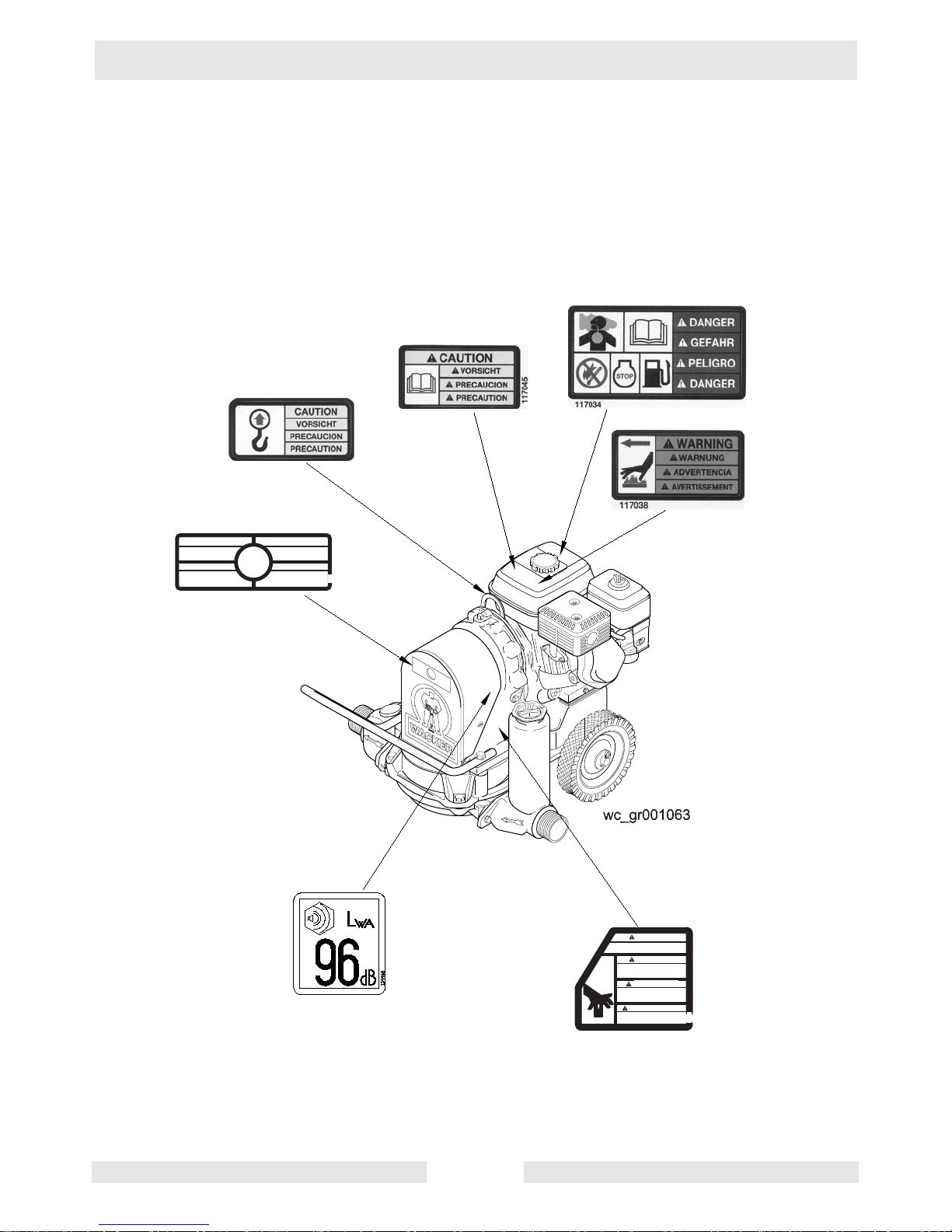

1.4 Label Locations ................................................................................... 6

1.5 Safety Labels ........................................................................................ 7

2. Technical Data 10

2.1 Engine—Machines with Honda Engines ............................................10

2.2 Pump—Machines with Honda Engines .............................................. 11

2.3 Sound Measurements—Machines with Honda Engines .................... 11

2.4 Dimensions—Machines with Honda Engines ..................................... 12

2.5 Engine—Machines with Wacker Engines .................................. ......... 13

2.6 Pump—Machines with Wacker Engines ......................... ..... .............. 14

2.7 Sound Measurements—Machines with Wacker Engines ................... 14

3. Operation 15

3.1 Application .......................................................................................... 15

3.2 Recommended Fuel ........................ ............................ .... ..... ..... ......... 15

3.3 Priming Pump ................................................ .... ..... ..... ....................... 16

3.4 Before Starting ................................................................................... 16

3.5 To Start—Machines with Honda Engines ............................. ..... .... .....17

3.6 To Stop—Machines with Honda Engines .................................. .... .....17

3.7 To Start—Machines with Wacker Engines ......................................... 18

3.8 To Stop—Machines with Wacker Engines .........................................18

3.9 Operation ............................................................................................ 19

3.10 Accessories ........................................................................................ 19

3.11 Hoses and Clamps ............................................................................. 20

4. Maintenance 22

4.1 Periodic Maintenance Schedule ......................................................... 22

4.2 Changing Engine Oil—Machines with Honda Engines ...................... 23

4.3 Changing Engine Oil—Machine s with Wacker Engines ..................... 24

4.4 Cleaning Fuel Strainer—Machines with Wacker Engines .................. 24

Table of Contents PD 2/3

wc_br0163153001enTOC.fm 2

4.5 Cleaning Sediment Cup—Machines with Honda Engines ..................25

4.6 Carburetor Adjustment—Machines with Honda Engines ....................25

4.7 Servicing Air Cleaner—Machines with Honda Engines .......................26

4.8 Servicing Air Cleaner—Machines with Wacker Engines .....................27

4.9 Spark Plug ...........................................................................................28

4.10 Gear Case ...........................................................................................29

4.11 Lubricating Connecting Rod Bearing ...................................................30

4.12 Cleaning Pump ............................ ..... .... ..... ..... .....................................30

4.13 Storage ................................................................................................31

4.14 Troubleshooting ...................................................................................32

5. Disassembly/Assembly Procedures 33

5.1 Tools ....................................................................................................33

5.2 Ordering Parts .....................................................................................33

5.3 Reference Numbers ( ) ................................................. .... ..... ..... .........33

5.4 Replacing the Flapper Valve ...............................................................34

5.5 Replacing the Diaphragm ................................................. ..... ..............36

5.6 Replacing the Connecting Rod and Bearing .......................................38

5.7 Replacing the Engine ........................... ..... ..... .... ............................ .....40

5.8 Gearbox Exploded View ............................ ..........................................42

5.9 Gearbox Components ............................... ..........................................43

5.10 Gearbox Disassembly .................................... .... .................................44

5.11 Gearbox Reassembly ................................................... .... ..... ..............46

5.12 Testing .................................................................................................48

PD 2/3 Safety Information

wc_si000176gb.fm 3

1. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE

callouts which must be followed to reduce the po ssibility of personal

injury, damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid pos sible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous si tuation w hich, if no t avoided, co uld

result in death or serious injury.

CAUTION indicat es a hazardous situation which, i f n ot a voi de d, co ul d

result in minor or moderate inj ury.

CAUTION: Used without the safety alert symbol, CAUTION indicates

a potentially hazardous situation which, if not avoided, may result in

property damage.

Note: Contains additional information important to a procedure.

DANGER

WARNING

CAUTION

Safety Information PD 2/3

wc_si000176gb.fm 4

1.1 Operating Safety

Internal combustion eng ine s present sp ecial ha zard s during op eratio n

and fueling. Read and follow the warning instructions in the engine

owner’s manual and t he saf ety gu ideli nes belo w. Failu re to follow the

warnings and saf ety guidelines could result in severe injury or death.

1.1.1 NEVER allow anyone to operate this equipment without proper

training. People operating this equipment must be familiar with the

risks and hazards associated with it.

1.1.2 NEVER touch the engine or muffler while the engine is on or

immediately after i t has been turned off. The se areas get hot and may

cause burns.

1.1.3 NEVER use accessories or attachm ents that are not recom mended by

Wacker. Damage to equipment and injury to the user m ay result.

1.1.4 NEVER pump vola tile, flam mable or l ow flash poi nt fluids. The se fluids

could ignite or explode.

1.1.5 NEVER pump corrosive chemicals or water containing toxic

substances. These fluids could create serious health and

environmental hazards. Contact local authorities for assistance.

1.1.6 ALWAYS read, understand, and follow procedures in the Operator’s

Manual before attempting to operate the equipment.

1.1.7 ALWAYS be sure operator is familiar with proper safety precau tions

and operation techniques before using machine.

1.1.8 ALWAYS be sure the machine is on a firm, level surface and will not

tip, roll, slide, or fall while operating.

1.1.9 ALWAYS close fuel valve on engines equipped with one when

machine is not being oper ate d.

1.1.10 ALWAYS store the equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the reach of

children.

DANGER

PD 2/3 Safety Information

wc_si000176gb.fm 5

1.2 Operator Safety while using Internal Combustion En gines

Poorly maintained equipment can become a safety hazard! In order

for the equipment to operate safely and prop erly over a long period of

time, periodic maintenance and occasional repairs are necessary.

1.2.1 DO NOT smoke while operating the machine.

1.2.2 DO NOT smoke when refueling t he engine.

1.2.3 DO NOT refuel a hot or running engine.

1.2.4 DO NOT refuel the engine near an open flame.

1.2.5 DO NOT spill fuel when refueling the engine.

1.2.6 DO NOT run the engine near open flames.

1.2.7 ALWAYS refill the fuel tank in a well-ventilated area.

1.2.8 ALWAYS replace the fuel tank cap after refueling.

1.3 Service Safety

Poorly maintained equipment can become a safety hazard! In order

for the equipment to operate safely and prop erly over a long period of

time, periodic maintenance and occasional repairs are necessary.

1.3.1 DO NOT attempt to clean or service the machine while it is running.

Rotating parts can cause severe injury.

1.3.2 DO NOT crank a flooded engine with the spark plug removed on

gasoline-powered en gines. Fuel trappe d in the cylinder will sq uirt out

the spark plug opening.

1.3.3 DO NOT test for spark on gasoline-powered engines if the engine is

flooded or the smell of gasoline is present. A stray spark could ignite

the fumes.

1.3.4 DO NOT use gasoline or othe r typ es of fuel s or fl am mab le solv en ts to

clean parts, especially in enclosed areas. Fumes from fuels and

solvents can become explosive.

1.3.5 ALWAY S operate the machine with all safe ty devices and guards in

place and in workin g or der.

1.3.6 ALWAYS keep the area around the muffler free of debris such as

leaves, paper, cartons, etc. A ho t muffler could igni te the d ebris and

start a fire.

1.3.7 ALWAYS replace worn or damaged components with spare parts

designed and recommended by Wacker Corporation.

1.3.8 ALWAYS disconnect the spark plug on machines equipped with

gasoline engines, before servicing, to avoid accidental start-up.

WARNING

WARNING

Safety Information PD 2/3

wc_si000176gb.fm 6

1.4 Label Locations

DO NOT OPERATE WITHOUT SAFETY GUARDS.

READ AND UNDERSTAND INSTRUCTION BOOK.

NICHT OHNE SCHUTZVORRICHTUNG

BETREIBEN. BEDIENUNGSANWEISUNG

GENAU DURCHLESEN.

NO OPERE SIN LOS DISPOSITIVOS

DE SEGURIDAD. LEA Y ENTIENDA

PRIMERO LAS INSTRUCCIONES.

NE PAS OPERER SANS DEFLECTEUR

PROTECTIF. LIRE ET COMPRENDRE

LES INSTRUCTIONS DE SERVICE.

117431

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

GREASE CONNECTING

ROD BEARING MONTHL

Y

30744

CAUTION

PRECAUTIONPRECAUCION

ENGRASE RODAMIENTO

DE LA BIELA

MENSUALMENTE

GRAISSER ROULEMENT

DE LA BIELLE TOUS

LES MOIS

VORSICHT

PLEUELLAGER JEDEN

MONAT SCHMIEREN

PD 2/3 Safety Information

wc_si000176gb.fm 7

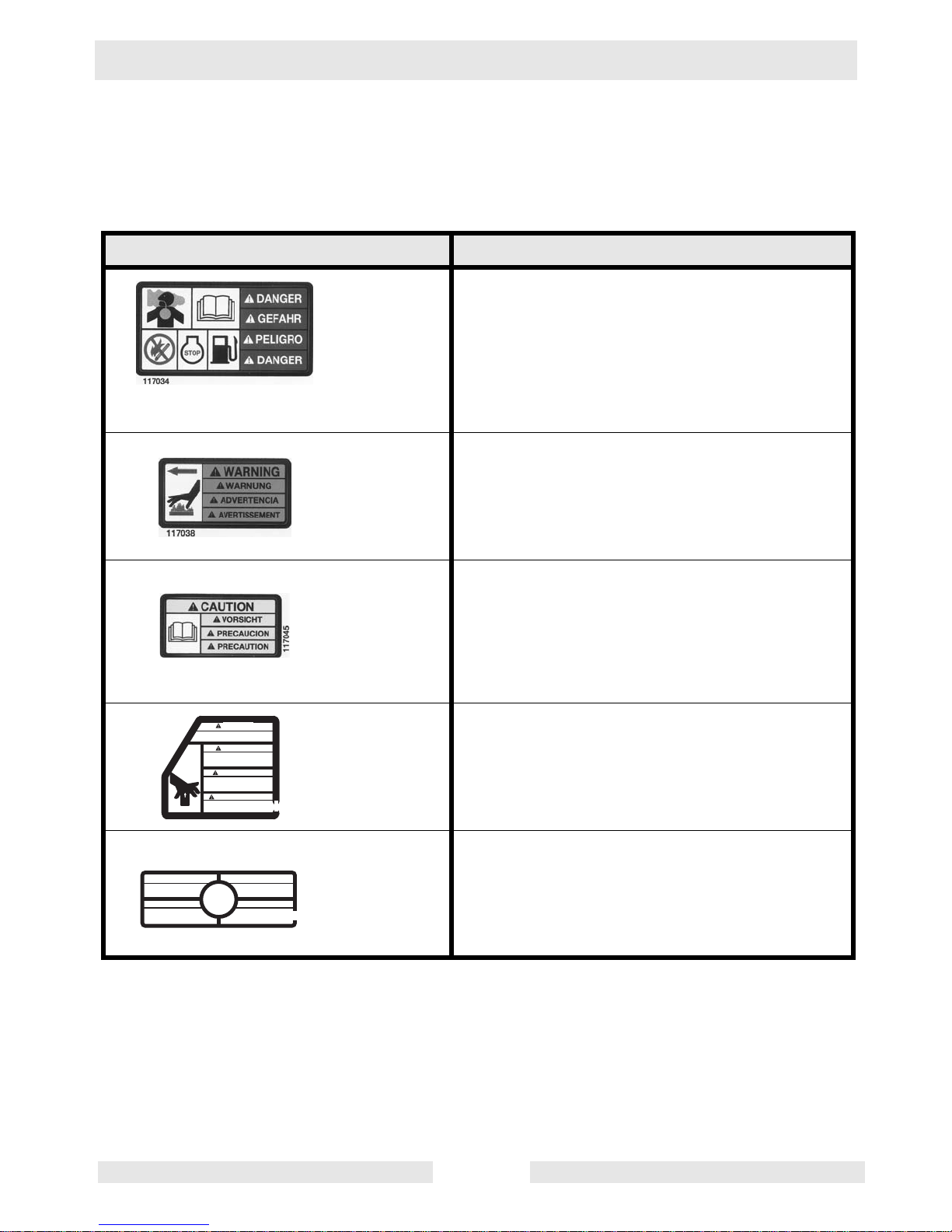

1.5 Safety Labels

Wacker machines use international pictorial labels where needed.

These labels are described below:

Label Meaning

DANGER!

Engines emit carbon monoxide; operate only

in well-ventilated area. Read the Operator’s

Manual.

No sparks, flames, or burning ob ject s ne ar the

machine. Shut off the engine before refueling.

WARNING!

Hot surface!

CAUTION!

Read and understand the supplied Operator’s

Manuals before operating this machine. Failure to do so increases the risk of injury to yourself or others.

WARNING!

Pinch point! Do not operate without safety

guards. Read and understand the operator’s

manual.

CAUTION!

Grease connecting rod bearing monthly.

DO NOT OPERATE WITHOUT SAFETY GUARDS.

READ AND UNDERSTAND INSTRUCTION BOOK.

NICHT OHNE SCHUTZVORRICHTUNG

BETREIBEN. BEDIENUNGSANWEISUNG

GENAU DURCHLESEN.

NO OPERE SIN LOS DISPOSITIVOS

DE SEGURIDAD. LEA Y ENTIENDA

PRIMERO LAS INSTRUCCIONES.

NE PAS OPERER SANS DEFLECTEUR

PROTECTIF. LIRE ET COMPRENDRE

LES INSTRUCTIONS DE SERVICE.

117431

WARNING

WARNUNG

ADVERTENCIA

AVERTISSEMENT

GREASE CONNECTING

ROD BEARING MONTHL

Y

30744

CAUTION

PRECAUTIONPRECAUCION

ENGRASE RODAMIENTO

DE LA BIELA

MENSUALMENTE

GRAISSER ROULEMENT

DE LA BIELLE TOUS

LES MOIS

VORSICHT

PLEUELLAGER JEDEN

MONAT SCHMIEREN

Safety Information PD 2/3

wc_si000176gb.fm 8

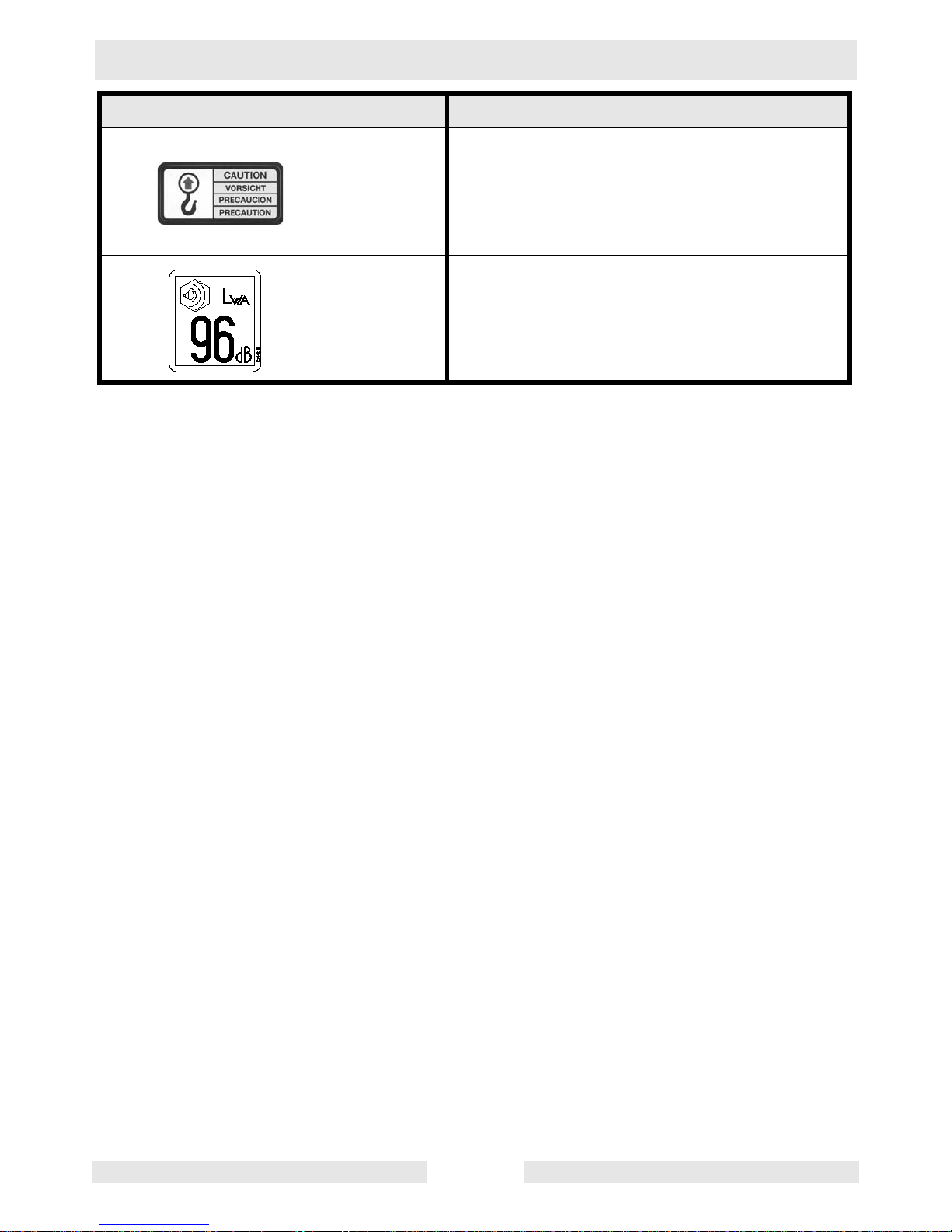

CAUTION!

Lifting point

Guaranteed sound power level in dB(A)

Label Meaning

PD 2/3 Safety Information

wc_si000176gb.fm 9

Technical Data PD

wc_td000178gb.fm 10

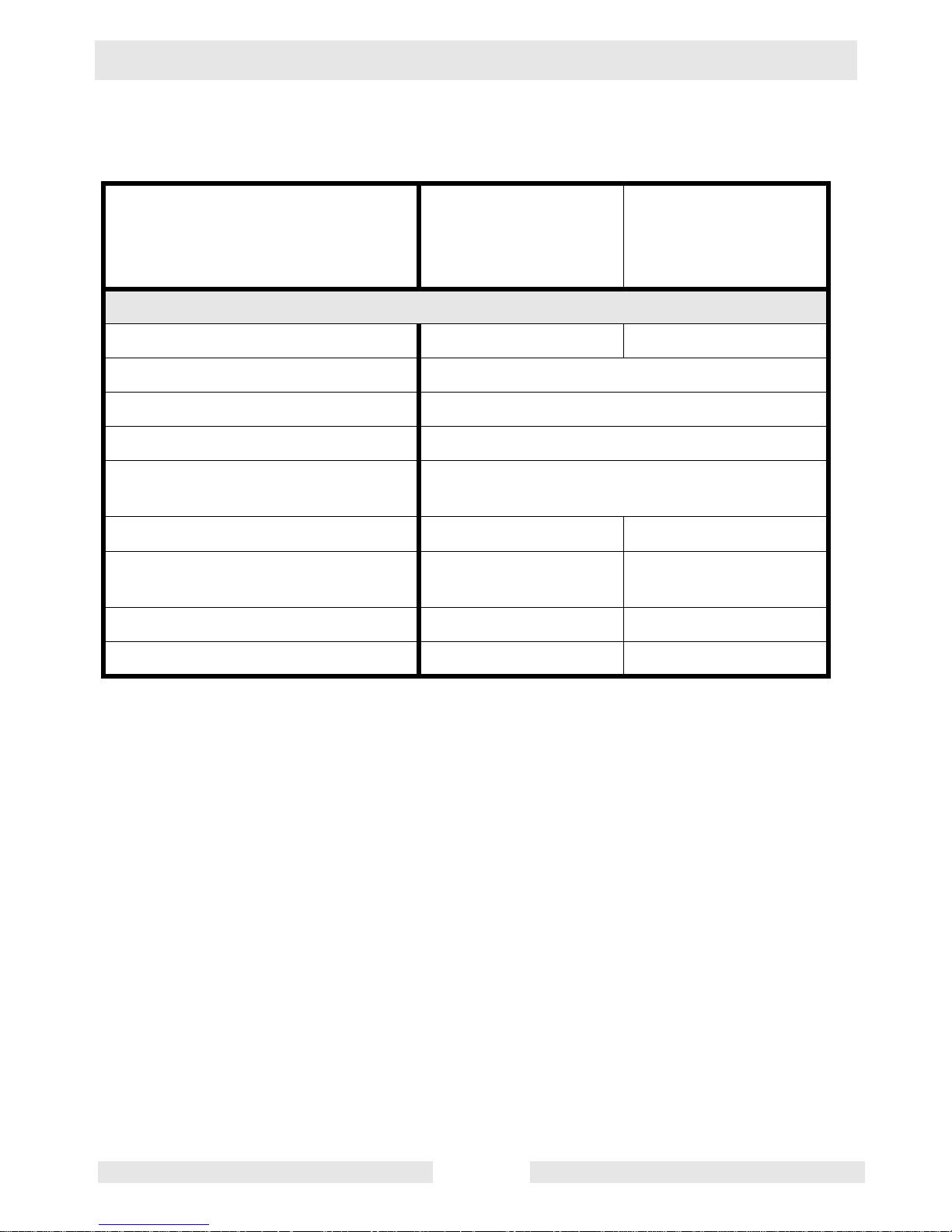

2. Technical Data

2.1 Engine—Machines with Honda Engines

Item Number:

PDT/PDI 2A

0007610, 0007611

0007624, 0007625

PDT/PDI 3A

0007614, 0007615 ,

0007616, 0007628 ,

0007629, 0009407

Engine

Engine Make Honda

Engine Model GX 120 K1 QX

Rated Power

kW (Hp)

3.0 (4.0)

Spark Plug

type

(NGK) BPR 6ES, BOSCH WR 7DC

Electrode Gap

mm (in.)

0.7 – 0.8 (0.028 – 0.031)

Engine speed

rpm

2700 ± 100

Air Cleaner

type

Dual element

Engine Lubrication

oil grade

SAE10W30 - service class SF, SE, SD, or SC

Engine Oil Capacity

ml (oz.)

600 (20)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (qts.)

2.5 (2.6)

PD Technical Data

wc_td000178gb.fm 11

2.2 Pump—Machines with Honda Engines

2.3 Sound Measurements—Machines with Honda En gines

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• the guaranteed sound power level (LWA) = 96 dB(A).

• the sound pressure level at operator’s location (L

pA

) = 82 dB(A).

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 6081 for the sound pressure level

(L

pA

) at the operator’s location.

Item Number:

PDT/PDI 2A

0007610, 0007611

0007624, 0007625

PDT/PDI 3A

0007614, 0007615,

0007616, 0007628,

0007629, 0009407

Pump

Weight

kg (lbs.)

52 (114) 63 (138)

*Max. Suction Li ft

m (ft.)

7.5 (25)

Max. Discharge Head

m (ft.)

7.5 (25)

Max. Total Head

m (ft.)

15 (50)

Max. Discharge

Pressure

kg/cm2

(psi)

0.76

(10.8)

Max. Discharge Flow

m3h (gpm)

11 (50) 20 (88)

Gear Case Lubric ation

oil grade

ml (oz.)

SAE 80W-90

532 (18)

SAE 80W-90

532 (18)

Suction / Discharge Dia.

mm (in.)

50 (2) 75 (3)

Maximum Solid Size

mm (in.)

30 (1.25) 45 (1.75)

* Based on pump operating at sea level. Maximum suction lift will be less at higher altitudes.

Technical Data PD

wc_td000178gb.fm 12

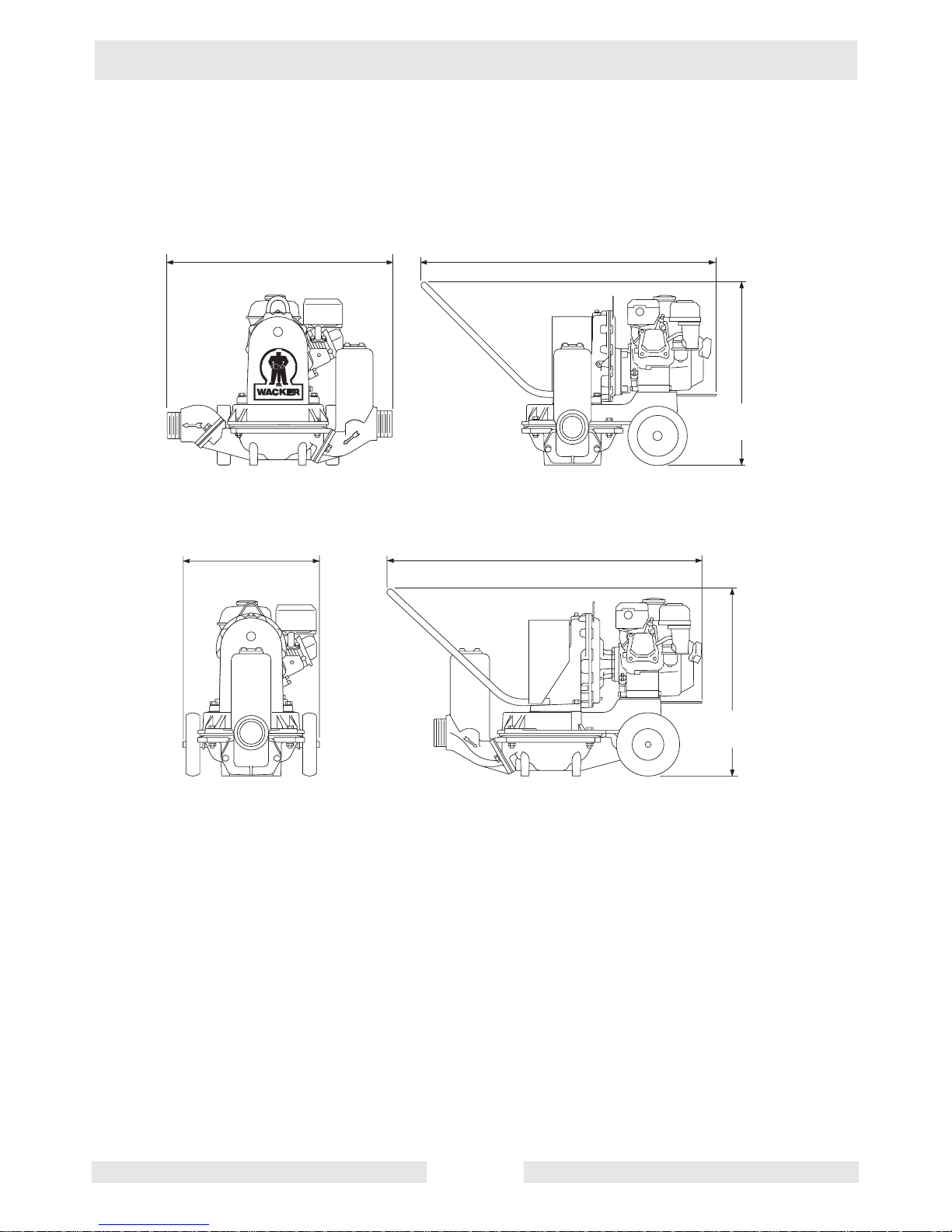

2.4 Dimensions—Machines with Honda Engines

mm (in.)

w c _ g r 0 0 1 0 6 2

P D T 2 A / 3 A

P D I 2 A / 3 A

P D T 2 A

- 6 3 5 ( 2 5 )

P D T 3 A

- 7 5 0 ( 2 9 . 5 )

P D T 2 A

- 1 0 1 5 ( 4 0 )

P D T 3 A

- 1 0 1 5 ( 4 0 )

P D I 2 A

- 4 4 5 ( 1 7 . 5 )

P D I 3 A

- 4 4 5 ( 1 7 . 5 )

P D I 2 A

- 1 0 1 5 ( 4 0 )

P D I 3 A

- 1 0 1 5 ( 4 0 )

P D T 2 A

- 5 7 2 ( 2 2 . 5 )

P D T 3 A

- 6 1 0 ( 2 4 )

P D I 2 A

- 5 7 2 ( 2 2 . 5 )

P D I 3 A

- 6 1 0 ( 2 4 )

PD Technical Data

wc_td000178gb.fm 13

2.5 Engine—Machines with Wacker Engines

Item Number:

PDI/PDT 2

0009489, 0009494

PDI/PDT 3

0009491, 0009492,

0009495

Engine

Engine Make Wacker

Engine Model WM 130

Displacement

cm3 (in3)

126 (7.7)

Engine Spee d

rpm

2800

Max. Operating Power

kW (Hp)

3.2 (4.3)

Spark Plug

type

NGK BR6HS (Champion RL8 6C)

Electrode Gap

mm (in.)

0.6–0.7 (0.024–0.0 28 )

Air Cleaner

type

Dual element

Engine Lubrication

oil grade

SAE10W30 - SE or higher

Engine Oil Capacity

ml (oz.)

600 (20)

Fuel

type

Regular unleaded gasoline

Fuel Tank Capacity

l (qts.)

2.7 (2.9)

Fuel Consumption

l (qts.)/hr.

1.1 (1.2)

Running Time

hr.

2.5

Technical Data PD

wc_td000178gb.fm 14

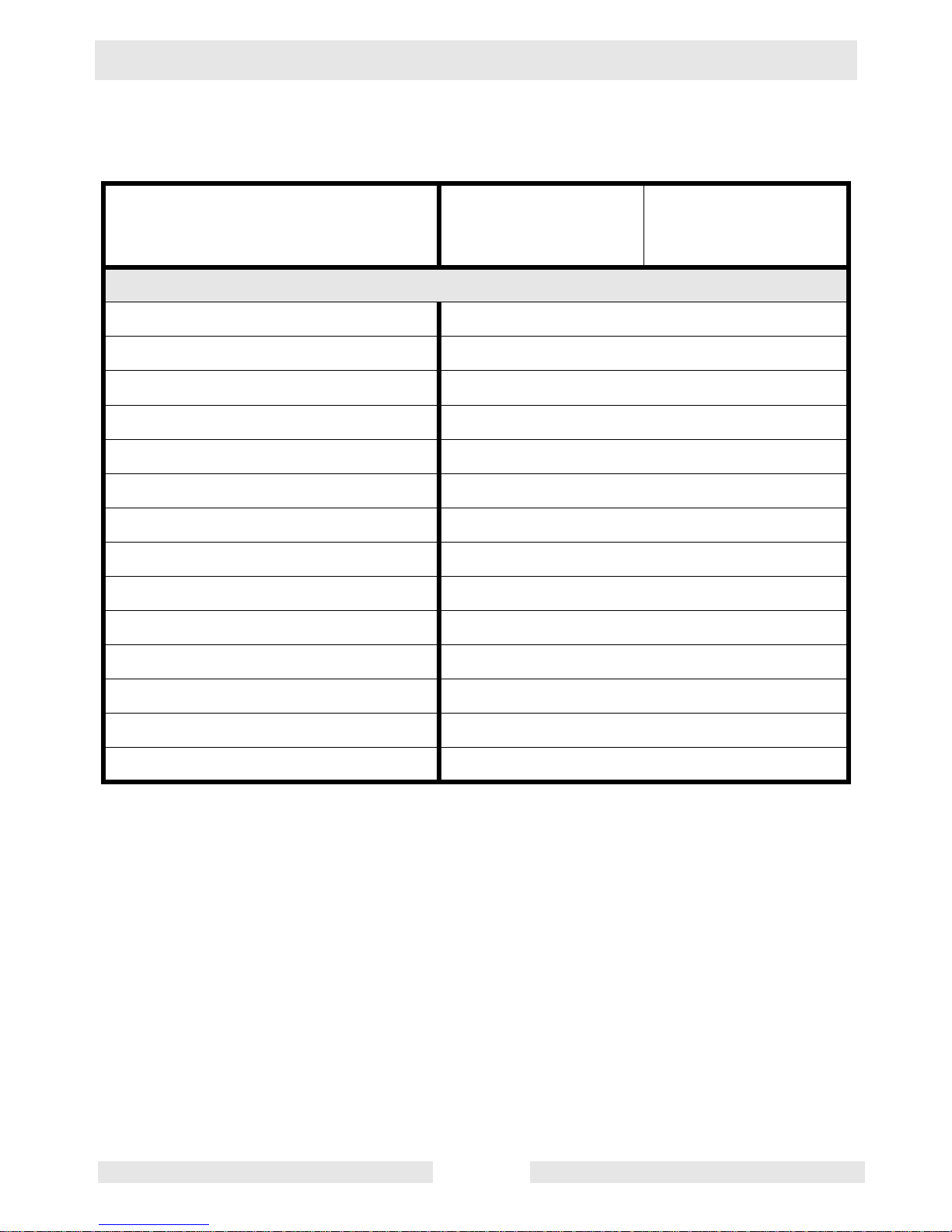

2.6 Pump—Machines with Wacker Engines

2.7 Sound Measurements—Machines with Wacker Engines

The required sound specification, Paragraph 1.7.4.f of 89/392/EEC

Machinery Directive, is:

• the guaranteed sound power level (LWA) = 96 dB(A).

• the sound pres sure level at oper ator’s location (LpA):

PDT 2 = 78.8, PDT 3 = 82.

These sound values were determined according to ISO 3744 for the

sound power level (LWA) and ISO 608 1 for the sound pre ssure level

(LpA) at the operator ’s location.

Item Number:

PDI/PDT 2

0009489, 0009494

PDI/PDT 3

0009491, 0009492,

0009495

Pump

Dimensions

(L x W x H)

mm

(in.)

1010 x 630 x 570

(40 x 25 x 22.5)

1010 x 745 x 605

(40 x 29.3 x 24)

Operating Weight

kg (lbs.)

52 (114) 61 (133)

*Max. Suction Lift

m (ft.)

7.5 (25)

Max. Discharge Head

m (ft.)

7.5 (25)

Max. Flow Rate

l/m (gpm)

189 (50) 333 (88)

Gear Case Lubrication

oil grade

ml (oz.)

SAE 80W-90

532 (18)

Suction / Discharge Dia.

mm (in.)

50 (2) 75 (3)

Maximum Solid Size

mm (in.)

32 (1.25) 45 (1.75)

* Based on pump operating at sea level. Maximum suction lift will be less at higher altitudes.

Loading...

Loading...